Abstract

The global shift towards using biomass for biofuels and chemicals is accelerating due to increasing environmental concerns and geopolitical strategies. This study investigates a biorefinery model using citrus-processing-waste, specifically citrus pulp, to produce high-value products for various industries, including cosmetics, pharmaceuticals, flavours, fragrances, and food packaging. In Italy, particularly Sicily region, citrus processing generates significant amounts of waste, often improperly disposed of, contributing to environmental problems. Researchers have demonstrated that citrus waste can yield commercially valuable compounds. This study specifically focuses on orange peel waste (OPW), which constitutes about half of the fruit's weight, aiming to extract pectin and limonene through a combined process. The extraction process was carried out on a laboratory scale, and its sustainability was evaluated using a life cycle assessment (LCA) with SimaPro 8.1 software and the Impact 2002 + method. The functional unit adopted for this study is 300 g of OPW, obtained after the pre-treatment phase, from which 0.14 g of limonene and 8.22 g of pectin were extracted. The LCA results revealed that pectin extraction has a significantly higher environmental impact compared to limonene extraction, primarily due to the use of ethanol as a solvent, followed by electricity consumption. To mitigate this impact, the LCA assessed alternative, more sustainable solvents, resulting in a 73.4% reduction in the environmental footprint of the pectin extraction process. These findings underscore the critical role of LCA, even at the laboratory scale, in identifying environmental hotspots and providing insights for improving and optimizing processes for potential industrial-scale applications.

Keywords: Green chemistry, Sustainability, Agricultural waste, By-products, Circular economy

Subject terms: Environmental sciences, Environmental chemistry, Environmental impact, Green chemistry

Introduction

The world is currently witnessing ongoing and significant regression, and heightened apprehension regarding the planet’s future largely stems from global climate change1. Carbon dioxide emissions have increased by over 80% since 1970, primarily due to increased fossil fuel consumption and alterations in land use2,3. Among the primary goals of the European Union (EU) is the reduction of greenhouse gas (GHG) emissions through the more sustainable utilization of land and agricultural resources4–6. Notably, the agricultural sector and the agro-food industry play pivotal roles in emission generation among human activities, largely owing to the substantial volume of biomass without proper utilization or allocation7. In recent years, the need to manage such waste has escalated into a global priority8, with approximately 21 million tonnes of waste estimated from the agricultural sector in Europe alone in 20209. Biomass derived from agriculture in the form of by-products and waste has garnered attention from researchers, who have demonstrated its potential applications in several fields (e.g., energy, chemicals, building) and its contribution to devising novel and sustainable waste management strategies10,11. In line with the Europe 2020 strategy12,13, the objective is not only to find uses for this waste but also to minimize reliance on conventional disposal methods such as landfill or incineration by fostering a circular economy14. Several authors have delineated the potential valorisation of food waste and its role in fostering a future bio-based economy8. Within this context, this study explores a pioneering citrus-processing-waste (CPW) based biorefinery, promoting such biomass to more valuable products applicable across several industries (e.g., pharmaceutical, cosmetic, food packaging)15–17. Italy hosts a significant citrus fruit sector, particularly in the South and notably in Sicily, which accounts for approximately 56% of the national citrus fruit production18,19 Oranges constitute 61.7% of the total Italian citrus production, followed by clementines (17.7%), lemons (13.7%), and mandarins (5.1%). Most citrus production is directed towards fresh consumption, with a minor portion utilized for fruit juice extraction. Citrus fruit processing yields various waste types, including solid and liquid effluents. Solid waste comprises peels, seeds, and residue, collectively identified as citrus pulp19,20. Liquid waste encompasses cannery effluents, can-cooler overflow, fruit-washing waste waters, peeling and sectioning table wastewaters, and floor flushing water. The management of this waste poses contemporary environmental challenges due to difficulties in obtaining information regarding its location, quantification, and disposal methods19,20. Frequently, this waste is directly discharged into lakes, ponds, forests, or wells or channelled into municipal sewer system, resulting in adverse environmental impacts. The solid fraction, comprising seeds, peels, pulp and residues, commonly referred to as orange peel waste (OPW), represents the primary waste output in the fruit juice processing industry21,22. Specifically, depending on the citrus fruit variety, only around 35–40% of the fruit is used for juice production, while a minor fraction, ranging between 0.2 and 0.5%, designated for essential oils extraction (such as limonene), occasionally conducted concurrently with juice extraction. The residual 60–65% constitutes the solid fraction, i.e., the OPW waste23. It has been demonstrated that this waste, representing almost half of the fruit total weight, harbours numerous commercially significant compounds or phytochemicals of commercial relevance8. By valorising this biomass through specific chemical processes, it is feasible to extract some of these structural components, with diverse applications across various sectors, as exemplified by limonene and pectin. Specifically, these two biomolecules are derived from distinct parts of the fruit, termed albedo and flavedo. Pectin, a structural polysaccharide, is situated in the albedo, while limonene, a cyclic terpene, is predominantly found in the flavedo of citrus fruits24. The burgeoning demand for these biomolecules and their derivatives in the market is attributed to their multifaceted utility across diverse industrial sectors. Limonene and its derivatives find widespread application in the food industry as flavouring or sweetening agents25, in the production of cleaning products such as resins and solvents26, and in the pharmaceutical sector, exhibiting chemotherapeutic activity against various tumours27. Pectin also has functional importance in the food industry owing to its thickening and gelling properties28 and is instrumental in the development of environmentally friendly food packaging29. The incessant growth of the market surrounding these two biomolecules attests to the abundant availability of these wastes worldwide. The global pectin market size was estimated to be $1 billion in 2019 and is projected to reach $1.5 billion by 202530, while for limonene, a market size of $312.1 million was estimated in 2022, with an expected increase to $331.0 million by 202331. However, given the escalating attention on production sustainability of and the burgeoning interest in renewable resources, such as citrus fruit waste, which mitigate the issue of illegal disposal with consequential environmental ramifications, by obtaining value-added products capable of substituting those traditionally derived from non-renewable sources, it is imperative not only to explore its potential applications but also to validate its environmental impact. From this standpoint, assessing the extraction of these two pivotal biomolecules from OPW is as crucial as evaluating the environmental sustainability of the process itself. Accordingly, this study aims to evaluate, in terms of environmental impact, a combined extraction process of pectin and limonene at the laboratory level using orange peel waste (OPW) provided by Ortogel Spa, Sicily (Italy), derived from the industrial juice production process. The Life Cycle Assessment (LCA) methodology is considered a reliable tool for evaluating the environmental potential of new technologies even in the laboratory phase. As highlighted in a recent review32, most LCA studies in the citrus sector primarily focus on the cultivation and processing phases for juice and essential oil production, typically adopting a “cradle-to-gate” approach. In these studies, the agricultural phase emerges as having the highest environmental impact, mainly due to the use of land, water, energy, and fertilizers33. While the transformation phase within the juicing industry has a lower impact compared to the agricultural phase, it is still significant due to the substantial consumption of water and energy34,35. However, the same review32 points out that only a few studies address the environmental impact of managing and valorising the waste generated during processing, such as OPW. In the existing literature, the environmental impacts of extracting limonene and pectin are often analyzed separately. LCA studies on limonene extraction tend to focus on using residues for biogas and digestate production36, whereas pectin-related LCA studies primarily compare different extraction methodologies37,38. The only study that addresses both limonene and pectin extraction considers limonene as an intermediate compound in producing value-added products like p-cymene39. Our study aims to bridge this gap by investigating the combined extraction of limonene and pectin from citrus industry waste, employing experimental methods on a laboratory scale and adopting a “gate-to-gate” approach. This approach focuses exclusively on the post-transformation phases of citrus processing, specifically the extraction of pectin and limonene from the waste product (OPW). Given the growing industrial interest in modeling and optimizing more sustainable extraction processes for value-added products, analyzing the environmental impacts of limonene and pectin extraction separately is also gaining traction37. Therefore, by applying the LCA methodology, this study aims to evaluate the environmental sustainability of the limonene and pectin extraction process at the laboratory scale, following international standards 14,040–44:200640,41. Utilizing the LCA methodology, as demonstrated in this study, allows for the identification of key environmental hotspots within the laboratory extraction process and facilitates the development alternative improvement scenarios.

