Highlights

-

•

PHA bioplastics from food waste offer a sustainable alternative for packaging.

-

•

PHA production achieves up to 87 % yield using optimized fermentation processes.

-

•

Low-cost carbon sources (VFAs, waste oils) reduce PHA production expenses.

-

•

PHA’s biodegradability and biocompatibility make it ideal for replacing plastics.

-

•

Overcoming production costs and scalability can enhance PHA industry adoption.

Keywords: Bio-packaging, Cupriavidus necator, Food waste, Polyhydroxyalkanoate, Volatile fatty acids

Abstract

The growing demand for sustainable food packaging and the increasing concerns regarding environmental pollution have driven interest in biodegradable materials. This paper presents an in-depth review of the production of Polyhydroxyalkanoates (PHA), a biodegradable polymer, from food waste. PHA-based bioplastics, particularly when derived from low-cost carbon sources such as volatile fatty acids (VFAs) and waste oils, offer a promising solution for reducing plastic waste and enhancing food packaging sustainability. Through optimization of microbial fermentation processes, PHA production can achieve significant efficiency improvements, with yields reaching up to 87 % PHA content under ideal conditions. This review highlights the technical advancements in using PHA for food packaging, emphasizing its biodegradability, biocompatibility, and potential to serve as a biodegradable alternative to petroleum-based plastics. However, challenges such as high production costs, mechanical limitations, and the need for scalability remain barriers to industrial adoption. The future of PHA in food packaging hinges on overcoming these challenges through further research and innovation in production techniques, material properties, and cost reduction strategies, along with necessary legislative support to promote widespread use.

1. Introduction

Plastic is a polymer composed of carbon atoms that are linked to each other in a chain structure. Plastic is used in almost every industry because of its low price, easy manufacture, water resistance, high strength properties, and diverse functions (Thiounn and Smith, 2020). Since its invention in the late 19th century, the use of plastic in everyday life has increased rapidly and exponentially. It is estimated that annual plastic production reached 359 million tons in 2018, with about 8.3 billion tons produced over the past 70 years (Filho et al., 2021, Kaushal et al., 2021). As of 2019, plastic waste reached 368 million tons. About 19 to 23 million tons of unmanaged plastic waste moves annually from land to water sources (Veneral et al., 2023). Certainly, since plastic materials are not widely biodegradable, the problem raises environmental concerns (Li et al., 2023). The large-scale use of plastic accumulates large amounts of residue, causing serious environmental problems and adversely affecting the economy, wildlife, and human health (Veneral et al., 2023). In this regard, scientists are working to develop technologies that allow products and processes to have less impact on the environment, greater energy efficiency, and less waste production. These technologies range from the production and optimization of classical recycling processes, such as mechanical and chemical processes, to recycling through bioprocessing or the production of biodegradable bioplastics (Chen et al., 2020, Liu et al., 2021, Shen et al., 2021).

Food waste has become a global focus that requires attention and requires urgent action (Jabeen et al., 2023). Despite high levels of hunger and environmental problems, another worrying thing is that about one-third of food produced for human consumption is wasted (Asioli and Grasso, 2021, Hellali et al., 2023). Where half of all types of food are wasted and 30–50 % of food produced is not eaten, while one-third of edible food is wasted worldwide. In addition, food waste that is increasingly piling up is also caused by the rapid rate of world population growth (Cederberg and Sonesson, 2011, Chong et al., 2021). This not only has an impact on the social side but can affect environmental stability because many smell bad.

At this time, a lot of engineering was done to convert food waste into polyhydroxyalkanoate (PHA). Previously, food waste could be converted into bioactive compounds, biofuels, bioenergy, single-cell protein source fertilizers, and various other products by means such as bioconversion, enzymatic hydrolysis, microbial digestion, and so on (Rifna et al., 2024). PHA is a linear polyester synthesized by various microorganisms and serves as an intracellular carbon and energy reserve (Jendrossek and Pfeiffer, 2014, Prieto et al., 2016, Yadav et al., 2020) PHA is produced by different microorganisms under stress conditions. PHAs are stored as cytoplasmic inclusions and serve as a metabolic strategy for microorganisms to adapt to fluctuations in nutrient availability (Han et al., 2015). PHA synthesis increases in microbial cells when they have an abundance of carbon but a limited supply of nitrogen or phosphorus (Jendrossek and Pfeiffer, 2014).

PHA polymers, as bio-derived products, are widely regarded as the most attractive petrochemical-derived thermoplastic polyolefins (Taguchi and Matsumoto, 2021). This is mainly due to the sustainability of polyhydroxyalkanoates (PHAs) that have similar material properties with widely used polyolefins, such as polyethylene and polypropylene, so that they can attract interest in applications in agricultural plastics, food packaging, biomedical devices, 3D printing, etc (Gupta et al., 2022, Mehrpouya et al., 2021). The use of PHA is very promising as a substitute for petroleum-based plastics due to its higher thermal stability, easy biodegradability ability, and biocompatibility properties (Sirohi et al., 2020, Yadav et al., 2020). Biobased characters and various properties make PHA a superior material to replace oil-based plastics to be made into food packaging (Khatami et al., 2022).

The conversion of food waste into PHA has been extensively explored, recognizing food waste as a promising low-cost carbon source. Given the significant waste streams produced during food production, processing, and consumption, various technologies have been proposed to facilitate the conversion of food waste into PHA (Mustapha and Wan, 2022, Wellenreuther et al., 2022). Food waste can be a cost-effective raw material for PHA production when converted into a substrate form that can be utilized for PHA-producing bacteria (Bhatia et al., 2021, Jõgi and Bhat, 2020, Talan et al., 2022, Varghese et al., 2022). Previous research on the conversion of food waste into PHA is shown in Table 1.

Table 1.

Research on food waste into PHA (Notes: PHB = polyhydroxybutyrate; PHBV = poly(3-hydroxybutyrate-co-3-hydroxyvalerate); P(3HB-co-3HHx) = 3-hydroxybutyrate-co-3-hydroxyhexanoate) (Raunhan et al., 2023).

| Microorganism | Carbon sources |

PHA |

References | ||

|---|---|---|---|---|---|

| Type | Content (wt%) | Production (g/L PHA) | |||

| Bacillus megaterium ATCC 14945 | Mixture of VFAs from the acidogenic fermentation of food waste | PHB | 8.6 | 0.16 | Vu et al. (2021) |

| Bacillus cepacia DSM 50181 | Digestate liquor from food waste and primary sludge | PHB | 77.5 | 1.39 |

Khatami et al. (2022) |

| Cupriavidus necator DSM 545 | PHB | 54.9 | 1.09 | ||

| Cupriavidus necator H16 ATCC 17699 | Mixture of VFAs from food waste fermentate | PHB | 87.0 | − |

Hafuka et al. (2011) |

| Cupriavidus necator H16 (DSM 428) | Waste cooking oil | PHB | 76.9 | 103.8 |

Loan et al. (2022) |

| Waste fish oil | PHB | 72.5 | 83.2 | ||

| Pseudomonas oleovorans ATCC 29347 | Mixture of VFAs from the acidogenic fermentation of potato peels | PHBV | 39.0 | 0.82 | Aremu et al. (2021) |

| Engineered Ralstonia eutropha Re2133/pCB81 | The mixture of VFAs from food waste fermentate | P(3HB-co-3HHx) | 55.0 | 0.67 | Bhatia et al. (2019) |

| Rhodopseudomonas palustris | The mixture of VFAs from food waste fermentate | PHBV | 48.6 | − | Dan et al. (2023) |

| Thauera sp. Sel9 | Alfalfa hydrolysate | PHBV | − | 1.4 | Critelli et al. (2022) |

| Thauera mechernichensis TL1 | Food waste anaerobic digestate | PHBV | 24.0 | 0.52 | Raunhan et al. (2023) |

The purpose of this article is to explain the processing to convert complex compounds present in food waste into precursors of PHA, biodegradable polymers that can be used as basic materials in the manufacture of bioplastics. Research on bioplastics is increasingly gaining attention as a way to create a sustainable and environmentally friendly environment. Biodegradable bioplastics have the same characteristics as conventional plastics. Therefore, the use of organic waste i.e., food waste for bioplastic production not only reduces dependence on the raw materials that plastic uses but can effectively help solid waste management. With food waste research and development for PHA production a sustainable solution, PHA can be a more environmentally friendly alternative to conventional plastic and help address global problems related to food waste.

2. Polyhydroxyalkanoate (PHA)

2.1. Source of PHA

Table 2 shows that the naturally-occurring sources of PHA are diverse and primarily consist of various bacterial strains with the inherent ability to synthesize these biopolymers. Naturally occurring sources of PHAs are diverse and primarily consist of various bacterial strains with the inherent ability to synthesize these biopolymers. These bacteria accumulate PHA as intracellular energy reserves under specific environmental conditions, often using readily available carbon sources. Understanding the range of bacterial PHA producers and their preferred carbon sources is crucial for researchers seeking to optimize PHA production for various applications. Analyzing these natural sources can provide valuable insights into the metabolic pathways involved in PHA biosynthesis and guide the selection of suitable bacterial strains for further study and development. Notably, among these sources, Cupriavidus necator has emerged as a particularly promising candidate due to its exceptional PHA production efficiency. This bacterium’s ability to produce a wide range of PHA titers warrants further investigation for optimizing industrial-scale PHA production processes (Stadio et al., 2024, Subagyo et al., 2021).

Table 2.

