Abstract

Ship recycling industries play a significant role in the economic development of South Asian countries, including Bangladesh. In the wake of entering the Hong Kong Convention (HKC) in June 2025, the industry aims to improve its overall safety standards cost-effectively. However, due to the restrictive nature of the industry, solutions based on field surveys are limited. This study successfully articulates the indigenous industry knowledge of the recycling process in Bangladesh after carefully studying the practices followed by the existing ship recycling yards in the country. Based on field surveys conducted across 18 ship recycling yards in Bangladesh, the risk patterns inherent in the ship recycling industry are studied; for example, highly hazardous tasks in the ship recycling process are found to be (i) explosion hazards during primary cutting operations at the intertidal zone, (ii) falling hazards during inspections at the outer anchorage, (iii) falling and crushing hazards during block cutting and handling heavy objects. Industry experts and scholars consider the perception of the risk pattern regarding the current practices of ship recycling activities to cover a broader perspective of this issue. The correlation of survey outcomes with actual accident cases is comparable. Finally, practical recommendations for minimising risks have been recommended, especially in high-risk workplace areas. The study adds knowledge to the existing literature by giving a clear picture of evidence-based findings for this sector and helps improve the industry's overall safety standard.

Keywords: Ship recycling, Risk patterns, Field surveys, High-risk workplace

1. Introduction

According to the United Nations Conference on Trade and Development (UNCTAD) estimation, the global commercial fleet of ships grew by 63 million DWT between January 2021 and January 2022. The international merchant fleet comprises over 55 thousand vessels with gross tonnage equal to or more than 1000 tons [1]. In recent years, the ship's average life has decreased from more than 30 years to around 25 years or less, where the operation cost becomes more significant than the revenue, and the market condition of the ships become less profitable for the ship owner [2,3]. Hence, with the growing number of merchant fleets and the decline in the average age of the ship, ship recycling has been the most effective way of reusing the vast stockpile of reusable materials from end-of-life ships; thus, the trend of recycling activities of these ships has witnessed a remarkable surge. On a global scale, thousands of ships reach their end of life, resulting in around 20 million tons of potentially recyclable materials [4]. The global demand for ship recycling will increase exponentially between 2020 and 2036 at an average rate of approximately 10 per cent annually. Current global recycling capacity is insufficient to meet this vast demand, which can be sustained by the ship recycling yards of the Indian Subcontinent (Bangladesh, India, and Pakistan) [2].

The Indian subcontinent has dominated the ship recycling market since the late 1980s [[5], [6]]. Regarding gross tonnage, approximately 82 % of the ship recycling was covered by the Indian subcontinent in 2022, where Bangladesh scrapped a total of 122 ships, having a gross tonnage of 2,927,006. In contrast, India crossed the number of recycled ships by 127 of the total gross tonnage of 2,358,150, and Pakistan has recycled 43 ships of 1,297,965 gross tonnage [7]. This region's low costs and permissive regulatory frameworks conferred unparalleled competitiveness in the global marketplace [8]. Countries having developed facilities and stringent laws regarding ship recycling operations can offer only USD 37 per light displacement ton (LDT), whereas the countries from the Indian subcontinent can offer USD 260 per light displacement ton (LDT) without compromising profit [9]. While ship recycling yard proprietors in these countries can generate profits by offering substantial sums to ship owners, the toll on the environment and workers in this industry is overwhelming. In the developing nations of Asia, the ship recycling industry primarily relies on labour-intensive methods. Medical expenses borne by the labourers due to working in a low mechanised accident-prone environment, along with the external cost arising from the clean-up of the coastal environment, are not reflected in the market price of a ship [10]. Developed nations are duty-bound to adhere to the tenets of the “the polluter pays” principle when disassembling their vessels [11]. This matter has been deemed a paramount concern for worldwide governance.

Therefore, the global concern for safety and risk management in the ship recycling industries is significant. Researchers have recently attempted to address the issues from health, safety and environmental protection perspectives. Ozturkoglu et al. [12] introduced a sustainable risk management model to improve safety and environmental practices throughout the ship dismantling. Soner et al. [13] presented a fuzzy Best-Worst Method (BWM) to prioritise environmental risks, highlighting the need for better regulation and pollution management. Sezer et al. [14] took a holistic approach by combining Dempster-Shafer's evidential theory and Failure Mode, Effects, and Criticality Analysis (FMECA) to assess ship recycling hazards, focusing on human and ecological risks. Together, these studies emphasise the importance of sustainable, comprehensive frameworks for mitigating the environmental and safety challenges in ship recycling.

In addition, many international organisations and associations have been working for a long time to improve health, safety, and environmental pollution during large-scale dismantling operations [15]. To recognise the need for improving the process and to manage the increasing volume of vessels centred in Pakistan, India, Bangladesh, and China, the Technical Working Group of the Basel Convention provided guidelines to address insufficiencies of ship dismantling practices in 2002 [16]. In the very next year, the International Labour Organisation (ILO) provided the guidelines to assist shipbreakers and competent authorities in implementing the relevant provisions of ILO standards, codes of practice, and other policies on occupational safety and health and working conditions [17]. In the same year, the IMO came up with IMO Guidelines on Ship Recycling, but the revolutionary step taken by IMO was the adaptation of The Hong Kong Convention (HKC) in 2009. HKC specifies regulations and shares responsibilities with all stakeholders during different stages of the life of a ship: design, manufacturing, operation, recycling preparation, and demolition [18]. Since the HKC could not produce any significant impact on improving the conditions of the recycling yards, predominantly South Asian Recycling yards, due to its inherent limitations, European Union Ship Recycling Regulation (SRR) was adopted in 2013 to reduce dumping of toxic substances in developing nations to prevent their negative impact on the environment and human beings [19]. Although HKC had to wait a long time for the fulfilment of its three specific conditions by member states to become effective, the positive development is that Bangladesh ratified the Convention along with Liberia in June 2023. Therefore, this paved the way for HKC to fulfil all required conditions for it to become effective, and hence, HKC will enter into force in June 2025.

Seventy-five per cent of the Indian ship recycling yards have been certified under HKC compliance. In contrast, in Bangladesh, only four yards have been certified as green ship recycling yards of the 50 operational yards [20]. Though Bangladesh is currently leading in this business, being in good competition with India, if the situation does not improve from the occupational health and safety and environmental compliance perspective, it will lose its current market in the global platform due to the lack of green ship recycling yards. This industry is one of the significant prospective sectors to maintain a circular economy cycle for a developing country. Such a potential downturn will have adverse effects, presenting challenging times ahead [21].

In Bangladesh, the ship recycling industry satisfies approximately sixty per cent of the domestic needs for 5 million tons of steel. Also, it is a direct earning source for 50,000 individuals living below the poverty line. A significant yearly revenue comes from this industry's tax counting [22]. As a developing nation, seeking alternatives to the ship recycling industry is challenging and economically burdensome for Bangladesh. Historically, shipbreaking activities started four decades ago. The advancement of the yards started after the government of Bangladesh declared this sector an industry and framed the regulations known as the Ship Breaking and Ship Recycling Rules 2011 [23]. The government also passed the Ship Recycling Act 2018 [24], and the recent ratification of HKC will put extra pressure on ship recycling yard owners to upgrade their industry by June 2025. Hiremath et al. [25] emphasised the need to understand the prevailing “know-how” of the ship dismantling sector. A clear understanding of the steps and processes involved in ship dismantling and recycling is needed to upgrade the industry. This will help improve the process conditions and generate valuable information for reducing risks to humans and the surrounding environment.

The literature review suggests that few studies describe the in-depth “know-how” of ship dismantling and recycling in Bangladeshi yards. For example, Pasha et al. [26] described the ship-breaking process in Bangladesh in a more generic way; Rahman et al. [27] described the process flow diagram of secondary rebar production from ship recycling. Sujauddin et al. [28] gave an overview of the beaching method without elaborating on the ship recycling process. On the other hand, Choi et al. [4] described a simplified process flow of standard and substandard ship recycling methods without elaboration. They referred to beaching as the substandard method, the most prevalent method used in South Asian Countries, including India, Bangladesh, and Pakistan. It is a prevalent notion that there are many similarities among beaching methods practised by India, Bangladesh, and Pakistan. However, due to different geographical locations, the detailed ship recycling process (beaching) is different in South Asia from one another. For example, the existing ship recycling industry at Alang of India uses the natural energy of tidal motion combined with some unique geographical and coastal conditions, e.g., a slope of 10 degrees of sandy beach and the relatively quiet ocean [25] and the process flow of ship recycling yards practised by Indian yards are depicted here. On the contrary, Ship-breaking yards in Bangladesh clustered at the Sitakunda–Bhatiyari coast near Chittagong have relatively flat slopes and must follow some unique features different from Indian yards. Hence, a detailed process flow of this indigenous ship recycling knowledge of Bangladesh is essential to document and comprehend.

Furthermore, the ship recycling industry, particularly in Bangladesh and South Asia, has been criticised for its unsafe working conditions and environmental practices for a long time. Many significant accidents occur due to the absence of safety precautions, including measurement devices, safety suites, ventilation, etc., while workers work in a confined space inside the ships. Also, inadequate gas freeing and monitoring techniques sometimes create major fire threats while cutting plates from cargo ships. Minor mishaps like brushing, broken bones from moving heavy metals, and cuts from sharp edges frequently happen on occasion in shipbreaking yards. In the shipbreaking industry in Bangladesh, neglecting first aid, emergency exits, emergency response, and rescue is also widespread. The prime accidental cause is the explosion of leftover gas and fumes in the tanks, and falling from high heights is also one of the significant accidents [22]. Over the past decade, several workshops, international conferences, and seminars have raised the impoverished health and safety issues persistent in the ship recycling facilities of South Asia, particularly Bangladesh. Since then, there has been growing awareness across the community and pressure on the industry to improve the safety and environmental soundness of ship recycling [29] to satisfy the requirements and expectations of various ship recycling stakeholders.

Zhou et al. [30] found that workers' safety is directly decided by dismantling operation safety and indirectly decided by ship recycling management, ship recycling equipment, hazardous materials, and workers' safety awareness. Although the study was carried out in the context of China, the authors opined that the findings could also be adapted or used in the ship recycling industry in other countries/regions since the workers’ safety is a common concern by the governments, ship recycling companies and policymakers around the world. Tanha et al. [31] described that occupational injuries and fatalities in shipbreaking can be preventable, and workplace injuries and deaths depend on the understanding of worker safety. Major injuries and fatalities at work are not the fault of the worker; instead, they are the combination of unsafe work environments, insufficient safety training, and negligible employee supervision. It is well understood that for systematic management to ensure occupational safety during ship recycling, it is necessary to know the pattern of the risks involved in each step of the ship recycling process in Bangladesh. Hossain et al. [32] identified the common hazards that are likely to cause work-related injuries and death, ill health, diseases, and incidents among ship-breaking workers in Bangladesh. They concluded that scientific research methodologies needed to be adopted in the ship-breaking industries to monitor the impact of ship-breaking processes on the environment. Uddin and Islam [33] categorised the hazards and their causes or mechanisms for ship recycling workers in Sitakundo and Vatiary, Chattogram. Ahamad et al. [34], concluded that although ship-breaking workers are among the most vulnerable communities in Bangladesh due to frequent accidents and occupational health hazards, many workers from Bhatiari rely on the ship-breaking industry to maintain their livelihood. Worker safety is jeopardised due to inadequate safety measures and proper planning. However, no literature elaborates on the risks involved in each step of the ship recycling process in Bangladesh.

