Abstract

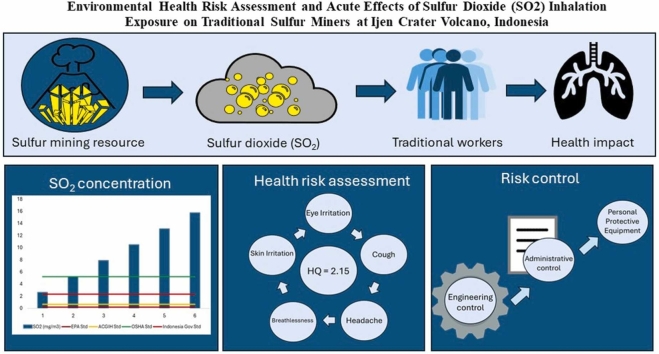

The Ijen Crater volcano is one of the geological wonders recognized by UNESCO. Inside it is a blue lake with a high acidity level, and a blue fire phenomenon has formed due to the very high concentration of sulfur. This crater is also one of Indonesia's largest sources of sulfur and is used by locals as a traditional sulfur mine. This study aims to measure SO2 concentrations and assess the health risks of SO2 exposure in traditional sulfur mine workers. The SO2 measurements were taken using impingers at six sample points along the mine workers' path. In addition, anthropometric data, work activity patterns, and health complaints during work were collected through direct interviews with 30 respondents selected based on inclusion criteria. Short-Term Health Impact Method was carried out based on a comparison of threshold level values and acute effects obtained from interviews regarding health complaints. The Hazard Question Index (HQ Index) of SO2 exposure was calculated using the health risk assessment method. The SO2 concentrations between 3.14 and 18.24 mg/m3. All sample points were above the quality standard threshold set by the EPA of 1.97 mg/m3. The most common health complaints workers experienced were eye irritation and coughing while working, followed by headache, shortness of breath, and skin irritation. The HQ index of SO2 exposure in workers was 1.02 for real-time exposure and 2.15 for long-term exposure. An HQ index ≥ 1 indicates a potential health risk for workers. Therefore, it is important to control workers' SO2 exposure.

Keywords: Environmental health risk assessment, SO2 exposure, Traditional sulfur mining, Ijen Crater Volcano

Graphical Abstract

Highlights

-

•

The Ijen Crater volcano is one of the highest sulfur resources in Indonesia, but only traditional workers work there.

-

•

High SO2 pollution and extreme locations make traditional sulfur mining workers vulnerable to accidents.

-

•

SO2 exposure, acute impacts, and environmental health risk assessment has been discussed.

-

•

Risk management controls and suggestion has been discussed to improve worker health and safety and meet SDGs No 8 and 15.

1. Introduction

Ijen Crater, located in East Java, Indonesia, is one of the world's most geological wonders. This crater has a blue lake containing high concentrations of sulfuric and hydrochloric acid, as well as a unique blue fire phenomenon resulting from burning sulfur gas. It has received recognition from UNESCO as part of the World Biosphere Reserve, which emphasizes the importance of this area for biodiversity and geology [1], [2]. In addition, this area is also a popular tourist destination, attracting thousands of visitors every year who are interested in witnessing its natural beauty and rare geological phenomena [3].

Sulfur produced from the Ijen Crater is one of the largest sources of sulfur in Indonesia and has been exploited for years by traditional miners [4]. This sulfur mining process not only presents physical challenges for workers but also puts them at risk of exposure to sulfur dioxide (SO2). SO2 gas is a dangerous air pollutant that can cause irritation to the respiratory tract, eyes, and skin. In the Ijen Crater, high concentrations of SO2 result from volcanic activity and sulfur mining, which creates a dangerous working environment for workers who are directly and continuously exposed to it [5], [6].

Previous studies of SO2 exposure in mining in Kankoyo, Zambia, showed a correlation with health effects on workers, namely coughing, chest tightness, asthma) and neonatal mortality [44]. While previous studies have touched upon the issue of SO2 exposure in the traditional sulfur mining environment at Ijen Crater, a comprehensive health risk assessment is still lacking. Most of these studies have focused on the geological aspects and sulfur's characteristics, neglecting the crucial aspect of worker health. Therefore, this study aims to bridge this gap by measuring SO2 concentrations in mining areas and evaluating the health risks faced by traditional mining workers, offering a unique perspective on the issue.

