Abstract

Tantalum is not only one of the critical metals applied in various advanced industries such as electronics, aerospace, military, and medical applications, but also is considered a conflict mineral, posing a threat to its global supply security. China plays a significant role in the tantalum industrial chain; however, the complete picture of its anthropogenic tantalum cycle remains unknown. This study investigates the tantalum cycles in China from 2000 to 2021 by conducting a dynamic material flow analysis. The results reveal that China's domestic tantalum consumption surged from 91 tons in 2000 to 580 tons in 2021. China heavily relied on importing tantalum minerals to support its domestic production, with a trade dependence rate of 90 %. Moreover, the trade volume of tantalum-related commodities experienced substantial growth from 2000 to 2014 and then fluctuated, with tantalum concentrates as the primary imported goods and electronic products as the primary exported goods. Approximately 24.9 % of the overall tantalum demand was met with secondary tantalum, in which 80 % of such secondary material being recovered during the refining and production stages. Policy recommendations are proposed accordingly, including diversifying tantalum mineral resources and increasing the recovery rates from end-of-life products. These policies can significantly contribute to achieving sufficient tantalum supply and maintaining sustainable tantalum supply chain in China.

Keywords: Tantalum, Material flow analysis, China, Recycling, Electronics, Conflict mineral

Graphical abstract

Highlights

-

•

China's Ta lifecycle is revealed for 2000–2021 using a dynamic MFA method.

-

•

Demand for Ta had increased by six folds and the EoL recycling rate was low in China.

-

•

China heavily depends on importing raw Ta from Africa.

-

•

Ta recovery from electronic waste is of high necessity in securing Ta supply.

1. Introduction

Tantalum (Ta) is a rare metal with its exceptional resistance to corrosion by acids and a high melting point. These properties render it invaluable in the chemical industry, high-temperature alloys, and the production of cutting tools. The demand for tantalum has experienced a significant upsurge since the emerging use of tantalum capacitors, which are widely applied in electronics owing to their compact dimensions, high capacitance per unit volume, and excellent stability. Additionally, tantalum's remarkable biocompatibility makes it possible for integrating it into medical materials. These outstanding properties make tantalum an indispensable metal in several advanced industries, such as electronics, military, aerospace, and surgery [1]. Consequently, tantalum has been selected as a critical mineral by industrialized regions and countries, including the United States (U.S.), the European Union (EU), Japan, and Australia [2].

To a large extent, the criticality of tantalum depends on its supply risk. Although Brazil and Australia possess the majority of tantalum reserves (61 %), the global primary tantalum production has shifted to African countries over the past two decades [3]. To date, the market price of tantalum is relatively low since such resource is mainly extracted from artisanal mining operations. But its supply is unstable in the Great Lakes region of Africa [4] since geopolitical conflicts frequently occur in this region [5]. Under such circumstances, tantalum has been classified as a conflict mineral by the U.S. and the EU [6]. Several relevant studies found that primary tantalum production in this Great Lakes Region still dominates the global tantalum supply [4,7]. Therefore, there are more concerns on how to ensure the security of tantalum supply.

With rapid development, China has become a major consumer market for electronics products, as well as in other emerging sectors, leading to its soaring demand for tantalum. China is now the largest producer of tantalum-based intermediate and final products in the world [4]. Although the Chinese government reported that there are approximately 292.5 kilotons of tantalum-niobium oxide resources in China [8], most of these have been deemed economically unviable for tantalum extraction considering the current tantalum metal price and mining technologies. The annual domestic tantalum production remains very low, with a figure of less than 100 tons [9].

Material Flow Analysis (MFA) is one of the most widely used methods for tracking material stocks and their flows within a specified system boundary over time [10]. This method has been extensively applied in characterizing the metabolic patterns of various mineral elements, both at global and national scales, such as tungsten [11], rare earth elements [[12], [13], [14], [15]], vanadium [16], palladium [17], chromium [18], rhenium [19], germanium [20], gold [21], magnesium [22], gallium [23]. Similarly, this MFA method has been used to analyze tantalum in diverse regional and temporal contexts, such as in Europe (2007) [24], in the U.S. (2002–2020) [6], and at a global scale for year 2014 [4,25], for the period of 1970–2015 [7], and for the period of 2010–2019 [26]. These endeavors provide valuable insights to support sustainable tantalum supply chain management. However, such MFA study has not been conducted for China, one of the most important tantalum producers and consumers.

In view of these challenges, this study aims to track the tantalum stocks and flows in China for the period of 2000–2021 by employing MFA so that the entire tantalum metabolism features in China can be uncovered. The remainder of this paper is organized as below: Section 2 proposes an MFA framework and its accounting methods, as well as data sources and sensitivity analysis. Section 3 presents our MFA results, including tantalum production, consumption, international trade, and sensitivity analysis. Section 4 discusses policy implications for both industry and policymakers. Finally, section 5 draws research conclusions.

2. Methods and data

2.1. System definition

In this study, we apply a dynamic MFA method to uncover the key features of tantalum metabolism along its entire life cycle in China's mainland during 2000–2021. As shown in Fig. 1, six tantalum life cycle stages are considered in this study, including mining and beneficiation, refining and separation, fabrication, manufacturing, use, and waste management [7]. Most of tantalum concentrates are first mined and beneficiated from mineral tantalite. During the refining and separation stage, primary concentrates, imported tin slags, or recycled scraps are processed to produce potassium heptafluorotantalate (K2TaF7, also named as ‘K-salt’) or tantalum pentoxide (Ta2O5), which are further converted into tantalum metal [27]. Then, the majority of tantalum metals are utilized by the electronics industry, specifically fabricated as tantalum capacitors and sputtering targets in semiconductors. Tantalum metals or alloys are then applied in chemical equipment, medical materials, aerospace, and military fields. Additionally, other tantalum compounds are used to make tantalum carbide tools, surface acoustic wave (SAW) filters (LiTaO3), and optical glass (Ta2O5). Finally, once those tantalum-containing products reach the ends of their lifespans, they are either discarded into local landfills or incinerated, or collected as old scraps in the waste management stage and then delivered back to the refining and separation stage for recycling.

