Abstract

This article presents and describes a dataset for the bills of materials for the buildings constructed with mass timber (MT), structural steel (SS), and reinforced concrete (RC), which are generated using Athena's Impact Estimator for Buildings (IE4B) software to conduct a whole building life-cycle assessment (WBLCA). These data are associated with the research article Environmental Impact Assessment of Mass Timber, Structural Steel, and Reinforced Concrete Buildings Based on the 2021 International Building Code Provisions [1]. This dataset was utilized to estimate their environmental impacts but can be used to estimate the costs of buildings constructed with MT, SS, and RC building materials. These data could be replicated using the same layout, system boundaries, reference study period (RSP), and building assemblies’ information as used in the published work [1]. This dataset is related to conceptual design of a building with 11 apartment units per floor. However, a detailed design that includes the analysis of interior architectural finishes such as internal partitions within the units, kitchen and washroom fixtures, internal doors, flooring, and so on, could be developed and analyzed to obtain a more comprehensive estimates of life cycle assessment. This dataset was originally developed to compare the environmental impacts of structural materials selection for three common framing typologies.

Keywords: Residential occupancy, Mid-and high-rise buildings, Whole building life cycle assessment (WBLCA), Life cycle cost analysis, Environmental impacts

Specifications Table

| Subject | Engineering |

| Specific subject area | Civil and Structural Engineering |

| Data format | Raw, Analyzed |

| Type of data | Excel file/Table |

| Data collection | Bills of material generated using Athena's Impact Estimator for Buildings (IE4B) |

| Data source location | Bills of material data were generated using Athena's IE4B for the United States with different construction materials (i.e., mass timber (MT), structural steel (SS), and reinforced concrete (RC). |

| Data accessibility | Repository name: A Bills of Materials Dataset for Buildings Made of Mass Timber, Structural Steel, and Reinforced Concrete Using the 2021 International Building Code Provisions Mendeley data repository (https://data.mendeley.com/datasets/pgjvbwznk5/1) Data identification number: 10.17632/pgjvbwznk5.1 Direct URL to data: https://data.mendeley.com/datasets/pgjvbwznk5/1 |

| Related research article | V. Kumar, M. Lo Ricco, R.D. Bergman, P. Nepal, N.C. Poudyal, Environmental impact assessment of mass timber, structural steel, and reinforced concrete buildings based on the 2021 international building code provisions, Build Environ (2024) 111,195. https://doi.org/10.1016/j.buildenv.2024.111195 [1] |

1. Value of the Data

-

•

This dataset provides bills of material for buildings made of mass timber, structural steel, and reinforced concrete in the United States. The materials are designed per the prescriptive provisions of the 2021 and 2024 International Building Code (ICC-IBC 2021) [2,3].

-

•

This data can be useful to architects and environmentalists working in the construction industry in assessing the environmental impacts of buildings at the design and construction phases.

-

•

Dataset is also useful in estimating the life cycle cost of buildings. Architects can use cost data and cost estimating techniques presented in this article in budgetary and feasibility determinations.

2. Background

The built environment is a substantial contributor to global human-made greenhouse gas (GHG) emissions, representing approximately 37 % annually, with building operational energy contributing 27 % and embodied carbon emissions contributing 10 % [4]. The adoption of greener construction materials is pivotal for curbing net carbon emissions of the built environment throughout a building's life cycle. As technologies to reduce operational energy continue to advance, focus on curbing embodied energy with greener construction materials will take on even greater urgency.

In recent years, mass timber (MT), characterized by engineered wood products like cross-laminated timber (CLT) and glued laminated timber (glulam), has gained international acclaim as a sustainable construction material [5], offering a viable alternative to traditional materials in tall buildings [6]. The International Code Council's (ICC) approval of proposals to integrate tall wood buildings into the 2021 International Building Code (IBC) underscores the industry's shift towards sustainability [7]. The 2021 IBC introduces three new construction types: IVA-18 stories, IVB-12 stories, and IVC-8 stories, facilitating construction of MT materials with specific provisions for fire risk mitigation [7]. This regulatory adoption standardizes the secure construction of tall wood buildings in the United States, a sizable construction market that has bolstered the global growth of MT construction via technological innovation [8], large-scale testing [9,10], and manufacturing standards [11].

This article describes the dataset used by Kumar et al. [1] in estimating the life cycle environmental impacts of multistory residential occupancy buildings (R2) constructed with MT, SS, and RC in accordance with the 2021 IBC provisions for tall wood buildings, encompassing nine buildings across the IVA-18 stories, IVB-12 stories, and IVC-8 stories categories. Their whole building life-cycle assessment (WBLCA) used a cradle-to-grave (A-C) system boundary while including module D but excluding use (B1), repair (B3), refurbishment (B5), operating energy (B6), and water (B7) modules under the use stage, which was conducted via the Athena Impact Estimator for Buildings (IE4B) software tool.

This article provides background information on building assemblies as well as a complete dataset including the generated bills of materials for buildings designed with MT, SS, and RC based on the 2021 International Building Code Provisions.

