Abstract

The European cranberry bush, known for its health benefits, can only be consumed through fermentation. This study aimed to develop a fruit leather made from European cranberry bush using quince seed gel and the foam drying method. For this purpose, quince seed gel was added to European cranberry juice to increase consistency. Then, European cranberry fruit leather was obtained by drying at 70, 80, and 90 °C air temperatures using foam mat drying technology. Spectral reflectance, color, drying kinetics, anthocyanin, ascorbic acid, and total phenolic content, antiradical activity, and macro-micronutrient concentrations of the resulting fruit pulp were investigated. The foam mat drying process at 90 °C had the greatest values of ascorbic acid (0.996 mg g− 1), anthocyanin (275.9 mg kg− 1), DPPH (47.77%), and ABTS.+ (68.76 µg TE g− 1). In addition, the highest value of total phenolic content (37.75 mg g− 1) was obtained in the foam mat drying process at 80 °C. The highest concentration of P, Na, Mg, K, Ca, and Mn in fruit leather was obtained at 70 °C, and the highest concentration of S, Cu, and Zn was obtained at 90 °C. The lowest spectral reflectance values were measured at 90 °C. In conclusion, the present study explored the fact that adding quince seed gel, extremely rich in biochemical content, significantly enhanced the bioactivity properties of European cranberry bush fruit leather.

Keywords: Foam mat drying, Quince seed gel, Ascorbic acid, Antioxidants, Spectral reflectance

Subject terms: Biochemistry, Plant sciences

Introduction

The European cranberry bush is commonly known as Viburnum opulus L. It is often called the ‘kidney doctor’ and belongs to the honeysuckle family Caprifoliaceae1. Antioxidant compounds that strengthen the immune system are abundant2, including organic acids, total phenolic compounds, and vitamins3. The European cranberry bush is a fruit whose high anthocyanin content helps to control insulin levels4. Eating fresh European cranberry bush is difficult because of its high polyphenol and tannin content, which imparts a rancid (bitter) flavor5. European cranberry bush supports the recovery of cardiac conditions. It regulates blood pressure6, and improves digestive health7. Therefore, the fruit is typically prepared as follows: pickling, jam and marmalade making, fermenting and pressing juice, and obtaining European cranberry bush sugar8. Fruit leather is a dehydrated snack made by extracting moisture from the cellular structure of fruits9. Various thickeners or gelling agents, such as gum, starch, flour, and milk, shorten the processing time during fruit leather-making10,11. It is a product that has been consumed from past to present in terms of its practical consumption, being a light snack, the high nutritional value of the fruit leather products obtained, and easy production12.

Drying is a technological procedure that decreases the excessive water content in fruits and vegetables, suppresses the proliferation of different enzymes and microorganisms, and enhances the product’s durability13. Various drying methods are often used in practice, including microwave, convective, vacuum, freeze, infrared, sun, and shade drying14. However, the expenses associated with convective, microwave, infrared, vacuum, and freeze-drying methods are substantial 15. Simultaneously, these drying methods, characterized by extended drying durations, result in higher energy consumption and harm the bioactivity characteristics of vegetables and fruits16. While both sun and shade processes for drying are not expensive, they extensively diminish the nutritious content of items exposed to outside factors for an extended period17. Hence, choosing an appropriate drying technique is critically significant about the cost and the quality of that final product18. The foam mat drying process offers notable benefits compared to conventional drying techniques, including a substantial reduction in drying time, maximization of energy efficiency, and excellent preservation of the bioactive components of the vegetables and fruits19,20. Foam mat drying is an innovative approach that uses foaming agents to dry liquid substances21. The foaming agents used in this method highly influence the nutritional value of the dried end products22. The foam mat drying process is economical, easy to apply, and energy efficient as it provides short-term drying23. Foam mat drying has become highly sought-after in fruit and vegetable drying24.

Quince seed gel is a new source of hydrocolloid compared to other gum (gel) sources, and it has not been studied in foam mat drying. Quince seed gum has a higher intrinsic viscosity than other gums25. In addition, quince seeds are rich in protein, ascorbic acid, antioxidants, anthocyanins, total phenolics, and flavonoids26. The kernel biopolymers are extracted when soaked in water, forming a sticky and tasteless gel27. This is associated with increased gelling capacity in aqueous solutions due to the critical polymer concentration of quince kernels and high hydrodynamic volume with high intrinsic viscosity25.

There is limited research on quince seeds as a food supplement. However, has become widespread the use of quince seeds in yogurt production28, ice cream production29, cheese production30, and crema production31 in recent years. Fresh European cranberry bush fruits are usually preserved by being soaked in water for fermentation due to their slightly bitter taste, and the juice of the fruits is extracted for drinking. Therefore, the shelf life is limited. The importance of the drying process, which is a way to enhance the durability of products, is gaining popularity daily. The foam mat drying technique, such as the European cranberry bush, is often preferred for drying products with heat sensitivity. The foam mat drying technique reduces drying time and energy consumption, improving the final product’s quality. Previous literature suggests milk, gum, and egg white were commonly used as the primary foaming agents in foam mat drying. This study is the first report to explore the characteristics (kinetic, spectral reflectance, macro-micronutrient concentration, color, and bioactivity properties) of European cranberry bush fruit leather obtained through the foam mat drying technique using quince seed gel.

The purpose of this study is (i) to dry European cranberry bush fruits with quince seed gel by foam drying technique, (ii) to assess the effect of varying temperature levels and quince seed gel on spectral reflectance, kinetics, bioactivity, color, and nutrient concentration of European cranberry bush fruit leather, and (iii) to perform a detailed comparative analysis of the new product characteristics obtained. Besides, this study introduces a new approach: to utilize quince seed gel as a foaming agent, producing European cranberry bush fruit leather. At the end of the study, quince seed gel used as a foaming agent is expected to effectively prevent the fruit’s bioactivity, color, and macro-micronutrient concentrations. At the same time, increasing the temperature of the drying air is thought to shorten the drying time. It is assumed that with shorter drying times, there will be less color change, the spectral reflectance will be at the highest level, and the product’s appealingness and chroma will be at the desired level.

Materials and methods

Chemicals and reagents

Analytical grade reagents of all chemicals (nitric acid, hydrogen peroxide, di-sodium hydrogen phosphate, sodium dihydrogen phosphate, trichloroacetic acid, Folin-Ciocalteu reagent, sodium bicarbonate, 2,2-diphenyl-1-picrylhydrazyl, methanol 2,2’-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid), potassium persulfate) used in this study were purchased from Sigma-Aldrich Co. (Buchs, Switzerland) and Merck (Darmstadt, Germany).

Fresh product

The fruits of the European cranberry bush (Viburnum opulus L.) were harvested in the Gesi district (38° 45′ 41.4″ N, 35° 40′ 50.2″ E) of Kayseri province. The fresh fruits were kept in a fridge at 4 ± 0.5 ºC during drying. Fresh fruits were squeezed into a juicer for the foam mat drying process. Subsequently, 45% quince seed gel was added to 100 mL of fruit juice. It was mixed with a mixer for 20 min until a foam form was formed. The drying process was carried out by spreading the resulting foamy form in a thin layer on the drying tray.

Drying equipment and techniques

A hybrid microwave-convection dryer (KMF 833 W, Arçelik, Istanbul, Turkiye) has been used for the process of drying using hot air of European cranberry seedlings using the foam mat drying. The dryer is 220–240 V ~ 50 Hz (voltage/frequency), provides 3.6 kW (total electrical power), and has a microwave frequency of 2465 MHz. The dryer has a capacity of 40 L and a drying area of 455 mm x 594 mm x 567 mm. The programmable dryer has a touch control panel and a digital LCD screen. A digital timer monitored drying time. The dryer could operate in all air temperatures ranging from 40 °C to 280 °C with 5-degree intervals. The hybrid dryer could operate at five different microwave power settings with an output power range from 100 W to 900 W.

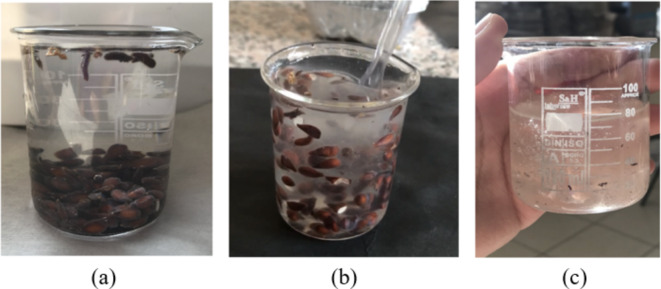

Quince seed gel was obtained by soaking the seeds in distilled water25. In the study, 50 mL of distilled water was given to 50 quince seeds and kept for 24 h. In the foam mat drying method, fresh European cranberry bush fruits were squeezed in a solid fruit juicer to obtain European cranberry bush juice, and then quince seed gel was added. Then, 45% quince seed gel was added to 100 mL of European cranberry bush juice. The mixture of European cranberry bush juice and quince seed gel was whipped with a mixer for 20 min to a foam consistency. The resulting foamy product was spread as a thin layer on the drying oven tray and convectively dried at 70, 80, and 90 °C air temperatures. Consequently, the European cranberry bush fruit leather intended in the study was obtained. The weight decreases at the given temperatures in the foam drying method were measured every 45, 30, and 15 min, respectively. The weight variations of the pestils were recorded using a high-precision balance (WL6002, WeightLab, Istanbul, Turkiye) with a precision of 0.01. The stages of quince seed gel formation in the present study are given in (Fig. 1).