Fig. 1.

System definition of the tantalum life cycle.

2.2. Tantalum flows and stocks accounting

Based on the principle of mass conservation, the mass of the tantalum inflows equals to the mass of the tantalum outflows and stock changes. For each life cycle stage, such flows can be calculated by using equations (1), (2), (3).

| (1) |

| (2) |

| (3) |

where , and denote the inflow, outflow, and stock change of tantalum in each life stage in year , respectively. and denote the domestic flow from previous stage to this stage and from this stage to the next stage. and denote the tantalum embodied in import and export as tantalum metallic equivalent content. and denote the recycled tantalum amount and tantalum loss in this stage. The details of these accounting methods and equations are presented in Table S1 of the Supporting Information. It is important to note that these parameters (such as tantalum contents, market shares, loss rates, and recycling rates) remain constant for each year in our MFA throughout the whole study period due to the lack of detailed information, which does not reflect the influences of technological advancements. These flows and stocks are classified into six accounting processes and are calculated as below:

-

(1)

Domestic flows: domestic flows refer to the inputs and outputs of domestic production and consumption within all the tantalum life cycle stages. In the mining and refining stage, the domestic flows are calculated by multiplying the masses of different primary products with their tantalum contents. The domestic flows in the fabrication and manufacturing stages were mainly estimated by summing up the tantalum amounts in different end use sectors and their market statistic parameters collected from previous studies [6,7]. A top-down MFA method is applied to estimate the tantalum flows for both mining and refining stages, while the tantalum flows in fabrication, manufacturing, and use stages are calculated by using a bottom-up approach [11].

-

(2)

Trade flows: we use the Harmonized Commodity Description and Coding System (HS) of China to track the total amounts of traded tantalum-containing products. These trade flows are accounted by using equation (4):

| (4) |

where represents the import flow or export flow of tantalum in one traded product category , denotes the total mass of product under a six-digit tariff code, denotes the market share of one tantalum-containing product within product category when there is not a specific HS code for such a tantalum product (Table S2). For example, the HS code “282690″ corresponds to fluorine salts, not exclusively for the K-salt. denotes the tantalum content of a traded tantalum commodity within product category (Table S3).

-

(3)

Loss flows: most losses are incorporated in tailings, slags, and wastes during the transformation processes due to their low economic benefits or high technical difficulties. For a specific product, its loss flow is calculated based on its amount and loss rate. Details are listed in Table S4 of the supporting information.

-

(4)

Recycling flows: the high price of tantalum provides an economic incentive for those fabrication factories to collect new tantalum scraps from the production stage. Old scraps from end-of-life (EoL) products are also considered to re-enter this refining stage. These recovered tantalum amounts are estimated based on the recycling rates (Table S4) from previous studies [6,7].

-

(5)

In-use stocks: the tantalum in-use stocks are tantalum accumulation changes by summing up the inflows and outflows of various final products over this study period. The in-use stock in year is calculated by using equation (5):

| (5) |

where represents the number of categories of final products containing tantalum, represents the inflow of those products under category in the use stage, is the outflow by considering the inflow and lifetime distribution.

| (6) |

where is the probability that a product under category has a service life of years (Table S5). These in-use stocks have been accounted for since 1994. China began to develop its tantalum industry in 1994, which was spurred by the substantial demand growth for tantalum from the mid-1990s [27]. Owing to a lack of data, tantalum consumption in China during 1994–1999 is estimated by extrapolating from the consumption pattern observed in 2000 and using the average global consumption growth rate during the same period [[28], [29]]. Finally, all the mismatches between tantalum supply and demand from six tantalum life cycle stages are considered to be the domestic tantalum stocks (Fig. 1) that do not enter the corresponding stage (e.g., the unreported concentrates from miners, traders, smelters, and refineries) and are calculated by aggregating the annual net additions over this study period [30].

2.3. Data sources

The application of this dynamic MFA relies on extensive data and parameters from multiple sources. For instance, annual production amounts of tantalum concentrates used in this study were collected from the United States Geological Survey [9] and the Yearbooks of Nonferrous Metals Industry of China. The import and export data were collected from the UN Comtrade database [31] and China Customs Database. The tantalum contents, market shares of tantalum-containing semi-products and final products, their lifespans, losses, and recycling rates were collected from relevant literatures [4,6,7,23] and China Bulk Commodity Metal Database. Moreover, we interviewed several experts in this field as they have rich experiences and can provide valuable information and verify our collected data and accounted results. These detailed data sources are provided in the Supporting Information.

2.4. Sensitivity analysis

We applied a sensitivity analysis by using a Monte Carlo simulation method to measure the uncertain impacts of different parameters involved in this MFA study [32]. The normally distributed coefficient variations were graded into three levels (10 %, 20 %, and 30 %, representing low, medium, and high levels, respectively) to test the sensitivities of these parameters. We assign those data collected from official statistical reports (e.g., production amounts of tantalum commodities) to have low uncertainties. Those data derived from literatures or export interviews were set to be medium (e.g., tantalum intensities, market shares and lifetime distribution parameters of different products), while those data estimated based on assumptions were assumed to be high (e.g., the penetration rates of traded tantalum-containing products in a “not specified” HS 6-digit code group; the in-use stocks before 2000). By applying Monte Carlo simulations, we estimate the uncertainty bounds of tantalum flows and in-use stocks.

