Abstract

Utilising agricultural byproducts specifically fruit wastes for bioethanol production offers a promising approach to sustainable energy production and waste mitigation. This approach focuses on assessing the biochemical composition of fruit wastes, particularly their sugar content, as a key aspect of bioethanol production. This study evaluates the potential of pineapple, mango, pawpaw and watermelon fruit wastes for bioethanol production, highlighting the substantial organic waste generated during fruit processing stages such as peeling and pulping. Various techniques, including enzymatic hydrolysis, fermentation, and distillation, are reviewed to optimise bioethanol yields while addressing challenges such as seasonal availability, substrate variability and process optimisation. Besides, the environmental benefits of bioethanol derived from fruit wastes, such as reduced environmental pollution, decreased reliance on fossil fuels, and promotion of sustainable agricultural practices, are emphasised. The study deployed a comprehensive literature review using keywords, specific research questions, and a search strategy that included academic databases, library catalogues, and Google Scholar. Search results were systematically screened and selected based on their relevance to the topic.

Keywords: Bioethanol, Energy, Fruit waste, Pretreatment, Fermentation

Graphical abstract

Highlights

-

•

Fruit waste is a renewable, affordable, and readily available resource for bioethanol production.

-

•

Fossil fuel dependence as energy sources has adverse environmental effects.

-

•

Bioethanol is the emerging important alternative energy source over fossil fuels.

-

•

Fruit wastes as feedstocks have potentials for bioethanol production.

1. Introduction

Population growth and changing dietary habits are driving a high rate of fruit consumption, with the fruit processing industry generating over 887 million metric tons of fruits annually in 2017 [1,2]. Fruit wastes (FWs), including damaged, rotten fruits, peels, seeds and cores, contribute to over 57 million tons of global waste annually, causing environmental pollution and health issues due to improper dumping [1]. Over 50 % of fresh fruits consist of byproducts and wastes such as bagasse, peels and seeds [3,4]. Around 37.5 % of FWs are peels generated from juice-processing industries and remnants from cafeterias, vendors and restaurants commonly discarded into the surroundings [5]. The FWs generated due to damage, spoilage, and over-ripening of fruits during their transportation, storage and processing often end up in municipal waste systems and pose environmental and health risks [3]. The FWs constitute a significant part of Tanzania's municipal solid waste, contributing 57.21 %, thus posing environmental concerns in urban areas [6]. The FWs exhibit high levels of biodegradability and fermentability, which pose environmental risks such as health problems, pollution, and water supply contamination [7]. Still, FWs are sustainable and environmentally friendly resources for bioethanol generation, given their abundance of reducing sugars, organic compounds, and other valuable nutrients [8]. The high sugar content in FWs presents a promising source for bioethanol production through fermentation, indicating their potential for sustainable energy production [9]. Common FW management methods like landfills, incineration, and open burning generate secondary waste, necessitating the recycling of FWs into marketable products and promoting the "circular economy" principle [4,10]. Therefore, effectively controlling and recycling FWs into valuable products is crucial for minimising environmental waste and promoting sustainable practices [9]. Processing FWs into bioethanol through fermentation can offer an environmentally friendly and cost-effective approach to FWs management. Various microorganisms ferment fruit and vegetable juices; Saccharomyces cerevisiae strains, known for high bioethanol yield and efficient sugar conversion, have evolved significantly for bioethanol production. Still, S. cerevisiae is a model organism used in genetic engineering, molecular biology, genetics, and synthetic biotechnology [11]. It can glycolysing hexose carbohydrates to produce carbon dioxide and bioethanol [12]. It has been shown that genetically modified bacteria, including Bacillus subtilis WB600, Kluyveromyces marxianus, Saccharomyces cerevisiae CCUG 53310, and Clostridium cellulolyticum ATCC 35319, are effective at producing lignocellulosic bioethanol [12]. These microorganisms have been modified to improve their capacity to decompose complex plant structures into sugars that can ferment and produce bioethanol [11]. Global bioethanol production is projected to increase from 100.2 billion litres in 2016 to 134.5 billion by 2024, driven by sustained output as illustrated in Fig. 1 [13].

Fig. 1.

Global bioethanol production [13].

Approximately 40 % of global bioethanol production is derived from sugar cane and sugar beet, while 60 % originates from starch-containing feedstock [14]. Bioethanol production costs are primarily influenced by raw material prices, which account for 40–75 % of the total expenses, with costs varying across countries [15]. Bioethanol production costs vary significantly across countries. Brazil leads with costs ranging from 0.54 to 0.62 USD per litre, followed by the USA at 0.51 to 0.58 USD and China at 0.28 to 0.46 USD. These costs are influenced by factors such as feedstock availability and government policies [16]. Studies report the quality and quantity of bioethanol derived from various FW as they offer a cost-effective alternative feedstock for bioethanol production [17]. Pineapple waste fermented with Saccharomyces cerevisiae yielded bioethanol with a concentration of 21.3 g/L, and pineapple peels hydrolysed with Trichoderma harzianum yielded 5.98 g/L of bioethanol [17,18]. Additionally, the waste from mango pulp produced 15 g/L of bioethanol, whereas the use of S. cerevisiae to ferment mango peels produced 8.45 g/L of alcohol [19]. Even yet, 4.19 g/L of alcohol was created from pawpaw's bioethanol production using S. cerevisiae [20].

The primary objective of this review was to investigate the potentiality of FWs in producing bioethanol as a competitive alternative energy source to fossil fuels. Examining the various types of FWs, their biochemical characteristics and the technological procedures involved in converting these wastes into bioethanol highlights the environmental and economic benefits of using FWs. It also examines the sustainability of bioethanol production, highlighting its role in reducing greenhouse gas emissions and enhancing energy security for both developed and developing countries. Through a comprehensive analysis, this review emphasises the importance of bioethanol derived from FWs in maximising global energy resources.

2. Feedstock for bioethanol production

Biomass encompassing sugar, starch and lignocellulosic-containing substrates holds excellent promise as a feedstock source for bioethanol generation owing to its carbohydrate composition [21]. Due to their diverse biological variety, plant-based materials, rich in sugars and starch, aid as starting materials for bioethanol generation [22]. Bioethanol production utilises raw materials categorised into four generations: first-generation, second-generation, third-generation and fourth-generation [23].

First-generation bioethanol feedstock includes sugar crops such as sugarcane, sugar beet, sweet sorghum and starch crops like corn, wheat and barley [24]. First-generation industrial bioethanol production in Europe uses wheat, sugar beet, and barley as feedstock [25], corn in the USA [26] and sugarcane in Brazil [27]. First-generation bioethanol production offers cost-effective, energy-efficient solutions that reduce dependence on non-renewable energy sources and the release of gases contributing to the greenhouse effect [28]. Despite their ease of processing and availability, the first-generation feedstock use raises concerns as they threaten food security and biodiversity due to resource competition [28]. Bioethanol production in first-generation can cause competition for food resources and land use and increased food costs due to diverting agricultural resources for bioethanol production [27,29]. This imbalance in food supply, demand, deforestation, habitat loss and decreased availability of staple food crops can lead to food price spikes [24]. Non-food lignocellulosic materials can mitigate food security and biodiversity concerns by minimising pressure on arable land and natural ecosystems [30]. Second-generation bioethanol production utilises feedstock derived from lignocellulosic crops, focusing on the residual non-food components such as stems, leaves, husks, rotten fruits and fruit peels [23]. Second-generation bioethanol production offers a sustainable alternative to first-generation feedstock, primarily composed of agricultural residues, forest residues, and energy crops [24]. Bioethanol production from waste feedstock to reduce food-versus-fuel debate, greenhouse gas emissions and climate change while providing additional income for farmers through energy crop cultivation and agricultural residue utilisation [13]. Sustainable generation of bioethanol from second-generation feedstock aligns with the goals of achieving energy security and transitioning towards a low-carbon economy [31]. Expanding bioethanol production to non-food lignocellulosic materials offers numerous benefits, including an abundance of renewable resources from agricultural residues, forestry residues and FWs without competing with food crops [32]. Bioethanol production from second-generation feedstock faces challenges in the pretreatment of lignocellulosic biomass due to its complex structures and specialised techniques for degrading them into fermentable sugars [33]. Moreover, Lignocellulosic hydrolysate fermentation into bioethanol faces challenges like microbial inhibitors and low efficiency, necessitating improvement to improve second-generation bioethanol production process economics [28]. Although second-generation bioethanol production encounters obstacles, diversifying into alternative feedstock like algae and aquatic plants could offer promising solutions.

Besides, in third-generation bioethanol production, diverse photosynthetic algae as feedstock contribute to sustainable and environmentally friendly processes due to their unique characteristics and diverse phylogenetic groups [24]. The organic content in algae is between 25 % and 60 % carbohydrates, which is significant for bioethanol production [34]. The technology addresses food security concerns through non-competitive food production, but challenges like complex harvesting methods and processing costs must be addressed [34]. However, in fourth-generation bioethanol production, advanced technologies and non-food feedstock focus on sustainability and environmental impact [35]. The advancement of synthetic biology, engineered microorganisms, and non-food crops is being utilised to improve efficiency and increase biofuel productivity, surpassing previous generations' limitations [24].

