Abstract

Tissue damage due to cancer, congenital anomalies, and injuries needs new efficient treatments that allow tissue regeneration. In this context, tissue engineering shows a great potential to restore the native architecture and function of damaged tissues, by combining cells with specific scaffolds. Scaffolds made of natural and/or synthetic polymers and sometimes ceramics play a key role in guiding cell growth and formation of the new tissues. Monolayered scaffolds, which consist of uniform material structure, are reported as not being sufficient to mimic complex biological environment of the tissues. Osteochondral, cutaneous, vascular, and many other tissues all have multilayered structures, therefore multilayered scaffolds seem more advantageous to regenerate these tissues. In this review, recent advances in bilayered scaffolds design applied to regeneration of vascular, bone, cartilage, skin, periodontal, urinary bladder, and tracheal tissues are focused on. After a short introduction on tissue anatomy, composition and fabrication techniques of bilayered scaffolds are explained. Then, experimental results obtained in vitro and in vivo are described, and their limitations are given. Finally, difficulties in scaling up production of bilayer scaffolds and reaching the stage of clinical studies are discussed when multiple scaffold components are used.

Keywords: bilayered scaffolds, biomaterials, biomimetism, material design, medical applications, tissue engineering

Scaffolds are commonly used in tissue engineering as supporting structures for cell growths. They must be appropriately designed, in terms of properties and functionality, to mimic the architecture of the native tissue of interest. Moreover, osteochondral, cutaneous, vascular, and many other native tissues are based on multilayered structures, therefore their regeneration in an appropriate manner needs multilayered scaffolds.

1. Introduction

Tissues and organs of the human body can be damaged because of such pathologies as cancer, congenital anomalies, traumas, and injuries.[ 1 ] Current clinical approaches for repairing damaged tissues refer to autografts and organ transplantation (primarily allografts), but each has limitations. Autografts, which are grafts transferred from the same individual, include additional surgical procedures at the site of tissue harvest. They increase the complexity of the surgical procedure, as well as functional and aesthetic consequences for the patient, such as donor site morbidity and post‐operative pain, not to mention the limited availability of tissue. An alternative to autografts is allografts, or cadaveric tissues. Allografts are the best alternative but show limitations because of the limited availability of donors, the risk of disease transmission, and the risk of immune rejection. To prevent the latter, long‐term immunosuppressive treatment is usually required, but the long‐term risks of such treatment are elevated (cancers, infections, cardiovascular diseases…).[ 2 ] Therefore, full regeneration of a tissue with all its functionalities remains challenging. Nowadays, tissue engineering (TE) is an actively developing field that aims to overcome the limits of conventional treatments.[ 3 ] TE refers to the combination of cells and scaffolds to build a structure that would be able to restore and maintain the native architecture and function of damaged tissues and/or organs.[ 1 ]

Scaffolds are supporting structures for the cells and can be made of natural and/or synthetic polymers, as well as ceramics in certain cases. They must be appropriately designed to mimic the architecture of the native tissue of interest, facilitate integration in host tissue, and new tissue formation in vivo. For this to happen, biomimetic scaffolds must provide structural support for the cells to adhere, spread, migrate, proliferate, and produce an extracellular matrix (ECM).[ 4 ] Therefore, parameters such as porosity, pore size, and pore structure are of the outmost importance and should be taken into consideration during early phases of the design.[ 5 ] In addition, scaffolds should be biocompatible, i.e., nonthrombogenic, non‐immunogenic, and resistant to infections.[ 6 ] Moreover, scaffolds have to be able to maintain their shape and withstand mechanical constraints during surgical operations, when they are implanted into the body. More precisely, they should not break during the procedure, fit within the target tissue, and do not cause any mechanical damage to the body.[ 7 ]

During the development of new scaffolds for TE, some studies focus on monolayered scaffolds, which have uniform material composition and structure.[ 8 ] However, monolayered scaffolds were reported as not being able to mimic the biological environment, and not to be optimal for tissue repair.[ 9 ] Hence, inspired by the natural multilayered structure of natural tissues (such as osteochondral, cutaneous, osseous, nervous, vascular tissues, and urinary bladder), more complex multilayered scaffolds were proposed, and appeared to be more advantageous for TE.[ 10 ] Indeed, 3D scaffolds, typically porous with interconnected pore networks, have gained much attention. They better mimic in vivo tissue organization, compared to conventional monolayered scaffolds. They can provide an appropriate environment for the cells by ensuring mechanical support, as well as physical and biochemical stimuli for optimal cell growth and functions.[ 11 ] They should be chemically and structurally similar to the targeted tissue to achieve the optimal regeneration.[ 12 ] For that, a wide range of materials is used, classified into three principal groups: synthetic polymers, natural polymers, and (bio)ceramics.[ 11 ] From these biomaterials, different scaffolding design strategies are reported in the literature.[ 13 ]

In this review, we focus on biomimetic bilayered scaffolds used in a wide range of TE applications. The use of bilayered scaffolds allows the creation of a tissue‐specific environment with two or more different regions resembling the stratified anatomical architecture. The fabrication of this type of scaffold can be achieved by one or more components, by similar or different techniques, by assembling two scaffolds produced separately in a final unique entity. To fabricate such biomimetic scaffolds, numerous fabrication techniques have been developed, with more or less success, and can generally be classified into two categories: conventional and advanced. The benefits and drawbacks of each one have been described in detail. The described design approaches in this review include cellular scaffold structures (cells and scaffolds) or acellular structures (scaffolds that are later colonized by the host cells). In both cases, biomolecules such as growth factors can also be incorporated. This article offers an overview of current advances in the field of bilayered scaffolds for the engineering of multilayered tissues. The multilayer tissues discussed in this review are vascular, bone/cartilage, skin, periodontal, urinary bladder, and trachea tissues. Furthermore, in the present review, we decided to focus only on newly synthesized bilayered materials, and not to mention bilayered scaffold produced from decellularized graft tissues. Decellularized materials derived from different tissues and organs have been extensively described in the literature.[ 14 , 15 ] Their advantage is the ability to provide support for the cells, comparatively good biocompatibility, weak immune response, and abundance of bioactive molecules. However, the drawbacks include the necessity to obtain quality grafts, long decellularization protocols, and the risk of the presence of toxic agents used during decellularization.

In this review, we will first present a brief description of the anatomy and the functionality of each native tissue. Second, we will focus on various scaffold design strategies, i.e., the selection of materials and fabrication techniques, used in order to build an appropriate structure with desired mechanical and biological properties existing in the native target tissues (Figure 1 ). Furthermore, this review will highlight the versatility of 3D bilayered scaffolds in achieving tissue regeneration in vitro and in vivo, with descriptions of animal models and human clinical trials. Finally, future outlooks of scaffold engineering for TE will be given.

Figure 1.

Overview of the strategies to design bilayered scaffolds for TE. TE refers to the combination of cells and scaffolds to build a structure, which would be able to restore and maintain the native architecture and function of damaged tissues and/or organs. Scaffolds are supporting structures for the cells and must be appropriately designed, in terms of properties and functionality, to mimic the architecture of the native tissue of interest. It exists various scaffold design strategies, i.e., selection of raw materials and fabrication techniques. Scaffolds can be made of natural and/or synthetic polymers, as well as bioceramics and can be built with several fabrication techniques. Selecting the appropriate scaffold design strategies is crucial.

2. Overview of Scaffold Fabrication Techniques

Designing and manufacturing are key steps is the conception process of 3D scaffolds for tissue repair. To date, there are numerous fabrication techniques that have been developed, more or less successful, to build 3D scaffolds for TE applications. They can be classified into two categories: conventional and advanced. According to the specific requirements that a scaffold should meet to mimic the target tissue (in particular in terms of matrix composition with chemical and structural similarities), selecting the appropriate fabrication technique is crucial. Indeed, various properties of tissue‐engineered scaffolds, such as the shape, porosity, and mechanical properties, are closely related to the manufacturing techniques. Conventional techniques including casting/particle leaching, freeze‐drying, phase separation method, and electrospinning can be used to build the scaffolds with interconnected porous structures, but do not provide enough control over scaffold architecture, pore network, and pore size. To overcome these limitations, the researchers are developing advanced fabrication techniques as an alternative to conventional scaffold fabrication methods such as 3D printing and bioprinting. Indeed, advanced fabrication techniques are capable of creating customized scaffolds with precise control over their structure. Both conventional and advanced techniques are described below, followed by a discussion of the advantages and drawbacks of each.

2.1. Conventional Fabrication Methods

In this section, we describe in detail conventional fabrication methods for 3D scaffolds. This description is based on the following references.[ 16 , 17 , 18 , 19 , 20 , 21 ]

2.1.1. Solvent Casing/Particle Leaching

Solvent casting/particle leaching is one of the most common methods to prepare porous scaffolds with interconnection networks. An organic solvent is used to dissolve the polymer of choice in which salt or polymer particles, which are used as porogens, are dispersed. From all porogens, sodium chloride is the best known; potassium chloride, sugar (glucose, saccharose), or gelatin also can be added to the solution in order to create pores by forming a polymer–porogen network. The polymer/porogen mixture in solvent is then cast into a mold and when the solvent evaporates, it leaves behind a solid composite material consisting of polymer matrix and porogens. This resulting matrix is submerged in water to leach out the particles and create a porous structure. It is a relatively easy‐to‐process and low‐cost approach. In a general manner, one of the main benefits is the effective control and tunability of porosity (up to 90%) and pore size (average between 100 and to 700 µm) to build appropriate structures with desired mechanical and biological characteristics. However, because of the casting and solvent evaporation step, this method is clearly limited to the fabrication of scaffolds up to 3 mm thick and is time‐consuming. Another drawback is the use of organic solvent, and the presence of its residues, which is hard to be completely removed from the scaffold during the drying step.