2. Method

2.1. Location study and sampling points

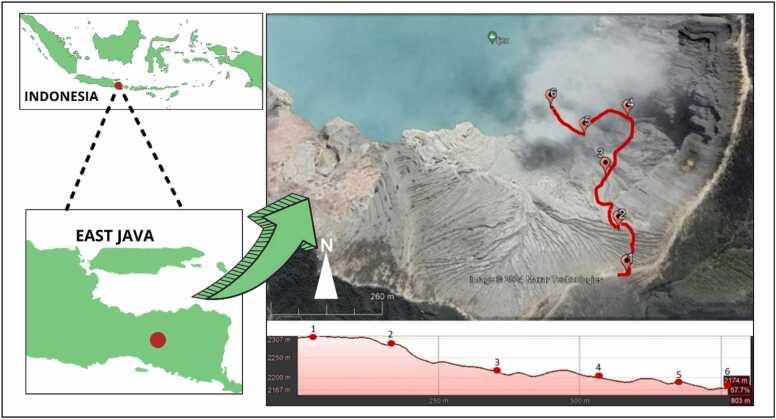

This research was conducted in the Ijen crater area, located in Banyuwangi district, East Java province, Indonesia, which is the location of the largest traditional sulfur mine in Indonesia. Health risk assessment is carried out by identifying SO2 sources and measuring SO2 concentrations along worker activity routes. SO2 measurements were carried out at six sampling points using a stratified sampling method [7]. The location of the sampling point was taken based on a spot that has a foothold for resting, which is used by workers transporting and carrying out sulfur mining activities at a distance of 75 – 180 m per point (Fig. 1).

Fig. 1.

Sampling point and elevation of location.

Sampling point 1 is the peak of Mount Ijen, which is a temporary sulfur collection point and a resting location for workers. Points 2, 3, 4 and 5 are access roads used by workers to transport sulfur from sulfur sources. Points 2 and 5 only have steps to help mine workers take a short break when transporting sulfur, while there is a temporary rest route at point 3, which workers can use to take shelter from the smoke with the provision of emergency tent facilities. Meanwhile, point 6 is a sulfur source location which is the main location in sulfur mining with activities for breaking sulfur rock, collecting and watering sulfur locations where flames are thought to be present. This route is a steep route with an elevation of ± 150 m over a distance of ± 800 m (Fig. 1). SO2 measurements were carried out using an impinger instrument with a flow rate of 1 liter/minute for 1 hr. The sampling location and elevation height can be seen in Fig. 1.

2.2. Respondents

The respondent population in this study was taken based on inclusion criteria, namely, respondents were willing to be the object of research, have work experience of at least one year or more, are 18–55 years old, and Work a minimum of 8 hr per day. Based on these criteria, the total number of respondents was 30 workers [8], [9].

Respondents were interviewed directly by collecting data from anthropometric characteristics and health symptoms that occurred while working and that they had experienced. The anthropometric data taken were weight, gender, age, and education level. Thus, the health symptom criteria are based on each worker's health complaints based on interviews. Analysis was then carried out from the interview data to determine exposure time (Te), exposure frequency (Fe), and exposure duration (Dt).

2.3. Short-term health impacts and acute effects

The Short-Term Health Impact Method was carried out based on a comparison of threshold level values from standards issued by the EPA, NIOSH, and OSHA, which are international organizational bodies that specifically work in the field of environmental health and occupational safety. Meanwhile, acute effects were obtained from physical interviews regarding health complaints received while working.

2.4. Health risk assessment non-carcinogenic compound

Health risk assessment is a quantitative technique used to identify, evaluate, and measure potential risks associated with exposure to environmental or occupational factors on human health, which aims to understand and measure the extent to which SO2 exposure can cause negative effects on human health, as well as to plan the necessary mitigation steps to reduce these risks [10], [11].

SO2 is included in the non-carcinogenic risk category, which means that although SO2 can cause various health problems, such as respiratory problems, irritation of the eyes, nose, and throat, as well as worsening existing lung conditions such as asthma and bronchitis, this gas does not classify as a substance that can cause cancer in humans [12], [13]. So, the calculation of daily exposure intake through inhalation uses E.q 1 [14].

| (1) |

Note:

Iinhalation = Intake inhalation (mg/kg/day)

C = Concentration (mg/m3)

R = inhalation rate (0.83 m3/hr)

e = time of exposure (hr/day)

Fe = Frequency of exposure (days/year)

Wb = Weight of body (kg)

Dt = Duration time, real time or 30 years projection

Tavg = Time average period (30 years, 365 days/year for noncarcinogenic substances)

Then, the hazard quotient due to exposure to SO2 is calculated using Eq. 2 [15]. Apart from that, to calculate the safe duration of time, it can be calculated using Eq. 3 [16].

| (2) |

| (3) |

Note

HQ = Hazard Quotient

RfC = Reference concentration (mg/kg/day)

Rfd = Reference of dose (mg/kg/day)

SD = Safe duration (year)

The health risk assessment for SO2 with an HQ value < 1 indicates that there is no impact on health, whereas if the HQ value ≥ 1 indicates that the exposure that occurs has an impact on health [17]

2.5. Ethical clearance

The respondent of human has been suitable with Ethical that have approved by The Research Ethics Committee of Bandung Institute of Technology with No. KEP/II/2024/X/M200224SHS-SOOH.

3. Results and discussion

3.1. SO2 concentration and working hour activities

Exposure time is obtained based on the length of worker activity spent at each location point. The distance to each point, the duration of activity, and the SO2 concentration can be seen in Table 1.