3. Results

3.1. Evaluation of tantalum life cycle in China

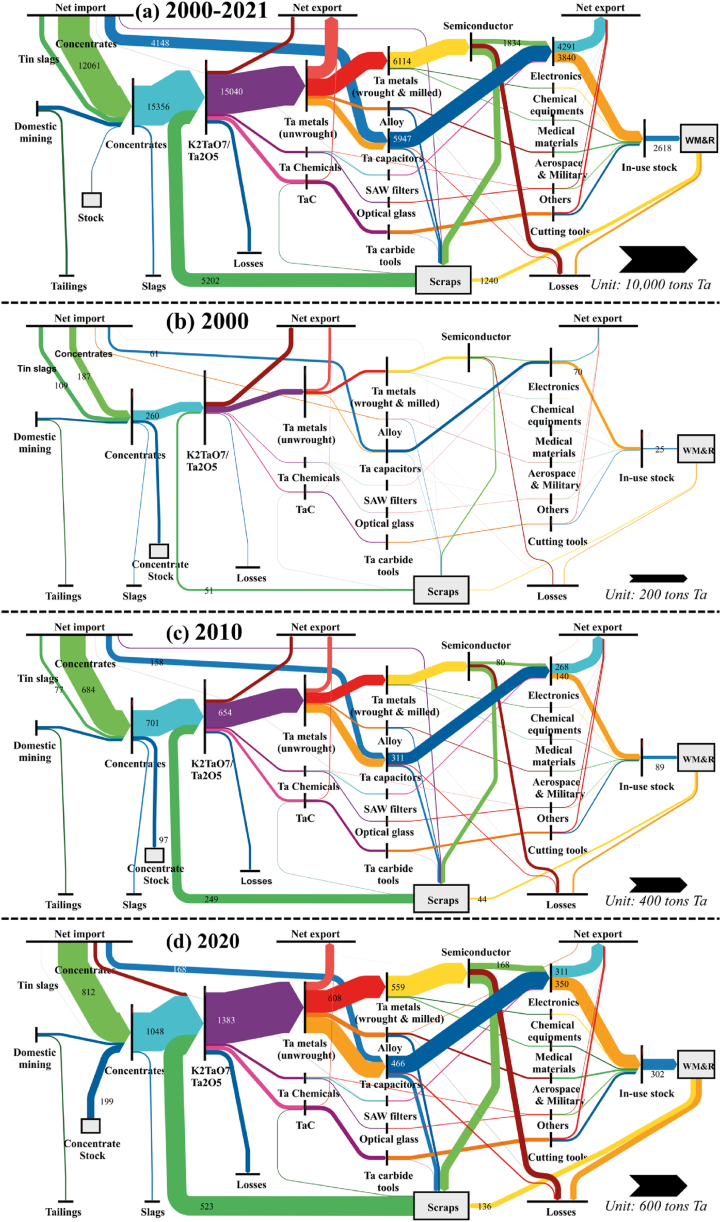

Fig. 2 illustrates the tantalum life cycles in China during the period of 2000–2021, as well as for the years of 2000, 2010, and 2020. In total, approximately 15,600 tons of tantalum flowed into China's socioeconomic system during this study period, including 1605 tons from domestic mining operations, 12,061 tons from imported tantalum concentrates and 1933 tons from imported tin slags.

Fig. 2.

Sankey diagrams of cumulative tantalum cycles in China during 2000–2021(a) and for 2000(b), 2010(c) and 2020(d).

In the fabrication stage, 15,040 tons of tantalum were fabricated over this study period. Most of such tantalum metal was used to make tantalum capacitors and semiconductors, meaning that electronic products dominated tantalum applications, with a share of 75.1 % (8131 tons).

The annual final tantalum consumption in China increased from 91 tons in 2000 to 580 tons in 2021. Annually, sector of electronics was the largest tantalum consumption sector, ranging from 66 % to 76 %. Sector of cutting tools was the second largest final tantalum consumption sector, annually ranging from 10 % to 16 %, followed by aerospace sector and military sector, both annually ranging from 5 % to 9 %. Such results imply that tantalum was mainly used in traditional fields, rather than emerging fields.

The domestic scrap was an important secondary source to meet the demand for tantalum, accounting for 24.9 % (5072 tons) of the total tantalum refinery production. Unfortunately, the ratio of the total recovered scraps to the total primary processing flow is relatively lower in China than the global average (30 %) [4], and significantly lower than that in the U.S. (50 %) [6]. Thanks to the high price of tantalum metal, both smelting and manufacturing enterprises fully engaged in collecting new scraps from their manufacturing processes. Also, recycling tantalum from tantalum-containing capacitors in the retired electronics and electrical equipment (WEEE) is another major source for secondary tantalum supply in China, which contributed approximately 100 tons of old scraps in 2021. Different from the EoL recycling of tantalum in the United States and Europe [6,23], the retrieval of capacitor components upon the artisanal disassembly of WEEE is widely applied in China, making it economically feasible for subsequent tantalum reuse or recovery. Both domestic retired capacitors and imported retired capacitors are currently collected by the Chinese firms as a major secondary tantalum source although it is difficult to entirely distinguish them due to the formidable complexities in the international trade surveillance of WEEE [33]. This also makes it challenging to accurately estimate the total recovery amount of old scrap in this study. In addition, China completely banned the import of electronic wastes in 2021 and began to phase out illegal WEEE disassembling activities. These efforts may decrease the amount of WEEE-based old scrap in the coming years.

