Abstract

Background

It was aimed to investigate the effect of sandblasting and laser surface treatment on shear bond strength in composite restoration repair in vitro.

Methods

A micro-hybrid composite (Filtek Z250, 3 M-ESPE, USA) was used to prepare 120 samples. The samples were subjected to a thermal cycle test 5,000 times between 5 and 55 0C, and they were randomly divided into 12 groups (n = 10). No surface treatment was performed in Groups 1 to 4, which were designed as control groups. The surfaces of the samples in Groups 5 to 8 were sandblasted with a Cojet device, and the surfaces of the samples in Groups 9 to 12 were applied Er, Cr: YSGG laser. After the sample surfaces were divided into groups with and without acid etching, universal adhesive was applied, and the repair process was performed using Filtek Z250 or nano-filled resin composite (Filtek Ultimate, 3 M-ESPE, USA). The thermal cycle test was repeated 5,000 times between 5 and 55 0C on all repaired samples. The repair shear bond strength of the samples was measured using a universal testing device (Shimadzu IG-IS, Kyoto, Japan). The fracture types were evaluated by optical microscopy and scanning electron microscopy (SEM). Statistical analyses of the findings were evaluated by the Kruskal Wallis test and Mann Whitney U test at 0.05 significance degree.

Results

The highest mean shear bond strength values were obtained from the samples sandblasted with CoJet, followed by Er, Cr: YSGG laser, and the control group. It was determined that there was a significant difference between the mean shear bond strength values obtained from the control group and the other surface treatment groups (p < 0.05). In general, significantly higher mean shear bond strength values were obtained when the universal adhesive was applied in total-etch mode compared to the application in self-etch mode (p < 0.05). Additionally, it was determined that higher shear bond strength values were obtained with Filtek Ultimate compared to Filtek Z250 (p < 0.05).

Conclusion

Within the limitations of this study, it can be concluded that the use of universal adhesive in total-etch mode, in addition to surface treatments on the resin composite surface in the repair protocol and the use of nano-filled resin composite as repair material can increase the mean shear bond values in repair.

Keywords: Adhesives, Composite resins, Lasers, Shear strength

Introduction

The concept of a minimally invasive approach in dentistry has led to a more conservative removal of caries. Today, the restoration of cavities prepared with this technique, combined with resin composite and adhesive systems, has enabled the attainment of clinically acceptable results [1, 2]. However, some problems such as secondary caries formation, marginal deterioration, fracture, and discoloration at the restoration margins due to deterioration of adhesive bonding over time have persisted [3]. The restoration should be replaced or repaired when such a situation is encountered.

Repair is defined as restoring the part of the restoration that is accepted as failed without touching the intact part of the restoration [4, 5]. Repairing the restoration results in less removal of intact tooth tissue and, therefore, decreases the risk of complications in the pulp. Today, repairing failed resin composite restorations is widely accepted as a popular treatment technique, due to advancements in adhesive technologies [6].

Repair of a resin composite restoration that functions in the oral environment is performed clinically using a new resin composite [7]. During this treatment, a good bonding of the new resin composite to the existing resin composite surface is desired. However, this may not be achieved sufficiently due to the decrease in the amount of unreacted methacrylate groups on the existing resin composite surface due to aging [8] For this reason, in in vitro studies, samples are subjected to water storage or thermal cycle tests in order to imitate the oral environment [7, 8]. In this way, hydrolytic degradation occurs in the structure of the resin composite. Additionally, it is not possible for the clinician to know the structure of the resin composite restoration present in the patient. This causes doubt about the bonding between the two materials in the repair made with a resin composite of different structure [9].

To increase the bonding of the new resin composite to the aged resin composite surface, it has been recommended to apply some physical or chemical treatment methods to the aged resin composite surface. Physical surface treatments such as diamond bur roughening, phosphoric acid, hydrofluoric acid, sandblasting, air abrasion, and laser roughen the aged resin composite surface, creating an irregular surface. This causes micromechanical bonding to occur between the aged resin composite and the resin composite used for repair, thus increasing the shear bond strength [6, 10]. It has been reported that the treatment of silane coating agents or adhesive resins to the roughened resin composite surface moisturizes the aged resin composite surface and enables the formation of chemical bonding between the aged resin composite and the repair resin composite [11, 12].

Universal adhesive systems developed in recent years are adhesive systems in which the bonding agent and the primer containing acidic monomer are combined in a single bottle. Manufacturers have introduced these adhesive systems as universal adhesive systems because they can bond to enamel, dentin, composite resin, ceramic, and metal surfaces [13]. The major advantage of these adhesive systems is that they can be used in total-etch, self-etch, and selective-etch modes. They contain 10-MDP, methacrylate resins, polyalkenes acid copolymer, filler, ethanol, water, polymerization initiator, and silane. Silane has been additionally added to the content of some universal adhesive systems to increase the bond strength. It has been reported that this way, especially the silane treatment step, will be eliminated, and therefore, the clinical application time will be reduced, and clinical use will be easier [13]. Some universal adhesives, such as Scotchbond Universal Plus, contain double silane monomer and have a pH of 2.7 [14]. It has been reported to show good binding to dental tissues thanks to the polyalkenoic acid copolymer, and 10-MDP contains [15]. This is realized by replacing the carboxyl groups in the polyalkenoic acid copolymer with phosphate ions and establishing ionic bonds with calcium in hydroxyapatite. However, there is a lack of information about the place of universal adhesives in resin composite repair. There is not enough information in the literature about the effectiveness of universal adhesives, which have the advantage of being applied in different modes, on repair bond strength in cases where different surface treatments are applied. Additionally, in scenarios where these adhesives are used in the repair protocol, there is a lack of information on the choice of resin composites to be used for repair purposes.