Materials and methods

The orange peel waste (OPW) utilized in this extraction process originated from a citrus juice processing industry, specifically from Ortogel Spa, located in Sicily (Italy). This waste belonged to the Tarocco variety (Citrus sinensis). As reported in several studies, it is crucial to emphasise that the quantity of juice and structural components, such as pectin and lemon, can vary depending on the citrus fruit variety24. Consequently, the quantities extracted from this process, given identical OPW inputs and technologies employed, differ from results obtained in other studies, depending on the citrus variety utilised. Additionally, it is noteworthy regarding limonene, as previously mentioned, a percentage between 0.2 and 0.5% is already mechanically recovered during the juice extraction process. Therefore, the quantity of limonene extracted in this combined limonene and pectin extraction process represents the additional amount that could be recovered through the implementation of a biorefinery.

To estimate the environmental impacts associated with the analysed biorefinery process, a gate-to-gate LCA approach was developed in accordance with the specific international standards 14,040–44:200640,41 and organised as follows: (1) goal and scope definition; (2) life cycle inventory (LCI); (3) life cycle impact assessment (LCIA); and (4) life cycle interpretation. These phases constitute the well-standardised framework according to which this LCA was developed, with each discussed in subsequent sections. The adopted method offers a holistic approach for a comprehensive environmental assessment, following as stated, the standardised method ensuring reproducibility of results.

Goal and scope definition

The study aims to explore the extraction of limonene and pectin from OPW to identify environmental hotspots and potential enhancements of a biorefinery based on citrus processing wastes. This objective is driven by the need to mitigate conventional disposal practices, such as incineration or environmental dispersion of such waste, which contribute to environmental degradation. The analysed process adopts a gate-to-gate approach, wherein OPW serves as the incoming raw material for the combined extraction of pectin and limonene. Conducted at a laboratory scale, all data concerning material and energy flows were gathered through a questionnaire tailored for the implementation of the LCA methodology obtained from National Research Council of Italy (CNR). In this way, the system boundary was defined, encompassing three distinct phases: pre-treatment (Section “1”), lemon extraction (Section “2”), and pectin extraction (Section “3”), as depicted in Fig. 1.

Fig. 1.

Boundaries of the system under investigation.

Section 1: pre-treatment phase. Orange peel waste (OPW) from the juice processing industry was mixed with distilled water and pulped using a manual extractor. The aim of this first phase was to reduce the size of the OPW to 2 mm and then centrifuge it. After centrifugation, two fractions were obtained: one liquid and one solid. The liquid fraction exits the analysed system boundary, while the solid fraction leaving Section “1” is transferred to Section “2” for the combined extraction process (Comb-HD).

Section 2: limonene extraction. In the combined extraction process (Comb-HD), distilled water and hydrochloric acid were added to the solid fraction from Section “1”. The resulting mixture was used for lemon extraction and subsequently for pectin extraction (Section “3”). For limonene extraction, the mixture underwent hydro distillation followed by purification using cyclic methyl ether (CPME) and sodium sulphate (Na2SO4).

Section 3: pectin extraction. For pectin extraction, the mixture obtained from the combined extraction process (Comb-HD) underwent filtration and heat treatment, leading to the separation of the liquid fraction from the solid fraction. The solid fraction exits the analysed system boundary, while the liquid fraction is utilized in the extraction process. The liquid fraction was mixed with ethanol and centrifuged to obtain liquid and solid fractions. Pectin was extracted from the solid fraction after centrifugation. Notably, about 33% of the ethanol from the liquid fraction produced during centrifugation was recovered through distillation.

The selection of the functional unit (FU) was determined by considering the total incoming raw material flow and the maximum capacity of the laboratory machinery. The FU represents the unit of the product, provides a reference linking inputs to outputs and resulting impacts and damages42. In this small-scale study, the input OPW was approximately 422 g, corresponding to the maximum capacity of the manual extractor used during the pre-treatment phase, necessary to obtain the chosen functional unit, equivalent to 300 g of pre-treated OPW exiting the pre-treatment phase.

Life cycle inventory (LCI)

The inventory phase is crucial step in LCA processing involving the compilation, qualification, and quantification of all the input and output flows essential for assessing the environmental impact of the process. Inputs include resources, materials, and energies, while the outputs encompass material emissions into the air, water, and soil, as well as the exploitation of natural and primary-energy resources43. To collect the information provided by CNR on the primary laboratory stages of the process, product quantities, and waste quantities to be treated, a tailored questionnaire was developed. This questionnaire comprised several sections, including discussions on the developing process, details of each process step, and tables related to machinery used, electricity consumption, and time required for each phase. Additionally, tables for inputs and outputs were included, specifying the source and disposal procedure for each input and output identified as waste. Primary data collection involved three repetitions of laboratory tests, and the data used represents the average of results obtained from these repetitions. Following data collection, a detailed mass and energy balance was performed, referencing inputs and outputs to the functional unit of the system, equal to 300 g of OPW. The LCA developed in this study thus represents the limonene and pectin extraction process from OPW. Given the uncertainty and variability in LCA studies, it is essential to determine the validity of the collected data and the reliability and robustness of the results44. The robustness of the data and modelling in this study is considered very high, as it is based on real data acquired from three different repetitions of laboratory tests. Finally, the primary data were combined with secondary data extracted from databases of acknowledged scientific value and relevance, particularly Ecoinvent v.3.3 available in SimaPro 8.1. This database is globally recognized for accommodating most commonly used background materials and processes in LCAs45. The information used to calculate the life cycle analysis (LCI) is shown in Table 1, which details the quantities of limonene and pectin obtained, as well as the inputs and outputs used and produced in the extraction process. Specifically, electricity consumption was calculated to be 10.49 kWh, considering the electrical power of the machines used and their operational time. Further details on the modelling of secondary inputs derived from the Ecoinvent database are provided in Supplementary Table 1. The combined extraction process illustrated in Fig. 1 yielded 0.14 g of limonene and 8.22 g of pectin, as indicated in Table 1.

Table 1.

