Abstract

The most recent strategies available for upcycling agri‐food losses and waste (FLW) into functional bioplastics and advanced materials are reviewed and the valorization of food residuals are put in perspective, adding to the water–food–energy nexus. Low value or underutilized biomass, biocolloids, water‐soluble biopolymers, polymerizable monomers, and nutrients are introduced as feasible building blocks for biotechnological conversion into bioplastics. The latter are demonstrated for their incorporation in multifunctional packaging, biomedical devices, sensors, actuators, and energy conversion and storage devices, contributing to the valorization efforts within the future circular bioeconomy. Strategies are introduced to effectively synthesize, deconstruct and reassemble or engineer FLW‐derived monomeric, polymeric, and colloidal building blocks. Multifunctional bioplastics are introduced considering the structural, chemical, physical as well as the accessibility of FLW precursors. Processing techniques are analyzed within the fields of polymer chemistry and physics. The prospects of FLW streams and biomass surplus, considering their availability, interactions with water and thermal stability, are critically discussed in a near‐future scenario that is expected to lead to next‐generation bioplastics and advanced materials.

Keywords: biopolymers, circularity, food losses, food waste, functional materials, sustainable plastics, upcycling

The state‐of‐the‐art strategies to upcycle agri‐food losses and wastes (FLW) into advanced materials are reviewed. The right accent is put on the feasible means of effectively deconstructing and reassembling, synthesizing, or engineering FLW‐derived monomeric, polymeric, and colloidal building blocks targeting multifunctional, sustainable bioplastics. The food–materials–energy nexus is put in perspective as far as the next‐generation bioplastics fitting the circular bioeconomy.

1. Introduction

In the quest to achieve a circular bioeconomy, bioresources such as renewable and/or recycled streams are considered for their sustainable utilization along with strategies for end‐of‐life disposal and/or recirculation. Bioplastics or bioplastic‐forming compounds derived from biomass have been demonstrated as viable options that can meet the demands of product manufacturing and functions.[ 1 ] In parallel, an increasing concern is building up as massive volumes of biomass are generated from agro‐industrial operations and consumption, best exemplified by food loss and waste, thereafter referred to as FLW. Some of the FLW biomass can be utilized, for instance, as nutrients for livestock; however, the associated economic and environmental costs remain as important barriers for such use, for example, considering feed quality control, stream management, and others. Therefore, the transformation into “green” materials is as an emerging option that utilizes residual biomass and streams in the food supply chain.

The complex and heterogenous chemical make‐up of FLW‐derived biomass is a challenge but can also offer great opportunities, e.g., if appropriate fractionation tactics are applied. FLW offers an unparalleled potential for upcycling into materials sourced from monomeric, polymeric, and colloidal building blocks (Figure 1 ). Additionally, FLW can be utilized without extensive purification or separation (bulk waste), and as sources of nutrients for biotechnological routes. Beyond packaging, FLW versatility allows upcycling into advanced materials, suitable for biomedical devices, sensors, actuators, and energy storage and conversion devices. In this review, we critically discuss the recent breakthroughs in FLW valorization, associated sustainability aspects, and the prospects to meet the fabrication demands toward advanced, functional materials, and devices. Our contribution is expected to serve as a basis to catalyze new efforts in developing next‐generation bioplastics from agri‐food side streams. Indeed, taking the stratosphere as a boundary, there is no throwing out, and FLW streams should be regarded as useful resources in our efforts to achieve circularity. We put into perspective the interplay between FLW composition and building block origin, considering the different stages that exist during the lifetime of the given bioresource, as a waste or residual stream or as a product loss or purge. We analyze the properties of the resulting building blocks based on those of the precursor FLW and targeted materials. We discuss proposed strategies to obtain bioplastics from FLW, the steps that lead to efficient processing, as well as the approaches needed to meet the performance gap that exists between bioplastics and conventional plastics. Lastly, we present the main challenges in the utilization of FLW as a widespread source of materials, also considering aspects related to socioeconomical, environmental, and sustainability impacts.

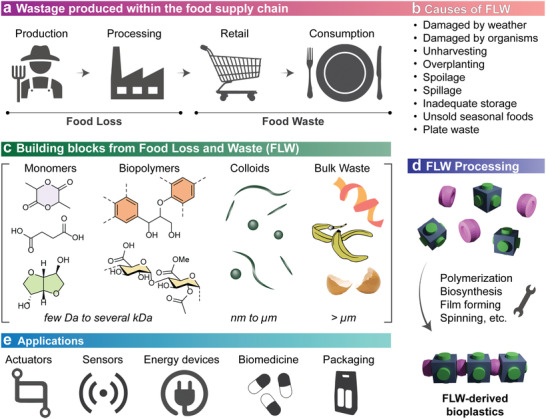

Figure 1.

Illustrative landscape covering the utilization of food losses and waste (FLW) to produce bioplastics aimed to fulfill advanced applications. a) Food wastage is divided into loss and waste, depending on its origins. While losses take place during production and processing, waste is sourced at the retail and consumption stages. b) Several technical and behavioral reasons lead to FLW, spanning from agricultural losses from environmental conditions to human activities, for example, waste from eatery and catering utensils. c) A wide variety of building blocks can be obtained from FLW. Monomers (such as dilactide, succinic acid, and isosorbide), biopolymers (e.g., lignin and cellulose), colloids (with morphologies such as nanospheres, nanofibers, and nanocrystals), and bulk waste (e.g., unpurified peels and shells), all of which can be collected as FLW. Note: The polyaromatic structure shown corresponds to G‐type lignin with a β‐aryl ether (β‐O‐4) linkage. d) Processing of FLW‐derived building blocks, e.g., to synthesize bioplastics, can use several routes, including polymerization, self‐assembly, spinning, and others. e) FLW‐based bioplastics are finding application in traditional materials (for example, packaging) as well as advanced materials and systems, as noted.

2. Losses and Waste Associated with the Food Industry and Opportunities as Bioplastics

2.1. Food Losses and Waste in Numbers

A 2011 estimate from the Food and Agriculture Organization (FAO) indicated that roughly a third of the total food produced in the world was lost or wasted (around 1.3 Gt annually).[ 2 ] More recently, the FAO and the United Nations (UN) Environment Programme developed more precise estimates by the adoption of two main metrics, namely, the “Food Loss Index” (for losses in the production or supply chain, before retail) and “Food Waste Index” (for waste by retailers and consumers).[ 3 ] The key difference between these categories (food loss and food waste) considers the point along the supply chain from which the food item is removed, with losses taking place at earlier stages, and waste occurring later, usually influenced by consumer practices and behavior.[ 4 ] Initial estimates of the Food Loss Index indicated that ≈14% of food is lost before retailing. Meanwhile, the Food Waste Index involves more complex accounting. The largest volume of losses (≈48% of the total) is under the category of “cereals and pulses”, followed by “roots, tubers, and oil‐bearing crops” (≈32%), and fruits and vegetables (≈12%).[ 3 ] In developing countries, the absence (or insufficiency) of strategies to preserve perishable crops, associated with the first stages of the supply chain, represents a major challenge. By comparison, the waste generated at the final stages is a dominant contribution to losses in high‐income countries.[ 5 , 6 ]

2.2. What Is Wrong with Food Losses and Waste?

Food losses and waste (FLW) bring adverse economic consequences such as those associated with the nutrient and food life cycle cost as well as waste disposal. Such factors undermine the business structure and raise prices, producing social pressure and lowering food security, both representing major impacts to the poorest segments of society.[ 6 , 7 , 8 ] FLW have been recognized as a global challenge due to their environmental impacts.[ 9 , 10 ] In fact, meeting the increasing agricultural needs, in an environmentally sustainable manner, is part of the “Grand Challenge” of achieving food security. Such challenge includes “sustainability” (with particular reference to environmental aspects) as the fifth component dimension following those related to “availability”, “accessibility”, “utilization”, and “stability.”[ 11 ] Considering these challenges, the major footprints derived from FLW include the a) carbon footprint associated with the emission of greenhouse gases throughout the food's life cycle (mainly during the primary production phase, such as enteric fermentation by ruminants, manure management, and the use of fertilizers); b) land footprint, including the surface of land used for food production; and c) water footprint or water used at all stages of the supply chain. Overall, there is an increased need to consider new strategies to prevent and valorize FLW. For instance, in 2015 the UN defined seventeen Sustainable Development Goals in the “2030 Agenda for Sustainable Development,” whose objectives were intended to guide UN actions over the next 15 years. According to Target 12.3, the per capita global food waste should be halved by 2030 together with a considerable reduction of food loss. Therefore, reducing FLW while limiting energy consumption, environmental and social impacts are critical to meet the challenge of feeding the world in a sustainable manner.[ 3 , 12 ] Such FLW mitigation has evolved from initiatives such as food charity and campaigns for consumer awareness, as well as strategies that include the reutilization of by‐products, within given industrial processes,[ 13 ] adding operational improvements,[ 14 ] or applying machine learning for optimization of stream and process integration.[ 15 ]

Although FLW minimization is crucial in feeding more people and in reducing the environmental impacts of the food chain, there are unavoidable losses resulting from food production and processing. Hence, FLW valorization is a complementary approach that allows the recovery or upcycling of resources for a variety of purposes, including those associated with energy,[ 15 , 16 ] animal feed, chemicals,[ 17 ] and materials.[ 18 ] Since the transformations needed for FLW valorization, on their own, might involve additional environmental impacts, one needs to consider the feasibility of each valorization initiative in a holistic manner, for example, by using life cycle assessments (LCA) and other approaches to support decision‐making. The fact that a product/material has a renewable origin does not necessarily mean that it has a better environmental performance, for example, compared to conventional options. Thus, a case‐based evaluation is always required.[ 19 ]

FLW streams usually contain valuable components, as shown in Table 1 , which should be regarded as resources that will help to meet the major global challenge associated with the transition from a fossil‐based to a bio‐based economy. In this context, the term “food by‐products,” has been adopted to indicate that biomass converted into marketable products.[ 20 ] The complementary concepts of bioeconomy and circular economy have been presented as sustainable alternatives to the dominant economic development model following the “take‐make‐dispose” plan.[ 21 ] The bioeconomy is based on the transformation of renewable resources into end‐products and materials; meanwhile, the circular economy proposes the transformation of the current linear supply chain into a circular model, focused on optimizing resource efficiency and processes by reusing and recycling products, thus enabling a closed‐loop, ideally leading to a waste‐free system. Such concepts are designed to counterbalance the socioeconomic and environmental shortcomings that exist under the current linear model. Hence, generally, food losses are usually preferred for use over food waste, as the former ones are abundant, spatially concentrated (facilitating collection), and usually less deteriorated than the latter, which is normally produced at the end of the food supply chain.[ 20 ] The abundant food waste, on the other hand, is fragmented (from households and commercial establishments), heterogeneous in composition, and inconsistent as far as generation rate and volume, making handling difficult.[ 22 , 23 , 24 ]

Table 1.

