Abstract

Field-effect transistors (FETs) based on two-dimensional materials (2DMs) with atomically thin channels have emerged as a promising platform for beyond-silicon electronics. However, low carrier mobility in 2DM transistors driven by phonon scattering remains a critical challenge. To address this issue, we propose the controlled introduction of localized tensile strain as an effective means to inhibit electron-phonon scattering in 2DM. Strain is achieved by conformally adhering the 2DM via van der Waals forces to a dielectric layer previously nanoengineered with a gray-tone topography. Our results show that monolayer MoS2 FETs under tensile strain achieve an 8-fold increase in on-state current, reaching mobilities of 185 cm²/Vs at room temperature, in good agreement with theoretical calculations. The present work on nanotopographic grayscale surface engineering and the use of high-quality dielectric materials has the potential to find application in the nanofabrication of photonic and nanoelectronic devices.

Subject terms: Nanoscale devices, Techniques and instrumentation

Improving the performance of 2D transistors is essential to enable their future application for beyond-silicon electronics. Here, the authors report a method to induce localized tensile strain in monolayer MoS2 transistors, leading to enhanced electron mobilities up to 185 cm2/Vs and an 8-fold increase of the on-state current densities.

Introduction

Semiconducting 2D transition metal dichalcogenides (TMDCs), such as MoS2, are widely investigated for next-generation nanoelectronics and optoelectronics1,2. The recent demonstrations of MoS2 transistors with sub-nanometer channels or gate lengths make them encouraging candidates for extending Moore’s law3–5. However, due to electron-phonon scattering6,7, a significant limitation for 2DM transistors lies in their charge carrier mobilities. It is thus essential to develop novel strategies for the engineering of the 2DMs’ intrinsic properties; these nanofabrication processes need to be compatible with the methods suitable for manufacturing transistors based on these materials.

To enhance the performance of 2DM transistors, numerous approaches have been proposed, each with its own advantages and disadvantages. Channel doping8–10, contact engineering2,11, and defect modulation12,13 have improved the electron mobility of TMDC-based transistors. Yet, intrinsic intervalley scattering critically limits the carrier transport, and thus alternative approaches are needed to engineer the valley structures14–17. For silicon electronics, strain engineering is an established approach to modify band structure and carrier mobility, and it is used in production to improve the mobility of silicon-based metal-oxide-semiconductor field-effect transistors (MOSFETs)18,19. For semiconducting 2DMs, strain plays an equally significant role in modifying the band structure and phonon dispersion, thereby influencing scattering processes20–23. The use of thermally actuated micromechanical devices24, substrate heating25, thermomechanical nanoindentation20, thin-film stress induced by electric fields26, bulging devices with pressurized components21,27, tip indentation to stretch 2DMs via direct contact28, and the bending and/or stretching of flexible polymer substrates29–33 have been employed to induce strain and study its physical effects in 2DMs. However, most of these techniques are incompatible with existing silicon-based technologies with high-density integration capabilities. Strain induced by substrate lattice mismatch34, thermal expansion mismatch35, integration with thin film stressors27,36 or underlying thin film stress constrains the choice of substrate. For scalability purpose, strain engineering of atomically thin materials using pre-patterned substrates has been developed22,37–43. For instance, crested substrates have been introduced to enhance the performance of optical and/or electrical devices based on 2DMs with induced strain effects. However, the use of pre-structured substrates often results in suspended 2DMs, leading to potentially unstable semiconductor-dielectric interfaces. Therefore, the fabrication of compact nanoscale 2DM transistors with deterministic strain distribution compatible with advanced device architecture has yet to be achieved.

In this work, we demonstrate that monolayer MoS2 FETs subjected to a permanent multiaxial tensile strain on gate oxide patterned with sinusoidal waves achieve significantly higher electron mobilities compared to unstrained devices. The fabrication is based on a sequence of advanced nanofabrication techniques, including thermal scanning probe lithography (t-SPL) for grayscale nanopatterning44–46. The t-SPL with a lateral resolution below 10 nm and sub-nanometer vertical depth control enables fabrication of high-resolution grayscale nanopattern with deterministic aspect ratio control45,47. The tensile strain in the 2DM is induced through the elongation of the 2DM during the process of contact-transferring a planar 2DM flake using an elastomeric stamp onto a grayscale sinusoidal silicon dioxide (SiO2) dielectric. This sinusoidal topography is previously fabricated by t-SPL and dry etching and can be programmed by adjusting the aspect ratios, also referred to as depth-to-pitch ratios. The depth-to-pitch ratio control capability of t-SPL, which cannot be achieved with such precision through other grayscale nanopatterning techniques such as electron beam lithography48 and interference lithography49, provides deterministic control of strain induced in 2DMs. Varying the depth-to-pitch ratios of nanotopographies allows for the introduction of areas with strain gradients within a single 2DM flake by adjusting the amplitude and spatial frequency of the sinusoidal waves. Compared to other approaches such as nanopillar arrays and rippled or crested substrates, grayscale nanotopographies also offer improved conformal attachment of 2DMs by reducing wrinkles and suspended parts. This results in improved dielectric-semiconductor interfaces and a mechanically more stable environment compatible with subsequent fabrication processes. In contrast to the 2DMs strained by sharp crested patterns, where strain is non-uniform and is very high at peaks and very low on flat parts, grayscale nanopatterns offer a more homogeneous distribution of strain while still keeping the strain localized within the pattern area. We systematically study how the tensile strain affects the electrical performance of 2DM transistors. We find noticeable enhancements both in electron mobility and in on-state current of the strained 2DM transistors, up to 8 times compared to the unstrained ones. First-principles calculations of electron-phonon scattering, which consider doping and valley profile as parameters, are used to estimate theoretically the effect of strain on electronic transport. The theoretical findings are in good agreement with the experimental results and predict the enhancement of electron mobilities in the presence of strain obtained by surface topography engineering of the gate dielectric.

Results and discussion

Design and fabrication of strained 2D FETs

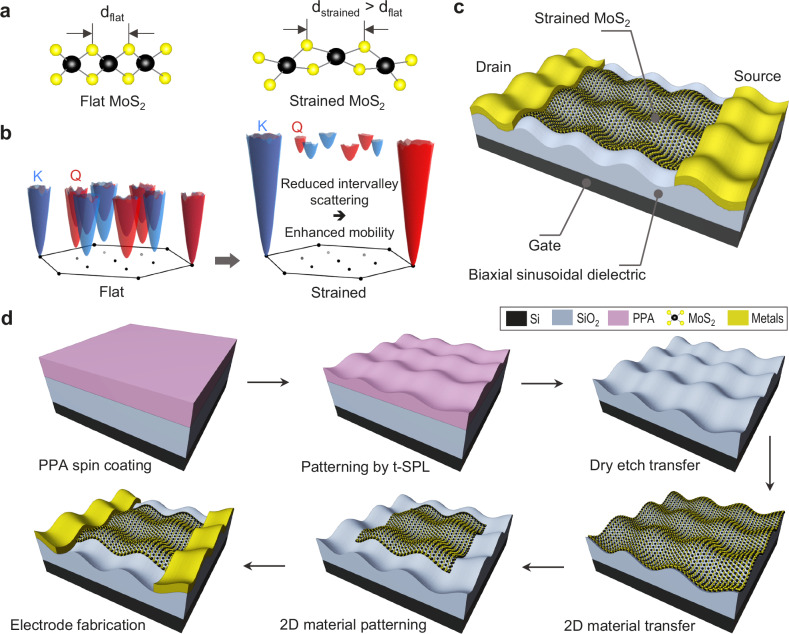

When exposed to tensile strain, a MoS2 monolayer undergoes an expansion in lattice parameter and in out-of-plane atomic displacements (see Fig. 1a). This tensile strain translates into an increased energy separation between the K- and Q-valleys, as shown in Fig. 1b, blocking some of the available electron-phonon scattering channels and resulting in a reduction of electron-phonon scattering23 and consequently in increased mobility14,15. Fig. 1c shows the configuration of the strained monolayer MoS2 FET, where the MoS2 layer adheres conformally via van der Waals forces to a nanopatterned SiO2 gate dielectric. The surface of the gate dielectric is patterned with sinusoidal wave topographies to introduce tensile strain in the monolayer flake of MoS2 placed on top (Supplementary Fig. 1). During the transfer to the topographically shaped gate dielectric, the MoS2 flake deforms along multiaxial in-plane directions of the sinusoidal waves, leading to a tensile stress for the 2DM lattice.

Fig. 1. Concept drawing of a strain-engineered 2D transistor made by grayscale nanopatterning of the gate dielectric.

a Atomic structures of the flat MoS2 (without strain) and the MoS2 with tensile strain illustrating the variation in lattice parameters. b Density-functional theory (DFT) calculations of the electron spin-valley landscape of MoS2, showing the difference in the K- and Q-valley profiles arising under tensile strain and resulting in reduced intervalley scattering. c 3D illustration of a strained monolayer MoS2 FET with a sinusoidally shaped gate dielectric, inducing tensile strain in the transistor’s two-dimensional material (2DM) channel. d Device fabrication steps: polyphthalaldehyde (PPA) spin coating, thermal scanning probe lithography (t-SPL) patterning, dry etch transfer, 2D material transfer, 2D material patterning by electron beam lithography (EBL) and dry etching, and electrode fabrication by EBL and metal evaporation.

