Abstract

With the increase in population at an immense rate, electricity demand is growing exponentially. Researchers and policymakers are seeking alternating means of power generation to meet the load demand. These resources should be cost-effective, environmentally friendly and least carbon emissions. To mitigate the load demand Renewable Energy Sources (RES) are integrated into electrical networks. In this work, an off-grid solar photovoltaic (PV) system is designed for rural areas of Dera Ghazi Khan (DG Khan), Pakistan. These areas often lack access to reliable grid power. Installing PV systems in these areas can help provide a reliable source of electricity, reduce reliance on fossil fuels, and improve living conditions. This case study is simulated using PVsyst 7.2. of Roonghan village such as hospitals, shops, and residential houses for techno-economic analysis of off-grid solar PV. The economic viability shows that installing off-grid solar PV in DG Khan is much cheaper. The electricity taken from the grid that's almost 80.01%is expensive. This case study helps other researchers and policymakers to mitigate the electricity requirement of remote areas located far away from the national grid. To install a transmission line, having cost $26.98 corer but using an off-grid to provide electricity to the same area is $2.16 corer. Additionally, it integrates Battery Energy Storage (BES) with Renewable Energy Sources (RES) to achieve a 5 % annual energy cost reduction and enhanced self-sufficiency, filling a gap in existing literature.

Keywords: PV system, Distributed generation, Energy, Renewable energy sources, Technoeconomic analysis

1. Introduction

The world population is increasing at an immense rate and people want reliable, secure, and cost-effective means that make their lives easier. Still, the backward area having no supply of electricity. Due to the lack of roads, infrastructure and scattered population in the potohar plateau of Pakistan. It is beyond the capacity of government to supply power in these areas through the national grid. The Multan Electric Power Company (MEPCO) had planned to supply the power in those areas having houses of more than 50 in number. The major problem in those areas are scattered population and lesser electric load.

Previously too many surveys and planning have been done for the people of urban areas with different kinds of objectives and planning. This off-grid photovoltaic (PV) electrification is a vital step towards green energy and meeting the user demands in those remote areas. This study is carried out to electrify the remote areas of DG Khan having no infrastructure of transmission lines and power supply. According to Ref. [1], Pakistan has the potential to PV resources 11.4 % of overall PV energy consumption across the globe. In Pakistan, the energy security indicator clearly shows [2,3] to move renewable energy sources. People are feeling reluctance to adopt RES due to its uncertainty as presented in Refs. [[4], [5], [6], [7]]. PV Stand-alone design is a wonderful solution to tackle these uncertainties. Many technoeconomic advantages are discussed in PV stand-alone systems [8,9].

In Pakistan almost more than 305 sunny days and 2.1 MWh/m2 irradiations [10]. In this scenario, off-grid PV energy is the optimal solution for the remote area. Asian Development Bank report clearly shows that for mitigation of energy in Pakistan, through off-grid is the best solution [11]. Off-grid PV installation has many advantages, like easy installation, cost effective, net energy, low life cycle cost, environmental benefits, improving living standards, no carbon emissions, no human health hazards, free noise pollution, entrepreneurship opportunities and uplift socio-economic [[12], [13], [14]].

A stand-alone system is a system that is carrying a battery backup system. PV array supplies the power to the user and charges the battery at the same time. The users that are associated with the stand-alone system have a clear voltage profile daily. A small standalone system is mostly installed in houses and delivers almost 50 to 200 Wp [15]. With this system TV, radio, computer, and fridge are mostly connected. One PV module is usually used and connected to the battery. The PV module is 36 or 72 cells in this category. The medium power stand-alone PV system ranges between 200 and 2 KW. In this system, the controller has maximum power tracking MPPT topology, which is used for PV array tracking. The controller is used for load control at the user end by compensating the power from the battery [16]. The high-power stand-alone PV system has a power range of 2 KW to several dozen KW. This system has solar chargers, DC/AC batteries as well as MPPT converters [17]. In PVsyst solar chargers are used as the controller of the standalone system. It has a backup solution in the form of a Genset. The inverter is also used to manage the power that is coming from the backup Genset. Many studies are employed to access the performance evaluation of standalone PV system. These studies include optimization and artificial control techniques to manage the inverter power [[18], [19], [20], [21]]. The key insight of these studies to optimize the power tracking.

The total production of the off-grid solar PV system that is designed for the shops in Roonghan is 602,649 kWh but at the load end is 459,523 kWh. The losses are almost 143,126 kWh including the temperature losses which is almost 11.3 % of the total power produced, almost 4.5 % are ohmic and wiring losses, 4.1 % losses are because of the converter. In operation mode: and few other losses 2.2 % battery efficiency losses, 2.1 % modules and string losses, 1.8 % charging and discharging losses and current efficiency losses. The comparison between national grid supply and off-grid solar PV systems involves a comprehensive analysis of various cost factors. Firstly, examining the grid connection costs. The expense varies significantly depending on the type of tower required. The suspension tower's price is approximately $2,698,029.92 per piece, culminating in a staggering total of $1,432,653,888 for 531 towers. Similarly, angle-suspension towers and tension towers incur even higher costs, totaling $2,507,144,670 and $4,297,961,668 respectively for the same quantity.

Therefore, this study was carried out to explore solar energy potential, analyze economic analysis, and technical analysis for the proposed area. The main purpose of this study is to get familiar with off-grid solar energy technology for the electrification of remote areas. To harvest the maximum benefit of PV energy as discussed above for the said area. The contribution of my work has been stated below.

-

•

To analyze the techno-economic feasibility of solar PV based off-grid system

-

•

To design a plan for remote area electrification of DG Khan

-

•

To lessen the operational cost of PV panels.

-

•

To minimize the operational cost of PV panels.

2. Methodology and modelling

2.1. Creation of a stand-alone system

A stand-alone system is a system that is carrying a battery backup system.

-

•

PV array supplies the power to the user and charges the battery.

-

•

The users that are associated with the stand-alone system have a clear voltage profile on daily bases. Daily profile hour-wise load will be mentioned so that if surplus energy is needed, the requirement should have been fulfilled.

Approximately every hour, the simulation attempts to strike a balance between PV production (which varies depending on the irradiance) and the needs of the user. Ideally, the difference should be found in the battery, either positively (charge) or negatively (discharge). A controller is in charge of maintaining this energy balance. The controller's primary function is to manage the flow of energy and protect the battery.

-

•

When the battery is completely charged, the PV array should be turned off.

-

•

When the battery is completely depleted, the user should be unplugged from the system.

Furthermore, when the battery is completely depleted and the solar gain is insufficient, the controller may be programmed to oversee the start of an eventual backup generator.

2.2. Small stand-alone system

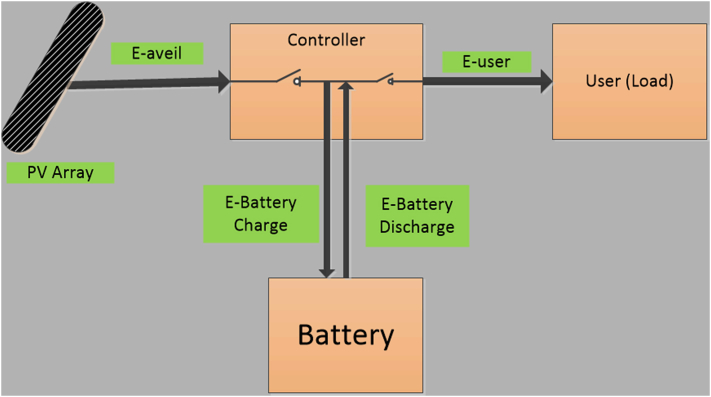

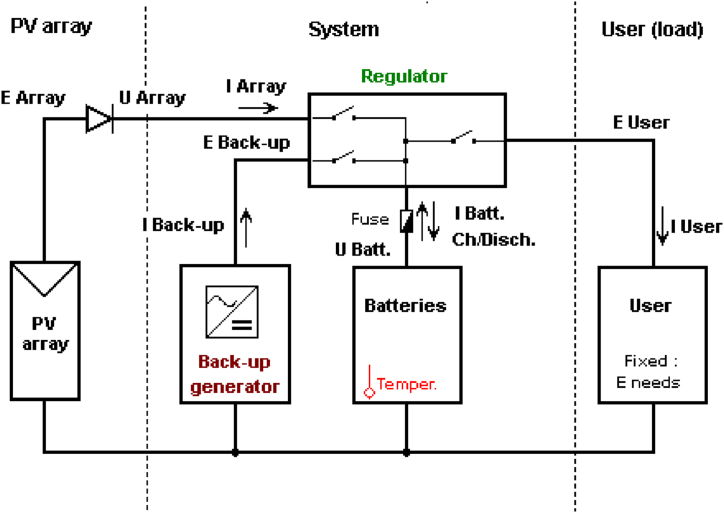

A small standalone system is mostly installed in houses and delivers almost 50 to 200 Wp. With this system TV, radio, computer, and fridge are mostly connected. One PV module is usually used and connected to the battery. The PV module is 36 or 72 cells. The system is very simple and assembled shown in Fig. 1. A PV array is connected to a controller that is attached to the batter and fed to power to the consumer.

