Abstract

Programmable biomaterials are distinguished by their ability to adjust properties and functions on demand, in a periodic, reversible, or sequential manner. This contrasts with traditional biomaterials, which undergo irreversible, uncontrolled changes. This review synthesizes key advances in programmable biomaterials, examining their design principles, functionalities and applications in bone regeneration. It charts the transition from traditional to programmable biomaterials, emphasizing their enhanced precision, safety and control, which are critical from clinical and biosafety standpoints. We then classify programmable biomaterials into six types: dynamic nucleic acid-based biomaterials, electrically responsive biomaterials, bioactive scaffolds with programmable properties, nanomaterials for targeted bone regeneration, surface-engineered implants for sequential regeneration and stimuli-responsive release materials. Each category is analyzed for its structural properties and its impact on bone tissue engineering. Finally, the review further concludes by highlighting the challenges faced by programmable biomaterials and suggests integrating artificial intelligence and precision medicine to enhance their application in bone regeneration and other biomedical fields.

Keywords: Programmable biomaterials, Bone regeneration, Development of biomaterials, Bone tissue engineering, Artificial intelligence

Graphical abstract

1. Introduction

Bone and cartilage diseases, induced by factors such as aging, trauma and poor lifestyle choices, including osteoarthritis, bone defects and cartilage degeneration, significantly compromise human health. The most common treatment for bone defects is bone grafting, which involves using bone from the patient (autografts), from donors (allografts), from other species (xenografts), or synthetic materials. Autografts are preferred for their compatibility and bone-growth properties. However, they are costly, require additional surgery, and have limited availability, along with risks like immune rejection and disease transmission [[1], [2], [3]]. The development of biomaterials has significantly improved this clinical scenario, offering a broader range of functionalities to support bone tissue mechanical stability and cellular repair processes. However, most biomaterials offer limited functionality, focusing either on mechanical support or targeting specific cellular functions in bone repair. Bone tissue repair is a complex, dynamic and long-term biological process that encompasses inflammation, repair and remodeling phases. Each stage is important for successful bone tissue healing [[4], [5], [6]]. Consequently, biomaterials capable of dynamically responding to and regulating these biological processes, tailored to specific needs, hold the greatest promise for advancement and clinical application potential in the field of regenerative medicine [7].

Programmable materials can change their morphology, physical properties, or chemical functions in a predetermined sequence in response to external stimuli or environmental changes. This programmability enables time-dependent control methods, thereby offering extensive application potential in various fields such as drug delivery, tissue engineering, regenerative medicine, smart medical devices, and biosensors [8]. In bone regeneration, it means that implant materials can dynamically respond and regulate on demand based on the natural bone repair process or microenvironmental characteristics and finally achieve the ideal bone repair [9,10]. Resveratrol (Res) is a polyphenol with antioxidant, anti-inflammatory, and cardiovascular protective effects. It also boosts the osteogenic potential of bone marrow mesenchymal stem cells (BMSC), showing potential for treating osteoporosis and bone repair. Due to its poor water solubility and rapid decomposition upon exposure to oxygen, liposomes are frequently employed to enhance Res's stability and bioavailability. Moreover, bone norphogenetic protein-2 (BMP-2) can stimulate deoxyribonucleic acid (DNA) synthesis and cell replication, thereby promoting the directional differentiation of mesenchymal cells into osteoblasts. It is an important growth factor for bone repair and regeneration. Although BMP-2 is crucial for osteogenesis, its clinical use is limited by its short half-life, high cost, and potential side effects. Cai et al. develops novel delivery systems using film dispersion and static loading to prepare chitosan-coated resveratrol liposomes (CS-Res@Lipo) and HAMA@HepMA hydrogel microspheres (MS) via a chemical grafting condensation reaction. These systems utilize non-covalent interactions at MS binding sites to efficiently anchor BMP-2, forming a programmed release system. This strategy uses Res to control the immune response, while BMP-2 is released slowly to aid bone healing. This dual-release system not only targets inflammation management but also enhances the osteogenic process, leveraging the coordinated release profiles to maximize therapeutic efficacy and optimize bone regeneration outcomes [11]. In addition, a silk fibroin (SF)-based scaffold mimicking cartilage can programmatically regulate the timed release of bioactive factors to enhance in-situ cartilage regeneration. Initially, transforming growth factor-β1 (TGF-β1) is incorporated into the SF cryogel scaffolds through physical adsorption, subsequently followed by the encapsulation of E7 within a rapidly degrading SilMA/HAMA coating. This setup allows for rapid release of E7 in the initial days and a slow, sustained release of TGF-β1 over several weeks, synergistically promoting BMSC recruitment and their chondrogenic differentiation in vitro. These SF scaffolds maintain outstanding structural integrity and mechanical properties similar to cartilage, offering an optimal 3D microenvironment for cartilage reconstruction [12]. Programmable biomaterials are engineered to respond dynamically to the physiological environment of the injury site, allowing for tailored therapeutic actions based on the specific needs of the tissue repair process. These materials hold substantial clinical advantages in the field of bone repair, presenting a promising approach to regenerative medicine.

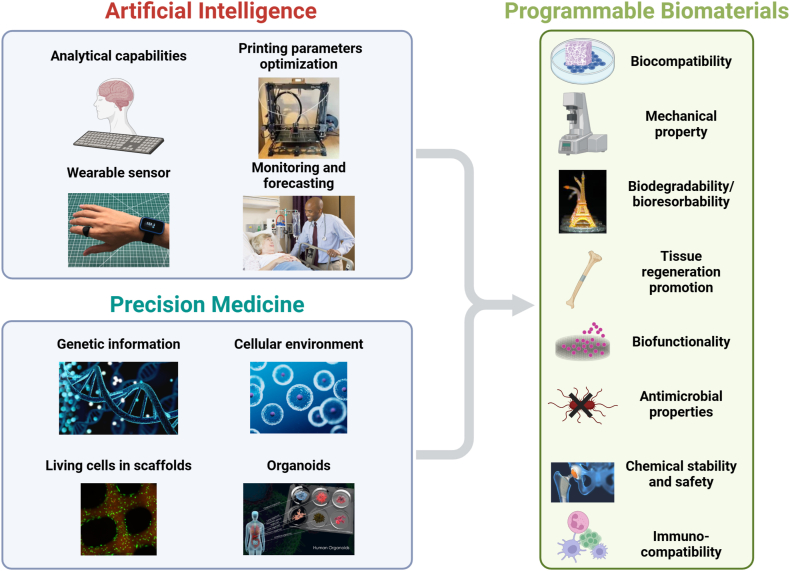

Research on programmable biomaterials for bone repair is flourishing and shows considerable clinical potential. However, there is currently a lack of comprehensive overviews on the use of these materials for bone healing. This review begins by briefly outlining the develop history of biomaterials, then contrasts the notable advantages of programmable biomaterials over traditional ones from clinical application and safety perspectives. It categorizes programmable materials based on their structural properties into six types: dynamic nucleic acid-based biomaterials, electrically responsive biomaterials, bioactive scaffolds with programmable properties, nanomaterials for targeted bone regeneration, surface-engineered implants for sequential regeneration and stimuli-responsive release materials (Fig. 1), systematically summarizing the cutting-edge research in bone repair. Furthermore, we address its existing challenges and forecast future trends by integrating artificial intelligence and precision medicine to enhance their application in bone regeneration and other biomedical fields. Overall, the review lays a theoretical foundation for the development of programmable biomaterials and underscores their impact on bone tissue engineering, focusing on the capacity of programmable biomaterials to fulfill the complex requirements of bone regeneration.

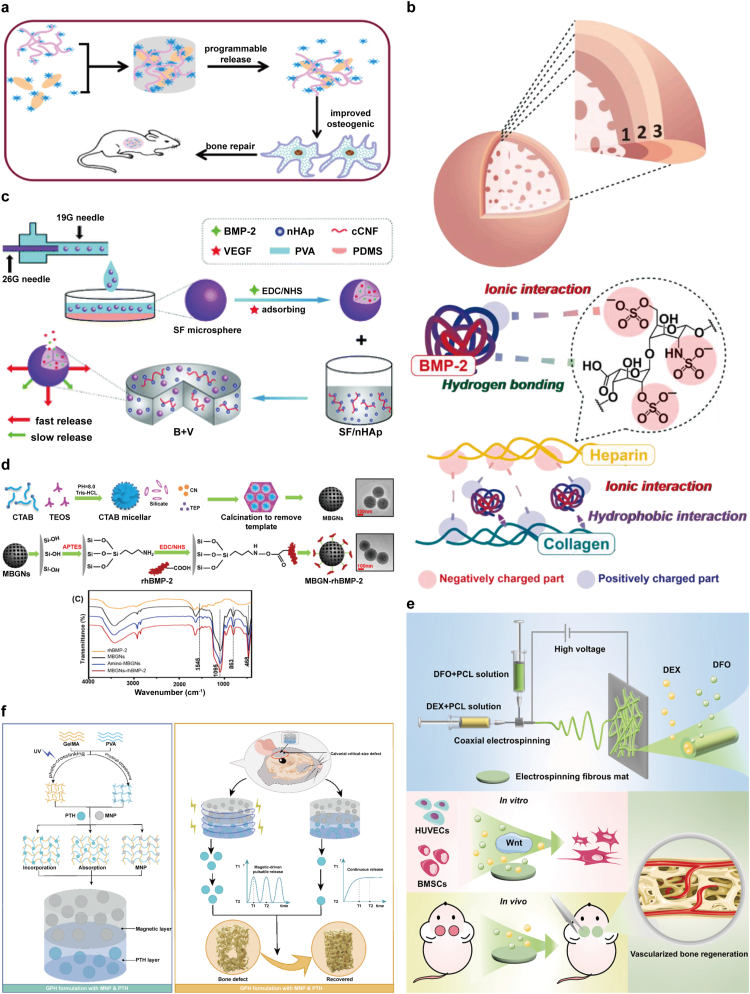

Fig. 1.

Classification of programmable biomaterials.