Notable wild-type PHA producers (Tan et al., 2014).

| Producer organism(s) | PHA type | Carbon source | Time (h) | Cell titre (g/L) | PHA titre (g/L) | References |

|---|---|---|---|---|---|---|

| Azotobacter vinelandii | scl | Glucose | 28 | 45.5 | 30.3 | Subramanian et al. (2020) |

| Bacillus megaterium | scl | Molasses (sucrose) | 24 | 90.7 | 41.6 | Kanjanachumpol et al. (2013) |

| Burkholderia cepacia | scl | Wood sugars | 96 | 17.0 | 8.7 | Pan et al. (2012) |

| Chelatococcus daeguensis | scl | Glycerol | 40 | 25.4 | 17.4 | Cui et al. (2015) |

| Cupriavidus necator | scl | Palm oil | 72 | 161.0 | 109.5 | Zainab-L and Sudesh (2019) |

| Haloferax Mediterrane | scl | Glucose | 117 | 85.8 | 41.7 | Don et al. (2006) |

| Halomonas sp. | scl | Glucose, corn powder | 56 | 90.5 | 71.3 | Ren et al. (2018) |

| Pseudomonas oleovorans | mcl | Octanoic acid | 38 | 63.0 | 39.0 | Marsudi et al. (2007) |

| Pseudomonas putida | mcl | Glucose, nonanoic acid | 32 | 98.0 | 31.4 | Davis et al. (2015) |

| Paraburkholderia sacchari | scl | Xylose | 70 | 30.0 | 16.0 | Oliveira-Filho et al. (2020) |

2.2. Structures and properties of PHA

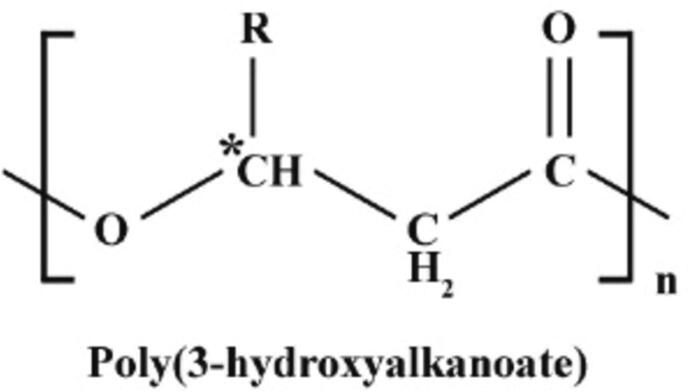

PHA mainly consists of 3-hydroxy and 4-hydroxy fatty (Prieto et al., 2016). PHA synthesis involves the formation of ester bonds between hydroxyl groups on one monomer and carboxyl groups on another (Sehgal and Gupta, 2020). These biopolymers have an R group, with the R group representing a hydrogen atom or alkyl group varying from a methyl group (C1) to a tridecyl (C13), as illustrated in Fig. 1 (Żur-Pińska et al., 2023). In Table 3, if this R group is a methyl group (CH3), which contains only one carbon atom, the resulting bioplastic is named poly(3-hydroxybutyrate) because there are a total of four carbons in the monomer unit (three from the main chain and one from the main chain methyl group). Similarly, if the R group has three carbons (C3H7), the bioplastic is called poly(3-hydroxyhexanoate) because the total number of carbons in the monomer becomes six.

Fig. 1.

PHA backbone structure that can be decorated with various side clusters “R clusters” (Tan et al., 2014).

Table 3.

The specific identity of the R group determines the total number of carbon atoms and the resulting PHA nomenclature (Tan et al., 2014).

| R group | Carbon | PHA polymer |

|---|---|---|

| methyl | C4 | Poly(3-hydroxybutyrate) |

| ethyl | C5 | Poly(3-hydroxyvalerate) |

| propyl | C6 | Poly(3-hydroxyhexanoate) |

| butyl | C7 | Poly(3-hydroxyheptanoate) |

| pentyl | C8 | Poly(3-hydroxyoctanoate) |

| hexyl | C9 | Poly(3-hydroxynonanoate) |

| heptyl | C10 | Poly(3-hydroxydecanoate) |

| octyl | C11 | Poly(3-hydroxyundecanoate) |

| nonyl | C12 | Poly(3-hydroxydodecanoate) |

| decyl | C13 | Poly(3-hydroxytridecanoate) |

| undecyl | C14 | Poly(3-hydroxytetradecanoate) |

| dodecyl | C15 | Poly(3-hydroxypentadecanoate) |

| tridecyl | C16 | Poly(3-hydroxyhexadecanoate) |

Based on the number of carbon atoms in repeating units, PHAs can be categorized into PHAs with short chain length (scl-PHA), PHA with medium chain length (mcl-PHA), and PHA with long chain length (lcl-PHA) (Zhang et al., 2024). Scl-PHA consists of 3 to 5 carbon atoms that have a well-crystallized structure so that they are generally more rigid and have a higher melting temperature than other types of PHA (Liu et al., 2021, Żur-Pińska et al., 2023). On the other hand, mcl-PHA consists of 6 to 14 carbon atoms, while lcl-PHA consists of 15 or more than 15 carbon atoms (Paduvari et al., 2024, Sharma et al., 2021). Mcl-PHA and lcl-PHA have a less crystallized structure so they have a flexible texture and are more elastic compared to scl-PHA (Chacón et al., 2024, Dalton et al., 2022).

Briefly, the biosynthesis approach requires three important steps: (i) catalytic conversion of acetoacetyl-CoA to acetoacetyl-CoA by the enzyme ketothiolase (PhaA); (ii) catalytic hydrogenation of acetoacetyl-CoA by the enzyme PHA reductase (PhaB) to obtain monomers (R)-3-hydroxy-butyryl-CoA; and (iii) catalytic polymerization of (R)-3 hydroxy-butyryl-CoA by the enzyme PHB polymerase (Kinyanjui Muiruri et al., 2023). PHA synthase is categorized into four different classes (I-IV) based on amino acid sequence, subunit composition, and size of constituent material that can be handled (substrate specificity). Class I, III, and IV phases show a preference for substrates with short chain lengths (C3 to C5) and are responsible for the production of PHAs with short chain lengths (scl-PHA). In contrast, Class II PhaC favors substrates with longer chain lengths (C6 to C14) and is used for the biosynthesis of medium chain length PHAs (mcl-PHA). The specific biosynthetic pathway used by microorganisms for PHA production depends on the class of PhaC to which it belongs. Bacteria that store Class I, III, or IV PhaC, such as Cupriavidus necator, Haloferax mediterranei, and Bacillus megaterium, utilize conserved pathways to produce precursors. This pathway involves the sequential action of two enzymes: PhaA (a β-ketothiolase) and PhaB (an acetoacetyl-CoA reductase). They work together to convert acetyl-CoA into direct precursors for the polymerization of poly(3-hydroxybutyrate) (P3HB), (R)-3-hydroxybutyryl-CoA [(R)-HB-CoA)]. Pseudomonas species, known as Class II PhaC depositors, apply a different strategy. These bacteria lack enzymes for conserved pathways and instead divert the intermediate chain precursors (R)-HA-CoA from two sources: β-oxidation, facilitated by PhaJ (a transenoyl-CoA hydratase), and fatty acid synthesis, through a combination of the actions of PhaG ((R)-3-hydroxyacylacyl thioesterase-carrying protein) and AlkK (a mcl-fatty acid-CoA ligase) (Acuña and Poblete-Castro, 2023, Mezzina et al., 2021, Neoh et al., 2022).

Haloferax mediterranei stands out among manufacturers of scl-PHA. These organisms have the unique ability to synthesize the precursor (R)-3-hydroxyalkyl-CoA [(R)-HV-CoA]] de novo, allowing their incorporation into co-polymers with (R)-HB-CoA (P3HBV). In H. Mediterranei, propionyl-CoA, the primary precursor for the synthesis of (R)-HV-CoA, is obtained via one of four endogenous routes and then condensed with acetyl-CoA. This ability highlights the impressive metabolic versatility observed in PHA-producing microorganisms (Han et al., 2013).

2.3. PHA production from food waste streams

Based on various scientific studies, diverse by-products and food processing wastes have emerged as promising raw materials for PHA production. These materials include food and pulp (Acuña and Poblete‐Castro, 2023), molasses (Tyagi et al., 2022), waste oil (Ingram et al., 2022, Pan et al., 2021), animal processing waste (Ali et al., 2023), and even organic fractions of municipal waste (Ji et al., 2023, Li et al., 2023). The composition of these feedstocks determines the level of pre-processing required to convert larger molecules into usable PHA precursors. For example, fatty acids derived from lipids can be directly incorporated into PHAs (Zhang et al., 2023), while other components such as glycerol (from lipids), sugars (derived from starch or lignocellulose), or even aromatics from lignocellulose require metabolic conversion through de novo fatty acid synthesis (Bhatia et al., 2023, Tao et al., 2024). The choice of raw materials greatly affects both the substrate content and the extent of pre-processing required. Starchy waste, such as leftover pasta, is more easily decomposed compared to more complex lignocellulose materials such as grain flour, although both can ultimately produce high amounts of glucose (Brojanigo et al., 2022, Sirohi et al., 2021).

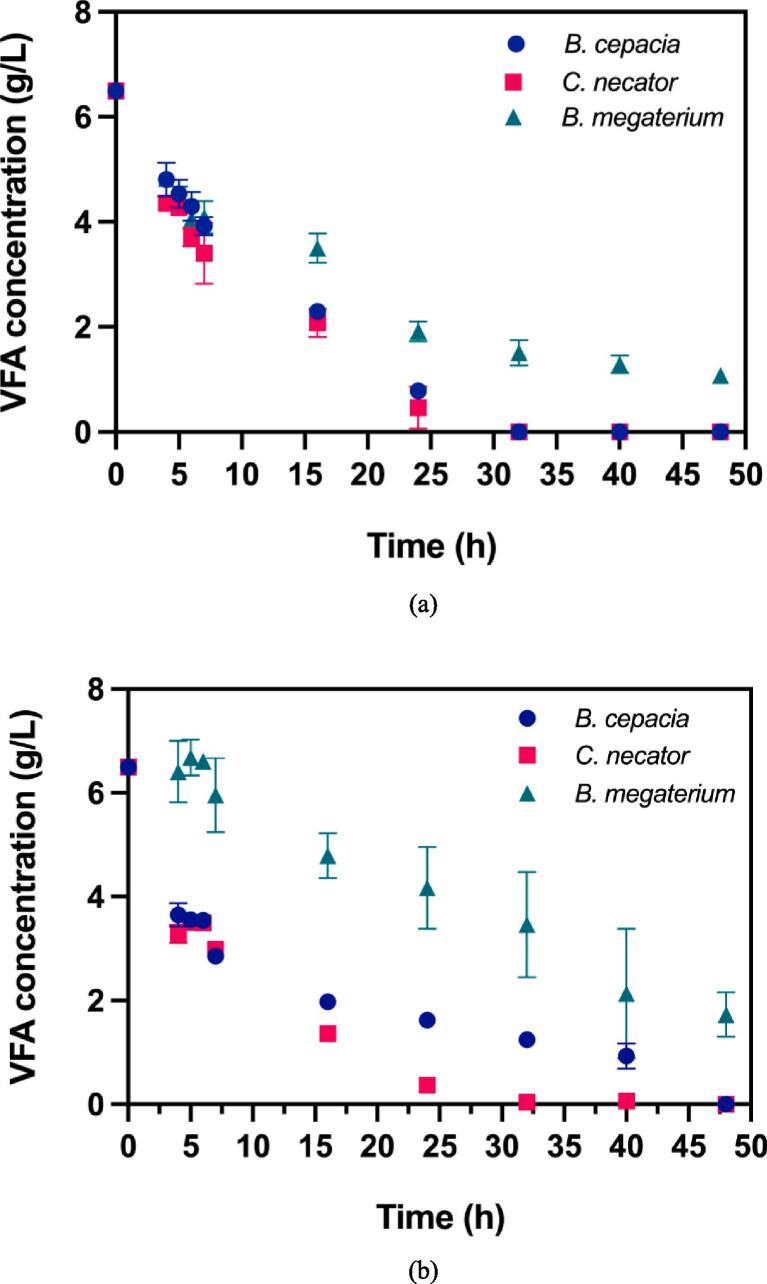

Minimizing processing steps and associated costs is critical to expanding the utilization of diverse raw materials and improving the economic viability of PHA production. Khatami et al. (2022) investigated how food waste-derived volatile fatty acids (VFAs) can be effectively utilized as low-cost carbon sources for bacterial production of PHA. The study highlights that Cupriavidus necator can accumulate up to 77.54 % PHA from VFAs derived from food waste and primary sludge. These findings indicate that waste-derived VFAs, such as acetic and propionic acids, are vital for improving the metabolic conversion into PHA. Fig. 2 illustrates how VFAs are consumed over time in both synthetic medium and digestate liquor, representing the metabolic pathways used by various bacterial strains in PHA biosynthesis (Khatami et al., 2022). This insight into microbial fermentation processes underlines the efficiency of food waste valorization into bioplastics.