Table 1.

Distance, Time activity and concentration of SO2.

| Sampling point | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| SO2 concentration (mg/m3) | 3.14 | 3.46 | 3.62 | 6.29 | 18.24 | 16.98 |

| Time activities (hr) | 3.5 | 0.5 | 0.75 | 0.5 | 0.25 | 2.5 |

| Distance (m) | 150 | 180 | 180 | 150 | 75 | 75 |

| Humidity (%) | 80 | 80 | 80 | 80 | 80 | 80 |

| Threshold level value (mg/m3) * | 1.97*1 | 13.1*2 | 5.24*3 | |||

| SO2 concentration average (mg/m3) | 8.2 | |||||

Table 1 reveals that the SO2 concentration varies from 3.14 – 16.98 mg/m3, indicating a significant difference between measurement points. Points closer to the emission source tend to have higher concentrations, a variation influenced by factors such as distance from the pollution source and the direction of the wind carrying SO2. This underscores the importance of comprehending the spatial distribution and factors that influence SO2 concentrations, a crucial aspect for the safety of mine workers and the health of individuals who visit the Ijen Crater as a tourist attraction.

The exposure time of workers at each point varies quite significantly from 0.25 to 3.5 hr of time spent along the work route. Point 1 is the initial meeting point, temporary collection point, and rest area, with the average worker spending time at this point 3.5 hr with SO2 exposure of 3.14 mg/m3. Point 6 is the main location for the sulfur source. Workers spend around 2.5 hr exposed to SO2 of 16.98 mg/m3, and this point is the main activity site for digging sulfur stones and collecting and watering the land caused by sulfur activity.

Apart from that, points 2, 3, 4, and 5 are the routes used by workers to go up and down carrying sulfur stone from the source. At this point, there is only a short rest area, which is used to refresh the workers' bodies so they can raise the sulfur stone to point 1. At points 2 and 4, the time spent is around 0.5 hr with SO2 exposure of 3.46 and 6.29 mg/m3. A quite striking difference is at point 3, where there is a temporary shelter that is used by workers to take a slightly longer break than the other points with SO2 exposure of 3.62 mg/m3. Meanwhile, at point 5 the exposure received was 18.24 mg/m3 for 0.25 hr.

Point 5 is located 75 m above the sulfur source location area and is a wind flow area that always blows towards the point. This causes the SO2 smoke collection to continuously expose this area. Point 6, located at the bottom of the crater with a height position of the impinger measuring instrument of 1.5 m, is not always exposed to the SO2 smoke collection, where SO2 is dominantly directed upwards. This caused the SO2 concentration at point 5 to be higher than at point 6.

SO2 concentration average is the average concentration received by workers during one day of work. This equation can be seen in Eq. 4. This equation calculates the time-weighted average of SO2 exposure based on the concentrations and the duration of each point sample.

| (4) |

Where:

C1, C2, C3, C4, C5 and C6 = Concentration SO2 at each point sample

T1, T2, T3, T4, T5 and T6 = duration time the worker work at the point sample.

3.2. Respondent characteristics

Respondent characteristics data (Table 2) shows that all workers are men. Sulfur mining has a very high risk. Apart from that, the distance from the location of the initial base camp to the Ijen Crater can only be accessed by walking and carrying loads up and down Mount Sulfur Stone, causing there to be no female workers in sulfur mining activities in the area.

Table 2.

Respondent characteristic.

| Variable characteristic respondent | Frequency | Percentage (%) |

|---|---|---|

| Gender | ||

|

30 | 100 |

|

0 | 0 |

| Age | ||

|

8 | 27 |

|

22 | 73 |

| Education level | ||

|

10 | 34 |

|

14 | 46 |

|

4 | 13 |

|

2 | 7 |

| Length of work | ||

|

0 | |

|

5 | 17 |

|

6 | 20 |

|

7 | 23 |

|

12 | 40 |

| Weight | ||

|

5 | 17 |

|

14 | 47 |

|

11 | 36 |

| Smoking habit | 25 | 83 |

The majority of respondents were over 40 years old, with 73 percent, whereas the youngest was 37 years old, and the oldest was 52 years old. Apart from that, the level of work experience is quite long, with the majority, around 40 %, having worked for more than 20 years and only 17 % having at least 6–10 years of experience. This indicates that this job is not popular for young people at high risk who rely on physical strength. Apart from that, with such a high age distribution, the sustainability of mining is predicted to have problems in the future if there is no innovation in the mining process that can attract young people to work in this field.

Apart from the striking age, the level of education is also dominated by low education, where 46 % of workers have graduated from junior high school, 34 % have graduated from elementary school, and 7 % have not attended school, only 13 % of workers have graduated from senior high school. Meanwhile, the average body weight is 156–160 kg. Apart from that, traditional mining work is direct manual labor, so education is not really needed for this job. This affects the behavior of workers who are less aware of the risks they face and, therefore, carry out mining work using only minimal personal protective equipment [22].