2. The development of biomaterials and the emergence of programmable biomaterials

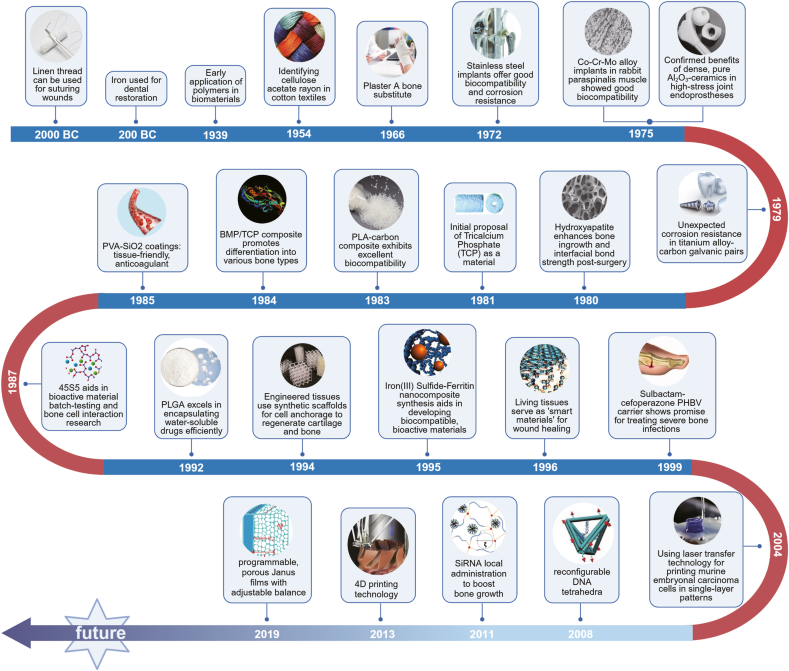

The development of biomaterials has been a journey of continuous innovation, evolving through three distinct generations, each marked by significant scientific advancements and shifting paradigms in materials science (Fig. 2) [[13], [14], [15]]. The first generation of biomaterials, primarily used from the 1950s to the 1980s, focused on materials that were biologically inert. These included gypsum, various metals, rubber and cotton. The primary objective during this era was to create materials that would not react adversely with biological tissues. However, the inert nature of these materials often led to host reactions and long-term compatibility issues, prompting the need for more sophisticated solutions. Despite their limitations, these materials laid the groundwork for future developments by establishing the fundamental criteria for biocompatibility [16,17]. The second generation, spanning from the 1980s to the 1990s, saw a shift towards bioactive materials. This era was characterized by an interdisciplinary approach, combining insights from medicine, materials science, biochemistry and physics. The development of technologies like advanced polymer materials science and enhanced physical testing methods allowed for the creation of materials that interacted beneficially with biological tissues. Key materials from this period include hydroxyapatite, tricalcium phosphate, polyhydroxy acids, hydroxyethyl methacrylate polymers, collagen and fibrin. These materials were designed not just to be compatible with the body but also to actively participate in biological processes, such as tissue regeneration and healing. The focus on bioactivity opened up new avenues for medical applications, including more effective implants and scaffolding for tissue engineering [[18], [19], [20], [21]]. The advent of the third generation of biomaterials, beginning in the 1990s and continuing to the present day, marked a revolutionary shift towards materials that could actively interact with and influence biological systems. This generation focuses on cell, protein and gene-activated materials, which are essentially biomedical composites designed to enhance the body's inherent healing and regenerative capabilities. These materials are a blend of active components that promote physiological responses and inactive components for control and stability. They are designed to achieve an optimal balance between material properties and biological function [[22], [23], [24], [25], [26]]. Third-generation biomaterials are characterized by their ability to adapt to physiological conditions, respond to cellular environments and facilitate the natural regenerative processes of the body. Representative materials include BMP and other biologically active compounds, which have found extensive applications in regenerative medicine and tissue engineering.

Fig. 2.

The evolution of biomaterials: from simple replacements to advanced regeneration.

Programmable biomaterials mark a pivotal advancement, merging disciplines such as materials science, biology and computer science. These biomaterials are engineered to integrate computational principles, such as coding and data processing, into their structure and functionality. This innovative approach enables the meticulous modulation of material characteristics via targeted molecular interactions, tailored chemical alterations and sensitivity to external stimuli. Programmable biomaterials are adept at altering their attributes or behavior in reaction to environmental fluctuations, including changes in temperature, pH levels, or mechanical forces, rendering them exceedingly versatile and responsive. The application of programmable attributes within biomaterials has catalyzed the creation of groundbreaking medical technologies. These include intelligent drug delivery mechanisms capable of precisely timing and locating the release of therapeutic agents, as well as sophisticated tissue engineering scaffolds that can adjust and progress in harmony with recuperating tissues. Such materials are engineered to be dynamic, in terms of both structure and functionality, fostering a new era of research in materials science. Programmable materials can respond to specific stimuli in several ways. In some materials, a stimulus may cause changes in non-covalent interactions within the material, leading to a reversible physical change [27]. Another type of programmable material is shape memory materials. Shape memory is a property that both organic materials and alloys can exhibit, and it may occur in one direction, two directions or multiple directions [28]. Programmable biomaterials epitomize the fusion of materials science, biology and computer science, yielding materials that are not only biocompatible but also equipped for dynamic interactions with their surroundings. This synergy between material characteristics and biological systems is key to devising more efficacious and customized medical interventions. It holds immense promise for advancing regenerative medicine, targeted drug delivery systems and other medical fields, heralding a new chapter in healthcare innovation [8,29,30].

As the research and development of programmable biomaterials continue to advance, we can expect these materials to play an increasingly vital role in addressing complex medical challenges. The future of biomaterials is likely to see even more sophisticated integration of biological and synthetic components, leading to innovative solutions that can adapt and respond to the body's needs in real-time. The evolution from inert to bioactive and programmable materials shows our growing understanding of interactions between materials and biological systems. This evolution heralds the onset of a new era of bio-inspired and bio-integrated materials science. As our understanding of these complex interactions continues to deepen, we can design more intelligent biomaterials that can not only interact precisely with biological systems, but also adapt self-regulation and repair in specific biological environments, greatly promoting the development of regenerative medicine and tissue engineering.

3. Programmable biomaterials versus traditional biomaterials

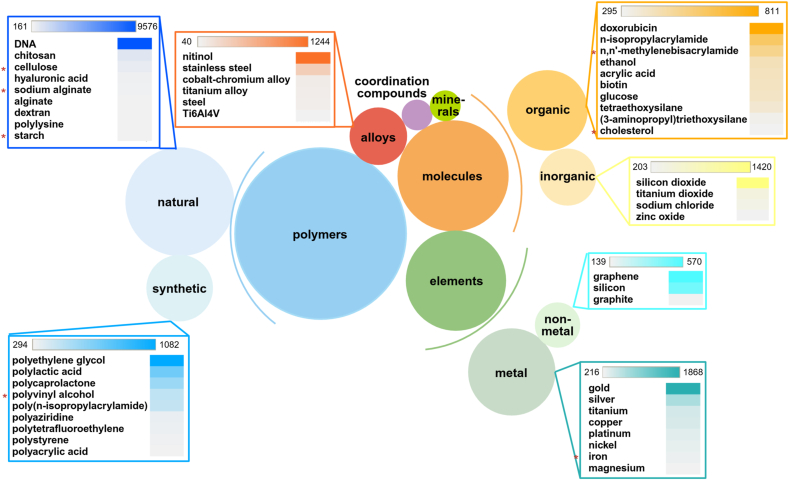

There is a significant difference between programmable materials and traditional material preparation and synthesis processes. Traditional large-scale material manufacturing often struggles to precisely create required components, leading to defects, deformations, or functional deviations [[31], [32], [33], [34]]. The programmability of programmable biomaterials comes from their ability to respond to small changes in the environment, such as pH, temperature, light, electric or magnetic fields, or specific chemical or biological signals. DNA-based materials represent a special class of programmable biomaterials. Their particularity lies in the fact that DNA can achieve precise structural adjustability through Watson-Crick base pairing [35,36]. The directed self-assembly of single-stranded DNA can produce different two-dimensional and three-dimensional structures, whose formation and dynamics can be controlled at the molecular level [37]. In addition to the ability to generate specific structures, DNA can also be modified to respond to specific chemical environments and further modified by using CRISPR technology. Currently, commonly used programmable biomaterials mainly include polymers (natural and synthetic), inorganic and organic small molecules, metal and non-metal elements, minerals, coordination compounds and alloys [[38], [39], [40]] (Fig. 3).

Fig. 3.

Distribution of publications (journals and patents) on substances used in programmable biomaterials from 2003 to 2023. Larger circles represent more publications, and materials with relatively faster growth rates are marked with asterisks.

Programmable biomaterials have increasingly become a part of our daily lives. Take, for instance, Nitinol, an alloy composed of nickel and titanium, known for its shape-memory properties. This alloy can be molded into a specific shape and then alter its form when exposed to heat. This characteristic has led to its designation as a shape-memory alloy. In the realm of orthodontics, the archwires in braces, made from Nitinol, contract upon exposure to the warmth of the human body, exerting the necessary force to correct the alignment of teeth [41,42]. Additionally, Nitinol finds extensive applications in medical devices such as stents used in heart surgeries, temperature controllers and mechanisms controlling the stable configuration of space systems [43]. Since its discovery in 1959, new applications of Nitinol have been identified almost every year, demonstrating its versatility and utility across various fields [44].

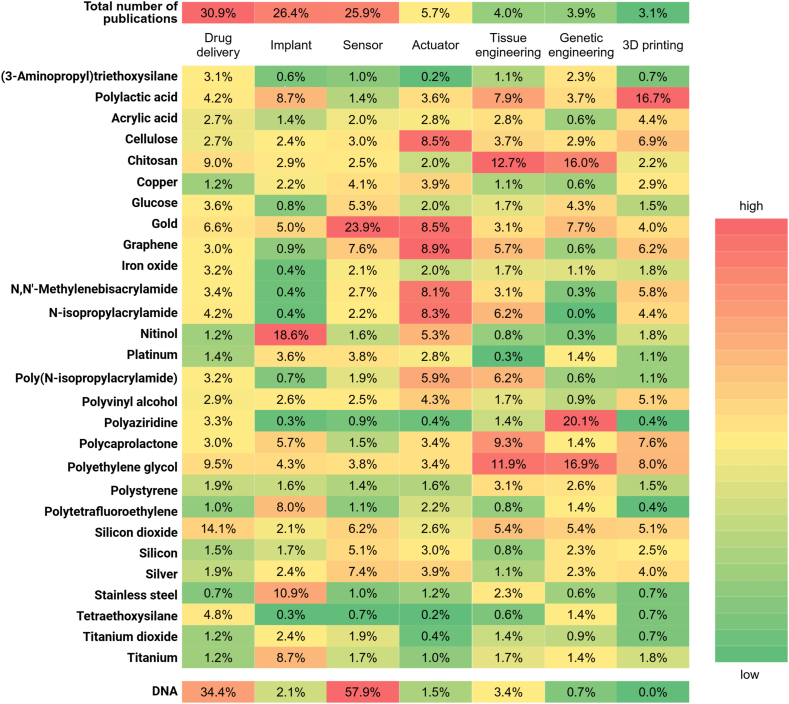

Another representative example of programmable materials is Jahn-Teller metals, which exhibit varying electrical properties depending on environmental changes. Named after the Jahn-Teller effect, which describes the distortion of molecules and ions with geometrically arranged electrons under low pressure environments, these metals enable scientists to transform insulators into conductors simply through the application of pressure. The Jahn-Teller effect allows for the manipulation of electronic states, opening up possibilities for innovative applications in various technological domains. This adaptability to external conditions underscores the significant potential of Jahn-Teller metals in advancing material science and engineering [[45], [46], [47]]. As shown in Fig. 4, the heatmap illustrates the primary applications of programmable biomaterials in biomedicine and the relationships between these applications and the substances used. Because DNA is not a single chemical substance, it is treated separately in this figure, representing DNA-based materials. The color gradient from green to red reflects the relative frequency of each substance mentioned in each application.

