Abstract

Soft robotics inspired by the movement of living organisms, with excellent adaptability and accuracy for accomplishing tasks, are highly desirable for efficient operations and safe interactions with human. With the emerging wearable electronics, higher tactility and skin affinity are pursued for safe and user‐friendly human–robot interactions. Fabrics interlocked by fibers perform traditional static functions such as warming, protection, and fashion. Recently, dynamic fibers and fabrics are favorable to deliver active stimulus responses such as sensing and actuating abilities for soft‐robots and wearables. First, the responsive mechanisms of fiber/fabric actuators and their performances under various external stimuli are reviewed. Fiber/yarn‐based artificial muscles for soft‐robots manipulation and assistance in human motion are discussed, as well as smart clothes for improving human perception. Second, the geometric designs, fabrications, mechanisms, and functions of fibers/fabrics for sensing and energy harvesting from the human body and environments are summarized. Effective integration between the electronic components with garments, human skin, and living organisms is illustrated, presenting multifunctional platforms with self‐powered potential for human–robot interactions and biomedicine. Lastly, the relationships between robotic/wearable fibers/fabrics and the external stimuli, together with the challenges and possible routes for revolutionizing the robotic fibers/fabrics and wearables in this new era are proposed.

Keywords: actuators, fibers/fabrics, power sources, sensors, soft robotics

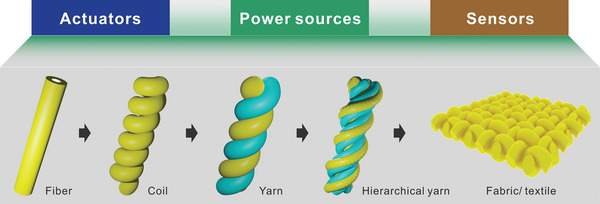

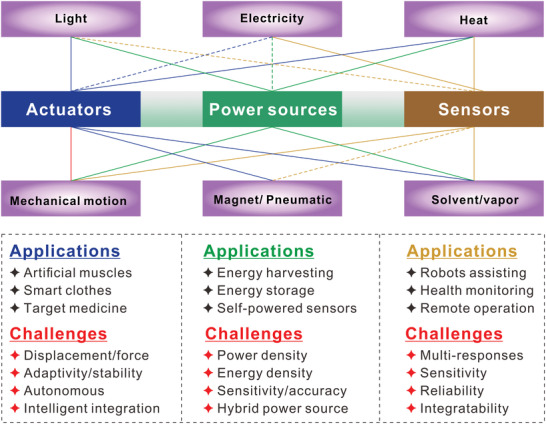

A relation map of dynamic fibers/fabrics with responsive functions, including actuation, sensing, and energy harvesting, is built for potential construction of a soft, safe, user‐friendly human–robot interface. It promises the seamless integration between actuators, sensors, and power sources into fibers/fabrics, envisaging self‐regulated, autonomous, and intelligent robotic fibers/fabrics for daily functions and biomedical services.

1. Introduction

Human–robot interface (HRI) is an emerging smart interface that allows operations, interactions and collaborations between human and robots/machines in a colocated or coordinatedway, fulfilling works with higher efficiency or addressing some complicated/dangerous tasks. Soft robotics, often inspired by the adaptability of living organisms, are capable of delivering excellent mechanical adaptability to enable safe and friendly interactions with human. Fiber that has been known for thousands of years for textile engineering, is a kind of thin 1D material with large length–diameter ratio and softness. Fiber can be further processed into 1D or 3D yarns and 2D or 3D fabrics and can be subjected to well‐established textile manufacturing techniques, such as dyeing, twisting, sewing, knitting, weaving, braiding, etc.[ 1 ] As commercially available material, fabric has been widely used for clothing, bedding, or furniture. Such wide‐adoption demonstrates fabrics/textiles to be important and adaptable as daily useable material due to their merits of protection, breathability, comfort, and durability.[ 2 ] In recent years, novel smart responsive functions are desirable to be implemented on fibers and fabrics for seamless integrations of actuators, sensors, power sources, etc., to realize the robotic fibers/fabric‐based manipulators and human–robot interfaces. These emerging responsive fibers/fabrics are desirable to offer programmable functions, actuations, perception and capable of building an intuitive and dynamic collaborative scenarios with human, promising in enabling applications such as remote operation, human motion assistance, human perception, health monitoring and biomedical detection and therapy.[ 3 , 4 , 5 ] It is an attractive concept that the future human–robot interfaces could be embodied in familiar forms for humans such as textiles or clothes. Compared with the polymeric and elastomeric soft robotics,[ 6 , 7 , 8 , 9 ] fibers and fabrics are advantageous in applications of soft robotics and wearables for human. The devices could be programmable to have accurate designs in configuration and high performance by traditional manufacturing processes of textile, applying twist to transform fibers into coils, yarns with hierarchical structures, which could be further fabricated into fabrics or textiles by sewing, weaving, knitting, etc., techniques (Figure 1 ), guaranteeing good wearability, skin affinity, washability, and durability, which are intriguing and necessary for friendly robotics interactions with human.

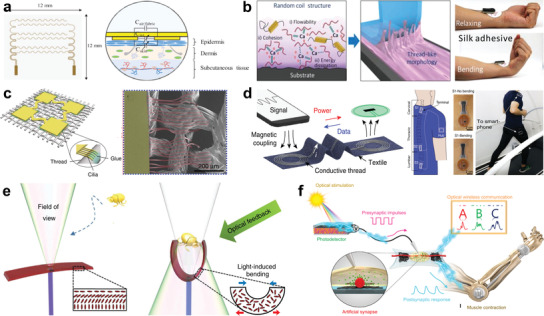

Figure 1.

The available forms of fibers in 1D, 3D, and 2D configurations include yarns and fabric/textile for application in actuators, sensors, and power sources.

Soft robotics include three main components of actuators, sensors, and control modules with power sources.[ 10 , 11 ] Of which, actuators, sensors and power sources all could be designed in the form of fibers or fabrics, rendering facile assembly, and integration by interlocking.[ 12 ] Common actuations can be achieved under external stimuli such as electricity, light, heat, magnetic field, solvent, and vapor conditions, realizing various displacements in 1D, 2D, or 3D directions. For example, fiber actuators could deliver linear motion, enabling important applications in some special 1D or space‐limited scenarios, such as biomedical targeted delivery and therapy in vessels.[ 13 ] Twisting manipulation through internal contraction or relaxation forces could be realized using the yarn‐based actuators, capable of simulating the motions such as contraction, relaxation, and expansion, alike of artificial muscles for operating the robots and assisting the human motions especially the disabled.[ 14 ] Besides, weaving or knitting the actuation fibers and yarns could be further fabricated into fabric actuators, attaining higher actuation displacement and force, with the potential to produce smart garments that have active responses, such as thermal‐regulation under the stimuli from solvent/vapor, heat, light, electricity, magnetic field, etc., and self‐protection actions against mechanical attacks or invasions.[ 15 ] These smart responsive clothes are significant for improving the human perception and quality of life.

Sensors are essential for feedback‐control of the soft robots. Fiber/fabric‐based sensors possess intrinsic merits for wearable applications and human–robot interactions, providing good skin affinity and safer interactive platforms for users.[ 16 ] In terms of fabrication, fibers, yarns, and fabrics/textiles are all feasible to be designed as sensors, such as mechanical sensor (strain sensor, pressure sensor), thermal sensor, humidity sensor, electrochemical sensor, etc.[ 17 ] They can perceive and convert various mechanical motions, temperature/humidity changes, metabolite, and various bio/chemical inputs into electricity signals, detecting the actuation displacement/force, human motions, and environmental conditions, enabling precise feedback‐controls for actuators/robots. Besides, the fiber/fabric‐based sensors are also compatible for integration with human body and garments for wearable applications, bridging the connections between soft robots and human body, rendering more‐friendly and effective human–robot interactions and internet of things.

Among the external stimuli, electricity shows more potential in controlling the robots or power the sensors, capable of driving most of the robotic components to realize highly‐integrated smart systems. Simultaneously, fibers/fabrics with rational designs could be also applied as power sources, harvesting and storing energy from human body or environment.[ 18 , 19 , 20 , 21 , 22 , 23 , 24 ] In recent years, increasing efforts are dedicated to develop power‐fibers/fabrics for self‐powered wearables and intelligent robotic systems. It has been proven that thermal energy, mechanical energy, water energy, solar irradiance energy, etc., can be harvested and stored individually or simultaneously by fibers/yarns or fabrics/textiles‐based devices, such as thermoelectric generator, piezo‐/triboelectric nanogenerators, and solar cells.[ 25 , 26 , 27 ] These devices can power traditional devices, or serve as self‐powered sensors and functional components, enabling seamless integrations with actuators and sensors to simplify the robotic fiber/fabric systems, which are especially effective for wearables power sources or sensors to bridge the connections for more‐friendly human–robot interactions. In addition, efforts were also made to integrate other functions such as color changing and data storage/processing for applications of fibers/fabrics in camouflage, displays, memories, artificial synapses and information communications, assisting to construct more intelligent interfaces for robots–environments and human–machines.[ 28 , 29 , 30 , 31 , 32 , 33 , 34 , 35 , 36 ]

Herein, we summarize the progress of fibers/yarns and fabrics/textiles for soft robots, wearables, and human–robot interface. First, mechanisms of fiber/fabric‐based actuators responding to various stimuli were introduced, the latest achievements of each kind of actuators were reviewed with classifications to figure out the device designs and working processes. Combining various responsive mechanisms, we summarize the types of artificial muscles assembled by fibers and yarns, presenting attractive functions for soft‐robots manipulation, human motions, and the disabled assistance, furthermore, we show the smart responsive clothes for human perception and smart actuation. Secondly, we summarize the fiber/fabric‐based wearable sensors for detection of mechanical motions, temperature, humidity, metabolite, etc., and power fibers/fabrics to harvest energy from human body heat, human motions, and environments. The configurations, fabrications, mechanisms and functions of the sensors are covered, presenting their capability and integrability to build the multiple‐responsive platforms for human–robot interfaces with self‐powered potential. In addition, we introduce the integration concerns and routes between electronics with fabrics/textiles and human skin. We show the potential of emerging fiber‐robots for biomedical applications in vivo. Lastly, we propose a relationship map of robotic/wearable fibers/fabrics with the external stimuli from environments or human body. We expect that while some of the challenges may persist, several possible solutions are outlined to tackle the shortcomings, presenting an outlook for development of the fiber/fabric‐based soft robots and wearables in the new era.