Average data collected from three different laboratory tests. All data are reported with their corresponding units of measurement (UM).

| Items | Average amount | UM |

|---|---|---|

|

Outputs Products | ||

| Limonene | 0.14 | g |

| Pectin | 8.22 | g |

|

Inputs Material and energy commodities |

||

| Orange peel waste (OPW)*1 | 421.90 | g |

| Distilled water | 1.8 | L |

| Hydrochloric acid (HCl) | 36.90 | mL |

| Cyclopentyl methyl ether (CPME) | 25.00 | mL |

| Sodium sulphate (Na2SO4) | 9.50 | g |

| Ethanol (EtOH) | 2.2 | L |

| Electricity | 10.49 | kWh |

| Waste | ||

| Water due to evaporation | 1682.79 | g |

| Hydroalcoholic residue | 1183.5 | g |

| Municipal solid waste | 14.24 | g |

*1 Corresponding to the quantity necessary to obtain the functional unit (FU), which is equivalent to 300 g of OPW leaving the pre-treatment phase.

Life cycle impact assessment (LCIA)

The LCIA phase, which provide information for the interpretation phase46, aims to evaluate the significance of potential environmental impacts associated with the analysed systems. This is achieved by examining the system from an environmental perspective, using the category indicators in the LCI results. The resulting flows quantified within the inventory analysis are aggregated into a limited number of Impact Categories (ICs), specifically midpoint categories46. LCIA development followed International Standards40,41, considering two mandatory steps: classification and characterization of the output inventories into damage and impact categories, and two optional steps: normalization and weighing of results with respect to a common reference. According to Jolliet et al.46, damages and impacts categorization for the assessment followed the scheme provided by Impact 2002+ , available in SimaPro 8.1 (Table 2). The Impact 2002+ method was selected due to its broad acceptance and its ability to incorporate both normalization and weighting, which allows for a more comprehensive and detailed assessment of environmental impacts. This method effectively bridges midpoint and damage-oriented approaches by integrating 14 midpoint categories with 4 damage categories, providing a holistic evaluation framework. Its versatility makes it well-suited to the study's scope and objectives, ensuring a thorough analysis of the environmental impacts. As shown in Table 2, this LCIA method employs a combination of midpoint impact categories and endpoint damage categories to assess the environmental repercussions of a system. In the midpoint approach, LCIA results were expressed using equivalent indicators, such as kgCO2eq for ‘Global Warming,’ MJ primary for ‘Non-renewable Energy,’ and kgPM2.5 eq for ‘Respiratory Inorganics.’ These ICs were subsequently grouped into Damage Categories (DCs) to describe the environmental compartments damaged by the product throughout its life cycle. Thus, normalization and weighing points were included in the assessment as part of the endpoint approach. As it is known, the endpoint approach provides results estimated using equivalent numerical parameters, expressed as ‘weighing points,’ ‘damage points,’ ‘eco-points,’ or simply ‘points.’ This approach quantitatively represents the environmental damage associated not only with the investigated system but also with all included materials, energies, processes, and phases, highlighting significant aspects for potential improvements. Finally, weighing points were obtained by multiplying dimensionless results from the normalization phase by 1 mPt. As known, the latter represents the factor (equal for all DCs and ICs) to convert results from normalization to weighing, according to the Impact 2002 + method.

Table 2.

ICS and DCs provided by Jolliet et al.36 in the Impact 2002 + method.

| Damage category (DC) | Impact category (IC) |

|---|---|

| Human Health (HH) | Carcinoges |

| Non-Carcinoges | |

| Respiratory inorganics | |

| Respiratory organics | |

| Ionizing radiations | |

| Ozone layer depletion | |

| Ecosystem quality (EQ) | Aquatic eco-toxicity |

| Terrestrial eco-toxicity | |

| Terrestrial acidification/nitrification | |

| Aquatic acidiphication | |

| Aquatic eutrophication | |

| Land occupation | |

| Climate change (CC) | Global warming |

| Resources (R) | No-renewable energy |

| Mineral extraction |

Results and life cycle interpretation

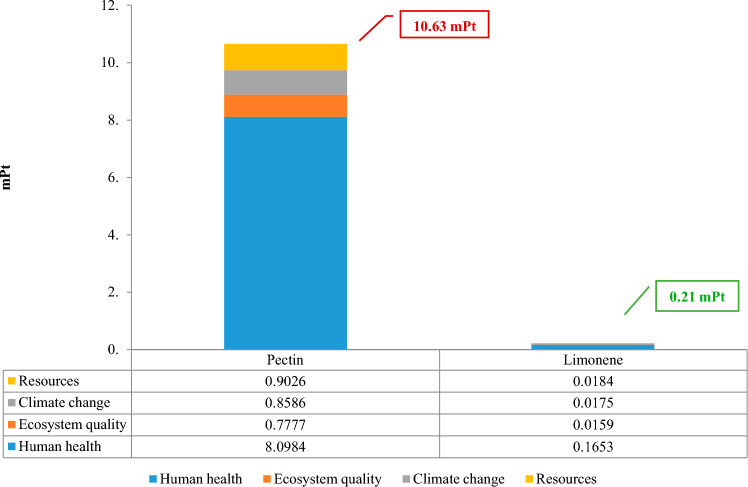

The most damaging processes were depicted using endpoint assessment results. Figure 2 shows the environmental impacts related to pectin and limonene extraction processes expressed as weighing points (mPt), referred to 300 g of OPW (FU), and classified by damage categories: Resource (R), Climate Change (CC), Ecosystem Quality (EQ), and Human Health (HH). Results shown in Fig. 2 demonstrate that the limonene extraction process is less impactful than the pectin extraction one. The assessment showed that the environmental damage related to the whole investigated extraction processes accounted for 10.84 mPt, with 10.63 mPt assigned to pectin and 0.21 mPt to limonene. Moreover, the Damage Category (DC) most significantly impacted was Human Health (HH), in contrast to the other DCs, which ranged between 0.8 and 0.9 mPt, as highlighted in Fig. 3. Specifically, Human Health (HH) emerged as the most influential DC throughout the entire process, accounting for 8.264 mPt, of which 8.098 mPt (i.e., 8%) were attributed to the pectin extraction process and only 0.165 mPt to the limonene extraction (Fig. 2).

Fig. 2.

Weighing results per DC. Results are elaborated from the Impact 2000 + LCIA and expressed per functional unit (300 g of OPW).

Fig. 3.

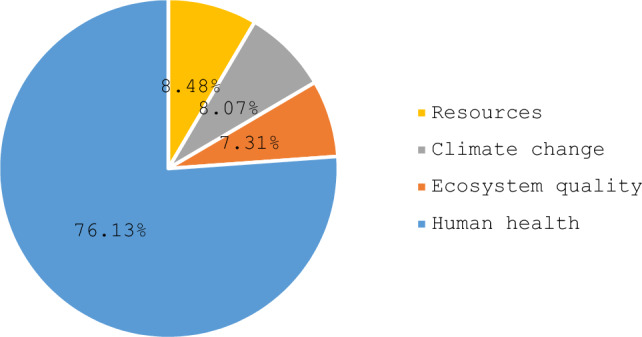

Percentage distribution of the total damage (10,84 mPt/FU) amongst the DCs considered by Impact 2000+ . Values are derived from endpoint results.

