Abstract

Poly(glycerol sebacate) (PGS) continues to attract attention for biomedical applications owing to its favorable combination of properties. Conventionally polymerized by a two‐step polycondensation of glycerol and sebacic acid, variations of synthesis parameters, reactant concentrations or by specific chemical modifications, PGS materials can be obtained exhibiting a wide range of physicochemical, mechanical, and morphological properties for a variety of applications. PGS has been extensively used in tissue engineering (TE) of cardiovascular, nerve, cartilage, bone and corneal tissues. Applications of PGS based materials in drug delivery systems and wound healing are also well documented. Research and development in the field of PGS continue to progress, involving mainly the synthesis of modified structures using copolymers, hybrid, and composite materials. Moreover, the production of self‐healing and electroactive materials has been introduced recently. After almost 20 years of research on PGS, previous publications have outlined its synthesis, modification, properties, and biomedical applications, however, a review paper covering the most recent developments in the field is lacking. The present review thus covers comprehensively literature of the last five years on PGS‐based biomaterials and devices focusing on advanced modifications of PGS for applications in medicine and highlighting notable advances of PGS based systems in TE and drug delivery.

Keywords: biodegradable polyester, bioelectronics, biomedical applications, composites, poly(glycerol sebacate), tissue engineering

The present review paper covers comprehensively the published literature of the last 5 years on poly (glycerol sebacate) (PGS)‐based biomaterials including advanced preparation and processing techniques. It focuses on the ongoing modification of PGS for medical applications and its remarkable developments in tissue engineering and drug delivery applications.

1. Introduction

Among a large number of different polymeric biomaterials, poly (glycerol sebacate) (PGS) has been applied in versatile applications in recent years (Figure 1 ).[ 1 ] Since 2002 when, for the first time, the synthesis of PGS as a tough biodegradable polyester was reported by Wang et al.,[ 2 ] it became increasingly attractive for tissue engineering (TE) due to its straightforward and controllable production. The synthesis can be performed under appropriate conditions with specific reaction times and temperatures resulting in extraordinary properties.[ 3 ] All methods for the synthesis of PGS are based on the polycondensation reaction of glycerol and sebacic acid leading to a covalently cross‐linked, 3D network of random coils with hydroxyl groups attached to the backbone.[ 2 ] Both precursors used in synthesizing PGS are natural components found in the body; glycerol, the basic building block for lipids, and sebacic acid, a natural metabolic intermediate in ω‐oxidation of medium‐ to long‐chain fatty acids.[ 2 , 4 ] The synthesis parameters enable a tunable degree of esterification, which, in turn, determine the chemical and mechanical properties and the degradation behavior of this polymer. Thus, PGS is a flexible elastomer with a nonlinear stress–strain behavior, which can almost completely recover from large deformations, due to cross‐linking and hydrogen bonding interactions between the hydroxyl groups.[ 2 , 4 , 5 ] Also, shape‐memory properties were observed for this polymer.[ 6 ] These outstanding mechanical properties can be designed and customized by adjustments of the molar ratio of glycerol and sebacic acid, reaction temperature and reaction time.[ 7 , 8 , 9 , 10 ] In in vivo as well as in vitro applications, PGS is a bioresorbable material that under hydrolytic cleavage of ester linkages, loses slowly the mechanical strength relative to mass loss.[ 2 , 11 , 12 ] In‐vitro, dense PGS disks subjected to 2 d of cross‐linking at 120 °C and 40 m torr were found to be degraded by 17 ± 6% after immersion in phosphate buffered saline (PBS) solution at 37 °C for 60 d.[ 2 ] In comparison to in vitro conditions in the absence of enzymes, the degradation rate is accelerated in vivo by enzymes, altering the polymer structure catalyzing the hydrolysis reaction in ester group‐containing polymers like PGS.[ 13 ] When implanted in Sprague–Dawley rats subcutaneously, the same PGS samples were entirely degraded after 60 d.[ 2 ]

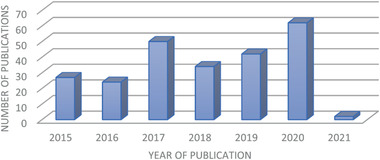

Figure 1.

Number of published articles of PGS‐based materials during 2015 and the beginning of 2021. Data from WEB OF SCIENCE using POLY (GLYCEROL SEBACATE) in the field “topic” from 2015 to 2021.

A further advantage of PGS, compared to other frequently used polymers in TE such as poly(ɛ‐caprolactone) (PCL), poly(lactic‐co‐glycolic acid) PLGA and poly(glycolic acid) PGA is the ability to tune its mechanical properties, especially stiffness, by introducing simple changes to the polymerization and curing procedures. For example, Young's moduli of PGS are reported in the 0.77–1.9 MPa range when solely the curing time is changed and values ranging from 0.01 to 5 MPa are reported when the monomer stoichiometry of PGS is altered, respectively.[ 14 ] In comparison, PCL, PGA, and PLGA exhibit less adjustable stiffness values of approximately 0.2–0.3 MPa, ≈7 GPa and 1.4–2.8 MPa, respectively.[ 15 ] In addition to the elastic modulus, the ultimate tensile strength (UTS) and elongation at break of PGS can also be controlled in wide ranges by varying the process parameters. PGS exhibits UTS values of above 5 MPa and an elongation higher than 267%.[ 15 ] In comparison, values of PLGA, PGA and PCL range from 41 to 55 MPa and 3–10%, 70 MPa and below 3% and 21 MPa and 300–500%, respectively.[ 15 ] Thus, a wide range of properties can be covered using PGS, which is relevant to support the wider applications of this polymer in the biomedical field.

PGS is nonimmunogenic, and it was shown to be noncytotoxic in vitro and provoked only a minimal inflammatory response with little fibrous capsule formation in vivo.[ 2 , 16 ] Due to its tailorable mechanical properties and degradation behavior, aiming to fulfil criteria for a particular application, PGS won its place as a relevant scaffold material, especially for the regeneration of soft tissue like the myocardium, blood vessels, cornea, and nerve tissue.[ 1 , 4 , 16 , 17 ] Over the years, PGS‐based biomaterials have been increasingly investigated for drug delivery and TE applications such as cardiac and cardiovascular,[ 18 ] skin and wound healing,[ 19 ] nerve,[ 20 ] corneal and oral tissues,[ 16 ] musculoskeletal,[ 21 ] adipose,[ 22 ] cartilage,[ 23 ] dental and bone as well as for soft bioelectronic applications.[ 24 , 25 , 229 ]

Since biomedical applications of PGS with advancing technological developments, e.g., novel fabrication techniques and PGS modifications are continuously growing, this review aims to consolidate the existing knowledge of the past five years following previous reviews on PGS‐based materials for biomedical applications published in 2012[ 4 ] and later in 2015.[ 26 ] This article focuses on recent modification techniques of PGS and fabrication techniques for PGS‐based biomaterials. Furthermore, latest advances in the main application fields of PGS‐based biomaterials, i.e., cardiac TE (CTE), vascular TE, nerve TE, skin and wound healing TE, bone TE (BTE), and drug delivery, will be closely presented. This article seeks to give a concise overview of the recent developments in the broad field of PGS‐based materials.

The literature search for this review article was conducted in the databases WEB OF SCIENCE as well as SCOPUS using the keyword POLY(GLYCEROL SEBACATE) or POLY GLYCEROL SEBACATE in the field “topic” search box. In the time range from 2015 to 2021, about 241 papers were published (Figure 1).

2. Modification of PGS

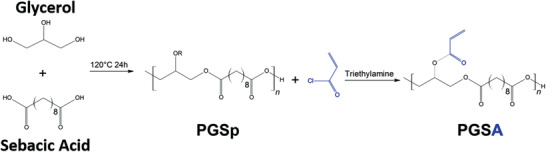

Conventionally, PGS follows a two‐step synthesis route via prepolycondensation and cross‐linking.[ 2 , 4 , 27 ] Briefly, prepolycondensed PGS (PGSp) is synthesized by a polycondensation reaction of an equimolar mixture, typically, of glycerol and sebacic acid at 120 °C under a nitrogen or argon atmosphere for 24 h (Figure 2 ). For a subsequent cross‐linking step during the conventional synthesis of PGS, PGSp is kept in a vacuum for at least 48 h at 120 °C. With a kinetic model of the polycondensation of sebacic acid and glycerol created by Matyszczak et al.[ 5 ] a prediction and optimization of the synthesis reaction are possible. The model is used to determine the moment of the desired reaction at which desired product parameters like average molecular weight and polydispersity can be achieved. Perin and Felisberti[ 28 ] on the other hand, developed an alternative polymerization technique for PGS using Candida antarctica lipase B (CALB) as a catalyst for the polycondensation of glycerol and sebacic acid, allowing them to synthesize PGS in acetone at temperatures between 30 and 50 °C with different molecular weights and degrees of branching.[ 28 ] However, due to the harsh cross‐linking conditions (≥120 °C, vacuum) and relatively long reaction times (≥24 h) required for its curing, pure, unmodified PGS exhibits a lack of processability.[ 27 ] Alternative processing strategies are required to address these limitations, mostly achieved by blending PGS prepolymer with other materials or by chemical modification of its pre‐condensed form (Figure 2).

Figure 2.

Chemical modification of PGS through introducing reactive moieties (Route A) or block copolymers (Route B).

2.1. Blending of PGS with Other Biopolymers

The processing of thermoset polymers like PGS is typically limited to simple reproduction techniques due to the subsequent required harsh cross‐linking, making it challenging to fabricate complex 3D architectures. A simple way of improving the processability of PGSp is by blending it with other materials.[ 29 , 30 ]

The key is to design compositions containing both the thermoplastic precursors of the thermoset PGS and a sacrificial or non‐sacrificial carrier material, respectively, which serves as an aggregate to provide mechanical support, helping to retain the desired 3D shape before and during cross‐linking.[ 31 ]

So far, blending of PGS with other polymers was mainly conducted to produce suitable solutions for electrospinning. Indeed, neat PGSp exhibits difficulties for electrospinning due to its low viscosity in a solution for example, in common electrospinning solvents like chloroform (CF): ethanol mixtures.[ 32 ] A well‐investigated method to address this problem is to mix PGS prepolymer with PCL.[ 17 , 29 , 33 , 34 ] PCL is a highly used thermoplastic polymer in TE. It is approved by the Food and Drug Administration (FDA), biocompatible, and exhibits a long‐term biodegradability with high stiffness.[ 37 ] For blending PGSp with PCL, both polymers are dissolved in a solvent, mostly tetrahydrofuran (THF) or a CF/ethanol mixture, with varying weight ratios.[ 38 ] After stirring the mixture for a certain amount of time, the solution is either processed directly, as in the case of solution‐electrospinning or used after the solvent has been removed. Mixing PGSp with PCL produces stable scaffolds, which do not need any further post‐processing, such as thermal curing or photo‐cross‐linking. Variation of the ratio of PGS and PCL in the blended solution showed it could alter the mechanical properties of the blend, degradation rate and hydrophilicity of the structure. Studies have shown that increasing the concentration of PGS enhanced the degradation rate and hydrophilicity of PCL and lowered the stiffness of PCL while PCL‐PGS electrospun fibers with 3:1 ratio (PCL: PGS), showed three times lower storage modulus (0.6 MPa) than that of PCL fibers (1.9 MPa).[ 29 , 30 ]