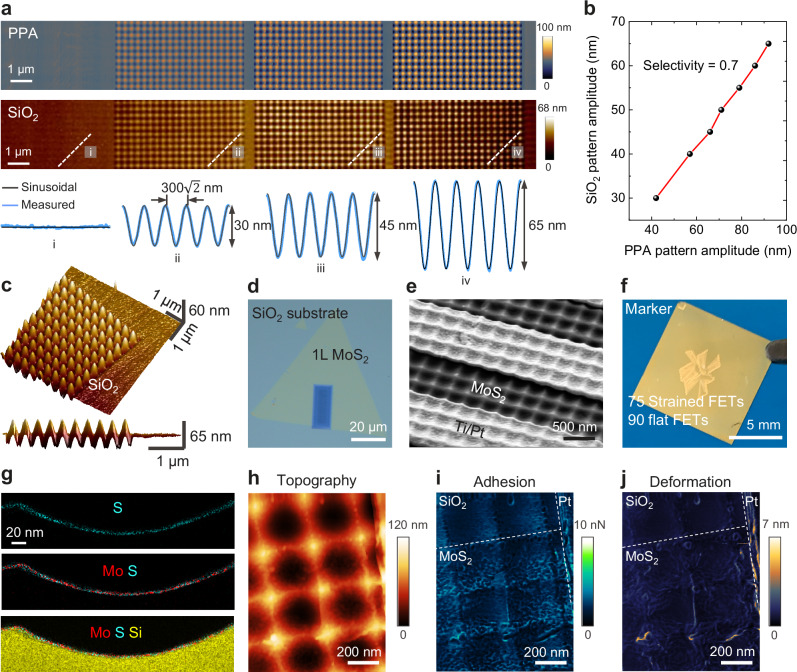

To demonstrate the effect of strain on the carrier transport, we fabricated tensile strained FETs made from monolayer MoS2 flakes, following the process flow detailed in Fig. 1d. First, a thermally sensitive resist, polyphthalaldehyde (PPA), is spin-coated on the SiO2/Si chip. Then, biaxial sinusoidal waves with a diagonal pitch of 300 nm and varying peak-to-peak diagonal amplitudes are patterned on PPA by t-SPL (Fig. 2a and Supplementary Fig. 2). Since PPA is not a reliable gate dielectric, we transferred the pattern by dry etching into the underlying SiO2 layer (Fig. 2a and Supplementary Fig. 3). This process allows introducing a variability of strain gradients into the 2DM by adjusting the amplitude of the nanotopography (see Fig. 2b). To limit surface roughness that could cause nano-sized cracks in the transferred 2D flakes, a low etch selectivity between SiO2 and PPA of 0.7 is developed to transfer the pattern into SiO2 dielectric, resulting in a surface roughness of ~ 1.2 nmrms (Fig. 2c). The 2DM layer is then transfer printed using a polymer support, whereby the 2DM deforms and adheres to the wavy SiO2 surface by van der Waals forces. After removal of the transfer polymer, the 2DM remains in conformal contact with the wavy surface. To minimize the risk of the 2DM sliding on the SiO2 surface during the transfer step that would result in a subsequent release of deliberately induced intrinsic stress, we designed the wavy area of the substrate to be smaller than the 2DM flake (Fig. 2d), effectively mitigating sliding.

Fig. 2. Fabrication and characterization of strained monolayer MoS2 transistors.

a Biaxial sinusoidal pattern of PPA resist with varying depth profiles and the corresponding patterned SiO2 substrate fabricated by dry etching-based pattern transfer from PPA nanopatterns, with its measured depth profiles in the selected regions showing periodic sinusoidal waves. b Graph showing the peak-to-peak diagonal amplitude of the sinusoidal nanopattern after pattern transfer into SiO2 by plasma etching with a SiO2 to PPA etch selectivity of 0.7 favoring smooth surfaces. c Atomic force microscope (AFM) image showing the 3D topography of the biaxial sinusoidal SiO2 substrate having a surface roughness of ~1.2 nmrms. The side view of the topography shows the regular symmetry of the sinusoidal wave periods. d Optical microscopy image of the metal-organic chemical vapor deposition (MOCVD) grown MoS2 flake transferred on the pre-patterned substrate. e Scanning electron microscope (SEM) image of a representative device showing the MoS2 channel and S/D electrodes both with the biaxial sinusoidal pattern surface. Image tilt angle is 45°. f Optical image of a fabricated chip (1 cm × 1 cm) consisting of 75 strained FETs and 90 flat FETs. g Element mappings of the transistor cross-section between 2DM and dielectric showing continuous wavy monolayer MoS2 layer that has intimate contact with the corrugated SiO2 substrate. h AFM topography (height) showing no difference in pattern amplitudes between the flake and SiO2 substrate. i AFM image showing the adhesion map of the strained MoS2 transistor indicating the position of the 2D flake. j AFM deformation image indicating conformal contact between the 2D flake and SiO2 substrate with exception of a few wrinkles with ≤ 6 nm deformations. Dashed lines represent the borders of materials. Peak Force setpoint is 10 nN for AFM characterization.

To structure the MoS2 flakes into a transistor configuration, we lithographically patterned the 2DM in order to obtain isolated FET channels. Source (S) and Drain (D) electrodes are subsequently created by lift-off metallization of Ti/Pt. To protect the 2DM layer during the fabricating process, it is covered by a PMMA resist layer until the final lift-off step (Supplementary Figs. 8–10). The SEM image in Fig. 2e shows the nanopatterned MoS2 channel and the S/D electrodes.

We fabricated 75 strained FETs and 90 flat FETs on a single chip (1 cm × 1 cm), as shown in Fig. 2f, with the fabrication process detailed in Supplementary Fig. 9. To be able to validate our hypotheses it is of utmost importance that we can assert that the 2DM follows the nanotopographic contours conformally. We thus systematically investigated the 2DM/dielectric interface using various characterization techniques. First, SEM and cross-sectional TEM along with energy dispersive X-ray (EDX) elemental maps were performed (Fig. 2e, g and Supplementary Fig. 11). This was followed by quantitative nanomechanical AFM mapping in various imaging modes (Fig. 2h–j). The adhesion map consistently reveals a sinusoidal pattern, whether 2DM is present or not (Fig. 2i). Notably, the presence of 2DM is scarcely discernible in both the topography and deformation maps, which are characterized by relatively high tip forces of 10 nN for monolayer flakes, indicating a strong adhesion between the 2DM and the dielectric surface (Figs. 2h and 2j). However, a few wrinkles with tens of nanometers width are also shown in Fig. 2j. All characterization steps undertaken confirm the conformal contact of the 2DM layer with the underlying wavy SiO2 dielectric.