2.1.2. Freeze‐Drying

Freeze‐drying, also known as lyophilization, refers to a versatile method that allows to obtain 3D porous scaffolds with a high porosity (>90%) without the requirement of porogens. This method involves the use of a polymer solution that is frozen at a temperature between −20 °C and −80 °C, leading to ice crystal formation. The next step consists of the elimination of the solvent by complete sublimation with help of a lyophilizer to form a solid scaffold with various interconnecting pores. In fact, the resulting macro porosity corresponds to the empty area initially occupied by ice crystals. This technique is mostly favorable for designing scaffolds with high porosity (between 20 and 400 µm) and interconnectivity, with the considerable benefit to adjust structure and pore size by changing parameters such as the nature and the concentration of polymer and the freezing temperature. However, the pore size usually achieved with this technique corresponds to the lower limit for TE applications. On the other hand, the process is conducted at low temperatures, which can be beneficial to maintain the integrity of the biological factors embedded in the scaffold. In conclusion, the freeze‐drying technique is a suitable method for TE to fabricate a wide range of polymer‐based scaffolds, but the small pore size of the scaffold, the polydispersity in porosity, and above all the use of cytotoxic solvents for mixing the polymer limit its application. In addition, it only concerns a small group of synthetic polymers, which are water‐soluble, comprising polyglycolide (PGA) or poly(lactic‐co‐glycolic acid) (PLGA).

2.1.3. Phase Separation Method

Phase separation is a simple technique based on changes in thermal energy to induce demixing of a homogenous polymer/solvent solution: it can become thermodynamically unstable under certain conditions and tends to separate into two phases. Indeed, demixing, or phase separation, leads to the formation of two phases: the polymer‐rich phase which solidifies or precipitates allowing to obtain a nanofibrous structure in the polymer matrix, and the solvent‐rich phase which is eliminated by evaporation, sublimation, or extraction to produce porosity in the polymer matrix. Phase separation can be induced by two processes: by decreasing the temperature—thermally induced phase separation (TIPS) method, the most often used—or by adding nonsolvent to the polymer solution—diffusion induced phase separation (DIPS). Phase separation technique provides 3D scaffolds with a wide span of pore sizes and morphologies, and can be easily combined with other fabrication technologies, such as particulate leaching or 3D printing, to appropriately tune scaffolds for TE applications. However, it requires the use of organic solvents, results in poor pore interconnectivity and is limited to a small range of polymers with low melting temperatures.

2.1.4. Electrospinning

Electrospinning is electrohydrodynamic‐based process widely used for the fabrication of nanofibers from a polymer solution. The most basic set up needs an injection pump, a syringe tipped with a needle, a high voltage power source and a collector plate. Briefly, a high voltage is applied in the system to create an electric field between the tip of the needle and the collector plate. A polymer solution, contained in the syringe, is pumped to the tip of the needle. When a liquid droplet is formed out of the needle, it is electrified and this generates an electrically charged jet of polymer solution that moves toward the collector and forms fibers. This method has been extensively explored in TE because nanofibers are tunable in terms of size and spatial arrangement. Indeed, many parameters can be adjusted, among them polymer's molecular weight, conductivity, viscosity of the solution, surface tension, flow rate, voltage and distance between the nozzle tip and the collector. Another potentially interesting advantage of this technique is the possibility to use a wide range of materials such as PLGA, polycaprolactone (PCL), polylactide (PLA), silk fibroin (SF), collagen, and many other polymers. However, this process requires the use of organic solvents, and there remains a challenge to obtain electrospinning‐based 3D structures with appropriate pores size and shape to fulfill the needs in TE.

2.2. Advanced Fabrication Methods

In this section, we describe in detail advanced fabrication methods for 3D scaffolds. This description is based on the opposite references.[ 16 , 17 , 18 , 19 , 20 , 21 ]

2.2.1. 3D Printing

Over the past decades, 3D printing, also called additive manufacturing, has gained much interest and has been extensively used in TE. This computer‐aided design (CAD) technology can fabricate objects with complex structures by adding materials —ceramics, powders, plastics, metals, or liquids—by a layer‐by‐layer process with a bottom‐up approach. There are many various 3D printing techniques that can be classified into: i) laser‐based 3D printing which includes in particular stereolithography (SLA), selective laser sintering (SLS), digital laser printing (DLP); ii) extrusion‐based 3D printing which includes fused deposition modeling (FDM), and iii) ink‐based 3D printing which includes in particular ink jet printing (IJP), and aerosol jet printing (AJP). Among them, extrusion‐based 3D printing is the most commonly known printing technique in which the material is drawn through a nozzle and then selectively deposited layer by layer. 3D printing has led to considerable improvements in scaffold design and repeatability. It has the advantage to provide custom‐made porous complex scaffolds with detailed control over spatial geometry, microarchitecture, surface area‐to‐volume ratio, and porosity. It is an easy, cost‐effective process with less waste production, but requiring a high setup cost. With the rise of this technology, we will certainly be able, within a few years, to print detailed and clinically accurate scaffolds.

2.2.2. Bioprinting

Bioprinting is an advanced form of 3D printing to create structures from a bioink, a mixture of both materials and cells, or cells alone. Three main bioprinting techniques are extrusion‐based (EBB), droplet‐based (DBB), and laser‐based bioprinting (LBB). Whatever the technique is, once printed, the scaffold is commonly placed in a bioreactor to promote cell proliferation and maturation prior to implantation. Extrusion bioprinting is the most commonly used and consists of a nozzle that dispenses bioink continuously by physical force and pneumatic pressure to print scaffolds. Bioprinting provides customized/personalized 3D scaffolds with greater shape complexity, high accuracy, and high speed of printing. Cellular bioprinting allows to quickly manufacture complex 3D tissue structures with high cell viability and distribution, and ensures rapid tissue maturation for an effective tissue repair. However, 3D bioprinting is still costly and has to be further developed to reach a good control over the resulting materials/scaffolds properties.

Table 1 summarizes the advantages and disadvantages of each fabrication method that have been described in details in this section.

Table 1.

Advantages and disadvantages of different types of scaffolds fabrication techniques for tissue engineering application

| Technique | Advantages | Disadvantages |

|---|---|---|

| Conventional fabrication methods | ||

| Solvent casting/particle leaching |

High porosity (50‐90%) Controlled and tunable pore size and structure Easy‐to‐process and low cost |

Low pore interconnectivity Use of organic solvents High energy and time consuming Limited to thin membranes (<3 mm) |

| Freeze‐drying |

High porosity (>90%) and interconnectivity High interconnectivity of the porous network Tunable pore size and structure Capability of integrated bioactive molecules Capability of obviating high temperatures |

Poor control of scaffold porosity and morphology Use of organic solvents High energy and time consuming |

| Phase separation method |

Controlled and tunable pore size and structure Easily combined with other techniques Capability of integrated bioactive molecules Capability of obviating high temperatures |

Limited to a very few range of polymers Use of organic solvents Poor control scaffold morphology |

| Electrospinning |

Wide range of polymer Controllable process parameters to tune fibers Simple and low cost |

Mostly 2D scaffolds – Limited to produce 3D scaffolds Poor control of pore size and shape |

| Advanced fabrication methods | ||

| 3D printing |

Complex 3D shapes with high resolution Independent control of porosity and pore size Wide range of polymers |

Time‐consuming layer‐by‐layer processing and high cost |

| Bioprinting |

Greater shape complexity with high accuracy High speed of printing Suitable for incorporating cells into the scaffold with high cell viability (80/90%) |

High cost |

3. Vascular Tissue Engineering

Cardiovascular diseases, affecting the heart or blood vessels, are the leading causes of death worldwide.[ 22 ] In the field of vascular disease treatment, autologous vascular grafts are the most well‐established and common clinical option allowing to replace native vessels.[ 23 ] However, an ever‐persistent demand to reconstruct blood vessels, combined with the limited availability of autologous grafts (which may be of poor quality) and the complexity of the surgical procedure (which can potentially cause donor site morbidity), have motivated researchers to design scaffolds for tissue‐engineered vascular grafts (TEVGs).[ 24 ]

3.1. Architecture and Characteristics of Native Blood Vessels

The architecture of blood vessels depends on the vessel size and type, but a basic structure can be described independently of size and type, except capillaries. Blood vessels can be classified into three groups: arteries, capillaries, and veins. Arteries bring oxygenated blood to the tissues and veins return deoxygenated blood to the heart. Capillaries ensure exchanges of oxygen, nutrients, and wastes between blood and tissues, thanks to their thin walls and small diameter. The wall of the arteries and veins is formed by three layers: tunica intima, tunica media, and adventitia. Tunica intima is the inner layer, which is in contact with the blood, and consists of a monolayer of endothelial cells (ECs) and a basement membrane composed of mesh‐like substrate of type IV collagen. ECs are oriented along the blood flow direction[ 25 ] and play a key role in many biological processes such as coagulation, blood flow regulation, hemostasis, or inflammation.[ 26 ] Deeper there is a subendothelial connective tissue followed by an internal elastic membrane that separates intima and media. Tunica media is the middle layer and contains vascular smooth muscle cells (VSMCs), networks of elastin (elastic lamellae), and crimped collagen fibers (Col I and III). VSMCs are contractile cells that allow vessel contraction or dilatation, maintaining the proper blood pressure. They are arranged concentrically along the axis of the vessel. Media and adventitia are separated by an external elastic membrane,[ 27 ] and adventitia is the outmost layer, composed of fibroblasts, mainly aligned collagen fibers (Col I and III), and some elastin. It maintains the vessel's structure by preventing over‐extending or over‐retracting of the vessel.[ 26 , 27 ] The general structure of blood vessels is illustrated in Figure 2 . Finally, capillaries are the smallest vessels; they are lined by an only single layer of ECs and connect arteries and veins.[ 28 ]