Besides PCL, thermoplastic polyurethane (TPU) has also been used to gain a suitable electrospinnability of PGSp.[ 35 ] TPU pellets and PGSp with polymer ratios of 6:6, 6:4, and 6:2 have been dissolved in a 6:4 CF and N,N‐dimethylformamide (DMF) solution. The concentration of TPU was kept constant at 6% (w/v). In the reported study, either 1,1,1,3,3,3‐hexafluoroisopropanol (HFIP) alone or a binary solvent of 2,2,2‐trifluoroethanol (TFE) with acetic acid in a ratio of 5:5 could serve as a solvent system for TPU/PGSp.[ 35 ]

As an alternative to electrospinning, O'Brien et al. used the electro‐less Substrate Translation and Rotation for Aligned Nanofiber Deposition (STRAND) process.[ 36 ] In order to perform the STRAND process with PGS, the biocompatible polymer polyethene oxide (PEO) was added to act as a strengthening agent. Molar ratios of 1:1, 2:1, and 1:2 of PGS: PEO, ranging from 10 to 25% (w/v), were dissolved in a 1:1 CF: ethanol solution. Several concentrations were tested regarding their effect on fiber diameter and morphology.[ 36 ]

2.2. PGS‐Based Composites with Inorganic Fillers

Apart from blending PGSp with different polymers, another frequently used method is the incorporation of inorganic particles into precondensed PGS to produce composite scaffolds or structures with tailored properties for various TE applications.[ 39 , 40 , 41 , 42 , 43 , 44 , 45 ] The most conventional approach is the combination of PGSp with sodium chloride (NaCl) particles. In this so‐called salt leaching technique, molten PGS prepolymer is mixed with salt particles acting as a sacrificial carrier material, which is then removed after cross‐linking to develop porous PGS structures. By adjusting the weight ratio of PGSp:NaCl, different microporous architectures can be achieved. At weight ratios of 1:2 or 1:3 (PGSp:NaCl), sodium salt granules provided adequate mechanical support and shape retention during the harsh cross‐linking conditions of PGS. Moreover, it was shown that this mixture was suitable for 3D printing applications.[ 31 ] In addition to NaCl, various other particulate materials have been incorporated into PGS as a matrix mainly to control the mechanical properties and the degradation susceptibility of pure PGS. From these particle fillers directly added to the PGS as a matrix, few to name are, i.e., bioactive glass (BG),[ 46 ] silica,[ 47 ] β‐tricalcium phosphate (TCP),[ 48 , 49 , 50 , 51 ] cellulose nanocrystals,[ 52 ] and those added to PGS as a fiber are, i.e., silk fibroin,[ 53 ] chitosan (CH),[ 53 , 54 , 55 ] or BG fibers.[ 42 ]

2.3. Chemical Modification

Chemical modification of PGS is generally undertaken to alter its chemical, mechanical, and degradation properties in order to adapt them closer to the specific target application. Modified PGS is more flexible regarding its cross‐linking conditions without the need of further processing of high temperature or in a vacuum, making it more suitable for a variety of applications. The synthetic strategies can be separated into two main modification routes (Figure 2). Route A describes the introduction of reactive moieties into the PGS matrix, whereas route B focuses on the block copolymerization of PGS with other linear polymers.

2.3.1. Introduction of Reactive Moieties (Route A)

The most widely used modification of PGS, especially for additive manufacturing, is its acrylation or methacrylation.

Nijst et al. reported a photopolymerization approach by chemically modifying the PGS prepolymer by introducing reactive acrylate moieties.[ 27 ] Briefly, PGS prepolymer with anhydrous dichloromethane (DCM) and 4‐(dimethylamino) pyridine (DMAP) was cooled in a reaction flask to 0 °C under nitrogen atmosphere. Acryloyl chloride was then slowly added parallel to an equimolar amount of trimethylamine (Figure 3 ). After reaching room temperature, the mixture was stirred for an additional 24 h. The resulting mixture was dissolved in ethyl acetate, filtered, and dried at 45 °C in a vacuum (5 Pa).[ 27 ] Vinyl bonds in poly (glycerol sebacate) acrylate (PGSA) could be subsequently cross‐linked via redox polymerization or photoinitiated free radical polymerization via ultraviolet (UV) radiation in the presence of a photoinitiator, mostly 2‐dimethoxy‐2‐phenyl acetophenone.[ 27 ] Via photopolymerization, the PGSA cured rapidly within a few minutes, which is more efficient than the previous long curing time (48h) reported in the conventional synthesis process.[ 2 ]

Figure 3.

Schematic representation of the chemical synthesis of PGSp and its further modification using trimethylamine to produce acrylated PGS (PGSA). Modified from.[ 27 ]

An alternative approach to introduce reactive moieties besides acryloyl chloride into the PGSp network was proposed by Wu et al.:[ 57 ] 2‐ureido‐4[1H]‐pyrimidone‐hexamethylene diisocyanate (UPy‐HDI) was used to generate chemically cross‐linked supramolecular PGS (PGS‐U). In this process, PGS prepolymer dissolved in THF and HDI were mixed and after reacting for 4 h at 55 °C under a nitrogen atmosphere and evaporation of the solvent, a PGS‐U polymer film formed via strong non‐covalently hydrogen bonding.[ 57 ]

Yeh et al. designed an alternative method to produce photocurable PGS using thiolene click chemistry to control PGS cross‐linking. In short, PGS prepolymer was dissolved in anhydrous DCM containing 500 ppm 4‐methoxy phenol and 0.1 wt% DMAP. The reaction flask was purged with nitrogen for 10 min at 0 °C. 5‐Norbornene‐2‐carbonyl chloride in DCM was added dropwise into the PGS solution parallel to triethylamine, which was subsequently stirred at room temperature overnight. After several filtration and drying steps, the remaining DCM was removed using a rotary evaporator leaving a viscous liquid, which was further dried in an oven at 37 °C overnight, purged with nitrogen afterwards, and then stored at −20 °C. Norbornene modification of PGS (Nor‐PGS) was ≈15% (calculated based on nuclear magnetic resonance (NMR) analysis) with a yield of Nor‐PGS of ≈96%.[ 58 ] Norbornene modification on NorP‐GS and therefore its cross‐linking could also be altered by changing the initial amount of PGSp. Tsai et al.[ 59 ] further modified the Nor‐PGS approach by copolymerizing Nor‐PGS with polyethylene glycol (PEG). As a result, NorPGS‐co‐PEG could be controlled in its mechanical and degradation properties as well as in vitro swelling behavior.[ 59 ]

In general, by controlling the percentage of reactive moieties, like acryloyl chloride, UPy‐HDI, or norbornene in PGS, it is also possible to control mechanical as well as hydrolysis and in vitro enzymatic degradation profiles of the modified PGS to meet specific requirements for various applications.[ 4 , 56 , 57 , 60 , 61 ]

2.3.2. Introduction of Block Copolymers (Route B)

The most common method to alter cross‐linking densities of polymers is to change the molecular weights of their precondensed form. However, this could lead in some polymers to physical entanglements and chain extension when cross‐linked via radical polymerization, limiting their applications in further processing steps.[ 62 ]

An alternative approach is a polycondensation of PGSp with linear polymers (Figure 2 Route B), such as PCL[ 63 ] and PEG[ 62 , 64 , 65 , 66 , 67 ] and their acrylated forms, poly(ethylene glycol) methyl ether methacrylate (PEGMEMA),[ 68 ] poly(tetramethylene oxide) glycol (PTMO),[ 69 ] or simply with gelatin.[ 70 ]

Briefly, precondensed PGS could be added via a two‐step polycondensation approach. In the first step, segments of the linear modifier polymer and sebacic acid are polymerized. Addition of glycerol leads to a polycondensation of PGS, whereby parts of sebacic acid combine with the linear polymer (Figure 2 Route B).[ 64 , 65 , 66 , 67 ] Through altering the modifier polymer content and the ratio of sebacic acid to glycerol, a series of PGS‐co‐polymers can be designed and synthesized.

Wilson et al. investigated the copolymerization of PTMO with PGS. They either synthesized PGS with PTMO or mixed PGS‐co‐PTMO with the thermoplastic polyester elastomer Hytrel 3078.[ 69 ] A two‐step polymerization resulted in the copolymer PGS‐b‐PTMO. In the first step, sebacic acid‐co‐PTMO (SA‐co‐PTMO) was synthesized in molar ratios of 1:0.65/0.75/0.85 with 0.5 wt% of FASCAT 9100 (mono‐n‐butyl tin oxide or butylstannoic acid) as a catalyst. The educts were molten and reacted under reduced vacuum for 8 h at 150 °C. In the second step, glycerol (0.35/0.25/0.15 mol) was added and reacted for another 8 h at 135 °C. Cross‐linking of PGS‐b‐PTMO was carried out using 2 wt% (for glycerol) of 4,4′‐methylene bis (phenyl isocyanate) (MDI). PGS‐b‐PTMO and MDI were then dissolved in CF and stirred for 4 to 5 h. The solution was kept in a fume hood for 12 h to evaporate the solvent and subsequently cross‐linked in a vacuum oven at 170 °C under reduced vacuum for 8 h.[ 69 ]

In the case of gelatin as a modifying polymer, copolymerization is realized via an endothermic reaction step of PGSp and gelatin without the need of any cross‐linking agent. In this manner, gelatin is introduced in the PGSp network via ester and amide linkages rather than extending the polymer network chains.[ 70 ] Therefore, elastomeric properties, water swelling capability, as well as pH‐responsive behaviors of the two distinct materials are maintained.[ 70 ]

Rostamian et al.[ 63 ] demonstrated the successful incorporation of hydroxyapatite nanoparticles in PGS‐co‐PCL, which was synthesized by melt polycondensation. The authors found a beneficial effect of the addition of caprolactone section in PGS‐co‐PCL regarding its viscoelastic properties and wettability. The incorporation of hydroxyapatite nanoparticles enhanced a potential application in BTE.[ 63 ]

3. Fabrication Techniques for PGS‐Based Biomaterials

Since PGS prepolymer can be either melted or dissolved in several solvents including THF, HFIP, DCM, DMF, CF, ethanol, methanol, acetic acid, and formic acid, its processing is relatively uncomplicated and many different fabrication techniques can be used. The fabrication technique has to be chosen according to the target application and specifically the required morphology, e.g., whether a strong solid sheet, macro‐ or microporous membranes or structures with/without anisotropic behavior or injectable scaffolds are desired. Popular fabrication techniques for PGS‐based components are presented in the following sections (Figure 4 ).