3. Fruit production and fruit waste generation

Fruit production globally significantly boosts agricultural output and food supply generating waste, including byproducts and residues from processing, handling and consumption [4,36]. Major fruit-producing countries include China, India, Brazil, the US, and the EU, which grow various fruits in large-scale commercial orchards and smallholder farms, including apples, oranges, bananas, grapes, mangoes, and watermelon [37]. Fruit production has been increasing significantly, reaching 59 % with a total output of 910 million tons from 2000 to 2021 due to its health potentiality and population growth [38]. High fruit production and consumption result in significant FW generation, with 41 million tons of FWs produced annually from common fruits like banana, orange, lemon, mango, and watermelon [7]. Apart from seeds and rotten fruits, fruit peel waste alone contributes about 15 %–60 % of the FWs and is typically disposed of [4]. Fruit variety, seasonality, and processing methods influence the quantity and composition of FWs generated by factors, including post-harvest losses, market demand, transportation, and consumer behaviour [39]. The FWs can cause environmental problems and health risks if not adequately managed; thus, proper FWs management is required to avoid the environmental and health effects resulting from improper FWs disposal, necessitating proper FWs management.

4. Fruit waste management

The FWs management is concerning with the creation, prevention, characterisation, monitoring, treatment, modification, reuse and residual elimination of FWs [2]. The production of FWs causes environmental consequences such as emitting greenhouse gases during decomposition, pollution in land and water due to improper disposal and resource depletion due to food wastage [40,41]. Such environmental effects can be mitigated by developing novel waste management techniques, improving post-harvest operations, and implementing efficient production methods [40,42]. Although FWs management techniques differ by region, common approaches include landfill disposal, animal feed supplementation, anaerobic digestion for biogas production, composting, and industrial processing. The management of FWs often places a high priority on turning FWs into commercial products, encouraging a circular economy, and taking the environment into account to reduce the production of secondary waste [43]. Landfilling, a typical practice where waste is disposed of at approved sites, is the principal technique of handling FWs [44]. However, this strategy has several serious drawbacks, such as the possibility of soil and groundwater contamination, the creation of methane, a potent greenhouse gas that contributes to climate change, and the occupation of important land [45]. Among the recycling methods are anaerobic digestion, which produces biogas, composting to create soil nutrients, and the generation of bioethanol, which turns trash into a valuable energy source [46]. In the anaerobic digestion method, organic matter is broken down by bacteria without oxygen. This technique is effective for waste reduction and energy recovery since it generates digestate, a nutrient-rich material, and biogas, a mixture of methane and carbon dioxide [46]. However, it requires significant initial investment, technical expertise, and continuous monitoring, while the composition and consistency of FWs affect process efficiency [47]. On the other hand, incinerating FWs reduces waste volume significantly and produces power by burning the waste [48]. This process has significant start-up and running expenses and, if not adequately managed, can emit hazardous emissions [48]. Moreover, burning causes the loss of beneficial nutrients that could have been recycled back into the environment.

4.1. Limitations of current methods of fruit waste management

There are various drawbacks to the FWs management techniques used today. Everyday activities like incineration and landfilling greatly increase greenhouse gas emissions and pollutants, worsening the environmental effects [49]. Furthermore, these techniques frequently fall short of fully utilising FWs' ability to create beneficial products like biofuels, bioplastics, or biofertilisers, missing out on possibilities to make the most use of resources [49]. Economic constraints arise from the high costs of modern waste management systems, especially in low-income areas where infrastructure and technological investment may not be sufficient for efficient waste management [50]. Inconsistent or inadequate regulatory and legislative frameworks in various countries further impede efficient waste management procedures.

4.2. Need for improved fruit waste management

Improved FWs management plans that put sustainability and resource efficiency are urgently needed. Developing sustainable strategies that maximise resource utilisation and reduce environmental effects is essential. The conversion of feedstock waste into high-value products like biofuels, bioplastics, and biofertilisers can be achieved through innovative recycling technologies that improve economic viability and foster environmental sustainability. Integrating several waste management technologies, such as anaerobic digestion, recycling, and composting, can significantly enhance overall efficacy and efficiency in waste reduction and utilisation. Adequate education and knowledge regarding the advantages of appropriate waste management at the individual, community, and industrial levels are crucial for promoting behavioural modifications and enhancing waste management procedures. Governments are essential to this change because they make and enforce laws and policies that encourage sustainable waste management methods and provide incentives for larger-scale recycling and trash reduction programs. There has been some documented improvement in sustainable FWs management techniques in recent years. These tactics include employing FWs as soil amendments, extracting bioactive chemicals, bioremediation, biotechnological processes, and bioconversion [51].

4.3. Bioremediation

Bioremediation is a sustainable biotechnology method that uses microbes to break down pollutants into harmless byproducts like water and carbon dioxide (CO2), effectively cleaning up polluted areas [52]. Bioremediation and FW management are interconnected through sustainability and environmental conservation [53]. Bioremediation involves using microorganisms, plants or their enzymes to detoxify or remove pollutants from contaminated environments [54]. In the context of FWs management, bioremediation involves the action of microorganisms in composting the complex organic compound present in FWs. Composting reduces waste volume and improves soil health by degrading complex organic compounds into simpler molecules like organic acids using aerobic microorganisms [54,55]. Microorganisms further metabolise this process, producing CO2, water, and heat and eventually transforming into stable humus [55]. The FWs can be composted by using microorganisms which degrade organic matter into nutrient-rich compost, thus reducing waste volume and providing soil amendments that improve soil health and fertility [54]. Actinomycetes, fungi, and bacteria break down organic matter into simpler chemicals during composting, producing heat while they do so [54]. These bacteria can purify contaminated soil by using their normal metabolic processes to break down toxic substances found in fruit debris [56]. Using bioremediation techniques in FW management procedures provides an environmentally friendly and sustainable method of treating waste [57]. Still, the bioremediation approach in FWs management faces challenges due to the rapid decomposition of FWs, which can produce unpleasant odours and attract pests, making their management more difficult. Also, the cost of bioremediation, including the purchase and maintenance of microbial cultures, monitoring equipment, and additional nutrients, may be prohibitive. Thus, converting FWs into added-value products like bioethanol can help minimise costs and overcome challenges concerning environmental pollution.

4.4. Biotechnological processes

Because biotechnological methods offer creative solutions for resource recovery, waste reduction, and environmental sustainability, they are essential for managing FWs [58]. These procedures entail using microbial fermentation or enzymatic processes to transform organic matter into useful products like biofuels, enzymes, organic acids, or bioplastics [59]. The FWs can undergo bioconversion to produce a variety of bioproducts with a wide range of uses, including in food, medicine, cosmetics, and bioplastics [60]. Biotechnological methods provide flexible and environmentally friendly ways to handle FWs, turning them from a possible environmental hazard into a helpful resource for business, agriculture, and energy options. By utilising biotechnology, FWs management can support resource conservation, environmental protection, and the shift to a circular economy. In particular, FWs can be bioconverted into bioethanol, a renewable biofuel that helps provide energy in a sustainable manner. When producing bioethanol from FWs, an eco-friendly method is used to lower greenhouse gas emissions and promote the use of cleaner energy sources instead of fossil fuels.

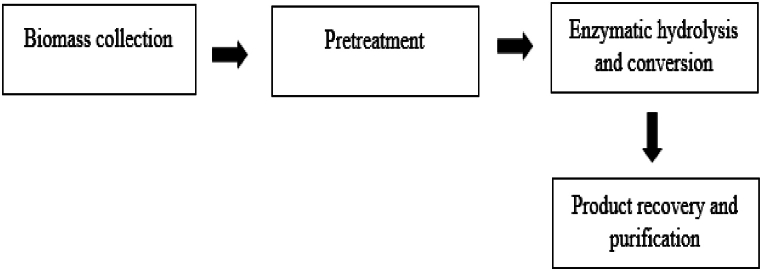

4.5. Biorefining process of fruit wastes

Lignocellulosic biomass is one of the most common and promising feedstocks for biorefining. Through various biochemical and thermochemical processes, complex biomass materials such as forestry wastes, agricultural residues, and specific energy crops are transformed into a range of valuable products during the biorefining of lignocellulosic biomass [61]. The primary components of lignocellulosic biomass are cellulose, hemicellulose, and lignin; each requires a unique process for effective conversion into biofuels and biochemicals [61]. As shown in Fig. 2, the biorefining of lignocellulosic biomass generally consists of four primary steps: biomass collection, pretreatment, enzymatic hydrolysis and conversion, and product recovery and purification [61].

Fig. 2.

Biorefining process involved in lignocellulosic biomass [61].