Examples of FLW sources, their major components, and potential for material production. Also included are the fractions/components proposed for use in bioplastics, according to the recent literature, as cited

| FLW | Annual generation [Mt] | Useful components/fractions a) | Fractions used for bioplastics |

|---|---|---|---|

| Apple pomace | 24[ 61 ] | Pectin (3–14%),[ 62 ] lignin (15–23%),[ 62 ] cellulose (7–44%),[ 62 ] phenolics (0.5%)[ 63 ] | Cellulose;[ 64 ] bulk apple pomace [ 65 , 66 ] |

| Banana peels | 34.7[ 67 , 68 ] | Starch (30%),[ 69 ] cellulose (18.7%), pectin (14.2%), lignin (16.8%),[ 70 ] phenolics (≈1%)[ 71 ] | Pectin,[ 72 ] cellulose,[ 72 , 73 ] phenolics[ 74 ] |

| Brewer's spent grains | 39[ 75 ] | Arabinoxylans (22–29%),[ 76 , 77 ] cellulose (17.9%),[ 77 ] lignin (12–28%),[ 77 , 78 ] protein (15– 30%)[ 75 , 78 ] | Arabinoxylans,[ 79 ] feruloylated arabinoxylo‐oligosaccharides,[ 79 ] protein[ 80 ] |

| Coconut fiber | 23[ 81 ] | Cellulose (31.6%), hemicelluloses (25.5%), lignin (35.1%)[ 82 ] | Cellulose,[ 83 ] phenolics[ 84 ] |

| Coffee husks | 1.8[ 67 , 85 ] | Cellulose (29.2%), lignin (22.3%)[ 85 ], phenolics (≈0.3%)[ 86 ] | Cellulose,[ 87 , 88 ] phenolics[ 88 ] |

| Corn gluten meal | 1.1 only in USA[ 89 ] | Proteins (zein, 41–48%; glutelin, 17–20%)[ 90 ] | Zein[ 91 , 92 , 93 ] |

| Corn stover | 1,836[ 67 , 94 ] | Cellulose (32.7%), hemicelluloses (31.1%), lignin (10.1%)[ 94 ] | Cellulose[ 95 ] |

| Grape pomace | 10[ 96 ] | Pectin (32%),[ 97 ] cellulose (16.4%),[ 98 ] phenolics (<4%)[ 99 ] including anthocyanins (0.5%)[ 100 ] | Cellulose,[ 101 ] phenolics,[ 102 , 103 ] anthocyanins;[ 104 ] bulk grape pomace[ 105 ] |

| Mango stones (kernels + shells) + peels | 22.5[ 106 ] | Stones: cellulose (55%),[ 107 ] lignin (23.8%),[ 107 ] starch (33%).[ 108 ] Peels: pectin (16–27%),[ 109 ] cellulose (8.2%),[ 35 ] lignin (6.4%),[ 35 ] phenolics (1.5%)[ 110 ] | Starch,[ 60 , 111 ], cellulose,[ 111 ] fat,[ 60 ] phenolics;[ 35 , 60 , 112 ] bulk mango peel [ 35 ] |

| Oil palm empty fruit bunch (OPEFB) | 54[ 67 , 113 ] | Cellulose (24–65%), hemicelluloses (21–33%), lignin (14–30%)[ 114 ] | |

| Olive pomace | 2[ 118 ] | Lignin (43.2%), hemicelluloses (22.3%), cellulose (12.5%), lipids (16.6%)[ 119 ] | Bulk olive pomace[ 120 , 121 , 122 ] |

| Orange peels/pomace | 15.6[ 123 ] | Cellulose (30–38%),[ 124 ] pectin (11.5%)[ 125 ] | Bulk orange pomace (sugars removed)[ 126 ] |

| Pineapple leaf | 76.4[ 127 ] | Cellulose (70–85%), hemicelluloses (6–19%), lignin (4–15%)[ 128 ] | Cellulose;[ 129 , 130 ] pineapple leaf pulp[ 131 ] |

| Potato peels | 0.07– 0.14[ 132 ] | Starch (44.8%), cellulose (34.3%), lignin (4.3%)[ 133 ] | Bulk potato peels[ 134 , 135 ] |

| Rice husk | 800[ 136 ] | Cellulose (25–35%), lignin (26–31%), silica (15–17%)[ 136 ] | Cellulose,[ 87 , 88 , 137 ] phenolics[ 88 ] |

| Rice straw | 650– 975[ 136 ] | Cellulose (37%), lignin (14%)[ 138 ] | Cellulose,[ 139 , 140 , 141 ] hemicelluloses,[ 140 ] lignin;[ 140 ] bulk rice straw[ 142 ] |

| Spent coffee grounds (SCG) | 6[ 143 ] | Hemicelluloses (30–40%, mainly mannans and arabinogalactans),[ 143 ] cellulose (12.4%),[ 144 ] lignin (23.9%),[ 144 ] proteins (13.6%),[ 145 ] phenolics (≈2%)[ 145 ] | (Total) polysaccharides,[ 146 , 147 ] hemicelluloses,[ 148 ] cellulose;[ 149 ] bulk SCG;[ 150 ] SCG extract (with caffeine, chlorogenic acids, and fatty acids)[ 151 ] |

| Sugarcane bagasse | 533[ 67 , 152 ] | Cellulose (42.2%), hemicelluloses (27.6%), lignin (21.6%)[ 153 ] | Cellulose,[ 154 ] hemicelluloses;[ 155 ] bulk sugarcane bagasse fibers[ 156 , 157 , 158 ] |

| Tomato pomace | 5.4–9.0[ 159 ] | Cellulose (13.9%),[ 160 ] pectin (28%),[ 161 ] phenolics (0.1%),[ 162 ] lipidic fraction (25%)[ 163 ] including cutin (20%)[ 162 ] | Lipidic fraction[ 163 , 164 , 165 ] |

| Wheat straw | 807[ 67 , 166 ] | Cellulose (32.6),[ 167 ] hemicelluloses (29.9%, mainly arabinoxylans),[ 167 , 168 ] lignin (≈20%)[ 169 ] | Hemicelluloses,[ 167 , 168 , 170 ] cellulose;[ 168 ] alkali‐treated wheat straw[ 171 ] |

| Meat (beef, pork, chicken) by‐products | 201 (for a meat: residue ratio of 1.5)[ 172 ] | Collagen: ≈30% in hides, [ 173 ] 25% in bones,[ 174 ] 70–80% in tendons.[ 175 ] Keratin: 90% in chicken feathers[ 176 ] | Collagen,[ 177 , 178 ] gelatin,[ 179 , 180 , 181 ] keratin[ 182 , 183 , 184 ] |

| Crustacean shells | 6–8[ 185 ] | Chitin: 15–40%[ 185 , 186 ] | Chitin,[ 187 , 188 , 189 ] chitosan[ 188 , 190 , 191 ] |

| Fish waste | 76[ 192 ] | Collagen/gelatin: up to 70% in skins[ 193 ] | Collagen,[ 194 , 195 ] gelatin,[ 180 , 196 , 197 ] gelatin hydrolysate[ 198 , 199 ] |

| Milk whey | 180[ 200 ] | Protein (12%)[ 201 ] | Whey protein isolate[ 202 ] |

If provided in the literature, the actual component content (from chemical evaluations) is provided on a dry basis. Otherwise, extraction yields are provided instead (shown in italics).

Given that competitive and environmentally friendly alternatives are needed to replace fossil resources, including energy, chemicals, and materials, several efforts have been applied for FLW valorization. The latter uses a variety of approaches, which depend on several factors, mainly related to the nature of the raw materials as well their chemical composition and physical structure. FLW have been traditionally examined for the production of biofuels[ 25 , 26 , 27 ] and energy recovery[ 28 , 29 ] and, to a lesser extent, to synthesize biobased materials, the subject of this review, given the promising prospects of such efforts.

2.3. Bioplastics—Volume, Properties, and Prospects

We emphasize the utilization of FLW to produce biobased polymeric materials, here loosely termed as “bioplastics” and considered in more detail in other sections of this review. Bioplastics can either replace traditional, non‐renewable counterparts or create new solutions to current technological challenges, thus improving the sustainability and circularity aspects of material manufacturing. The annual plastic production from fossil sources is ≈360 Mt worldwide, which poses a threat to the environment, for example, if one assumes that 0.1% of this amount ends as microplastics, accounting for hundreds of thousands of tons. Such highly mobile and persistent particulate materials would bioaccumulate in plants and animals (see recent reports on microplastics[ 30 , 31 , 32 ]). In 2017, 115 Mt of plastics were used only for packaging,[ 33 ] mainly single‐use plastics of short service life (a year, on average). These materials persist for centuries in the environment, with serious ecological impacts, especially on marine ecosystems.[ 34 ] To compound the global concerns related to the consequences of persistent materials, it is worth noting that the packaging market (particularly food packaging) is continuously growing, following the ever increasing demand for convenience foods and the rising urban population.[ 35 ] Bioplastics represent only a small fraction (≈1%) of the total plastic production, with packaging being the main application (more than 53%, representing 1.14 million ton in 2019).[ 33 ] The use of bioplastics, however, has diversified into other segments such as those related to the biomedical (e.g., tissue engineering),[ 36 , 37 , 38 ] transportation (e.g., automotive parts),[ 39 , 40 , 41 ] and construction (e.g., thermal insulation materials).[ 42 , 43 ] It is worth mentioning that the use of food packaging is rather essential to protect foodstuff (from spoiling agents, mechanical damage, dehydration, among others). Hence, the main goal should be to minimize FLW while using long‐lasting materials, considering circularity and persistence of the natural resources within the economic cycle. At any rate, it is clear that the use of non‐biodegradable plastics for single use is a great concern, even if derived from biomass.