Dey et al. [35] concluded that research in this sector has tripled from 2001 to 2010 to 2011–2020, but the technology and management-based study percentage is only 14.7 % and 4.5 %. The percentage of the study relevant to social aspects is 24.1, where they have included some of the work discussing worker's health issues under the social elements, but the number is very few. Perhaps this is due to the restrictive nature of the shipbreaking industry in Bangladesh; hence, entering a shipyard to collect data in person is extremely difficult. So, knowledge about dismantling a ship from the beginning to the end and maintaining health and safety regulations is scarce. Also, neither are survey-based findings available to recognise the risks involved in each step of ship recycling processes practised uniquely in this part of the world nor is there any consensus-based risk mitigation proposal available in the literature. As a result, developing a survey-based study to improve health and safety for the ship recycling industries in Bangladesh is urgently required, especially after Bangladesh ratifies the HKC Convention.

This paper stands unique and different from the research works (mentioned above) in that it presents the Indigenous Knowledge of the ship recycling process in Bangladesh in an elaborate form that documents first-hand knowledge directly from the workers (over one thousand respondent workers from eighteen ship recycling yards participated in the survey). Hence, under the survey, two specific aims are set in this paper. The first aim is to comprehend the process of ship recycling in Bangladesh from primary data and identify the prevailing high-risk zones of Bangladesh's ship recycling industry based on detailed process analysis and to depict the industry's risk pattern based on the outcome of the first round of the survey. Furthermore, the second aim is to provide a quantified analysis of potential solutions for the high-risk jobs in this industry. Thus, this paper is structured as follows: Section 1 presents an introduction and literature review; Section 2 describes the methodologies applied in this study; Section 3 presents the indigenous ship recycling process in Bangladesh; Section 4 shows the obtained results and discussions; and finally, Section 5 concludes the findings.

2. Methodology

2.1. Research design

The present study commenced by conducting an in-depth investigation of the current ship recycling process utilised in the ship recycling yards. To achieve this objective, the research team examined available documents provided by the yard authorities and the Ministry of Industries (MoI) of Bangladesh, conducted multiple interviews with the personnel from the ship recycling yards, and performed a comprehensive literature review. As a result of this effort, a flowchart of the ship recycling process in Bangladesh was produced. The present research is also designed to delineate the risk patterns inherent in the ship recycling industry in Bangladesh and put forward cost-effective recommendations for minimising risks in high-risk workplace areas. The suggestions are formulated based on the feedback obtained from industry experts and scholars based on current practices.

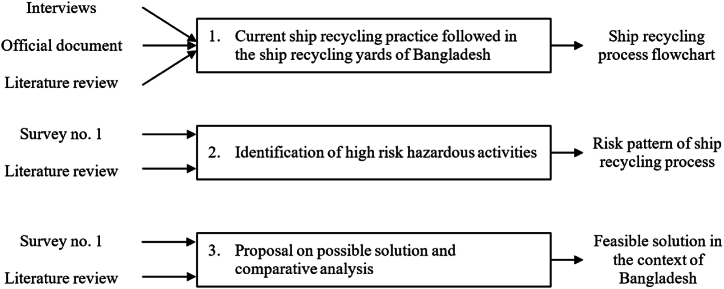

A step-based questionnaire was developed to identify the loopholes in the process that are responsible for the casualties occurring in the ship recycling yards. Using the risk patterns acquired from the survey, the research team then created another questionnaire that included reasoning, probable accident scenarios, and alternative solutions based on the literature review. The team collected responses from industry professionals in various sectors and stages inside the ship recycling yards to determine the most feasible solution. It should be noted that the analysis procedure used in this study was carefully designed to ensure that a knowledge base will be established based on existing ship recycling safety standards and practices. A simple workflow diagram of the progression of this research work is shown in Fig. 1.

Fig. 1.

Workflow diagram.

2.2. Sample description

As mentioned earlier, the ship recycling process discussed in section 3 has been studied by examining documents, conducting multiple interview sessions with the personnel from the ship recycling yards of Bangladesh and performing available literature reviews. The data used in this paper for hazard identification, risk evaluation, and finding a feasible solution have been collected through extensive field surveys and brainstorming sessions from participants of workshops.

After completing the ship recycling process flowchart, potential hazards with varying levels of severity were identified and recorded. Table 1 presents the most common hazards categorised by severity based on a thorough literature review. For each hazard, based on their severity and frequency of occurrence, a questionnaire consisting of 114 questions was developed and administered to individuals directly involved in fieldwork. The questionnaire underwent a pre-test phase involving academic and industrial experts working in this field for the past 5–10 years. Following revisions, the final version of the questionnaire contained 50 questions explicitly addressing the risk levels of the identified hazards.

Table 1.

List of potential hazards.

| Low | Nausea, vertigo, headache, skin infection |

| Medium | Fractures, cuts and bruises, loss of breathing, immune system disorder, muscle strain |

| High | Broken bones, amputation, slow poisoning, asbestosis, lung cancer, mesothelioma, respiratory diseases, cancer, liver diseases, neurological disorder, radiation sickness, reproduction system disorder, heart-related disease, kidney-related disease, hearing loss, carcinogenic diseases, anaemia, concussion |

| Undefined | Burn injuries |

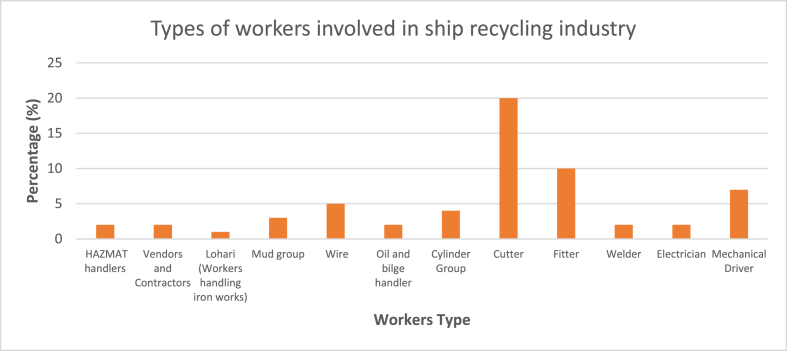

With the help of the Ministry of Industries (MoI) of Govt. of the People's Republic of Bangladesh and the Bangladesh Ship Breakers and Recyclers Association (BSBRA), a survey was conducted for three months (August 2022 to October 2022) to collect responses from workers involved in ship recycling activities. One thousand seventy-four workers (1074) of different types from eighteen (18) ship recycling yards in Bangladesh actively participated in the survey, offering valuable insights and perspectives. Fig. 2 provides a graphical representation illustrating the distribution of workers across various segments of the ship recycling process in Bangladesh.

Fig. 2.

Percentage of workers engaged in each category of work.

In addition to the participation of industry workers, the survey also included contributions from academic researchers actively studying this field. This broader inclusion of participants from both industry and academia ensures a more comprehensive and balanced representation of perspectives regarding the ship recycling industry. The survey also received responses from 8 individuals from both local and international arenas, further enriching the diversity of insights gathered.

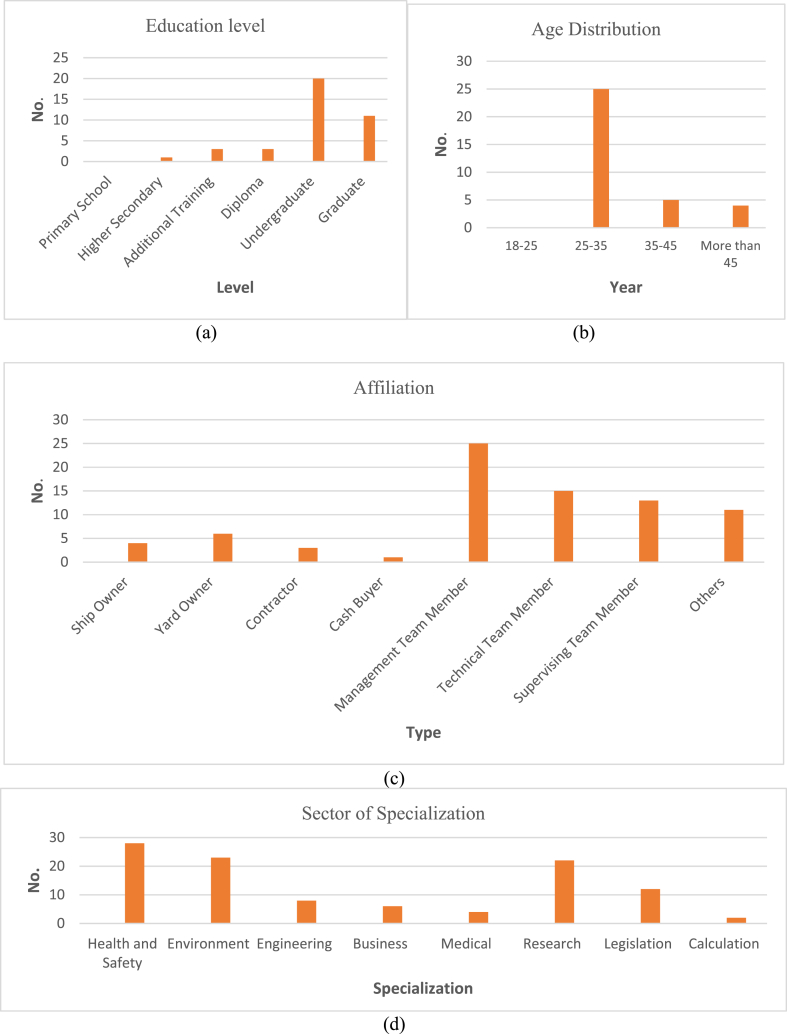

A subsequent questionnaire was developed based on the survey findings by considering the most potential hazard scenarios. A workshop was organised near the location of ship recycling yards at Chattogram on March 2023 to gather responses for this questionnaire; 52 participants attended, and 36 participants participated in the survey. The workshop attendees participated in the survey, which primarily consisted of individuals from ship recycling yards working at management and technical departments and specialising in health, safety, and environment within the age of 25–35 years. Representatives from various stakeholders, such as Surveyors from Classification Societies and members from ship recycling associations, safety agencies, and government agencies, also attended the workshop. Fig. 3 provides an overview of the backgrounds of the workshop participants who participated in the survey.