5. Fruits waste utilisation

The FWs utilisation involves converting FWs into beneficial use in an environmentally responsible way while preserving or enhancing soil and plant resources [2]. Many FWs are rich in biological compounds, which can cause environmental and health problems if poorly managed [62]. The FWs can offer low-cost, environmentally friendly raw materials for various uses like nutrient sources, therapeutics, animal feeds, and bioethanol production with proper management [63]. The FWs utilisation encompasses a diverse range of methods and applications aimed at maximising the value of fruit byproducts while reducing environmental harm [64]. The FWs utilisation is addressed in the following subsections.

5.1. Nutritional value of fruits wastes

The FWs, including pineapple, watermelon, orange, apple and mango peels, are rich in nutrients that contribute to health and well-being. These wastes contain essential vitamins, minerals, lipids, carbohydrates, carotenoids, and dietary fibres [2]. For instance, watermelon and pineapple peels from FWs are valuable sources of nutrients, aiding in waste management and providing low-cost nutrition for both human consumption and animal feeds [65]. Biotechnological processes utilise these nutrient-rich FWs to extract valuable nutrients for various applications [66]. This integrated approach supports efficient FWs utilisation, reduces environmental impact, and promotes circular economy principles by maximising resource recovery from fruit processing residues [67]. Thus, FWs' management, through extracting valuable nutrients, not only addresses environmental challenges but also enhances resource efficiency and sustainable development in multiple sectors. The nutritional value of various FWs is presented in Table 1.

Table 1.

Nutritional value of fruit wastes.

| No | Fruit Waste | Nutritional Value | Reference |

|---|---|---|---|

| 1 | Apple Peels | High in dietary fibres, vitamin C, and antioxidants | [68] |

| 2 | Orange Peels | Rich in dietary fibres, vitamin C, and flavonoids | [69] |

| 3 | Watermelon Rinds | Good source of citrulline, vitamin C, and fibres | [70] |

| 4 | Pineapple peels | Contains bromelain enzyme, vitamin C, and fibres | [71] |

| 5 | Mango Peels | High in vitamin C, dietary fibres, and polyphenols | [72] |

5.2. Therapeutic properties of active compounds from fruit wastes

Researchers are increasingly focusing on using FWs as a primary source of valuable compounds in medicine, including polyphenols, flavonoids, carotenoids, vitamins, terpenoids, and antioxidants [73]. Studies show that bioactive compounds from FWs Polyphenols, Flavonoids, Carotenoids, Vitamins, Terpenoids, and Vitamins C, E and A are used as an anticancer, antidiabetic, anti-inflammatory, antimicrobial, antioxidant and neuroprotective [74]. For example, pulp waste is an antioxidant and antimicrobial that enhances human health and well-being [75]. Besides, orange flesh and peels contain polyphenol that protect human white blood cells against oxidative and DNA damage [4,75]. Still, reports reveal that pineapple and orange waste contain antimicrobial agents which play an essential role in protecting the human body against pathogens, particularly Bacillus subtillis and Klebsiella pneumonia [4]. On the other hand, watermelon rinds contain an amino acid citrulline, which protects the human body from free-radical damage and efficiently scavenges the hydroxyl group. Citrulline can be transformed into another form of amino acid, arginine, which is useful in the immune, respiratory, and cardiovascular systems [76]. Thus, FWs are useful as cheap and highly available sources of active compounds that have the potential to manufacture different drugs.

5.3. Fruit wastes as a microbial growth medium

The FWs can serve as an effective growth medium for various microorganisms, offering a cost-effective alternative for microbial cultivation [77]. The substrate used significantly impacts the production costs of microbial-derived goods, making inexpensive substrates essential for enhancing manufacturing viability [7]. FWs can be an effective growth medium for various microorganisms due to their rich nutrition content and organic composition [78]. When FWs undergo decomposition, they release a range of organic compounds, including sugars, amino acids, vitamins and minerals, which provide essential nutrients for microbial growth and metabolism [79]. Certain FWs have been successfully utilised as growth media for microorganisms, including bacteria and fungi, that manufacture valuable metabolites such as enzymes, lipids, and pigments [80]. Researchers have increasingly explored FWs as a substitute low-cost growth media for microbial cultivation, aiming to optimise production processes and reduce production costs [7].

5.4. Fruit wastes as a source of bioethanol

The FWs show potential as a bioethanol source due to their abundant fermentable sugars, making them suitable for bioethanol production [81]. Bioethanol production from FWs belongs to the second generation because non-edible food materials are used [82]. Bioethanol is produced from FWs such as pineapple, mango, and watermelon through a series of steps: waste collection, pretreatment, juice extraction, addition of fermentable sugars, fermentation, and distillation [8,81]. The FWs offer several bioethanol production advantages, including their abundance, low cost and high sugar content [83]. Therefore, the application of FWs for bioethanol production contributes to waste reduction, promotes sustainable practices, is cost-friendly and provides an eco-friendly alternative to non-renewable fuel sources [41]. Beyond its environmental advantages, FWs represent a promising, cost-effective, abundant and renewable resource for bioethanol production [84]. The FWs offer sustainable raw materials for bioethanol production, thus addressing the waste management issues and contributing to the renewable energy sector despite the challenges like seasonal availability and waste composition [85]. However, the generation of bioethanol from individual FWs by supplementing with additional fermentable sugars such as millet and sorghum flour can increase the enzymes that help in FW sugar hydrolysis [86]. The use of FWs to produce bioethanol decreases the amount of organic waste introduced into landfills, thereby mitigating environmental damage [87]. This technique is cost-effective because FWs are inexpensive byproducts of the food industry and far less expensive to produce bioethanol than specific crops. The agriculture and food processing sectors continue to produce FWs, a renewable resource that guarantees a steady supply of raw materials [88]. Furthermore, the energy-efficient conversion method emphasises the promise of FWs as a cost-effective and sustainable source of bioethanol, particularly when the waste material contains a high concentration of fermentable sugars. This review examines the optimal proportions of FWs to fermentable sugars, evaluates various FWs, and assesses the feasibility of scaling up the process for commercial bioethanol production using natural enzymes.

6. Potentiality of pineapple, mango, pawpaw and watermelon fruit wastes for bioethanol generation

In selecting the kinds of FWs for bioethanol production, several criteria have been considered including sugar content, abundance and economic viability.

6.1. Sugar contents

The FWs contain various nutrients, including sugars, vitamins and minerals [1]. These nutrients support microbial growth and enhance the efficiency of the fermentation process. Pineapple waste contains 19 % cellulose, 22 % hemicellulose, 5 % lignin and 53 % cell soluble matter with soluble sugars like sucrose, glucose and fructose, which can be fermented to release bioethanol [89]. The composition of mango peel includes pectin (20–35 %), cellulose (15–18 %), hemicellulose (5–11 %) and lignin (9–12 %) [90]. Besides, FWs contain an estimated total sugar content of 12.29 % for pineapple waste, 13.2 % for mango waste and 9.2 % for pawpaw waste, whereas watermelon waste contains approximately 4.1 % for total sugar content [91]. Furthermore, as shown in Table 2, it has been found that even a small quantity of FWs can provide a significant volume of juice for the production of bioethanol [93]. The stated TSS and FWs juice pH levels are essential for bioethanol production [93]. Table 2 shows the total soluble solids (TSS) that can be fermented into bioethanol. The activity of the microorganisms involved in fermentation is influenced by pH levels, which, in turn, affects the efficiency of the fermentation process. A smooth fermentation process and maximum bioethanol yield depend on optimal TSS and pH levels.

Table 2.

Mass of fruit wastes, volume of extracted juice, total soluble solids and the ratio of volume to mass [93].

| Fruit wastes sample | Mass (Kg) | Volume of juice (L) | TSS (°Brix) | pH | Ratio |

|---|---|---|---|---|---|

| Watermelon | 12 | 8 | 4.13 ± 0.09 | 4.65 ± 0.01 | 0.67 |

| Pineapple | 13 | 9 | 12.0 ± 0.03 | 3.59 ± 0.05 | 0.69 |

| Mango | 11 | 9 | 11.2 ± 0.15 | 3.61 ± 0.01 | 0.82 |

| Pawpaw | 13 | 10 | 7.70 ± 0.17 | 4.50 ± 0.01 | 0.77 |

These figures underline the potential for utilising FWs as valuable resources in various fields, including bioethanol production and animal feed. Repurposing FW reduces environmental burdens associated with disposal and can harness valuable sugars for sustainable energy production.

6.2. Abundance

The FWs from widespread consumption can be utilised for bioethanol production, thus enhancing waste management and reducing environmental impact. Studies show that the global pineapple output is around 12.6 million tons, with Thailand being the largest producer at 16 %, followed by the Philippines and Brazil at 12 % and 10 %, respectively [7]. Nigeria is Africa's leading producer, producing 900,000 tons, with 114,263 tons produced in Tanzania [92,93]. Investigations indicate that one pineapple fruit has approximately a total weight of 400 g, of which 60 g is of peel waste, revealing that pineapple consumption results in a high amount of waste produced [89]. In 2020, watermelon was reported as the second most-produced globally, with 101.62 million metric tons [7]. Algeria's annual production totals 1.87 million tons, while Tanzania produced 68,687 million tons of watermelon in the 2019/2020 period [94]. Studies show that 60 %–70 % of watermelon fruits are edible, with 30–40 % containing seeds and non-edible parts globally [95]. Globally, 118 million tons of watermelon waste are produced [96]. Still, pawpaw output was around 310,000 tons in 2019 and is expected to rise to 16.6 million tons in 2029 [97].

