Abstract

The use of nano additives to improve the cold properties of biodiesel is encouraged by its drawbacks and incompatibility in cold climate. Waste cooking oil (WCO) was transesterified to create biodiesel. A 20% by volume was used for combination of diesel and methyl ester. Current study aims to evaluate diesel engine emissions and performance. TiO2, alumina, and hybrid TiO2 + Al2O3 nanoparticles are added to WCO biodiesel mixture at 25 mg/liter. When B20 combined with nano materials such as TiO2, Al2O3, and hybrid nano, the highest declines in brake specific fuel consumption were 4, 6, and 11%, respectively. As compared to biodiesel blend, the largest gains in thermal efficiency were 4.5, 6.5, and 12.5%, respectively, at maximum engine output power. Introduction of TiO2, Al2O3, and hybrid nano particles to B20 at 100% load resulted in the highest decreases in HC concentrations up to 7, 13, and 20%, and the biggest reductions in CO emissions, up to 6, 12, and 16%. Largest increases in NOx concentrations at full load were about 7, 15, and 23% for B20 + 25TiO2, B20 + 25 Al2O3, and B20 + 25TiO2 + 25 Al2O3, respectively. Up to 8, 15, and 21% less smoke was released, correspondingly, which were the largest reductions. Recommended dosage of 25 ppm alumina and 25 ppm TiO2 achieved noticeable improvements in diesel engine performance, combustion and emissions about B20.

Keywords: WCO biodiesel, Hybrid nano, Performance: combustion chracteristics, Emissions

Subject terms: Energy science and technology, Engineering

Introduction

Due to risks from global warming, fossil fuel resources shortage, stronger environmental laws in the global energy market and the use of renewable energy sources have been increased during the past ten years. Biodiesel is one of the forms of sustainable energy. Biodiesel is frequently used by scientists as a substitute fuel. Because of its higher density, lower cetane number, and lower calorific value, pure biodiesel cannot fully replace conventional diesel in diesel engines. However, it may be utilized in diesel engines. Using biodiesel in cold areas might cause problems with the fuel filter and injection system. Issues with fuel atomization and spray were observed1.

Numerous studies indicate that high viscosity fuels have a number of detrimental consequences on diesel engines. Opium poppy (OP) oil methyl ester-diesel mixtures' impact on the efficiency and emissions of CI engines was investigated. The thermal efficiency of the OP10 and OP20 blend ratios fell were decreasesd by roughly 5.73% and 13.05% related to crude diesel due to the lower calorific value of OP biodiesel. CO emissions were reduced by OP10 and OP20, however NOX emissions were raised. In low temperature and cold start circumstances of diesel engine, impact of iron nano materials added to B20 on carbon monoxide and HC concentrations was studied2. Using biodiesel in marine operations offers benefits such as reduced carbon emissions, enhanced air quality, increased energy security, support for sustainable agriculture, and alignment with global environmental goals. Using biodiesel in the marine industry is a viable opportunity to significantly advance environmental stewardship and sustainability3. Since most engines use extra biodiesel and has a reduced thermal efficiency due to its high viscosity and carbon residue, it is imperative to determine the appropriate alternative fuel and ideal mixture percentage for diesel engine combustion. When rubber seed oil (RSO) was used in dual fuel mode with hydrogen and diethyl ether, smoke and nitrogen oxides were greatly decreased and engine performance was improved4.

By using nano materials, these problems are remedied while also improving engine performance, combustion, and exhaust pollution reduction. Another breakthrough in fuel development is the result of advances in nanotechnology. Nanoparticles are blended with liquid fuel using a novel process known as modified fuel. Iron nanoparticles were combined with palm methyl ester and B20 to create 500 ppm diluted homogenous mixture. The viscosity of blend biodiesel was reduced by 14% with the use of iron nanoparticles. BSFC, CO, and hydrocarbons emissions were decreased by 10%, 42%, and 54%, respectively.The declines in CO and HC emissions from 0 to 10 °C were up to 31% and 23.7%, respectively, while the increase in nitrogen oxide emissions were from 79 to 90 ppm5. Various diesel fuel/mono ethylene glycol supported emulsion (MEGSE) molar ratios was studied. At 15.6% MEGSE, the engine’s output was at its peak and its exhaust emissions were at their lowest6.

The experiments were done to find the best blending for enhanced fuel characteristics, improved engine combustion, and declined exhaust emissions. Impact of hybrid ZnO:TiO2, TiO2:Al2O3, CeO2:CuO, and MnO2:Al2O3 in various ratios was examined. The biofuel and the sol–gel process were used to create the nanoparticles, which were then characterised by scanning electron microscopy (SEM).By combining nanoparticles with the gasoline, BTE was raised from 1.11 to 2.21%. In comparison to standard diesel oil, the combined biodiesel with nano additions had lower NOx, HC, and CO emissions by 16.29–23.76%, 14.07–17.32%, and 5.51–8.27%, respectively7. The impact of biodiesel-diesel blends of 25 and 50% on the emissions of marine diesel engines at varying loads was investigated. Biodiesel blends increased nitrogen oxides emissions while reducing HC and smoke concentrations are due to the oxygen concentration in fuel8. Limits of using methyl ester in CI engines were evaluated by included high NOx, cold weather, low cetane number, high viscosity, engine parts, fuel tanks, and fuel filters replacement9. Methyl ester properties may be enhanced by the utilization of nano materials. Impact of magnetic nanoparticles inclusion to biofuel (40 and 80 vol.%) on emissions and CI engine performance were studied. With the inclusion of nano materials, the engine's performance and combustion considerably were enhanced, and NOx emissions significantly were decreased10.

Diesel engine emissions and performance using mixed of waste frying oil (WFO) methyl ester and crude diesel at blended ratios of 0%, 5%, 20%, and 100% were studied. As the biodiesel mixture ratio increases, the engine brake power and thermal efficiency were decreased11. WFO biodiesel use results in higher NO, lower CO2 and CO emissions12. Areca nut husk (ANH) nano additive impact on engine pollutants and performance were displayed13. PGB-derived oil water diesel emulsion (D10EPO) mixture was used to power the engine. ANH was combined at 5, 10, and 15 ppm concentrations. Compared to D10EPO, the specific fuel consumption was reduced by 9.1% and NOx emissions was increased. In comparison to D10EPO, CO, HC, and smoke for D10EPO of 15 ppm dose were declined by 17.9, 14.7, and 17.6% at full load, respectively. Experimental research on the effects of titanium dioxide (TiO2) addition to Mahua oil biodiesel on engine's emissions and performance was done. When compared to the other blends, the Mahua oil biodiesel mixture with 150 ppm TiO2 reduced CO emissions. When compared to other mixtures, biodiesel containing TiO2 (150 ppm) has the lowest NOx emissions. Nano titanium oxide at a concentration of 150 ppm can be utilised as a useful addition to reduce emissions while boosting engine performance14. Effects of main alcohols as ethanol, methanol, n-butanol and aluminium inclusions on emissions at various loads and constant speed were examined. Al2O3 nanoparticles were introduced to alcohol/diesel blends at ratios of 25–100 ppm. The lowest levels of carbon dioxide, nitrogen oxides, and smoke were produced by inclusion of methanol and nano additives15.

The use of silver thiocyanate from 7.23 to 7.98 nm as a supplement to enhance diesel engines' performance and emissions was studied. Several diesel/WCO biodiesel (D50B50) blends containing 200, 400, and 600 ppm silver thiocyanate nanoparticles were created. In comparison to other mixtures, a dose of 400 ppm nanosized silver thiocyanate exhibits greater performance and emissions.If 400 ppm concentration of nanoparticles were utilised, the improvement rate in brake thermal efficiency was 11.6%. Dose of 600 ppm of silver thiocyanate nanoparticles produced 20.7% decrease in exhaust gas temperature. At 600 ppm and 200 ppm, respectively, concentrations of carbon monoxide and UHC were lowered by ratios of 50.3% and 40.0%. In compared to pure diesel D100B0 and a D50B50 mixture, 400 ppm of silver thiocyanate nano materials reduced the smoke opacity by 55.3% and 32.0%, respectively16. Aluminium oxide nanoparticles at various dose levels were studied for their impact on honge oil biodiesel and diesel oil mixtures. Preparation of nanofuel blends involved dispersing of aluimena in HOME(B20). Sodium dodecyl sulphate (SDS) was utilised to stabilise the diffusion of these nanoparticles in fuel mixtures. Aluiminum oxide nano additives doses of 20, 40, and 60 ppm were found in B20. Nano materials at a concentration of 40 ppm in methyl ester blend significantly reduced CO, HC, and smoke concentrations by 47.43%, 37.72%, and 27.84%, respectively. All nanofuel blends' higher NOX emissions are brought on by higher flame temperature and oxygen content17.

