Abstract

In the food industry, meeting food quality demands is challenging. The quality of wheat flour, one of the most commonly used ingredients, depends on the extent of debranning done to remove the aleurone layer before milling. Therefore, the end product management can be simplified by predicting the properties of wheat flour during the debranning stage. Therefore, the chemical and rheological properties of grains were analyzed at different debranning durations (0, 30, 60 s). Then the images of wheat grain were taken to develop a regression model for predicting the chemical quality (i.e., ash, starch, fat, and protein contents) of the wheat flour. The resulting regression model comprises a convolutional neural network and is evaluated using the coefficient of determination (R2), root-mean-square error, and mean absolute error as metrics. The results demonstrated that wheat flour contained more fat and protein and less ash with increasing debranning time. The model proved reliable in terms of root-mean-square error, mean absolute error, and R2 for predicting ash content but not starch, fat, or protein contents, which can be attributed to the lack of features in the collected images of wheat kernels during debranning. In addition, the selected method, debranning, was beneficial to the rheological characteristics of wheat flour. The proportion of fine particles increased with the debranning time. The study experimentally revealed that the end product diversity for wheat flour can be controlled to provide selectable ingredients to customers.

Keywords: Ash content, Chemical property, Food quality, Preprocessing, Regression model

1. Introduction

Wheat is one of the most consumed edible plant species that makes up 19 % of crops produced globally [1]. It is edible as grain but mostly used as flour for various end products. Producing wheat flour from grain mainly comprises cleaning, tempering, and milling steps [2]. The quality of wheat flour is determined by the aleurone layer and the characteristics of endosperm (the grain's inner part) and germ. However, the main difference in opinions regarding wheat flour is about the proportion of aleurone layer in it.

The presence of aleurone in wheat flour increases the dietary fiber content and consequently health benefits [3,4]. It contains valuable nutrients, such as arabinoxylan, β-glucan, and minerals, which can mitigate the risk of such ailments as colon cancer and cardiovascular diseases [[5], [6], [7], [8]]. Additionally, varying the bran particle size in flour products improves their sensory properties [9], a feature increasingly sought after by consumers, owing to the risen awareness of dietary health [10]. Despite the acknowledged health advantages of dietary nutrients, consumer preference for white wheat flour products, which lack aleurone layers, remains prevalent in various countries [[11], [12], [13], [14], [15]]. The inclination toward white wheat flour primarily originates from its sensory and aesthetic qualities.

Pure wheat flour can be produced by removing the aleurone layers with high ash content, which affects the texture of food. Separating the aleurone layers and endosperm is a complex process [16,17]. The influence of ash content on baking properties has been investigated, revealing that increased bran content extends the dough development time and reduces its stability [18]. Moreover, bread baked with the aleurone layer exhibits enhanced hardness and reduced chewiness [19,20]. Food technologists have initiated the removal of the aleurone layer from whole wheat grains, conferring multiple advantages, including improved cooking properties and reduced microbial load, mycotoxins, and ash contents [[21], [22], [23]]. Notably, the depletion of aleurone layers using debranning technologies enhances food quality [24]. Such modifications have diversified palatability while maintaining protein content in biscuits [25], improved sensory attributes in spaghetti [26], and yielded superior dough, baking, and water absorption properties in bread [[27], [28], [29]].

Given the impact of bran removal on wheat flour products [[30], [31], [32]] and the health benefits conferred by bran, consumer preferences remain varied, and debates concerning bran inclusion in end products persist. Therefore, reconciling these divergent views by controlling wheat flour quality becomes important [33]. To produce white wheat flour, numerous studies have attempted to eliminate the aleurone layer and minimize bran fractures. Various methodologies for aleurone removal was explored and concluding that physical methods are predominantly employed to peel off this layer [34]. Utilizing mechanical methods to study the rheological and chemical properties of wheat flour containing the aleurone layer was studied [35], while the alternative milling processes aimed at producing white wheat flour with controlled compositional variations between the inner and outer layers [36]. However, the challenge in controlling them remains, and advanced technology could be adopted for high precision even using the general milling method for the present flour industry.

Remarkable advancements in precision control within the food industry have been substantially propelled by technological evolution, including image processing and predictive algorithms. Moreover, the application of artificial intelligence (AI) for predicting food quality has been investigated across diverse crops. For instance, the color grading system for carrots, employing vision systems and deep learning in alignment with postharvest technological demands [37]. Portable system was suggested to evaluate multicomponent powdery foods, integrating near-infrared (NIR) technologies with machine learning [10]. Detecting system for a sugar adulteration in honey utilizing convolutional neural networks (CNNs) and vision systems was taken [38]. Other notable applications include a method for identifying moldy peanuts using CNNs and hyperspectral imaging [39], the application of CNNs in detecting defective apples [40], and AI technologies as one of the most effective approaches for ensuring quality across various stages of food processing, cultivation, harvesting, and storage [41]. The application of AI in the cereal industry also provides relevant advances. Physicochemical properties of US wheat flours were analyzed with AI technology [42] and widely used YOLOv5 (Ultralytics Inc., MD, USA) take account for rapid flaw detection on wheat grain surfaces [43]. However, the previous studies were focused on the raw material itself, which is costly, and meeting various demands for wheat flour end products requires studying food quality control in preprocessing steps. Therefore, the quality of white wheat flour, especially ash content, should be effectively controlled using AI.

To develop a machine learning model, it is essential to have representative data. Therefore, we designed a framework to systematically collect the data by varying the debranning time and analyze the properties of the wheat flour after milling. We also analyzed the physical properties of wheat grains to study the effect of preprocessing (debranning) on the RGB images’ features that would be useful in training a regression-based model. The obtained data was used to develop the regression model. The fundamental aim of this study was to develop a predictive model for the properties of white wheat flour using AI. The aleurone layer was mechanically removed from whole wheat grain to produce white wheat flour, which served as a comparison group. Whole-wheat flour was employed as a control group. Images of the grain were taken for machine learning purposes, and validation tests were conducted. The developed regression model can predict the flour quality before the milling operation. This fundamental study has a possibility of saving time and cost for maintaining the quality of their product in the cereal industry and accomplishing precise manufacturing industry.