Fig. 4.

Heatmap showing the relationship between commonly used substances in programmable biomaterials (left column) and common applications (second row). The percentages indicate the frequency of each substance used in the respective applications.

The burgeoning research in programmable materials has brought a paradigm shift in materials science and engineering, encompassing synthetic biology, chemistry and computational design. These materials, with their unique adaptability for various applications, have opened new opportunities in processing technology, particularly in terms of uniformity and scalability. Recent advancements in programmable materials and associated manufacturing technologies hold great promise, potentially impacting both research and industrial applications significantly [48].

4. Different types of programmable biomaterials and their functions

4.1. Dynamic nucleic acid-based biomaterials

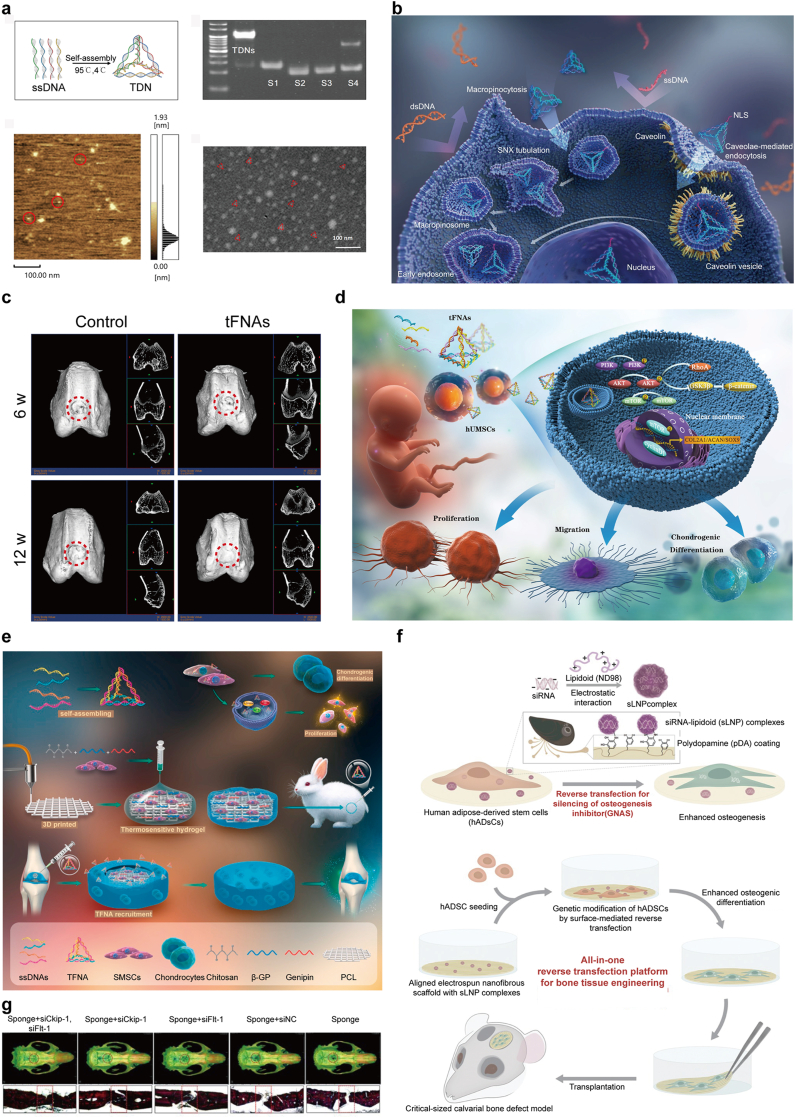

Since the advent of DNA nanotechnology in the 1980s, self-assembled DNA nanostructures have gained global interest for their inherent biocompatibility, remarkable programmability and diverse functionalities. These dynamic DNA nanostructures, which respond to alterations in temperature, pH, metal ion concentration, enzymes and specific oligonucleotides, can be meticulously designed for self-assembly into well-ordered, precisely defined systems [25,[49], [50], [51], [52]]. This is achieved through the reversible nature of hydrogen bonds, following the Watson-Crick base pairing principle. DNA's unique properties facilitate the design and creation of intricate, dynamic and functional nanostructures. Being composed of DNA, these nanostructures exhibit low cytotoxicity, are biocompatible and biodegradable and minimally trigger immune responses. This compatibility enables their use both in vivo and in vitro. Leveraging the reversible hydrogen bonding principle, researchers can engineer various DNA nanostructures with customizable structures and potent functionalities. These structures can adapt their conformation in response to different external stimuli [53] (see Table 1). A particularly noteworthy development in this field is tetrahedral framework nucleic acids (tFNAs). tFNAs, known for their excellent biocompatibility, have been shown to positively influence cellular behaviors such as proliferation, migration, differentiation and preservation of cell phenotype. Due to these properties, tFNAs are extensively utilized in the biomedical domain as three-dimensional DNA nanomaterials, marking significant advances in the application of DNA-based structures in medicine and biotechnology (Fig. 5a and b).

Table 1.

Dynamic nucleic acid-based biomaterials for bone repair.

| Materials | Signaling pathway | Relevant gene/protein expression | Cell type | Function | Ref. |

|---|---|---|---|---|---|

| tFNAs | Wnt/β-catenin | ALP↑, Runx2↑, OPN↑, β-catenin↑, Lef-1↑, cyclin-D↑ | Adipose-derived stem cells | Increased osteogenic potential and proliferation | [70] |

| tFNAs | notch | Runx2↑, OPN↑, NOTCH 1↑, HES 1↑, HEY 1↑ | Dental pulp stem cells | Enhanced proliferation and osteogenic differentiation | [71] |

| tFNAs | Wnt/β-catenin | ALP↑, Runx2↑, OPN↑, β-catenin↑, Lef-1↑, GSK-3β↓ | Periodontal ligament stem cells | Enhanced proliferation and osteogenic differentiation | [72] |

| tFNAs | Wnt/β-catenin | C-Fos↑, NFATc1↑, p-AKT↑, GSK-3↓ | Osteoclasts | Protective effect on the viability | [73] |

| tFNAs | Notch, Wnt/β-catenin | β-catenin↑, Lef-1↑, cyclin-D↑, collagen II↑ | Chondrocytes | Enhanced chondrocyte phenotype and proliferation | [74] |

| tFNAs | Wnt/β-catenin | β-catenin↑, Lef-1↑, cyclin-D↑, Col 2↑, Acan↑, Sox 9↑ | Synovial mesenchymal stem cells | Promoted the proliferation and chondrogenic differentiation | [75] |

| tFNAs | / | RhoA↑, Rock2↑, vinculin↑ | Chondrocytes | Promote chondrocyte motility, migration and chondrogenic differentiation | [76] |

| tFNAs | Tiam1/Rac1, Rhoa/Rock2 | Tiam1↑, Rac1↑, Rhoa↑, Rock2↑, Vcl↑ | Adipose-derived stem cell | Promote cell migration | [77] |

| tFNAs | PI3K/Akt | β-catenin↑, cyclin D1↑, GSK3β↓, RhoA↑, Sox9↑, ACAN↑, COL2↑ | Human umbilical cord mesenchymal stem cells | Enhance the proliferation, migration and chondrogenic differentiation | [62] |

| tFNAs | Wnt/β-catenin, TGF | β-catenin↑, Lef-1↑, cyclin-D↑, CD73↑, CD105↑, collagen II↑, SOX9↑, Smad2/3↑ | Synovium-derived MSCs | Enhanced proliferation, migration and regeneration | [61] |

| tFNAs | MAPK/ERK | ALP↑, RUNX 2↑, OPN↑, TNF-α↓,IL-6↓,IL-1β↓, ERK↓,JNK↓,P38↓ | Periodontal ligament stem cells | Decreased the release of pro-inflammatory cytokines, promoted osteogenic differentiation | [59] |

| tFNAs, miR-2861 | / | HDAC5↓, Runx2↑, ALP↑ | Bone marrow mesenchymal stem cells | Promote osteogenic differentiation | [58] |

| tFNAs-miR(miR-2861) | / | HDAC5↓, ALP↑, Runx2↑ | Bone marrow mesenchymal stem cells | Promoting osteogenic differentiation | [58] |

| tFNAs- clindamycin (CLI) | / | ALP↑, OCN↑, OPN↑, Runx2↑ | Bone mesenchymal stem cells | Outstanding osteogenic and antimicrobial Activity |

[78] |

| tFNAs, Curcumin | MAPK | ALP↑, Runx2↑, Osx↑, p-JNK↓, Bax↓, Caspase 3↓, Bcl 2↑, cytochrome c↓ |

Bone marrow mesenchymal stem cells | Antioxidant, anti-Apoptotic, promote bone regeneration | [57] |

| hydrogel-blended scaffold, CRISPR/Cas9 | / | CD 31↑, vWF↑, OCN↑ | Ob-like cells (mg-63), HUVECs | Promote osteogenesis and angiogenesis | [63] |

| polydopamine-siRNA(lipidoid nanoparticle)-poly(lactic-co-glycolic acid) | / | GNAS↓, OPN↑, COL↑ | Human adipose-derived Stem cells |

Enhanced Osteogenesis and mineralization |

[66] |

| PLLA scaffold, siRNA- semaphorin4d | / | / | Femur osteoporotic defect model | Did not affect osteoclasts, increased osteoblasts, improved new bone formation | [79] |

| chitosan sponge, siCkip-1, siFlt-1 | / | VEGF↑, ALP↑, OCN↑, vWF↑ | Primary rat bone marrow-derived MSCs | Promote osteogenesis and angiogenesis | [67] |

| MiR@TDNs/Li-hep-gel | Wnt/β-catenin | VEGF↑, β-catenin↑, DKK1↓, ALP↑, OCN↑ | Bone mesenchymal Stem cells |