Fig. 2.

VFA concentration over time in mono cultures using: (a) synthetic medium and (b) digestate liquor. This figure illustrates the key metabolic pathways and the consumption of VFAs by Cupriavidus necator, Burkholderia cepacia, and Bacillus megaterium, which are essential for PHA accumulation from food waste streams (Khatami et al., 2022).

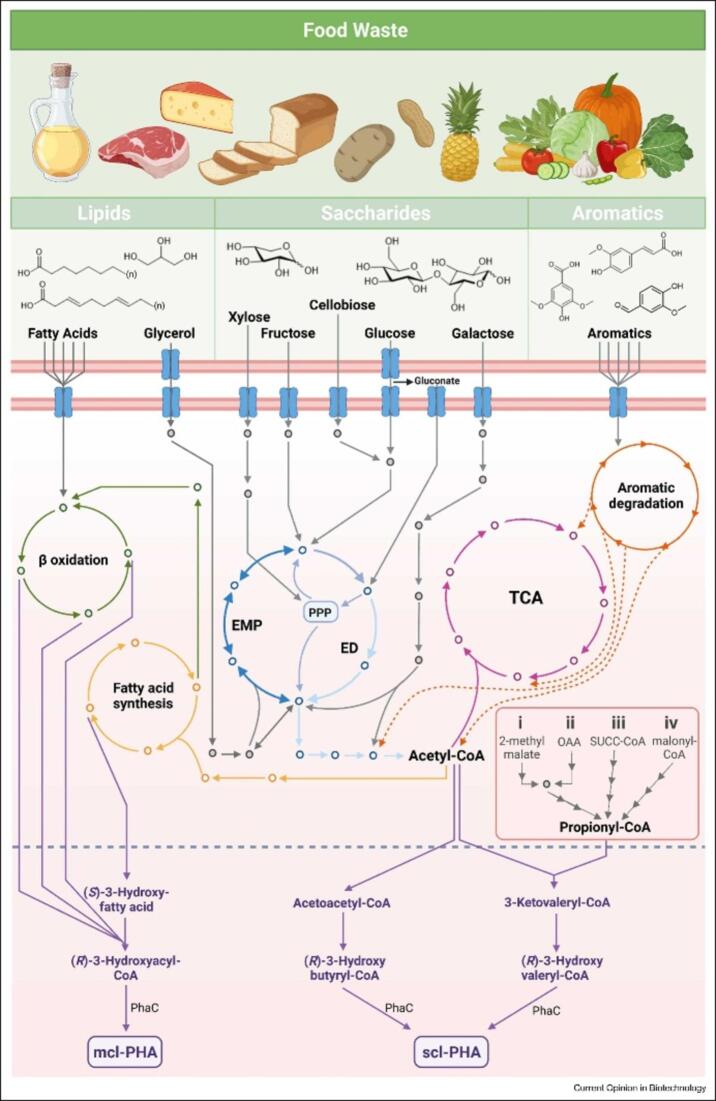

In Fig. 3, the colored pathways visually represent these processes: green for beta-oxidation (fatty acid breakdown), yellow for fatty acid synthesis, and blue for sugar breakdown (dark blue − Embden-Meyerhof-Parnass pathway, medium blue − Entner-Doudoroff pathway, light blue − Pentose Phosphate pathway). The pink pathway represents the tricarboxylic acid cycle (TCA), a cycle for energy production, and the orange pathway highlights the degradation of aromatic compounds. A separate inset details four pathways used by archaeon H. mediterranei to produce propionyl-CoA from food scraps. Finally, the purple pathway for PHA biosynthesis (medium and short chain forms) (Chacón et al., 2024).

Fig. 3.

Various metabolic pathways are utilized by bacteria and archaea to process food waste components (Chacón et al., 2024).

Many hydrolysates derived from food waste can serve as an important source of nitrogen for microbial cell growth in addition to providing a carbon source for PHA production. Research on the utilization of food waste hydrolysate as a source of nitrogen mainly focuses on byproducts with high protein content, such as whey hydrolysate, soybeans, and rapeseed (Alsafadi et al., 2020, Hierro-Iglesias et al., 2022, Wongsirichot et al., 2022). However, it is important to note that the use of these high-nitrogen hydrolysates may require additional strategies. This strategy may involve the addition of hydrolysates with carbon sources or the use of microorganisms with growth-associated PHA production, such as Haloferax mediterranei (Khamplod et al., 2023). This approach ensures that microbes have the building blocks (carbon and nitrogen) needed for cell growth and PHA biosynthesis.

2.3.1. Production of PHA from lipid waste

The production of mcl-PHA from lipids is known as “de novo fatty acid biosynthesis,” offering a unique route for the production of PHAs from unrelated substrates such as glycerol, glucose, or acetate in Pseudomonas (Lim et al., 2023). The main enzyme in this pathway is 3-hydroxy-ACP-CoA transacylase, which is encoded by the PhaG gene (ACP: acyl carrier protein). This enzyme catalyzes the important conversion of (R)-3-hydroxy acyl-ACP to the corresponding CoA derivative, (R)-3-hydroxy acyl-CoA, which serves as a direct precursor to the polymerization of mcl-PHA (Lim et al., 2023). Interestingly, studies have shown that PhaG overexpression occurs in strains of Pseudomonas putida that experience nitrogen-deficient conditions (Mohammad and Bhukya, 2022). The pathway leading to (R)-3-hydroxy acyl-ACP begins with the conversion of acetyl-CoA, a product of glycerol catabolism, to malonyl-CoA. This ATP and CO2-dependent reaction is catalyzed by a biotin-dependent enzyme, acetyl-CoA carboxylase. Malonyl-CoA then reacts with acyl carrier protein (ACP) to form the malonyl-ACP complex, releasing CoA. Furthermore, ketoacyl-ACP synthase condenses one molecule each of acetyl-ACP and malonyl-ACP, producing acetoacetyl-ACP and liberating CO2 And ACP-SH. This intermediate undergoes reduction by ketoacyl-ACP reductase to form (R)-3-hydroxybutyrate-ACP (Morya et al., 2021).

This pathway then proceeds through the removal of water molecules by hydroxyl-ACP-dehydrase, producing unsaturated pontony-ACP. Lastly, enoyl-ACP reductase reduces pontoyl-ACP to butyryl-ACP (Reddy et al., 2020). Chain elongation in the synthesis of longer mcl-PHA building blocks is accomplished by coupling butyryl-ACP with malonyl-CoA, with each cycle contributing two additional carbons to the chain. Specifically, propionyl-CoA acts as the initiating molecule (Reddy et al., 2020). The de novo synthesis of odd-numbered mcl-PHA building blocks instead of acetyl-CoA. This efficient metabolic pathway offers significant advantages to Pseudomonas putida when using glycerol as a substrate. Studies by Beckers et al. show that P. putida KT2440 requires only 0.039 mmol/g carbon dry weight (CDM) hours of glycerol for energy maintenance in continuous culture, a much lower value (about 17-fold) compared to that observed in organisms such as E. coli (Koller and Obruča, 2022). This translates into substantial economic benefits for the biotechnological application of glycerol as a substrate.

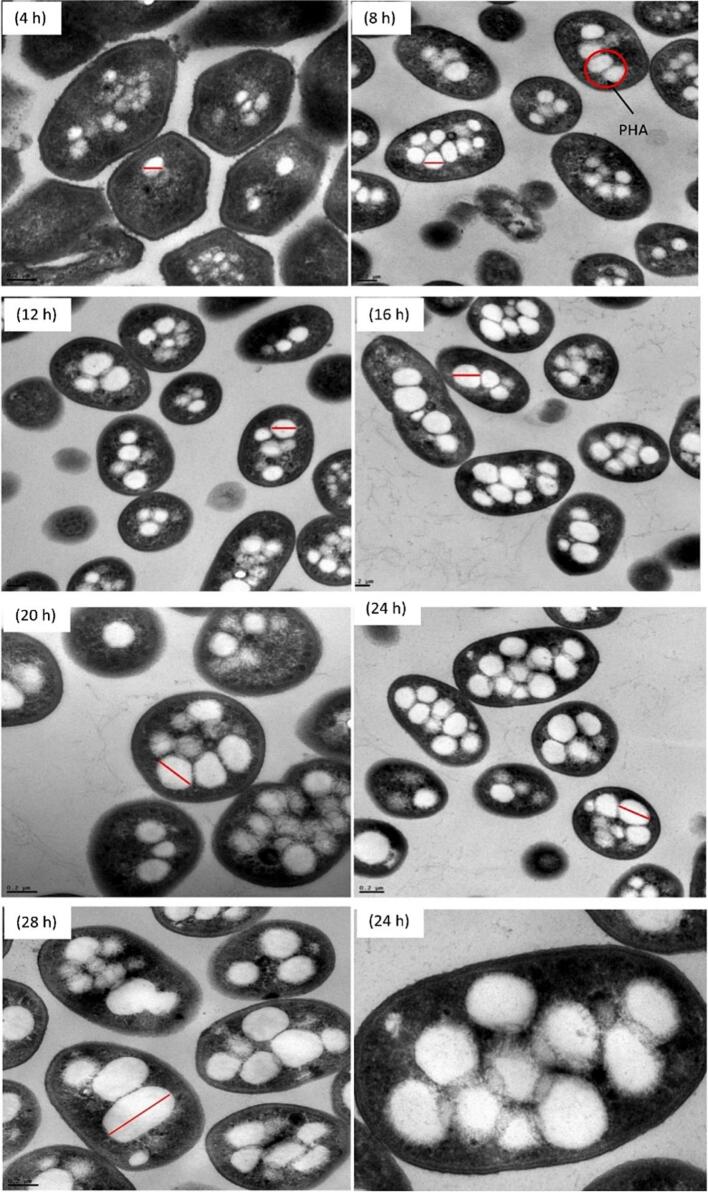

An important factor affecting mcl-PHA biosynthesis is the interaction between carbon and nitrogen availability. In Fig. 4, the transition from glycerol (carbon source) to nitrogen-restricted states triggers modulation of gene expression for processes such as glycerol degradation, cellular respiration chains, energy sensing mechanisms, and PHA biosynthesis. The transition from glycerol (carbon source) to nitrogen-restricted states triggers modulation of gene expression for processes such as glycerol degradation, cellular respiration chains, energy sensing mechanisms, and PHA biosynthesis. This metabolic shift directs the carbon flux toward the formation of PHA precursors (acetyl-CoA derived from the Entner-Doudoroff pathway and pyruvate decarboxylation) while minimizing respiration through glyoxylate shunt. Under nitrogen limitations, and favorable conditions for PHA biosynthesis, Beckers et al. reported a significant increase in PHA content in the dry mass of cells (CDM) to 0.297 g/g at a low dilution rate (D) of 0.044/h compared to 0.128 g/g at a higher dilution rate (D) of 0.205/h. These cultivation conditions also lead to a specific modulation of by-product formation, characterized by reduced levels of succinate and malate, intermediates of the TCA cycle (Wang et al., 2024).