3. Data Description

This dataset compiles bills of materials for buildings designed to be constructed of mass timber (MT), structural steel (SS), and reinforced concrete (RC). These buildings are classified as IVA-18-story, IVB-12-story, and IVC-8-story and are designed in compliance with the 2021 IBC (ICC 2020) [2,7]. The Athena IE4B software was used to generate the bills of materials to assess the life-cycle environmental impacts of these buildings for the reference study period (RSP) of 75 years. Additionally, bills of material for the RSP of 60 years were generated for sensitivity analysis of their life-cycle environmental impacts. Due to one of several changes in the fire rating in the recently updated International Building Code (ICC 2023) [3,[12], [13], [14], [15]], an additional dataset for the buildings in the category IVB-12-story was created to perform sensitivity analysis with respect to 2021 IBC fire rating guidelines.

4. Experimental Design, Materials, and Methods

The bills of material presented in this article could be replicated using the same system boundary, functional units, assemblies' information, reference study period (RSP), and the layout (Fig. 1) of the designed buildings. The details of the layout, assemblies, system boundary, and RSP information are described in detail in the following text.

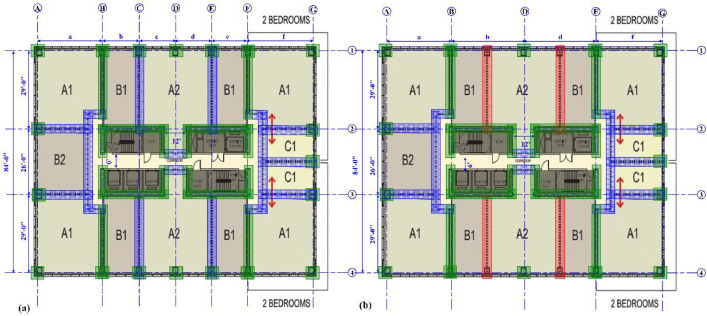

Fig. 1.

Building layout design [16] for comparative whole building environmental impact assessment of (a) mass timber (MT), (b) structural steel (SS), and reinforced concrete (RC) buildings.

4.1. Building design

4.1.1. Layout

The general apartment building architectural layout used in this assessment is based on the Timber Tower research project [16]. The dimensions and fire ratings of the hypothetical buildings were specifically redesigned to optimize the floor area within the categories of 2021 IBC for R-2 residential occupancies (IV-A-18-stories, IV-B-12-stories, and IV-C-8-stories) [2,7]. Detailed information on these modifications is provided in Table 1, Table 2. For example, a Type IV-A building has dimensions of 37.19 m × 25.60 m (122 ft×84 ft) and a floor area of 17,137.27 m² (184,464 ft²). We have used capital letters for gridlines and small letters for dimensions in Fig. 1. So, A, B, C, D, E, F, and G are gridlines, and a, b, c, d, e, and f indicate the dimension between gridlines in Fig. 1a. In Fig. 1b, we have removed gridlines C and E and dimensions c and e because RC and SS framing systems can span longer distances, and columns, beams, and foundation pillars along gridlines C and E were eliminated to ensure functional equivalence. Each floor was designed to accommodate a total of 11 residential units. The original hypothetical MT buildings (known as Timber Tower) were initially designed for a generic location in Chicago, Illinois. However, for the purposes of this study, U.S. national average values for lifecycle inventory data were considered in the default selection of the Athena's Impact Estimator for Building (IE4B) software. The layouts of the 8-, 12-, and 18-story structures are depicted in Figs. 1a(MT) and 1b (SS and RC). In this study, the buildings were also redesigned to meet the prescriptive fire resistance requirements outlined in the tall wood building provisions of 2021 and 2024 IBC [3,7]. For instance, a Type IV-A primary structural frame constructed with MT and requiring a 3-hour fire rating would necessitate the use of five layers of 5/8″ Type X gypsum wallboard.

Table 1.

Building characteristics for the comparative whole building environmental impact assessment of R-2 residential occupancy buildings considered in this study.

| MT buildings category as per 2021 IBC | Stories | Building height m (ft) |

Total Floor area m2 (ft2) |

Dimensions m x m (ft x ft) |

|---|---|---|---|---|

| IV-C | 8 | 25.6 (84) | 7717.1 (76,608) | 34.75×25.6 (114×84) |

| IV-B | 12 | 38.4 (126) | 11,424.8 (122,976) | 37.19×25.6 (122×84) |

| IV-A | 18 | 57.6 (189) | 17,137.3 (184,464) | 37.19×25.6 (122×84) |

Table 2.