Strain characteristics of strained 2DM transistors

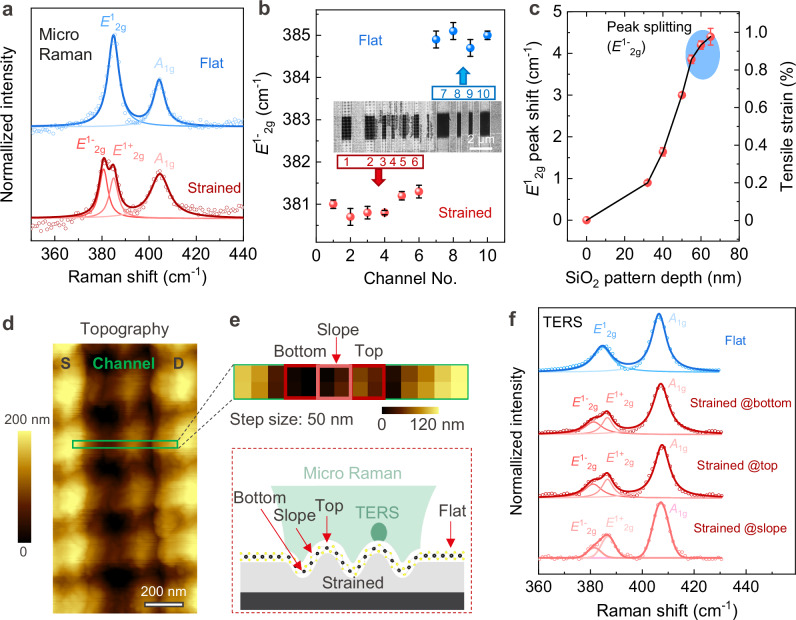

Introducing tensile strain in 2DMs without causing substantial material damage (e.g., folds or cracks) is one of the key assets of our approach. As illustrated in Supplementary Fig. 14, the monolayer MoS2 flake is picked up with a PDMS or PC film and then transferred onto the target pre-patterned gate dielectric. Micro-Raman spectroscopy of the nanopatterned MoS2 shows a clear redshift of the E12g peak as a result of the induced tensile strain (Fig. 3a). The Raman measurements are performed at three different positions along the channel, resulting in consistent redshifts. The splitting of the Raman peak E12g indicates significant strain in the nanopatterned MoS2 transistors. However, no shift in the Raman peak A1g is observed. An increase in the A1g FWHM of MoS2 also indicates the effect of strain31 as compared in Supplementary Table 1. To determine the reproducibility of our method, we examined an array of transistors fabricated on the same flake and found similar redshifts (Fig. 3b and Supplementary Fig. 15). The strain in the transistor is derived from the biaxial sinusoidal wave pattern engineered in the substrate prior to the 2DM transfer printing. As expected, increasing the SiO2 pattern amplitudes results in a proportional increase in the induced tensile strain on the MoS2 layer, corresponding to the surface area increase. In our design, we implemented wavy nanopatterns with peak-to-peak amplitudes up to 65 nm and a diagonal pitch of 300 nm, resulting in up to 5.6% increase in surface area per unit design area. With this configuration, we anticipated a theoretical strain of up to 2.8%, calculated using the strain formula based on elongation (Supplementary Fig. 16). In our fabricated sample, we measured a shift of the E12g peak by −4.4 cm−1, corresponding to a strain of 1% based on the widely reported and theoretically predicted Raman peak shift of −4.5 cm−1/% strain for E12g phonon22,30. However, other works have reported a range of values for the peak redshifts ranging from 2.1 cm−1/% strain50 to 5.2 cm−1/% strain37 for E12g phonons. These minimum and maximum values lead to an estimated strain range from 0.85% to up to 2.10% when our measured Raman shifts are considered. While it is possible to derive intermediate values from existing literature20,22,30, we opted to utilize the extensively documented and theoretically anticipated Raman peak redshift of 4.5 cm−1/% strain for the E12g phonon as our benchmark. The discrepancy between the theoretically calculated strain, which is related to surface area increase through sinusoidal nanopatterning, and measured strain might arise from several factors, including flake sliding and strain relaxation during transfer, as well as imperfect attachment of the 2DM on a sinusoidal surface with a high spatial frequency pitch. During the elongation of the 2D flake, the sliding between the 2D layer and the sinusoidal patterned substrate is inevitable due to the weak van del Waals force51, which is one of the critical challenges in strain engineering of 2DMs. The transfer of 2D flakes involves a few temperature-related steps (see Supplementary Figs. 4, 7) that cause strain relaxation of the 2D flakes. The 1% strain achieved remains relatively high, which is sufficient to approach the upper mobility limits in MoS2 according to first-principles calculations.

Fig. 3. Strain characterization of strained monolayer MoS2 transistors.

a Raman spectra of the strained and unstrained MoS2 channels. The circles represent the raw data and the solid lines represent the Lorentzian fit. b E12g Raman peak position variation in different channels of the same flake. The inset is the SEM image of the strained and unstrained transistors made from the same monolayer MoS2 flake. c Variation of E12g Raman peak position as a function of the pattern amplitude for 0, 30, 40, 50, 55, 60, and 65 nm. The blue shaded area represents data from peak splitting measurements. The error bars in panels b and c represent the maximum and minimum values with the representative points corresponding to the average values. d AFM topography showing the strained transistor composed of sinusoidally patterned structures supporting the monolayer MoS2 sheet as channel and the metal electrodes as source and drain. The region of tip-enhanced Raman spectroscopy (TERS) mapping is highlighted with a green rectangle. e Topography image measured during hyperspectral TERS mapping with a step size of 50 nm. The position of the sinusoidal wave structure on the bottom, the top and the slope is marked with red squares and illustrated in the scheme below where the resolutions of micro-Raman spectroscopy and TERS are compared. f Comparison of the average TERS spectra of the flat region and the strained regions on the bottom, the top and the slope. A splitting of the E12g peaks is observed in the strained region, confirming the presence of strain in the MoS2 sheet.

We used micro-Raman spectroscopy to visualize the strain distribution as a map, confirming that strain is present throughout the entire nanopatterned 2DM without significant local variations (Supplementary Fig. 17). To visualize the strain distribution below the optical diffraction limit, we performed high resolution AFM-based tip-enhanced Raman spectroscopy (AFM-TERS)52. Fig. 3d shows the AFM topography of a strained 2D FET with the S/D electrodes and the patterned 2D channel. Hyperspectral line TERS mapping was performed across the nanopatterned channel in the rectangular area marked in Fig. 3d, with a step size of 50 nm. The AFM topography data captured simultaneously with the TERS data is presented in Fig. 3e. Figure 3f shows the average TERS spectra, computed from 4 pixels covering an area of 100 × 100 nm², of the patterned MoS2 on the bottom, the top and the slope of the sinusoidal wave pattern, in comparison to the spectrum of the flat unstrained MoS2. The TERS spectra of the strained MoS2 show a splitting of the E12g band into E1-2g and E1+2g bands, consistent with the results obtained from micro-Raman measurements. Notably, the E1-2g and E1+2g bands are found to be separated by about 5 cm−1 both on the bottom, the top and the slope of the patterned MoS2, as shown in Fig. 3f. This indicates that both techniques, micro-Raman and AFM-TERS, measure a similar level of strain in the MoS2 layer, and this consistent strain level is observed on the bottom, the top and the slope of the sinusoidal nanopatterns. Additional TERS measurements from other patterned structures are shown in Supplementary Fig. 18.

Electrical characteristics of strained transistors

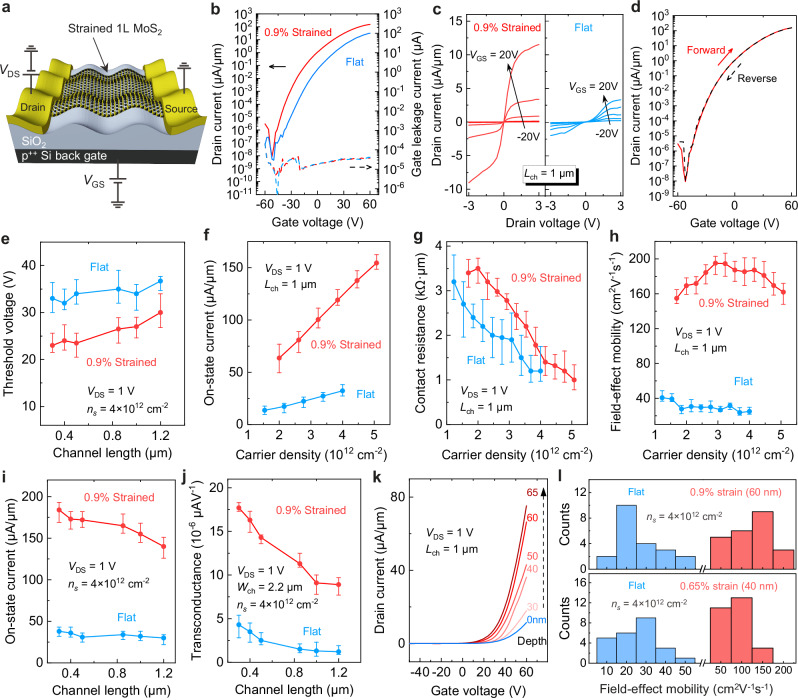

The electrical performance of the strained and unstrained transistors is experimentally measured using a semiconductor analyzer, as shown in Fig. 4a. Figure 4b compares the transfer curves (drain-to-source current, ID versus gate-to-source voltage, VGS) of the strained and flat transistors patterned within a single monolayer MoS2 flake. The gate leakage currents in all the measured transistors are in the order of a few pA, i.e., much smaller than the drain currents in the ‘on’ region. The output characteristics (ID versus drain-to-source voltage, VDS) of both strained and flat transistors show a nearly linear regime of VDS in the range of −0.5 to 0.5 V at room temperature (T = 300 K) (Fig. 4c) and at lower temperatures (T ranging from 80 to 260 K) (Supplementary Figs. 21, 22), indicating a nearly ohmic behavior with low Schottky barriers in 2DM-metal configuration (Supplementary Figs. 23–25). Approximate current saturation of both devices is observed at VDS = 3 V. The forward and reverse transfer curves of the strained transistor are plotted together on a logarithmic scale in Fig. 4d. Importantly, the devices show a hysteresis-free transfer curve across a wide range of VGS and demonstrate good reproducibility and stability (Supplementary Figs. 28, 29), thanks to the high-quality interface contact between 2DM and dielectric. This provides an additional and convincing demonstration that the flake transfer strategy and the design of the gate dielectric topography are compatible with standard transistor fabrication processes, which in turn preserves the potential for integration of strained 2DM FETs in advanced electronic devices.