Fig. 3.

Survey participant's details: (a) Education level, (b) Age distribution, (c) Affiliation, and (d) Sector of specialisation.

2.3. Hazard identification

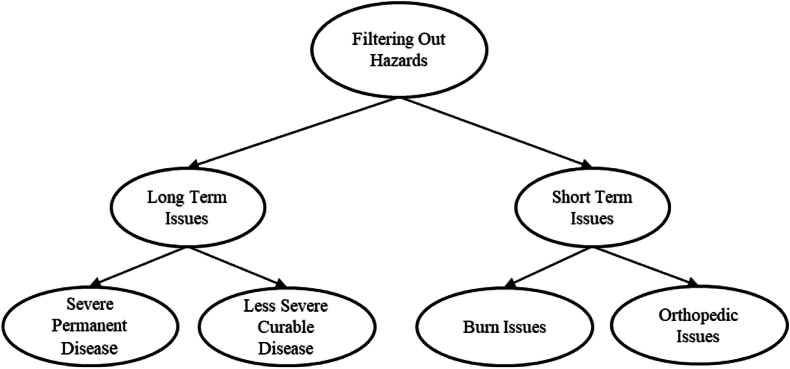

A ship recycling yard generally consists of 12 categories of workers who are directly engaged in the field job, as presented earlier in Fig. 3. In addition, other human resources are engaged in the overall process and perform the crucial portions of the administrative tasks. The identification of hazards in this research includes all of them. The survey performed for data acquisition for hazard identification purposes was based on the questionnaire acquired from the interview sessions following the ship recycling flowchart and previously published research articles. The structure of the survey questionnaire is shown in Fig. 4. The hazards have been initially divided into two parts: long-term and short-term. Hazards responsible for health issues that cause temporary work loss and no immediate visual disturbance to the worker's health and the workplace are considered long-term issues. Though these issues do not cause any immediate visible disruption, some can be as severe as they can lead to death. This type of serious health issue is mainly the result of direct exposure to hazardous substances from obsolete vessels. In Table 2, these toxic substances have been listed. Hazardous materials, four of them: Asbestos, Polychlorinated Biphenyl (PCB), Ozone Depleting Substances (ODS), and Tributyltin (TBT), are the primary concerns for workers [36]. Table 3 represents long-term issues associated with hazards. Different codes separately address each scenario causing respective diseases. The first row of hazards shows the effects of these four toxic substances. In the second and third rows, the less severe phenomenon, caused mainly by waste oil and bilge water, has been represented.

Fig. 4.

Categorisation of hazards.

Table 2.

Toxic substances found during ship recycling.

| POPs | PCB, Dioxin, PVC, PAHs, Organotin |

| Asbestos | Glass Wool (Similar substance) |

| Heavy Metal | Mercury, Lead, Arsenic, Chromium |

On the contrary, the subsequent consequences of the short-term issues are easily discernible, leading to immediate disruptions in the workplace, the duration of which depends on the severity of the incident. It is to be mentioned here that different environmental groups and Non-Governmental Organisations (NGOs), both inside and outside Bangladesh, show significant concerns for this specific industry due to these short-term issues. For this research, these problems have been categorised into two parts. The first involves fire-related risks leading to burn injuries, while the second pertains to orthopaedic issues primarily caused by mismanaged work processes. Both types of issues are grave, and a single incident of this nature can result in multiple casualties. In Table 4, probable scenarios in different steps of the ship recycling process that can lead to fire hazards of varying degrees of severity have been shown, and each of these has been addressed by code. Table 5 provides an overview of orthopaedic issues of varying severity, highlighting probable scenarios that can occur at different stages of the process. It is to be noted that Tables 3–5 are presented in the supplementary information section at the end of this paper.

2.4. Risk evaluation method

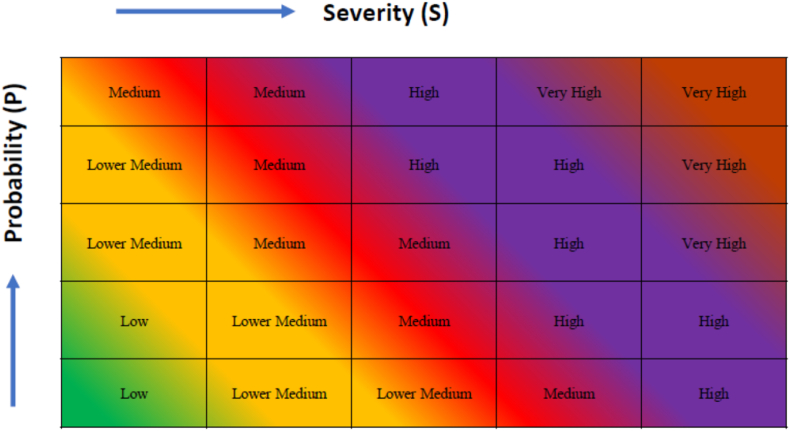

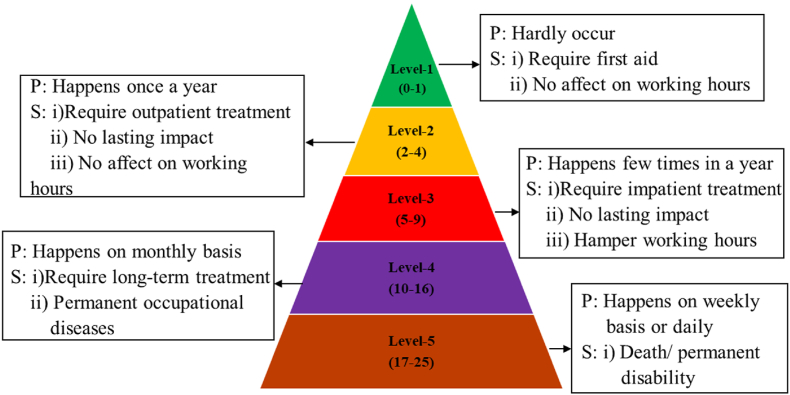

The probable scenarios for each type of hazard, as shown in Tables 3–5 given in the supplementary information section at the end of this paper, have been quantified based on respective severity and frequency of occurrence and presented through risk matrices. According to the method by Garvey and Lansdowne [37], an event's risk level is the occurrence frequency and severity multiplication. Thus, a five-by-five (5 × 5) risk matrix is generated in this process, with low-risk factors placed in the bottom-left portion and higher-risk elements progressively moved toward the upper-right section. Fig. 5 illustrates the risk matrix used in this research work. This approach is considered semi-quantitative and combines qualitative event descriptions with quantitative ranking. In this research paper, risk levels in terms of the probability and severity of an event have been segmented, and the definition of each scale has been shown in Fig. 6. The proposed risk scale has been finalised based on the discussion with the industry professionals from ship recycling and a relevant literature review [37] to depict the risks in Bangladesh's ship recycling yards.

Fig. 5.

Risk matrix format.

Fig. 6.

Risk scale definition.

2.5. Methodology for mitigation proposal

The outcome of the first survey shows the ranking of the hazardous activities of the process. Subsequently, these findings were validated by cross-referencing with real-life accident logbooks. Several brainstorming sessions addressed the hazards classified as falling within the high-risk zone to identify optimal solutions and critical factors influencing these events. Participants from the workshop then assessed the identified features and ranked them according to their priority. The collected responses were scaled from 1 to 5, and the average was calculated to yield the final result for comparative analysis.

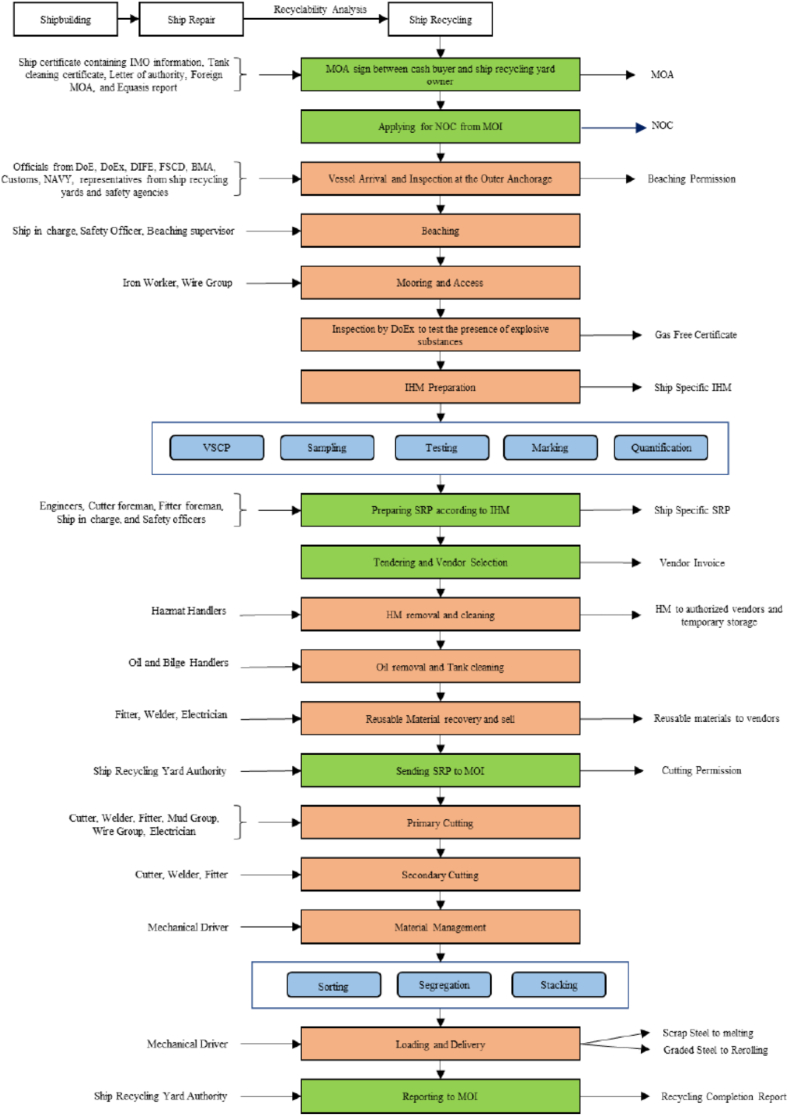

3. Ship recycling process in Bangladesh

The life of a ship is segmented into three stages. After building a new ship, its operational phase starts, where the ship needs to keep its seaworthiness by performing necessary maintenance and repair. Her working life usually ends after 20–25 years, so it comes to its graveyard for recycling purposes. Usually, a recyclability analysis of a ship is conducted considering various factors such as onboard materials, reusability potential, market price, and many others [38]. A ship that is decided to be recycled goes through many procedures. In Fig. 7, the steps of ship recycling are shown through a flowchart, the currently practised procedure in Bangladesh. Alongside the labour-intensive fieldwork, the successful execution of this ship recycling process relies on crucial administrative tasks. While the overall smoothness and safety of the process depend on the clarity of these administrative tasks, they do not involve any hazardous activities directly. In the flowchart, the administrative tasks are highlighted in green, while the field tasks are highlighted in orange. The field tasks primarily involve workers who are directly associated with potential hazards.