3.3. Short-term health impact and acute effect

Short-term health impact assessment of SO₂ exposure involves measuring the concentration of the gas in the air and comparing it with health standards set by several organizations, namely OSHA, NIOSH, and EPA [23]. Based on Fig. 2. The sulfur dioxide (SO2) concentrations at six different locations (P1 to P6) compared to the threshold values (TLV) set by OSHA, NIOSH, and EPA show significant variations. At locations P1 to P3, SO2 concentrations were 3.14 mg/m3, 3.46 mg/m3, and 3.62 mg/m3, respectively. Although these values are below the TLV set by OSHA (13.1 mg/m3) and NIOSH (5.24 mg/m3), they still exceed the TLV set by the EPA (1.97 mg/m3). This indicates that exposure at this location still has the potential to be hazardous to health according to EPA standards. At site P4, SO2 concentrations reached 6.29 mg/m3, which is still below the OSHA TLV but exceeds the NIOSH and EPA TLVs, indicating a medium health risk for workers. A more serious situation was seen at locations P5 and P6, with concentrations of 18.24 mg/m3 and 16.98 mg/m3, respectively. Both values exceed all TLV standards set by OSHA, NIOSH, and EPA, indicating that SO2 exposure at these locations is very high and may pose a serious health risk to workers. Short-term exposure to SO2 at high concentrations can cause irritation of the respiratory tract, eyes, and skin, while long-term exposure can worsen lung conditions and increase the risk of respiratory infections [24], [25].

Fig. 2.

Comparison of SO2 concentration and threshold level value.

The differences in quality standards for SO2 exposure between NIOSH, EPA, and OSHA are caused by the different focus, goals, and approaches of each organization [26]. NIOSH focuses on research and recommendations to protect worker health based on the latest scientific evidence regarding long-term impacts on the work environment, so it tends to be more conservative. EPA sets stricter standards to protect human health and the environment, covers the general population, including vulnerable groups such as children and the elderly, and considers exposure from multiple sources. Meanwhile, OSHA establishes and enforces workplace safety and health standards by considering practical considerations, economics, as well as scientific data, so these standards may not be as stringent as NIOSH or EPA but are designed to protect workers during work hr by considering industrial and economic factors [27], [28].

Based on interview data collected (Table 3), the health symptoms experienced by sulfur mining workers in the Ijen Crater, it was found that all workers (100 %) experienced eye irritation and coughing. This shows that exposure to SO₂ and sulfur particles in the mining environment is very high and has the potential to cause significant irritation to the respiratory tract and eyes of workers.

Table 3.

Health symptoms at work.

| Variable | n | Percentage (%) |

|---|---|---|

| Eye Irritation | 30 | 100 |

| Cough | 30 | 100 |

| Headache | 20 | 67 |

| Breathlessness | 20 | 67 |

| Skin Irritation | 18 | 60 |

As many as 67 % of workers reported experiencing headaches and shortness of breath. Headaches can be caused by inhalation of toxic gases, physical stress, and lack of oxygen, while shortness of breath indicates a narrowing of the airways due to exposure to sulfur dioxide. The high percentage of these symptoms indicates that the working environment in sulfur mines has a serious impact on the respiratory and neurological health of workers.

Skin irritation was reported by 60 % of workers, most likely caused by direct contact with sulfur or gases produced during the mining process. These symptoms indicate that in addition to inhalation, direct contact with hazardous chemicals is also a significant risk for mine workers. Overall, these data indicate that exposure to sulfur in the Ijen Crater has serious health impacts on workers. Due to these health impacts, workers can only mine three times a week. The majority of workers carry out activities with a pattern of one day on and one day off. This gives workers time to recover.

The Agency for Toxic Substances and Disease Registration (ATSDR) [29] states that health effects vary based on SO₂ concentration levels. At low levels (up to 0.1 ppm), health impacts are minimal or not noticeable for most of the population, although sensitive individuals such as asthma sufferers may experience mild respiratory symptoms [30]. At moderate levels (0.2–0.5 ppm), the likelihood of respiratory symptoms increases in sensitive groups, such as children, the elderly, and individuals with pre-existing respiratory conditions, and short-term exposure may cause throat irritation, coughing, and shortness of breath. Breath [28], [31]. Respiratory effects are more pronounced at high levels (0.5–1 ppm), including wheezing and increased asthma attacks. Acute exposure can cause respiratory distress and irritation of the mucous membranes of the eyes and throat [28], [32]. At very high levels (above 1 ppm), severe respiratory effects include bronchoconstriction and increased asthma attacks, and prolonged exposure can cause chronic respiratory problems and long-term lung damage [28], [33].

This impact shows that acute illnesses can occur in workers, considering that constant exposure to these hazardous materials can worsen health conditions and cause serious complications if not treated properly.