Fig. 4. Electrical characteristics of the strained transistors.

a Schematic cross-section and electrical connections of a back-gate strained metal-organic chemical vapor deposition (MOCVD) grown monolayer MoS2 FET. The structure comprises the heavily p-type doped Si substrate as global back-gate, and a dry thermally grown SiO2 as back-gate dielectric. b Room-temperature transfer curve of the strained FET measured at drain-to-source bias voltage (VDS), VDS = 1 V. The gate leakage current (IGS) versus gate-source voltage (VGS) is plotted as well. c ID as a function of VDS at varying VGS for strained (left) and unstrained (right) transistors fabricated on the same MoS2 flake with the same channel length and width. d Forward (red solid curve) and reverse (black dash curve) transfer curves on logarithmic scales. The curves are hysteresis-free in the entire voltage range of the device after thermal annealing. e Threshold voltage (VT) varying with channel length at VDS = 1 V and carrier density at ns = 4 × 1012 cm−2. f–h Transistor metrics (f: on-state current, Ion, g: contact resistance and h: field-effect mobility) of strained ones and flat ones are compared with the varying carrier density at VDS = 1 V. i, j Ion and transconductance (gm) of both transistors are compared with varying channel lengths. The error bars in panels e–j represent the maximum and minimum values with the representative points corresponding to the average values for 120 transistors in panels e, i, and j, and for 30 transistors in panels f–h. k Typical ID–VGS of strained FETs (red) and flat FET (blue) on SiO2 dielectrics with various pattern amplitudes. l Statistical distribution of electron mobility of the strained FETs on the substrate with different strains (or pattern amplitude).

The threshold voltage (VT) of the strained transistors is lower than that of the flat ones (Fig. 4e and Supplementary Fig. 20), suggesting that the electron density increases with the decreasing bandgap under tensile strain. To account for shifts in VT, we compared transistor metrics, i.e., on-state current (Ion), contact resistance (Rc) and field-effect mobility (Fig. 4f–h) at the same carrier density calculated using ns = Cox(VGS – VT) / q where Cox is the gate dielectric capacitance and q is the elementary charge. The Ion of strained and flat transistors linearly increases with the carrier density. The Rc of both strained and unstrained FETs is less than 2 kΩ·μm at ns ≥ 4 × 1012 cm−2, indicating that the devices are channel-dominated (Fig. 4g and Supplementary Fig. 26). For a fair comparison, the carrier-density-dependent field-effect mobility of both transistors was compared at the same carrier density (Fig. 4h). We also compared the transconductance of both transistors for different channel lengths (Fig. 4j). Key parameters of the strained and unstrained FETs are shown in Supplementary Tables 2, 353.

With the electrical characterization of both strained and unstrained transistors performed, we next analyze the effect of strain on the field-effect electron mobility and on-state current. By increasing the pattern amplitude from 30 nm to 65 nm and thereby intensifying the strain effect, a noticeable enhancement in the drain current density (Fig. 4k) is observed. To avoid flake-to-flake variabilities, we only compared devices (strained and unstrained) fabricated within same single flakes. To show the reproducibility of the electron mobility enhancement of MoS2 transistors under tensile strain, we fabricated and measured around 400 transistors made from 8 flakes. The statistical distribution of electron mobilities, measured in flat (unstrained), 0.65%-strain, and 0.90%-strain transistors, is summarized in Fig. 4l. The results are in the range of 8 to 60 cm2/Vs, 50 to 150 cm2/Vs, and 50 to 180 cm2/Vs at 300 K, respectively, with the strained transistors exhibiting a clear increase in electron mobility compared to the flat ones. The mobilities of the flat 2DM transistors do not exceed 60 cm2/Vs, consistent with data in the literature for MoS2 FETs without channel encapsulation11,54,55.

Analytical calculations and simulations of the electrical field distribution and capacitance in the strained transistors show no significant difference in the gate capacitance, indicating that it exerts no discernible impact on the strained transistors. While flat transistors exhibit a gate capacitance of 2.47 × 10−8 F/cm2, that of strained transistors with a 60 nm peak-to-peak depth is 2.56 × 10−8 F/cm2 (Supplementary Figs. 30, 31). The variation in gate dielectric thickness leads to differing doping concentrations in the FET channel, impacting mobilities. However, our comparison is based on flat dielectrics with a 140 nm gate dielectric thickness and sinusoidal dielectrics with a mean thickness of 140 nm, both having the same surface quality. This results in a doping concentration change of only 3.5%, which does not introduce significant alterations, according to theoretical and experimental studies56. Consequently, our findings let us conclude that the mobility enhancement primarily arises from the drastic reduction in intervalley scattering due to the induced strain.

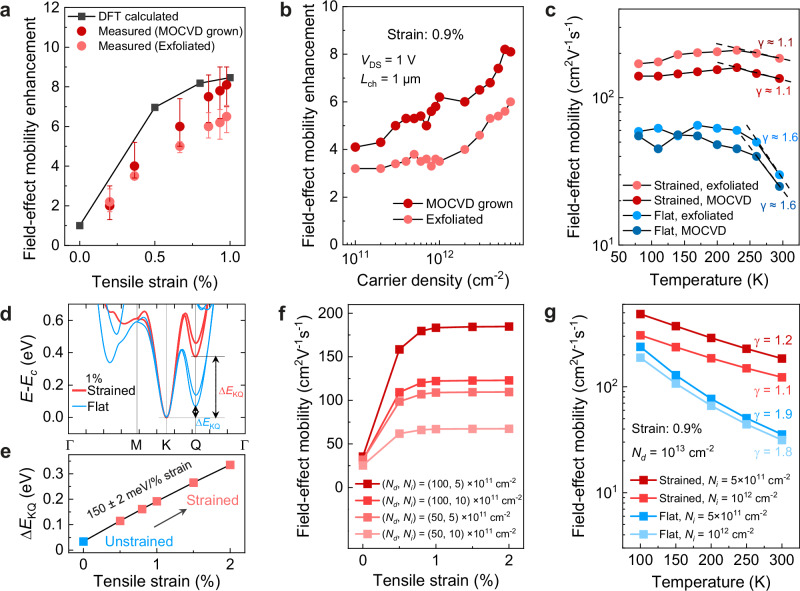

Quantitative analysis of the electron mobility enhancement under various strains is summarized in Fig. 5, with Fig. 5a showing a linear increase in mobility enhancement with strain, followed by a gradual saturation. A similar tendency is observed for both types of flakes, whether they are metal-organic chemical vapor deposition (MOCVD) grown or mechanically exfoliated. Figure 5b shows a comparison of the electron mobility enhancement of the 0.90% strained transistors under different electrostatically induced carrier densities. Linear growth is found as a function of carrier density for both types of flakes. To further investigate the origin of the main scattering mechanisms in the strained transistor, the mobility as a function of temperature is shown in Fig. 5c. In flat MoS2 transistors, the mobility decreases as expected slightly with increasing temperature with a power exponent γ of 1.6 at higher temperatures (T > 200 K), which is typical for phonon-limited transport57,58. However, in the case of strained MoS2 transistors, the temperature exponent changes its value to γ ≈ 1.1, which indicates a substantial reduction of electron-phonon scattering in strained MoS2 at room temperature.

Fig. 5. Effect of strain on mobility: experiments and DFT calculation.

a Mobility enhancement as a function of tensile strain for the strained exfoliated flake and strained MOCVD grown flake, comparing with the DFT-calculated value at doping concentrations of 5 × 1012 cm−2, excluding impurity effects to illustrate the enhancement limit for phonon-limited mobility. The error bars represent the maximum and minimum values with the representative points corresponding to the average values. b Mobility enhancement as a function of carrier density for the strained exfoliated flake and strained MOCVD grown flake. c Electron mobility as a function of temperature fitted with the power law μ ≈ T–γ, where electron-phonon scattering transport is suppressed in strained FETs compared to flat FETs. d A zoom on the band structure of the K and Q valleys for flat (blue) and strained (red) MoS2 with an electron doping of Nd = 5 × 1012 cm−2. In each case, the two band structures are aligned with respect to the bottom of the conduction band (Ec). e Variation of valley energy separation, ∆EKQ as a function of the applied strain. See Supplementary Fig. 19 for the experimental results on the strain induced bandgap modulation obtained through photoluminescence (PL) measurements. f Analysis of DFT mobility variation under strain, considering both phonon and impurity scattering, across varying impurity and doping concentrations. g DFT mobility (with phonon and impurity scattering) as a function of temperature for the highest experimental doping, Nd = 1013 cm−2, in flat (blue) and strained (red) systems.

Comparison of experimental results with calculations

We support the experimentally measured improvements in electron mobility under strain with extensive first-principles calculations of electron-phonon coupling and mobilities by applying uniform tensile strain across the material. To this aim, we note that the temperature dependence of the mobility (Fig. 5c) reveals distinct contributions to the total enhancement: extrinsic disorder-related mechanisms dominate at low temperatures ( < ~150 K), while intrinsic phonon scattering prevails at higher temperatures. We first study the intrinsic phonon-limited mobility using density-functional perturbation theory (DFPT)59,60 and the Boltzmann transport equation (BTE)61,62, establishing an ideal limit for the potential enhancement through strain. We then include a model for disorder16 and show a decrease in the enhancement towards experimental values (Fig. 5a). Details on the model and calculations are reported in Methods and Supplementary Information.

Considering phonon-limited mobility, we note its strong dependence on the occupation of MoS2’s Q valley14. This is attributed to increased electron-phonon scattering through activated intervalley scattering and enhanced intravalley coupling14,15,17,63. The Q valley occupation depends on doping and the relative energy positions of K and Q valleys, ∆EKQ. Straining the 2DM results in a reduction of the layer thickness under tensile strain64–66, which increases the energy separation ∆EKQ, as sketched in Fig. 1c, depleting the Q valley of electrons and enhancing the phonon-limited mobility.