Fig. 1.

Stages of formation of quince seed gel: soaking the seeds in water (a), formation of gel form (b), removing seeds from the gel (c).

Moisture content

The moisture content was recorded by subjecting the fruit leather to 70 °C for 48 h32. The samples wet and dry moisture contents were calculated using the Eqs. 1 and 2.

|

1 |

|

2 |

Where, My0: the initial moisture content (w.b.), Mk0: moisture content on a dry basis of samples (kgwater kgDM−1), W0: weight of samples before drying (kg), Wk: weight of samples after drying (kg), Ws: is the weight of water in the samples (kg).

Moisture ratio

The separable moisture ratio refers to the maximum quantity of water that may be extracted from a product at any moment. This value is obtained by dividing the initial moisture content by the separable moisture ratio. The method utilized for determining the separable moisture content is the one clarified by Wang et al.33, and the Eq. 3 was used.

|

3 |

where M0 is the initial water content, kg kg− 1; Me is the water content at equilibrium, kg kg− 1; and Mt is the water content when drying for the t time, kg kg− 1.

Drying rate

The determination of the drying rate based on moisture content was calculated using the methodology described by Çetin32 and Eq. 4.

|

4 |

Where DR is the drying rate (g water gDM− 1 min), Mt + dt is the moisture level at the time tdt (g water gDM− 1), and dt is the drying duration (min).

Chromatic parameters

The fruit leather’s color characteristics (L*, a*, b*, and C) were quantified using calorimetry (PCE-CSM 5, PCE Instruments, Meschede, Germany). The color measurement was repeated 15 times in each experiment. The parameter L* refers to the degree of lightness or darkness of the color of the product. Besides, the parameter a* expresses the redness or greenness of the color. Positive values for parameter b*, which indicates yellow or blue tones, correspond to yellow tones, while negative values correspond to blue tones. The C (chroma) value indicates the matte or vivid tones of the product color.

The measurement of total color change (ΔE) is a vital factor in assessing the impact of the drying operation on the products. In the present study, the color change of European cranberry bush samples was calculated using Eq. 5.

|

5 |

Where, t represents the color of fresh samples, k represents the color of dried samples.

The calculation of the Browning Index (BI) is crucial for evaluating the impact of the drying operation on the samples34.

|

6 |

|

7 |

Macro and micronutrient elements

The samples were analyzed on an ICP-MS device (7900 ICP-MS, Agilent, California, USA). 0.15–0.20 g of sample was added to 9 mL HNO3 (Merck, Germany) and 1 mL H2O2 (Merck, Germany). The wet combustion method was applied in a closed-system microwave solubilizer using a pressure and temperature program. The resulting solutions were complemented to a volume of 25 mL by adding distilled water. Standards containing the elements of interest at various concentrations (0, 1, 5, 10, 20, 30, 40, and 50 ppb) were prepared before analysis. The instrument performance was adjusted by running a tuning solution (200 ppb Li, Yb, and Cs) through the instrument to ensure that the measurement parameters were accurate. After using the tuned solution to confirm performance, the method containing the minerals to be analyzed and the standards for the instrument have been selected. We then began to explore the solubilized and diluted samples. The instrument was fed a solution to analyze containing 200 ppb of internal standard elements (Sc, In) and all the elements representing the periodic table35.

Anthocyanin analysis

The pH differential method determined the total amount of anthocyanins in the samples36. In this method, the color changes of anthocyanin pigments according to the pH values of the medium are taken into account. The discrepancy in readings at various pH levels, specifically at wavelengths with the highest absorbance, strongly correlates to the sample’s anthocyanin concentration. In this scenario, buffers with pH values of 1.0 and 4.5 were created using 0.02 M Na2HPO4 and 0.02 M NaH2PO4 (Merck, Germany). Subsequently, these buffers (4 mL) were added to a 1 mL extract and incubated for 30 min in a dark atmosphere at room temperature. Then, the absorbance values of all samples were measured concurrently at wavelengths of 510 nm and 700 nm. The total amounts of anthocyanin were calculated by using Eq. 8.

|

8 |

Where, ΔA: Absorbance difference (A= ((A510nm- A700nm) pH 1.0) - ((A510nm- A700nm) pH 4.5)), Ɛ: Molar absorbance, L: Layer thickness of absorbance measuring cuvette (= 1), MW: Molecular weight, DF: Dilution factor.

Ascorbic acid analysis

The fruit leathers were tested for ascorbic acid (AA) content using the methodology suggested by Shin et al.37. To do this, 0.5 mL of a solution containing 7.5% trichloroacetic acid was combined with 0.5 mL of the liquid extract. The resultant mixture was maintained at a temperature of 4 °C for 5 min and passed through a filter with a pore size of 4.5 μm. Then, 0.2 mL filtrate was added to 2 mL distilled water and 0.2 mL Folin-Ciocalteu (1:10 v/v) reagent. The resultant solution was allowed to stand at room temperature (20 ± 1 °C) for 10 min while shielding from light. The absorbance was then measured at a wavelength of 760 nm using a spectrophotometer (C7100; Peak Instruments Inc., Houston, TX). Different ascorbic acid concentrations (50–500 mg L− 1) were used for the calibration curve (y = 0.001x + 0.0221 R2 = 0.981), and the results were calculated as mg AA g− 1 sample.

Total phenolic content analysis

The approach Khatri & Chhetri38 proposed was partially modified and employed to ascertain the total phenolic content of the samples. 1.8 mL distilled water was combined with 0.2 mL of liquid extract. Subsequently, 1 mL of diluted (1:10) Folin-Ciocalteu standard was added. After 5 min, 2 mL of a solution containing 2% sodium carbonate (Na2CO3) was added to the samples. Following this procedure, the tubes were hermetically sealed, vigorously mixed, and placed in a dark environment for 2 hours. Following the incubation duration, the spectrophotometer (C7100; Peak Instruments Inc., Houston, TX) was employed to quantify the absorbance values of the samples relative to the blank. The samples’ total phenolic content was quantified using a standard curve (y = 0.0038x + 0.0024, R2 = 0.999) which entailed measuring the different concentrations of gallic acid (25–500 mg L− 1). The results were quantified in milligrams of gallic acid equivalent to each gram of dried material (mg GAE g− 1 dry sample).

Antiradical capacity

The antiradical capacity of the samples was evaluated using the DPPH and ABTS.+ radical tests. The materials were assessed for their 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity using the Köprü et al.39 method. To do this, 100 µL of the extract was combined with 3900 µL of a DPPH radical solution (0.1 mM methanol) and vigorously agitated by vortexing using a tightly sealed container. Following this stage, the samples were placed in a regulated environment with a 20–25 ºC temperature range and shielded from light for 30 min. Following the incubation duration, the UV-vis spectrophotometer (C7100; Peak Instruments Inc., Houston, TX) measured the absorbance values of the samples at a specific wavelength of 517 nm. Subsequently, the DPPH radical scavenging activity of the samples was determined by formulating the percentage of inhibition using Eq. 9:

|

9 |

The ABTS+ radical scavenging activity of the samples was assessed using the method suggested by Wettasinghe et al.40. An aqueous solution containing seven millimoles of ABTS.+ was dissolved and combined with 2.45 millimoles of potassium persulfate. The mixture was subsequently maintained at ambient temperature for 16 h until a discernible intense blue hue emerged, signifying its readiness for examination. The highly concentrated solution, which had a dark blue color, was mixed with a buffer solution (pH 7.4) until the absorbance at a wavelength of 734 nm reached a value of 0.7. Subsequently, a mixture of 2 mL of the diluted ABTS.+ solution and 100 µL of the sample extract, which had been diluted at a ratio of 1:10, was prepared. The UV-visible spectrophotometer (C7100; Peak Instruments Inc., Houston, TX) was utilized to quantify the absorbance values at a wavelength of 734 nm after 6 min of incubation the decrease in ABTS.+ radical cation was determined as % inhibiton using the following mathematical formulation (Eq. 10). The data were subsequently transformed into Trolox equivalent antiradical capacity (TEAC) values using a calibration curve established using Trolox at different doses (2–10 µg mL− 1 ) (y = 6.9947x + 7.2402, R2 = 0.989). The experiments were carried out using two duplicates and five repetitions.

|

10 |

VIS/NIR (visible/near-infrared) spectra measurement

Spectral reflectance spectrums were acquired at various wavelengths using a hand-held VIS/NIR spectroradiometer (HandHeld 2 Pro, ASD FieldSpec, Malvern, United Kingdom). The device offered spectra ranging from 325 to 1075 nm with a bandwidth of 3.5 nm. The reflectance data was interpolated to 1-nanometer intervals. The gadget was placed 100 mm above the sample surface with a field of view (FOV) of 25° to acquire reflectance measurements. The reflectance (R) was determined by comparing the spectral energy reflected from the sample to a reference standard. Three reflection spectra were collected at rotating locations spaced approximately 120° apart around the sample’s center. Ten scans were conducted at the same spot for each reflection spectrum41.