Fig. 1.

Small stand-alone system.

2.3. Medium stand-alone system

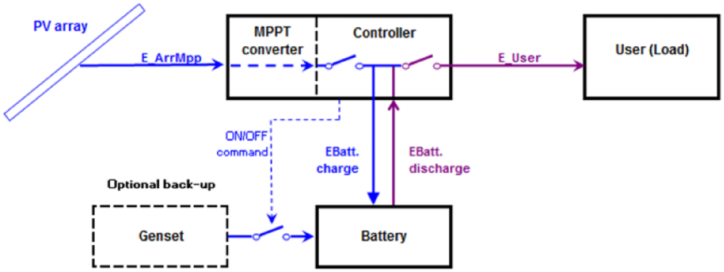

This medium power standalone system ranges between 200 to 2 KW. This system is shown in Fig. 2, the controller has maximum power tracking MPPT topology, which is used for PV array tracking. The controller is used for load control at the user end by compensating the power from the battery, and Genset is used as a backup. In this system energy at the load end will be taken as DC or AC according to the requirement. The Genset is used as a backup solution so this is quite a reliable solution for getting power. This system is mostly used to feed the load to the houses as well as for communication purposes.

Fig. 2.

Medium stand-alone system.

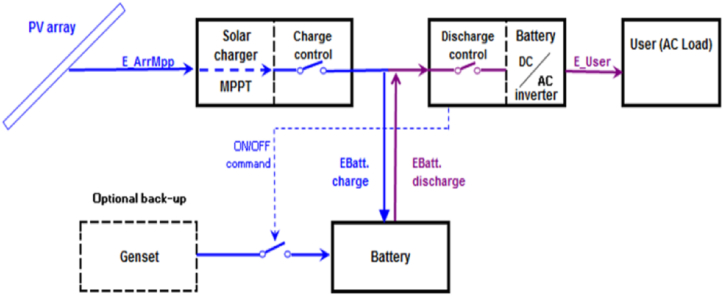

2.4. High power stand-alone system

This high-power PV system has a power range of 2 KW to several dozen KW. This system has solar chargers, DC/AC batteries as well as MPPT converters. In PVsyst solar chargers are used as the controller of the stand-alone system. It has a backup solution in the form of a Genset. The inverter is also used to manage the power that is coming from the backup Genset. Fig. 3 shows the high-power stand-alone PV array model for the load end. This type of system is mostly used for houses, communication, isolated small industries, small buildings, etc.

Fig. 3.

High-power stand-alone system.

2.5. PVsyst working

PVsyst is a software tool that is widely used in the solar industry for designing and analyzing photovoltaic (PV) systems. The software is designed to model and simulate the performance of solar energy systems, including the sizing of components, energy yield, and financial analysis [22,23].

Data of the given site is fed to this software to generate a detailed model of the PV system. The simulation study estimates the energy yield, calculates the expected return on investment (ROI), and performs other analysis tasks. PVsyst can also be used to model shading effects on the PV array. The shading effect has a significant impact on the energy yield of a system. The software includes a 3D shading simulation tool that allows you to model shading from nearby objects such as trees or buildings. Overall, PVsyst is a powerful tool for designing and analyzing PV systems. It is widely used by solar professionals around the world. It has the following attributes.

-

•

PVsyst includes a comprehensive database of solar panels and inverters, which can save time in the design process. However, it's important to note that the software does not include every product on the market, so you may need to manually input data for certain components.

-

•

PVsyst allows you to model different types of PV systems, including grid-connected, off-grid, and hybrid systems. You can also model systems with multiple inverters or strings, and you can customize the layout of the PV modules to optimize energy production.

-

•

In addition to energy yield analysis, PVsyst can also perform financial analysis of PV systems. The software can calculate the net present value (NPV), internal rate of return (IRR), and other financial metrics to help you evaluate the economic feasibility of a project.

-

•

PVsyst is often used in conjunction with other software tools, such as CAD software for 3D modelling of the PV system and weather data software for inputting local meteorological conditions. PVsyst also has an application programming interface (API) that allows it to be integrated with other software systems.

-

•

PVsyst is a proprietary software tool developed by a Swiss company called PVsyst SA. The software is available for purchase on a subscription basis, with different pricing options based on the number of installations and the level of support needed.

2.6. Types of PV power plant

There are three types of PV power plants which have their pros and corns.

-

•

Off-grid PV power plant

-

•

On-grid PV power plant

-

•

Hybrid PV power plant

2.6.1. Off-grid PV power plant

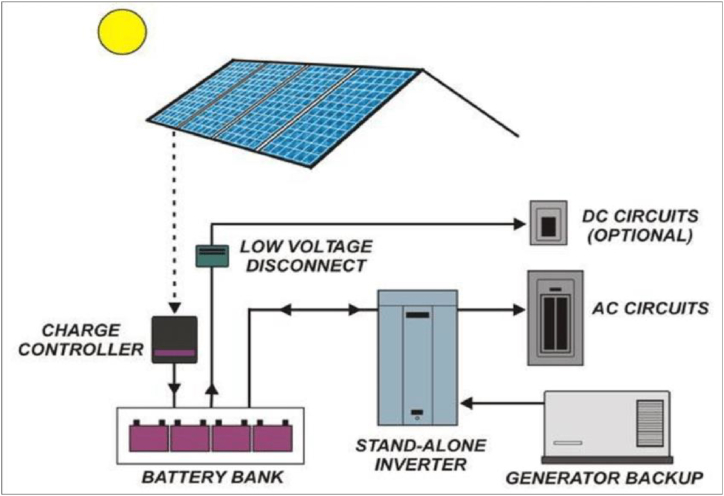

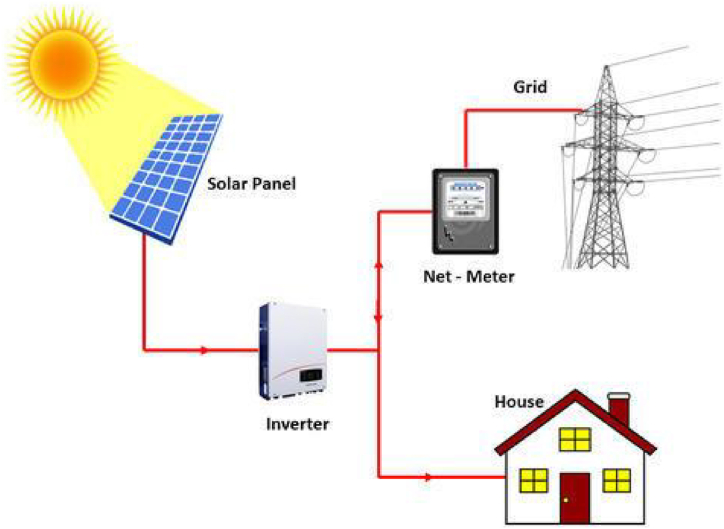

This type of PV power plant does not have any connection with a grid station and uses battery backups or cells for storage of surplus energy produced by the PV system. This system is suitable to supply power to remote areas [[24], [25], [26], [27]]. To cover 100 % of load demands there should be an alternative power source in case the weather conditions are not good. Multiple charging sources or generators will be used in that case which makes this system quite expensive. In this type of PV system (Fig. 4), a stand-alone inverter is used to convert DC power produced by PV modules to AC power.

Fig. 4.

Off-grid PV power system.

2.6.2. On-grid PV power plant

This type of PV system (Fig. 5) does not have any alternate source for energy storage. It is simply connected to the grid station and sends surplus power produced by PV modules to the utility grid. A grid-tied inverter is used for this type of PV plant. It is suitable for those areas which are directly connected to the grid station [[28], [29], [30], [31]]. In the case of the rainy season or windy season time, the generation of PV modules decreased due to the unavailability of solar radiation. In this case, the required power demand is fulfilled by the grid station. This system is cheaper than an Off-grid system because it does not require any alternate energy storage system. The main disadvantage of an on-grid system is that when the supply from the grid goes off, this PV system will also shut down. The main reason for this is to protect the lineman working on transmission and distribution lines (see Fig. 6).

Fig. 5.

ON-grid PV system.

Fig. 6.