The rest of this paper is structured as follows. Section 2 provides general information on the experiment, such as the status of wheat grains, mechanical methods used, chemical qualities of wheat flour, and image acquisition, plus an explanation of machine learning. Section 3 presents the experimental results and discussion. Section 4 comprises conclusions from this work and future directions.

2. Materials and methods

2.1. Materials

The wheat grain utilized herein is a common cultivar in the Republic of Korea, specifically Baekgang (Triticum aestivum L), sourced from Haman, Gyeongsangnam-do (37°34′21.1″N and 126°52′43.9″E). It was planted in October 2022 and harvested in late June 2023, with a cultivation period of 270 d. To assess the basic characteristics of the wheat grain, we measured its physical properties including weight, length, width, diameter, test weight, and thousand-kernel mass (Table 1). Subsequently, the grain was stored in separate vacuum bags at 4 °C to maintain a moisture content of 20 % postharvest. The moisture content was verified using a grain moisture meter (GMK-303, G-Won High Tech. Co., Ltd., Republic of Korea) to confirm the appropriate storage conditions.

Table 1.

Physical properties of Baekgang.

Weight of one kernel.

Length.

Width.

Diameter.

Test weight.

Thousand-kernel mass.

2.2. Debranning and milling method

The preprocessing step involved the removal of the aleurone layer from the whole-wheat grain at three levels of debranning time (0, 30, and 60 s). For the preprocessing step, 300 g of grain was weighed using an electronic scale (PAG 4102, OHAUS, NJ, USA) and polished using a debranning machine (TM05, SATAKE, Japan). Wheat flour was produced using a roller mill (Screw 20, Doosan Robotics Inc., Republic of Korea), following the treatment of residual kernels. This method was deemed the most acceptable among general milling approaches [44]. The process yield was calculated using the following equations:

where Yp represent the yield of wheat grain after debranning step and Ym represent the yield of the wheat flour made with debranned wheat kernel, Wp indicates the weight of polished wheat kernel, Wi denotes the weight of initial wheat kernel, and Wf represents the weight of wheat flour.

2.3. Experimental preparation

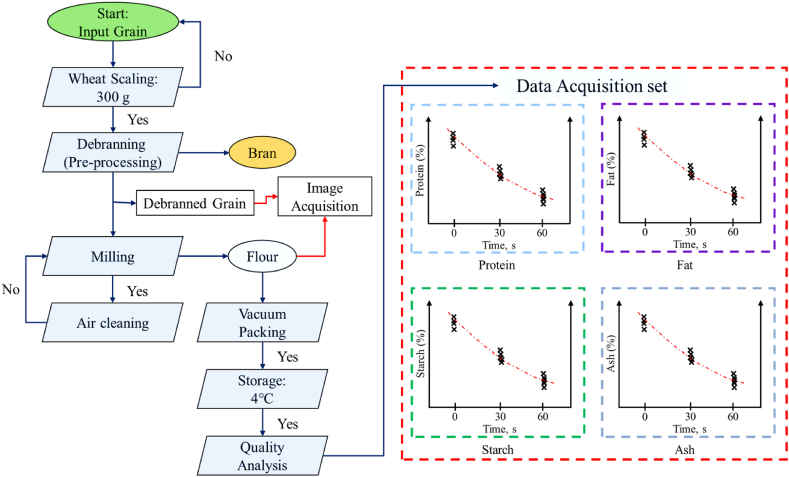

In the first step, we prepared a 300-g sample of wheat grain for preprocessing and took images of the whole and debranned wheat grains. Next, we produced flour from both and took images of the flour as well. We then vacuum-sealed the flour in nylon bags and stored it at 4 °C. Finally, we analyzed the chemical composition of the wheat flour and conducted machine-learning analyses based on the collected images and chemical analysis results (Fig. 1).

Fig. 1.

Flowchart of the milling process with pre-processing.

2.4. Wheat flour quality

The chemical properties of the wheat flour were assessed according to the guidelines established by the American Association of Cereal Chemists [45]. We analyzed starch (method 76–13), fat (method 30–10), protein (method 46–8), and ash (method 8–1) contents to understand the composition of wheat flour [46] and compare its various groups. The RGB data were extracted from the images of polished wheat grains and subsequently converted into Lab data (L – Lightness, a – red–green, and b – blue–yellow). Color differences were observed as functions of debranning time and calculated as follows:

where denotes the color difference between the targeted and observed color; , and are the differences in lightness, red–green, and blue–yellow, respectively.

2.5. Data collection

The images were captured using a portable photo studio (Foldio 3, ORANGEMONKIE, INC, CA, USA) and a standard camera (LM-G710N, LG Electronics, Republic of Korea) (Fig. 2). The studio was assembled, and a black board was positioned at its center. A 60-W light-emitting diode was mounted atop the studio. Original and polished wheat grains were sampled at 80 g, dispensed into Petri dishes, and placed consecutively on the central black board. The camera was stabilized using a tripod, and the studio was enclosed with a blackout curtain to eliminate external light interference, thereby ensuring accurate color identification. A total of 240 images were captured for each debranning duration (0, 30, and 60 s), yielding a dataset of 720 images.

Fig. 2.

Image taking process.