The broad term “bioplastic” comprises three distinct polymer categories:[ 44 ] a) bio‐based and biodegradable (e.g., polylactide—PLA—and thermoplastic starch—TPS); b) bio‐based and nonbiodegradable (e.g., the “drop‐in” replacements of conventional plastics, such as bio‐based polyethylene—PE); and c) nonrenewable and biodegradable (such as poly(ε‐caprolactone)—PCL). In this Review, we indicate “bioplastics” referring to bio‐based materials obtained from FLW, irrespective whether being biodegradable or not (although biodegradability is desirable for short‐term applications). The term “bio‐based plastic” relates to the ‘rate or kinetics of renewability’ of the raw material used in its manufacture. A widely neglected fact is that virtually everything that comes from nature is renewable, although at different timescales. Thinking of sustainability, it is reasonable to target raw materials that can be restored in nature, following a timescale that is comparable to the intended lifetime of the bioplastic‐based material, where the environmental fate should also be included. Furthermore, if one looks into the ‘thermodynamics of renewability', it becomes evident that the terms “circularity” and “close‐loop” are idealized, as there must be some energy input (sun irradiation, at least) involved in the process. This energy input, in turn, is demanded at given extent and can derive from clean (e.g., sunlight, wind, hydropower, geothermal) or less clean (e.g., burning oil, gas, and coal) sources. There is consensus in achieving an environment that largely benefits from energy inputs that should be minimized and as clean as possible, considering resource depletion and emissions.

Most current bioplastics are first‐generation, i.e., produced from carbohydrate‐rich plants that, at least in some instances, could instead be used as food or animal feed (e.g., corn, sugarcane, soybean, wheat, and potato), which leads to disagreements around food versus nonfood applications. On the other hand, second‐generation bioplastics are derived from feedstocks that are not intended for food use (including wood cellulose and FLW). A third generation of bioplastics, still in development, involves the direct production of plastics (or their building blocks) from living organisms.[ 45 ] So, FLW utilization to obtain materials is compatible with both the second‐ and third‐generation bioplastics. Regardless, bioplastics are presented as sustainable materials compared to those produced from fossil sources. However, due to information gaps, the evaluation of the global sustainability performance has been mainly focused on a few aspects, particularly global warming potential (GWP). In this regard, it is telling that substitution of ≈65.8% of all conventional plastics by bioplastics would save 241 to 316 Mt of CO2‐equivalent per year,[ 46 ] signifying a great impact on GWP.

Albeit more environmentally advantageous, most bioplastics lack in their properties, for instance, to match those of petroleum‐based plastics.[ 44 ] “Drop‐in” replacements of conventional plastics provide bio‐based alternatives with the same chemical structures (as well as properties and applications); however, associated costs need to be reduced given the relatively smaller production scale and processing capacity, as well as the higher raw material costs.[ 44 ] Most bioplastics, on the other hand, do not share the chemical structure typical of conventional plastics, and might present challenges in processability. These are barriers preventing bioplastics to enter the traditional, highly competitive markets. For instance, as far as performance, biopolymers may have a glass transition temperature (T g) that is too close to their degradation temperature,[ 44 ] thus limiting common heat processing, such as extrusion, compression, injection molding, and melt spinning. Therefore, processing of bioplastics does not typically follow that of synthetic counterparts, and requires engineering adaptations or new methods, such as continuous casting (see Section 5). Moreover, given their brittleness, bioplastics might require plasticizers,[ 44 , 47 ] i.e., to increase elongation at break or to accommodate plastic deformations.[ 44 , 48 , 49 ] Compositing, the addition of crosslinking agents[ 50 , 51 ] or nanofillers[ 52 , 53 ] are used to tailor the mechanical strength of bioplastics but usually compromise elongation.[ 50 , 54 ] Nanofillers may improve the thermal and barrier properties of bioplastics,[ 55 , 56 ] while blending with other polymers can be cost‐effective to enhance the properties according to the intended use.[ 44 ] For instance, materials for food packaging must fulfill safety demands associated with biological, chemical, or physical stability, for example, during storage. Moreover, antimicrobial properties in food packaging materials are useful to minimize microbial spoilage[ 57 , 58 ] (e.g., in cheese, fruits, and vegetables). Additional properties include antioxidant, and UV‐absorbing activity, relevant to lipid oxidation (e.g., in vegetable oils and edible nuts).[ 59 , 60 ]

3. Food Losses and Waste as Precursors of Biocolloids and Advanced Bioplastics

3.1. Biocolloids for Materials Assembly

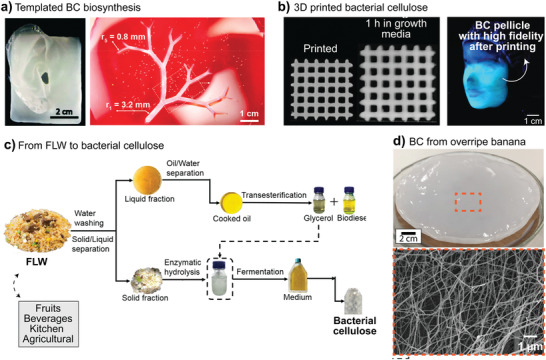

The use of biocolloids for assembling materials has mostly involved highly pure systems, such as those derived from dissolving wood fibers, cotton, and, more recently, micro‐ and nanocelluloses. However, given the large volumes of FLW available, they can be considered as a source of biocolloids. In this section, we review the isolation of nanocelluloses, nanochitins, carbon dots, and biogenic silica from plant‐ (e.g., fruit peels, stems, and bagasse) and animal‐based FLW (e.g., crab shells). We discuss extraction yields and biocolloid properties as far as the recalcitrance and chemical composition of the source biomass.

3.1.1. Nanocelluloses

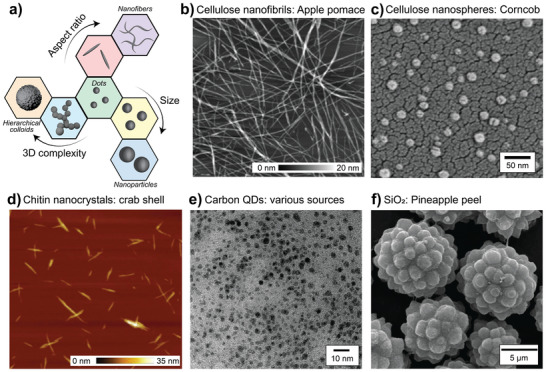

Wood is currently the major source of nanocelluloses, i.e., cellulose nanofibrils (CNF) and nanocrystals (CNC). It has been estimated that around 40,000 metric tons of nanocelluloses were produced in 2018, and forecasted to grow ≈30% yearly, surpassing 250 000 metric tons by 2025.[ 203 ] Nanocelluloses derived from woody biomass represented a market value of ≈USD 300 million in 2020 and are expected to double by 2025. North America, Northern Europe, and Japan are major nanocellulose markets. We suggest that sourcing nanocelluloses from FLW would rapidly increase the worldwide market value, given the possibility of creating globally reaching, decentralized units that produce nanocelluloses in smaller scales, using waste available locally, e.g., from agriculture and food chains. Under this scenario, regions with consolidated agriculture‐based economies, such as Western Europe and Latin America, could become important players in the nanocellulose market. Along the food chain, nanocelluloses can be sourced from the primary processing (e.g., fruit tree cuttings)[ 204 ] to the final consumption (e.g., peels and bagasse).[ 205 , 206 , 207 , 208 ] Some high‐quality nanocelluloses have been successfully isolated from bagasse,[ 207 ] peels,[ 209 ] stems,[ 210 ] or leaves[ 211 ] of a variety of fruits,[ 205 , 206 , 209 ] nuts,[ 212 ] vegetables,[ 208 ] and cereals.[ 213 , 214 ] In addition to the typical nanocelluloses (high‐aspect ratio CNC and CNF, Figure 3b), cellulose nanospheres (with enhanced surface activity compared to CNC and CNF) have been produced from corncob waste.[ 215 ] These nanospheres (Figure 3c), comprising cellulose II crystal structures, have been reported to feature a soft particle shell structure,[ 216 , 217 , 218 ] which is suitable for adsorption and biosensing.[ 218 ]

Figure 3.

Formation of high‐quality, well‐defined biocolloids from various FLW. a) FLW biocolloids can be obtained into different sizes, aspect ratios, and 3D complexities. Examples include: b) CNF from apple pomace (Adapted with permission.[ 281 ] Copyright 2019, Elsevier B.V). c) Cellulose nanoparticles from corncob (Adapted with permission.[ 215 ] Copyright 2020, The Authors, under exclusive license to Springer Nature Limited). d) ChNC from crab shell (Adapted with permission.[ 260 ] Copyright 2020, Elsevier B.V.). e) Carbon QD from mixed FLW (Adapted with permission.[ 275 ] Copyright 2014, American Chemical Society). and f) Hierarchically structured silica particles from pineapple peels (Adapted under the terms of the CC BY 4.0 license.[ 209 ] Copyright 2018, The Authors, published by Springer Nature).