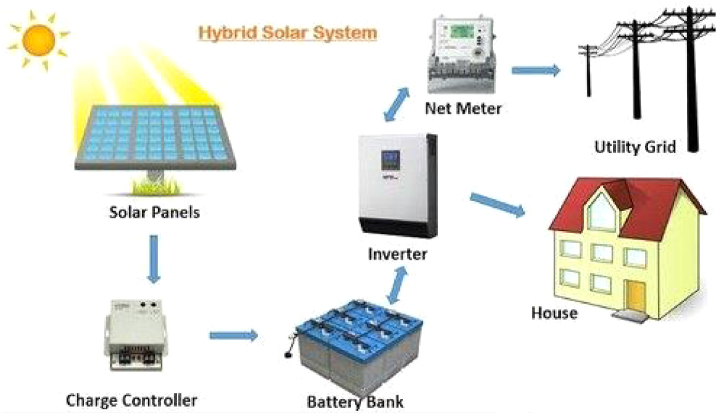

Hybrid PV system.

2.6.3. Hybrid power plant

In this type of PV system despite having connected to a grid station, an al-ternate source for backup is also there to avoid power outages. For industries, offices and highly imported places where there is always a need for power supply in any case. In this system battery backup or other storage system is used for power supply in case of power outage from PV modules and by utility grid [32,33]. It also required a sub-panel to choose which equipment will only use backup power. A charge controller is required to protect batteries from overcharging. As more components are required in this system, it becomes more expensive.

2.7. Types of PV technology

There are three types of PV technologies. The combination of PV cells combine to form a PV panel. The PV panels combine to form a PV array. There are three different types of technologies of PV cells manufactured from different techniques as.

-

•

Monocrystalline silicon PV panel

-

•

Polycrystalline PV panel

-

•

Amorphous silicon PV panel

2.7.1. Monocrystalline silicon PV panel

The other name used for the monocrystalline panel is “single-crystalline” is easily identifiable by its colour. It is made from a pure type of silicon material. Pure type means that the alignment of silicon molecules is perfectly arranged. This arrangement makes this material more efficient at converting sunlight to electrical energy. The highest efficiency documented of the monocrystalline cell is 22.8 %. It is the best-performing PV panel in today's market.

2.7.2. Polycrystalline PV panel

The polycrystalline panel has a blue hue instead of a black colour. It generally has a lower efficiency than monocrystalline panels but a lesser cost. Instead of using a single crystalline cell, manufacturers melt the fragments of silicon and make a wafer of the polycrystalline panel. That's why it is also known as a multi-crystalline panel. As there are numerous crystals in each cell, the electrons have less freedom to move and consequently convert a lower amount of solar energy into electrical energy as a result. It has lower efficiency as compared to monocrystalline panels. The maximum efficiency of the polycrystalline documented is 17.2 %.

2.7.3. Amorphous silicon PV panel

Amorphous silicon PV panels are less efficient. The maximum efficiency documented is ranges from 7 % to 13 % and researchers’ efficiency round 16 %. Amorphous PV panels are characterized by the way that different semi-conductor materials are coated on one another from the top to make a series of thin films. The advantage associated with this technology is that it is cost-affected as compared to other crystalline technologies. It is flexible and installed easily where the applications are required.

2.8. PV plant operational performance parameters

The International Energy Agency (IEA) has developed several parameters to examine the performance of On-grid photovoltaic power plants. These parameters define the overall performance of the plant.

-

•

Reference yield

-

•

Final yield

-

•

Capacity utilization factor

-

•

Performance ratio

-

•

PV module efficiency

-

•

Inverter efficiency

-

•

System efficiency

2.8.1. Reference yield

The reference yield (Yr) is given by the total in-plane irradiation (Ht) divided by the PV's reference irradiation (G). If G is considered to be equal to 1 kW/m2, then Yr will be the peak sun hours or the solar irradiation as kWh/m2. The Yr defines the solar irradiance resource for photovoltaic plants. It is a function of the location, the orientation of the Photovoltaic array and the weather variability throughout the year.

Its unit is kWh/kW per day.

| (1) |

| (2) |

2.8.2. Final yield

The final yield (Yf) is defined as the total output of AC energy (EAC) during a fixed time interval divided by the nameplate DC power of the installed photovoltaic array (Pmax). It shows the time for the operation of the Photovoltaic array at its rated power to give the same amount of energy.

The Yf is given by:

| (3) |

2.8.3. Performance ratio

The performance ratio (PR) is simply defined as the final yield of the PV plant divided by the reference yield. The PR is dependent on the total losses of the plant during the conversion process made by different components such as cables, solar panels, and inverters. The outdoor parameters which include solar irradiation, ambient temperature, and size of the aperture area are also impacting factors.

| (4) |

2.8.4. Capacity utilization factor

The capacity utilization factor (CUF) for a specific period is defined as the actual output of the photovoltaic power plant divided by the theoretical output of the PV plant for the same period. The capacity utilization factor is given as,

| (5) |

2.8.5. PV module efficiency

The efficiency photovoltaic module is given by,

| (6) |

Where Edc is the total energy generated by the PV modules, Ht is the total in-plane solar radiation and, St is the total area which is occupied by the PV modules.

2.8.6. Inverter efficiency

The inverter efficiency is given by the AC power produced by the inverter divided by the DC power generated by the photovoltaic power plant. The instantaneous efficiency of the inverter is given as,

| (7) |

2.8.7. System efficiency

The instantaneous efficiency of the system is given by the product of inverter efficiency and the efficiency of PV module,

| (8) |

2.9. Outdoor performance parameters

The weather conditions at the plant site affect the performance of the PV power plant. These conditions are dynamic for any site. So, the performance of PV plant varies according to these conditions. Following are the outdoor weather conditions or outdoor performance parameters which are used to analyze the efficiency of the performance of PV plants.

-

•

Solar irradiance

-

•

Ambient temperature

2.9.1. Solar irradiance

Sunlight falling on the earth is called solar irradiation. These radiations can be converted into the electrical forms of energy. The PV modules are used for this purpose. The solar irradiance falling on the PV panels is converted into the electrical form of power. The more solar irradiations falling on the PV module produce more energy. The feasibility of PV plant installation for any site is checked by the solar irradiations falling on that site throughout the year.

2.9.2. Ambient temperature

Ambient temperature is the outdoor temperature of any place where the sunlight is falling directly. The ambient temperature is one of the main factors hurting the performance of PV plants. The PV module has specific operating values of ambient temperature. After increasing the operating cell temperature. The voltages of the PV panel start to decrease due to which the power generation of the plant starts decreasing. The ambient temperature of the site should be considered during the design phase.

In this article, PVsyst software is used for planning and electrifying the remote areas of Roonghan. The data is taken from three different places in Roonghan that's Shops located in specific areas, Residential houses and the Basic Health Unit Hospital.

3. Results

3.1. PV panel Modeling for shops

PV panel simulation is done for the shops of Roonghan which is located at 30° 09′16″N 70° 12′37″E and 646m above sea level. There are 3–4 shops for which the simulation is done. The average daily time of usage of power for different types of appliances is mentioned in Table 1.

Table 1.

Average daily usage of various appliances.

| No. of Appliances | Appliances | Power | Daily Use (h/day) | Daily Energy (Wh) |

