Abstract

Dielectrics are essential for storing and controlling electrical energy in the electrical and electronic industries. However, their production from non-renewable sources raises environmental concerns. This review investigates sustainable polymer-based dielectric composites made from agricultural waste, focusing on the various parameters that affect dielectric characteristics. These composites offer improved dielectric properties and contribute to waste reduction and environmental sustainability. Agricultural waste, including crop residues and by-products, offers a promising, sustainable source of dielectric composite materials. This review also highlights the feasibility of using agricultural waste-based polymer dielectric composites for dielectric material in various electronics applications. Dielectric composite's permittivity is influenced by carbon, oxygen, filler, temperature, cellulose, and morphological changes. Biodegradable materials like agricultural waste, which have good fibre and carbon content, can produce good dielectric constants, making them suitable for antennas and microwave absorbers. In conclusion, the review underscores the importance of sustainable practices in dielectric composite material development and the valuable role of agricultural waste in advancing environmentally friendly solutions.

Keywords: Agriculture waste, Dielectric properties, Polymer composite, Dielectric material

Graphical abstract

Highlights

-

•

Overview of various agricultural waste types and their characteristics.

-

•

Procedural overview of composite development using agricultural waste.

-

•

Discussion and comparison of characteristics of various dielectric composites.

-

•

Examination and comparison of dielectric characteristics and measurement methods.

-

•

Summary of challenges, solutions, and environmental/economic impacts.

1. Introduction

Dielectric composite materials are crucial for several electronic and electrical applications. A dielectric material is an insulating substance that conveys electric force without being conducted. It possesses the distinctive characteristic of storing electrical energy within an electric field. The composite material, consisting of two components, fibre (the reinforcement) and glue (the matrix), asserts that combining these materials yields properties superior to those of the individual components used separately [1]. Composite materials offer several key advantages over metal or plastic [2]. These include superior strength and stiffness, as well as a lower density, which enables weight reduction in the final product [3]. A composite material with better electrical, chemical, and physical properties has a crucial role in increasing or reducing the size of components and improving the effectiveness of electronic devices like antennas, sensors, capacitors, and energy storage devices [4], especially in microwave-absorbing applications. Additionally, they have a crucial function in electromagnetics and are indispensable for conveying and retaining electrical energy in power systems [5]. They are also important in regulating electric fields and capacitance, impacting signal transmission, and guaranteeing electromagnetic compatibility in today's technological environment [6].

The industry heavily relies on dielectric materials such as Teflon, mica, and alumina due to their exceptional electrical properties [7]. However, these conventional dielectric materials possess a significant drawback in that they are non-biodegradable and pose environmental hazards, hence worsening the growing global issue of electronic waste (e-waste) [8]. Polychlorinated biphenyls (PCBs), for example, in e-waste, are persistent organic pollutants that pose risks to ecosystems, wildlife, and human health. Besides that, the production of Teflon, for example, is progressively phasing out the use of perfluorooctanoic acid (PFOA) due to its deleterious effects on the environment [9] and becoming a persistent contaminant [10]. The use of halogenated flame retardants in dielectric materials is also persistent in the environment and causes issues due to their toxicity [11]. The disposal of dielectric components in electronic waste contributes to the growth of electronic waste and the occupation of landfills [12]. Industrial processes that require a significant quantity of energy can contribute to carbon emissions and have detrimental impacts on the environment. Inadequate handling of dielectric materials during chemical disposal might result in environmental risks [7]. However, technological advancements and growing awareness of environmental issues have stimulated efforts to develop more sustainable materials and production techniques based on natural resource waste. Processing agricultural waste for sustainable practices can reduce environmental impact by repurposing waste materials into valuable resources, thereby mitigating the need for non-biodegradable conventional dielectric composite materials [13].

Agricultural waste primarily comprises cellulose, hemicellulose, and lignin, the building blocks that provide plant structure and stability [14]. Cellulose, a key component, imparts strength and rigidity via hydrogen bonds [15], whereas hemicellulose binds fibres and influences moisture absorption, and lignin provides rigidity and waterproofing [16]. Agricultural waste predominantly comprises carbon, which plays a significant role in its electrical properties [17]. Generally, natural fibres are regarded as effective insulators. Compared to conventional plastic and ceramic insulators, natural fibres provide comparable or even superior electrical insulation properties, especially when subjected to physical or chemical treatment [18]. Natural fibres possess excellent dielectric properties due to their inherent insulating characteristics. The primary concept related to dielectric properties is the degree of polarisation in natural fibres when an external electric field is imposed [19,20]. Dielectric properties of natural fibres, including jute, ramie, cotton, and sisal, for example, have been investigated through dielectric studies conducted within the audio frequency range. Furthermore, it was discovered that the loss factor directly correlated with the rising frequencies [21]. These fibre's excellent dielectric properties, studied within the audio frequency range, suggest a promising future for utilising agricultural waste-based composites in diverse electronic applications.

The novelty of this review paper lies in critically analysing the existing research on developing dielectric composites from agricultural waste. The main points of this in-depth study are outlined, along with the factors that affect the dielectric performance of these composites and possible uses as alternatives to common dielectric materials. It is crucial to address the research gap in this study because the existing literature has not thoroughly investigated the potential of using different types of agricultural waste to create dielectric composites. Furthermore, there is a significant lack of research examining these composite's effectiveness, durability, and practical uses, impeding their widespread acceptance. Furthermore, the precise impact of different parameters on the dielectric performance has not been sufficiently investigated, which hampers our comprehension of how to effectively enhance these materials for specific uses. Hence, this review paper aims to fill these voids by thoroughly examining current studies, pinpointing areas that require additional research, and elucidating the potential of agricultural waste-based dielectric composites as environmentally friendly substitutes for conventional materials. Therefore, the following sections present an exhaustive analysis of various agricultural by-products and their potential as dielectric materials. Through a comprehensive literature review, Section 2 delineates a literature review on various dielectric composite developments. Section 3 provides an overview of a general methodology for fabricating a polymer composite from agricultural waste until the process of characterising the fabricated and the significance of agricultural waste as a polymer composite. Section 4 explains the theoretical part of dielectric properties and discusses various factors affecting the permittivity of dielectric composites. Section 5 explores the potential applications of sustainable agriculture waste-based dielectric materials as an alternative to conventional dielectrics. Section 6 examines the challenges, solutions, and environmental and economic impacts. Finally, Section 7 provides conclusions, highlighting the primary findings and analysis throughout the review.

2. Literature review

2.1. Dielectric composites from agriculture waste

This section presents a range of studies on innovative methods for polymer-based agriculture waste-based dielectric composite materials. The studies highlight these composite's versatility and potential applications in electronic fields, such as printed circuit boards and dielectric materials, showcasing the combination of natural fibres with advanced polymers. Significant trends include using advanced characterisation techniques and simulations, considering environmental factors in design, and customising compositions to achieve specific attributes.

Mishra et al. [22] conducted a study on microwave absorption materials, utilising sugarcane bagasse fibre, silicone gel, acrylic acid, methanol, epoxy polymer, and hardener. The study employs a range of methodologies, such as ultrasonic blending, scanning electron microscopy analysis (SEM), Fourier transform infrared spectroscopy (FTIR), microwave characteristics measurement, and energy-dispersive X-ray spectroscopy (EDX) analysis. The study determines that the utilisation of methanol and acrylic acid is crucial in altering the surface properties of sugarcane bagasse fibre, enabling it to absorb microwaves effectively. At a frequency of 10 GHz, the composite substantially enhances microwave absorption within the X-band range. The data on ultrasonic velocity and acoustic parameters indicate significant intermolecular interactions in treated sugarcane bagasse, resulting in the creation of hydrogen bond complexes. This technique is highly effective for the process of bleaching and improving the quality of sugarcane bagasse material, which is then used for composite fabrication. Ultrasonic treatment enhances the bonding and strengthening of fibres, making it a viable method for producing dielectric composites and developing hybrid composites for energy storage devices and micro-responsive materials. The SEM image of the composite is depicted in Fig. 1(a). The microwave characteristics of carbonised dielectric material are determined by analysing loss tangent (tan δε) and reflection loss. The material exhibits good microwave response at frequencies 8.5–12.5 GHz, with a peak at 10 GHz and 11.5 GHz. This is due to the material's polarisation effect in the presence of electromagnetic waves. Variations in dielectric constant, ε′ and loss part, ε″ enhance the dipole moment of the activated carbon, making the material conductive below 10 GHz and low-loss conductive above 10 GHz. Fig. 2 depicts the characteristic peaks in loss tangent and the reflection loss of the composite samples across various frequencies. Zahid et al. [23] worked on combining sugarcane bagasse, rice husks, polyester, and methyl ethyl ketone peroxide (MEKP) to create a pyramidal microwave absorber. The dielectric probe technique is used to measure the dielectric parameters of the absorber, and the design of the absorber is simulated using computer simulation technology (CST) software. Two essential results include a loss tangent of 0.161 and a dielectric constant of 1.44. Regarding reflection loss performance, the sugarcane bagasse (SCB)-polyester-MEKP absorber performs better than commercially available alternatives, demonstrating its cost-effectiveness and environmental friendliness.