Statistical analysis

The study followed the randomized experimental design technique and conducted three replications for all experiments. Color measurements were taken as 15 repetitions. The data were analyzed using the SPSS 14.0 statistical program, which calculated means and standard error values. Variance analysis (ANOVA) was used to determine relationships between drying parameters. In addition, Tukey′s multiple comparison test was used to evaluate significant means at a 95% significance level, and in the present study, five different drying models were used, listed in (Table 1). Separable moisture content was determined through the Sigmaplot 15.0 program.

Table 1.

Equations of the mathematical models used in the study.

| Model | Equations | References |

|---|---|---|

| Newton |

|

Ertekin & Firat42 |

| Page |

|

Ertekin & Firat42 |

| Weibull distrubiction |

|

Babalis et al.43 |

| Diffusion approach |

|

Ertekin & Firat42 |

| Jena&Das |

|

Jena & Das44 |

MR moisture content, a, b, c coefficients, k drying constants, (min− 1), n drying parameter, t drying durations.

The R2 value is a crucial metric used to forecast the model’s accuracy compared to experimental data. The closer the numerical value of R2 is to 1.000, the more successful the prediction is. In addition, the other significant criterion in selecting the most successful mathematical model is the RMSE. A value close to 0.000 is required for the RMSE. RMSE and χ2 were then calculated using the Eqs. 11 and 12.

|

11 |

|

12 |

Where RMSE is the root mean square error; χ2 is the chi-square value of the estimate; MRexp, i is the experimental separable moisture ratio; MRpre, i is a separable moisture fraction estimated by the model; N is the number of observations; ni is the sum of drying constants and coefficients.

Results and discussion

Drying kinetics and mathematical modeling

The foam mat drying process was employed to decrease the moisture content of the European cranberry bush juice-quince seed gel mixture from an initial level of 77.00 ± 0.20% to a final level of 24.33 ± 0.85%. The drying procedures were carried out in a conventional oven at air temperatures of 70, 80, and 90 °C, and results showed that the drying processes took 135, 90, and 45 min, respectively. Herein, it was found that the time it took to dry as the drying air temperature decreased. Increasing the temperature from 70 to 90 °C caused a diminishing drying time. High viscosity and stabilizing agents in meals dramatically diminish the likelihood of phase separation caused by creaming and precipitation. Quince seed gel, used as a thickening agent, helped the drying material gain elasticity under the influence of temperature, thus forming the fruit leather structure25. This can also be explained by quince seed gel’s high viscosity and stabilization ability, which increases creaming under the influence of temperature27. Watharkar et al.45 used foam mat drying technology to dehydrate bananas from 50 to 70 °C. Furthermore, it has been reported that the drying duration was shortened by increasing the air temperature. Brar et al.46 noted that high dryer air temperatures shortened the drying time of peaches with foam mat drying at 65–75 °C. Macedo et al.47 used foam mat drying technology to dry red pitaya fruit at 50 and 70 °C air temperatures and observed that the drying time decreased with temperature.

Drying rate and moisture ratio

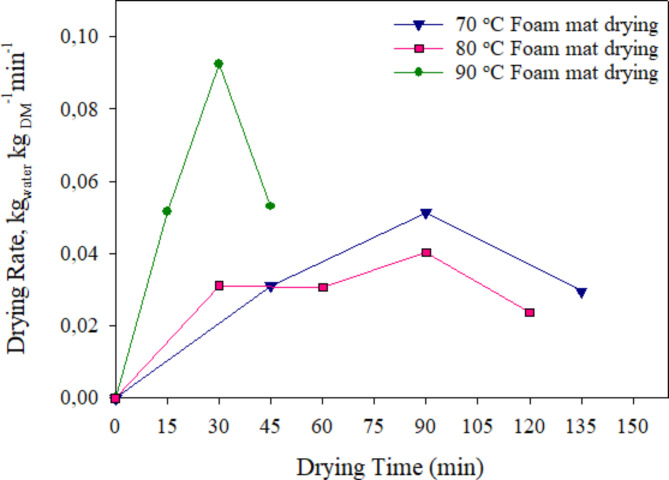

Figure 2 illustrates the drying rate graph of the foam mat drying technique used to produce European cranberry fruit leather. The mean drying rates of evaporation for air temperatures of 70, 80, and 90 °C were 0.0251, 0.0279, and 0.0492 kgwater kg DM−1 min− 1, respectively. During the first stage of the drying process, the drying rate reached its maximum point because of the increased moisture content of the dried product. As the moisture level of the sample decreased, the drying rate also decreased. Azizpour et al.48 reported that during the foam mat drying of shrimp, there was a notable decrease in moisture content towards the end of the drying process, leading to a reduction in the drying rate. According to Thuwapanichayanan et al.49 the drying rate during banana foam mat drying at 60–80 °C reduced as the moisture content of the products decreased. Kaba et al.50 reported that the drying rate of cranberry fruit during convective drying using the foam drying technique was positively correlated with the dryer air temperature. Kumar et al.51 highlighted that the drying rate of mango during convective drying using the foam mat drying technique rose as the temperature was increased to 60, 70, and 80 °C. Djaeni et al.52 used foam mat drying at air temperatures of 60, 80, and 100 °C to dry seaweed and found that the drying rate increased as the temperature increased.

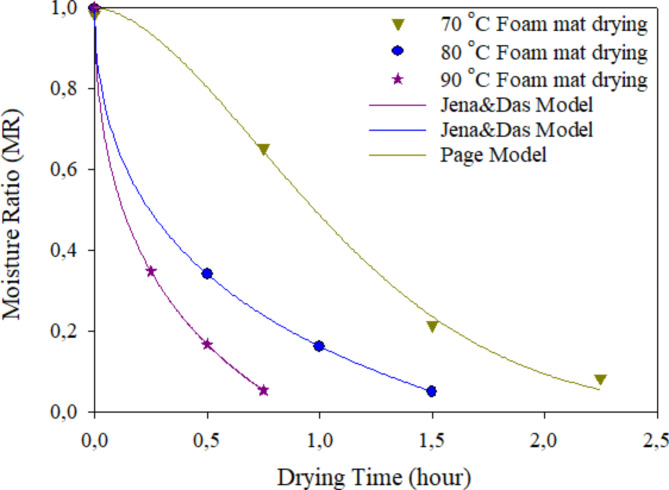

The drying constants, coefficients, and statistical parameters for drying European cranberry bush fruit leathers by the foam-mat drying method are given in Table 2. Page and Jena & Das were selected as the most successful models in the study. Page had the most significant regression coefficient of 0.9961 at 70 °C, and Jena & Das had the most significant regression coefficient of 0.9965 and 0.9987 for 80 and 90 °C, respectively. The graph of the separable moisture content of European cranberry bush fruit leather dried by the foam drying method is shown in Fig. 3. Approximately 67, 50, and 30% of the moisture were removed from the product during the first 15 min of using the foam drying technique at temperatures of 70, 80, and 90 °C, respectively. Li et al.53 indicated the Page model as the best thin-layer drying method for melon drying at 55 °C using gum Arabic. Brar et al.46 foam-dried peaches at 65, 70, and 75 °C and found the Page model optimum.

Table 2.

Statistical performance results of the drying models used in the study.

| Model | R 2 | RMSE | χ 2 | SEE | |

|---|---|---|---|---|---|

| 70 °C | Newton | 0.9660 | 0.0835 | 3.29E-01 | 0.0496 |

| Page | 0.9961 | 0.0348 | 5.63E-01 | 0.0530 | |

| Weibull distribution | 0.9876 | 0.0735 | 2.17E-01 | 0.0496 | |

| Diffusion | 0.8990 | 0.2511 | 5.37E-02 | 0.0477 | |

| Jena&Das | 0.9929 | 0.0664 | 1.09E-00 | 0.0522 | |

| 80 °C | Newton | 0.9883 | 0.0456 | 4.41E-01 | 0.0574 |

| Page | 0.9927 | 0.0441 | 6.32E-02 | 0.0674 | |

| Weibull distribution | 0.9957 | 0.0187 | 2.73E-02 | 0.0490 | |

| Diffusion | 0.9883 | 0.0790 | 1.24E-00 | 0.0557 | |

| Jena&Das | 0.9965 | 0.0195 | 1.09E-00 | 0.0609 | |

| 90 °C | Newton | 0.9969 | 0.0234 | 4.42E-01 | 0.0575 |

| Page | 0.9988 | 0.0178 | 7.47E-01 | 0.0611 | |

| Weibull distribution | 0.9987 | 0.0177 | 1.09E-00 | 0.0841 | |

| Diffusion | 0.9969 | 0.0405 | 1.24E-00 | 0.0557 | |

| Jena&Das | 0.9987 | 0.0029 | 1.194-00 | 0.0794 |

Fig. 2.

Time-dependent drying rate graph of European cranberry bush pestil.

Color attributes, browning index, and total color change

The color characteristics of the fruit leather obtained utilizing the foam mat feature are displayed in (Table 3). It was found that the method with the lowest L* value was the foam drying method at 90 °C air temperature. An increase in the darkness of the product color was observed at 90 °C in the air temperature. This phenomenon is believed to be associated with the oxidation event that arises from the product’s exposure to increased temperatures. The greatest value of a*, which is the redness/greenness parameter of European cranberry bush fruit leather with a red color, was measured in the fresh product. An increase in temperature from 70 to 90 °C resulted in an observed increase in the redness value of the pestils. According to the findings, the highest redness value was measured at 90 °C. This was attributed to the fact that quince seed gel degrades the color pigments under the influence of high temperatures and stores the redness on the surface54.