|---|---|---|---|---|

| 9 | Lamps (LED or Florescent) | 40 W/lamp | 10 | 3600 |

| 3 | TV/PC/Mobile | 30 W/app | 06 | 540 |

| 5 | Fridge/Deep Freezer | 250 KWh/day | 24 | 1250004 |

| 4 | Fans | 80 W/app | 15 | 4800 |

| Total daily energy | 1258968 Wh/day | |||

| Monthly energy | 37769.0 KWh/mth | |||

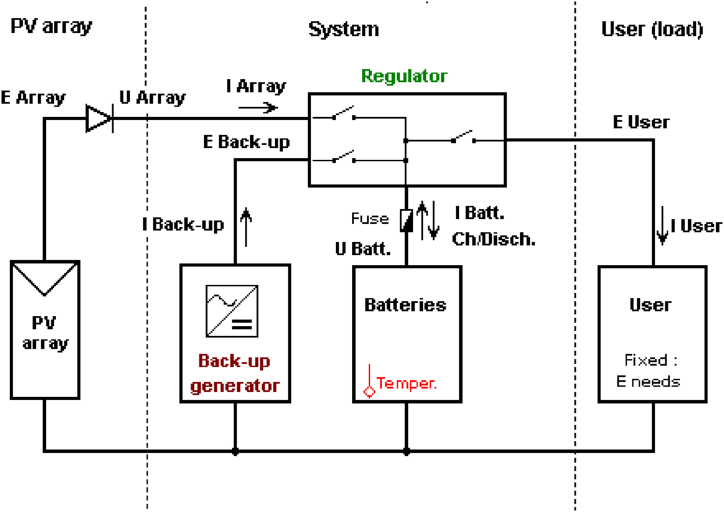

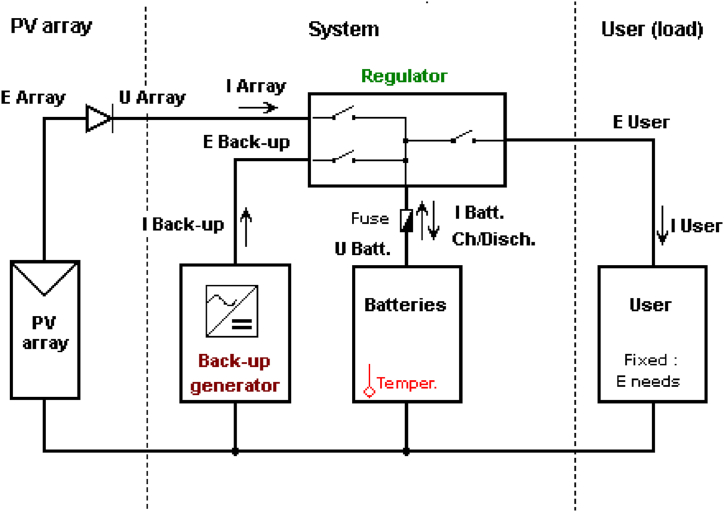

The storage system that is installed is comprised of Generic Pb open plate 100, 12V, and 100Ah. The lead-acid batteries installed are 247 in parallel and 20 in series. The fixed temperature at which they are installed is 20oC. After the selection of batteries, the PV array is selected that is of Jinko solar polysilicon type plates having 200Wp, 21V, and the model is JKM 200 PP-48. It is installed at a 30° tilt angle which is an average angle of winter and summer sun path to get maximum power output. The PV array is between 1179 and 1769, in our case 1473 strings are used for getting the required power. The number of modules that are installed is 315 that covered almost 414 m2 of area for the installation of PV plates. For taking the power at the output side MPPT converter is also used which is 240V and 48A. The overall system is an off-grid solar PV battery backup system so there is no need for backup generators. The overall stand lone system model is shown in Fig. 7. Right side of this model shows PV array. Left side of this model shows the consumer side. However, in the middle portion there is a regulator, batteries. The backup generator is bypassed in this model.

Fig. 7.

Typical Layout of the stand-alone system for shops in Roonghan.

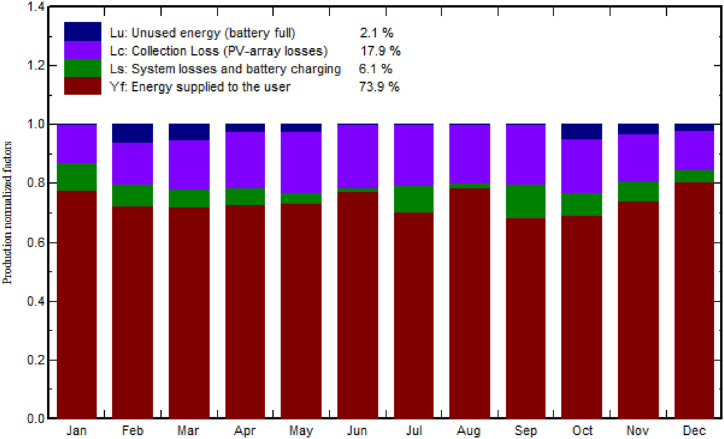

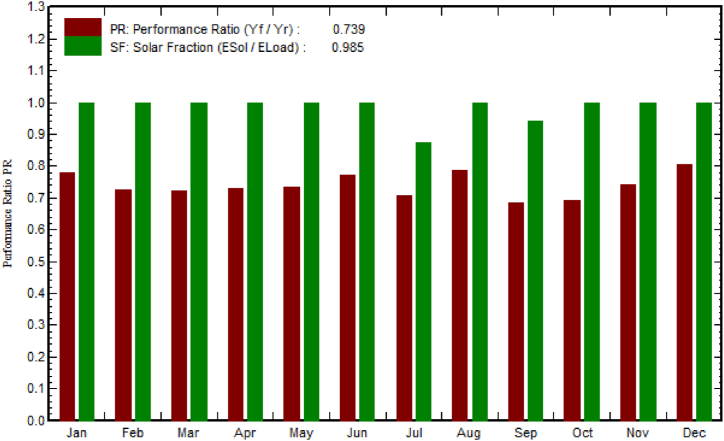

The simulation is done for the whole year 365 days that contain the data for summer and winter. The data used from the simulation is taken from the NASA-SSE satellite data 1983–2005 [34]. The simulation results show in Fig. 8, the production normalized factor is discussed over the month of the whole year.

Fig. 8.

Normalized production and loss factors: Nominal power 295 kW.

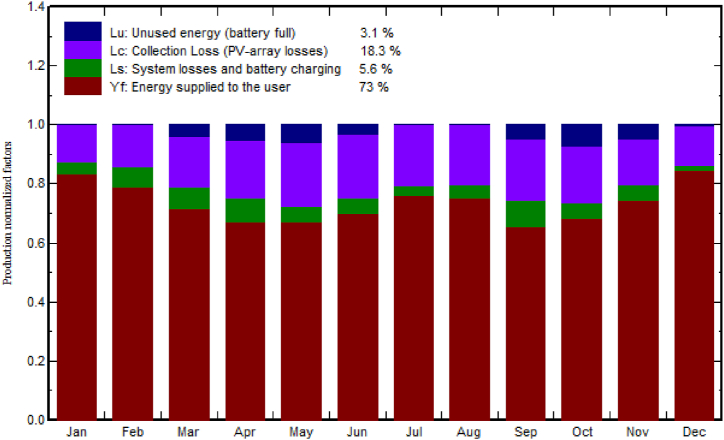

In Fig. 9, shows the performance ratio (PR) and solar fraction (SF) of 12. The SF is constant over a year that is 0.985 but the PR is affected over the year due to various factors including the losses and load variations. The average PR is 0.739 for the complete year.

Fig. 9.

Performance ratio and Solar fraction over a year.

Monthly data used for simulation is presented in Table 2. This data is arranged for the global horizons, global effects on the PV panels, user demands in a month, and the load.

Table 2.

Monthly data used for the simulations.

| GlobaHor kWh/m2 | GlobEff kWh/m2 | E_Avail kWh | EUnused kWh | E_Miss kWh | E_User kWh | E_Load kWh | SolFrac ratio | |

|---|---|---|---|---|---|---|---|---|

| January | 111.3 | 166.8 | 41865 | 0 | 0 | 39028 | 39028 | 1.000 |

| February | 121.2 | 161.9 | 40129 | 2887 | 0 | 35251 | 35251 | 1.000 |

| March | 155.6 | 179.7 | 43316 | 2665 | 0 | 39028 | 39028 | 1.000 |

| April | 169.5 | 171.5 | 40160 | 1239 | 0 | 37769 | 37769 | 1.000 |

| May | 191.6 | 176.0 | 40307 | 1155 | 0 | 39028 | 39028 | 1.000 |

| June | 183.0 | 161.2 | 36691 | 0 | 0 | 37769 | 37769 | 1.000 |

| July | 176.7 | 160.0 | 36596 | 0 | 4889 | 34139 | 39028 | 0.875 |

| August | 169.0 | 164.6 | 38071 | 2 | 0 | 39028 | 39028 | 1.000 |

| September | 156.9 | 172.5 | 39673 | 2 | 2195 | 35574 | 37769 | 0.942 |

| October | 147.3 | 187.8 | 44222 | 2638 | 0 | 39028 | 39028 | 1.000 |

| November | 115.8 | 1690.8 | 41344 | 1546 | 0 | 37769 | 37769 | 1.000 |

| December | 102.9 | 161.0 | 40174 | 829 | 0 | 39028 | 39028 | 1.000 |

| Year | 1800.8 | 2032.7 | 482548 | 12963 | 7081 | 452438 | 459519 | 0.985 |

The total production of the off-grid solar PV system that is designed for the shops in Roonghan is 602,649 kWh but the power at the load end is 459,523 kWh. The losses are almost 143,126 kWh. These losses including the temperature losses that is almost 11.3 % of the total power produced, almost 4.5 % are Ohmic and wiring losses, 4.1 % losses of the converter when it is in operation mode, and few other losses 2.2 % battery efficiency losses, 2.1 % modules and string losses, 1.8 % charging and discharging losses and current efficiency losses, etc. shown in Fig. 10.

Fig. 10.

Losses profile of shops in Rooghan.

3.2. PV panel Modeling for residential areas

PV panel simulation is done for the shops of Rooghan that are located at 30° 09′35″N 70° 12′08″E and 654m above sea level. There are almost 20 to 25 houses. The simulation is done according to the load. The average daily time of usage of power for different types of appliances is considered as mentioned in Table 3.

Table 3.