Therefore, the aim of this in vitro study was to examine the effects of applying a universal adhesive in different modes (total-etch or self-etch) on resin composite surfaces with different surface treatments (CoJet sandblasting and Er, Cr: YSGG laser), as well as the effect of using different resin composites as a repair material on the repair shear bond strength. The null hypotheses are that the surface treatment has no effect, the adhesive application mode has no effect, and the repair material has no effect on the repair bond strength, respectively.

Methods

This study was supported by the Gazi University Scientific Research Projects Unit. The materials used in the study and their properties are given in Table 1.

Table 1.

Materials used in the study and their properties

| Materials used | Type | Content | Lot Numbers |

|---|---|---|---|

|

Filtek Z250 (3 M ESPE, St. Paul, USA) |

Mikro-hybrid resin composite | Bis-GMA, Bis-EMA, UDMA, TEGDMA SiO2/ZrO2 (60% v, 75–85% wt) | NE63820 |

|

Filtek Ultimate (3 M ESPE, St. Paul, USA) |

Nano-filled resin composite |

Bis-GMA, Bis-EMA, UDMA, TEGDMA Silica, Zr (63.3% v, 72.5% wt) |

NE85554 |

|

Scotchbond Universal Etchant (3 M ESPE, St. Paul, USA) |

Acid | 37% orthophosphoric acid | 582491 |

|

Scotchbond Universal Plus (3 M ESPE, St. Paul, USA) |

Universal adhesive system | 10-MDP, dimethacrylate resins, polyalkenoic acid copolymer, filler, ethanol, water, polymerisation initiator and double silane | 8658701 |

|

CoJet and Sand (3 M ESPE, St. Paul, USA) |

Tribochemical silica coating device | Silica-coated aluminum oxide sand grains of 30 μm size | |

|

Er, Cr: YSGG Laser (Waterlase MD, Biolase Technology, California, USA) |

Non-contact laser MGG 6 laser tip |

Preparation of samples

Power analysis was used to determine the number of samples of the groups in the study. For the power analysis, the effect level was taken as 0.50, and the α value was 0.05, and the power value (1- β) was calculated as 0.90. Accordingly, it was determined that the number of samples for each group should be 8, and the total number of samples for 12 groups should be 96. Based on this result, a total of 120 samples were prepared, 10 in each group, to avoid any negative situation that could affect the results during the study process.

Teflon molds with a depth of 4 mm and a diameter of 5 mm were used to prepare the resin composite samples. Filtek Z250 was placed in the molds in 2 mm thick layers. Each layer was then photopolymerized using a LED curing unit (D-Light Pro, GC, Leuven, Belgium) with a wavelength of 430–480 nm and a light intensity of 1.200 mW/cm2 according to the manufacturer’s instructions.

The polymerized resin composite samples were embedded in cylindrical molds with an inner diameter of 15 mm and a length of 35 mm filled with cold acrylic resin. Then, the prepared resin composite samples were exposed to the thermal cycle test 5,000 times between 5 and 55 0C with an immersion time of 30 s in each bath and an inter-bath change time of 5 s [16].

After the thermal cycle test, the surfaces of all prepared samples were roughened for 30 s under running water using 320 grit silicon carbide abrasive paper to imitate the clinical conditions. Subsequently, the samples were randomly divided into 12 groups of 10 specimens each, and the following repair protocols were applied to each group.

Control groups were selected by not applying any surface treatment to the surface of the samples from Groups 1 to 4.

The surface of the samples in Groups 5 to 8 were sandblasted using a tribochemical silica coating device, CoJet. For this purpose, 30 μm sized silica coated aluminum oxide sand particles (CoJet Sand, 3 M-ESPE, St. Paul, USA) were used. The device was applied perpendicularly to the sample surfaces from a distance of 10 mm for 15 s with a pressure of 2.3 bar.

In Groups 9 to 12, Er, Cr: YSGG laser (Waterlase MD, Biolase Technology, California, USA) device was applied to the sample surfaces with a power output of 5 W, frequency of 20 Hz, using a 0.6 mm diameter tip, with 30% air for 20 s. To simulate clinical practice, the laser treatment was performed by the same physician at a distance of approximately 1 mm from the tooth, in high mode, in the vertical and horizontal direction for a homogeneous scan, without water. Laser treatment was applied to the resin composite surface by moving the laser tip both vertically and horizontally at a distance of 1 mm from the surface. Thus, the laser was able to scan the surface homogeneously.

