Abstract

This study investigates the application of the multiobjective grey wolf optimizer (MOGWO) for optimal placement of thyristor-controlled series compensator (TCSC) to minimize power loss in power systems. Two conflicting objectives are considered: (1) minimizing real and reactive power loss, and (2) minimizing real power loss and TCSC capital cost. The Pareto-optimal method is employed to generate the Pareto front for these objectives. The fuzzy set technique is used to identify the optimal trade-off solution, while the technique for order preference by similarity to the ideal solution suggests multiple optimal solutions catering to diverse utility preferences. Simulations on an IEEE 30 bus test system demonstrate the effectiveness of TCSC placement for power loss minimization using MOGWO. The superiority of MOGWO is confirmed by comparing its results with those obtained from a multiobjective particle swarm optimization algorithm. These findings can assist power system utilities in identifying optimal TCSC locations to maximize their performance.

Keywords: Thyristor controlled series compensator, FACTS, Multiobjective grey wolf optimizer, Pareto-optimal technique, TOPSIS

Subject terms: Energy science and technology, Engineering

Introduction

Electrical energy demand across the globe is exponentially rising as a consequence of rapid urbanization and industrialization. On the other hand, deterrents like environmental and economic limitations have contained the installation of new transmission lines and generating plants. Under these circumstances, it has become inevitable for the utilities to operate electric power systems at their full capacities making the system vulnerable to cascaded outages1. This scenario has led to finding ways to utilize the existing infrastructure more efficiently.

Fortunately, with the emergence of power electronic switching circuits, the concept of the flexible alternating current transmission system (FACTS) introduced by Hingorani and Gyugyi2 unfolded as a promising solution for a plethora of electrical engineering issues like power quality, congestion management and power loss reduction3–7. In8, THE AUTHORS PRESENTED A comprehensive review of FACTS devices, their deployment methods and MERITS are presented. To yield the potential benefits of FACTS devices, they should be installed at an optimal location in the power system9. TCSC is an exceptional FACTS device that can be introduced into the system at a strategic location to improve the transient stability, augment the power transfer capacity and reduce the loss in power transmission10–13. ALTHOUGH VARIOUS FACT DEVICES EXIT, TCSC can modify the reactance of the line, thereby augmenting the peak power that can be transferred on that line in addition to diminishing the effective reactive power losses14. The TCSC can be operated as the capacitive or inductive compensation respectively by directly modifying the reactance of the transmission line. Hence in this study, we explore the BENEFITS of optimal installation of TCSC.

Literature review

In the last decade, umpteen techniques have been proposed for tracing the optimal location of TCSC. A sensitivity index is introduced in15 for tracing the optimal location of TCSC. To cater TO the optimal location problem of TCSC and other FACTS devices, many researchers suggested the use of intelligent optimization algorithms. In16, the authors highlighted the application of genetic algorithms (GA) to solve the optimal siting problem of TCSC. A particle swarm optimization (PSO) technique is suggested, considering system loadability and installation cost for optimal TCSC location in17. The superiority of the bacterial swarming optimization algorithm in solving the optimal location problem over its peers GA and PSO is illustrated in18. The concept of differential evolution (DE) is used for locating FACTS devices in19. A strategy taking cues from adaptive particle swarm optimization and DE is suggested in20 to offer an optimal solution for FCATS device installation. A hybrid algorithm combining ant lion optimization, moth flame optimization, and salp swarm optimization is implemented21 to locate the optimal position of TCSC.

A whale optimization technique is proposed22 to solve the optimal TCSC installation problem for reactive power planning. The objectives considered are loss minimization and MINIMIZATION OF THE OPERATION COST OF TCSC. SIMILAR WITH THE SAME OBJECTIVES, a study is presented in23 to solve the optimal TCSC installation problem using some hybrid optimization techniques. Authors in24 explored the BENEFITS of optimal TCSC installation for enhancing the available transfer capability of transmission lines. A technical and economic analysis is presented25, to OPTIMALLY LOCATE TCSC USING THE algorithm. Authors in26 conducted investigations to optimally install multiple FACTS devices INCLUDING TCSC for operational enhancement of the power system. The annual cost of FACTS devices is also considered ONE OF THE OBJECTIVES IN THE multiobjective function formulated. Recently in27, authors solved the optimal positioning problem of the TCSC in the presence of electrical vehicle charging stations using PSO.

Research gap and motivation

The abundant existing literature on power loss minimization and the optimal location of the FACTS device is focused on either solving one objective alone or converting a multiobjective problem into a single objective function by employing weighted sum method. In this method, a weight is given to each objective DEPENDING ON its relative importance. Although this method is simple, it cannot trace the optimal trade-off solution in the non-convex region; consequently, the obtained solution may not be the first-rate optimal solution for the weights chosen28. To avoid such a problem, in this study Pareto optimal method29 is adopted to obtain the Pareto-optimal frontier. Real and reactive power loss, REAL POWER LOSS, AND CAPITAL COST OF TCSC are the two multiobjective functions considered for minimization. We ATTEMPT TO EXPLORE THE CAPABILITIES OF THE multiobjective grey wolf optimizer (MOGWO) presented in30 to solve multiobjective problems under consideration. Further, to underscore the precedence of the MOGWO algorithm, a comparative analysis with MOPSO is also presented.

Contributions of the work

The contributions of this paper are as follows:

A Pareto-optimality-BASED multiobjective optimization approach is proposed for optimal installation of TCSC.

Two case studies are formulated FOR THE OPTIMAL INSTALLATION of TCSC using the proposed approach. Case study 1, deals with real and reactive power loss as multiple objectives. Whereas, in case 2, the real power loss and capital cost of TCSC are considered in the multiobjective function.

A COMPARISON of MOGWO algorithm is performed with MOPSO in solving the multiobjective-BASED OPTIMAL TCSC INSTALLATION PROBLEM.

A fuuzy set technique is used to select the optimal trade-off solution from the Pareto-optimal solutions in each case study. However, to provide more diversity in the solutions provided, technique for order preference by similarity to the ideal solution (TOPSIS) methodology is adopted and multiple optimal trade-off solutions are suggested.

Paper orginazation

The remnant of this article is categorized as follows. Section "Thyristor controlled series compensator" is about TCSC and its modelling. In section "Problem formulation", the objective function and the constraints considered are presented. The MOGWO algorithm and the selection of the best optimal solution using the fuzzy and TOPSIS approach ARE DISCUSSED in Section "Optimization methods". In Section "Results and discussion", the results generated are presented and discussed. Finally, the conclusion of the article is presented in Section "Conclusion".

Thyristor controlled series compensator

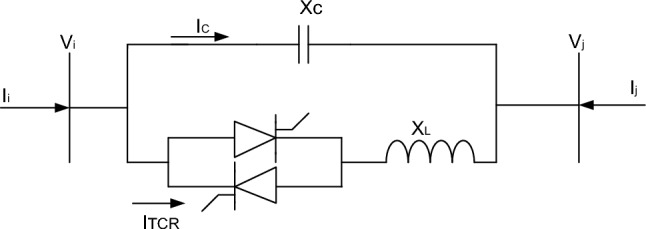

TCSC is a series compensator that comprises of thyristor thyristor-controlled reactor in parallel with a capacitor, as shown in Fig. 1.

Fig. 1.

TCSC Model.

In the above model, Ii is the current flow through branch ij, Ij is the current flow through branch ji, Vi is the magnitude of the voltage at bus i and Vj is the magnitude of the voltage at bus j.