In 2018, 43 million metric tons were generated annually; in 2020, it accounted for 54.83 million metric tons [98]. The production of byproducts from mango consumption, encompassing fresh and industrialised forms, is estimated to be between 14.7 and 25.2 million tons annually [99]. Utilising FW to produce valuable materials is crucial, considering the substantial amount of FW produced and the environmental challenges it poses [2]. With good management, FW may provide a high amount of valuable raw materials at a low cost and be environmentally friendly for other uses such as the source of nutrients, therapeutic, animal feeds, and bioethanol production [62,63].

7. Bioethanol production steps

Bioethanol production from FWs entails several crucial steps, each pivotal approach used to convert sugars within the FWs into bioethanol. These steps include collecting and preparing feedstock, pretreatment, hydrolysis, fermentation, distillation, storage, and distribution [100]. An expanded overview of the procedures involved in bioethanol generation from FWs has been examined.

7.1. Collection and preparation of fruit wastes

The FWs, including peels, seeds, pulp and rotten fruits, are collected from processing facilities, markets, or agricultural operations [100]. The wastes are sorted, cleaned and prepared for further processing. Sorting may involve separating different parts of the FW to optimise the utilisation of each component [101]. Cleaning ensures the removal of any contaminants or foreign materials that may interfere with the subsequent processing steps. Proper collection and preparation of FW are crucial to ensure the quality and consistency of the feedstock for bioethanol production.

7.2. Fruit waste pretreatment techniques

The pretreatment step is crucial in converting lignocellulosic materials in FW into fermentable sugars due to its complex structure, which resists microbial activity, degrading the rigid structure to make sugars more accessible for fermentation [100]. Plant cell walls are very tough to hydrolyse; hence, pretreatment is required to expose cellulose and hemicellulose for subsequent enzymatic hydrolysis [102]. Effective pretreatment methods are vital for overcoming the inherent challenges of lignocellulosic materials and maximising ethanol production from FW. Pretreatment procedures are categorised into physical, chemical, physiological and biological [103]. Various pretreatment strategies for FWs have been explored and discussed herein.

7.3. Physical pretreatment

The physical structure of FW materials is disrupted by mechanical or thermal pretreatments, such as size reduction, milling, grinding, or heat treatments [104]. These techniques try to increase the biomass's surface area, which will increase its accessibility to enzymatic or microbial action later on in the fermentation process [105]. When FWs are physically pretreated before being used to produce bioethanol, the accessibility of fermentable sugars in biomass is improved, which facilitates easy microbial activities. Physical pretreatment procedures include a range of techniques, including thermal, mechanical, ultrasonic, and microwave treatments [106]. Mechanical pretreatment through cutting, milling, chipping, shearing, and stirring reduces the lignin concentration, particle size, and polymerisation by dissolving the lignocellulose's rigid structure [106]. By increasing the biomass's surface area and porosity, these techniques aid in increasing its accessibility for microbial and enzymatic digestion. Mechanical pretreatment is an essential first stage in the practical and long-term management of FWs and resources [95]. It has many benefits that support financial savings, environmental preservation, and the efficiency of further processing and recycling operations [107]. By reducing waste volume and increasing recycling, mechanical pretreatment minimises the need for landfills, protecting important landfill space, reducing environmental damage, and advancing environmentally friendly waste management techniques [108]. Additionally, mechanical pretreatment of wastes reduces greenhouse gas emissions by facilitating more effective recycling and waste processing, lowering emissions related to conventional disposal methods [107]. The crystalline structure of lignocellulose is penetrated and broken down by high-energy vibrations during the ultrasonic pretreatment, which facilitates the deconstruction of the material [106]. By breaking down large materials, ultrasonic waves help reduce the volume of garbage generated and support municipal solid waste management by making it easier to treat or dispose of the waste. Additionally, the use of ultrasonic technology to disinfect hazardous materials and biomedical waste is being investigated. Chemical disinfectants and mechanical effects eradicate microorganisms and improve waste safety.

Because of this, ultrasonic pretreatment of wastes offers a variety of applications across different waste management situations, from boosting cleaning and disinfection outcomes to enhancing processes of extraction and degradation [109]. Its efficacy mostly depends on the particular waste type and treatment goals, but in general, it helps implement more effective and ecologically friendly waste management techniques. In addition, thermal pretreatment includes heating lignocellulose to a high temperature, which facilitates the disintegration of its intricate matrix [110]. Increasing the organic elements in garbage to be more biodegradable and digestible is the main objective of thermal pretreatment [111]. Complex organic components are broken down into simpler forms by heating the waste, which increases the accessibility of those forms to microorganisms in later biological treatment processes such as anaerobic digestion. Thermal pretreatment sanitises waste by reducing pathogens through elevated temperatures that kill or deactivate harmful microorganisms, thereby improving safety for handling and disposal [112]. In general, thermal pretreatment enhances waste digestibility, lowers pathogen content, and makes it easier to recover energy from organic materials, all of which are important components of contemporary waste management techniques [113]. It encourages sustainable techniques in managing a variety of waste streams and solves several issues related to waste disposal. Furthermore, because physical pretreatment methods frequently do not require the use of harsh chemicals or solvents, which lessens their impact on the environment, they are generally regarded as eco-friendly [102,111]. However, the high energy consumption, limited efficacy in breaking down lignin and hemicellulose linkages, and probable loss of biomass owing to over-grinding or milling present challenges to physical pretreatment procedures [80]. As a result, physical pretreatment might not completely remove lignin, exposing cellulose and hemicellulose. This fact reduces the effectiveness of enzymatic hydrolysis and affects the subsequent steps in the manufacture of bioethanol.

7.4. Chemical pretreatment

Chemical pretreatment entails breaking down FW's lignocellulosic structure using various chemicals to make it more suited for enzymatic hydrolysis and fermentation [114]. Commonly employed substances in this procedure are oxidising agents, bases, and acids [115]. Sulfuric or hydrochloric acid is used in acid pretreatments like diluted acid hydrolysis to break down hemicellulose and release sugars that release lignin for fermentation [116]. Acid pretreatment is a very effective chemical process that increases cellulose's accessibility to enzyme action by dissociating lignin and hemicellulosic components and breaking down glucosidic connections in the lignocellulosic substrate [117]. Conversely, alkaline pretreatment breaks lignin linkages and solubilises hemicellulose, improving cellulose's enzymatic accessibility using alkalis such as sodium hydroxide or ammonia [118]. These chemical pretreatment techniques can be tailored to the unique composition of FWs, improving the production efficiency of bioethanol by breaking down complex organic components into sugars that can be fermented. There is a considerable reduction in the risk of disease transmission during handling and disposal of biomedical waste and sewage sludge thanks to the effectiveness of certain chemicals, such as oxidising agents or disinfectants based on chlorine. Chemical pretreatments are effective, but come with drawbacks. These include high chemical costs, loss of soluble nutrients needed for microbial fermentation, and environmental issues from chemical residues that could remain in the finished bioethanol product and the surrounding environment [115,118]. Chemical residues that are handled or disposed of improperly can contaminate the environment, harming ecosystems and endangering human health. Additionally, energy-intensive chemical pretreatment techniques like oxidation procedures can raise waste management facilities' overall operating costs and carbon footprints. In light of this, using these pretreatment methods still requires careful assessment of the possible environmental impact while weighing the advantages of higher ethanol yield.

7.5. Biological pretreatment

Biological pretreatment involves using microorganisms such as fungi, bacteria or enzymes to degrade lignocellulosic materials in FW [119]. Fungi, bacteria or specialised enzymes focus on cellulose and hemicellulose elements, with white-rot and brown-rot fungi favoured due to their enzymatic prowess in decomposing lignocellulosic structures [22]. The main objective of biological pretreatment is to make organic waste more biodegradable. Enzymes, fungi, and bacteria are examples of microorganisms used to convert complex organic substances into simpler forms [120]. When cellulose and hemicellulose are hydrolysed into fermentable sugars by enzymes, the waste becomes more accessible and appropriate for further biological treatment processes such as anaerobic digestion or composting [121]. Still, cellulolytic and xylanolytic bacteria also play a key role in biological pretreatment by producing enzymes that degrade cellulose and hemicellulose [122]. Besides, enzymatic pretreatment uses purified or commercial enzymes to catalyse lignocellulose breakdown in FW sourced from microbial cultures or genetically engineered organisms [114]. Challenges such as longer processing times, susceptibility to contamination, and the need for controlled fermentation conditions must be addressed to optimise the efficiency of biological pretreatment processes [119]. The biological pretreatment approach is preferred due to its low energy requirement, eco-friendliness and simplicity. In addition, it doesn't require any chemicals instead, a wide range of natural microorganisms is used. Also, biological pretreatment can reduce the toxicity of waste materials by metabolising toxic compounds into less harmful substances. This detoxification process is crucial for ensuring the safety of waste handling and disposal. This strategy is desirable for businesses looking to leave as little of an ecological footprint as possible because it frequently leads to lower production costs, a smaller environmental effect, and increased sustainability. Additionally, by efficiently using trash, natural microorganisms can promote the circular economy and result in the generation of byproducts with added value. Biological pretreatment generally uses microorganisms to turn waste materials into products that are easier to handle, less hazardous, and possibly even useful. Its promotion of resource recovery, mitigation of environmental impact, and improvement of total waste treatment process efficiency make it a cornerstone of sustainable waste management techniques.