After surface treatment, universal adhesive was applied to the sample surfaces using total-etch or self-etch mode. For use in total-etch mode, after 37% orthophosphoric acid (Scotchbond Universal Etchant, 3 M ESPE, St. Paul, USA) was applied to the sample surfaces for 30 s, the sample surfaces were washed with water for 20 s and dried with light air for 15 s. Then, Scotchbond Universal Plus (3 M ESPE, St. Paul, USA) was applied with a rubbing motion by the manufacturer’s instructions, dried with light air for 5 s, and polymerized with an LED light device for 10 s. In self-etch mode, Scotchbond Universal Plus was applied to the sample surfaces in the same way as in total-etch mode, without applying acid.

Following the adhesive treatment, a mold with a diameter of 2 mm and a depth of 2 mm was placed in the center of the resin composite samples. During the repair procedure, slight pressure was applied to prevent the formation of a gap at the interface (Fig. 1). Then, micro-hybrid resin composite (Filtek Z250, 3 M ESPE, St. Paul, USA) or nano-filled resin composite (Filtek Ultimate, 3 M ESPE, St. Paul, USA) used as repair material is placed into these molds and polymerized by applying light for 20 s with LED light device.

Fig. 1.

Image after applying the repair treatment to the resin composite sample surface

All samples to which the repair protocol was applied were kept in distilled water in the incubator at 37 °C for 24 h. Then, the thermal cycle test between 5 and 55 0C was repeated 5,000 times with an immersion time of 30 s in each bath and an inter-bath change time of 5 s [16].

Measurement of Shear Bond Strength

The shear bond strength of the samples was measured using a Universal testing machine (Shimadzu IG-IS; Kyoto, Japan). The load was applied to the interface at a cross-head speed of 1 mm/min until failure, and the stress-strain curve was analyzed with the machine’s software program. The force causing fracture was recorded in Newtons (N). This value was then divided by the sample surface area to convert the mean shear bond strength values to Megapascals (MPa).

Fracture analysis

The fracture type at the failure surface of the samples subjected to the shear bond strength test was examined at x10 magnification under a stereomicroscope (Olympus SZ2-LGB, Tokyo, Japan) and evaluated according to the following fracture types.

Adhesive fracture; fracture at the bonding surface,

Cohesive fracture; fracture of the repaired resin composite,

Mixed fracture; both adhesive and cohesive fracture [17].

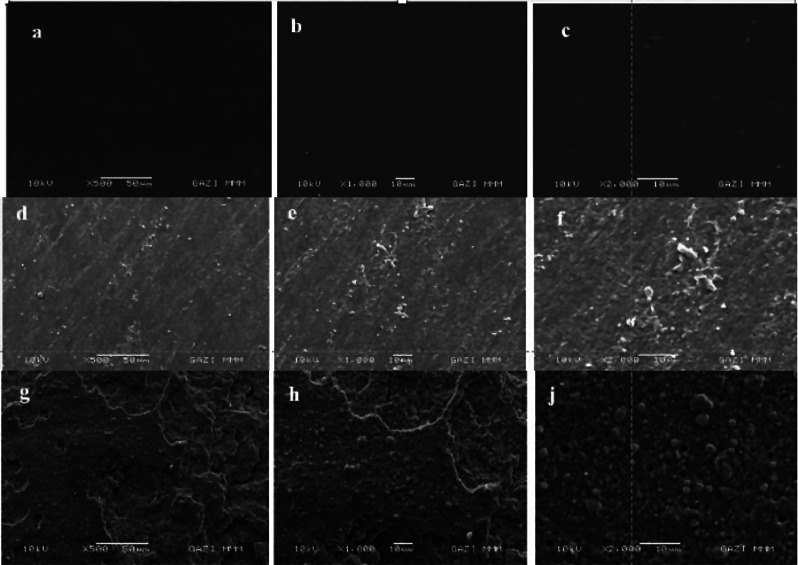

Scanning Electron Microscopy (SEM) evaluation

In the study, one sample from each group was selected for SEM imaging to examine the fracture surfaces after the shear bond strength test. The surface of the selected samples was coated with gold for 90 s under a vacuum in a gold plating device (Polaron Range SC7620, Quorum Technologies, West Sussex, UK). Then, the sample surfaces were examined in SEM (JEOL JSM-6060 LV, Tokyo, Japan), and the images were recorded.

In addition, a sample was prepared for each of the tested surface preparation methods to observe the changes created by CoJet sandblasting and Er, Cr: YSGG laser treatment on the sample surfaces in SEM. After the surface of these prepared samples was coated with gold, the SEM images of the sample surfaces were examined at x500, x1000, and x2000 magnification, and the images were recorded.

Statistical analysis

Statistical analysis of the data was performed with the SPSS 26 program at a 95% confidence interval. Mean (Mean), standard deviation (SD), minimum, maximum, and median (M) statistics for measurements, frequency (n), and percentage (%) statistics for grouped variables were calculated. In the study, the Kruskal-Wallis test was used for the comparison of the mean shear bond strength values according to groups, and the Mann-Whitney U test was used for the pairwise comparison of all groups.

Results

The statistical findings of the mean shear bond strength values obtained from all groups tested in the study are given in Table 2. The effect of repair resin, surface treatment, and adhesive application modes on repair bond strength are given in Table 2. Pairwise comparisons between repair resin composites and adhesive application modes are given in Table 3.

Table 2.