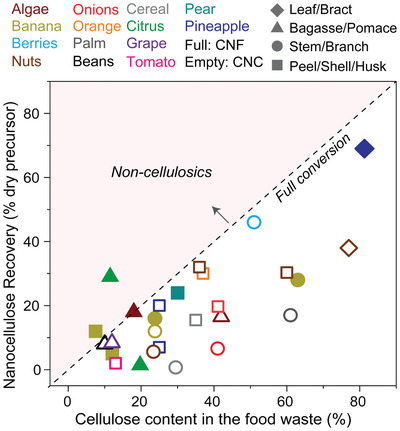

Small‐scale and high‐value markets of FLW‐sourced nanocelluloses could become prominent in the future bioeconomy. In this regard, however, there is a differentiation between food losses and waste, namely, the isolation of nanocelluloses from food waste is considered more challenging than from food losses. Food waste, e.g., peels and bagasse, are usually enriched with nutrients, including low‐molecular weight (MW) sugars[ 219 ] that favor the growth of unwanted microorganisms (e.g., fungi). Thus, transportation and storage of food waste must be considered along with the incorporation of preservatives. On the other hand, wood, the prevalent source of nanocelluloses, is associated with a relatively low total yield. For example, if one considers the production of Kraft pulp, the most common route for wood processing, the yield from wood to Kraft pulp ranges from 45% to 60%, depending on the process parameters and extent of lignin removal.[ 220 ] Wood pulp can be converted into CNF in high yields; in contrast, CNC yield from the same source is clearly lower, ≈20–40%, depending on the process used.[ 221 , 222 ] The yield of nanocelluloses produced from FLW varies widely according to the source, based on their chemical composition and the stage from which the material is resourced, along the supply chain (Figure 2 ). Biomass from early stages of the supply chain, such as fruit tree pruning (e.g., branches and stems), includes lignified tissues that are chemically comparable to wood.[ 223 ] Therefore, the isolation and associated yields of nanocelluloses from branches and stems are analogous to those of wood. Isolation typically involves pulping (with NaOH and Na2S, as in the Kraft process), bleaching (ClO2, H2O2, ozone, and others), mechanical defibrillation, and acid hydrolysis.

Figure 2.

Extraction of nanocelluloses, represented by nanofibrils (CNF) and nanocrystals (CNC), from vegetal FLW. Primary biocolloid sources include leaves, bagasse, branches, and peels of a variety of edible vegetal species (note: here we include algae, which is not part of the plant kingdom). The data shown in the figure were collected from the available literature, discussed in the text.[ 101 , 129 , 130 , 204 , 205 , 206 , 207 , 209 , 210 , 212 , 213 , 229 , 230 , 231 , 232 , 233 , 234 , 235 , 236 , 237 , 238 , 239 , 240 , 241 , 242 , 243 ] The plot includes the percent nanocellulose recovery as a function of the cellulose content in the FLW source.

Compared to wood, bagasse and peels are relatively richer in cellulose and low‐MW carbohydrates. Also, they include less lignified tissues.[ 219 ] However, the higher cellulosic fraction does not necessarily imply a higher nanocellulose recovery, for example, when compared to woody branches and stems (Figure 2). This is related to the fact that part of the cellulosic matter is degraded during the fractionation into nanocellulose. A low nanocellulose recovery yield in such cases results from the poor structural integrity, for example, in peel/pomace biomass, owing to i) the inherent chemical composition (rich in low‐MW carbohydrates) and ii) microstructural disintegration of the biomass during food processing (e.g., thermomechanical methods) to extract pulp or juice. Processing and associated yields also follow biomass recalcitrance, which in turn depends on chemical factors such as the degree of polymerization of cellulose, lignin, and non‐cellulosic polysaccharides, protein content and the presence of acetyl groups, syringyl/guaiacyl (S/G) ratio of lignin, as well as physical factors such as the degree of crystallinity and surface accessibility.[ 224 , 225 ] Biomass that is rich in noncellulosic carbohydrates is not as recalcitrant compared to lignified biomass, with well‐developed plant cell walls,[ 226 ] which require more severe conditions for disassembling into single fibers. Unfortunately, selective processes to solubilize pectins or hemicelluloses, without attacking the cellulose scaffold, are not fully developed in either case.[ 223 , 227 ] Hence, most efforts to isolate nanocelluloses from fruit peels and bagasse are designed to produce CNC (see Figure 2 comparing CNF and CNC production from different sources and respective yields), given that acid hydrolysis (typically used to obtain CNC) degrades the amorphous (and low‐MW) carbohydrates, leaving behind the cellulose crystals. On the other hand, CNF production from peels and bagasse involves large amounts of low‐MW sugars, unless stepwise purification is considered, affecting colloidal and cohesive properties as well as susceptibility to biodegradation, given the low MW of the sugars.[ 228 ]

3.1.2. Nanochitins

Unlike nanocelluloses, whose major source includes nonfood biomass (wood and others), nanochitin is primarily extracted from wastes from the fishing industry[ 244 , 245 ] along with other emerging sources, such as insects.[ 246 , 247 ] Shellfish residuals represent an important source of chitin biocolloids, given the significant volume of marine waste available, for example, considering that only 40% of crab mass is meat.[ 185 ] Over 90% of the recent literature addresses the isolation of chitin from the exoskeleton (shell) of shellfish (e.g., crab, lobster, prawn etc.). Currently, shellfish waste is a common source of chitin biocolloids, in addition to chitosan (see Section 3.2.1), following processing conditions that lead to the isolation of both short and long nanofibers as well as nanocrystals.[ 248 ] Here we discuss the composition‐processing‐property correlations that exist for chitin colloids derived primarily from shellfish, most relevant in the context of FLW upcycling.

The exoskeleton of shellfish varies with species, but includes 20–30 wt% of chitin, 30–40 wt% proteins, 20–50 wt% inorganic salts (calcium carbonate and phosphates), as well as a smaller fraction of lipids (up to 14 wt%).[ 185 ] Therefore, the isolation of chitin is a stage‐wise chemical process that comprises deproteination, demineralization, and purification with organic solvents. Proteins can be removed from the chitin plywood structure primarily by dilute alkaline solution (1–10% w/v NaOH) at temperatures ranging from 65 to 100 °C, and using times from 30 min up to 72 h.[ 249 ] Processing time and temperature can be lowered by increasing alkali concentration and vice‐versa. The solubilized protein can be further recovered by precipitation, lowering the pH of the solution to its isoelectric value. Demineralization procedures have been optimized considering calcium carbonate (CaCO3) as the main exoskeleton inorganic salt. The main goal is to transform the insoluble CaCO3 into a soluble calcium form (for instance, CaCO3 + 2HCl → CO2 + CaCl2 + H2O) that can be washed out, thus exposing the chitin building blocks. This step is usually carried out at room temperature using dilute solutions of HCl (1–10 wt%); however, other acids (HNO3, HCOOH, H2SO4, and CH3COOH) have been also employed.[ 249 ] The final step for chitin purification usually involves extraction with organic solvents, to remove carotenoids and lipids, yielding pure chitin biomass that can be further processed as nanofibers (ChNF) or nanocrystals (ChNC) (Figure 3d). Although deproteination and demineralization involve simple chemical reactions, they are bottlenecks in the production of chitin biocolloids, as they consume significant chemicals and water. Deproteination takes place at very high pH, whereas demineralization is carried out in very acidic conditions. A typical chitin yield is 15–20 wt%,[ 250 , 251 , 252 ] or as low as 3 wt% in the case of cuttlefish bones.[ 253 ] Thus, many efforts are being directed to optimize the reaction conditions for chitin extraction and to match high‐valued applications.

At least five different types of nanochitins can be produced from the exact same source, only by taking different deconstruction routes.[ 254 ] Surface deacetylation, acid hydrolysis, and TEMPO‐mediated oxidation can be used to generate positively or negatively charged nano‐sized fibers or crystals as well as zwitterionic crystals.[ 254 ] Surface deacetylation (with, e.g., NaOH), which converts the chitin acetyl groups into primary amines, is a common process that facilitates the defibrillation of chitin flakes into single fibrils (ChNF), driven by weakened hydrophobic interactions and increased electrostatic repulsion.[ 255 ] The process to obtain ChNF from deacetylated chitin is then analogous to the preparation of CNF, for example, by mechanical (microfluidization) or sonochemical (ultrasound) processing, to mention only a few. Controlled deacetylation can lead to the formation of ChNF with aspect ratios going from 15 to over 60,[ 248 ] featuring colloidal stability with zeta potential (ζ) values near +80 mV.[ 255 ] On the other hand, TEMPO‐oxidation induces negative charges (ζ = −50 mV) in the chitin backbone, e.g., by selective reaction at the C6 group, similarly to cellulose, thus yielding individualized chitin fibrils, with diameters as low as 10 nm.[ 256 , 257 ] As it is observed for cellulose, hydrolysis of chitin's amorphous regions yields nanocrystals that are ≈150–400 nm long and twisted along the main axis;[ 255 ] they assemble into liquid crystals in suspension,[ 258 ] and chiral nematic order upon consolidation.[ 259 ] Upon TEMPO‐oxidation of deacetylated ChNF, zwitterionic ChNC are obtained by regioselective treatment, with oxidation taking place at C6 and deacetylation at C2.[ 254 ] With such treatments, a variety of high‐aspect ratio biocolloids are generated, with tailored characteristics (length, diameter, charge density and type, and crystallinity).

The purified nanochitin yield (from pure chitin) is ≈75–90% for ChNF[ 260 ] and up to 50% for ChNC.[ 261 ] However, the yield drops significantly if FLW are used as starting material (5–25% for ChNF and 10% for ChNC from shellfish‐based FLW).[ 250 , 251 , 252 ] For instance, one kilogram of wet prawn residues yields only 90 g of dry matter after removal of meat tissue. Therefore, highly efficient and green isolation processes (e.g., urea‐based hydrothermal treatment and others) still yield a low total ChNF < 5%.[ 252 ] Considering the low yield and harsh conditions often applied for isolation, efforts are in development to isolate biocolloids, including enzymatic routes to modify (deacetylate) chitin,[ 262 , 263 ] fractionation with acidic deep eutectic solvents,[ 260 ] and ball‐milling pretreatments.[ 264 ] Process engineering simulation has been used to assess the techno‐economic feasibility of ChNF and ChNC isolation from purified chitin. Water consumption can reach 34% of the total process costs for ChNC and ≈7 € kg–−1 for ChNFs and 12 € kg−1 for ChNC were determined in the year 2018.[ 251 ] Hence, so far, biomedicine, pharma as well as other high‐value‐added products are the most prominent markets expected for such biocolloids.