We also establish that effective masses, phonons, and electron-phonon interactions exhibit negligible variations under strain (Supplementary Information Section 8). Thus, the main changes in phonon-limited mobility arise from strain-induced shifts in the valley positions. We compute ∆EKQ as a function of strain (Fig. 5e) and use a previously reported ab-initio model14 to determine the corresponding changes in mobility at doping concentrations of 5 × 1012 and 1 × 1013 cm−2 at room temperature. The energy separation variation rate is around 150 meV/% strain, close to the experimental value obtained from the photoluminescence measurement (Supplementary Fig. 19). The model was precisely designed to describe the changes in electron-phonon scattering as a function of doping and ∆EKQ. Our results show a strain-induced mobility enhancement up to 12.7 and 8.5, respectively for the highest and the lowest electron doping, and mobilities larger than that found in experiments for similar doping (Fig. 5a), establishing an ideal upper limit. Notably, the increase saturates rapidly at modest strains ( ~ 0.8–1%) as the Q valley is fully emptied. The saturation point depends on the initial ∆EKQ at 0%; a larger separation requires less strain for maximum enhancement.

Disorder is mainly induced by charged impurities that involve local distortions in the scattering potential, predominantly affecting low temperatures. For more realistic comparisons with experiments, we incorporate electron scattering from charged defects into our calculations16, adopting typical densities Ni of 5 × 1011 cm−2 and 1 × 1012 cm−2, following the literature67,68. These are meant to provide an effective model for unknown sources of disorder, notably excluding strain-induced modifications in impurity scattering. In Fig. 5f, we compare strain-dependent mobilities for two different values of doping and impurity concentrations. At constant doping, including impurities significantly reduces mobilities and brings them closer to experiments. Although the saturation point at ~0.8–1% strain remains, the overall enhancement (5.2–3.9) slightly underestimates experimental data (Fig. 5a, f). This could be due to the simulation’s fixed doping and impurity concentrations, whereas experimental fluctuations in these levels under varying strain would lead to deviations from theoretical predictions. At saturation, with an empty Q valley, mobility can be further boosted by increasing doping or reducing impurities. In flat systems, doping and defects play a smaller role, as the Q valleys are filled and intervalley scattering dominates, explaining why the curves join towards zero strain in Fig. 5f. While some uncertainty remains about disorder, we further characterized the phonon contribution via the power exponents of the computed temperature-dependent mobilities in Fig. 5g. These findings agree with our experimental results shown in Fig. 5c, particularly within the same high-temperature range. These calculations confirm that the increased energy separation due to strain in the 2DM effectively reduces electron-phonon scattering, consequently enhancing electron mobility. Importantly, defects within the MoS2 layer itself and at the underlying gate dielectric interface, which cause extrinsic scattering, are also predicted to play a role in the variations of mobility under strain.

We demonstrated that tensile strain effectively modulates the band structure of MoS2, splitting the K and Q valleys and greatly reducing intervalley phonon scattering in the latter. This significantly enhances electron mobility and provides a powerful approach to extending the performance limits of 2DM transistors. To achieve this, we developed a nanoengineering process for fabricating permanently strained 2DM transistors at the nanoscale. We used grayscale nanolithography based on thermal scanning probe lithography and dry etching to create 2D sinusoidal waves on SiO2 substrates, providing controlled tensile strain in MoS2 transistors at predetermined locations by design. Precisely patterned surface topography at the single-digit nanometer scale enables deterministic changes in the tensile strain induced in 2D materials, thereby locally altering their electrical and optical properties while offering a seamless device integration option. As a result, the intrinsic phonon-limited mobility of these strained MoS2 transistors is improved by over a factor of 8, also corroborated by first-principles calculations of phonon-limited electron mobilities. Our proposed approach, involving surface nanotopography for fabricating strained MoS2 transistors and the resultant performance enhancement engineered through the reduction of electron-phonon scattering, opens novel design and integration possibilities toward high-performance 2DM devices.

Methods

Material synthesis and exfoliation

Monolayer MoS2 flakes were grown by MOCVD. A c-plane sapphire chip was selected as growth substrate, which was annealed in air for 6 h to get an atomic smooth surface and spin-coated with 0.026 mol/L NaCl solution in deionized water to suppress nuclear density and accelerate growth rate. The chip was then loaded into a tube furnace, where the temperature and gas flow rate can be controlled by LabView. During growth, molybdenum hexacarbonyl (Mo(CO)6) and hydrogen sulfide (H2S) was carried into the quartz tube as precursors by argon (Ar) with flow rates of 6 sccm and 3 sccm, respectively. The Mo(CO)6 precursor was stored in a bubbler immersed in water bath whose temperature was kept at 15 °C to achieve a constant vapor rate. To obtain a monolayer by balancing the growth rate, small amounts of H2 and O2 were introduced separately into the growth chamber. The growth process lasted for 30 min at 850 °C with a pressure of 850 mbar. At the end of the growth, the precursor supply was abruptly cut-off and the furnace cooled down naturally to room temperature with a 200 sccm of Ar flow to remove gaseous residues. Monolayer MoS2 flakes were also exfoliated from 2H-MoS2 bulk crystal (HQ Graphene) onto PDMS substrates.

Fabrication of grayscale dielectric nanopatterns

A 10 wt% solution of polyphthalaldehyde (PPA, Allresist) in anisole (Sigma–Aldrich Chemie GmbH) was spin-coated at 5000 rpm on SiO2 (200 nm thick thermally grown dry oxide)/Si (500 μm thick) substrate and soft baked at 110 °C for 2 min. Grayscale nanostructures, biaxial sinusoidal wave (f(x,y) = A[cos(gx) + cos(gy)]), were patterned on PPA utilizing a commercial t-SPL system (Nanofrazor, Heidelberg Instruments Nano AG) and thermal cantilevers (NanoFrazor Monopede). Biaxial sinusoidal wave designs are converted into grayscale bitmaps consisting of 20 × 20 nm2 pixel grids. The normalized depth was set to 256 levels. MATLAB (version R2020b) was utilized for grayscale bitmap generation. Then, the grayscale bitmap image was imported into the t-SPL software by assigning the minimum depth (white pixel) and maximum depth (black pixel) as 5 nm and 90 nm, respectively. The writing heater temperature for t-SPL was set to 1050 °C, and patterning was performed with a step size of 20 nm. A scan speed of 25 μs per pixel was used with a force pulse of 5 μs. The nanopatterns were transferred from PPA to thin films of SiO2 by using a commercial inductively coupled plasma (ICP)-based reactive ion etching (RIE) system (Alcatel AMS 200 SE). In the dry etching process, SF6/C4F8 plasma with a flow rate of 30/70 sccm at 0.015 mbar pressure was used. RF ICP power was set to 1500 W (13.56 MHz RF field). 15 W RF was applied at the bottom electrode through a blocking capacitor that allows to build up a constant DC bias voltage to attract the ions. The wafer was positioned on the bottom electrode and was gripped on that bottom electrode with electrostatic clamping (ESC). That bottom electrode was kept at 20 °C and thermal contact with wafer was ensured thanks to Helium backpressure through the ESC. After pattern transfer by dry etching, the substrates were cleaned with Piranha solution (3:1 mixture of H2SO4(96%):H2O2(30%)) for 10 min.

Fabrication of strained 2D transistors

The monolayer MoS2 flakes were picked up and then transferred onto patterned SiO2 chips using the dry-transfer method. The 2D flakes were first etched into a suitable geometry covering the patterned substrate by using e-beam lithography and XeF2 etching. A second step of e-beam lithography was used to make electrode patterns. O2 plasma was used to clean the PMMA residues and etch the 2D flake exposed. Then, a layer composed of 2 nm/60 nm thick Ti/Pt was thermally evaporated for the electrodes. Finally, a lift-off process was performed in acetone to remove the PMMA layer. The fabricated devices were annealed in a tube furnace to remove polymer residues and strengthen the contact adhesion before characterization. The devices were supported by a boat-shape holder and loaded into the quartz tube. Then, the tube was sealed tightly and pumped down to a low pressure around 10−7 mbar before annealing started. Afterwards, the temperature ramped up to 200 °C with several steps (50 °C per step) and lasted for 6 h. When the annealing process was done, the temperature went down naturally to room temperature.

Raman spectroscopy

Raman spectroscopy was performed to measure the Raman shift caused by strain. Raman spectra were collected using a confocal Raman microscope system (inVia Qontor, Renishaw) coupled with an Olympus inverted optical microscope, and using a laser source with an excitation wavelength of 532 nm. A low excitation laser power (84 µW) was used to avoid sample damage. Raman spectra were acquired in the range of 0 to 1800 cm−1 with a 30 s exposure time and an average of three measurements.