Influence of introducing nanoparticles to biodiesel and diesel mixtures on diesel engine and exhaust concentrations were described. In comparison to methyl ester, application of nanofuel resulted in an increase in NOXemissions from 2.78 to 19.01%. The decline was brought on by the nanoparticles catalytic activity and secondary atomization which raise the rate of oxidation18. Utilization of nanoparticles in CI engine using B20 waste frying oil was studied. BTE, soot, and CO concentrations were increased by nano particles addition19. Engine performance and emissions powered by B20 WCO biodiesel-diesel mixtures doped with nanomaterials were depicted20. At 10 N.m engine load and nano additive concentration of 98 ppm, the engine operates at its best condition. Inclusion of NPs improves the biodiesel's HC, CO, and NOX emissions. Impact of mixed nano particles on diesel engines was studied. High performance fuel (HPF), combination of biodiesel, diesel, and ethanol that also contains alumina nanoadditives, was used to power the engine. Different injection timings of 21°, 22°, 23°, and 24° TDC are applied to HPF. The ideal working condition was blending with a 20 ppm alumina nano addition at 22° TDC because it boosted performance while minimising HC and CO emissions21. Impact of nano TiO2 and Al2O3 inclusions to crude diesel in percentages of 25, 50, 100, and 150 ppm was shown. BTE was raised from 18.9 to 24.25%22. The behaviour of C. racemosa algal oil biodiesel with nano additive in diesel engines was researched. Due to the lowered viscosity and enhanced volatility of the blend, which improves atomization, vaporisation, and air–fuel mixing formation, C. racemosa algal oil biodiesel-diesel mixture with nano additions can be used as substitute fuel in CI engine23. The impact of ternary blend of 80% D80E10nB10, 10% ethanol, and 10% n-butanol on engine combustion and emission was studied. Nano TiO2 addition increased the thermal efficiency by 23.24%24.

The effects of adding Fe2O3 and Al2O3 nanoparticles (30, 60, and 90 ppm) as well as Fe2O3–Al2O3 hybrid nanoparticles to pure diesel fuel on diesel engine's performance, combustion, and emission characteristics were studied. The findings demonstrated that the inclusion of the nanoparticles enhanced the peak cylinder pressure by 4% and improved the heat release rate by 15% when compared to pure diesel. The effects of Fe2O3 fuel blends on brake power, BTE, and CO emissions were greater than those of Al2O3 fuel blends; they increased power and thermal efficiency by 7.40 and 14%, respectively, and decreased CO emissions by 21.2%. Additionally, blends containing Al2O3 nanoparticle additives performed better in reducing of BSFC (9%), NOx (23.9%), and SO2 (23.4%) than blends without such additives25. Among the most well-known biofuels for use in diesel engines is biodiesel. Because free fatty acids, monoglycerides, and diglycerides are components of biodiesel and contribute to improve its lubricating characteristics and reduce friction more than other mixtures. The friction coefficient was decreased as the proportion of biodiesel increased. Because lower viscosity leads to oxidation, which facilitates the biodiesel's exposure to air at higher temperatures, friction and wear of diesel mixtures including biodiesel increase at higher rotational speeds. When it comes to lubricity, biodiesel outperforms conventional fuel mixtures26.

It is clear from the previous evaluation of the literature review, several research investigations have been done to show and further throwlight on the effect of introduction different types with different configurations of nanoparticles to biodiesel blended with diesel oil on the emissions and performance characteristics of diesel engines. Pure biodiesel may be used in diesel engines, but it cannot completely replace conventional diesel due to its greater density, lower cetane number, and lower calorific value. Injection system and fuel filter issues arise when biodiesel is used in cold climates. There were produced problems in fuel atomization and spray. These issues are resolved by adding nano compounds, which also enhance engine performance, combustion and lower exhaust emissions. The introduction of nano additives highlights the disadvantages and limitation of using biodiesel. Disposal of waste cooking oil (WCO) requires higher cost and causes pollution and risks in water sources and environment. Other studies do not see waste cooking oil as edible, despite the assertions made in prior studies by several other researchers that it is not edible. Consequently, it might be argued that utilising the oil as a feedstock for biodiesel in safer application. Waste oil can be transformed to useful energy. The analysis reveals that, however, no studies on the performance and emissions of diesel engines employing mixtures of WCO methyl ester and diesel with nanoparticle additions such TiO2 and aluimena have been documented. Previous research has mostly concentrated on analyzing different types of nano additives or their concentrations. Nevertheless, not all of the intended benefits could be obtained by using a single kind of nano additive. Investigating the combination of these two nanoadditives as Al2O3 and TiO2 is necessary to fill in any research gaps that may emerge. Hybrid nanoparticles can improve a base fluid's physical, chemical, thermal, evaporation and heat transfer characteristics. As a result, the present experimental investigation specifically uses B20 diesel mixture with biodiesel to examine how hybrid nanoparticles TiO2 and Al2O3 additions affect CI engine emissions, combustion and performance characteristics. Waste cooking oil was converted to biodiesel and blended with diesel oil in 20% by volume. Aluimena and TiO2 nano additives of 25 mg/litre concentrations were blended with B20.

Materials and methods

Biodiesel production

WCO can not be utilised directly in CI engines due to its high viscosity, so it is converted to biodiesel. The methyl ester and the oil are divided during transesterification. By preheating the oil to 110 °C, WCO was filtered and the moisture iseliminated. After that, the oil was added to a flask that was held steady by a thermometer, condenser, and magnetic stirrer. 1.5% of potassium hydroxide (KOH) by weight was dissolved in 1:9 molar solution of methanol and alcohol to obtain methoxide. To create the glycerin and methyl ester, the oil and methoxide combination were vigorously agitated for 90 min at 60 °C27. Mixture was left to sit for 24 h in the separating funnel in order to separate the ester about glycerin28. The catalyst, impurities, and unreacted methanol were flushed away with warm water. After the water had been removed, the biodiesel was dried using a rotary evaporator. Biodiesel and diesel oil were combined at a volume ratio of 20%.

Biodiesel blends with nano additives preparation

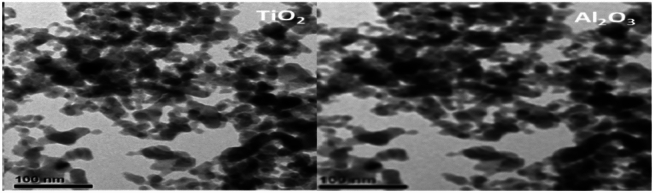

The biodiesel mixture included titanium oxide (TiO2) and alumina (Al2O3) as additions. The nanomaterials were supplied by Nanotech Egypt. Scanning electron microscope (SEM) (Model: Quanta FEG250) and a transmission electron microscope (TEM) (Model: JOEL JEM-2100) were used to examine the internal structure of nano additives. Figures 1 and 2 display TEM and SEM photos, respectively. Alumina and titanium oxide both have typical diameters of 10 and 35 nm in TEM images, indicating their spherical form. By using ultrasonication, the nano additives were evenly distributed throughout the biodiesel mixture. The mixture was continually stirred for 30 min to ensure even dispersion of additives. A biodiesel mixture with nano material content of 25 mg per litre was created. Using good dispersion and stability conditions, titanium and alumina nanoparticles were mixed in the current study with WCO biodiesel of 20% (B20), B20 + 25 TiO2, B20 + 25 Al2O3, and B20 + 25 Al2O3 + 25 TiO2. Nano materials were supplied from Nanotech company, Egypt in the form of powder, water soluble, spherical shape and white color. The bulk densities of TiO2 and Al2O3 are 0.24 and 3.95 gm/cm3, respectively. The averge size from TEM images of aluimena and titanium oxide are 10 ± 2 nm and 35 ± 5 nm, respectively. Methyl ester and diesel oil blend with nano additives characteristics were stated in Table 1. Viscosity and density of Al2O3 were lower than TiO2. Lower calorific value and cetane number of Al2O3 were greater than TiO2. Improved physical and chemical properties of alumina about TiO2 were shown. Average size of alumina is lower than titanium oxide which improves the dispersion, homogeneity and air- fuel mixing. Higher oxygen content in alumina about TiO2 leads to the highest emissions reductions. All these advantages of Al2O3 about TiO2 lead the highest engine performance improvement and emissions reduction.

Figure 1.

SEM image of Al2O3 and TiO2.

Figure 2.

TEM image of TiO2 and Al2O3.

Table 1.