2.6. Machine learning analysis

The use of computer vision techniques and learning networks in general for predicting properties and activities of enzymes in wheat has received some level of attention in the literature. In [A two-camera machine vision in predicting alpha-amylase activity in wheat], by leveraging images acquired from two camera and hand-crafted features, alpha-amylase activity in wheat was predicted. In [Prediction of selected rheological characteristics of wheat based on Glutopeak test parameters], based on features obtained from Glutopeak test, selected rheological characteristics of wheat were predicted. From the above it is clear that most works in the literature on carefully hand-crafted features and employ morphological image processing or statistical models for prediction of the properties of interest. This can limit the deployment of such models in real applications because the process of extracting the associated features can be time consuming. Hence the need for models capable of automatic feature extraction is imminent. Therefore, in this work, a Machine Learning framework capable of automatic feature extraction is proposed for prediction of wheat properties. As depicted in Fig. 3, the prediction model predominantly comprised two-dimensional (2D) CNN layers in conjunction with fully connected dense layers. The 2D CNN layers served to facilitate feature extraction from the RGB images of the grains. Each subsequent CNN block incorporated the rectified linear unit activation function and a 2D max pooling layer, which reduced the dimensionality of the features generated by the CNN layer. These extracted features were then input to the fully connected dense layer for the quality indicator or property prediction.

Fig. 3.

Process for the flour quality prediction model.

To train the prediction model, we employed a dataset of 750 images of wheat grains. Specifically, 450, 115, and 135 images were allocated for training, validation, and testing, respectively. Separate models were constructed for each target quality indicator or property and were trained over 100 epochs.

The models’ performance was evaluated using common regression metrics, such as coefficient of determination (R2), root-mean-square error (RMSE), and mean absolute error (MAE). Furthermore, to demonstrate the importance of the results, we compared the results from the learning networks with baseline models, which simply used the mean value of a quality indicator or a property for prediction for all the test images.

where n denotes the total number of images for wheat kernel, An indicates the actual value for the chemical properties of wheat flour, Pn represents the predicted values for the chemical properties of wheat flour, and M denotes the mean value of An.

2.7. Statistical analysis

Analysis of variance (ANOVA) was performed with the chemical quality data of wheat flour, and differences in debranning level were identified with Duncan's host hoc test at the statistical significance of 0.05 using SPSS Statistics 26 (IBM, NY, USA).

3. Results and discussion

3.1. Debranning and milling yield

As preprocessing time increased, so did the peeled-off portion of the bran layer. The average weight of the wheat kernel was 290.96 ± 0.11 and 278.38 ± 0.93 g for 30 and 60 s of debranning, respectively. The debranning yield for each controlled group decreased by 4 % for every additional 30 s of debranning (100 %, 96.99 ± 0.04 %, and 92.79 ± 0.31 % for 0, 30, and 60 s of debranning time, respectively). The weights of the produced wheat flour were 214.52 ± 9.23, 191.37 ± 3.83, and 173.69 ± 5.95 g for debranning times of 0, 30, and 60 s, respectively. A milling yield of 71.51 ± 3.08 % was observed for non-preprocessed wheat kernels, consistent with previous reports on the use of roller mills in wheat flour production [47,48]. However, the milling yield decreased with prolonged preprocessing time, making 65.77 ± 1.31 % and 62.38 ± 1.96 % at 30 and 60 s of debranning, respectively (Fig. 4). The original intention of debranning was to eliminate the aleurone layer which is harder than the endosperm but it seemed the longer preprocessing time not only eliminate the target layer but also removing inner layer. This decline can be attributed to the higher density of wheat bran compared to that of the endosperm, a finding corroborated through end product analysis, which involved comparing the specific volumes of bread and bran [49].

Fig. 4.

Results of yield analysis of wheat grain with debranning time.

3.2. Effect of preprocessing on the flour qualities

The color of the polished wheat grains degraded under varying processing periods (Table 2). The green and blue parameters considerably increased with the debranning time. Within the Lab method for classification, grains with longer debranning times exhibited Lab values closer to whiteness. Lightness increased upon the removal of the bran, which inherently has low lightness, consistent with previous research [50]. Both a and b were reduced with increasing debranning time, indicating a convergence toward white coloration. As for color difference, ΔE of 52.9, 49.2, and 45.3 was observed at debranning times of 0, 30, and 60 s, respectively. Low ΔE values indicate color similarity, with the grain polished for 60 s having the highest level of whiteness.

Table 2.

Color determination of polished grain with different processing time.

| PT, s | Color parameter |

Image* | ||||||

|---|---|---|---|---|---|---|---|---|

| RGB |

Lab |

|||||||

| R | G* | B* | L* | a* | b* | |||

| 0 | 196.0a | 160.6a | 88.8a | 67.9a | 4.4c | 41.9c | 52.9 |  |

| 30 | 195.1a | 163.9b | 98.5b | 68.8b | 3.0b | 38.0b | 49.2 |  |

| 60 | 193.9a | 168.3c | 109.0c | 70.0c | 1.2a | 34.0a | 45.3 |  |

PT, debranning time.

Values with different letter in the same parameter are significantly different (p<0.05).

Image was acquired by the author.

The results indicated that preprocessing through milling effectively reduced the particle size of wheat flour. Specifically, the proportion of particles larger than 100 μm decreased (S1) at 30 s of debranning, while the quantity of flour with a particle size range of 10.0–60.0 μm increased (S2) when debranning time was extended to 60 s (Fig. 5). Also, the changed proportion was validated with the statistical analysis. The particle distribution was classified into four group (G1: 0–60 μm, G2: 60–100 μm, G3: 100–200 μm, G4: 200–400 μm). Then the increasing proportion of fine particle distribution was found with polishing time of 60 s and it was significantly different with polishing time of 0 s and 30 s (Table 3). Regarding the end products fabricated from wheat flour, their physical, mechanical, and rheological characteristics were amenable to manipulation through preprocessing. Flour without preprocessing proved suitable for baking tortillas as the reduced particle size yielded a stronger, more extensible product [51]. Smaller particle sizes enhanced the pasting properties of noodles [52], reduced development time, improved mixing stability, and lowered starch content in bread dough [53,54]. They positively impacted the rheological properties of crackers [55]. Given that diverse end products necessitate different flour particle sizes, debranning as a preprocessing technique presents a novel approach to controlling their properties.