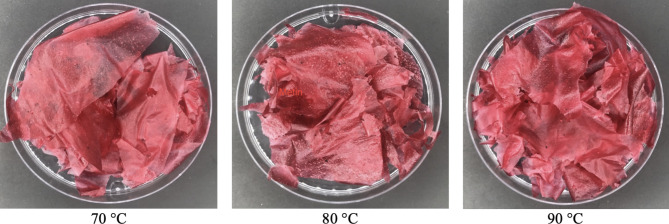

The greatest value of the b*, which represents the yellowness and blueness of the color, was measured in the fresh product. While the lowest b* value was estimated at 70 °C in the foam drying technique, it was found that the b* exhibited a positive correlation with rising temperature levels. The highest value of C, an indicator of dull and light shades of color, was observed at 90 °C. At lower temperatures, the color of the products became dull. The lowest value of the browning index was obtained with the foam drying method at 70 °C. The greatest positive b* (yellowness) values were observed at 70 °C. The highest browning index values were obtained at 90 °C. Considering the overall color change, the fresh sample exhibited a total color change value of 0. The foam mat drying process at a temperature of 90 °C produces the greatest browning index value. On the other hand, the method with the lowest total color change was foam drying at 90 °C. In the present study, prolonged exposure to hot air at low temperatures caused free anthocyanins to react with polyphenols and disrupt their chemical structure55. In this sense, using low temperatures and long periods adversely affected the color properties of the fruit leathers56. It was concluded that foam drying at 90 °C is suitable for obtaining European cranberry bush fruit leathers regarding color characteristics.

The appearance of European cranberry bush fruit leathers obtained by the foam drying technique using quince seed gel as a foaming agent and different temperature applications are shown in Fig. 4 for 70, 80, and 90 °C air temperatures. The present findings are consistent with other studies reported in the literature. Belal et al.57 aim to produce a natural tomato powder colorant using the foam mat drying technique. They varied the quantities of egg albumin (3, 5, and 7% w/w) and carboxymethyl cellulose (0.5 and 1%) as foaming agents and dried the powder at three different temperatures (60, 65, and 70 °C). Researchers found the level of redness (a*) in tomato powder produced by foam mat drying increased as the temperature increased. Similarly, our study determined that the redness level in the fruit skin increased parallel to the increase in drying temperature. Li et al.53 dried melon with the foam mat drying technique at 55 °C with gum arabic at 5, 10, and 15%. According to the study, gum Arabic increased melon redness. Furthermore, the investigation highlighted that the gum arabic content of 15% obtained the closest yellowness value to that of the fresh sample. The fresh samples exhibited the greatest rise in darkness. The observed darkness was attributed to enzymatic and non-enzymatic browning in the sample without gum arabic. Ng & Sulaiman58, by adding 10% and 5% egg white and fish gelatin to red beet juice, the foam drying technique at a temperature of 50 °C for 6 h in a conventional dryer. Their study showed an increase in the a* and b* values of dried red beetroot powders and a decrease in the L* value. In addition, researchers reported that different amounts and types of foaming agents increased the redness of the samples due to the degradation of heat-sensitive polyphenols under the effect of heat. Paiva et al.59 made use the foam mat drying technology to dehydrate red tropical fruits at air temperatures of 50, 60, 70, and 80 °C. In the study, gum arabic, guar gum, and albumin were used as foaming agents at 6 and 1% concentrations. The research highlighted that the croma value increased as the drying air temperature increased. Increasing temperature in our study similarly raised the chroma value. Franco et al.60 dehydrated yacon juice using the foam mat drying method, including 20% egg albumin, at 50, 60, and 70 °C temperatures. The researchers observed a drop in the L* (brightness) value as the drying temperature increased. This was attributed to the higher water content on the surface and the deterioration of pigments. Similarly, in our investigation, the L* value of the fruit pulp declined as temperature levels increased, owing to the deterioration of pigments at elevated temperatures.

Fig. 3.

Time-dependent separable moisture content graph of European cranberry bush pestil.

Table 3.

Color parameters of European cranberry bush pestils.

| Method | L* | a* | b* | C | BI | ΔΕ |

|---|---|---|---|---|---|---|

| Fresh | 10.85 ± 0.5c | 41.46 ± 0.9a | 18.70 ± 0.2a | 45.50 ± 0.2a | 184.34 ± 0.3a | 0.00 ± 0.0b |

| 70 °C | 23.49 ± 0.7b | 30.77 ± 0.9c | 8.16 ± 0.3c | 31.52 ± 0.2b | 70.99 ± 0.3b | 20.89 ± 0.2a |

| 80 °C | 38.59 ± 0.4a | 37.18 ± 0.7ab | 9.25 ± 0.7bc | 38.32 ± 0.1ab | 80.76 ± 0.5b | 30.05 ± 0.3a |

| 90 °C | 16.51 ± 0.3bc | 39.13 ± 0.3a | 14.50 ± 0.2ab | 41.82 ± 0.8a | 142.60 ± 0.6a | 9.24 ± 0.2b |

P < 0.05 Differences between groups are significant. L brightness/darkness, a redness/greenness, b jaundice/blueness, C chroma, BI browning index, ΔΕ total color change, ± SE standard error.

Macro and micronutrient concentrations

Quince seeds are rich in macro and micronutrients61. The present study presents the macro and micronutrient concentrations of European cranberry bush fruit leather in (Table 4). The highest value of P content was obtained at 90 °C, and P concentration was 50% higher than in the fresh product. The greatest P, Na, Mg, K, Ca, and Mn concentrations were measured at 70 °C. It was found that the P and Na contents were 50% and 66% higher than the fresh product, respectively. In addition, the Mg, K, Ca, and Mn contents at 70 ℃ were 3.82, 7.83, 6.76, and 3.41 times higher than the fresh product, respectively. However, the foam drying procedure at 80 °C yielded the highest Fe content. On the other hand, the foam drying process at 90 °C yielded the highest levels of S, Cu, and Zn concentrations. Increasing the drying temperature decreased Mg, K, Ca, Mn, and Zn contents. The observed reduction in mineral content at the highest temperature of 90 °C. It can be described as either the chemical interaction between chemicals and minerals at increased temperatures or the transportation of these micronutrients within the cell gaps62. Adak et al.63 dried strawberry slices using infrared (100–300 W) and convective (60–80 °C) drying techniques and reported that Fe concentration decreased, and Zn content increased with increasing drying temperature. In compliance with the present study, Czerwinski64 stated that magnesium (Mg) is oxidized at high temperatures. Alibas et al.65 highlighted that long drying times lead to mineral losses by increasing product oxidation. Garti et al.66 emphasized that extended drying times lead to significant reductions in Ca, Fe, K, Mg, P, and Zn levels.

Table 4.

Macro and micronutrient element composition (ppm).

| Method | P | S | Mg | K | Ca |

|---|---|---|---|---|---|

| Fresh | 141.82±2.0d | 77.11±1.5d | 197.01±0.7d | 487.32±0.6d | 119.22±0.5d |

| 70℃ | 211.96±2.0a | 96.10±0.1b | 754.11±0.4a | 3820.24±0.8a | 806.19±0.2a |

| 80℃ | 185.88±1.3c | 86.30±2.7c | 730.84±0.7b | 3513.10±0.9b | 770.74±0.4b |

| 90℃ | 190.05±1.2b | 97.21±1.6a | 679.29±0.4c | 3232.59±1.5c | 716.15±0.1c |

| Method | Na | Mn | Fe | Cu | Zn |

|---|---|---|---|---|---|

| Fresh | 400.63±0.7d | 1.22±0.3d | 52.97±1.8b | 31.57±0.9b | 10.11±0.4b |

| 70℃ | 668.35±0.7a | 4.17±0.6a | 43.22±1.8c | 45.04±1.5c | 8.92±1.2c |

| 80℃ | 564.04±0.3b | 4.03±0.6b | 67.76±1.2a | 28.56±0.9d | 8.55±0.5c |

| 90℃ | 541.72±0.1c | 3.71±0.7c | 40.63±0.6d | 64.86±2.0a | 12.00±1.4b |

Ca calcium, P phosphorus, K potassium, S Sulphur, Mg magnesium, Mn manganese, Cu copper, Zn zinc, Fe iron, Na sodium, ± SE standard error.

**P < 0.05; The mean values of columns with various superscripts differ substantially.

Bioactivity properties

Ascorbic acid plays a crucial role in determining the nutritional value of dried samples. However, its stability is affected by variables such as temperature and oxygen content, which can lead to the destruction of the product structure67. There is a correlation between the amount of ascorbic acid and the levels of macro and micronutrients4. In the present study, 90 °C treatment (0.996 mg g− 1) had the greatest ascorbic acid content and it has been observed that the amount of ascorbic acid decreases as the temperature decreases. The foam mat drying technique increased the ascorbic acid concentration in European cranberry bush fruit leather by 2.68, 2.82, and 2.87 times compared to the fresh sample at temperatures of 70, 80, and 90 °C, respectively.