Fig. 4.

Transmission electron micrograph of Priestia megaterium DSM 509 grown on glycerol in a nitrogen-deficient medium (scale bar: 0.2 μm) (Shahid et al., 2024).

Using basic flux mode analysis, the study by Beckers et al. further revealed the remarkable potential of P. putida KT2440 for PHA biosynthesis from glycerol. The analysis also identifies potential targets for metabolic engineering aimed at increasing PHA production capabilities (Liu et al., 2023). These findings highlight the complex interaction between individual gene expression and metabolic flux under conditions that favor or inhibit PHA biosynthesis on glycerol as a carbon source. This knowledge provided a valuable basis for the development of engineered P. putida strains that demonstrated superior PHA production efficiency.

2.3.2. Production of PHA from Saccharide waste

Leftover hydrolysates often contain a mixture of simple sugars and more complex carbohydrates, including disaccharides such as sucrose, lactose, and cellobiose. Direct utilization of these disaccharides for PHA production offers significant advantages by eliminating the need for additional pre-processing steps to convert them into monosaccharides, thereby reducing overall production costs. Several studies have explored this concept by engineering bacteria to express enzymes capable of hydrolyzing certain disaccharides. For example, the strain Pseudomonas putida EM42 was engineered to express the bglC (β-glucosidase-coding) gene of Thermobifida fusca. This modification allows the strain to grow on ac obiose as the sole source of carbon by hydrolyzing glycosidic β-1,4 bonds in the disaccharide (Sachan et al., 2024). Similarly, Cupriavidus necator NCIMB11599 was engineered to secrete ac (β-fructofuranosidase) from Mannheimia succiniciproducens. This recombinant strain showed the ability to accumulate up to 73.2 % PHA (dry weight of cells) when grown on sucrose, a disaccharide that wild-type strains cannot utilize (Sohn et al., 2021).

Another study investigated lactose utilization by C. necator DSM545 expressing the lacZ β-galactosidase gene from Escherichia coli. Although the strain is capable of growing on lactose, it is believed that only the glucose part of the disaccharide is utilized, whereas galactose remains unutilized (Chavan et al., 2024). However, subsequent research by Peabody et al. (2019) succeeded in engineering P. putida KT2440 for galactose growth as the only carbon source. This feat was achieved by introducing the De Ley-Doudoroff galactose catabolic pathway into the bacterial genome (Chacón et al., 2024).

2.3.3. Production of PHA from aromatic waste

Lignin, a complex aromatic polymer that makes up 15–30 % of lignocellulose, provides significant opportunities for valorization. Although some PHA producers may utilize certain lignin-derived aromatic monomers for PHA growth and production (Andhalkar et al., 2024), expanding their metabolic capabilities to cover a wider range of residues will allow for more efficient conversion of lignin feedstock. Ferulic and coumaric acids are the main constituents of lignin. However, Cupriavidus necator H16 shows limited growth on coumaric acid as its sole carbon source and is completely incapable of utilizing ferulic acid (Morya et al., 2021). To overcome these limitations, metabolic engineering approaches are used. Recognition of genes encoding enzymes from Pseudomonas putida (fcs – feruloyl-CoA synthase; ech – enoyl-CoA hydratase/aldolase; vdh – vanillin dehydrogenase) and from Rhodopseudomonas palustris and Sphingomonas paucimobilis (vanAB2/ligM – vanillate-O-demethylase), respectively, allowed strains of C. necator H16 is engineered to utilize ferulic and coumaric acids for the growth and production of P3HB (poly-3-hydroxybutyrate) (Kawaguchi et al., 2022).

Another important strategy to promote microbial growth on mixed substrates involves eliminating carbon catabolite repression (CCR). In P. putida KT2440, this is achieved through the deletion of the crc gene (which codes for the catabolite repression control protein). The resulting strain, P. putida KT2440Δcrc, was further engineered for the utilization of xylose and arabinose. This genetically modified strain shows the ability to co-utilize glucose, xylose, arabinose, coumaric acid, and acetic acid simultaneously, eliminating the phenomenon of diauxic growth and consequently reducing overall cultivation time (Sun et al., 2020).

2.4. Comparative analysis of PHA production methods

PHAs are biodegradable biopolymers synthesized by microorganisms under nutrient-limited conditions. Various methods are employed to produce PHA, each offering unique advantages and facing specific challenges in terms of yield, cost, scalability, and environmental impact. This section presents a comparative analysis of the major PHA production methods, including microbial fermentation, enzymatic production, and the use of mixed waste streams. The choice of bacterial species, substrates, and production techniques significantly influences the feasibility of scaling PHA production for industrial applications.

Microbial fermentation is the most established and widely used method for producing PHA, leveraging bacteria such as Cupriavidus necator, Burkholderia cepacia, and Bacillus megaterium. In this process, microorganisms synthesize PHA from carbon-rich substrates under nutrient-limited conditions, typically when nitrogen or phosphorus is depleted. The carbon source is a critical factor affecting both yield and cost of production.

The study by Khatami et al. (2022) provides a detailed comparison of these bacterial strains using two distinct substrates: synthetic medium and digestate liquor (a byproduct of food waste and primary sludge). The performance of these strains varies significantly based on the substrate used. Cupriavidus necator exhibited the highest PHA yields in both synthetic medium and digestate liquor, accumulating up to 77.54 % of cell dry weight (CDW) in the latter. This highlights the ability of C. necator to efficiently metabolize volatile fatty acids (VFAs) such as acetic acid and propionic acid, which are abundant in digestate liquor derived from food waste. Burkholderia cepacia achieved moderate PHA yields of 54.9 % CDW, suggesting that while it is capable of PHA production, its efficiency is lower compared to C. necator. This reduced efficiency may be attributed to differences in metabolic pathways and substrate preferences between the two species. Bacillus megaterium, despite being known for PHA production, performed poorly in both synthetic medium and digestate liquor, accumulating only 3.42 % CDW in digestate liquor. This could be due to its lower capacity for metabolizing VFAs, particularly in complex substrates like digestate liquor.

The choice of substrate plays a crucial role in determining the cost-effectiveness and scalability of PHA production. Synthetic medium is commonly used in laboratory studies because it allows for precise control over nutrient availability. However, its high cost makes it unsuitable for industrial-scale production. In contrast, digestate liquor, a waste product from anaerobic digestion of food waste, offers a low-cost alternative that aligns with circular economy principles. Khatami et al. (2022) demonstrated that using digestate liquor not only reduces production costs but also leads to higher PHA yields for certain bacterial strains, particularly C. necator.

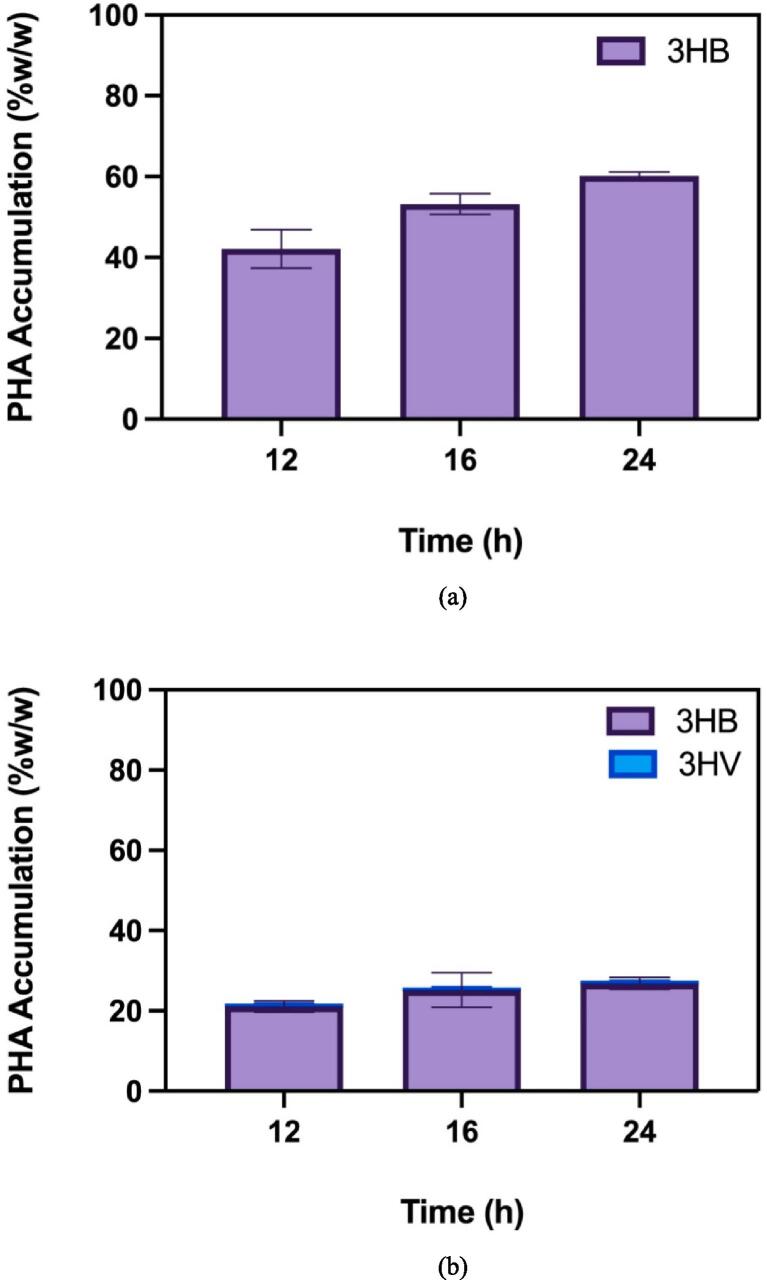

The performance of these bacterial strains in synthetic medium is illustrated in Fig. 5, where Cupriavidus necator outperformed Burkholderia cepacia in terms of PHA accumulation over time. This highlights the superior efficiency of C. necator in controlled environments like synthetic media. However, despite the high yields achieved in synthetic medium, its high cost limits its feasibility for large-scale production.

Fig. 5.

