Abstract

The global community faces critical energy and environmental challenges, necessitating innovative solutions to ensure a sustainable future.In response to these challenges, this paper explores the potential of integrating microalgal biotechnology with renewable energy systems within buildings. This innovative approach could transform architecture into a "bio-factory" capable of producing food, energy, and other valuable products.The success of this concept hinges on developing highly efficient photobioreactors specifically designed for building integration. Optimizing these systems requires careful consideration of design parameters, growth rate models, and factors influencing performance within diverse urban environments.Furthermore, integrating these systems must prioritize productivity and aesthetics to promote urban self-sufficiency and a sustainable built environment. By utilizing microalgae and renewable energy sources, building-integrated photobioreactors offer a promising solution for reducing energy consumption and carbon footprints in modern buildings.

Keywords: Microalgae, Building-integrated photobioreactors (B-PBRs), Urban sustainability, Renewable energy, Bio-based products, Green architecture

1. Introduction

Sustainable building design is a growing concern due to the environmental impact of traditional construction methods. Various concepts like climber and herb-shrub systems, which respectively rely on mechanical support and operate independently of plant species, have driven improvements in building design [1,2]. Green facades, often populated with plants, offer several benefits, such as improved thermal insulation and air quality. However, microalgae provide unique advantages in this context [1,3,4]. Emphasizing the importance of design classification and the integration of microalgae as a significant design element is crucial [5,6].Integrating well-designed buildings with green walls holds promise for achieving outstanding thermal efficiency and substantial energy savings. Green walls are pivotal in mitigating heat impact on structures and supporting air conditioning systems, particularly during warm summers. Additionally, green walls serve as effective wind barriers during colder periods, limiting convective heat loss and acting as natural insulators to regulate building temperatures. According to practical uses and simulations described in the scientific literature, the thermal effect of green walls varies by as much as 50 % depending on construction orientation, building insulation, environmental parameters, location of buildings, foliage thickness, climate, planttype, plant, and wall design [7].Standardizing the effectiveness of green walls is challenging due to the complex interactions among these variables [8],yet their positive impact on building performance warrants further investigation.Many configurations of photobioreactors have been designed and constructed. These photobioreactors vary from flatpanels and vertical systems to tubular and cylindrical systems. Various configurations of photobioreactors have been developed, ranging from flat panels and vertical systems to tubular and cylindrical designs [[9], [10], [11]].Enclosed photobioreactors, in particular, have seen advancements in microalgae cultivation technologies, contributing to enhanced productivity and efficiency [[12], [13], [14]].

However, conventional photobioreactors often necessitate high initial costs, require expensive maintenance, and pose contamination risks, making them suitable primarily for high-value microalgae cultivation.Microalgae contribute to improved air quality and visual aesthetics, enhancing energy efficiency and offering opportunities for artistic architecture [[15], [16], [17]].While green plants are commonly used in green wall applications, microalgae offer unique advantages, including their capacity for photosynthesis, carbon cycle contribution, and oxygen generation.Plants emerge as a manageable resource and provide a novel opportunity for green façade applications across various contexts. Additionally, certain microalgae species hold promise and merit specific consideration regarding their potential contributions.The increase in culture density, coupled with the shading effect, helps to mitigate heat loss while facilitating natural ventilation [18].

Moreover, the productivity potential of microalgae biomass extends to diverse sectors such as food, feed, pharmaceuticals, and biofuels. Integration into biofuel production, including biohydrogen and biogas, aligns with the bio-refinery concept, further highlighting microalgae's versatility and potential applications in building structures. These factors encourage the possible use of microalgae to make artistic architectural illustrations a reality [19].

The objective of the review:

This paper investigates the design and integration of photobioreactors (PBRs) within building designs. It also explores various photobioreactor configurations and their suitability for building an integration that optimizes economic cost-effectiveness and high microalgae cultivation efficiency. This objective will be achieved by:

-

•

Reviewing the concept, theory, and classification of BIPBR designs.

-

•

Analyzing the critical factors influencing BIPBR design, including input parameters and material selection.

-

•

Discussing the modeling tools to evaluate the BIPBR performance design that prioritizes both economic feasibility and efficient microalgae cultivation

-

•

Assessing the overall viability and potential challenges of BIPBR technology through SWOT analysis

2. Concept and theory of building integrated photobioreactor

Integrating photobioreactor (PBR) elements within the building envelope cultivates microalgae and harnesses thermal energy. The resulting generation of microalgae biomass and solar heat can be utilized to meet the energy needs of the entire building, aligning with the environmental targets set forth by green building concepts for 2030. The specification of the façade system is analyzed with consideration given to energy design requirements, structural engineering, building physics, operational technology, and integration with modern architecture.

To maximize solar radiation absorption, PBR components are strategically positioned around a

a vertical central axis aligned with the sun's trajectory to minimize shadowing and maximize the sunlight capture. An essential aspect of the core concept is the insulation of the façade element to avoid heat loss in winter [16].The PBR system operates in a vertical configuration to optimize circulation and algae biomass yield while mitigating the risk of biofouling. Flat glass plates, known for their durability, mechanical strength, radiolucence, and non-flammability, are suitable for constructing PBR walls. However, the façade system must withstand local transient loads such as wind, rain, and temperature fluctuations. Employing double glazing, additional glass panes, and heat-resistant coatings enhances the thermal efficiency of the PBR element [2].

Assessing the systemic adequacy of photobioreactor components, particularly glass components, involves evaluating their resilience against various loads. While biomass from algae holds potential for construction applications, its broader utilization as a renewable energy source remains limited. Extensive research into microalgae and other algae species suggests their potential to address global clean energy challenges within the next century [[3], [4], [5], [6]]. This conclusion is based on the organisms' CO2 absorption ability, wastewater treatment quality, O2 production potential, and other organismal characteristics.Architects and sustainability professionals are increasingly interested in the potential of microalgae for building applications.Microalgae release oxygen as a byproduct of photosynthesis, enhancing the indoor air quality within buildings.Microalgae biomass can be converted into biofuels, potentially contributing to a building's energy needs.Microalgae can be used to treat wastewater, offering a sustainable solution for on-site water management.Strategically placed microalgae systems can provide shading and controlled sunlight penetration, contributing to more comfortable and energy-efficient buildings.Microalgae can thrive in wastewater or brackish water environments, making them a water-efficient solution for building applications.Fig. 1 illustrates the various inputs for the microalgal culture (light, CO2, and nutrients) to produce food, energy, and electricity.

Fig. 1.

Systematic energy flow in BIPBR.