In Fig. 1, two thyristors are connected in anti-parallel in series with the inductor. By controlling the firing angle , the TCSC can be operated as either a capacitive compensator or an inductive compensator.

The reactance of the TCSC can be expressed as follows31:

| 1 |

| 2 |

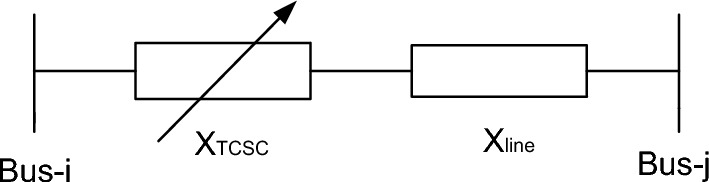

TCSC can be connected to the power transmission line as a series compensator32. In the steady-state analysis, the reactance of TCSC can be adjusted as a static reactance.

The block diagram representation of the transmission line with TCSC is shown in Fig. 2.

| 3 |

| 4 |

| 5 |

where is the transmission line reactance with compensation, is the line reactance without compensation, is the reactance of TCSC and is the degree of compensation. The range of to avoid overcompensation is given as6:

| 6 |

Fig. 2.

Block diagram of TCSC.

Problem formulation

Objective function

The minimization functions considered are33:

| 7 |

| 8 |

where and are the real and reactive power loss of line m and denotes the total number of lines

| 9 |

| 10 |

where Vi and Vj are the ith bus & jth bus voltages, denotes the phase difference between ith bus & jth bus, Gij denotes the real part of the admittance between buses i & j and Bij denotes the imaginary part of line admittance between buses i & j.

The fitness function for reduction of the capital cost of TCSC is framed as per Eq. (11)6.

| 11 |

where is the capital cost of TCSC in US$/KVar, = is the operating range of TCSC in MVar, , and are reactive power flow through the branch before TCSC installation and after TCSC installation, respectively.

Constraints

The constraints are taken as shown below:

-

(b)Inequality Constraints34:

14 15 16 17 18

where and are the values of voltages at load bus and generator bus respectively, denotes the generated reactive power generator bus, is reactive power injected by the shunt capacitor at bus, is the transformer tap setting of the is the reactance of TCSC at line-19

Optimization methods

Multiobjective grey wolf optimizer algorithm

MOGWO algorithm is proposed by Mirjalili et al.30. Like many other infamous metaheuristic optimization algorithms, MOGWO also draws its inspiration from nature. This algorithm simulates the pack hierarchy and the hunting strategy of grey wolves. Grey wolves naturally prefer to forage in packs of 5–12 members. The pack hierarchy of grey wolves consists of four hierarchal levels of wolves, namely alpha (α), beta (β), delta (δ), and omega (ω), with α wolves being the most dominant ones and ω wolves being the least dominant ones. The hunting strategy of grey wolves is yet another intriguing social behavior of grey wolves. Searching, encircling, harassing, and attacking the prey are the main phases of grey wolves hunting strategy. The encircling phase is mathematically modeled as30 :

| 20 |

| 21 |

Here and denote the position vectors of grey wolf and prey respectively for the iteration tth iteration. and are the coefficient vectors which are evaluated by equations given below.

| 22 |

| 23 |

The elements of the vector are decreased linearly from 2 to 0 as the iterations progress and r1, r2 represent random vectors in [0, 1]. It is observed that the coefficient vectors and have the capacity to control exploration and exploitation. |A|> 1 diverges the grey wolves from the location of the prey, thereby assisting exploration. The coefficient vector also assists exploration; it takes random values in [0,2]. The random values of either emphasize (C > 1) or deemphasize (C < 1) the effect of prey in determining the distance. Unlike the value of is not decreased linearly; this enables the GWO algorithm to exhibit stochastic behavior through the search process. As a consequence, exploration is favored, and local optima stagnation is avoided. |A|< 1 converges the grey wolves towards the location of prey which assists the exploitation.

The GWO algorithm emulates the pack hierarchy and encircling phase of hunting to determine the best solution for a given problem. During the search process, the α, β, and δ wolves are assumed to possess superior knowledge regarding the location of the prey. The pack hierarchy of grey wolves is mathematically modeled by considering the best solution as α. Consequently, the next best solution as β, and the third best solution as δ. All the other solutions are assumed as ω wolves. The first three best solutions obtained so far are saved, and the other search agents are forced to modify their positions as per the position of α, β, and δ using the following formulas30.

| 24 |

| 25 |

| 26 |

| 27 |

| 28 |

| 29 |

| 30 |

Two new components are inserted in the GWO algorithm to facilitate multiobjective optimization. The first component is an archive, which is nothing but a memory to store the non-dominated solutions generated so far. The second component is the leader-choosing mechanism that aids in selecting the best solutions from the archive to determine the alpha, beta, and delta wolves.

Multiobjective PSO

Particle swarm optimization algorithm is initially proposed by Dr Kennedy and Dr Eberhart35. This optimization technique mimics the group behavior of bird flocks and fish schools. Shorter running time and the requirement of fewer parameters are some of the noteworthy advantages of PSO. In the PSO algorithm, each particle has a velocity and position. While hovering in the search space, a particle's position is adjusted, balancing the particle's own knowledge and the knowledge of the swarm. The velocity and position equations are as follows34:

| 31 |

| 32 |

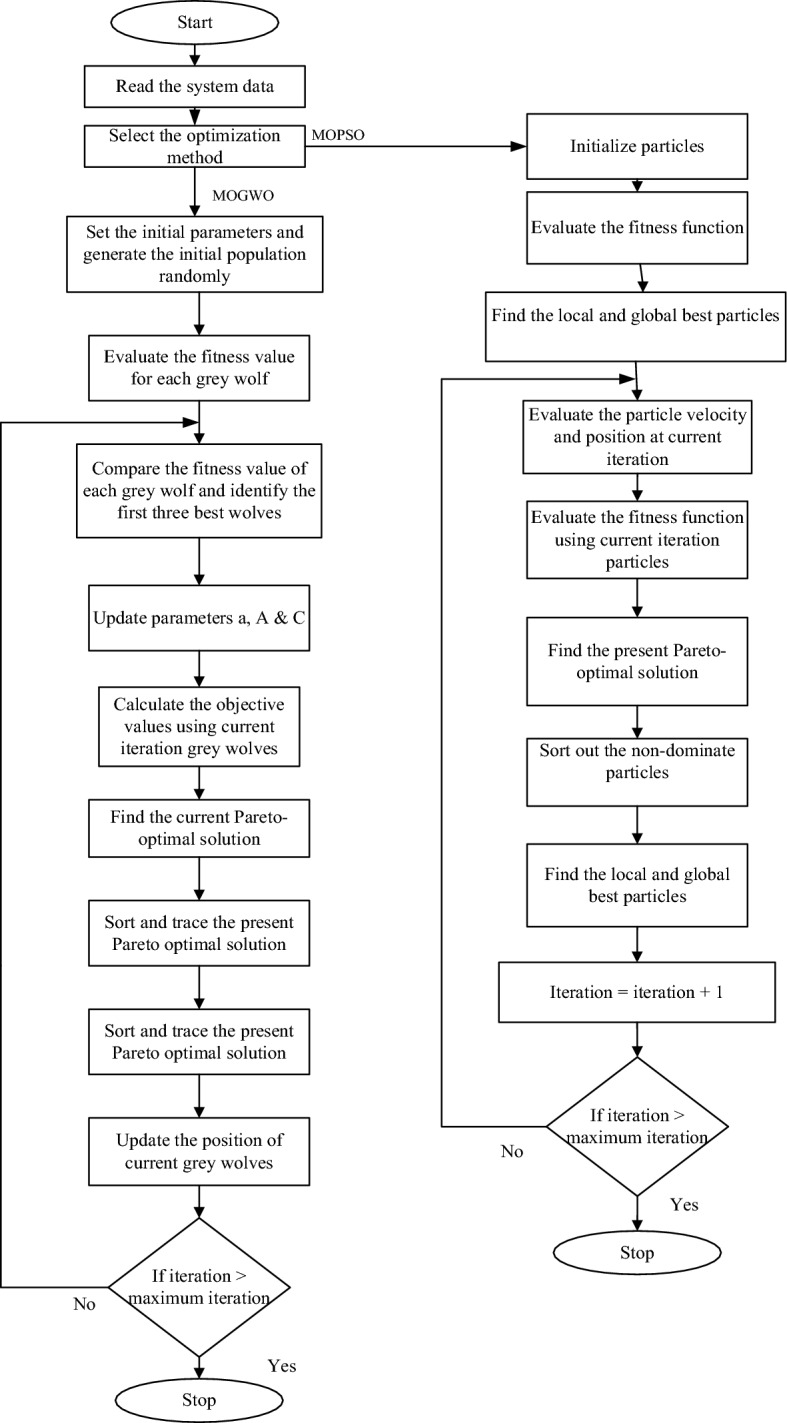

where k denotes the present iteration while k + 1 is the next iteration, Vi and Xi represent the velocity and position of the ith particle, respectively, is the ith particle's best value, and denotes the global best value. The flow chart of the algorithms used is presented in Fig. 3.

Fig. 3.

MOPSO and MOGWO flowchart.

Pareto-optimal technique

To provide a solution to conflicting multiple objective functions, the Pareto-optimal technique is explored in this study to generate a Pareto-front. The Pareto-front is a set of compromise solutions denoting the best trade-offs among the conflicting objectives. The idea of dominance is the basic principle of the Pareto-optimal technique. Vector V2 is dominated by vector V1 for the conditions stated below29,36 .

| 33 |

| 34 |

where is the total number of variables.

Selection of optimal trade-off solution

Fuzzy set technique

The optimal trade-off solution from Pareto-front is extracted by the fuzzy set technique37. A fuzzy membership function is developed to this purpose for every objective function, which is given is Eq. (35)33.

| 35 |

where and for the kth objective function denote the acceptable and unacceptable values, respectively. The membership function33 is given in Eq. (36).

| 36 |

where NO and ND respectively denote the number of objective functions and number of solutions in the Pareto-front for the rth non-dominated solution. The solution corresponding to the maximum membership is the optimal trade-off solution.

Technique for order preference by similarity to an ideal solution

The fuzzy set-based approach presented above identifies a single, optimal trade-off solution from the numerous Pareto-optimal solutions. However, this solution might not be universally preferred by all decision makers (electrical power transmission utilities) due to potential variations in their priorities regarding the study's objectives. To address this limitation, this work employs the TOPSIS method to generate a range of trade-off solutions, catering to a broader spectrum of decision-maker preferences. The following are the steps that makeup TOPSIS38 :

Step 1: Create a decision matrix with the size that contains Pareto optimal solutions, . In this case, j = 1, 2,…., indicates the objectives or criterion, while i = 1, 2,…., indicates the number of solutions/alternatives.

- Step 3: If necessary, a weighted normalized decision matrix can be created to assign weights to the objectives. If every goal is equally significant, you can skip this stage. The matrix's components are represented as:

where is the decision-makers preference weight assigned to the jth criterion and38 - Step 4: The weighted normalized choice matrix provides the positive ideal solution (PIS) and the negative ideal solution (NIS)38.

39 40 - Step 5: As indicated below, calculate the Euclidean distances and d for every solution derived from PIS and NIS.

41 42 - Step 6: The relative closeness index (RCI) is computed for each option using the Euclidean distances determined in the preceding step, as shown below38:

43

Among the Pareto optimum solutions, the solution with the highest closeness ratio value will be selected as the BTS.

Results and discussion

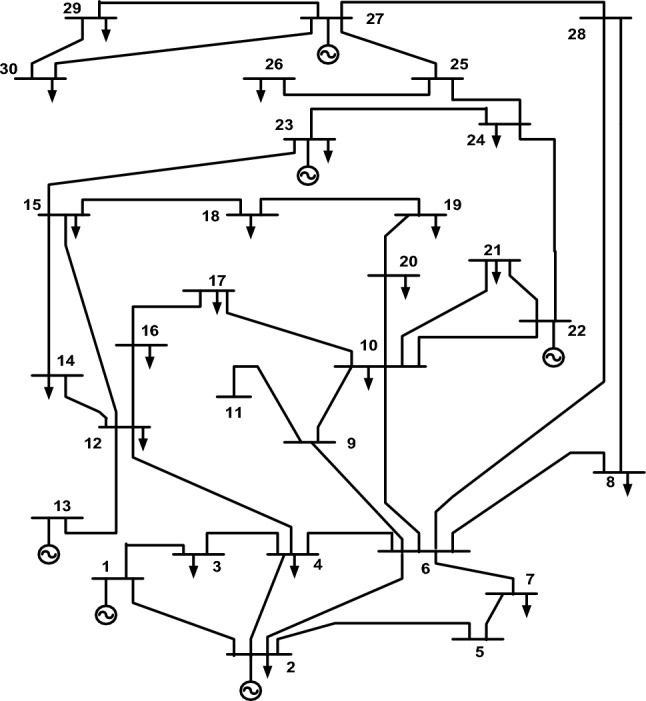

To evaluate the effect of TCSC placement on power loss reduction, analysis is performed on an IEEE 30 bus standard system. The structure of the test system is shown in Fig. 4. The parameters considered for the MOGWO and MOPSO are as follows: population size is 50, iterations are 10 and the archive size is 50. To emphasize the merit of TCSC installation, the power loss is computed without TCSC at first and later; the two multiobjective functions are minimized in the presence of TCSC at the optimal site.

Fig. 4.

IEEE 30 bus test system.

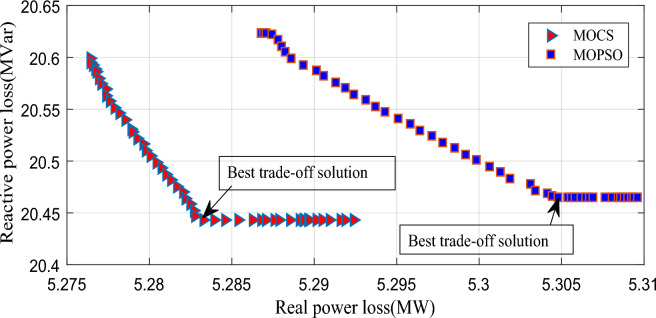

Power losses reduction without TCSC

The power loss of the 30 bus system is computed by load flow analysis. The total real power loss and reactive power loss are 5.5933 MW and 21.0658MVar, respectively. These loss values are treated as base case losses for the comparison of results. To the test system, MOGWO and MOPSO algorithms are applied, and the total real and reactive power losses are calculated. The Pareto-optimal solution, thus generated, is presented in Table 1. The optimal trade-off solution is captured from the Pareto-optimal frontier by the fuzzy set technique. The optimal trade-off solution found from the Pareto-optimal frontier of the MOPSO algorithm is 5.3048 MW and 20.4656 MVar. The optimal trade-off solution obtained from the Pareto-optimal frontier of the MOGWO algorithm is 5.2833 MW and 20.4436 MVar. It is visible that the MOGWO algorithm gave relatively better results. The comparative depiction of results from both algorithms is presented in Fig. 5.