Statistical relationship between all groups tested in the study

| Repair material used | Universal adhesive application mode | Surface Preparation Methods | |||||

|---|---|---|---|---|---|---|---|

| Control | Sandblasting with CoJet | Er, Cr: YSGG Laser | |||||

| Groups | Mean shear bond strenght values ± SD |

Groups | Mean shear bond strenght values ± SD |

Groups | Mean shear bond strenght values ± SD |

||

| Filtek Z250 | Total-etch | Group 1 | 23.28a, b,c, A,B ± 1.65 | Group 5 | 41.21a, b,A ± 3.85 | Group 9 | 38.59a, b,B ± 2.75 |

| Self-etch | Group 2 | 18.66a, d,e, A,B ± 2. 19 | Group 6 | 37.68a, c,A, C ± 2.91 | Group 10 | 34.84a, c,d, B,C ± 2.56 | |

| Filtek Ultimate | Total-etch | Group 3 | 27.12b, d,A, B ± 1.68 | Group 7 | 44.48b, c,d, A ± 3.49 | Group 11 | 43.90b, c,e, B ± 2.83 |

| Self-etch | Group 4 | 26.28c, e,A, B C | Group 8 | 40.68 d, A ± 4.13 | Group 12 | 38.48d, e,B ± 2.37 | |

The same small letters in the column indicate that there is a significant difference between the subgroups of each surface treatment group (p < 0.05)

The same big letters in the row indicate that there is a significant difference between the surface treatment methods in each group, Mann Whitney U test (p < 0.05)

Table 3.

Effect of universal adhesive application mode and different repair materials on shear bond strength

| Repair material used | Surface Preparation Methods | Universal adhesive application mode | |||

|---|---|---|---|---|---|

| Groups | Total-etch | Groups | Self-etch | ||

| Mean ± SD | Mean ± SD | ||||

| Filtek Z250 | Control | Group 1 | 23.28*± 1.65 | Group 2 | 18.66*± 2.19 |

| Sandblasting with CoJet | Group 5 | 41.21*± 3.85 | Group 6 | 37.68*,≠± 2.91 | |

| Er, Cr: YSGG Laser | Group 9 | 38.59*± 2.75 | Group 10 | 34.84*± 2.56 | |

| Filtek Ultimate | Control | Group 3 | 27.12± 1.68 | Group 4 | 26.28± 2.56 |

| Sandblasting with CoJet | Group 7 | 44.48*± 3.49 | Group 8 | 40.68*,≠± 4.13 | |

| Er, Cr: YSGG Laser | Group 11 | 43.90*± 2.83 | Group 12 | 38.48*± 2.37 | |

In the row * indicates that there is a significant difference between the use of universal adhesive in total-etch and self-etch mode (p < 0.05), in the column ≠ symbol indicates that there is no significant difference between the use of Filtek Z250 and Filtek Ultimate as repair material (p > 0.05), Mann Whitney U test

When surface treatment groups were analyzed, while the highest mean shear bond strength values were obtained in the group sandblasted with CoJet, the lowest values were obtained in the control groups (p < 0.05) (Table 2).

In the control group, the highest mean bond strength values were obtained in Group 3. When the relationship between the control groups was analyzed, no significant difference was observed only between Group 3 and Group 4 (p > 0.734).

In the groups sandblasted with CoJet, the highest mean shear bond strength values were obtained from Group 7. It was shown that there was a significant difference between the groups sandblasted with Cojet (p < 0.05).

In the Er, Cr: YSGG laser-treated groups, the highest mean shear bond strength values were obtained from Group 11. In the groups where this surface treatment was applied, no statistically significant difference was detected only between the mean shear bond strength values of Group 9 and Group 12 (p > 0.705).

When adhesive application modes were compared, in all groups, total-etch modes showed higher bond strength than the self-etch mode. When compared in terms of adhesive application modes, significant differences were observed between all groups except Group 3 and Group 4 Filtek Ultimate was used as repair material (p < 0.05) (Table 3).

Higher mean shear bond strength values were obtained in the groups using Filtek Ultimate as the repair material compared to the groups using Filtek Z250. When a pairwise comparison is performed between groups in terms of repair resin composites, statistically significant differences were obtained between all groups except Group 6 and Group 8 sandblasting was applied with CoJet, and the universal adhesive was used in self-etch mode (p > 0.05) (Table 3).

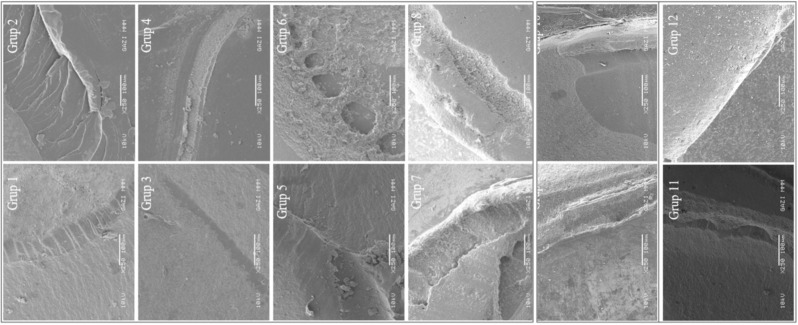

When the fracture types were examined, it was found that adhesive fracture was generally observed in the control group. In the sandblasting with Cojet groups, cohesive fractures were observed in the total-etch adhesive application, while mixed-type fractures were observed in the self-etch etch application groups. In laser application groups the fracture types were generally adhesive type (Fig. 2).