3. Classification of BIPBR

Photobioreactors (PBRs) are sealed chambers of cultivation explicitly designed for the photosynthesis cultivation of microalgae. PBRs have been utilized for many years, roughly 55–60 years after the microalgae biotechnology boom of the late 1950s. Understanding microalgae as an economically feasible source has opened different paths for cultivation systems for many sectors that shape pharmaceuticals to biofuels. Considering the drawbacks of open production designs, PBRs are therefore acknowledged in a more controlled manner as a fruitful system for cultivatingmasscultivation of microalgae. Thus, understanding the PBR design for the optimum growth of microalgae is essential. Microalgae use light energy to reproduce, grow, and maintain cells. Microalgae utilize inorganic CO2 sources during reproduction as the primary source of oxygen.It also assimilates essential organic substances crucial for photosynthesis [20]. However, optimized PBR design is critical to keeping microalgae cells active and alive. There are several traditionally used PBR designs. These PBRs are called tubular type and panel type and are stirred-typePBRs [14] with the integration of traditional fermenters. These crucial designs have introduced new PBRs with sophisticated technology or approaches. When considering facade applications, panel PBRs are more efficient.

3.1. BIPBR description

Insulated flat plate PBRs, like the one proposed for this BIPBR system, serve as a transitional barrier (façade) between indoor and outdoor environments. The amount of sunlight reaching the BIPBR system's exterior surfaceis a good indicator of the geographical region's climate, similar to how outdoor temperature reflects the system's external environment.The internal temperature, nutrient availability, and CO2 levels provide insights into the condition of the specific building where the BIPBR system is installed and maintained.However, indoor light is unlikely to significantly contribute to the Photosynthetic Photon Flux Density (PPFD),a light measurement crucial for achieving the BIPBR's photosynthesis target.This is because the model focuses on light conditions within the BIPBR itself. However, if interior lights are integrated into an open living area within the light model, their PPFD during nighttime would warrant consideration. Given the exact architectural space required to incorporate the BIPBR system, the influence of indoor PPFD on the BIPBR light model has to be considered.Therefore, the modeling will focus on the interplay of light and temperature dynamics within the BIPBR system. Additionally, modeling nutrient dynamics and CO2 within the BIPBR is a critical aspect of the study.

3.1.1. Panel type PBRs

Panel PBRs, also known as flat-plate PBRs due to their flat surfaces resembling solar collectors, offer some design flexibility, as shown in Fig. 2. The vertical size of the panels can be adjusted within constraints imposed by factors like temperature, dissolved oxygen levels, light intensity, and aeration needs [[21], [22], [23]]. These limitations, arising from microalgae metabolism, influence the design and operation of panel PBRs.However, larger volumes can achieve better aeration through mixing within individual panels or external mixers, improving heat and mass transfer rates. Ensuring a homogeneous dispersion of cells, gases, nutrients, and metabolic waste is crucial [[24], [25], [26]]. Inefficient mixing, particularly at the bottom of the PBR, can lead to cell settling and mass die-off.Panel PBRs can be illuminated using various natural and artificial light sources. While artificial lights offer more control, outdoor sunlight is generally preferred due to cost-effectiveness. However, using natural light in buildings introduces challenges due to fluctuating light intensity, which can impact cell growth and the culture's response to light saturation. To optimize light exposure for culture growth, panel tilting based on sun angle can be employed [5]. Detailed classification of BIPBR, along with their advantages and disadvantages, is shown in Table 1.

Fig. 2.

Flat panel building integrated Photobioreactor.

Table 1.

Classification of BIPBR along with their advantages and Disadvantages.

| S.No. | Type of BIPBR | Properties | Advantages | Disadvantages | Schematic |

|---|---|---|---|---|---|

| 1. | Panel Type PBRs | Fixed, adjustable, movable, and innovative panels can be used. | Long-term benefits include extreme durability and longevity, safety, energy efficiency, low maintenance, and sustainability [27,28]. PBR panel Installation provides another advantage in that they can be installed over open framing or solid substrate. |

Limited prospects due to supporting structure. Reduction in useable space Costly construction and maintenance. It may negatively affect the view. |

|

| 2. | Green facade design | The PBRs can be engineered more aesthetically to give the environment a visual appeal. Double-skinned façade panels provide heat and sound insulation for the building [29]. |

Lack of flexibility Limited prospects due to the fixed supporting structure Reduction in useable space It may have a detrimental impact on the perception Threat of violation of construction rules Seasonal changes affect the growth and productivity of microalgae as they do in plant systems. |

|

|

| 3. | Advanced hybrid façade | Work on the symbiosisbetween building integrated photobioreactor construction and microalgal cultivation [30,31]. | Durable, longevity, safety, energy efficiency, low maintenance, and sustainability. | Costly construction and maintenance Design complexity |

|

| 4. | Helical Tubes PBR | A modular system of algal tubes is coiled around the CO2 scrubbing units in a spiral manner on the tops of both towers. In addition, the semicircular algal tubes can be installed in several floors. | The helical PBRs are wrapped around the entire parameter of the cylinder-shaped building. | Costly construction and maintenance Design complexity Use of expensive materials |

|

| 5. | Flat vertical panel PBR | PBR's are installed on the southwest and southeast facades. PBR is covered on both sides with laminated safety glass for added security and thermal insulation. | The flat- plate PBRs are installed on the southeast and southwest facades [[32], [33], [34]] Flat panels PBR have been recommended in areas where full sun protection is required. |

Fouling Scaling up necessitates the addition of several compartments and supporting materials. Temperature regulation is complicated. Low level of hydrodynamic stress A certain amount of wall growth [21,22] |

|

| 6. | Tube Panel PBR | The tubular PBR panels cover different building facades [[23], [35], [36]] | Modular or flexible design Controlled sunlight is provided, Designed to be used for sun shading. |