Table 1.

MOGWO and MOPSO comparison.

| MOGWO | MOPSO | |||

|---|---|---|---|---|

| Solution No | Real power losses (MW) | Reactive power losses (MVar) | Real power losses (MW) | Reactive power losses(MVar) |

| 1 | 5.2764 | 20.5992 | 5.2868 | 20.6241 |

| 2 | 5.2764 | 20.5958 | 5.2868 | 20.6238 |

| 3 | 5.2766 | 20.5926 | 5.2869 | 20.6236 |

| 4 | 5.2767 | 20.5893 | 5.2871 | 20.6231 |

| 5 | 5.2768 | 20.5861 | 5.2874 | 20.6223 |

| 6 | 5.2769 | 20.5804 | 5.2878 | 20.6165 |

| 7 | 5.2771 | 20.5747 | 5.2880 | 20.6106 |

| 8 | 5.2774 | 20.5691 | 5.2882 | 20.6049 |

| 9 | 5.2774 | 20.5634 | 5.2886 | 20.5991 |

| 10 | 5.2776 | 20.5574 | 5.2893 | 20.5932 |

| 11 | 5.2779 | 20.5516 | 5.2901 | 20.5876 |

| 12 | 5.2782 | 20.5457 | 5.2906 | 20.5819 |

| 13 | 5.2785 | 20.5396 | 5.2913 | 20.5760 |

| 14 | 5.2789 | 20.5312 | 5.2919 | 20.5702 |

| 15 | 5.2790 | 20.5279 | 5.2924 | 20.5645 |

| 16 | 5.2793 | 20.5221 | 5.2931 | 20.5587 |

| 17 | 5.2796 | 20.5162 | 5.2937 | 20.5528 |

| 18 | 5.2798 | 20.5104 | 5.2943 | 20.5471 |

| 19 | 5.2801 | 20.5046 | 5.2951 | 20.5413 |

| 20 | 5.2804 | 20.4987 | 5.2958 | 20.5357 |

| 21 | 5.2807 | 20.4930 | 5.2964 | 20.5299 |

| 22 | 5.2810 | 20.4872 | 5.2971 | 20.5240 |

| 23 | 5.2813 | 20.4816 | 5.2978 | 20.5183 |

| 24 | 5.2817 | 20.4757 | 5.2985 | 20.5124 |

| 25 | 5.2820 | 20.4698 | 5.2992 | 20.5066 |

| 26 | 5.2822 | 20.4643 | 5.2998 | 20.5010 |

| 27 | 5.2825 | 20.4586 | 5.3006 | 20.4952 |

| 28 | 5.2827 | 20.4526 | 5.3013 | 20.4894 |

| 29 | 5.2828 | 20.4472 | 5.3019 | 20.4837 |

| 30 | 5.2833 | 20.4436 | 5.3031 | 20.4780 |

| 31 | 5.2839 | 20.4433 | 5.3034 | 20.4721 |

| 32 | 5.2846 | 20.4431 | 5.3041 | 20.4692 |

| 33 | 5.2854 | 20.4431 | 5.3044 | 20.4659 |

| 34 | 5.2863 | 20.4431 | 5.3048 | 20.4656 |

| 35 | 5.2868 | 20.4428 | 5.3054 | 20.4654 |

| 36 | 5.2871 | 20.4428 | 5.3056 | 20.4652 |

| 37 | 5.2876 | 20.4428 | 5.3058 | 20.4650 |

| 38 | 5.2879 | 20.4428 | 5.3062 | 20.4650 |

| 39 | 5.2885 | 20.4428 | 5.3065 | 20.4649 |

| 40 | 5.2891 | 20.4428 | 5.3067 | 20.4649 |

| 41 | 5.2893 | 20.4427 | 5.3069 | 20.4649 |

| 42 | 5.2894 | 20.4427 | 5.3076 | 20.4649 |

| 43 | 5.2896 | 20.4427 | 5.3081 | 20.4649 |

| 44 | 5.2897 | 20.4427 | 5.3084 | 20.4648 |

| 45 | 5.2901 | 20.4427 | 5.3086 | 20.4648 |

| 46 | 5.2905 | 20.4427 | 5.3088 | 20.4648 |

| 47 | 5.2909 | 20.4427 | 5.3090 | 20.4648 |

| 48 | 5.2916 | 20.4426 | 5.3092 | 20.4648 |

| 49 | 5.2919 | 20.4426 | 5.3094 | 20.4648 |

| 50 | 5.2924 | 20.4426 | 5.3096 | 20.4647 |

Fig. 5.

Pareto-frontier comparison without TCSC.

Power losses reduction with TCSC

The power loss of the test system considered is computed considering TCSC.Table 2 presents the overall system losses after the installation of TCSC. It can be noted from Table 2 that the total losses of the system are lowest when TCSC is located at line joining buses 27–29. Therefore the optimal site for installing TCSC in the system under consideration is the line joining buses 27 and 29. With TCSC at its optimal site two different cases related to the two multiobjective minimization functions are studied.

Table 2.

System losses considering TCSC.

| Line No | From bus-to bus | Power loss | Line No | From bus–to bus | Power loss | ||