Average daily usage of various appliances.

| No. of Appliances | Appliances | Power | Daily use (h/day) | Daily energy (Wh) |

|---|---|---|---|---|

| 88 | Lamps (LED or Florescent) | 40 W/lamp | 12 | 42240 |

| 16 | TV/PC/Mobile | 25 W/app | 09 | 3600 |

| 11 | Fridge/Deep Freezer | 1.50 kWh/day | 24 | 16500 |

| 22 | Water Pump/Motors | 250 W/app | 08 | 44000 |

| 57 | Fans | 78 W/app | 17 | 75582 |

| Total daily energy | 181946 Wh/day | |||

| Monthly energy | 5458.4 KWh/mth | |||

The storage system comprises of a Generic li LFP 25.6V, 180Ah, Lithium-ion batteries that are 46 in parallel and 4 in series. The fixed temperature at which they are installed is 20oC. The Jinko solar polysilicon type plates having 200Wp, 21V, and the model is JKM 200 PP-48. It is installed at a 30° tilt angle that is an average angle for winter and summer to get maximum power output. The PV array is between 178 and 266, in our case 222 strings are used for getting the required power. The number of modules that are installed is 222 that covered almost 292 m2 of area for the installation of PV plates. The MPPT converter is used with 240V and 48A for sun tracking. The overall system is an off-grid solar PV battery backup system. The overall stand-alone system model is shown in Fig. 11.

Fig. 11.

Typical Layout of the stand-alone system for residential load in Roonghan.

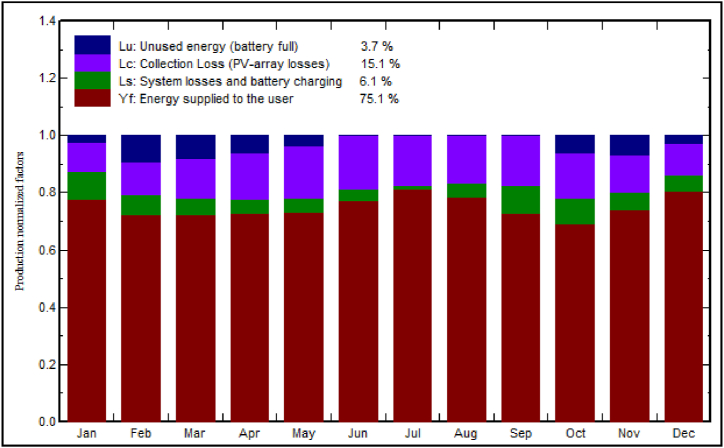

The simulation is done for the whole year 365 days that contain the data for summer and winter. The data used for simulation purpose is taken from the NASA-SSE satellite data [34]. The simulation results show production of normalized factor and loss factor over the year month wise (Fig. 12).

Fig. 12.

Normalized production and loss factors: Nominal power 295 kW.

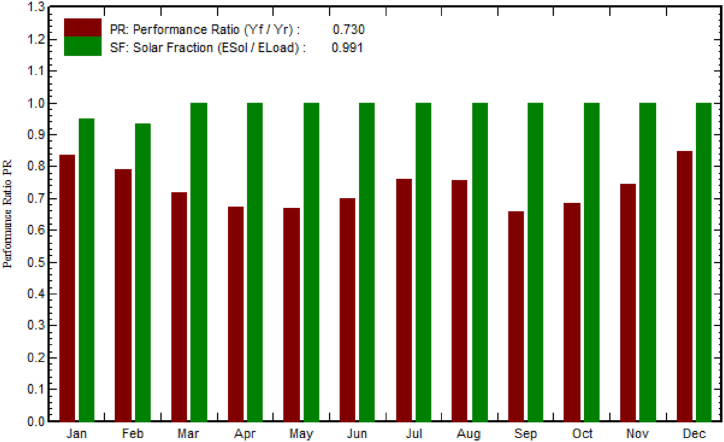

Fig. 13 shows the performance ratio PR over the 12 months of the year and the solar fraction SF. SF is constant over a year that is 0.991 but the performance ratio is affected over the year due to various factors including the losses and load variations. The average PR is 0.730 for the complete year.

Fig. 13.

Performance ratio and Solar fraction over a year.

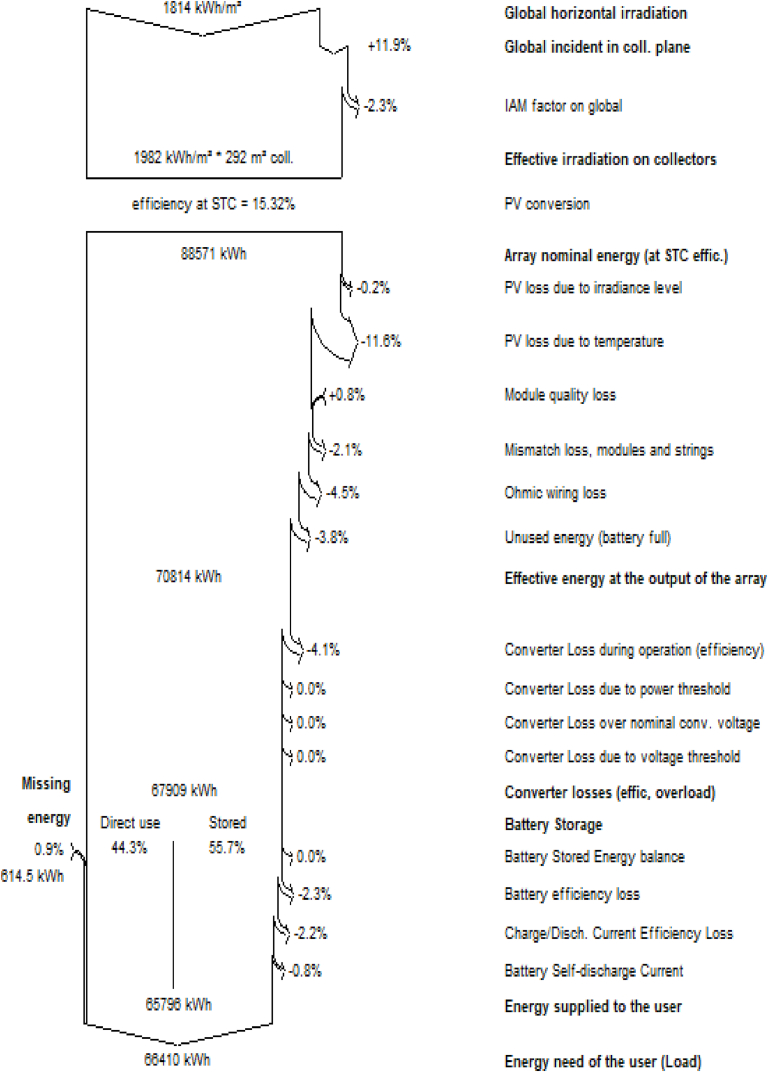

Table 4 present the load data for the global horizons and effects on the PV panels for a month. The total production of the off-grid solar PV system is 88,571 kWh and demand is 66,410 kWh. The losses are almost 22,161 kWh including the temperature losses that is almost 11.6 % of the total power produced, almost 4.5 % are Ohmic and wiring losses, 4.1 % of losses are because of the converter when it is in operation mode, 3.8 % are those losses that are because of unused battery power when the battery is fully charged and few other losses 2.2 % battery efficiency losses, 2.1 % modules and string losses, 1.8 % charging and discharging losses and current efficiency losses, etc. shown in Fig. 14.

Table 4.

Monthly data used for the simulations.

| GlobaHor kWh/m2 | GlobEff kWh/m2 | E_Avail kWh | EUnused kWh | E_Miss kWh | E_User kWh | E_Load kWh | SolFrac ratio | |

|---|---|---|---|---|---|---|---|---|

| January | 101.0 | 141.7 | 5407 | 0.2 | 279.8 | 5361 | 5640 | 0.950 |

| February | 107.6 | 133.1 | 4970 | 0 | 334.7 | 4760 | 5094 | 0.934 |

| March | 153.8 | 173.4 | 6278 | 319.7 | 0 | 5640 | 5640 | 1.000 |

| April | 177.2 | 178.3 | 6282 | 413.5 | 0 | 5458 | 5458 | 1.000 |

| May | 201.1 | 184.4 | 6351 | 506.8 | 0 | 5640 | 5640 | 1.000 |

| June | 191.7 | 170.9 | 5862 | 228.7 | 0 | 5458 | 5458 | 1.000 |

| July | 179.7 | 162.5 | 5608 | 0 | 0 | 5640 | 5640 | 1.000 |

| August | 170.1 | 164.3 | 5683 | 0.2 | 0 | 5640 | 5640 | 1.000 |

| September | 169.2 | 183.0 | 6361 | 407.3 | 0 | 5458 | 5458 | 1.000 |

| October | 147.9 | 181.8 | 6428 | 587.3 | 0 | 5640 | 5640 | 1.000 |

| November | 114.9 | 161.7 | 5953 | 331.3 | 0 | 5458 | 5458 | 1.000 |

| December | 99.5 | 147.2 | 5566 | 25.2 | 0 | 5640 | 5640 | 1.000 |

| Year | 1813.7 | 1982.2 | 70730 | 2820.2 | 614.5 | 65796 | 66410 | 0.991 |

Fig. 14.