WCO methyl ester and its mixtures properties.

| Fuel properties | Biodiesel | Diesel oil | B20 | B20 + 25 TiO2 | B20 + 25 Al2O3 |

|---|---|---|---|---|---|

| Density at 15 °C, kg/m3 (D1298) | 878 | 830 | 844 | 849 | 847 |

| Kinematic viscosity at 40 °C, cSt (D445) | 4.2 | 2.73 | 2.8 | 3.1 | 3 |

| Flash point, °C (D92) | 148 | 58 | 79 | 80 | 81 |

| Cetane number | 52 | 48 | 49 | 50 | 51 |

| Pour point, °C (D2500) | − 7 | − 33 | − 21 | − 20 | − 20 |

| Lower heating value, MJ/kg (D240) | 39.8 | 42.7 | 41.9 | 42.1 | 42.2 |

Experimental test rig

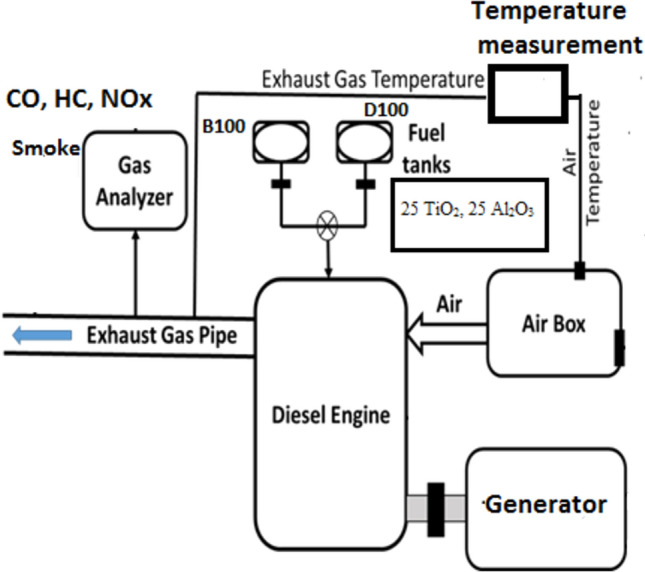

A four-stroke, single-cylinder, air-cooled diesel engine with a maximum output of 7.5 kW at 1500 rpm was used for the testing. The engine has 100 mm diameter, 105 mm stroke, and 17.5:1 compression ratio. Figure 3 displays a schematic description of the experimental equipment used in this investigation. AC generator with highest power of 10.5 kW was connected with the test engine to show the engine's maximum output power. Flow rate of intake air is observed using an air box equipped with an orifice. The amount of time needed to consume a fixed measured fuel volume of 25 cm3 was used to compute the fuel flow rate. In order to evaluate the intake air and exhaust temperatures, K type calibrated thermocouples were utilised. A gas analyzer (Germany's MRU DELTA 1600-V model) was used to monitor the emissions of HC, NOx, and CO. To measure smoke emission, a smoke metre (Model: OPA, France) was employed. When fully loaded, an engine operating between 800 and 1800 rpm was used for the testing. A water-cooled piezoelectric pressure transducer with an accuracy of 1.118% and sensitivity of 16.5 pc/bar was used to monitor cylinder pressure up to 250 bar. The piezoelectric pressure transducer was flush mounted with the cylinder head. The pressure measurements across 125 engine cycles were averaged. Using a data acquisition system, the pressure crank angle diagrams were recorded and examined to determine the combustion parameters. The engine was then warmed until the exhaust temperature was consistent without loading with pure diesel fuel. After switching the fuel line that was being tested, the engine load was then managed. Readings were eventually recorded after the steady state condition was reached. Each test was measured three times to check for repeatability errors.Calculations showed that the greatest degree of uncertainty for the entire experiment was 3.33%. To decrease repeatability errors, each measurement was repeated three times. Biodiesel engine performance indicators including BSFC, EGT, BTE, as well as exhaust CO, HC, smoke, and NOx concentrations were tested.

Figure 3.

Test setup schematic diagram.

Throughout the testing, the load fluctuated between no load and full load, yet the rated speed of 1500 rpm was consistently maintained. To ensure the stability of the engine's state, pure diesel fuel was first used for the warm-up, and the engine was run without load until the exhaust temperature was stabilised. To ensure the precision and coherence of the results, each test was conducted three times. The thermocouples had a notable range of 0–1300 K, with an uncertainty of ± 0.15 and a precision of ± 1 °C. The load indicator covered a range of 250–5000 Watt with an accuracy level of ± 10 Watt and an uncertainty of ± 0.2. The following ranges were used to test exhaust gases: NO (1–4000 ppm), HC (0–20,000 ppm), and CO (0–10%). There was ± 0.2 uncertainty and ± 1, ± 1, and ± 0.5 accuracy for each gas. With a precision level of ± 1 and an uncertainty of ± 2, the pressure transducer measured pressure between 0 and 250 bar. Based on the calculation of Eq. (1), the total uncertainty of the experiment was found to be maximum of 3.33%.

| 1 |

The whole uncertainty of the test rig is represented by WR. The independent and dependent measurements are indicated by the parameters R and x, respectively.

Results and discussions

At constant loads of 0%, 20%, 40%, 60%, and 80%, the engine was put through the tests while running at rated speed of 1500 rpm. WCO biodiesel-diesel mixture (B20) with TiO2 and Al2O3 nanoparticle concentrations of 25 mg/l are the two fuels utilised to run the engine. In order to achieve best fuel utilisation in diesel engines, the calorific value and kinematic viscosity requirements for effective atomization, vaporization and combustion are met by the 20% blending ratio. These experimental tests are used to evaluate the engine emissions and performance parameters.

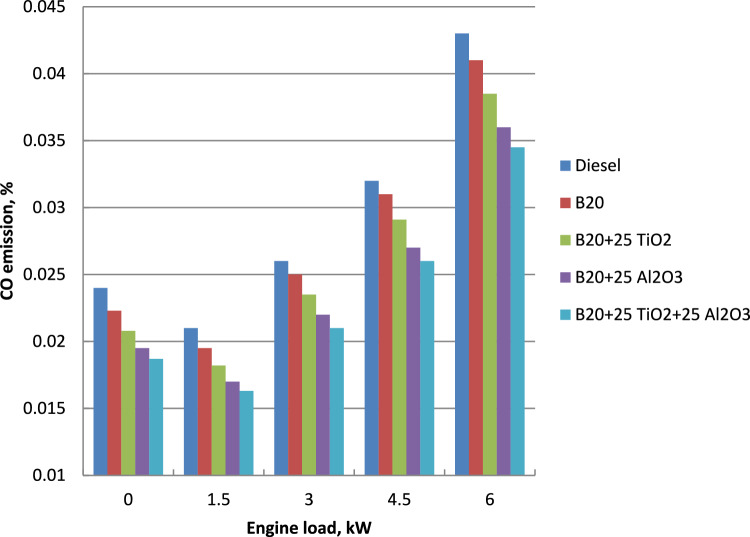

Carbon monoxide (CO) emission

Figure 4 studies how CO concentrations of methyl estermixtures blending with nano additives varies with load. Up to around 60% load, CO concentration steadily declines with the load increase; after that, the trend shifts to increased CO concentration with load. More fuel was delivered to the engine under situation of high load, this may be the result of incomplete combustion. Rich combustion conditions at high loads results in increased CO emissions for all evaluated fuels. Due to the increased oxygen content of biodiesel compared to conventional diesel fuel, there was a drop in CO emissions at all engine loads23. The nanomaterial's increased surface contact area reduces the ignition delay and increases chemical reactivity. The surface reactivity of nanoparticles ensures that combustion is complete and lowers CO when combined with the nano additive's oxidation capabilities. It is important to note that, compared to B20, blended biodiesel with TiO2 and Al2O3 nanoadditives has much lower carbon monoxide concentrations. This can be explained by the fact that the decreased ignition delay of nanoparticles boosts rapid combustion processes29. When compared to diesel without nanoparticles, the necessary fuel–air mixing and improved fuel atomization to ensure complete combustion have a significant impact on lowering CO concentrations30. Increasing the amount of titanium oxide and alumina nanoparticles lowers the CO emission. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties about single nano material. At 100% engine load, the combination of alumina and titanium oxide nanoparticles reduces CO on average respectively by 6% for B20 + 25 TiO2, 12% for B20 + 25 Al2O3, and 16% for B20 + 25 TiO2 + 25 Al2O3.

Figure 4.

Impact of nano materials mixed with B20 on carbon monoxide emission.