|---|---|---|---|---|---|---|---|

| (MW) | (MVAR) | (MW) | (MVAR) | ||||

| 1 | 1–2 | 6.2189 | 21.2073 | 22 | 15–18 | 5.6409 | 21.1456 |

| 2 | 1–3 | 6.1119 | 21.5027 | 23 | 18–19 | 5.6466 | 21.1860 |

| 3 | 2–4 | 5.7564 | 21.0080 | 24 | 19–20 | 5.6808 | 21.2499 |

| 4 | 3–4 | 5.6268 | 20.8843 | 25 | 10–20 | 5.6001 | 21.0748 |

| 5 | 2–5 | 6.2614 | 21.0076 | 26 | 10–17 | 5.6043 | 21.1404 |

| 6 | 2–6 | 5.9868 | 21.1433 | 27 | 10–21 | 5.6182 | 21.1075 |

| 7 | 4–6 | 5.7239 | 21.1022 | 28 | 10–22 | 5.6182 | 21.0967 |

| 8 | 5–7 | 6.2226 | 21.7256 | 29 | 21–22 | 5.7648 | 21.4997 |

| 9 | 6–7 | 5.6841 | 20.8136 | 30 | 15–23 | 5.6288 | 21.1426 |

| 10 | 6–8 | 5.5868 | 20.6692 | 31 | 22–24 | 5.6372 | 21.0740 |

| 11 | 6–9 | 5.5423 | 21.3805 | 32 | 23–24 | 5.6218 | 21.1226 |

| 12 | 6–10 | 5.5986 | 21.0992 | 33 | 24–25 | 5.6164 | 21.1109 |

| 13 | 9–11 | 5.6094 | 22.1306 | 34 | 25–26 | 5.6052 | 21.0455 |

| 14 | 9–10 | 5.6324 | 21.2136 | 35 | 25–27 | 5.6268 | 21.0607 |

| 15 | 4–12 | 5.8303 | 23.0641 | 36 | 28–27 | 5.3946 | 20.4586 |

| 16 | 12–13 | 5.7334 | 21.3289 | 37 | 27–29 | 5.3810 | 20.1497 |

| 17 | 12–14 | 5.6085 | 21.0659 | 38 | 27–30 | 5.4056 | 20.2408 |

| 18 | 12–15 | 5.6525 | 21.1366 | 39 | 29–30 | 5.8092 | 21.8134 |

| 19 | 12–16 | 5.6232 | 21.1439 | 40 | 8–28 | 5.6232 | 21.1439 |

| 20 | 14–15 | 5.6108 | 21.1308 | 41 | 6–28 | 5.5696 | 21.1308 |

| 21 | 16–17 | 5.6142 | 21.1446 | ||||

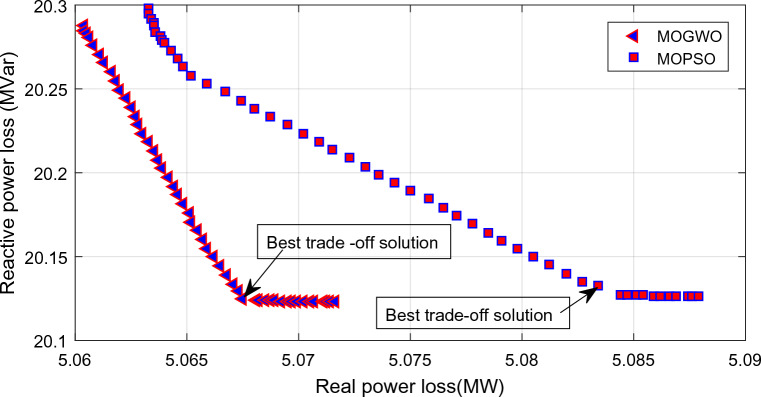

Case a: real and reactive power losses

After placing the TCSC at its optimal site, MOGWO and MOPSO algorithms are applied to the test system, and the multiobjective function relating to total real and reactive power losses is solved. The Pareto-optimal solution, thus generated, is presented in Table 3. The optimal trade-off solution is captured from the Pareto-optimal frontier by the fuzzy set technique. The optimal trade-off solution found from the Pareto-optimal frontier of the MOPSO algorithm is 5.0834 MW and 20.1323 MVar. The optimal trade-off solution obtained from the Pareto-optimal frontier of the MOGWO algorithm is 5.0675 MW and 20.1246 MVar. The reduction in real power losses when compared with the base case is 9.11% and 9.4% by MOPSO and MOGWO respectively. In the case of reactive power losses, the reduction is seen as 4.44 and 4.48% by MOPSO and MOGWO respectively. The MOGWO algorithm gave relatively better results. The results attained indicate that the installation of TCSC and the application of MOGWO and MOPSO algorithms minimized the power losses. It is also visible that the MOGWO algorithm gave relatively better results. The comparative depiction of results from both algorithms after locating TCSC at its optimal site is presented in Fig. 6.

Table 3.

MOGWO and MOPSO comparison with TCSC–case a.

| MOGWO | MOPSO | |||

|---|---|---|---|---|

| Solution No | Real power losses (MW) | Reactive power losses (MVar) | Real power losses (MW) | Reactive power losses (MVar) |

| 1 | 5.0604 | 20.2880 | 5.0633 | 20.2980 |

| 2 | 5.0604 | 20.2850 | 5.0633 | 20.2945 |

| 3 | 5.0605 | 20.2830 | 5.0634 | 20.2915 |

| 4 | 5.0606 | 20.28110 | 5.0635 | 20.2890 |

| 5 | 5.0608 | 20.2759 | 5.0635 | 20.2875 |

| 6 | 5.0611 | 20.2706 | 5.0636 | 20.2840 |

| 7 | 5.0613 | 20.2654 | 5.0638 | 20.2815 |

| 8 | 5.0616 | 20.2601 | 5.0639 | 20.2795 |

| 9 | 5.0618 | 20.2547 | 5.0640 | 20.2778 |

| 10 | 5.0620 | 20.2494 | 5.0643 | 20.2729 |

| 11 | 5.0623 | 20.2442 | 5.0646 | 20.2681 |

| 12 | 5.0625 | 20.2390 | 5.0648 | 20.2631 |

| 13 | 5.0627 | 20.2337 | 5.0652 | 20.2582 |

| 14 | 5.0628 | 20.2285 | 5.0659 | 20.2533 |

| 15 | 5.0630 | 20.2233 | 5.0667 | 20.2482 |

| 16 | 5.0633 | 20.2182 | 5.0674 | 20.2432 |

| 17 | 5.0635 | 20.2130 | 5.0680 | 20.2383 |

| 18 | 5.0637 | 20.2077 | 5.0687 | 20.2334 |

| 19 | 5.0639 | 20.2024 | 5.0695 | 20.2284 |

| 20 | 5.0642 | 20.1972 | 5.0702 | 20.2235 |

| 21 | 5.0644 | 20.1920 | 5.0709 | 20.2187 |

| 22 | 5.0646 | 20.1869 | 5.0715 | 20.2138 |

| 23 | 5.0648 | 20.1815 | 5.0723 | 20.2089 |

| 24 | 5.0651 | 20.1761 | 5.0730 | 20.2039 |

| 25 | 5.0652 | 20.1708 | 5.0736 | 20.1990 |

| 26 | 5.0655 | 20.1654 | 5.0743 | 20.1941 |

| 27 | 5.0657 | 20.1601 | 5.0750 | 20.1893 |

| 28 | 5.0659 | 20.1549 | 5.0758 | 20.1843 |

| 29 | 5.0662 | 20.1497 | 5.0765 | 20.1794 |

| 30 | 5.0665 | 20.1445 | 5.0771 | 20.1744 |

| 31 | 5.0668 | 20.1392 | 5.0778 | 20.1695 |

| 32 | 5.0671 | 20.1338 | 5.0785 | 20.1645 |

| 33 | 5.0673 | 20.1293 | 5.0791 | 20.1597 |

| 34 | 5.0675 | 20.1246 | 5.0798 | 20.1547 |

| 35 | 5.0681 | 20.1241 | 5.0805 | 20.1498 |

| 36 | 5.0682 | 20.1240 | 5.0812 | 20.1449 |

| 37 | 5.0685 | 20.1238 | 5.0820 | 20.1399 |

| 38 | 5.0687 | 20.1238 | 5.0827 | 20.1351 |

| 39 | 5.0689 | 20.1238 | 5.0834 | 20.1323 |

| 40 | 5.0692 | 20.1236 | 5.0844 | 20.1275 |

| 41 | 5.0695 | 20.1236 | 5.0847 | 20.1270 |

| 42 | 5.0697 | 20.1236 | 5.0851 | 20.1270 |

| 43 | 5.0699 | 20.1236 | 5.0854 | 20.1270 |

| 44 | 5.0702 | 20.1236 | 5.0859 | 20.1265 |

| 45 | 5.0705 | 20.1235 | 5.0862 | 20.1265 |

| 46 | 5.0707 | 20.1235 | 5.0866 | 20.1265 |

| 47 | 5.0711 | 20.1235 | 5.0869 | 20.1265 |

| 48 | 5.0712 | 20.1235 | 5.0874 | 20.1260 |

| 49 | 5.0714 | 20.1235 | 5.0876 | 20.1260 |

| 50 | 5.0716 | 20.1234 | 5.0879 | 20.1260 |

Fig. 6.

