Abstract

We proposed and fabricated a miniaturized multi-core fiber grating vibration sensor. The size of the miniaturized vibration sensor is 10mm × 10mm × 10 mm with a mass of only 0.25g. Finite element analysis and experimental tests were carried out to validate the performance of the vibration sensor. The experiment results indicate that the sensor has a sensitivity of 68.72 pm/g in the X direction and 64.52 pm/g in the Y direction within the operating frequency range of 20–240Hz. The cross-interference between the two directions of vibration measurement falls within 4 %. The sensor is suitable for measuring mechanical vibrations in the mid-low frequency range, especially in cases where size, quality, and distributed measurement are of particular concern.

Keywords: Miniaturization structure, Multi-core fiber (MCF), Ultra-short fiber grating, Two-dimensional vibration measurement

1. Introduction

At present, many mature vibration sensors are mostly designed and fabricated based on electrical principles, such as piezoelectric, piezoresistive and eddy current. This kind of sensor has the advantages of wide frequency measurement range, large range, and high resolution, and is widely used in the field of vibration measurement [1]. However, the operating environment of some mechanical equipment is relatively harsh. For instance, power equipment may be exposed to strong magnetic fields, hydraulic equipment may face oil pollution and corrosion, and process equipment might experience extreme temperature variations. [2]. This has brought great limitations to the application of electrical vibration sensors. In recent years, fiber Bragg grating (FBG) vibration sensors have been widely used in structural health monitoring fields such as mechanical equipment [3], aerospace [4], and petrochemical industry [5] due to their advantages of anti-electromagnetic interference, small size [6], light-weight, corrosion resistance [7], long-distance transmission [8], high sensitivity, and multi-point distributed measurement [9].

Optical fiber vibration sensors can be classified into three types depending on their demodulation principles: (i) intensity-based demodulation; (ii) interference demodulation; (iii) fiber Bragg sensors based on wavelength demodulation. The demodulation method of an optical fiber vibration sensor based on intensity demodulation is simple, low-cost, and has a high measurement bandwidth; nevertheless, measurement results are erroneous due to optical fiber bending and light source intensity instability [10]. The fiber optic vibration sensor based on interference demodulation has excellent sensitivity and a large dynamic range, but it is restricted by bandwidth, and the measuring device is expensive [11].

The fiber Bragg vibration sensor based on wavelength demodulation has become a hot topic for scholars at home and abroad due to its advantages of high measurement accuracy, good stability, strong multiplexing ability, and ingenious design [12]. Jiang et al. [13] designed a fiber Bragg grating acceleration sensor based on cantilever beam. The sensor has good performance in the detection of low-frequency vibration signals because it has a flat response from 1 Hz to 60 Hz, and the sensitivity is about 59.3 dB re pm/g. The overall size after packaging is up to 80 mm × 28 mm × 23 mm. Xu et al. [14] proposed a novel FBG sensor with a pendulum structure for simultaneous measurement of tilt and acceleration. The results show that the tilt sensitivity and acceleration sensitivity of the proposed FBG sensor can reach 408.3 p.m./° and 2.43 nm/(m/s2), respectively, and the operating frequency is lower than 32 Hz in weak vibration detection. The size of the pendulum is 22 mm × 24 mm × 47 mm, and the mass of the pendulum is 281.51g. Antunes C F P et al. [15] proposed biaxial optical accelerometer and high-angle inclinometer with temperature sensitivities of 87.848 and 92.351 p.m./g−1, for each sensitive direction with resonant frequencies of 846.01 and 845.33Hz, respectively, are achieved. The obtained tilt sensitivities are 1.43 ± 0.03pm/° and 1.38 ± 0.03pm/°, for the directions along the x-axis and the y-axis, respectively, for angular rotations smaller than 45°. The size of the proposed sensor is 15.0 cm × 15.0 cm × 8.5 cm, which makes it difficult to install and apply it in a small space. The above sensors have high sensitivity and a wide operating frequency band, but the large volume makes it difficult to meet the needs of mechanical equipment installation and space vibration test of compact structures.