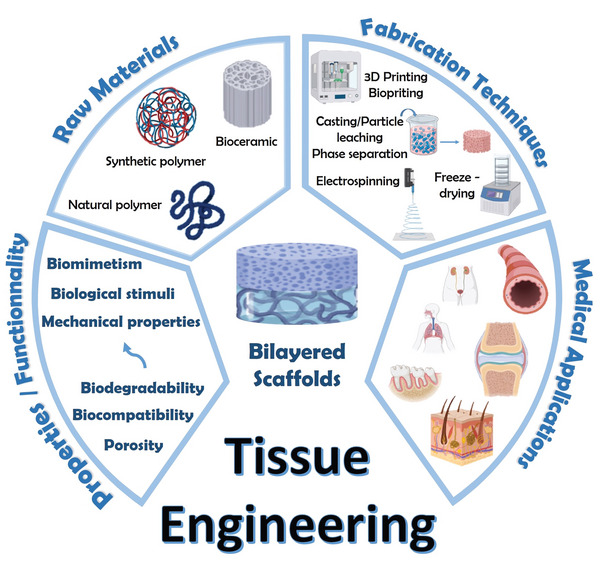

Figure 2.

General structure of blood vessels composed of three main layers: tunica intima, tunica media, and tunica adventitia. Reproduced under the terms of the Creative Commons License.[ 27 ] Copyright 2021, the Author(s). Published by Frontiers Media S.A.

From a mechanical perspective, the vascular wall is composed of approximately 70% of water, 30% in dry mass of collagen and elastin, with complementary percentages comprising glycosaminoglycans, proteoglycans, and vascular cells.[ 29 ] Collagen is the most common structural protein in the arterial wall, providing mechanical support and strength. Elastin is the second most common structural protein in the arterial wall and is secreted by VSMCs. As a key component of arterial ECM, it provides elasticity/recoil and allows interlamellar communication. Elastin fibers are 1000 times more flexible than collagen and are found in high abundance in the aorta.[ 30 ]

The composition and thickness of blood vessels vary according to the vessel type (artery or vein) and diameter. For instance, large arteries, like the aorta, are composed of a thick media layer and a high amount of elastin. Narrow vessels (i.e., small arteries) contain less elastin, but more smooth muscle cells. On the contrary, veins have a thinner media layer and, therefore, a less amount of elastic tissue.[ 29 ]

3.2. Strategies and Approaches

TE of vascular vessels is a promising approach to compensate the lack of native graft materials and to properly induce the regeneration of the tissue in terms of its architecture and properties. Blood vessels are dynamic tissues suited to withstand both the flow of blood and pressure, therefore, good understanding of the structural architecture of native tissues—including dimensions, composition, structure, and mechanical properties—is required to develop biomimetic scaffolds for vascular TE. From a biomimetic perspective, an ideal vascular scaffold should ideally replicate the structure and the functionality of the three distinct layers of a native blood vessel: tunica intima, tunica media, and tunica adventitia.[ 31 ] Additionally, native blood vessel faces warping, stretching, and expansion in the human body. Thus, high elasticity and a high degree of mechanical strength are also the main criteria for designing vessel‐like structures.

3.2.1. Building Bilayered Scaffolds for Vascular TE with One Component

Synthetic vascular grafts made of polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), or polyurethane (PU) have been developed and are still currently considered as gold standard materials for vascular TE.[ 32 ] Even so, these existing synthetic grafts have two main limitations: i) a limited patency and ii) a lack of appropriate tissue colonization.[ 27 ] Considering this, most of the TE approaches rely now on aliphatic polyesters, such as PLA, PGA, and PLGA copolymers.[ 33 ] Aliphatic polyesters represent the largest group of synthetic biodegradable polymers commonly used in vascular TE due to their good physical and mechanical properties comparable to those of native vascular tissues such as elasticity, mechanical/tensile strength, or degradation rate.

To cite another example of aliphatic polyester, PCL is also a competitive material used for medical applications.[ 34 ] For example, based on the specific architectural feature of blood vessels, Zhu et al. designed a PCL‐based bilayered vascular graft, in which VSMCs orientation is precisely respected (Figure 3a).[ 35 ] His goal was to develop a small‐diameter vascular graft mimicking the structure of native blood vessels by inducing the regeneration of circumferentially aligned VSMCs. The inner layer is composed of circumferentially aligned PCL microfibers prepared by wet‐spinning. In the wet‐spinning technique, a polymer is dissolved in a spinning solvent, then it is extruded out through a spinneret submerged in a chemical bath, and precipitates in fiber form. On the other hand, the outer layer made of random PCL electrospun nanofibers significantly enhanced the mechanical properties of vascular grafts, preventing bleeding due to the implantation (Figure 3b). The in vitro tests demonstrated: i) alignment of the cytoskeleton of VSMCs after 3 days of culture; ii) cell alignment along the circumferentially oriented fibers; iii) functional regenerated neoartery and iv) high viability of VSMCs in the scaffold. Furthermore, in the in vivo experiments, VSMCs and ECs were first seeded on the scaffolds and cultured in vitro in a bioreactor, then implanted in rat abdominal aorta. The results showed that the VSMCs layer with circumferential orientation and longitudinally aligned ECs layer were successfully regenerated. In this regard, Zhu et al. have developed a strong candidate for vascular tissue regeneration. However, further investigations are needed to evaluate the performance of this scaffold in large animals.

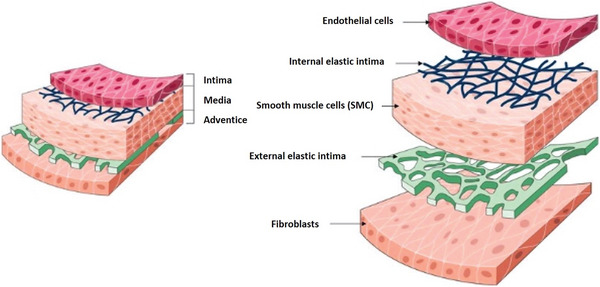

Figure 3.

Schematic illustration of the fabrication process set up by Zhu et al. a) Hypothesis orientation of circumferentially aligned PCL microfibers which could guide VSMCs regeneration. b) The two‐step fabrication process that has been used to manufacture the inner layer with circumferentially oriented PCL fibers by wet‐spinning and the outer layer randomly with oriented nanofibers by electrospinning. Reproduced with permission.[ 35 ] Copyright 2015, Elsevier. Schematic illustration of the fabrication process set up by Li et al. c) The custom‐made electrospinning technique to develop a PCL‐based two‐layer‐tubular scaffold in which the directions of the fibers of these two layers were orthogonal. d) Heparinization of PCL to improve its hydrophilicity. e) ECs and VSMCs co‐culture: ECs were seeded on the inner layer in which nanofibers are oriented along a axial direction whereas VSMCs were seeded on the outer layer in which nanofibers are oriented with a circumferential direction. Adapted under the terms of the Creative Commons License.[ 36 ] Copyright 2021, the Authors. Published by the Royal Society of Chemistry.

With a similar strategy, Li et al. have proposed a simple method to coculture ECs/VSMCs, mimicking cellular structure of native vascular vessels: ECs grow along the direction of blood flow while VSMCs grow circumferentially along the vessel wall.[ 36 ] Via a custom‐made electrospinning technique, they developed a two‐layer tubular scaffold in which the directions of the fibers of these two layers were orthogonal (Figure 3c). In fact, nanofibers of the inner layer for ECs culture were oriented along an axial direction, whereas nanofibers of the outer layer for VSMCs culture were with a circumferential direction (Figure 3e). It should be noted that heparin, a natural anticoagulant, has been grafted onto the scaffold to improve the hydrophilicity of PCL (Figure 3d). First of all, they investigated the guiding effect of the aligned fibers for cell orientation. For that, ECs and VSMCs were separately cultured on heparinized PCL films composed of aligned fibers and compared with random nanofibers used as a control. The two main results have shown that: i) grafted‐heparin has significantly enhanced adhesion between the substrate and the cells and cell proliferation, and ii) aligned fibers had a crucial guiding effect and induced cell orientation. Afterward, ECs and VSMCs were co‐cultured on the inner and outer layers of the tubular scaffold, respectively (Figure 3e). After 10 days, ECs and VSMCs lined almost the entire inner and outer side of the scaffold and growth in the desired orientations, along their fibrous directions. Additionally, mechanical properties’ characterization showed tensile stress similar to native human coronary arteries. Using electrospinning methods, this study was the first to develop a scaffold mimicking the orientation of native blood vessels. It may bring synthetic vascular grafts closer to clinical application.

Most research today focuses on polymer blends to produce blend materials with unique structural and mechanical properties based on specific properties of each of them. In vascular TE, PCL is the most commonly used synthetic polymer, but its main disadvantage concerns slow degradation rate and low cell attachment due to its high hydrophobicity.[ 34 ] Therefore, blending PCL with other materials may be a good strategy.[ 37 ] One of them, poly(L‐lactide‐co‐ε‐caprolactone) (PLCL), a copolymer of PLA and PCL, has been investigated for its potential use in TE. It was previously reported that PLCL tubular scaffolds were fabricated for small‐diameter vessel replacement by an extrusion‐particulate leaching technique.[ 38 ] However, these extruded PLCL scaffolds presented a lack of mechanical strength (tensile strength), making them unable to resist to the stitching process during in vivo implantation, as well as to physiological blood pressure.