Fig. 5.

Distribution of particle size of wheat flour with different debranning time.

Table 3.

Statistical analysis of particle distribution on debranning time.

| Particle Distribution, μm |

Variable | DF | Adj SS | Adj MS | F-value | P-value | Classification |

|---|---|---|---|---|---|---|---|

| 0–60 | PTa | 2 | 111.864 | 55.9319 | 103.18 | 0.000*** | 0 sBa |

| Error | 6 | 3.252 | 0.5421 | 30 sB | |||

| Total | 8 | 115.116 | 60 sA | ||||

| 60–100 | PT | 2 | 1.760 | 0.8801 | 1.96 | 0.221 | 0 sA |

| Error | 6 | 2.691 | 0.4485 | 30 sA | |||

| Total | 8 | 4.451 | 60 sA | ||||

| 100–200 | PT | 2 | 37.5996 | 18.7998 | 137.88 | 0.000*** | 0 sA |

| Error | 6 | 0.8181 | 0.1363 | 30 sB | |||

| Total | 8 | 38.4177 | 60 sC | ||||

| 200–400 | PT | 2 | 30.4870 | 15.2435 | 459.60 | 0.000*** | 0 sA |

| Error | 6 | 0.1990 | 0.0332 | 30 sA | |||

| Total | 8 | 30.6860 | 60 sB |

Values with different letter in the same parameter are significantly different (p<0.05).

PT, debranning time.

All qualities of the flour, excluding the starch content, were substantially influenced by the debranning period, suggesting that debranning could serve as a viable preprocessing method for modulating its characteristics to fulfill varying consumer demands (Table 4). Starch content remained largely unchanged during preprocessing, stabilizing at 76 g/100 g. However, fat and protein contents increased, demonstrating the potential of aleurone removal to enhance these properties. Conversely, the ash and moisture contents decreased. In terms of flavor and texture, high ash content in wheat flour products is generally considered undesirable as it increases the hardness while reducing cohesiveness and springiness, thereby compromising texture quality [30]. Additionally, aleurone layer removal appeared to facilitate thermal conductivity, thereby accelerating the drying process during milling. This was evidenced by the moisture content reduction from 8.43 % at 0 s of debranning to 7.49 % at 60 s.

Table 4.

The results of wheat flour qualities with debranning time.

| Debranning time (s) | Qualities |

||||

|---|---|---|---|---|---|

| Starch (g/100g) | Fata (g/100g) | Proteina (g/100g) | Asha (%) | M.Ca. (%) | |

| 0 | 76.66 ± 0.30a | 2.32 ± 0.05a | 12.60 ± 0.07a | 1.38 ± 0.01c | 8.43 ± 0.18c |

| 30 | 76.86 ± 0.50a | 2.38 ± 0.08 ab | 13.02 ± 0.25b | 1.30 ± 0.008b | 7.80 ± 0.10b |

| 60 | 76.33 ± 0.28a | 2.47 ± 0.07b | 13.45 ± 0.11c | 1.23 ± 0.008a | 7.49 ± 0.21a |

Values with different letter in the same parameter are significantly different (p<0.05).

Significant effect of debranning time (p<0.05).

The findings above demonstrated the notable impact of eliminating the aleurone layer on reducing ash content, consistent with the results reported previously. The least ash content was revealed with refined white wheat flour which has the smallest particle size. Also, when they came into the end product such as paste and bread, they were led to the higher viscosity peak and greater water absorption [56]. Therefore, the method employed herein is promising for controlling the properties of wheat flour end products. Regarding baking applications, this study suggests that the rheological properties of wheat bread could be effectively manipulated [57].

In overall, the effect of debranning has both positive and negative aspects on the food industry. The increased proportion of fine particle size (10–60 μm), fat and protein content and decreased ash content indicates improvement in productivity of the wheat flour with greater quality but the total yield based on equal input raw material is decreased. Therefore, selected preprocessing method is considered to be applicated in requirement of a wheat flour with high quality. On the other hand, wheat flour without any preprocessing can be supplied to the country where the food itself is more critical than the quality.

3.3. Prediction model of the ash content

A CNN with rectified linear unit activation functions was utilized for predictive modeling of wheat flour attributes. Various debranning levels were examined, and the efficacy of the developed prediction models was assessed using RMSE, MAE, and R2 (Table 5). The models were subsequently compared to baseline models. According to RMSE values, the developed model for predicting ash contents outperformed its baseline.

Table 5.

Results of ash content prediction performance.

| Property | Model | RMSE | MAE | R2 |

|---|---|---|---|---|

| Ash | CNN | 0.0169 | 0.0125 | 0.9204 |

| Baseline | 0.0599 | 0.0521 | 0.0000 |

Root-mean-square errors for ash content were 0.0169 and 0.0599 for the CNN and baseline models, respectively. The CNN model exhibited a MAE of 0.0125, which excelled over its baseline, and a high R2 of 0.9204, which also proved it reliable. Thus, the developed model was deemed apt for predicting the ash content of wheat flour.

The wheat cultivar used in this study was Baekgang, cultivated in Haman, Gyeongsangnam-do in South Korea and it was genetically modified for baking as an end product. For the quality of bread, predicting ash content seems significantly important in relevant industry. However, the precision of developed model can be decreased considering the preprocessing environment or the performance of milling machine. Also, predicting other chemical properties with selected wheat cultivar is not appropriate but takes alternative cultivars into account for targeting end product.