In order to meet the needs of multi-dimensional vibration measurement and the goal of sensor miniaturization, some scholars have used multi-core optical fibers to develop new FBG vibration sensors. Fender et al. [16] designed a two-dimensional acceleration sensor with cantilever beam structure based on four-core optical fiber. The experimental results show that the sensitivity and natural frequency of the sensor can be adjusted by adjusting the length of the end of the optical fiber cantilever beam and the mass of the end epoxy resin mass. The sensor can measure the acceleration of two orthogonal axes, the frequency is lower than 300 Hz, and the accuracy is at least 5 %. Zhou [17] et al. wrote gratings on three of the seven core fibers, and calculated the azimuthal Angle and magnitude of the vibration acceleration on the XY plane according to the wavelength drift of the fiber Bragg grating in different directions. Combined with the fiber Bragg grating engraved on the Z axis, the three-dimensional vibration vector could be obtained, but the length of the sensor reached 130 mm, the outer diameter of 28 mm. Cui et al. [18] used a 10 mm long seven-core fiber as the inertial mass block of the acceleration sensor. In the case of only two outer cores, the direction, acceleration and vibration frequency were measured simultaneously by monitoring the FBG wavelength drift, and the intermediate core was used for temperature compensation. The experiment shows that the resonant frequency of the sensor is 68 Hz, and the sensitivity is 274.8 p.m./g. Yaokang Yu et al. proposed a two-dimensional accelerometer with cantilever beam structure based on seven-core optical fiber. The hollow cylindrical metal block is used to cause the bending deformation of the optical fiber to perceive the acceleration direction when it is excited by vibration. The volume of the sensor is 23 mm × 10 mm × 10 mm, the natural frequency is 75Hz, and the sensitivity in air and oil is 85pm/g and 18pm/g, respectively. In summary, the use of multi-core fiber grating to prepare vibration sensors can achieve multi-dimensional vibration measurement and effectively reduce the size of the sensor [19].

In this paper, a two-dimensional vibration sensor based on five-core fiber grating cantilever beam structure is proposed. The bending characteristics of multi-core fiber are used to realize the multi-dimensional vibration detection capability of compact structure. The rest of this article is organized as follows: Firstly, the structure design and working principle of the vibration sensor are introduced. The sensor is theoretically calculated and analyzed by finite element simulation method, and the performance of multi-core fiber grating is introduced. Secondly, the packaging process, amplitude-frequency characteristics, sensitivity and cross-interference experiments of the sensor were tested and verified. Finally, the work is systematically summarized.

2. SENSOR design, operating mechanism and fabrication

2.1. Structure designing of the sensor

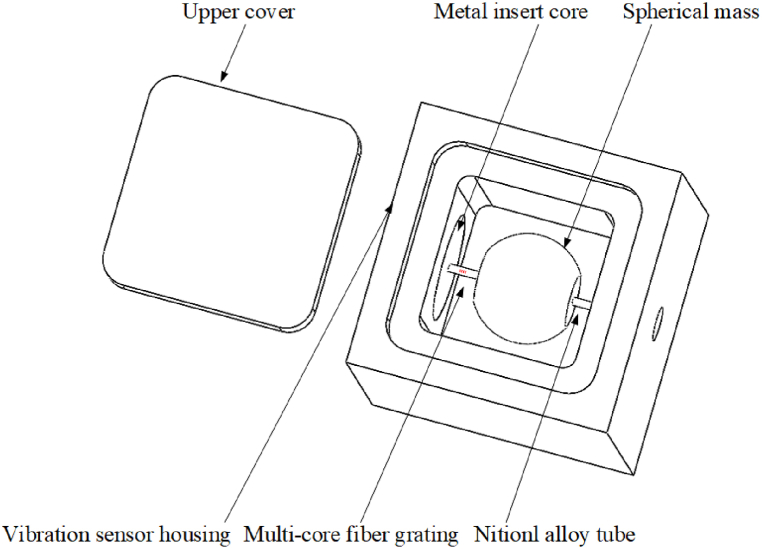

Miniaturization is an important parameter in sensor design. In order to meet the design requirements of small space installation, the volume of the vibration sensor is 10 mm × 10 mm × 10 mm. Fig. 1 illustrates the structural schematic of the FBG vibration sensor. The vibration sensor is composed of an upper cover, vibration sensor housing, metal insert core, spherical mass block, multi-core fiber, nitinol alloy tube, and multi-core fiber grating. In the packaging process, the multi-core fiber grating is passed through the nickel-titanium alloy tube, and the middle is filled with epoxy resin adhesive to protect it. The nickel-titanium alloy tube and the multi-core fiber constitute the elastic body of the sensor. The thin-diameter tube packaging method can not only ensure that the fiber grating is in the center of the capillary Nitinol tube but also ensure that the adhesive is completely filled with the capillary Nitinol tube. This packaging process is simple and easy to implement and has good repeatability, which can make the vibration sensors made of FBG produced in the same batch have the same sensing characteristics.

Fig. 1.

Structure diagram of two dimensional FBG vibration sensor.