Fig. 7.

Ship recycling process flowchart.

3.1. Before beaching the ship at the yard

The acquisition of a ship for recycling begins with signing a Memorandum of Agreement (MoA) between the cash buyer and the ship recycling yard owner based on the required documents. Subsequently, the yard authority applies for a No-Objection Certificate (NOC) from the Ministry of Industries (MoI), and upon obtaining the NOC, an inspection is conducted when the vessel arrives at the outer anchorage. The inspection team consists of representatives from the Ministry of Industries (MoI), Department of Environment (DoE), Department of Explosive (DoEx), Department of Inspection for Factories and Establishment (DIFE), Fire Service and Civil Defence (FSCD), Bangladesh Marine Academy (BMA), Bangladesh Customs, Bangladesh Navy, Ship Recycling Yard and Safety Agencies. Afterwards, in the presence of the ship-in-charge, the beaching supervisor, and the safety officer, the ship is beached near the yard, and workers from the wire and iron group secure the vessel and ensure its stability for further activities. Next, representatives from the Department of Explosives (DoEx) perform another inspection to detect any traces of explosive substances. Upon completion of this inspection, they grant a gas-free certificate.

3.2. Hazardous material identification, removal, and cleaning

After obtaining the gas-free certificate, a team of representatives from the safety agencies and hazmat handlers conduct a six-segment-based step to produce a ship-specific inventory of hazardous materials (IHM) to trace, mark, and quantify them. This inventory is used to prepare the ship recycling plan (SRP). Later, the yard authority initiates the tendering process for disposing and selling the resalable, approved hazardous, and reusable materials. Till these points, all these steps are done sequentially, but as the process moves forward, individuals work in parallel, and, in most cases, workers deal with hazardous tasks. The hazmat handlers work on the removal and cleaning of the hazardous material. This step of ship recycling is dangerous as it can cause different diseases due to exposure to many hazardous elements. More details regarding the disposal of these hazardous materials can be found in the research paper of Mehtaj et al. [39]. After removing the hazardous materials, oil and bilge are also removed, and the cargo tank cleaning process starts after recovering oil inside the tank. The oil removal process depends on the amount of pumpable and un-pumpable oil, which is generally assessed by visual inspection. Since there is a probability of explosive gases being present inside the cargo tank, gas analysis is initially conducted by a safety officer and his team. If it is possible to unscrew the tanks, they are kept open for gas dissipation. Ironworkers create holes via cold work to open the tanks. Then, at least two multi-gas meters are used to trace toxic/explosive/harmful gas availability. Pumps are lowered to the tanks via the tank holes to ensure suction for pumping out the oil to drums or barrels or directly to the yards. Unpumpable oil is collected using barrels or drums and then transferred with the help of a rubber nylon belt on a trolley or conveyor. When all the oil is transferred, the tanks are cleaned using wood powder and sand. The remaining sludge is mixed with water and separated using oily-water separators. In a few cases, sludge is also sold in drums. Besides removing hazardous material, these oil and bilge removal parts may carry many substances harmful to the workers.

3.3. Selling of reusable materials

A group of fitters, welders, and electricians work on recovering and selling the reusable materials according to the vendor's invoice. If the internal workers are insufficient, contractors come with the equipment and workers to transfer the items accordingly. The process is documented, including detailed specifications of all reusable and resalable items categorised as ferrous and non-ferrous materials, outfitting and furniture, electrical items, machinery, equipment, kitchen items, etc. Upon completion or near the end of these steps, the ship recycling yard authority sends the recycling plan to the MoI to approve cutting permission.

3.4. Cutting process

Upon getting the cutting permission, a team comprising the cutter, welder, fitter, mud group, wire group, and electrician initiates the cutting procedures. It takes one to two weeks to complete the intermediate steps from beaching to the start of the cutting procedure. The first phase of cutting is termed primary cutting, the most vital step in recycling a ship in Bangladesh. It takes place in the intertidal zone. In the case of primary cutting, two cutting procedures are practised. During primary cutting, the entire ship is divided into three units, the fore part, middle part, and aft part, respectively, if the cargo hold is not present. The cutting starts from the fore section of the ship, and to balance the weights, similarly, blocks are cut on the aft section of the ship. At the front and aft sections, when cutting starts, gradually, access is created within the ship for the passage of workers, and at the very end, the engine room section is finally cut. Another approach to primary cutting is starting the cutting in safe areas, according to the IHM. Gradually, the cutting proceeds over the risky areas, according to the Ship Recycling Plan (SRP).

Fire pumps are set when cutting across risky areas, spraying water, and activating the blower. Blocks are cut according to the capacity of winches. Cutters and fitters work together to disorient and cut the blocks. Throughout the process, welders make gateways, access, or temporary structures to make the block-cutting process easy and efficient. Also, electricians are present throughout the process to disconnect and disorient electrical machinery, as a ship carries a significant amount of electrical machinery. The blocks decided to be cut are cleaned before being dropped by the mud cleaner group so that the blocks dropped on the intertidal zone are not dirty. After these blocks are landed at the inter-tidal zones, the wire group helps to pull them towards the shores and secondary cutting zone within the yard premise as close as possible. These large blocks are towed toward the yard area using winches. Sometimes, oily blocks are carried from the intertidal zone to the yard using a mounted barge.

In the secondary cutting zone of the yard, the large-sized ship blocks are segregated into smaller metal slices. The secondary cutting zone is on the inward side of the yard premises. In most ship recycling yards, the blocks are transferred from onshore to the secondary cutting zone via crawler cranes. Cutter, welder, and fitter groups work together in this section. Once the ship blocks are dissected into smaller slices, the yard authority decides whether they will go for tertiary cutting as per the requirement of local scrap vendors or directly sell the secondary cut metal or scrap items. During tertiary cutting, the medium- and small-sized metal pieces are further cut to make plates as per thickness, such as 8 mm, 10 mm, 12 mm, and 16 mm. These sizes are produced as they are in good demand within the scrap market and secondary rebar industry. Thus, the primary blocks are now cut into medium-sized and small-sized metal parts and eventually divided further into fine-cut or smooth-finished metal plates of a certain thickness per the market demand.

3.5. Material management

Once the cutting activities are adequately done and secondary or tertiary cut metal parts and plates have been produced, the material management process begins. This procedure is completed following three segments. The materials are mostly sorted and segmented following the division of material streams [40]. Pick-and-carry or crawler cranes are used while moving the materials inside the yard. In the case of ferrous elements, magnetic cranes are also used. Mechanical drivers of the yards play the most significant roles in this phase. Based on the demand of the vendors, the stacked materials are then loaded and delivered. The scrap steels are sent to the melting shops, and graded steels are sent to the rerolling mills. Upon the completion of the delivery, a report is made by the yard authority to submit and notify the MoI about the accomplishment of the recycling of the specific ship.

4. Results and discussions

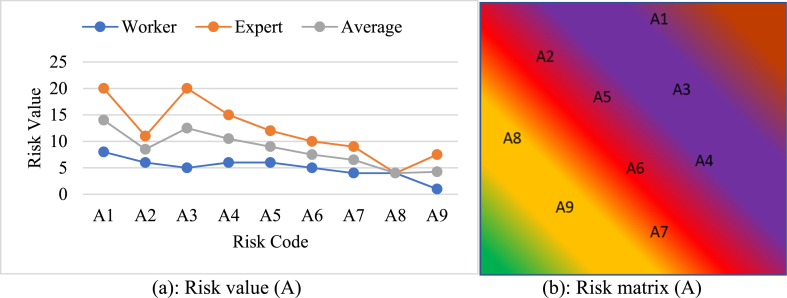

4.1. Risk evaluation: long-term issues

In this work, specific tasks (as per Table 3) have been identified and labelled A1 to A9, which pose significant long-term risks and can lead to severe health issues. The risk assessments conducted by experts and field workers have revealed a substantial discrepancy, as illustrated in Fig. 8(a). Workers often lack awareness about these issues because the symptoms do not manifest immediately; instead, they develop over a prolonged period. However, experts are well-informed about these risks, so the risk values obtained from their surveys are considerably higher. The primary cause of these health problems is the workers' exposure to hazardous materials at various stages of the ship recycling process, as shown in Table 2. Asbestos is particularly concerning and associated with three highly debilitating diseases: lung cancer, asbestosis, and mesothelioma. Fig. 8(b) indicates that lung cancer and mesothelioma are in the high-risk zone. It is important to note that these two issues are classified as high-risk not because of their frequency of occurrence but due to their severity. Doll's [41] extensive study highlighted the elevated mortality rate among asbestos-exposed workers due to lung cancer.

Fig. 8.

(a): Risk value (A) Fig. 8(b): Risk matrix (A).

Similarly, a separate study on the mortality rates from mesothelioma among workers dealing with asbestos revealed that many workers exceed the permissible asbestos exposure limit established by the Occupational Safety and Health Administration (OSHA). In most cases, the devastating consequences of mesothelioma become apparent during the workers’ later years [42]. Asbestosis, another medical condition that can lead to lung cancer and heart failure, is also the result of asbestos exposure [43]. Experts consider this disease less severe as it is a middle condition to lung cancer and is curable. Workers are unaware of this disease, resulting in its classification in the medium-risk zone, as seen in Fig. 8(b).

Following asbestos, another perilous substance commonly found in obsolete ships’ electrical cables and painted surfaces is PCB (Polychlorinated Biphenyl) [44]. The most significant exposure to PCB occurs through inhalation or absorption via the skin, resulting in liver cancer and a specific type of dermal cancer known as Melanoma [45]. According to the survey data, liver cancer caused by PCB is classified as a high-risk disease that can lead to fatality. On the other hand, Melanoma, which is one of the most hazardous forms of skin cancer, falls within the medium-risk zone as it is curable with appropriate treatment. In Fig. 8(b)–A4 represents the designation for liver cancer resulting from PCB exposure, while A5 pertains to Melanoma.

Moreover, the impact of ozone-depleting substances (ODS) on various ocular diseases is denoted by code A5 [46]. Another significant occupational and environmental pollutant of note is Tributyltin (TBT), which is primarily responsible for developing malignant tumours that ultimately lead to liver cancer [47]. Code A6 has assigned this particular concern. Both A5 and A6 have been categorised as medium-risk health issues, given that they are curable and the rarity of causing permanent disabilities.