3.4. Prediction of starch, fat and protein contents

The regression models for predicting the other chemical properties were developed with the same architecture as for ash content, and the results are presented in Table 6. The model was unreliable for predicting starch content, with RMSEs of 0.7385 and 0.3785 for the CNN and baseline, respectively. The MAE also did not excel over its baseline, and R2 was poor at −2.8071. However, the performances of predicting fat and protein contents were better than for starch. The RMSE values were 0.0709 and 0.0912 for fat content and 0.2111 and 0.3847 for protein content, for the CNN and baseline, respectively. The MAE values for the CNN excelled over their baselines for both fat and protein contents, and R2 values were 0.4029 and 0.6991 for fat and protein respectively.

Table 6.

Results of property prediction performance except ash content.

| Property | Model | RMSE | MAE | R2 |

|---|---|---|---|---|

| Starch | CNN | 0.7385 | 0.5509 | −2.8071 |

| Baseline | 0.3785 | 0.3183 | 0.0000 | |

| Fat | CNN | 0.0709 | 0.0525 | 0.4029 |

| Baseline | 0.0912 | 0.0717 | 0.0000 | |

| Protein | CNN | 0.2111 | 0.1641 | 0.6991 |

| Baseline | 0.3847 | 0.3534 | 0.0000 |

Comparing these performance results, the selected preprocessing method only exhibited a significant effect in predicting ash content. The aleurone layer contributing the main proportion of ash in wheat grain was eliminated, so the ash content could be predicted based on preprocessing levels, which was not the case with the other properties. Therefore, alternative methods are needed for accurate quality prediction in wheat flour. Scanning technologies, such as NIR hyperspectral imaging, have been used in other studies, and spectral data have shown efficacy in predicting the general physicochemical properties of wheat flour [58]. Furthermore, the integration of NIR data with artificial neural network technologies has yielded high accuracy in predicting protein content [59]. The use of various spectrometers has also advanced the methods for predicting the chemical properties of both wheat grain and flour [60,61]. Remarkably, the current prediction model for ash content required no high-cost equipment and yet achieved a comparable level of accuracy.

4. Conclusions

Despite the acknowledge nutrients benefits of whole wheat flour, providing white wheat flour is still required. The quality of wheat flour can be varied with eliminating the aleurone layer but precise technology is required in food industry. In this study, a representative data of wheat kernel was acquired with varying the debranning time to develop a prediction model for the quality of white wheat flour before milling and the relationship between variables and physical properties were analyzed. The three levels of debranning time (0, 30, 60 s) were considered as preprocessing for milling. As a result, decreasing yield of polishing and milling were observed with the longer debranning time but improved RGB and Lab color data were acquired which is close to a pure white in color. Moreover, the proportion of fine wheat flour particle size in 10–60 μm was increased with preprocessing time while the proportion of wheat flour with particle size in 100–400 decreased significantly. The flour qualities (starch, fat, protein, ash and M.C.) were analyzed with three levels of debranning time. The fat and protein value of wheat flour was significantly increased with the longer debranning time while that of ash and M.C. value was decreased. The longer debranning time of wheat kernel is seemed to have a great effect on improving the food quality of end product such as bread, pasta and cookies by providing the fine and qualified wheat flour.

Total 750 images of wheat kernel were acquired (250 images for each debranning level) for developing the quality prediction model of wheat flour. The models were developed using machine learning technology then evaluated in tems of R2, RMSE and MAE. However, only the model for ash content proved reliable regarding high value of R2 (R2: 0.9204), RMSE and MAE values were excelled over their baseline. Regarding the performance of developed regression model, the ash content mainly contained in aleurone layer whereas the others (starch, fat and protein) are in the endosperm and germ. Considering the structure of wheat grain, selected pretreatment could only control the outer layer, the aleurone layer, so the high performance of predicting the ash content. Therefore, the future works for improving the reliability of other chemical properties except ash content were remained. The preprocessing step additionally conferred the advantage of reduced particle size in wheat flour, potentially enhancing the rheological properties of the end products. These findings amplify the feasibility of satisfying diverse and extensive demands in the food market through controlling the ash content in wheat flour.

Data availability

The authors do not have permission to share data.

CRediT authorship contribution statement

Seokho Kang: Writing – original draft, Formal analysis, Conceptualization. Yonggik Kim: Methodology, Investigation. Oladayo S. Ajani: Software, Formal analysis. Rammohan Mallipeddi: Writing – review & editing. Yushin Ha: Project administration, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by Rural Development Administration (RDA) through Cooperative Research Program for Agriculture Science and Technology Development (PJ016981), funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA).

References

- 1.Reynolds M.P., Braun H. Springer Nature; 2022. Wheat Improvement: Food Security in a Changing Climate. [DOI] [Google Scholar]

- 2.Campbell G.M. Roller milling of wheat. Handbook of powder technology. 2007;12:383–419. doi: 10.1016/S0167-3785(07)12010-8. [DOI] [Google Scholar]

- 3.Bresciani L., Scazzina F., Leonardi R., Dall'Aglio E., Newell M., Dall'Asta M., Melegari C., Ray S., Brihenti F., Del Rio D. Bioavailability and metabolism of phenolic compounds from wholegrain wheat and aleurone-rich wheat bread. Mol. Nutr. Food Res. 2016;60(11):2343–2354. doi: 10.1002/mnfr.201600238. [DOI] [PubMed] [Google Scholar]

- 4.Fardet A. New hypotheses for the health-protective mechanisms of whole-grain cereals: what is beyond fibre? Nutr. Res. Rev. 2010;21(1):65–134. doi: 10.1017/S0954422410000041. [DOI] [PubMed] [Google Scholar]

- 5.Brouns F., Hemery Y., Price R., Anson N.M. Wheat Aleurone: separation, composition, health aspects, and potential food use. Crit. Rev. Food Sci. Nutr. 2012;52(6):553–568. doi: 10.1080/10408398.2011.589540. [DOI] [PubMed] [Google Scholar]