Pareto-frontier comparison with TCSC–case a.

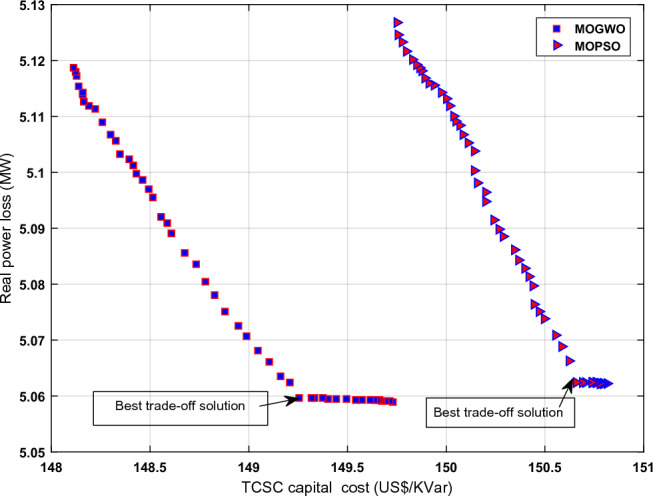

Case b: Real power loss and capital cost of TCSC

Here MOGWO and MOPSO algorithms are applied to the test system, and the multiobjective function relating to real power loss and capital cost of TCSC is solved. The Pareto-optimal solution, thus generated, is presented in Table 4. The optimal trade-off solution is captured from the Pareto-optimal frontier by the fuzzy set technique. The optimal trade-off solution obtained from the Pareto-optimal frontier of the MOPSO algorithm is 5.0625 MW and 150.6561US$/KVar. The optimal trade-off solution obtained from the Pareto-optimal frontier of the MOGWO algorithm is 5.0596 MW and 149.2531US$/KVar. The reduction in real power losses when compared with the base case is 9.48% and 9.53% by MOPSO and MOGWO respectively. The MOGWO algorithm gave relatively better results. The comparative depiction of results from both algorithms after locating TCSC at its optimal site is presented in Fig. 7.

Table 4.

MOGWO and MOPSO comparison with TCSC–case b.

| MOGWO | MOPSO | |||

|---|---|---|---|---|

| Solution No | Real power losses (MW) | Capital cost of TCSC(US$/KVar) | Real power losses (MW) | The capital cost of TCSC (US$/KVar) |

| 1 | 5.0590 | 149.7295 | 5.0623 | 150.8165 |

| 2 | 5.0591 | 149.7133 | 5.0623 | 150.8012 |

| 3 | 5.0591 | 149.6923 | 5.0623 | 150.7951 |

| 4 | 5.0591 | 149.6743 | 5.0623 | 150.7829 |

| 5 | 5.0592 | 149.6643 | 5.0623 | 150.7784 |

| 6 | 5.0592 | 149.6493 | 5.0624 | 150.7635 |

| 7 | 5.0592 | 149.6343 | 5.0624 | 150.7556 |

| 8 | 5.0593 | 149.6143 | 5.0624 | 150.7429 |

| 9 | 5.0593 | 149.5734 | 5.0625 | 150.7343 |

| 10 | 5.0593 | 149.5393 | 5.0625 | 150.7036 |

| 11 | 5.0594 | 149.4943 | 5.0625 | 150.6893 |

| 12 | 5.0594 | 149.4443 | 5.0625 | 150.6561 |

| 13 | 5.0595 | 149.3994 | 5.0663 | 150.6211 |

| 14 | 5.0596 | 149.3758 | 5.0688 | 150.5867 |

| 15 | 5.0596 | 149.3343 | 5.0708 | 150.5515 |

| 16 | 5.0596 | 149.3194 | 5.0739 | 150.4963 |

| 17 | 5.0596 | 149.2531 | 5.0751 | 150.4698 |

| 18 | 5.0624 | 149.2054 | 5.0764 | 150.4462 |

| 19 | 5.0636 | 149.1601 | 5.0797 | 150.4414 |

| 20 | 5.0661 | 149.1053 | 5.0813 | 150.4185 |

| 21 | 5.0681 | 149.0456 | 5.0828 | 150.3964 |

| 22 | 5.0706 | 148.9903 | 5.0843 | 150.3672 |

| 23 | 5.0726 | 148.9457 | 5.0861 | 150.3444 |

| 24 | 5.0751 | 148.8802 | 5.0886 | 150.2884 |

| 25 | 5.0781 | 148.8254 | 5.0898 | 150.2661 |

| 26 | 5.0805 | 148.7805 | 5.0915 | 150.2426 |

| 27 | 5.0835 | 148.7356 | 5.0947 | 150.1993 |

| 28 | 5.0855 | 148.6755 | 5.0965 | 150.1969 |

| 29 | 5.0891 | 148.6103 | 5.0981 | 150.1559 |

| 30 | 5.0909 | 148.5894 | 5.1003 | 150.1437 |

| 31 | 5.0921 | 148.5552 | 5.1038 | 150.1392 |

| 32 | 5.0956 | 148.5151 | 5.1053 | 150.1123 |

| 33 | 5.0969 | 148.4915 | 5.1067 | 150.0865 |

| 34 | 5.0986 | 148.4606 | 5.1083 | 150.0691 |

| 35 | 5.0998 | 148.4319 | 5.1091 | 150.0456 |

| 36 | 5.1012 | 148.4148 | 5.1100 | 150.0382 |

| 37 | 5.1024 | 148.3927 | 5.1118 | 150.0158 |

| 38 | 5.1033 | 148.3495 | 5.1131 | 150.0001 |

| 39 | 5.1057 | 148.3281 | 5.1143 | 149.9727 |

| 40 | 5.1068 | 148.2999 | 5.1156 | 149.9388 |

| 41 | 5.1089 | 148.2596 | 5.1160 | 149.9103 |

| 42 | 5.1114 | 148.2196 | 5.1168 | 149.8916 |

| 43 | 5.1119 | 148.1925 | 5.1182 | 149.8778 |

| 44 | 5.1126 | 148.1643 | 5.1186 | 149.8654 |

| 45 | 5.1139 | 148.1592 | 5.1192 | 149.8482 |

| 46 | 5.1143 | 148.1579 | 5.1201 | 149.8266 |

| 47 | 5.1154 | 148.1385 | 5.1216 | 149.7994 |

| 48 | 5.1173 | 148.1292 | 5.1233 | 149.7785 |

| 49 | 5.1180 | 148.1202 | 5.1246 | 149.7569 |

| 50 | 5.1186 | 148.1112 | 5.1268 | 149.7483 |

Fig. 7.

Pareto-frontier comparison with TCSC–case b.

The summary of the results obtained is presented in Table 5. It is worth noting that after the application of the optimization algorithms, the power losses got minimized. After installing TCSC at its optimal site, the power losses further reduced. The performance of the MOGWO algorithm in minimization of power losses is superior to that MOPSO algorithm in both the considered cases.

Table 5.