Initial symptoms of these aforementioned acute diseases often include nausea, vertigo, fever, cough, headaches, and more. These symptoms are captured by the code A7. Experts and workers agree that these issues are relatively common among workers, and they barely cause significant loss of working hours and typically require only basic first aid. Consequently, they fall within the low-medium risk zone. However, over time, these initial side effects may develop into serious health problems, impacting multiple organ systems, such as the neurological, respiratory, and reproductive systems. These intermediate disorders are identified by the code A9, which also falls within the low-medium risk zone. It is worth noting that while workers tend to overlook these specific issues, experts possess a certain level of awareness regarding these matters.

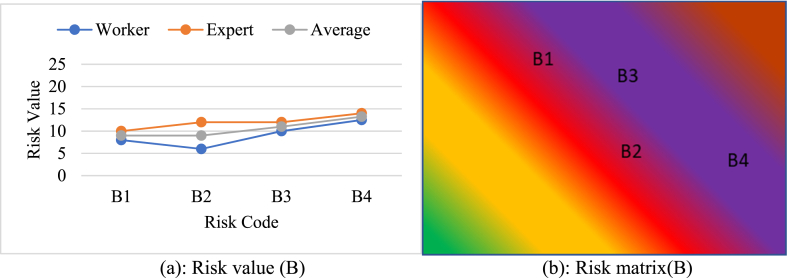

Workers get the highest exposure to hazardous materials from the initiation of making the inventory of hazardous materials to their disposal. Nevertheless, except for these acute conditions, respiratory disease, skin disease, and eye contamination are prevalent among workers. The issues related to respiratory system disorders, such as breathing difficulties, chest pain, asthma, and many others, have been assigned to code B. This study outlines four common scenarios contributing to respiratory system-related health issues. Unlike problems assigned with code A, there is notable agreement between the risk assessments provided by workers and experts for code B, suggesting that workers may possess a good grasp of these issues or frequently encounter them. Oil removal and tank cleaning are potential segments where workers may face breathing difficulties while unscrewing the fuel tanks or transporting oil barrels without wearing PPE. These scenarios are assigned as B1 and B2, falling within the medium risk zone according to the survey data analysis presented in Fig. 9(a).

Fig. 9.

(a): Risk value (B) Fig. 9(b): Risk matrix(B).

Meanwhile, workers recovering cylinders have breathing difficulty due to the dissipation of various gases, namely Freon, LPG, and others, assigned with B3, which is more frequent and severe, thus falling into the high-risk zone. Additionally, respiratory problems arising from the toxic fumes generated during cutting are a widely discussed issue. This problem is labelled as B4 and falls into the high-risk zone category.

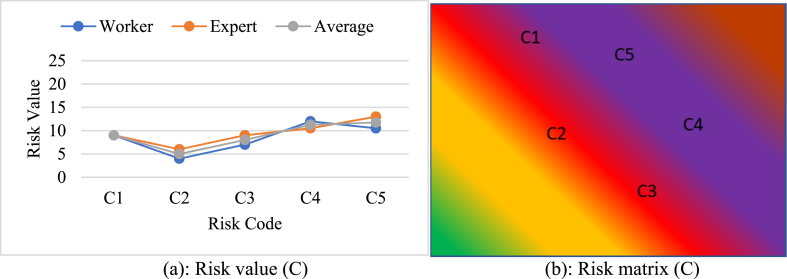

Fig. 10(a) presents an evaluation by experts and workers regarding five potential skin and eye contamination tasks, all classified under code C. The assessment reveals that the initial three issues fall within the medium-risk range, while the remaining two are positioned within the high-risk range, as shown in Fig. 10(b). Although the risk value assigned to these problems may appear relatively elevated, given that skin or eye-related concerns can often be addressed through immediate first aid or, in severe cases, necessitate short-term hospitalisation without lasting consequences, they are still predominantly considered as falling within the medium or high-risk categories due to their frequency of occurrence.

Fig. 10.

(a): Risk value (C) Fig. 10(b): Risk matrix (C).

4.2. Risk evaluation: short-term issues

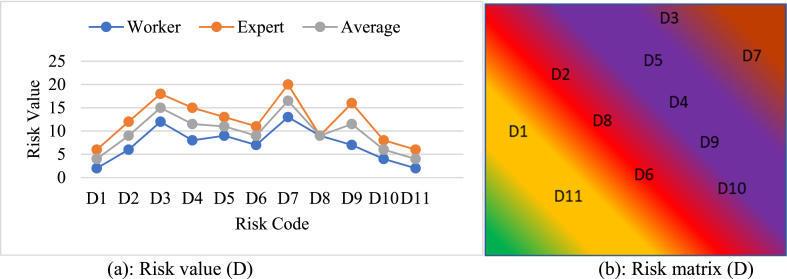

In this study, short-term issues are addressed and classified under codes D and E. Specifically, codes D1 to D11 pertain to problems associated with fire and explosions. On the other hand, codes E1 to E21 are designated for orthopaedic issues. In Table 4, probable fire-related casualties of different segments of the ship recycling process have been shown sequentially. When handling hazardous elements, the risk of burn injury may be non-existent as workers do not have to deal with fire in this segment. However, incineration is sometimes carried out, and fire accidents occur during the disposal of some hazardous materials. The probability of fire accidents while doing the incineration is relatively uncommon as the risk of this particular issue is addressed under code D1, which is in the low-medium zone. From D2 to D4, fire hazards caused during the oil removal and tank cleaning process have been discussed. The scenario indicated under code D2 of keeping the tank open for the whole night to dissipate the gas is quite common. However, any explosion resulting from this kind of activity is quite rare; if an explosion occurs, it can affect many people severely. Thus, D2 falls into the medium-risk zone. In comparison, a devastating explosion due to improper detection of gas leakage is quite common, causing D3 to fall into the high-risk zone.

Inappropriate storing of heavy oil or improper cleaning can cause significant-scale fire accidents; thus, D4 indicates that this particular issue also falls into the high-risk zone according to the survey outcome. Gas leakage-related issues can also happen during the recovery of cylinders, which have been addressed using D5. Leakage of cylinders carrying ammonia, Freon, or carbon dioxide can cause serious explosions, thus falling into the category of high-risk zone. In D6, burn injuries during welding have been addressed. These particular fire accidents relevant to welding fall into the medium category because of the low frequency of occurrence, as in the ship recycling yard, welding works are carried out only during some exceptional cases, such as the making of access ways or any temporary structure to make the cutting process smoother. The next one is the primary cutting in the enclosed space of the ship, one of the riskiest tasks. Workers carrying LPG cylinders to the enclosed space for cutting purposes may encounter severe explosions if any leakage occurs. According to experts, the severity of this particular accident can cause massive destruction. The survey data shows that the workers are unaware of the consequences of this type of accident as these are not frequent enough. However, much destruction may happen in a single case of this type of accident; thus, it falls into the high-risk zone category.

In D8, burn injuries due to faulty electrodes or torches have been addressed, which falls into the medium category in the risk scale. The perceptions of the workers and experts are found to be similar. By D9, electric shock while disconnecting the cables has been addressed. This issue is frequent and sometimes even leads to death, thus falling into the high-risk zone. However, electric shock during the cutting process conducted in the primary zone in the contact of sediment of seawater addressed by the very next code D10 falls into the medium risk zone due to the lower chance of occurrence. Finally, another issue regarding burn injuries during welding in the secondary cutting zone is addressed by code D11, which falls into the low-medium zone, as such accidents in the secondary cutting zone are rare.

Fig. 11.

(a): Risk value (D) Fig. 11(b): Risk matrix (D).

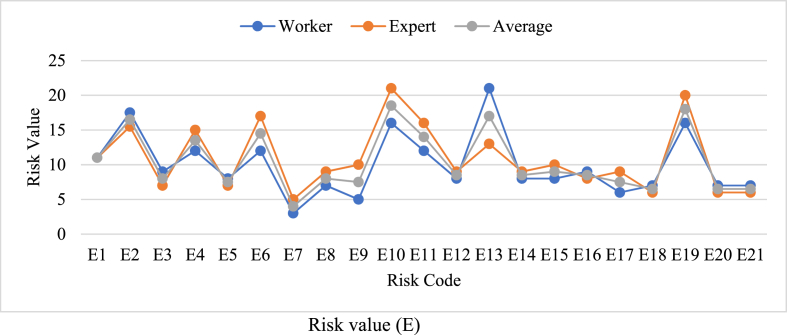

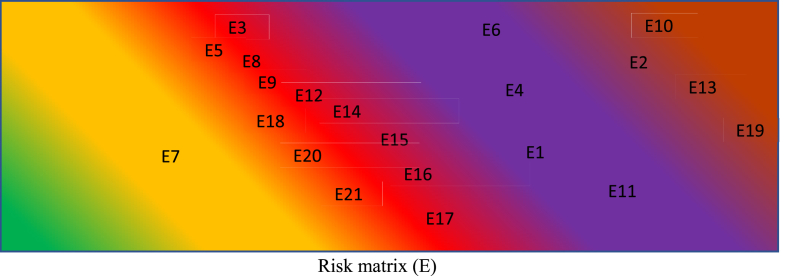

In Table 5, the risks associated with orthopaedic issues have been presented. These are matters of significant public interest. Codes E1 to E3 pertain to accidents that occur during the inspection of obsolete ships at the outer anchorage. Fig. 12(a) illustrates that expert and field-level data concur, likely due to the heightened awareness of occupational health and environmental risks among those involved in the inspection compared to individuals working in the ship recycling yard. During the making of the survey questionnaire, three risk scenarios were considered severe issues. E1 addresses accidents that occur while individuals are en route to the outer anchorage by tug or patrol boats. Both experts and those involved in the inspection agree that this particular issue falls within the high-risk zone. While such accidents are rare, they can potentially result in a significant loss of life. E2 also represents a high-risk issue involving incidents where people going for inspections have fallen from heights while accessing the ship's deck using ladders. Often, these ladders are worn out or unstable, leading to severe accidents. The issue presented by E3 relates to injuries caused by a lack of personal protective equipment (PPE) during ship inspections, predominantly resulting in cuts and bruises. This issue is categorised as falling within the medium-risk zone.

Fig. 12.

(a)Risk value (E).

(b)Risk matrix (E).

Another high-risk issue, represented by E4, pertains to accidents while beaching ships, where tow winches might be worn out or malfunctioning. Both experts and workers perceive this as a hazardous job. E5 addresses injuries during the opening of the anchor lock due to a lack of awareness, which is considered a medium-risk issue by both parties. Moving on to E6, workers cutting holes in the bow section may face various injuries, such as cuts or bruises due to the use of faulty equipment or working at heights above 3 m without proper support, which can lead to falls resulting in severe consequences like broken bones, amputations, internal organ injuries or fatalities. This issue is classified within the high-risk zone. Code E7 pertains to bruises or cuts caused by metal fragments during cold work, which falls into the low to medium-risk zone, as these accidents usually necessitate only first aid or outdoor treatment without causing any loss of working hours. Casualties during the removal of the anchor windlass, represented by code E8, fall within the medium-risk zone. Codes E9 to E15 encompass potential accident scenarios within the primary cutting zone. Before commencing cutting operations in this zone, cleaning blocks that have fallen into the intertidal area is imperative. When cleaning blocks or metal parts, metal fragments inclusion causing cuts or bruises are addressed under E9 and fall into the medium category. In this case, these accidents occur frequently but cause comparatively less harm.