3.4. Health risk assessment non-carcinogenic

Based on Table 4, workers are exposed to sulfur dioxide (SO₂) with a concentration of 8.2 mg/m³. With an inhalation rate of 0.83 m³/hr [14], workers breathe contaminated air for 8 hr per day and 180 days per year for an average of 14.3 years. The average body weight of workers is 59 kg. These data provide a comprehensive picture of the significant levels of SO₂ exposure experienced by workers.

Table 4.

Health risk assessment non-carcinogenic.

| Factor | Notation | value | Ref |

|---|---|---|---|

| Concentration SO2 (mg/m3) | C | 8.2 | This study |

| Inhalation rate (m3/hr) | R | 0.83 | [14] |

| Time exposure (hr/day) | Te | 8 | This study |

| frequency of exposure. days/years) | Fe | 180 | This study |

| Duration time (year) | Dt | 14.3 | This study |

| Weight (kg) | kg | 59 | This study |

| Response of dose (mg/kg/day) | Rfd | 0.03 | [18] |

| Intake inhalation (mg/kg/day) | I inh | ||

| I inh Realtime | 0.0308 | ||

| I Inh lifetime | 0.0645 | ||

| Hazard Quotient Inhalation | HQ | ||

| HQ Realtime | 1.0254 | ||

| HQ Lifetime | 2.1512 | ||

| Safe Duration inhalation exposure (year) | SD | 13.95 |

Daily intake of SO₂ is calculated based on air concentration, inhalation rate, time and frequency of exposure, and duration of work. The results show a realtime intake of 0.0308 mg/kg/day and a lifetime intake of 0.0645 mg/kg/day. These values indicate the amount of SO₂ that enters a worker's body per unit of body weight each day, both in the short term and during their working period.

Hazard Quotient (HQ) is used to assess non-carcinogenic health risks by comparing intake with the EPA safe reference dose (Rfd) of 0.03 mg/kg/day. The Realtime HQ was 1.0254, slightly above the safe threshold, indicating a potential short-term health risk. A lifetime HQ of 2.1512 indicates that long-term exposure significantly exceeds safe limits, indicating a serious health risk. The safe duration calculation produces a figure of 13.95 years, which means workers are at significant risk if they work longer than this duration.

The sulfur mine workers in the Ijen Crater volcano experience SO₂ exposure at levels that can cause non-carcinogenic health risks, both short and long-term. This is in accordance with workers' health complaints where all workers experience eye irritation and coughing during work.

The HQ value is an important measure in assessing potential non-carcinogenic health risks from SO2 exposure. Based on Table 5. HQ in various industrial activities shows that there are variations in health risks in various types of industries.

Table 5.

Comparison of Health risk assessment values in other industries.

| Kinds of Industry | HQ | Ref. |

|---|---|---|

| Ijen crater traditional Sulfur mining, Indonesia | 1.03 | This Research |

| Combined cycle power plant (CCPP) Indralaya | 0.26 | [9] |

| Cement plant in pangkep, Sulawesi, indonesia | 0.02 | [34] |

| Rolling industry, Iran | 0.042 | [35] |

| Industrial Region, South Durban, South Africa | 0.1 | [36] |

| Fertilizer Industry, Indonesia | 1.398 | [37] |

| Refinery gas Industry, Iran | 0.806 | [38] |

| Coal mining area, Brazil | 0.002 | [39] |

| Medical waste incinerator, Malaysia | 0.071 | [40] |

| Coal Fired Power Plant, Pakistan | 1.35 | [41] |

Compared with several other industries, the health risk in Ijen Crater is indeed higher compared to industries such as cement factories in Pangkep, Sulawesi (HQ = 0.02) and coal mining areas in Brazil (HQ = 0.002), which have very low HQ values and indicates minimal risk. However, the risk at Kawah Ijen is still lower compared to the fertilizer industry in Indonesia (HQ = 1.398) and coal-fired power plants in Pakistan (HQ = 1.35), which have the highest HQ value.

Each industry has specific production processes that produce various pollutants, including SO2. The level of SO2 emissions produced by a particular industry greatly influences the HQ value, which indicates potential non-carcinogenic health risks due to SO2 exposure. The SO2 concentration value released depends on the production process and pollutant processing technology used by each industry. The better the pollutant processing technology, the smaller the concentration of SO2 released in the air and the smaller the HQ value of SO2 exposure in the industry.

3.5. Risk management control

Efforts to control SO2 exposure faced by traditional sulfur mining workers can be carried out using the safety hierarchy method created by NIOSH [19]. The safety hierarchy consists of five levels: elimination methods, substitution methods, engineering control, administrative control, and personal protective equipment (PPE) [42].

The elimination method is eliminating sources of hazard, while the substitution method is replacing the main dangerous ingredients with safer ones [42]. In this case, the SO2 source that comes out of the bowels of the earth and produces sulfur cannot be removed and replaced, so the concepts of elimination and substitution cannot be used.

Furthermore, engineering control is controlled by engineering techniques to reduce SO2 exposure to workers [45]. This technical control can be carried out by creating local ventilation by designing exhaust ventilation that sucks SO2 from the work location and then disposes of it through stack treatment so that workers can work more safely, and the SO2 that comes out of the stack can also be neutralized. This method has yet to be implemented at the study location.