Antioxidants protect the body from various illnesses, including cancer, cardiovascular disorders, and respiratory diseases, by inhibiting the oxidation of vulnerable substances68. Ascorbic acid undergoes thermal degradation and is eliminated through evaporation. Due to its low reduction potential, ascorbic acid readily reacts with reactive species, immediately influencing the products’ antioxidant activity69. The fresh sample exhibited the highest antioxidant content, as determined by the DPPH method. In the DPPH method, the highest antiradical capacity value was obtained at 90 °C (47.77%). However, the lowest antiradical capacity value of European cranberry bush fruit leather was obtained at 80 °C (33.39%). Moreover, the highest value of antiradical capacity in the ABTS.+ method was measured at 90 °C (68.76 µgTE g− 1). Generally, a temperature change led to a decrease in the antiradical capacity of the fruit leather compared to the fresh sample. The anthocyanin concentration reached its highest level at 90 °C (275.90 mg kg− 1), exceeding the content of the fresh product by approximately five times. However, the lowest anthocyanin content was measured at 80 °C (181.87 mg kg− 1). Increasing the temperature led to a decrease in total phenolic compounds. This may be related to the temperature sensitivity of phenolic substances70. Generally, quince seed gel is rich in bioactivity, significantly increasing fruit leather’s biochemical activities71. Table 5 presents the bioactivity properties of the fruit leather in the present study.

Table 5.

Bioactivity results of European cranberry bush fruit pestils.

| Method | Ascorbic acid content (mg g− 1) | Anthocyanin content (mg kg− 1) |

Total phenolic content (mg g− 1) |

DPPH (% inh.) |

ABTS.+ (µgTE g− 1 ) |

|---|---|---|---|---|---|

| Fresh | 0.346 ± 0.8c | 54.74 ± 0.5d | 48.38 ± 0.2a | 53.79 ± 0.1a | 111.72 ± 0.1a |

| 70 ℃ | 0.928 ± 0.1b | 219.68 ± 0.9b | 33.44 ± 0.7b | 43.80 ± 0.3b | 62.04 ± 0.9b |

| 80 ℃ | 0.978 ± 0.5a | 181.87 ± 0.6c | 37.75 ± 0.8ab | 33.39 ± 0.2c | 54.08 ± 0.7b |

| 90 ℃ | 0.996 ± 0.5a | 275.90 ± 0.2a | 29.44 ± 0.6b | 47.77 ± 0.3ab | 68.76 ± 0.2b |

Differences between groups are significant at the P < 0.05 level. ± SE standard error.

Hossain et al.22 found a positive correlation between temperature and antioxidant capacity in drying tomato juice containing 3, 5, and 7% protein with a foam mat at 60, 65, and 70 °C. Researchers observed a negative correlation between temperature and ascorbic acid content. Besides, it has been reported that antioxidant activity determined by the DPPH technique increases as temperature increases. In the present study, the increasing temperature increased the DPPH and ABTS.+ of European cranberry bush fruit leather. Abd El-Salam et al.72 used egg white (5–20%) and xanthan gum (0-0.5%) as foaming agents during the drying process of papaya fruit using a foam mat at air temperatures of 60 and 80 °C. Researchers indicated that rising temperatures decreased ascorbic acid and total phenolics. Chaux-Gutiérrez et al.73 reported that high temperatures during drying increased the ability to retain carotenoids in the products. Gunaydin & Alibas74 found that enhanced drying temperatures resulted in an increased amount of carotenoids. López et al.75 revealed that utilizing lower drying temperatures resulted in a drop in ascorbic acid content. Santos & Silva24 observed a significant decrease in ascorbic acid as the drying time increased. Brar et al.46 dried peaches using the foam mat technique at 65, 70 and 75 °C air temperatures. Soy and pea protein isolates were used as foaming agents in the study. Researchers reported that the total phenolic content and antioxidant capacity increased with temperature. Pinar et al.76 have found that increased drying temperatures and prolonged drying durations can adversely impact the overall phenolic content. Jakkranuhwat & Kunchansombat77 dried purple sweet potatoes using the foam mat drying technique at three different drying air temperatures (50, 60, and 70 °C) and with foaming agents of carboxymethyl cellulose (1%) and hydroxypropyl cellulose (1%). Complying with the present findings, the authors emphasized that increasing the drying air temperature resulted in higher concentrations of antioxidants and anthocyanins. Van Tai et al.78 used egg albumin (5%) and maltodextrin (2%) as foaming agents while drying bananas at air temperatures of 60, 70, and 80 ° C with foam mat technology. The study reported that the total amount of phenolic substance decreased with increasing drying temperature. Increasing the drying temperature reduced the total phenolic matter content of the fruit leather in our investigation, which is similar to the findings of this study. Gupta et al.79 used maltodextrin (7%) and egg albumin (5, 10, and 15%) as foaming agents to dry jujube fruit with a foam mat at air temperatures of 45 and 65 °C. As a result of the findings obtained in the study, it was reported that the total phenolic amount decreased with increasing the drying air temperature. The researchers reported this situation because phenolic substances are extremely sensitive to high temperatures.

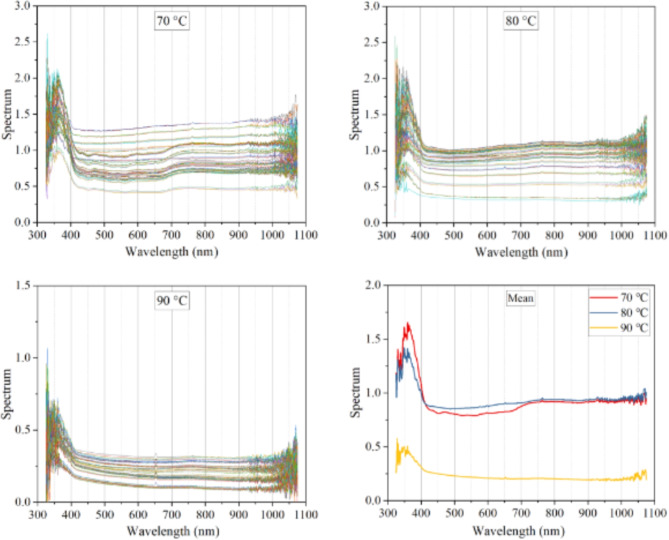

Spectral reflectance values

Spectral reflectances produce different shapes of electromagnetic energy at specific wavelengths, depending on the quality of the food. Spectral properties provide information about objects’ surface and subsurface properties, which are diverse and componentized80. Chemical constituents selectively capture light energy at specific wavelengths, and data is collected from the resulting spectra, which are subsequently examined using spectrometers81. The primary substances that absorb near-infrared (NIR) wavelengths include carotenoids, anthocyanins, lipids, carbohydrates, chlorophylls, and proteins. The visible wavelength range of foods between 400 and 750 nm is perceived by humans as color82. In the present study, spectral reflectance values of European cranberry bush fruit leather were explored using quince seed gel at three different temperatures. The variation in the reflectance spectra of the samples is shown in Fig. 5. The products dried using the foam drying technique had the highest reflectance values at 70, 80, and 90 °C, respectively. Initial spectral reflectance values were low for all fruit leather samples but showed a peak at 470 nm. Color changes during drying are not homogeneous and can cause irregularities in the spectral pattern83. The spectral reflectance of the products dried at 80 and 90 °C showed similar results, although those dried at 70 °C had the highest reflectance values. The highest reflectance values measured at 70 °C can be explained by the carotenoid deterioration and the samples’ color properties associated with the long drying time84.

Fig. 4.

The pestil of the European cranberry bush is obtained by the foam mat drying procedure at various temperatures utilizing quince seed gel.

Carotenoids in fruits and vegetables absorb light very strongly85. In the present study, 970 nm pits were seen in fruit leather samples dried by all foam mat drying methods. This phenomenon shows that quince pits increase the carotenoids present86. Besides, a decrease in spectral reflectance values around 970 nm was observed for all methods. This is because fluctuations occur hereafter air drying the products to a constant weight. After all, very little water remains in the tissue87. In other words, as the amount of free water in the sample decreased, so did the absorbance. The decrease in the number of water molecules caused the absorption of infrared radiation88.

The variations in spectral reflectance after the drying process can be attributed to color and chemical composition modifications resulting from the thermal degradation of total carotenoids and the loss of moisture during drying. A higher reflectance value before 970 nm might be connected to creating chromophores, like melanoidin’s, through Maillard reactions while the material is dried in hot air89. In the present study, the lowest spectral reflectances were measured at 90 °C, which was attributed to the absorption of light by the brown color pigment and carotenoids formed as due to the elevated temperature throughout the drying process90. Çetin & Sağlam87 dried apple varieties using different drying techniques. The study emphasized that the spectral reflectance peaks in the range of 375–400 nm, and fluctuations in spectral reflectance values occur at 970 nm about the products reaching equilibrium moisture. Md Saleh et al.84 dried carrot slices at 50, 60, and 70 °C, and the low spectral reflectance values at 531 nm were related to the number of carotenoids in the slices. Nguyen-Do-Trong et al.90 convective-dried banana slices at varied times and found that spectral reflectance was reduced at 760 nm, associated with increased browning in the banana tissue. Brar et al.46 found that protein denaturation from high-temperature dehydration lowered FTIR reflectances in peach foam mat drying. Besides, it was reported that the significant decline in peaks seen in various places of foam mat dried samples showed a slight structural change due to temperature changes. In contrast to the present study, Ihsan et al.91 reported a peak of spectral reflections in apple leaves between 700 and 1000 nm wavelengths associated with high carotenoid content. Merzlyak et al.92 found that the enhanced apple carotenoid concentration enhanced spectral reflectance in the 400–550 nm wavelength range.

Fig. 5.