TERS

To prepare TERS probes, Si AFM cantilevers (Nanosensors, Switzerland) were first oxidized in a furnace (Carbolite Gero, UK) at 1000 °C for 23 h to increase the refractive index of the surface, followed by UV-ozone (Ossila, UK) cleaning for 1 h. The cleaned probes were placed in a thermal evaporation chamber of a N2 glovebox (MBraun, Germany). The AFM cantilevers were coated with a 150 nm thick layer of Ag (Advent Research Materials, UK) at a rate of 0.5 nm/s under 10−7 mbar pressure. TERS measurements were performed under ambient conditions using a side-illumination system consisting of a Raman spectrometer (HORIBA Scientific, France) and an atomic force microscope (AIST-NT, USA). 532 nm excitation laser was incident on the sample at an angle of 60° with respect to the surface and focused on the sample using a 100×, 0.7 NA objective lens (Mitutoyo, Japan). TERS line mapping was performed using a step size of 50 nm, spectrum acquisition time of 10 s and a laser power of ca. 260 μW at the sample. TERS spectra were collected using a spectrometer grating of 1800 lines/mm and a CCD detector.

AFM and SEM analyses

AFM topography characterization of the fabricated grayscale nanostructures on SiO2 thin films were performed with a Bruker FastScan AFM (ScanAsyst mode). The scanning-probe analysis software Gwyddion (version 2.59) was used for the purposes of data visualization and surface profile characterization. AFM images of the monolayer MoS2 flake on the grayscale substrates were taken in PeakForce QNM® mode using the Multimode (Bruker) Scanhead and Nanoscope V controller (Bruker). ScanAsyst-Air cantilevers with a spring constant of 0.4 N/m were utilized, and peak forces were set to 10 nN for quantitative mechanical characterization. The devices were imaged using SEM (Zeiss MERLIN SEM) to analyze if the 2D flake follows the substrate.

TEM analysis

A lamella of the cross-section device was prepared using focused ion beam (FIB) and SEM imaging. The target area was selected, and a carbon layer was deposited by electron beam-assisted (5 kV) and ion beam-assisted (30 kV, 150 pA) depositions. The former is used to protect MoS2 from following ion implantation and surface damage. A lamella was cut perpendicular to the device surface to observe the interface between the MoS2 and the patterned SiO2. A FEI Talos TEM was used to study the interface between the MoS2 and the SiO2. The high-angular annular dark field (HAADF) STEM detector was used to image the sample with an accelerating voltage of 200 kV. EDX was then performed to analyze the material composition of the interface.

Electrical measurement

Electrical measurements of all devices were performed at room temperature and ambient conditions. Some devices were also characterized in vacuum (4 × 10−6 mbar). For the Schottky barrier height extraction, some of the selected devices were measured for a set of temperatures ranging from 80 to 300 K, also in vacuum. The standard DC measurements were performed using a HP4156A Semiconductor Parameter Analyzer and a Cascade Summit probe station.

DFT calculations

First-principles calculations are performed using the Quantum ESPRESSO (QE) distribution69,70 in the framework of 2D density-functional and density-functional perturbation theory60, including a cutoff on the Coulomb interaction to implement the correct 2D boundary conditions and gates to simulate electrostatic doping as induced in common FET setups. The exchange-correlation functional is approximated using the Perdew-Burke-Ernzerhof (PBE) formulation of the generalized-gradient approximation71. We explicitly include spin-orbit coupling in our simulations by using fully relativistic norm-conserving pseudopotentials72 from the Pseudo-Dojo library73 with a kinetic energy cutoff of 70 Ry. To ensure fine sampling close to the Fermi level, we use a non-uniform grid14 with the equivalent of a 96 × 96 × 1 grid for electron momenta and Fermi-Dirac smearing corresponding to room temperature (0.002 Ry). A denser grid of 120 × 120 × 1 is used for the non-self-consistent calculation of the valley structure. Using the model of the Ref. 14 we corrected the results of a reference first-principles calculation for mobility by adjusting ∆EKQ during post-processing, before solving the BTE to determine the mobility. The model accounts for the fact that changes in ∆EKQ modify energy selection rules for intervalley scattering, as well as the magnitude of intravalley electron-phonon coupling via a peculiar multivalley screening mechanism. Its parametrization relies on a single full first-principles calculation for the flat system, where ∆EKQ is the sole external parameter14. ∆EKQ as a function of strain is computed with DFT, as shown in Figs. 5d and 5e. The results are shifted by a constant such that the zero-strain value matches ∆EKQ of 34 meV obtained using the experimental structure parameters74. See Supplementary Figs. 32–35 for further details.

Supplementary information

Acknowledgements

The authors thank the Center of Micro/Nanotechnology (CMi) of EPFL for the AFM facility support. X.L., B.E., A.C., G.B., and J.B. acknowledge funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Project “MEMS 4.0”, ERC-2016-ADG, grant agreement No. 742685), NFFA-Europe Pilot Project (the EU’s H2020 framework program for research and innovation, grant agreement No. 101007417). X.L. acknowledges fundings from the National Natural Science Foundation of China (No. 62274013) and the National Key Research and Development Program of China (No. 2023YFB3405600). M.B. acknowledges the support of SNSF Eccellenza grant No. PCEGP2_194528, and support from the QuantERA II Programme that has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No 101017733. R.Z. acknowledges funding from the Swiss National Science Foundation through the NCCR MARVEL (project number 200021-143636) and the R’Equip program (grant number 206021-205312), as well as computational support from the Swiss National Supercomputing Centre. N.R. and N.M. acknowledge funding from the Swiss National Science Foundation (SNSF) and its National Centre of Competence in Research MARVEL on ‘Computational Design and Discovery of Novel Materials’ (grant number 182892). They also acknowledge computational support from the Swiss National Supercomputing Centre CSCS under project ID mr24. Z.W. and A.K. acknowledge financing from European Union’s Horizon 2020 research and innovation program under grant agreements 881603 (Graphene Flagship Core 3) and No 964735 (EXTREME-IR). G.F. and M.P. received funding through Innosuisse (AFM with PORT: Atomic force microscope with photothermal off-resonance tapping, grant number 7879, ext ref. 36938.1 IP-EE), FNS (Video-rate nanomechanical properties mapping using atomic force microscopy, grant number 7288, ext. ref. 200021_182562), H2020 (InCell - High speed AFM imaging of molecular processes inside living cellsInCell - High speed AFM imaging of molecular processes inside living cells, grant number 6823, ext ref. 773091, ETH Domain (An ecosystem for community driven scanning probe microscopy research and development, grant number 10126) and Eurostars (Correlated Analysis System for in-vivo Inspection of Semi-Conductor Process Wafers, grant number 9953, ext. ref. E!665 CAS-C).

Author contributions

X.L., B.E., A.C., G.B., and J.B. conceived and designed the experiments for fabricating and characterizing strained 2D transistors. X.L., with the help of B.E. and A.C. and with the supervision of G.B. and J.B., performed preparation and transfer of 2D flakes, patterning/etching of 2D flakes and metal deposition/liftoff experiments. B.E., with the supervision of A.C., G.B., and J.B., performed t-SPL and dry etching. J.J. and M.B. helped transfer of 2D flakes and EBL. Z.W. and A.K. conceived and developed MoS2 growth process. Z.W., with the supervision of A.K., performed MoS2 growth. X.L., with the help of B.E. and A.C., performed Raman measurements and data analysis. X.L. performed SEM and TEM. X.L. performed electrical measurements and data analysis. M.P. and G.F. conceived and performed AFM on 2D transistors and data analysis. X.L., B.E., and J.J. helped AFM imaging. N.R. and T.S., with the supervision of N.M., performed the first-principles calculations. B.E., under the supervision of G.B., performed the calculation on electrical field. N.K. and S.B., with the supervision of R.Z. performed TERS measurement. X.L., B.E., N.M., G.B., and J.B. wrote the manuscript with input from all the authors. J.B. coordinated and supervised the research. All authors contributed to discussions regarding the research.

Peer review

Peer review information

Nature Communications thanks Wenhui Hou, Guoli Li, and Tara Peña for their contribution to the peer review of this work. A peer review file is available.

Data availability

All data that support the key findings in this study are available within the main text and the Supplementary Information file. All raw data generated during the current study are available from the corresponding authors upon request. The data used to produce the simulation results presented in this work are available at the Materials Cloud Archive (10.24435/materialscloud:j5-7n).

Code availability

The relevant implementation/code is already in Quantum ESPRESSO, as detailed in Ref. 60 Concerning the ab-initio model, the code and tools are available in Ref. 14, and the modifications introduced can be found at the Materials Cloud Archive (10.24435/materialscloud:j5-7n).

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

These authors contributed equally: Xia Liu, Berke Erbas.

Contributor Information

Xia Liu, Email: xia.liu@bit.edu.cn.

Juergen Brugger, Email: juergen.brugger@epfl.ch.

Supplementary information

The online version contains supplementary material available at 10.1038/s41467-024-51165-4.