Administrative control is control by making work regulations using work operational standards that must be adhered to before carrying out work [46]. This stage can be carried out by ensuring that workers know and follow training such as basic safety training, emergency response, and introduction to work areas. This administrative control may be less influential for traditional miners because they mine not under the auspices of a particular agency. The role of the local government and the Ijen Crater authorities, as well as companies that collect sulfur from miners, can be used to provide outreach regarding this matter so that workers care about occupational health and safety.

The use of personal protective equipment (PPE) is the final step that can be used to reduce the impact of SO2 exposure received by workers [43]. The exposure that can occur is inhalation and dermal, so personal protective equipment that can be used to prevent inhalation exposure is a gas mask with a specific mask that can be used but is still easy to carry out, namely a Chemical Cartridge Respirator, which is capable of filtering SO2 and neutralizing it. Meanwhile, protective clothing, gloves, footwear, and face and eye protection should be used to reduce the impact of dermal exposure. The use of PPE is also still minimally used by workers due to the absence of worker obligations, and the costs incurred for personal protective equipment are quite expensive, so there is a need for efforts by the local government, the Ijen Crater Authority and sulfur collection companies from miners to provide incentives in procuring equipment of PPE

4. Conclusion

Traditional sulfur mining at Ijen Crater volcano has SO₂ concentrations ranging from 3.14 to 18.24 mg/m³, with significant variations between these points. Points closer to the emission source tend to have higher SO₂ concentrations. Short-term health impact assessments indicate that SO₂ concentrations at sites P1 through P3 are below OSHA and NIOSH thresholds but exceed EPA standards, indicating a potential health risk, according to EPA. At site P4, SO₂ concentrations also exceeded NIOSH and EPA standards, indicating a moderate health risk. A more serious situation was found at sites P5 and P6, where SO₂ concentrations were very high and exceeded all TLV standards set by OSHA, NIOSH, and EPA. The real-time Hazard Quotient (HQ) of 1.0254 indicates a potential health risk. This is supported by the most common health complaints felt by workers, namely eye irritation and coughing, which all workers experience; apart from that, 67 % of workers also complain of headaches and difficulty breathing, and 60 % complain of rashes or symptoms of skin irritation while working. To managing hazard control can be use engineering controls such as local ventilation, administrative control such as basic safety training, emergency response and introduction working area, then using of personal protective equipment to protect workers from the risk of SO2 exposure.

Funding

There is no funding.

CRediT authorship contribution statement

Septian Hadi Susetyo: Writing – original draft, Visualization, Validation, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Azham Umar Abidin: Writing – original draft, Methodology, Investigation. Taiki Nagaya: Writing – review & editing, Project administration. Nobuyuki Kato: Writing – original draft, Validation, Supervision. Yasuto Matsui: Writing – review & editing, Writing – original draft, Supervision, Resources, Methodology, Funding acquisition, Data curation.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors would like to thank all the team members who helped in the completion of this publication. The authors also thank the Ministry of Education, Culture, Sports, Science and Technology of Japan (MEXT) for supporting the author scholarship.

Handling Editor: L.H. Lash

Data Availability

The data have showed in the manuscript.

References

- 1.Permanadewi S., Samodra H., Irzon R., Prabowo A., Ansori C. Quantitative assessment for geosites of the Ijen Geopark in Banyuwangi Regency, East Java, Indonesia. Int. J. Geoheritage Parks. 2024 [Google Scholar]

- 2.Hakim L. Cultural landscape preservation and ecotourism development in Blambangan Biosphere Reserve, East Java. Landsc. Ecol. Sustain. Soc. 2017:341–358. [Google Scholar]

- 3.Andrews R.G. WW Norton & Company; 2021. Super Volcanoes: What They Reveal about Earth and the Worlds Beyond. [Google Scholar]

- 4.Protschky S., Morgan R.A. Historicising sulfur mining, lime extraction and geotourism in Indonesia and Australia. Extr. Ind. Soc. 2021;8(4) [Google Scholar]

- 5.Singh G.K., Rai S., Jadon N. Major ambient air pollutants and toxicity exposure on human health and their respiratory system: a review. J. Environ. Manag. Tour. 2021;7(55):1774–1788. [Google Scholar]

- 6.Iwasawa S., Kikuchi Y., Nishiwaki Y., Nakano M., Michikawa T., Tsuboi T.…Omae K. Effects of SO2 on respiratory system of adult Miyakejima resident 2 years after returning to the island. J. Occup. Health. 2009;51(1):38–47. doi: 10.1539/joh.l8075. [DOI] [PubMed] [Google Scholar]

- 7.Cox R.M. The use of passive sampling to monitor forest exposure to O3, NO2 and SO2: a review and some case studies. Environ. Pollut. 2003;126(3):301–311. doi: 10.1016/s0269-7491(03)00243-4. [DOI] [PubMed] [Google Scholar]