3.2. Tantalum production, stocks, and waste in China

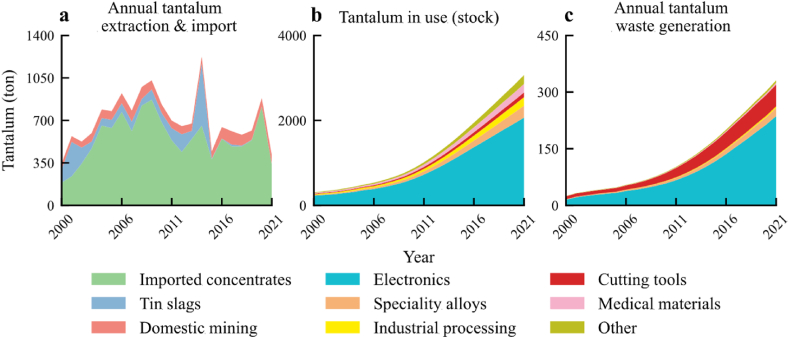

Fig. 3a presents the annual production of tantalum, which first rapidly increased from 2000 to 2009 and then experienced fluctuations during 2010–2019. In 2014, China peaked its tantalum import because the Chinese tantalum smelters imported a large amount of tin slags. In particular, tin slags from Southeast Asia are tantalum-enriched minerals so that tantalum can be economically extracted from such slags. However, China has banned its solid waste imports since 2015. Moreover, the outbreak of the COVID-19 pandemic induced more consumption of electronic commodities since many people had to work at home, leading to an abrupt demand surge for importing tantalum in 2020. However, this pandemic-induced disruptions influenced tantalum mining operations in Africa in 2021 [34], leading to less tantalum concentrates flowing to China. Since China highly relies on importing such concentrates (with an import dependence rate of 90 %), this supply shortage heavily influenced China's tantalum supply chain.

Fig. 3.

Tantalum production, in-use stocks, and waste generation in China.

In 2021, the in-use stock and tantalum waste reached 3066 tons and 331 tons, with an average annual growth rate of 11.0 % and 12.5 % respectively. Again, electronic products contributed the largest share of in-use tantalum stock and tantalum waste. The tantalum waste from the sector of cutting tools accounted for 10 % of the overall tantalum waste due to their short life spans (normally less than one year). Other applications, such as aerospace turbines and chemical equipment, contributed less tantalum waste due to their longer life spans (more than ten years). Consequently, electronic products and cutting tools are major sources of old scraps.

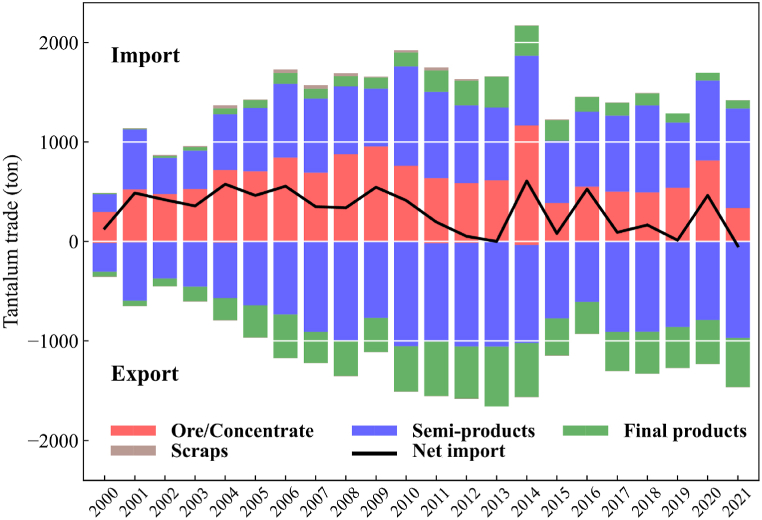

3.3. International tantalum trade flows

Fig. 4 shows China's international tantalum trade dynamics during this study period. China has steadily served as a net importer of tantalum-containing products, with an exception in 2021. This import reliance is based upon its limited domestic tantalum reserves and low grades of its domestic ores. China continuously imported tantalum ores and concentrates during this study period but had both import and export activities for semi-finished products. Specifically, tantalum metals and chemicals are major exported semi-products, while tantalum capacitors are major imported semi-products. Also, China increased its export of tantalum-containing final products from 2000 to 2014, even with a serious influence of the global economic crisis during 2007–2009. But since 2015 the export of final products experienced a moderate growth in China, partly due to the trade frictions between the United States and China. In addition, the trade of tantalum scraps had a very marginal share during this study period, indicating that more scrap trade efforts should be made in the future.

Fig. 4.

Trade volumes of Ta-containing commodities in China during 2000–2021.

Fig. 5 shows the interactions of tantalum trade between China and its eight major trade partners (see regional classifications in Fig. S1). Africa, especially characterized by artisanal mining sector in Rwanda and the Democratic Republic of Congo, was the largest supplier of tantalum mineral concentrates to China. In addition, both Australia and Southeast Asia supplied considerable tantalum resource to China. But with the closure of industrial tantalum ore production at the Wodgina Mine in Australia, China stopped importing such ores from Australia. Similarly, China began to ban the import of tin slags in 2015, which led to that Southwest Asia stopped selling their tin slags to China.

Fig. 5.

Trade flows of Ta-containing commodities between China and its eight trade partners in the world.

Regarding semi-products, China mainly imported capacitors and sputtering targets from Japan and South Korea. China also imported K-salt and tantalum metals from Latin America and other Asian regions. Moreover, China began to become a net exporter of semi-products to Southwest Asia, with tantalum metallurgical products as the major exported items. Both the United States and European Union were the top two net importers of both semi and final products during this study period. Especially, both strengthened their tantalum trade with China during 2008–2015. However, such trade activities shrank after 2015 due to the trade skirmish between the U.S and China, which also partly influenced such trade linkages between the European Union and China.