Horizontal layout dimensions in m(ft) for the mass timber (MT), steel structure (SS), and reinforced concrete (RC) are shown in Fig. 1.

| MT (Fig. 1a) | |||||||

|---|---|---|---|---|---|---|---|

| Stories | a | b | c | d | e | f | l |

| 8 | 8.23(27) | 4.57(15) | 4.57(15) | 4.57(15) | 4.57(15) | 8.23(27) | 2.44(8) |

| 12 | 8.84(29) | 4.87(16) | 4.87(16) | 4.87(16) | 4.87(16) | 8.84(29) | 3.65(12) |

| 18 | 8.84(29) | 4.87(16) | 4.87(16) | 4.87(16) | 4.87(16) | 8.84(29) | 3.65(12) |

| SS and RC (Fig. 1b) | |||||||

| a | b | d | f | l | |||

| 8 | 8.23(27) | 9.1(30) | 9.1(30) | 8.23(27) | 2.44(8) | ||

| 12 | 8.84(29) | 9.75(32) | 9.75(32) | 8.84(29) | 3.65(12) | ||

| 18 | 8.84(29) | 9.75(32) | 9.75(32) | 8.84(29) | 3.65(12) | ||

A total of 9 foundation configurations were developed based on the three structure types and three variations in height (Table 3). The egress cores central to the architectural layout were assumed to be supported by a mat foundation. Wherever practical, perimeter columns were supported by spread footings until allowable soil pressures exceeded 96 kPa (2000 psf) or footings grew to sizes that practically warranted a mat foundation beneath the entire building footprint. Notably, MT and SS buildings may utilize spread footing foundations up to 12 stories, whereas the RC superstructure requires a foundation mat underneath the full building plan when the number of stories exceeds eight.

Table 3.

Foundation design for mass timber (MT), reinforced concrete (RC), and structural steel (SS) buildings considered in this study.

| Building System | Construction material |

||

|---|---|---|---|

| MT | RC | SS | |

| IV-C-8-story | Perimeter spread footings with central mat | Perimeter spread footings with central mat | Perimeter spread footings with central mat |

| IV-B-12-story | Perimeter spread footings with central mat | Mat footing | Perimeter spread footings with central mat |

| IV-A-18-story | Mat footing | Mat footing | Mat footing |

The scope of the building systems included in the lifecycle analysis includes the structural frame, decking or slabs, foundations, and related architectural systems. Building envelope and demising wall assemblies were included, because each structure floor type had slightly varying depths. The modest differences in depth, however, accumulate and amount to significant height that would add to the quantity of exterior wall assembly. In addition, some architectural finish systems are required for fire protection of the structure, particularly in the case of mass timber. The plan views of Fig. 1 illustrate the types of walls included in the study. Structural walls that participate in the lateral system are highlighted in green. Demising walls that primarily function as fire and sound barriers between units are highlighted in blue, except for the red-highlighted walls of the right plan view (b), where structural columns along the perimeter were omitted to reflect the increased span capabilities of steel and concrete structural systems. In general, the building shell is the scope of the lifecycle analysis, excluding mechanical systems and architectural partitions and finishes within individual units.

The functional equivalence of the various buildings is based on the same plan layout and code compliance for Type IV construction. The vertical walls forming the stair and elevator core were varied to match the lateral system with the gravity framing. The mass timber system, therefore, utilized a core of CLT walls encapsulated by layers of fire-resistant gypsum. The steel system utilized a core of steel stud infill walls similarly encapsulated by gypsum. The concrete system utilized reinforced concrete walls. As a result, the lateral systems have various stiffnesses and levels of fire endurance. Reinforced concrete cores typically have the greatest lateral stiffness and most robust protection from fire, which is why reinforced concrete cores are often paired with gravity systems of all materials in hybrid construction. The data for concrete systems organizes the amount of reinforced concrete and rebar used in walls, which is attributed to the vertical core structure of the lateral system. Similarly, the amount of CLT used in walls is attributed to the vertical core structure of the lateral system.

4.2. Buildings assemblies

The plan layouts of Fig. 1 define the functional equivalence and scope of building systems compared in the study. The major difference between MT buildings (Fig. 1a) and buildings constructed with SS and RC (Fig. 1b) is the layout of the red-highlighted columns, beams, and foundation pillars along gridlines C and E that were eliminated because the RC and SS framing systems are capable of spanning longer distances. Demising walls along these gridlines, however, were retained for all structural systems because the division of residential units provides a logical location for shear walls or lateral bracing components that typically resist lateral wind or seismically induced forces. The magnitude of earthquake, wind, or snow loading may vary greatly across geographic regions due to site-specific parameters of soil strength and stiffness, geological and topographical features, or climate, which typically factor into equations used to apply design loads. To ensure a consistent comparison of the buildings, a consistent set of assumptions was made. Earthquake design was based on Seismic Design Category B (ASCE/SEI 7-22) [17], and wind loads were estimated using urban Exposure B without higher wind gust speeds and topographical features that would typically magnify wind pressures in coastal regions (ASCE/SEI 7-22) [17]. A minimum roof live load of 0.96 kPa (20 psf) was assumed due to snow. As a result, the structural design load combinations were dominated by gravity loads with modest contributions to load combinations by lateral forces.