3.1.3. Biogenic Mineral Particles and Carbon Quantum Dots

Residues obtained at the beginning of the food production‐consumption chain, i.e., agricultural residues, have potential for the isolation of biogenic silica. Rice and wheat biomass are the main sources of biogenic silica, accounting for up to 20 wt% of their dry biomass. Given the volume of rice and wheat produced worldwide, associated residual biomass is a considerable source of SiO2 colloids, which is relevant to the widespread utilization of silica colloids in advanced materials. Examples include 3D printing inks[ 265 , 266 ] and porous particle carriers for pharmaceuticals[ 267 ] and agrochemicals.[ 268 , 269 ] The production of silica colloids from biorefinery platforms of waste biomass is a timely topic within the bioeconomy, especially when compared to traditional routes used to produce synthetic silica (mining, energy‐demanding chemical reactions, and toxic reactants).[ 270 ] Biogenic silica displays a self‐similar nanostructure, with primary SiO2 units (<10 nm), but aggregating into porous, submicron, and kinetically stable supracolloids. For instance, the specific surface area (SSA) of biogenic SiO2 derived from rice can reach up to 500 m2 g‐1, with a low pore tortuosity, yielding a highly percolating nanostructure,[ 268 ] differently from the highly directional, templated mesoporous silica (e.g., MCM‐41).

The isolation of biogenic silica from Si‐accumulating biomasses is simple and scalable. The process comprises a hydrolysis step with dilute acid (e.g., HCl or H2SO4 at 2% w/v) that is used to digest the cellulosic matter and to disassemble the plant microstructure, followed by calcination at temperatures ranging from 500 to 700 °C. The hydrolysis step is important to extract (leach out) other alkali and earth alkaline metals from the plant. Their presence decreases extensively the T g of the mineral mixture, thus causing the sintering of the primary mineral nanoparticles and closure of their pores. Interestingly, some fruits, such as pineapples, contain silica in their peels.[ 209 ] It has been demonstrated that rosette‐like biogenic silica microparticles (Figure 3f) can be obtained after the extraction of CNC from pineapple peels. The silica recalcitrance to all reactants involved allows the recovery of the particles at the end of the process, as an insoluble matter that can be collected.[ 209 ] Complex 3D particles find use in many applications where the colloidal interactions between particles or between particles and surfaces need to be controlled.[ 271 ]

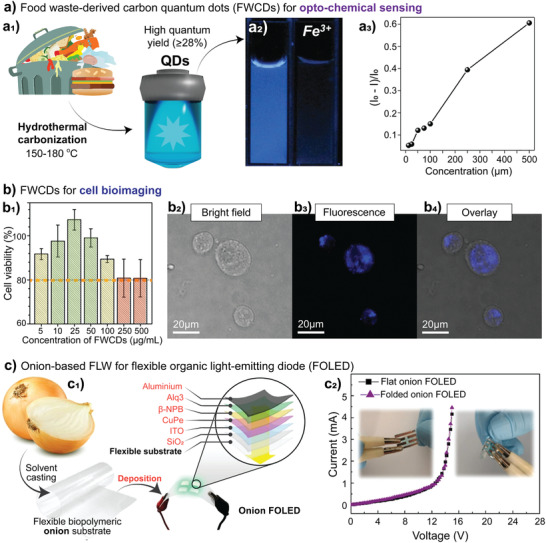

Other types of particles that can be derived from FLW, from the end of the production‐consumption line, are carbon quantum dots (CQD). CQD are very small carbon nanoparticles (usually < 10 nm in diameter; Figure 3e) that display prominent photoluminescence given quantum effects, relevant to optoelectronic, biomedical, and sensing platforms.[ 272 ] Many processing technologies (e.g., microwave, plasma, ultrasonic, solvothermal) have been developed to produce CQD from carbon sources; however, those related to FLW mostly comprise (hydro)solvothermal approaches. Solvothermal routes, using mostly water as a solvent, aim to oxidize the FLW at temperatures ranging from 150 to 300 °C for 2–36 h, thus yielding —COOH functionalized nanoparticles with quantum yield from 20 up to 60%, depending on the source.[ 273 ] Contrarily to what is required for the isolation of nanofibers or particles, FLW are highly degraded as they serve only as carbon source for the bottom‐up production of CQD. Hence, fast‐food and mixed waste from restaurants (which contain complex mixtures of protein, carbohydrates, lipids etc.),[ 274 , 275 , 276 ] soft drinks,[ 277 ] chewing gums,[ 278 ] animal cartilage[ 279 ] and skins,[ 273 ] fruit bagasse and peels,[ 280 ] among others, have been used to produce CQD.[ 280 ] Production yields, if put in perspective with other food‐sourced biocolloids, are relatively low (≈0.2 wt% from the initial wet FLW);[ 275 ] however, the possibility to use basically any FLW, under given conditions, align with the high value of CQD applications and pushes forward efforts to up‐scale and implement CQD platforms.[ 275 ]

3.2. Soluble Biopolymers for Material Assembly

Colloidal matter, as discussed in Section 3.1, is mostly obtained from the residues of water‐insoluble polysaccharides (Figure 4a). Regarding nanocellulose, the precursors are generally purified and upconverted to cellulose‐rich fractions, which are then further processed into nanomaterials. During this purification, noncellulosic components are removed, mainly water‐soluble biopolymers, including heteropolysaccharides, proteins, and polyphenols. The structure and composition of these biopolymers in FLW are diverse and are mostly dependent on the FLW source. Interestingly, the season of the plant harvesting or the ripening state of fruits can strongly affect the composition and quantity of polysaccharides and sugars,[ 282 ] which are factors that need to be understood to devise suitable extraction processes and to unlocking the full potential of biopolymers from FLW.[ 61 ] In this section, we review the isolation of a group of water‐soluble biopolymers from given FLW sources, with a focus on plant‐based fractions used to isolate polysaccharides and polyphenolics. We also consider FLW for the valorization of protein fractions.

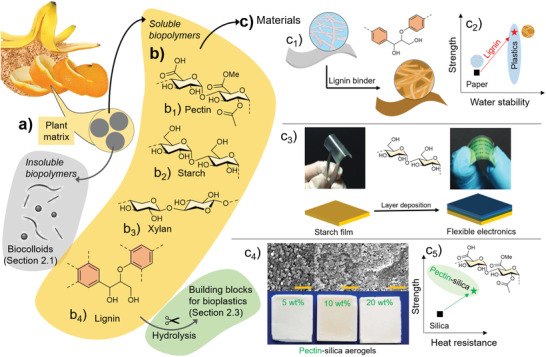

Figure 4.

The major fractions extracted from plant‐derived FLW include a,b) polysaccharides and polyphenols. a) Soluble polysaccharides are extracted from the complex plant biomatrix and the most common ones include b1) pectin, b2) amylose (starch), and b3) xylan (hemicellulose). Apart from these polymers, nonsoluble fractions can be processed into biocolloids (Section 3.1) and polyphenols, e.g., b4) lignin. c) These biopolymers can be either hydrolyzed into monomeric buildings blocks for bioplastic synthesis (Section 3.3) or directly applied in materials. c1) Lignin can be used as a binder in paper and to develop c2) strong and water‐resistant biodegradable bioplastics (Adapted with permission.[ 294 ] Copyright 2020, John Wiley & Sons). c3) Starch can be processed into flexible and transparent substrates to prepare biodegradable disposable electronics (Reproduced with permission.[ 295 ] Copyright 2019, John Wiley & Sons). c4) Pectin can be used to reinforce silica aerogels to prepare c5) super‐insulating materials with high compressive strength and low heat conductivity (respective aerogels were prepared at pH 1.5) (Adapted with permission.[ 296 ] Copyright 2015, John Wiley & Sons).

Water‐soluble biopolymers are obtained as soluble fractions derived from complex FLW matrices, with hemicelluloses as the most prominent extractable polysaccharides from plants,[ 283 ] as well as starch,[ 284 ] and pectin (Figure 4b).[ 285 ] In addition, water‐soluble polysaccharides from animals can be obtained in the form of hyaluronic acid and chitosan.[ 286 ] Besides, the extraction of polyphenols, mostly from water‐soluble lignins and tannins, has received increased attention due to their abundance and the fact that they have been largely underutilized.[ 287 , 288 ] Also, valuable proteins can be extracted from FLW, including collagen,[ 289 , 290 ] gelatin,[ 291 , 292 ] as well as whey and soybean proteins.[ 293 ] In short, most of the current, commercially available biopolymers could be sourced from FLW, to optimize the usage of resources within the food supply chain. In addition, due to their diverse structures, new types of biopolymer derivatives are available, which could be important to enabling the mission of the bioeconomy.

3.2.1. Isolation of Polysaccharides and Polyphenols

Hemicelluloses

Hemicelluloses are some of the most abundant renewable plant material,[ 297 ] with an annual production in nature in the range of 60 Gt.[ 298 ] According to their primary structure, there are three main groups of hemicelluloses, namely, xylans (Figure 4b 3), mannans, and β‐glucans. The major sources of hemicelluloses from FLW derive from sugar and soybean production,[ 299 ] but also from spent coffee grounds[ 300 ] and other plant‐based FLW residues (Table 1). In most cases, a preliminary removal of extractives and nonpolymeric sugars is required, considered as impurities.[ 283 , 301 ] Hemicelluloses are mostly extracted by alkaline treatments using diluted aqueous NaOH or KOH solutions, but other treatments, for example, based on H2O2, have also been reported.[ 302 ] After solubilization, hemicelluloses are isolated by precipitation from the soluble phase. Different hemicellulose fractions can be separated based on their solubility through acidification or precipitation in ethanol/water mixtures.[ 283 , 301 ]

Hemicelluloses in sugarcane bagasse (SCB), mainly arabinoxylans, can be extracted with alkaline aqueous solutions (NaOH concentration 1–8 wt%, 3 h at 50 °C),[ 302 ] with a mass yield of 25% (i.e., ≈75% of original hemicellulose present in SCB). Owing to their good film‐forming capability, a main opportunity for xylans and other hemicelluloses is the synthesis of films and coatings (see Section 4).[ 303 , 304 ] Xylans from SCB have been extracted using a H2O2‐treatment at higher yields, up to 95% of total xylan content in SCB.[ 302 ] The amount of lignin could be controlled in this treatment, from 5 to 14 wt%, by varying the extraction temperature. Xylans could be as well extracted from cereal grain flours.[ 295 , 296 ] Due to their high protein and starch content, pretreatments are required. Starch can be hydrolyzed by enzymatic means, whereas soluble proteins can be removed with enzymes, adsorbed by clay or coagulated by heat treatment.[ 305 , 306 ] β‐Glucans have been isolated from such sources as well, and separated from xylans based on their solubility in ethanol/water mixtures.[ 306 ] Apart from the application of hemicelluloses and starch in film and coatings, they can be also used to prepare nanoparticles for drug delivery applications.[ 307 ] Additionally, their high water‐binding capability makes them promising materials for other biomedical applications as well, e.g., as wound dressings[ 308 ] or scaffolds for bone tissue engineering.[ 309 ]