- 8.Oginawati K., Sidhi R., Susetyo S.H. Lead exposure in trader communities in industrial area of the battery recycling plant: Tangerang, Indonesia. J. Ecol. Eng. 2020;21(4):264–270. [Google Scholar]

- 9.Nurhisanah S., Hasyim H. Environmental health risk assessment of sulfur dioxide (SO2) at workers around in combined cycle power plant (CCPP) Heliyon. 2022;8(5) doi: 10.1016/j.heliyon.2022.e09388. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Gul M., Ak M.F. A comparative outline for quantifying risk ratings in occupational health and safety risk assessment. J. Clean. Prod. 2018;196:653–664. [Google Scholar]

- 11.Sahmel J., Devlin K., Paustenbach D., Hollins D., Gaffney S. The role of exposure reconstruction in occupational human health risk assessment: current methods and a recommended framework. Crit. Rev. Toxicol. 2010;40(9):799–843. doi: 10.3109/10408444.2010.501052. [DOI] [PubMed] [Google Scholar]

- 12.Piccardo M.T., Geretto M., Pulliero A., Izzotti A. Odor emissions: a public health concern for health risk perception. Environ. Res. 2022;204 doi: 10.1016/j.envres.2021.112121. [DOI] [PubMed] [Google Scholar]

- 13.Ghosh B., Chowdhury M., Ghosh S., Padhy P.K. Air Quality and Human Health. Springer Nature Singapore; Singapore: 2024. Outdoor air quality and assessment of its potential health risk to human being; pp. 121–134. [Google Scholar]

- 14.Abidin A.U., Maziya F.B., Susetyo S.H., Yoneda M., Matsui Y. Heavy metal air pollution in an Indonesian landfill site: characterization, sources, and health risk assessment for informal workers. Environ. Adv. 2024 [Google Scholar]

- 15.Gusti A., Yurnal R.A. Health risk assessment of total suspended particulate exposure to employee of PT Semen Padang, Indonesia. Iran. J. Public Health. 2019;48(8):1535. [PMC free article] [PubMed] [Google Scholar]

- 16.Swartjes F.A., Cornelis C. Dealing with Contaminated Sites: From Theory towards Practical Application. Springer Netherlands; Dordrecht: 2010. Human health risk assessment; pp. 209–259. [Google Scholar]

- 17.Cao S., Duan X., Zhao X., Ma J., Dong T., Huang N.…Wei F. Health risks from the exposure of children to As, Se, Pb and other heavy metals near the largest coking plant in China. Sci. Total Environ. 2014;472:1001–1009. doi: 10.1016/j.scitotenv.2013.11.124. [DOI] [PubMed] [Google Scholar]

- 18.US. EPA. Criteria Air Pollutants. accessed at 〈https://www.epa.gov/criteria-air-pollutants/naaqs-table#4〉.

- 19.CDC - NIOSH Pocket Guide to Chemical Hazards: Sulfur Dioxide (SO₂). Accessed at 〈https://www.cdc.gov/niosh/npg/npgd0575.html〉.

- 20.Lopez L. OSHA compliance issues sulfur dioxide exposure in an electroplating establishment. Appl. Occup. Environ. Hyg. 2000;15(11):809–810. doi: 10.1080/10473220050175661. [DOI] [PubMed] [Google Scholar]

- 21.Badenhorst C.J. Occupational health and safety risks associated with sulphur dioxide. J. South. Afr. Inst. Min. Metall. 2007;107(5):299–303. [Google Scholar]

- 22.Hentschel T. Artis. small-Scale Min.: Chall. Oppor. 2003 [Google Scholar]

- 23.Ogah A.T., Opaluwa O.D., Alkali M., Lass K. Assessment of air quality within Maiganga coal mining area in Akko local government Area, Gombe State, Nigeria. World J. Biol. Pharm. Health Sci. 2020;4(3) 001-012. [Google Scholar]

- 24.Lin C.C., Chiu C.C., Lee P.Y., Chen K.J., He C.X., Hsu S.K., Cheng K.C. The adverse effects of air pollution on the eye: a review. Int. J. Environ. Res. Public Health. 2022;19(3):1186. doi: 10.3390/ijerph19031186. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Schraufnagel D.E., Balmes J.R., Cowl C.T., De Matteis S., Jung S.H., Mortimer K.…Wuebbles D.J. Air pollution and noncommunicable diseases: a review by the forum of international respiratory societies’ environmental committee, Part 2: air pollution and organ systems. Chest. 2019;155(2):417–426. doi: 10.1016/j.chest.2018.10.041. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Zhang H., Srinivasan R. A systematic review of air quality sensors, guidelines, and measurement studies for indoor air quality management. Sustainability. 2020;12(21):9045. [Google Scholar]

- 27.Connolly W.B., Jr, Crowell D.R. Law Journal Press; 2017. A Practical Guide to the Occupational Safety and Health Act. [Google Scholar]

- 28.Berger J.L., Riskin S.D. Economic and technological feasibility in regulating toxic substances under the occupational safety and health act. Ecol. LQ. 1978;7:285. [Google Scholar]

- 29.The Agency for toxic substances and disease registry (ATSDR) Accessed at 〈https://wwwn.cdc.gov/TSP/PHS/PHS.aspx?phsid=251&toxid=46〉.