Summary of results with and without TCSC.

| Without TCSC | With TCSC (Case a) | With TCSC (Case b) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Base case | MOGWO | MOPSO | MOGWO | MOPSO | MOGWO | MOPSO | |||||||

| Real Power Loss (MW) | Reactive power loss (MVAR) | Real Power Loss (MW) | Reactive power loss (MVAR) | Real Power Loss (MW) | Reactive power loss (MVAR) | Real Power Loss (MW) | Reactive power loss (MVAR) | Real Power Loss (MW) | Reactive power loss (MVAR) | Real Power Loss (MW) | Capital Cost of TCSC (US$/KVar) | Real Power Loss (MW) | Capital Cost of TCSC (US$/KVar) |

| 5.593 | 21.0658 | 5.2833 | 20.4436 | 5.3048 | 20.4656 | 5.0675 | 20.1246 | 5.0834 | 20.1323 | 5.0596 | 149.2531 | 5.0625 | 150.6561 |

Suggestion of multiple optimal trade-off solutions

From the above case studies it is evidient that optimal installation of TCSC can demnish the power losses. However, the fuzzy set approach employed could only provide one one optimal trade-off solution. In many cases, the solution provided may not be acceptable to all the utilities. Hence, it would be a better approach to put forward multiple solutions to serve a large range of utilities with diverse preferences to objectives. To this extent, the TOPSIS methodology is used and three solutions are suggested from the Pareto front, obtained from MOGWO algorithm for both case a and case b. The suggested solutions with respective objective preferences are presented in Table 6. Solution 1 in both cases represents the scenario where the utilities have a preference to the first objective i.e., real power losses in both cases. For selecting solution 2, equal preference is given to both objectives. At last, solution 3 represents the scenario where the utilities have a preference to the second objective i.e., reactive power losses in case a and capital cost of TCSC in case b.

Table 6.

Suggestion of multiple solutions using TOPSIS.

| Case a | ||

|---|---|---|

| Objective preference | Real power losses (MW) | Reactive power losses (MVar) |

| Soultion 1—Preference to real power losses | 5.0604 | 20.2880 |

| Soultion 2—Equal preference to both objectives | 5.0675 | 20.1246 |

| Solution 3—Preference to reactive power losses | 5.0716 | 20.1234 |

| Case b | ||

|---|---|---|

| Objective preference | Real power losses (MW) | The capital cost of TCSC (US$/KVar) |

| Solution 1–Preference to real power losses | 5.0590 | 149.7295 |

| Solution 2–Equal preference to both objectives | 5.0751 | 148.8802 |

| Solution 3–Preference to Capital cost of TCSC | 5.1186 | 148.1112 |

Conclusion

The work presented in this paper underscores on optimal placement of TCSC for power loss reduction. Real and reactive power loss minimization, real power, and capital cost of TCSC minimization are considered as the multiobjective optimization functions. In the proposed approach, MOGWO, an efficient multiobjective algorithm, is used to optimize the considered minimization problems. The task of generating the non-dominated solutions is fulfilled by the Pareto-optimal technique. The fuzzy set technique is applied to obtain a compromised solution and TOPSIS method has been applied to generate multiple compromised solutions. The study is performed on an IEEE 30 bus standard test system. To establish the worthiness of TCSC installation in the minimization of power loss, the multiobjective functions are solved before and after the location of TCSC. Simulation results suggest that the optimal siting of TCSC can help in the reduction of power losses. Alleviation of power losses can facilitate augmenting the utility of the system without increasing the generation volume. In addition, the multiobjective problem under study is also solved using MOPSO. MOGWO algorithm provided relatively superlative results than the MOPSO algorithm. The work proposed is limited to single type FACTS device i.e. TCSC. The incorporation of multi-type FACTS devices may be treated as a future scope of this work. Further, the proposed investigations can be carried out on a larger benchmark test systems.

Acknowledgements

The authors acknowledge the funding from Researchers Supporting Project number (RSPD2024R665), King Saud University, Riyadh, Saudi Arabia.

Author contributions

All the authors have contributed equally to this article.

Funding

No funding was supported for this research work.

Data availability

The data used to support the findings of this study are included in the article.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Ramakrishna S S Nuvvula, Email: ssramanuvvula@gmail.com.

C. Dhanamjayulu, Email: dhanamjayuluc6947@gmail.com

Baseem Khan, Email: baseemkh@hu.edu.et.

References

- 1.Lubis, R. S. & Hadi, S. P. Selection of suitable location of the FACTS devices for optimal power flow. Int. J. Electr. Comput. Sci. IJECS-IJENS.12(03), 38–49 (2012). [Google Scholar]

- 2.Hingoranl, N.G., Gyugyi, L., El-Hawary, M.E. Understanding FACTS: Concepts and technology of flexible ac transmission systems. In Underst FACTS Concepts Technol Flex AC Transm Syst. (Published online January 1, 1999) 1–432. 10.1109/9780470546802

- 3.Singh, S. N. & David, A. K. Optimal location of FACTS devices for congestion management. Electr. Power Syst. Res.2(58), 71–79 (2001). [Google Scholar]

- 4.Kumar, A. & Sekhar, C. Congestion management with FACTS devices in deregulated electricity markets ensuring loadability limit. Int. J. Electr. Power Energy Syst.46(1), 258–273. 10.1016/J.IJEPES.2012.10.010 (2013). [Google Scholar]

- 5.Gandoman, F. H. et al. Review of FACTS technologies and applications for power quality in smart grids with renewable energy systems. Renew. Sustain. Energy Rev.82, 502–514. 10.1016/J.RSER.2017.09.062 (2018). [Google Scholar]

- 6.Abdullah, N.R.H., Musirin, I., Othman, M.M. Thyristor controlled series compensator planning using evolutionary programming for transmission loss minimization for system under contingencies. In PECon2010 - 2010 IEEE Int Conf Power Energy. (Published online 2010) 18-23. 10.1109/PECON.2010.5697550

- 7.Rao, N. T., Sankar, M. M., Rao, S. P. & Rao, B. S. Comparative study of Pareto optimal multi objective cuckoo search algorithm and multi objective particle swarm optimization for power loss minimization incorporating UPFC. J. Ambient Intell. Humaniz. Comput.12(1), 1069–1080. 10.1007/s12652-020-02142-4 (2021). [Google Scholar]

- 8.Alajrash, B. H. et al. A comprehensive review of FACTS devices in modern power systems: Addressing power quality, optimal placement, and stability with renewable energy penetration. Energy Rep.11(May), 5350–5371. 10.1016/j.egyr.2024.05.011 (2024). [Google Scholar]

- 9.Munnu Mandeep Kumar, C. J. Optimal placement and sizing of custom power devices using APSO and JAYA optimization in radial distribution network Optimal placement and sizing of custom power devices using APSO and JAYA optimization in radial distribution network. Eng. Res. Express.5, 015068 (2023). [Google Scholar]

- 10.Rahimzadeh, S. & Bina, M. T. Looking for optimal number and placement of FACTS devices to manage the transmission congestion. Energy Convers. Manag.52(1), 437–446. 10.1016/J.ENCONMAN.2010.07.019 (2011). [Google Scholar]

- 11.Galiana, F. D. et al. Assessment and control of the impact of facts devices on power system performance. IEEE Trans. Power Syst.11(4), 1931–1936. 10.1109/59.544666 (1996). [Google Scholar]

- 12.Pérez, M.A., Messina, A.R., Fuerte-Esquivel, C.R. Application of facts devices to improve steady state voltage stability. In Proc IEEE Power Eng Soc Transm Distrib Conf. 2:1115-1120. (2002) 10.1109/PESS.2000.867535

- 13.Rahimzadeh, S., Tavakoli Bina, M. & Viki, A. H. Simultaneous application of multi-type FACTS devices to the restructured environment: Achieving both optimal number and location. IET Gener. Transm. Distrib.4(3), 349–362. 10.1049/IET-GTD.2009.0287/CITE/REFWORKS (2010). [Google Scholar]