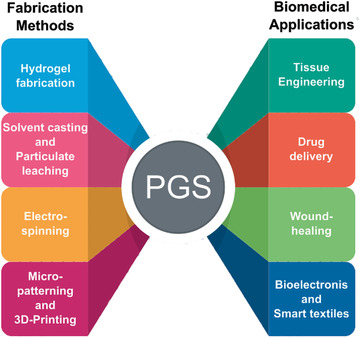

Figure 4.

Representative manufacturing methods and biomedical applications with PGS as the primary material. (Figure generated using Freepik.com).

3.1. Solvent Casting/Particulate Leaching

Solvent casting/particulate leaching is a technique used to produce either dense films or porous membranes. It is a simple, reproducible method, which does not require sophisticated lab equipment. The pore size, porosity, and geometry can be easily controlled by the amount, size, and shape of the porogen, e.g., salt particles.[ 71 ] However, this method requires long soaking periods in water to leach all porogens from the membrane, which limits the applications such as drug loading/delivery. Moreover, limited interconnectivity of the pores in the structure affects the mechanical properties and residues of the salt particles or solvents can influence the biocompatibility of the resulted scaffolds.[ 71 ]

Pure PGS,[ 72 , 73 ] modified[ 64 , 74 , 75 , 76 , 77 , 78 , 79 ] (see Section Modification of PGS), or combined with other materials[ 21 , 24 , 47 , 52 , 57 , 80 , 81 , 82 , 83 , 84 , 85 , 86 , 87 , 88 ] has been processed into films and porous scaffolds using the salt leaching method. Initially, this technique was used to develop PGS‐based cardiac patches.[ 8 , 89 ] Since then, its application field changed to mainly hard TE. For the application in BTE, inorganic fillers like BG[ 47 ] and nanosilicates[ 24 , 83 ] have been applied to enhance the mechanical properties of the PGS network by improving its stiffness without affecting the elastomeric properties. The in vitro degradation rate of PGS composites has been shown to be tunable by the addition of inorganic fillers. In the case of using nanohydroxyapatite (nHA) as a reinforcement,[ 82 ] the elastic modulus and tensile strength were increased, however, the flexibility of the films decreased, and the degradation rate was accelerated. PGS/nanosilicate porous scaffolds[ 83 ] supported cell adhesion, spreading, proliferation, and osteogenic differentiation, and showed in vivo biocompatibility, whereas PGS–BG composites[ 47 ] showed significantly enhanced proliferation of MC3T3 cells compared to neat PGS films. In contrast to inorganic fillers, also synthetic (e.g., polylactic acid (PLA)[ 80 ]) or natural (cellulose nanocrystals,[ 52 ] ureido‐pyrimidinone[ 57 ]) polymers or metabolic compounds like tyramine[ 84 ] have been successfully blended with PGS to improve the mechanical, hydrophilic, and degradation properties. The addition of electrically conductive compounds like carbon nanotubes,[ 88 ] aniline pentamer,[ 81 , 85 ] graphene,[ 86 ] or plasma polymerization of polypyrrole[ 90 ] has been investigated to create highly tunable conductive films with enhanced cell survival and attachment[ 86 ] and enhanced Schwann cells (SCs) myelin gene expression.[ 81 ]

3.2. Electrospinning

Electrospun fibrous meshes have attracted much attention in TE and regenerative medicine as scaffold constructs as they closely resemble the fibrous native extracellular matrix (ECM) and offer suitable structures for cell attachment and subsequent tissue organization.[ 91 , 92 ] Moreover, electrospun meshes are porous with interconnected porosity made of fibers in nano‐ to micrometer range of diameter and high surface‐to‐volume‐ratio. The fibrous structure can be spun from a variety of synthetic and natural polymers with random and aligned arrangements or core–shell structures.[ 93 , 94 ] In electrospinning briefly, a high voltage is generated between a polymeric solution (or melt) and the grounded collector and a polymeric fiber is ejected and stretched toward the collector if the voltage is sufficiently high and is able to surpass the critical voltage threshold and thereby the surface tension of the polymer solution.[ 94 ] Various parameters, like solution viscosity, processing (e.g., voltage, distance between needle and collector, flow rate) and ambient parameters (e.g., temperature, humidity) influence the electrospinning process and the resulting fiber morphology.[ 95 ]

As mentioned above, PGS itself cannot be electrospun into stable fibers due to its low solution viscosity,[ 32 ] the low glass transition temperature (below room temperature) of precondensed PGS (PGSp) as well as the insolubility of its cross‐linked form in organic solutions. As a result, electrospun fibers of PGSp have fused into a nonporous film instead of a porous fiber mat. During the subsequent high‐temperature cross‐linking, this fusion is even intensified.[ 96 ] As a result, PGSp must be blended with a spinnable carrier polymer to allow non‐destructive fiber formation by electrospinning. According to its specific application ranging from soft to hard TE also including drug delivery, synthetic polymers like PCL,[ 16 , 19 , 21 , 29 , 33 , 38 , 45 , 97 , 98 , 99 , 100 , 101 , 102 , 103 , 104 , 105 , 106 , 107 , 108 , 109 , 110 , 111 ] poly(vinyl alcohol) (PVA),[ 96 , 112 , 113 , 114 ] poly(butylene succinate‐co‐dilinoleic succinate) PBS‐DLS,[ 115 , 116 ] PLA,[ 117 ] poly(l‐lactic acid) (PLLA),[ 118 , 119 ] (PEO),[ 120 ] PLGA,[ 121 , 122 ] polyethersulfone (PSF),[ 123 ] polyhydroxybutyrate (PHB),[ 124 ] polyvinylpyrrolidone (PVP),[ 125 , 126 ] TPU,[ 35 ] and natural polymers like collagen,[ 127 ] gelatin,[ 128 ] fibrinogen,[ 129 ] zein,[ 130 , 131 ] and chitin and lignin[ 132 ] have been used for blending with PGS for successful electrospinning. Additional to blending PGS with another polymer, electrospinning of PGS within a core–shell system has been reported too where the sacrificial polymer is used as a shell which will be removed after PGS cross‐linking. Generally, PVA[ 96 , 112 , 133 ] or a combination of PEO and PLA,[ 120 , 134 ] are commonly used as sacrificial polymers. Pure PGS fiber mats show appropriate mechanical properties (for selected applications) and in vitro cytocompatibility has been proven with 3T3 fibroblasts[ 96 ] and human umbilical artery smooth muscle cells (HUASMCs).[ 112 , 120 , 133 , 134 ] Lang et al.[ 135 ] showed the synthesis of PGS by CALB catalysis, whereby different fractions of glycerol units in PGS were replaced by 1,8‐octanediol units, enabling the fabrication of fibers via electrospinning without the need of a second component.[ 135 ]

Electrospun fiber mats have been further functionalized by incorporation of inorganic particles like β‐TCP,[ 51 ] nHA,[ 100 ] or BG[ 136 ] for increased bioactivity and osteoblast adhesion properties, binding of vascular endothelial growth factor (VEGF),[ 106 , 129 ] or sputtering of electrospun membranes with silver showing excellent pathogenic antibacterial properties.[ 45 , 97 ] Moreover, biomacromolecules or drugs can be loaded in PGS‐based fibers either directly by blending drugs within the fiber material and core‐shell fibers or by covalently immobilizing the drug on the final mats.[ 98 , 99 , 124 , 128 ]

A different approach to produce PGS fibers without applying an electric field can be made using pressurized gyration.[ 137 ] Thus, the polymer solution is forced out a cylindrical aluminum drum via rapid rotation (36 000 rpm) and an applied nitrogen pressure (0.1 MPa N2).[ 137 ]

An overview of all electrospinning approaches involving PGS, which have been reported in the last five years, is shown in Table 1 .

Table 1.

Overview of PGS used in electrospinning approaches. Abbreviations: KGN, kartogenin, mAcr‐PGS, methacrylated PGS; PBS‐DLS, poly(butylene succinate‐co‐dilinoleic succinate); PBMCs, peripheral blood mononuclear cells; PMMA, poly(methyl methacrylate); PSF, polyethersulfone; PVA, poly(vinyl alcohol); AcOH, acetic acid, EtOH, ethanol, FA, formic acid; MeOH, methanol; SRB, sulforhodamine B; TFA, trifluoroacetic acid; YM, Young's modulus

| PGS in combination with | Solvents | Mechanical properties | Other specifics | Cells/animal model | Cellular response | Proposed application | Refs. |

|---|---|---|---|---|---|---|---|

| PCL | CF/EtOH |

YM: 6.3 MPa (random) ‐ 9.6 MPa (aligned) UTS: ‐ Strain: ‐ |

Aligned fibers | HUVECs | Enhanced cellular proliferation and organization by alignment; formation of highly organized endothelial constructs | Vascular TE | [ 105 ] |

| PCL, VEGF | DCM/MeOH |

YM: 8 ± 2 MPa UTS: 3 ± 0.5 MPa Strain: 142 ± 29% |

VEGF functionalization; potential for the formation of vascular tree in fiber mat | C2C12 myoblasts, rat cardiac progenitor cells, rat aortic endothelial cells | Attachment and growth of myogenic and vasculogenic cell lines | CTE | [ 106 ] |

| Sacrificial PVA, PCL | HFIP (PGS/PVA), TFE/H2O (PCL) | YM: 0.67– 0.871 MPa | Removal of PVA leaving neat PGS fibers behind | In vivo mice model | No thrombosis or stenosis; organization of contractile SMCs and neotissue in the inner part of the graft, macrophage driven‐inflammatory response to remaining polymer up to 12 months postimplantation | Vascular TE | [ 107 ] |

| PCL | DCM/MeOH | – | Patterned topography | C2C12 myoblasts, neonatal rat cardiomyocytes | Alignment of both cell types due to the surface topography | CTE | [ 110 ] |

| PCL | CF/EtOH |

YM: 4.25– 7.61 MPa UTS: 1.78– 3.14 MPa Strain: 218 – 453% |

Good anticoagulation property with low hemolysis percentage | Human vascular endothelial cell line EAhy926 | Good biocompatibility | Vascular TE | [ 111 ] |

| PCL, silver | CF/EtOH |

YM: 3.3 MPa (uncoated) –≈8 (with Ag) MPa UTS: ≈1.5 (uncoated) ‐ ≈2.6 (with Ag) MPa Strain: ≈200 (uncoated) ‐ ≈175 (with Ag) % |

Silver coating with antibacterial properties | – | – | Diverse | [ 45 ] |

| PCL | CF/EtOH | – | Aligned fibers | Human corneal epithelial cells, human corneal keratocytes | Good biocompatibility, formation of a confluent cell layer | Corneal TE | [ 38 ] |

| PCL | CF/EtOH |

Surface moduli of 0.26 GPa, 0.29 GPa, 0.12 GPa, and 0.16 GPa for PGS/PCL 4:1, 3:1, 2:1 1:1 |