E10 sheds light on one of the most alarming and well-documented hazards within the shipbreaking yards of Bangladesh, which involves workers falling from heights during block cutting due to a lack of awareness and inadequate cutting plans. Tragically, fatalities from these accidents are prevalent, making this a grave concern. Experts recognise this issue as a very high-risk problem, as the frequency and severity of such accidents are significant enough to warrant urgent attention. Code E11 addresses the issue of falling from a height, specifically during side block cutting while utilising a body harness. Although instances of falling during cutting due to the loosening of the body harness or experiencing a pendulum effect are relatively infrequent, the potential severity of such accidents remains significant. As a result, code E11 is classified as a high-risk concern. Moving to E12, it pertains to injuries such as cuts or bruises caused by worn-out or damaged cutting tools. This issue falls within the medium-level category. While such cutting-related injuries are relatively common in ship recycling yards in Bangladesh, their severity is generally minor, leading to their placement in the medium-risk level on the risk scale. Code E13 highlights one of the gravest and potentially hazardous situations occurring within the ship recycling yards of Bangladesh, where workers risk being crushed under heavy blocks or plates, primarily in the primary cutting zone. Such incidents typically arise from unplanned cutting sequences or a need for more awareness during cutting operations. Given its alarming severity and frequency, this scenario is considered a very high-risk concern.

Due to the complex structure of ships, workers working inside the ship can face issues like tripping or stumbling. At this time, workers who do not wear PPE can get injured. These injuries fall into the medium-level category addressed by the code E14. Along with the complexity of the structure, another issue is the need for more sources of light inside the ship, for which workers may face issues like tripping or stumbling. This issue assigned by code E15 also falls into the medium category.

Issues addressed by codes E16 to E19 are primarily about the workers working in the muddy region. The first is about stumbling with metal parts while walking on a muddy surface. Not wearing proper shoes, which are recommended, may cause cuts, bruises, or metal inclusion. These types of accidents are considered to be medium-level risky issues by both the experts and workers. Sometimes, workers carry heavy metal, blocks, or ropes and transfer them through the muddy zone; there are good chances of workers facing issues like tripping, stumbling, cuts, bruises, or metal inclusion as it is tough to carry the heavy loads and being aware while walking on the muddy surface. These issues addressed by code E17 also fall into the medium category.

Another problem while carrying the heavy load or ropes is that the workers can feel muscle pain; this issue is also in the medium category addressed by code E18. The last one, the most severe issue that the mud group workers can face, is getting injured due to a winch or cable malfunction while towing heavy blocks from the intertidal zone to the shore. This particular issue falls into the very high-risk zone as it can lead to death or amputation of a particular part of the body, and this kind of scenario is not uncommon. The last two issues of this segment concern the workers working on the inside premises of the ship recycling yard. By E20, the issue of workers getting hit by moving cranes is addressed, which falls into the medium category as this sort of event is rare. The last one, about the accidents inside the yard due to the movements of trucks or excavators while transferring the material, also falls into the medium risk level category due to the low frequency of occurrence.

4.3. Comparative analysis

Based on the risk evaluation considering both long-term and short-term issues as per Section 4.1, 4.2 above, a comparative analysis of very high-risk and high-risk activities across different stages of ship recycling has been summarised and given in Table 6 below:

Table 6.

Comparative analysis of hazardous activities in ship recycling stages.

| Hazard | Segments | Scenario | Code | Category |

|---|---|---|---|---|

| (Long-term issues) Disease (Lung/Liver/Dermal Cancer, Asbestosis, Mesothelioma, Melanoma, Ocular disease, Malignant Tumor) |

IHM (Inventory of Hazardous Material) Preparation and HM (Hazardous Material) removal and cleaning | Workers have lung cancer due to the direct handling of asbestos. | A1 | High-risk zone |

| Workers are suffering from mesothelioma due to the direct handling of asbestos. | A3 | High-risk zone | ||

| Workers have liver cancer due to direct handling of PCB | A4 | High-risk zone | ||

| During the recovery of cylinders, the dissipation of any gas, such as freon or liquid petroleum gas (LPG) from cylinders, can cause difficulties in breathing. | B3 | High-risk zone | ||

| Cutting (Block Cleaning, Cutting, Loading, and Unloading) | During primary cutting, it is very much possible that workers get severe respiratory problems due to continuous inhalation of toxic fumes. | B4 | High-risk zone | |

| Cutting (Block Cleaning, Cutting, Loading, and Unloading) | During mud cleaning from blocks, not using gloves, working in direct contact with mud, and not wearing any PPE may cause workers different skin problems. | C4 | High-risk zone | |

| During cutting flammable material containing tanks, skin contamination may occur. | C5 | High-risk zone | ||

| Short-Term Issues (Burn Injuries) | Oil removal and tank cleaning | Due to the use of faulty multi-gas meters, a wrong reading of the amount of gas can lead to an explosion. | D3 | High-risk zone |

| Fire hazards can occur when storing heavy fuel oil/diesel oil or not ensuring proper cleaning of oily substances, which may substantially cause burn injuries to the workers. | D4 | High-risk zone | ||

| Reusable Material Recovery | Explosion can occur from cylinder bursting due to high temperature, corroded/eroded cylinder, uneven pressure distribution, or faulty accessories of the cylinders. | D5 | High-risk zone | |

| Cutting (Block Cleaning, Cutting, Loading, and Unloading) | Workers carrying LPG cylinders inside the ship during primary cutting can cause severe accidents if there is any possibility of trapped flammable gas or leakage in the cylinder pipe. | D7 | Very high-risk zone | |

| Workers may get electric shock while disconnecting electric cables, causing burn injuries. | D9 | High-risk zone | ||

| Short-Term Issue: Cuts and Bruises Muscle Strain Fracture Broken Bones Amputation Death |

Inspection at Outer Anchorage | While travelling to the outer anchorage by boat, a collision may happen with nearby ships/boats. | E1 | High-risk zone |

| Inspection team members may fall from a height when boarding the ship from tug/patrol boats using the captain's ladder. | E2 | Very high-risk zone | ||

| Beaching | After beaching, pulling the ship toward shore using the winch may sometimes lead to sudden breakage of the winch rope, leading to severe accidents. | E4 | High-risk zone | |

| Mooring and Access | While making holes in the bow section, workers may fall from height. Injuries may happen this way as they use sharp and pointed tools due to unawareness or faulty equipment. | E6 | High-risk zone | |

| Workers can fall from height during cutting blocks due to unawareness or improper cutting plane. | E10 | Very high-risk zone | ||

| During cutting the side section and using the body harness, a worker may fall from a height due to the loosening of the body harness or pendulum effect. | E11 | High-risk zone | ||

| Due to unplanned working or cutting sequences, workers can crush under heavy plates, blocks, or metal parts or be hit by flying objects. | E13 | Very high-risk zone | ||

| Due to the rupture of wires/chain ropes/shackles/hooks while towing heavy blocks or plates, workers may get seriously injured. | E19 | Very high-risk zone |

4.4. Correlation of survey outcome with actual accident cases

The research group obtained accident data from a recent year of ship recycling yards in Bangladesh. Most accident cases in the logbook align with the short-term issues discussed in section 3.2. According to the accident record data, ten significant accidents have occurred in a single year, causing the death of nine workers, four fatal injuries, and a considerable number of mild injuries. Among the accidental incidents, four are fire accidents closely aligned with the issues addressed by code D. The remaining five are closely related to the concerns addressed by code E. In this section, from case 1 to case 10, the accident events have been presented in detail, and their likeness to the possible scenario is discussed under sections 3.1, 3.2.

Case 1

A worker has died during hot work, coming with direct contact with LPG gas. According to the logbook details, the worker was working and became unconscious. Unfortunately, the logbook does not specify whether the accident happened in the primary or secondary cutting zone. Also, whether the worker was conducting a cutting or welding operation was not mentioned. The accident scenario in this case only presents that the worker died during hot work due to unconsciousness. However, considering the circumstances, the accident scenario outlined in codes D6, D8, and D11 may be considered probable causes. Based on data analysis, it has been determined that three of the identified scenarios fall within the medium-risk category zone. According to the outcome of the survey data, it is to be mentioned that these events (D6, D8, D9) leading to death are not a typical scenario of the ship recycling yards of Bangladesh.

Case 2

During gas cutting at the top deck, a fire accident occurred from the spark generated due to the combustion of leftover oil particles. The accident was dangerous enough to cause the death of one worker, along with affecting two other workers severely. One of the primary reasons behind this particular accident is not cleaning the oil properly. This type of hazardous activity causing severe burn injuries has been depicted in code D4. According to the outcome of the survey data, it can be seen that the workers may not be aware of the consequences of this type of hazardous activity. However, experts are aware of this, which has resulted in this issue falling into the high-risk zone.

Case 3

An explosion occurred during the ship's cabin cutting, resulting in the instant death of one worker, fatal injury of two workers, and mild injury for people in closer proximity. This kind of explosion at the primary cutting zone is one of the predominant accidents. Specific issues such as gas leakage, open fuel tanks, and imperfect gas detection systems during gas cutting, mainly in an enclosed space, are the leading causes of this explosion-related mass-scale fire accident. These issues have been addressed by codes D2, D3, D7. Except for D2, explaining the explosion's tendency to keep the fuel tank open for gas dissipation falls into the medium category of the risk scale. The remaining two issues are considered high-risk or very high-risk and require immediate treatment to avoid this deadly explosion.

Case 4

An explosion occurred from the sudden cylinder bursting. In this paper, by code D5, this kind of unwanted explosion from cylinder bursting has been presented. It is classified as a high-risk issue according to the outcome of the survey data.

Case 5

A worker died from a collision with a falling Iron Slice. The logbook does not provide precise details. These types of accidents have been addressed by code E13, which points to workers getting hit by flying objects or crushed under heavy blocks due to unplanned working or cutting sequences. This situation falls in the very high-risk category as the severity and occurrence frequency are alarming per the survey data outcome.

Case 6

In this case, a worker suffered a tragic loss of life resulting from a head injury sustained during the loading of wires. The survey data indicates that this incident falls under E13, which pertains to workers getting hit by flying objects or crushed under heavy blocks or plates due to unplanned working sequences and unawareness. This issue has been classified as a very high-risk problem, and avoiding these severe occurrences is crucial.