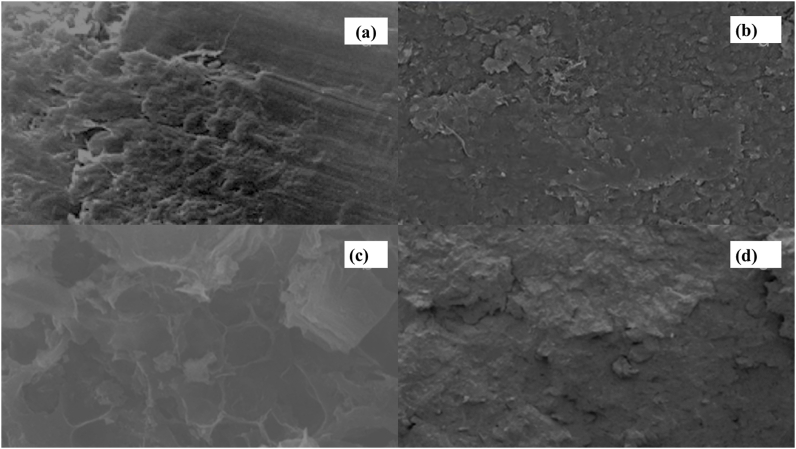

Fig. 1.

(a) SEM image of sugarcane bagasse with 1 h sonicated [30] (b) SEM image of activated-derived mango leaves [29] (c) SEM image of activated-derived mango leaves [29] (d) SEM image of activated-derived mango leaves [29].

Fig. 2.

Variation in loss tangent (tan δε) of sugarcane bagasse composite [30,31].

Duggal et al. [24] focus on studying the absorption characteristics of a pyramidal microwave absorber made of coal and sugarcane bagasse. In addition to simulating absorption qualities through software optimisation, the study involves testing dielectric properties using a network analyser and a dielectric probe approach. The outcomes show the success of combining coal and sugarcane bagasse and adding coal to increase absorptive capacity. Rice husk and rubber tyre dust are two more substitute materials that have the potential as microwave absorbers. Panwar et al. [25] investigated the impact of incorporating a frequency selective surface (FSS) on the microwave absorption properties of composites. They blended 10 % Bisphenol A Novolac epoxy with sugarcane bagasse, resulting in a composite with remarkable absorption bandwidth (3.6 GHz) and peak reflection loss (−28.4 dB at 10.7 GHz), demonstrating excellent electromagnetic properties. The study highlights the effectiveness of the Minkowski loop FSS in enhancing absorption capabilities. Understanding the electrical behaviour of these composites requires a thorough understanding of their dielectric and magnetic properties. The dielectric parameters exhibit frequency-dependent behaviour in the 8.2–12.4 GHz range, with ε′ peaking at 1.5 at 12.4 GHz and dropping to 0.59 at 8.6 GHz. Similarly, the complex permittivity versus frequency spectra indicates an inverse relationship between dielectric constant, ε′ and dielectric loss, ε″, with ε″ reaching a maximum of 1.5 at 12.4 GHz and a minimum of 0.59 at 8.6 GHz. Frequency-dependent electromagnetic properties and loss tangents in the frequency range of 8.2–12.4 GHz are depicted in Fig. 3. The dielectric and magnetic loss tangents vary, with the magnetic loss tangent's peak value spanning from 8.8 to 10.3 GHz [19].

Fig. 3.

Frequency dependent electromagnetic properties (a) dielectric loss, εr′ and dielectric loss factor, εr″, and (b) loss tangent (tan δε), in the frequency range of 8.2–12.4 GHz [25].

Using pineapple leaves, distilled water, resin, and hardener as factors, Rasid et al. [26] explore the use of pineapple plantation waste for producing dielectric composite materials. They use factorial analysis to design the experimental work and analyse the response towards the factors involved. The result reveals the ideal circumstances for processing pineapple leaves into dielectric materials, resulting in a cellulose concentration of 59.25 % and a dielectric constant value of 2.8876. The study highlights how the properties of the dielectric material are affected by variables such as the mass of the leaf powder, the ratio of leaves to water, the boiling time, and the heating options [26]. While using pineapple leaves also, Giamasrow et al. [27] examined the impact of carbon content on the dielectric constant performance of dielectric materials. Researchers employ a two-level factorial analysis (TLFA) method and utilise SEM and EDX analyses to examine the morphology and elements of the fabricated materials, respectively. An example of an SEM image is shown in Fig. 1(b). The findings indicate that carbon concentration highly influences dielectric constant performance, with higher carbon content improving the dielectric constant.

Percolative polyurethane-polypyrrole-paddy straw-based composites with enhanced mechanical strength and dielectric constant are the subject of research by Chaturvedi et al. [28]. The composites have better tensile strength, less water absorption, and a higher dielectric constant because they contain polypyrrole-coated paddy straw particles. This work highlights the potential of these composites to enhance mechanical strength and dielectric performance. The SEM image of percolative polyurethane-polypyrrole-paddy straw composites is shown in Fig. 1(c). Negi et al. [29] investigate the microwave absorption properties of activated carbon from mango leaves. After developing, cleaning, and drying, they added activated carbon (ACM) to paraffin wax at different loaded percentages. The results show that the activated carbon's porous structure contributes to the effective microwave absorption of composites loaded with 20 % ACM. The study draws attention to the composite's broad effective absorption bandwidth in the X and Ku bands [30]. The SEM image of activated carbon mango leaves is given in Fig. 1(d) for reference.

Table 1 summarises various studies on agricultural waste-based polymer composites, detailing processing methods and microwave absorption capabilities based on dielectric constant values. These studies underscore the potential of these composites for applications in electronic fields by combining natural fibres with advanced polymers. Significance trends include incorporating advanced characterisation techniques and simulations, considering environmental factors in design, and tailoring compositions to achieve specific attributes.

Table 1.

Studies on agriculture waste polymer-based composites.

| Author | Title | Agriculture Waste Type | Composite Components | Methods Used | Maximum Value of Dielectric Constant, εr′ | Max Value of Loss Tangent, tan δε | Ref. |

|---|---|---|---|---|---|---|---|

| Mishra et al. | Synthesis and Characterization of Microwave Absorbing Material | Sugarcane Bagasse Fibre | Acrylic Acid Methanol, Epoxy Polymer | Grinding | – | 0.0750 | [30] |

| Zahid et al. | Development of Pyramidal Microwave Absorber Using Sugar Cane Bagasse | Sugar Cane Bagasse (SCB) | Polyester, Methyl Ethyl Ketone Peroxide (MEKP) | Grinding | 1.44000 | 0.1610 | [23] |

| Rasid et al. | Factorial Analysis on the Preparation of Pineapple Plantation Waste as Dielectric Materials | Pineapple Leaves | Epoxy | Pulping | 2.93370 | 0.0800 | [26] |

| Negi et al. | Activated Carbon Derived from Mango Leaves as an Enhanced Microwave Absorbing Material | Mango Leaves | Potassium Hydroxide (KOH), Paraffin Wax, Hydrochloric Acid (HCl) | Carbonisation | [29] | ||

| Chaturvedi et al. | Percolative Polyurethane-Polypyrrole-Straw Composites with Enhanced Dielectric Constant and Mechanical Strength | Paddy Straw | Polypyrrole (Ppy), Polyurethane (PU) Pellets | Grinding | 13.6100 | 0.0600 | [28] |

| Panwar et al. | Microwave Absorption Properties of FSS-Impacted Composites as a Broadband Microwave Absorber | Sugarcane Bagasse | Epoxy | Grinding | 5.40000–5.90000 | 0.2900 | [25] |

| Giamasrow et al. | Effect of Carbon Composition on Permittivity Performance of Dielectric | Pineapple Leaves | Epoxy 100 | Carbonisation | 3.13000 | 0.0800 | [27] |

| Duggal et al. | Investigation of Absorption Properties of Sugarcane Bagasse - Coal Pyramidal Mic | Sugarcane Bagasse, Coal | Polyester Resin, Cobalt, MEKP (Methyl Ethyl Ketone Peroxide) | 2.00000 | 0.0204 | [24] |