The level of detail in the building models, moreover, is generally consistent with early schematic design, the stage during which life cycle comparisons are most timely in decision making. Three superstructures of MT, SS (steel and composite concrete deck), and RC (post-tensioned and reinforced concrete) were modeled for comparison. The MT system comprised of post-and-beam glulam frame decked with 5-layer CLT panels and topped with 0.0508 m (2 inches) of 20.68 MPa (3000 psi) normal weight concrete that was used as a material substitution for commonly used gypsum concrete. The steel structural system used standard wide flange sections to frame columns and beams, composite with 0.0762 m (3 inch) deep fluted metal decking topped with normal weight concrete of 27.579 MPa (4000 psi) compressive strength to achieve a 0.1905 m (7-½-in.) total slab depth at each floor level [18]. The concrete superstructure comprised of normal weight concrete of 34.473 MPa (5000 psi) compressive strength and a flat slab modeled with grade 60 mild reinforcement. In cities across North America, post-tensioned flat slab concrete superstructures are typically used for multiunit residential occupancies, but because of limited life cycle inventory data on post-tensioning cable from only a few environmental products declarations [19,20], an average of mild steel reinforcement ratio of 85 kg per cubic meter (143 pounds of steel per cubic yard) of concrete was inputted into the LCA model. All floors were subject to a 1.915 kPa (40 psf) live load for residential occupancy plus 0.718 kPa (15 psf) for partitions. The floor dead load, in contrast, varied among the three structural system types and respectively totaled 2.633, 4.452, and 5.649 kPa (55, 93, and 118 psf) for the MT, SS, and RC floor assemblies when structural and architectural components were estimated. The decking materials weighed 0.718 kPa (15 psf) for 5-ply CLT of 175 mm (6.875 in.) thickness used in the MT buildings, 3.591 kPa (75 psf) for a normal-weight concrete and steel composite system used in the SS buildings, and 4.788 kPa (100 psf) for a normal-weight concrete slab of 205 mm (8 in.) thickness used in the RC buildings. Although architectural finishes were generally assumed consistent among buildings, MT floors commonly implement a nonstructural concrete topping and additional gypsum fire encapsulation for IV-A and -B occupancies, which was included in total dead load. MT and SS floor dead load further accounted for weight of beams and girders, in contrast to concrete which typically only needs a post-tensioned flat slab in buildings of these heights.

The variation in building weight was most pronounced on the foundation design. In the absence of a site-specific geotechnical report, we assumed an allowable soil-bearing pressure of 13.789 MPa (2000 psf) and soil spring stiffness of 2068.427 MPa (300 kpi) for foundation design. A total of 9 foundation configurations were developed based on the three structure types and three variations in height. The egress cores central to the architectural layout were assumed supported by a mat foundation. Wherever practical, perimeter columns were supported by spread footings until soil pressures warranted a mat foundation beneath the entire building footprint. Generally, if spread footings exceeded 6.1 m (20 ft) square in soil contact area, a mat was considered more economical. Notably, MT and SS buildings can utilize spread footing foundations up to 12 stories, whereas the RC superstructure required a foundation mat underneath the full building plan when the number of stories exceeded eight. The volume of normal weight foundation concrete of 20.68 MPa (3000 psi) compressive strength and grade 60 steel reinforcement was consequently less for MT, as MT buildings tend to be lighter than SS and RC.

4.2.1. Columns and beams

Columns and beams in the building serve as part of the primary structural frame, with a 3-hour fire rating for IV-A and a 2-hour fire rating for IV-B and IV-C categories. As a result, the MT building requires 5 layers of 5/8″ Type X gypsum wallboard for fire protection in IV-A areas and 3 layers for IV-B and IV-C areas. In the MT building layout (Fig. 1a), there are 18 columns designed for each floor. However, due to the removal of 4 columns from the MT layout, the RC and SS buildings (Fig. 1b) have 14 columns designed per floor. Steel columns are typically sprayed with fireproofing coating, cementitious or alternative fiber, and then concealed within an architectural wrap. Concrete columns that have sufficient cover do not require fireproofing. Whether the concrete columns are exposed to view or wrapped with finish materials is typically a matter of architectural preference.

4.3. Calculated and prescriptive fire requirements

4.3.1. Primary structural wall

The primary structural wall, highlighted along gridlines B and F in Fig. 1, has a 3-h fire rating for IV-A and a 2-h fire rating for IV-B and IV-C. Additionally, the primary structural walls encompass the core, which is indicated in green of the Fig. 1 layout. For the lateral systems, the core and stiffening walls varied to match the gravity materials. CLT walls were used in the mass timber system. Steel stud walls were used in the steel system. Reinforced concrete walls were used in the concrete system. Additionally, reinforced concrete walls could have been used for all three types of systems, but hybrid concrete and mass timber or concrete and steel systems were excluded from comparisons, based on the objective of economizing construction with the use of similar materials throughout the building superstructure.