Promote osteogenesis and angiogenesis | [56] |

| hybrid nanoparticle (NP), PEG)-based hydrogel, siRNA(WW domain-containing E3 ubiquitin protein ligase 1) | / | Wwp1↓, Runx2↑, OC↑, ALP↑, type 1 collagen↑, | Mesenchymal stem cells | Promote bone regeneration | [80] |

| poly-D,L-lactic acid-p-dioxanone-polyethylene glycol block co-polymer (PLA-DX-PEG), siRNA(Noggin) | / | Noggin↓ | Mouse dosal muscle pouches | Promote bone regeneration | [81] |

| stearylamine/cholesterol sterosome, siRNA(Noggin) | / | Noggin↓, ALP↑, Runx2↑, OCN↑ | Mesenchymal stem cells | Promoted differentiation | [82] |

Fig. 5.

a) Characterization of TDNs. Reproduced with permission [72]. Copyright 2019, Wiley-VCH Verlag. b) tFNAs can enter cells, unlike naked DNA which cannot cross cell membranes. tFNAs with nuclear localization sequences (NLSs) also reach the nucleus, showcasing their targeted delivery potential. Reproduced with permission [53]. Copyright 2022, Springer Nature. c) tFNAs enhance transformation of SMSC into cartilage cells and boost joint cartilage repair in living organisms. Reproduced with permission [61]. Copyright 2021, KeAi Communications Co. d) Bone regeneration in the rat skull defect model. Reproduced with permission [67]. Copyright 2014, Dove Medical Press Ltd. e) TFNA boosts SMSC growth and aids their transformation into cartilage cells. Combined with a CS hydrogel and 3D-printed polycaprolactone (PCL) scaffold, it effectively repairs rabbit cartilage defects. Reproduced with permission [75]. Copyright 2021, Elsevier BV. f) pDA helps attach sLNP complexes to PLGA scaffolds for efficient siRNA delivery, boosting bone formation from ADSCs. This method offers a unified solution for stem cell engineering, differentiation and implantation, effectively repairing large bone defects in mice. Reproduced with permission [66]. Copyright 2016, Wiley-VCH Verlag.

tFNAs are highly effective biological carriers. They have a very stable tetrahedral structure that can maintain its shape under various physiological conditions, which is crucial for carrying drugs or genetic material in vivo. Additionally, the surface of tFNAs can be functionalized through chemical or biological methods, allowing them to attach various drugs, gene fragments, proteins, or other bioactive molecules, thereby achieving multifunctionality [54]. tFNAs can also efficiently enter cells and release their payloads, making them highly promising for biomedical applications [55]. Wang et al. developed tFNAs to act as delivery vehicles for MiR335-5p and synthesized a heparin lithium hydrogel (Li-hep-gel) as a dual delivery agent for lithium and MiR@tFNAs. Following the insertion of MiR@tFNAs/Li-hep-gel into a steroid-associated osteonecrosis (SAON) model, considerable bone regeneration was noted within the osteonecrotic defect through modulation of the Wnt signaling pathway [56]. Bai et al. developed tFNAs/Cur complexes, an innovative nucleic acid drug system designed to enhance bone regeneration. This system delivers Curcumin (Cur) into BMSC, providing antioxidant and anti-apoptotic benefits. The tFNAs/Cur complexes effectively neutralize the osteogenic suppression induced by TNFα, markedly enhancing the expression of ALP, Runx2 and Osx proteins. Additionally, these complexes reduce the levels of proapoptotic proteins such as Bax and caspase3, while increasing the levels of the anti-apoptotic protein Bcl2 [57]. Li et al. used an RNase H-responsive sequence to link a sticky-end tetrahedral framework nucleic acid (stFNA), a special type of tFNAs characterized by sticky ends designed at the termini of its DNA single strands, with miR-2861, a targeted microRNA designed to regulate histone deacetylase 5 (HDAC5) expression in bone marrow mesenchymal stem cells (B-MSCs). This novel approach culminated in the development of a bioswitchable nanocomposite (stFNA–miR), which effectively unloads and deploys miR-2861 upon intracellular delivery. This targeted mechanism leads to the suppression of HDAC5 expression, thereby enhancing osteogenic differentiation [58].

tFNAs have been shown to suppress the release of pro-inflammatory cellular factors (including IL-6, TNF-α and IL-1β) and in decreasing the production of cellular reactive oxygen species (ROS). This method promotes the migration of periodontal ligament stem cells (PDLSCs) in vitro. It also facilitates their osteogenic differentiation. Additionally, in rat models suffering from periodontitis, tFNAs substantially decreased the infiltration of inflammatory cells and significantly lowered the levels of IL-6 and IL-1β. This led to the inhibition of osteoclastogenesis [59,60]. In rabbit models with articular cartilage defects, injecting tFNAs into the joint cavity enhanced the therapeutic outcomes for cartilage repair compared to control treatments that did not use tFNAs (Fig. 5c) [61]. Human umbilical cord mesenchymal stem cells (hUMSCs) are increasingly recognized as a valuable choice for regenerating cartilage. However, the ongoing challenge remains in developing suitable biomaterials that can reliably guide their self-renewal and differentiation. Fu et al. have explored the use of tFNAs as an innovative method in vitro to influence hUMSC behavior. Their research reveals that tFNAs alter the transcriptome and several signaling pathways in hUMSCs, particularly activating the PI3K/Akt pathway. Moreover, tFNAs modulate the expression of various proteins, including glycogen synthase kinase-3β (GSK3β), RhoA and (mechanistic target of rapamycin) mTOR, along the PI3K-Akt axis. This leads to improved cell proliferation, migration and chondrogenic differentiation of hUMSCs, offering fresh insights on augmenting the chondrogenic potential using tFNAs [62].

CRISPR technology is a revolutionary RNA-guided genome editing method utilizing a nuclease, such as Cas9, in conjunction with a single guide RNA (sgRNA). The sgRNA is structured with a scaffold domain and a spacer region that identifies and attaches to the protospacer adjacent motif (PAM) on the target DNA. This interaction allows the Cas9/sgRNA complex to bind to genomic DNA, causing a double-strand break that facilitates gene editing. In the realm of regenerative medicine, CRISPR has emerged as a pivotal tool for regulating gene expression in pluripotent stem cells, enabling precise modifications in cellular function and characteristics, which is crucial for advancing therapies and understanding cellular mechanisms. Shahabipour and colleagues engineered a hydrogel-based scaffold by blending gelatin methacryloyl (GelMA) with alginate and enhancing it with hydroxyapatite nanoparticles (HAP) to construct an in vitro prevascularized bone model. They utilized CRISPR/Cas9 technology to integrate GFP into the human-like ROSA locus within the genome of human umbilical cord vascular endothelial cells (HUVECs). GFP-labeled HUVECs were then co-cultured with osteoblast-like cells (MG-63) within this 3D hydrogel scaffold to study the interactions between osteoblasts and endothelial cells in a three-dimensional environment. In contrast to mono-cultures, these cells arranged themselves into vessel-like structures and the cells in the co-culture model exhibited actin extensions and spike-like filopodia. Moreover, genes associated with angiogenesis and osteogenesis, such as CD31 and osteocalcin (OCN), showed higher expression in the co-culture compared to the mono-culture [63].

Small interfering RNAs (siRNAs) are double-stranded non-coding molecules that regulate gene expression with high specificity, capable of inactivating a single gene. siRNA therapy targets and suppresses genes hindering osteogenesis, thus promoting bone repair and growth. It modulates osteoblast activity, enhancing differentiation and mineralization and is particularly effective when used with scaffolds in bone tissue engineering. Critical inhibitors of bone regeneration, such as Noggin, WW domain-containing E3 ubiquitin-protein ligase 1, Semaphorin4d (Sema4d) and casein kinase-2 interacting protein-1 (Ckip-1), represent promising molecular targets for siRNA therapies aimed at enhancing bone growth [64,65]. Traditional siRNA delivery methods into stem cells, which depend on solution-based transfection, encounter obstacles such as low transfection efficiency and minimal interaction time between cells and siRNA during prolonged culture periods. To address these limitations, a new method inspired by biology has been developed using polymer-based reverse transfection. This approach utilizes implantable poly(lactic-co-glycolic acid) (PLGA) scaffolds that are modified with siRNA-lipidoid nanoparticle (sLNP) complexes through a polydopamine (pDA) coating. This novel pDA-sLNP-PLGA system is non-toxic and effectively silences genes inhibiting osteogenesis in ADSCs, thereby substantially promoting their osteogenic differentiation [66]. Jia et al. engineered a chitosan sponge scaffold that incorporates two targeted siRNAs: siCkip-1, which targets casein kinase 2 interaction protein 1 and siFlt-1, aimed at the soluble Vascular Endothelial Growth Factor Receptor 1 (VEGFR1). Both siRNAs are recognized for their efficacy in enhancing osteogenesis and angiogenesis. This scaffold is designed to steadily release siRNAs in a neutral phosphate buffer solution (PBS) for over two weeks. Additionally, in the presence of lysozyme, the scaffold demonstrates enhanced degradation capabilities. This characteristic ensures the scaffold's optimal biodegradability within a simulated in vivo environment, facilitating both effective drug delivery over the intended period and subsequent biological clearance once drug release concludes, thus enhancing the implant's biocompatibility and functionality. The application of this scaffold significantly suppressed the expression of targeted genes while elevating levels of osteocalcin, alkaline phosphatase and vascular endothelial growth factor (VEGF)-key factors in the mineralization of the extracellular matrix. Immunofluorescence analysis further verified that the siRNA-modified scaffold amplified the expression of bone and vascular health markers, specifically osteocalcin and von Willebrand factor. In vivo experiments employing a critical-size skull defect model in rats demonstrated substantial bone regeneration following the administration of siCkip-1 and siFlt-1, confirming the scaffold's potential for clinical applications in bone repair and regeneration (Fig. 5d) [67].

The ability of dynamic nucleic acid-based biomaterials to target specific genes and provide a sustained, tailored release of bioactive molecules makes them highly effective in promoting bone regeneration while minimizing side effects. In addition, engineered cells for bone regeneration represent a cutting-edge approach in regenerative medicine, utilizing genetic modification and cellular engineering to enhance the body's natural healing processes. These cells, often derived from mesenchymal stem cells (MSCs), are modified to overexpress osteogenic factors such as BMP-2 or VEGF, which promote bone formation and vascularization [68,69]. By integrating with bioactive scaffolds or delivering targeted gene therapies, engineered cells significantly improve the efficiency of bone repair, offering a promising strategy for addressing complex bone injuries and diseases.