When reviewing existing literature, a significant gap is evident in the comprehensive study of the electrical, chemical, elemental, and mechanical characteristics of agricultural waste-derived composites. A review of current literature reveals a scarcity of detailed studies examining the correlation between morphological characteristics and electrical performance, particularly in relation to the effects of surface treatments and the influence of various processing parameters. While certain studies have explored individual agricultural wastes, such as sugarcane bagasse, pineapple leaves, rice husks, and rice straw, these investigations remain fragmented, lacking a systematic, cross-comparative analysis of the diverse agricultural waste materials and their performance metrics. Moreover, there is limited focus on the interplay between chemical composition, mechanical integrity, and electrical properties in these composites, with many studies narrowly addressing only one aspect. This deficiency highlights the need for a holistic approach that integrates the evaluation of structural morphology, chemical modification, and their direct influence on dielectric behaviour. Bridging this gap is essential to unlocking the full potential of agricultural waste as a sustainable and high-performance resource for advanced composite materials.

2.2. Dielectric composites material from alternative sources

While section 2.1 has focused on agricultural waste as a source for developing dielectric composites, examining composites derived from alternative filler materials offers valuable insights for optimising the performance of agricultural waste-based composites. Studies on dielectric composites containing ceramics, metals, and carbon fillers provide important references, helping identify techniques and mechanisms that can enhance agricultural waste-based materials. These alternative dielectric composites illustrate significant trends and processing techniques that may be useful for future agricultural waste-based dielectric materials developments.

Dielectric composites are typically categorized according to the filler material used, such as ceramics, metals, or carbon. Understanding the dielectric behaviour of these composites is crucial for developing agricultural waste-based dielectric materials. This section highlights critical studies from the literature, exploring dielectric parameters relevant to designing agricultural waste-based materials [32].

Zheng et al. [33] conducted research on ceramic-based dielectric composites, specifically focusing on CaO-Li2O-Sm2O3-TiO2 (CLST)/polytetrafluoroethylene (PTFE) composites. Their findings revealed that increasing the volume fraction of ceramic fillers improved both the dielectric constant and loss, with a 40 % filler volume fraction yielding optimal properties. Similarly, Mo et al. examined epoxy/mica composites, demonstrating how functionalising mica fillers through self-polymerisation and in situ grafting significantly enhanced both dielectric and thermal properties. Adding polydopamine and fluoro-chemicals increased thermal conductivity by 42 % and impact strength by 72 %, demonstrating that ceramic fillers like mica can significantly improve composite performance.

Research on metal-based dielectric composites has shown that metal fillers can significantly enhance the dielectric properties of polymer matrices due to their conductive nature. However, while metal fillers often lead to higher dielectric constants, they can also increase dielectric losses and cause challenges in dispersion [34]. Careful control of particle size and morphology is essential for minimising these issues [35].

Bai et al. [36] investigated carbon-based dielectric composites, particularly focusing on the effects of carbon nanotubes and graphene on dielectric properties. Their study highlighted the importance of factors such as the geometry of carbon particles, the volume fraction, the type of polymer matrix, and processing conditions, including electron irradiation and temperature. Ceramic powder volume percentage in polymer composites significantly impacts the dielectric constant. Increased ceramic filler volume increases the dielectric constant (see Fig. 4). Proper dispersion of carbon fillers is essential to achieving uniform properties, with benefits such as increased dielectric constants and reduced losses.

Fig. 4.

(a) Variation of the dielectric constant of the composites with the volume percentage of the ceramic (b) Dielectric constant of the composites with 50% volume percentage of ceramic powder under different irradiation doses (c) Dielectric properties of the composite with 50% volume percentage of the ceramic powder and irradiated with 40 Mrad doses as a function of frequency measured at room temperature (d) Cole–Cole plot of the dielectric data [36][.

For hybrid metal-ceramic composites, Wang et al. [37] developed a ternary composite of zinc (Zn) coated with zinc oxide (ZnO) and carbon fibres (CF) in silicone rubber (SR). They highlighted the importance of selecting appropriate fillers to achieve dielectric elastomers (DEs) with excellent dielectric and thermal properties. This hybrid filler system provided synergistic improvements in dielectric permittivity or dielectric constant (εr′) and thermal conductivity (TC) while maintaining low dielectric loss and electrical conductivity. The ZnO shell facilitated polarisation and phonon transport. At the same time, CF enhanced both εr′ and TC, making the Zn@ZnO/CF/SR composite suitable for high-performance applications such as artificial muscles, soft robotics, and flexible electronics.

Zhang et al. [38,39] examined carbon-metal composites by focusing on the effects of incorporating core-shell structured graphite nanosheets (GNS) coated with an aluminum oxide (Al2O3) shell into a poly (vinylidene fluoride) (PVDF) matrix. The Al2O3 shell was critical in reducing dielectric loss and conductivity by preventing leakage currents and improving insulation. Additionally, the shell alleviated dielectric mismatch, enhanced breakdown strength by introducing charge carrier traps, and improved thermal conductivity by facilitating phonon transport. By adjusting the Al2O3 shell thickness, the dielectric and thermal properties of GNS@Al2O3/PVDF nanocomposites could be optimized for specific applications.

Metal oxide nanofillers have also been studied for their impact on dielectric properties. Chen et al. [40], the dielectric constant (εr′) of nanocomposites decreases as the frequency of the applied electric field increases, a typical behavior in dielectric materials. At lower frequencies, dipole and space charge polarisation can align with the electric field, resulting in a higher dielectric constant. However, as frequency rises, these polarisations struggle to keep up with the rapid changes, leading to a reduced contribution to overall polarisation and, consequently, a lower dielectric constant. Conversely, the dielectric constant increases with higher filler loading, as introducing more core@double-shell structured Cu@CuO@MgO nanofillers creates additional interfaces within the PVDF matrix. These interfaces act as microcapacitors, enhancing interfacial polarisation and boosting the dielectric constant. This relationship aligns with the Maxwell-Wagner-Sillars (MWS) polarisation model, which suggests that increasing filler content enhances polarisation and dielectric properties [41].

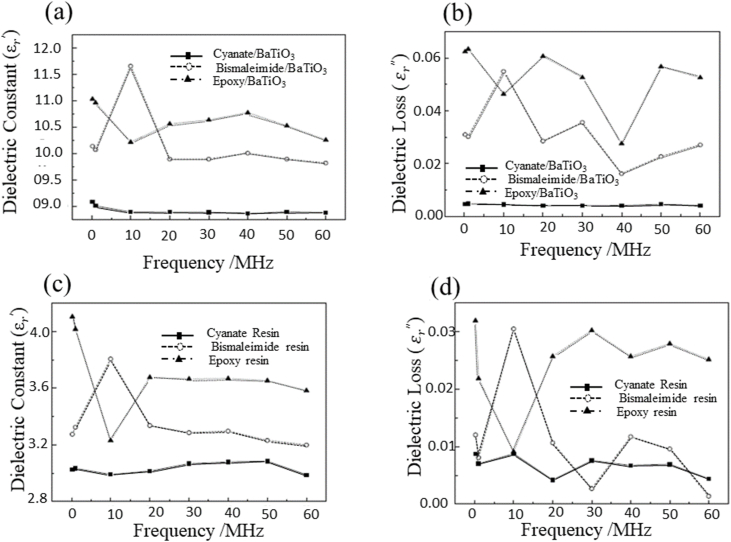

The interface between the polymer matrix and the filler plays a critical role in determining dielectric properties. Chao et al. [42] studied polymer/ceramic composites with thermosetting polymers such as cyanate resin, bismaleimide resin, and epoxy resin, where barium titanate (BaTiO3) particles were used as fillers. They found that the cyanate/BaTiO3 composite exhibited superior dielectric properties, with the Lichterecker mixing rule providing an accurate prediction of the effective dielectric constant. As the frequency increases, the dielectric constant and dielectric loss of the composites made with bismaleimide resin and epoxy resin tend to increase, while the dielectric loss of the cyanate/BaTiO3 composite decreases with the increase of BaTiO3 content. The dielectric properties of cyanate resin are more stable across various frequencies, further enhancing the overall performance of the composite as shown in Fig. 5. This study highlights the role of interface quality in determining the dielectric properties of the composite. Functionalised interfaces, such as those found in polymer/ceramic composites, improve the interaction between the filler and the matrix, resulting in higher dielectric constants and better mechanical properties [43].