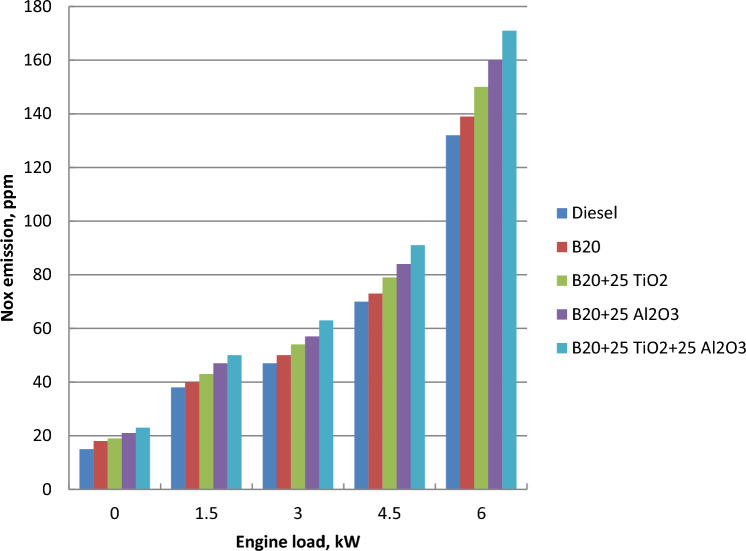

Oxides of nitrogen (NOx)

Maximum heat release rate, combustion time, and burning temperature all have major impact on NOx generation in engines. Figure 5 depicts the variance in NOx emission for B20 engine running at constant speed with and without titanium dioxide and alumina nanoparticles. Because of the higher cylinder temperature and adiabatic flame temperature produced under high load, NOx emissions were increased with load for all examined fuels31. When mixtures of biodiesel feedstock are used, the higher combustion temperatures that result from the greater heat released rate cause the increase in NOx emissions. Across the whole engine load range, the B20 emits more NOx. At all operating circumstances, NOx emissions for B20 with nanoparticles were steadily higher than for B20 without nanoparticles32. The catalytic behaviour of nanoparticles, which encourages heterogeneous combustion and lessens the breakdown of hydrocarbon molecules, is most likely to increase the likelihood of thermal NOx generation.With increasing engine load, this impact is lessened and the likelihood of thermal NOx generation is increased. Nitrogen oxides are created in the reaction zone during the diffusion combustion phase. Amount of nanoparticles has very an impact on biodiesel blends' ability to increase NOx33. Aluiminum and titanium oxide hybrid nanoadditives enhance the thermal, physical, and chemical characteristics of a single nanomaterial. At peak load, the nano materials mixing with methyl ester mixture B20 exhibits average increase in NOx of 7% for B20 + 25 TiO2, 15% for B20 + 25 Al2O3, and 23% for B20 + 25 TiO2 + 25 Al2O3.

Figure 5.

Influence of nano materialsmixed with biodiesel on NOxconcentration.

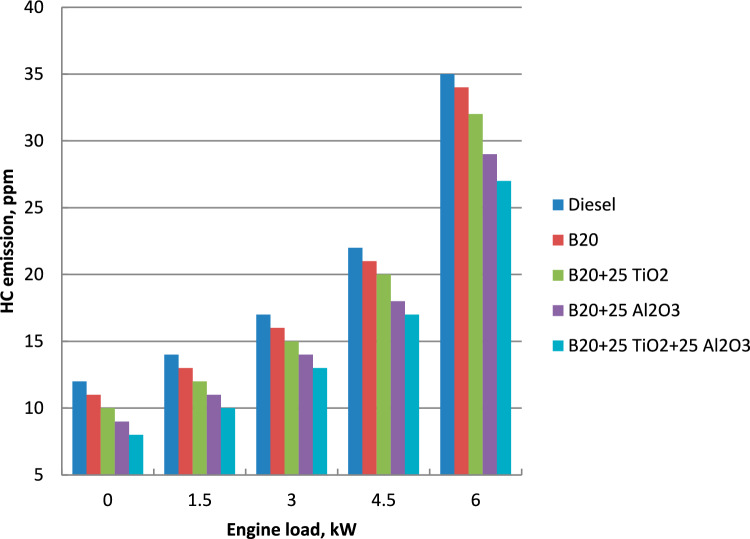

HC emission

Figure 6 displays the HC emissions of a biodiesel blend containing nanoparticles at various engine brake power. Since there is substantially less oxygen and more fuel at higher loads, HC trends showed decreased emissions at lower engine loads followed by an increase at greater engine loads. The greatest levels of HC were released at greater engine loads due to decreased oxygen availability and increased fuel consumption. In comparison to diesel oil, all of the assessed biodiesel feedstock blends have lower HC emissions due to their shorter ignition delay, higher cetane number and higher oxygen content34. Adding nano additions to the biodiesel blend increases its surface to volume ratio, air–fuel mixing degree, vaporization, and catalytic activity. These improvements contribute to an efficient burning process with reduced HC emissions. The fast ignition of biodiesel resulted in the decrease in HC emissions from diesel oil. Nano additions improve fuel–air homogeneity and vaporisation when added to biodiesel blends35. The subsequent fuel atomization is encouraged by the nanoparticles' lower size. This enables complete combustion and enhances reactant mixing. Catalytic activity, surface reactivity and surface-to-volume ratio all promote combustion and lessen the amount of unburned hydrocarbons produced36. The introduction of nanoparticles led to the improvements in fuel oxidation and lower activation temperature for carbon combustion. Aluiminum and titanium oxide hybrid nanoadditives enhance the thermal, physical, and chemical characteristics of a single nanomaterial. When compared to a biodiesel mixture, nanoparticles of B20 + 25 TiO2, B20 + 25 Al2O3, and B20 + 25 TiO2 + 25 Al2O3 each reduced HC emissions by 7, 13, and 20%, respectively when used at highest engine brake power.

Figure 6.

Influence of nano particlesinclusionon hydrocarbons concentrations.

Smoke opacity

Variations in smoke of tested fuels across the engine output power is shown in Fig. 7. Due to rising fuel consumption and rich air–fuel mixture, smoke concentrations were increased with the engine load increase. Because biodiesel blends include more oxygen than crude diesel, they burn more efficiently and produce less smoke. High concentrations of nano additives enhance fuel–air homogeneity and accelerate vaporization development when applied to biodiesel37. Furthermore, the nanoscale size of nano aluminum oxide enhances the secondary fuel atomization. As a result, this enhances reaction mixing and guarantees improved combustion. Difference in smoke concentrations between the waste cooking biodiesel blend and crude diesel is because of the oxygen presence which improves combustion24. Improved combustion, shorter ignition delay and higher fuel combustion during the combustion diffusion stage are responsible for the decrease in smoke. Utilization of nano particles results in catalytic reactivity and larger surface area to volume ratio, which also enhance ignition, combustion characteristics, and minimise smoke28. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties about single nano material. In relation to B20 at full load, addition of TiO2, Al2O3, and hybrid nanoparticles to waste cooking biodiesel blends reduces smoke by up to 8, 15, and 21%, respectively.

Figure 7.

Smoke emissions of nano materials blended with B20.

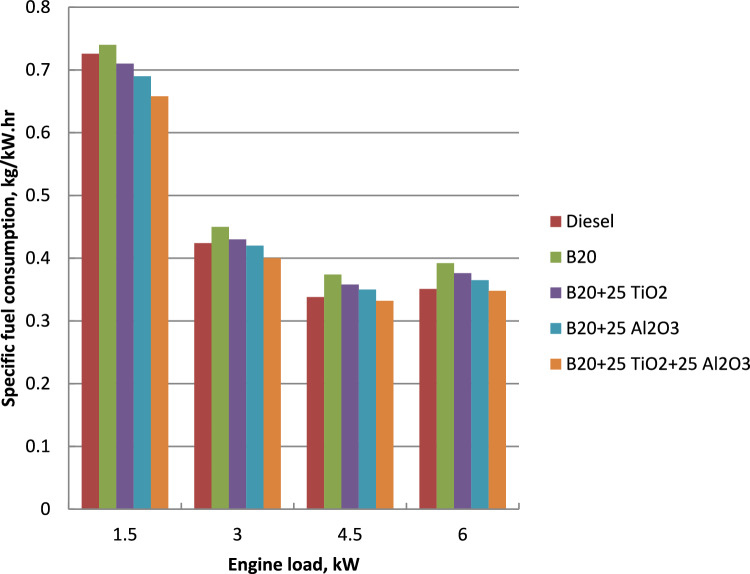

Brake specific fuel consumption (BSFC)

This section discusses the performance aspects of methyl ester mixture in tested engine, both with and without nanoparticles. Figure 8 illustrates how BSFC varies depending on engine load and the different used fuels. All fuels shown an inverse connection between specific fuel consumption and engine load.

Figure 8.

Nano additives inclusion effect on BSFC.

Brake specific fuel consumption was increased for biodiesel blend about diesel oil due to the greater density, viscosity and lower calorific value. All these leads to the problems in fuel atomization and vaporization. Because of how nanoparticles affect the physical characteristics of fuel and shorten the ignition delay, the blended biodiesel's BSFC was lower than diesel and WCO biodiesel. Because of the better combustion and catalytic activity brought about by the higher surface/volume ratio, less fuel was used38. By adding nanomaterials, the fuel's physical delay and evaporation time were decreased, and its attributes relative to pure biodiesel were enhanced. The air–fuel mixing and micro-explosion are enhanced by the addition of alumina and titanium oxide. Additionally, it falls with the addition of nanoparticles, and this fall becomes more dramatic with higher nanoparticle concentrations since titanium oxide and aluimena nano additives improve combustion efficiency and the atomization process39. The higher oxygen supply provided by nanoparticles, which is required to complete the chemical processes, may be the cause of drop in BSFC. Incorporating nanoparticles lessens the buildup of carbon residue, which lowers the cylinder's friction losses and lowers fuel consumption. The engine requires more fuel than diesel engine to yield the same output power because of biodiesel's higher molecular weight and lower calorific value. Decrease of BSFC for blending biodiesel with nano may be ascribed to the quick evaporation, which led to the enhancement in combustion efficiency40. Aluiminum and titanium oxide hybrid nanoadditives enhance the thermal, physical, and chemical characteristics of a single nanomaterial. In comparsion to B20 at full load, waste cooking biodiesel blends with nano additions B20 + 25 TiO2, B20 + 25 Al2O3, and B20 + 25 TiO2 + 25 Al2O3 achieve BSFC reductions of up to 4, 6, and 11%, respectively.