4.2. Electrically responsive biomaterials

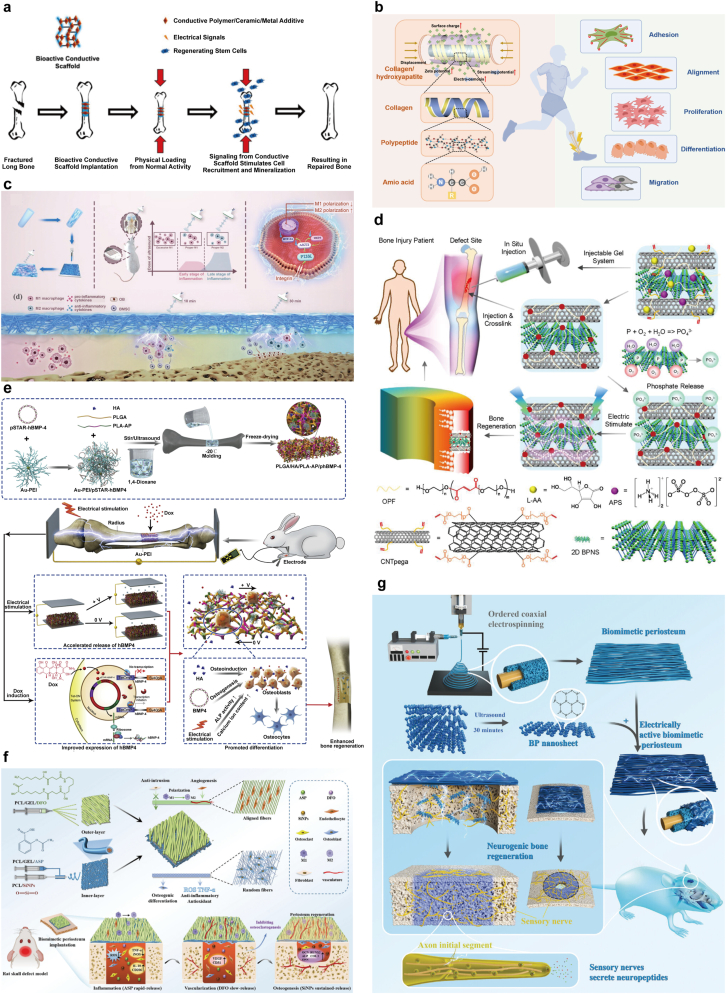

The discovery that endogenous electric fields (EnEFs) are important biophysical cues for maintaining bone homeostasis and promoting regeneration has led to the emergence of electrical stimulation as an external intervention to accelerate bone defect healing. EnEFs are critical in various biological processes such as tissue remodeling and cellular stability. As a biophysical indicator within the extracellular matrix (ECM), EnEFs are recognized for their ability to facilitate the regeneration of multiple tissues and organs, including nerves, bones, skin, muscles and the heart. While bone tissue itself does not conduct electricity, EnEFs are crucial for its growth, homeostasis, remodeling and metabolic processes. The electric fields within bones primarily arise from the piezoelectric effects within the collagen matrix, which makes up 85–90 % of the ECM and about 22 % of the bone structure. They have a non-centrosymmetric polar hexagonal crystal structure and a nanoscale helical morphology that can convert physiological pressure into electrical potential. Based on this, electroactive biomaterials (EABMs) that can change their physical properties in response to electrical stimulation have been developed and these changes can be precisely programmed and controlled by electrical signals. This programmability allows scientists to dynamically adjust the behavior and function of materials to suit different biomedical applications. EABMs consist of various types, including conductive biomaterials like carbon-based materials, conductive polymers, metal nanomaterials and MXenes. They also comprise piezoelectric biomaterials like ceramics and polymers that respond to mechanical stress, as well as other intelligent biomaterials capable of producing electrical signals in response to specific environmental triggers like changes in pH, light, or temperature. The development of these materials not only promotes innovation in biomedical engineering but also provides new strategies and tools for future regenerative medicine and tissue repair (Fig. 6a, b and 6e) [83].

Fig. 6.

a) Under compressive stress, the bone scaffold creates electrical dipoles, attracting osteoblasts to the negative side. There, osteoblasts produce new ECM and minerals, forming healthy bone tissue. Reproduced with permission [93]. Copyright 2022, Multidisciplinary Digital Publishing Institute (MDPI). b) Piezoelectric properties of bone and cellular responses to electrical signals. Reproduced with permission [83]. Copyright 2023, Elsevier. c) Schematic of a smart electroactive tissue engineering scaffold enabling controlled release and expression via electrical stimulation. Reproduced with permission [94]. Copyright 2023, American Chemical Society. d) Schematic of the innovative injectable hydrogel (BP-CNTpega) showcasing its superior mechanical and electrochemical traits. It continuously releases phosphate ions and responds electrically, enhancing cell osteogenesis and bone healing. Reproduced with permission [97]. Copyright 2020, American Chemical Society. e) Schematic of a Smart Electroactive Tissue Engineering Scaffold Enabling Controlled Release and Expression via Electrical Stimulation. Reproduced with permission [83]. Copyright 2023, Elsevier. f) Schematic diagram of the preparation and mechanism of a biomimetic periosteum to programmatically promote bone regeneration. Reproduced with permission. Copyright 2024, John Wiley and Sons Ltd [98]. g) Schematic of PD@BP Enhancing Neurogenic Bone Repair. The electrically active periosteum fosters nerve-stimulated bone healing, offering a promising approach for bone regeneration in clinical settings. Reproduced with permission [99]. Copyright 2023, John Wiley and Sons Ltd.

In vitro studies have shown that electrical stimulation applied via direct, capacitive and inductive coupling can activate key cellular signaling pathways that promote osteogenesis, particularly through calcium/calmodulin-dependent pathways [84]. Direct coupling and capacitive coupling mainly affect the cell membrane, thereby increasing intracellular Ca2+ concentration and promoting the synthesis of prostaglandin E2. This process occurs through voltage-gated calcium channels that activate calcium transport across the membrane. In contrast, inductive coupling stimulation acts on cells through electromagnetic fields, mainly targeting the cytoplasm, triggering the release of intracellular calcium ions in calcium storage areas inside the cell, such as the endoplasmic reticulum. These different electrical stimulation methods further affect cell physiology and metabolic processes by regulating the dynamic balance of intracellular calcium ions and have an important regulatory effect on cell growth and differentiation processes, especially in the osteogenic activity of bone cells and their biological effects. These external stimulations collectively result in cellular activities that elevate calcium levels, in turn, enhancing calmodulin activation. This process is crucial for the proliferation of osteoblasts. Furthermore, these stimulations boost the synthesis of crucial proteins, including VEGF and transforming growth factor-beta1 (TGF-β1), which are vital for bone formation [85,86]. Additionally, membrane proteins, which function as signal integrators, respond to variations in extracellular signals and shifts in transmembrane potential. The mitogen-activated protein kinase (MAPK) signaling pathway is central to cellular signal transduction, mediating critical cellular responses to a variety of external stimuli. This pathway influences key processes such as cell growth, differentiation and apoptosis, thereby playing an indispensable role in cellular function and communication [87]. ATPases on the membrane utilize energy from electrical stimulation at specific frequencies and amplitudes to control the activity of membrane proteins [88,89]. Moreover, the production of ROS may also represent an alternative mechanism through which cells to react to electrical signals [90,91].

Cui and colleagues developed a composite scaffold composed of PLGA/HA/PLA-AP/pSTAR-hBMP-4 (phBMP-4), specifically designed for the controlled and programmable release and expression of growth factors. In this study, the plasmid vector (pSTAR) was utilized to control the expression of human bone morphogenetic protein 4 (hBMP-4) with doxycycline present. This vector is embedded into a triblock copolymer (poly(L-lactic acid)-block-aniline pentamer-block-poly(L-lactic acid), PLA-AP) combined with poly(lactic-co-glycolic acid) and hydroxyapatite to form a composite scaffold (PLGA/HA). In vitro experiments showed that hBMP-4 gene release can be regulated under electrical stimulation, thereby promoting cell proliferation and osteogenic differentiation. In vivo experiments were conducted using a rabbit model with a radial bone defect, in which the scaffold promoted effective bone healing. Research results indicate that the scaffold not only promotes the controllable expression and release of genes, but also holds considerable promise in boosting bone regeneration through the combined influence of biochemical and electrical stimulation. This provides a promising approach for combining gene therapy and electroactive materials in tissue engineering to treat large-scale bone defects [92]. Electroactive scaffolds with electrical conductivity are known to enhance intercellular communication. This capability promotes osteogenesis, especially in the presence of an electric field effect (EnEF) [93]. Sun et al. designed an electroactive membrane combining PCL with potassium-sodium niobate (KNN) to form a biodegradable 3D scaffold featuring efficient nanogenerators. This advanced membrane enables the creation of programmable electrical signals by adjusting the timing and duration of ultrasound stimulation (US) treatment. The customized electric output is intended to precisely control macrophage polarization. Their research introduces a temporal immunomodulation strategy in vivo, aimed at promoting stem cell recruitment by initially activating M1 macrophages and subsequently enhancing osteogenic differentiation through a proliferation of M2 macrophages, driven by reduced AKT2 expression and phosphorylation (Fig. 6c) [94]. Castro et al. developed a bioreactor that electromechanically stimulates piezoelectric scaffolds. This system, through a biomimetic approach, effectively mimics the microenvironment essential for the development and differentiation of bone cells. A distinctive aspect of the bioreactor is its ability to magnetically stimulate magnetoelectric scaffolds, providing mechanical and electrical stimuli to cells via magnetomechanical or magnetoelectrical actions, which rely on the scaffold's piezoelectric characteristics. The proposed magnetic bioreactors enable remote stimulation without direct contact with the material. This experiment validates the effectiveness of these magneto-responsive scaffolds in fostering the adhesion and growth of pre-osteoblasts [95]. Electro-active scaffolds are key in tissue engineering for areas like bone and cartilage repair, where Their ability to provide targeted electrical stimulation enhances the efficacy of these regenerative processes. Lei and colleagues developed a chitosan/hydroxyapatite (HAp) composite Janus film, which functions effectively as a scaffold for guided bone regeneration. By varying the salt concentrations in the electrolyte under an electric field, the internal pore structure of the polysaccharide film can be precisely adjusted. Additionally, the use of bioactive, partially soluble calcium phosphate (CaP) salts helps to create a porous structure within the Janus film, making it well-suited for bone regeneration applications [26]. Panda et al. developed a composite platform using poly(vinylidene difluoride) (PVDF) and barium titanate (BaTiO3, BT) to satisfy stem cell differentiation. The research indicated that direct current (DC) stimulation promoted early osteogenesis in human mesenchymal stem cells (hMSCs), accompanied by an elevated level of intracellular ROS. Conversely, square wave stimulation was observed to guide late osteogenesis, characterized by reduced ROS regeneration [96]. Liu et al. adeptly combined carbon nanotube (CNT)-poly(ethylene glycol)-acrylate (CNTpega) with black phosphorus (BP) in osteoinductive peptide-functionalized (OPF) hydrogel, creating an injectable BP-CNTpega hydrogel. This hydrogel exhibited exceptional mechanical strength and electrical conductivity, making it suitable for bone tissue engineering. The introduction of cross-linkable CNTpega in the hydrogel provided both mechanical support and electrical conductivity. When subjected to electrical stimulation, the hydrogel significantly enhanced the osteogenesis of preosteoblast cells, evident by the upregulated expression of critical genes involved in osteogenic pathways. In vivo applications have shown that the BP-CNTpega hydrogel is capable of efficient in situ gelation and cross-linking, as confirmed by X-ray imaging (Fig. 6d) [97]. Inspired by the natural structure and functionality of the periosteum, Zhao et al. created a biomimetic periosteum designed for the controlled release of multiple agents, aimed at enhancing bone regeneration (Fig. 6f) [98]. Su et al. developed a biomimetic periosteum using coaxial electrospinning, consisting of a PCL core and a DNM shell (PD), enhanced with 2D black phosphorus (BP) for electrical activity (PD@BP). This periosteum promotes nerve regeneration, aided by 2D BP and endogenous electric fields, with DNM providing the necessary extracellular matrix. Its primary function is to stimulate axon growth and neurotransmitter secretion, fostering osteogenesis. Demonstrated through both in vivo and in vitro studies, the PD@BP biomimetic periosteum effectively induces neurogenic osteogenesis, primarily via the Fanconi anemia pathway, offering a novel strategy for bone regeneration with significant clinical application potential (Fig. 6g) [99].