PHA accumulation over time in mono cultures using synthetic medium: (a) Cupriavidus necator and (b) Burkholderia cepacia (Khatami et al., 2022).

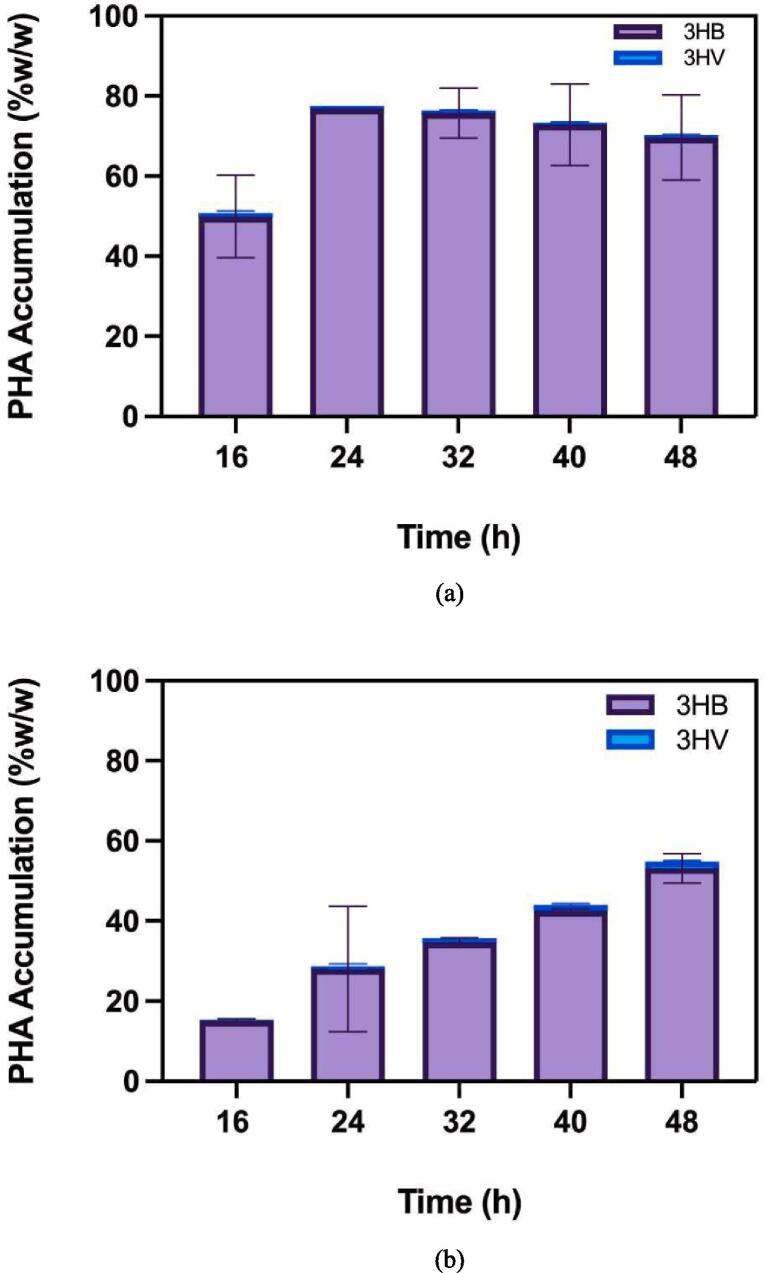

Fig. 6 illustrates the performance of these strains in digestate liquor. As seen in the figure, Cupriavidus necator again exhibited the highest PHA accumulation, followed by Burkholderia cepacia and Bacillus megaterium, which had much lower yields. This shows the potential of using waste-derived substrates like digestate liquor to produce PHA at a lower cost, though variability in the composition of digestate liquor may introduce challenges in process control.

Fig. 6.

PHA accumulation over time in mono cultures using digestate liquor: (a) Cupriavidus necator; (b) Burkholderia cepacian; and (c) Bacillus megaterium (Khatami et al., 2022).

Another method for PHA production involves the use of enzymes to catalyze the polymerization of hydroxyalkanoates (HA) into PHA. Enzymatic production is less commonly used compared to microbial fermentation but offers advantages in producing PHAs with specific molecular structures and properties. This method allows for greater selectivity and customization, making it ideal for producing specialized PHAs tailored to specific industrial applications (Khatami et al., 2022).

Despite these advantages, enzymatic production has several drawbacks. It is generally more expensive due to the cost of enzymes and the complexity of the purification process. Moreover, enzymatic methods are less scalable than microbial fermentation, limiting their use to small-scale or niche applications. As such, enzymatic production is not currently considered viable for large-scale PHA production.

The use of mixed waste streams as feedstock for PHA production is an increasingly popular approach, especially in the context of circular economy principles. Waste streams such as food waste, agricultural residues, and municipal waste are abundant, low-cost carbon sources that can be utilized in microbial fermentation to produce PHA. Khatami et al. (2022) demonstrated that digestate liquor derived from the anaerobic digestion of food waste can be effectively used to produce PHA, with Cupriavidus necator achieving high yields.

The major advantage of using mixed waste streams is the significant reduction in feedstock costs, making PHA production more economically viable. However, the composition of waste streams can vary, introducing variability in microbial growth and PHA synthesis. Pretreatment of waste streams is often necessary to remove contaminants or inhibitory compounds, adding complexity to the production process. The Table 4 summarizes the advantages and disadvantages of the three main PHA production methods.

Table 4.

The advantages and disadvantages of the three main PHA production methods.

| Method | Advantages | Disadvantages |

|---|---|---|

| Microbial Fermentation | High yield, flexible feedstock options, scalable | Requires precise nutrient control, energy-intensive, byproduct purification needed |

| Enzymatic Production | Selective, customizable PHA properties | Expensive, less scalable, complex purification required |

| Mixed Waste Streams | Low-cost feedstock, aligns with circular economy principles | Variable feedstock quality, pretreatment often required |

3. Food packaging

The global shift toward sustainable practices has increased interest in biodegradable materials as alternatives to conventional plastic packaging. Biodegradable biological resources such as proteins, lipids, and polysaccharides are increasingly being used to address plastic pollution concerns (Amin et al., 2021). Plastics remain dominant in food packaging due to their low cost, ease of processing, and versatile production methods (Asdagh et al., 2021), but overuse and poor recycling practices contribute significantly to environmental pollution (Sani et al., 2021). Consequently, biodegradable materials, particularly biopolymers, are being explored as replacements.

PHAs is a type of biodegradable polymer produced by microorganisms, hold significant promise as a sustainable alternative to traditional plastics. PHA’s biodegradability and compatibility with existing plastic-processing techniques make it a strong candidate for various food packaging applications. However, challenges related to production cost, scalability, and material properties limit its large-scale adoption in the food packaging industry. Addressing these barriers is crucial for transitioning PHA from a niche product to a mainstream packaging solution.

This study provides several key insights into how PHA production can be optimized for industrial use, particularly in the food packaging sector. The use of food waste-derived volatile fatty acids (VFAs) as a carbon source for PHA production has been shown to reduce production costs while maintaining high PHA yields. Specifically, Cupriavidus necator was able to produce up to 77.54 % of cell dry weight (CDW) as PHA when grown in digestate liquor, a waste byproduct from food waste and primary sludge processing (Khatami et al., 2022). This finding is critical for industries aiming to adopt sustainable practices, as it demonstrates how waste can be repurposed to produce high-value bioplastics.

The versatility of PHA is another important factor that enhances its industrial potential. PHAs can be processed into various packaging forms, including flexible films, trays, and containers, through standard manufacturing techniques such as injection molding, extrusion, and thermoforming. This adaptability makes PHA suitable for a wide range of food packaging applications, from fresh produce packaging to more rigid containers for processed foods. However, while PHA has advantages in biodegradability, its mechanical and barrier properties need improvement to match those of conventional plastics.

One of the primary limitations of PHA is its relatively high production cost compared to petroleum-based plastics such as polyethylene (PE) or polypropylene (PP). Scaling up production using low-cost feedstocks like food waste is one approach to reducing these costs (Loan et al., 2022, Vu et al., 2021). Additionally, the mechanical properties of PHA—such as flexibility and barrier performance against moisture and gases—are lower than those of traditional plastics. These limitations pose challenges for its widespread adoption in food packaging, where durability and food preservation are critical.

However, research has shown that blending PHA with other biopolymers or incorporating functional additives, such as plasticizers or nanoparticles, can significantly improve these properties (Khatami et al., 2022). Such modifications can increase flexibility, enhance moisture resistance, and improve gas barrier properties, making PHA more competitive for a wider variety of food packaging applications. For instance, biopolymer-based membranes are hydrophilic, which can reduce mechanical strength, but they excel in gas barrier properties, which is beneficial for food preservation (Luangapai et al., 2019).

Moreover, the incorporation of functional active ingredients into PHA-based packaging such as antibacterial agents, antioxidants, and colorants can further enhance the quality and safety of packaged foods (Tavassoli-Kafrani et al., 2022). This capability allows PHA to contribute to extended shelf life, improved food safety, and enhanced consumer appeal through smart packaging innovations. These developments are crucial for industries looking to meet both environmental standards and consumer demands for safer, more sustainable packaging solutions.

The environmental benefits of PHA packaging are considerable. Unlike petroleum-based plastics, PHA is fully biodegradable, breaking down naturally into non-toxic by products, thus reducing long-term environmental impact. Moreover, PHA’s biocompatibility makes it safe for direct contact with food, minimizing the risk of chemical migration that can occur with traditional plastics. These factors make PHA an attractive option for companies aiming to reduce their environmental footprint while ensuring food safety.

In the context of food safety, the ability of PHA to degrade safely without leaving harmful microplastics behind is a key benefit. As public awareness of microplastic contamination grows, packaging materials that do not contribute to this problem are becoming more attractive to both consumers and regulatory bodies.

3.1. Biodegradable food packaging process using PHA

Biodegradation of bio-based polymers utilizes fermentation methods to transform raw biomass into feedstock (e.g., lactic acid for PLA production) and polymers (e.g., polyester PHA synthesized by bacteria under nutrient-limited conditions) (Beltrán et al., 2019). The steps of processing biodegradable food packaging involve the polymerization of the basic constituent materials, the addition of additives and blending with another polymer, and processing include extrusion, injection molding, blow molding, and thermoforming, to achieve the final product (Soroudi and Jakubowicz, 2013).