- 6.Costabile G., Vitale M., Della Pepa G., Cipriano P., Vetrani C., Testa R., Mena P., Bresciani L., Tassotti M., Calani L., Del Rio D., Brighenti F., Bapoli R., Rivellese A.A., Riccardi G., Giacco R. A wheat aleurone-rich diet improves oxidative stress but does not influence glucose metabolism in overweight/obese individuals: results from a randomized controlled trial. Nutr. Metabol. Cardiovasc. Dis. 2022;32(3):715–726. doi: 10.1016/j.numecd.2021.12.016. [DOI] [PubMed] [Google Scholar]

- 7.Vitaglione P., Mennella I., Ferracane R., Rivellese A.A., Giacco R., Ercolini D., Gibbons S.M., Storia A.L., Gilbert J.A., Jonnalagadda S., Thielecke F., Gallo M.A., Scalfi L., Fogliano V. Whole-grain wheat consumption reduces inflammation in a randomized controlled trial on overweight and obese subjects with unhealthy dietary and lifestyle behaviors: role of polyphenols bound to cereal dietary fiber. Am. J. Clin. Nutr. 2015;101(2):251–261. doi: 10.3945/ajcn.114.088120. [DOI] [PubMed] [Google Scholar]

- 8.Ye E.Q., Chacko S.A., Chou E.L., Kugizaki M., Liu S. Greater whole-grain intake is associated with lower risk of type 2 diabetes, cardiovascular disease, and weight gain. J. Nutr. 2012;142(7):1304–1313. doi: 10.3945/jn.111.155325. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Zhang D., Moore W.R. Wheat bran particle size effects on bread baking performance and quality. J. Sci. Food Agric. 1999;79(6):805–809. doi: 10.1002/(SICI)1097-0010(19990501)79:6<805::AID-JSFA285>3.0.CO;2-E. [DOI] [Google Scholar]

- 10.Zhou T., Ying R., Huang M., Tang Z. Effect of aleurone-rich fraction on texture and nutritional properties of breads. Int. J. Food Sci. Technol. 2022;57(12):7942–7951. doi: 10.1111/ijfs.16150. [DOI] [Google Scholar]

- 11.AbuKhader M., Abdelraziq R., Al-Azawi M., Ali S.K. A comparative examination of dietary sodium content in bread and its public consumption pattern in Muscat, Osman, Nutrition and. Food Sci. (N. Y.) 2019;50(1):116–130. doi: 10.1108/NFS-02-2019-0058. [DOI] [Google Scholar]

- 12.Gonzalez-Anton C., Artacho R., Ruiz-Lopez M.D., Gill A., Mesa M.D. Modification of appetite by bread consumption: a systematic review of randomized controlled trials. Crit. Rev. Food Sci. Nutr. 2017;57(14):3035–3050. doi: 10.1080/10408398.2015.1084490. [DOI] [PubMed] [Google Scholar]

- 13.Engindeniz S., Bolatova Z. A study on consumption of composite flour and bread in global perspective. Br. Food J. 2021;123(5):1962–1973. doi: 10.1108/BFJ-10-2018-0714. [DOI] [Google Scholar]

- 14.Ilktac H.Y., Sadik M., Garipagaoglu M. Types of bread preferred by adult individuals and bread's place in daily nutrition. Prog. Nutr. 2021;23 doi: 10.23751/pn.v23i3.10858. [DOI] [Google Scholar]

- 15.Sandvik P., Kihiberg I., Lindroos A.K., Marklinder I., Nydahl M. Bread consumption patterns in a Swedish national dietary survey focusing particularly on whole-grain and rye bread. Food Nutr. Res. 2014;58(1) doi: 10.3402/fnr.v58.24024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Greffeuille V., Abecassis J., L'Helgouac’h C.B., Lullien-Pellerin V. Differences in the aleurone layer fate between hard and soft common wheats at grain milling. Cereal Chem. 2005;82(2):138–143. doi: 10.1094/CC-82-0138. [DOI] [Google Scholar]

- 17.Kamal-Eldin A., Laerke H.N., Knudsen K.B., Lampi A., Piironen V., Adlercreutz H., Katina K., Poutanen K., Aman P. Physical, microscopic and chemical characterization of industrial rye and wheat brans from the Nordic countries. Food Nutr. Res. 2022;53(1):1912. doi: 10.3402/fnr.v53i0.1912. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Gomez M., Jimenez S., Ruiz E., Oliete B. Effect of extruded wheat bran on dough rheology and bread quality. LWT--Food Sci. Technol. 2011;44(10):2231–2237. doi: 10.1016/j.lwt.2011.06.006. [DOI] [Google Scholar]

- 19.Curti E., Carini E., Bonacini G., Tribuzio G., Vittadini E. Effect of the addition of bran fractions on bread properties. J. Cereal. Sci. 2013;57(3):325–332. doi: 10.1016/j.jcs.2012.12.003. [DOI] [Google Scholar]

- 20.Lin S., Jin X., Gao J., Qiu Z., Ying J., Wang Y., Dong Z., Zhou W. Impact of wheat bran micronization on dough properties and bread quality: Part Ⅱ - quality, antioxidant and nutritional properties of bread. Food Chem. 2022;396 doi: 10.1016/j.foodchem.2022.133631. [DOI] [PubMed] [Google Scholar]

- 21.Singh S., Singh N. Effect of debranning on the physico-chemical, cooking, pasting and textural properties of common and durum wheat varieties. Food Res. Int. 2010;43(9):2277–2283. doi: 10.1016/j.foodres.2010.07.016. [DOI] [Google Scholar]

- 22.Tibola C.S., Guarienti E.M., Dias A.R.G., Nicolau M., Devos R.J.B., Teixeira D.D. Effect of debranning process on deoxynivalenol content in whole-wheat flours. Cereal Chem. 2019;96(4):717–724. doi: 10.1002/cche.10168. [DOI] [Google Scholar]