Electrically responsive biomaterials offer significant advantages in bone regeneration due to their ability to respond dynamically to electrical stimuli, promoting cellular activities crucial for osteogenesis. These materials, such as conductive polymers, piezoelectric biomaterials, and metal nanomaterials, enhance intercellular communication and stimulate osteoblast proliferation through calcium/calmodulin pathways and other signaling mechanisms. Electrically responsive biomaterials enable the controlled and sustained release of bioactive molecules and growth factors, thereby improving the precision of tissue engineering approaches. By integrating electrical and biochemical cues, electrically responsive biomaterials facilitate the regeneration of bone tissue, providing an adaptable and programmable platform that enhances bone healing and promotes cellular differentiation.

4.3. Bioactive scaffolds with programmable properties

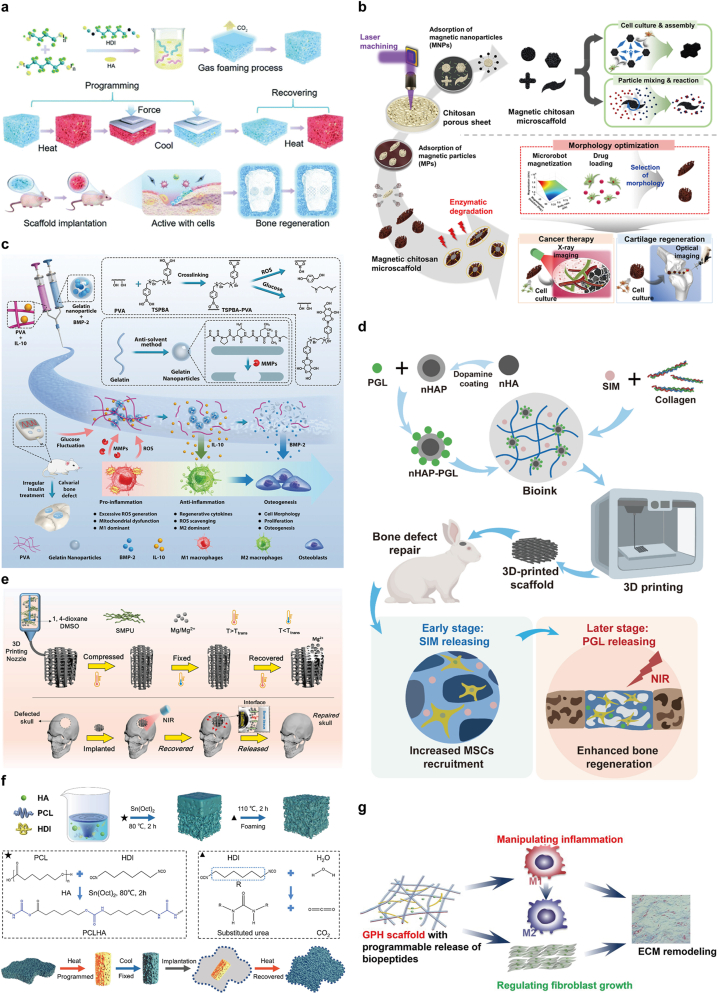

Bioactive scaffolds with programmable properties combine structural support with dynamic, tailored biological functionality. This programmability allows the scaffold to respond to different biological phases of healing, ensuring that signals are delivered at the right time to enhance cellular activity and promote efficient bone repair (see Table 2). Wang et al. designed and synthesized a series of biomimetic hydroxyapatite/shape memory composite scaffolds. These scaffolds feature programmable pore structures, exhibiting diverse parameter and high connectivity, along with adjustable mechanical properties and excellent shape memory capabilities. By altering the amount of hydroxyapatite (HA), the microstructure and pore configuration of these composite scaffolds can be precisely regulated, which further enhances the creation of perforated pores. In addition, changing the HA content can also improve the hydrophilicity, expansion rate, melting point and mechanical properties of the scaffold, making it more suitable for biomedical applications (Fig. 7a) [100]. A magnetic chitosan microscaffold (Mag-C) was designed for adaptability in shape and movement for various biomedical applications, demonstrating its versatility. Mag-C comprises a chitosan microscaffold (CMS) and surface-attached magnetic particles (MPs). The CMS is rapidly and precisely shaped using laser micromachining on a porous chitosan sheet, capitalizing on chitosan's biocompatibility and biodegradability. Adsorption of MPs onto the CMS surface imparts magnetic responsiveness. This surface modification maintains chitosan's inherent properties while enhancing Mag-C's magnetic actuation and cell adhesion capabilities. Mag-C is capable of performing specific roles based on its shape, enabling particle manipulation and assembly by loading various cells and magnetic fields, thus making it suitable for in vitro biomedical applications. The effectiveness of the developed microscaffold was demonstrated in both in vitro and in vivo, especially in the regeneration of knee cartilage. The optimal design and fabrication of this microscaffold are expected to significantly enhance the development of biopolymer-based microscaffolds and micro/nanorobots (Fig. 7b) [101].

Table 2.

Bioactive scaffolds with programmable properties for bone repair.

| Materials | Key Features | Applications | Ref. |

|---|---|---|---|

| Biomimetic Hydroxyapatite/Shape Memory Composite Scaffold | Programmable pore structure, adjustable mechanical properties, shape memory, hydrophilicity | Bone regeneration, adaptable scaffolds | [100] |

| Magnetic Chitosan Microscaffold | Magnetic responsiveness, biocompatibility, biodegradability, enhanced cell adhesion | Knee cartilage regeneration, micro/nanorobots | [101] |

| Injectable Hydrogel Systems | Supports cell viability, differentiation, angiogenesis, bioactive molecule release, native ECM mimicry | Bone tissue engineering, osteoblast promotion | [102,103] |

| Dual-Network Composite Hydrogel | Viscoelastic properties, stress relaxation, biodegradable, ROS and glucose-responsive | Diabetic bone regeneration, tissue repair | [104,105] |

| 3D-Printed Dual-Drug Biomimetic Scaffold | NIR light-responsive, on-demand drug release (SIM, PGL), promotes osteogenesis and stem cell migration | Bone regeneration, rabbit skull defect model | [106] |

| Shape Memory Polyurethane Scaffold | NIR light response, shape recovery, Mg ion release for osteogenesis, strong mechanical properties | Bone repair, minimally invasive applications | [107] |

| Composite SMP Scaffold with Hydroxyapatite | Shape memory, enhanced mechanical properties, promotes bone-like mineralization and tissue repair | Minimally invasive bone repair | [108] |

| Silk Fibroin (SF) Cartilage Repair Scaffold | Sequential release of TGF-β1 and E7, BMSC recruitment | Cartilage regeneration | [12] |

| PCL-Based Electrospun Nanofibrous Scaffold | Programmable release of aprotinin and Tβ4, reduces inflammation, promotes ECM reconstruction | ECM remodeling, tissue engineering | [109] |

| Alginate/Calcium Phosphate Scaffold | Sequential release of PDGF and BMP-2, promotes osteoblast differentiation, cellular infiltration | Bone regeneration, stem cell differentiation | [110] |

| Biodegradable Polyurethane Scaffold with HA | Shape memory, tunable porosity, HA integration for osteoconductivity, in vivo biocompatibility | Bone defect implantation, bone repair | [114] |

| NIR-Responsive PLMC Scaffold with PDA | Shape recovery under NIR, self-fitting for irregular defects, enhanced osteogenesis, minimally invasive | Bone regeneration, cranial bone defects | [115] |

| ZnSr.TCP-SF Scaffold | Bone-mimicking architecture, tunable pore size, enhanced scaffold integrity and bone regeneration potential | Osteoregeneration, in vitro bone modeling | [116] |

| Functionally Graded TPMS Scaffold | Programmable pore size, tailored mechanical properties, smooth interconnectivity, bone-mimicking structure | Bone scaffolds, tissue engineering | [117] |

Fig. 7.

a) A range of biomimetic hydroxyapatite/shape-memory composite scaffolds with programmable pore designs were developed, utilizing poly(ε-caprolactone), polytetrahydrofuran (PTMG) and osteoconductive hydroxyapatite (HA). These programmable porous scaffolds show promising potential for bone regeneration applications. Reproduced with permission [100]. Copyright 2021, Royal Society of Chemistry. b) Schematic of a multifunctional, biodegradable magnetic chitosan microscaffold (Mag-C) with customizable shape for medical uses. These microscaffolds have tunable pores and sizes for specific needs, offering multiple functions. Their versatility was shown in lab tests and real-world treatments for liver cancer and knee cartilage repair. Reproduced with permission [101]. Copyright 2021, American Chemical Society. c) Diagnostic Strategy for Sensing Pathological Signals (like glucose changes, ROS, MMPs) in Diabetes, Guiding Timed Drug Release for Enhanced Tissue Repair. Reproduced with permission [105]. Copyright 2022, Wiley-Blackwell. d) Schematic of a 3D-printed scaffold responsive to NIR light, enabling controlled drug release and improved bone healing [106]. e) Infrared-responsive scaffold, made with low-temperature rapid prototyping (LT-RP) 3D printing, supports bone growth in both in vitro and in vivo studies. Reproduced with permission [107]. Copyright 2022, KeAi Communications Co. f) Developed a porous, biocompatible bone scaffold from shape memory polymers (SMP), using poly(ε-caprolactone) diol, hexamethylene diisocyanate (HDI)and hydroxyapatite (HA). These scaffolds can be programmed to a temporary shape and then return to their original form to fit bone defects. Reproduced with permission [108]. Copyright 2022, Elsevier Ltd. g) Bioactive PCL scaffolds designed for controlled release of aprotinin and thymosin β4 in a programmable manner. Reproduced with permission [109]. Copyright 2023, Oxford University Press.