Polyphenols

Lignins (Figure 4b4) can be extracted from FLW following two main avenues: 1) by solubilization during pulping, for example, of sugarcane bagasse via Kraft or soda processes.[ 310 , 311 ] In this case, lignin is precipitated by acidification, mostly due to the protonation of charged carboxylate groups.[ 312 ] Alternatively, lignin can be isolated from 2) a lignin‐rich residue by enzymatic digestion of residual polysaccharides or solubilization in organic solvents and subsequent precipitation by acidification from the concentrated residue.[ 313 ]

In contrast to xylan extraction, lignin isolation from SCB requires harsher alkaline conditions (aqueous 40 wt% NaOH solution and heating under stirring at 90 °C for 4 h).[ 314 ] Thereby, a total lignin yield of 20% has been reported, with low hemicellulose content (<0.5 wt%). Partial substitution of water with ethanol in this treatment can be used to increase further the lignin purity. Extracted SCB lignin has been valorized as a coating material for fresh fruits (limes) and shown to display superior properties compared to technical Kraft lignin, exhibiting antimicrobial properties and reducing weight and color losses of the coated fruits.[ 314 ] Solubilization of SCB lignins is also achieved at slightly alkaline conditions (0.5 to 1.5% w/v NaOH) by using relatively higher temperatures, 130 to 170 °C.[ 315 ] This treatment was successfully applied in the pilot scale and the dissolved lignin was recovered by acid‐induced precipitation.[ 312 ] Higher lignin yields have been achieved via acid‐catalyzed glycerol treatment, enabling the recovery of 63% of the initial lignin in SCB at a high purity of 90%.[ 313 ]

Lignin solutions can be transformed into nano‐ and microparticles by aerosolization or solvent exchange routes.[ 316 ] The size of lignin particles can be controlled by the processing conditions,[ 317 ] and their surface chemistry can be tailored by selecting the lignin source material.[ 318 ] Nanoparticles prepared with different SCB lignins were used in the stabilization of Pickering emulsions and encapsulation of curcumin as bioactive compound, where the more hydrophobic organosolv lignin showed superior stabilization performance compared to that of soda SCB lignin.[ 319 ] Lignins have also been used as binder to overcome limited wet strength of celluloses, thereby strong lignin‐cellulose bioplastics were obtained that surpassed conventional cellulose paper and some fossil‐based plastics (Figure 4c1,c2).[ 294 ]

Tannins represent important polyphenolic compounds. They contribute to the sensory properties in food (particularly mouthfeel and color) as well as stability due to their antioxidant and antibacterial effects.[ 320 , 321 ] Tannins are classified as hydrolysable tannins and flavonoids.[ 322 ] Hydrolysable tannins mostly consist of water‐soluble gallic acid esters, gallotannins, and ellagitannins (MW of 500–5000 g mol−1),[ 320 ] and can be extracted from various FLW.[ 288 , 320 , 321 ] Conventionally, hydrolysable tannins are extracted with mixtures of water and organic solvents,[ 320 ] including acetone:water (8:2, v:v), which was used with grape seeds to extract phenols and flavonoids, with strong anti‐oxidant properties.[ 321 ] The extraction of hydrolysable tannins can be also accomplished with aqueous solvents, e.g., in alkaline media (1–5 wt% NaOH).[ 321 , 323 ] The NaOH concentration can be selected depending on the FLW source. For example, a high yield of hydrolysable tannins (4 mg g−1) was obtained from chestnut peels using 1 wt% of NaOH. Due to the strong interactions of tannins with other biopolymers, they have strong adhesive properties.[ 324 ] Tannins have been used together with isocyanates in wood adhesives,[ 325 ] and can increase the wet shear strength (by 91%) of soy protein isolate (SPI)‐based adhesives.[ 326 ] Finally, tannins can be readily processed into colloids of different morphologies (cuboid, platelet, needle‐like, rhomboid, and others) by adjusting the base and pH used in the morphogenesis process.[ 327 ]

Starch

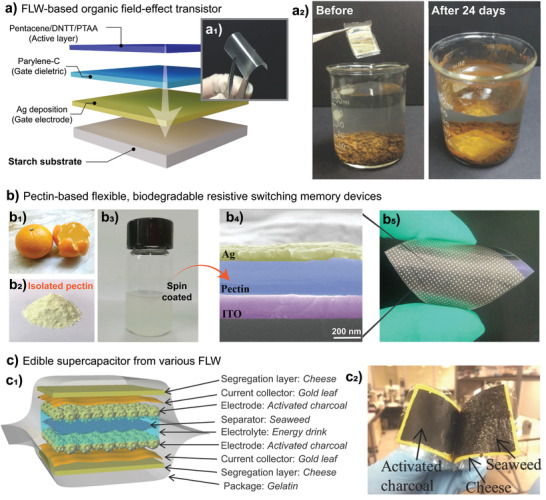

Given the competition with food applications, starch extracted from cereals and tubers is a less preferred source for material development. Yet, significant amounts of starch can be potentially extracted from FLW to replace other sources.[ 284 , 328 ] Chemically, starch is a mixture of linear amylose (Figure 4b2) and branched amylopectin. Native starch granules are usually non‐soluble in cold water, but starch gelatinization at temperatures of 60–70 °C causes granule swelling, loss of crystallinity, and dissolution of amylose.[ 329 ] Several FLW sources of starch are available (Table 1), including waste associated with the processing of fruits such as pineapple, mango, banana, and others.[ 284 ] Indeed, pineapple production generates large amounts of FLW, as plants have to be replanted every other year and each pineapple plant produces ≈6−8 kg waste as leaves, stems, and roots.[ 330 ] Starch was successfully extracted from pineapple stems by mixing the stems with water (1:1, w:w), grounding, and separating the starch slurry by filtration. The starch slurry (in case no suspension is obtained, starch can be precipitated overnight by cooling[ 331 ]) was further washed prior to drying.[ 330 ] The extracted starch had a high purity (98%) with a process mass yield of 9 wt%, amounting to ≈80% of the starch content in the initial biomass. Starch can be also extracted from banana peels by homogenization with 0.03 wt% aqueous sodium bisulfite solution.[ 332 , 333 ] Sodium bisulfite was used as a reducing agent to enhance, among others, protein solubility (dependent on the biomass solid content in this process, also higher amounts of bisulfite are required).[ 331 ] The precipitate was further purified with aqueous 0.2 wt% NaOH solution, water, and ethanol, yielding starch with a granular size of ≈17 µm, an amylose content of 21–26 wt%, and a gelatinization temperature of ≈70 °C.[ 333 ] Banana peels contain ≈30 wt% starch and 36 Mt peel waste is produced annually,[ 69 ] representing a major source of starch. Separation of starch from other soluble fractions, such as proteins, is possible at the industrial scale and achieved through hydrocyclones that separate two phases by densities.[ 334 ] Starches extracted from fruit FLW have unique features and are expected to expand the possible range of uses in industry.[ 284 ] Starch can be processed by various conventional processing techniques, such as extrusion or injection molding and offers an opportunity for the preparation of biodegradable bioplastics (see Section 5).[ 335 ] Starch can be as well processed by casting to obtain, e.g., flexible and biodegradable films for food packaging or as substrate for organic transient electronics (Figure 4c3).[ 295 ]

Pectins

FLW are valuable sources of pectins, which are compounds of diverse structure and properties, enabling utilization in a wide range of applications.[ 336 ] Pectins consist primarily of galacturonic acid, which occurs either in free carboxyl or methoxyl ester form. Homogalacturonan is the major type of pectin in the cell wall, representing 60% of total pectin amount,[ 337 ] which is partly methyl esterified at C6 position and/or O‐acetylated at C2‐OH and/or C3‐OH (Figure 4b1). The structure of pectins is highly complex and contains up to 17 different monosaccharides and 20 different types of linkages.[ 338 ] The ratio of esterified to nonesterified galacturonic acids defines the gelation properties, and pectins with low amount of ester groups, i.e., low‐methoxyl pectins, form strong hydrogels with Ca2+.[ 337 ] In contrast, high‐methoxyl pectins form stronger and tougher films due to their higher cohesive strength.[ 339 ] A high amount of pectins in plants is calcium‐bound, meaning that they are rendered insoluble due to ionic complexation between the carboxylate group and Ca2+.[ 340 ] This is why pectin extraction usually involves treatment with a chelating agent to complex Ca2+ for isolation of water‐soluble pectins or an acidic treatment to break such complexes.[ 341 ] Common chelating agents used for extraction include cyclohexanediamine tetraacetic acid and ethylenediamine tetraacetic acid (EDTA).[ 337 ] The remaining pectins are then extracted in alkaline media, usually with aqueous Na2CO3 solution.[ 340 ] Alternatively, high‐methoxyl pectins are extracted using dilute and hot acid, which is preferentially used over alkaline extraction because no depolymerization reactions via ß‐elimination occur.[ 337 ]

Several FLW contain high amounts of pectins (Table 1), up to 25 wt% in case of orange peels and pumpkin (pulp and peel) or even around 32 wt% in grape pomace;[ 97 ] onion hulls and endive roots contain significant amounts of ≈10 wt%.[ 336 ] It has been reported that pectin structures in these streams are hardly affected during food processing and storage, except for a visible reduction of methyl ester and acetyl groups.[ 341 ] A high‐yield extraction of pectins is usually accompanied by time‐consuming protocols to remove starch by solvent‐extraction with DMSO and/or enzyme treatment. However, there are straightforward avenues to isolate pectic polysaccharides, for instance by using 0.5 m HCl as extractant, achieving high yields (≈20%) by applying pressure, heating or microwave treatments.[ 341 ] Such isolated pectins have been further purified by a cascade of ethanol washing and filtration steps, which remove non‐polymeric sugars. The purified polysaccharides featured higher MW and gelling power compared to commercial pectin.