There is a small hole in the middle of the spherical mass block that can be heated and cured through the nickel-titanium alloy tube. The multi-core fiber grating should be adjusted to the 1.25 mm gap reserved at the back of the mass block. The nickel-titanium alloy tube is glued and heated, and cured on the metal insert to form a "multi-core fiber grating nickel-titanium alloy tube-mass block-metal insert connector". Then the connector structure is glued to the vibration sensor housing. When the external excitation generates a vibration response, it will act on the mass block and the nickel-titanium alloy tube to generate vibration, so that the multi-core fiber grating will be bent and deformed, and the external vibration signal can be monitored by detecting the change of its center wavelength. The equivalent model of the proposed multi-core FBG vibration sensor is shown in Fig. 2.

Fig. 2.

Equivalent model of the proposed multi-core FBG vibration.

2.2. Working principle of the sensor

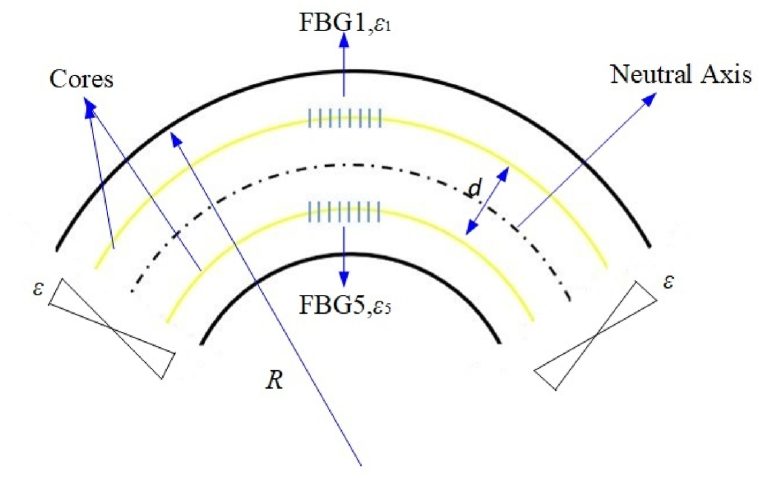

When the sensor is forced to vibrate, the mass will exert an inertial force on the nickel-titanium alloy tube, which causes the multi-core fiber in the nickel-titanium alloy tube to bend and deform. In other words, the fiber bends in response to vibration. In multi-core Fiber Grating, fiber cores No. 1 and No. 5 are inscribed in the same position and have the same central wavelength. A schematic diagram of force bending sensing after FBG is in-scribed in multi-core optical fiber grating, as shown in Fig. 3. When the spherical mass vibrates along the detection direction, the FBG on the neutral plane is almost unaffected, the FBG on the outer core 1 of the multi-core fiber is subjected to tensile force, and the FBG on the inner core is subjected to compressive force. Therefore, the bending sensing principle of multi-core fiber grating can be explained by the following theories [20]:

Fig. 3.

Schematic diagram of bending sensing after FBG is written in multi-core optical fiber core.

Let the central wavelength of the written FBG be λB, and when the micro-strain is applied, the wavelength drift is:

| (1) |

Where λB is the central wavelength of core FBG, ρe is the elastic optical effect coefficient, and its value is expressed as:

| (2) |

In the formula, n is the effective refractive index of the fiber core, ν is Poisson's ratio, P11, P12 is the Pockel coefficient of optical fiber photoelasticity. For quartz fiber, at the wavelength window of 1550 nm, ρe value is 0.22, and the wavelength shift to strain is generally 1.15 p.m./με [21]. When the distance between the fiber cores is d and the radius of curvature generated by bending is R, the strain difference between the two FBGs is:

| (3) |

Therefore, it can be obtained that the drift of FBG wavelength when bending occurs is:

| (4) |

Since the curvature of the MCF is constrained by the bending radius of the fiber break, the sensor's ability to measure acceleration is limited within a range indicated by equation (5) [16]. This measurement range depends on the length lf of the fiber cantilever and the mass m of the spherical mass block. Young's modulus Ef and radial end area Af are the inherent properties of optical fiber.

| (5) |

The sensor sensitivity is calculated as follows:

| (6) |

The multi-core fiber vibration sensor is equivalent to a cantilever beam structure with single-ended fixed intermediate loading. When subjected to vibration, the elastic coefficient of the elastomer can be expressed as:

| (7) |

In the above formula, Ln is the length of the NiTi alloy tube, En is the Young's modulus of the NiTi alloy tube, J is the rotational inertia of the NiTi alloy tube, DO is the outer diameter of the NiTi alloy tube, and DI is the inner diameter of the NiTi alloy tube. The moment of inertia of the nickel-titanium alloy tube is:

| (8) |

Combining equations (7), (8), we can obtain the natural frequency of the sensor, which can be expressed as:

| (9) |

2.3. Simulation analysis of the sensor

2.3.1. Numerical analysis of the sensor

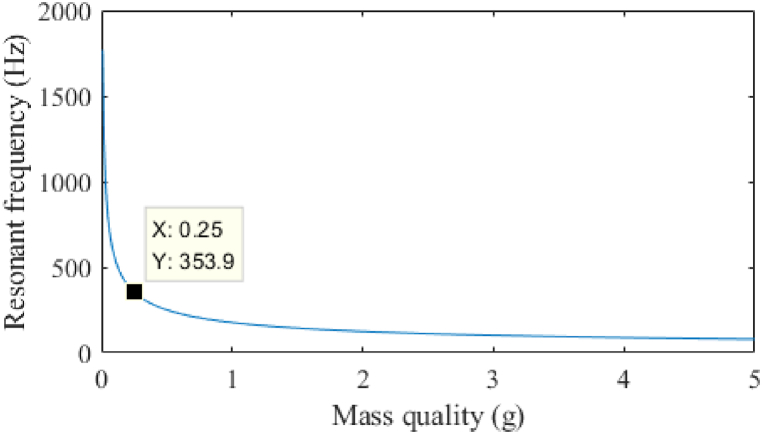

The relationship between the natural frequency of the sensor and the spherical mass is obtained by combining the parameters of the vibration sensor in (7), (8), (9),and Table 1, as shown in Fig. 4. It can be seen from the figure that the natural frequency of the sensor decreases with the increase of the mass of the spherical mass. There is a negative correlation between the sensitivity and the natural frequency of the sensor [22]. Considering the natural frequency and sensitivity of the sensor and the feasibility of machining, the mass of the designed spherical mass is 0.25g, and the length of the nickel-titanium alloy tube is Ln = 8 mm. The theoretical natural frequency of the sensor is 353.9Hz.

Table 1.

Design parameters of the sensor.

| Symbol | Parameter name | Value |

|---|---|---|

| Af | Fiber cross-sectional area | 0.005024 mm2 |

| Ef | Fiber Elastic Modulus | 72Gpa |

| LFBG | FBG package length | 1 mm |

| λ1 | The center wavelength of core 1 fiber grating | 1549.99 nm |

| λ2 | The center wavelength of core 2 fiber grating | 1550.07 nm |

| λ4 | The center wavelength of core 4 fiber grating | 1550.10 nm |

| λ5 | The center wavelength of core 5 fiber grating | 1550.15 nm |

| dg | Distance from hole to the end of mass block | 1.25 mm |

| DI | Inner diameter of nickel-titanium alloy tube | 0.16 mm |

| Do | Outer diameter of nickel-titanium alloy tube | 0.20 mm |

| Ln | Length of nickel-titanium alloy tube | 8 mm |

| Lv | Length of vibration sensor | 10 mm |

| Wv | Width of vibration sensor | 10 mm |

| Hv | Height of vibration sensor | 10 mm |

| Lm | Length of the mass block | 4 mm |

| Wm | Width of the mass block | 4 mm |

| Hm | Height of the mass block | 3.5 mm |

| DSI | Inner diameter of spherical mass block | 0.20 mm |

| mw | Quality of the mass block | 250 mg |

Fig. 4.

The relationship between the mass of the mass block and the natural frequency.

2.3.2. Finite element analysis of the sensor

To better study the dynamic features of the multi-core fiber vibration sensor, SolidWorks software creates a three-dimensional model of the sensor, which is then loaded into Ansys for finite element simulation analysis. In the Workbench module, the material properties of the sensor shell, spherical mass block, metal insert, optical fiber and nickel-titanium alloy tube are set according to the parameters in Table 2, and then the corresponding constraints are added to the modal module. After solving, the stress distribution map of the multi-core optical fiber vibration sensor is obtained as shown in Fig. 5. When the spherical mass is excited by vibration, the bending deformation will occur, and the stress is mainly concentrated on the right side of the mass. Combined with the bending characteristics of the multi-core fiber grating, the multi-core fiber grating should be arranged at the gap between the spherical mass and the inner wall of the shell, so as to ensure that the grating is located at the place where the deformation and bending are large, and can avoid the fiber grating in the area where the stress concentration is distributed. The natural frequency of the sensor is about 351.26 Hz, which is basically consistent with the theoretical value.

Table 2.

Properties of the sensor material.

| Symbol | Material | Young's modulus(Gps) | Poisson's ratio | Density (kg/m3) |

|---|---|---|---|---|

| Nitinol tube | nitinol | 83 | 0.33 | 5300 |

| Mass block | orichalcum | 90 | 0.324 | 8700 |

| Metal insert/Shell | aluminium | 71.7 | 0.33 | 2700 |

| Optical fiber | quartz | 72 | 0.22 | 2200 |

Fig. 5.

The modal shape diagram of the sensor.