- 30.Reno A.L., Brooks E.G., Ameredes B.T. Mechanisms of heightened airway sensitivity and responses to inhaled SO2 in asthmatics. Environ. Health Insights. 2015;9 doi: 10.4137/EHI.S15671. EHI-S15671. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Johns D.O., Linn W.S. A review of controlled human SO2 exposure studies contributing to the US EPA integrated science assessment for sulfur oxides. Inhal. Toxicol. 2011;23(1):33–43. doi: 10.3109/08958378.2010.539290. [DOI] [PubMed] [Google Scholar]

- 32.Wigenstam E., Elfsmark L., Bucht A., Jonasson S. Inhaled sulfur dioxide causes pulmonary and systemic inflammation leading to fibrotic respiratory disease in a rat model of chemical-induced lung injury. Toxicology. 2016;368:28–36. doi: 10.1016/j.tox.2016.08.018. [DOI] [PubMed] [Google Scholar]

- 33.World Health Organization . World Health Organization; 2021. WHO Global Air Quality Guidelines: Particulate Matter (PM2. 5 and PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide. [PubMed] [Google Scholar]

- 34.Wahyu A., Irwandy S.P., Yasin M. Environmental health risk assessment of particulate matter (PM2, 5) and sulfur dioxide (SO2) exposure at workers in production unit of a cement plant in Indonesia. Int. J. Chem. Biochem. Sci. 2024 [Google Scholar]

- 35.Hesami Arani M., Jaafarzadeh N., Moslemzadeh M., Rezvani Ghalhari M., Bagheri Arani S., Mohammadzadeh M. Dispersion of NO2 and SO2 pollutants in the rolling industry with AERMOD model: a case study to assess human health risk. J. Environ. Health Sci. Eng. 2021;19(2):1287–1298. doi: 10.1007/s40201-021-00686-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Matooane M., Diab R. Health risk assessment for sulfur dioxide pollution in South Durban, South Africa. Arch. Environ. Health.: Int. J. 2003;58(12):763–770. doi: 10.3200/AEOH.58.12.763-770. [DOI] [PubMed] [Google Scholar]

- 37.Latifa Y.T.N., Tualeka A.R., Solichin R., Rahmawati P., Russeng S.S., Wahyu A. Determination of sulfur dioxide (SO2) safe duration in residential population around the fertilizer industry X in Indonesia. Indian J. Public Health Res. Dev. 2019;10(10):2766–2770. [Google Scholar]

- 38.Kiaei, R., Pardakhti, A., & Zahed, M.A. (2023). Human health risk assessment for NO2, SO2 and CO emissions from a refinery using CALPUFF; A case study Kangan, Iran.

- 39.Honscha L.C., Reis F.O., Aikawa P., Coronas M.V., Muccillo-Baisch A.L., Baisch P.R.M., da Silva Júnior F.M.R. Human health risk assessment of air pollutants in the largest coal mining area in Brazil. Environ. Sci. Pollut. Res. 2023;30(21):59499–59509. doi: 10.1007/s11356-023-26708-9. [DOI] [PubMed] [Google Scholar]

- 40.Rahim F.L., Hassim M.H., Mokhtar M.M., Kidam K. Health risk assessment due to emissions from medical waste incinerator in Malaysia. J. Teknol. 2016;78(8-3) [Google Scholar]

- 41.Iqbal J., Amjad S., Javed H. Environmental and health risk assessment of a coal fired power plant-effect of stack height. GMSARN Int. J. 2024 [Google Scholar]

- 42.Ajslev J.Z., Møller J.L., Andersen M.F., Pirzadeh P., Lingard H. The hierarchy of controls as an approach to visualize the impact of occupational safety and health coordination. Int. J. Environ. Res. Public Health. 2022;19(5):2731. doi: 10.3390/ijerph19052731. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Baldessari G. Basic characteristics of PPE (II): industrial applications. Clin. Handb. air Pollut. -Relat. Dis. 2018:577–601. [Google Scholar]

- 44.Chihana S., Mbale J., Chaamwe N. Unveiling the nexus: sulphur dioxide exposure, proximity to mining, and respiratory illnesses in kankoyo: a mixed-methods investigation. Int. J. Environ. Res. Public Health. 2024;21(7):850. doi: 10.3390/ijerph21070850. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Ganesan K., Theodore L. Air pollution control engineering. Handb. Environ. Eng. 2018:453–492. [Google Scholar]

- 46.Gavrilenko V., Shenshin V. Control and supervisory activities as an institute of administrative law. BRICS Law J. 2023;10(2):156–183. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data have showed in the manuscript.