7.6. Physicochemical pretreatment

Physicochemical pretreatment combines physical and chemical methods to achieve optimal results by enhancing the efficiency of sugar extraction from FWs [21,123]. These techniques seek to lessen waste's adverse environmental effects, increase resource recovery, or improve downstream treatment procedures. In waste treatment processes, physicochemical pretreatment frequently entails mechanical procedures like shredding, grinding, or milling to lower the particle size of waste materials [124]. Reduced particle sizes improve the efficiency of the bioethanol production process by increasing the surface area accessible for further chemical reactions or biological degradation. Compared to chemical pretreatment alone, physicochemical pretreatment techniques have several benefits, such as higher sugar yields, lower enzyme requirements, and fewer environmental effects [114]. However, challenges such as high energy consumption, equipment corrosion and generation of inhibitory byproducts need to be addressed to optimise the efficiency and sustainability of the processes [125]. Moreover, chemical and physicochemical pretreatment techniques involve the use of chemicals which are not environmentally friendly [126]. Therefore, physicochemical pretreatment is vital to contemporary waste management techniques by boosting resource recovery, lessening environmental effects, and improving waste features. These techniques support sustainable development objectives and provide flexibility in tackling a range of waste management concerns in addition to biological and thermal treatments. Table 3 provides an overview of the bioethanol yield and the conditions of the FWs hydrolysis process.

Table 3.

Fruit wastes, hydrolysis technique, condition and bioethanol yield from fruit waste.

| Fruit Waste | Part of fruit waste | Hydrolysis technique | Conditions | Bioethanol yield | Reference |

|---|---|---|---|---|---|

| Apple pomace | Peels | Enzymatic hydrolysis | pH 4.8, 50 °C, 24 h | 15–20 g/L | [127] |

| Orange peel | Peel | Acid hydrolysis | H2SO4, 1.5 % (v/v), 120 °C, 2 h | 10–15 g/L | [128] |

| Banana peel | Peel | Microbial fermentation | Saccharomyces cerevisiae, 30 °C | 12–18 g/L | [129] |

| Watermelon Rind | Rind | Enzymatic hydrolysis | Cellulase, pH 5.0, 50 °C, 48 h | 8–12 g/L | [130] |

| Pineapple core | Core | Acid hydrolysis | HCl, 2 % (v/v), 90 °C, 1 h | 10–32.2 g/L | [131] |

A summary of the various FWs, the fruit portion utilised, the hydrolysis method, certain process parameters, and the yield or concentration of bioethanol produced are given in Table 3. The kind of FWs utilised, and the particular experimental settings would affect the actual data. Referring to scholarly literature or research papers on bioethanol production from FWs would be required for the most thorough and correct information.

8. Hydrolysis

The FWs are hydrolysed, using water and enzymes to break down complex organic molecules like proteins, lipids, and carbs into simpler ones [60]. This procedure is essential for removing important components, cutting down on waste, and making it easier for them to be used in other industries. Hydrolysis plays a crucial role in bioethanol production from FW, as it breaks down complex carbohydrates such as cellulose and hemicellulose into simpler sugars that can be fermented into bioethanol [132]. Hydrolysis can be accomplished using different approaches, including enzymatic and chemical methods [133]. The choice between enzymatic and chemical hydrolysis depends on cost, efficiency and environmental considerations [134]. Enzymatic hydrolysis utilises carbohydrates (e.g., amylase, cellulase), proteases, and lipases to break down complex sugars, proteins, and fats into monosaccharides (e.g., glucose, fructose), amino acids, and fatty acids, respectively. Moreover, enzymatic hydrolysis involves using enzymes such as cellulases and hemicellulases, naturally produced by microorganisms or commercially produced [135]. These enzymes catalyse the breakdown of cellulose and hemicellulose into glucose and other fermentable sugars [136]. Enzymatic hydrolysis generally occurs at mild temperatures (30 °C–60 °C) to maintain enzyme activity.

Besides, acid hydrolysis utilises acidic conditions to hydrolyse the complex carbohydrates [137]. Conversely, chemical hydrolysis is typically faster but may involve harsh chemicals that pose environmental risks [17,135]. Depending on the desired product results and the substrate's content, the hydrolysis length varies [138]. Because enzymatic hydrolysis involves enzymatic breakdown, it usually necessitates more extended reaction periods than acid or alkaline hydrolysis [139]. Thus, optimising the hydrolysis process for bioethanol production from FWs requires balancing cost-effectiveness, efficiency, and environmental impact. Due to microorganisms' hydrolytic and oxidative enzymes, enzymatic hydrolysis is more effective than concentrated and diluted acid hydrolysis [22]. Establishing hydrolysis by relying on the natural enzymes present in FW along with incorporation of supplementary fermentable sugars presents a significant advantage [86]. This approach is more environmentally friendly as compared to using synthetic enzymes. The eco-friendly strategy aligns with sustainable and cost-effective practices, highlighting the potential of harnessing the enzymatic capabilities within FW and from additional fermentable sugar for efficient hydrolysis in bioethanol production.

9. Fermentation process

Fermentation of FW juice is a critical stage in bioethanol production, where fermentable sugars present in the juice are transformed into bioethanol and CO2 by microorganisms [140]. Typically, yeast strains such as Saccharomyces cerevisiae are employed for their efficiency in metabolising sugars and producing bioethanol [137]. Three processes, hydrolysis and separate fermentation (SHF), saccharification and simultaneous co-fermentation (SSCF) and saccharification, are often used in the production synthesis of bioethanol [141]. SSF and SSCF combine fermentation and enzymatic hydrolysis to maintain low glucose levels, while SSCF ferments glycose and pentose [142]. Generally, bioethanol and CO2 are produced as microbes consume the sugar during fermentation.

However, the utilisation of fermentation in a natural environment has not been well-established; thus, establishing this approach could significantly reduce the costs associated with bioethanol production. Utilising natural fermentation processes presents advantages in terms of cost-effectiveness and environmental sustainability. Enhancing the essential microbial activity in the natural environment makes it possible to carry out fermentation without the need for controlled environments or specialised equipment.

10. Distillation

Distillation is favoured in industrial settings because of its ability to achieve high rates of alcohol recovery and energy efficiency, even with moderate feed concentrations [143]. Different separation methods have been employed, including conventional distillation, azeotropic distillation, extractive distillation, hybrid liquid fermentation extraction, absorption and membrane secession [144]. The distillation process involves boiling a liquid mixture and collecting the condensed vapours as they emerge [145]. Bioethanol and water have disparate boiling points, with bioethanol boiling at 78 °C and water at 100 °C. Consequently, during the distillation process, bioethanol will evaporate before water due to its lower boiling point [145]. However, the techniques employed in distillation are often intricate and costly. Therefore, employing a straightforwardly designed distiller could potentially enhance production efficiency by yielding large quantities of high-quality bioethanol within a shorter time frame. This enhancement makes bioethanol production more accessible and economically viable, particularly for small-scale or resource-constrained operations.

11. Bioethanol as a promising biofuel

Bioethanol presents a promising renewable energy option, providing sustainability and decreased greenhouse gas emissions compared to traditional fossil fuels [8]. Bioethanol, with its superior chemical and physical properties, is widely utilised in transportation and energy industries as a fuel and is often added to petrol as a fuel additive [146]. It can be mixed with conventional gasoline to improve octane numbers, reduce CO2 emission and enhance air quality [83]. It has a high oxygen content (35 % w/w), which helps to reduce hydrocarbon and CO2 emissions [83]. Besides, bioethanol has a high latent heat of vaporisation (0.91 MJ/kg), which stops internal engine cylinder knocking and early ignition [22]. Still, it has low energy content (21.2 MJ/dm3) due to improvements in the ratio of power to compression, which shortens the combustion time [22]. In contrast to the combustion of fossil fuels, bioethanol exhibits more excellent environmental friendliness and reduces adverse impacts on the environment, resulting in a 12–19 % reduction in greenhouse gas emissions [69]. As part of the solution, bioethanol can be mixed with the fuel without engine modifications [147]. The mixture of bioethanol and essential oxygen causes the fuel to burn more thoroughly and emit fewer harmful emissions, thus helping to minimise the emission of greenhouse gases [69].