4.3.2. Demising/Separation wall

Primary structural walls, as described in the preceding paragraph, also function as demising walls. Nonstructural demising or separation walls, shown in Fig. 1 along gridlines highlighted in blue and red, were included in the LCA to account for materials that may contribute significantly to the embodied energy and emissions of the building. Although nonstructural demising walls may conceal structural components, such as columns, the primary function is visual, sound, and fire separation. These walls have an 80-min fire rating for IV-A and IV-B, while IV-C does not require a fire rating. For mass timber (MT) buildings, 2 layers of 5/8″ Type X gypsum wallboard are needed. Steel buildings require 3 layers of ½" fire-rated gypsum wallboard [17,56], RC buildings only need ample concrete cover for an 80-minute fire rating. Although typically not necessary for fire protection, at least one layer of gypsum commonly covers concrete wall surfaces as an architectural finish. Therefore, this layer has been included in the floor and wall assemblies of the RC system.

4.3.3. Exterior wall

Regarding the exterior wall, the opaque versus transparent portions were calculated using a predesign methodology since the LCA model did not include exterior facades. The percentage of the exterior facade consisting of opaque areas was determined based on the draft design. Opaque areas that were considered uniform for all building types were those with different wall assemblies and R-ratings. The R-values for the opaque area in the comparative models were determined from specific wall assemblies and detailed material takeoffs for each building. A typical transparent assembly of the façade includes glass fenestration with extruded aluminum alloy frames. The opaque portions of the wall include interior gypsum, insulation such as extruded polystyrene (XPS), moisture control barriers, and exterior cladding, namely brick. Although materials like mass timber or architectural precast panels could have profound effects on the thermal insulation values along the exterior wall, only conventional and lightweight cladding systems were considered because they are commonly applicable to all building types.

4.3.4. Floors

For floors, MT structures require three layers of 5/8″ Type X gypsum wallboard due to the 2-h fire rating for IV-A, IV-B, and IV-C. Steel structures necessitate four layers of ½" fire-rated gypsum wallboard based on fire resistance calculations [16] RC buildings, on the other hand, only need a specified minimum concrete cover to achieve the minimum 1 layer of 5/8″ Type X gypsum wallboard for an 80-min fire rating [16].

4.3.5. Roofs

Roofs in IV-A require an 80-min fire rating, while roofs in IV-B and IV-C need a 60-min fire rating. Thus, MT structures would require 2 layers of 5/8″ Type X gypsum wallboard for the roof.

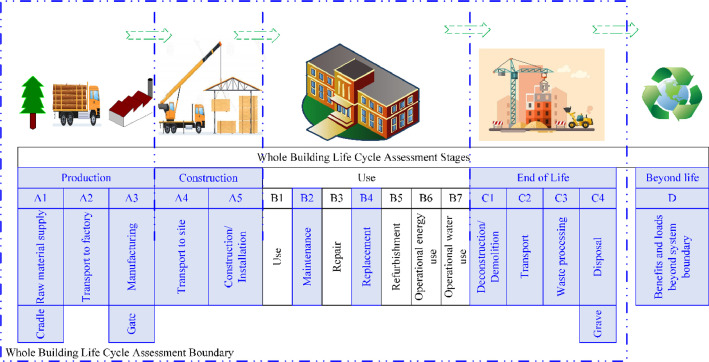

4.4. System boundary and functional units

The system boundary of the WBLCA considered in this study is shown in Fig. 2, which employed a cradle-to-grave (modules A-C) system boundary. Module D (beyond life) was included in the assessment, while use (B1), repair (B3), refurbishment (B5), operating energy (B6), and water usage (B7) modules under the use stage were excluded. This decision aligns with prior research suggesting that the choice of structural materials has a minimal impact on building operations but significantly influences embodied carbon and energy [[21], [22], [23], [24]]. Furthermore, the exclusion of modules B1, B3, and B5 is justified by the limitations of IE4B, which does not fully support use (B1), repair (B3), and refurbishment (B5) modules [25]. The functional unit adopted for this analysis was one square meter (m2) of floor area of a multistory building, of residential occupancy, for 75 years.

Fig. 2.

System boundary considered for Whole Building Life Cycle Assessment (WBLCA) in this study (stages highlighted in blue are considered for the evaluation): adopted from ISO 21930 [26].

4.5. Reference study period

The Reference Service Period (RSP) is a timeframe used to analyze the environmental impacts of an object, such as a building, over its lifetime. The estimated environmental impacts are highly sensitive to the chosen RSP because various factors contribute differently to a building's environmental impacts over its lifetime, including operational energy and water usage, maintenance, repair, replacement, and refurbishment. Determining the appropriate RSP for buildings is challenging due to non-technical considerations like occupant behaviors, environmental factors, climate severity, and maintenance schedules. Different frameworks and methodologies define different RSPs; for example, LEED suggests an RSP of 60 years [27,28]. The current work follows guidelines from ASTM E2921-22 [29] and EN15978 [30], setting the RSP at 75 years for comparative analysis purposes [29,30] although 60 years was used as part of the sensitivity analysis.

Limitations

This dataset could be useful for a variety of tasks, such as estimating environmental impacts and cost estimation for the construction of the buildings. Even though this study has only considered the conceptual design of these building systems with 11 units per floor for the environmental impacts, a detailed design that includes an internal structural analysis, such as internal walls within the units, kitchen, washroom utensils, internal doors, etc., could also be designed and analyzed to provide a clearer picture.