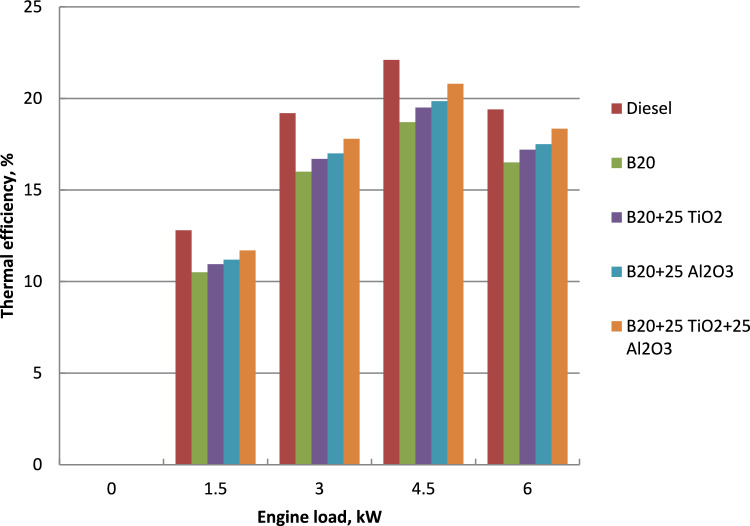

Brake thermal efficiency (BTE)

Figure 9 illustration of BTE for methyl estermixture and nano fuels at varying engine loads shows that it rises as engine load rises. This is true since BSFC decreases as engine output power rises. The higher density, higher viscosity, and lower calorific value of biodiesel mixture over diesel oil resulted in the increase in brake-specific fuel consumption. All of them contribute to the atomization and vaporization issues with fuel. The efficient combustion and energy conversion of fuel is enhanced by the use of nanomaterials. An increase in the surface to volume ratio of the nanoparticles led to an increase in the rate of heat transfer23. The dispersion and spread of injected fuel droplets are facilitated by the presence of nano additives. Both fuel air mixing and combustion properties are enhanced by the presence of nanoparticles. Carbon deposits were oxidized and less fuel was used when nanoparticles were present. Compared to pure diesel, the diesel–biodiesel nano mixtures have higher thermal efficiency41. The dose of nanoparticles in the fuel was increased, resulting in enhanced combustion and efficient energy transfer from fuel to usable work. Higher oxygen supply provided by nanoparticles, which is required to complete the chemical processes, may be to blame for the decline in BSFC. By using nanoparticles, the accumulation of carbon residue is reduced, which minimizes friction losses in the cylinder and reduces fuel consumption22. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties about single nano material. At full load, biodiesel mixture B20 with titanium oxide nano materials (B20 + 25 TiO2, B20 + 25 Al2O3, and B20 + 25 TiO2 + 25 Al2O3) demonstrates average increases in BTE of 4.5%, 6.5%, and 12.5%.

Figure 9.

Effect of nano materialsintroductionon BTE.

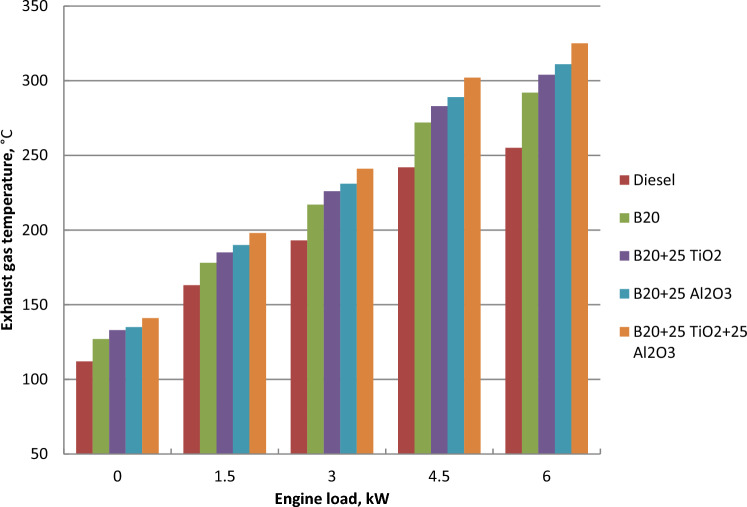

Exhaust gas temperature (EGT)

Figure 10 displays EGT for mixtures of diesel–biodiesel, and nano additives at various engine loads. The exhaust gases temperature increases with the load rise. This rise may be the consequence of the engine cylinder's temperature rising, which causes more fuel to be used to accommodate the increased load requirements. As the peak output power, there is a rise in the exhaust gas temperature. Fuel usage was increased due to the biodiesel mixture's higher viscosity, and lower calorific value compared to diesel oil15. They're all part of the problems with fuel atomization and vaporization. Because of the greater engine cylinder temperature and increased fuel burning to meet the higher output power demand, the exhaust gas temperature rises with engine load. The small nanoparticle dispersion shortens the igniting delay, increasing the exhaust's enthalpy24. A greater cylinder temperature was the outcome of the reduction in ignition time due to the homogeneity impact of nanoparticles. The temperature of the exhaust was increased by nanoparticles mixing with biodiesel. As a result of improved combustion, improved engine thermal efficiency, and enthalpy loss in the exhaust was decreased due to tha addition of nano particle42. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties. WCO biodiesel blends with nano additions B20 + 25 TiO2, B20 + 25 Al2O3, and B20 + 25 TiO2 + 25 Al2O3 achieve EGT increases up to 5, 7, and 12%, respectively related to biodiesel blend at 100% of engine load.

Figure 10.

EGT of nano materials blended with B20.

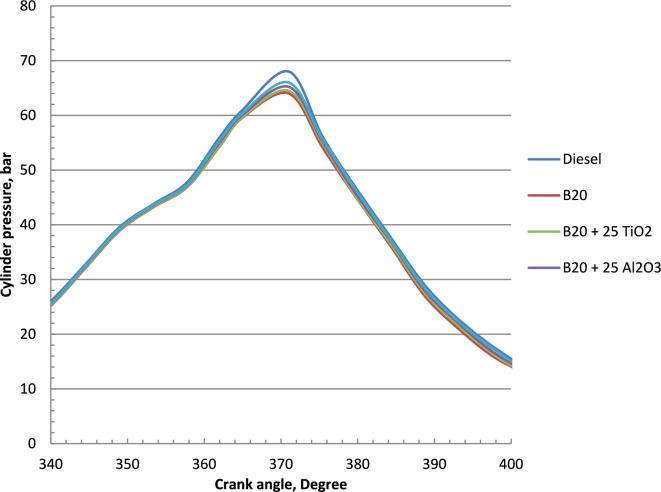

Cylinder pressure

Figure 11 shows the changes in cylinder pressure as a function of crank angle for all the fuels. Lower cylinder pressure is associated with biodiesel due to the lower calorific value, higher density and viscosity about diesel oil. Atomization and vaporization problems of biodiesel produced the lower cylinder pressure. Higher peak cylinder pressure is correlated with the maximum rate of pressure increase, which may be explained by the significant amount of fuel consumed during the premixed combustion phase. Premixed combustion involves burning a large percentage of the fuel, which raises the pressure inside the cylinder and causes it to rise quickly. This occurrence is a sign of quick and effective combustion processes, which are frequently linked to the addition of nanoparticles14. Moreover, nano additives are essential for improving the characteristics of biodiesel combustion, mostly because of their catalytic actions and the increased surface area to volume ratio21. Nano additives were added to biodiesel blends to improve their properties, primarily by reducing physical delay and evaporation time. Nanoparticles play a critical role in improving micro-explosion, air–fuel mixing, and thermal characteristics while also reducing fuel consumption. Together, these elements encourage the premixed combustion phase, which raises the maximum cylinder pressure and enhances evaporation rates, heat transfer, and thermal conductivity43. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties.The maximum cylinder pressures rise for B20 + 25 Al2O3, B20 + 25 TiO23, and B20 + 25 Al2O3 + 25 TiO2 were 1.3%, 2%, and 2.5%, respectively.

Figure 11.

Cylinder pressure against crank angle variation for B20 with nano additives.