Conventional applications of pectins include those as texturizing and stabilizing agents in food and cosmetics, but their properties make them also suitable for the preparation of high value‐added materials. For instance, pectins from orange peels have been used to produce resistive memory devices as transient electronics.[ 342 ] The SSA of pectin aerogels has been found to be tunable, from 300 to 600 m2 g−1.[ 343 ] Pectins have been tested as important additives in silica aerogels, to obtain mechanically robust, thermal superinsulators.[ 296 ] Incorporation of pectins lowered the heat conductivities, down to 14 mW m−1 K−1, and increased the compressive strength of silica aerogels (Figure 4c4,c5).

Other Polysaccharides

Hyaluronic acid is a high value‐added polysaccharide with a broad range of medical applications,[ 344 ] with worldwide market estimated to be over US $1 billion.[ 345 ] It is composed of repeating disaccharide units of β‐1, 3‐N‐acetyl glucosamine and β‐1, 4‐glucuronic acid. Due to the high market potential, recent efforts have focused on extracting hyaluronic acids from fish FLW, mostly from fish eyeballs.[ 286 , 346 ] Apart from hyaluronic acid, also chitosan can be extracted from seafood waste. Chitosan is generally prepared by deacetylating chitin, as previously discussed in Section 3.1.2, to degrees exceeding 50% degree of deacetylation;[ 347 ] and is performed in industrial scale under acidic conditions.[ 348 ] Chitosan in the fully deacetylated state is composed of β‐1,4‐glucosamine units. Hence, it can be extracted from the same FLW as chitin, e.g., marine chitinous waste,[ 349 , 350 ] as well as insect exuviae.[ 351 ] Chitosan has versatile applications, for example, for bone tissue engineering.[ 352 ] In solution, chitosan is pH sensitive and can form, in combination with a crosslinkable polymer, double network hydrogels of high strength and toughness.[ 353 ] Chitosan gels can be also further processed into robust aerogels, with high SSA, for application as high‐performance thermal insulator.[ 354 , 355 ]

3.2.2. Isolation of Proteins

Collagen and Gelatin

Extraction of protein from FLW is already commercially implemented. Gelatin, which is obtained through hydrolysis of collagen, is currently extracted in large volumes from pork and cattle by‐products,[ 359 ] as well as from the fishery industry,[ 360 ] satisfying a worldwide demand of gelatin estimated at ≈0.6 Mt per year (2019).[ 361 ] Gelatin is commercially prepared either by alkaline or acidic treatment of animal tissue; the obtained alkali‐ or acid‐degraded collagen is then heat‐treated causing dissociation of collagen to various products, loosely termed as gelatin.[ 362 ] Both alkali and acid treatments influence and loosen the intrinsic fibrillar quaternary structure of collagen (Figure 5a), yielding a collagen that is more prone to hydrolysis reactions at elevated temperatures.[ 363 , 364 ] Depending on the animal tissue, specific pretreatments are required to remove other components, such as non‐collagenous proteins, fats, or inorganics.[ 289 ] Collagen has been extracted by acid treatment with 0.5 m acetic acid for mass yields of 11% and 2% from bigeye snapper skin and bone, respectively. In analogous procedures, collagen has been extracted at higher yields, 15% and 20%, from silver carp and shark skin, respectively.[ 290 , 365 ] Endeavors to further increase the yield by a subsequent pepsin treatment found no success, showing that simple acid treatment is sufficient for removing the most of extractable collagen.[ 365 ] These extracts are due to their high purity valuable alternatives to commercial collagen,[ 290 ] and can be further processed into gelatin by heat‐induced denaturation, i.e., gelatinization.[ 291 , 292 ]

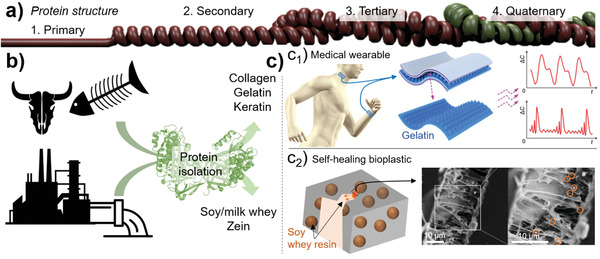

Figure 5.

Extraction of soluble proteins from FLW. a) The properties of proteins are structurally dependent and in the native state they occur as tertiary or quaternary structures (Reproduced with permission.[ 356 ] Copyright 2019, American Chemical Society). Their extraction is usually associated with a protein deconstruction into lower structural order, e.g., from tertiary to secondary. b) Valuable protein fraction such as collagen, gelatin, milk whey, and keratin can be obtained from animal‐based FLW, while soy whey and zein can be extracted from crop‐derived FLW. c) Such proteins can be used to obtain advanced materials such as c1) gelatin‐based wearable tactile sensors to monitor physiological signals or physical motions (Adapted with permission.[ 357 ] Copyright 2020, John Wiley & Sons) and c2) soy whey‐loaded microcapsules (orange spheres) incorporated into PLA to introduce self‐healing properties (Adapted with permission.[ 358 ] Copyright 2016, John Wiley & Sons).

Collagen, as one of the main components in the extracellular matrix of mammalians, can be used in biomedical applications, such as in scaffolds for bone tissue engineering.[ 366 ] As collagen can be processed into flexible and transparent films, it is also a promising substrate for electronics, such as artificial synaptic devices.[ 367 ] Gelatin offers temperature‐sensitive and reversible gelation behavior, explaining its application in food, but also in inks for additive manufacturing. In particular, a UV‐crosslinkable gelatin methacrylate is widely used to prepare hydrogels for medical applications,[ 368 ] but can be also used as a substrate for tactile sensors in medical wearables (Figure 5c1).[ 357 ] The processing of biopolymers and their promise in emerging applications are further discussed in Sections 5 and 6, respectively.

Soy and Milk Whey Proteins

Efforts have been devoted to replace collagen and gelatin with plant‐derived proteins, such as soy whey or soy protein isolates (SPI),[ 369 , 370 ] as well as with whey proteins from the dairy industry.[ 371 ] Soybean protein represents a valuable alternative to animal counterparts, as it is one of the main components in waste from soy industries,[ 372 ] amounting to 40 Mt per year.[ 373 ] Soybean proteins have been isolated from waste liquors via acid extraction.[ 374 ] These liquors contain also mono‐ and oligosaccharides as well as other non‐proteinaceous components, which are separated from by ultrafiltration. Isolation of valuable soy protein fractions increases the sustainability and efficiency of the processing plants.

Soy whey accumulates in the aqueous waste of tofu production and is usually disposed in the sewage, polluting water bodies.[ 293 ] The recovery of proteins from soybean wastewaters is key to further improve the efficiency and competitiveness of soybean products and reducing water pollution and ecological footprint.[ 375 , 376 ] Whey can be also generated as animal FLW from the dairy industry. Similar to the soybean industry, whey wastewater from dairy streams is currently disposed in sewage, fields, or used as animal feed, which is associated with high costs, but also environmental concerns due to pollution of water bodies.[ 371 , 377 ] Besides the suggested application as food additives, these protein fractions are suitable precursors for high value‐added materials. Taking advantage of its biodegradability, biocompatibility, and film‐forming capability, milk whey has been used in coatings and films for food packaging,[ 378 ] as well as in advanced drug delivery systems.[ 379 ] Soy whey is commonly used for materials applications and has excellent water‐binding capability, which makes it suitable for wound dressings.[ 380 ] Due to their amphiphilic properties, they can stabilize emulsions and act as active components in resins, given their chemical reactivity, enabling the production of reactive microcapsules in self‐healing PLA composites (Figure 5c2).[ 358 ] The reader is referred to Section 6 to gain further insights about applications in bioplastics.

Other Proteins

FLW are sources of a variety of additional proteins that are used in materials manufacturing. Other than those previously addressed, keratin and zein are relevant proteinaceous biopolymers extracted from FLW by solubilization. Zein is a prolamine that is abundant in corn and contains large amounts of hydrophobic amino acids. For this reason, it is insoluble in pure water but it has been isolated by using mixtures of water and aliphatic alcohols, including ethanol.[ 381 ] Although zein is the main storage protein in corn, it occurs exclusively in the edible endosperm; hence, its application in materials competes with food options. The water insolubility of zein makes it useful in moisture‐resistant bioplastics, such as water‐barrier packaging, coatings, capsules, and pouches. Examples of FLW serving as protein sources include dry milled corn, corn gluten meal, and distiller's dried grains with solubles.[ 382 ]

Keratin is a fibrous protein present in epithelial cells of mammals, birds, and reptiles. Abundant keratinaceous FLW particularly those derived from butchery, including swine and bovine hair, as well as poultry feathers. The latter represents ≈24 wt% of the produced poultry meat, in which the feather waste alone accounts for 3.1 Mt annually in the European Union.[ 383 ] Chicken feathers (containing 90–92 wt% keratin) have been used to extract keratin and to further assembly solid‐state materials, such as fibers,[ 176 ] 3D cryogels,[ 384 ] and nanocomposite films.[ 385 ] Like cellulose and chitin, keratin plays a role as a structural element, enabled by the tightly packed 3D network formed by disulfide bonds among cysteine residues, which render keratin sources quite recalcitrant. Keratin extraction from FLW, particularly chicken feathers, have involved a) combined pretreatments with sodium bisulfite, sodium hydroxide, and heat (87 °C),[ 386 ] or b) processing with urea, sodium dodecyl sulfate, and cysteine at 70 °C and pH 10.5, to facilitate keratin dissolution by full cleavage of the original disulfide bonds.[ 176 ] These procedures lead to protein yields in the range of 65–67 wt%.