Fig. 5.

(a) Dielectric constant of compositions change with the variation of the frequency (b) Dielectric loss of compositions change with the variation of the frequency (c) Dielectric constant of pure resins change with the variation of the frequency (d) Dielectric loss of pure resins change with the variation of the frequency [42]

From these studies, it is evident that dielectric properties are influenced by various factors, including the type of filler, its morphology, dispersion, and interactions between the filler and matrix. The shape and volume fraction of fillers, as well as the frequency of the applied electric field, significantly affect the dielectric behaviour of composites [44]. The SEM images of various composites are provided in Fig. 6. These insights provide a foundation for further development of agricultural waste-based dielectric composites. By carefully selecting and processing the filler materials and composite structures, researchers can optimise the dielectric properties of these materials. Table 2 summarises key findings from studies on dielectric composites with various filler materials.

Fig. 6.

(a) SEM image PTFE composite [48] (b) Surface and cross-sectional SEM images of PTFE-glass fibre composite [49] (c) SEM micrograph of hot-pressed polymer ceramic composite [50] (d) SEM image of carbon nanotube polymer composite [51].

Table 2.

Sources of dielectric composite from various filler types.

| Composite | Matrix | Filler | Dielectric Constant | Application | Ref. |

|---|---|---|---|---|---|

| Ceramic-PTFE composite | Polytetrafluoroethylene (PTFE) | Ceramic oxides (Al2O3, BaTiO3) | 3–50 | High-permittivity capacitors, microwave substrates | [33] |

| Mica-epoxy composite | Epoxy resin | Mica | 5–7 | High-temperature capacitors, motor commutators | [45] |

| Glass fibre-PTFE composite | Polytetrafluoroethylene (PTFE) | Glass fibres | 2.0–2.2 | High-frequency PCBs, microwave components | [46] |

| Polymer-ceramic composite | Polypropylene | Barium titanate (BaTiO3) | 3–10 (depending on filler content) | Low-cost capacitors, temperature sensors | [42] |

| Polymer-carbon nanotube composite | Polyimide (PI) | Carbon nanotubes (CNTs) | 2.5–3.5 (PI) with potential for higher depending on CNT alignment | Lightweight, high-performance capacitors for flexible electronics | [47] |

3. Process of making dielectric composites from agriculture waste

Composite materials improve mechanical, thermal, and electrical properties by combining a matrix material with reinforcement like natural fibres or agricultural waste particles. The methodical process of developing samples starts with gathering agricultural waste and thorough cleaning to remove contaminants. After being cleaned, the waste material goes through a customised processing stage that uses techniques such as fibre extraction, grinding, soda pulping, and carbonisation. Fig. 7 shows the process of fabricating a sample composite material until the material characterisation process is completed.

Fig. 7.

Guide to process flow of sample preparation and dielectric material characterisation methods.

In Phase 1 of composite development, depicted in Fig. 7, the collection and cleaning of agricultural waste to ensure the removal of impurities and contaminants that could affect the material's performance. Cleaning methods include washing with water, chemical treatments, and drying, which help eliminate dirt, pesticides, and organic residues. This step is crucial as agricultural waste often contains hazards such as bacteria, fungi, and chemical residues, which could pose health risks and compromise the quality of the final composite.

Phase 2 of composite development involves processing agricultural waste to create useable materials for composite fabrication. This phase includes methods like fibre extraction, soda pulping, carbonisation, and grinding. Fibre extraction involves separating fibrous material from waste to improve its mechanical properties and compatibility with polymer matrices. This process is essential for producing high-strength composites and ensuring uniformity in the final product [52,53]. Soda pulping is a chemical process that breaks down lignin and hemicellulose in agricultural waste, resulting in cellulose pulp. This process, which involves treating the waste at high temperatures in a soda pulping digester, improves the purity and quality of the cellulose, making it more suitable for composite production. Carbonisation is the thermal decomposition of agricultural waste in an inert atmosphere at high temperatures to produce carbon-rich materials like biochar [53]. This process enhances the electrical conductivity and thermal stability of composites, making it crucial for applications requiring enhanced dielectric properties, such as in electronic devices [54]. There are various methods, such as open fire, hydrothermal, and pyrolysis, that can be used to turn biochar. Grinding reduces the size of agricultural waste particles to a fine powder, improving the uniformity and surface area of the material and its interaction with polymer matrices.

In Phase 3, natural fibres or agricultural waste particles are combined with synthetic polymers to create robust and environmentally beneficial composite materials [21]. These composites exhibit better mechanical, thermal, or electrical properties than their individual components because they comprise a matrix and reinforcement. The matrix, usually a polymer, provides structural support, while the reinforcement, such as natural fibres or agricultural waste, enhances strength and other desirable properties [55]. Usually, the materials required for the dielectric composite material include epoxy resin as the matrix material, a hardener for curing, and agricultural waste in various forms such as fibre, cellulose, and carbonised forms. These components are carefully selected and processed to ensure the final composite meets the desired performance criteria. It is illustrated in Fig. 8. In the investigation conducted by Dhal and Mishra [56], epoxy resin was utilized as the matrix for a hybrid polymer composite, integrating fly ash and coir dust as fillers. Similarly, Omah et al. [57] employed epoxy resin for composites incorporating cow bone particles and later cassava cortex particles, demonstrating the adaptability of epoxy resin in agricultural waste composites. Panwar et al. [25] used Bisphenol A Novolac epoxy as the matrix material in the study of sugarcane bagasse composites, emphasizing epoxy's role in enhancing mechanical and dielectric properties. Conversely, Chaturvedi et al. [28] used polyurethane as the matrix material for composites with paddy straw particles, though the specific type of polyurethane was not specified. Cao et al. [58] employed poly (vinylidene fluoride) (PVDF) as the matrix for composites incorporating graphene oxide (GO) and organic insulating shells, focusing on the matrix-filler interaction to enhance dielectric performance.

Fig. 8.

Illustration of fabrication of composite [59].

These studies demonstrate that epoxy resin is commonly chosen due to its superior adhesive properties, high mechanical strength, and excellent electrical insulation, making it a preferred choice in agricultural waste composites. While epoxy is prevalent, other polymers, such as polyurethane and PVDF offer unique benefits, including flexibility, low density, or improved dielectric properties, depending on the application. The selection of matrix material is critical, as it dictates the interaction between the filler and the matrix, influencing the composite's dielectric, mechanical, and thermal characteristics. This underscores the importance of matrix selection in optimising the performance of sustainable composite materials.

In Phase 4, material characterisation involves examining and quantifying the properties and behaviour of materials to gain insight into their composition and structure. EDX is employed for elemental analysis, while chemical analysis determines the chemical composition of the material. EDX analysis, used alongside electron microscopy techniques such as SEM stimulates atoms in the sample, captures them, and quantifies their energy and intensity to produce X-rays. This analysis generates a spectrum that depicts the elements found in the sample and their respective abundances, providing essential insights into the material's suitability for particular applications, such as improving dielectric properties in composites [60]. Dielectric measurements can be carried out using several methods, including the parallel plate capacitor, the transmission line, the open-ended coaxial probe, the free-space, and the resonant methods. This process involves using a Vector Network Analyzer (VNA) and a rectangular waveguide to measure dielectric properties over a wide frequency range. The setup includes a VNA for transmission coefficient measurement, a rectangular waveguide with a frequency range of 4 GHz–6 GHz, and a sample composite material prepared to fit the waveguide's dimensions. The waveguide mode is used for propagation. The sample must be solid and cut precisely to fit the waveguide's dimensions. The VNA calibration is performed using a two-port Short-Open-Load-Thru (SOLT) procedure. The transmission coefficient is measured using the VNA, and the permittivity and loss tangent of the composite material are estimated using an inverse technique [61].