Aligned fibers | Human corneal endothelial cells, human conjunctival epithelial cells, and PBMCs | Best cell organization, cyto‐ and immunocompatibility in a higher content of PGS in PGS–PCL blend | Corneal TE | [ 16 ] |

| PCL, silver | CF/EtOH | – | Silver coating with pattern | NIH 3T3 fibroblasts | Good biocompatibility | Diverse | [ 97 ] |

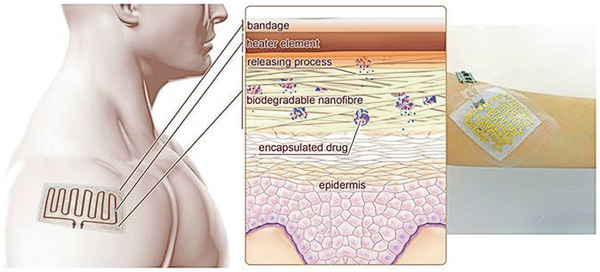

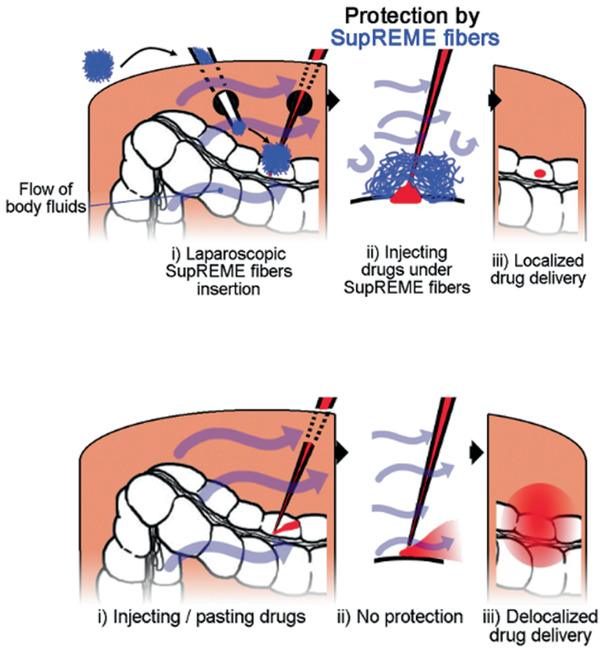

| PCL, PEGylated‐CH nanoparticles | CF/EtOH | – | Additional patterning of a bioresorbable metallic heater for thermal stimulation of on‐demand antibiotic release; antibacterial properties | Keratinocytes | Good biocompatibility | Wound healing, drug delivery | [ 19 ] |

| PCL, gelatin, dexamethasone | CF/MeOH (PGS‐PCL‐dex), AcOH/H2O (gelatin) |

YM: 6.3 (wet) ‐7.8 (dry) MPa UTS: 0.74 (dry) ‐1.64 (wet) MPa Strain: 36.8 (dry) ‐ 102 (wet) % |

Sustained drug release for 30 d | Gingival fibroblast cells | No evidence of cytotoxicity; cell proliferation not adversely affected by Dex release | Soft TE | [ 98 ] |

| PCL, heparin | TFE |

YM: ≈3 –≈15.5 MPa UTS: ≈2–≈4 MPa Strain: ≈250 –≈900% |

Heparin functionalization | HUVECs | Improved cell attachment and proliferation after grafting of heparin | Diverse | [ 99 ] |

| PCL, CH, β‐TCP | CF (PGS‐PCL‐β‐TCP), TFA (PGS‐PCL‐CH) |

YM: ‐ UTS: ≈1.1 –≈1.4 MPa Strain: ≈0.8 –≈2.4 |

Bilayered | Human fetal osteoblasts | Optimum cell behavior in blend composition with 10% β‐TCP | BTE | [ 51 ] |

| PCL, hydroxyapatite nanoparticles | d.n.a. | d.n.a. | d.n.a. | Bone marrow‐derived MSCs | Excellent biocompatibility and osteoblast adhesion | Bone and cartilage TE | [ 100 ] |

| PCL | CF/acetone (PGS‐PCL), AcOH/FA (PCL) |

YM: 2.6– 3.1 MPa UTS: 0.8– 1.5 MPa Strain: ≈58 –≈65% |

Nonhemolytic behavior | MSCs | Supported attachment, growth, and infiltration of cells by blend fiber mat | Vascular TE | [ 101 ] |

| PCL | AcOH |

YM: 7– 11 MPa UTS: 4.4– 5 MPa Strain: 304–333% |

Use of mildly cross‐linked PGS for electrospinning | Bone marrow‐derived stroma cell line ST2 | Better cytocompatibility and cell adhesion after sterilization by 70% ethanol compared to UV sterilization | CTE | [ 33 ] |

| PCL | CF/EtOH/DMF |

YM: 8.32 (dry) – 8.62 (wet) MPa UTS: ‐ Strain: 783 (dry)–1133 (wet) % |

Bilayered construct with PU membrane layer | Mouse lung fibroblast cells (L929), HUVECs | No toxic effect of leachable components on fibroblasts; endothelial cell adhesion and proliferation on PGS/PCL fiber mat | Hernia treatment | [ 104 ] |

| PCL, KGN | TFE |

YM: 5.06 (nonaligned)– 11.78 (aligned) MPa UTS: ≈2.3 (non‐aligned) –≈3 (aligned) MPa |

Aligned core–shell fibers | Human bone marrow MSC (hBMSC) | Significant proliferation and chondrogenic differentiation on KGN‐loaded aligned nanofibrous scaffold | Cartilage TE | [ 103 ] |

| Sacrificial PVA | H2O (PVA), THF (PGS) |

YM: ≈3 MPa (wet) –≈33 MPa (dry) UTS: ≈ 1.5 MPa (wet) –≈7 MPa (dry) Strain: 95 % (wet)– ≈130% (dry) |

PGS only fibers | SNL mouse fibroblasts | Good biocompatibility | Soft TE | [ 133 ] |

| Sacrificial PVA | HFIP |

YM: 0.1– 0.8 MPa UTS: ≈1 MPa Strain: 200 –800% |

PGS only fibers | 3T3 fibroblasts, Human cord blood endothelial cells (hcbEC), in vivo mice model |

Round to elongated adhered cell morphology; higher cytocompatibility of highly cross‐linked materials; In vivo: surrounded by collagen‐rich matrix and multinucleated giant cells and fibroblast‐like cells in implant bulk |

Diverse | [ 96 ] |

| PVA | DMF/H2O |

YM: 0.04 (wet)– 7.08 (dry) MPa UTS: 2 (dry)–70 (dry) MPa Strain: 34.5 (dry)–287 (wet) % |

Modified PGS synthesis (1:0.8 molar mixture of glycerol and sebacic acid; 170 °C; 3, 5, and 7 h); Aligned fibers |

Rat pheochromocytoma cells (PC12) | Good biocompatibility | Nerve TE | [ 114 ] |

| PVA, lignin | H2O, DMF |

YM: 0.1– 0.4 MPa UTS: 20.24–72.8 MPa Strain: 51– 179.5% |

– | Rat pheochromocytoma cells PC12 | Cell proliferation and neural cell differentiation in the presence of lignin | Nerve TE | [ 113 ] |

| PLLA | CF/DMF (PLLA), THF (PGS) |

YM: 6.5– 15.8 MPa UTS: 2.2– 4.5 MPa Strain: 25.1–43.4% |

Aligned core–shell fibers | – | – | Diverse | [ 118 ] |

| PLLA | DMF/DMC |

YM: 7.2– 336.2 MPa UTS: 1.1– 6.8 MPa Strain:13– 66% |

During cross‐linking creation of core (PLLA)–shell (PGS) fibers | Hypothalamus A59 nerve cells | Enhanced cell adhesion and proliferation for core–shell samples | Nerve TE | [ 119 ] |

| PLGA | HFIP (PGS), NaCl, SRB dye, HFIP (PLGA) | – | – | – | – | Diverse | [ 121 ] |

| PLGA | HFIP |

YM: 1.3 ± 0.66 MPa UTS: ‐ Strain: – |

– | SIMS salivary ductal epithelial cell, NIH3T3 mesenchymal cells | Cell penetration in the structure and apical localization of tight junction proteins; coculture facilitated epithelial tissue reorganization and significantly increased apical localization of tight junction protein | Soft TE | [ 122 ] |

| PLA | HFIP | – | Different esterification levels of PGS | – | – | Diverse | [ 117 ] |

| Sacrificial PEO/PLA | THF (PGS), THF/DMF (PEO/PLA) |

YM: ≈1– 140 MPa UTS: ≈0.5–6 MPa Strain: ≈1.05–2.5% |

PGS only fibers | HUASMCs | Good biocompatibility | Soft TE | [ 120 ] |

| Sacrificial PEO/PLA | THF (PGS), DCM/DMF (PEO‐PLA) |

YM: ≈0.5 (perpendicular) – ≈ 1 (in alignment) MPa UTS: ≈0.36 (perpendicular) –≈0.72 (in alignment) MPa Strain: ≈160 (perpendicular) – ≈ 170 (in alignment) % |

Aligned core–shell fibers | HUASMCs | Cell adhesion on random and aligned fibers, and cell alignment on aligned fibers | Diverse | [ 134 ] |

| Collagen type I, silk fibroin | HFIP |

YM: 2.3– 5.0 MPa UTS: 0.8– 1.5 MPa Strain: 30–70% |

Low thrombogenic potential | Endothelial cells | Cells adhered, proliferated, and formed cell–cell junctions | Vascular TE | [ 127 ] |

| Fibrinogen, VEGF | HFIP | – | VEGF functionalization | In vivo porcine model | Improvement in ejection fraction (EF) and prevention of LV enlargement; expression of cardiac marker proteins | CTE | [ 129 ] |

| PBS‐DLA | DCM/MeOH |

YM: 1.2– 7.5 MPa UTS: 1.58–2.7 MPa Strain: 85.5–147.6% |

– | C2C12 myoblasts, postnatal rat cardiomyocytes | Cytocompatibility with C2C12 myoblasts, the higher the PBS–DLA content in the fiber mats, the better the cell attachment and proliferation; postnatal rat cardiomyocytes better attachment on higher PGS content fibers with well‐aligned sarcomeres and high amounts of connexin43 | CTE | [ 115 ] |

| PBS‐DLS | DCM/MeOh |

YM: 3.5 (37 °C)–4.7 (RT) MPa UTS: 1.23 (37 °C)– 1.8 (RT) MPa Strain: ≈132% |

Surface modification by exposing carboxylic groups | – | – | Soft TE | [ 116 ] |

| Zein | AcOH |

YM: 6.5– 14 MPa UTS: 0.32–13 MPa Strain: 5–7% |

– | – | – | CTE | [ 130 ] |

| Zein | AcOH |

YM: 7– 32 MPa UTS: 1–‐ 2 MPa Strain: 5– 11 MPa |

Use of mildly cross‐linked PGS for electrospinning | – | – | Soft TE | [ 131 ] |

| PGS–PMMA, gelatin | HFIP | – | Methyl mAcr–PGS | Rat PC12 cells | Fiber mats promoted cell proliferation, elongated cell morphology, potential for neurite outgrowth | Nerve TE | [ 20 ] |