Data Availability Statement

The dataset files are accessible under the Creative Commons Attribution 4.0 International license, permitting free use. Additional details are available in the data accessibility section of the specification table.

Ethics Statement

The authors (Vaibhav Kumar, Marco Lo Ricco, Richard D. Bergman, Prakash Nepal, and Neelam C. Poudyal) have read and followed the ethical requirements for publication in Data in Brief and confirm that the current work did not involve human subjects, animal experiments, or any data collected from social media platforms.

CRediT authorship contribution statement

Vaibhav Kumar: Conceptualization, Data curation, Formal analysis, Investigation, Software, Validation, Visualization, Writing – original draft. Marco Lo Ricco: Data curation, Formal analysis, Investigation, Supervision, Validation, Writing – review & editing. Richard D. Bergman: Data curation, Investigation, Resources, Supervision, Validation, Writing – review & editing. Prakash Nepal: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Project administration, Resources, Supervision, Validation, Visualization, Writing – review & editing. Neelam C. Poudyal: Project administration, Supervision, Writing – review & editing.

Acknowledgments

The funding for this study was provided by the USDA Forest Service Resources Planning Act Assessment Program through a joint venture agreement between the Forest Products Laboratory and the University of Tennessee Institute of Agriculture (21-JV-11111137-030). As some authors of this paper are employees of the USDA FS, the findings and conclusions in this report are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy. Any use of trade, firm, or product names is for descriptive purposes only and does not imply endorsement by the U.S. government.

Declaration of Competing Interest

The authors (Vaibhav Kumar, Marco Lo Ricco, Richard D. Bergman, Prakash Nepal, and Neelam C. Poudyal) declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix A. Sample Data

Table A1.

Bills of material for building system (IVC-8 Story; MT).

| Material | Unit | Total Quantity | Columns & Beams | Floors | Foundations | Roofs | Walls | Project Extra Materials | Mass Value | Mass Unit |

|---|---|---|---|---|---|---|---|---|---|---|

| 2″ Insulated Metal Panel | m2 | 5109.3058 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 5109.3058 | 0.0000 | 75.3449 | Tonnes |

| 5/8″ Fire-Rated Type X Gypsum Board | m2 | 48,546.5233 | 0.0000 | 23,485.4724 | 0.0000 | 1957.1227 | 11,695.0403 | 11,408.8878 | 510.2240 | Tonnes |

| 6 mil Polyethylene | m2 | 4614.6724 | 0.0000 | 0.0000 | 455.3081 | 907.3933 | 3251.9710 | 0.0000 | 0.6922 | Tonnes |

| Air Barrier | m2 | 0.9476 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.9476 | 0.0001 | Tonnes |

| Aluminum Clad Wood Window Frame | kg | 15,769.1252 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 15,769.1252 | 0.0000 | 15.7691 | Tonnes |

| Aluminum Extrusion | Tonnes | 15.1050 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 15.1050 | 0.0000 | 15.1050 | Tonnes |

| Ballast (aggregate stone) | kg | 182,755.0349 | 0.0000 | 0.0000 | 0.0000 | 182,755.0349 | 0.0000 | 0.0000 | 182.7550 | Tonnes |

| Blown Cellulose | m2 (25 mm) | 934.0919 | 0.0000 | 0.0000 | 0.0000 | 934.0919 | 0.0000 | 0.0000 | 0.5978 | Tonnes |

| Concrete Benchmark USA 2500 psi | m3 | 373.6325 | 0.0000 | 373.6325 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 855.5919 | Tonnes |

| Concrete Benchmark USA 3000 psi | m3 | 271.5524 | 0.0000 | 0.0000 | 271.5524 | 0.0000 | 0.0000 | 0.0000 | 622.7700 | Tonnes |

| Cross Laminated Timber | m3 | 2676.3975 | 0.0000 | 2086.7367 | 0.0000 | 234.3503 | 355.3105 | 0.0000 | 1272.4932 | Tonnes |

| EPDM membrane (black, 60 mil) | m2 | 5238.4217 | 0.0000 | 0.0000 | 0.0000 | 4717.1105 | 521.3112 | 0.0000 | 9.9530 | Tonnes |

| Extruded Polystyrene | m2 (25 mm) | 5487.5936 | 0.0000 | 0.0000 | 1786.8567 | 3700.7369 | 0.0000 | 0.0000 | 6.7497 | Tonnes |

| Galvanized Sheet | Tonnes | 0.3859 | 0.0000 | 0.0000 | 0.0000 | 0.3859 | 0.0000 | 0.0000 | 0.3859 | Tonnes |

| Glazing Panel | Tonnes | 72.1305 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 72.1305 | 0.0000 | 72.1305 | Tonnes |

| GluLam Sections | m3 | 498.0075 | 498.0075 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 232.7189 | Tonnes |