To overcome this problem, Kim et al. studied a PLCL‐based (molar ratio 50:50) bilayered tubular scaffold having high mechanical properties, fabricated using a custom‐made gel‐spinning technique.[ 39 ] The bilayered scaffold was composed of i) an inner porous layer as a blood barrier to block blood leakage and ii) an outer fibrous layer for mechanical strength. They reported better mechanical strength and increased cell adhesion and proliferation, as compared to the extruded PLCL tubular scaffolds. Further in vivo studies (on the canine model) to evaluate the mechanical stability have to be conducted because blood leakage pressure would change along the biodegradation of scaffold in the body. In another study, Shin et al. prepared a dual‐layered electrospun scaffold from PLCL, composed of microfibrous and nanofibrous layers. Then, gelatin was grafted on the scaffold using acrylic acid (AAc) and γ‐ray irradiation to improve cell adhesion.[ 40 ] This grafting improved scaffold hydrophilicity, VSMCs proliferation and infiltration toward the microfibrous layer. In addition, they seeded human umbilical vein endothelial cells (HUVECs) on the entire surface of the nanofibrous layer to develop the intimal layer mimicking tunica intima.

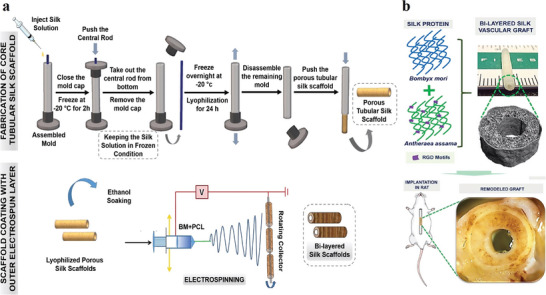

Natural biopolymers like collagen, SF or polysaccharides are very promising for various TE applications.[ 41 ] Sometimes, natural polymers exhibit better mechanical properties than synthetic polymers, making them of particular interest. It is the case of silk, a natural protein that is widely used as a potential biopolymer for designing TE scaffolds.[ 42 ] There are many different silk‐producing sources: silkworms, spiders, lacewing, glow‐worm, and mites. Bombyx mori, a mulberry‐feeding domesticated silkworm, is the most famous silk source commonly producing silk for the TE field.[ 43 ] Interestingly, a recent study reported the investigation of the endemic non‐mulberry silk from Antheraea assama. Indeed, Gupta et al. have first demonstrated the superior performance, in terms of mechanical and biological traits, of A. assama silk compared to B. mori silk, and its promising features for vascular TE applications.[ 44 ] In their previous in vitro studies, they had already suggested that A. assama silk i) supported vascular cell growth and functionality; ii) had superior mechanical/elastic properties compared to mulberry silk, and iii) reduced acute thrombosis in vivo thanks to the natural presence of RGD sequences (arginine‐glycine‐aspartic acid) on surface of non‐mulberry A. assama silk.[ 45 ] In their study, they designed a bilayered biomimetic small diameter vascular graft composed of i) an inner porous layer with interconnectivity—mimicking tunica media—to allow cellular infiltration; and ii) an outer dense electrospun layer—mimicking adventitia—to confer mechanical resistance. They adopted molding and freeze‐drying method to design the inner porous layer followed by coating of an electrospun outer nanofibrous layer (Figure 4a). With this pioneering method, parameters such as porosity, pore size, degradation rate and mechanical properties can be controlled by tuning protein percentage, freezing temperature and thickness of both layers. The results demonstrated that bilayered A. assama‐silk grafts fabricated using this method led to morphologically and mechanically biomimetic structures. In vivo short‐term implantation in rat aorta showed long‐term patency, suturability, and strength (Figure 4b). This A. assama silk is of great potential for designing vascular grafts and could be further extended for engineering other tissues as well. However, further studies are needed to improve in vivo performance and to investigate neo‐vessel formation in a long‐term in vivo implantation models.

Figure 4.

Schematic illustration of fabrication process set up by Gupta et al. a) Fabrication methodology of bilayered small vascular graft using silk‐based scaffolds. It is composed of an inner porous layer prepared by molding and freeze‐drying, followed by coating with electrospun outer nanofibrous layer. b) Graphical description of the bilayered scaffold and in vivo implantation in rat. Adapted with permission.[ 44 ] Copyright 2020, American Chemical Society.

3.2.2. Building Bilayered Scaffolds for Vascular TE with More Than One Component

Until now, a large range of biodegradable synthetic polymers has been considered as a well‐performing choice for TE of blood vessels.[ 23 ] One of the relatively new polyesters that are being increasingly explored is poly(glycerol sebacate) (PGS). Kharazi et al. aimed to combine PCL with PGS to find an appropriate balance between hydrophobic and hydrophilic characteristics.[ 46 ] Indeed, PGS has a superior cellular response, compared to PCL, and attractive blood compatibility owing to its hydrophilic nature. PGS is very fast‐degrading both in vitro and in vivo and a non‐electrospunable polymer (due to its low viscosity at low molecular weights and its rigidity due to harsh cross‐linking at high molecular weights), which limits its potential in TE.[ 47 ] That is why, by blending PGS and PCL together, Kharazi et al. have succeeded in production of electrospun nanofibers (thanks to the presence of PCL) suitable to improve cell attachment and proliferation (thanks to the presence of PGS). Regarding this, they fabricated a bilayered nanofibrous scaffold composed of i) PGS/PCL electrospun nanofibers as an inner layer which mimicked the antithrombotic features of the native intima and supported the attachment, growth, and infiltration of mesenchymal stem cells (MSCs); and ii) PCL nanofiber as an outer layer which reduced the degradation rate, reinforced and kept the integrity of the scaffold during the regeneration process (Figure 5 ).

Figure 5.

a) Entire view of the bilayered tubular scaffold composed of PGS/PCL electrospun nanofibers. b) SEM image of PGS/PCL nanofibers layer. c) SEM image of PCL layers. d) Cross section. e) SEM image of the interface between outer and inner layers. Reproduced with permission.[ 46 ] Copyright 2018, John Wiley & Sons Ltd.

More recently, on the same topic, Rekabgardan et al. mixed PGS with PU to introduce a novel fibrous scaffold which comprised two layers: i) an electrospun pure PU layer beneath another ii) electrospun PGS‐PU layer.[ 48 ] Based on the advantages and drawbacks of each, combining PU and PGS improved mechanical properties, biodegradation rate, and cell growth and proliferation on the scaffold.

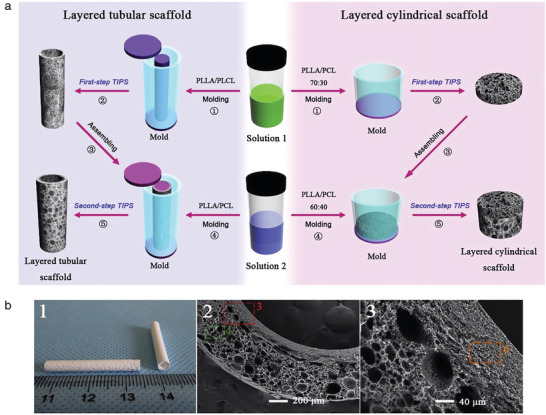

Many other studies have reported polymer blends for vascular TE. Wang et al. developed a bilayered tubular scaffold with a macroporous and biomimetic nanofibrous structure: a poly(L‐lactic acid) (PLLA)/PLCL microporous inner layer, and a PLLA/PCL macroporous outer layer (Figure 6b).[ 49 ] This work focused on the production of interconnected porous architecture which provides sufficient space for cell infiltration and proliferation, thereby facilitating new tissue formation. It was the first study fabricating a porous‐heterogeneous scaffold without using porogens, but via a two‐step phase separation technique (Figure 6a). Additionally, this method allowed tuning pore size in a simple way by adjusting polymer ratio. The microporous nanofibrous inner and outer layers were respectively used for endothelialization with ECs and VSMCs infiltration. Besides, after 3 months in vivo implantation into the jugular vein of New Zealand white rabbits, the implanted scaffolds kept patency and displayed favorable repair performance for small diameter blood vessels.

Figure 6.

a) Scheme of the two‐steps thermal‐induced phase separation technique to fabricate heterogeneous porous bilayered nanofibrous vascular grafts. The bilayered scaffold is PLLA‐based: a PLLA/PLCL microporous as an inner layer, and a PLLA/PCL macroporous as an outer layer. b) Reproduced with permission.[ 49 ] Copyright 2018, Elsevier.

In many works, a mix of bioderived materials and high‐molecular polymer materials are used. Liu et al. demonstrated that PCL can also be used with SF as a promising candidate for vascular TE applications.[ 50 ] Indeed, the electrospun PCL/SF microfiber scaffold has shown better mechanical strength and degradability compared to those of natural SF.

Moreover, by combining two of the most popular methods—electrospinning and freeze‐drying—Norouzi and Shamloo fabricated a dual‐layer scaffold with PCL fibers as an inner layer and heparinized‐based gelatin hydrogel as an outer layer.[ 51 ] Introduction of (heparinized‐based) gelatin into the blend greatly improved HUVECs proliferation and decreased the risk of thrombosis, thanks to the presence of heparin. In order to tune biodegradability, Li et al. added PLGA into the same blend, despite lower flexibility of PLGA, as compared to PCL.[ 52 ] The mixture exhibited a fast biodegradation rate and desired mechanical properties. They also focused on the cell‐specific orientation of native blood vessels (two oriented structures with circumferentially aligned VSMCs and longitudinally aligned ECs), already pointed out in Zhu et al.[ 35 ] and Li et al.[ 36 ] in their study.