|

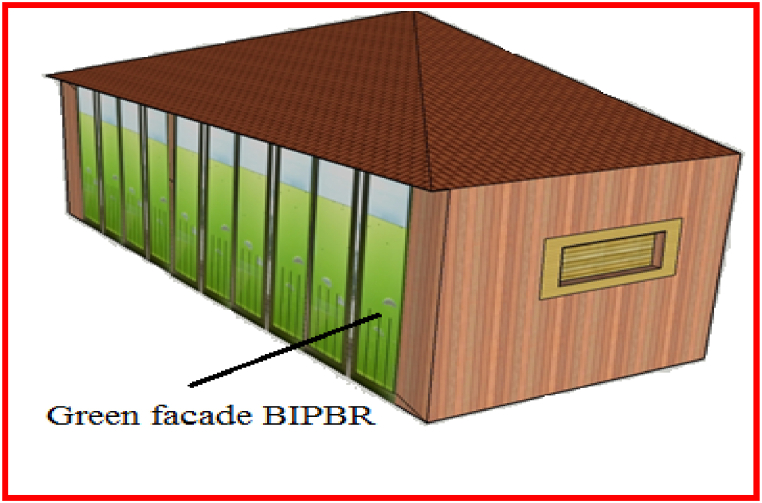

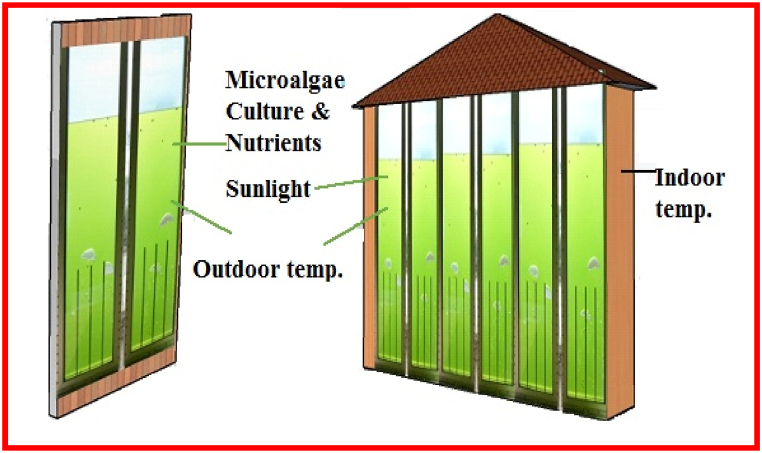

3.1.2. Green facade

Unlike traditional green facades using plants, building-integrated photobioreactors (PBRs), as shown in Fig. 3, offer greater design flexibility for building aesthetics. However, similar toplants, microalgae growth and productivity in PBR systems are influenced by seasonal variations.An additional benefit of microalgae is the potential for biomass processing into valuable products like food, feed, or biofuels through a biorefinery approach [[25], [26], [37]].

Fig. 3.

Green façade BIBPR design.

Furthermore, PBR design can be optimized to achieve both functionality and visual appeal, integrating technological advancements with aesthetic considerations [8]. Eco-friendly approaches should prioritize visual attractiveness alongside environmental benefits.From a broader perspective, microalgae hold significant promise for the future of building facades in modern architecture. Leveraging this natural resource has the potential to benefit a growing human population, but careful evaluation is needed to understand the specific advantages and challenges of this technology.

3.1.3. Advanced hybrid façade

Advanced hybrid facade systems, as shown in Fig. 4, utilize the principle of mutualism, where both the building and the microalgae cultivation within the integrated photobioreactor (PBR) benefit from each other [[38], [39], [40], [41]]. This is achieved by incorporating flat-panel microalgae PBRs designed to optimize interactions with the building structure.

Fig. 4.

Advanced Hybrid façade [20].

These interactions can:

Reduce thermal requirements: The PBRs can help regulate the building's temperature, potentially lowering energy consumption for heating or cooling.

Facilitate carbon capture: The microalgae in the PBRs can utilize carbon dioxide (CO2) from the building's flue gas for photosynthesis, contributing to carbon sequestration.

3.1.4. Helical tubes PBR

Helical PBRs offer a promising design for cultivating microalgae due to their high surface area to culture volume ratio.This design allows for better light penetration, leading to a higher incident light energy input per unit volume than other PBR geometries [9,10]. This efficiency is reflected in the frequent use of helical PBRs as experimental systems for evaluating microalgae cultures in research studies [11,12].However, the curved design of helical PBRs can also affect light distribution within the culture, potentially reducing overall energy intake. Therefore, optimizing helical PBRs' curvature is crucial to balancing light utilization and energy efficiency.Tubular PBRs, commonly used for biomass production, require high energy input for mixing the culture, increasing operational costs. Zhu et al. [24] highlighted the importance of optimizing PBR design for light penetration and mixing while minimizing energy consumption. Research by Ref. [2] further emphasizes this point, suggesting that reducing the energy required for mixing can significantly improve the overall economic performance of PBR systems.

3.1.5. Flat vertical panel PBR

Flat-panel PBRs typically utilize glass or polymer plates arranged vertically or horizontally, with a thin algal culture layer sandwiched between them. This design improves overall light conditions within the system.Flat-panel PBRs offer a promising design due to their increased light exposure potential. These systems are commonly installed on southeast and southwest facades for optimal light capture. They can also be used in situations requiring complete solar shading.However, scaling up flat-panel PBRs presents challenges. Maintaining consistent temperature, minimizing hydrodynamic stress on the culture, and controlling wall growth become increasingly complex with larger systems. Scaling often necessitates adding multiple compartments and supporting materials.Economically viable PBR design is a critical factor for the success of solar biofuel production. While closed PBRs have gained recent attention, achieving cost-effectiveness and scalability for large-scale algal cultures remains challenging [[35], [36], [42], [43]]. Light availability and interphase mass transfer are identified as crucial limiting factors [44].The overall cost of PBR construction is heavily influenced by material prices, fabrication costs, and labor [45]. Therefore, the focus should be on developing low-cost PBRs coupled with automated online control systems to streamline the cultivation process.

3.1.6. Tube panel PBR

Tube panel PBRs utilize tubes made of glass or polymer, arranged vertically or horizontally depending on the application. The culture medium is typically circulated within the tubes using a pump system, with a holding tank for temporary storage. This design allows for efficient production planning based on desired output volume and quality. Additionally, tube panel PBRs are highly productive, utilize available floor space effectively, and are relatively easy to clean.The selection of a PBR design depends on several factors, including the geographical location of the cultivation site and the available space. Closed PBRs come in various configurations, with one of the most common being the tubular panel PBR.

3.2. Temperature tolerance and biofilm formation in BIPBR system

While Tetraselmis strains have been reported to tolerate temperatures up to 40 °C, high temperatures can significantly impact the profitability of BIPBR systems. Culture collapse due to overheating is a major concern. For instance, studies have shown that non-temperature-controlled outdoor photobioreactors can experience productivity losses of D. salina by 35 % and 40 % in arid and Mediterranean climates, respectively. However, several microalgae species exhibit temperature tolerance and biofilm formation capabilities, which can be beneficial for outdoor cultivation. For example, Chlorococcum sp. and Botryococcusbraunii, both green algae, have been successfully cultivated as biofilms. Additionally, Nitzschia palea is a highly adherent microalga known for forming strong biofilms, leading to greater biomass yields than species like Scenedesmus obliquus. Furthermore, D. salina has been shown to tolerate temperatures up to 43 °C. These observations underscore the importance of species selection and temperature management in optimizing the performance of algal cultivation systems.

4. Design factors of BIPBR

BIPBR systems offer a sustainable solution by transforming building-generated wastewater and CO2 into valuable resources, eliminating the need to discharge them into the environment. Specific parameters for Microalgae cultivation in BIPBR are discussed in Table 2. Future development of BIPBR elements will focus on optimizing parameters like solar Energy Conversion Efficiency: The efficiency of converting solar radiation into heat and biomass will be a key performance metric.Effective BIPBR design requires careful consideration of several factors [[42], [43], [44], [45], [46]]:

-

(a)

Microalgae Cultivation and Climate: The specific microalgae species chosen and the climatic conditions where the BIPBR will be installed (on a vertical facade) are crucial factors.

-

(b)

Biomass Productivity Optimization: Conservative but effective strategies will be employed to maximize biomass production.

-

(c)

Thermal Exchange with Buildings: The BIPBR system should be designed to facilitate beneficial thermal exchange with the building it supports.

-

(d)

Flat Panel Hydrodynamic Optimization: Optimizing the hydrodynamics of flat-panel PBRs is essential to prevent biofouling on the optical glass, which can hinder light penetration.