3.1.1. Film extrusion process

Extrusion techniques have garnered attention in biopolymer film processing research in recent years due to their potential as a low-cost, high-demand alternative (Chevalier et al., 2018). Because it achieves high temperatures quickly and has a very easy operation, the extrusion process is the most popular method for producing industrial plastics at large production levels (Borries-Medrano et al., 2016). The polymer resin is first melted and then forced into an extrusion die to create a film. It then rapidly cools and solidifies on cooling rollers. The thickness of the continuous film extrusion process can be adjusted. The drawback of biopolymers is that, in comparison to traditional plastics, they are more heat-sensitive. Furthermore, during the extrusion process, certain elements including excessive heat, friction force, and pressure break down biopolymers. Screw configuration, temperature profile, duration, and correct fusion and homogenization are important factors to optimize to prevent degradation of biopolymers. Adding plasticizers serves the purpose of boosting process capacity. The twin-screw extrusion approach is recommended, if more costly since it provides superior controllability for naturally occurring biopolymers. Biopolymers such as PLA (polylactic acid), starch, chitosan, and cellulose derivatives are frequently extruded into films. A revolutionary food packaging film based on starch was created by Gutiérrez and Valencia, and it has better qualities than traditional TPS (thermoplastic straw) films (Gutiérrez and Valencia, 2021). The application of starch films in most food products as coatings or packaging without changing their appearance or taste because they are tasteless, odorless, and colorless (Basiak et al., 2017). In this case, the researchers tried to overcome the shortcomings of TPS films, namely reduced sensitivity and brittleness to water (Mendes et al., 2020). The researchers' hypothesis was to use reactive extrusion to link the starch chains with sodium TPP (tripolyphosphate) and modify the structure of regular starch in an attempt to fortify the starch network. In this instance, SNC (ordinary corn starch), which has a greater amylose content, was used to create four film systems. Reactive extrusion was used in the film-making process to progressively alter the starch and cross-linking. Every movie has its unique qualities. Because of the increased hydrogen bonding caused by cross-linking, the resultant starch phosphate plastic is more hydrophilic and has better crystallinity than regular TPS. SNC addition enhanced the crystallinity as well. However, no appreciable adjustments were made to enhance the standard TPS's membrane properties. Although the technical procedure is the same, the problem with water sensitivity persists. The starch-phosphate layer did not release phosphorus as predicted for fertilization of lettuce seedlings. This is probably because of the reduced bioavailability and lower phosphorus concentration. The starch chain structure was altered as a result of this change; however, the plastic properties were not noticeably improved. Reactive extrusion can alter starch-based plastics, as demonstrated by this work; nonetheless, more investigation is required to address TPS materials' drawbacks. Effective mixing, the production of gelatinized starch, and chemical cross-linking are made possible by the extrusion process, which produces packaging that is both high-quality and environmentally friendly (Gutiérrez and Valencia, 2021). One type of packaging material composed of natural polymer compounds is an edible film (Galus and Kadzińska, 2015). The benefits of edible film include non-toxicity, convenience, safety, biodegradability, and hygiene. It may also be utilized as a plastic inner packaging and additive carrier, replacing traditional packaging and offering a wide range of development opportunities (Gómez-Guillén et al., 2011, Limpisophon et al., 2010). The protein-based edible film is easily absorbed and digested by the human body. The intermolecular crosslinking that results from the hydrogen bond, hydrophobic action, and disulfide bond between protein molecules gives the film exceptional mechanical strength and barrier performance. At the moment, a lot of research is being done on edible films based on proteins, including zein, whey protein, gelatin, and soybean protein isolate as the primary raw materials (Jin et al., 2021). Extrusion techniques with temperatures ranging from 85 °C to 150 °C can be used to create edible films (Huntrakul et al., 2020). Nonetheless, an edible film produced by solvent-casting techniques is expected to be more effective than extrusion techniques (Park et al., 2008). Pranata et al. conducted research to produce bioplastic films from Eggs with Protein (EWP) using extrusion and calendering processes, both of which are commonly used methods for producing plastic films in industrial environments (Pranata et al., 2019). Egg white protein (EWP) has the characteristics of a wide source, easy digestibility, high biological valence, rich nutritional value, and excellent functional properties, such as gelling, foaming, and emulsifying properties (Jin et al., 2021). The purpose of this study was to determine whether extrusion and calendering-produced EWP films may be utilized in food packaging as an alternative, sustainable material. Initially, the goal of the study was to determine the minimum temperature needed for the roll calendering and extrusion operations in order to create sustainable and uniform EWP films. Consequently, it was discovered that extruder temperatures between 40 °C and 75 °C and rolling temperatures between 115 °C and 120 °C can be used to manufacture transparent and thin EWP films. The EWP film was exposed to varying temperatures and humidity levels, which affected the food packaging's properties and allowed for further evaluation. The thickness, resilience, flexibility, permeability, color, transparency, and removal of plasticity of EWP films were all found to be impacted by humidity. Temperature, meantime, had an impact on the transparency, brightness, and transmittance of the films. The primary conclusions show that while EWP films have stronger stiffness, heat resistance, and oxygen barrier qualities, they are less flexible and brittle than PLA plastic films that are sold in stores. The clarity, brightness, color, ethanol barrier qualities, and moisture resistance of PLA and EWP films are comparable. The goal of this extrusion technology is to make it possible to generate EWP bioplastic films sustainably in a manner akin to that of plastic films made in factories. This study demonstrated that using extrusion procedures that comply with conventions can result in the production of films based on EWP (Pranata et al., 2019).

3.1.2. Blown film extrusion process

The blown film extrusion process is a conventional plastic process to produce thin films for commercial packaging applications (Khumkomgool et al., 2020). In this process, a liquid biopolymer tube is extruded vertically up through the ring mold and pumped into it with deep air pressure. To saturate it, cooling air is blown into the tubes that are expanding before the tube compresses and rolls. Compared to the printed film, the biaxial orientation of the chain increases the strength of the film and the barrier properties. The comparison between biopolymers is limited to their melting elasticity. Pump films made of aliphatic starch, PLA, and polyester can be made, but low melt strength can cause bubbles to become unstable. When extruding a pump film, using long chain branched material helps improve melt resistance and bubble stability. In this study, the composite film HPDSP (hydroxypropyl distarch phosphate)/PHA was produced using a pump extrusion process in laboratory conditions. Compared to solvent casting, blower extrusion attracts attention because it is highly productive, efficient, and similar to the actual industrial production rate (Gao et al., 2012). As a result, the research concentrated on a blower extrusion film made of starch or a starch/PHA mixture that is ideal for making large-scale packaging films. Using inflatable film extrusion technology, Phothisarattana et al. showed a new biodegradable nanocomposite film containing ZnO nanoparticles as an antimicrobial packaging on meat products (Phothisarattana et al., 2022). Biodegradable polymers such as PBAT (Poly(Butylene Adipate-Co-Terephthalate)) are extremely flexible and easily converted into food and packaging films. However, the high PBAT costs limit its use for commercial packaging applications (Wadaugsorn et al., 2022). However, PBAT cannot prevent food degradation due to its poor barrier properties compared to conventional plastics. To deal with this, ZnO nanoparticles are added, which can have an antimicrobial effect and increase food shelf life (Phothisarattana et al., 2022).

ZnO nanoparticles have high stability as a low-cost nanofiller with beneficial properties, such as high ultraviolet (UV) absorption and strong antibacterial activity on various bacteria (Yu et al., 2021). The scientists used the double screw extrusion method accompanied by pump film extrusion to insert ZnO nanoparticles (1–5 %) into the PBAT/TPS polymer mixture. The pump film extraction method was chosen because it allowed sustainable film production on a commercial scale, unlike the solvent casting method used in most previous experiments. The PBAT/TPS/ZnO nanocomposite film made shows that some ZnO nanoparticles are agglomerated. This leads to a decline in mechanical properties, such as a decrease in traction. Nevertheless, the use of ZnO nanoparticles increased the interaction of hydrogen bonds with the TPS biopolymers domain, which resulted in increased dispersion. FTIR (Fourier Transform Infrared Spectroscopy) shows that ZnO nanoparticles alter the bonding of CO and CO in PBAT. The presence of higher ZnO content, i.e., 5 %, strong interaction between ZnO and TPS increases nanoparticle dispersion and reduces nanoparticle compression along with increased amorphous particle content. When used to store pork in packaging, PBAT/TPS/ZnO nanocomposite films show antimicrobial effects and reduce microbial growth and lipid oxidation in meat when compared to conventional ZnO free films. It also extends the shelf life of pig meat in packing for more than three days during storage in the refrigerator, with ZnO concentrations higher than 3 %. ZnO nanoparticle characteristics, as well as control of oxygen permeability in the film and surface morphology, contribute to the antimicrobial and antioxidant effects (Phothisarattana et al., 2022). Using pump film extrusion techniques, Fehlberg et al. investigated whether there was a mixture of OP powder (Orange Peel) into a polyethylene film, which made the packaging material more environmentally friendly. Using Low Linear Density Polyethylene Polymer Matrix (LLDPE). LLDPE is a cheap conventional plastic that is widely used in food packaging applications due to its good mechanical properties (Panrong et al., 2020). The process is as follows: the OP powder is mixed with LLDPE in a double-screw extrusion machine to produce a base mixture containing 22 % OP. Then, the blown film of the extruder is blended with LLPDE to produce the film with 5–12,5 % OP. The blower film extrusion method is used to process the mixture film up to 11.5 % OP. The loss of the film during the melting process was caused by an operational improvement above 11.5 %. After that, the morphology, thickness, mechanics, barriers, optics, and thermal properties of the made LLDPE/OP film were checked. The results of the research showed that LLDPE/OP films blown with 11.5 % OP had the same crystallinity, melt temperature, and water vapor barrier properties as the unblown LLDPE films. The use of OP increases the barrier capacity of visible light and ultraviolet rays. Traction strength and prolongation break the mixed film, however, decreased (Fehlberg et al., 2023).

3.1.3. Multilayer film process

Multilayer films have emerged as a viable strategy to circumvent the inherent limitations of biopolymers. These engineered systems incorporate multiple layers, each designed to impart specific functional attributes. Typical components include external protective layers, moisture and gas barriers, and heat-sealable or food-contact linings. The fabrication of these multilayer structures commonly involves lamination, extrusion, or coextrusion processes (Morinval et al., 2024). A common approach involves the integration of natural biopolymer films with synthetic polymers. To enhance the overall properties of these composite materials, nanomaterials are often incorporated. Illustrative examples include multilayer inflatable films and thermoformed containers produced from starch (Grzebieniarz et al., 2023), poly(lactic acid) (PLA) (Martin and Avérous, 2001), chitosan (Kruk et al., 2023), and aliphatic polyesters (Yang et al., 2024). Recent research has explored current trends in bioactive multilayer films, which combine natural biopolymers and additives to create sustainable and environmentally friendly food packaging solutions. These films achieve optimal properties, such as mechanical strength, excellent barrier properties, and low hydrophilicity (Fotie et al., 2020, Le Gars et al., 2020). This approach effectively overcomes the limitations inherent in single-layer biopolymer films. Common biopolymers utilized in these multilayer structures include gelatin, chitosan, zein, PLA, cassava starch, potato starch, and soy isolate protein (Martin and Avérous, 2001). These multilayer plastic systems enable the controlled incorporation of naturally derived bioactive compounds, such as plant extracts and essential oils. This approach facilitates the development of active packaging with functionalities including antibacterial, antioxidant, and UV protection (Avila et al., 2023).