4. Dielectrics and influential factors affecting dielectric properties

Dielectric materials, which are inherently non-conductive, have played an important role in numerous technological advancements since the 19th century [62,63]. These materials can store electrical energy when exposed to an external electric field, necessitating a comprehensive analysis of their development, properties, and applications [64]. A key parameter in understanding dielectric behavior is the dielectric constant, or permittivity, which governs the material's response across different frequencies. Equally important is dielectric loss, which requires detailed analysis through the loss tangent to evaluate energy dissipation in the form of heat. Insulation resistance further elucidates a dielectric's ability to resist electrical stress without breakdown [65]. The polarisation behaviour of dielectric materials involves multiple processes, including electronic, ionic, and dipolar polarisation, each contributing to the material's overall response to an electric field [66,66] (see Fig. 9).

Fig. 9.

Pictorial representation of polarisation in dielectrics [67].

The interaction of an electric field with a dielectric can be understood by considering the material's atoms as having a negative charge (-Q) and a positive charge (+Q). When subjected to an external electric field (E0), the material undergoes electric dipole induction, with the induced electric field opposing E0, thereby reducing the overall electric field (Enet) within the dielectric [68].

Permittivity, a fundamental property of dielectrics, determines the material's ability to transmit an electric field and is categorized into the electric constant (ε0) and relative permittivity (εr or ε) [69]. The influence of temperature introduces additional complexity, requiring thermal analysis to fully understand its effect on dielectric properties [70,71]. Researchers studying composite dielectrics must examine the intricate interactions between components and how this influences overall dielectric behaviour [72]. The dielectric permittivity, i.e., relative permittivity, is a complex quantity that consists of two components: the real part and the imaginary part; the real part of the dielectric constant is referred to as ε′r, while the imaginary part is known as dielectric loss, denoted as εr″. The relationship is expressed in Equation (1).

| 1 |

The dielectric constant, or the real part of the relative permittivity (ε′r), is crucial in characterising a material's interaction with an electric field [73]. It represents the material's capacity to polarise in response to the external field, thereby affecting the overall field strength. A higher ε′r value indicates an increased capacitance in a given configuration compared to a vacuum. This constant not only determines the material's ability to store energy but also influences its interaction with electromagnetic fields. Dielectric loss, indicated by a phase shift between the applied electric field and the resulting displacement current, reflects the conversion of electromagnetic energy into heat [74]. Dielectric strength, which measures the maximum electric field a material can withstand before breakdown, is essential in assessing its insulating capabilities degree [75,76].

This section also explores the factors influencing the dielectric properties of materials derived from agricultural waste. The composition of the materials, particularly carbon and oxygen, affects their permittivity values. Filler content, which incorporates waste materials, also affects the dielectric constant and loss tangent. Temperature variations also affect the properties, with higher cellulose content leading to lower permittivity values. Morphological changes in cellulose fibre structure can also affect dielectric properties. Understanding these factors is crucial for developing sustainable, high-performance dielectric materials that can replace traditional, less eco-friendly options in electronic applications. This knowledge is crucial for developing sustainable, high-performance dielectric materials.

4.1. Influence of elements

The researchers Hossain et al. [77] have found that increasing the oxygen content in the dielectric material leads to a reduction in the permittivity value. Pattanayak et al. [78] have highlighted the crucial significance of carbon in the absorption or storage of electromagnetic signals.

Yusof et al. [79] examine the relationship between the elemental compositions and permittivity values of dielectric composite materials made from pineapple leaf fibre. The study revealed that the presence of carbon and oxygen substantially affects the permittivity value of the composite materials. The presence of carbon enhances the material's capacity to absorb and retain electromagnetic signals, whereas the presence of oxygen diminishes its capacity to absorb and retain signals. The study additionally discovered that pineapple fibre could serve as a valuable resource for producing dielectric composite materials, thereby reducing electronic waste pollution through its biodegradable properties. Future suggestions entail incorporating diverse botanical constituents to enhance the dielectric characteristics of the composite material, catering to a wide range of electrical applications. Fig. 10 illustrates the relationship between the dielectric constant and the percentage of carbon and oxygen in the cellulose powder derived from pineapples.

Fig. 10.

Graph on dielectric constant value of pineapple leaves cellulose powder composite with carbon and oxygen percentage [79].

Nitrogen content enhances the dielectric property of diamond-like carbon sheets, which correlates with the dielectric constant value. Nitrogen doping may serve as a regulatory mechanism for modulating the dielectric properties of composite materials [80]. Guler et al. [81] found that nitrogen doping had a similar effect on the electrical and dielectric properties of zinc oxide. This was because it increased the zinc oxide capacitance value. The dielectric property of diamond-like carbon sheets is augmented by nitrogen content, correlating with the dielectric constant value. Nitrogen doping may serve as a regulatory mechanism for modulating the dielectric properties of composite materials. Dhari et al. [82] discovered that the potassium-doped composite exhibits a higher dielectric constant compared to the undoped composite. The incorporation of surplus potassium in the sodium-potassium niobate ceramic composite led to enhanced dielectric permittivity and reduced dielectric loss. This may also elucidate the increase in the dielectric constant value with the augmentation of potassium components in waste materials. Sharma et al. [83] investigated the dielectric characteristics of soil samples enriched with ammonium sulfate and potassium nitrate, discovering that the soil dielectric constant progressively increases with higher concentrations of these compounds. Ammonium sulfate yields a superior increase in dielectric constant compared to potassium nitrate, likely because of the slower decay of potassium nitrate relative to ammonium sulfate.

Understanding the relationship between elemental composition and dielectric properties offers valuable insights into the behaviour and efficacy of dielectric materials across various applications. However, drawing conclusions about the impact of different elemental percentages on the dielectric constant is challenging due to insufficient data and research regarding how these elements influence the dielectric constant.

4.2. Filler percentage

Zulkifli et al. [84] examines the dielectric constant and loss tangent of different proportions of rice husk, rice straw, sugarcane bagasse, and banana leaves. The dielectric properties were assessed using a dielectric probe. The results indicate that increasing the percentage of filler leads to an increase in both the dielectric constant and loss tangent. When it comes to dielectric properties, banana leaves exhibit superior performance. The readings of rice husk, rice straw, and sugarcane bagasse are inconsistent. Banana leaves containing 50 % filler exhibit the highest dielectric constant, making them well-suited for antenna applications. When various agricultural waste materials have a filler percentage of 10 %, the resulting loss tangent is less than 0.1, which is considered acceptable for antenna applications. Agricultural waste samples, with a filler content of 40 %, demonstrate promise for utilisation as microwave absorbers. Varying the percentage of filler material results in varying dielectric constant and loss tangent performances. Utilising agricultural waste in microwave applications can result in cost savings and reduced environmental impact when compared to conventional materials [84]. Fig. 11, Fig. 12 show the graphical representation of dielectric constant value and loss tangent for the particular filler percentage. The investigation conducted by Khan et al. [85] also demonstrated that an increased quantity of filler can result in a higher dielectric constant while maintaining a moderate dissipation factor. The study by Jayamani et al. [86] on pineapple leaf composites also shows that composites with a higher fibre loading have the highest dielectric constant value in all the noted frequencies.

Fig. 11.

Value of dielectric constant of rice husk, rice straw, sugarcane bagasse, banana leaves with various filler percentages [87].

Fig. 12.

Value of loss tangent of rice husk, rice straw, sugarcane bagasse, banana leaves with various filler percentage [84].

4.3. Temperature

Mishra et al. [31] conducted a study on the dielectric properties (permittivity and loss factor), alternating current (AC) conductivity, and AC resistivity of pure epoxy resin and composites with varying amounts of coir dust reinforced polymer composite. The study was carried out in the frequency range of 100 Hz to 1 MHz and at temperatures ranging from 30 to 150 °C. The experimental findings suggest that as the frequency increases, both the dielectric constant and dielectric loss factor decrease. This occurrence may be attributed to the orientation polarisation. Conversely, as the temperature rises, both the dielectric constant and dielectric loss factor increase. This can be attributed to the increased movement of polar molecular dipoles. This effect is more pronounced on the dielectric constant and dielectric loss at low frequency and high temperature. At room temperature, the AC conductivity has shown an increase while the AC resistivity has decreased as the frequency increases [88]. The most significant changes in conductivity and resistivity with frequency were observed in the composite reinforced with 40 wt% coir dust.