2. Fiber/Fabric‐Based Actuators

2.1. Mechanisms of the Fiber Actuators

The emerging fiber actuators, which are inspired by biological muscles, have attracted a lot of interest. Unlike traditional mechanical motors, the 1D fibers are intrinsically simple, flexible, and anisotropic.[ 37 ] Moreover, the fibers can be twisted, sewed, weaved and knitted into 3D or 2D configurations through the mature textile processing, forming yarns or fabrics/textiles with complex structures and functions. The fiber/yarn actuators can perform rotation, elongation, and bending motion with tunable strain and stroke, showing intriguing application potentials in robotics and wearable devices.[ 38 , 39 , 40 ]

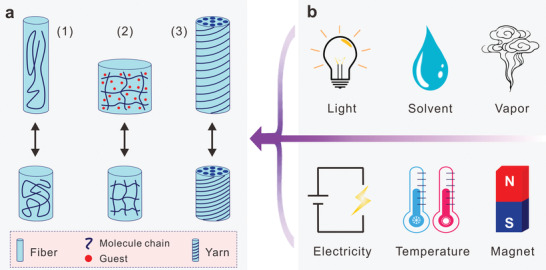

Fibers are the constitutional units of yarns and fabrics, the actuations of the fibers are mainly due to the change in the properties of the constituting materials when the environmental conditions change such as electricity, light, temperature, solvent, and vapor. The principles of fiber/yarn actuations can be classified into three mechanisms, 1) change of order of the molecule chains, 2) change of volume of the fibers, and 3) change of distance between the twisted fibers (Figure 2a).[ 15 , 41 , 42 , 43 , 44 , 45 , 46 ]

Figure 2.

The actuation mechanisms and different stimuli for fiber/yarn actuators. a) Three kinds of reversible deformation principles. 1) Order change, 2) volume change, and 3) distance change. b) The actuation stimuli. The purple arrow indicates the infliction of stimuli on the fiber/yarn actuators.

The order change of fiber molecule chains is usually actuated by electricity, light and thermal, which in principle does not involve mass exchange and volume changes.[ 47 ] For example, shape memory polymers and alloys perform reconfiguration upon thermal stimulus due to internal molecular chains rearrangements and crystal/molecular structural changes. At higher temperature, the shape memory materials that fixed at temporary configurations will restore its original shapes because of the relaxation and reordering of the lattices or molecular structures.[ 48 ] Besides, dielectric materials can be squeezed and deformed in the presence of an electric field due to the Coulomb forces induced electrostatic pressure, namely, electromechanical effect. When sandwiched by two electrodes with applied voltage, the piezoelectric materials[ 49 , 50 ] and dielectric elastomers[ 51 , 52 , 53 , 54 ] contract and elongate along the field direction. In addition, liquid crystal elastomers undergo nematic‐to‐isotropic phase transition under multiple stimuli like thermal, light, and electric field.[ 55 , 56 , 57 ]

The second type of the fiber actuation is dominated by the volume change of the constitutional materials. Mass exchange between fibers and environment usually causes volume change, which results in the contraction or expansion in all direction. Charged species like electrons and ions were transported in and out of the porous and conductive fibers due to the electrical potential differences. Mediated by concentration differences (osmosis) or chemical affinity, even small molecules can be absorbed/desorbed from the fibers, causing swelling or shrinkage.[ 58 ] Besides, the variation of temperature also causes the volume change due to thermal expansion or phase transitions like melting and crystallization, which does not involve mass exchange.[ 59 ]

The distance change is specific to a yarn or thread that consists of a lot of fibers. The yarn/thread contracts and rotates because of the change of gaps between fibers. The gaps enlarge due to the guest's infiltration and thermal expansion. Moreover, the actuation can be achieved simply by passing current through it. Based on the Ampere's Law, there is electrostatic attraction or repulsion between every conductive fiber. When the distance changes of all the aligned fibers are added up and magnified, which generate both rotational and translational motions of the yarn, in sharp contrast to volume change‐based fibers.[ 45 , 60 , 61 , 62 , 63 ]

In brief, the mechanisms of the fiber actuators are mainly originated from the change of material properties, like the change of molecule order, sample volume, and fibers distance. The material property changes can be actuated by several stimuli. Each stimulus can cause different changes according to the fiber's material and geometry. In our daily life, the most common physical and chemical stimuli are mainly electricity, light, temperature, magnet, solvent, and vapor (Figure 2b). The fiber actuators absorb energy from these stimuli and respond to it. Compared to traditional electromagnetic motors and actuators, fiber actuators involve a variety of materials, energy sources, and configurations, which are promising in soft robotics and smart wearable systems.

2.2. Fiber Actuators Responses to Different Stimuli

Various stimuli from environments and human body are able to activate the fiber/fabric actuators, promising diverse interactions between human and robots. Here, the fiber/fabric actuators are classified into five categories according to the stimuli, which is application oriented. They are electric field, light, heat, solvent/vapor, and others (include pneumatic and magnetic).[ 64 , 65 ] The geometric design, working principle, performance, and application of devices under every stimulus are discussed, as well as their pros and cons are deliberated.

2.2.1. Electric Actuation

Electricity is the most commonly used energy, which is easily available and highly controllable. All the electrical parameters, like voltage, charge, and current can be precisely measured and controlled. Accordingly, scientists have developed different kinds of fiber actuators that rely on electricity. High voltage usually induces the order change of dielectric materials like liquid crystal, elastomers, and piezoelectric materials. When passing through current, conductive yarns can be actuated due to the distance change of twisted fibers by the current–magnetic or electrostatic force. In the case of electrochemical actuation, charges are intercalated into porous electrode, inducing the volume changes and strains that lead to actuation.

Piezoelectric materials could generate mechanical strain in response to an applied electrical field. Torsional rotation of the piezoelectric ceramic fiber was achieved by wounding a pair of parallel helical electrodes on their outer surface. When applying a high voltage of several thousand volts, the fiber easily generated precisely torsional displacement. Although the degree of rotation was very small, the working frequency of this fiber was as high as 10 kHz.[ 66 , 67 ] In addition to the rigid and brittle ceramics, there are flexible piezoelectric polymers such as polyvinylidene fluoride (PVDF), poly(vinylidene fluoride‐co‐trifluororethylene (PVDF‐TrFE), Nylon, polyurea, etc., which are easier to process and integrate. A multiple materials fiber with micro‐electromechanical systems (MEMS) was fabricated by the thermal drawing process (Figure 3a).[ 68 ] Piezoelectric polymer cantilever was integrated inside the fiber, which was deliberately placed off‐center. When voltage was applied on the cantilever, asymmetric strain will be generated in the fiber with transverse bending. Because the thickness was reduced, the actuation voltage can be reduced to 200 V, producing the displacement of ≈80 µm. Due to the high frequency and high stress, piezoelectric fibers can be used for color tuning, spectral filtering, microfluidic pumps. Especially, the high working frequency piezoelectric fibers can be used as ultrasonic sensors or actuators, and integrated into the ultrasonic imaging steerable catheter.[ 69 ] However, the high working voltage and small displacement are the most serious limitations.

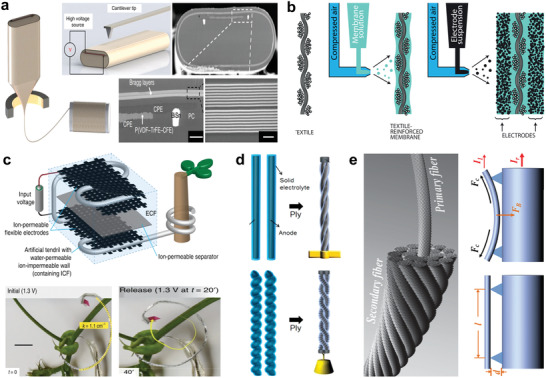

Figure 3.

Electric actuated fibers/yarns. a) The thermally drawn fiber with piezoelectric PVDF. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/).[ 68 ] Copyright 2017, The Authors, published by Springer Nature. b) An ionic and capacitive laminate actuator. Reproduced with permission.[ 73 ] Copyright 2017, Elsevier. c) A tendril like osmosis actuator that reversibly changed stiffness and performed hooking/anchoring. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0).[ 79 ] Copyright 2019, The Authors, published by Springer Nature. d) All‐solid‐state actuator consisting of twisted CNTs fiber that infiltrated with solid electrolyte. Reproduced with permission.[ 80 ] Copyright 201, American Chemical Society. e) Current‐actuated hierarchal CNTs fiber. Reproduced with permission.[ 81 ] Copyright 2014, Wiley‐VCH.