2.4. Multicore fiber grating

The five-cores fiber (FCF) is produced by Chang fei Fiber Optic Cable Co, Ltd., and its termination surface is depicted in Fig. 6. The cladding diameter of the FCF was 125um, and the four outer cores were distributed in a rhombus in the cladding of the fiber, namely cores 1, 2, 4 and 5. The central core was 3. All five cores had a diameter of 8 μm, and the distance from the central core to the outer core was 46 μm. FBGs with the same length were in-scribed in the same sections of cores 1, 2, 4 and 5.

Fig. 6.

The structure of the coated five-core fiber stripped under an electron microscope.

In order to enhance the photosensitivity of the five-core fiber, the five-core fiber was subjected to hydrogen loading for 15 days in a thermostatic furnace at a temperature of 70 °C and a pressure of 10 MPa before writing. An automatic fiber coating stripper was used to strip the fiber coating layer with a length of 1 mm to achieve a stripping process with almost zero cladding damage (Fujikura, PCS-100, Japan). Multi-core fiber grating writing is realized by using 800 nm titanium sapphire femtosecond laser combined with phase mask. The multi-core fiber grating fan-in and fan-out device (Ifiber, MCF-5A-46–125, China) is used to monitor the FBG changes of each fiber core. The reflection spectrum of FBG engraved in the core is shown in Fig. 7. Due to the lens effect of the fiber, the Bragg wavelength of each core will fluctuate between 1549.99 and 1550.15 nm, the maximum wave-length difference is 0.16 nm, and the reflection spectrum is −80 dBm —- −50 dBm. The multi-core grating can effectively identify the curvature and direction of the bending.

Fig. 7.

Reflection spectra of the FBGs inscribed in the fiber cores.

3. Experiments and discussion

3.1. Packaging process of the sensor

The core component of the multi-core fiber grating vibration sensor is the multi-core fiber grating, which is not only a sensitive element but also an elastic beam. As shown in Fig. 8-a, a two-point packing technique is used by the multi-core fiber grating sensor to significantly increase the sensor's sensitivity. Through the fan-in and fan-out devices, the multi-core fiber grating is connected to the multi-core fiber writing real-time monitoring system built on the Labview platform. Preloading the fiber causes the center wavelength of the fiber grating to shift by approximately 1–1.5 nm, which can significantly increase the sensor's sensitivity. The metal parts of the sensor are fixed on the 3-axis displacement platform, and the fiber grating and mass block are wiped with alcohol dipped in dust-free paper. The multi-core fiber grating area is adjusted to be located in the gap area and groove of the elastic structure, and then the multi-core fiber grating is placed in the rotating fixture and prestressed. The CCD camera is used to capture the image and display it on the display in real time. The fiber grating will be occluded after passing through the nickel-titanium alloy. The pixel coordinate conversion method is used to record the pixel coordinates of the marker points in the imaging system, and the fiber grating can be accurately adjusted to the reserved gap position. The epoxy resin adhesive 353ND with good adhesion and heat resistance was coated by a glue coater. The coating of multi-core optical fiber and NiTi alloy tube, NiTi alloy tube and spherical mass block, metalcore and sensor shell was completed by moving and rotating the optical fiber. The hot air gun (TTEN 858D + ) is used for heating and curing. The local amplification diagram of the cured sensor head is shown in Fig. 8-b, and then the assembly of optical fiber and mass block, optical fiber and optical fiber insert is realized by moving the dis-placement platform. Fig. 8-b intuitively demonstrates the preparation of fiber grating interface, gluing, the preparation of ' multi-core fiber-nickel-titanium alloy tube-metal insert-mass ' sensor head and the detection process of sensor shape and size.

Fig. 8.

Packaging process of FBG vibration sensor (a) Schematic diagram (b) Physical prototype.

3.2. Vibration sensor performance test and calibration system

After the sensor packaging was completed, a vibration test system was built to better analyze the characteristics of the fiber optic vibration sensor, as shown in Fig. 9. The experimental device system consists of a charge-amplifier, power amplifier, Signal generator and Data Collector (YM92), multi-core fiber fan-in and fan out device, Multichannel fiber Bragg grating demodulator, vibration test stand, Fiber optic vibration sensor, data acquisition card (NI9234) and computer. The wavelength demodulation instrument of multi-channel fiber Bragg grating is an instrument and equipment independently developed by Beijing Information Science and Technology University(The wavelength demodulation range is 1525–1565 nm, the resolution is 2pm.), and the data acquisition host computer software based on LabVIEW is developed, which can simultaneously realize the demodulation of the change of central wavelength of multi-core fiber Bragg grating.

Fig. 9.

Vibration testing and signal acquisition system (a) Schematic diagram; (b) Experimental diagram.