4.4. Cellulose content

The study of Rasid et al. [26] indicates an inverse relationship between cellulose content and permittivity. Higher cellulose content is achieved with longer boiling times, which tends to reduce the permittivity values. Conversely, shorter boiling times, which reduce cellulose content, result in higher permittivity values. Therefore, to produce dielectric materials with higher permittivity, a shorter boiling time is preferable, even though it results in lower cellulose content. This trade-off suggests that optimising boiling time is crucial for balancing cellulose content and permittivity in dielectric materials.

4.5. Morphological changes

The study of Yusof et al. [89] analysed the effect of morphological changes in cellulose fibres on dielectric constant values, also described as permittivity values. The results showed that the dielectric constant value increased as the diameter of the cellulose fibre decreased and vice versa. Out of the six samples taken, the highest dielectric constant value was obtained with the smallest cellulose fibre diameter of 3.78 ± 0.89 μm, while the lowest dielectric constant value was achieved with a sample with a cellulose fibre diameter of 5.40 ± 1.37 μm. The small diameter of the cellulose fibres benefited not only their permittivity but also their mechanical properties. Both mechanical and dielectric properties depend on porosity, density, and fibre morphology properties. Fibres with smaller diameters possess better mechanical properties, such as higher strength and modulus. The distance between cellulose fibres also showed a similar trend, with the dielectric constant value decreasing as the distance increased due to the increase in porosity. The presence of large air voids between the cellulose fibres resulted in low dielectric constant values due to the fibre's high porosity. The loose arrangement between fibres due to large air voids reduced the fibre content in the pineapple leaf, reducing the dielectric constant value. The cellulose content and dielectric constant values showed parallel behaviour with cellulose content. The loose arrangement of fibres with large air voids caused the lowest cellulose content among other samples, at 14.83 wt%. The SEM image of the sample with the highest permittivity value is shown in Fig. 13, which has the smallest cellulose fibre diameter of 3.78 ± 0.89 μm and the smallest distance between fibres of 4.90 ± 0.45 μm. Its cellulose content is 27.81 wt%. The EDX analysis reveals that carbon is the most abundant element in the sample, with a composition of 55.08 wt%, followed by oxygen at 43.04 wt%. Other elements like Na, Mg, and Ca are present in smaller amounts. The fibres are tightly packed together due to their small diameter, contributing to the high permittivity value. The finest fibre diameter and tightest arrangement of fibres contribute to a high permittivity value, while loose arrangements with large air voids result in lower cellulose content and permittivity values. The study found that the dielectric constant value increased with the diameter of cellulose fibres, with the smallest diameter achieving the highest value. Distance between cellulose fibres decreased as porosity increased. Large air voids between fibres resulted in low dielectric constant values due to high porosity. The loose arrangement of fibres with large air voids reduced cellulose content, resulting in the lowest dielectric constant value. The effect of fibre diameter and the distance on dielectric constant value and cellulose content in the study is depicted in Fig. 14.

Fig. 13.

SEM image of the sample with the highest dielectric constant value pineapple cellulose fibre [89].

Fig. 14.

Relationship between the value of cellulose content across the (a) diameter, (b) distance between fibres, and the permittivity values of pineapple leaf fibre across (c) diameter, and (d) distance between fibres [89].

Mishra et al. [30] conducted a study on the morphological analysis of sugarcane bagasse-based composites. Their findings indicate that morphological alterations in the fibre lead to improved interlocking between the reinforcement and matrix of the composite, thereby enhancing its dielectric properties. The particle size of natural fillers significantly influences the mechanical and dielectric properties of composite materials. Studies by Pattanayak et al. [90] and Omah et al. [57,91] have shown that nanoscale fillers, such as banana leaf fillers, enhance the surface area-to-volume ratio, improve filler-matrix interactions, and lead to better dispersion within the polymer matrix. This results in composites with superior mechanical and electrical properties due to reduced agglomeration and enhanced bonding. Omah et al.’s [57]study also showed that nanoparticles provide better reinforcement by creating a denser filler-matrix interface, reducing voids and defects that may compromise the composite's performance. Yusof et al.’s [89] study used fillers with an average diameter of 3.78 ± 0.89 μm, which falls in the micron scale. While larger particles offer advantages like ease of processing and cost-effectiveness, they may result in less effective filler dispersion and increased void formation, negatively impacting the composite's performance. Similar findings were also observed by Jayamani et al. [86], in which the dielectric properties of jute and bamboo fibres significantly increased with increased fibre content.

4.6. Surface modification of fillers

Surface modification of fillers is essential for improving the compatibility between fillers derived from agricultural waste and the polymer matrix. Raw fillers often have poor compatibility, leading to defects or voids that can negatively affect dielectric properties. Surface modifications enhance bonding, dispersion, and overall dielectric performance [88]. Key areas to expand include addressing surface impurities and irregularities in raw materials like biochar or natural fibres, which can cause poor interfacial adhesion and increased dielectric losses. Surface treatments like ultrasonic treatments [30], salinisation [92], grafting with coupling agents [93], and plasma treatments are commonly used to improve filler-matrix interaction. For example, silane coupling agents improve the compatibility of natural fillers with the matrix, enhancing bonding and reducing voids that could lead to electrical breakdown. Surface-modified bio-based fillers exhibit better interfacial interactions, reducing dielectric loss and improving dielectric constant, ensuring stable dielectric properties over a more comprehensive frequency range, which is crucial for electronic applications.

Mishra et al. [22] used ultrasonic treatment, which uses high-frequency sound waves to generate cavitation bubbles in a liquid medium. These bubbles, when collapsed near the filler surface, produce localized high-energy microjets and shock waves that can remove surface impurities, disrupt agglomeration, and enhance surface reactivity. The process removes adsorbed gases, weakly bonded layers, and contaminants, leading to a cleaner filler surface. It also disperses filler agglomerates into smaller particles, producing more uniform filler dispersion within the polymer matrix. The cavitation process can also create functional groups on the filler surface, enhancing its chemical reactivity and improving the filler-matrix interaction. Ultrasonic treatment enhances the dielectric properties of polymer composites by promoting better dispersion of agricultural waste fillers, reducing the occurrence of voids, defects, and air pockets, which contribute to dielectric loss. This improves interfacial adhesion, reducing the likelihood of electrical breakdowns and ensuring more stable dielectric properties across a more comprehensive frequency range.

In the study by Rajamanikandan et al. [94], surface modifications play a crucial role in enhancing the performance of natural fibre composites. The research highlights that alkaline treatment effectively removes lignin, wax, and oils from banana fibres, thereby improving bonding strength and increasing the fibres’ hydrophobicity. This process significantly enhances the overall adhesion between the fibres and the polymer matrix. The study also talks about the effects of treating with benzoyl chloride, which makes it easier for hydrophilic fibres to stick to the hydrophobic polymer matrix. This makes the composite stronger. The research further explores other surface modification techniques, such as mercerisation, salinisation, isocyanates, acetylation, and grafting. These treatments not only improve adhesion but also increase the crystallinity of the fibres, leading to enhanced electrical properties. Modified fibre surfaces, whether even or uneven, contribute to better fibre-matrix bonding, reduced voids, and improved mechanical and dielectric properties. Conversely, untreated fibres result in rough and disrupted surfaces, leading to poor adhesion to the matrix, weak mechanical properties, and compromised dielectric performance.

4.7. Breakdown strength

Breakdown strength is a crucial parameter for dielectric materials, especially in high-voltage applications. It refers to the maximum electric field a material can withstand before it fails [95]. Agricultural waste fillers, particularly carbon-based ones like biochar, may have lower breakdown strength if not adequately treated or incorporated into the matrix [96]. Filler and surface modifications influence the breakdown strength of a composite material. Studies have shown that surface-modified fillers have significantly higher breakdown strength compared to untreated fillers due to improved filler-matrix adhesion and reduced defects. Surface modification can mitigate structural irregularities in agricultural waste-derived fillers, enhancing filler dispersion and matrix interaction. Future research should also focus on the interplay between filler surface modification and breakdown strength optimisation in agricultural waste-based composites [97]. Understanding the combined influence of filler dispersion and electrical breakdown characteristics can enhance the development of high-performance, eco-friendly dielectric materials [98].