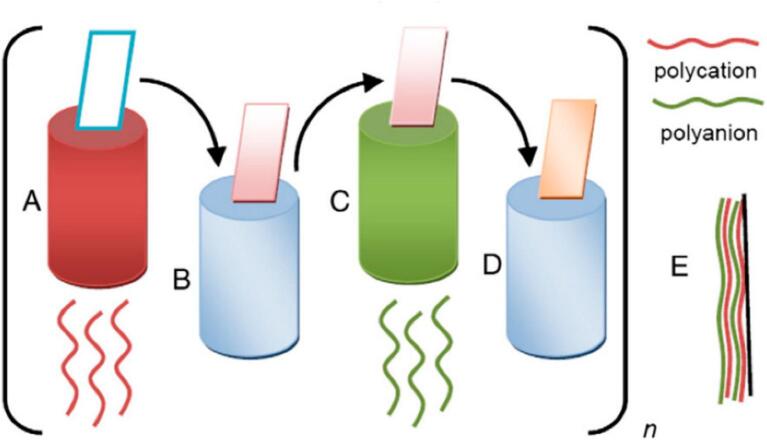

In addition to these methods, electrostatic interactions between polymers with opposite charges offer another approach for creating multilayer films. This process involves immersing a substrate in a polycation solution followed by immersion in a polyanion solution (Fotie et al., 2020, Garrido et al., 2016). This Layer-by-Layer deposition technique, as outlined by De Villiers et al., is advantageous for producing uniform multilayer films with controlled thickness at the nanoscale (Gontard et al., 1992). The process can be divided into several key steps: Step A involves immersing the substrate in a polycation, Step B consists of washing the substrate in a solvent for polycation, Step C involves immersing the substrate in a polyanion, and Step D is washing the substrate in a solvent for polyanion. These steps can be repeated multiple times to build up the desired multilayer system, as represented by Step E (Granda-Restrepo et al., 2009). The schematic process of Layer-by-Layer method is illustrated in Fig. 7.

Fig. 7.

Schematic process of Layer-by-Layer method (Granda-Restrepo et al., 2009).

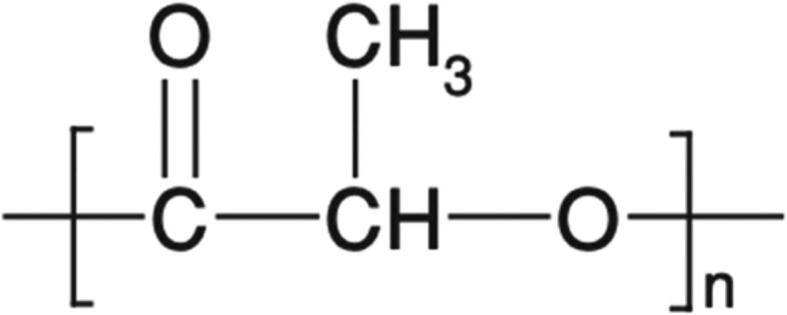

A study characterized fully biodegradable multilayer films comprising PLA and organoclay nanoparticles for potential food packaging applications (Maleki et al., 2022, Mujtaba et al., 2019). These films were fabricated through an extrusion process resulting in a three-layer structure (Naser et al., 2021). The core layer contained 4 % organoclay nanoparticles, while the outer layers consisted of pure PLA as illustrated in Fig. 8. The incorporation of organoclay notably improved both the oxygen barrier and mechanical properties of the multilayer film compared to a pure PLA film, with a 40 % increase in tear resistance (Scarfato et al., 2017). Moreover, the organoclay layer facilitated heat sealing at higher temperatures (80–100 °C) (Velásquez et al., 2021). Lactic acid migration rates for all multilayer films remained well below the EU’s total food migration limit of 60 mg/kg, despite significant morphological changes observed during the migration test, particularly in the ethanol trial (Velásquez et al., 2021). These findings suggest the potential for developing high-performance, fully biodegradable PLA/organoclay multilayer structures that meet regulatory standards for food packaging (Vidal et al., 2023). However, multilayer plastic packaging-based products are still difficult to recycle and this aspect, besides undermining the sustainability of materials, also slows down the transition towards a circular economy. The main problem blocking the proper recycling path is caused by the fact that standard technologies are currently incapable of identifying, selecting, and easily separating the various layers that comprise these packaging materials (Velásquez et al., 2019). Hence, in European countries, the leading solution for multilayer flexible packaging disposal is represented by its combustion with the recovery of energy. Alternatively, in low-income countries, this waste will be sent to landfills (Costamagna et al., 2023).

Fig. 8.

The chemical structure of PLA (Naser et al., 2021).

3.1.4. Film casting process

Solvent casting involves dissolving biopolymers in a solvent and applying the solution to a substrate using a coating blade. The solvent evaporates, leaving behind a biopolymer film (Murueva et al., 2024). Common solvents include dimethyl sulfoxide and dimethylacetamide. Multiple layers can be sequentially applied to create multilayer films. While this method allows for the incorporation of additives like lipids and antimicrobial agents, it is a batch process unsuitable for large-scale production (Rakkan et al., 2024). Edible films offer a sustainable packaging alternative to traditional plastics, reducing waste and extending the shelf life of fresh products like meat (Murueva et al., 2024). These films are produced through wet casting (solvent evaporation) or dry casting (heat and pressure). Biopolymers, such as starch, proteins, and lipids, form the basis of these films. By combining different materials, desired barrier, mechanical, and optical properties can be achieved (Tomietto et al., 2022). Edible films act as protective barriers for meat, preventing moisture loss, gas exchange, lipid oxidation, and microbial growth. Incorporating antibacterial and antioxidant compounds further enhances the film's protective properties. Accurate moisture control, consistent film thickness, and careful biopolymer selection are crucial for successful film production. Although sustainable and biodegradable, edible films can be costly and may alter food texture or flavor (Prakoso et al., 2023).

3.1.5. Thermoforming

A popular manufacturing process named thermal forming is heating a thermoplastic sheet and using a mold to shape it into the desired shape (Leite et al., 2018). The process is categorized into three stages: heating, forming, and cooling. The process begins with heating the thermoplastic sheet until it is soft and forming it using a mold with the help of a vacuum or pressure while cooling it until the desired shape is obtained. The process of pressing results in drying and densification, which increases the density and improves the mechanical properties of the molded product (Pasquier et al., 2023). In this process, there are three types depending on the load applied, namely pressure, vacuum, and contact forming methods. Aliphatic starch, PLA, and polyester materials thermoformed into food packaging, trays, refrigerator doors, tubs, and cups, are some of the thin and thick gauge thermoforming products produced by pressure, vacuum, and contact forming methods. Sheet thickness and temperature must be kept neither too hot nor too cold to prevent product damage. The low melting force of these products limits the pull ratio and therefore plasticizers are often required (Hosseinionari and Seethaler, 2024, Patil et al., 2021).

3.1.6. Compression and injection molding process

Plastic materials in particular are molded through the Injection Process. This process is said to be preferred for the production of a wide variety of products with varied specifications such as shapes and sizes, etc. In fact, the type of raw material varies, depending on the function or service that the final product will provide (Mourya et al., 2023). The cycle time is shorter than thermoforming, but the flexibility of the mold is limited. The injection molding process involves injecting a liquid polymer into a mold that is reinforced under high pressure to create complex shapes. The main injection molding products are Poly Lactic Acid (PLA) tableware and stationery. Starch-like materials can be molded through compression and injection processes using plasticizers. The focus of thermocompression is to make the production method more scalable while saving energy than conventional solvent casting techniques (Lopez et al., 2014). In spite of the fact that infusion molding has higher generation rate, exactness compression molding is competent of manufacturing focal points with higher quality (lower leftover stresses and more precise geometries) (Li et al., 2017).

3.2. Implementation of biodegradable food packaging

3.2.1. Meat and seafood

Biodegradable packaging products manufactured from food waste and by-products offer promising applications for products like meat and seafood. Gelatin-based packaging infused with grapefruit seed extract demonstrated significant antimicrobial effectiveness against several meat spoilage bacteria, including Escherichia coli, Staphylococcus aureus, Salmonella Typhimurium, and Listeria monocytogenes. This packaging extended the storage life of beef by six days compared to conventional packaging (Abreu et al., 2012). In conclusion, biodegradable packaging derived from food waste demonstrates considerable potential for enhancing the quality, safety, and shelf life of perishable meat and seafood products (Bhargava et al., 2020). Scaling up laboratory-based research on biodegradable packaging from food waste to industrial applications requires further investigation. Key areas of focus include plastic formation, mechanical properties, food-packaging interactions, production feasibility, and economic viability. Addressing these challenges is essential for the successful commercialization of such innovative packaging materials (Dilkes-Hoffman et al., 2018).

These packaging materials minimize moisture loss, maintain product texture, and prevent unsightly juice leakage, ultimately reducing food waste. Edible packaging further safeguards food quality by inhibiting biochemical degradation, protecting lipids and proteins from oxidation, delaying rancidity, and preventing discoloration (Yb and Kola, 2019). The application of this food packaging is presented in Table 5.

Table 5.

Applications of edible food packaging on meat and seafood (Petkoska et al., 2021).

| Food product | Edible materials | Beneficial effect | References |

|---|---|---|---|

| Sliced ham | Na-alginate edible films as vehicles for delivering probiotic bacteria | Some probiotic bacteria were successfully delivered into the product using edible film | Pandhi et al., 2019, Pavli et al., 2019 |

| Oregano essential oil (OEO) is incorporated in Na-alginate edible films | Decrease in Listeria population. The presence of OEO on the film resulted in a difference in color compared to the control test sample which showed a decrease in product quality but an increase in aroma | ||

| Sliced cooked ham | Film matrix composed of poly(lactic acid) containing cellulose nanocrystals (PLA-CNC); films converted to bioactive films using nisin as an antimicrobial agent | Ability to inhibit Listeria monocytogenes and its physicochemical and structural properties (stored for 14 days at 4 °C). Significant reduction of L. monocytogenes in ham from day 1 and complete inhibition from day 3. | Salmieri et al. (2014) |

| Muscle foods | Collagen edible films | Lower moisture content, minimize lipid oxidation, prevent discoloration, and reduce water droplets | Pandhi et al. (2019) |

| Shrimps | Bilayer films based on agar and Na-alignate with cinnamon oil | Antioxidant activity; effective against Photobacterium phosphoreum | Arancibia et al. (2014) |

| Lamb meat | Nano-encapsulated Satureja khuzestanica essential oils (SKEO) in chitosan coatings (containing free or nano-encapsulated SKEO) | Effectively inhibited microbial growth and chemical spoilage; the encapsulation process slowed down the release of SKEO and led to longer lasting antimicrobial and antioxidant activities; improved sensory attributes | Pabast et al. (2018) |