The signal generator outputs a sinusoidal signal to the power amplifier, which regulates the frequency and acceleration of the vibration table output signal. The 502 glue is used to secure the FBG vibration sensor to the vibration table. The multi-core fiber grating core signals from the sensor are then extracted and connected to a four-channel fiber wavelength demodulation instrument via a Fan-in Fan-out device. The demodulation instrument demodulated and analyzed the FBG wavelength change signals of each fiber core separately, and then it was connected to the computer to enable real-time monitoring of the vibration signals.

3.2.1. Amplitude frequency response experiment

The amplitude-frequency characteristics of FBG vibration sensor reflect the dynamic response [23]. The amplitude of the output signal changes with the input vibration frequency. The curve can visually see the natural frequency and working frequency range of the sensor. The amplitude of excitation acceleration is kept at 1G (G = 9.8 m/s2) and the excitation frequency varies in the range of 20–700 Hz. As can be seen from Fig. 10, the experimental test of the sensor's natural frequency yields a value of 355 Hz, while the modal simulation analysis conducted using ANSYS Workbench in Fig. 5 reveals a natural frequency of 351.26 Hz. The striking similarity between the simulation analysis data and the measured data underscores the high degree of accuracy achieved by the simulation model, reinforcing its validity and reliability. The flat range is 20Hz–240Hz, which suggests that the X/Y-axis sensor are suitable for vibration measurement at low and medium frequencies.

Fig. 10.

Amplitude-frequency characteristic curve of the FBG vibration sensor.

3.2.2. Sensitivity experiment

The sensitivity of the FBG vibration sensor is the ratio of the difference of the center wavelength drift of the different fiber cores in the axis direction to the acceleration amplitude [19]. The high sensitivity enhances the energy of the signal and improves the detection ability of the weak signal. In order to obtain the sensitivity and linear characteristics of FBG vibration sensor, the sensitivity of FBG vibration sensor is calibrated by the experimental system shown in Fig. 9. During the experiment, the FBG vibration sensor is fixed on the vibration table to ensure that the test direction of the FBG vibration sensor is parallel to the vibration direction of the vibration table. The excitation frequency is kept at 100 Hz, the amplitude of the excitation acceleration is set to change from 0.25 G to 3 G (G = 9.8 m/s2), and the increment step is 0.25 G. The wavelength changes of the fiber Bragg grating vibration sensor in two directions under different accelerations are collected respectively. The curve of sensitivity with acceleration is drawn as shown in Fig. 11. The sensitivity of the FBG vibration sensor in the x direction is 68.72 p.m./g, and the sensitivity in the y direction is 64.52 p.m./g. The center wavelength and acceleration of the FBG vibration sensor have a good linear relationship.

Fig. 11.

The sensitivity of the X-axis and Y-axis.

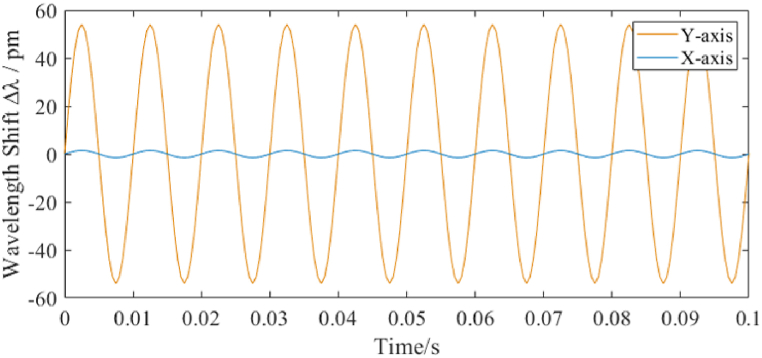

3.2.3. Cross-interference experiment

The transverse vibration sensitivity refers to the ratio of output to input when the vibration is perpendicular to the sensitive axis. The ratio of the transverse and sensitive direction sensitivity reflects the anti-interference force, and the lower the ratio, the stronger the anti-transverse interference [22]. The FBG vibration sensor will be affected by vibration in multiple directions during actual use, so it is necessary to analyze its cross-interference in non-measurement directions. In the experiment, the sensor is turned 90° as the cross direction, the amplitude of the vibration signal is adjusted to 1G (G = 9.8 m/s2), and the frequency is 100Hz. The FBG center wavelength data information is obtained by using the fiber grating demodulator. In Fig. 12, the peak value of the central wavelength drift in the X direction is 59.7 p.m., and the central wavelength drift in the Y direction is 2.1 p.m. The cross-interference error of the sensor in the X direction is 3.52 %. In Fig. 13, the peak value of the center wavelength drift in the Y direction is 54.2 p.m., and the center wavelength drift in the X direction is 1.6 p.m. The cross-interference error of the sensor in the Y direction is 2.95 %. Experiments show that the lateral interference of the FBG vibration sensor in the X and Y directions is less than 4 %, and it has good anti-interference ability.