Spectral reflectance values of European cranberry bush pestils obtained by foam mat drying at different wavelengths.

Conclusion

This study is the first report on obtaining European cranberry bush fruit leather using the foam mat drying technique using quince seed gel. The foam mats were dried using the air convective technique at 70, 80, and 90 °C for 135, 90, and 45 min, respectively.

The greatest values in color, ascorbic acid, anthocyanin, and antiradical activity were observed at 90 °C.

The highest value of total phenolic content was obtained at 80 °C.

Present results also showed that the fruit leather had the highest P, Na, Mg, K, Ca, and Mn contents at 70 °C, Fe at 80 °C, and S, Cu, and Zn at 90 °C.

The highest spectral reflectance values were measured at 70 °C, associated with a long drying time and a significant deterioration in the chromatic attributes of the fruit leather. In other words, spectral reflectance values at different wavelengths were found to be an informative method about the amount of darkening in the structure of the products. These results validate our hypothesis.

The foam mat drying technique using quince seed gel indicates excellent potential for conducting future research in food processing.

The present study found that using quince seed gel significantly increased the contents of antiradical activities, anthocyanins, total phenolics, and ascorbic acid of the European cranberry bush fruit leather. The results suggest that quince seed gel can increase the thickness of foods and aid in effective drying investigations. Testing the rich biochemical content of quince seed gel in different products and drying conditions can be a technique that strengthens confidence.

Author contributions

Seda Günaydın: Investigation, Resources, Methodology, Formal analysis, Data curation, Visualization, Writing-Editing. Necati Çetin: Conceptualism, Methodology, Formal analysis, Data curation, Visualization, Writing-Editing. Cevdet Sağlam: Supervision, Writing-Editing. Kevser Karaman: Supervision, Formal analysis, Data curation, Writing-Editing.

Data availability

“Data is provided within the manuscript or supplementary information files”.

Declarations

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Kodikara, C., Bandara, N., Netticadan, T. & Wijekoon, C. Canadian prairie berries: bioactive compounds and their potential health benefits. Food Rev. Int. 1–28. 10.1080/87559129.2023.2273934 (2023).

- 2.Gülada, B. Ö. et al. Gilaburu (Viburnum opulus L.) fruit extract has potential therapeutic and prophylactic role in a rat model of acetic acid-induced oxidant colonic damage. J. Ethnopharmacol. 322, 117624. 10.1016/j.jep.2023.117624 (2024). [DOI] [PubMed] [Google Scholar]

- 3.Goławska, S., Łukasik, I., Chojnacki, A. A. & Chrzanowski, G. Flavonoids and phenolic acids content in cultivation and wild collection of European Cranberry Bush Viburnum opulus L. Molecules 28, 2285. 10.3390/molecules28052285 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Dönmez, A. & Kadakal, Ç. Hot-air drying and degradation kinetics of bioactive compounds of gilaburu (Viburnum opulus L.) fruit. Chem. Ind. Chem. Eng. Q. 30(1), 59–72. 10.2298/CICEQ220614011D (2023). [Google Scholar]

- 5.Sevindik, O. et al. Impacts of selected lactic acid bacteria strains on the aroma and bioactive compositions of fermented gilaburu (Viburnum opulus) juices. Food Chem. 378, 132079. 10.1016/j.foodchem.2022.132079 (2022). [DOI] [PubMed] [Google Scholar]

- 6.Pietrzyk, N., Zakłos-Szyda, M., Koziołkiewicz, M. & Podsędek, A. Viburnum opulus L. fruit phenolic compounds protect against FFA-induced steatosis of HepG2 cells via AMPK pathway. J. Funct. Foods 80, 104437. 10.1016/j.jff.2021.104437 (2021). [Google Scholar]

- 7.Kajszczak, D., Zakłos-Szyda, M. & Podsędek, A. Viburnum opulus L.-A review of phytochemistry and biological effects. Nutrients 12(11), 3398. 10.3390/nu12113398 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Zakłos-Szyda, M., Kowalska-Baron, A., Pietrzyk, N., Drzazga, A. & Podsędek, A. Evaluation of Viburnum opulus L. fruit phenolics cytoprotective potential on insulinoma MIN6 cells relevant for diabetes mellitus and obesity. Antioxidants 9(5), 433. 10.3390/antiox9050433 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Sonkar, C. & Immanuel, G. Refractance window drying: influence of drying parameters on drying characteristics and quality attributes of orange pestil. Emergent Life Sci. Res. 8, 214–221. 10.31783/elsr.2022.82214221 (2022). [Google Scholar]

- 10.Barman, M., Das, A. B. & Badwaik, L. S. Effect of xanthan gum, guar gum, and pectin on physicochemical, color, textural, sensory, and drying characteristics of Kiwi fruit leather. J. Food Process. Preserv. 45(5), e15478. 10.1111/jfpp.15478 (2021). [Google Scholar]

- 11.Jayakody, M. M., Kaushani, K. G., Vanniarachchy, M. P. G. & Wijesekara, I. Hydrocolloid and watersoluble polymers used in the food industry and their functional properties: a review. Polym. Bull. 80(4), 3585–3610. 10.1007/s00289-022-04264-5 (2023). [Google Scholar]

- 12.Incedayi, B., Dogan, N. & Copur, O. U. Assessment of cactus pear leather (pestil) as a new snack food. J. Food Sci. Technol. 59(8), 3158–3166. 10.1007/s13197-022-05366-8 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Deng, L. Z. et al. Chemical and physical pretreatments of fruits and vegetables: effects on drying characteristics and quality attributes–a comprehensive review. Crit. Rev. Food Sci. Nutr. 59(9), 1408–1432. 10.1080/10408398.2017.1409192 (2019). [DOI] [PubMed] [Google Scholar]

- 14.Tan, C. H. et al. Valorization of fruits, vegetables, and their by-products: drying and bio-drying. Dry. Technol. 40(8), 1514–1538. 10.1080/07373937.2022.2068570 (2022). [Google Scholar]

- 15.Adeyeye, S. A. O., Ashaolu, T. J. & Babu, A. S. Food drying: a review. Agric. Rev. 1(8). 10.18805/ag.R-2537 (2022).

- 16.Samoticha, J., Wojdyło, A. & Lech, K. The influence of different the drying methods on chemical composition and antioxidant activity in chokeberries. LWT 66, 484–489. 10.1016/j.lwt.2015.10.073 (2016). [Google Scholar]

- 17.Babu, A. K., Kumaresan, G., Raj, V. A. A. & Velraj, R. Review of leaf drying: mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 90, 536–556. 10.1016/j.rser.2018.04.002 (2018). [Google Scholar]

- 18.Prajapat, N. Foam mat drying of high value foods. nt J. Agric. Sci. 15(7), 12455–12457 (2023). [Google Scholar]

- 19.Maciel, K. S., Teixeira, L. J. Q., Lucia, S. M. D. & Saraiva, S. H. Optimization of foam mat drying for instant coffee processing and its effect on drying kinetics and quality characteristics. Dry. Technol. 40(9), 1866–1880. 10.1080/07373937.2021.1887210 (2022). [Google Scholar]

- 20.Phuong, N. N. M., Le, T. T., Van Camp, J. & Raes, K. Dehydration of phenolic-rich extract from rambutan (Nephelium lappaceum L.) peel by foam mat drying. LWT 198, 115973. 10.1016/j.lwt.2024.115973 (2024). [Google Scholar]

- 21.Kumar, G., Kumar, N., Prabhakar, P. K. & Kishore, A. Foam mat drying: recent advances on foam dynamics, mechanistic modeling and hybrid drying approach. Crit. Rev. Food Sci. Nutr. 63(26), 8275–8291. 10.1080/10408398.2022.2053061 (2023). [DOI] [PubMed] [Google Scholar]

- 22.Hossain, M. A., Mitra, S., Belal, M. & Zzaman, W. Effect of foaming agent concentration and drying temperature on biochemical properties of foam mat dried tomato powder. Food Res. 5(2), 291–297. 10.26656/fr.2017.5 (2021). [Google Scholar]

- 23.Qadri, O. S., Srivastava, A. K. & Yousuf, B. Trends in foam mat drying of foods: special emphasis on hybrid foam mat drying technology. Crit. Rev. Food Sci. Nutr. 60(10), 1667–1676. 10.1080/10408398.2019.1588221 (2020). [DOI] [PubMed] [Google Scholar]

- 24.Santos, P. H. S. & Silva, M. A. Retention of vitamin C in drying processes of fruits and vegetables a review. Dry. Technol. 26, 1421–1437. 10.1080/07373930802458911 (2008). [Google Scholar]

- 25.Abbastabar, B., Azizi, M. H., Adnani, A. & Abbasi, S. Determining and modeling rheological characteristics of quince seed gum. Food Hydrocoll. 43, 259–264. 10.1016/j.foodhyd.2014.05.026 (2015). [Google Scholar]

- 26.Stojanović, B. T. et al. Phenolic profiles and metal ions analyses of pulp and peel of fruits and seeds of quince (Cydonia oblonga Mill). Food Chem. 232, 466–475. 10.1016/j.foodchem.2017.04.041 (2017). [DOI] [PubMed] [Google Scholar]

- 27.Kirtil, E. & Oztop, M. H. Characterization of emulsion stabilization properties of quince seed extract as a new source of hydrocolloid. Int. Food Res. 85, 84–94. 10.1016/j.foodres.2016.04.019 (2016). [DOI] [PubMed] [Google Scholar]