| Hollow Structural Steel | Tonnes | 5.2946 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 5.2946 | 0.0000 | 5.2946 | Tonnes |

| Joint Compound | Tonnes | 37.0640 | 0.0000 | 23.4389 | 0.0000 | 1.9532 | 11.6719 | 0.0000 | 37.0640 | Tonnes |

| MW Batt R20 | m2 (25 mm) | 17,393.7054 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 17,393.7054 | 0.0000 | 22.9829 | Tonnes |

| Nails | Tonnes | 1.0405 | 0.0000 | 0.2199 | 0.0265 | 0.2016 | 0.5925 | 0.0000 | 1.0405 | Tonnes |

| Paper Tape | Tonnes | 0.4254 | 0.0000 | 0.2690 | 0.0000 | 0.0224 | 0.1340 | 0.0000 | 0.4254 | Tonnes |

| Rebar, Rod, Light Sections | Tonnes | 22.4456 | 0.0000 | 0.0000 | 22.4456 | 0.0000 | 0.0000 | 0.0000 | 22.4456 | Tonnes |

| Screws Nuts & Bolts | Tonnes | 1.8393 | 0.0000 | 0.7330 | 0.0000 | 0.0916 | 1.0146 | 0.0000 | 1.8393 | Tonnes |

| Small Dimension Softwood Lumber, kiln-dried | m3 | 13.6011 | 0.0000 | 0.0000 | 0.0000 | 1.9371 | 11.6640 | 0.0000 | 5.7550 | Tonnes |

| Softwood Plywood | m2 (9 mm) | 18.0986 | 0.0000 | 0.0000 | 0.0000 | 18.0986 | 0.0000 | 0.0000 | 0.0822 | Tonnes |

| Spandrel Panel | Tonnes | 6.2862 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 6.2862 | 0.0000 | 6.2862 | Tonnes |

| Triple Glazed Hard Coated Argon | m2 | 2953.6890 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 2953.6890 | 0.0000 | 73.6244 | Tonnes |

| Water-Based Latex Paint | L | 18,176.7921 | 0.0000 | 12,630.9141 | 0.0000 | 0.0000 | 5545.8780 | 0.0000 | 13.6326 | Tonnes |

Data Availability

References

- 1.Kumar V., Lo Ricco M., Bergman R.D., Nepal P., Poudyal N.C. Environmental impact assessment of mass timber, structural steel, and reinforced concrete buildings based on the 2021 international building code provisions. Build. Environ. 2024 doi: 10.1016/j.buildenv.2024.111195. [DOI] [Google Scholar]

- 2.ICC Digital Codes . International Code Council; 2021. International Building Code (IBC)https://codes.iccsafe.org/content/IBC2021P1/preface (accessed 27 March 2023) [Google Scholar]

- 3.ICC Digital Codes . International Code Council; 2024. International Building Code (IBC)https://codes.iccsafe.org/content/IBC2024P1/preface (accessed 12 December 2023) [Google Scholar]

- 4.United Nations Environment Programme, 2022 Global status report for buildings and construction: towards a zero‑emission, efficient and resilient buildings and construction sector, Nairobi, 2022. https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed 12 August 2023).

- 5.Brashaw B., Bergman R. Vol. 17. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory; 2021. Wood Handbook Wood as an Engineering Material.https://www.fs.usda.gov/research/treesearch/62241 (Wood Handbook Wood as an Engineering Material). General Technical Report FPL-GTR-282. [Google Scholar]

- 6.Nepal P., Prestemon J.P., Ganguly I., Kumar V., Bergman R.D., Poudyal N.C. The potential use of mass timber in mid-to high-rise construction and the associated carbon benefits in the United States. PLoS ONE. 2024;19 doi: 10.1371/journal.pone.0298379. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Timmers M., John Martin S.A., Dennis Richardson A., Breneman Scott. WoodWorks Wood Products Council; Washington, DC, USA: 2019. Tall Wood Buildings in the 2021 IBC up to 18 Stories of Mass Timber.https://www.woodworks.org/resources/tall-wood-buildings-in-the-2021-ibc-up-to-18-stories-of-mass-timber/ [Google Scholar]

- 8.Zelinka S.L., Bergman R., Lo Ricco M., Martin W.A., Parsons B., Macdonald I., Cover J. 13th World Conference on Timber Engineering, WCTE 2023, World Conference on Timber Engineering (WCTE) 2023. Findings from the 2022 North American mass timber research needs assessment workshop; pp. 4576–4582. [DOI] [Google Scholar]

- 9.S. Pei, Proved the resilient seismic performance of a novel tall-timber rocking-wall system in unprecedented shake-table tests, engineering news-record. https://www.enr.com/articles/58048-shiling-pei-proved-the-resilient-seismic-performance-of-a-novel-tall-timber-rocking-wall-system-in-unprecedented-shake-table-tests (accessed 25 January 2024).