Table 2.

| S.No | Parameters for BIPBR design | Effects |

|---|---|---|

| 1. | Orientation | The ideal placement for a BIPBR system depends on its location's latitude. In the Northern Hemisphere, including India, a southward orientation maximizes sunlight exposure throughout the day.Conversely, in the Southern Hemisphere, a northward orientation is preferred. This general rule ensures the BIPBR receives direct sunlight for most of the day |

| 2. | Thickness | It shouldn't be more than 5–6 cm |

| 3. | Materials | There are numerous varieties of glass and plastic (plexiglass, laminated safety glass, transparent polycarbonate, polyethylene film, transparent polycarbonate) |

| 4. | Temperature | An optimal temperature range (which varies based on the algae strain) is necessary for algae to bloom. A temperature range of 17–32 °C is ideal for algae growth, with the average temperature range. |

| 5. | Light Intensity | Light is essential for photosynthesis, and so is the amount of time. Algae are exposed to light, which is a significant element in determining the rate at which they grow. Because direct sunlight can reduce efficiency, photo-bleaching, and photo-inhibition, most algae species require indirect or intermediate-intensity light levels (1000-10,000 lux) to thrive. |

| 6. | Carbon dioxide | To produce 1t of microalgae biomass, approximately 1.8t of CO2 is required. Various sources of CO2 include manufacturing plants, refineries, flue gas emissions from power plants, and small-scale combined heat and power (MCHP) systems. |

| 7. | Nutrients/Media | Additionally, carbon dioxide, the amount of salinity, phosphate, ammonia, and oxygen present in the water all impact the cultivation of algae. |

| 8. | pH | Many researchers agree that for algae to thrive in the long run, the pH level has to be between 7 and 11. |

| 9. | Water | Chlorinated water is preferred for most algae strains. |

| 10. | Algae strain | Different varieties of algae develop at different rates; for example, heterotrophic microalgae grow faster than phototrophic microalgae and grow larger. Therefore, choosing the right algae species based on the other variables is critical. |

| 11. | Photoperiod | Microalgae undergo photosynthesis in the same way as other plants do. Light intensity, spectral quality, and photoperiod are all crucial for algal growth. Still, the specific conditions needed to achieve optimal growth vary widely depending on the depth of the culture and the density of the algal cells. |

| 12. | Air circulation | Algae must interact sufficiently with their environment to take in enough atmospheric CO2. Algae aeration in reactors or ponds ensures that all cells are exposed to the same quantity of light and reduces the likelihood of sedimentation of green growth. |

Developing a BIPBR prototype requires a data-driven approach.Mathematical modeling and simulation of critical factors like sunlight and temperature affecting microalgae growth can be used as an initial step [20]. This approach helps improve the sustainability of the BIPBR design by reducing uncertainties before building a physical prototype.An adaptive design methodology emphasizes understanding a system before creating a prototype. In the context of BIPBRs, this involves constructing mathematical models to describe how sunlight, temperature, and other relevant factors will directly impact the development of a prototype.While integrating green walls with buildings is not new, microalgae offers a modern and potentially more efficient approach. Traditional green walls rely on planting as a critical design component [11]. BIPBR systems, on the other hand, integrate PBRs directly into the building's facade [12].Unlike ground-based plant systems, Microalgae are cultivated within these controlled PBR environments [9].The aeration system with a tri-meter sensor in the Aquarium system algae cultivation is shown in Fig. 5.

Fig. 5.

Aeration system and tri-meter sensors.

5. Modeling aspects of BIPBR

Effective design and optimization of BIPBR systems rely heavily on modeling and simulation techniques.Dynamic mathematical models, particularly for novel applications like BIPBRs, can be invaluable tools before embarking on empirical research [37]. These models can predict process effectiveness, optimize operating conditions, and inform design decisions.

5.1. Two primary areas of modeling are crucial for BIPBRs

Microalgae Growth Modeling: Research on growth models for microalgae in PBRs is essential. Optimizing these models using process dynamics and control techniques can significantly enhance microalgae productivity within bioreactors. PBR modeling has traditionally focused on maximizing microalgae production by analyzing and optimizing light intensity and its impact on photosynthesis [1].

Abiotic Factor Modeling: Certain abiotic factors, such as culture temperature and nutrient concentration (media/nutrients and CO2), significantly influence microalgae growth in PBRs. These factors can independently or interactively limit growth. While single-limitation modeling is valuable, advanced models that consider the interaction of multiple limiting factors provide a more comprehensive understanding (e.g., temperature and nutrient concentration) [[27], [28], [29], [39], [40], [41]].

5.2. Key limiting factors for BIPBRs

Four key parameters limit the growth of a bio-regenerative BIPBR system in the built environment: light intensity, temperature, media/nutrients, and CO2. However, the mechanical characterization of BIPBRs often focuses only on light and temperature.Different growth parameters of indigenous Chlorella microalgae species are given in Table 3.To address this gap, a fundamental modeling method is needed that explicitly studies these limiting factors, emphasizing how light interacts with each factor. This model should account for the combined and interactive effects on BIPBR growth, oxygen evolution, carbon dioxide consumption, biomass productivity, and energy consumption.

Table 3.

Different growth parameters of IndigenousChlorella microalgae species.

| Parameter | Value | Unit |

|---|---|---|

| 0.8 | – | |

| 1.8 × 10−3 | Kgx−1 s−1 | |

| 1.13 | – | |

| 1.1 × 10−7 | μmolhυ−1 | |

| Mx | 0.024 | KgxC-mol−1 |

| 2 | – | |

| KA | 30,000 | μmolhυKg−1s−1 |

| Kr | 150 | μmolhυKg−1s−1 |

| A | 1500 | μmolhυKg−1s−1 |

| Ea | 200 | m2Kg−1 |

| Es | 2870 | m2Kg−1 |

| B | 0.002 | – |

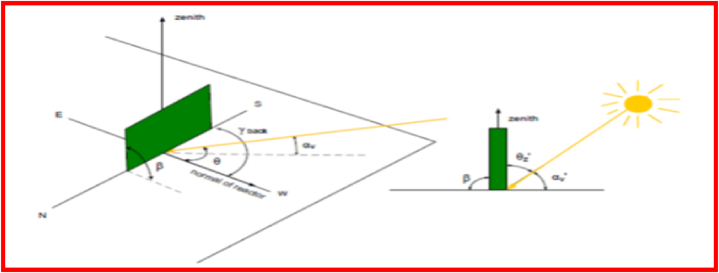

5.2.1. Solar incidence light

Direct light varies with the solar position on a flat-panel reactor. The solar incidence angle on a flat-plate reactor depends on the solar declination, the angular position of the solar at midday relative to the equator plane, the latitude location of the reactor, the reactor surface slope β, the azimuth surface angle between the reactor normal. And the solar hour angle changes shifts ω [20]. The interpretation of sunlight parameters is shown in Fig. 6.

Fig. 6.