Fig. 2.

SEM images of all the examined groups after shear bond strength test

When SEM images were evaluated, it was observed that the sample surfaces were smooth in the control groups. On the other hand, it was observed some grains on the surface, as well as rougher surface structures in the groups sandblasted with CoJet. In the Er, Cr: YSGG laser-treated groups, crater-shaped formations were detected on the surfaces. In this group, no findings such as burns or vitrification due to the use of laser on the sample surfaces were observed (Fig. 3).

Fig. 3.

SEM images of sample surfaces after surface tretaments were performed (a, b, c: SEM image of the sample surfaces of the control group at x500, x1000, x2000 magnification, d, e, f: SEM image of the sample surfaces of the Sandblasting with CoJet group at x500, x1000, x2000 magnification, g, h, j: SEM image of the sample surfaces belonging to the Er, Cr: YSGG laser treatment group at x500, x1000, x2000 magnification)

Discussion

In this in vitro study, the lowest mean shear bond strength were obtained in the control group, followed by Er, Cr: YSGG laser application groups. This finding supports the findings of Cavalcanti et al.‘s [18]. study, that reported roughening the resin composite surface only with a diamond bur resulted in lower bond strength values. In our study, the smear layer formed on the surface obtained with abrasive paper application may be the reason for lower bond strength in the control groups. In SEM images, while smear layer formation was observed after the abrasive paper application, no smear layer was formed after the Er, Cr: YSGG laser treatment. The findings of studies reporting higher bond strength were obtained with surfaces treated with Er, Cr: YSGG laser compared to groups without surface treatments support the findings of our study [18–21]. Regardless of the repair material used, a significant difference was found between laser application groups regarding adhesive application mode. However, significantly higher bond strength values were obtained in the sandblasting with Cojet groups compared to the laser application groups, regardless of the repair material. This finding is similar to that of Dursun et al. [22], and Rashidi et al. [23], who reported that higher bond strength values were obtained in CoJet blasted samples compared to Er, Cr: YSGG laser-treated samples. In the context of these findings, the first null hypothesis of our study, “Different surface treatments have no effect on repair bond strength.” was partially rejected.

In this study, higher shear bond strength values in all surface treatment groups were obtained in total-etch application mode. This finding is similar with the literature that higher bonding to dental tissues and resin composite is obtained with the use of adhesive systems in total-etch mode [24, 25]. Based on these findings, the second null hypothesis of our study, “The application of the universal adhesive system in different modes (total-etch or self-etch) has no effect on the repair bond strength.” was partially rejected. The universal adhesive Scotchbond Universal Plus used in the study differs from other universal adhesive systems in that it contains a double silane monomer. The manufacturer claimed that that monomer eliminates the need of appliying additional silan [26]. For that reason, no additional silane step was applied to the surfaces in the study.

Another finding obtained in this study is that higher mean shear bond strength values were obtained in the groups where Filtek Ultimate was used as repair material compared to Filtek Z250, and a statistical difference was generally detected between them. Based on this finding, the third null hypothesis of our study, “The use of different resin composites as repair material has no effect on repair bond strength.” was generally rejected. Although the organic matrix of both resin composites is similar, the filler percentages and types are different. The organic matrix of both resin composites used in the study contains Bis-GMA, Bis-EMA, UDMA, and TEGDMA monomers [27]. The inorganic components of the micro-hybrid resin composite Filtek Z250 consist of 0.01–3.5 μm silica and zirconium fillers. The percentage of filler added is 75–85 by weight and 60 by volume. The inorganic components of the nano-filled resin composite Filtek Ultimate consist of 20 nm silica, 4–11 nm zirconium, and 0.6–10 μm silica. The proportion of fillers added is 72.5 by weight and 55.6 by volume [27]. Nassoohi et al. [28] reported that they obtained higher repair bond strength values with micro-hybrid resin composites than with nano-filled resin composites in the study in which they examined the repair bond strength of two nano-filled and one micro-hybrid resin composites. This finding is opposite to the findings obtained in our study. This may be due to the different surface treatment methods as well as the structural properties of the resin composites tested in both studies.

Based on all the findings obtained in the study conclude that the use of the universal adhesive in total-etch or self-etch mode does not affect the bond strength values if the repair treatment is performed using Filtek Ultimate after only bur removal on the resin composite surface, on the contrary, Filtek Z250 is used, higher bond strength values can be obtained by using the universal adhesive in total-etch mode. This finding is partially opposite to the findings of Irmak et al. [29] This may be due to the different adhesive systems used in both studies. When sandblasting was performed with CoJet on the resin composite surface, it was determined that using universal adhesive in total-etch mode in both resin composites used as repair material caused an increase in bond strength values. This finding is in agreement with the findings of Nassoohi et al. [28] who reported that they obtained higher bond strength values with 35% phosphoric acid treatment after sandblasting. However, their methodology was different from our study. The findings obtained from the Er, Cr: YSGG laser-treated groups were similar to the findings obtained from the CoJet sandblasting group. Therefore, we believe that if Er, Cr: YSGG laser is to be applied to the sample surfaces, the use of universal adhesive in total-etch mode, regardless of what is used as repair material, will increase the bond strength values. We think that the use of the adhesive system in total-etch mode contributes to the cleaning of the sample surfaces after Cojet blasting or Er, Cr: YSGG treatment. Accordingly, the adhesive system may have penetrated the irregularities formed on the surface better, and higher bonding values may have been obtained.