References

- 1.Radisavljevic, B., Radenovic, A., Brivio, J., Giacometti, V. & Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol.6, 147–150 (2011). 10.1038/nnano.2010.279 [DOI] [PubMed] [Google Scholar]

- 2.Shen, P.-C. et al. Ultralow contact resistance between semimetal and monolayer semiconductors. Nature593, 211–217 (2021). 10.1038/s41586-021-03472-9 [DOI] [PubMed] [Google Scholar]

- 3.Li, M. Y., Su, S. K., Wong, H. S. P. & Li, L. J. How 2D semiconductors could extend Moore’s law. Nature567, 169–170 (2019). 10.1038/d41586-019-00793-8 [DOI] [PubMed] [Google Scholar]

- 4.Wu, F. et al. Vertical MoS2 transistors with sub-1-nm gate lengths. Nature603, 259–264 (2022). 10.1038/s41586-021-04323-3 [DOI] [PubMed] [Google Scholar]

- 5.Liu, L. et al. Transferred van der Waals metal electrodes for sub-1-nm MoS2 vertical transistors. Nat. Electron.4, 342–347 (2021). 10.1038/s41928-021-00566-0 [DOI] [Google Scholar]

- 6.Park, C.-H. et al. Electron–phonon interactions and the intrinsic electrical resistivity of graphene. Nano Lett.14, 1113–1119 (2014). 10.1021/nl402696q [DOI] [PubMed] [Google Scholar]

- 7.Poncé, S., Royo, M., Gibertini, M., Marzari, N. & Stengel, M. Accurate prediction of hall mobilities in two-dimensional materials through Gauge-covariant quadrupolar contributions. Phys. Rev. Lett.130, 166301 (2023). 10.1103/PhysRevLett.130.166301 [DOI] [PubMed] [Google Scholar]

- 8.Zou, J. et al. Doping concentration modulation in vanadium-doped monolayer molybdenum disulfide for synaptic transistors. ACS Nano15, 7340–7347 (2021). 10.1021/acsnano.1c00596 [DOI] [PubMed] [Google Scholar]

- 9.Kang, D.-H. et al. Controllable nondegenerate p-type doping of tungsten diselenide by octadecyltrichlorosilane. ACS Nano9, 1099–1107 (2015). 10.1021/nn5074435 [DOI] [PubMed] [Google Scholar]

- 10.Shi, W. et al. Reversible writing of high-mobility and high-carrier-density doping patterns in two-dimensional van der Waals heterostructures. Nat. Electron.3, 99–105 (2020). 10.1038/s41928-019-0351-x [DOI] [Google Scholar]

- 11.Conde-Rubio, A., Liu, X., Boero, G. & Brugger, J. Edge-contact MoS2 transistors fabricated using thermal scanning probe lithography. ACS Appl. Mater. Interfaces14, 42328–42336 (2022). 10.1021/acsami.2c10150 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Lee, H., Bak, S., Kim, J. & Lee, H. The effect of the dopant’s reactivity for high-performance 2D MoS2 thin-film transistor. Nano Res.14, 198–204 (2021). 10.1007/s12274-020-3068-2 [DOI] [Google Scholar]

- 13.Zhao, Y. et al. Electrical spectroscopy of defect states and their hybridization in monolayer MoS2. Nat. Commun.14, 44 (2023). 10.1038/s41467-022-35651-1 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Sohier, T., de Melo, P. M. M. C., Zanolli, Z. & Verstraete, M. J. The impact of valley profile on the mobility and Kerr rotation of transition metal dichalcogenides. 2D Mater.10, 025006 (2023). 10.1088/2053-1583/acb21c [DOI] [Google Scholar]

- 15.Sohier, T. et al. Enhanced electron-phonon interaction in multivalley materials. Phys. Rev. X9, 031019 (2019). [Google Scholar]

- 16.Kaasbjerg, K., Low, T. & Jauho, A.-P. Electron and hole transport in disordered monolayer MoS2: atomic vacancy induced short-range and Coulomb disorder scattering. Phys. Rev. B100, 115409 (2019). 10.1103/PhysRevB.100.115409 [DOI] [Google Scholar]

- 17.Hosseini, M., Elahi, M., Pourfath, M. & Esseni, D. Strain induced mobility modulation in single-layer MoS2. J. Phys. D. Appl. Phys. 48, 375104 (2015).

- 18.Thompson, S. et al. A 90 nm logic technology featuring 50 nm strained silicon channel transistors, 7 layers of Cu interconnects, low k ILD, and 1 μm2 SRAM cell. In Digest. International Electron Devices Meeting, 61–64 (IEEE, 10.1109/IEDM.2002.1175779. 2002).

- 19.Thompson, S. E. et al. A logic nanotechnology featuring strained-silicon. IEEE Electron Device Lett.25, 191–193 (2004). 10.1109/LED.2004.825195 [DOI] [Google Scholar]

- 20.Liu, X. et al. Thermomechanical nanostraining of two-dimensional materials. Nano Lett.20, 8250–8257 (2020). 10.1021/acs.nanolett.0c03358 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Lloyd, D. et al. Band gap engineering with ultralarge biaxial strains in suspended monolayer MoS2. Nano Lett.16, 5836–5841 (2016). 10.1021/acs.nanolett.6b02615 [DOI] [PubMed] [Google Scholar]

- 22.Li, H. et al. Optoelectronic crystal of artificial atoms in strain-textured molybdenum disulphide. Nat. Commun.6, 1–7 (2015). 2015 61. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Sohier, T., Gibertini, M., Campi, D., Pizzi, G. & Marzari, N. Valley-engineering mobilities in two-dimensional materials. Nano Lett.19, 3723–3729 (2019). 10.1021/acs.nanolett.9b00865 [DOI] [PubMed] [Google Scholar]

- 24.Pérez Garza, H. H., Kievit, E. W., Schneider, G. F. & Staufer, U. Controlled, reversible, and nondestructive generation of uniaxial extreme strains (>10%) in graphene. Nano Lett.14, 4107–4113 (2014). 10.1021/nl5016848 [DOI] [PubMed] [Google Scholar]

- 25.Plechinger, G. et al. Control of biaxial strain in single-layer molybdenite using local thermal expansion of the substrate. 2D Materials2, 015006 (2015).

- 26.Hou, W. et al. Strain-based room-temperature non-volatile MoTe2 ferroelectric phase change transistor. Nat. Nanotechnol.14, 668–673 (2019). 10.1038/s41565-019-0466-2 [DOI] [PubMed] [Google Scholar]

- 27.Hou, W. et al. Strain engineering of vertical molybdenum ditelluride phase-change memristors. Nat. Electron.7, 8–16 (2024). 10.1038/s41928-023-01071-2 [DOI] [Google Scholar]

- 28.Manzeli, S., Allain, A., Ghadimi, A. & Kis, A. Piezoresistivity and strain-induced band gap tuning in atomically thin MoS2. Nano Lett.15, 5330–5335 (2015). 10.1021/acs.nanolett.5b01689 [DOI] [PubMed] [Google Scholar]

- 29.Mohiuddin, T. M. G. et al. Uniaxial strain in graphene by Raman spectroscopy: G peak splitting, Grüneisen parameters, and sample orientation. Phys. Rev. B—Condens. Matter Mater. Phys.79, 205433 (2009). 10.1103/PhysRevB.79.205433 [DOI] [Google Scholar]

- 30.Conley, H. J. et al. Bandgap engineering of strained monolayer and bilayer MoS2. Nano Lett.13, 3626–3630 (2013). 10.1021/nl4014748 [DOI] [PubMed] [Google Scholar]

- 31.Li, Z. et al. Efficient strain modulation of 2D materials via polymer encapsulation. Nat. Commun.11, 1–8 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Yang, S. et al. Tuning the optical, magnetic, and electrical properties of ReSe2 by nanoscale strain engineering. Nano Lett.15, 1660–1666 (2015). 10.1021/nl504276u [DOI] [PubMed] [Google Scholar]

- 33.Datye, I. M. et al. Strain-enhanced mobility of monolayer MoS2. Nano Lett.22, 8052–8059 (2022). 10.1021/acs.nanolett.2c01707 [DOI] [PubMed] [Google Scholar]

- 34.Duerloo, K. A. N., Li, Y. & Reed, E. J. Structural phase transitions in two-dimensional Mo- and W-dichalcogenide monolayers. Nat. Commun.5, 1–9 (2014). 10.1038/ncomms5214 [DOI] [PubMed] [Google Scholar]

- 35.Ahn, G. H. et al. Strain-engineered growth of two-dimensional materials. Nat. Commun.8, 1–8 (2017). 10.1038/s41467-017-00516-5 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Azizimanesh, A., Peña, T., Sewaket, A., Hou, W. & Wu, S. M. Uniaxial and biaxial strain engineering in 2D MoS2with lithographically patterned thin film stressors. Appl. Phys. Lett.118, 213104 (2021). 10.1063/5.0049446 [DOI] [Google Scholar]

- 37.Liu, B. et al. Strain-engineered van der Waals interfaces of mixed-dimensional heterostructure arrays. ACS Nano13, 9057–9066 (2019). 10.1021/acsnano.9b03239 [DOI] [PubMed] [Google Scholar]

- 38.Chaste, J. et al. Intrinsic properties of suspended MoS2 on SiO2/Si pillar arrays for nanomechanics and optics. ACS Nano12, 3235–3242 (2018). 10.1021/acsnano.7b07689 [DOI] [PubMed] [Google Scholar]