12. Future outlook of fruit wastes in bioenergy generation

The future outlook for FWs in bioenergy generation is promising, with several key trends and developments. Market expansion: as awareness of environmental issues grows and consumers increasingly prioritise sustainability, there is a rising demand for greener energy alternatives. Bioenergy derived from FWs is well-positioned to capitalise on this trend, offering a renewable and environmentally friendly energy source. The growing market for bioenergy from FWs gives opportunities for stakeholders like fruit producers, waste management companies, and investors with regulatory support for promoting renewable energy sources.

Valorisation of byproducts resulting in efforts to valorise the byproducts generated during bioenergy production from FWs are anticipated to increase. These byproducts, including nutrient-rich residues, have significant potential for various applications beyond energy generation. For instance, nutrient-rich residues can be utilised as organic fertilisers or soil amendments, enriching soil health and promoting sustainable agriculture practices. The utilisation of these byproducts in agriculture contributes to circular economy principles by closing the loop on waste streams and reducing reliance on synthetic fertilisers. Additionally, valorising byproducts creates new revenue streams for bioenergy producers and enhances the overall economic viability of FWs bioenergy systems.

The growing awareness of the environmental benefits of byproducts in agriculture is expected to boost their adoption, thereby enhancing the sustainability of FWs bioenergy production. Sustainability considerations in which the growing concerns about environmental degradation and climate change have an increasing focus on sustainability across various sectors, including energy production and waste management. Utilising FWs for bioenergy production aligns with these sustainability goals by offering a renewable and carbon-neutral energy source while simultaneously addressing waste management challenges. By diverting FWs from landfills and incineration facilities, bioenergy production helps reduce greenhouse gas emissions and mitigate environmental pollution. Moreover, integrating FWs bioenergy into broader renewable energy strategies contributes to diversifying the energy mix and reducing reliance on fossil fuels, enhancing energy security and resilience. Additionally, the circular economy principles inherent in FWs bioenergy production promote resource efficiency and minimise environmental impact by valorising waste materials and maximising their utility throughout their lifecycle. As sustainability becomes increasingly central to policy agendas and consumer preferences, greater emphasis will likely be on incentivising and supporting FWs' bioenergy initiatives as part of comprehensive sustainability strategies.

13. Conclusion and recommendation

Exploring bioethanol production from FWs, particularly pineapple, mango, pawpaw, and watermelon, offers promising prospects for sustainable waste management and renewable energy. While FW exhibits sugar content variability, its effectiveness in fermentation, environmental benefits, cost advantages, and waste management solutions make it a viable option. The agricultural and industrial practices surrounding these fruits generate significant waste volumes, which can be efficiently converted into bioethanol. This transition to bioenergy from fossil fuels is cost-effective and environmentally friendly, encouraging further research to minimise waste accumulation.

Consideration for enhancing bioethanol production from FWs should involve exploring natural enzymes present in the wastes for hydrolysis and fermentation in conducive environments. Identifying enzymes like cellulases and hemicellulases can minimise exogenous enzyme supplementation, optimising bioethanol production. Controlling fermentation conditions like temperature and pH is crucial for maximising efficiency and incorporating additional fermentable sugars from alternative sources like millet and sorghum. Techno-economic assessments should be conducted for commercial viability. Implementing these strategies can significantly enhance bioethanol production efficiency, sustainability, and environmental stewardship using FWs. Since revision maintains clarity and comprehensiveness, it is recommended that the potentiality of the FWs and other feedstock be further evaluated in the production of quality bioethanol. These FWs' leftovers could offer opportunities for extracting valuable compounds or utilisation in biotechnological applications. Moreover, assessing the environmental impact of FWs and determining their optimal management practices is also paramount.

Funding statement

The authors have no financial interest attached to this work.

Data availability statement

No data was used for the research described in the review paper.

Additional information

No additional information is available for this article.

CRediT authorship contribution statement

Shedrack Thomas Mgeni: Conceptualization. Herieth Rhodes Mero: Writing – review & editing, Conceptualization. Lewis Atugonza Mtashobya: Writing – review & editing, Conceptualization. Jovine Kamuhabwa Emmanuel: Writing – review & editing, Conceptualization.

Declaration of competing interest

The author declares that there is no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The authors thank Mkwawa University College of Education fo material support.

References

- 1.Kandemir E., K, Piskin E., Xiao J., Tomas M., Capanoglu Fruit juice industry wastes as a source of bioactives. J. Agric. Food Chem. 2022;70(23):6805–6832. doi: 10.1021/acs.jafc.2c00756. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Fierascu J., R C., Sieniawska E., Ortan A., Fierascu I., Xiao Fruits by-products – a source of valuable active principles. A short review. Front. Bioeng. Biotechnol. 2020;8:1–8. doi: 10.3389/fbioe.2020.00319. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Torres-León C.N., C, Ramírez-Guzman N., Londoño-Hernandez L., Martinez-Medina G.A., Díaz-Herrera R., Navarro-Macias V.…Aguilar Food waste and byproducts : an opportunity to minimize malnutrition and hunger in developing countries. Front. Times. 2018;2(September):1–17. doi: 10.3389/fsufs.2018.00052. [DOI] [Google Scholar]

- 4.Rifna M., J E., Misra N.N., Dwivedi Recent advances in extraction technologies for recovery of bioactive compounds derived from fruit and vegetable waste peels: a review. Crit. Rev. Food Sci. Nutr. 2023;63(6):719–752. doi: 10.1080/10408398.2021.1952923. [DOI] [PubMed] [Google Scholar]

- 5.Li S., Y, Chen Z., Peng Y., Zheng K., Ye C., Wan K., Zhang Changes in aerobic fermentation and microbial community structure in food waste derived from different dietary regimes. Bioresour. Technol. 2020;317(May) doi: 10.1016/j.biortech.2020.123948. [DOI] [PubMed] [Google Scholar]

- 6.Kazuva E., Zhang J. Analyzing municipal solid waste treatment scenarios in rapidly urbanizing cities in developing countries: the case of dar es salaam, Tanzania. Int. J. Environ. Res. Public Health. 2019;16(11):1–21. doi: 10.3390/ijerph16112035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Leong Y.K., Chang J.S. Valorization of fruit wastes for circular bioeconomy: current advances, challenges, and opportunities. Bioresour. Technol. 2022;359(September):1–7. doi: 10.1016/j.biortech.2022.127459. [DOI] [PubMed] [Google Scholar]

- 8.Bhuvaneswari M., Sivakumar N. Bioethanol production from fruit and vegetable wastes. Bioprocess. Biomol. Prod. 2019:417–427. doi: 10.1002/9781119434436.ch20. [DOI] [Google Scholar]

- 9.Conrad Z., Niles M.T., Neher D.A., Roy E.D., Tichenor N.E., Jahns L. Relationship between food waste , diet quality , and environmental sustainability. PLoS One. 2018;13(4):1–18. doi: 10.1371/journal.pone.0195405. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Ciccullo A., F, Cagliano R., Bartezzaghi G., Perego Implementing the circular economy paradigm in the agri-food supply chain: the role of food waste prevention technologies. Resour. Conserv. Recycl. 2021;164 [Google Scholar]

- 11.Hon L.R., S, Olson D.G., Holwerda E.K., Lanahan A.A., Murphy S.J., Maloney M.I.…Lynd “The ethanol pathway from Thermoanaerobacterium saccharolyticum improves ethanol production in Clostridium thermocellum,”. Metab. Eng. 2017;42:175–184. doi: 10.1016/j.ymben.2017.06.011. [DOI] [PubMed] [Google Scholar]

- 12.Sriariyanun P., M, Ratanapoompinyo J., Yasurin P., Cheenkachorn K., Rodiahwati W., Tantayotai Biorefinery approaches for production of cellulosic ethanol fuel using recombinant engineered microorganisms. J. Appl. Sci. Eng. 2024;27(2):1985–2005. doi: 10.6180/jase.202402_27(2).0001. [DOI] [Google Scholar]

- 13.Devi D., A, Bajar S., Sihag P., Sheikh Z.U.D., Singh A., Kaur J.…Pant “A panoramic view of technological landscape for bioethanol production from various generations of feedstocks,”. Bioengineered. 2023;14(1):81–112. doi: 10.1080/21655979.2022.2095702. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Lalman J.A., Shewa W.A., Gallagher J. 2016. Biofuels Production from Renewable Feedstocks. November 2017. [DOI] [Google Scholar]

- 15.Bušić B., A, Marđetko N., Kundas S., Morzak G., Belskaya H., Ivančić Šantek M.…Šantek “Bioethanol production from renewable raw materials and its separation and purification: a review,”. Food Technol. Biotechnol. 2018;56(3):289–311. doi: 10.17113/ftb.56.03.18.5546. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Dao E.C., N C., Mupondwa E., Tabil L., Li X., Castellanos . CSBE/SCGAB 2018 Annu. Conf.; 2018. A Review on Techno-Economic Analysis and Life-Cycle Assessment of Second Generation Bioethanol Production via Biochemical Processes; pp. 1–29. [Google Scholar]