Electroactive polymers (EAP) respond to electricity with fast response speed and significant displacement.[ 70 ] Plasticized PVC gel is a promising electroactive polymer, which manifests advantages of flexibility, large deformation, and high stability.[ 71 ] PVC gel based fiber actuator was reported, which consists of conductive PVC inner core and nonconductive PVC shell. Two identical fibers were loosely twisted together as a yarn actuator. When voltage was applied in the two fibers’ inner core, the two fibers attracted and got closer to each other, leading to the elongation of the yarn. Furthermore, the PVC fibers and common conductive wires were weaved into a textile. When applying a voltage, the deformed PVC fibers surrounded the anode wires, which generated about 27% contraction strain.[ 72 ]

The actuation of these piezoelectric and electroactive dielectric materials relies on the electrostatic pressure, which usually requires high voltage to form a strong local electric field. Soft electrochemically driven actuators that have a laminate structure similar to the electrical double‐layer capacitors work under relative low voltage. Kaasik et al. introduced an ionic and capacitive laminate (ICL) actuators based on the ionically conductive laminates. As shown in Figure 3b, a continuous scalable fabrication method of the ICLs actuator was developed. The glass fiber as reinforcement layer was spray coated with the electroactive membrane and the electrodes. The ICL actuator was driven by applying electrochemical potential of about 5 V. The electromechanical actuation is due to the electro‐osmotic relocation of mobile ions, so the actuator can also be used as a flexible energy‐storage unit.[ 73 ] Baughman et al. reported a carbon nanotubes (CNTs) twisted fiber actuator. Upon voltage application, electrons were injected into the CNTs fibers to generate electrochemical double‐layer in the presence of electrolyte, which caused the CNTs fibers to expand. The length of fibers changed with about 0.75 MPa stress generated by a voltage of 2 V, capable of deflecting a cantilever and changing the reflection of light. With absence of ion intercalation, the performances of the CNTs fiber actuators were largely enhanced in terms of life and rate, strain, and stress.[ 74 , 75 ]

Unlike animals that have muscles, plants like the Venus flytrap can perform reversible motions through osmotic hydrostatic pressure.[ 76 , 77 , 78 ] By imitating the plant's tendril, Must et al. presented a reversible osmotic actuation based on the ions osmosis (Figure 3c).[ 79 ] Upon applying a voltage, ions from the solvent can be adsorbed on the electrode surface and immobilized, which can be released back to the fluid bulk at a short‐circuited state. The electrosorption and desorption built up the osmotic pressure difference, inducing water loss and injection. The water exchange between the electrode and soft effector caused the stiffness change and actuation of the tendril‐like soft effector. When applying a voltage as low as 1.3 V, water was pumped into the soft effector, which gradually stiffen by about 5 folds and straightened from crimp state. In this way, the tendril performed the hooking and anchoring tasks just like the climbing plants. The bionic tendril actuator shows advantage to operate under very low voltage but achieved large displacement and stiffness modulation, the only shortcoming is that liquid electrolyte is required to be encapsulated.

To this end, solid‐state electrolyte has been developed to replace the liquid electrolyte. Lee et al. reported an all‐solid‐state fiber actuator that worked under low voltage with high energy efficiency (Figure 3d).[ 80 ] The helical yarns with twisted CNTs were infiltrated and covered with electrolyte, which insulated the CNTs from each other. Two identical yarns were plied together using an opposite twist direction to act as anode and cathode. When applying a voltage, the yarns produced torsional stroke and tensile contraction because of the charge intercalation. Because the yarns were insulated from each other like a capacitor, it is able to maintain the stroke even after the voltage was removed.

In addition to volume change by charges intercalation, the conductive yarns can be also directly actuated by passing through current to change the fibers distance. The yarns are actuated by the Coulomb force depending on the current density based on the Ampere's law. When the electric current passed through the helically aligned CNTs, the CNTs exerted electromagnetic field. The electromagnetic interaction between these CNTs resulted in the simultaneous lengthwise contraction and rotary torsion. Peng et al. investigated the principle, performance, and applications of these electromechanical yarn actuators in detail. The yarn actuators could work under all available environment media such as air or solvent and produced large stress when passing through a low current. But these current responsive yarns require continuous energy consumption to maintain the deformed state (Figure 3e).[ 63 , 81 , 82 ]

The electric actuation is fast and highly controllable, high diversity of actuators can be realized accordingly, including voltage‐based actuator, charge intercalation actuator, current‐based electromagnetic actuator. More importantly, fibers/fabrics actuated by electricity could be easily integrated with other electronic devices or textile substrate to form a highly operable system, exhibiting excellent potential for robots or smart wearable platforms.

2.2.2. Light Actuation

Sunlight is the ultimate energy source, which is omnipresence and ubiquitous. Light responsive fiber actuators are promising due to its advantages of remote and contactless controllability, precise positioning and wide range of frequencies. The light actuated fibers (not photo‐thermal effect) usually originate from molecular order change, for example, the change of optical chirality, amphiphilicity, conformation and conjugation.[ 46 , 83 ]

Liquid crystals (LCs) are the most common photoresponsive materials, with the merits of rapid and reversible deformation. The actuation principle is based on the light‐induced molecular realignment of the polymer network.[ 84 ] Xu et al. illustrated a hollow fiber actuator for liquid manipulation based on the photodeformation effect of the LC (Figure 4a).[ 85 ] The hollow fiber actuator possessed a bilayer structure, the EVA tube as a flexible substrate covered by a layer of LC on the inner surface. The hollow fiber was filled with various liquid slugs, which could be propelled by light. When illuminance was applied, the LC molecules were reoriented, the molecules deformation induced capillary force change to propel movement of the liquid slugs. Experiments showed that the liquid slugs were propelled in the preset direction and even crawled up an incline with a speed of 0.4 mm s−1. The performance of micropump was enhanced by connecting several in series and parallels. Owning to the flexibility, the fiber micropumps can be customized into different structures like spiral and loop. Moreover, the fiber actuator shows excellent reliability because of its photoinduced self‐healing property, exhibiting potential applications in wearable and implantable integrated microfluidic systems.

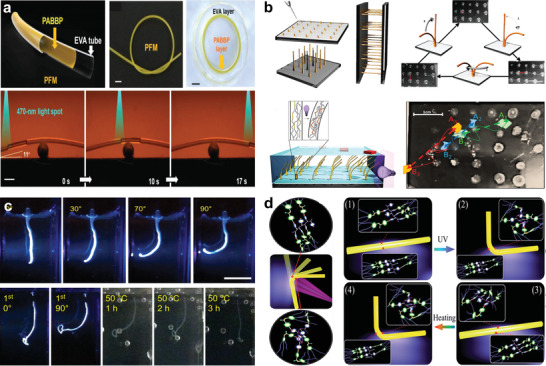

Figure 4.

Light‐responsive fibers/yarns. a) LC coated hollow fiber for liquid manipulating by light induced capillary force change. Reproduced with permission.[ 85 ] Copyright 2019, Wiley‐VCH. b) LC fibers array controlled by space resolution light, working collectively to display patterns and transport objects. Reproduced with permission.[ 87 ] Copyright 2016, The Authors, published by Wiley‐VCH. c) Fiber actuator fabricated by hierarchical self‐assembly of supramolecular motors. Reproduced with permission.[ 91 ] Copyright 2008, Springer Nature. d) Photodeformable fiber for actuation and information encryption. Reproduced with permission.[ 92 ] Copyright 2019, Royal Society of Chemistry.

Aligned liquid crystal fiber was phototropic and can bend toward light. The fiber was simply fabricated by dipping and quickly pulling out from the precursor mixtures. The bending direction of the fiber in 3D space can be precisely controlled by the light. The LC fiber took only about 3 s to bend from 0° to 90° and generated a stress of ≈210 kPa. The deformed fiber returned to its original shape under the irradiation of visible light within 9 s, showing fast response and good reversibility.[ 86 ]

An array of slender parallel LC fibers was also fabricated by the dipping and pulling process by Gelebart et al. The dimension and position of the LC fibers can be accurately controlled through tuning the solution viscosity and droplet dimensions (Figure 4b).[ 87 ] The fibers were bent toward the light when exposed to UV light. When changed the incident angle of the light source, the tips of the fibers followed the movement and kept pointing to the light source. Moreover, the motion of every fiber in the array can be independently controlled. The fibers were bent to display a patterned by a space resolution light source. When immersing in paraffin oil, the fibers demonstrated better performance and could transport small objects that floating on it by regular oscillation. In addition to the molecular orientation rearrangement, a light‐driven rotary molecular motor was reported.[ 88 ] But it is very challenging to achieve macroscopic deformation by harnessing molecular motors’ rotation, which needs to precisely control the rotations of all molecules in space and time to achieve concerted manipulations.[ 89 , 90 ]

Inspired from the nature of the stimuli‐responsive system that are capable of converting molecular motion into macroscopic movement, Chen et al. developed an artificial muscle by the hierarchical self‐assembly of supramolecular motors (Figure 4c).[ 91 ] The molecules were modified with groups as designed to gain the photo‐responsive and amphiphilic properties. The rotations of the aligned molecular motors were accumulated, amplified and propagated to provide macroscopic motion. Irradiated with UV light, the artificial muscle string bent toward the light and lifted a piece of paper, both in air and when immersed in CaCl2 aqueous solution. However, the repeatability of the actuators was very poor. It took several hours for the string to recover the original conformation by being heated at 50 °C in the dark. It only could bend to 45° at the second round of photoirradiation. It suggests the possibility to design the artificial muscle by self‐assembly in molecular level.

Liao et al. reported a series of hydrogen‐bonded polymer fibers, which showed excellent photoinduced deformation ability in terms of both bending speed and bending angle (Figure 4d).[ 92 ] The cyanostilbene‐based polymers were used as photodeformable materials, which underwent an order–disorder phase transition when irradiated by UV light. The fiber bent toward the light with a high speed of 11.25° s−1 and a stroke of above 130°. Furthermore, by precisely controlling the incident directions of the lights and spot locations on the fiber, the fiber bent into 3D appearances such as a box. The deformation of the fiber could be eliminated via external stretching force and deformed again, showing good reversibility. More excitingly, the fiber displays reconfigurable shape memory effect, which could be shaped by UV light and recovered via‐heating. For example, fibers were deformed into the shape of letters by shining light on specific sites. Even when the letters were straightened by an external force, the fibers also could recover to the shape of the letters by heating. This process enables information writing, encryption and reading in fibers by light, mechanical force and heat, respectively, providing a new level of information security by fiber actuators.

The light‐responsive fiber is possible to form an automatic closed‐loop system. Because when the fiber is deformed at the light spot, the deformation in return changes the location of the light spot, leading to fiber deformation again. Self‐regulated actuation and self‐oscillation have been demonstrated based on this property.[ 93 ] However, the performances of the light‐responsive fibers need to be improved, especially the actuation speed, stress and reversibility. The straight‐line propagation of the light limits the application in unstructured places.