- 39.Reserbat-Plantey, A. et al. Strain superlattices and macroscale suspension of graphene induced by corrugated substrates. Nano Lett.14, 5044–5051 (2014). 10.1021/nl5016552 [DOI] [PubMed] [Google Scholar]

- 40.Chen, Y. et al. Mobility enhancement of strained MoS2 transistor on flat substrate. ACS Nano17, 14954–14962 (2023). 10.1021/acsnano.3c03626 [DOI] [PubMed] [Google Scholar]

- 41.Liu, T. et al. Crested two-dimensional transistors. Nat. Nanotechnol.14, 223–226 (2019). 10.1038/s41565-019-0361-x [DOI] [PubMed] [Google Scholar]

- 42.Henry Hinnefeld, J., Gill, S. T. & Mason, N. Graphene transport mediated by micropatterned substrates. Appl. Phys. Lett.112, 173504 (2018). 10.1063/1.5027577 [DOI] [Google Scholar]

- 43.Ng, H. K. et al. Improving carrier mobility in two-dimensional semiconductors with rippled materials. Nat. Electron.5, 489–496 (2022). 10.1038/s41928-022-00777-z [DOI] [Google Scholar]

- 44.Skaug, M. J., Schwemmer, C., Fringes, S., Rawlings, C. D. & Knoll, A. W. Nanofluidic rocking Brownian motors. Science359, 1505–1508 (2018). 10.1126/science.aal3271 [DOI] [PubMed] [Google Scholar]

- 45.Lassaline, N. et al. Optical fourier surfaces. Nature582, 506–510 (2020). 10.1038/s41586-020-2390-x [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Rawlings, C. D. et al. Control of the interaction strength of photonic molecules by nanometer precise 3D fabrication. Sci. Rep.7, 1–9 (2017). 10.1038/s41598-017-16496-x [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Erbas, B. et al. Combining thermal scanning probe lithography and dry etching for grayscale nanopattern amplification. Microsyst. Nanoeng.10, 1–10 (2024). 10.1038/s41378-024-00655-y [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Kirchner, R., Guzenko, V. A. & Schift, H. Single-digit 6-nm multilevel patterns by electron beam grayscale lithography. Adv. Opt. Technol.8, 175–180 (2019). 10.1515/aot-2019-0016 [DOI] [Google Scholar]

- 49.Fallica, R., Kirchner, R., Schift, H. & Ekinci, Y. High-resolution grayscale patterning using extreme ultraviolet interference lithography. Microelectron. Eng.177, 1–5 (2017). 10.1016/j.mee.2017.01.007 [DOI] [Google Scholar]

- 50.Yang, R. et al. Tuning optical signatures of single- and few-layer MoS2 by blown-bubble bulge straining up to fracture. Nano Lett.17, 4568–4575 (2017). 10.1021/acs.nanolett.7b00730 [DOI] [PubMed] [Google Scholar]

- 51.Satterthwaite, P. F. et al. Van der Waals device integration beyond the limits of van der Waals forces using adhesive matrix transfer. Nat. Electron.7, 17–28 (2023). 10.1038/s41928-023-01079-8 [DOI] [Google Scholar]

- 52.Pandey, Y., Kumar, N., Goubert, G. & Zenobi, R. Nanoscale chemical imaging of supported lipid monolayers using tip‐enhanced Raman spectroscopy. Angew. Chem. Int. Ed.60, 19041–19046 (2021). 10.1002/anie.202106128 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Cheng, Z. et al. How to report and benchmark emerging field-effect transistors. Nat. Electron.5, 416–423 (2022). 10.1038/s41928-022-00798-8 [DOI] [Google Scholar]

- 54.Fiori, G. et al. Electronics based on two-dimensional materials. Nat. Nanotechnol.9, 768–779 (2014). 10.1038/nnano.2014.207 [DOI] [PubMed] [Google Scholar]

- 55.Zheng, X. et al. Patterning metal contacts on monolayer MoS2 with vanishing Schottky barriers using thermal nanolithography. Nat. Electron.2, 17–25 (2019). 10.1038/s41928-018-0191-0 [DOI] [Google Scholar]

- 56.Cui, X. et al. Multi-terminal transport measurements of MoS2 using a van der Waals heterostructure device platform. Nat. Nanotechnol. 10, 534–540 (2015). [DOI] [PubMed]

- 57.Kim, S. et al. High-mobility and low-power thin-film transistors based on multilayer MoS2 crystals. Nat. Commun.3, 1011 (2012). 10.1038/ncomms2018 [DOI] [PubMed] [Google Scholar]

- 58.Kaasbjerg, K., Thygesen, K. S. & Jacobsen, K. W. Phonon-limited mobility in n-type single-layer MoS2 from first principles. Phys. Rev. B85, 115317 (2012). 10.1103/PhysRevB.85.115317 [DOI] [Google Scholar]

- 59.Baroni, S., de Gironcoli, S., Dal Corso, A. & Giannozzi, P. Phonons and related crystal properties from density-functional perturbation theory. Rev. Mod. Phys.73, 515–562 (2001). 10.1103/RevModPhys.73.515 [DOI] [Google Scholar]

- 60.Sohier, T., Calandra, M. & Mauri, F. Density functional perturbation theory for gated two-dimensional heterostructures: theoretical developments and application to flexural phonons in graphene. Phys. Rev. B96, 075448 (2017). 10.1103/PhysRevB.96.075448 [DOI] [Google Scholar]

- 61.Sohier, T., Campi, D., Marzari, N. & Gibertini, M. Mobility of two-dimensional materials from first principles in an accurate and automated framework. Phys. Rev. Mater.2, 114010 (2018). 10.1103/PhysRevMaterials.2.114010 [DOI] [Google Scholar]

- 62.Sohier, T., Gibertini, M. & Marzari, N. Profiling novel high-conductivity 2D semiconductors. 2D Mater.8, 015025 (2020). [Google Scholar]

- 63.Li, X. et al. Intrinsic electrical transport properties of monolayer silicene and MoS2 from first principles. Phys. Rev. B87, 115418 (2013). 10.1103/PhysRevB.87.115418 [DOI] [Google Scholar]

- 64.Faria Junior, P. E. et al. First-principles insights into the spin-valley physics of strained transition metal dichalcogenides monolayers. N. J. Phys.24, 083004 (2022). 10.1088/1367-2630/ac7e21 [DOI] [Google Scholar]

- 65.Zollner, K., Junior, P. E. F. & Fabian, J. Strain-tunable orbital, spin-orbit, and optical properties of monolayer transition-metal dichalcogenides. Phys. Rev. B100, 195126 (2019). 10.1103/PhysRevB.100.195126 [DOI] [Google Scholar]

- 66.Roldán, R. et al. Electronic properties of single‐layer and multilayer transition metal dichalcogenides MX2 (M = Mo, W and X = S, Se). Ann. Phys.526, 347–357 (2014). 10.1002/andp.201400128 [DOI] [Google Scholar]

- 67.Castillo, I. et al. Metal-insulator crossover in monolayer MoS2. Nanotechnology34, 335202 (2023). [DOI] [PubMed]

- 68.Mignuzzi, S. et al. Effect of disorder on Raman scattering of single-layer MoS2. Phys. Rev. B - Condens. Matter Mater. Phys. 91, 195411 (2015).

- 69.Giannozzi, P. et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter21, 395502 (2009). 10.1088/0953-8984/21/39/395502 [DOI] [PubMed] [Google Scholar]

- 70.Giannozzi, P. et al. Advanced capabilities for materials modelling with Quantum ESPRESSO. J. Phys. Condens. Matter29, 465901 (2017). 10.1088/1361-648X/aa8f79 [DOI] [PubMed] [Google Scholar]

- 71.Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett.77, 3865–3868 (1996). 10.1103/PhysRevLett.77.3865 [DOI] [PubMed] [Google Scholar]

- 72.Hamann, D. R. Optimized norm-conserving Vanderbilt pseudopotentials. Phys. Rev. B88, 085117 (2013). 10.1103/PhysRevB.88.085117 [DOI] [Google Scholar]

- 73.van Setten, M. J. et al. The PseudoDojo: training and grading a 85 element optimized norm-conserving pseudopotential table. Comput. Phys. Commun.226, 39–54 (2018). 10.1016/j.cpc.2018.01.012 [DOI] [Google Scholar]

- 74.Bollinger, M. V., Jacobsen, K. W. & Nørskov, J. K. Atomic and electronic structure of MoS2 nanoparticles. Phys. Rev. B67, 085410 (2003). 10.1103/PhysRevB.67.085410 [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data that support the key findings in this study are available within the main text and the Supplementary Information file. All raw data generated during the current study are available from the corresponding authors upon request. The data used to produce the simulation results presented in this work are available at the Materials Cloud Archive (10.24435/materialscloud:j5-7n).

The relevant implementation/code is already in Quantum ESPRESSO, as detailed in Ref. 60 Concerning the ab-initio model, the code and tools are available in Ref. 14, and the modifications introduced can be found at the Materials Cloud Archive (10.24435/materialscloud:j5-7n).