- 10.Pei S., van de Lindt J.W., Berman J., Ryan K., Dolan J.D., Pryor S., Wichman S., Busch A., Zimmerman R. 13th World Conference on Timber Engineering, WCTE 2023, World Conference on Timber Engineering (WCTE) 2023. Full-scale 3-D shake table test of a ten-story mass timber building; pp. 2084–2089. [DOI] [Google Scholar]

- 11.ANSI/APA PRG 320 . 2018. pp. 1–40. [Google Scholar]

- 12.Stegner H., Fotheringham N. Research and testing lead to historic code change the history of getting a sustainable tall building option mass timber approved in the U.S. building codes. For. Prod. J. 2022;72:226–234. doi: 10.13073/2376-9637-72.4.226. [DOI] [Google Scholar]

- 13.WoodWorks, Wood Products Council, Status of building code allowances for tall mass timber in the IBC. https://www.woodworks.org/resources/status-of-building-code-allowances-for-tall-mass-timber-in-the-ibc/ (accessed 12 December 2023).

- 14.ICC Digital Codes, Chapter 6 Types of construction, 2024 International Building Code (IBC). https://codes.iccsafe.org/content/IBC2024P1/chapter-6-types-of-construction (accessed 12 December 2023).

- 15.Structure magazine, 2024 IBC and IFC Mass Timber Changes. https://www.structuremag.org/?p=25433 (accessed 12 December 2023).

- 16.Skidmore, Owings & Merrill, L.L.P., Timber tower research project, 2013. https://www.som.com/wp-content/uploads/2021/08/timber-tower-final-report-and-sketches-1633640951.pdf. (accessed 21 February 2023).

- 17.Updated ASCE 7-22 standard | ASCE, (n.d.). https://www.asce.org/publications-and-news/civil-engineering-source/article/2021/12/02/updated-asce-7-22-standard-now-available (accessed 27 August 2023).

- 18.Vulcraft, Steel Roof & Floor Deck Manual Aug 2018. https://vulcraft.com/catalogs/Deck/Vulcraft-Steel-Roof-Floor-Deck-Manual-Aug2018.pdf.

- 19.Martin SL, Environmental product declaration. 2020. https://www.kiwa.com/49bf9f/globalassets/germany/veroffentlichte-epds/epd_-slm_pc_strand-final.pdf. (accessed 22 February 2023).

- 20.Garvey T., Gloria T., Environmental product declaration Suncoast post-tension, Post tensioning system, SCS Global Services, Version 3.2. UL Environment 2018. https://cdn.scscertified.com/products/cert_pdfs/SCS-EPD-06741_Suncoast-PT_PT-Strand_030121.pdf).

- 21.Hellmeister M. The University of Maine; United States, Maine: 2022. Comparative Life Cycle Assessment of Embodied Carbon and Operational Energy of Different Building Systems.https://digitalcommons.library.umaine.edu/etdd [Google Scholar]

- 22.Puettmann M., Pierobon F., Ganguly I., Gu H., Chen C., Liang S., Jones S., Maples I., Wishnie M. Comparative LCAs of conventional and mass timber buildings in regions with potential for mass timber penetration. Sustainability (Switzerland) 2021;13 doi: 10.3390/su132413987. [DOI] [Google Scholar]

- 23.Allan K., Phillips A.R. Comparative cradle-to-grave life cycle assessment of low and mid-rise mass timber buildings with equivalent structural steel alternatives. Sustainability (Switzerland) 2021;13 doi: 10.3390/su13063401. [DOI] [Google Scholar]

- 24.Chen Z., Gu H., Bergman R.D., Liang S. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the Athena's Impact estimator for buildings. Sustainability (Switzerland) 2020;12 doi: 10.3390/su12114708. [DOI] [Google Scholar]

- 25.Athena Sustainable Materials Institute, IE for Buildings. http://www.athenasmi.org/our-software-data/impact-estimator/ (accessed April 10, 2023).

- 26.ISO. ISO 21930:2017 - Sustainability in buildings and civil engineering works — Core rules for environmental product declarations of construction products and services. https://www.iso.org/standard/61694.html. (accessed 1 March 2023).

- 27.U.S. Green Building Council, LEED rating system. https://www.usgbc.org/leed (accessed 8 June 2023).

- 28.One Click LCA, LCA in LEED, Whole building Life Cycle Assessment. https://www.oneclicklca.com/fi/whole-building-life-cycle-assessment-for-leed-v4-credits/ (accessed 8 June 2023).

- 29.ASTM, ASTM E2921:22, Standard practice for minimum criteria for comparing whole building life cycle assessments for use with building codes, standards, and rating systems. https://global.ihs.com/doc_detail.cfm?document_name=ASTM/20E2921&item_s_key=00616543 (accessed 22 March 2023).

- 30.EN, EN 15978:2011 - Sustainability of construction works - Assessment of environmental performance of buildings - Calculation method. https://standards.iteh.ai/catalog/standards/cen/62c22cef-5666-4719-91f9-c21cb6aa0ab3/en-15978-2011. (accessed 22 March 2023).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The dataset files are accessible under the Creative Commons Attribution 4.0 International license, permitting free use. Additional details are available in the data accessibility section of the specification table.