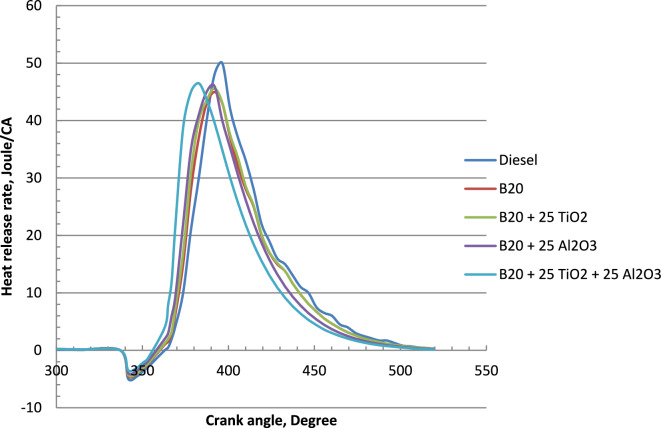

Heat release rate (HRR)

The Heat Release Rate (HRR) of nanoparticle-enhanced biodiesel blends at various crank angles under full load is shown in Fig. 12. As compared to crude diesel, heat release rate is lowered by the atomization and vaporization difficulties biodiesel mixtures due to higher viscosity amd lower calorific value. Addition of nanoparticles to these mixtures increases the HRR by improving the catalytic reactivity. Moreover, the enhanced thermal characteristics, heat transfer, and the availability of high surface area to volume ratio were shown for biodiesel with nano additives44. A greater heat release rate is the end consequence of combustion processes progressing considerably as more fuel is used during the premixed combustion phase. Additionally, owing to the enhanced fuel–air mixing and combustion characteristics brought about by nanoparticles, less fuel is consumed21. The inclusion of nanoparticles has a noteworthy impact of oxidizing carbon deposits, which further reduces fuel use. Reactive surfaces on nanoscale particles improve their catalytic potential23. The parameters of combustion and fuel air mixing were enhanced by the nanoparticles addition. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties.When 25 ppm of Al2O3, TiO2 and hybrid additions were mixed with B20, respectively, the maximum HRR values increases were 1.3%, 2.2%, and 3.3% relative to biodiesel blended at peak load.

Figure 12.

HRR of methyl ester with various nano materials at different crank angles.

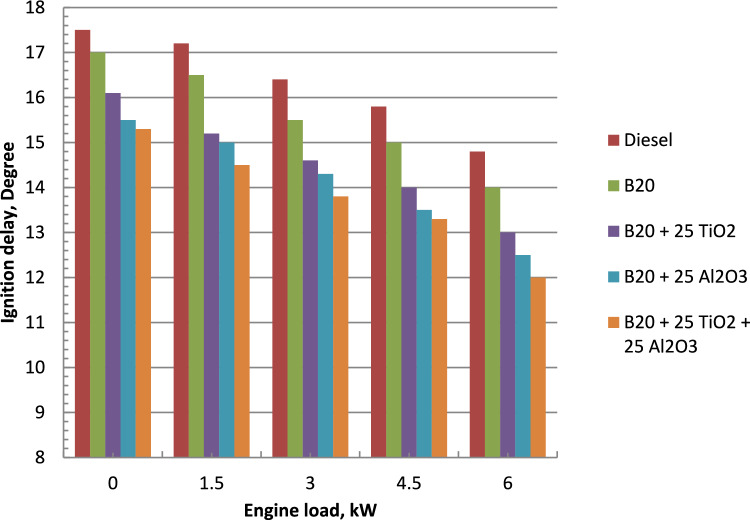

Ignition delay

The effect of nano materials inclusion on the ignition delay period is shown in Fig. 13. The amount of time that passes between the start of fuel injection and the start of combustion is known as the ignition delay. The decrease in ignition delay with increasing engine load is one noteworthy trend that has been seen. Ignition delay was decreased for biodiesel about pure diesel due to the higher cetane number21. The reduction of igniting delay is facilitated by the concentration of nanoparticles. This decrease is explained by the air–fuel mixture's greater homogeneity, higher catalytic activity, and improved surface area to volume ratio, all of which work together to improve burning chracteristics and combustion efficiency. Premixed combustion uses more fuel, which causes the pressure within the cylinder to rise quickly. This phenomenon suggests that the combustion processes linked to the inclusion of nanoparticles are both efficient and fast. Hybrid nano additives of aluiminum and titanium oxides improve the thermal, physical and chemical properties23. It is clear from comparing these findings to the baseline reference case of biodiesel blend that the maximum ignition delay reductions for B20 + 25 Al2O3, B20 + TiO2 and B20 + TiO2 + Al2O3 were 7%, 10%, and 14%, respectively.

Figure 13.

Ignition delay for biodiesel with nano additives at different loads.

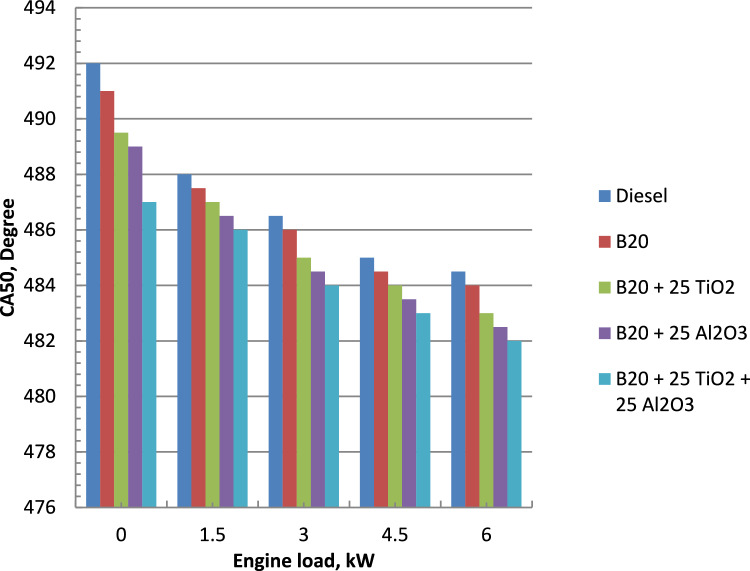

Burning analysis (CA50)

The combustion process may be shown by using the location of the CA50, which characterizes the energy released during combustion. The combustion phasing can also be ascertained by looking at the crank angle position at which 50% of the injected fuel was utilized. The location of CA50 for tested fuels at various engine loads is shown in Fig. 14. Because of the larger volumes of injected fuel mixture, the areas of CA50 for fuels grow with engine loads; however, other variables including turbulence in mixture formation, shorter ignition delay time, and improved injection timing may also be at play. Due to the fast rate of mixture evaporation, increase in surface-to-volume ratio, high oxygen content of nanoparticles, and expected improvement in spray characteristics, when using B20 in different proportions, delay the combustion phasing or CA50 sites. Diesel oil's ignition delay was lowered by adding biodiesel, although this had a negative impact on the reaction rate and combustion properties. Its reduced ignition time may be attributed to the greater cetane number, increased oil viscosity, and inadequate air–fuel mixing. Diesel oil had higher ignition delays and combustion periods than biodiesel. At full load, the degrees for CA50 were 484.5, 484, 483.5, 482.5, and 482 CA, respectively (Fig. 14).

Figure 14.

CA50 of biodiesel with various nano materials at different loads.

Comparative analysis

Table 2 compares emissions and performance CI engine burning B20 with TiO2, Al2O3 and hybrid nano.

Table 2.

Relative variations in performance and emissionssaboutmethyl estermixture B20 at full load ((+) indicates of increase and (−) of decrease).

| Relative change (%) | B20 + 25 TiO2 (%) | B20 + Al2O3 (%) | B20 + 25 TiO2 + 25 Al2O3 (%) |

|---|---|---|---|

| Specific fuel consumption | − 4 | − 6 | − 11 |

| Thermal efficiency | + 4.5 | + 6.5 | + 12.5 |

| Exhaust gas temperature | + 5 | + 7 | + 12 |

| HC emission | − 7 | − 13 | − 20 |

| Carbon monoxide emission | − 6 | − 12 | − 16 |

| Smoke concentration | − 8 | − 15 | − 21 |

| NOx concentration | + 7 | + 15 | + 23 |

| Peak cylinder pressure, bar | + 1.3 | + 2 | + 2.5 |

| Peak heat release rate, Joule/CA | + 1.3 | + 2.2 | + 3.3 |

| Ignition delay | − 7 | − 10 | − 14 |

Conclusion

Biodiesel was created by converting waste cooking oil. Physical and chemical characteristics of methyl esters complied with ASTM requirements. Diesel oil was blended with biodiesel at a volume ratio of 20%. A titanium dioxide (TiO2) and alumina (Al2O3) fueled diesel engine's performance and emissions were evaluated experimentally. WCO biodiesel blend (B20) has hybrid titanium dioxide and alumina nanoparticles added at 25 mg/l dose. At steady state conditions with load variation at 1500 rpm engine speed, all parameters were assessed. Conclusions that were addressed were as follows:

When B20 was combined with nanomaterials such as TiO2, Al2O3, and hybrid nano, the corresponding decreases in brake-specific fuel consumption were 4, 6, and 11%, respectively. However, as compared to a biodiesel blend, the largest gains in thermal efficiency were 4.5, 6.5, and 12%, respectively, at maximum load.At 100% of output power, the waste cooking oil methyl ester blends including nanoparticles B20 + 25TiO2, B20 + 25 Al2O3, and B20 + 25TiO2 + 25 Al2O3 exhibited greater increases in EGT up to 5, 7 and 12%, respectively, than B20.