Figure 3 clearly confirms that the DCs with the greatest environmental impact, corresponding to 76.13%, are Human Health (HH), followed by the Resource (R) category with 8.48%, Climate Change (CC) with 8.07%, and finally, Ecosystem Quality (EQ) with the lowest percentage at 7.31%.

This was also confirmed from data reported in Table 3 where the damage-assessment values for each DC were evaluated and reported. In detail, DALY (Disability-Adjusted Life Year) considers the overall severity of a disease as the number of years lost due to illness, disability, or premature death; PDF (Potential Damage Fraction) is the fraction of species that have a high probability of not surviving in the selected area due to unfavourable living conditions. In terms of damage-assessment values, the pectin extraction process has a much more significant environmental impact compared to the limonene extraction one, for all analysed DCs. Specifically, 98% of the overall environmental impact is associated with the pectin extraction process, while only the remaining 2% is attributable to limonene extraction (Table 3).

Table 3.

Damage-assessment values for each considered damage category. Values were obtained from Impact 2022 + LCIA and are referenced to the FU.

| Damage assessment | ||||

|---|---|---|---|---|

| Damage category | Pectin | Limonene | Total | UM |

| Value | ||||

| Human health | 5.74 × 10–5 | 1.17 × 10–6 | 5.86 × 10–5 | DALY |

| Ecosystem quality | 10.65 | 0.22 | 10.87 | PDF m2 y |

| Climate change | 8.50 | 0.17 | 8.67 | kgeq CO2 |

| Resources | 137.17 | 2.80 | 139.97 | MJ Primary-energy |

The emission data were organized into emission to air, to water, and to soil for both pectin and limonene extraction (Table 4). Substances and resources contributing for < 1% (each) were excluded as their impact was considered not relevant. In the case of soil emissions, since all substances reported an impact of less than 1%, e.g., 0.06% of the total, a different criterion to select the substances and resources was considered. Indeed, the emissions to soils have not a relevant impact if compared with the air emissions, e.g., 95.24%, and water emissions, e.g., 4.70%. Therefore, only substances and resources that accounted for more than 50% of the total soil emissions were considered and reported in Table 4.

Table 4.

Emissions of substances and resources accounting for more than 50% of total emissions. Data are presented with their corresponding Unit of Measurement (UM).

| Emissions | ||||

|---|---|---|---|---|

| Amount | ||||

| Items | Pectin | Limonene | Total | UM |

| To air | ||||

| Carbon dioxide, fossil | 7.82 | 1.60 × 10–1 | 7.98 | kg |

| Carbon dioxide, biogenic | 7.12 | 1.45 × 10–1 | 7.26 | kg |

| Water | 1.65 | 3.37 × 10–2 | 1.68 | kg |

| Carbon monoxide, biogenic | 4.03 × 10–1 | 8.22 × 10–3 | 4.11 × 10–1 | kg |

| Radon | 8.43 × 105 | 1.72 × 104 | 8.60 × 105 | Bq |

| Noble gases, radioactive | 1.03 × 105 | 2.10 × 103 | 1.05 × 105 | Bq |

| Heat, waste | 3.13 × 10–1 | 3.07 × 10–1 | 6.27 × 10–3 | MJ |

| To water | ||||

| Nitrate | 2.58 × 10–1 | 5.27 × 10–3 | 2.64 × 10–1 | kg |

| Water | 4.33 × 101 | 8.84 × 10–1 | 4.42 × 101 | m3 |

| Heat, waste | 9.00 × 10–2 | 1.84 × 10–3 | 9.18 × 10–2 | MJ |

| To soil | ||||

| Calcium | 3.31 × 10–3 | 6.76 × 10–5 | 3.38 × 10–3 | kg |

| Oils, unspecified | 1.63 × 10–3 | 3.32 × 10–5 | 1.66 × 10–3 | kg |

The emission to air from pectin and limonene extraction processes in terms of kg of emission were carbon dioxide (biogenic and fossil), water, and carbon monoxide. Fossil and biogenic carbon dioxide emissions to air are significant at 7.98 kg and 7.26 kg respectively (Table 4). Water emissions of 1.68 kg represent the amount of water vapour released into the air during the limonene and pectin extraction processes, while carbon monoxide emissions of biogenic origin are present at 0.411 kg. Additionally, in terms of the becquerel (Bq) produced in the air, it was found, as shown in Table 4, that random and other radioactive noble gases are 8.60 × 105 and 1.05 × 105 respectively. This unit of measurement provides information about the amount of radioactivity present in a substance. Finally, again for emissions to air, the thermal energy lost during the extraction process is reported for a total of 6.27 × 10–3 MJ (Table 4).

Emissions to water from pectin and limonene extraction included nitrate in kg, water in m3, and Heat waste in MJ. Nitrate emissions in water are equivalent to 0.264 kg, water-related emissions are equivalent to 4.42 m3, while heat emissions in water are equivalent to 9.19 × 10–2 MJ (Table 4). Soil emissions include small amounts of calcium and oils released or deposited in the soil amounting to 3.38 × 10–3 and 1.66 × 10–3 respectively. The results in Table 4 show that for all types of emissions, the highest impacts are due to the pectin extraction process.

Furthermore, the contribution of each input considered for the whole process was analysed to evaluate the impact for each DC. As shown in Table 5, the most impactful resources were electricity and ethanol for all the DCs. In particular, the use of ethanol has a greater impact on the Human Health (HH) and Ecosystem Quality (EQ) damage categories, while electricity consumption proves to be more impactful in the damage categories related to Climate Change (CC) and Resource (R).

Table 5.

Substances and resources categorized based on the damage assessment.

| Damage assessment | |||||

|---|---|---|---|---|---|

| Substance/resource | Value | UM | DC | ||

| Pectin | Limonene | Total | |||

| Ethanol (from fermentation) | 5.36 × 10–5 | 1.09 × 10–6 | 5.47 × 10–5 | DALY | HH |