5. Application of agriculture waste-based dielectric materials

Dielectric composite materials are crucial in electronics, particularly in capacitors and antennas. Different types of antennas have varying permittivity requirements depending on their applications. For example, materials such as polytetrafluoroethylene (PTFE), commonly known as Teflon, and flame retardant 4 (FR-4) [99], which have dielectric constant ranges between 2.1 and 2.4, are widely used in printed circuit boards, dielectric resonators, and microstrip patch antennas. These components are frequently found in base stations, radar systems, global positioning units, and Wi-Fi routers. A wide variety of antennas, including log-periodic, horn, reflector, Yagi-Uda, parabolic dish, and slot antennas [100,101], utilise different dielectrics with specific dielectric constant values tailored for various applications [102], from mobile radio systems to satellite communication [103]. Capacitors are also essential in filters, power supplies, and high-voltage circuits, necessitating specific dielectric requirements that usually demand a higher dielectric constant of 500 or more [104,105]. Table 3 compares different antennas and capacitors using conventional dielectric materials along with their respective applications, opening avenues for exploring sustainable substitutes.

Table 3.

Comparison of Various Antennas and Capacitors in terms of their Dielectric Constant Value.

| Device | Dielectric Constant | Conventional Dielectric material | Application | Ref. |

|---|---|---|---|---|

| Dielectric Resonator Antenna | 2.25–2.4 | Teflon, Polyethylene | Base station antenna, radar application, RFID, UWB | [106] |

| Microstrip Patch Antenna | 2.1–2.4 | Teflon, Polyethylene | GPS, RFID, WiMAx, Telemedecine, Radar | [107] |

| Printed Circuit Board Antenna | 2.1–2.4 | FR-4, Rogers RO4003C, Teflon (PTFE) | Radar, Wifi, UWB, GSM, WLAN | [108] |

| Horn Antenna | 2.1–2.4 | Polyethylene (PE), Teflon (PTFE) | Radar systems, Satellite communication, Electronic warfare systems, Radio astronomy | [109] |

| Reflector Antenna | 4.5–5.5 | Fiberglass | Satellite communication, RFID, Radar astronomy, Deep space communication | [110] |

| Yagi-Uda Antenna | 4.5–5.5 | Fibreglass, Plastic | Television reception, Two-way radio communication, Wireless data transmission systems | [111] |

| Parabolic Dish Antenna | 4.5–5.5 | Fibreglass, Metal plates | Satellite communication, Radio astronomy, Radar systems, Microwave point-to-point links, Deep space communication | [112] |

| Log-Periodic Antenna | 2.4–4.8 | FR-4, Teflon (PTFE) | HF communication systems, Mobile radio communication, Radar systems, Broadcast applications, Military communication systems | [113] |

| Slot Antenna | 2.1–4.8 | FR-4, Teflon (PTFE) | Mobile phones and wireless devices, Microwave circuits, Radar systems, RFID | [114] |

| Ceramic Capacitor | 10–3000 | Ceramic | Filters, Decoupling | [115] |

| Electrolytic Capacitor | 8–20 | Aluminium Oxide | Power supplies, audio circuits | [116] |

| Mica Capacitor | 5–7 | Mica | High voltage, RF | [117] |

| Polymer Film Capacitor | 2.2–6 | Polyester, Polypropylene | High Temperature Applications, Timing circuits | [118] |

The potential for agricultural waste-based dielectric composites as an alternative to conventional materials is promising. Table 3 showcases various applications that require dielectric materials, such as dielectric resonators, microstrip patches, horns, and log-periodic and slot antennas. Conventional materials like PTFE/Teflon, polyethylene, and fibreglass typically possess dielectric constant values ranging from 2.1 to 5.5. Findings in Table 1 demonstrate that agricultural waste, such as coconut shells (3.769), oil palm empty fruit bunches (3.455), and pineapple leaves (4.210), exhibit dielectric constant values within this range. This alignment suggests the feasibility of replacing conventional dielectrics with these sustainable composites, particularly for applications in antennas like dielectric resonators, microstrip patches, printed circuit boards, and horns. However, capacitors generally necessitate higher dielectric constant values, warranting further research to optimise agricultural waste composites for this purpose.

6. Challenges, promising solutions, and environmental and economic impact

Analysing various applications that rely on dielectric materials and their specific permittivity requirements reveals a promising path toward sustainable alternatives made from agricultural waste. Comparing Table 1, Table 3 shows that agriculture waste-based dielectric materials could benefit antenna applications with dielectric constant needs between 2 and 6. However, further research is necessary to evaluate their performance in these applications fully. This includes costs, size, long-term stability, and overall sustainability compared to traditional materials. One compelling solution lies in combining carbonised agricultural waste with composite dielectric materials. This approach offers a balance between environmental and economic concerns [119]. These composites promote a circular economy by repurposing waste resources like rice husk and sugarcane bagasse [120]. This, in turn, reduces environmental impact by minimising the waste accumulation [121]. Additionally, their production requires fewer chemicals and less equipment, leading to a smaller environmental footprint [122]. The economic benefits are equally promising, with lightweight composites offering significant cost reductions, optimized production processes, job creation potential, and lower energy consumption during transportation.

However, challenges remain in the development and implementation of these sustainable dielectrics. Optimising the dielectric properties and managing the variations in agricultural waste materials are crucial [123]. Standardisation is essential for achieving consistent performance in composite materials. Additionally, surface modification techniques and exploration of various treatment procedures are needed to enhance compatibility with matrix materials. Furthermore, advancements in manufacturing methods, remarkably improved dispersion techniques, are necessary to achieve improved characteristics and scalability. Future research should prioritise optimising dielectric properties, refining production methods, and exploring novel electromagnetic interference shielding and sensor technologies applications. A strategic focus on these elements will encourage broader integration of these materials across various industries. This will represent a significant step towards a more environmentally conscious and sustainable future.

7. Conclusion

The potential of using sustainable polymer-based dielectric composites made from agricultural waste as a practical substitute for non-renewable conventional materials is highlighted in this review. Several key factors, including filler content, elemental composition (carbon and oxygen), temperature, morphology changes, treatment, and cellulose content, influence the dielectric constant value of these composites. Augmenting the filler content of materials such as rice husk, rice straw, sugarcane bagasse, and banana leaves amplifies the dielectric constant and loss tangent. The presence of carbon enhances the absorption and retention of signals, whereas the presence of oxygen reduces these properties. The rise in temperature increases the dielectric constant and loss factor due to the heightened movement of polar molecular dipoles. Morphological alterations, such as the size of cellulose fibres and the spacing between fibres, also affect permittivity/dielectric constant measurements. In addition, treatment can alter the surface properties and structure of the filler material, thus impacting the overall dielectric properties of the composite. The complex interaction between the material composition, structure, and external conditions determines the dielectric properties of composite materials made from agricultural waste. Gaining a thorough understanding of these connections is crucial for maximising the performance of these materials in different applications, such as antennas and microwave absorbers. It is also important to address environmental issues by using biodegradable resources. Additionally, the study highlights that the permittivity values needed for different antennas correspond to those of specific dielectric composites made from agricultural waste. This suggests that replacing conventional dielectric materials with agricultural waste-based composites could provide sustainable solutions and contribute to sustainable development.

CRediT authorship contribution statement

Mekha K B: Writing – review & editing, Writing – original draft, Visualization, Resources, Methodology, Investigation, Data curation, Conceptualization. Nurhafizah Abu Talip Yusof: Supervision, Funding acquisition, Conceptualization, Validation, Writing – review & editing, Data curation. K. Sudhakar: Validation, Conceptualization. Norazwina Zainol: Validation. Nurulfadzilah Hasan: Validation. Mohamad Shaiful Abdul Karim: Validation.