Fig. 12.

The cross-interference characteristics of the FBG sensor in X direction.

Fig. 13.

The cross-interference characteristics of the FBG sensor in Y direction.

In Table 3, compared with other multi-core FBG vibration sensors, the sensor prepared in this paper has a smaller volume and a wider frequency range.

Table 3.

Performance comparison of multi-core optical fiber sensor.

4. Conclusion

In this paper, a miniaturized and two-dimensional multi-core fiber grating vibration sensor is proposed. The sensor inscribes fiber grating in five-core fiber using a femtosecond laser and phase mask. Its significant advantages are as follows: (1) The spherical mass has a mass of only 0.25 g, making it appropriate for measuring mass-sensitive structural vibration in addition to ensuring that each size is consistently consistent to minimize interference. (2) Because of its small volume (10 mm × 10 mm × 10 mm), it can be used in small spaces for two-dimensional vibration monitoring. (3) The experimental results show that the sensitivity of the optical fiber vibration sensor is 64.52 pm/g and 68.72 pm/g, respectively, with a flat operating frequency band of 20–240Hz in the x/y direction. There is little cross interference while measuring vibration in both directions. In the future, we will utilize the central core of the five-core fiber to simultaneously measure temperature and angle measurements. The two-dimensional multi-core fiber sensor is orthogonally arranged in series to achieve multi-dimensional and multi-point distributed measurement, and it is applied to the field of state monitoring of satellites and oil pipelines.

Funding

This research was funded by the Research Project of Beijing Municipal Natural Science Foundation (Grant No. BJXZ2021-012-00046), the Research Project of Beijing Municipal Natural Science Foundation & Beijing Education Committee (Grant No. KZ201911232044) and the Xuzhou Science and Technology project (Grant No.90250886701313).

Data availability

The majority of the data used to generate the results of this article are presented in the publication. Some details are not currently available, but can be obtained from the author upon reasonable request.

CRediT authorship contribution statement

Kun Li: Writing – review & editing, Writing – original draft, Validation, Software, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Mingli Dong: Visualization, Funding acquisition, Conceptualization. Wu Zhao: Visualization, Project administration, Funding acquisition, Formal analysis, Conceptualization. Le Wang: Visualization, Investigation, Data curation, Conceptualization. Hongshun Zhang: Resources, Project administration, Data curation, Conceptualization.

Declaration of competing interest

The authors declare no conflicts of interest.

Contributor Information

Kun Li, Email: 2022030002@bistu.edu.cn.

Mingli Dong, Email: lxs1125307774@126.com.

Wu Zhao, Email: zhaowu@jsjzi.edu.cn.

Le Wang, Email: 2022030009@bistu.edu.cn.

Hongshun Zhang, Email: 2022030019@bistu.edu.cn.

References

- 1.Khatun H., Sharma C., Sarma U. Investigation of ambient vibration sources for direct energy harvesting by optimizing resonant frequency using proof mass. Meas. Sci. Technol. 2024 doi: 10.1088/1361-6501/ad214e. [DOI] [Google Scholar]

- 2.Zhang Xiaofei, Long Zhuo, Peng Jian, et al. Fault prediction for electromechanical equipment based on spatial-temporal graph information. IEEE Trans. Ind. Inf. 2023:1413–1424. doi: 10.1109/tii.2022.3176891. [DOI] [Google Scholar]

- 3.Kim S.M., Dandu P., Gusarov A., et al. Assessment of the structural vibration effect on plasma current measurement using a fiber optic current sensor in ITER. Sensors. 2023:1460. doi: 10.3390/s23031460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Goossens S., Berghmans F., Khodaei Z.S., et al. Practicalities of BVID detection on aerospace-grade CFRP materials with optical fibre sensors. Compos. Struct. 2021 doi: 10.1016/j.compstruct.2020.113243. [DOI] [Google Scholar]

- 5.He R.J., Teng C.X., Kumar S., et al. Polymer optical fiber liquid level sensor: a review. IEEE Sensor. J. 2022:1081–1091. doi: 10.1109/jsen.2021.3132098. [DOI] [Google Scholar]

- 6.Jiang Peng, Xu Qiang, Zhang Rui, et al. High-temperature and stress response behavior of femtosecond laser pulses inscribed eccentric fiber Bragg gratings. Heliyon. 2023 doi: 10.1016/j.heliyon.2023.e17185. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Liu Chi, Feng Yue, Liu Xin, et al. Multiparameter sensor based on micro/nano-structured optical fiber and composites. Heliyon. 2022 doi: 10.1016/j.heliyon.2022.e10941. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Nsengiyumva Isidore, Mwangi Elijah, George Kamucha. A comparative study of chromatic dispersion compensation in 10 Gbps SMF and 40 Gbps OTDM systems using a cascaded Gaussian linear apodized chirped fibre Bragg grating design. Heliyon. 2022 doi: 10.1016/j.heliyon.2022.e09308. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Pant S., Umesh S., Asokan S. Pulp chamber temperature variation evaluation using fiber Bragg grating sensor. Appl. Opt. 2020:10953–10958. doi: 10.1364/ao.409340. [DOI] [PubMed] [Google Scholar]