Injectable hydrogel systems have advanced significantly in biomedical applications, notably in tissue engineering. These hydrogels play a key role in supporting the cell survival environment, not only improving cell viability and adhesion, but also promoting cell differentiation and effective integration with host tissues. They replicate the native ECM, offering a biocompatible and regenerative environment, particularly for bone tissue engineering. Hydrogels have shown unique potential in promoting bone formation and repair, primarily by promoting osteoblast differentiation, angiogenesis and the controlled release of bioactive molecules. Their porous, dilute crosslinked structure and high water content, akin to the natural ECM, enable them to effectively tailor cell activities through architectural, chemical and drug delivery features [102,103]. In recent decades, hydrogels have received increasing attention for their application potential in tissue engineering, especially when combined with advanced technologies such as microfluidic platforms and 3D bioprinting. These high-tech methods allow researchers to precisely control polymer precursors within microscale channels, thereby greatly improving the ability to build complex structures and broadening design possibilities. Scaffold biomaterials are designed to mechanically mimic the viscoelastic properties of the native ECM to accommodate complex local defects that may include irregular shapes, shear, tension and the structural integrity of surrounding tissues. Recent studies have shown that stem cells are extremely sensitive to the mechanical environment and that the viscoelastic properties of the hydrogel matrix, such as stress relaxation and creep behavior, can significantly promote bone regeneration. Based on these findings, a dual-network composite hydrogel was developed in this study, whose design not only reproduces the mechanical properties of natural ECM but also provides more physiologically relevant viscoelastic cues to optimize the cell regeneration and tissue repair environment. A dual-logic hydrogel, both diagnostic and therapeutic, was created for diabetic bone regeneration. It comprises a double network of phenylboronic-acid-crosslinked poly(vinyl alcohol) (PVA) and gelatin colloids. The PVA network, responsive in the diagnostic logic, can reversibly degrade upon exposure to ROS or high glucose levels. The gelatin colloidal network offers bioactive patterns that enhance cell affinity and allow for matrix metalloproteinase (MMP)-induced degradation, enabling cargo delivery initiation in response to the dynamic diabetic microenvironment. Therapeutically, the hydrogel, loaded with interleukin 10 (IL-10) and bone morphogenetic protein-2 (BMP-2), releases IL-10 initially for immune regulation, followed by BMP-2 delivery later, aligning with osteoblast activation during the later stages of tissue regeneration (Fig. 7c) [104,105].

A 3D-printed dual-drug-loaded biomimetic scaffold utilizing near-infrared (NIR) light-responsive properties was developed to optimize the bone regeneration process. The scaffold effectively delivers the bone formation-promoting drug pargyline (PGL) via polydopamine-coated hydroxyapatite nanoparticles. In addition, to enhance its drug release capability and therapeutic effect, the small molecule chemoattractant drug simvastatin (SIM) is integrated into the scaffold and is added directly to the hydroxyapatite/collagen bioink used for 3D printing. This scaffold was designed for an on-demand, sequential drug release where SIM is rapidly released in the initial stages, followed by PGL released in a NIR light-responsive manner. The SIM-loaded scaffold effectively accelerated stem cell migration. Furthermore, the results of the rabbit skull defect model showed that the on-demand sequential release mechanism of the biomaterial effectively enhanced the activity of alkaline phosphatase (ALP), significantly increased the gene expression of markers related to osteogenesis and promoted new bone formation (Fig. 7d) [106]. Taking advantage of the thermal response properties of shape memory polyurethane (SMPU) and the photothermal effect and bioactive properties of magnesium (Mg), a scaffold with near-infrared light response function was developed. This scaffold, produced using low-temperature rapid prototyping (LT-RP) 3D printing technology, recovers its shape under NIR light post-implantation, ensuring tight contact with surrounding tissues. Gradual release of Mg ions, due to the degradation of Mg particles, aids in promoting osteogenesis, essential for bone repair. Significantly, this compressed composite scaffold exhibited the ability to lift a weight of 100 g under NIR light, an amount over 1700 times its own weight (Fig. 7e) [107]. A porous, composite, biocompatible bone scaffold utilizing shape memory polymer (SMP) materials was developed, incorporating poly(ε-caprolactone) diol, hexamethylene diisocyanate (HDI) and hydroxyapatite (HA). Programmed to adopt a temporary shape, these scaffolds are capable of reverting to their original form, effectively occupying the site of a bone defect. The incorporation of HA not only enhances the mechanical properties of the scaffolds but also fosters cell adhesion and modulates the speed of shape recovery. During in vitro mineralization studies, HA has been shown to facilitate the formation and deposition of bone-like hydroxyapatite, thereby accelerating the repair of damaged tissues. Importantly, no inflammatory issues were observed following in vivo implantations. This innovative approach to programmable scaffolds shows great promise for minimally invasive bone repair applications (Fig. 7f) [108].

Mao et al. developed a cell-free cartilage repair scaffold based on silk fibroin (SF) that can programmatically release bioactive molecules specifically targeting cartilage regeneration. The scaffold is designed to sequentially release two bioactive factors: transforming growth factor-β1 (TGF-β1) and a BMSC-specific affinity peptide (E7). TGF-β1 was initially loaded onto the SF scaffold via physical absorption and E7 was subsequently incorporated through a gradient degradation coating of silk fibroin methacryloyl (SilMA) and hyaluronic acid methacryloyl (HAMA). This biomimetic scaffold was shown to maintain excellent structural and cartilage-like mechanical properties, creating a favorable 3D microenvironment for cartilage reconstruction. In vitro studies demonstrated that the scaffold effectively induced BMSC recruitment and chondrogenic differentiation due to the initial rapid release of E7 followed by the slow and sustained release of TGF-β1. Further in vivo experiments using a rabbit cartilage defect model showed that the scaffold significantly enhanced in situ cartilage regeneration. The synergistic release of E7 and TGF-β1, combined with the intrinsic properties of the SF scaffold, provides a promising approach to improving cartilage tissue engineering [12].

Xiang et al. developed a PCL-based electrospun nanofibrous scaffold with a core-shell structure designed for the programmable release of aprotinin and thymosin β4 (Tβ4). The core of the scaffold contains hyaluronic acid (HA) and Tβ4, while its shell is composed of PCL and the outer layer is coated with a heparin/gelatin/aprotinin layer. This design allows aprotinin to be gradually released from the shell after implantation, effectively reducing the inflammatory response caused by excessive recruitment of inflammatory cells on the scaffold surface. Within the first three days after implantation, Tβ4 is released, a process that not only hinders the fusion of macrophages to form multinucleated foreign giant cells but also promotes the transformation of macrophages from M1 to M2 types, thereby contributing to the ECM remodeling and tissue repair. At the same time, the gelatin in the scaffold is conducive to cell proliferation and migration due to its gradual degradation, while the heparin coating effectively prevents fibrosis of the ECM around the implant and maintains the health of the implanted area. This PCL-based scaffold not only effectively controls local inflammatory responses through its strategic, programmable biopeptide release mechanism but also promotes normal ECM reconstruction of damaged tissues, showing great potential in the fields of regenerative medicine and tissue engineering due to its application potential (Fig. 7g) [109].

A novel biomaterial scaffold, integrating alginate matrices with calcium phosphate scaffolding, was designed to enable a programmed release for growth factors. This scaffold consists of a strategic blend of alginate microspheres, alginate hydrogels and a novel resorbable calcium phosphate-based cement (ReCaPP). Within this structure, platelet-derived growth factor (PDGF) and BMP-2 were sequentially released, achieving a desired three-day overlap in the delivery of PDGF followed by BMP-2. Investigations using a three-dimensional coculture model revealed that this specific sequence of PDGF and BMP-2 release significantly influenced cellular infiltration into the scaffold and the expression of ALP. These findings suggest that the strategically timed presentation of PDGF followed by BMP-2 effectively promotes the differentiation of human mesenchymal stem cells (hMSCs) toward an osteoblast phenotype while concurrently enhancing cellular infiltration within the scaffold [110]. Microcapsules containing various bioactive molecules were immobilized on scaffold surfaces, allowing for multimodal activation through physical (ultrasound, laser radiation) and biological (enzymatic treatment) stimuli. This arrangement facilitates controlled release of the encapsulated substances from the scaffolds [111].

While 3D printing offers exciting possibilities in biofabrication, it faces challenges in creating complex, non-linear shapes and in varying the properties of multi-material structures over time. Compared to 3D bioprinting, 4D bioprinting can construct dynamic active structures that accurately mimic the intrinsic dynamics and conformational changes of natural tissues, thus meeting higher application demands in biomedical engineering. Since the advent of 4D printing technology in 2013, the field has garnered extensive attention. Two key factors for achieving ideal 4D printing outcomes are smart materials and intelligent design. Smart materials refer to materials that can change their shape or properties under external stimuli, while intelligent design aims to achieve programmable transformations by fully considering the time-dependent characteristics of the printed objects [112,113]. In the future, 4D printing technology is expected to further develop to handle biocompatible smart materials, biochemical substances, and living cells, thereby generating dynamic 3D living structures. Programmable active scaffold materials are designed to provide not just physical support for tissue regeneration but also to actively participate in the healing process. Their "programmability" lies in their ability to respond to biological signals and environmental changes, making them dynamic participants in the regeneration of tissues.

Bioactive scaffolds with programmable properties offer significant advantages in bone regeneration by providing not only mechanical support but also actively participating in the healing process. Their programmability allows them to release bioactive molecules in a controlled and sequential manner, tailored to the different phases of bone healing. This ensures that growth factors such as BMP-2, IL-10, and PDGF are delivered at the optimal time to promote osteoblast differentiation, angiogenesis, and immune regulation. Furthermore, these scaffolds can be designed with customizable pore structures and materials that mimic the natural extracellular matrix, enhancing cellular infiltration, proliferation, and differentiation. The dynamic and responsive nature of these scaffolds makes them highly effective in promoting the regeneration of complex bone structures while minimizing inflammation and ensuring tissue integration.