Last, Zhao et al. combined all these polymers to take advantage of their properties: spider silk for its stability, flexibility, and elasticity superior to artificial fiber; PCL for its mechanical properties; chitosan for its biocompatibility; and gelatin for its excellent biocompatibility and hydrophilicity.[ 53 ] In terms of mechanical and biological properties, the results reported by Zhao et al. are close to the studies described above.[ 50 , 51 , 52 ]

Despite lower rigidity and mechanical strength, as compared to synthetic polymers, blends of natural polymeric materials are also used by the researchers. However, biofabrication techniques (such as microfabrication techniques, fiber‐based technologies and 3D bioprinting) to design large complex tissues from natural polymers, such as blood vessels for transplantation, are limited.[ 54 ] Indeed, the resulting scaffolds clearly present lack of strength and suture retention strength. Nevertheless, a recent work proved the possibility to develop advanced multilayered tubular structures by 3D bioprinting technology, with an enhanced mechanical strength.[ 55 ] This bioprinting method has a great potential to create multitude of tubular tissue architectures and is advantageous for controlling gradient composition/porosity/strength. It can definitely be extended for the fabrication of bilayered scaffold, as has already been explored by Xu et al.[ 56 ] Another alternative is to use a hierarchical approach for scaffold fabrication, called “bottom‐up” approach, where the layers are built sequentially and allow to modify and tailor each layer's properties independently, resulting in more complex structures.

In the study of Ryan et al., this kind of approach was used, allowing highly tailorable structures.[ 57 ] The researchers created vascular grafts using combination of three fabrication techniques: casting/solvent evaporation, crosslinking, and freeze‐drying. As raw materials, they focused on ECM proteins like collagen and elastin, to mimic native blood vessel ECM composition. Thus, a collagen‐elastin‐based biomimetic bilayered tubular scaffold was developed, containing i) a porous outer layer (mimicking the tunica media) offering a suitable environment for smooth muscle cells (SMCs) infiltration and proliferation and ii) a dense inner film‐like layer (mimicking the tunica intima) providing mechanical support. With their fabrication technique, each layer can be independently optimized to create a multilayered structure with tailored properties for desired mechanical and/or biological performance. Furthermore, it displays good layer integration, uniform wall thickness, and low immunogenicity.

Few articles deal with ECM components to mimic vascular scaffolds. Collagen (type I) and glycosaminoglycans (GAGs) are the major molecules of the extracellular matrix.[ 58 ] Both enable to build scaffolds to integrate and support new tissues. They provide elasticity, tissue strength, and flexibility. Zhou et al. were the first to build up a bilayered scaffold with collagen‐heparin (Col‐HP) to manufacture the inner layer, and collagen‐hyaluronic acid (Col‐HA) for the outer layer.[ 59 ] Both of them were cross‐linked via EDC reaction (chemical reticulation between carboxylic acid and amine groups from two different molecules thanks to the presence of 1‐ethyl‐3‐(3‐dimethylaminopropyl)carbodiimide (called “EDC”)). The resulting cross‐linked scaffold exhibited more favorable physicochemical, mechanical and biological properties compared to non‐crosslinked structures. Fibroblast cells (Cos‐7) and human microvascular endothelial cells (HMECs) were seeded for 3 days on Col‐HA surface and on Col‐HP layer, respectively. As a result, the authors have demonstrated that a bilayered cross‐linked scaffold promotes vascular regeneration by inducing fibroblasts and endothelial cell growths on each layer. However, strategies using crosslinking agents have many drawbacks: very often there is a lack of cells in the central part of the scaffolds, and there is a risk of cytotoxicity due to cross‐linking agent residues. Further in vivo evaluations are under consideration and will provide information on these eventual drawbacks.

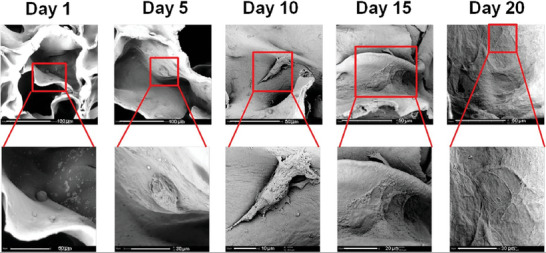

In TE, hydrogels have become an important basic biomaterial. Thus, Badhe et al. have developed a macroporous scaffold based on a chitosan/gelatin hydrogel which clearly, from a morphological and mechanical point of view, mimics blood vessels.[ 60 ] They used a modified solvent casting/particulate leaching method. However, gelatin‐based hydrogel melts easily at high temperatures (even with the body temperature), and therefore chemical crosslinking or copolymerization step is required to match the appropriated mechanical and elasticity strength. That is why a curing step in scaffold preparation was added. The resulting scaffold was composed of chitosan/gelatin‐based two layers with the following structure: i) an inner macroporous layer providing a large surface area which allowed strong cell adhesion and proliferation; and ii) an outer nonporous layer used as a barrier protection for cells and providing additional flexibility as well as elasticity. To evaluate cell proliferation, primary human dermal fibroblasts (HDFs) were seeded onto the bilayered scaffold for 20 days. SEM images clearly show cells attaching to the surface of the scaffold (Figure 7 ). On day 10, they observed extended and attached filopodia and on day 20, cells almost reached confluence and covered the scaffold surface. Thus, this result confirms the optimal biological properties of the designed bilayered scaffold, allowing fibroblast adhesion, growth, and proliferation.

Figure 7.

HDFas cell seeding onto the chitosan/gelatin‐based bilayered scaffold at days 1, 5, 10, 15, and 20 after culture in proliferation medium. Reproduced with permission.[ 60 ] Copyright 2016, Elsevier.

These different studies, summarized in Table 2 , showed that a wide variety of polymers, natural or synthetic, individually or mixed together, can be used to mimic human vascular tissue. In general, it is clear that electrospinning has gained popularity over the past decades in vascular TE, and has been clearly detailed in the literature.[ 23 , 37 , 61 ] Indeed, it has demonstrated a great potential to produce mimicking bilayered TEVG scaffolds. However, several challenges still remain open: use of toxics solvents, poor control over mechanical properties and degradation, problematic to obtain 3D structures with difficulty to control pore size for biomedical applications needs, insufficient cell infiltration to the scaffolds’ core, and finally inhomogeneous cell distribution.[ 37 ] To overcome the limitations, we believe that the use of advanced fabrication techniques should be a good alternative. Thus, 3D printing, and especially material extrusion additive manufacturing, is advantageous for designing structures with higher accuracy and greater shape complexity. Moreover, a fine controlling of gradient composition/porosity/strength will be possible, and combining bioprinting to incorporate cells to the scaffold is also possible. However, it is surprising that in the literature only few articles deal with 3D (bio)printing of multilayered scaffolds, including bilayered scaffolds.[ 55 , 62 , 63 ] We believe that researchers have to pay attention to this, and extensive work has to be conducted in future years. Furthermore, after many years of research, the future of TEVGs appears to be promising with arrival of new disruptive technologies, although many pre‐clinical and clinical studies will be necessary to validate these innovative solutions.

Table 2.

Summary of raw materials and fabrication methods used in vascular TE and corresponding to articles described above

| Clinical application | Raw materials | Fabrication methods | Refs. | ||

|---|---|---|---|---|---|

| Vascular TE | Building bilayered scaffolds with one component | ||||

| Natural materials |

Inner layer Outer layer |

Silk fibroin |

Molding/freeze‐drying Electrospinning |

Gupta et al. [44] | |

| Synthetic materials |

Inner layer Outer layer |

PCL |

Wet‐spinning Electrospinning |

Zhu et al. [35] | |

|

Inner layer Outer layer |

PCL | Electrospinning | Li et al. [36] | ||

|

Inner layer Outer layer |

PLCL | Gel spinning molding | Kim et al. [39] | ||

|

Inner layer Outer layer |

PLCL | Electrospinning | Shin et al. [40] | ||

| Building bilayered scaffolds with more than one component | |||||

| Blends of natural materials |

Inner layer Outer layer |

Collagen/chitosan | Solvent casting‐co‐particulate leaching | Badhe et al. [60] | |

|

Inner layer Outer layer |

Collagen Collagen/HA |

Cross‐linking | Zhou et al. [59] | ||

|

Inner layer Outer layer |

Collagen/elastin | Solvent evaporation/freeze‐drying/cross‐linking | Ryan et al. [57] | ||

| Blends of synthetic materials |

Inner layer Outer layer |

PGS/PCL PCL |

Electrospinning | Kharazi et al. [46] | |

|

Inner layer Outer layer |

PLLA/PLCL PLLA/PCL |

Dual‐phase separation | Wang et al. [49] | ||

|

Inner layer Outer layer |

PU PGS/PU |

Electrospinning | Rekabgardan et al. [48] | ||

| Blends of natural/synthetic materials |

Inner layer Outer layer |

Silk/PCL/gelatin/chitosan | Electrospinning | Zhao et al. [53] | |

|

Inner layer Outer layer |

PCL Gelatin |

Co‐electrospinning Freeze‐drying |

Norouzi et al. [51] | ||

|

Inner layer Outer layer |

PCL/PLGA/gelatin | Electrospinning | Li et al. [52] | ||

|

Inner layer Outer layer |

PGS/silk fibroin | Electrospinning | Liu et al. [50] | ||

4. Osteochondral Tissue Engineering

Osteochondral defects (OCD) refer to structural damage of the articular cartilage surface and the underlying subchondral bone, provoked by accidental injuries or osteoarthritis and resulting in severe pain, swelling and catching of the joint.[ 64 ] In the most serious cases, OCD repair is necessary, but these tissues are still hard to regenerate, because of the complexity of natural osteochondral tissue in terms of composition, structure, and function.[ 65 ] Surgical procedure is the most common current clinical approach to treat OCD injuries. It can be palliative (arthroscopic debridement, abrasion arthroplasty, and chondroplasty), reparative (microfracture, drilling, autologous or allogeneic osteochondral transplantation) or restorative (autologous chondrocyte implantation) according to the level of repair.[ 65 ] However, these approaches are not ideal because of intrinsic shortcomings, limitations, and complications in the final repair.