Case 7

A worker died after falling from a height by slipping when working during the monsoon. This type of incident is categorised as very high-risk and is explained under the code E10. Among the accidents in the primary cutting zone, the frequency of this type of accident in the ship recycling yards of Bangladesh is pretty high, and mostly, the consequence leads to the worker's death.

Case 8

A worker lost his life in an accident occurring from a collision with an iron plate/slice. The logbook indicates that this unfortunate incident occurred during a winch operation while towing a plate from the intertidal zone to the yard premises. The accidents resembled the scenario under code E19, classified as a very high-risk job.

Case 9

Another incident of a worker dying by falling from a height has been found in the accident record. The logbook does not provide specific details regarding the cause of the accident, only mentioning the fall during block cutting as the incident. From the survey's outcome, it is known that the workers sometimes face such accidents due to improper cutting plans, unawareness, or an unorganised working environment. Code E10 specifically addresses this issue.

Case 10

A worker died from an electric shock while charging his mobile phone. Although the logbook indicates that this accident occurred, this is very rare, and we did not find this type of risk in the field survey.

4.5. Risk mitigation proposal

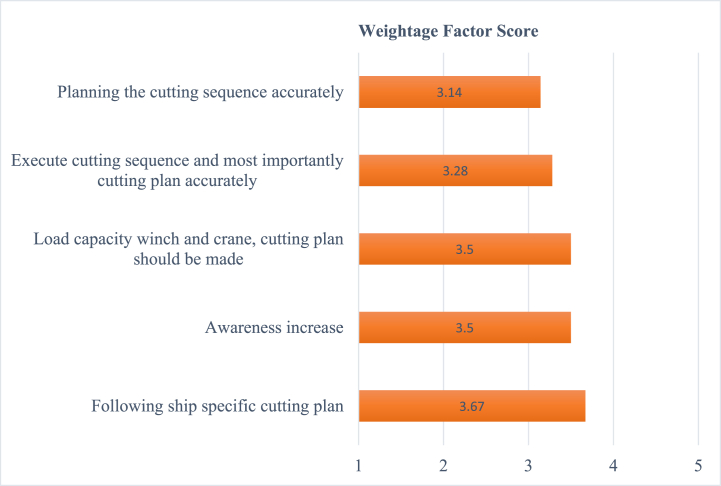

This section presents some comparison-based analysis for proposing solutions for the hazardous activities placed in the high-risk and very high-risk range, along with the factors affecting them most based on the survey conducted during the workshop. From the data analysis, it can be seen that only three issues have been addressed as very high-risk issues. The first one is addressed under E10, falling from a height due to unawareness. Another one under E13 is crushing under heavy blocks or plates or impacting heavy metal objects. Based on the literature review and interview session with experts, some solutions to avoid these two issues were proposed to the workshop participants. The solutions have been presented in Fig. 13.

Fig. 13.

Comparative analysis of solutions to avoid scenarios E10 and E13.

Fig. 14 shows that on a scale of 1–5, following a ship-specific cutting plan carries the highest weightage factor, resembling it as the most crucial aspect to avoid accidental issues. In contrast, cutting sequence planning affects the lowest. Rather than planning, the participants emphasised the strict execution of the cutting plan with proper awareness. The immediate important factor after the ship-specific cutting is to make the plan and keep an eye on the safe load capacity of the winch and crane.

Fig. 14.

Comparative analysis of features affecting cutting plan.

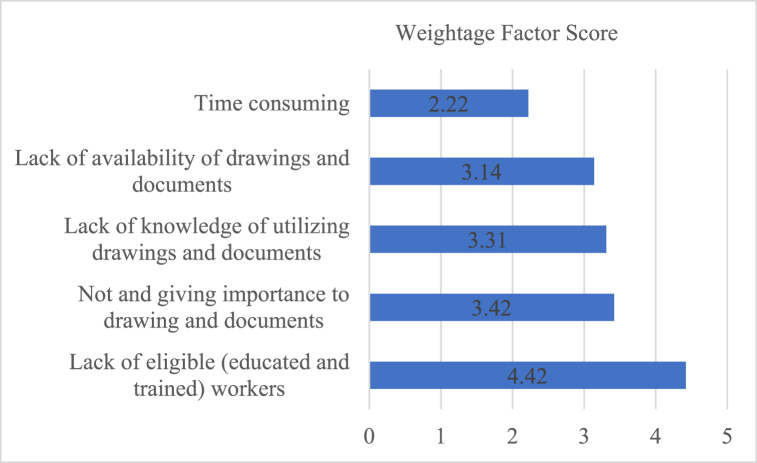

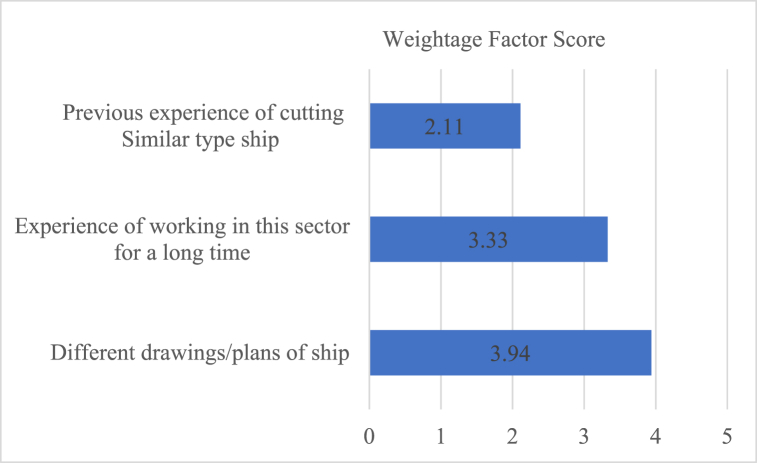

As a sub-factor of making the ship-specific cutting plan, yard authority faces some problems. According to the participant, this most crucial issue is the lack of educated and trained people. Participants responded that workers in the ship-cutting plan need to appreciate the value of drawings and documents. In some cases, though drawings and documents are present, workers are unwilling to use them due to their inability to use them adequately. In addition, sometimes, the papers containing drawings and necessary information are also unavailable. The least essential factor found by the respondents is the time allocation needed to make a proper cutting plan. It indicates that, generally, this industry runs smoothly, and there is provision for conducting a proper cutting plan ahead of operation.

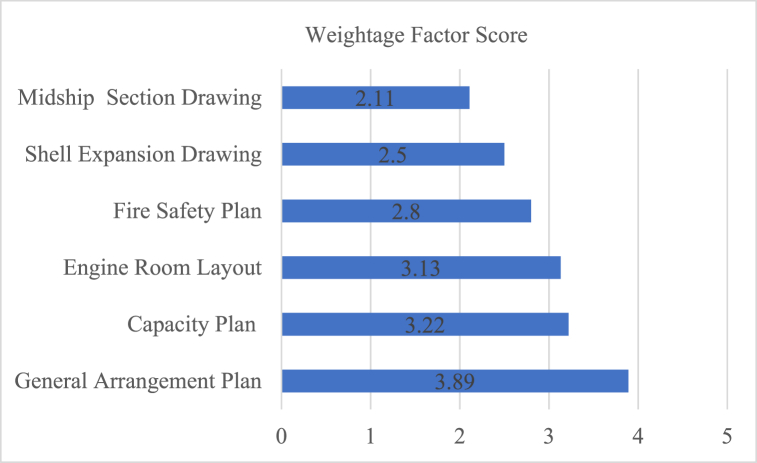

Ship drawings play a pivotal role in ship cutting for ship recycling, as they are the foundational blueprints guiding the dismantling process. The workshop survey considered six drawings/plans: Midship Section Drawing, Shell Expansion Drawing, Fire Safety Plan, Engine room Layout, Capacity Plan, and General Arrangement Plan. These drawings provide critical information on the vessel's structural integrity, including the location of bulkheads, compartments, and vital components, enabling safe and efficient performance. Ship drawings assist in determining the most efficient cutting sequence, which can significantly impact the overall cost and time required for recycling. In essence, ship drawings are the essential reference point for ship recyclers, ensuring that the process is conducted safely, efficiently, and environmentally responsible. Fig. 15 shows the respondents' priorities on different ship drawings/plans. Most of the basic drawings/plans from the survey are considered essential. However, the General Arrangement plan is the most prioritised drawing compared to the Midship Section Drawing in the ship recycling yards.

Fig. 15.

Comparative analysis of the necessary drawing and documents.

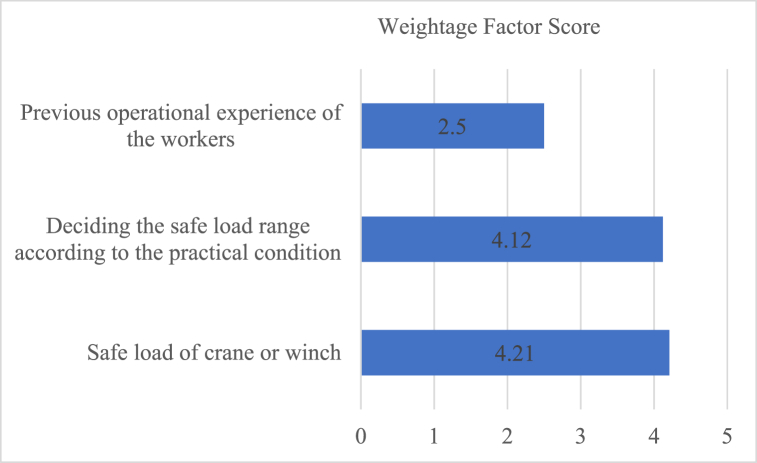

Another crucial hazardous activity from the very high-risk zone is towing heavy blocks or plates using the winch. Due to the malfunction of the winch, serious accidents can take place. Worn-out ropes or shackles can be an issue, but other factors that need to be considered to avoid this kind of accident have been shown in Fig. 16 with their weightage value. According to the response, the safe load range of the winch, considering all technical issues, is the most crucial factor. The mentioned fixed safe load capacity sometimes can mislead the decision if other practical issues, such as weather conditions, rope or shackle condition, operational age of winch, location of the blocks, and others, are not considered. Before deciding on cutting the block size, consider these practical conditions, which can make the operation much safer rather than only focusing on the winch or crane's theoretical or mentioned safe load. Also, it can be seen that whether the people carrying out the whole operation have previous years of experience will not significantly affect the avoidance of these kinds of accidents as most of these incidents are very uncertain. Carrying out these kinds of operations based on assumptions just because the operator has previous knowledge can bring unfortunate situations for the worker.

Fig. 16.

Comparative analysis of features affecting scenario E19.

As per the general practice of the ship recycling industry in Bangladesh, deciding the block size to cut is based on the factors mentioned in Fig. 17. Different documents containing drawings and previous years of experience are now considered when deciding the block-cutting size.