| Electricity | 3.60 × 10–6 | 7.34 × 10–8 | 3.67 × 10–6 | ||

| Cyclopentyl methyl ether | 8.52 × 10–8 | 1.74 × 10–9 | 8.69 × 10–8 | ||

| Water ultrapure | 8.16 × 10–8 | 1.67 × 10–9 | 8.33 × 10–8 | ||

| Hydrochloric acid | 2.51 × 10–8 | 5.12 × 10–10 | 2.56 × 10–8 | ||

| Sodium sulphate | 5.11 × 10–9 | 1.04 × 10–10 | 5.21 × 10–9 | ||

| Wastewater | 1.51 × 10–9 | 3.08 × 10–11 | 1.54 × 10–9 | ||

| Municipal solid waste | 4.29 × 10–10 | 8.75 × 10–12 | 4.37 × 10–10 | ||

| Ethanol (from fermentation) | 9.69 | 1.98 × 10–1 | 9.89 | PDF * m2 * y | EQ |

| Electricity | 8.97 × 10–1 | 1.83 × 10–2 | 9.15 × 10–1 | ||

| Water ultrapure | 4.14 × 10–2 | 8.44 × 10–4 | 4.22 × 10–2 | ||

| Cyclopentyl methyl ether | 9.05 × 10–3 | 1.85 × 10–4 | 9.23 × 10–3 | ||

| Wastewater | 7.48 × 10–3 | 1.53 × 10–4 | 7.63 × 10–3 | ||

| Hydrochloric acid | 7.41 × 10–3 | 1.51 × 10–4 | 7.56 × 10–3 | ||

| Sodium sulphate | 1.41 × 10–3 | 2.88 × 10–5 | 1.44 × 10–3 | ||

| Municipal solid waste | 1.16 × 10–4 | 2.38 × 10–6 | 1.19 × 10–4 | ||

| Electricity | 6.29 | 1.28 × 10–1 | 6.42 | kg CO2 | CC |

| Ethanol (from fermentation) | 2.03 | 4.14 × 10–2 | 2.07 | ||

| Cyclopentyl methyl ether | 7.76 × 10–2 | 1.58 × 10–3 | 7.92 × 10–2 | ||

| Water ultrapure | 6.68 × 10–2 | 1.36 × 10–3 | 6.82 × 10–2 | ||

| Hydrochloric acid | 2.81 × 10–2 | 5.74 × 10–4 | 2.87 × 10–2 | ||

| Sodium sulphate | 6.01 × 10–3 | 1.23 × 10–4 | 6.13 × 10–3 | ||

| Municipal solid waste | 1.88 × 10–3 | 3.83 × 10–5 | 1.92 × 10–3 | ||

| Wastewater | 7.24 × 10–4 | 1.48 × 10–5 | 7.39 × 10–4 | ||

| Electricity | 1.06 × 102 | 2.15 | 1.08 × 102 | Primary-energy MJ | R |

| Ethanol (from fermentation) | 2.75 × 101 | 5.62 × 10–1 | 2.81 × 101 | ||

| Cyclopentyl methyl ether | 2.34 | 4.78 × 10–2 | 2.39 | ||

| Water ultrapure | 1.04 | 2.13 × 10–2 | 1.07 | ||

| Hydrochloric acid | 5.65 × 10–1 | 1.15 × 10–2 | 5.76 × 10–1 | ||

| Sodium sulphate | 1.18 × 10–1 | 2.40 × 10–3 | 1.20 × 10–1 | ||

| Wastewater | 8.93 × 10–3 | 1.82 × 10–4 | 9.11 × 10–3 | ||

| Municipal solid waste | 5.35 × 10–3 | 1.09 × 10–4 | 5.46 × 10–3 | ||

Furthermore, it is observed that for Human Health (HH) and Ecosystem Quality (EQ) damage categories, Ethanol and Electricity together account for 99.65% and 99.37% of the total, respectively. In the case of the Climate Change (CC) damage category, this percentage drops to 97.87%, while for the Resource (R) damage category, it is 97.02%. When considering the entire process and the individual contributions of each substance and/or resource, as depicted in Fig. 4, 81% of the total impacts are attributed to Ethanol, 18% to electricity, and only the remaining 1% is due to the rest of the employed resources. This corresponds to single scores of 8.83 mPt for Ethanol, 1.94 mPt for electricity, and 0.08 mPt for other resources (Fig. 4). The significant impact of Ethanol, as revealed in this study, is consistent with findings from similar research, confirming that ethanol is one of the primary contributors to environmental impact in processes involving the extraction of compounds like pectin and limonene. For example, a study by Santiago et al.36 compared the environmental impacts of various limonene extraction techniques, including solvent extraction with Ethanol. Their findings highlighted that this method carries a substantial environmental burden, both due to the use of the solvent and the high energy consumption required for its recovery. Similarly, Garcia et al.37 found that the impact of ethanol use surpasses that of electricity and increases significantly if ethanol is not recovered, making it a key factor in the overall process. Duggal Muskanna et al.38 further emphasize the importance of Ethanol recovery to mitigate its environmental footprint and suggest that more efficient and sustainable extraction techniques, such as microwave heating or sourcing ethanol from more sustainable origin, could minimize its use. By focusing attention on Impact Categories (ICs), selected from those considered by Impact 2002 + (Table 2) and analysing the results, it was possible to highlight that among the considered ICs, the most environmentally significant was Non-renewable Energy, belonging to the Resource (R) damage category (Table 6). The other two ICs that were less impactful but still relevant were Global Warming and Terrestrial Eco-toxicity, belonging to Climate Change (CC) and Ecosystem Quality (EQ) damage categories, respectively.

Fig. 4.

Major processes contribution to Damage-assessment (weighing points).

Table 6.

Most representative and impactful ICs, referenced to the Unit of Measurement (UM).

| Impact category | Amount | UM | DC | ||

|---|---|---|---|---|---|

| Pectin | Limonene | Total | |||

| Non-carcinogens | 4.40 × 10–5 | 8.98 × 10–7 | 4.49 × 10–5 | DALY | HH |

| Carcinogens | 7.22 × 10–6 | 1.47 × 10–7 | 7.37 × 10–6 | DALY | |

| Respiratory inorganics | 6.19 × 10–6 | 1.26 × 10–7 | 6.32 × 10–6 | DALY | |

| Ionizing radiation | 2.86 × 10–8 | 5.84 × 10–10 | 2.92 × 10–8 | DALY | |

| Respiratory organics | 5.14 × 10–9 | 1.05 × 10–10 | 5.24 × 10–9 | DALY | |

| Ozone layer depletion | 1.23 × 10–9 | 2.52 × 10–11 | 1.26 × 10–9 | DALY | |

| Terrestrial ecotoxicity | 6.44 | 1.31 × 10–1 | 6.57 | PDF*m2*yr | EQ |

| Land occupation | 3.88 | 7.92 × 10–2 | 3.96 | PDF*m2*yr | |

| Terrestrial acid/nutr | 2.32 × 10–1 | 4.74 × 10–3 | 2.37 × 10–1 | PDF*m2*yr | |

| Aquatic ecotoxicity | 1.05 × 10–1 | 2.14 × 10–3 | 1.07 × 10–1 | PDF*m2*yr | |

| Non-renewable energy | 1.37 × 10–2 | 2.79 | 1.40 × 102 | MJ primary | R |

| Mineral extraction | 3.59 × 10–1 | 7.33 × 10–3 | 3.67 × 10–1 | MJ primary | |

| Global warming | 8.50 | 1.73 × 10–1 | 8.67 | kg CO2 eq | CC |

However, the impact categories relating to Aquatic Acidification and Aquatic Eutrophication were not reported because they did not produce any impact for this process. The most representative and significant ICs were selected and listed in Table 6, based on results from the midpoint. Regarding the Human Health (HH) damage category, all impact categories were negligible compared to those belonging to Resource (R), and, above all, those belonging to Ecosystem Quality (EQ) and Climate Change (CC) damage categories. For the Climate Change (CC) damage category, all impacts coming from the IC Global Warming were 98% from the pectin extraction process, with the remaining less than 2% from the limonene extraction. According to this author team, the output inventory pack discussed in Tables 4 and 5, as well as the ICs reported in Table 6, can be considered highly significant environmental aspects and representative of the investigated process. The obtained results made it possible to identify the life cycle phases that contribute the most to environmental impacts. Therefore, since all the DCs were highlighted as mostly affected by Ethanol, especially during the pectin extraction phase, as reported in Table 5 and shown in Fig. 4, a new analysis of the pectin extraction process was carried out with the aim of reducing the environmental impacts for the improvement of the process.