| Turkey deli meat | Pullulan films with silver nanoparticles (Ag Nps), zinc oxide nanoparticles (ZnO NPs) oregano oil (OR) 2 % and rosemary oil (RO) 2 % | Ag NPs and OR edible films were more active than ZnO NPs and RO. Films based on Ag NPs, ZnO NPs, OR, and RO had antibacterial activity against pathogens: Listeria monocytogenes and Staphylococcus aureus. | Guo et al., 2014, Khalaf et al., 2013 |

| Edible coatings incorporating chitosan, lauric arginate ester (LAE) and nisin | Reduction of Listeria innocua. Combining antimicrobial coatings or films with flash pasteurization (FP) will reduce L. innocua. | ||

| Roasted turkey | Four polysaccharide-based edible coatings (starch, chitosan, alginate and pectin) incorporating sodium lactate (SL) and sodium diacetate (SD) and commercial preparations Opti.Form PD4, NovaGardTM CB1, Protect-M and GuardianTM NR100 | Pectin coatings using SL/SD, Opti. Form PD4 with or without Protect-M, and NovaGARDTM CB1 showed higher antimicrobial efficacy against L. monocytogenes. Frozen storage significantly increased the anti listeria activity of various coating treatments | Jiang et al. (2011) |

| Harbin red sausage | Edible chitosan (CTS) coatings (0, 1, 2, and 3 %) | Improved storage stability by increasing the concentration of edible CTS coating. Maintaining storage stability (pH and water distribution) and inhibiting microbial growth (total aerobic bacteria and lactic acid bacteria). | Dong et al. (2020) |

| Ham and bologna | Antimicrobial effects of carvacrol and cinnamaldehyde incorporated into apple, carrot, and hibiscus-based edible films | Antimicrobial effect against Listeria monocytogenes. Carvacrol film showed better antimicrobial activity than cinnamaldehyde film. The cream is more effective on ham than bologna. | Ravishankar et al. (2012) |

| Fresh pork | Chitosan-gelatine edible coatings incorporating grape seed extract and/or nisin | Effectively inhibited pork oxidation and microbial spoilage; grape seed extract further strengthened the antioxidant activity against meat oxidation, but incorporating nisin into the coating did not enhance the antimicrobial and antioxidant effects further | Xiong et al. (2020a) |

| Fresh pork loin | Oregano essential oil (OEO) and resveratrol (RES) nanoemulsion loaded in pectin (PEC) edible coating | It can significantly extend the shelf life of pork by minimizing pH and color changes, slowing down lipid and protein oxidation, maintaining meat tenderness, and preventing microbial growth | Xiong et al. (2020b) |

| Beef meat | Antioxidants naturally present in olives, hydroxytyrosol (HT) and 3,4-dihydroxyphenylglycol (DHPG) added to a pectin-fish gelatin edible film. A new composite film included beeswax is also compared. | Films with antioxidants were able to reduce the formation of oxidation products compared to standard films without antioxidants. Lower lipid oxidation. The combined effect of oxygen barrier action and specific antioxidant activity of beeswax-based composite film (lipid oxidation was inhibited and could be stored for 7 days at 40 °C). | Bermúdez-Oria et al. (2019) |

| Sea bass (Dicentrarchus labrax) fillets | A combination of liquid smoke and thymol encapsulated in chitosan nanofibers | Delays the total growth of mesophilic aerobic bacteria, psychrophilic bacteria, as well as yeasts and molds throughout the storage period | Ceylan et al. (2018) |

Table 5 presents several examples of how edible food packaging has been used to preserve the quality and extend the shelf life of meat and seafood products. This table illustrates the practical applications of various biopolymer-based films and coatings, such as those made from chitosan, alginate, and gelatin, which have shown significant antimicrobial and antioxidant activity in preventing spoilage and degradation. While the data in this table comes from previous studies, our contribution lies in expanding on this information by discussing how PHA-based packaging offers a sustainable, scalable solution that can address the limitations of traditional edible coatings in the meat and seafood industry.

Edible coatings for meat and seafood, such as those made from collagen, chitosan, and pectin, have been proven to reduce microbial growth, inhibit lipid oxidation, and improve moisture retention, thereby extending product shelf life (Pandhi et al., 2019, Salmieri et al., 2014). For example, chitosan-based coatings have demonstrated strong antimicrobial effects against pathogens like Listeria monocytogenes and Staphylococcus aureus, which are common in meat products (Guo et al., 2014). However, these edible coatings often face limitations in terms of scalability and industrial applicability, as they require direct application to the product surface, which may not be feasible in large-scale food production (Pabast et al., 2018).

PHA-based films, in contrast, offer several advantages for large-scale meat and seafood packaging. PHA is biodegradable, compostable, and can be processed into rigid or flexible films using conventional plastic-forming techniques, making it suitable for automated packaging systems (Shankar et al., 2021). This is particularly important in the meat and seafood industry, where packaging must not only preserve product quality but also meet high standards for food safety and shelf life extension. Unlike traditional edible coatings, PHA films can incorporate antimicrobial agents such as essential oils or plant extracts directly into the packaging material, providing continuous protection against microbial contamination throughout the storage and distribution process (Kumar et al., 2010).

Maintaining the moisture balance and preventing oxidation are two of the most critical factors in preserving the quality of meat and seafood products. Edible coatings like those made from Na-alginate, chitosan, and collagen have demonstrated effectiveness in preventing moisture loss and minimizing lipid oxidation, thereby extending the shelf life of products like sliced ham, shrimp, and lamb meat (Arancibia et al., 2014, Pandhi et al., 2019). For example, collagen films have been used on muscle foods to reduce lipid oxidation and prevent discoloration (Pandhi et al., 2019). Similarly, chitosan coatings with nano-encapsulated essential oils were shown to enhance the sensory attributes of lamb meat while inhibiting microbial growth (Pabast et al., 2018).

However, while these coatings work effectively on a small scale, PHA-based films provide a more robust solution for industrial-scale packaging. PHA films can be engineered to have superior barrier properties, including moisture resistance and oxygen permeability, making them ideal for preventing lipid oxidation and rancidity in meat and seafood products. Additionally, PHA films can be designed to offer controlled release of antimicrobial agents like essential oils, providing long-term protection against spoilage microorganisms (Shankar et al., 2021). This continuous antimicrobial activity helps maintain the freshness of products like beef, pork, and turkey, while preventing oxidation and microbial growth (Xiong et al., 2020, Xiong et al., 2020).

One of the key advantages of edible coatings highlighted in Table 5 is their ability to act as carriers for antimicrobial agents, such as oregano essential oil and nisin, which have proven effective in inhibiting pathogens like Listeria monocytogenes and Staphylococcus aureus (Guo et al., 2014, Salmieri et al., 2014). However, these coatings often require manual application or surface contact, limiting their scalability for industrial use.

PHA-based packaging can overcome these limitations by integrating antimicrobial agents directly into the packaging material during production. For example, PHA films with embedded essential oils or nanoparticles could provide continuous antimicrobial activity, reducing the need for additional treatments or preservatives. Studies have shown that combining antimicrobial agents like grapefruit seed extract or oregano oil with PHA films can effectively extend the shelf life of pork, turkey, and seafood by inhibiting microbial growth and slowing down oxidation (Guo et al., 2014, Xiong et al., 2020).

By using PHA packaging, manufacturers can achieve the dual benefits of enhanced food safety and environmental sustainability. PHA’s biodegradable nature ensures that these packaging materials can be safely disposed of or composted after use, reducing the environmental impact associated with conventional plastic packaging.

As concerns about plastic pollution and sustainability continue to grow, there is increasing pressure on the food packaging industry to adopt eco-friendly alternatives. Traditional edible coatings, while biodegradable, often come with limitations in terms of cost and scalability (Abreu et al., 2012). In contrast, PHA offers a more sustainable solution by being fully biodegradable and compostable in natural environments. Additionally, PHA can be produced from renewable resources like food waste and agricultural by-products, further reducing its environmental footprint (Kumar et al., 2010).

The meat and seafood industries, which rely heavily on packaging to preserve product freshness and prevent contamination, stand to benefit significantly from the adoption of PHA-based films. By replacing petroleum-based plastics with PHA, these industries can reduce their reliance on non-renewable resources and contribute to the reduction of plastic waste in both land and marine environments (Yb and Kola, 2019).

3.2.2. Fresh food

Fresh produce, including vegetables and fruits, undergoes significant transpiration and respiration, leading to weight loss, sensory quality decline, and microbial contamination. Biodegradable film packaging offers a potential solution by modifying the package atmosphere to accommodate product respiration while minimizing condensation (Shankar et al., 2021). Biopolymers such as polysaccharides, proteins, and PLA can be engineered to create packaging with effective gas and moisture barrier properties. This enables the preservation of crucial quality attributes, including texture, color, flavor, and nutrient content, in fresh fruits and vegetables. Notably, these materials are fully biodegradable upon disposal, minimizing environmental impact (Kumar et al., 2010, Rhim, 2013, Siracusa et al., 2008). The utilization of biodegradable packaging materials for fresh produce aligns with sustainable agricultural practices and contributes to the reduction of plastic waste and environmental pollution (Jafarzadeh et al., 2024).

Edible packaging applied to fresh fruits or vegetables can effectively regulate gas permeability, particularly oxygen diffusion, thereby retarding the ripening process. This extended product freshness and visual appeal by acting as a barrier to gas exchange and preventing the absorption of unwanted odors. Furthermore, edible packaging maintains product moisture, adheres well due to its hydrophilic nature, prevents off-flavor development, enhances visual appearance through a glossy finish, preserves fruit firmness, reduces weight loss, and minimizes liquid leakage (Monteiro Fritz et al., 2019, Rudra et al., 2020, Yousuf and Qadri, 2020). Various food packaging applications for fruits and vegetables are summarized in Table 6.

Table 6.

Applications of edible food packaging from fruits and vegetables (Petkoska et al., 2021).

| Food product | Edible materials | Beneficial effect | References |

|---|---|---|---|

| Cherry tomato | Edible film incorporated with chitosan and liposome encapsulation of Artemisia annua oil. Edible coating based on nanoemulsion-thymol-quinoa protein/chitosan | Inactivation of Escherichia coli O157:H7. Inhibition of Botrytis cinerea. | Cui et al., 2017, Robledo et al., 2018 |

| Tomato | Aloe vera based edible coating | Delays ripening and extends shelf life (up to 39 days compared to 19 days for control sample) | Athmaselvi et al. (2013) |

| Cucumber | Corn starch and mint (Mentha viridis L.) extract edible coating | Improved shelf life and quality stored at room temperature/low temperature (25 °C/10 °C) | Raghav and Saini (2018) |

| Brocolli (fresh cut) | Chitosan coatings with bio actives: tea tree, rosemary, pollen and propolis, pomegranate and resveratrol | Effect of Inhibition on the Survival of Escherichia coli and Listeria monocytogenes | Alvarez et al. (2013) |