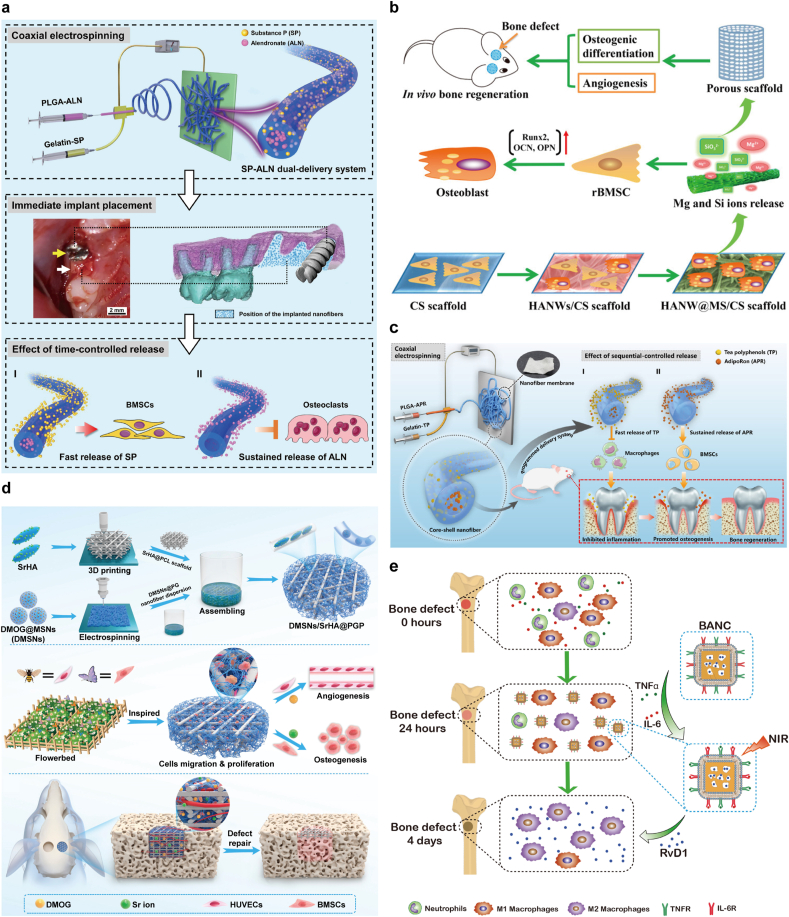

4.4. Nanomaterials for targeted bone regeneration

Nanomaterials for targeted bone regeneration for bone repair represent a cutting-edge convergence of nanotechnology and bone tissue engineering. These materials are engineered at the nanoscale to interact specifically with bone tissues, offering innovative approaches to promote bone repair and regeneration. A dual delivery system was developed using coaxial electrospinning to create a core-shell structure with alendronate (ALN) in the core and Substance P (SP) in the shell, ensuring a programmed release consistent with treatment needs. SP aimed to promote bone regeneration while ALN was intended to inhibit bone resorption, thereby enhancing implant osseointegration. The dual-delivery system successfully controlled the release rates of SP and ALN, thereby enhancing mesenchymal stem cell recruitment and osteogenesis while reducing osteoclast activity (Fig. 8a) [118]. Developing novel strategies that utilize magnetic nanoparticles (MNPs), magnetic field technology and stem cells is enhancing development of bone tissue engineering. These innovative strategies significantly enhance osteogenic differentiation, angiogenesis and bone regeneration by combining magnetic nanoparticles (MNPs) and scaffolds with magnetic fields and stem cells. This approach has been shown to increase the effects of bone tissue engineering by 2–3 times compared to the control group. This approach not only enhances the interaction between cells and scaffolds, but also regulates the local microenvironment through magnetic fields, promoting the directional differentiation of stem cells and new bone formation, thereby accelerating the bone repair process. The potential clinical applications of these strategies significantly improve bone repair and regeneration outcomes [119]. Sun et al. synthesized hydroxyapatite nanowire@magnesium silicate nanosheet core-shell structured hierarchical nanocomposites, referred to as nanobrushes. They were integrated into a chitosan matrix to form a scaffold. Nanobrushes exhibit large specific surface areas and pore volumes, which benefit high-performance drug loading and sustained release. The biological performance of the scaffolds was evaluated both in vitro and in vivo. In vitro, the scaffold demonstrated enhanced attachment and proliferation of rat bone marrow mesenchymal stem cells (rBMSCs) and promoted the expression of osteogenic differentiation-related genes and VEGF. In vivo studies using a rat bone defect model demonstrated that the scaffold significantly stimulated bone regeneration and angiogenesis. This ability is attributed to the scaffold's provision of a favorable environment for cell attachment, proliferation and differentiation, facilitated by the sustained release of bioactive ions necessary for bone tissue regeneration (Fig. 8b) [120]. He et al. developed core-shell nanofibers designed for programmed, sequential release of tea polyphenols (TP) and AdipoRon (APR), targeting inflammation control and bone regeneration enhancement. These nanofibers, synthesized through electrospinning, feature controlled sequential release functionality. The release profiles revealed an initial rapid release of TP, followed by a sustained release of APR. This design effectively diminished proinflammatory cytokine levels and augmented osteogenic differentiation in an inflammatory microenvironment (Fig. 8c) [121].Controlling pro-inflammation triggered by cytokines and promoting the anti-inflammatory response of M2 macrophages are crucial for osteogenesis during bone tissue repair. Zhou et al. used 3D printing and electrospinning technology to develop a biomimetic scaffold that mimics the extracellular matrix for bone regeneration. The scaffold adopts a core-shell structure incorporating dimethyloxalylglycine (DMOG)-loaded mesoporous silica nanoparticles and a 3D-printed framework containing strontium-enriched hydroxyapatite and PCL. This design promotes the sequential release of DMOG and strontium ions, enhancing angiogenesis and osteogenesis. In vitro tests showed that the scaffold enhanced cell attachment, proliferation and differentiation. It significantly upregulated genes related to osteogenic differentiation and promoted the expression of VEGF, which is critical for blood vessel formation. In vivo experiments using a rat bone defect model demonstrated that the scaffold effectively supported new bone formation and vascularization, performing significantly better than controls and showing promising applications in bone defect repair (Fig. 8d) [122]. Yin et al. synthesized and characterized biomimetic anti-inflammatory nanocapsules (BANCs) designed to reduce inflammation and promote M2 macrophage polarization for bone tissue repair. These nanocapsules were coated with lipopolysaccharide-treated macrophage membranes containing cytokine receptors and were encapsulated in gold nanocages containing the resolving agent Resolvin D1 (RvD1). This structure allows the controlled release of RvD1 by near-infrared laser irradiation, consistent with the healing phase of bone tissue repair. Experimental results showed that in vitro, BANCs effectively block pro-inflammatory cytokines and promote M2 polarization of macrophages, which is critical for bone tissue regeneration and repair. In vivo testing was performed using a rat model with a femoral defect. These studies demonstrated that BANCs significantly enhanced bone regeneration and angiogenesis compared to controls. This is attributed to the ability of the nanocapsules to modulate the inflammatory environment and promote beneficial cellular activity at the defect site. Using biomimetic nanomaterials with anti-inflammatory properties, this approach offers a potential treatment for bone defects caused by trauma or associated with inflammation (Fig. 8e) [123]. Programmable nanoparticle materials offer a promising and innovative approach for enhancing bone repair. Their ability to deliver targeted therapies, support bone regeneration and provide diagnostic capabilities positions them at the forefront of advancements in bone tissue engineering. As research in this field progresses, these nanoparticles are expected to play an increasingly significant role in the treatment of bone-related injuries and diseases.

Fig. 8.

a) The SP-ALN dual-delivery system created by coaxial electrospinning and its application in an implant model with dual-delivery fibers in the tooth socket. Reproduced with permission [118]. Copyright 2021, Elsevier BV. b) Synthesis of hydroxyapatite nanowire@magnesium silicate sheet (HANW@MS) core-shell nanocomposites is detailed. The HANW@MS/CS scaffold significantly promotes bone healing by enhancing rBMSC osteogenesis and angiogenesis. Reproduced with permission [120]. Copyright 2017, American Chemical Society. c) Core-shell nanofibers designed for sequential release of tea polyphenols (TP) and AdipoRon (APR) to manage inflammation and enhance bone healing in periodontitis-related alveolar bone defects. Reproduced with permission [121]. Copyright 2021, American Chemical Society. d) Schematic of DMSNs/SrHA@PGP Scaffold Creation for Dual Delivery of Angiogenic Drugs and Osteogenic Ions, Using 3D Printing and Electrospinning. Reproduced with permission [122]. Copyright 2023, American Chemical Society. e) Biomimetic anti-inflammatory nano-capsules (BANC) with surface cytokine receptors neutralize pro-inflammatory cytokines, easing inflammation. BANC encourages M2 macrophage polarization and inhibits M1 with Resolvin D1 (RvD1) released under NIR light, enhancing femoral bone repair. Reproduced with permission [123]. Copyright 2020, Elsevier BV.

Nanomaterials for targeted bone regeneration provide precise and controlled delivery of therapeutic agents, enabling enhanced bone regeneration by targeting specific cellular processes. Their nanoscale design allows for effective interaction with bone tissues, promoting osteogenesis, angiogenesis, and inflammation control. By utilizing systems such as core-shell nanofibers, magnetic nanoparticles, and biomimetic nanocapsules, these materials can sequentially release bioactive molecules, regulate the local microenvironment, and support mesenchymal stem cell differentiation. This advanced level of programmability, combined with their ability to modulate immune responses and promote cell attachment and proliferation, positions nanomaterials for targeted bone regeneration as a tool in bone tissue engineering and regenerative medicine.

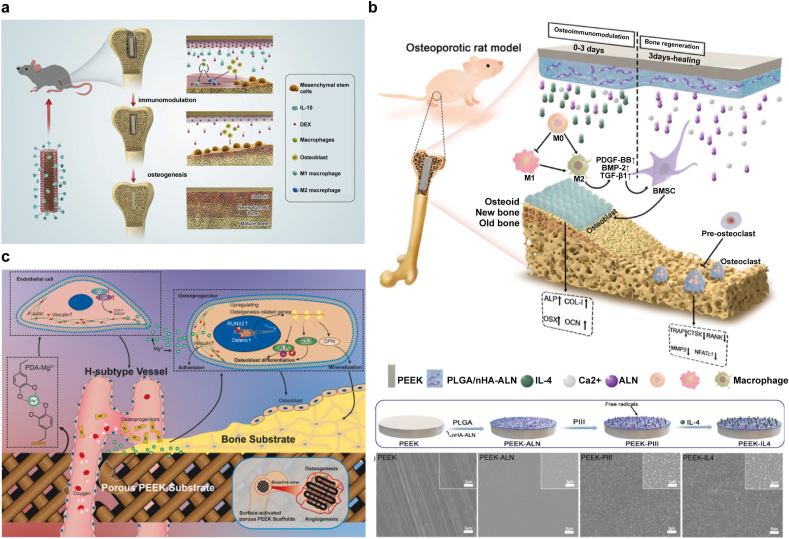

4.5. Surface-engineered implants for sequential regeneration