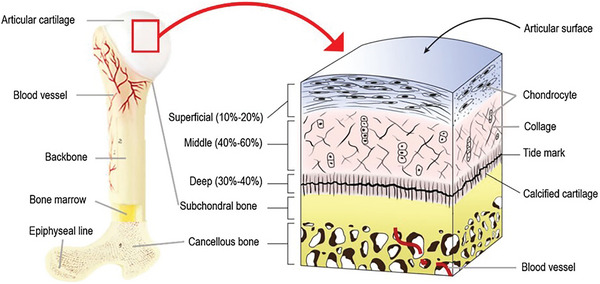

4.1. Osteochondral Tissue Structure

Osteochondral tissue is a cartilage–bone interface and is composed of cartilage and subchondral bone (Figure 8 ).[ 65 ] Cartilage is an avascular tissue composed of chondrocytes and ECM, containing water, collagen, and proteoglycans.[ 13 ] It can be separated into four zones, according to the composition and organization of each component.[ 13 , 64 ] The superficial/tangential zone is the 10–20% upper zone of cartilage. It is composed of densely packed collagen fibrils (type II and IX), parallel to the cartilage surface and many flattened ellipsoidal‐like aligned chondrocytes. It is an articulating surface, in contact with synovial fluid, with cells secreting proteins that maintain tissue lubrification and tensile properties.[ 8 ] The middle/transitional zone is the largest one (40–60%), with collagen fibrils being randomly oriented. In the deep/radial zone (30%–40%), cells and collagen fibrils are oriented perpendicularly to the cartilage surface. Deep and middle zones are the areas resisting against compressive forces.[ 8 , 64 ] Under these three articular cartilage zones, the tidemark is a structure that separates uncalcified cartilage from the last small region, the calcified cartilage.[ 8 , 64 ] Calcified cartilage is a transition zone between the flexible uncalcified cartilage and the rigid subchondral bone. It is permeable to small nutritional solutes, playing a role in maintaining the microenvironment between cartilage and subchondral bone.[ 8 ] The underlying subchondral bone is a vascularized tissue that can be separated into two layers. The subchondral cortical bone (or subchondral bone plate) has low porosity and few blood vessels, while the subchondral trabecular bone is highly vascularized and more porous. Bone tissue is composed of the bone ECM and osteoblasts, osteocytes, and osteoclasts (cells involved in perpetual bone breakdown and remodeling).[ 65 ] Subchondral bone transmits mechanical loads and provides nutriments for the cartilage. Moreover, it contains nerves, which explain its contribution to pain in diseases.[ 8 ]

Figure 8.

Osteochondral tissue structure. Cross section of a long bone and a schematic presentation of the osteochondral unit. Reproduced with permission.[ 66 ] Copyright 2020, Springer Nature.

4.2. Strategies and Approaches

Osteochondral tissue engineering (OCTE) is now considered as the best strategy for treating OCD and engineering such complex tissues. To design and fabricate a scaffold for OCD regeneration, several requirements have to be met:[ 8 ] i) in terms of composition, it should be biocompatible (with no rejection) and have stable physicochemical properties after implantation into the body; ii) structurally, it should have desired biomechanical properties and be a suitable environment (with an appropriate pore size and porosity) for cell attachment, proliferation, in‐growth, and neo‐tissue formation; iii) functionally, it should induce simultaneous regeneration of both cartilage and subchondral bone, maintain the cell phenotype, and be integrated into the surrounding cartilage and bone. Ideally, the aim would be to develop stratified scaffolds in order to mimic the native osteochondral tissue interface, comprising: i) a cartilage phase divided into four zones with the superficial one inducing the alignment and the morphology of chondrocytes, ii) a calcified cartilage zone, and iii) a subchondral bone zone (Figure 8).

4.2.1. Building Bilayered Scaffolds for Osteochondral TE with One Component

Synthetic polymers such as PLA, PLGA, and PCL are promising candidates for OCTE.[ 67 ] Indeed, the structure and properties of synthetic materials can be easily tailored and varied according to specific clinical applications, by altering the chemical composition, crystallinity, and molecular weight of the polymers.

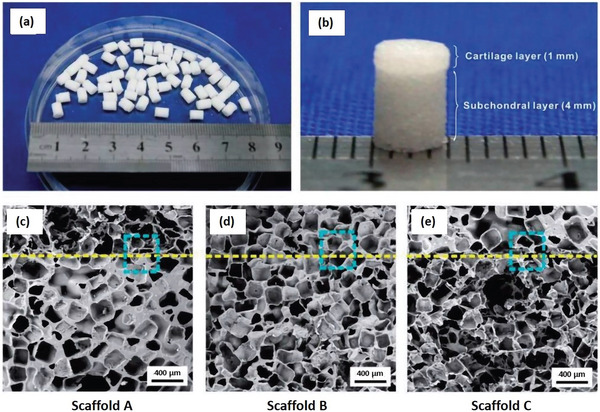

It is known that regeneration of specific tissues mostly depends on the following properties of the scaffolds: porosity, pore size, pore shape, pore distribution (interconnection between the pores), and architecture (overall shape of the object). On this, Pan et al. investigated the effect of scaffold porosity on spontaneous in vivo osteochondral repair in New Zealand white rabbit models.[ 68 ] For that, PLGA was used as a scaffold matrix. By molding/particulate leaching method, they created a porous structure using salt particles as porogens, with which pore size, shape, and porosity can be easily controlled. However, this fabrication method is often criticized because it uses toxic solvents (here dichloromethane) and often leaves residues. To solve the problem, we found interesting that several authors had the idea to replace the solvent casting step by a melt‐molding step: it is called melt‐molding/particulate leaching method.[ 69 ] Their goal was to find the appropriate porosity balance: avoiding too high porosity leading to mechanically weak scaffold or too low porosity preventing interconnectivity of the pores. For that, the PLGA‐based bilayered scaffolds (Figure 9a,b) were fabricated with the same porosity or different ones (pore size: 200–300 µm) on the cartilage and bone layers, respectively, and the porosity effect was then examined in vivo. Three porosity combinations were tested on rabbit models, with pre‐seeded bone marrow‐derived mesenchymal stem cell scaffolds (BMSCs), one of the main sources of cells used for OCTE. Indeed, it should be noted that MSCs have gained considerable attention and have been explored as attractive cell source, thanks to their multipotency with the ability to easily differentiate into osteoblasts and chondrocytes.[ 8 , 70 , 71 ] The three scaffolds porosities are the following: Scaffold A: porosity = 92%–77%, Scaffold B: porosity = 85%–85%, and Scaffold C: porosity = 77%–92% (Figure 9c–e). Six and 12 weeks after surgery, the group with 92% porosity in the chondral layer and 77% porosity (Porosity A) in the subchondral layer resulted in the best efficacy in terms of repair of osteochondral defects.

Figure 9.

a,b) General view of the bilayered PGLA scaffold structure with the cartilage and the subchondral layer. c–e) SEM micrographs of the three groups of bilayered scaffolds porosities. The dashed line indicates the border of the two layers. Reproduced under the terms of the Creative Commons License.[ 68 ] Copyright 2015, the Author(s). Published by Oxford University Press.

4.2.2. Building Bilayered Scaffolds for Osteochondral TE with More Than One Component

Previous studies have reported that pure polymer‐based scaffolds are not always suitable and effective for the rapid treatment of osteochondral defects.[ 70 ] Therefore, incorporating bioactive factors into biomaterials may be a good strategy for accelerating osteochondral tissue regeneration.[ 72 ] In this regard, Zheng et al. decided to combine synthetic polymers with natural polymers and add bioactive factors to promote osteochondral regeneration.[ 73 ] They aimed to develop a composite scaffold with 2 layers as following: i) hydrogel chondral layer (gelatin/silk‐fibroin/dextran blend) in which a cartilage‐inducing molecule, called kartogenin (KGN), is loaded into, and ii) a porous nanofibrous subchondral layer (PLLA/PLGA/PCL blend) in which bone morphogenetic protein 2 (BMP‐2) derived peptide (osteogenic factor) is loaded into. For in vitro release study, rhodamine B was used as a model drug to test the release profile of KGN whereas the fluorescein isothiocyanate (FITC) was chosen for BMP‐2 derived peptides. The two different bioactive factors could be released from the corresponding layers for more than 28 days (cumulative release ≥ 60%), with nevertheless the observation of an initial burst within the first few days for the rhodamine B. To study the cartilage differentiation potential, they seeded BMSCs on the KGN‐loaded hydrogel cartilage layer. The expression of several chondrogenic markers (COLI, COLII, SOX9, and aggrecan), measured by RT‐PCR at 7 and 14 days of culture, was significantly higher compared to non‐KGN‐loaded hydrogel, and confirmed that KGN loading promoted cartilage differentiation of BMSCs. Similar results were found for osteogenic differentiation of BMSCs on BMP‐2‐derived peptide‐loaded nanofibrous subchondral layer (RUNX2, COLI, OPN, and OCN specific osteogenic markers). In vivo experiments in rabbit knee joint model suggested that dual‐factor‐loaded bilayered scaffold might be a successful candidate for the treatment of osteochondral defects, by simultaneously enhancing the regeneration of cartilage and subchondral bone. However, with a total of eight different products, it may be difficult to bring it to the market for end‐use, given the regulations (regulatory affairs) of implantable devices.