| PSF | THF/DMF | – | Compressible, moldable, 3D, drug delivery | In vivo mice model | – | Diverse | [ 123 ] |

| Chitin, Lignin, PEO | EtOH, NaOH, H2O |

YM: ≈7–≈12 MPa UTS: ≈0.75 –≈3 MPa Strain: ≈20 –≈140% |

Antibacterial and antifungal activity | – | – | Wound healing | [ 132 ] |

| SIM, PHB, CIP | CF/DMF(PGS‐Sim), TFA (PHB‐CIP) | – | Dual drug incorporation in core–shell fibers; burst release of CIP, slower release SIM; antibacterial activity | – | – | Wound healing | [ 124 ] |

| Gelatin, CIP | Aqueous AcOH | – | Antibacterial activity | Fibroblast cell line (L929) | Promoted cell attachment, growth, proliferation, and immigration from the surface into interconnected pores | Wound healing | [ 128 ] |

| TPU |

CF/DMF or HFIP or TFE/AcOH |

YM: 0.83– 1.14 MPa UTS:8.76–9.67 MPa Strain: 339–375% |

Leaf‐like structure observed for HFIP | Swiss mouse NIH 3T3 fibroblasts | Improved biocompatibility compared to TPU only scaffolds | Vocal fold TE | [ 35 ] |

| PVP | HFIP (PGS), DMF/EtOH/H2O (PVP) |

YM: 1.3– 170 MPa UTS: 1.1– 3.5 MPa Strain: 3.1–328% |

Nozzle free electrospinning | Human skin fibroblast cells (HDF‐hTERT) | Good cell viability and proliferation | Skin TE | [ 232 ] |

| Poly(glycerol‐1,8‐octanediol‐sebacate) | CF/EtOH |

YM: 3.61 MPa uncross‐linked, 106.1 MPa cross‐linked UTS: 0.13 MPa uncross‐linked, 4.94 MPa cross‐linked Strain: 8% uncross‐linked, 23% cross‐linked |

PGS synthesized by Candida antartica lipase B catalysis; different fractions of glycerol units replaced by 1,8‐octanediol units | – | – | Diverse | [ 135 ] |

3.3. Hydrogels

Hydrogels have gained increasing interest in recent years thanks to their extraordinary composition and structure, which is similar to the native ECM, thus, providing a desirable framework for cellular behavior.[ 139 , 140 ] Being a 3D network of hydrophilic polymers, where chains are cross‐linked either by covalent bonds or by physical intra‐ and intermolecular attractions, hydrogels can absorb large quantities of fluids and they swell while maintaining their structure without dissolving.[ 139 ] Hydrogels can be processed in various shapes and architectures by using common techniques like emulsification, lyophilization, combinations of both, solvent casting‐leaching, gas foaming‐leaching, photolithography, electrospinning, micromolding, and 3D printing.[ 139 ]

The incorporation of PGS into hydrogels has been shown to positively influence hydrogels’ molecular network structure and elastomeric properties affecting also hydrogels’ biodegradability.[ 70 ] In various studies, it was shown that PGS could also be combined with hydrogels and the most common example is PEG which could be copolymerized with PGS.[ 66 , 141 , 142 , 143 ] Copolymer of PEGMEMA–PGS hydrogels showed tunable storage and loss moduli in a range between cells and human tissue[ 68 , 144 ] and in the case of PEG‐co‐PGS with grafted tyramine, a highly cytocompatible behavior was reported.[ 142 ] Injectable scaffolds based on PEG‐co‐PGS have been developed, which are very attractive from a clinical perspective as they can be minimally invasively applied and thereby reduce patient discomfort, risk of infection, scar formation, and the cost of treatment.[ 145 ] In contrast to these conventional hydrogels, Yoon and Chen[ 70 ] fabricated an elastomeric and pH‐responsive hydrogel, which has been made of PGS and gelatin without using any additional cross‐linking agent. Their proposed polycondensation reaction between PGSp and gelatin hydroxyl and carboxyl groups revealed ester bonds, whereas amine and carboxyl groups led to amide bonds. Afterwards, PGSPp was finally cross‐linked at elevated temperatures. By this process, highly flexible and stretchable films and also 3D scaffolds with an interconnected porous structure with shape recovery ability could be fabricated. Mouse fibroblasts confirmed the good cell cytocompatibility of such scaffolds.[ 70 ] Recently, a physical double‐network hydrogel adhesive consisting of catechol–Fe3+ coordination cross‐linked PGS‐co‐PEG‐g‐catechol and quadruple hydrogen bonding cross‐linked ureido‐pyrimidinone modified gelatin (GTU) was developed. This injectable adhesive hydrogel was designed to treat multidrug‐resistant bacteria infection and full‐thickness skin wound repair.[ 143 ] In contrast to these PGS‐based hydrogels, Eslami et al.[ 146 ] fabricated hydrogels from methacrylated gelatin and hyaluronic acid reinforced with PGS–PCL microfibers. Similarly, high cell viability and metabolic activity were measured for the hydrogel/microfibrous composites compared to neat hydrogels and neat fiber mats, but significantly higher levels of collagen I and elastin gene expression were reported. Additionally, the composite scaffold demonstrated suitable mechanical properties for CTE.

3.4. Freeze‐Drying

A wide range of highly developed technologies (i.e., electrospinning, 3D printing, micropatterning) has been considered for processing PGS as a porous scaffold. However, they all result in relatively small scaffolds with nonsufficient porosities, which, in turn, may limit the full capability and acceptance of PGS in a broader range of TE applications.[ 147 ] A different approach introduced to generate highly interconnected porous scaffolds is freeze‐drying. Freeze‐drying, also known as lyophilization, is a solvent removal process in which the solvent of the polymer solution crystallizes below its triple point, followed by subsequent pressure reduction, and by adding heat, the frozen solvent in the material can sublimate from the solid into the vapor phase.[ 147 ] Freeze drying of PGS requires the addition of a structure‐supporting polymer, e.g., PLLA,[ 22 ] silk fibroin microfibers (mSF), CH,[ 53 ] or poly (glycerol sebacate urethane) (PGSU).[ 148 , 149 ] As mentioned above, the cross‐linking of PGS takes place at high temperatures, which liquefies precondensed PGS. This process annihilates the porous structure from the freeze‐drying process during curing. A structure‐supporting polymer is then needed, that can withstand the harsh conditions of the curing process, protecting the pore structure obtained by freeze‐drying.[ 147 ]

In short, the freeze‐drying of PGS includes pouring a PGS solution into a Teflon mold, which is then frozen at ‐20 °C and placed in a freeze dryer for lyophilization. Solutions are typically cooled down to ‐30 °C to ‐50 °C and held at such low temperatures for several hours. The frozen solutions are then heated up and sublimated under vacuum. The temperature is raised to room temperature and hold again for several hours, completing the freeze‐drying procedure.[ 22 , 50 , 53 , 148 , 150 ]

Frydrych et al.[ 22 ] used a PGS/PLLA mixture to replicate native fatty tissue. Fatty tissue is a specialized connective soft tissue composed of adipocytes. Defects can arise from various causes including complex trauma, tumor resections, and congenital abnormalities.[ 151 ] In their research, Frydrych et al.[ 22 ] dissolved various combinations of PGS and PLLA in either 1,4‐dioxane or DMC, exhibiting two different freezing points of 10–12 °C and 2–4 °C, respectively. Scanning electron microscopy (SEM) showed that the produced scaffolds had different microstructural properties depending on the type of the used organic solvent. The reported elastic modulus was 0.030 MPa, tensile strength 0.007 MPa, elongation at maximum stress of 25% as well as a complete shape recovery upon release of the compressive load were 73 v%. The PGS–PLLA combinations revealed comparable mechanical strength to native high and low stress adapted adipose tissue. Additionally, the highly interconnected open‐pore structure with porosities and pore sizes ranging between 91–92% and 109–141 µm, respectively, confirmed the suitability of PGS/PLLA scaffolds for applications such as adipose TE.[ 22 ]

To avoid heat curing, Frydrych and Chen[ 148 ] and Samourides et al.[ 149 ] used chemically cross‐linkable PGSU to create porous structures. PGSU is an altered form of PGS using hexamethylene diisocyanate (HDI), as described in the chemical modification section (Section 2.3). Despite eliminating the heat cross‐linking step, scaffolds with an interconnected open‐pored microstructure and exhibiting excellent mechanical and cyclic load properties were produced. The as‐produced scaffolds were biodegradable, biocompatible, and conducted proangiogenic properties tissue ingrowth as well as angiogenesis.[ 148 , 149 ]

In a study by Zhang et al.,[ 53 ] PGS has been blended with mSF and CH, respectively, which should act as modifiers for a combined particulate leaching and freeze‐drying technique. NaCl particles, precondensed PGS, and one of the modifiers were mixed in a Teflon mold and cured for 12 h at 140 °C to produce mSF/PGS and CH/PGS composites, respectively. After curing, the salt particles were removed using deionized water and subsequently, the samples were lyophilized for 24 h to obtain a porous structure. Highly cross‐linked and open‐porous scaffolds with an increased cross‐link density as well as improved water absorption capacity compared to neat PGS has been achieved with both, mSF/PGS and CH/PGS scaffolds. Furthermore, the degradation rate could be controlled with different amounts of modifiers. Suitable biocompatibility for the use in skin replacement therapy was evaluated using mouse dermal fibroblasts of C57 BL/6 mice. Cell culture experiments showed suitable cell attachment as well as proliferation and deep ingrowth into the porous structure of the scaffold.[ 53 ]

3.5. Micropatterning

Micropatterning is the creation of specifically patterned and textured surfaces to gain a defined material behavior or to mimic the extracellular microenvironment of tissues or organs. It allows better control over particular constraints in a 3D platform compared to traditional 2D culture in tissue culture plates.[ 152 , 153 ] Cells are forced to adopt a shaped pattern of adhesion, which helps to study the cell behaviors exposed to micro topographic features as well as developing microfluidic devices.[ 153 ]

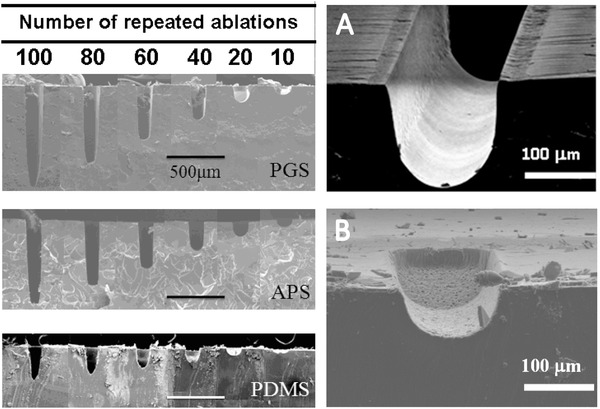

Future constructions of implantable tissue structures will require novel 3D microfluidic environments with high potential for TE. The biodegradable and biocompatible elastomer PGS is widely used in such approaches. Its transparency and thermoset properties are suitable for microfabrication techniques such as laser ablation.[ 154 ] On the other hand, micropatterning using laser ablation is considered as a green and rapid manufacturing process with low material selection barrier and high adjustability.[ 155 ] As Hsieh et al.[ 155 ] and Yeh et al.[ 156 ] assessed in their work, creating micro‐channels directly on cross‐linked PGS showed no nano/micro‐sized fractures or cracks across the PGS surface compared to silicone polydimethylsiloxane (PDMS), which is often used as a material for a subsequent molding of PGS (Figure 5 ).[ 155 , 156 ]

Figure 5.