Interpretation of sunlight parameters as surface azimuth angle γbackthe solar incidence angle θ, the solar elevation αv and the projected αv', solar incidence angle θ and slope of the reactor surface β

Figure provides an overview of the parameters engaged in solar incidence angle θ calculation:

The angles β, γ, ϕ are fixed, the angle ω depends on the solar hour and angle δ on theday of the year.

Application to the solar situation shows a distinct treatment of direct and diffuse radiation elements due to their difference in angular distribution on the PBR surface, considering the sub-normal incidence of radiation. (i.e., the incident angle h).

The total hemispherical incident light flux density (or PFD) q is divided into the direct and diffuse components

| (1) |

Total irradiance is provided by summing the resulting collimated and diffuse radiation contribution (indicating the quantity of light obtained in the bulk culture):

| (2) |

where Is the collimated radiation irradiance field as indicated by:

| (3) |

and the irradiance field for diffuse radiation

| (4) |

Where, = linear scattering modulus

.

= two-flux collimated and diffuse extinction coefficients

.

.

.

.

.

.

.

5.2.1.1. Oxygen evolution rate

The determination of the irradiance field makes it easier to determine the respective reference photosynthetic growth rate of the culture volume. Growth kinetic relationship gives a specific rate of oxygen evolution for local microalgae photosynthetics [20,37].

.

.

.

.

.

.

= Specific cofactor regeneration rate in the respiratory chain associated with stoichiometric oxygen consumption

= the Cofactor regeneration coefficient stoichiometric on the respiratory chain

= Constant saturation describing the inhibition of respiration in light

| (6) |

= C-molar mass for the biomass

= stoichiometric coefficient of the oxygen production

Finally, the determination of the mean growth rate makes it possible to solve the mass balance equation for biomass. This equation (7) is for a continuous system that assumes perfectly mixed conditions.

| (7) |

= mean biomass volumetric growth rate in the system

= residence time resulting from the liquid flow rate of the fresh medium

The volumetric growth rate of the mean biomass in Eq. (6) Local average volumetric growth rate over culture volume in Eq 5 can be studied. For a 1D light attenuation cultivation system, this consists of a simple integration along the depth of culture z, and L denotes the total PBR depth:

| (8) |

The variable PFD in sunlight conditions implies that the irradiance field within the culture bulk and the subsequent local and mean volumetric growth rates vary continuously and can, therefore not be presumed to be stable in Eq. (8). This indicates resolving the transient mass balance equation form.

5.2.1.2. Biomass productivity

After finally determining the timing of biomass concentration, biomass, the corresponding productivity of biomass can be calculated [[20], [24], [25], [26], [37]].System and species (Chlorella microalgae) specific parameter values for water and CO2are given in Table 4. Areal productivity Ps (g m−2 day−1) is being used as a valuable variable for extrapolating the production of land as specified byEq (9):

| (9) |

Table 4.

System and species (Chlorella microalgae) specific parameter value for water and CO2.

| Parameters | Raceway Pond | Flat Panel | Horizontal and vertical tubular |

|---|---|---|---|

| Awaterm2 | 8000 | N.A. | N.A. |

| d (m) | 0.30 | 0.03 | 0.06 |

| fCO2 (Kg kg−1) | 2.0651 | 2.0651 | 2.0651 |

| fwater(Kg kg−1) | 0.6239 | 0.6239 | 0.6239 |

| h (m) | N.A | 1 | N.A |

| L (m) | N.A | 100 | 100 |

| Number of vertical rows | N.A | N.A | 1(hor), 9 (vert) |

| ηCO2 | 1.5 | 1.5 | 1 |

| ηwater | 0.05 | 0.05 | 0.05 |

5.2.1.3. CO2 consumption

The uptake of CO2 is directly linked to the growth of algae [[20], [24], [25], [26], [37]]. The CO2 requirement in the three cultivation systems is determined by Eq (10):

| (10) |

Where.

= CO2 consumption (kg hectare−1 year−1)

= biomass production (kg hectare−1 year−1)

= the stoichiometric factor of CO2 consumption for growth

= assimilation efficiency of CO2

5.2.1.3.1. Energy consumption for transport

The CO2 and water transport energy consumption [28,29].

Water transport energy consumption is obtained byEq 11:

| (11) |

The photosynthetic quotient, PQ, ratio between the evolution rate of O2 and the rate of absorption of CO2 relies on the composition of biomass production and the use of substrates. The PQ is mainly affected by oxidized sources of nitrogen, which need to be reduced before they are incorporated into the biomass. Suppose the biomass composition is equal to the ratio of Redfield, CH2O(NH3) 0.15, and NO3, which is the nitrogen source, is expected to have a PQ of 1.3. With the lower NO2as a nitrogen source, the expected PQ is 1.2.

Growth on NH4+

If the composition of biomass production varies, the PQ is likely to change as various molecules incorporated in the biomass may not be reduced equally.

If no organic products are produced in addition to biomass and NH4 + is the source of nitrogen, the molar ratio between the production of oxygen and the fixation of carbon, yO2 = x can be found from a degree of reduction balance and can be given by Eq (12).

| (12) |

where = x is the molar ratio between ammonium uptake and carbon fixation. The degrees of reduction of CO2, H2O and NH3, gCO2; gH2O, and gNH3, respectively, all equal zero, and the degree of reduction O2, gO2 1⁄4 4. If carbohydrates are the only compounds formed, gx = 4 for the biomass, while protein and lipid synthesis results in higher gx values. If no organic products are secreted from the cells, all CO2 absorbed is integrated into the biomass, and the PQ is equal to γ (O2) = x.

| (13) |

Equation (13) estimates that carbohydrate synthesis outcomes in PQ = 1, while higher PQ values result in the synthesis of more reduced cell components. The equation can also predict the PQ in cultures using NO2 or NO3 as a nitrogen source, although gx is assigned slightly higher values in cultures using these nitrogen sources.

6. SWOT analysis of the BIPBR

6.1. Benefits/strength of BIPBRs

CO2 Bio-scavenger: Microalgae act as a bio-scavenger, consuming CO2 produced within the building [24].

Oxygen Supply: PBRs continuously pump oxygen into the building through exhaust ducts, serving as a supplementary oxygen source.

Insulation: PBRs have the potential to act as an insulating material, mitigating temperature variations and some sound from noisy environments, particularly in urban areas [11,12].

Air Filtration: The exchange of indoor air (CO2) through the photobioreactor acts as a bio-filter. Microalgae use CO2 for photosynthesis, producing oxygen and air filtering [24].

Thermal Comfort: As the microalgae culture matures, the PBR can act as a bio-curtain by limiting or reflecting light. This can be a valuable feature for regulating building temperature, especially in hot climates.