- 28.Gürbüz, Z., Erkaya-Kotan, T. & Şengül, M. Evaluation of physicochemical, microbiological, texture and microstructure characteristics of set-style yoghurt supplemented with quince seed mucilage powder as a novel natural stabiliser. Int. Dairy. J. 114, 104938. 10.3390/agriculture12091289 (2021). [Google Scholar]

- 29.Kurt, A. & Atalar, I. Effects of quince seed on the rheological, structural and sensory characteristics of ice cream. Food Hydrocoll. 82, 186–195. 10.1016/j.foodhyd.2018.04.011 (2018). [Google Scholar]

- 30.Erkaya-Kotan, T., Gürbüz, Z., Dağdemir, E. & Şengül, M. Utilization of edible coating based on quince seed mucilage loaded with thyme essential oil: Shelf life, quality, and ACE-inhibitory activity efficiency in Kaşar cheese. Food Biosci. 54, 102895. 10.1016/j.fbio.2023.102895 (2023). [Google Scholar]

- 31.Farahmandfar, R., Asnaashari, M., Salahi, M. R. & Rad, T. K. Effects of basil seed gum, Cress seed gum and quince seed gum on the physical, textural and rheological properties of whipped cream. Int. J. Biol. Macrom. 98, 820–828. 10.1016/j.ijbiomac.2017.02.046 (2017). [DOI] [PubMed] [Google Scholar]

- 32.Çetin, N. Comparative assessment of energy analysis, drying kinetics, and biochemical composition of tomato waste under different drying conditions. Sci. Hortic. 305, 111405. 10.1016/j.scienta.2022.111405 (2022). [Google Scholar]

- 33.Wang, J. et al. Pulsed vacuum drying enhances drying kinetics and quality of lemon slices. J. Food Eng. 224, 129–138. 10.1016/j.jfoodeng.2018.01.002 (2018). [Google Scholar]

- 34.Sarpong, F. et al. Drying characteristic, enzyme inactivation and browning pigmentation kinetics of controlled humidity-convective drying of banana slices. J. Heat. Mass. Transf. 54, 3117–3130. 10.1007/s00231-018-2354-y (2018). [Google Scholar]

- 35.Mertens, D. AOAC official method 975.03. Metal in plants and pet foods. Official Methods of Analysis, 18th edn. Horwitz, W., and GW Latimer, (Eds), 3–4 (2005).

- 36.Taghavi, T., Patel, H. & Rafie, R. Comparing pH differential and methanol-based methods for anthocyanin assessments of strawberries. Food Sci. Nutr. 10(7), 2123–2131. 10.1002/fsn3.2065 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Shin, D. J., Choe, J., Hwang, K. E., Kim, C. J. & Jo, C. Antioxidant effects of lotus (Nelumbo nucifera) root and leaf extracts and their application on pork patties as inhibitors of lipid oxidation, alone and in combination. Int. J. Food Prop. 22(1), 383–394. 10.1080/10942912.2019.1588295 (2019). [Google Scholar]

- 38.Khatri, D. & Chhetri, S. B. B. Reducing sugar, total phenolic content, and antioxidant potential of nepalese plants. Biomed Res. Int. 7296859. 10.1155/2020/7296859 (2020). [DOI] [PMC free article] [PubMed]

- 39.Köprü, S., Say, R., Karaman, K., Yilmaz, M. M. & Kaplan, M. Optimization of processing parameters for the preparation of clove (Syzygium aromaticum) hydroalcoholic extract: a response surface methodology approach to characterize the biofunctional performance. J. Appl. Res. Med. Aromat. Plants 16, 100236. 10.1016/j.jarmap.2019.100236 (2020). [Google Scholar]

- 40.Wettasinghe, M., Bolling, B., Plhak, L., Xiao, H. & Parkin, K. Phase II enzyme-inducing and antioxidant activities of beetroot (Beta vulgaris L.) extracts from phenotypes of different pigmentation. J. Agric. Food Chem. 50(23), 6704–6709. 10.1021/jf020575a (2002). [DOI] [PubMed] [Google Scholar]

- 41.Li, Z. et al. Dirac charge dynamics in graphene by infrared spectroscopy. Nat. Phys. 4(7), 532–535. 10.1038/nphys989 (2008). [Google Scholar]

- 42.Ertekin, C. & Firat, M. Z. A comprehensive review of thin-layer drying models used in agricultural products. Crit. Rev. Food Sci. Nutr. 57(4), 701–717. 10.1080/10408398.2014.910493 (2017). [DOI] [PubMed] [Google Scholar]

- 43.Babalis, S. J., Papanicolaou, E., Kyriakis, N. & Belessiotis, V. G. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus carica). J. Food Eng. 75, 205–214. 10.1016/j.jfoodeng.2005.04.008 (2006). [Google Scholar]

- 44.Jena, S. & Das, H. Modelling for vacuum drying characteristic of coconut presscake. J. Food Eng. 79, 92–99. 10.1016/j.jfoodeng.2006.01.032 (2007). [Google Scholar]

- 45.Watharkar, R. B., Chakraborty, S., Srivastav, P. P. & Srivastava, B. Foaming and foam mat drying characteristics of ripe banana [Musa balbisiana (BB)] pulp. J. Food Process. Eng. 44(8), e13726. 10.1111/jfpe.13726 (2021). [Google Scholar]

- 46.Brar, A. S. et al. Optimization of process parameters for foam-mat drying of peaches. Int. J. Fruit Sci. 20(3), S1495–S1518. 10.1080/15538362.2020.1812017 (2020). [Google Scholar]

- 47.Macedo, L. L., Corrêa, J. L. G., Araújo, C. D. S., Vimercati, W. C. & Pio, L. A. S. Process optimization and ethanol use for obtaining white and red dragon fruit powder by foam mat drying. J. Food Sci. 86(2), 426–433. 10.1111/1750-3841.15585 (2021). [DOI] [PubMed] [Google Scholar]

- 48.Azizpour, M., Mohebbi, M., Khodaparast, M. H. H. & Varidi, M. Foam-mat drying of shrimp: characterization and drying kinetics of foam. Int. Agric. Eng. J. CIGR J. 15(3), 159–165 (2013). [Google Scholar]

- 49.Thuwapanichayanan, R., Prachayawarakorn, S. & Soponronnarit, S. Drying characteristics and quality of banana foam mat. J. Food Eng. 86(4), 573–583. 10.1016/j.jfoodeng.2007.11.008 (2008). [Google Scholar]

- 50.Kaba, B. et al. Production of cornelian cherry (Cornus mas L.) pulp powder by foam-mat drying: analysis of physicochemical and antioxidant properties. Biomass Conv Bioref. 1–16. 10.1007/s13399-023-05234-1 (2023).

- 51.Kumar, A., Kandasamy, P., Chakraborty, I. & Hangshing, L. Analysis of energy consumption, heat and mass transfer, drying kinetics and effective moisture diffusivity during foam-mat drying of mango in a convective hot-air dryer. Biosyst Eng. 219, 85–102. 10.1016/j.biosystemseng.2022.04.026 (2022). [Google Scholar]

- 52.Djaeni, M., Prasetyaningrum, A., Sasongko, S. B., Widayat, W. & Hii, L. C. Application of foam-mat drying with egg white for carrageenan: drying rate and product quality aspects. J. Food Sci. Technol. 52, 1170–1175. 10.1007/s13197-013-1081-0 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Li, T. S., Sulaiman, R., Rukayadi, Y. & Ramli, S. Effect of gum arabic concentrations on foam properties, drying kinetics and physicochemical properties of foam mat drying of cantaloupe. Food Hydrocoll. 116, 106492. 10.1016/j.foodhyd.2020.106492 (2021). [Google Scholar]

- 54.Kurniadi, M. et al. The effect of kappa-carrageenan andgum arabic on the production of guava-banana fruit leather. J. Food Technol. 59(11), 4415–4426. 10.1007/s13197-022-05521-1 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Yuan, J. F. et al. Microwave irradiation: effects on the change of colour characteristics and main phenolic compounds of cabernet gernischt dry red wine during storage. Foods 11(12), 1778. 10.3390/foods11121778 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Zia, M. P. & Alibas, I. Influence of the drying methods on color, vitamin c, anthocyanin, phenolic compounds, antioxidant activity, and in vitro bioaccessibility of blueberry fruits. Food Biosci. 42, 101179. 10.1016/j.fbio.2021.101179 (2021). [Google Scholar]

- 57.Belal, M., Hossain, M. A., Mitra, S. & Zzaman, W. Effect of foaming agent concentration and foam stabilizer on the foaming capacity and physical properties of tomato powder at dried at different temperature. J. Microbiol. Biotechnol. Food Sci. 12(4), e4741. 10.55251/jmbfs.4741 (2022). [Google Scholar]

- 58.Ng, M. L. & Sulaiman, R. Development of beetroot (Beta vulgaris) powder using foam mat drying. Lwt 88, 80–86. 10.1016/j.lwt.2017.08.032 (2018). [Google Scholar]

- 59.Paiva, Y. F. et al. red d., d., d., Tropical red fruit blend foam mat drying: effect of combination of additives and drying temperatures. Foods 12, 2508. 10.3390/foods12132508 (2023). [DOI] [PMC free article] [PubMed]

- 60.Franco, T. S., Perussello, C. A., Ellendersen, L. N. & Masson, M. L. Effects of foam mat drying on physicochemical and microstructural properties of yacon juice powder. LWT 66, 503–513. 10.1016/j.lwt.2015.11.009 (2016). [Google Scholar]

- 61.Krzepilko, A. & Prazak, R. Quince seeds as a potential source of mineral and biological active compounds. J.Elem. 28(1) 10.5601/jelem.2022.27.3.2317 (2023).