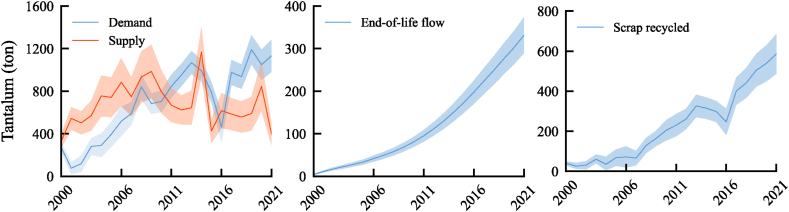

3.4. Sensitivity analysis results

Fig. 6 presents our sensitivity analysis results, including tantalum demand and supply, EoL flows, and recovered scrap flows. The deviations in mineral supply and manufacturing demand range from 19.5 % to 27.7 % and from 10.0 % to 72.2 %. Regarding those EoL flows, the accounting of in-use stocks and ±20 % changes in lifetime distribution parameters can lead to ±12.7 % variations in EoL flows. The recovered scraps have mediate uncertainties within a range of ±16.9 %. These results indicate that these parameters had very negligible effects on our key findings.

Fig. 6.

Sensitivity analysis results of tantalum demand and supply, end-of-life flows, and recovered scraps in China during 2000–2021.

4. Discussion

4.1. Policy recommendations

In comparison to the estimated global tantalum supply and demand in previous studies [4,7,35], our results reflect that China has emerged as a primary importer of tantalum mineral sources, a key supplier of tantalum primary products, and a prominent manufacturer of tantalum-containing final products. Our research findings also confirm that China is the third largest tantalum consumer, following the United States and European Union. These MFA results provide valuable insights to facilitate sustainable tantalum resource management. Based upon these findings and considering the Chinese realities, we propose the following policy recommendations.

4.1.1. Diversification of tantalum resource supply

It is essential to diversify the supply of tantalum raw minerals. The heavy import dependence from the Great Lakes region in Central Africa (over 70 %) has induced a potential supply risk. Unfortunately, this region is facing military conflicts and unstable governance [36]. The price of tantalum minerals derived from alluvial and soft rock deposits in Africa is low [37], making other regions lack economic incentives to seek new tantalum mines. In order to respond to this potential risk, the Chinese government should consider the establishment of strategic tantalum resource stockpile so that the short-term supply stability can be ensured. Also, the Chinese government should support domestic prospecting so that potential tantalum mines can be identified within the Chinese territories. In addition, with the soaring demand for lithium, which is driven by the lithium-ion batteries, there is a potential to increase primary tantalum supply from lithium mines, as tantalum is a by-product of the hard-rock lithium mining industry [38]. This means that initiatives such as the integration of tantalum extraction into lithium mining processes at locations such as Wodgina in Australia and Yichun in China should be supported [39]. This approach may help increase tantalum resource supply in the future [40].

4.1.2. Promotion of tantalum recycling

It is urgent to prepare appropriate policies to support tantalum recycling from tantalum-containing EoL products. Our findings reflect that the recycling rates of tantalum between the waste management stage and the refining and manufacturing stages are different. Previous studies also found that it is often unfeasible to recycle tantalum from EoL products due to the trace use of tantalum in different final products [4,6]. But the recovery of tantalum from capacitors within WEEE seems more promising [41], which has a significant recycling potential when more matured recycling technologies are available [42,43]. However, its effectiveness relies on the efficient collection and separation of tantalum-containing capacitors, which are mainly from printed circuit boards within WEEE. To date, the dismantle of WEEE is a labor-intensive process associated with both environmental and health risks [44,45]. But the recovery rate of tantalum is less than 1 % in those developed countries [6,7,23]. In China, many small workshops engage in manual WEEE disassembly [46], especially in the Guiyu town of Guangdong province [47]. Their aim is to recover valuable metal components through labor-intensive methods, in which tantalum-containing capacitors are collected for reuse or recycling. Such recovered tantalum reached approximately 100 tons in 2020. But China has decided to ban the import of solid wastes from other countries, including WEEE. Meanwhile, the Chinese government has determined to phase out illegal WEEE dismantling activities. These measures may reduce the potential of recovering tantalum from such EoL products. Therefore, we recommend that the Chinese government adjusts their policies to allow the operation of such recovery efforts with the application of more advanced and environmentally friendly technologies, as well as effective governance. We also suggest that more research and development efforts should be made to support automatic and intelligent dismantling of WEEE so that more tantalum resource can be recycled from such retired capacitors [48]. Moreover, the establishment of an innovative information system is essential so that all the stakeholders can share their information, data, and technologies. Similarly, we encourage a comprehensive consideration of different WEEEs so that other precious metals such as nickel [49] and indium [50] can be collected and recovered simultaneously.

4.2. Research limitations and future research perspectives

There are several research limitations in this study. First, due to data limitations, this study only investigates the period of 2000–2021. Although the total use of tantalum in the last century is quite limited, it is still necessary to trace such use so that potential in-use stocks can be traced. Second, tantalum recycling potential should be further evaluated, especially from those in-use stocks, so that appropriate policies can be prepared to collect such EoL products and advanced recycling technologies can be incubated to increase the overall tantalum recycling efficiency. Third, our results present the historical patterns of tantalum stocks and flows in China, which provide valuable insights for future research aiming at enhancing the sustainability of the entire tantalum industry chain. The future demand for tantalum is expected to shift toward more emerging sectors. In particular, with the rapid development of the digital economy, many emerging sectors, such as electric vehicles, 5G communications, and intelligent devices, heavily rely on tantalum capacitors due to their exceptional performance and efficiency [51]. Moreover, China is actively promoting the manufacturing of aircraft engines and gas turbines, which will lead to more demands for tantalum in high-temperature superalloys [52,53]. Hence, it is crucial to conduct scenarios analyses to project future demands for tantalum in various sectors so that accurate supply pathways can be identified.

Additionally, our tantalum MFA study results reveal that China is the primary smelter and manufacturer in the global tantalum industrial chain. However, such smelting and refining processes involve in both chemical digestion and thermal treatment and generate a large amount of different environmental contaminants (such as waste acid fluid and solid waste) and consume substantial electricity [54]. Consequently, we expect that future research may measure such impacts by applying life cycle assessment (LCA). In this regard, Aromaa et al. [55] found that the environmental impact of secondary tantalum production is much less than that from primary tantalum production. As such, the application of renewable and clean electricity in the pyrometallurgical processes, such as electricity from wind and solar power, would reduce the total greenhouse gas emission associated with both primary and secondary tantalum productions [56]. These perspectives deserve to be further investigated in the future so that the overall environmental burdens from tantalum production can be mitigated.