Fig. 17.

Comparative analysis of factors currently affect block size cutting.

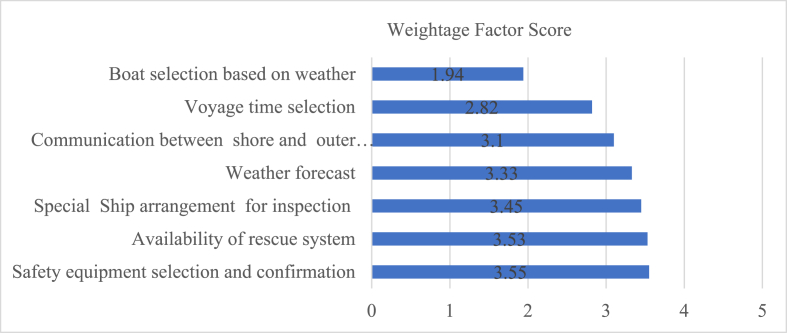

Another very high-risk issue was identified during the inspection at the outer anchorage. Among the three issues relevant to this particular step, one under code E2 is classified as a very high-risk task, another under code E1 is considered a high-risk job, and the other one addressed by code E3 falls into the medium-risk zone. In Fig. 18, factors that affect the frequency of these issues are shown in their weightage value. The weightage factor of the four features mentioned in Fig. 18 regarding the outer anchorage inspection, which are selection and confirmation of the safety equipment, availability of rescue team, special boat arrangement, and weather forecast, are very close and high, which makes them the most important features among all. Four of them are considered essential aspects that should be taken care of to make the inspection at outer anchorage safer and smoother. After ensuring these four factors, sequentially following the other aspects to improve the inspection process can make the process an event of zero accidents.

Fig. 18.

Comparative analysis of factors affecting safety of the inspection at outer anchorage.

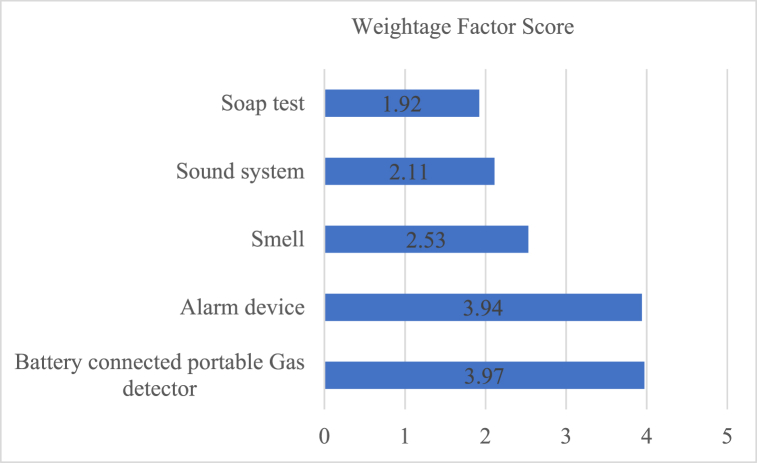

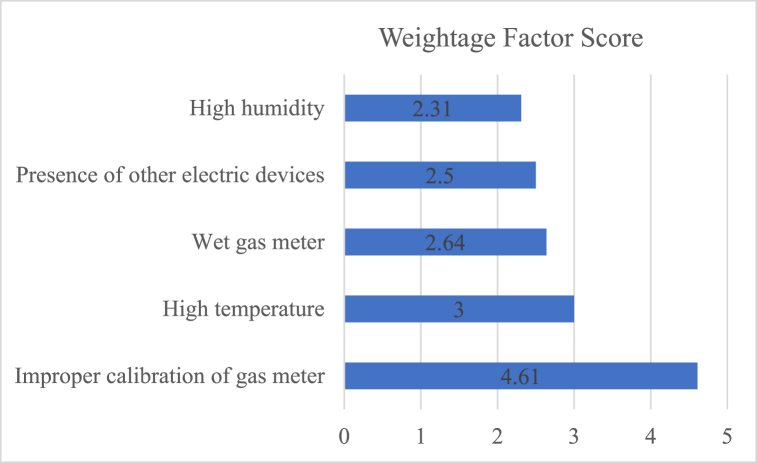

Among the burn injury-related issues, one scenario under code D7 where workers carrying LPG gas cylinders into enclosed spaces of the ship has fallen into the very high-risk zone in the risk scale. Incidents of explosions from gas leakage also pose a high risk for the workers, as discussed in case 3 under section 3.2. To avoid these issues, checking the gas accumulation is necessary before starting gas cutting or continuing cutting operations at a safe time interval. In Fig. 19, current gas procedure methods have been shown. From the figure, it is clear that battery-connected portable gas detectors or alarm devices are primarily used. However, instead of using these devices, the number of accidents is not decreasing. From the study, it has been identified that these devices sometimes mislead and fail to detect the presence of gas leakage. The reasons have been shown in Fig. 20, with their weightage factor revealing the most common issue. It can be seen from Fig. 19 that most of the time, workers using gas meters or alarm devices need proper guidance on how to calibrate the instrument before usage. Thus, it results in faulty detection of the presence of the gas. Another common issue is that the temperature in the workplace remains high; cutting or welding-like activities are continuously carried out everywhere. Nevertheless, if the temperature of any place crosses a certain level, these gas detector devices give a wrong reading. Not sticking to only battery-connected devices or alarm devices, having proper knowledge about each option mentioned in Fig. 19, and utilising them in different environmental conditions can make the workplace safer.

Fig. 19.

Comparative analysis of conventional methods of gas detection.

Fig. 20.

Comparative analysis of issues needed to be considered while gas detection.

5. Conclusions

In conclusion, the ship recycling industry holds a crucial position in the economies of South Asian countries, with particular significance for Bangladesh. The awaited fulfilment of Hong Kong Convention (HKC) conditions by IMO member states, including ratification by Bangladesh and Liberia, signifies a milestone. Consequently, the HKC is set to come into force on June 26, 2025. However, Bangladesh needs to catch up to its competitors in the number of HKC-compliant shipyards, necessitating urgent attention to developing the ship recycling sector.

This research provides a comprehensive depiction of the process flow in the ship recycling industry, drawing insights from meticulous field surveys of practices in Bangladesh's recycling yards. A field survey spanning 18 ship recycling yards reveals inherent risk patterns in the industry, leading to the formulation of cost-effective recommendations for mitigating risks in high-risk workplace areas. Complying with the process flow in the ship recycling industry in Bangladesh, the whole ship recycling process is divided into different scenarios, such as long-term and short-term issues. Seven of 18 scenarios considered in long-term issues fall under the high-risk zone. On the other hand, out of 32 scenarios considered in short-term issues, five fall under very high-risk zones, and eight fall under high-risk zones. Very high-risk zone involves activities such (as fire hazards due to) primary cutting operations at the intertidal zone, inspection at outer anchorage by team members, workers falling from height during block cutting, workers crushing under heavy objects, and failure of mooring components while towing heavy block.

To avoid fire hazards during the primary cutting operation, proper calibration of the gas meter and prevailing conditions of the cutting area, such as temperature, humidity and the inherent limitation of the gas detector, must be considered. During the inspection at the outer anchorage, the availability of safety equipment, rescue team, and special boat arrangements must be ensured, and weather forecasts must be considered to avoid any accident. Regarding the activities related to falling from a height, crushing under heavy blocks or plates or impacting heavy metal objects, executing a ship-specific cutting plan considering the safe load capacity of the winch and crane during the dismantling of the ship is found to be most important. However, yard authority faces some problems because of a need for educated and trained people and the availability of necessary drawings and documents. Regarding mitigating accidents during the winching of heavy blocks or plates, a safe working load of winch and crane and fixing the block's size based on actual ship drawings are the most important.

It is to be noted that these recommendations stem from insights gathered from industry experts and scholars, aligning with current practices. The study also establishes a correlation between survey outcomes and accident cases, yielding satisfactory results. This research contributes to the existing literature by offering a clear understanding of the ship recycling process and evidence-based solutions to enhance the ship recycling industry's overall health and safety strategy.

CRediT authorship contribution statement

Nafisa Mehtaj: Writing – original draft, Data curation. N.M. Golam Zakaria: Writing – review & editing, Supervision, Project administration, Conceptualization. Zobair Ibn Awal: Writing – review & editing, Supervision, Conceptualization. Shaumik Sharif Dipto: Data curation. M.A. Hannan: Supervision, Conceptualization. A.K. Dev: Project administration, Funding acquisition. Mir Tareque Ali: Supervision.

Declaration of competing interest

This research is funded by Engineering X, an international collaboration founded by the Royal Academy of Engineering and Lloyd's Register Foundation.

Acknowledgement

The authors of this research acknowledge funding support provided by Engineering X, an international collaboration founded by the Royal Academy of Engineering and Lloyd's Register Foundation. In addition, the support from the Ministry of Industries (MoI) of the Government of the Peoples Republic of Bangladesh and the cooperation from the Bangladesh Ship Breakers and Recyclers Association (BSBRA) are also acknowledged.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2024.e39344.

Appendix A. Supplementary data

The following is/are the supplementary data to this article:

References

- 1.UNCTAD UNCTAD handbook of statistics 2022. 2022. https://unctad.org/meeting/launch-handbook-statistics-2022

- 2.Solakivi T., Kiiski T., Kuusinen T., Ojala L. The European Ship Recycling Regulation and its market implications: ship-recycling capacity and market potential. J. Clean. Prod. 2021;294 [Google Scholar]

- 3.Garmer K., Sjöström H., Hiremath A.M., Tilwankar A.K., Kinigalakis G., Asolekar S.R. Development and validation of three-step risk assessment method for ship recycling sector. Saf. Sci. 2015;76:175–189. [Google Scholar]

- 4.Choi J.K., Kelley D., Murphy S., Thangamani D. Economic and environmental perspectives of end-of-life ship management. Resour. Conserv. Recycl. 2016;107:82–91. [Google Scholar]

- 5.Zakaria N.G., Ali M.T., Hossain K.A. Underlying problems of ship recycling industries in Bangladesh and way forward. J. Nav. Architect. Mar. Eng. 2012;9(2):91–102. [Google Scholar]

- 6.Abdullah A., Awal Z.I., Alamgir M.Z., Mia M.J., Mim F. A review on ship recycling industry in Bangladesh from global perspective. J. Ocean. Coast. Econ. 2023;10:1–27. 1, 4, [Google Scholar]

- 7.NGO Shipbreaking Platform The toxic tide. 2022. https://shipbreakingplatform.org/spotlight-data-2022/ Available at:

- 8.Alcaidea J.I., Piniella F., Rodríguez-Díaza E. The “Mirror Flags”: ship registration in globalised ship breaking industry. Transport. Res. Transport Environ. 2016;48:378–392. [Google Scholar]