2.2.3. Thermal Actuation

Thermal property is one of the most important parameters of the materials, which relates to the reordering, expansion, melting, decomposition. Thermally actuated fibers are mainly based on order changes of molecule chains, like glass transition and volume changes along with expansion and melting. It has wide applications in temperature sensing and regulation, as well as waste heat recovery. Moreover, the thermal‐responsive fibers can be actuated by electrical Joule heating and photothermal effect, showing the advantages of both electric actuation and light actuation, such as highly controllable and remotely operable actuation.[ 94 , 95 ]

Temperature triggered shape memory materials are based on the glass transition of the switching segments. The deformable shape memory materials can temporally change the bulky and complex structure into small simple pieces for the convenience of transportation or implantation.[ 96 ] Lendlein et al. developed a biodegradable shape memory polymer (SMP) for minimally invasive surgical (Figure 5a).[ 97 ] The biodegradability was achieved by introducing the hydrolysable ester bonds into the thermoplastic polymer. Under physiological conditions, the polymers continuously cleaved and linearly lost mass. A smart surgical suture line was demonstrated from the biodegradable SMP, with important applications in endoscopic surgery where manipulating the suture line is difficult and time consuming.

Figure 5.

Thermally actuated fibers/yarns. a) Biodegradable SMP for minimally invasive surgical as smart suture. Reproduced with permission.[ 97 ] Copyright 2002, The American Association for the Advancement of Science (AAAS). b) Twisted SMP fiber actuator with high strain and stress and application in propeller engine. Reproduced with permission.[ 98 ] Copyright 2019, The Authors, published by The American Association for the Advancement of Science (AAAS). c) Janus structured actuator made of two ordinary materials with different thermal properties. A tripod walking robot was demonstrated. Reproduced with permission.[ 101 ] Copyright 2016, American Chemical Society. d) Twisted and coiled polymer fiber actuator from fishing line and sewing thread. Reproduced with permission.[ 105 ] Copyright 2014, The American Association for the Advancement of Science (AAAS). e) Twisted CNTs yarn infiltrated with viscous guest, showing fast and accurate controlling. Reproduced with permission.[ 109 ] Copyright 2014, Springer Nature.

However, the application of SMP is limited by the small stroke, low stress and low speed. Elastic energy was additionally stored into the SMP to overcome the challenges by Yuan et al. (Figure 5b).[ 98 ] The SMP fibers were isobarically twisted at higher temperature and then cooled down to fix the torsional structure. Once the SMP fibers were heated to the glass transition temperature, it will be untwisted to recover to the original straight shape. Higher energy and faster rotation can be achieved by twisting the fibers with greater torque. Furthermore, the trigger temperature was tunable at a wide range, so the SMP fibers can be customized and programmed to release stroke under predefined temperature for special application. As a demonstration, the SPM fibers were served as an engine to drive the propeller of a boat. Upon heating, the SMP fibers untwisted and propelled the boat to cruise 1 m in only 7 s. The limitation is obvious that the fibers only produces a one‐time stroke and need to be twisted again every time. Reversible torsional actuation of the SMP fibers was realized by combine two SMP crosslinked polymer with a different melting temperature range, producing a two‐way fiber actuator.[ 99 ] At a certain temperature, one component fixed the twisted structure while another melted to provide actuation, and vice versa. By repeatedly changing the temperature between 10 and 70 °C, the SMP fibers repeated the forward and reverse rotations.[ 99 ] Besides, Nafion fiber was reported to have multiple shape memory at a series of temperatures, but controllable reversibility of the multiple shape memory is low and complicated, more efforts should be deserved.[ 100 ]

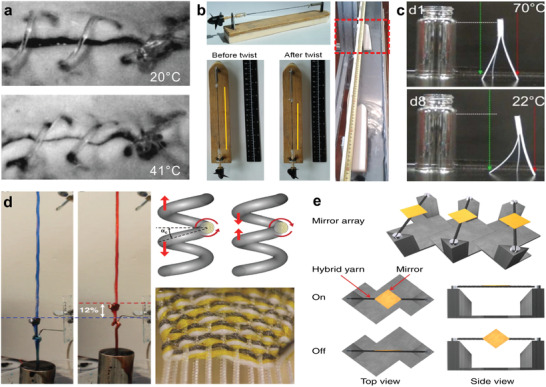

Besides the crosslinked SMP, shape memory and reversible actuation were achieved through a bilayer structure constructed with two materials of different thermal properties. Ionov et al. designed a fiber that comprised of two polymers in side by side as Janus structure. The fiber was made by dual extruder 3D print or melt spinning of two common printing filaments, like fusible polycaprolactone (PCL), and acrylonitrile butadiene styrene (ABS) or polylactide (PLA) (Figure 5c).[ 101 ] When cooling down, the ABS or PLA crystallized and contracted, leading to the Janus structure bending toward these materials. At high temperature, the Janus structure recovered its original shape because the ABS or PLA melt and the nonfusible component PCL released the stress. Accordingly, a self‐walking tripod robot assembled by the Janus fibers with different thicknesses (two 0.4 mm and one 1 mm) was demonstrated, which moves in one direction because of the structural asymmetry. When heated to 70 °C, the thicker fiber kept still but the two thin fibers moved toward it. When cooled to 22 °C, all three fibers outspread with the same amplitude. In this way, the tripod moved away from the glass bottle step by step. The Janus fiber actuator was different from the bilayer metal or bilayer hydrogel actuators because it undergoes melting and crystallizing processes, it takes advantages of the simple and economical processing, with robust, fast, and reversible actuation.

A novel fiber actuator based on coiled fishing line has received great attention because of its extremely low cost but high performance. The commercially available polyethylene or nylon fibers are the most often used precursors.[ 102 , 103 ] The polymer chains inside the fiber are highly oriented alongside the length. Upon heating, the fiber provides large reversible thermal contraction in length and expansion in radial direction. The thermal actuation process is linearly related to temperature and shows little hysteresis, which is more controllable than SMP.[ 104 ] The actuation speed, strain and stress are largely amplified by twisting and coiling the fibers. The coiled fiber muscle contracts with high speed and stress by switching between cold and hot water bath, which provides active cooling and uniform heating. In addition, Haines et al. reported a twisted polymer fiber actuator based on fishing line and sewing thread (Figure 5d).[ 105 ] The fiber actuators can be woven into a smart textile, which contained twelve coiled fibers in parallel and silver‐plated fibers as heaters. The textile could lift a 3 kg object. Accordingly, the fibers were braided into a sleeve. When the temperature rose, the fibers contracted, delivering a 20.6% change in pore area and 16.4% stroke of the sleeve. These sewed threads‐based textile actuators have important applications in smart clothing and wearable robot/prosthesis, but the actuating temperature is too hot for wearing (95 °C) and the cooling process is too slow.

Low temperature actuation is realized by infiltrating guests into the gaps of the twisted nanofibers yarn. The volumetric thermal expansion of the guests changes the distances between nanofibers, and then deforms the yarns. The guests are usually low temperature melting materials like wax or liquid metal. The wax melts at ≈40 °C and provides a 30% volume expansion, which drives the host yarn to untwist and provide contractive and torsional actuation. The liquid wax will be confined in the gaps of the yarn even without package due to the interfacial energy. Upon cooling, the wax solidifies and shrinks back to the original volume, bringing the yarn to restore the twisted structure. The actuation that relied on the wax melting shows high cycle life, high energy and power densities.[ 106 ] Besides, the guest also can be filled into a hollow microtube to achieve actuation[ 59 ] and stiffness change.[ 107 , 108 ]

The infiltrated guests play a key role in the dynamic torsional actuation of the yarn. Chun et al. investigated the dynamic properties of the yarn infiltrated with mixtures of wax and polystyrene–poly(ethylene–butylene)–polystyrene (SEBS) copolymer (Figure 5e).[ 109 ] The resultant yarn with large viscosity had an overdamped dynamic response and minimum dynamic oscillations, which was of importance to realize fast and accurate control. As an example, the yarns were used to control the mirrors of an optical switch. The mirrors were attached to the yarn and rotated concurrently. Controlled by Joule heating, the mirrors rotated from horizontal to vertical in 0.13 s without oscillatory. These fast and accurate controls of the mirrors can be used for image display or laser scanner with an acceptable refresh rate.

The limitation of the thermally actuated fiber is the low cycling rate due to the poor heat diffusion/dissipation, especially during the slow cooling process. Besides, the high working temperatures usually influence the thermal stability of materials, causing the possible discomfort and injuries for human, thus limited demonstrations were achieved for wearable applications.

2.2.4. Solvent and Vapor Actuation

In addition to thermal expansion of the infiltrated guest, porous fibers made of hygroscopic materials are actuated by adsorbed and desorbed guests like solvents or vapors. The fibers are deformed because of the mass exchange induced volume change, like swelling and shrinkage as the small molecular species are transported in and out.[ 110 , 111 , 112 ]

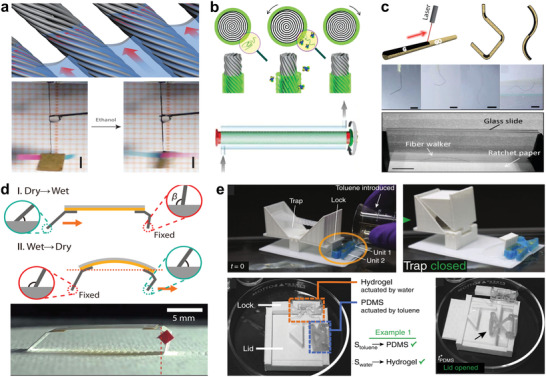

Chen et al. and Deng et al. showed that CNTs fiber responded to solvent and vapor with high speed and stroke (Figure 6a).[ 113 , 114 ] In contrast to the electric current induced distance change and infiltrated guests’ thermal expansion, the CNTs fiber actuator here emphasized the mass transport. The CNTs were twisted and coiled into a helical fiber with hierarchical structure, which contained a lot of nanoscale and microscale gaps. The fiber strongly imbibed the solvent and vapor due to the hydrophilic property and capillary force, the guests’ infiltration in the gaps would enlarge the distance between the CNTs and lead to both contractive and rotational actuation of the fiber. The CNTs fiber rapidly contracted ≈15% in 45 ms upon contact with solvent. The actuation was reversed when the solvent and vapor were removed from the fiber due to the gaps narrowed down. The optimized fiber generated contractive stress of 1.5 MPa and rotary speed of 2050 rpm. By the virtue of such high performance, the fibers were used for humidity energy harvesting. A copper coil was connected to the fibers and placed in a magnetic field. The fibers rotated when sprayed with ethanol, which drove the generator output an alternating current of 0.11 mA. Besides, the fibers were strong and flexible enough to be woven into a smart textile. Upon spraying with ethanol, the smart textile can lift a 240 mg ball up 4.5 mm. The actuation process of the fiber was tunable and programmable by changing the fiber materials, helical structures and solvents. The fiber actuator promises for artificial muscles and self‐powered sensors.