Losses profile of residential load in Rooghan.

3.3. PV panel Modeling for hospital

PV panel simulation is done for the Basic Health Unit (BHU) hospital in Roonghan that is located at 30° 09′16″N 70° 12′40″E and 641m above sea level. The average daily time of usage of power for different types of appliances is shown in Table 5.

Table 5.

Average daily usage of various appliances at BHU.

| No. of Appliances | Appliances | Power | Daily Usage (h/day) | Daily Energy (Wh) |

|---|---|---|---|---|

| 25 | Lamps (LED or Florescent) | 40 W/lamp | 19 | 19,000 |

| 2 | TV/PC/Mobile | 26 W/app | 14 | 720 |

| 1 | Refrigerator | 250 KWh/day | 24 | 1,250,004 |

| Total daily energy | 269,744 Wh/day | |||

| Monthly energy | 37769.0 KWh/mth | |||

The system parameters are as 12V, 100Ah lead-acid batteries (53 in parallel and 20 in series). The fixed temperature at which they are installed is 20oC. The PV array is selected that is Jinkosolar polysilicon type plates having 200Wp, 21V and its model is JKM 200 PP-48. It is installed at a 30° tilt angle that is an average angle of winter and summer to get maximum power output. The PV array is between 17 and 23, in our case 21 strings are used for getting the required power. The number of modules that are installed is 315 that covered almost 414 m2 of area for the installation of PV plates. For taking the power at output side MPPT converter is also used which is 240V and 48A. The overall system is an off-grid solar PV battery backup system so there is no need for backup generators. The overall stand alone system model is shown in Fig. 15.

Fig. 15.

Typical Layout of the stand-alone system for the hospital in Roonghan.

The simulation is done for the whole year 365 days that contain the data for summer and winter. The data used from the simulation is taken from the NASA-SSE satellite data 1983–2005 [34]. The simulation results shown in Fig. 16. The production normalized and loss factor is discussed over the whole year month wise.

Fig. 16.

Normalized production and loss factors: Nominal power 295 kW.

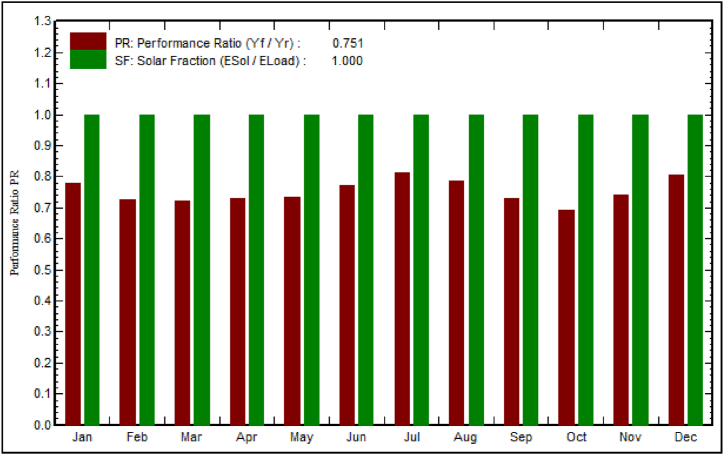

The PR and SF is shown in Fig. 17 over the 12 months of the year. The SF is constant over a year that is 1.0 but the PR is affected over the year due to various factors including the losses and load variations. The average PR is 0.751 for the complete year.

Fig. 17.

Performance ratio and Solar fraction over a year.

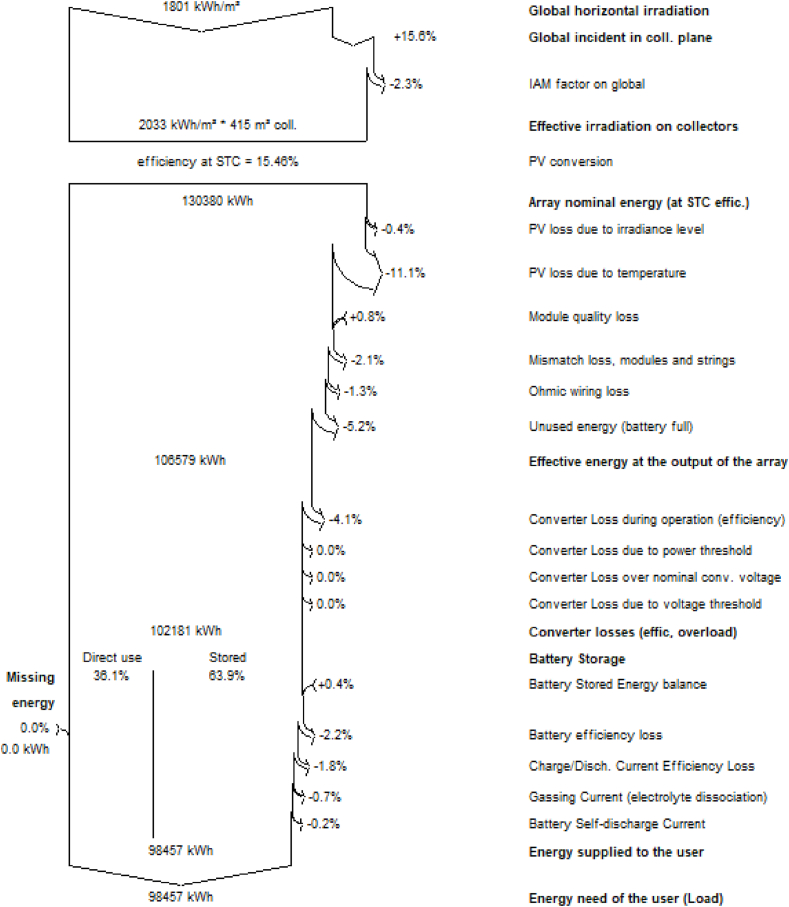

Table 6 present the load data use for simulation purpose for BHU. The total production of the off-grid solar PV system is 130,380 kWh but the load is 98,457 kWh. The losses are almost 31,923 kWh that including the temperature losses that is almost 11.1 % of the total power produced, almost 5.2 % are those losses that are because of unused battery power when the battery is fully charged, 4.1 % of losses are because of the converter when it is in operation mode and few other losses 2.2 % battery efficiency losses, 2.1 % string losses, 1.8 % current efficiency losses, as shown in Fig. 18.

Table 6.

Monthly data used for the simulations BHU.

| GlobaHor kWh/m2 | GlobEff kWh/m2 | E_Avail kWh | EUnused kWh | E_Miss kWh | E_User kWh | E_Load kWh | SolFrac ratio | |

|---|---|---|---|---|---|---|---|---|

| January | 111.3 | 167.4 | 9279 | 246.1 | 0 | 8362 | 8362 | 1.000 |

| February | 121.2 | 162.4 | 8888 | 938.2 | 0 | 7553 | 7553 | 1.000 |

| March | 155.6 | 179.6 | 9568 | 903.2 | 0 | 8362 | 8362 | 1.000 |

| April | 169.5 | 172.0 | 8935 | 663.0 | 0 | 8092 | 8092 | 1.000 |

| May | 191.6 | 175.6 | 8934 | 410.9 | 0 | 8362 | 8362 | 1.000 |

| June | 183.0 | 161.6 | 8135 | 0 | 0 | 8092 | 8092 | 1.000 |

| July | 176.7 | 158.7 | 8109 | 0 | 0 | 8362 | 8362 | 1.000 |

| August | 169.0 | 164.6 | 8478 | 0.3 | 0 | 8362 | 8362 | 1.000 |

| September | 156.9 | 172.0 | 8805 | 0 | 0 | 8092 | 8092 | 1.000 |

| October | 147.3 | 188.0 | 9792 | 723.9 | 0 | 8362 | 8362 | 1.000 |

| November | 115.8 | 170.3 | 9162 | 724.2 | 0 | 8092 | 8092 | 1.000 |

| December | 102.9 | 161.7 | 8904 | 276.5 | 0 | 8362 | 8362 | 1.000 |

| Year | 1800.8 | 2032.9 | 106990 | 4886.2 | 0 | 98457 | 98457 | 1.000 |

Fig. 18.

Losses profile of BHU in Rooghan.

3.4. Techno-economic analysis

3.4.1. Technical and economic analysis of power from the grid system

To build a transmission line for remote area is challenge for governments. Specially those area having scatter population and lesser load. There are technical barriers to erect a transmission line from nation grid to remote area. Firstly, the high voltage alternative current (HVAC) lines need powerful and strong poles for long distance. Secondly, communication line is compulsory for long transmission line for communication and protection. Thirdly, for long transmission line losses is increased, even huge capital cost, land cost. The operational cost is also not a reliable solution. One of the key factors in the Southern Punjab region is theft. The theft rate in southern areas is high but lower as compared to Sindh and Khyber Pakhtunkhwa. According to the survey report that is published in 2021. The rate of theft of electricity in 2018 reached to rupees 53 billion. Due to lack of monitoring policies and planning this theft rate is increased to 2.3 trillion rupees in 2019. A transmission line 177 Km from Multan to Roonghan has been proposed. According to the length and technical point of view 132 KV voltage level has been considered. There is no proper road approach to this remote area. To monitoring such a long transmission line is another issue. Due to long distance the power losses will be dominant. A number of issues are related to economic analysis like installation, maintenance, operation, and other charges. Due to these problems to erect the transmission like is not the viable solution. Table 7 present the economic analysis of power supply through grid.