For the simultaneous regeneration of osteochondral tissues, Natarajan et al. also added bioactive factors into their bilayered 3D printed scaffold.[ 74 ] PCL and PLGA were used for the chondral and subchondral layers, respectively, loaded with two bio‐factors. They added chondroitin sulfate (CS) in PCL and beta‐tricalcium phosphate (β‐TCP) in PLGA. More interestingly, they focused their strategy on 3D printed bilayered scaffolds having various infill densities, in terms of pore gradients and cell arrangement. Indeed, 3D printing technology is commonly known to be advantageous for controlling gradient composition/porosity/strength. They 3D‐printed a bilayered scaffold with an infill density which supported easy cell seeding at the top of the scaffold and prevented cell leakage during the seeding at the bottom. In vitro experiments showed that the open and interconnected pore structure of the scaffold enhanced cell adhesion/attachment, spreading and proliferation of MCSs. Moreover, the bilayered scaffold greatly induced the simultaneous differentiation of rabbit adipose‐derived multipotent cells (ADMSCs) into two cell lineages: chondrocytes (on the chondral layer) and osteoblasts (on the subchondral layer). Besides, the addition of bioactive factors promoted proliferation of ADMSCs and conveniently supported their differentiation.

In another work, Chen et al. explored the possibility to design a bilayered gene‐activated composite osteochondral scaffold, by using growth factor plasmids to induce MSCs differentiation.[ 75 ] They chose hydroxyapatite (HAP), chitosan and gelatin as raw materials for the scaffold, which was fabricated by conventional methods (namely mixing, molding and freeze‐drying). Indeed, previous studies have shown that chitosan/gelatin‐based scaffolds were ideal candidates to simulate cartilage ECM formation and provide a favorable matrix for chondrogenesis.[ 76 , 77 ] On the other hand, HAP has been naturally used for its composition, similar to human bone. In more details, a mix of HAP/chitosan‐gelatin (HCG) was used for design the subchondral bone layer, whereas chitosan/gelatin (CG) was used for the hyaline cartilage layer. For gene activation, they directly incorporated transforming growth factor‐β1 (TGF‐β1) and BMP‐2 plasmids in chondral and subchondral layers, respectively, and seeded MSCs in these layers (Figure 10 ). In vitro results demonstrated that spatially controlled and localized gene delivery could induce by MSCs expression and differentiation of the specific proteins of each layer: collagen type II and aggrecan, which are cartilage‐specific markers, and osteonectin, osteopontin and collagen I, which are bone‐specific markers. This was done in vitro for 14 days before differentiation into chondrocytes and osteoblasts, respectively. In the same study, osteochondral repair was evaluated in rabbit knee defect model. The results showed simultaneous cartilage and bone regeneration, with the appropriate restoration of the osteochondral architecture. Finally, the authors developed a promising strategy, based on a gene delivery system and multidifferentiation from a single stem cell population, to promote the engineering of complex tissues.

Figure 10.

Schematic representation of the preparation of the bilayered gene activated composite osteochondral scaffold: the hyaline cartilage layer was made with a mix of chitosan‐gelatin (CG) whereas HAP/chitosan‐gelatin (HCG) were used for the subchondral bone layer. pTGF‐ β1: plasmid TGF‐ β1; pBMP‐2: plasmid BMP‐2; MSC: mesenchymal stem cell; CG: chitosan‐gelatin; HCG: hydroxyapatite/chitosan‐gelatin. Reproduced with permission.[ 75 ] Copyright 2011, Elsevier.

Human bone ECM is a complex structure that comprises an organic component based on a network of collagen fibers reinforced with an inorganic phase composed of phosphate crystals.[ 78 ] Current osteochondral‐based materials refer to natural and synthetic polymers, even metallic materials. But recently, a specific class of materials—namely bioceramics, which are made with calcium phosphate (CaP) materials—have been proposed as the main constituent of osteochondral scaffolds.[ 79 ] Indeed, they possess unique bioactive properties like osteoinductivity (capacity to induce osteogenesis) and osteoconductivity (capacity to bone grow on a surface), making them suitable candidates for bone regeneration.

In OCTE, CaP‐based materials have been investigated alone, but several studies have reported their combination with proteins.[ 80 ] Among a lot of suitable polymers, Yan et al. made the combination of SF and CaP attractive for bone and osteochondral regeneration.[ 81 ] They developed a bilayered scaffold composed of i) a SF chondral layer and ii) a SF‐nanoCaP subchondral layer. Briefly, physicochemical characterization revealed good mechanical properties (compressive modulus), homogeneous porosity distribution, and CaP distributed in the silk‐nanoCaP layer, without any migration of this CaP migration in the chondral layer. In vitro, cultivated rabbit bone marrow mesenchymal stromal cells (BMSCs) attached well and proliferated on the scaffold with a good viability. Subcutaneous implantation in rabbit knee defects showed that after 4 weeks the scaffold was well‐integrated into the host tissue and supported tissue ingrowth and angiogenesis, with no real sign of inflammation. Histological and immunohistochemical staining confirmed cartilage regeneration in the top silk layer and novo bone ingrowths and vessel formation in the silk‐nanoCaP layer.

Four types of CaP materials are commonly used in bone/osteochondral TE: namely hydroxyapatite (HAP), tricalcium phosphate (TCP), biphasic calcium phosphates (BCP), and amorphous calcium phosphates (ACP).[ 82 ] Combining natural or synthetic polymers with these calcium phosphate materials is a promising strategy for OCTE.

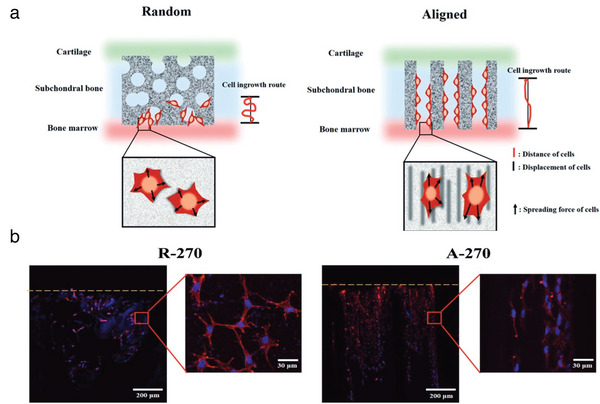

Seong et al. originally mixed collagen (type I) with CaP‐based materials, namely BCP, to mimic the cartilage and bone tissue, respectively.[ 83 ] They focused on the stratified design of aligned channels in a bilayered scaffold to enhance the efficiency of osteochondral tissue repair. Indeed, it is already known that the structure (pore orientation and pore size) of a scaffold can play a critical role in TE, particularly here in cell migration up to the cartilage region.[ 84 ] Aligned BCP/collagen scaffolds were successfully fabricated by sequential coextrusion and unidirectional freezing. Aligned structures exhibited significantly better mechanical properties compared to random structures. As shown in Figure 11A, cells could spread along the aligned channels which provide a driving force for their migration up to the damaged cartilage zone. In vitro evaluations demonstrated that: i) aligned channels effectively guided preosteoblast cells (MC3T3‐E1) to attach to the structure in highly stretched shapes, thereafter, migrating upward faster (Figure 11B); ii) aligned channels supported a superior osteochondral tissue regeneration compared to the random structure; and iii) smaller channels (140 µm) exhibited better cell migration and proliferation. At the same time, in vivo analysis performed on rabbit osteochondral defect model significantly revealed that bilayered scaffolds with aligned channels having an optimal channel diameter of 270 µm exhibited an accelerated BMSC migration and higher osteochondral regeneration, compared with a random porous structure. For their part, Ribeiro et al. chose β‐tricalcium phosphate (β‐TCP), and more specifically ion‐doped β‐TCP with pure zinc (Zn) and strontium (Sr).[ 85 ] Indeed, doping β‐TCP with the combination of Zn and Sr (elements existing in the bone) significantly enhances mechanical properties of the scaffold and positively affects human adipose‐derived stem cell growth and osteogenesis. More precisely, the researchers fabricated a bilayered scaffold composed of: i) horseradish peroxidase (HRP)‐cross‐linked silk fibroin (SF) as a cartilage‐like layer fully integrated into a ii) HRP‐SF/ZnSr‐doped β‐tricalcium phosphate subchondral bone‐like layer. The ion‐doped bilayered scaffolds presented high mechanical properties, controllable porosity, and TCP distribution. In terms of biological performances, in vitro coculture of human osteoblasts (HOBs) and human articular chondrocytes (HACs) was performed: the bilayered scaffold exhibited adequate properties for cell proliferation, infiltration, and ECM production. Nevertheless, in vivo evaluations need to be done.

Figure 11.

a) Schematic representation of hypothetic cell migration in the random and aligned structures randomly structure compared to the aligned structure. b) Observation of migrating cell morphology on BCP‐based bilayered scaffold through R‐270 (Random structure‐270 µm pore size) and A‐270 (Aligned structure‐270 µm pore size) after 7 d of seeding. The yellow line indicates the top surface of the bilayered scaffold. The yellow line represented the top surface of the BCP scaffold. Adapted with permission.[ 83 ] Copyright 2017, Wiley‐VCH GmbH.