Figure 6.

Solvent and vapor actuated fibers/yarns. a) Hierarchically arranged helical CNTs fiber actuators driven by solvents and vapors. Reproduced with permission.[ 113 ] Copyright 2014, Springer Nature. b) Sheath‐run artificial muscle composed of PEO–SO3 guest and a CNTs yarn host. Reproduced with permission.[ 115 ] Copyright 2019, The Authors, published by The American Association for the Advancement of Science (AAAS). c) Laser patterned GO–G fiber actuator and robot. Reproduced with permission.[ 118 ] Copyright 2013, Wiley‐VCH. d) Aligned nanofibers based self‐locomotive hygrobot. Reproduced with permission.[ 121 ] Copyright 2019, The Authors, published by The American Association for the Advancement of Science (AAAS). e) A smart flytrap automatic respond to multiple solvents with embodied logic. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).[ 122 ] Copyright 2019, The Authors, published by Springer Nature.

However, the CNTs fiber used a large number of expensive CNTs and the CNTs in the inner core are not functioning, which is not economical. Therefore, a sheath‐run artificial muscle (SRAM) was reported with higher performance and cost effectiveness by Mu et al. (Figure 6b).[ 115 ] The core of the fiber was made of twisted and coiled CNTs yarn, which was replaceable by common commercial yarns like nylon 6 and silk to reduce the cost. The CNTs yarn was covered by a layer of sheath by drawing through the polymer solution. SRAM was achieved by further twisting and coiling the fiber. The sheath of the fiber swells and softens by absorbing ethanol vapor, leading to the untwisting of the core yarn. The actuation was reversed when the vapor was removed, which can be repeated for thousands of cycles. The SRAM generated linearly tensile stroke in response to the guest concentration, which can be used as a sensor. Owing to the response to certain solvent at fix concentration, the SRAM promises for automatic drug release at the lesion site. The SRAMs were woven into a comfort‐adjusting textile, capable of tuning its porosity in response to water, humidity and sweat for improving the human feeling and perception. To improve the wettability of the CNTs yarn to get larger responses to water, modifications such as oxygen plasma treatment and blending with the hydrophilic graphene oxide were demonstrated.[ 116 , 117 ]

The hydrophilicity of GO is attributed to the abundant oxygen containing functional groups, which can be reduced into hydrophobic graphene (G) by laser beam irradiation. A GO/G fiber actuator with sophisticated and well‐confined motion was reported by Cheng et al. (Figure 6c).[ 118 ] By rational designed and positioned laser reduction, some parts of the GO fiber were reduced to G, forming the predefined GO–G patterns. Once exposed to moisture or water, the hygroscopic GO regions swelled and expanded because of water infiltration while the G regions kept unchanged. In this way, the GO–G fiber deformed into a specific shape, which was reversed by the desorption of water. The fiber actuation was programmable by the arrangement of GO–G patterns. Through changing the parameters of the responsive GO regions, such as dimensions, positions and angle, the GO/G fibers can deform into different shapes including hook, spring and letters. Owing to the reversible and programmable properties, a single GO/G fiber was customized into a walking robot. The robot navigated through a narrow‐slit step by step when humidity periodically changed. The GO/G fibers were further woven into a network and a fabric, demonstrating the applications in smart cloth and smart window that respond to weather with adjustable configurations.

The asymmetric bilayer structure is an effective strategy to realize actuation.[ 119 , 120 ] Shin et al. developed a water responsive actuator by combining two common materials poly(ethylene oxide) (PEO) and polyimide (PI) (Figure 6d).[ 121 ] The active layer was based on the aligned PEO nanofibers layer produced by directional electrospinning. The aligned nanofibers limited the expansion along the fiber's length direction while enhanced the swelling in the perpendicular direction. The aligned fibers demonstrated a faster and stronger response, which was proved by both experiment and theory. A hygrobot was constructed by the bilayer actuators. The legs of the hygrobot were designed into asymmetry configuration. The hygrobot moved in a single direction by reversible bending of the actuator under periodic humidity change. Besides, the hygrobot automatically and continually crawled through a place where existed vertical humidity gradient, by periodically bending upward (low humidity) and downward (high humidity). This self‐sustaining automatic robot designed by asymmetric structure and materials shows the possible application for cleaning wet surface or sanitizing skin.

More complex and logical actuations are desirable, which can be achieved simply through the composition and structural organization. Jiang et al. reported an actuator system that automatically responded to multiple stimuli with embedded logic (Figure 6e).[ 122 ] The bistable and anisotropic structures were printed by direct ink writing. Two materials that respond to different stimuli were used, a PDMS‐aligned glass fibers composition (respond to nonpolar solvents) and a hydrogel‐aligned cellulose fibers composition (respond to water). The response time was tunable by changing the thickness of the structure. As a demonstration, a Venus flytrap like box was designed. The box had two locks that were controlled by two actuators. Upon nonpolar solvent, the flytrap was unlocked by the first actuator and able to close if a mass is placed on it, while the second actuator was designed to relock it after 10 s delay when the flytrap will not respond to the mass. In addition, a smart box was designed and printed, who had a lock that responds to water and a lid that responds to toluene. Only when the box encountered with both water and toluene, the box opened the lock and the lid to release the objects inside.

Fibers actuators that respond to solvent and vapor have wide applications, because water covers 70% of the Earth's surface and makes up 70% of human beings. It can be used to sense the humidity and harvesting energy from stream, rain, ocean wave, achieving self‐powered platform and self‐regulating actuation system, especially at the harsh conditions. In addition, it is implantable for body fluid sensing and drug release controlling, showing great potential as fiber robots for biomedical diagnosis and therapy in vivo.[ 123 ]

2.2.5. Magnetic and Pneumatic Actuations

Apart from the aforementioned stimuli‐responsive actuators, there are two kinds of actuation that play a key role in soft robotics, magnetic and pneumatic actuation. The pneumatic soft actuator consists of a series of elastomer chambers and is deformed by pressurized fluid expanding the chambers. Fibers and fabrics which could limit the expansion of the chambers, are widely used to program the deformation process of the pneumatic actuators.[ 124 , 125 ] Fibers composed of magnetic materials are actuated in response to the external magnetic field. The magnetic fiber actuators play an important role in untethered robot, because they take advantages of fast, dexterous, large force, and offers high compliance.[ 126 , 127 , 128 ]

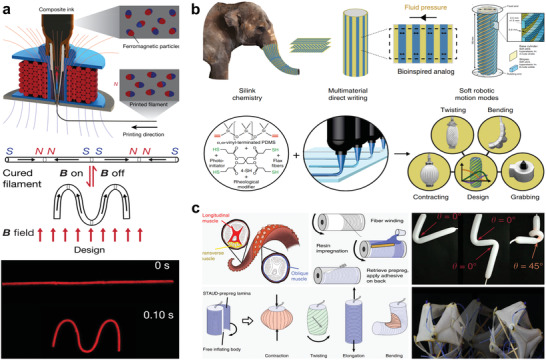

To produce the magnetic fibers, several methods are developed, such as coating,[ 129 ] electrospinning,[ 130 ] and 3D printing of the magnetic microparticles–polymers composition. Lee at al. reported a remotely driven torsional magnetic fiber actuator that could be operated at any temperature and in any environment.[ 131 ] Kim et al. reported a direct ink writing system to extrude silicone‐magnetic particles composite fiber (Figure 7a).[ 132 ] The magnetic domains of the fiber can be tuned by the printing direction and applied field direction. A printed filament that with patterned magnetic domains changed its shape very quickly in response to the external magnetic field. Different kinds of planar structures were printed with specific designed ferromagnetic domains. Under the magnetic field, the planar structure bent and folded into complex 3D shapes by the magnetic forces according to the origami design. Furthermore, 3D structured magnetic metamaterials were printed. The metamaterials were designed to have negative Poisson's ratio, which shrunk in both length and width in magnetic field. Applications such as picking robot and jumping robot were demonstrated.

Figure 7.

Magnetic and pneumatic actuators. a) 3D printed fiber actuator with patterned magnetic polarity. Reproduced with permission.[ 132 ] Copyright 2018, Springer Nature. b) 3D printed programmable pneumatic actuator. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).[ 134 ] Copyright 2018, The Authors, published by Springer Nature. c) 3D printed reprogrammable pneumatic actuator. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).[ 135 ] Copyright 2019, The Authors, published by Springer Nature.

Fibers architecture of many animals and plants serves to passively restrict the expansion of local elastic matrix to achieve programmable motion. The fibers reduce the active components and simplify the control strategy. Inspired by elephant trunk and octopus, pneumatic soft actuators are developed by embedding fibers to define the morphological information.[ 133 ] A multimaterials 3D printing platform was developed by Schaffner et al. to directly print both the elastic expansion matrix and the strain limiting fibers with precisely preprogrammed architectures (Figure 7b).[ 134 ] Altering the arrangement of fibers, the actuators were regulated to perform bending, elongation, contraction, or twisting and more complex motion. The 3D printed actuator could generate a large strain to support a load of 500 g. Furthermore, there were no pressure instabilities in the actuator because of the structured topology and stress–strain characteristics of materials. Through elaborate design and digital fabrication, the programmed pneumatic soft robotic is close to the practical application.

However, the printed pneumatic soft robot is predefined to certain motion permanently. Reprogrammable versatile robotics are more attractive. Kim et al. reported a reprogrammable pneumatic soft robot based on the self‐adhesive fiber‐constrained unidirectional prepreg (Figure 7c).[ 135 ] The motion of the pneumatic soft robot was governed by the prepreg, which can be easily detached and reattached to another one to reconfigure inflation trajectories. Multiple prepregs were stacked up to achieve combined movements. By attaching the prepregs, an ordinary balloon was programmed to perform bending, twisting and wrapping motions. Particularly, a versatile gripper and a rolling robot were demonstrated.