- 62.Babiker, E. E., Juhaimi, F. A., Ghafoor, K. & Abdoun, K. A. Effect of drying methods on nutritional quality of young shoots and leaves of two moringa species as non-conventional fodders. Agrofor. Syst. 92, 717–729. 10.1007/s10457-016-0043-8 (2018). [Google Scholar]

- 63.Adak, N., Heybeli, N. & Ertekin, C. Infrared drying of strawberries. Food Chem. 219, 109–116. 10.1016/j.foodchem.2016.09.103 (2017). [DOI] [PubMed] [Google Scholar]

- 64.Czerwinski, F. The reactive element effect on high-temperature oxidation of magnesium. Int. Mater. Rev. 60(5), 264–296. 10.1179/1743280415Y.0000000001 (2015). [Google Scholar]

- 65.Alibas, I., Yilmaz, A., Asik, B. B. & Erdoğan, H. Influence of drying methods on the nutrients, protein content and vitamin profile of basil leaves. J. Food Compos. Anal. 96, 103758. 10.1016/j.jfca.2020.103758 (2021). [Google Scholar]

- 66.Garti, H., Garti, H. A. & Nyarko, G. Comparative studies on the nutrient composition of shade-dried and sun-dried leaves of Rosselle (Hibiscus sabdariffa L). Afr. J. Hortic. Sci. 16, 29–42 (2019). [Google Scholar]

- 67.Peleg, M., Normand, M. D., Dixon, W. R. & Goulette, T. R. Modeling the degradation kinetics of ascorbic acid. Crit. Rev. Food Sci. Nutr. 58(9), 1–17. 10.1080/10408398.2016.1264360 (2016). [DOI] [PubMed] [Google Scholar]

- 68.Turgut, D. Y. & Topuz, A. Bioactive compounds and biological activities of kumquat (Fortunella spp). TURJAF 7(10), 1581–1588. 10.24925/turjaf.v7i10.1581-1588.2628 (2019). [Google Scholar]

- 69.Duan, Y. et al. Genotypic variation of flavonols and antioxidant capacity in broccoli. Food Chem. 338, 127997. 10.1016/j.foodchem.2020.127997 (2021). [DOI] [PubMed] [Google Scholar]

- 70.Guiné, R. P. et al. Effect of drying on total phenolic compounds, antioxidant activity, and kinetics decay in pears. Int. J. Fruit Sci. 15(2), 173–186. (2015).

- 71.Lu, W. et al. Choosing the appropriate wall materials for spray-drying microencapsulation of natural bioactive ingredients: taking phenolic compounds as examples. Powder Technol. 394, 562–574. 10.1016/j.powtec.2021.08.082 (2021). [Google Scholar]

- 72.Abd El-Salam, E. A. E. S., Ali, A. M. & Hammad, K. S. Foaming process optimization, drying kinetics and foam mat dried papaya pulp quality. J. Food Sci. Technol. 58, 1449–1461. 10.1007/s13197-020-04657-2 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 73.Chaux-Gutiérrez, A. M., Santos, A. B., Granda-Restrepo, D. M. & Mauro, M. A. Foam mat drying of mango: Effect of processing parameters on the drying kinetic and product quality. Dry. Technol. 35(5), 631–641. 10.1080/07373937.2016.1201486 (2017). [Google Scholar]

- 74.Gunaydin, S. & Alibas, I. The influence of short, medium, and long duration common dehydration methods on total protein, nutrients, vitamins, and carotenoids of rosehip fruit (Rosa canina L). J. Food Compos. Anal. 124, 105631. 10.1016/j.jfca.2023.105631 (2023). [Google Scholar]

- 75.López, J. et al. Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning and firmness of blueberries variety O Neil. Food Bioproc Tech. 3, 772–777. 10.1007/s11947-009-0306-8 (2010). [Google Scholar]

- 76.Pinar, H., Çetin, N., Ciftci, B., Karaman, K. & Kaplan, M. Biochemical composition, drying kinetics and chromatic parameters of red pepper as affected by cultivars and drying methods. J. Food Compos. Anal. 102, 103976. 10.1016/j.jfca.2021.103976 (2021). [Google Scholar]

- 77.Jakkranuhwat, N. & Kunchansombat, P. Effect of foam-mat drying conditions on antioxidant activity, total phenolic compound, anthocyanin content and color of purple-fleshed sweet potato powder. Nat. Sci. 20(2), 1–8. 10.12982/CMUJNS.2021.045 (2021). [Google Scholar]

- 78.Van Tai, N., Van Hao, H., Han, T. T. N., Giau, T. N. & Thuy, N. M. Thanh, N. Effect of foaming conditions and drying temperatures on total polyphenol content and drying rate of foam-mat dried banana powder: modelling and optimization study. J. Agri Food Res. 101352. 10.1016/j.jafr.2024.101352 (2024).

- 79.Gupta, V. et al. Foam mat drying of Jujube (Ziziphus mauritiana) juice: process optimisation, physico-functional, Phenolic content and antioxidant analysis. J. Inst. Eng. India Ser. A 102, 1013–1025. 10.1007/s40030-021-00566-5 (2021). [Google Scholar]

- 80.Nawrocka, A. & Lamorska, J. Determination of food quality by using spectroscopic methods. Adv. Agrophy Res. IntechOpen 10.5772/52722 (2013). [Google Scholar]

- 81.Wu, D. & Sun, D. W. Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: a review-part I: fundamentals. Innov. Food Sci. Emerg. Technol. 19, 1–14. 10.1016/j.ifset.2013.04.014 (2013). [Google Scholar]

- 82.El-Mesery, H. S., Mao, H. & Abomohra, A. E. F. Applications of non-destructive technologies for agricultural and food products quality inspection. Sensors 19(4), 846. 10.3390/s19040846 (2019). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 83.Fernandez, L., Castillero, C. & Aguilera, J. M. An application of image analysis to dehydration of apple discs. J. Food Eng. 67(1–2), 185–193. 10.1016/j.jfoodeng.2004.05.070 (2005). [Google Scholar]

- 84.Md Saleh, R., Kulig, B., Arefi, A., Hensel, O. & Sturm, B. Prediction of total carotenoids, color, and moisture content of carrot slices during hot air drying using non-invasive hyperspectral imaging technique. J. Food Process. Preserv. 46(9), e16460. 10.1111/jfpp.16460 (2022). [Google Scholar]

- 85.Ustin, S. L. & Jacquemoud, S. How the optical properties of leaves modify the absorption and scattering of energy and enhance leaf functionality. RSPD, 349–384. (International Publishing, 2020).

- 86.Górnaś, P. et al. Cold-pressed Japanese quince (Chaenomeles japonica (Thunb.) Lindl. Ex Spach) seed oil as a rich source of α‐tocopherol, carotenoids and phenolics: a comparison of the composition and antioxidant activity with nine other plant oils. Eur. J. Lipid Sci. Technol. 116(5), 563–570. 10.1002/ejlt.201300425 (2014). [Google Scholar]

- 87.Çetin, N. & Sağlam, C. Rapid detection of total phenolics, antioxidant activity and ascorbic acid of dried apples by chemometric algorithms. Food Biosci. 47, 101670. 10.1016/j.fbio.2022.101670 (2022). [Google Scholar]

- 88.Guo, F. & Altaner, C. M. Effects of mechanical stretching, desorption and isotope exchange on deuterated eucalypt wood studied by near infrared spectroscopy. Spectrochim Acta Mol. Biomol. Spectrosc. 211, 254–259. 10.1016/j.saa.2018.12.012 (2019). [DOI] [PubMed] [Google Scholar]

- 89.Do Trong, N. N. et al. Spatially resolved diffuse reflectance in the visible and near-infrared wavelength range for non-destructive quality assessment of ‘Braeburn’apples. Postharvest Biol. Technol. 91, 39–48. (2014). [Google Scholar]

- 90.Nguyen-Do-Trong, N., Dusabumuremyi, J. C. & Saeys, W. Cross-polarized VNIR hyperspectral reflectance imaging for non-destructive quality evaluation of dried banana slices, drying process monitoring and control. J. Food Eng. 238, 85–94. 10.1016/j.jfoodeng.2018.06.013 (2018). [Google Scholar]

- 91.Ihsan, M., Saputro, A. H. & Handayani, W. Hyperspectral imaging feature selection using regression tree algorithm: Prediction of carotenoid content velvet apple leaf. In 2019 3rd International Conference on Informatics and Computational Sciences (ICICoS). 1–5. 10.1109/ICICoS48119.2019.8982490 (IEEE, 2019).

- 92.Merzlyak, M. N., Solovchenko, A. E. & Gitelson, A. A. Reflectance spectral features and non-destructive estimation of chlorophyll, carotenoid and anthocyanin content in apple fruit. Postharvest Biol. Technol. 27(2), 197–211. 10.1016/S0925-5214(02)00066-2 (2003). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

“Data is provided within the manuscript or supplementary information files”.