To test the repair bond strength in the study, all sample surfaces prepared with Filtek Z250 were first roughened using 320-grit silicon carbide-coated sandpaper. Thus, it was aimed to simulate the procedure of restoration correction using a diamond bur in the clinic [30]. The samples were then tested for 5,000 times thermocycling ranging from 5 to 55 0C to simulate the process by which the restoration functions in the mouth [31, 32]. It has been demonstrated previously that the number of 5,000 cycles corresponds to the six-month aging process of the samples [31]. The thermal cycling test applied before the repair procedure was also applied to the samples after the repair procedure to expose the samples to the conditions of the oral environment during the six-month post-repair period.

Studies are showing that adhesive-type fracture is more common in adhesive systems with low bond strength values and cohesive and mixed fracture types are more common in adhesive systems with high bond strength values and that there is a relationship between bond strength values and fracture type [33]. When the fracture types obtained in the study are examined, it is difficult to make such a conclusion. This may be due to the methodology of the studies and the different materials used.

The study findings of Ahmadizenouz et al. [33], who reported that the most cohesive type fracture was observed on the sample surfaces roughened with diamond burs, are opposite to the findings obtained from the control group. This may be because the materials used in the study were different from the materials used in our study. Similar to our study, Fornazari et al. [34] reported that more cohesive fractures were observed in the specimens sandblasted with CoJet. The study findings of Kiomarsi et al. [35], who reported that more adhesive-type fractures were observed on Er, Cr: YSGG laser-treated sample surfaces, support our study findings.

In the evaluation made by SEM, a smoother surface image was obtained in the control group since no treatment was applied to the sample surfaces. On the opposite, it was observed that the sample surfaces in the group sandblasted with CoJet were rougher and aluminum oxide particles were present on the surface. In the Er, Cr: YSGG laser-treated group, it was found that wave-shaped craters were formed on the surface, but no side effects related to laser use occurred. These findings support the findings obtained as a result of the shear bond strength test. It is also in agreement with the findings of Cho et al. [36]. EDS scanning after SEM evaluation revealed that only the filler particles of the resin composite were present on the surfaces of the control group or Er, Cr: YSGG laser-treated samples. This shows that the laser parameters we used were correct, and no thermal damage occurred on the resin composite surface during laser treatment. The sample surfaces sandblasted with CoJet showed the formation of aluminum oxide particles in addition to the filler particles of the resin composite. This finding supports the findings of studies reporting that aluminum oxide particles are embedded in the surface after sandblasting with CoJet.

This study also has some limitations. The first one is that, the Filtek Z250 and Filtek Ultimate resin composite were used as repair materials. The findings obtained reflect the effects of using only these two resin composites in the repair protocol. Therefore, it is not possible for these findings to shed light on the repair protocol of all resin composites. Moreover, only one adhesive system was evaluated in this study. The adhesive system may be comparable to other adhesives with or without silane. Further studies should be carried out on this subject. Another limitation is that the samples were only subjected to aging by thermal cycling test. Although the thermal cycling test is the most preferred aging method, in clinical conditions, teeth and restorations are exposed to not only thermal but also mechanical and chemical factors such as parafunctional habits and acidic or alcoholic drinks consumption. Therefore, further in vitro and long-term clinical studies should be conducted to prolong the durability of repair restorations.

Conclusion

Within the limitations of this study:

CoJet sandblasting and Er, Cr: YSGG laser treatments demonstrated higher shear bond strength compared to control groups.

The use of universal adhesive in total-etch mode resulted in higher mean shear bond strength values than in self-etch mode.

Control groups exhibited predominantly weak adhesive failures, whereas groups treated with CoJet sandblasting showed predominantly cohesive failures.

As a result of these findings, it is emphasized that surface preparation methods and the choice of materials significantly influence shear bond strength in repair protocols. Clinicians should carefully consider these factors during clinical applications.

Acknowledgements

Not applicable.

Author contributions

All authors contributed to each stage of the study to the same degree. All authors read and approved the final manuscript.

Funding

This project was completed with the support of Gazi University Scientific Research Projects with ID code 7766.

Data availability

The raw data from the study is accesible and can be requested directly from the authors by contacting corresponding author by e-mail.