5. Conclusion

Tantalum is a critical metal and can support many advanced industries, particularly in the context of a digital economy. This study investigates China's tantalum life cycle for the period of 2000–2021 by using a dynamic MFA method. Results show that the consumption for tantalum in China increased from 91 tons in 2000 to 580 tons in 2021, in which electronic applications emerged as the largest tantalum consumption sector. The domestic products can only meet approximately half of this demand, while the remaining demand had to be met through international trade. Such rapid tantalum consumption led to a rapid rise of in-use tantalum stock, which reached approximately 3066 tons in 2021. Also, China heavily relied on importing tantalum minerals to meet its demand for tantalum (nearly 90 %), especially from several African countries. The trade volume of tantalum-containing commodities first rapidly increased from 2000 to 2014 and then kept a stable growth pattern with fluctuations from 2015 to 2021. Moreover, the tantalum recycling network was well established in the refining and manufacturing stages but relatively less developed in the waste management stage. These findings help understand the key features of tantalum metabolism in China and offer valuable insights for shaping sustainable tantalum resource management policies. Key recommendations include diversifying the supply sources of tantalum raw minerals and fostering the development of tantalum recycling. These measures are essential for ensuring tantalum supply and maintaining a sustainable future of China's tantalum industry.

Data availability

Data will be made available on request.

CRediT authorship contribution statement

Zhen Gao: Writing – original draft, Software, Methodology, Data curation, Conceptualization. Yong Geng: Writing – original draft, Supervision, Resources, Project administration, Methodology, Funding acquisition, Formal analysis, Data curation, Conceptualization. Ziyan Gao: Writing – original draft, Methodology, Data curation. Zhou Liang: Formal analysis, Conceptualization. Wendong Wei: Resources, Investigation.

Declaration of competing interest

The authors declare that they have no known competing interests that could have appeared to influence the content in this paper.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (72088101).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2024.e36336.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Espinoza L.A.T. POLINARES Consortium, Grant Agreement 224516. 2012. Case study: tantalum in the world economy: history, uses and demand. [Google Scholar]

- 2.Critical Minerals Office . 2023. Australia's Critical Minerals List.https://www.industry.gov.au/publications/australias-critical-minerals-list [Google Scholar]

- 3.Tantalum-Niobium International Study Center (TIC) Production of raw materials. 2023. https://www.tanb.org/about-tantalum/production-of-raw-materials (accessed September 9)

- 4.Mancheri N.A., Sprecher B., Deetman S., Young S.B., Bleischwitz R., Dong L., Kleijn R., Tukker A. Resilience in the tantalum supply chain. Resour. Conserv. Recycl. 2018;129:56–69. doi: 10.1016/j.resconrec.2017.10.018. [DOI] [Google Scholar]

- 5.Ayres C.J. The international trade in conflict minerals: coltan. Crit. Perspect. Int. Bus. 2012;8:178–193. doi: 10.1108/17422041211230730. [DOI] [Google Scholar]

- 6.Padilla A.J., Nassar N.T. Dynamic material flow analysis of tantalum in the United States from 2002 to 2020. Resour. Conserv. Recycl. 2023;190 doi: 10.1016/j.resconrec.2022.106783. [DOI] [Google Scholar]

- 7.Nassar N.T. Shifts and trends in the global anthropogenic stocks and flows of tantalum. Resour. Conserv. Recycl. 2017;125:233–250. doi: 10.1016/j.resconrec.2017.06.002. [DOI] [Google Scholar]

- 8.Ministry of Natural Resources, PRC . 2022. Statistics of China Mineral Resources.https://www.mnr.gov.cn/sj/sjfw/kc_19263/kczycltjb/202306/t20230616_2791726.html [Google Scholar]

- 9.USGS Niobium and tantalum statistics and information. 2023. https://www.usgs.gov/centers/national-minerals-information-center/niobium-and-tantalum-statistics-and-information (accessed September 9)

- 10.Brunner P.H., Rechberger H. second ed. CRC Press, Taylor & Francis Group; Boca Raton: 2017. Handbook of Material Flow Analysis: for Environmental, Resource, and Waste Engineers. [DOI] [Google Scholar]

- 11.Liang J.-J., Geng Y., Zeng X.-L., Gao Z.-Y., Tian X. Toward sustainable utilization of tungsten: evidence from dynamic substance flow analysis from 2001 to 2019 in China. Resour. Conserv. Recycl. 2022;182 doi: 10.1016/j.resconrec.2022.106307. [DOI] [Google Scholar]

- 12.Xiao S., Geng Y., Pan H., Gao Z., Yao T. Uncovering the key features of Dysprosium flows and stocks in China. Environ. Sci. Technol. 2022;56:8682–8690. doi: 10.1021/acs.est.1c07724. [DOI] [PubMed] [Google Scholar]

- 13.Zheng B., Zhang Y.W., Geng Y., Wei W., Ge Z., Gao Z. Investigating lanthanum flows and stocks in China: a dynamic material flow analysis. J. Clean. Prod. 2022;368 doi: 10.1016/j.jclepro.2022.133204. [DOI] [Google Scholar]

- 14.Zhong C., Geng Y., Ge Z., Rui X., Liang J., Wei W. Promoting future sustainable utilization of rare earth elements for efficient lighting technologies. Environ. Res. Lett. 2023;18 doi: 10.1088/1748-9326/acdf74. [DOI] [Google Scholar]