Table 7.

Comparison of grid supply vs off-grid solar PV.

| Types | Grid Connection cost analysis | From Multan to Roonghan cost analysis | Off-grid Solar PV system cost analysis | |

|---|---|---|---|---|

|

Tower Type |

Price, $/pc |

Price, $ for 531 towers |

Price $ 220 V, 60 towers |

|

| 132 kV |

Suspension tower | 2698029.92 | 1432653888 | 539605.98 |

| Angle-suspension tower | 4721553.05 | 2507144670 | 944310.60 | |

| Tension tower |

8094089.77 |

4297961668 |

1618817.95 |

|

|

Conductor Type |

Price, $/unit |

Price, $/unit |

Price, $/unit |

|

| ACSR 305/39 DUCK | 518183.20 $/km | 917183945.4 $ | 103636.63 | |

| ACSR 565/72 FINCH | 954548 $/km | 168954996 $ | 190909.59 | |

| HV Connections |

4090.92 $/pc |

2172278.52 $ |

818.184 |

|

|

Overhead ground wire |

Price, $/unit |

Price, $/unit |

Price, $/unit |

|

| AACSR 106/25 Sustrong | 238637 $/km | 42238749 $ | 47727.39 | |

| HV Connections | 4090.92 $/pc | 2172278.52 $ | 818.184 | |

| Earthing connections | 122.73 $/pc | 65169.63 $ | 24.546 | |

3.4.2. Technical and economic analysis for solar PV off-grid system

The Solar PV off-grid system is viable in remote areas because the transmission line cost has not been involved in that system. The solar PV is installed near the load center so that it does not require long transmission lines and a transmission network. The consumer associated with the off-grid solar PV system will be entertained by the PV harvested power. The production of DC can be converted to AC using the inverters. AC supply is integrated to local distribution network for end users. Residential and commercial appliances that includes the fans, lights, motors, freezers, television, laptops, air conditioners, etc for daily use. In off-grid system, there is least infrastructure because it is near to the load center. Specially those area that are far from the generation stations and scattered population. The off-grid solar PV is more reliable because of the easy availability of large and open space for installation. It's also need least maintenance and operation charges. For the continuity of supply battery bank can be use. During the off peak demand the battery bank can be charged and it can be use when there is no availability of sun. As compared to the other solution the off-grid solar PV system is the best solution. Those areas that are far away from the grid stations. Especially, those area less population and living in the form of tribes and settled in the scattered form over the mountains. In the off-grid solar PV system no long transmission line nor infrastructure is required. It is because the transmission lines are used in those areas having a large population. The off-grid solar PV contains only the PV arrays, MPPT, converters, wiring, battery banks, and some other things to drive the system properly like charge controllers. The off-grid solar PV model that is planned for the remote areas of DG Khan needs only a 220V distribution line to entertain the load connected.

4. Discussion

The comparison between grid supply and off-grid solar PV systems involves a comprehensive analysis of various cost factors outlined in Table 7. Firstly, examining the grid connection costs. It is evident that the expense varies significantly depending on the type of tower required. Suspension towers have priced at approximately $2,698,029.92 per piece. For 531 towers are needed for this distance. The total cost for all towers will be $1,432,653,888. Similarly, angle-suspension towers and tension towers incur even higher costs, totaling $2,507,144,670 and $4,297,961,668 respectively.

For ACSR 305/39 DUCK conductor, priced at $518,183.20 per kilometer. The total cost of 531 km will be $917,183,945.4 for 531. For ACSR 565/72 FINCH conductor, $954,548 per kilometer, total cost of 531 Km will be $168,954,996. Additionally, high-voltage (HV) connections add to the expenditure, with each piece costing $4090.92, accumulating to $2,172,278.52 in total. Overhead ground wire, for AACSR 106/25 Substring priced is $238,637 per kilometer. So, the total price will be $42,238,749. HV connections and earthing connections will further increase the costs, with each piece priced at $4090.92 and $122.73 respectively.

Comparing with the off-grid solar PV system presents a different cost structure. Tower types for this system are priced at $539,605.98 for 220V, with a total of 60 towers. Conductor types vary in price, with 220V and 380V options costing $103,636.63 and $190,909.59 respectively for 60 units each. HV connections for the off-grid system are priced at $818.184 for 60 pieces. Overhead ground wire costs include $47,727.39 for 60 units of 220V, along with HV connections and earthing connections, each priced at $818.184 and $24.546 respectively for 60 pieces each.

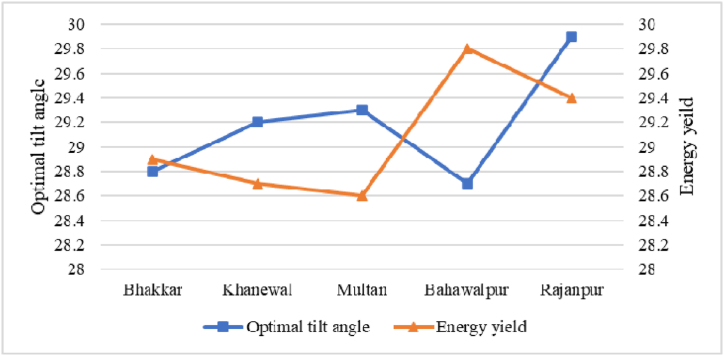

The results of Table 7 shows that if power plant is near to load center the cost of electricity will be lesser as compare to off-grid PV system. On other word, if load center is far away from load center than off-grid PV system will be more economic. For a long-distance cost of towers, conductor, and installation will become very expensive. However, due to off-grid PV connection is near to load center the over all cost is lesser. If other factor will be considered like fossil fuels prices, distance from consumer, environmental concerns, and reliability point of view, and potential of PV in particular area the calculation will be completely different. Fig. 19 illustrate the tilt angle with energy yield in Roonghan region.

Fig. 19.

Optimal tilt angles of specific regions.

5. Conclusion

Electrification of remote area is challenge for government in Pakistan. The main reason to provide the electricity to these regions is for improving living standard, promote economic development, reducing poverty. There are two model to provide electricity to those areas. Firstly, through national grid and secondly through non-conventional sources. A case study was carried out to find out which model is suitable. In this study a remote area Rooghan of DG Khan was consider that is 177 Km away from national grid, Multan. One way is to provide electricity through national grid and other one is through PV system. PV system was considered for comparison purpose due to high potential of PV generation in that region. Techno-economic analysis was carried out to find out the best possibility. Different model of PV system was discussed like off-grid, on-grid, and hybrid PV. According to the technicalities, off-grid PV system is more suitable option due to long distance from national grid. The results show that if distance is long from national grid. It is better to use off-grid PV system for power supply. Specially for long distance having lesser load and scattered population. To provide electricity in those area through national grid has technical and economic issues. Technical issues included high transmission loss, voltage fluctuation, and hefting. For economic point of view high cost of towers, conductors, monitoring and maintenance cost, etc. The results show that to provide electricity through national grid having cost $26.98 corer including installation of towers, conductor, and misalliances. However, to provide electricity through off-grid PV system having cost $2.16 corer that is almost 12 % cheaper. Technically the off-grid solar PV that is designed for shops of Rooghan village utilizes almost 73.9 % of energy, for the commercial sector it utilizes around 73 % of energy whereas the BHU the hospital utilizes 75.1 % of the generated energy. This research reveals that to provide electricity in remote area through off-grid is viable solution. The policy makers can make a concrete legislation to provide electricity in remote rear through off-grid for the betterment of peoples. Moreover, the integration of battery energy storage with renewable energy sources not only achieves a notable 5 % annual energy cost reduction but also enhances self-sufficiency, offering a significant advancement in the field.

Funding

This study was supported by the Science and Technology projects from State Grid Corporation, P. R. China (Grant number 5108-2018280A-2-379-XG).

Data availability statement

The data that support the findings of this study will be available on request from the corresponding author.