Declarations

Ethics approval and consent to participate

Ethical approval and consent to participate are not required as the research is conducted on publicly available internet data.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Mammadlı N. Minimally invasive treatment approaches in Pediatric Dentistry, HEALTH & SCIENCE 2022: Odontology-II, Assist Prof. Istanbul: Aycan DAL DÖNERTAŞ, Editor, Efe Academy; 2022. pp. 163–70. [Google Scholar]

- 2.De Munck J, Van Landuyt K, Peumans M. A critical review of the durability of adhesion to tooth tissue: methods and results. J Dent Res. 2005;84:118–32. 10.1177/154405910508400204. [DOI] [PubMed] [Google Scholar]

- 3.Demarco FF, Corrêa MB, Cenci MS, Moraes RR, Opdam NJ. Longevity of posterior composite restorations: not only a matter of materials. Dent Mater. 2012;28:87–101. 10.1016/j.dental.2011.09.003. [DOI] [PubMed] [Google Scholar]

- 4.Hickel R, Brüshaver K, Ilie N. Repair of restorations criteria for decision making and clinical recommendations. Dent Mater. 2013;29:28–50. 10.1016/j.dental.2012.07.006. [DOI] [PubMed] [Google Scholar]

- 5.Fernández E, Martín J, Vildósola P, Oliveira Junior OB, Gordan V, Mjor I, Bersezio C, Estay J, de Andrade MF, Moncada G. Can repair increase the longevity of composite resins? Results of a 10-year clinical trial. J Dent. 2015;43:279–86. 10.1016/j.jdent.2014.05.015. [DOI] [PubMed] [Google Scholar]

- 6.Moncada G, Vildósola P, Fernández E, Estay J, de Oliveira Júnior OB, De Andrade MF, Gordan VV. Longitudinal results of a 10-year clinical trial of repair of amalgam restorations. Oper Dent. 2015;40:34–43. 10.2341/14-045-C. [DOI] [PubMed] [Google Scholar]

- 7.Frankenberger R, Krämer N, Ebert J, Lohbauer U, Käppel S, ten Weges S, Petschelt A. Fatigue behavior of the resin-resin bond of partially replaced resin-based composite restorations. Am J Dent. 2003;16:17–22. [PubMed] [Google Scholar]

- 8.Fawzy AS, El-Askary FS, Amer MA. Effect of surface treatments on the tensile bond strength of repaired water-aged anterior restorative micro-fine hybrid resin composite. J Dent. 2008;36:969–76. 10.1016/j.jdent.2008.07.014. [DOI] [PubMed] [Google Scholar]

- 9.Özcan M, Corazza PH, Marocho SM, Barbosa SH, Bottino MA. Repair bond strength of microhybrid, nanohybrid and nanofilled resin composites: effect of substrate resin type, surface conditioning and ageing. Clin Oral Investig. 2013;17:1751–8. 10.1007/s00784-012-0863-5. [DOI] [PubMed] [Google Scholar]

- 10.Kim SH, Lee YK, Lim BS. Influence of porcine liver esterase on the color of dental resin composites by CIEDE2000 system. J Biomed Mat Res. 2005;72:276–83. 10.1002/jbm.b.30141. [DOI] [PubMed] [Google Scholar]

- 11.Baena E, Vignolo V, Fuentes MVF, Ceballos L. Influence of repair procedure on composite to composite microtensile bond strength. Am J Dent. 2005;28:255–60. [PubMed] [Google Scholar]

- 12.Stawarczyk B, Krawczuk A, Ilie N. Tensile bond strength of resin com- posite repair in vitro using different surface preparation conditionings to an aged CAD/CAM resin nanoceramic. Clin Oral Inves. 2015;19:299–308. 10.1007/s00784-014-1269-3. [DOI] [PubMed] [Google Scholar]

- 13.Uğurlu M, Sari F. The clinical success of repaired posterior composite restorations with and without silane application. Clin Oral Inves. 2022;26:5785–93. 10.1007/s00784-022-04535-5. [DOI] [PubMed] [Google Scholar]

- 14.Yoshida Y, Van Meerbeek B, Nakayama Y, Snauwaert J, Hellemans L, Lambrechts P, Vanherle G, Wakasa K. Evidence of chemical bonding at biomaterial-hard tissue interfaces. J Dent Res. 2000;79:709–14. 10.1177/00220345000790020301. [DOI] [PubMed] [Google Scholar]

- 15.Van Landuyt KL, Snauwaert J, Peumans M, De Munck J, Lambrechts P, Van Meerbeek B. The role of HEMA in one-step self-etch adhesives. Dent Mater. 2008;24:1412–9. 10.1016/j.dental.2008.02.018. [DOI] [PubMed] [Google Scholar]

- 16.Brendeke J, Ozcan M. Effect of physicochemical aging conditions on the composite-composite repair bond strength. J Adhes Dent. 2007;9:399–406. [PubMed] [Google Scholar]

- 17.Savas TY, Aykent F. Effect of Veneering techniques on Shear and Microtensile Bond strengths of Zirconia-based all-Ceramic systems. J Adhes Dent. 2017;19:507–15. 10.3290/j.jad.a39595. [DOI] [PubMed] [Google Scholar]

- 18.Cavalcanti AN, De Lima AF, Peris AR, Mitsui FH, Marchi GM. Effect of surface treatments and bonding agents on the bond strength of repaired composites. J Esthet Restor Dent. 2017;19:90–8. 10.1111/j.1708-8240.2007.00073.x. [DOI] [PubMed] [Google Scholar]