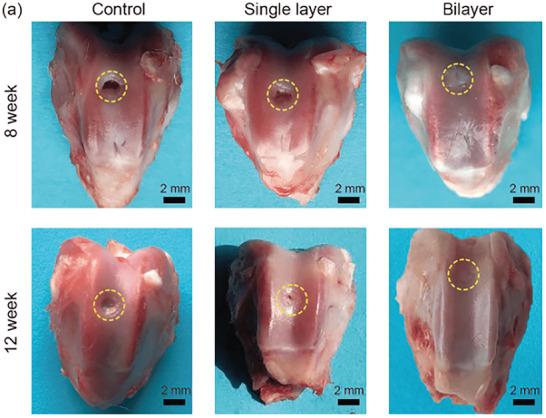

Among other materials, HAP represents nearly 65% of the weight of mineral phase of human bone tissue and is thus one of the best choice as osteochondral scaffold material.[ 86 ] HAP plays an important role in cartilage and bone TE and induces a biological activity with a full biocompatibility and no toxicity. In this regard, Liu et al. proposed a biomimetic scaffold made with a mix of human‐like‐collagen (HLC), hyaluronic acid (HA), and HAP particles to optimally simulate the composition and structural characteristics of natural cartilage and bone.[ 87 ] By combining three techniques—liquid phase synthesis, chemical cross‐linking and freeze‐drying—they designed a bilayered hydrogel scaffold consisting of: i) a macroporous HLC/HA chondral layer and ii) a small‐porous HLC/HA/HAP subchondral layer. All the tested physiochemical characteristics were similar to natural osteochondral support and suitable for new tissue formation: pore size (chondral layer: 120–300 µm; subchondral layer: 20–80 µm), high levels of porosity, and excellent mechanical properties. In vitro assays indicated that the scaffold was highly biocompatible and allowed significant human BMSC adhesion and proliferation with normal morphology. Moreover, in vivo experiments on rabbit models revealed that bilayered scaffold showed an effective repair and reconstruction of subchondral bone and cartilage, with a complete closure of the defect at the end of 12 weeks after surgery (Figure 12 ).

Figure 12.

Macroscopic evaluation of defect site of the control group (left in blank without any processing), single cartilage layer (HLC‐HA) and bilayered scaffold (HLC‐HA cartilage layer and HLC‐HA‐HAP subchondral) after 8 and 12 weeks after surgery. Reproduced with permission.[ 87 ] Copyright 2020, Science China Press and Springer‐Verlag.

In another study, Zhu et al. introduced HAP particles of two different sizes into both layers of their bilayered hydrogel scaffold: i) micro‐HA in the chondral layer for promoting cartilage matrix deposition and ii) HA nanocrystals in the subchondral layer for enhancing osteogenesis.[ 88 ] Furthermore, a major innovation consists in the use of a double‐network (DN) hydrogel system with the incorporation of bacterial cellulose (BC) to solve the poor mechanical properties of biopolymer‐based hydrogels. With its hydrophilic ultrafine fibers, bacterial cellulose can easily make chemical hydrogen bonds with the DN structure, resulting in a high‐strength biohydrogel. Their DN biohydrogel consisted of two polymer networks composed of i) poly(γ‐glutamic acid), lysine, and alginate, and ii) bacterial cellulose fabricated via chemical and physical cross‐linking. All the physicochemical characterizations (mechanical/rheological/morphological properties) and swelling behavior, as well as in vivo assays on osteochondral defect model of rabbits clearly showed that these bilayered scaffolds can be promising candidates for osteochondral regeneration. Recently, Kumbhar et al. also investigated if BC can be used in the treatment of osteochondral defects.[ 89 ] BC is widely used for biomedical applications for its unique physicochemical properties[ 90 , 91 ] and has already been explored as a biomaterial scaffold for cartilage TE.[ 92 , 93 ] To closely mimic cartilage and bone, the researchers designed a bilayered scaffold with, respectively: i) a BC‐glycosaminoglycans (chondroitin‐6‐sulfate) (BC‐GAGs) layer; and ii) a BC‐hydroxyapatite (BC‐HA) layer. They claimed being the first to develop high‐performing BC‐based acellular scaffolds for the repair of OCD. In vitro, the bilayered scaffold showed good biocompatibility and supported attachment and proliferation of HOBs and HACs. In vivo, subcutaneous implantations in rat model allowed tissue ingrowth, cartilage regeneration with deposition of ECM and regeneration of subchondral bone by the host cells, without any immunological reaction.

In another study, Sartori et al. incorporated magnesium‐doped hydroxyapatite (Mg/HA) crystals coprecipitated into collagen (type I) to design the subchondral layer, whereas the chondral layer was simply made with collagen (type I).[ 94 ] Being the most abundant of human tissues, Type I‐collagen was evidently chosen for its biocompatibility, low toxicity, biodegradability, and ability to guide cell proliferation and differentiation. Magnesium, highly present in bone structure, plays a key role in bone metabolism by stimulating, among others, osteoblast proliferation.[ 95 ] Therefore, with such elementary components, the results of the study confirmed that the bilayered scaffold was able to sustain human MSC attachment, proliferation, and chondrogenic and osteogenic differentiation with deposition of ECM. In vivo experiments with nude mice have only confirmed the potential of this scaffold in TE with bone and chondral neo‐tissues formation, tissue growth, and neoangiogenesis.

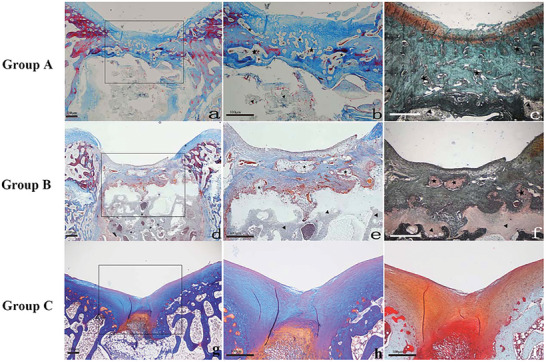

Recently, biodegradable polymer/hydroxyapatite composites as bone graft substitutes have been investigated. Nano‐hydroxyapatite/polyamide6 (n‐HAP/PA6) was reported as a good choice among all synthetic bone materials, due to its close composition and mimicking structure to natural bone minerals.[ 96 ] In another study, Li et al. used n‐HA/PA6 for the subchondral bone layer, and PVA/gelatin/vanillin for the cartilage layer to fabricate a PVA/gelatin/vanillin‐n‐HA/PA6 bilayered scaffold.[ 97 ] It is pointed out that vanillin, a natural phenolic aldehyde, could be added to the blend to improve the miscibility of polyvinyl alcohol (PVA)/gelatin composite by cross‐linking reactions and may also improve antioxidant and anti‐inflammatory activities. Additionally, an intervening nonporous PVA/gelatin layer allowed to bond of the two distinct porous layers together. In vivo implantation to rabbit knees for 12 weeks revealed that the cell‐seeded bilayered scaffold, carrying chondrogenically and osteogenically induced BMSCs on both layers, respectively, was able to successfully repair the osteochondral defect with similar characteristics to the native surrounding tissue. Histological examinations also confirmed the formation of cartilage‐like and underlying bone‐like tissues at 6 and 12 weeks after implantation, with a good integration with the native osteochondral tissues (Figure 13 ).

Figure 13.

Histological examination of PVA/Gel/V‐n‐HA/PA6 scaffolds at 12 weeks. a,b,d,e,g,h) Refer to Masson's trichrome stain, whereas c,f,i) to safranin‐O stain. a) Group A—cell‐seeded bilayered scaffold (×20). b,c) Detail of the PVA/gelatin/vanillin zone (×40). d) Group B—bilayered scaffold (×20). e,f) Detail of the PVA/gelatin/vanillin zone (×40). g) Group C—control group (×20). h,i) Detail of the defect zone (×40). The triangle symbol refers to the nHA/PA6 scaffold and the star symbol refers to the PVA/gelatin/vanillin scaffold. Reproduced with permission.[ 97 ] Copyright 2015, John Wiley & Sons.

Table 3 summarizes current TE strategies and shows how OCTE with bilayered scaffolds emerged as a potential alternative for repairing OCD. In this field of TE, we reviewed many approaches in recent studies: freeze‐drying, cross‐linking, or particulate leaching, which are used to create bilayered scaffolds suitable for the regeneration of OCD with controlled porosity, interconnected pores, and proper mechanical properties. However, these conventional methods are not efficient enough to fabricate an ideal substitute mimicking the native osteochondral tissues. Scaffolds for OCTE require to meet higher standards: uniform pore size, high interconnectivity, and high porosity. We think that this drawback can be reduced by introducing some other techniques such as electrospinning, 3D printing/bioprinting, and a combination of molding techniques. Considering this, many studies have been carried out but focusing on multilayered scaffolds.[ 98 , 99 , 100 , 101 ] In the future, we suggest that it can be easily extended to the fabrication of bilayered scaffolds.

Table 3.

Brief summary of raw materials and fabrication methods used in all the articles described above in osteochondral TE and using biomimetic bilayer scaffolds

| Clinical application | Raw materials | Fabrication methods | Refs. | ||

|---|---|---|---|---|---|

| Osteochondral TE | Building bilayered scaffolds with one component | ||||

| Synthetic materials |

Chondral layer Subchondral layer |

PLGA | Molding/particulate leaching method | Pan et al. [68] | |

| Building bilayered scaffolds with more than one component | |||||

| Blend of synthetic materials |