- 15.Xiao S., Geng Y., Rui X., Gao Z., Su C., Yao T., Zhong C. Anthropogenic cycles of praseodymium in China: 2000-2020. Resour. Pol. 2024;92 doi: 10.1016/j.resourpol.2023.105011. [DOI] [Google Scholar]

- 16.Graedel T.E., Miatto A. Vanadium: a U.S. Perspective on an understudied metal. Environ. Sci. Technol. 2023;57:8933–8942. doi: 10.1021/acs.est.3c01009. [DOI] [PubMed] [Google Scholar]

- 17.Gu W., Geng Y., Xiao S., Gao Z., Wei W. The anthropogenic cycles of palladium in China during 2001–2020. Sci. Total Environ. 2023;904 doi: 10.1016/j.scitotenv.2023.167248. [DOI] [PubMed] [Google Scholar]

- 18.Gao Z., Geng Y., Xiao S., Zhuang M. Mapping the global anthropogenic Chromium cycle: implications for resource efficiency and potential supply risk. Environ. Sci. Technol. 2022;56:10904–10915. doi: 10.1021/acs.est.2c00709. [DOI] [PubMed] [Google Scholar]

- 19.Mei Y., Geng Y., Xiao S., Su C., Gao Z., Wei W. Dynamic material flow analysis of rhenium in China for 2011-2020. Resour. Pol. 2023;86 doi: 10.1016/j.resourpol.2023.104141. [DOI] [Google Scholar]

- 20.Mei Y., Geng Y., Chen Z., Gao Z., Xiao S. Ensuring the sustainable supply of semiconductor material: a case of germanium in China. Int. J. Prod. Econ. 2024;271 doi: 10.1016/j.ijpe.2024.109198. [DOI] [Google Scholar]

- 21.Liu S., Geng Y., Gao Z., Li J., Xiao S. Uncovering the key features of gold flows and stocks in China. Resour. Pol. 2023;82 doi: 10.1016/j.resourpol.2023.103584. [DOI] [Google Scholar]

- 22.Guo T., Geng Y., Song X., Rui X., Ge Z. Tracing magnesium flows in China: a dynamic material flow analysis. Resour. Pol. 2023;83 doi: 10.1016/j.resourpol.2023.103627. [DOI] [Google Scholar]

- 23.Gao Z., Geng Y., Li M., Liang J., Houssini K. Tracking the global anthropogenic gallium cycle during 2000-2020: a trade-linked multiregional material flow analysis. Global Environ. Change. 2024;87 doi: 10.1016/j.gloenvcha.2024.102859. [DOI] [Google Scholar]

- 24.Deetman S., van Oers L., van der Voet E., Tukker A. Deriving European Tantalum flows using trade and production statistics: European substance flow analysis for Tantalum. J. Ind. Ecol. 2018;22:166–179. doi: 10.1111/jiec.12533. [DOI] [Google Scholar]

- 25.J. Achebe, Substance Flow Analysis of Tantalum: Tracking the Conflict-free Path.University of Waterloo, Waterloo, ON, Canada. Master’s Thesis.

- 26.Agrawal M., Jha R., Singh R., Singh K.K. Flow and stock estimation of tantalum for sustainable supply chain. Sustain. Prod. Consum. 2022;34:385–394. doi: 10.1016/j.spc.2022.10.002. [DOI] [Google Scholar]

- 27.Tantalum-Niobium International Study Center (TIC) Processing: extraction and refining. 2023. https://www.tanb.org/about-tantalum/processing-extraction-and-refining (accessed September 9, 2023)

- 28.He J., Liu W., Zhang H. Review of the development of tantalum-niobium industry in China in 2006. Rare Met. Lett. 2007:8–13. (In Chinese) [Google Scholar]

- 29.He J., Wang X., Liu W. Tantalum-niobium resources and the development of tantalum-niobium industry in China. Rare Met. Lett. 2005:1–5. (In Chinese) [Google Scholar]

- 30.Rostek L., Tercero Espinoza L., Goldmann D., Loibl A. A dynamic material flow analysis of the global anthropogenic zinc cycle: providing a quantitative basis for circularity discussions. Resour. Conserv. Recycl. 2022;180 doi: 10.1016/j.resconrec.2022.106154. [DOI] [Google Scholar]

- 31.U.N. Trade Statistics, U.N. Comtrade Database, https://comtrade.un.org/data (accessed September 9, 2023).

- 32.Laner D., Rechberger H., Astrup T. Systematic evaluation of uncertainty in material flow analysis: uncertainty analysis in material flow analysis. J. Ind. Ecol. 2014;18:859–870. doi: 10.1111/jiec.12143. [DOI] [Google Scholar]

- 33.Forti V., Baldé C.P., Kuehr R., Bel G. United Nations University (UNU), International Telecommunication Union (ITU) & International Solid Waste Association (ISWA); 2020. The Global E-Waste Monitor.https://ewastemonitor.info/wp-content/uploads/2020/11/GEM_2020_def_july1_low.pdf [Google Scholar]

- 34.Hilson G., Van Bockstael S., Sauerwein T., Hilson A., McQuilken J. Artisanal and small-scale mining, and COVID-19 in sub-Saharan Africa: a preliminary analysis. World Dev. 2021;139 doi: 10.1016/j.worlddev.2020.105315. [DOI] [Google Scholar]

- 35.Guo Y., Zheng R., Zhang H. Tantalum trade structural dependencies are what we need: a perspective on the industrial chain. Resour. Pol. 2023;82 doi: 10.1016/j.resourpol.2023.103469. [DOI] [Google Scholar]

- 36.Fitzpatrick C., Olivetti E., Miller T.R., Roth R., Kirchain R. Conflict minerals in the compute sector: estimating extent of tin, tantalum, tungsten, and gold use in ICT products. Environ. Sci. Technol. 2015;49:974–981. doi: 10.1021/es501193k. [DOI] [PubMed] [Google Scholar]