- 19.Cheung CK, Botelho MG, Matinlinna JP. Effect of surface treatments on zirconia ceramics on the bond strength to resin cement. J Adhes Dent. 2014;16:49–56. 10.3290/j.jad.a30753. [DOI] [PubMed] [Google Scholar]

- 20.Bonstein T, Garlapo D, Donarummo J, Bush PJ. Evaluation of varied repair protocols applied to aged composite resin. J Adhes Dent. 2005;7:41–9. 10.3290/j.jad.a10084. [PubMed] [Google Scholar]

- 21.Ozel Bektas O, Eren D, Herguner Siso S, Akin GE. Effect of thermocycling on the bond strength of composite resin to bur and laser treated composite resin. Lasers Med Sci. 2012;27:723–8. 10.1007/s10103-011-0958-2. [DOI] [PubMed] [Google Scholar]

- 22.Dursun MN, Ergin E, Ozgunaltay G. The effect of different surface preparation methods and various aging periods on microtensile bond strength for composite resin repair. Niger J Clin Prac. 2021;24:282–91. 10.4103/njcp.njcp_83_20. [DOI] [PubMed] [Google Scholar]

- 23.Rashidi M, Berangi S, Chiniforush N, Ahmadi E, Ranjbar Omrani L. Microtensile repair bond strength of a composite after accelerated artificial aging: effect of the air abrasion, bur, Er:YAG laser, two-step self-etch bonding and universal bonding repair system. J Lasers Med Sci. 2022;25:13–8. 10.34172/jlms.2022.18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Ahmed AA, Hassan MM, Abdalla AI. Microshear bond strength of universal adhesives to dentin used in total-etch and self-etch modes. Tanta Dent J. 2018;15:91–8. 10.4103/tdj.tdj_52_17. [Google Scholar]

- 25.Takamizawa T, Barkmeier WW, Tsujimoto A, Berry TP, Watanabe H, Erickson RL, Miyazaki M. Influence of different etching modes on bond strength and fatigue strength to dentin using universal adhesive systems. Dent Mat. 2016;32:9–21. 10.1016/j.dental.2015.11.005. [DOI] [PubMed] [Google Scholar]

- 26.Tsujimoto A, Fischer NG, Barkmeier WW, Latta MA. Bond durability of two-step HEMA-free universal adhesive. J Func Biomater. 2022;13:134. 10.3390/jfb13030134. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Ghiorghe CA, Iovan G, Topoliceanu C, Sandu AV, Andrian S. Comparative study regarding the colorimetric changes of two composite resins after immersion in several beverages and one antibacterial mouthwash. Revista De Chemie. 2013;64:1436–40. [Google Scholar]

- 28.Nassoohi N, Kazemi H, Sadaghiani M. Effects of three surface conditioning techniques on repair bond strength of nanohybrid and nanofilled composites. Dent Res. 2015;12:554–61. 10.4103/1735-3327.170575. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Irmak Ö, Celiksöz O, Yilmaz B, Yaman BC. Adhesive system affects repair bond strength of resin composite. J Istanbul Uni Dent. 2017; 51: 25–31. 10.17096/jiufd.31921. eCollection 2017. [DOI] [PMC free article] [PubMed]

- 30.Özcan M, Niedermier W. Clinical study on the reasons for and location of failures of metal-ceramic restorations and survival of repairs. Int J Prosthodont. 2002;15:299–302. [PubMed] [Google Scholar]

- 31.Li H, Burrow MF, Tyas MJ. The effect of thermocycling regimens on the nanoleakage of dentin bonding systems. Dent Mater. 2002;18:189–96. 10.1016/s0109-5641(01)00081-1. [DOI] [PubMed] [Google Scholar]

- 32.Inoue S, Koshiro K, Yoshida Y. Hydrolytic stability of self-etch adhesives bonded to dentin. J Dent Res. 2005;84:1160–4. 10.1177/154405910508401213. [DOI] [PubMed] [Google Scholar]

- 33.Ahmadizenouz G, Esmaeili B, Taghvaei A, Jamali Z, Jafari T, Daneshvar FA, Khafri S. Effect of different surface treatments on the shear bond strength of nanofilled composite repairs. J Dent Res Dent Clin Dent Prospects. 2016;10:9–16. 10.15171/joddd.2016.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Fornazari IA, Wille I, Meda EM, Brum RT, Souza EM. Effect of surface treatment silane and universal adhesive on microshear bond strength of nanofilled composite repairs. Oper Dent. 2017;42:367–74. 10.2341/16-259-L. Epub 2017 Apr 12. [DOI] [PubMed] [Google Scholar]

- 35.Kiomarsi N, Saburian P, Chiniforush N, Karazifard MJ, Hashemikamangar SS. Effect of thermocycling and surface treatment on repair bond strength of composite. J Clin Exp Dent. 2017;9:945–51. 10.4317/jced.53721. eCollection 2017 Aug. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Cho SD, Rajitrangson P, Matis BA, Platt JA. Effect of Er,Cr:YSGG laser, air abrasion, and silane application on repaired shear bond strength of composites. Oper Dent. 2013;38:1–9. 10.2341/11-054-L. Epub 2012 Nov 6. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The raw data from the study is accesible and can be requested directly from the authors by contacting corresponding author by e-mail.