- 17.Duque A.D., A, Álvarez C., Doménech P., Manzanares P., Moreno Advanced bioethanol production: from novel raw materials to integrated biorefineries. Processes. 2021;9(2):1–30. doi: 10.3390/pr9020206. [DOI] [Google Scholar]

- 18.Casabar R., T J., Unpaprom Y., Ramaraj Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Convers. Biorefinery. 2019;9(4):761–765. doi: 10.1007/s13399-019-00436-y. [DOI] [Google Scholar]

- 19.Murthy P., Kumar R. Bio-chemical characterization of fruit wastes as an alternative feedstock for bio-ethanol production and performance analysis with a diesel engine system using gasoline and ethanol blends. Chem. Sci. Eng. Res. 2022;4(10):31–45. doi: 10.36686/ariviyal.cser.2022.04.10.055. [DOI] [Google Scholar]

- 20.Azad M.A.K., Yesmin N. Bioethanol production from agriculturalproducts and fruits of Bangladesh. Int. J. GEOMATE. 2019;17(61):222–227. doi: 10.21660/2019.61.4795. [DOI] [Google Scholar]

- 21.Baral C.D., R N., Sundstrom E.R., Das L., Gladden J., Eudes A., Mortimer J.C.…Scown “Approaches for more efficient biological conversion of lignocellulosic feedstocks to biofuels and bioproducts,”. ACS Sustain. Chem. Eng. 2019;7(10):9062–9079. doi: 10.1021/acssuschemeng.9b01229. [DOI] [Google Scholar]

- 22.DE Silva A., J S., Arachchige U.S., Nilmini Production of bioethanol using waste fruits under acid and alkali catalytic hydrolysis: a review. Asian J. Chem. 2022;34(1):25–34. doi: 10.14233/ajchem.2022.23466. [DOI] [Google Scholar]

- 23.Dahman Y., Syed K., Begum S., Roy P., Mohtasebi B. Elsevier Ltd; 2019. Biofuels: Their Characteristics and Analysis. [DOI] [Google Scholar]

- 24.Niphadkar S., Bagade P., Ahmed S. Bioethanol production: insight into past, present and future perspectives. Biofuels. 2018;9(2):229–238. doi: 10.1080/17597269.2017.1334338. [DOI] [Google Scholar]

- 25.Marzo C., Díaz A.B., Caro I., Blandino A. Status and perspectives in bioethanol production from sugar beet. Bioethanol Prod. from Food Crop. Sustain. Sources, Interv. Challenges, no. June. 2018:61–79. doi: 10.1016/B978-0-12-813766-6.00004-7. [DOI] [Google Scholar]

- 26.Mohanty M.R., Swain Bioethanol production from food crops: sustainable sources. Interventions, and Challenges. 2019 doi: 10.1016/C2017-0-00234-3. September. [DOI] [Google Scholar]

- 27.de Souza A.F., J P., do Prado C.D., Eleutherio E.C., Bonatto D., Malavazi I., da Cunha. Improvement of Brazilian bioethanol production – challenges and perspectives on the identification and genetic modification of new strains of Saccharomyces cerevisiae yeasts isolated during ethanol process. Fungal Biol. 2018;122(6):583–591. doi: 10.1016/j.funbio.2017.12.006. [DOI] [PubMed] [Google Scholar]

- 28.Ayodele S.I., V B., Alsaffar M.A., Mustapa An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J. Clean. Prod. 2019;245 doi: 10.1016/j.jclepro.2019.118857. [DOI] [Google Scholar]

- 29.Ghimire R., A, Trably E., Frunzo L., Pirozzi F., Lens P.N., Esposito G.…Escudié “Effect of total solids content on biohydrogen production and lactic acid accumulation during dark fermentation of organic waste biomass,”. Bioresour. Technol. 2018;248:180–186. doi: 10.1016/j.biortech.2017.07.062. [DOI] [PubMed] [Google Scholar]

- 30.Hassan A.K., S S., Williams G.A., Jaiswal “Moving towards the second generation of lignocellulosic biorefineries in the EU: drivers, challenges, and opportunities,”. Renew. Sustain. Energy Rev. 2019;101:590–599. doi: 10.1016/j.rser.2018.11.041. [DOI] [Google Scholar]

- 31.Khan K. Sudhakar, Mamat R. Role of biofuels in energy transition, green economy and carbon neutrality. Sustain. Times. 2021;13(22) doi: 10.3390/su132212374. [DOI] [Google Scholar]

- 32.Broda M., Yelle D.J., Serwańska K. Bioethanol production from lignocellulosic biomass—challenges and solutions. Molecules. 2022;27(24) doi: 10.3390/molecules27248717. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Rajendran K., Drielak E., Sudarshan Varma V., Muthusamy S., Kumar G. Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production–a review. Biomass Convers. Biorefinery. 2018;8(2):471–483. doi: 10.1007/s13399-017-0269-3. [DOI] [Google Scholar]

- 34.Saratale G.D., Saratale R.G., Banu J.R., Chang J.S. Elsevier B.V.; 2019. Biohydrogen Production from Renewable Biomass Resources. [DOI] [Google Scholar]

- 35.Halder P., Azad K., Shah S., Sarker E. Prospects and technological advancement of cellulosic bioethanol ecofuel production. Adv. Eco-Fuels a Sustain. Environ. 2018;(January):211–236. doi: 10.1016/B978-0-08-102728-8.00008-5. [DOI] [Google Scholar]

- 36.Malenica R., Bhat D. Review article: current research trends in fruit and vegetables wastes and by-products management-scope and opportunities in the Estonian context. Agron. Res. 2020;18(Special Issue 3):1760–1795. doi: 10.15159/AR.20.086. [DOI] [Google Scholar]

- 37.Mukhametzyanov R.R., Zaretskaya A.S., Dzhancharova G.K., Platonovskiy N.G., Ivantsova N.N. Russia as a subject of the world market for staple tropical fruits. Proc. Int. Sci. Pract. Conf. Strateg. Dev. Reg. Ecosyst. “Education-Science-Industry” (ISPCR 2021) 2022;208(Ispcr 2021):594–602. doi: 10.2991/aebmr.k.220208.084. [DOI] [Google Scholar]

- 38.FAO FAOSTAT analytical brief 60 agricultural production statistics 2000-2021 faostat analytical brief 60 faostat crops and livestock production introduction. Agric. Prod. Stat. 2000-2021. 2021;60:1–17. [Google Scholar]

- 39.Sales G.S., V F.C., De Souza M., Trento L.R., Pereira G.M., Borchardt M., Milan Food waste in distribution: causes and gaps to Be filled. Sustain. Times. 2023;15(4) doi: 10.3390/su15043598. [DOI] [Google Scholar]

- 40.Esparza L.M., I, Jiménez-Moreno N., Bimbela F., Ancín-Azpilicueta C., Gandía Fruit and vegetable waste management: conventional and emerging approaches. J. Environ. Manage. 2020;265(February) doi: 10.1016/j.jenvman.2020.110510. [DOI] [PubMed] [Google Scholar]

- 41.Gupta A., N, Poddar K., Sarkar D., Kumari N., Padhan B., Sarkar Fruit waste management by pigment production and utilization of residual as bioadsorbent. J. Environ. Manage. 2019;244(May):138–143. doi: 10.1016/j.jenvman.2019.05.055. [DOI] [PubMed] [Google Scholar]

- 42.Gupta A., N, Poddar K., Sarkar D., Kumari N., Padhan B., Sarkar Fruit waste management by pigment production and utilization of residual as bioadsorbent. J. Environ. Manage. 2019;244(January):138–143. doi: 10.1016/j.jenvman.2019.05.055. [DOI] [PubMed] [Google Scholar]

- 43.Ciccullo F., Cagliano R., Bartezzaghi G., Perego A. Implementing the circular economy paradigm in the agri-food supply chain: the role of food waste prevention technologies. Resour. Conserv. Recycl. 2021;164(January 2020) doi: 10.1016/j.resconrec.2020.105114. [DOI] [Google Scholar]

- 44.Jalalipour M., H, Jaafarzadeh N., Morscheck G., Narra S., Nelles Potential of producing compost from source-separated municipal organic waste (A case study in Shiraz, Iran) Sustain. Times. 2020;12(22):1–17. doi: 10.3390/su12229704. [DOI] [Google Scholar]

- 45.Ayilara O., S M., Olanrewaju O.S., Babalola O.O., Odeyemi Waste management through composting: challenges and potentials. Sustain. Times. 2020;12(11):1–23. doi: 10.3390/su12114456. [DOI] [Google Scholar]

- 46.Odejobi F.N., J O., Ajala O.O., Osuolale Review on potential of using agricultural, municipal solid and industrial wastes as substrates for biogas production in Nigeria. Biomass Convers. Biorefinery. 2024;14(2):1567–1579. doi: 10.1007/s13399-022-02613-y. [DOI] [Google Scholar]