When TiO2, Al2O3, and hybrid nanoparticles were introduced to biodiesel blends with 100% engine load, HC emissions were reduced by 7, 13, and 20% but CO emissions were reduced by 11, 24, and 30%.

For B20 + 25TiO2, B20 + 25 Al2O3, and B20 + 25TiO2 + 25 Al2O3, the largest increases in NOx emission at maximum engine load were up to 7, 15, and 23%, respectively. Up to 8, 15, and 21% less smoke was released, correspondingly, which were the largest reductions.

The maximum cylinder pressures rise for B20 + 25 Al2O3, B20 + 25 TiO2, and B20 + 25 Al2O3 + 25 TiO2 were 1.3%, 2%, and 2.5%, respectively but the maximum HRR values increases by 1.3%, 2.2%, and 3.3%, respectively. the maximum ignition delay reductions for B20 + 25 Al2O3, B20 + TiO2 and B20 + TiO2 + Al2O3 were 7%, 10%, and 14%, respectively. At full load, the degrees for CA50 were 484.5, 484, 483.5, 482.5, and 482 CA, respectively.

While pure biodiesel may be used in diesel engines, its higher density, lower cetane number, and lower calorific value prevent it from fully substituting regular diesel. Using of biodiesel in cold climate leads to problems in injection system and fuel filter. Addition of nano additives solves these problems, improves engine performance and reduces exhaust emissions. Fuel consumptions with high costs were significantly reduced by using nano additives such as alumina, TiO2, and hybrid nano additives. Nanomaterials are used in small percentages with biodiesel. The cost difference between using nanomaterials with biodiesel and conventional fuel is compensated by the decrease in harmful emissions, fuel consumption and thermal efficiency improvement. Nanoparticles comprise a smaller portion of the fuel cost. Utilizing the suggested nano-based fuel has favorable environmental effects that meet the requirements of the Sustainable Development Goals (SDGs). Combination of biodiesel with low concentration of nanoparticles demonstrated lower fuel consumption, environmental, and financial aspects for the practical use in engines. In cold climate, this application promotes the usage of pure biodiesel.

The recommended dosage of 25 ppm alumina and 25 ppm TiO2 achieved a noticeable improvement in diesel engine emission, combustion and performance about WCO biodiesel mixture B20. When alumina and TiO2 were added at a concentration of 25 ppm, WCO blend B20 shows the highest engine performance, combustion characteristics, and emissions reductions when compared to biodiesel blend. This study supports the relevance of hybrid nano additives in improving B20 thermal conductivity, evaporation rate, catalytic reactivity, and heat transfer rate. Therefore, it is highly recommended to utilize waste cooking oil biodiesel blend B20 with 25 ppm of nano alumina and titanium oxide as alternative fuel in diesel engine.

Acknowledgements

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (Grant number IMSIU-RG23039).

Author contributions

Conceptualization, M.S.G. and H.M.A.H.; methodology, M.H.N. and A.K.H; software, M.B.B.H; validation, M.B.B.H.; formal analysis, M.B.B.H. and M.S.G.; investigation, R.A.; resources, R.A.; data curation, H.M.A.H. and M.H.N; writing—original draft preparation, M.B.B.H, M.S.G. and H.M.A.H; writing—review and editing, M.B.B.H. and A.K.H; visualization, M.H.N.; supervision, M.B.B.H.; project administration, M.B.B.H.; funding acquisition, R.A. All authors have read and agreed to the published version of the manuscript.”

Data availability

The data presented in this study are available on request from the corresponding author.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Abdelfattah, M. S. H., Abu-Elyazeed, O. S. M., Abd El Mawla, E. & Abdelazeem, M. A. On biodiesels from castor raw oil using catalytic pyrolysis. Energy143, 950–960 (2018). 10.1016/j.energy.2017.09.095 [DOI] [Google Scholar]

- 2.Amin, A., Gadallah, A., El Morsi, K. A., El-Ibiari, N. N. & El-Diwani, G. I. Experimental and empirical study of diesel and castor biodiesel blending effect, on kinematic viscosity, density and calorific value. Egypt. J. Pet.25, 509–514 (2016). 10.1016/j.ejpe.2015.11.002 [DOI] [Google Scholar]

- 3.Damian, C. S., Devarajan, Y. & Jayabal, R. The potential of inedible biodiesel as an eco-friendly and sustainable alternative fuel for marine diesel engines in India. J. Mar. Sci. Appl.22, 870–881 (2024). 10.1007/s11804-023-00382-2 [DOI] [Google Scholar]

- 4.Varuvel, E. G., Seetharaman, S., Shobana Bai, F. J. J., Devarajan, Y. & Balasubramanian, D. Development of artificial neural network and response surface methodology model to optimize the engine parameters of rubber seed oil—Hydrogen on PCCI operation. Energy283, 129110 (2023). 10.1016/j.energy.2023.129110 [DOI] [Google Scholar]

- 5.Atabani, A. E. et al. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev.16, 2070–2093 (2012). 10.1016/j.rser.2012.01.003 [DOI] [Google Scholar]

- 6.Baskar, G., Selvakumari, I. A. E. & Aiswarya, R. Biodiesel production from castor oil using heterogeneous Ni doped ZnO nanocatalyst. Bioresource Technol.250, 793–798 (2018). 10.1016/j.biortech.2017.12.010 [DOI] [PubMed] [Google Scholar]

- 7.Bejaoui, S., Lemaire, R. & Therssen, E. Analysis of laser-induced fluorescence spectra obtained in spray flames of diesel and rapeseed methyl ester using the multiple-excitation wavelength laser-induced incandescence technique with IR, UV, and visible excitations. Combust. Sci. Technol.187, 906–924 (2015). 10.1080/00102202.2014.973949 [DOI] [Google Scholar]

- 8.Berman, P., Nizri, S. & Wiesman, Z. Castor oil biodiesel and its blends as alternative fuel. Biomass Bioenergy35, 2861–2866 (2011). 10.1016/j.biombioe.2011.03.024 [DOI] [Google Scholar]

- 9.Bueno, A. V., Pereira, M. P. B., Pontes, J. V. O., Luna, F. M. T. & Cavalcante, C. L. C. Performance and emissions characteristics of castor oil biodiesel fuel blends. Appl. Thermal Eng.125, 559–566 (2017). 10.1016/j.applthermaleng.2017.06.114 [DOI] [Google Scholar]

- 10.Chen, A. F., Adam, A., Othman, M. F., Kamaruzzaman, M. K. & Mrwan, A. G. Combustion characteristics, engine performances and emissions of a diesel engine using nanoparticle-diesel fuel blends with aluminium oxide, carbon nanotubes and silicon oxide. Energy Conversion Manag.171, 461–477 (2018). 10.1016/j.enconman.2018.06.004 [DOI] [Google Scholar]

- 11.Dias, J. M., Araújo, J. M., Costa, J. F., Alvim-Ferraz, M. C. M. & Almeida, M. F. Biodiesel production from raw castor oil. Energy53, 58–66 (2013). 10.1016/j.energy.2013.02.018 [DOI] [Google Scholar]

- 12.El-seesy, A. I., Hassan, H. & Ookawara, S. Performance, combustion, and emission characteristics of a diesel engine fueled with Jatropha methyl ester and graphene oxide additives. Energy Conversion Manag.166, 674–686 (2018). 10.1016/j.enconman.2018.04.049 [DOI] [Google Scholar]

- 13.Fu, H. et al. Titanium dioxide nano-heterostructure with nanoparticles decorating nanowires for high-performance photocatalysis. Int. J. Hydrogen Energy43, 10359–10367 (2018). 10.1016/j.ijhydene.2018.04.150 [DOI] [Google Scholar]

- 14.Giakoumis, E. G., Rakopoulos, C. D., Dimaratos, A. M. & Rakopoulos, D. C. Exhaust emissions of diesel engines operating under transient conditions with biodiesel fuel blends. Progress Energy Combust. Sci.38, 691–715 (2012). 10.1016/j.pecs.2012.05.002 [DOI] [Google Scholar]

- 15.Hasan, M. M. & Rahman, M. M. Performance and emission characteristics of biodiesel–diesel blend and environmental and economic impacts of biodiesel production: A review. Renew. Sustain. Energy Rev.74, 938–948 (2018). 10.1016/j.rser.2017.03.045 [DOI] [Google Scholar]