In summary, the fiber actuators consisted of various materials are tabulated in Table 1 . The fiber actuators take advantages of being simple, light, actively stimuli‐responsive, with high specific power and high efficiency. Especially the CNT fiber can be actuated by several kinds of stimuli and has excellent performance in terms of strain, stress, reversibility and cycle life. By comparison, nylon thread actuators are extremely cost effective but have decent performance Fiber actuators can be produced by the well‐established textile engineering techniques such as melt extrusion, wet spinning, microfluidic spinning, cold/thermal drawing, electrospinning, or depositing/coating process. The fiber/yarn actuators are highly cost‐effective with spatially advantageous, enabling flexible operation with complicated motions like a muscle in the limited spaces. Under external stimuli, fibers/fabrics perform the bending, contraction or twisting to manipulate the objects such as lift and pull. Efforts should be made to improve the mechanical performance of fibers/yarns, including improvement of the actuation displacement and actuation force, enabling fast responses and feedback‐controls. To this end, different strategies have developed, for example, twisting a bundle of many individual fibers together into a single aggregate yarn, coiling hierarchical helical bundle. This assembled thread with increased surface area to volume ratio could have higher sensitive responses to the external stimuli such as light, heat, solvent, vapor, magnetite, etc., delivering faster actuation with higher actuation force. In addition, customizable and programable actuation is one of the most favorable strategy. Composites that respond to different stimuli are spatially patterned to perform predefined actuation with embedded logic, showing mechanical intelligence.

Table 1.

Performances of fiber/fabric‐based actuators enabled by different materials

| Stimulus | Material and geometry | Principle | Stress | Strain | Time | Frequency [Hz] | Work density | Cycle life | Rotate | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|

| Electric (±500 V) | Piezo fiber | Order | – | 20 µm | – | 10 | – | – | 1.7°–2.5° | [ 66 , 67 ] |

| Electric (300 V) | PVDF fiber | Order | 2–4 kPa | 8%, 80 µm | – | 158.3 | – | – | – | [ 69 ] |

| Electric (600 V) | PVC gels fiber | Distance | 300 kPa | 53% | – | – | – | 180k | – | [ 72 ] |

| Electric (1.3 V) | Activated carbon fiber | Volume | – | – | 25 min | – | – | – | 500° | [ 79 ] |

| Electric (2 V) | PPy | Volume | 0.50 MPa | 0.075–3% | 250–510 s | 0.05 | – | 8k | – | [ 136 ] |

| Electric (5 V) | CNT fiber | Volume | 17.8 MPa | 1.3% | 0.95 s | 0.8 | – | 100 | 53° mm−1 | [ 80 ] |

| Electric (5 mA) | CNT fiber helix | Distance | 10 MPa | – | 0.4 s | 0.17 | – | 2.4k | 51° | [ 63 ] |

| Light (365 nm) | Molecular motor | Order | – | – | 60 s | – | – | – | 90° | [ 91 ] |

| Light (365 nm) | P4VP(Z‐TCS)x | Order | – | – | 8 s | – | – | – | 135° | [ 92 ] |

| Light (488 nm) | LC | Order | – | – | – | 0.5–90 | – | >50 min | – | [ 93 ] |

| Thermal (40 °C) | SMP fiber | Order | 1.6 N | 200% | 20 s | – | – | – | – | [ 97 ] |

| Thermal 80–140 °C | SMP fiber | Order | – | – | 2 s | – | 1.8–2.8 kJ kg−1 | – | 6123 turns m−1 | [ 98 ] |

| Thermal 4–65 °C | Janus filaments | Order | 0.8 MPa | 16–30% | 2–20 s | – | – | – | – | [ 101 ] |

| Thermal (240 °C) | Nylon PE | Order | 10–35 MPa | 50% | – | 1–5 | 27.1 kW kg−1 | 1.2 million | – | [ 105 ] |

| Thermal 160 °C | PET | Order | 368 MPa | 12.1% | 10 s | – | – | – | – | [ 104 ] |

| Thermal 83 °C | CNT wax | Distance | 5.7–16.4 MPa | 3–5.6% | 15–30 ms | 20 | 27.9 kW kg−1 | 1.4 million | 12.6° mm−1 | [ 106 ] |

| Thermal 150 °C | LCE/CNT | Order | 840 kPa | 12% | 5 s | – | 97 kJ m−3 | 100 | – | [ 94 ] |

| Thermal 40–90 °C | CNT wax SEBS | Distance | – | – | 0.13 s | 0.5 | – | 40k | 80° mm−1 | [ 109 ] |

| Solvent | CNT helix | Distance | ≈1.5 MPa | ≈15% | 45 ms | 26.7 J kg−1 | 50 | ≈41 turns | [ 113 ] | |

| Solvent | PEO–SO3 CNT | Distance | 42 MPa | 8.5% | 0.1–12 | 4.44 W g−1 | 3k | 143° mm−1 | [ 115 ] | |

| Solvent | GO/G fiber | Volume | 100 MPa | 5% | 10 s | – | – | 1k | 140° | [ 118 ] |

| Solvent | Silk fiber | Distance | 12.5 MPa | 47% | 67 s | – | 73 J kg−1 | 500 | 547° mm−1 | [ 137 ] |

| Solvent | Alginate fiber | Distance | 95 MPa | 13.8% | 12 s | – | 14.8 kW kg−1 | 400 | 400 turns | [ 138 ] |

| Magnet | NdFeB elastomer | – | – | 15–25% | 0.1–0.5 s | – | 309.3 kW m−3 | – | – | [ 132 ] |

| Magnet | NdFeB CNT | – | – | 0.3% | 0.67 s | – | 8.42 Nm kg−1 | 8k | 71.2° mm−1 | [ 131 ] |

| Pneumatic | Rubber | – | – | 23% | 4–13 s | – | – | – | 112° | [ 139 ] |

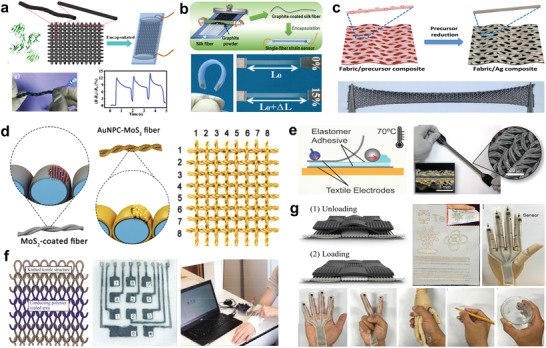

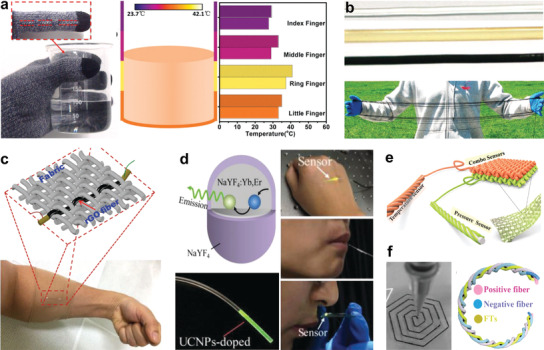

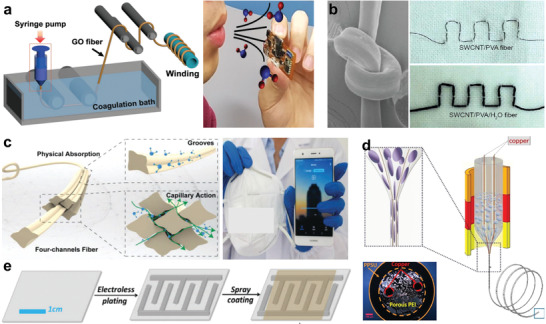

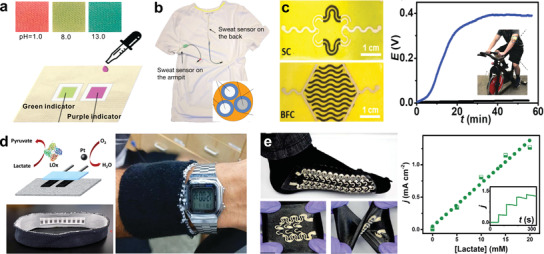

3. Fiber/Fabric‐Based Actuators for Artificial Muscle and Smart Clothing

The fiber actuators are similar to biological muscle in structure, function and performance, exhibiting potential applications in humanoid robotic and even for disabled patient rehabilitation. Furthermore, despite their apparent simplicity, actuating fibers allow very complex actuation behavior by being weaved and knitted into fabric/textile, representing a promising strategy to develop novel wearable devices for human–robot interaction.

3.1. Fiber‐Actuator‐Based Soft Grippers

Fiber actuator, attributed to its flexibility, is promising for the soft gripper. A fiber gripper can grasp and manipulate objects by the actuation of fiber, such as bending, elongating, stiffening. Compared to rigid grippers, a fiber gripper can grasp or manipulate a larger variety of objects with complex shapes and different softnesses due to its excellent mechanical compliance, allowing reduced operation complexity and higher safety.[ 140 , 141 ]

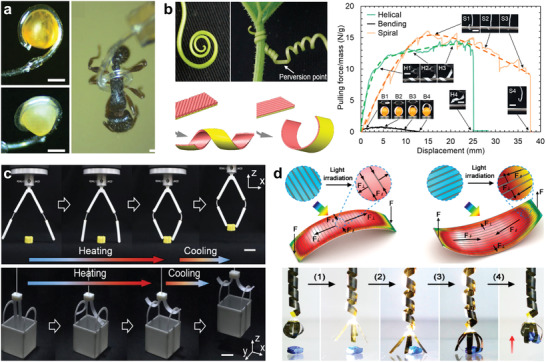

A tendril‐like gripper based on pneumatic microtube was developed by Paek et al. to handle delicate, soft, and fragile micro‐objects (Figure 8a).[ 142 ] The long and thin PDMS microtube was built by a direct‐peeling technique, which spiraled several turns when pressured. The microtentacle was able to grab and hold an egg of a fish and an ant by winding around them conformally. However, the 1D fiber may not easy to steadily hold the objects. To increase the stability, the gripper should have multiple fingers to balance the force and the fingers are preferred in ribbon shape to increase the contact area when catching objects. Wang et al. developed a preprogrammed gripper via 3D printing polymer filaments (polyester) on paper substrate to form a bilayer composite ribbon. The polymer filaments contracted in length direction when heated, causing the ribbon to perform bending, spiral, and helical distortions based on the different printed geometries. The tentacle‐type gripper with spiral and helical deformation could twin and grasp cylindrical objects with weight of ≈8.2 N, about 1557.7 times its weight. But this tendril‐like gripper needs a suitable host for twinning around and anchoring. To grasp a spherical object, a gripper with four self‐bending ribbons arranged in a cruciform shape was constructed to catch a ping‐pong ball by caging it. The actuation processes and the generated forces of the three types of grippers were compared in Figure 8b.[ 143 ] The authors also demonstrated a hinge‐like gripper that produced large angular deformation and large amount of force, as well as an outward bending gripper (Figure 8c).[ 144 ]

Figure 8.