3.3. Bioplastic Building Blocks via Synthetic Routes

In this section, FLW are presented as sources of monomers for polymerization into bioplastics. Albeit these polymers do not occur naturally, they are classified as carbon sinks. This particularly applies to durable bioplastics, suitable for long‐term applications, and synthesized from biorenewables. Regardless, even if not classified as carbon sinks, these biopolymers fit the circular bioeconomy framework and present a number of advantages compared to fossil feedstock‐derived counterparts.[ 387 ] Note that even if originated from readily available, renewable monomers, a bioplastic is not necessarily biodegradable. Biobased and biodegradable features are interchangeably used, which is a mistake. Moreover, “green” labels should be used appropriately, because polymerization processes may not be as clean as the production or isolation of the precursor monomers.[ 388 ]

Although varying remarkably in composition, agricultural waste is in general dominated by organic compounds, including film‐forming carbohydrates, proteins, and lipids. Biopolymers may be directly extracted or produced from breaking down waste components into mono/oligosaccharides, amino acids, and fatty acids/glycerol. These small molecules, in turn, can serve as precursors for the synthesis of macromolecules, after chemical modification, or after biotechnological conversion into any polymerizable monomer. While the topic used of polymerization reactions is outside the scope of this review, the next subsections focus on FLW‐derived monomeric precursors used for polymer synthesis.

3.3.1. Monomers Directly Isolated from FLW

Molecules isolated from FLW that serve as monomers for the polymerization of bioplastic‐forming polymers, without chemical conversion, are somewhat uncommon and include terpenes and fatty acids. Biomass‐derived monoterpenes (e.g., α‐pinene and limonene) have been extensively exploited for bioplastic synthesis.[ 389 ] As far as food sources, d‐limonene (4‐isopropenyl‐1‐methylcyclohexene) stands out as a by‐product of citrus peels and with the limonene enantiomer representing a surplus biomass, accounting for 3 wt%[ 390 ] of the generated citrus peel waste. d‐Limonene has been exploited as a polymerizable monomer to produce, via plasma polymerization, optically transparent thin films with smooth surfaces (Figure 6 ).[ 391 ] Even if d‐limonene meets the bifunctionality criterion needed for polymerization via its double bonds, free‐radical homopolymerization is prevented by the relatively high stability and steric hindrance of the formed allylic radical.[ 392 ] Related bioplastics are hence more commonly produced from polymerizable limonene oxide (LO), limonene dioxide (LDO), and limonene dicarbonate (LDC), as addressed in Section 3.3.2.

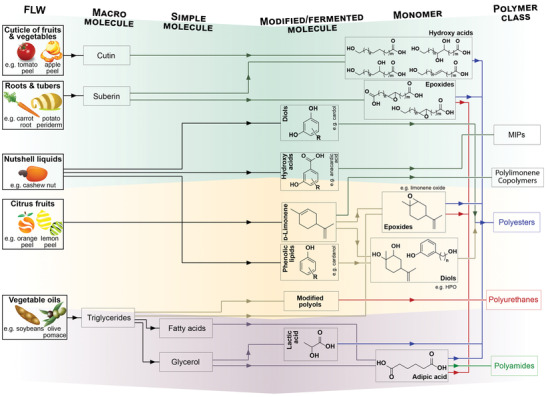

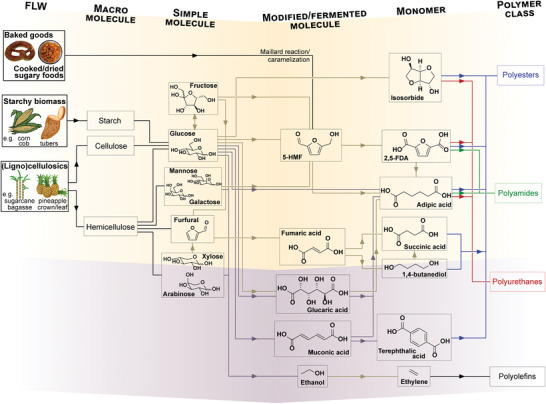

Figure 6.

Synthetic routes to produce bioplastic‐forming polymers can use monomers directly isolated (green background and related pathways), chemically modified (orange background and pathways), or produced by fermentation (purple background and pathways) of nonsugary FLW.

Cutin, a component of plant cuticles and an important by‐product of the tomato industry, is also found in the periderm of pepper, apple, watermelon as well as in leaves.[ 393 ] Cutin is a biopolyester consisting of esterified bi‐ and trifunctional fatty acids. Its monomers can be extracted by alkaline hydrolysis, using, for example, potassium methanolate[ 394 ] and particularly 10,16‐dihydroxyhexadecanoic acid (10,16‐DHPA) from agroresidual tomato waste and other naturally occurring fatty polyhydroxyacids. As such, they have been polymerized into aliphatic polyesters.[ 395 , 396 ] A polyaleurate was synthesized using 9,10,16‐trihydroxyhexadecanoic (aleuritic) acid as a monomer.[ 397 ] Suberin, a biopolyester analogous to cutin, is found in the organs (e.g., roots and tubers) and periderm layers (e.g., cork and bark) of vascular plants. Despite being of lower occurrence in FLW, at least when compared to cutin, suberin has been depolymerized by ester cleavage (i.e., hydrolysis, trans‐esterification, or reductive cleavage) into a complex mixture of aliphatic alcohols, (ω‐hydroxy)fatty acids, α,ω‐dicarboxylic acids, and aromatics. Some of these molecules serve as monomers for the polymerization of polyurethanes and polyesters.[ 398 , 399 , 400 ] Biopolyols derived from olive stones (an abundant by‐product of the olive oil industry) have been demonstrated as macromonomers for polyurethanes and polyesters upon oxypropylation,[ 401 ] similarly to what has been shown for sugar beet pulp[ 402 , 403 ] to produce (poly)urethanes.[ 404 ]

Finally, cardol and anacardic acid, derived from cashew nutshell liquid (CNSL), can be polymerized without chemical modification,[ 405 ] though in the presence of co‐monomers. We note that, contrary to the case of the molecules introduced in this section, most of the industrially relevant monomers deriving from FLW are polymerized after chemical modification.

3.3.2. Monomers Obtained from Chemical Modification of FLW

Some molecules isolated from FLW are polymerized only at low yields or cannot be polymerized at all, unless chemically modified. Here we introduce this latter case. As discussed previously, CNSL, the pericarp fluid in cashew nuts, is a major loss from the cashew industry and accounts for ≈20 wt% of the raw cashew nut, comprising typically 10–65% of cardanol, up to 65% of anacardic acid, and 15–20% of cardol, depending chiefly on the extraction method (Figure 6, where R stands for a hydrocarbon chain, with 15 carbons, either saturated or unsaturated).[ 405 ] In the context of polymer‐based systems, CSNL has found use as surfactants, in linings, paints, adhesives, and laminates.[ 405 ] Cardol has been co‐polymerized as such into polyesters using 8‐(3‐hydroxyphenyl) octanol (HPO), which can be produced from cardanol.[ 405 ] The literature on the polymerization of unmodified CNSL‐derived monomers is rather scarce. For polyurethane production, specifically, CNSL‐derived cardanol has been converted into polymerizable diols by reaction with aminophenol.[ 406 ] Finally, anacardic acid isolated from CNSL as well as its acrylate (anacardanyl acrylate) and methacrylate (anacardanyl methacrylate) are derivatives that serve as comonomers for radical polymerization in the presence of ethylene glycol dimethacrylate or divinylbenzene, for instance, to produce molecularly imprinted polymer structures.[ 407 ] This is another example of the polymerization of unmodified FLW‐derived molecules, but is not as efficient as the radical polymerization of d‐limonene.

The olefin groups in d‐limonene can be chemically processed into more reactive monomers, most commonly the epoxide, limonene oxide, or limonene diols.[ 408 ] Sustainable pathways toward novel limonene hydroxy‐acids have also been recently established.[ 409 ] These reactive limonene derivatives can be polymerized into polycarbonates, polyurethanes, and polyesters, as reviewed in the literature.[ 408 , 409 ] An advantage of limonene oxides is that resulting polycarbonates can be obtained via ring‐opening copolymerization with CO2, which may also originate from FLW. Thereby the polymerization process can be fully integrated into processes that include CO2 generation from waste streams.[ 408 , 410 ] CO2 itself can be also converted into a range of polymerizable organic monomers (e.g., carbonates, carbamates, and ureas) or copolymerized with other FLW‐derived comonomers into polycarbonates, polyurethanes, polyureas, and polyesters.[ 410 ]

Lignocellulosic biomass has been introduced as source of biocolloids (Section 3.1) and as precursor of soluble biopolymers (Section 3.2). These macromolecular building blocks can be converted into polymerizable monomers, e.g., upon hydrolytic degradation followed by fermentation (see Section 3.3.3) and/or chemical modification. Fructose, glucose, and other hexoses, such as galactose and mannose, give rise to an important platform chemical, namely, 5‐hydroxymethylfurfural (5‐HMF), through isomerization and dehydration reactions.[ 411 ] In the context of bioplastics, 5‐HMF can be converted into 2,5‐furan dicarboxylic acid (2,5‐FDA), a “drop‐in” replacement of terephthalic and isophthalic acids for the syntheses of polyesters such as PET, polyamides, and polyurethanes, being considered as one of the main sleeping giants that are envisaged for the next‐generation bioplastics.[ 412 ] 5‐HMF can react into adipic acid for polymerization into polyamides (e.g., Nylon‐6,6), polyester, or polyurethane resins, and can plasticize polyvinyl chloride (PVC) and polyvinyl butyral (PVB).[ 413 ] Adipic acid can be also produced directly from glucose via glucaric acid as an intermediate[ 413 ] or microbial fermentation (Section 3.3.3).

Furfural is another important platform chemical derived from lignocellulosics, particularly hemicelluloses. When oxidized, furfural leads to fumaric acid, which in turn can be hydrogenated to succinic acid or further into 1,4‐butanediol, both used as polyester monomers either via transesterification or polycondensation. This route to synthesize polyesters has been demonstrated using corn cob and other FLW, producing poly(butylene succinate), and poly(butylene terephthalate) (PBT), if polymerized in combination with terephthalic acid.[ 414 ] As mentioned earlier, terephthalic acid can be replaced by bio‐based 2,5‐FDA or produced directly from FLW‐derived muconic acid.