- 47.Lucarin A., M, Durazzo A., Bernini R., Campo M., Vita C., Souto E.B.…Romani “Fruit wastes as a valuable source of value-added compounds: a collaborative perspective.,”. Molecules. 2021;26(21):6338. doi: 10.3390/molecules26216338. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Zamli M.T., F A., Mahmood W.M.F.W., Ghopa W.A.W., Lim The research on food waste pre-treatment technology for incineration in Malaysia. J. Environ. Treat. Tech. 2020;9(1):139–147. doi: 10.47277/jett/9(1)147. [DOI] [Google Scholar]

- 49.Siddiqua W.A.K., A, Hahladakis J.N., Al-Attiya An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022;29(39):58514–58536. doi: 10.1007/s11356-022-21578-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Mmereki A.H., D, David Jr V.E., Brownell Wreh. The management and prevention of food losses and waste in low- and middle-income countries: a mini-review in the Africa region. Waste Manag. Res. 2024;42(4):287–307. doi: 10.1177/0734242X231184444. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Coman D.C., V, Teleky B.E., Mitrea L., Martău G.A., Szabo K., Călinoiu L.F., Vodnar Bioactive potential of fruit and vegetable wastes. Adv. Food Nutr. Res. 2020;91:157–225. doi: 10.1016/bs.afnr.2019.07.001. [DOI] [PubMed] [Google Scholar]

- 52.Sharma B., Dangi A.K., Shukla P. Contemporary enzyme based technologies for bioremediation: a review. J. Environ. Manage. 2018;210:10–22. doi: 10.1016/j.jenvman.2017.12.075. [DOI] [PubMed] [Google Scholar]

- 53.Ibegbulam-Njoku P.N., Chijioke-Osuji C.C., Ejeagba I.O. Bioremediation of industrial solid wastes. Br. Microbiol. Res. J. 2014;4(9):1013–1024. doi: 10.9734/bmrj/2014/7943. [DOI] [Google Scholar]

- 54.Mihai C., F C., Plana R., Taherzadeh M.J., Aswathi M.K., Ezeah Bioremediation of organic contaminants based on biowaste composting practices. Handb. Bioremediation Physiol. Mol. Biotechnol. Interv. 2021;(October):701–714. doi: 10.1016/B978-0-12-819382-2.00045-4. [DOI] [Google Scholar]

- 55.Lukić G., B, Huguenot D., Panico A., Fabbricino M., van Hullebusch E.D., Esposito Importance of organic amendment characteristics on bioremediation of PAH-contaminated soil. Environ. Sci. Pollut. Res. 2016;23(15):15041–15052. doi: 10.1007/s11356-016-6635-z. [DOI] [PubMed] [Google Scholar]

- 56.Prasad D.K., R K., Chatterjee S., Mazumder P.B., Gupta S.K., Sharma S., Vairale M.G.…Gupta Bioethanol production from waste lignocelluloses: a review on microbial degradation potential. Chemosphere. 2019;231:588–606. doi: 10.1016/j.chemosphere.2019.05.142. [DOI] [PubMed] [Google Scholar]

- 57.Narisetty V., V, Adlakha N., Singh N.K., Dalei S.K., Prabhu A.A., Nagarajan S.… & Kumar, “Integrated biorefineries for repurposing of food wastes into value-added products,”. Bioresour. Technol. 2022;363(September) doi: 10.1016/j.biortech.2022.127856. [DOI] [PubMed] [Google Scholar]

- 58.Luzón-Quintana L.M., Castro R., Durán-Guerrero E. Biotechnological processes in fruit vinegar production. Foods. 2021;10(5) doi: 10.3390/foods10050945. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Cho E.J., Trinh L.T.P., Song Y., Lee Y.G., Bae H.J. Bioconversion of biomass waste into high value chemicals. Bioresour. Technol. 2020;298 doi: 10.1016/j.biortech.2019.122386. [DOI] [PubMed] [Google Scholar]

- 60.Shrestha W., S, Khatiwada J.R., Sharma H.K., Qin Bioconversion of fruits and vegetables wastes into value-added products. Adv. Sci. Technol. Innov. 2021:145–163. doi: 10.1007/978-3-030-61837-7_9. [DOI] [Google Scholar]

- 61.Cheng M., Y S., Mutrakulcharoen P., Chuetor S., Cheenkachorn K., Tantayotai P., Panakkal E.J., Sriariyanun Recent situation and progress in biorefining process of lignocellulosic biomass: toward green economy. Appl. Sci. Eng. Prog. 2020;13(4):299–311. doi: 10.14416/J.ASEP.2020.08.002. [DOI] [Google Scholar]

- 62.Arias M.T., A, Feijoo G., Moreira Exploring the potential of antioxidants from fruits and vegetables and strategies for their recovery. Innov. Food Sci. Emerg. Technol. 2022;77(March) doi: 10.1016/j.ifset.2022.102974. [DOI] [Google Scholar]

- 63.Nile S.H., Nile A., Liu J., Kim D.H., Kai G. Exploitation of apple pomace towards extraction of triterpenic acids, antioxidant potential, cytotoxic effects, and inhibition of clinically important enzymes. Food Chem. Toxicol. 2019;131(June) doi: 10.1016/j.fct.2019.110563. [DOI] [PubMed] [Google Scholar]

- 64.Amran J.S., A M., Palaniveloo K., Fauzi R., Satar N.M., Mohidin T.B.M., Mohan G.…Seelan Sathiya. Value-added metabolites from agricultural waste and application of green extraction techniques. Sustain. Times. 2021;13(20):1–28. doi: 10.3390/su132011432. [DOI] [Google Scholar]

- 65.Caipang C.M.A., Mabuhay-omar J., Gonzales-plasus M.M. Plant and fruit waste products as phytogenic feed additives in aquaculture. AACL Bioflux. 2019;12(1):261–268. [Google Scholar]

- 66.Liu T. S. P. de Souza, Holland B., Dunshea F., Barrow C., Suleria H.A.R. Valorization of food waste to produce value-added products based on its bioactive compounds. Processes. 2023;11(3) doi: 10.3390/pr11030840. [DOI] [Google Scholar]

- 67.Vilas-Boas A.L., A A., Pintado M., Oliveira Natural bioactive compounds from food waste: toxicity and safety concerns. Foods. 2021;10(7) doi: 10.3390/foods10071564. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.Velciov N.G., A B., Riviş A., Popescu G.S., Cozma A., Stoin D., Petcov A.…Hădărugă “Corresponding authors: Preliminary research on the obtaining and nutritional characterization of apple peel powder,”. 2022;28(4):375–380. [Online]. Available: [Google Scholar]

- 69.Nwosu A.I., A N., Nweze B.C., Onwuchekwa Agro-science journal of tropical agriculture , food , environment and extension. CHEMICAL COMPOSITION OF BISCUITS SUPPLEMENTED WITH ORANGE PEEL AND PULP FLOURS Chemical Composition of Biscuit Su. 2022;21(2):24–32. Volume 21 Number 2 (April 2022) pp . 24 - 32 ISSN 1119-7455. [Google Scholar]

- 70.Dubey K., S, Rajput H., Batta Utilization of watermelon rind (Citrullus lanatus) in various food preparations: a review. J. Agric. Sci. Food Res. 2021;12(1000):5–7. doi: 10.37273/chesci.cs205205361. [DOI] [Google Scholar]

- 71.Campos M.M., D A., Ribeiro T.B., Teixeira J.A., Pastrana L., Pintado Integral valorization of pineapple (Ananas comosus L.) By-products through a green chemistry approach towards Added Value Ingredients. Foods. 2020;9(1) doi: 10.3390/foods9010060. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 72.Lebaka M., V R., Wee Y.J., Ye W., Korivi Nutritional composition and bioactive compounds in three different parts of mango fruit. Int. J. Environ. Res. Public Health. 2021;18(2):1–20. doi: 10.3390/ijerph18020741. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 73.Zafra-Rojas E., Q, Cruz-Cansino N., Delgadillo-Ramírez A., Alanís-García E., Añorve-Morga J., Quintero-Lira A.…Ramírez-Moreno “Organic acids, antioxidants, and dietary fiber of Mexican blackberry (rubus fruticosus) residues cv. Tupy,”. J. Food Qual. 2018;2018 doi: 10.1155/2018/5950761. [DOI] [Google Scholar]

- 74.Banerjee J., Singh R., Vijayaraghavan R., MacFarlane D., Patti A.F., Arora A. Bioactives from fruit processing wastes: green approaches to valuable chemicals. Food Chem. 2017;225:10–22. doi: 10.1016/j.foodchem.2016.12.093. [DOI] [PubMed] [Google Scholar]

- 75.Akter M.S., Rabeta B. Synbiotic and antioxidant activity of fruit by-products and their effect on human health. Food Res. 2021;5(1):24–35. doi: 10.26656/fr.2017. 5(1).401. [DOI] [Google Scholar]

- 76.Ibrahim S., K U., Kamarrudin N., Suzihaque M.U.H., Hashib Abd. Local fruit wastes as a potential source of natural antioxidant: an overview. IOP Conf. Ser. Mater. Sci. Eng. 2017;206(1) doi: 10.1088/1757-899X/206/1/012040. [DOI] [Google Scholar]