Fiber actuator for soft gripper. a) A tendril like pneumatic gripper catching a fish egg and an ant. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).[ 142 ] Copyright 2015, Springer Nature. b) A variety of grippers constructed from the 3D printed tendril like actuators. Reproduced with permission.[ 143 ] Copyright 2018, American Chemical Society. c) Hinge‐like gripper and the outward bending gripper. Reproduced with permission.[ 144 ] Copyright 2019, Elsevier. d) A robotic arm with a telescope arm and a claw. Reproduced with permission.[ 145 ] Copyright 2016, American Chemical Society.

In addition, Deng et al. demonstrated a light‐manipulated robotic arm. The actuator was fabricated by covering a layer of aligned CNTs/paraffin wax composite on a polyimide substrate (Figure 8d).[ 145 ] The bending motion, arose from the thermal expansion of the paraffin wax, was highly tunable by the patterns of the CNTs and the illumination. A robotic arm was assembled, which consisted of one phototropic helix actuator as the telescope arm and four apheliotropic bending actuators as the claw. When applying photothermal heating, the claw released and the telescopic arm elongated to reach an object on the table. When the light was removed, the claw grasped and clenched the object, and then the telescopic arm contracted to lift the object up. CNT and GO are important materials in the fiber actuators, because of its multiple‐responsiveness and high‐performance actuation. Moreover, the CNT sponge‐based gripper which was actuated by both electrothermal and electrochemical effect has been reported.[ 146 ] And a GO fiber‐based claw like gripper, that was actuated by humidity, temperature and light, could pick up and release a foam block.[ 147 ]

Apart from direct actuation, fibers were utilized to enhance the catchability of gripper by increasing the friction and contact area, inspired from the fibrillar adhesives of gecko.[ 148 ] However, the fiber actuator is used not only as a gripper but also as means to fabricate the fabric robotic, leading to grasping, locomotion, morph control, and thus enable key functions of smart fabric. Shah et al. developed a morphing robot that consists of a common Spandex fabric stitched with multiple tendon actuators. The fabric robot was able to overcome obstacles during locomotion, and adapted environments to perform variable tasks.[ 149 ] Fiber‐based grippers are inherent lighter, simpler, and more universal, but the actuation force is small and the speed is low, urging the need to develop new advanced materials. Besides, sensors are indispensable for the interaction control, high integration of the different devices is pursuing.[ 150 ]

3.2. Artificial Muscle for Exoskeletons and Humanoid Robots

One of the most promising applications of fiber actuators is in artificial muscle. The fiber actuated exoskeletons and robotics are more flexible, adaptable and safe, and versatile to accomplish different complex tasks.[ 151 ] These features are extremely important in human–robot cooperation, such as the exoskeletons for assisting disabled and aged people, and high‐intensity workers.[ 136 ]

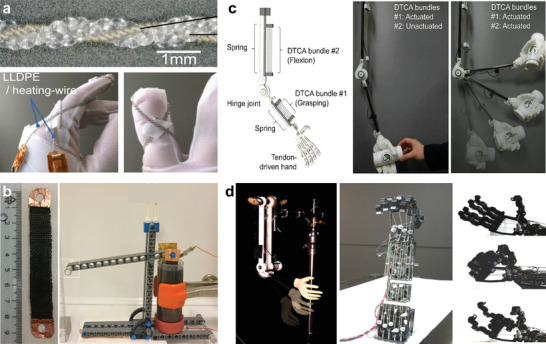

Harouka et al. reported a thermal responsive coiled fiber actuator for index finger movement assisting (Figure 9a).[ 152 ] The fiber actuator was made from low density polyethylene (PE), which operated at low temperature (60 °C) and generated higher stress and strain several times than skeletal muscle. The fiber was coated with conductive elastomer for Joule heating to improve heat transfer and actuation speed. Six fiber actuators were braided and attached to an index finger. When heated, the actuator pulled the index finger to bend about 3 mm. Due to the low actuating temperature, the fiber actuators could be integrated with daily fabrics/textiles to form power‐assisted clothes.

Figure 9.

Fiber actuator as artificial muscle for disabled human and humanoid robots. a) A low‐working‐temperature PE fiber actuator for human finger motion assisting. Reproduced under the terms of the CC‐BY Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/).[ 152 ] Copyright 2016, The Authors, published by Springer Nature. b) Soft artificial muscles made by weaving and knitting with tunable force and strain. Reproduced with permission.[ 136 ] Copyright 2017, The Authors, published by American Association for the Advancement of Science (AAAS). Reprinted/adapted from ref. [ 136 ]. © The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY‐NC) http://creativecommons.org/licenses/by‐nc/4.0/. c) A robot limb actuated by double helix nylon and spandex fiber to perform finger grasping and elbow bending. Reproduced with permission.[ 156 ] Copyright 2018, Wiley‐VCH. d) Electro‐thermal‐mechanical model controlled robotic hand powered by super coiled nylon fiber. Reproduced with permission.[ 157 ] Copyright 2017, IEEE.

Choe et al. applied fiber actuators as artificial muscle for robotic fingers. The polyacrylonitrile (PAN) fibers contracted when exposed to the acid solution and expanded when exposed to basic solutions due to the mass exchange. The 3D printed fingers were driven to perform bending and unbending motions and generated 0.36 N force and 15 mm displacement at the tip.[ 153 ] Both stress and stroke are relatively small. Nevertheless, it is inconvenient to alternatively contact the PAN fibers with acid and basic solution. Maziz et al. demonstrated a polypyrrole coated cellulose‐based soft artificial muscle with tunable force and strain (Figure 9b). An assistive fabric with increased output force and amplified strain was constructed by knitting and weaving. The fabric actuator was used to move a LEGO lever arm, which generated 125 mN force and lifted a 2 g weight. By replacing the electrolyte with ionic liquid, the fabric actuator can operate in air or dry condition, allowing for wearable exoskeleton suit.[ 136 ]

Besides, fiber actuators were used to control an underactuated humanoid hand. The three finger joints were driven by two fiber actuators, which served as flexor and extensor artificial muscles. The bending and unbending motions of the fingers were achieved by heating agonist and antagonist actuators, respectively.[ 154 ] Thanks to the mechanical compliance of the fiber actuators, the underactuated humanoid hand could rapidly and firmly grasp different kinds of objects with diversity in size, shape, weight, and rigidity.[ 155 ] Spandex was reported to have a larger strain than Nylon. Kim et al. developed a new double helix fiber actuator by twisting and coiling nylon and spandex together (Figure 9c).[ 156 ] The double helical fiber actuators combined the advantages of the large strain spandex and the silver‐plated conductive nylon. The fiber showed fast actuation and good reversibility. Several fibers were connected in parallel to enhance the force, and then attached to fingers and elbow of a humanoid hand. When the fibers were actuated by Joule heating, the tendon‐driven fingers bent and grasped a bottle. The fibers were also proved to drive the forearm to extend and flex, showing wearable potential for human motion assistance.

For real application, the motion of the artificial muscle and limb needs to be accurately controlled. Controller model was developed for the twisted and coiled polymer fibers.[ 158 ] Yip et al. developed an electro‐thermal‐mechanical model to fast control the dynamics of the 3D printed robotic hand, which was actuated by super coiled nylon fiber actuators (Figure 9d).[ 157 ] Upon the Joule heating that was controlled by the model, both the force and displacement of the fiber actuator were regulated to the desired value within a very short time. Three fiber actuators were attached to the robot arm to act as bicep muscle. Based on the open‐loop lead‐compensated control, the robotic upper limb precisely bent to 90° flexion. It took only half a second for the fingers to fully bend and make a fist. Therefore, fiber actuator based artificial muscle has the potential to replace the traditional motors in robot and exoskeleton, achieving bionic functions. Before that, the limited stress, strain, human friendliness, and controllability need to be addressed.

3.3. Smart Clothes for Human Assistance and Augmentation

The fiber/yarn actuators can be conveniently sewed or weaved into textile using the mature textile engineering technologies, which are promising for wearable rehabilitation, human motion assistance and human power augmentation, as well as comfort adjustment and fashion ornament.

Tonazzini et al. developed a stiffness tunable fiber for finger rehabilitation. The fiber was made by filling the silicone rubber tubes with low‐melting‐point alloys (LMPA) (Figure 10a).[ 159 ] Upon Joule heating, the LMPA changed from solid to liquid quickly. The melting of the LMPA enabled the fiber to switch between high‐load‐bearing rigid state and deformable soft state. The fibers were assembled into an adaptive splint for finger rehabilitation, which provides adequate strength to immobilize the injured articulation at a stiff state. When applying heating, the fiber‐woven splint became soft and allows the finger to practice extension/flexion. The soft splint shows reconfigurable merit to be shaped into a new structure for other usages upon applying heating and cooling in sequence. Moreover, the fibers can be customized into smart fixtures with different stiffness and shapes by weaving or knitting, delivering breathable and comfortable tool for wearable rehabilitation of injured fingers. The fibers with tunable stiffness also exhibit the potential applications in adaptive seating and orthopedic corsets.

Figure 10.