6.2. Challenges of BIPBRs

While microalgae integration into buildings holds promise, several challenges must be addressed. SWOT analysis of BIPBR is presented in Fig. 7. Factors like light intensity, temperature, nutrient availability, and aeration restrict the size of PBRs suitable for building facades [[39], [40], [41]]. These factors are interrelated and influence the overall operating conditions within the PBR.Effective PBR integration necessitates careful consideration of various design aspects [40]. This includes evaluating mixing units, construction materials, piping systems for water and culture media, aeration unit design, CO2/O2 transport pumps, and PBR installation methods – all crucial for successful building design. Maintaining the cleanliness of PBR surfaces, particularly the exterior facade, can be achieved using conventional techniques for cleaning large glass structures. However, PBRs present unique challenges due to their limited depth (typically 10–15 cm), hindering cleaning efforts. Additionally, microalgae species can adhere to the PBR's inner surfaces, forming an additional layer. This can lead to two problems: shading of underlying microalgae and increased contamination risks due to difficulty in cleaning. Therefore, an optimal method for internal PBR cleaning is essential [36,[48], [49], [50], [51], [52]].

Fig. 7.

SWOT analysis of BIPBR.

Significant reasons for adopting this technology [[53], [54], [55], [56], [57], [58], [59], [60], [61], [62]].

-

•

Biomass Productivity and biorefining are environmentally friendly

-

•

Green and clean fuel generation

-

•

Carbon dioxide sequestration

-

•

Carbon footprint reduction reduces greenhouse gas emissions

-

•

Need to Adopt green biotechnology in the built environment

-

•

A potential source of food and feed as the protein source

-

•

Future manufacturing or renewable chemicals sales

-

•

As a distinctive technology, asset value will improve

-

•

Fossil-based energy prices are rising for long-term investments.

-

•

Sector appeal when electricity, illumination, heating, and cool buildings can be powered by technology

-

•

Creative, exciting and modern.

7. Recommendations and future scope

Energy efficiency is a critical concern for buildings, and facades play a crucial role in design aesthetics. Traditionally, green facades have utilized land plants for their visual appeal. The term "green" comes from the chlorophyll pigment that gives most photosynthetic plants green color.However, microalgae offers a compelling alternative for building facades. Grown in controlled, closed settings, microalgae can go beyond the limitations of color associated with land plants [[63], [64]]. Microalgae integration with buildings can have several benefits:

Improved Indoor Air Quality and Temperature Regulation: Microalgae can be used with biotechnology tools to enhance indoor air quality and regulate building temperature, contributing to occupant comfort.

Decentralized Biorefinery for Social Impact: Buildings with integrated microalgae systems can become micro-refineries, producing valuable resources like biofuels on-site, minimizing the need for large, centralized factories. This distributed approach has the potential for significant social impact [[42], [65]].

Energy Production and Heat Management: The biomass and heat generated by the microalgae system can[[53], [54], [55], [56], [57], [58], [59], [60], [61], [62], [63], [64], [65]] be managed efficiently. Heat exchangers can recover both biomass and heat for various purposes. Excess heat can warm the building interior or be stored for later use. The biomass can be converted into biogas, which can then power micro-turbines for combined heat and power generation, providing electricity and additional heat for the building.

Light and Temperature Considerations: Sunlight plays a vital role in microalgae growth, promoting faster growth and higher productivity. However, temperature can be challenging, particularly in regions with significant climate variations like India. Therefore, selecting microalgae species that thrive in specific climatic conditions is crucial.A crucial challenge is balancing user views and effective microalgae integration. While flat-panel PBRs are favored for their compactness in facade applications, they can completely obstruct user views when filled with microalgae. Examples of algal architecture using tubular PBRs as secondary facades demonstrate a limitation on user views. However, this can be mitigated by reducing tube diameter and increasing spacing between them.Heat balance is another key concern for facade-integrated PBR systems. Current research primarily focuses on surface heat transfer or solar radiation for reactor heating, neglecting other potential heat sources [36].The potential benefits of microalgae integration extend beyond energy production. Bio-responsive building facades with microalgae offer additional advantages like summer shading and biomass generation. With technological advancements, microalgae holds promise as a future material for carbon-neutral construction, promoting sustainable built environments.Further research and development are necessary to bridge the gap between current limitations and achieving this goal. Prototype panels for evaluating performance and operation are crucial for advancing this technology.

8. Conclusion

This study reviewed the potential of photobioreactor (PBR) technology for building integration, highlighting its role in promoting sustainable architecture. Key findings include:

-

1.

Significant reductions in operational costs can be achieved by optimizing CO2 feeding and thermal control systems for different microalgae strains. Notably, heat symbiosis using microalgae PBR offers a promising approach to dramatically reduce energy demands compared to traditional solar systems prone to overheating.

-

2.

Developing a Building-Integrated PBR System (BIPBR) necessitates an adaptive design methodology. Evolutionary analysis can be crucial in reducing uncertainty and enhancing design robustness by fostering a deeper understanding of the system before prototype development.

-

3.

Informed design relies on theoretical studies, encompassing indoor and outdoor characterization studies, the PBR facade's thermal conductivity analysis, and the culture unit's hydrodynamic optimization. These studies help identify the integrated structure's optimal BIPBR geometry and operational processes.

-

4.

Secure cultivation methods offer compelling advantages, leading to significantly greater productivity, enhanced product quality, and improved production efficiency.

-

5.

Microalgae represents a promising future direction for designers seeking carbon-neutral construction solutions to achieve sustainable built environments.

In summary, integrating microalgae into building design, particularly in conjunction with green walls, presents a multifaceted solution for enhancing energy efficiency, improving air quality, and promoting sustainable architectural practices. This paper provides a foundation for further research, focusing on the design parameters of continuous culture photobioreactors (PBRs) to revolutionize the built environment and contribute to a more sustainable future.

CRediT authorship contribution statement

Ruma Arora: Writing – original draft. K. Sudhakar: Writing – review & editing, Supervision. R.S. Rana: Supervision.

Declaration of competing interest

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Contributor Information

Ruma Arora, Email: ruma.arora@cdgi.edu.in.

K. Sudhakar, Email: sudhakar@umpsa.edu.my.

References

- 1.Inam A., Oncel S.S. Photobioreactors as potential tools for environmentally friendly and sustainable buildings. Int. J. Environ. Sci. Technol. 2022;19(4):2353–2364. [Google Scholar]

- 2.Jaber S., Ajib S. Thermal and economic windows design for different climate zones. Energy Build. 2011;43(11):3208–3215. [Google Scholar]

- 3.Wang B., Wang Z. High-rise building integrated with solar chimney and bioenergy. In IOP conference series. Earth and Environmental Science. 2021, October;898(1) [Google Scholar]

- 4.Pruvost J., Le Gouic B., Lepine O., Legrand J., Le Borgne F. Microalgae culture in building-integrated photobioreactors: biomass production modelling and energetic analysis. Chem. Eng. J. 2016;284:850–861. [Google Scholar]

- 5.Olaizola M. Commercial development of microalgal biotechnology: from the test tube to the marketplace. Biomol. Eng. 2003;20(4–6):459–466. doi: 10.1016/s1389-0344(03)00076-5. [DOI] [PubMed] [Google Scholar]

- 6.Beer L.L., Boyd E.S., Peters J.W., Posewitz M.C. Engineering algae for biohydrogen and biofuel production. Curr. Opin. Biotechnol. 2009;20(3):264–271. doi: 10.1016/j.copbio.2009.06.002. [DOI] [PubMed] [Google Scholar]