Improvements of the process

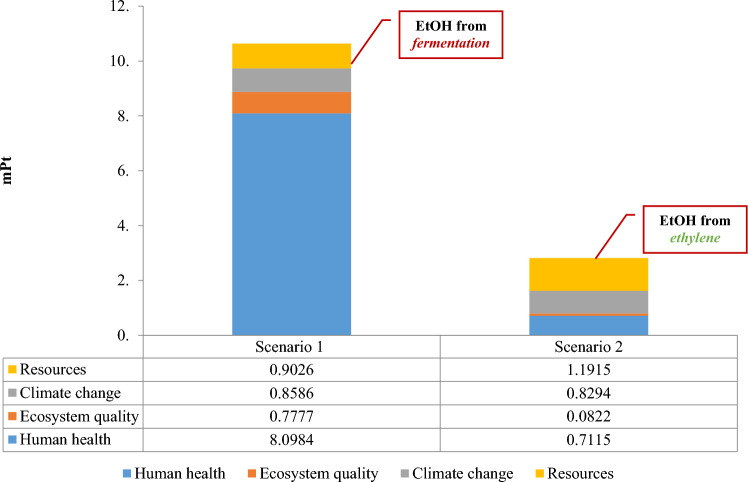

Therefore, since all the Damage Categories (DCs) were highlighted as mostly affected by Ethanol during the pectin extraction phase, a new analysis was carried out by replacing it. In detail, a comparison between two scenarios (i.e., Scenario 1—pectin extraction phase using ethanol from fermentation and Scenario 2—pectin extraction phase using Ethanol from ethylene) was carried out. Figure 5 shows the environmental impacts, making a comparison between the two considered scenarios by adopting Ethanol coming from different sources (i.e., fermentation and ethylene). The damage assessment showed that the environmental damages associated with the investigated scenarios are equal to 10.63 mPt and 2.81 mPt, respectively, for Scenario 1 and Scenario 2. Therefore, as highlighted in Fig. 5, Scenario 2 had a 73.4% lower impact than Scenario 1. In detail, the analysis of Fig. 5 reveals that the Impact Category (IC) most severely affected in Scenario 1, as already highlighted in Fig. 2, was Human Health (HH), with a total score of 8.0984 mPt. Transitioning to the second scenario, characterized using Ethanol produced from ethylene instead of fermentation-derived Ethanol, a significant reduction of 91.21% in this impact category was recorded, with the score decreasing from 8.0984 mPt to only 0.7115 mPt. In Scenario 2, the most significant damage category was Resource (R), highlighted by a single score of 1.1915 mPt, while the other DCs show variable values ranging from 0.08 to 0.82 mPt.

Fig. 5.

Comparison of Scenario 1 and Scenario 2 at the lab scale, including associated causes and damages (weighing points).

This was confirmed by the data reported in Table 7, where the damage-assessment values for each Damage Category (DC) were evaluated and reported. As stated before (Table 6), the analysis of the process revealed that the most significant environmentally impactful Impact Categories (ICs) included Non-Renewable Energy, belonging to the Resource (R) damage category, and to a lesser but still relevant extent, Global Warming, and Terrestrial Eco-toxicity, falling within the Climate Change (CC) and Human Health (HH) damage categories, respectively.

Table 7.

Damage-assessment values for the most representative and impactful ICs. Values, referred to FU, were obtained from Impact 2022 + LCIA.

| Impact category (IC) | |||||

|---|---|---|---|---|---|

| Scenario 1 | Scenario 2 | UM | DC | ||

| Non-carcinogens | 4.49 × 10–5 | Respiratory inorganics | 5.57 × 10–1 | DALY | HH |

| Carcinogens | 7.37 × 10–6 | Carcinogens | 1.25 × 10–1 | DALY | |

| Respiratory inorganics | 6.32 × 10–6 | Non-carcinogens | 2.38 × 10–2 | DALY | |

| Ionizing radiation | 2.92 × 10–8 | Ionizing radiation | 3.63 × 10–3 | DALY | |

| Respiratory organics | 5.24 × 10–9 | Respiratory organics | 1.47 × 10–3 | DALY | |

| Ozone layer depletion | 1.26 × 10–9 | Ozone layer depletion | 1.52 × 10–4 | DALY | |

| Terrestrial ecotoxicity | 6.57 | Terrestrial ecotoxicity | 6.51 × 10–2 | PDF*m2*yr | EQ |

| Land occupation | 3.96 | Terrestrial acid/nutri | 8.51 × 10–3 | PDF*m2*yr | |

| Terrestrial acid/nutri | 2.37 × 10–1 | Land occupation | 6.97 × 10–3 | PDF*m2*yr | |

| Aquatic ecotoxicity | 1.07 × 10–1 | Aquatic ecotoxicity | 1.54 × 10–3 | PDF*m2*yr | |

| Non-renewable energy | 1.40 × 102 | Non-renewable energy | 1.19 | MJ primary | R |

| Mineral extraction | 3.67 × 10–1 | Mineral extraction | 1.99 × 10–3 | MJ primary | |

| Global warming | 8.67 | Global warming | 8.29 × 10–1 | kg CO2 eq | CC |

In this comparison, considering the use of Ethanol from a different source (Ethanol from ethylene), a considerable decrease in the mentioned ICs in terms of environmental impact was observed (Table 7). Indeed, the Non-Renewable Energy impact category reduced by 99.15%, decreasing from 140 to 1.19 MJ for Scenario 1 and Scenario 2, respectively. Substantial reductions were also found for the other two ICs, namely Global Warming and Terrestrial Eco-toxicity, belonging to the Climate Change (CC) and Human Health (HH) damage categories, respectively. The former decreased by 90.44%, going from 8.67 to 0.82 kg CO2eq, while the latter decreased by 99.01%, going from 6.57 to 0.065 PDFm2yr.

In this case as well, ICs related to Aquatic acidification and Aquatic eutrophication were not reported because they showed no impact for this process. The most representative and significant ICs were selected and listed in Table 7, based on results obtained from the midpoint. Overall, as observed in Table 7, all impact categories experienced a significant reduction in terms of environmental impact due to the substitution of fermentation Ethanol with Ethanol from ethylene.

Although to a lesser extent, all the Damage Categories (DCs) were also significantly affected by electricity consumption (Table 5 and Fig. 4). However, according to other studies36, high energy consumption constitutes a recurring challenge in various biomass valorisation contexts, putting at risk the sustainability of the processes, including the recovery of citrus waste from the initial stages of the process. In an optimized process, considering a further improvement, this impact could be significantly reduced by replacing the use of energy from fossil fuels with renewable sources (i.e., solar, biomass, wind).