- 23.Qi Y., Yang Y., Hamadou A.H., Li B., Xu B. Gentle debranning as a technology to reduce microbial and deoxynivalenol levels in common wheat (Triticum aestivum L.) and its application in milling industry. J. Cereal. Sci. 2022;107 doi: 10.1016/j.jcs.2022.103518. [DOI] [Google Scholar]

- 24.Bottega G., Caramanico R., Lucisano M., Mariotti M., Franzetti L., Pagani M.A. The debranning of common wheat (Triticum aestivum L.) with innovative abrasive rolls. J. Food Eng. 2009;94(1):75–82. doi: 10.1016/j.jfoodeng.2009.03.002. [DOI] [Google Scholar]

- 25.Ayoub W.S., Zahoor I., Dar A.H., Anjum N., Pandiselvam R., Farooq S., Rusu A.V., Rocha J.M., Trif M., Jeevarathinam G. Effect of incorporation of wheat bran, rice bran and banana peel powder on the mesostructured and physicochemical characteristics of biscuits. Front. Nutr. 2022;9 doi: 10.3389/fnut.2022.1016717. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Aravind N., Sissons M., Egan N., Fellows C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012;130(2):299–309. doi: 10.1016/j.foodchem.2011.07.042. [DOI] [Google Scholar]

- 27.Hemdane S., Jacobs P.J., Dornez E., Verspreet J., Delcour J.A., Courtin C.M. Wheat (Triticum aestivum L.) bran in bread making: a critical review. Compr. Rev. Food Sci. Food Saf. 2016;15(1):28–42. doi: 10.1111/1541-4337.12176. [DOI] [PubMed] [Google Scholar]

- 28.Khalid K.H., Ohm J.B., Simsek S. Whole wheat bread: effect of bran fractions on dough and end-product quality. J. Cereal. Sci. 2017;78:48–56. [Google Scholar]

- 29.Seyer M.E., Gelinas P. Bran characteristics and wheat performance in whole wheat bread. Int. J. Food Sci. Technol. 2009;44(4):688–693. doi: 10.1111/j.1365-2621.2008.01819.x. [DOI] [Google Scholar]

- 30.Bagdi A., Toth B., Lorincz R., Szendi S., Gere A., Kokai Z., Sipos L. Effect of aleurone-rich flour on composition, baking, textural, and sensory properties of bread. LWT-Food Science and Techonology. 2016;65:762–769. doi: 10.1016/j.lwt.2015.08.073. [DOI] [Google Scholar]

- 31.Bagdi A., Szabo F., Gere A., Kokai Z., Sipos L., Tomoskozi S. Effect of aleurone-rich flour on composition, cooking, textural, and sensory properties of pasta. LWT--Food Sci. Technol. 2014;59(2):996–1002. doi: 10.1016/j.lwt.2014.07.001. [DOI] [Google Scholar]

- 32.Xu M., Hou G.G., Ma F., Ding J., Deng L., Kahraman O., Niu M., Trivettea K., Lee B., Wu L., Baik B.K. Evaluation of aleurone flour on dough, textural, and nutritional properties of instant fried noodles. LWT--Food Sci. Technol. 2020;126 doi: 10.1016/j.lwt.2020.109294. [DOI] [Google Scholar]

- 33.Pruckler M., Siebenhandl-Ehn S., Apprich S., Holtinger S., Haas C., Schmid E., Kneifel W. Wheat bran-based biorefinery 1: composition of what bran and strategies of functionalization. LWT--Food Sci. Technol. 2014;56(2):211–221. doi: 10.1016/j.lwt.2013.12.004. [DOI] [Google Scholar]

- 34.Lebert L., Buche F., Sorin A., Aussenac T. The wheat aleurone layer: optimisation of its benefits and application to bakery products. Foods. 2022;11(22):3552. doi: 10.3390/foods11223552. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Antoine C., Lullien-Pellerin V., Abecassis J., Rouau X. Effect of wheat bran ball-milling on fragmentation and marker extractability of the aleurone layer. J. Cereal. Sci. 2004;40:275–282. https://doii.org/10.1016/j.jcs.2004.08.002 [Google Scholar]

- 36.Shewry P.R., Wan Y., Hawkesford M.J., Tosi P. Spatial distribution of functional components in the starchy endosperm of wheat grains. J. Cereal. Sci. 2020;91 doi: 10.1016/j.jcs.2019.102869. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Deng L., Li J., Han Z. Online defect detection and automatic grading of carrots using computer vision combined with deep learning methods. LWT. 2021;149 doi: 10.1016/j.lwt.2021.111832. [DOI] [Google Scholar]

- 38.Li Q., Zeng J., Lin L., Zhang J., Zhu J., Yao L., Wang S., Du J., Wu Z. Mid-infrared spectra feature extraction and visualization by convolutional neural network for sugar adulteration identification of honey and real-world application. LWT. 2021;140 doi: 10.1016/j.lwt.2021.110856. [DOI] [Google Scholar]

- 39.Liu Z., Jiang J., Qiao X., Qi X., Pan Y., Pan X. Using convolution neural network and hyperspectral image to identify moldy peanut kernels. LWT. 2021;132 doi: 10.1016/j.lwt.2020.109815. [DOI] [Google Scholar]

- 40.Fan S., Li J., Zhang Y., Tian X., Wang Q., He X., Zhang C., Huang W. On line detection of defective apples using computer vision system combined with deep learning methods. J. Food Eng. 2020;286 doi: 10.1016/j.jfoodeng.2020.110102. [DOI] [Google Scholar]

- 41.Zhu L., Spachos P., Pensini E., Plataniotis K.N. Deep learning and machine vision for food processing: a survey. Curr. Res. Food Sci. 2021;4:233–249. doi: 10.1016/j.crfs.2021.03.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Jeong S., Lee D., Yang G., Kwon H., Kim M. Unravelling the physicochemical features of US wheat flours over the past two decades by machine learning analysis. LWT. 2022;169 doi: 10.1016/j.lwt.2022.114036. [DOI] [Google Scholar]