SEM cross‐section images of produced microchannels on PGS, poly(1,3‐diamino‐2‐hydroxypropane‐co‐polyol sebacate) and PDMS with increasing ablation times. A) Laser ablated 25 times on PGS showing high edge quality B) whereas PDMS presented low edge quality with the same ablation time. Adapted from Hsieh et al. Reproduced under the terms of the CC‐BY license.[ 155 ] Copyright 2017, the Authors. Published by MDPI.

A PDMS mold is mostly produced by using epoxy‐based negative masks on silicon wafers generated by photolithography. A mixture of PDMS elastomer is then poured on these patterned surfaces and deformed after drying. These forms allow the fabrication of highly elastic PGS substrates with defined micropatterned channels.[ 154 , 157 , 158 ]

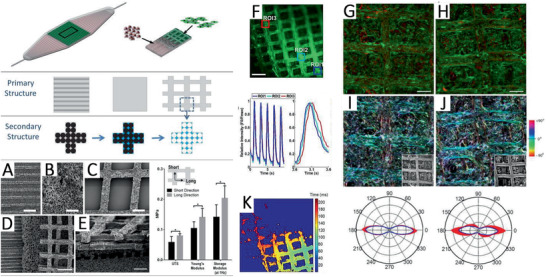

Besides laser ablation and photolithography, Morgan et al.[ 18 ] created a porous structure with primary (macroscale) and secondary (microscale) pores. Therefore, a combination of poly (limonene thioether) (PLT32i) and PGSp has been cast onto sintered spherical particles of poly(methyl methacrylate) (PMMA), which were leached out subsequently.[ 18 ] Those porous structures were intended to create spatially organized, contractile heart tissue. Primary pores were able to control the orientation of heart cells and implement sufficient perfusion, while the secondary pores extended the retention of heart cells and limited the volume fraction of the polymer.[ 18 ]

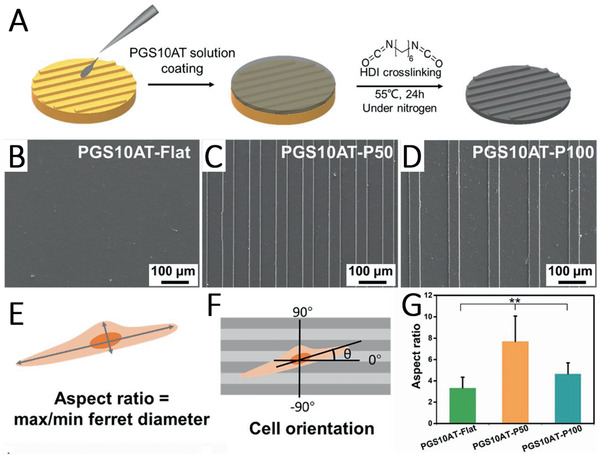

Hu et al.[ 159 ] developed a degradable micropatterned PGS scaffold copolymerized with aniline trimer (5 wt%, 10 wt., and 15 wt%) to obtain an electroactive property (Figure 6 ). The as‐produced films showed good cell viability as well as increased proliferation of rat cardiomyoblast‐derived H9c2 cells. Additionally, electroactive films with a 10 wt% aniline trimer content significantly enhanced cell–cell interaction, growth, and synchronous calcium transients of neonatal rat primary cardiomyocytes.[ 159 ]

Figure 6.

A) Scheme showing the fabrication of micropatterned PGS–aniline trimer (PGS‐AT) films. B) SEM images of flat PGS‐AT films, C) PGS‐AT films with a groove/ridge dimension of 50/50 µm and D) 50/100 µm. E) Scheme of a cellular aspect ratio and F) cellular alignment on the microstructured surface. G) Cellular aspect ratio on different patterned PGS‐AT films. Reproduced with permission.[ 159 ] Copyright 2019, Elsevier.

3.6. 3D Printing

Growing in popularity, another technique to fabricate complex structured scaffolds with a wide variety of design options is additive manufacturing. Unmodified PGS alone, however, exhibits as already mentioned, a lack of processability due to its harsh cross‐linking conditions.[ 27 ] Therefore, alternative strategies than thermal processing of PGS such as chemical modification or blending with other materials are developed.

3.6.1. Extrusion‐Based printing

Extrusion‐based 3D printing is widely used in TE. In this process, a printable material is pushed through a nozzle and the shape of the printed part is stabilized, mostly via cross‐linking of the material, in order to preserve the printed layer‐by‐layer structure. Extrusion‐based systems have the advantage of being easy to use and relatively cost‐effective compared to other 3D printing systems.

In 2016, for the first time, Yeh et al.[ 156 ] demonstrated the 3D printing of photocurable PGS. They used the potential of 3D printing for the production of sophisticated biocompatible, elastomeric tissue substitutes. An extrusion‐based 3D printing set‐up and a biodegradable and photocurable PGSA ink were used. Two different PGSA macromers were produced with two different molecular weights of PGS (low molecular weight PGS with a M n of 5.78 kDa and high molecular weight PGS with a M n of 6.32 kDa). Subsequently, these macromers were blended, which led to photocurable macromer inks with variable viscosities. With optimal ink viscosities, scaffolds could be printed with a high resolution up to ten layers in height. The mechanical properties of the 3D printed scaffolds depended on the respective printing density. Scaffolds with a lower printing density had lower moduli (Young's modulus of 310 kPa) and failure properties (failure strain of 40%) than scaffolds with a higher density (Young's modulus of 480 kPa and failure strain of 70%) compared to cast control samples (Young's modulus of 740 kPa and failure strain of 86%). The cytocompatibility was tested using 3T3 fibroblasts where significant adhesion, cell spreading, and proliferation were observed on PGSA showing the suitability of the elastomeric scaffolds in soft TE.[ 231 ]

The set‐up was further modified by Yeh et al.[ 58 ] using a specifically functionalized photocurable Nor‐PGS with thiol–ene click chemistry to control PGS cross‐linking. Subsequently, after extrusion of the viscous Nor‐PGS macromer paste, it was cross‐linked using UV light to obtain a high shape fidelity of the printed parts. The printed Nor‐PGS structures can be cross‐linked rapidly (<1 min) leading to porous, elastomeric scaffolds with mechanical properties comparable with the formerly produced PGSA scaffolds.[ 58 , 231 ]

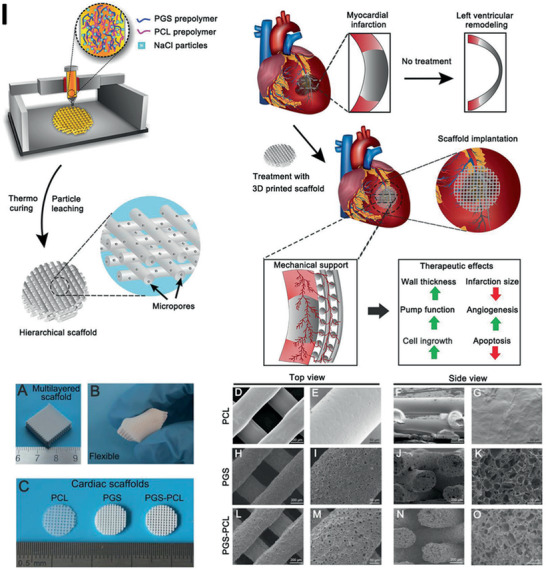

Lei et al.[ 31 ] and Yang et al.[ 37 ] investigated a different approach without a chemical modification of PGS by mixing either neat PGS or a PCL/PGS blend with NaCl as a removable thickener for printing and a reinforcer for curing. The combinations were directly printed using an extrusion‐based set‐up. The produced NaCl‐containing scaffolds possessed a stacked construction with regular crisscrossed filaments. Good printability was established with a PGS/salt ratio of 1:2 and a printing temperature of 50 °C. After leaching the salt particles, interconnected micropores formed.[ 31 ] A Young's modulus of 748.5 ± 21.0 kPa, a tensile strength of 302.7 ± 7.7 kPa and a failure strain of 57.3 ± 1.3% confirmed the suitability of this scaffold for CTE. In vivo studies of printed PCL/PGS scaffolds as cardiac patches in adult male Sprague‐Dawley rats showed increased wall thickness, pumping function, angiogenesis, and cell ingrowth after an induced myocardial infarction (MI). Decreased apoptosis and infarction size demonstrated its therapeutic suitability and versatile applicability of these novel 3D printed, cardiac patches.[ 37 ]

In a further innovative approach, Lei et al.[ 138 ] developed a four‐axis printer that applies the print strands to a rotating collector. This enabled the successful printing of hydrogels, thermoplastics, and thermosets. In this way, tubular structures would be produced relatively easily, e.g., for tracheal cartilage applications.[ 138 ]

Recently, Touré et al.[ 46 ] combined an electrospun PCL/PGS fiber mat with a 3D printed PCL/PGS structure, containing BG particles. Three different types of extrusion‐based scaffolds were produced using PCL/PGS as a reference, with 5 wt% BG and with 10 wt% BG. After producing the 3D scaffolds, a 14 wt% polymer solution of PCL/PGS (mixing ratio of 1:1) was electrospun directly on top of these scaffolds. Excellent adhesion between the layers resulted in Young's moduli of 240–310 MPa. The composite materials were biodegradability and a weight loss ≈14% and equilibrium in pH was measured after two months of incubation which was followed by the release of alkali ions from the BG particles. Cytotoxicity tests with fibroblasts proved the biocompatibility of PCL/PGS/BG constructs with a cell viability of over 125% on the second day, making these scaffolds suitable candidates for TE of tendons and ligaments.[ 46 ] Recently, Farizhandi et al.[ 161 ] focused their work on the printing of electronically conductive and flexible bioelectronic devices. For this purpose, they combined lithium phenyl‐2,4,6‐trimethylbenzoylphosphinate as photoinitiator with PGS and zinc (Zn). The resulting 3D printed scaffolds showed remarkable mechanical and adhesive properties as well as noncytotoxic behavior both in vitro and in vivo, rendering it suitable for several biocompatible applications.[ 161 ]