- 7.Djedjig R., Bozonnet E., Belarbi R. Analysis of thermal effects of vegetated envelopes: integration of a validated model in a building energy simulation program. Energy Build. 2015;86:93–103. [Google Scholar]

- 8.Manso M., Castro-Gomes J. Green wall systems: a review of their characteristics. Renew. Sustain. Energy Rev. 2015;41:863–871. [Google Scholar]

- 9.Pruvost J., Cornet J.F., Le Borgne F., Goetz V., Legrand J. Theoretical investigation of microalgae culture in the light changing conditions of solar photobioreactor production and comparison with cyanobacteria. Algal Res. 2015;10:87–99. [Google Scholar]

- 10.Scown C.D., Baral N.R., Yang M., Vora N., Huntington T. Technoeconomic analysis for biofuels and bioproducts. Curr. Opin. Biotechnol. 2021;67:58–64. doi: 10.1016/j.copbio.2021.01.002. [DOI] [PubMed] [Google Scholar]

- 11.Todisco E., Louveau J., Thobie C., Dechandol E., Hervé L., Durécu S.…Pruvost J. A dynamic model for temperature prediction in a façade-integrated photobioreactor. Chem. Eng. Res. Des. 2022;181:371–383. [Google Scholar]

- 12.Nwoba E.G., Parlevliet D.A., Laird D.W., Alameh K., Moheimani N.R. Light management technologies for increasing algal photobioreactor efficiency. Algal Res. 2019;39 [Google Scholar]

- 13.Achinas S., Achinas V., Euverink G.J.W. A technological overview of biogas production from biowaste. Engineering. 2017;3(3):299–307. [Google Scholar]

- 14.Nwoba E.G., Parlevliet D.A., Laird D.W., Alameh K., Louveau J., Pruvost J., Moheimani N.R. Energy efficiency analysis of outdoor standalone photovoltaic-powered photobioreactors coproducing lipid-rich algal biomass and electricity. Appl. Energy. 2020;275 [Google Scholar]

- 15.Kelly Z., Iqbal A. Canadian Society of Civil Engineering Annual Conference. Springer; Singapore: 2023. Indigenous housing practices as inspirations for modern green buildings; pp. 149–158. [Google Scholar]

- 16.Nwoba E.G., Parlevliet D.A., Laird D.W., Alameh K., Moheimani N.R. Pilot-scale self-cooling microalgal closed photobioreactor for biomass production and electricity generation. Algal Res. 2020;45 [Google Scholar]

- 17.Kerestecioglu F.O., Pekmezci Y.T. Defining the problems of integrated algae photobioreactor systems to architecture. International Journal of Engineering Science and Application. 2019;3(2):52–70. [Google Scholar]

- 18.Köktürk G., Ünal A., Tokuç A. Exergetic, Energetic and Environmental Dimensions. Academic Press; 2018. A new approach for a control system of an innovative building-integrated photobioreactor; pp. 71–85. [Google Scholar]

- 19.Elrayies G.M. Microalgae: prospects for greener future buildings. Renew. Sustain. Energy Rev. 2018;81:1175–1191. [Google Scholar]

- 20.Fauzi M.A., Malek N.A. Green Building assessment tools: evaluating different tools for green roof system. Int. J. Educ. Res. 2013;1(11):1–14. [Google Scholar]

- 21.Karemore A., Pal R., Sen R. Strategic enhancement of algal biomass and lipid in Chlorococcuminfusionum as bioenergy feedstock. Algal Res. 2013;2(2):113–121. [Google Scholar]

- 22.Ottelé M., Perini K., Fraaij A.L.A., Haas E.M., Raiteri R. Comparative life cycle analysis for green façades and living wall systems. Energy Build. 2011;43(12):3419–3429. [Google Scholar]

- 23.Sirohi R., Pandey A.K., Ranganathan P., Singh S., Udayan A., Awasthi M.K.…Sim S.J. Design and applications of photobioreactors-A review. Bioresour. Technol. 2022 doi: 10.1016/j.biortech.2022.126858. [DOI] [PubMed] [Google Scholar]

- 24.Zhu C., Han D., Li Y., Zhai X., Chi Z., Zhao Y., Cai H. Cultivation of aquaculture feed Isochrysiszhangjiangensis in low-cost wave driven floating photobioreactor without aeration device. Bioresour. Technol. 2019;293 doi: 10.1016/j.biortech.2019.122018. [DOI] [PubMed] [Google Scholar]

- 25.Liu Y., Guo X., Hu F. Cost-benefit analysis on green building energy efficiency technology application: a case in China. Energy Build. 2014;82:37–46. [Google Scholar]

- 26.Vo H.N.P., Ngo H.H., Guo W., Nguyen T.M.H., Liu Y., Liu Y.…Chang S.W. A critical review on designs and applications of microalgae-based photobioreactors for pollutants treatment. Sci. Total Environ. 2019;651:1549–1568. doi: 10.1016/j.scitotenv.2018.09.282. [DOI] [PubMed] [Google Scholar]

- 27.Ip K., Lam M., Miller A. Shading performance of a vertical deciduous climbing plant canopy. Build. Environ. 2010;45(1):81–88. [Google Scholar]

- 28.Soni R.A., Sudhakar K., Rana R.S. Spirulina–From growth to nutritional product: a review. Trends Food Sci. Technol. 2017;69:157–171. [Google Scholar]

- 29.Talaei M., Mahdavinejad M., Azari R., Prieto A., Sangin H. Multi-objective optimization of building-integrated microalgae photobioreactors for energy and daylighting performance. J. Build. Eng. 2021;42 [Google Scholar]

- 30.Nallapaneni M.K., Chopra S.S. 3rd International Conference on Renewable Energy, Sustainable Environmental and Agricultural Technologies, I-RESEAT 2021. 2021, December. Algal photobioreactor façades coupled with BAPV/BIPV in high-rise urban buildings improves indoor air quality and enables energy resilience in race to net-zero. [Google Scholar]

- 31.Soni R.A., Sudhakar K., Rana R.S. Comparative study on the growth performance of Spirulina platensis on modifying culture media. Energy Rep. 2019;5:327–336. [Google Scholar]

- 32.Hasnan M.T.I.M.T., Zaharin P.M.B. Exploration of microalgae photobioreactor (PBR) in tropical climate building envelope. Environment-Behaviour Proceedings Journal. 2020;5(14):263–278. [Google Scholar]

- 33.Ardiani N.A., Koerniawan M.D., Martokusumo W., Suyono E.A., Poerbo H.W. Feasibility of algae photobioreactor as façade in the office building in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2019, August;322(1) [Google Scholar]

- 34.Perini K., Ottelé M., Fraaij A.L.A., Haas E.M., Raiteri R. Vertical greening systems and the effect on air flow and temperature on the building envelope. Build. Environ. 2011;46(11):2287–2294. [Google Scholar]

- 35.Soni R., Sudhakar K., Rana R. Sustainable biomass production from microalgae for food, feed and biofuels: an integrated approach. Biosci. Biotech. Res. Comm. 2016;9:729–736. [Google Scholar]