- 43.Zhao W., Liu S., Li X., Han X., Yang H. Fast and accurate wheat grain quality detection based on improved YOLOv5. Comput. Electron. Agric. 2022;202 doi: 10.1016/j.compag.2022.107426. [DOI] [Google Scholar]

- 44.Liu C., Liu L., Li L., Hao C., Zheng X., Bian K., Zhang J. Effects of different milling processes on whole wheat flour quality and performance in steamed bread making. LWT--Food Sci. Technol. 2015;62(1):310–318. doi: 10.1016/j.lwt.2014.08.030. [DOI] [Google Scholar]

- 45.AACC, Approved methods of the American Association of Cereal Chemist . Methods 08-01 (Ash), 30-10(fat), 76-12(starch), 46-08(protein) eleventh ed. American Association of Cereal Chemists; St. Paul, Minnesota: 2000. [Google Scholar]

- 46.Bigne F., Puppo M.C., Ferrero C. Fibre enrichment of wheat flour with mesquite (Prosopis spp.): effect on breadmaking performance and staling. LWT--Food Sci. Technol. 2016;65:1008–1016. doi: 10.1016/j.lwt.2015.09.028. [DOI] [Google Scholar]

- 47.Baasandorj T., Ohm J.B., Dykes L., Simsek S. Evaluation of the quality scoring system of hard red spring what using four different roller mills. Int. J. Food Prop. 2018;21(1):1017–1030. doi: 10.1080/10942912.2018.1477160. [DOI] [Google Scholar]

- 48.Baasandorj T., Ohm J.B., Manthey F., Simsek S. Effect of kernel size and mill type on protein, milling yield, and baking quality of hard red spring wheat. Cereal Chem. 2015;92(1):81–87. doi: 10.1094/CCHEM-12-13-0259-R. [DOI] [Google Scholar]

- 49.Li C., Tilley M., Chen R., Siliveru K., Li Y. Effect of bran particle size on rheology properties and baking quality of whole wheat flour from flour different varieties. LWT. 2023;175 doi: 10.1016/j.lwt.2023.114504. [DOI] [Google Scholar]

- 50.Almeida E.L., Chang Y.K., Steel C.J. Dietary fibre sources in bread: influence on technological quality. LWT--Food Sci. Technol. 2013;50(2):545–553. doi: 10.1016/j.lwt.2012.08.012. [DOI] [Google Scholar]

- 51.Liu T., Hou G.G., Lee B., Marquart L., Dubat A. Effects of particle size on the quality attributes of reconstituted whole-wheat flour and tortillas made from it. J. Cereal. Sci. 2016;71:145–152. doi: 10.1016/j.jcs.2016.08.013. [DOI] [Google Scholar]

- 52.Ma S., Wang C., Li L., Wang X. Effects of particle size on the quality attributes of wheat flour made by the milling process. Cereal Chem. 2019;97(2):172–182. doi: 10.1002/cche.10230. [DOI] [Google Scholar]

- 53.Pang J., Guan E., Yang Y., Li M., Bian K. Effects of wheat flour particle size on flour physicochemical properties and steamed bread quality. Food Sci. Nutr. 2020;9(9):4691–4700. doi: 10.1002/fsn3.2008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Wang N., Hou G.G., Dubat A. Effects of flour particle seize on the quality attributes of reconstituted whole-wheat flour and Chinese southern-type steamed bread. LWT-Food Sci. Technol. 2017;82:147–153. doi: 10.1016/j.lwt.2017.04.025. [DOI] [Google Scholar]

- 55.Wang N., Hou G.G., Kweon M., Lee B. Effects of particle size on the properties of whole-grain soft wheat flour and its cracker baking performance. J. Cereal. Sci. 2016;69:187–193. doi: 10.1016/j.jcs.2016.03.010. [DOI] [Google Scholar]

- 56.Bressiani J., Oro T., Santetti G.S., Almeida J.L., Bertolin T.E., Gomez M., Gutkoski L.C. Properties of whole grain wheat flour and performance in bakery products as a function of particle size. J. Cereal. Sci. 2017;75:269–277. doi: 10.1016/j.jcs.2017.05.001. [DOI] [Google Scholar]

- 57.Kundu M., Khatkar B.S., Gulia N., Kumar R. Funtional characterization of whole wheat flours for chapatti quality and acceptability. J. Food Sci. Technol. 2019;56:2296–2304. doi: 10.1007/s13197-019-03721-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 58.Golea C.M., Codina G.G., Oroian M. Prediction of wheat flours composition using fourier transform infrared spectrometry (FT-IR) Food Control. 2023;143 doi: 10.1016/j.foodcont.2022.109318. [DOI] [Google Scholar]

- 59.Mutlu A.C., Boyaci I.H., Genis H.E., Ozturk R., Basaran-Akgul N., Sanal T., Evlice A.K. Prediction of wheat quality parameters using near-infrared spectroscopy and artificial neural networks. Eur. Food Res. Technol. 2011;233:267–274. doi: 10.1007/s00217-011-1515-8. [DOI] [Google Scholar]

- 60.Li J., Zhang S., Liu C., Yin Y., Sun X., We J. Characterization of ash content in wheat flour using data fusion. Infrared Phys. Technol. 2023;133 doi: 10.1016/j.infrared.2023.104792. [DOI] [Google Scholar]

- 61.Nagel-Held J., Kaiser L., Longin C.F.H. Prediction of wheat quality parameters combining Raman, fluorescence, and near-infrared spectroscopy (NIRS) Cereal Chem. 2022;99(4):830–842. doi: 10.1002/cche.10540. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The authors do not have permission to share data.