3.6.2. Laser‐Based Printing

Stereolithography (SLA),[ 162 ] direct laser writing (DLW), and digital light processing additive manufacturing (DLP‐AM)[ 62 ] are 3D printing methods, which exploit the cross‐linking between acrylated polymer chains via the exposure to light at various wavelengths involving radical polymerizations. These fabrication methods are considered as highly precise and efficient compared to fused deposition modeling or extrusion‐based 3D printing. Either a single laser beam (SLA, DLW) or a digital mirror device (DMD) (DLP‐AM) is used simultaneously to control the exposure of light in an array.[ 163 , 164 ]

Several research groups have studied the effect of degree of acrylation in PGS and the weight ratio between the pre‐polymers towards mechanical and degradation properties as well as processability.[ 62 , 162 , 165 , 166 ] Chen et al.[ 62 ] copolymerized PGSA either with polycaprolactone diacrylate (PCLDA) or poly(ethylene glycol) diacrylate (PEGDA) to form a polymer network and thus to overcome the relatively low degradation rate of neat PCLDA and PEGDA in vivo. They used a DLP‐AM set‐up to produce scaffold structures with adjustable mechanical and degradation properties. In their study, it was found that blending prepolymers of PGSA with various degrees of acrylation and various weight ratios, the viscosity of the prepolymers remained stable, but became even more suitable for 3D printing than the substances alone. By altering the weight ratios of the used materials, it was possible to control Young's moduli within a range of 0.67 to 10.54 MPa. Moreover, a significantly improved degradability of the scaffolds was achieved.[ 62 ]

Pashneh‐Tala et al.[ 165 ] investigated the effect of the molecular weight and degree of methacrylation of PGS‐methacrylate on the printability using a 2‐photon polymerization technique. The degree of methacrylation was observed to have the most substantial influence on degradability and mechanical properties. Using 2‐photon polymerization, they succeeded in creating 3D scaffolds with a minimum feature size of 10 µm. Cell culture studies showed a sustained growth and proliferation of vascular smooth muscle cells (SMCs), indicating that the material is a promising candidate for TE applications.[ 165 ]

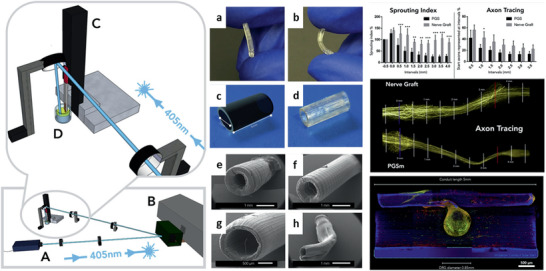

Singh et al.,[ 162 ] on the other hand, assessed the degradation rate and mechanical properties of PGS‐methacrylate and structured nerve guidance conduits (NGC) fabricated via SLA. As produced conduits of PGS‐methacrylate, with a 0.75 degree of methacrylation, were flexible and exhibited an appropriate compressive Young's modulus (3.2 MPa) as well as suture retention strength (12.3 MPa) for peripheral nerve repair. In vivo results in Thy‐1‐YFP‐H mice showed a supported regeneration of axons, neurites aligned toward the topographical conduit grooves and no increase of neuropathic pain, in comparison to native nerve grafts concluding that PGS‐methacrylate is an attractive synthetic alternative to native grafts.[ 162 ]

Wang et al.[ 166 ] used DLP‐based 3D printing of a PGSA/PEGDA combination to generate nature‐inspired double network structures consisting of interconnected segments with different mechanical properties. By assigning distinct exposure times at specific locations, it was possible to create networks with stiff, strong frames to maintain the rough shape of the scaffold and diagonal elastic struts to absorb tensile energy from the same material in a single shot. In this way, finely resolved structures could be printed with less than 100 µm in size and a volume of less than 1 mL as well as structures with a volume of more than 10 mL. Subsequent mechanical tests revealed an expected influence of both exposure time and PEGDA amount on the mechanical properties of the printed structures. The mechanical properties of these scaffolds could be tailored by an alternating double network structure.[ 166 ] Further advances regarding DLP‐based 3D printing of PGSA have been made by Wu et al.[ 167 ] in order to print porous tubular structures. Varying the PGSA concentration, the type of diluent (dimethyl sulfoxide, 2‐butoxyethyl acetate) and the degree of acrylation, PGSA based inks with viscosities below 5 Pa s and exposure time of less than 10 s were found as suitable for DLP fabrication. The final compositions enabled the fabrication of complex 3D models with high mimicry and a minimum feature thickness of 80 µm, which can be used in a variety of TE applications.[ 167 ] An overview of all printing approaches involving PGS of the last five years is shown in Table 2 .

Table 2.

Overview of PGS used in 3D printing approaches. Printing techniques are separated into extrusion‐based and laser‐based methods

| Printing technique | Material combination | Mechanical properties | Cell response | Special features | Proposed application | Ref. | |

|---|---|---|---|---|---|---|---|

| Extrusion‐based | commercially available 3D filament printer (Revolution XL, Quintessential Universal Building Devices) modified for syringe extrusion | Photocurable PGSA combining a ratio of 10:90 of

|

Depending on printing density

a)

:

E‐modulus: 310 kPa Tensile strength: 120 kPa Failure strain: 40%

E‐modulus: 350 kPa Tensile strength: 210 kPa Failure strain: 67%

E‐modulus: 480 kPa Tensile strength: 330 kPa Failure strain: 70% |

No cytotoxic response in contact with NIH 3T3 fibroblasts, increased cell proliferation within 4 d of culture |

|

Complex biocompatible, elastomeric tissue replacements (Soft TE) |

[ 231 ] |

| Specific functionalized photocurable Nor‐PGS with thiol–ene click chemistry | Depending on thiol/norbornene ratios (N):

E‐modulus: 110 kPa Tensile strength: 260 kPa Failure strain: 240%

E‐modulus: 340 kPa Tensile strength: 690 kPa Failure strain: 200%

E‐modulus: 400 kPa Tensile strength: 790 kPa Failure strain: 170% |

No cytotoxic response in contact with NIH 3T3 fibroblasts, increased cell proliferation within 8 d of culture |

|

Elastomeric, biodegradable and cytocompatible scaffolds for soft tissue applications | [ 58 ] | ||

| Commercially available fused depositioning system (HTS‐400; Fochif Mechatronics Technology) | Neat PGS with NaCl (NaCl‐PGS) at a ratio of PGS:NaCl = 1:2 | Depending on used needle gauge (G):

E‐modulus: 150.7 kPa Tensile strength: ≈80 kPa Failure strain: ≈40%

E‐modulus: 239.4 kPa Tensile strength: ≈90 kPa Failure strain: ≈30% |

Cytocompatible, biocompatible and biodegradable in vivo after subcutaneous and epicardial implantation in male Sprague Dawley rats Thickening of the LV wall and attenuated LV dilatation after 28 d postimplantation of 3D‐printed PGS patches |

|

Used in a vapo‐mechanical sensor and soft actuator or as a myocardial patch | [ 31 ] | |

| PGS:PCL combination in a ratio of 9:1 mixed with NaCl (NaCl‐PGS/PCL) at a 1:2 weight ratio (PGS/PCL : NaCl) |

E‐modulus: 190.1 kPa Tensile strength: 62.2 MPa Failure strain: 28.9%

E‐modulus: 31.5 MPa Tensile strength: 3.3 MPa Failure strain: 475.0%

E‐modulus: 748.5 kPa Tensile strength: 302.7 kPa Failure strain: 57.3% |

Epicardial implantation in male Sprague Dawley rats showed preserved heart function, increased LV wall thickness, reduced infarct size, promoted vascularization, induced tissue repair by recruiting M2 macrophages, and inhibited myocardial apoptosis |

|

Potential for treating multiple cardiovascular diseases (CTE) | [ 37 ] | ||

| Combination of a DIW‐3D printer (HTS‐400; Fochif Mechatronics Technology) and a rotary receiver | Neat PGS with NaCl (NaCl–PGS) at a ratio of PGS:NaCl = 1:2 combined with an electrospun gelatin fiber mesh post‐printing | Mechanical properties after 12 weeks in vivo implantation with and without cells:

E‐modulus: ≈2.40 MPa

E‐modulus: ≈8.00 MPa

E‐modulus: ≈11.5 MPa |

Chondrocytes from auricular cartilage of New Zealand white rabbits showed excellent cell proliferation without noticeable apoptosis within 4 d of culture; In vivo results in nude mice showed an increased DNA, GAG as well as collagen content after 12 weeks of implantation |

|

Potential for tracheal cartilage reconstruction | [ 138 ] | |

| Commercially available 3D‐Bioplotter Developer Series (EnvisionTec) | PGS/PCL combination in a ratio of PGS:PCL = 1:1 combined with BG particles and an electrospun PGS/PCL fiber mat postprinting | Depending on the amount of incorporated BG particles:

E‐modulus: 250 MPa Maximum load: 6 N Failure length: 1.5 mm

E‐modulus: 241 MPa Maximum load: ≈4 N Failure length: ≈1.4 mm

E‐modulus: 311 MPa Maximum load: ≈3.5 N Failure length: ≈0.6 mm |

NIH 3T3 fibroblasts showed no cytotoxic response with an improved cell proliferation within 7 d of culture |

|

Potential for tendon and ligament TE applications | [ 46 ] | |

| Commercially available 3D‐Bioplotter Allevi 2 | Photocurable PGSA with chemically sintered Zn powder in various ratios |

Depending on the amount of incorporated Zn powder: Conductivity: up to 11.8 mS m‐1 Compression modulus: up to 1179.5 kPa E‐modulus: up to 1099.9 kPa |

No cytotoxic response in contact with C2C12 myoblasts as well as in in vivo studies using Wistar rat models |

|

Bio‐integrated electronics in wearable electronics, electronic skin, robotics, implantable electronics and human–machine interfacing | [ 161 ] | |

| Laser‐based | DLP‐AM system developed by the Cheng lab at the National Taiwan University of Science and Technology | Photocurable PGSA with an altered degree of acrylation (30, 15, and 7%) combined with PCLDA (PGSA: PCLDA = 2:1) or PEGDA (PGSA: PEGDA = 1:1) | Depending on the degree of acrylation and mixing ratio:

E‐modulus: 0.12 MPa Tensile strength: 0.10 MPa Failure strain: 121.23%

E‐modulus: 1.55 MPa Tensile strength: 0.63 MPa Failure strain: 46.95%

E‐modulus: 5.10 MPa Tensile strength: 1.36 MPa Failure strain: 28.43%

E‐modulus: 18.98 MPa Tensile strength: 3.19 MPa Failure strain: 21.50%

E‐modulus: 4.25 MPa Tensile strength: 0.80 MPa Failure strain: 21.29%

E‐modulus: 7.58 MPa Tensile strength: 0.91 MPa Failure strain: 13.63%

E‐modulus: 10.54 MPa Tensile strength: 1.10 MPa Failure strain: 12.96% |

Not conducted in this study |

|

Potential for multiple TE applications | [ 62 ] |

E‐modulus: 4.35 MPa Tensile strength: 0.58 MPa Failure strain: 15.34%

E‐modulus: 1.42 MPa Tensile strength: 0.19 MPa Failure strain: 22.39%

E‐modulus: 2.85 MPa Tensile strength: 0.20 MPa Failure strain: 11.28%

E‐modulus: 7.00 MPa Tensile strength: 0.69 MPa Failure strain: 14.08% |

|||||||

| Femtosecond DLW using 2PP with a PHAROS femtosecond Yb:KGW laser (Light Conversion Ltd) | Photocurable mAcr‐PGS of

|

Depending on the degree of methacrylation (N) and molecular weight:

Low M w E‐modulus: ≈0.50 MPa Tensile strength: ≈0.80 MPa High M w E‐modulus: ≈0.90 MPa Tensile strength: ≈0.60 MPa

Low M w E‐modulus: ≈1.50 MPa Tensile strength: ≈0.90 MPa High M w E‐modulus: ≈1.50 MPa Tensile strength: ≈0.90 MPa

Low M w E‐modulus: ≈6.80 MPa Tensile strength: ≈3.80 MPa |

Cytocompatible with human dermal fibroblasts, human adipose‐derived stem cells (ADSCs) and human coronary artery SMCs, enhanced cell proliferation during the 7 and 14 d of culture, respectively |

|

Potential for multiple TE applications both in vitro and in vivo | [ 165 ] | |

| In house designed micro SLA set‐up |

Photocurable mAcr‐PGS with altered degree of methacrylation (N = 0.22–1.00) |

Mechanical compression testing of a produced NGC (N = 0.75b): Max compression: 0.57 mm Compression at break: 11.4% Stiffness: 3.2 MPa Suture retention strength: 12.3 MPa |

Neuronal NG108‐15 cells as well as primary SCs from male Wistar rats showed improved neuronal and glial cell growth in vitro |

|

Potential for nerve conduit guidance (nerve TE) | [ 162 ] | |

|

In vivo: an increased regeneration of axons, oriented axonal growth without an increase of neuropathic pain in comparison to native nerve grafts |

|||||||

| DLP‐based 3D printing using a DMD chip (Texas Instruments) | Photocurable PGSA combined with altered amounts of PEDGA (1%, 5% and 10%) | Depending on light exposure time (in s) and printed structure (single or double network):

E‐modulus: 11.91 kPa Tensile strength: 5.92 kPa Tensile strain: 62.58%

E‐modulus: 47.66 kPa Tensile strength: 14.11 kPa Tensile strain: 43.31%

E‐modulus: 32.09 kPa Tensile strength: 15.08 kPa Tensile strain: 64.18% |

HUVECs showed excellent viability (>90%) within 7 d of culture |

|

Specifically optimizable for different biomedical applications (soft TE) | [ 166 ] | |

| DLP‐based 3D printing using an Ember desktop 3D printer (Autodesk) with a built‐in light‐emitting diode projector | Photocurable PGSA with different degrees of acrylation mixed with 1wt% dipehyl (2,4,6‐trimethylbenzoyl) phosphine oxide photoinitiator | Mechanical tensile testing on films:

E‐modulus: 192.3 kPa Tensile strength: 460.2 kPa Tensile strain: 239%

E‐modulus: 859.0 kPa Tensile strength: 326.8 kPa Tensile strain: 39%

E‐modulus: 3668.7 kPa Tensile strength: 919.1 kPa Tensile strain: 26%

E‐modulus: 226.8 kPa Tensile strength: 556.9 kPa Tensile strain: 244%

E‐modulus: 3097.6 kPa Tensile strength: 1273.3 kPa Tensile Strain: 42% |

Not conducted in this study |

|

Potential for multiple TE applications | [ 167 ] | |

Printing density referred to as the amount of interior volume designated to be occupied by material (fill density setting, in Slic3r), including 30% for low density, 45% for medium density, and 60% for high density; b)NGC = nerve guidance conduit, Hounslow mechanical analysis was conducted along the axial direction of the NGC.

4. Biomedical Applications

4.1. Cardiac TE (CTE)

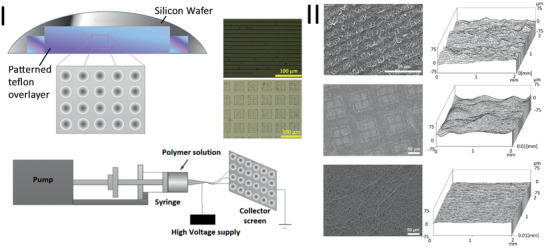

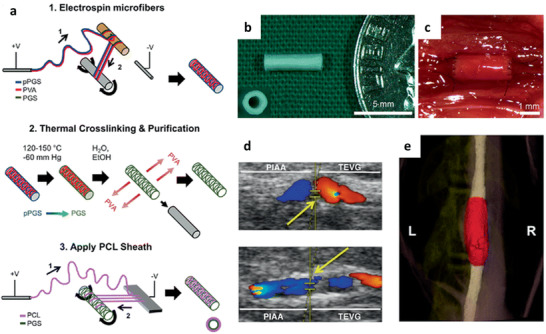

CTE is an important branch of TE aiming at developing cell‐scaffold constructs to induce cardiac tissue repair.[ 160 , 168 ] Today the primary fabrication method for cardiac tissue‐engineered scaffolds is electrospinning. Thus produced fiber mats can be fabricated with continuous fibers in nano‐ to microscale, which show morphological similarities to the native fibrous ECM regarding high surface‐to‐volume ratio, high porosity, and variable pore size.[ 169 ] As already mentioned, due to its low solution viscosity, PGS has been blended with other polymers to be spinnable. Often, PGS blended with PCL and spun as a fiber mat was used for CTE application.[ 32 , 170 ] In recent years, this blend has been further optimized. A patterned fiber mat of PGS/PCL was electrospun on a Teflon‐coated silicon wafer with imprinted topographical features, like squares and grooves (Figure 7 ).[ 110 ] In vitro experiments using C2C12 myoblasts and neonatal rat cardiomyocytes showed a successful alignment of both cell types after 24 h of culture. Furthermore, excellent cell‐to‐cell communication was confirmed by measuring the expression of connexin43 on imprinted scaffolds.[ 110 ] In contrast to topographical cues, Rai et al.[ 106 ] functionalized PGS‐based fiber mats chemically by conjugating VEGF via amide groups. VEGF was homogeneously immobilized on the fibers and the functionalized scaffolds supported the attachment, growth, and proliferation of C2C12, rat cardiac progenitor cells, and rat aortic endothelial cells (rAoECs) compared to unfunctionalized PGS/PCL scaffolds. Additionally, morphological changes of rAoECs confirmed the formation of a vascular tree in the fiber mat.[ 106 ] Compared to previously established work on PGS/PCL electrospun blends, in another study, the solvent system was exchanged from commonly used (harsh) solvents, e.g., CF, methanol, DCM or dimethyl carbonate, to the less toxic solvent acetic acid to lower the level of toxicity during the fabrication process as well as to maintain scaffold biocompatibility.[ 33 ] It could be observed that acetic acid had no negative influence on fiber formation, and a homogenous and defect‐free fiber mat was achieved. Moreover, this study revealed the significant influence of the disinfection method (UV vs immersion in 70% ethanol) on the biocompatibility. When samples were disinfected in ethanol, partially PGS and its unreacted monomers were leached out from the fiber mat, and created pores in the fibers leading to higher cell viability and cell proliferation compared to UV disinfected samples.[ 33 ] This behavior has also been reported by Apsite et al.[ 29 ] after incubation of PCL/PGS fibers in PBS where they also obtained porous fibers of PCL after 4 weeks of incubation in 37 °C. Modified PGS, i.e., poly(1,3‐diamino‐2‐hydroxypropane‐co‐glycerol sebacate)‐co‐PEG, has also been electrospun together with PCL in order to obtain fiber mats exhibiting uniaxial mechanical properties required for human aortic valve leaflets.[ 171 ]

Figure 7.

Scheme showing the microcasting process of PGS films via a patterned silicon wafer and its Teflon overlayer as well as the electrospinning setup, where the silicon wafer replaces the conventional collector (I). SEM images showing different topographical PGS/PCL fiber mats (left) and their corresponding surface roughness profiles (right) (II). Reproduced with permission.[ 110 ] Copyright 2016, Elsevier.

Furthermore, PGS/PCL electrospun fibers have been used as reinforcement for methacrylated gelatin/hyaluronic acid hydrogels via immersion technique.[ 146 ] PGS/PCL fiber/hydrogel composite scaffolds showed higher metabolic activity of valvular interstitial cells compared to the fiber mat and the hydrogel alone. Additionally, collagen type I and elastin expression significantly increased for PGS/PCL fiber‐reinforced composite scaffolds. Due to the optimal expression levels of collagen and elastin genes achieved with the composite scaffolds, the authors concluded the scaffold's suitability for treating congenital heart defects.[ 146 ]

PGS has also been blended with poly(butylene succinate‐butylene dilinoleate) (PBS‐DLA), a multiblock thermoplastic elastomer,[ 115 , 172 ] which led to suitable mechanical and degradation properties for cardiac patches and exhibited higher C2C12 cell viability on fiber mats with increasing PBS–DLA content.

On the other hand, PGS has also been combined with natural polymers as they 1) provide living cells important ligands required for adhesion and proliferation, 2) mainly degradation byproducts are nontoxic and 3) initiate a low immune response.[ 29 ] The combination of PGS with collagen and silk fibroin (1:4.5:4.5) has demonstrated mechanical properties which were close to those of heart valve tissue. Furthermore, it presented a low rate degradation and thrombogenic platelet adhesion compared with collagen hydrogels or fiber mats was reduced from 220% to 20%.[ 127 ]

The further potential of PGS/fibrinogen core/shell fibers was investigated in an in vivo porcine model with MI.[ 129 ] The results revealed that a combination of PGS/fibrinogen/VEGF and mesenchymal stem cells (MSCs) promoted recovery of left ventricle function after MI, proven by the improvement in EF and prevention of left ventricle enlargement. Furthermore, cardiac marker proteins troponin and actinin, as well as endothelial cell marker protein CD31 were expressed by the MSCs in contact with the core–shell fibrous scaffold showing differentiation of human bone marrow MSCs into cardiac and endothelial cells.[ 129 ] Functional and structural integrity, as well as a suitable matrix for entrapment of MSCs, was successfully obtained using these PGS/fibrinogen/VEGF fiber mats.

A vegetable protein, namely zein, the primary storage protein in corn,[ 173 ] was also chosen as blending material for PGS.[ 130 ] Compared to proteins from animal sources, vegetable proteins are readily available with low‐cost and as coproduct cereal grains can be processed as food or fuel. Moreover, they are biodegradable and exhibit less immunogenicity.[ 174 ] Bead free PGS/zein fiber mats were produced from an acetic acid solvent system and they were stable in PBS over 28 d, which could be beneficial for cardiac patch application.[ 130 ]