- 36.Talaei M., Mahdavinejad M. Probable cause of damage to the panel of microalgae bioreactor building façade: hypothetical evaluation. Eng. Fail. Anal. 2019;101:9–21. [Google Scholar]

- 37.Yen H.W., Hu I.C., Chen C.Y., Ho S.H., Lee D.J., Chang J.S. Microalgae-based biorefinery–from biofuels to natural products. Bioresour. Technol. 2013;135:166–174. doi: 10.1016/j.biortech.2012.10.099. [DOI] [PubMed] [Google Scholar]

- 38.Ahmad I., Abdullah N., Koji I., Yuzir A., Muhammad S.E. Evolution of photobioreactors: a review based on microalgal perspective. IOP Conf. Ser. Mater. Sci. Eng. 2021, April;1142(1) [Google Scholar]

- 39.Stec W.J., Van Paassen A.H.C., Maziarz A. Modelling the double skin façade with plants. Energy Build. 2005;37(5):419–427. [Google Scholar]

- 40.Assunção J., Malcata F.X. Enclosed “non-conventional” photobioreactors for microalga production: a review. Algal Res. 2020;52 [Google Scholar]

- 41.Chhabra J. Georgia Institute of Technology; 2020. Building-integrated Biotic Carbon Sequestration Technioques: Overview and Simulation Workflow. Doctoral dissertation. [Google Scholar]

- 42.Soni R.A., Sudhakar K., Rana R.S. Biophotovoltaics and Biohydrogen through artificial photosynthesis: an overview. Int. J. Environ. Sustain Dev. 2016;15(3):313–325. [Google Scholar]

- 43.Azkorra Z., Pérez G., Coma J., Cabeza L.F., Burés S., Álvaro J.E.…Urrestarazu M. Evaluation of green walls as a passive acoustic insulation system for buildings. Appl. Acoust. 2015;89:46–56. [Google Scholar]

- 44.Soni R.A., Sudhakar K., Rana R.S., Baredar P. Algae. Springer; Singapore: 2021. Food supplements formulated with spirulina; pp. 201–226. [Google Scholar]

- 45.Lehr F., Posten C. Closed photobioreactors as tools for biofuel production. Curr. Opin. Biotechnol. 2009;20(3):280–285. doi: 10.1016/j.copbio.2009.04.004. [DOI] [PubMed] [Google Scholar]

- 46.Soni R.A., Sudhakar K., Rana R.S. Simulation and analysis of open raceway pond system at Manit, Bhopal. IOP Conf. Ser. Mater. Sci. Eng. 2020;788(1) [Google Scholar]

- 47.Perini K., Ottelé M., Haas E.M., Raiteri R. Vertical greening systems, a process tree for green façades and living walls. Urban Ecosyst. 2013;16(2):265–277. [Google Scholar]

- 48.Rindi F., Allali H.A., Lam D.W., López-Bautista J.M. Biodiversity hotspots; 2009. An Overview of the Biodiversity and Biogeography of Terrestrial Green Algae; p. 125. [Google Scholar]

- 49.Anderson L.G. Effects of using renewable fuels on vehicle emissions. Renew. Sustain. Energy Rev. 2015;47:162–172. [Google Scholar]

- 50.Perini K., Rosasco P. Cost–benefit analysis for green façades and living wall systems. Build. Environ. 2013;70:110–121. [Google Scholar]

- 51.Arbye S., Arianti R.F., Pradana Y.S., Suyono E.A., Koerniawan M.D., Suwanti L.T.…Budiman A. 2020 International Conference on Science and Applied Science, ICSAS 2020. American Institute of Physics Inc.; 2020, November. The design of microalgae (Chlorella sp.) photobioreactor as a façade bus shelter building in Indonesia. [Google Scholar]

- 52.Ma K., Chen S., Wu Y., Ma Y., Qiao H., Fan J., Wu H. Dietary supplementation with microalgae enhances the zebrafish growth performance by modulating immune status and gut microbiota. Appl. Microbiol. Biotechnol. 2022;106(2):773–788. doi: 10.1007/s00253-021-11751-8. [DOI] [PubMed] [Google Scholar]

- 53.Sharanya B.K., Ghoshb S., Bhandari S.S., Poudel S., Padikkal G.M., Kumarc M.S. Green and sustainable building practices for museums. AIP Conf. Proc. 2018;20010 2039. [Google Scholar]

- 54.Oncel S.S., Kose A., Oncel D.S. Start-Up Creation. Woodhead Publishing; 2020. Carbon sequestration in microalgae photobioreactors building integrated; pp. 161–200. [Google Scholar]

- 55.Li J., Stamato M., Velliou E., Jeffryes C., Agathos S.N. Design and characterization of a scalable airlift flat panel photobioreactor for microalgae cultivation. J. Appl. Phycol. 2015;27(1):75–86. [Google Scholar]

- 56.Heining M., Sutor A., Stute S.C., Lindenberger C.P., Buchholz R. Internal illumination of photobioreactors via wireless light emitters: a proof of concept. J. Appl. Phycol. 2015;27(1):59–66. [Google Scholar]

- 57.Öncel S.S., Köse A. Photobioreactors for sustainable buildings. Dokuz Eylül ÜniversitesiMühendislikFakültesi Fen veMühendislikDergisi. 2016;18(52):77–88. [Google Scholar]

- 58.Outhwaite A. 2015. The Characterization of a Building-Integrated Microalgae Photobioreactor (Doctoral Dissertation) [Google Scholar]

- 59.Köhler M. Green facades—a view back and some visions. Urban Ecosyst. 2008;11(4):423–436. [Google Scholar]

- 60.Hong K.S., Pham P.T. Control of axially moving systems: a review. Int. J. Control Autom. Syst. 2019;17(12):2983–3008. [Google Scholar]

- 61.Rahman Q.M., Wang L., Zhang B., Xiu S., Shahbazi A. Green biorefinery of fresh cattail for microalgal culture and ethanol production. Bioresour. Technol. 2015;185:436–440. doi: 10.1016/j.biortech.2015.03.013. [DOI] [PubMed] [Google Scholar]

- 62.Vanthoor-Koopmans M., Wijffels R.H., Barbosa M.J., Eppink M.H. Biorefinery of microalgae for food and fuel. Bioresour. Technol. 2013;135:142–149. doi: 10.1016/j.biortech.2012.10.135. [DOI] [PubMed] [Google Scholar]

- 63.Kelly Z., Iqbal A. Canadian Society of Civil Engineering Annual Conference. Springer; Singapore: 2023. Indigenous housing practices as inspirations for modern green buildings; pp. 149–158. [Google Scholar]

- 64.Brager G., Zhang H., Arens E. Evolving opportunities for providing thermal comfort. Build. Res. Inf. 2015;43(3):274–287. [Google Scholar]

- 65.Zuo J., Zhao Z.Y. Green building research–current status and future agenda: a review. Renew. Sustain. Energy Rev. 2014;30:271–281. [Google Scholar]