- 16.Hosseini, S. H., Taghizadeh-Alisaraei, A., Ghobadian, B. & Abbaszadeh-Mayvan, A. Performance and emission characteristics of a CI engine fuelled with carbon nanotubes and diesel-biodiesel blends. Renew. Energy111, 201–213 (2017). 10.1016/j.renene.2017.04.013 [DOI] [Google Scholar]

- 17.Hawi, M. et al. Experimental investigation on performance of a compression ignition engine fueled with waste cooking oil biodiesel–diesel blend enhanced with iron-doped cerium oxide nanoparticles. Energies12(5), 798 (2019). 10.3390/en12050798 [DOI] [Google Scholar]

- 18.Holman, J. P. Experimental Methods for Engineers 8th edn. (McGraw-Hill, 2012). [Google Scholar]

- 19.Hoseini, S. S. et al. Novel environmentally friendly fuel: The effects of nanographene oxide additives on the performance and emission characteristics of diesel engines fuelled with Ailanthus altissima biodiesel. Renew. Energy125, 283–294 (2018). 10.1016/j.renene.2018.02.104 [DOI] [Google Scholar]

- 20.Javed, S., Baig, R. U. & Murthy, Y. V. V. S. Study on noise in a hydrogen dual-fuelled zinc-oxide nanoparticle blended biodiesel engine and the development of an artificial neural network model. Energy160, 774–782 (2018). 10.1016/j.energy.2018.07.041 [DOI] [Google Scholar]

- 21.Jiang, L. et al. Investigation on an innovative sorption system to reduce nitrogen oxides of diesel engine by using carbon nanoparticle. Appl. Thermal Eng.134, 29–38 (2018). 10.1016/j.applthermaleng.2018.01.116 [DOI] [Google Scholar]

- 22.Jiaqiang, E. et al. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Conversion Manag.169, 194–205 (2018). 10.1016/j.enconman.2018.05.073 [DOI] [Google Scholar]

- 23.Kennedy, I. M. et al. NOx and hydrocarbon emissions from a diesel engine fueled on digester gas. Combust. Sci. Technol.123, 63–82 (1997). 10.1080/00102209708935622 [DOI] [Google Scholar]

- 24.Khiratkar, A. G. et al. Transesterification of castor oil using benzimidazolium based Br Ønsted acid ionic liquid catalyst. Fuel231, 458–467 (2018). 10.1016/j.fuel.2018.05.127 [DOI] [Google Scholar]

- 25.Patel, H. K. & Kumar, S. Experimental analysis on performance of diesel engine using mixture of diesel and bio-diesel as a working fuel with aluminum oxide nanoparticle additive. Thermal Sci. Eng. Progress24, 252–258 (2017). 10.1016/j.tsep.2017.09.011 [DOI] [Google Scholar]

- 26.Metanawin, S., Panutumron, P., Thongsale, A. & Metanawin, T. The functionalization of hybrid titanium dioxide by miniemulsion polymerization technique. Materer. Today Proc.5, 9651–9657 (2018). 10.1016/j.matpr.2018.01.133 [DOI] [Google Scholar]

- 27.Nouri, M., Isfahani, A. H. M. & Shirneshan, A. Efects of Fe2O3 and Al2O3 nanoparticle-diesel fuel blends on the combustion, performance and emission characteristics of a diesel engine. Clean Technol. Environ. Policy23, 2265–2284 (2021). 10.1007/s10098-021-02134-8 [DOI] [Google Scholar]

- 28.Barsari, M. A. N. & Shirneshan, A. An experimental study of friction and wear characteristics of sunflower and soybean oil methyl ester under the steady-state conditions by the four-ball wear testing machine. J. Tribol.141(4), 044501 (2019). 10.1115/1.4042390 [DOI] [Google Scholar]

- 29.Nanthagopal, K., Ashok, B., Tamilarasu, A., Johny, A. & Mohan, A. Influence on the effect of zinc oxide and titanium dioxide nanoparticles as an additive with Calophyllum inophyllum methyl ester in a CI engine. Energy Conversion Manag.146, 8–19 (2017). 10.1016/j.enconman.2017.05.021 [DOI] [Google Scholar]

- 30.Nayak, S., Shet, V. P., Rao, C. V. & Joshi, K. Performance evaluation and emission characteristics of a 4 stroke diesel engine using green synthesized silver nanoparticles blended biodiesel. Mater. Today Proc.5, 7889–7897 (2018). 10.1016/j.matpr.2017.11.470 [DOI] [Google Scholar]

- 31.Okasha, A. et al. Spectroscopic analyses of the photocatalytic behavior of nano titanium dioxide. Spectrochimica Acta Part A Mol. Biomol. Spectrosc.136, 504–509 (2015). 10.1016/j.saa.2014.09.063 [DOI] [PubMed] [Google Scholar]

- 32.Örs, I., Sarıkoç, S., Atabani, A. E., Ünalan, S. & Akansu, S. O. The effects on performance, combustion and emission characteristics of DICI engine fuelled with TiO2 nanoparticles addition in diesel/biodiesel/n-butanol blends. Fuel234, 177–188 (2018). 10.1016/j.fuel.2018.07.024 [DOI] [Google Scholar]

- 33.Rajkumar, M. Heat Release Analysis and Modeling for a Common-Rail Diesel Engine (University of Tennessee, 2002). [Google Scholar]

- 34.Sajeevan, A. C. & Sajith, V. Synthesis of stable cerium zirconium oxide nanoparticle—Diesel suspension and investigation of its effects on diesel properties and smoke. Fuel183, 155–163 (2016). 10.1016/j.fuel.2016.06.048 [DOI] [Google Scholar]

- 35.D’Silva, R., Binu, K. G. & Bhat, T. Performance and Emission characteristics of a C. I. Engine fuelled with diesel and TiO2 nanoparticles as fuel additive. Mater. Today Proc.2, 3728–3735 (2015). 10.1016/j.matpr.2015.07.162 [DOI] [Google Scholar]

- 36.Sivakumar, M., Sundaram, N. S., Kumar, R. R. & Thasthagir, M. H. S. Effect of aluminium oxide nanoparticles blended pongamia methyl ester on performance, combustion and emission characteristics of diesel engine. Renew. Energy116, 518–526 (2018). 10.1016/j.renene.2017.10.002 [DOI] [Google Scholar]

- 37.Chaichan, M. T., Kadhum, A. A. H. & Al-Amiery, A. A. H. Novel technique for enhancement of diesel fuel: Impact of aqueous alumina nano-fluid on engine’s performance and emissions. Case Stud. Thermal Eng.10, 611–620 (2017). 10.1016/j.csite.2017.11.006 [DOI] [Google Scholar]

- 38.Verma, P. et al. An overview of the influence of biodiesel, alcohols, and various oxygenated additives on the particulate matter emissions from diesel engines. Energies12(1), 1987 (2019). 10.3390/en12101987 [DOI] [Google Scholar]

- 39.Wagner, I. P., Hood, D. M. & Hogan, H. A. Comparison of bending modulus and yield strength between outer stratum medium and stratum medium zona alba in equine hooves. Am. J. Veterinary Res.62, 745–751 (2001). 10.2460/ajvr.2001.62.745 [DOI] [PubMed] [Google Scholar]

- 40.Yousefali, S., Reyhani, A., Mortazavi, S. Z., Yousefali, N. & Rajabpour, A. UV-blue spectral down-shifting of titanium dioxide nano-structures doped with nitrogen on the glass substrate to study its anti-bacterial properties on the E. coli bacteria. Surfaces Interfaces13, 11–21 (2018). 10.1016/j.surfin.2018.07.003 [DOI] [Google Scholar]

- 41.Yuvarajan, D., Babu, M. D., Kumar, N. B. & Kishore, P. A. Experimental investigation on the influence of titanium dioxide nanofl uid on emission pattern of biodiesel in a diesel engine. Atmos. Pollut. Res.9, 47–52 (2018). 10.1016/j.apr.2017.06.003 [DOI] [Google Scholar]

- 42.Zhu, Q., Gu, H. & Ke, Z. Congeneration biodiesel, ricinine and nontoxic meal from castor seed. Renew. Energy120, 51–59 (2018). 10.1016/j.renene.2017.12.075 [DOI] [Google Scholar]

- 43.Gad, M. S., Abd El Razik, S. M., Manu, P. V. & Jayaraj, S. Experimental investigations on diesel engine using alumina nanoparticle fuel additive. Adv. Mech. Eng.13(2), 1–16 (2021). 10.1177/1687814020988402 [DOI] [Google Scholar]

- 44.Sathish, T. et al. Waste to fuel: Synergetic effect of hybrid nanoparticle usage for the improvement of CI engine characteristics fuelled with waste fish oils. Energy275, 127397 (2023). 10.1016/j.energy.2023.127397 [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.