Conclusion and future perspective

The responsible use of biomass and waste to produce high-value products is now a crucial global goal to address climate issues related to their underutilization or improper disposal, which has serious consequences for our planet's health. This study aims to promote an innovative biorefinery based on citrus processing waste (CPW), with the goal of laboratory-scale extraction of two essential molecules, pectin, and limonene, for various sectors and purposes. However, defining a use for waste to create new high-value products is not enough today; it is also crucial to ensure their environmental sustainability. Therefore, the laboratory process described in this study was assessed for its environmental impacts using the globally recognized Life Cycle Assessment (LCA) methodology. This approach allows the examination of products, processes, facilities, or services from resource acquisition to waste management.

In this context, the presented study analysed a laboratory process for the extraction of pectin and limonene, highlighting environmental critical points in this phase and providing a basis for identifying potential improvements. Specifically, the Life Cycle Assessment results identified ethanol and electricity as the main sources of environmental impact. The analysis revealed that 97% of the total damage resulted from ethanol use within the pectin extraction phase. Consequently, the study proposed an improvement measure, aiming to replace environmentally impactful fermentation-derived ethanol with ethanol from different sources, such as ethylene. The results showed a significant reduction in the environmental impact of 73.4% associated with pectin extraction, using ethanol derived from ethylene. This underlines the importance of the LCA methodology as a crucial tool for identifying and improving the environmental impacts of new industrial processes. Regarding electricity, although its impact on the overall extraction process is minor compared to ethanol use, future optimization could bring further improvements by substituting fossil energy sources with renewable sources like solar, biomass, and wind power.

Supplementary Information

Acknowledgements

The authors acknowledge the financial support of the Fondazione Cariplo, Grant number 2020-1070, project: CIRCLE – CItruswaste ReCycLing for added value products.

Author contributions

G.M.: Methodology; Software; Formal analysis; Investigation; Data Curation; Writing—Original Draft. G. C.i: Methodology; Software; Formal analysis; Investigation; Data curation. S.M.C. P.: Visualization, Funding acquisition. G.O.: Validation; Writing—Review & Editing. Jacopo Paini: Data Curation; Visualization. F.V.: Conceptualization; Methodology; Validation; Investigation; Writing—Review & Editing; Supervision.

Data availability

Data will be made available on request from the corresponding author [F.V.].

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-024-72468-y.

References

- 1.Ragauskas, A. J. et al. The path forward for biofuels and biomaterials. Science27, 484–489 (2006). 10.1126/science.1114736 [DOI] [PubMed] [Google Scholar]

- 2.Kucharik, C. J. et al. Measurements and modeling of carbon and nitrogen dynamics in managed and natural ecosystems in southern Wisconsin: Potential for SOC sequestration in the next 50 years. Ecosyst4, 237–258 (2001). 10.1007/s10021-001-0007-2 [DOI] [Google Scholar]

- 3.Allen, B. R., Keegan, D. & Elbersen,. Biomass and bioenergy in the wider land-use context of the European Union. Biofuel Bioprod. Biorefining7(2), 207–216 (2013). 10.1002/bbb.1359 [DOI] [Google Scholar]

- 4.United Nations Resolution 70/1. Transforming Our World, The 2030 Agenda for Sustainable Development, Adopted by the General Assembly on 25 September 2015. https://documents-dds-ny.un.org/doc/UNDOC/GEN/N15/291/89/PDF/N1529189.pdf?OpenElement.

- 5.United Nations Framework Convention on Climate Change, UNFCCC. The Paris Agreement - Publication. Paris Climate Change Conference - November 2015. Publication date. 29 Nov 2018. https://unfccc.int/documents/184656

- 6.European Commission. The European green deal. Eur. Comm.53, 24. 10.1017/CBO9781107415324.004 (2019). 10.1017/CBO9781107415324.004 [DOI] [Google Scholar]

- 7.FAOSTAT https://fenixservices.fao.org/faostat/static/documents/GT/GT_en.pdf.

- 8.Lin, C. S. K. et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci.6(2), 426–464 (2013). 10.1039/c2ee23440h [DOI] [Google Scholar]

- 9.Consiglio europeo 2020 https://www.consilium.europa.eu/it/policies/waste-trade/

- 10.Valenti, F., Liao, W. & Porto, S. M. C. A GIS-based spatial index of feedstock-mixture availability for anaerobic co-digestion of Mediterranean by-products and agricultural residues. Biofuel Bioprod. Biorefining12(3), 362–378 (2018). 10.1002/bbb.1875 [DOI] [Google Scholar]

- 11.Valenti, F., Porto, S. M. C., Cascone, G. & Arcidiacono, C. Potential biogas production from agricultural by-products in Sicily. A case study of citrus pulp and olive pomace. J. Agric. Eng.48(4), 196–202 (2017). [Google Scholar]

- 12.European Commision, Europe 2020 Strategy, Europe commission COM (2010) 2020 https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52010DC2020

- 13.European Commision, Europe 2020 Strategy, Europe commission COM (2011) 2021 https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2011:0021:FIN:IT:PDF

- 14.Valenti, F. et al. Anaerobic co-digestion of multiple agricultural residues to enhance biogas production in southern Italy. J. Waste Manag78, 151–157 (2018). 10.1016/j.wasman.2018.05.037 [DOI] [PubMed] [Google Scholar]

- 15.Moniri, M. et al. Production and status of bacterial cellulose in biomedical engineering. Nanomater.7, 257 (2017). 10.3390/nano7090257 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Perugini, P., Bleve, M., Cortinovis, F. & Colpani, A. Biocellulose masks as delivery systems: A novel methodological approach to assure quality and safety. Cosmetics5, 66 (2018). 10.3390/cosmetics5040066 [DOI] [Google Scholar]

- 17.Yang, W. et al. Poly(lactic acid)/lignin films with enhanced toughness and anti-oxidation performance for active food packaging. Int. J. Biol. Macromol.144, 102–110 (2020). 10.1016/j.ijbiomac.2019.12.085 [DOI] [PubMed] [Google Scholar]

- 18.Istat. Atlante dell’agricoltura in Sicilia. Una lettura guidata delle mappe tematiche. Published on 28 November 2014, Rome. Available at link: https://www.istat.it/produzione-editoriale/atlante-dellagricoltura-in-sicilia/ (2014).

- 19.Valenti, F., Porto, S. M. C., Chinnici, G., Cascone, G. & Arcidiacono, C. A GIS-based model to estimate citrus pulp availability for biogas production: An application to a region of the Mediterranean Basin. Biofuel Bioprod. Biorefining10(6), 710–727 (2016). 10.1002/bbb.1707 [DOI] [Google Scholar]

- 20.Valenti, F. et al. Use of citrus pulp for biogas production: A GIS analysis of citrus-growing areas and processing industries in South Italy. Land Use Policy66, 151–161 (2017). 10.1016/j.landusepol.2017.04.041 [DOI] [Google Scholar]

- 21.EC Agriculture and Rural development. Citrus fruit statistics [WWW Document]. https://agriculture.ec.europa.eu/data-and-analysis/markets/overviews/market-observatories/fruit-and-vegetables/citrus-fruit-statistics_en (accessed 12.4.23) (2023).