Smart clothes for human assistance and augmentation. a) Actuating fiber based smart splint for injured finger rehabilitation. Reproduced with permission.[ 159 ] Copyright 2016. The Authors, published by Wiley‐VCH. b) The breathable and fast‐dry clothes. Reproduced with permission.[ 138 ] Copyright 2018, Royal Society of Chemistry. c) A moisture‐responsive textile for breathable quick‐dry clothes. Reproduced with permission.[ 137 ] Copyright 2019, Wiley‐VCH. d) Thermal management clothes with functions of passive heat dissipation enhancement. Reproduced with permission.[ 160 ] Copyright 2019, American Chemical Society. e) A metatextile with smart and dynamically adaptive IR optical properties. Reproduced with permission.[ 167 ] Copyright 2019, The Authors, published by The American Association for the Advancement of Science (AAAS).

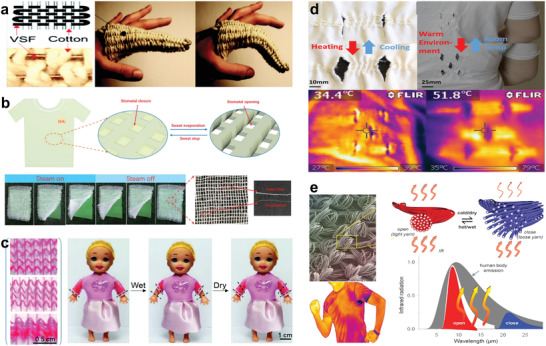

For ordinary people, comfort is the most basic and important requirement of smart clothes. Wang et al. prepared a natural alginate fiber actuator (Figure 10b).[ 138 ] When contacted with water or moisture, the fiber underwent reversible contraction and rotation. The rotation of the fiber controlled the opening‐closing motion of the fabric stomas. These breathable and fast‐dry clothes enable smart comfortability for human body. Jia et al. reported a moisture‐responsive textile (Figure 10c).[ 137 ] The actuators were fabricated by twisting and coiling silk fibers, which contracted and rotated in response to perspiration, water and humidity. As a demonstration, the silk fiber actuators were weaved into the sleeves of cloth in the warp direction. When humidity increased because of sweat or rain, the sleeves rolled up due to the contraction of the fiber actuators to enhance the evaporation, delivering cooling feeling. The sleeves were pulled down when the environment gets dry, presenting intelligent clothings that respond to the humidity and perspiration conditions.

In addition to humidity, temperature also takes a significant part in the wearable comfortability. Roach et al. developed a thermally responsive liquid crystal elastomer (LCE) fiber by direct ink writing. The LCE fibers were made into smart textiles by traditional textile fabrication processes like sewing, knitting, weaving (Figure 10d).[ 160 ] The LCE fibers would contract when temperature rises to about 80 °C, the pores of the textile will open to increase the heat dissipation and sweat evaporation. When the temperature cools down, the LCE fibers elongated and closed the pores. The fibers were demonstrated to sew into a common shirt daily life. The smart shirt shows fast response, which opened pores after the wearer stayed in the warm environment for 10 min, then returned to the original configuration when the wearer moved to a cool place for 5 min. In addition, thermal regulation textiles are reported by Cui and Hu's groups, designing textiles with nanophotonic structures to tailor infrared (IR) emission. The photonic textiles were able to perform both passive heating and cooling functions.[ 161 , 162 , 163 , 164 , 165 , 166 ]

However, the IR property of a textile is permanently predefined due to the fixed materials with certain weaving structure. Dynamic tunable thermal management is attractive for developing more intelligent garments. Zhang et al. produced a metatextile with smart and dynamically adaptive IR optical properties by combining the concept of fiber actuators and nanophotonic effect in a textile (Figure 10e).[ 167 ] When hot and/or wet, the yarn collapses and gets close together. The distance change induced resonant electromagnetic coupling and gated the IR radiation of the textile to enhance heat convection. At cold and/or dry conditions, the yarn responds in an opposite manner to reduce heat dissipation, enabling dynamic thermal management. Moreover, the active cooling shirt becomes possible owing to the torsional refrigeration effect of twisted fiber, namely, electrocaloric effect.[ 168 ] In addition, the textile patterning technology, originally developed for aesthetical reasons, is able to integrate a wider spectrum of functions into the smart clothing, like dynamic decoration, color change, and displays.[ 169 , 170 , 171 ] Textile processing permits scalable, rational and precise production. These mass‐produced fabric actuators showed good repeatability and controllability, paving the way for industrialization.[ 172 ] The many inherent advantages of textiles—omnipresence, pliability, wearability, and washability, are promising for the development of smart textiles, which can be integrated with the functional fiber/fabric actuators, sensors, energy sources and processor system.

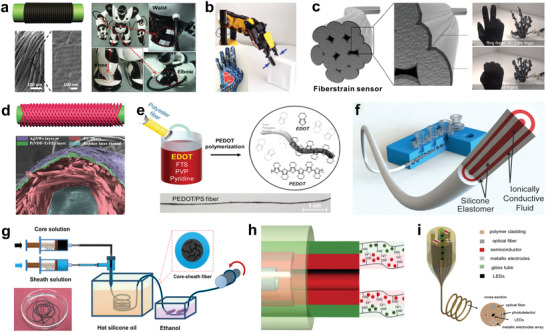

3.4. Fiber‐Based Actuators with Sensors

The integration of fiber actuators and fiber sensors is aimed to construct a standalone smart fibers/yarns system. Such multifunctional fibers system monitors specific signals and automatically respond to it.[ 173 , 174 ] A stimulus‐responsive fiber is a simple passive self‐control system, which senses the change of environment and makes a mechanical response.[ 175 , 176 ] Besides, sensors endow the soft actuator with proprioception[ 177 , 178 ] and perception,[ 179 , 180 , 181 , 182 ] which are very importance for controlling and interactions between human–robots. Liu et al. fabricated a sheath–core conducting fiber with the core of elastomer and the sheath of carbon nanotube, it acted as both a capacitive strain sensor and an electrical torsional actuator. The fiber generated torsional rotation under Joule heating. Although the resistance did not change under stress, the capacitance of the fiber changed linearly related to the strain with very high sensitivity.[ 183 ] Yuen et al. sewed the shape memory alloy fiber actuator and liquid metal‐based sensor into a fabric separately. The fabric was deformed by the actuator and the deformation can be measured through the resistance change of the liquid metal.[ 184 ]

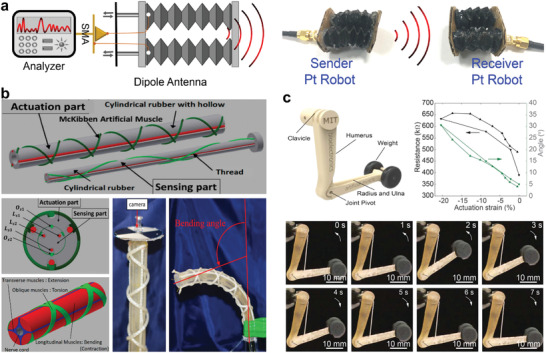

Yang et al. reported an origami robot integrated actuator, configuration sensor, and communication antenna (Figure 11a).[ 185 ] The metallic paper was synthesized by using graphene oxide coated cellulose paper as a sacrificial template. The metallic paper showed similar fiber structure network, which served as Joule heating resistor and strain sensor. Origami robot was demonstrated based on the metallic paper. When applying current, the metallic fiber backbone heated the shape memory alloy (nitinol) wires. The nitinol wires straightened out and brought the origami robot to bend about 60°. Besides, the metallic fiber network was an intrinsic strain sensor, whose electrical resistance was linearly related to the bending angle. The configuration of the robot can be monitored through the sensor in real time, allowing the feedback control of the movement. Furthermore, the metallic backbone also worked as a reconfigurable dipole antenna, which could receive and send electromagnet signals. Through the actuators, sensors and antennas, two robots communicated and cooperated with each other to fulfil obstacle avoidance and navigation tasks. The integration of actuating, sensing, and communicating enables the robots with multifunction and a wide range of applications.

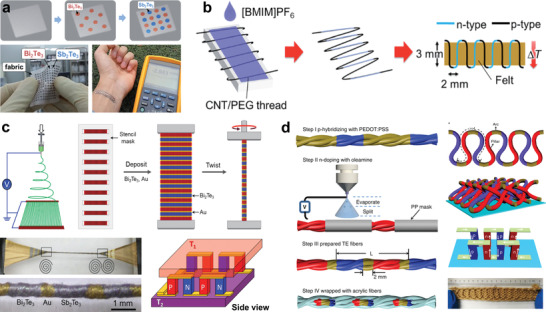

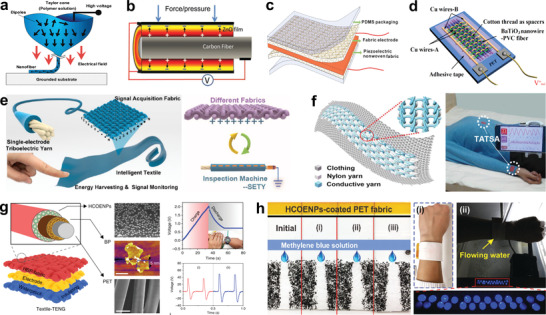

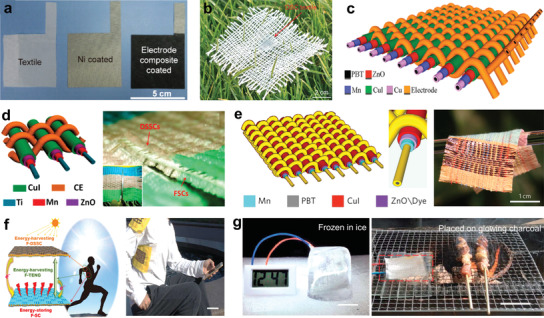

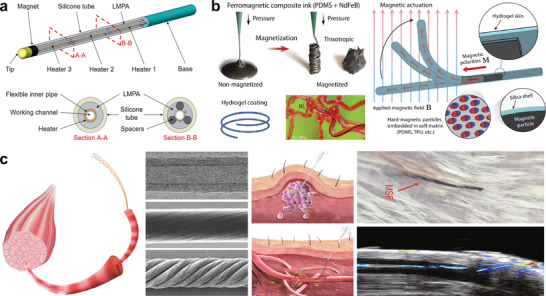

Figure 11.