- 37.Schütte P., Näher U. Tantalum supply from artisanal and small-scale mining: a mineral economic evaluation of coltan production and trade dynamics in Africa's Great Lakes region. Resour. Pol. 2020;69 doi: 10.1016/j.resourpol.2020.101896. [DOI] [Google Scholar]

- 38.Pell R., Tijsseling L., Goodenough K., Wall F., Dehaine Q., Grant A., Deak D., Yan X., Whattoff P. Towards sustainable extraction of technology materials through integrated approaches. Nat. Rev. Earth Environ. 2021;2:665–679. doi: 10.1038/s43017-021-00211-6. [DOI] [Google Scholar]

- 39.Li S., Liu J., Han Y., Zhang S. Review on the beneficiation of Li, Be, Ta, Nb-bearing polymetallic pegmatite ores in China. Miner. 2023;13:865. doi: 10.3390/min13070865. [DOI] [Google Scholar]

- 40.Sun X., Hao H., Hartmann P., Liu Z., Zhao F. Supply risks of lithium-ion battery materials: an entire supply chain estimation. Mater. Today Energy. 2019;14 doi: 10.1016/j.mtener.2019.100347. [DOI] [Google Scholar]

- 41.Nieberl M., Hornung A., Sajdak M., Majewski A.J., Ouadi M. Application and recycling of tantalum from waste electric and electronic equipment–A review. Resour. Conserv. Recycl. 2023;190 doi: 10.1016/j.resconrec.2023.106866. [DOI] [Google Scholar]

- 42.Niu B., Chen Z., Xu Z. Recovery of valuable materials from waste tantalum capacitors by vacuum pyrolysis combined with mechanical–physical separation. ACS Sustain. Chem. Eng. 2017;5:2639–2647. doi: 10.1021/acssuschemeng.6b02988. [DOI] [Google Scholar]

- 43.Ramon H., Peeters J.R., Sterkens W., Duflou J.R., Kellens K., Dewulf W. Techno-economic potential of recycling Tantalum containing capacitors by automated selective dismantling. Procedia CIRP. 2020;90:421–425. doi: 10.1016/j.procir.2020.01.110. [DOI] [Google Scholar]

- 44.Awasthi A.K., Wang M., Awasthi M.K., Wang Z., Li J. Environmental pollution and human body burden from improper recycling of e-waste in China: a short-review. Environ. Pollut. 2018;243:1310–1316. doi: 10.1016/j.envpol.2018.08.037. [DOI] [PubMed] [Google Scholar]

- 45.Ueberschaar M., Dariusch Jalalpoor D., Korf N., Rotter V.S. Potentials and barriers for tantalum recovery from waste electric and electronic equipment. J. Ind. Ecol. 2017;21:700–714. doi: 10.1111/jiec.12577. [DOI] [Google Scholar]

- 46.Sun B., Schnoor J.L., Zeng E.Y. Decadal journey of E-waste recycling: what has it achieved? Environ. Sci. Technol. 2022;56:12785–12792. doi: 10.1021/acs.est.2c01474. [DOI] [PubMed] [Google Scholar]

- 47.Zeng X., Gong R., Chen W.-Q., Li J. Uncovering the recycling potential of “new” WEEE in China. Environ. Sci. Technol. 2016;50:1347–1358. doi: 10.1021/acs.est.5b05446. [DOI] [PubMed] [Google Scholar]

- 48.Charles R.G., Douglas P., Dowling M., Liversage G., Davies M.L. Towards increased recovery of critical raw materials from WEEE–evaluation of CRMs at a component level and pre-processing methods for interface optimisation with recovery processes. Resour. Conserv. Recycl. 2020;161 doi: 10.1016/j.resconrec.2020.104923. [DOI] [Google Scholar]

- 49.Su C., Geng Y., Zeng X., Gao Z., Song X. Uncovering the features of nickel flows in China. Resour. Conserv. Recycl. 2023;188 doi: 10.1016/j.resconrec.2022.106702. [DOI] [Google Scholar]

- 50.Werner T.T., Ciacci L., Mudd G.M., Reck B.K., Northey S.A. Looking down under for a circular economy of Indium. Environ. Sci. Technol. 2018;52:2055–2062. doi: 10.1021/acs.est.7b05022. [DOI] [PubMed] [Google Scholar]

- 51.Lindagato P., Li Y., Yang G. Save the giants: demand beyond production capacity of tantalum raw materials. Miner. Econ. 2022:1–7. doi: 10.1007/s13563-022-00344-0. [DOI] [Google Scholar]

- 52.Helbig C., Bradshaw A.M., Thorenz A., Tuma A. Supply risk considerations for the elements in nickel-based superalloys. Resour. 2020;9:106. doi: 10.3390/resources9090106. [DOI] [Google Scholar]

- 53.Dolganova I., Bach V., Rödl A., Kaltschmitt M., Finkbeiner M. Assessment of critical resource use in aircraft manufacturing. Circ. Econ. Sustain. 2022;2:1193–1212. doi: 10.1007/s43615-022-00157-x. [DOI] [Google Scholar]

- 54.Shikika A., Sethurajan M., Muvundja F., Mugumaoderha M.C., Gaydardzhiev St. A review on extractive metallurgy of tantalum and niobium. Hydrometallurgy. 2020;198 doi: 10.1016/j.hydromet.2020.105496. [DOI] [Google Scholar]

- 55.Aromaa R., Rinne M., Lundström M. Life cycle assessment of tantalum and niobium recycling from hard metal scrap. ACS Sustain. Chem. Eng. 2023;11:14997–15005. doi: 10.1021/acssuschemeng.3c03540. [DOI] [Google Scholar]

- 56.Schäfer P., Schmidt M. Discrete-point analysis of the energy demand of primary versus secondary metal production. Environ. Sci. Technol. 2020;54:507–516. doi: 10.1021/acs.est.9b05101. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.