- 10.Li Tianliang, Guo Jinxiu, Tan Yuegang, et al. Recent advances and tendency in fiber Bragg grating-based vibration sensor: a review. IEEE Sensor. J. 2020:12074–12087. doi: 10.1109/jsen.2020.3000257. [DOI] [Google Scholar]

- 11.Wang R.H., Li Y.Z., Qiao X.G. Recent advances in multidimensional fiber Bragg grating accelerometers. J. Lightwave Technol. 2023:4238–4247. doi: 10.1109/jlt.2023.3241953. [DOI] [Google Scholar]

- 12.Guo Yongxing, Chen Min, Xiong Li, et al. Fiber Bragg grating based acceleration sensors: a review. Sens. Rev. 2021:101–122. doi: 10.1108/sr-10-2020-0243. [DOI] [Google Scholar]

- 13.Guo Yongxing, Chen Min, Jiang Shaodong, Wang Yingying, Zhang Faxiang, et al. A high-sensitivity FBG accelerometer and application for flow monitoring in oil wells. Opt. Fiber Technol. 2022 doi: 10.1016/j.yofte.2022.103128. [DOI] [Google Scholar]

- 14.Xu Hongbin, Li Feng, Gao Yang, et al. Simultaneous measurement of tilt and acceleration based on FBG sensor. IEEE Sensor. J. 2020:14857–14864. doi: 10.1109/jsen.2020.3010851. [DOI] [Google Scholar]

- 15.Antunes Paulo Fernando Costa, Marques Carlos Alberto, Varum Humberto, et al. Biaxial optical accelerometer and high-angle inclinometer with temperature and cross-Axis insensitivity. IEEE Sensor. J. 2012:2399–2406. doi: 10.1109/JSEN.2012.2190763. [DOI] [Google Scholar]

- 16.Fender Amanda, MacPherson William N., Maier Robert R.J., et al. Two-axis temperature-insensitive accelerometer based on multicore fiber Bragg gratings. IEEE Sensor. J. 2008:1292–1298. doi: 10.1109/jsen.2008.926878. [DOI] [Google Scholar]

- 17.Zhou Rui, Chen Fengyi, Li Shuangshuang, et al. Three-dimensional vector accelerometer using a multicore fiber inscribed with three FBGs. J. Lightwave Technol. 2021:3244–3250. doi: 10.1109/jlt.2021.3058240. [DOI] [Google Scholar]

- 18.Cui Jingxian, Liu Zhengyong, Serandi Gunawardena Dinusha, et al. Two-dimensional vector accelerometer based on Bragg gratings inscribed in a multi-core fiber. Opt Express. 2019:20848–20856. doi: 10.1364/OE.27.020848. [DOI] [PubMed] [Google Scholar]

- 19.Yu Yaokang, Dash Jitendra Narayan, Cui Jingxian, et al. Miniature two-Axis accelerometer based on multicore fiber for pantograph-catenary system. IEEE Trans. Instrum. Meas. 2023 doi: 10.1109/tim.2023.3295019. [DOI] [Google Scholar]

- 20.Gander M.J., MacPherson W.N., McBride R., et al. Bend measurement using Bragg gratings in multicore fibre. Electron. Lett. 2000:120–121. doi: 10.1049/el:20000157. [DOI] [Google Scholar]

- 21.Rao Yun-Jiang. Fibre Bragg grating sensors. Meas. Sci. Technol. 1997:355–375. doi: 10.1088/0957-0233/8/4/002. [In eng] [DOI] [Google Scholar]

- 22.Song Han, Song Enzhong, Liu Yi, et al. Miniature FBG vibration sensor with high performance and low angle dependence for two-dimensional vibration measurement. IEEE Trans. Instrum. Meas. 2023 doi: 10.1109/tim.2022.3223061. [DOI] [Google Scholar]

- 23.Li J.Z., Yang D.X., Jiang Y.J., et al. Cascadable four-core fiber Bragg gratings accelerometer for 2-D low-frequency vibration measurement. IEEE Sensor. J. 2023:22373–22379. doi: 10.1109/jsen.2023.3298430. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The majority of the data used to generate the results of this article are presented in the publication. Some details are not currently available, but can be obtained from the author upon reasonable request.