- 22.FAO. Citrus Fruit Fresh and Processed Statistical Bulletin 2020, (2021).

- 23.Costa, R., Albergamo, A., Arrigo, S., Gentile, F. & Dugo, G. Solid-phase microextraction-gas chromatography and ultra-high performance liquid chromatography applied to the characterization of lemon wax, a waste product from citrus industry. J. Chromatogr. A1603, 262–268 (2019). 10.1016/j.chroma.2019.06.049 [DOI] [PubMed] [Google Scholar]

- 24.John, I., Muthukumar, K. & Arunagiri, A. A review on the potential of citrus waste for D-Limonene, pectin, and bioethanol production. Int. J. Green Energy14(7), 599–612 (2017). 10.1080/15435075.2017.1307753 [DOI] [Google Scholar]

- 25.Alonso-Gutierrez, J. et al. Metabolic engineering of Escherichia coli for limonene and perillyl alcohol production. Metab. Eng.19, 33–41 (2013). 10.1016/j.ymben.2013.05.004 [DOI] [PubMed] [Google Scholar]

- 26.Paggiola, G. et al. Can bio-based chemicals meet demand? Global and regional case-study around citrus waste-derived limonene as a solvent for cleaning applications. Biofuel Bioprod. Biorefining10(6), 686–698 (2016). 10.1002/bbb.1677 [DOI] [Google Scholar]

- 27.Mukthar, Y. M. et al. Biochemical significance of limonene and its metabolites: Future prospects for designing and developing highly potent anticancer drugs. Biosci. Rep. 10.1042/BSR20181253 (2018). 10.1042/BSR20181253 [DOI] [PMC free article] [PubMed]

- 28.Mesbahi, G., Jamalian, J. & Farahnaky, A. A comparative study on functional properties of beet and citrus pectins in food systems. Food Hydrocoll.19, 731–738 (2005). 10.1016/j.foodhyd.2004.08.002 [DOI] [Google Scholar]

- 29.Siracusa, V., Rocculi, P., Romani, S. & Dalla, R. M. Biodegradable polymers for food packaging: A review. Trends Food Sci Tech2008(19), 634–643 (2008). 10.1016/j.tifs.2008.07.003 [DOI] [Google Scholar]

- 30.Pectin Market Size, Share & Trends Analysis Report. https://www.grandviewresearch.com/industry-analysis/pectin-market.

- 31.Limonene Market Size, Share & Trends Analysis Report. 2023—2030. https://www.grandviewresearch.com/industry-analysis/limonene-market-report

- 32.Falcone, G., Fazari, A., Vono, G., Gulisano, G. & Strano, A. Application of the LCA approach to the citrus production chain—A systematic review. Clean. Environ. Syst.12, 100156. 10.1016/j.cesys.2023.100156 (2024). 10.1016/j.cesys.2023.100156 [DOI] [Google Scholar]

- 33.Coltro, L., Mourad, A. L., Kletecke, R. M., Mendonça, T. A. & Germer, S. P. Assessing the environmental profile of orange production in Brazil. Int. J. Life Cycle Assess14, 656–664 (2009). 10.1007/s11367-009-0097-1 [DOI] [Google Scholar]

- 34.Beccali, M., Cellura, M., Iudicello, M. & Mistretta, M. Life cycle assessment of Italian citrus-based products. Sensitivity analysis and improvement scenarios. J. Environ. Manag.91(7), 1415–1428 (2010). 10.1016/j.jenvman.2010.02.028 [DOI] [PubMed] [Google Scholar]

- 35.Arzoumanidis, I., Petti, L., Raggi, A. & Zamagni, A. Life cycle assessment for the agri-food sector. In Product-oriented environmental management systems (POEMS) (eds Salomone, R. et al.) 105–122 (Springer, Dordrecht, 2013). [Google Scholar]

- 36.Santiago, B., Moreira, M. T., Feijoo, G. & González-García, S. Identification of environmental aspects of citrus waste valorization into D-limonene from a biorefinery approach. Biomass Bioenergy143, 105844. 10.1016/j.biombioe.2020.105844 (2020). 10.1016/j.biombioe.2020.105844 [DOI] [Google Scholar]

- 37.Garcia-Garcia, G., Rahimifard, S., Matharu, A. S. & Dugmore, T. I. Life-cycle assessment of microwave-assisted pectin extraction at pilot scale. ACS Sustain. Chem. Eng.7(5), 5167–5175 (2019). 10.1021/acssuschemeng.8b06052 [DOI] [Google Scholar]

- 38.Duggal, M. et al. Microwave-assisted acid extraction of high-methoxyl kinnow (Citrus reticulata) peels pectin: Process, techno-functionality, characterization and life cycle assessment. Food Chem. Mol. Sci.9, 100213. 10.1016/j.fochms.2024.100213 (2024). 10.1016/j.fochms.2024.100213 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Dávila, J. A., Rosenberg, M. & Cardona, C. A. Techno-economic and environmental assessment of p-cymene and pectin production from orange peel. Waste Biomass Valoriz.6, 253–261 (2015). 10.1007/s12649-014-9339-y [DOI] [Google Scholar]

- 40.ISO (International Organization for Standardization), 14040-Environmental Management—Life Cycle Assessment—Principles and Framework (2006a).

- 41.ISO (International Organization for Standardization), 14044-Environmental Management—Life Cycle Assessment—Requirements and Guidelines (2006b).

- 42.Ingrao, C., Faccilongo, N., Di Gioia, L. & Messineo, A. Food waste recovery into energy in a circular economy perspective: A comprehensive review of aspects related to plant operation and environmental assessment. J. Clean. Prod.184, 869–892 (2018). 10.1016/j.jclepro.2018.02.267 [DOI] [Google Scholar]

- 43.Notarnicola, B., Tassielli, G., Renzulli, P. A. & Monforti, F. Energy fl ows and greenhouses gases of EU (European Union) national breads using an LCA (Life Cycle Assessment) approach. J. Clean. Prod.140, 455–469 (2017). 10.1016/j.jclepro.2016.05.150 [DOI] [Google Scholar]

- 44.Frischknecht, R. & Rebitzer, G. The ecoinvent database system: A comprehensive web-based LCA database. J. Clean. Prod.13, 1337–1343 (2005). 10.1016/j.jclepro.2005.05.002 [DOI] [Google Scholar]

- 45.De Benedetto, L. & Klemes, J. The environmental performance strategy map: An integrated LCA approach to support the strategic decision-making process. J. Clean. Prod.17, 900e906 (2009). 10.1016/j.jclepro.2009.02.012 [DOI] [Google Scholar]

- 46.Jolliet, O. et al. IMPACT 2002þ: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess.8, 324e330 (2003). 10.1007/BF02978505 [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Citations

- Mukthar, Y. M. et al. Biochemical significance of limonene and its metabolites: Future prospects for designing and developing highly potent anticancer drugs. Biosci. Rep. 10.1042/BSR20181253 (2018). 10.1042/BSR20181253 [DOI] [PMC free article] [PubMed]

Supplementary Materials

Data Availability Statement

Data will be made available on request from the corresponding author [F.V.].