- 14.Dawn, S. & Tiwari, P. K. Improvement of economic profit by optimal allocation of TCSC & UPFC with wind power generators in double auction competitive power market. Int. J. Electr. Power Energy Syst.80, 190–201. 10.1016/j.ijepes.2016.01.041 (2016). [Google Scholar]

- 15.Ashpazi, M. A., Mohammadi-Ivatloo, B., Zare, K. & Abapour, M. Probabilistic allocation of thyristor-controlled phase shifting transformer for transient stability enhancement of electric power system. IETE J. Res.61(4), 382–391. 10.1080/03772063.2015.1023743 (2015). [Google Scholar]

- 16.Gerbex, S., Cherkaoui, R. & Germond, A. J. Optimal location of multi-type FACTS devices in a power system by means of genetic algorithms. IEEE Trans. Power Syst.16(3), 537–544. 10.1109/59.932292 (2001). [Google Scholar]

- 17.Saravanan, M., Slochanal, S. M. R., Venkatesh, P. & Abraham, J. P. S. Application of particle swarm optimization technique for optimal location of FACTS devices considering cost of installation and system loadability. Electr. Power Syst. Res.77(3–4), 276–283. 10.1016/J.EPSR.2006.03.006 (2007). [Google Scholar]

- 18.Lu, Z., Li, M.S., Tang, W.J., Wu, Q.H., Optimal location of FACTS devices by a Bacterial Swarming Algorithm for reactive power planning. In 2007 IEEE Congr Evol Comput CEC 2007. Published online (2007) 2344-2349. 10.1109/CEC.2007.4424764

- 19.Shaheen, H. I., Rashed, G. I. & Cheng, S. J. Optimal location and parameter setting of UPFC for enhancing power system security based on differential evolution algorithm. Int. J. Electr. Power Energy Syst.33(1), 94–105. 10.1016/J.IJEPES.2010.06.023 (2011). [Google Scholar]

- 20.Mahdad, B. & Srairi, K. Optimal location and control of combined SVC-TCSC controller to enhance power system loadability. Int. J. Syst. Assur. Eng. Manag.5(3), 427–434. 10.1007/S13198-013-0184-3/TABLES/4 (2014). [Google Scholar]

- 21.Dash, S., Subhashini, K. R. & Satapathy, J. Efficient utilization of power system network through optimal location of FACTS devices using a proposed hybrid meta-heuristic ant lion-moth flame-salp swarm optimization algorithm. Int. Trans. Electr. Energy Syst.30(7), e12402. 10.1002/2050-7038.12402 (2020). [Google Scholar]

- 22.Raj, S. & Bhattacharyya, B. Optimal placement of TCSC and SVC for reactive power planning using Whale optimization algorithm. Swarm Evol. Comput.2018(40), 131–143. 10.1016/j.swevo.2017.12.008 (2016). [Google Scholar]

- 23.Shehata, A. A., Tolba, M. A., El-Rifaie, A. M. & Korovkin, N. V. Power system operation enhancement using a new hybrid methodology for optimal allocation of FACTS devices. Energy Rep.8, 217–238. 10.1016/j.egyr.2021.11.241 (2022). [Google Scholar]

- 24.Singh, S. & Pujan, J. S. Enhancement of ATC of micro grid by optimal placement of TCSC. Mater. Today Proc.34, 787–792. 10.1016/j.matpr.2020.05.161 (2019). [Google Scholar]

- 25.Zadehbagheri, M., Ildarabadi, R. & Javadian, A. M. Optimal power flow in the presence of HVDC lines along with optimal placement of FACTS in order to power system stability improvement in different conditions: Technical and economic approach. IEEE Access.11(June), 57745–57771. 10.1109/ACCESS.2023.3283573 (2023). [Google Scholar]

- 26.Fawzy, S., Abd-Raboh, E. E. & Eladl, A. A. Optimal allocation of multi-type FACTS devices for mitigating wind power spillage with enhancing voltage stability and social welfare. Sci. Rep.13(1), 1–22. 10.1038/s41598-023-44977-9 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Pal, K., Verma, K. & Gandotra, R. Optimal location of FACTS devices with EVCS in power system network using PSO. e-Prime – Adv. Electr. Eng. Electron. Energy.7, 100482. 10.1016/j.prime.2024.100482 (2024). [Google Scholar]

- 28.Meena, N. K., Parashar, S., Swarnkar, A., Gupta, N. & Niazi, K. R. Improved elephant herding optimization for multiobjective der accommodation in distribution systems. IEEE Trans. Ind. Inform.14(3), 1029–1039. 10.1109/TII.2017.2748220 (2018). [Google Scholar]

- 29.Sankar, M. M. & Chatterjee, K. A posteriori multiobjective techno-economic accommodation of DGs in distribution network using Pareto optimality and TOPSIS approach. J. Ambient Intell. Humaniz. Comput.14, 4099–4114. 10.1007/s12652-022-04473-w (2022). [Google Scholar]

- 30.Mirjalili, S., Saremi, S., Mirjalili, S. M. & Coelho, L. D. S. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl.47, 106–119. 10.1016/J.ESWA.2015.10.039 (2016). [Google Scholar]

- 31.Ghawghawe, N. D. & Thakre, K. L. Computation of TCSC reactance and suggesting criterion of its location for ATC improvement. Int. J. Electr. Power Energy Syst.31(2–3), 86–93. 10.1016/J.IJEPES.2008.10.013 (2009). [Google Scholar]

- 32.Balamurugan, K. & Muthukumar, K. Differential Evolution algorithm for contingency analysis-based optimal location of FACTS controllers in deregulated electricity market. Soft Comput.23(1), 163–179. 10.1007/S00500-018-3141-X/TABLES/15 (2019). [Google Scholar]

- 33.Punitha, K. et al. An optimization algorithm for embedded raspberry Pi Pico controllers for solar tree systems. Sustainability16(9), 3788 (2024). [Google Scholar]

- 34.Nartu, T. R., Matta, M. S., Koratana, S. & Bodda, R. K. A fuzzified Pareto multiobjective cuckoo search algorithm for power losses minimization incorporating SVC. Soft Comput.23(21), 10811–10820. 10.1007/s00500-018-3634-7 (2019). [Google Scholar]

- 35.Chen, G., Liu, L., Guo, Y. & Huang, S. Multi-objective enhanced PSO algorithm for optimizing power losses and voltage deviation in power systems. COMPEL – Int. J. Comput. Math. Electr. Electron Eng.35(1), 350–372. 10.1108/COMPEL-02-2015-0030 (2016). [Google Scholar]

- 36.Mani, M. & Chatterjee, K. A posteriori multiobjective approach for techno-economic allocation of PV and BES units in a distribution system hosting PHEVs. Appl Energy.351(August), 121851. 10.1016/j.apenergy.2023.121851 (2023). [Google Scholar]

- 37.Kennedy, J., Eberhart, R. Particle swarm optimization. In Proc ICNN’95 - Int Conf Neural Networks. 4:1942–1948. 10.1109/ICNN.1995.488968

- 38.Kahourzade, S., Mahmoudi, A. & Bin, M. H. A comparative study of multi-objective optimal power flow based on particle swarm, evolutionary programming, and genetic algorithm. Electr. Eng.97(1), 1–12. 10.1007/S00202-014-0307-0/TABLES/8 (2015). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data used to support the findings of this study are included in the article.