CRediT authorship contribution statement

Li Bin: Project administration, Investigation, Funding acquisition. Muhammad Shahzad: Software, Methodology, Formal analysis, Conceptualization. Muhammad Farhan: Visualization, Validation. Muhammad Ayoub: Validation, Formal analysis. Saqib Ali: Writing – review & editing. Girmaw Teshager Bitew: Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Khatri S.A., Harijan K., Uqaili M.A., Shah S.F., Mirjat N.H., Kumar L. Solar photovoltaic potential and diffusion assessment for Pakistan. Energy Sci. Eng. 2022;10:2452–2474. [Google Scholar]

- 2.Bin Abdullah F., Iqbal R., Hyder S.I., Jawaid M. Energy security indicators for Pakistan: an integrated approach. Renew. Sustain. Energy Rev. 2020;133 [Google Scholar]

- 3.Qiu L., Wang X., Wei J. Energy security and energy management: the role of extreme natural events. Innov. Green Dev. 2023;2 [Google Scholar]

- 4.Bin L., Shahzad M., Bing Q., Ahsan M., Shoukat M.U., Khan H.M.A., Fahal N.A.M. The probabilistic load flow analysis by considering uncertainty with correlated loads and photovoltaic generation using copula theory. AIMS Energy. 2018;6:414–435. doi: 10.3934/energy.2018.3.414. [DOI] [Google Scholar]

- 5.Bin L., Shahzad M., Bing Q., Fahal N.A.M., Islam M.R., Shoukat M.U., Ahsan M. Probabilistic load flow analysis of power system network considering uncertainty with generation and correlated loads. IJSSST. 2018;19:1–6. doi: 10.5013/IJSSST.a.19.03.06. [DOI] [Google Scholar]

- 6.Li B., Muhammad S., Qi B., Muhammad R.Z., Rabiul I., Us M. Probabilistic power flow model to study uncertainty in power system network based upon point estimation method. Am. J. Electr. Power Energy Syst. 2017;6:64–71. [Google Scholar]

- 7.Bin L., Abbas R., Shahzad M., Safdar N. Probabilistic load flow analysis using nonparametric distribution. Sustainability. 2024;16 doi: 10.3390/su16010240. [DOI] [Google Scholar]

- 8.Khattak S., Yousif M., Hassan S.U., Hassan M., Alghamdi T.A.H. Techno-economic and environmental analysis of renewable energy integration in irrigation systems: a comparative study of standalone and grid-connected pv/diesel generator systems in khyber pakhtunkhwa. Heliyon. 2024;10 doi: 10.1016/j.heliyon.2024.e31025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Arif S., Taweekun J., Ali H.M., Ahmed A., Bhutto A.A. Building resilient communities: techno-economic assessment of standalone off-grid pv powered net zero energy (nze) villages. Heliyon. 2023;9 doi: 10.1016/j.heliyon.2023.e21426. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Tahir Z.R., Asim M. Surface measured solar radiation data and solar energy resource assessment of Pakistan: a review. Renew. Sustain. Energy Rev. 2018;81:2839–2861. [Google Scholar]

- 11.Cabraal R.A. 2nd Int. Conf. Dev. Renew. Energy Technol. (ICDRET 2012) IEEE; 2012. Experiences and lessons from 15 years of World Bank support for photovoltaics for off-grid electrification; pp. 1–4. [Google Scholar]

- 12.Gebrehiwot K., Mondal M.A.H., Ringler C., Gebremeskel A.G. Optimization and cost-benefit assessment of hybrid power systems for off-grid rural electrification in Ethiopia. Energy. 2019;177:234–246. [Google Scholar]

- 13.Prevedello G., Werth A. The benefits of sharing in off-grid microgrids: a case study in the Philippines. Appl. Energy. 2021;303 [Google Scholar]

- 14.Moussa R.K. Does solar home system promote entrepreneurship in off-grid areas? Heliyon. 2023;9 doi: 10.1016/j.heliyon.2022.e12726. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Ali W., Farooq H., Rehman A.U., Awais Q., Jamil M., Noman A. 2018 Int. Conf. Comput. Electron. Electr. Eng. (ICE Cube) IEEE; 2018. Design considerations of stand-alone solar photovoltaic systems; pp. 1–6. [Google Scholar]

- 16.Badza K., Sawadogo M., Soro Y.M. Adv. Clean Energy Syst. Technol. Springer; 2024. Evaluation of energy payback time (EPBT) and carbon emission by a medium-sized PV power plant in Burkina Faso; pp. 33–41. [Google Scholar]

- 17.Bonthagorla P.K., Mikkili S. Performance investigation of hybrid and conventional pv array configurations for grid-connected/standalone pv systems. CSEE J. Power Energy Syst. 2020;8:682–695. [Google Scholar]

- 18.Yahiaoui F., Chabour F., Guenounou O., Bajaj M., Hussain Bukhari S.S., Shahzad Nazir M., Pushkarna M., Mbadjoun Wapet D.E. An experimental testing of optimized fuzzy logic‐based mppt for a standalone pv system using genetic algorithms. Math. Probl Eng. 2023;2023 [Google Scholar]

- 19.Shrivastava A., Sharma R., Saxena M.K., Shanmugasundaram V., Rinawa M.L. Solar energy capacity assessment and performance evaluation of a standalone pv system using pvsyst. Mater. Today Proc. 2023;80:3385–3392. [Google Scholar]

- 20.Hichem L., Amar O., Leila M. Optimized ann-fuzzy mppt controller for a stand-alone pv system under fast-changing atmospheric conditions. Bull. Electr. Eng. Informatics. 2023;12:1960–1981. [Google Scholar]

- 21.Zheng S., Shahzad M., Asif H.M., Gao J., Muqeet H.A. Advanced optimizer for maximum power point tracking of photovoltaic systems in smart grid: a roadmap towards clean energy technologies. Renew. Energy. 2023;206:1326–1335. [Google Scholar]

- 22.Duhis A.H., Aljanabi M., Al-Kafaji M.S.S. Increasing photovoltaic system power output with white paint albedo–a scenario in al-mausaib city using pvsyst. software. Int. J. Power Electron. Drive Syst. 2023;14:1149–1159. [Google Scholar]

- 23.Roga S., Lokesh A., Jain S., Vinay A.A.N., Chauhan R., Karthik C., Das S., Kumar Y. Renew. Energy Optim. Plan. Control Proc. ICRTE 2022. Springer; 2023. Assessment of sessional solar energy using PVsyst and SAM; pp. 103–110. [Google Scholar]

- 24.Ghafoor A., Munir A. Design and economics analysis of an off-grid pv system for household electrification. Renew. Sustain. Energy Rev. 2015;42:496–502. [Google Scholar]

- 25.Rehman S., El-Amin I. Performance evaluation of an off-grid photovoltaic system in Saudi Arabia. Energy. 2012;46:451–458. [Google Scholar]

- 26.Liu K., Sheng W., Wang S., Ding H., Huang J. Stability of distribution network with large-scale pv penetration under off-grid operation. Energy Rep. 2023;9:1367–1376. [Google Scholar]

- 27.Kuo T.-C., Pham T.T., Bui D.M., Le P.D., Van T.L., Huang P.-T. Reliability evaluation of an aggregate power conversion unit in the off-grid pv-battery-based dc microgrid from local energy communities under dynamic and transient operation. Energy Rep. 2022;8:5688–5726. [Google Scholar]

- 28.Salameh T., Hamid A.K., Farag M.M., Abo-Zahhad E.M. Experimental and numerical simulation of a 2.88 kw pv grid-connected system under the terrestrial conditions of sharjah city. Energy Rep. 2023;9:320–327. [Google Scholar]

- 29.Salameh T., Hamid A.K., Farag M.M., Abo-Zahhad E.M. Energy and exergy assessment for a university of sharjah's pv grid-connected system based on experimental for harsh terrestrial conditions. Energy Rep. 2023;9:345–353. [Google Scholar]

- 30.Argyrou M.C., Marouchos C.C., Kalogirou S.A., Christodoulides P. Modeling a residential grid-connected pv system with battery–supercapacitor storage: control design and stability analysis. Energy Rep. 2021;7:4988–5002. [Google Scholar]

- 31.Bin L., Shahzad M., Omer M., Munir H.M., Raheem A., Shakoor R. Pure sine wave generation in battery-less solar system using advanced control through single machine. Energy Rep. 2024;11:4298–4310. [Google Scholar]

- 32.Da Silva R.M., Fernandes J.L.M. Hybrid photovoltaic/thermal (pv/t) solar systems simulation with simulink/matlab. Sol. Energy. 2010;84:1985–1996. [Google Scholar]

- 33.Abdelrazik A.S., Al-Sulaiman F.A., Saidur R., Ben-Mansour R. A review on recent development for the design and packaging of hybrid photovoltaic/thermal (pv/t) solar systems. Renew. Sustain. Energy Rev. 2018;95:110–129. [Google Scholar]

- 34.Whitlock C.H., Brown D.E., Chandler W.S., DiPasquale R.C., Meloche N., Leng G.J., Gupta S.K., Wilber A.C., Ritchey N.A., Carlson A.B. Release 3 nasa surface meteorology and solar energy data set for renewable energy industry use. Proc. Rise Shine. 2000 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data that support the findings of this study will be available on request from the corresponding author.