Declaration of competing interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: Dr. K. Sudhakar reports financial support was provided by Universiti Malaysia Pahang Al-Sultan Abdullah. Dr. K. Sudhakar reports a relationship with Universiti Malaysia Pahang Al-Sultan Abdullah that includes: Employment. Dr. K. Sudhakar reports a relationship with Elsevier Inc. that includes: Board membership. He is serving on the Editorial board of Heliyon as Associate Editor. If there are other authors, they declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors thank Malaysia's Ministry of Higher Education for providing financial support under the Fundamental Research Grant Scheme (FRGS) No. FRGS/1/2022/STG07/UMP/02/1 (university reference RDU220102) and Universiti Malaysia Pahang Al-Sultan Abdullah for laboratory facilities and additional financial support under Internal Research Grant RDU220382.

References

- 1.Bhong M., Khan T.K.H., Devade K., Vijay Krishna B., Sura S., Eftikhaar H.K., Pal Thethi H., Gupta N. Review of composite materials and applications. Mater. Today Proc. 2023 doi: 10.1016/j.matpr.2023.10.026. [DOI] [Google Scholar]

- 2.Abdullah R., Astira D., Zulfiani U., Widyanto A.R., Hidayat A.R.P., Sulistiono D.O., Rahmawati Z., Gunawan T., Kusumawati Y., Othman M.H.D., Fansuri H. Fabrication of composite membrane with microcrystalline cellulose from lignocellulosic biomass as filler on cellulose acetate based membrane for water containing methylene blue treatment. Bioresour. Technol. Rep. 2024;25 doi: 10.1016/j.biteb.2023.101728. [DOI] [Google Scholar]

- 3.George M., Chae M., Bressler D.C. Composite materials with bast fibres: structural, technical, and environmental properties. Prog. Mater. Sci. 2016;83:1–23. doi: 10.1016/j.pmatsci.2016.04.002. [DOI] [Google Scholar]

- 4.Wu X., Chen X., Zhang Q.M., Tan D.Q. Advanced dielectric polymers for energy storage. Energy Storage Mater. 2022;44:29–47. doi: 10.1016/j.ensm.2021.10.010. [DOI] [Google Scholar]

- 5.Sharma G., Tyagi N., Singh K., Sharma A., Preeti Km, Sharma S.K. Biogenic silicate glass-ceramics: physical, dielectric, and electrical properties. Bioresour. Technol. Rep. 2022;19 doi: 10.1016/j.biteb.2022.101176. [DOI] [Google Scholar]

- 6.Sharma K., Saini L.M. Power-line communications for smart grid: progress, challenges, opportunities and status. Renew. Sustain. Energy Rev. 2017;67:704–751. doi: 10.1016/j.rser.2016.09.019. [DOI] [Google Scholar]

- 7.Zainol N., Mustafa N., Aziz N.H., Azman A.N., Abdul Karim M.S. Dielectric materials development using bio-waste: a review. Journal of Electrical Systems and Information Technology. 2023;10:47. doi: 10.1186/s43067-023-00117-x. [DOI] [Google Scholar]

- 8.Appusamy S., Krishnan S., Gopikrishna M., Raman S. Bio-based materials for microwave devices: a review. J. Electron. Mater. 2021;50:1893–1921. doi: 10.1007/s11664-020-08672-z. [DOI] [Google Scholar]

- 9.Zhao Q., Zhao X., Cao J. In: Advanced Nanomaterials for Pollutant Sensing and Environmental Catalysis. Zhao Q., editor. Elsevier; 2020. 7 - advanced nanomaterials for degrading persistent organic pollutants; pp. 249–305. [DOI] [Google Scholar]

- 10.Liu Y., Zhao X.-Y., Sun Y.-G., Li W.-Z., Zhang X.-S., Luan J. Synthesis and applications of low dielectric polyimide. Resources Chemicals and Materials. 2023;2:49–62. doi: 10.1016/j.recm.2022.08.001. [DOI] [Google Scholar]

- 11.Lazar S.T., Kolibaba T.J., Grunlan J.C. Flame-retardant surface treatments. Nat. Rev. Mater. 2020;5:259–275. doi: 10.1038/s41578-019-0164-6. [DOI] [Google Scholar]

- 12.Ferdous S.N., Li X., Sahoo K., Bergman R. Toward sustainable crop residue management: a deep ensemble learning approach. Bioresour. Technol. Rep. 2023;22 doi: 10.1016/j.biteb.2023.101421. [DOI] [Google Scholar]

- 13.Li D., Yang C., Huang Y., Li L., Han W., Kang H., Yang F., Fang Q. Novel green resource material: eucommia ulmoides gum. Resources Chemicals and Materials. 2022;1:114–128. doi: 10.1016/j.recm.2022.01.005. [DOI] [Google Scholar]

- 14.Koul B., Yakoob M., Shah M.P. Agricultural waste management strategies for environmental sustainability. Environ. Res. 2022;206 doi: 10.1016/j.envres.2021.112285. [DOI] [PubMed] [Google Scholar]

- 15.Senadheera U.E., Jayasanka D.J., Udayanga D., Hewawasam C. Natural and designer cellulosomes: a potential tool for enhancing microbial additive-mediated lignocellulosic agricultural waste composting. Bioresour. Technol. Rep. 2024;25 doi: 10.1016/j.biteb.2023.101695. [DOI] [Google Scholar]

- 16.Tayeb A., Amini E., Ghasemi S., Tajvidi M. Cellulose nanomaterials—binding properties and applications: a review. Molecules. 2018;23:2684. doi: 10.3390/molecules23102684. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Dedousi M., Melanouri E.M., Diamantis I., Papanikolaou S., Diamantopoulou P. Biochemical, functional and antioxidant potential of higher fungi cultivated on agro-industrial residues. Part II: cultures on mixtures of spent mushroom substrates and mushroom cropping by-products. Resources Chemicals and Materials. 2024 doi: 10.1016/j.recm.2024.04.001. [DOI] [Google Scholar]

- 18.Zhu X., Jiang G., Wang G., Zhu Y., Cheng W., Zeng S., Zhou J., Xu G., Zhao D. Cellulose-based functional gels and applications in flexible supercapacitors. Resources Chemicals and Materials. 2023;2:177–188. doi: 10.1016/j.recm.2023.03.004. [DOI] [Google Scholar]

- 19.Ben Amor I., Rekik H., Kaddami H., Raihane M., Arous M., Kallel A. Studies of dielectric relaxation in natural fiber–polymer composites. J. Electrost. 2009;67:717–722. doi: 10.1016/j.elstat.2009.06.004. [DOI] [Google Scholar]

- 20.Raza A., Faizan M., Sultana I., Mustafa G.M., Atiq S., Bashir A., Naveed-Ul-Haq M., Razaq A. Morphology and dielectric studies of natural fibers and PbO2 based flexible composite sheets for potential energy storage applications. J. Electron. Mater. 2020;49:1896–1903. doi: 10.1007/s11664-019-07877-1. [DOI] [Google Scholar]

- 21.Väisänen T., Das O., Tomppo L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017;149:582–596. doi: 10.1016/j.jclepro.2017.02.132. [DOI] [Google Scholar]

- 22.Mishra S.P., Nath G., Mishra P. Ultrasonically synthesized dielectric microwave absorbing material from coconut coir dust. Waste Biomass Valorization. 2020;11:1481–1490. [Google Scholar]

- 23.Zahid L., Malek M.F.B.A., Nornikman H., Mohd Affendi N.A., Ali A., Hussin N., Ahmad B.H., Abdul Aziz M.Z.A. Development of pyramidal microwave absorber using sugar cane bagasse (SCB) Prog. Electromagn. Res. 2013;137:687–702. doi: 10.2528/PIER13012602. [DOI] [Google Scholar]

- 24.Duggal S., Aul G.D., Chawla V. 2016 Asia-Pacific Microwave Conference (APMC) 2016. Investigation of absorption properties of Sugarcane Bagasse-Coal pyramidal microwave absorber; pp. 1–10. [DOI] [Google Scholar]

- 25.Panwar R., Puthucheri S., Singh D., Agarwala V., Lee J.R. Microwave absorption properties of FSS-impacted composites as a broadband microwave absorber. Adv. Compos. Mater. 2017;26:99–113. doi: 10.1080/09243046.2016.1232009. [DOI] [Google Scholar]

- 26.Rasid N.F.N., Zainol N., Ya’acob A., Samad K.A., Yusof N.A.T., Aziz N.H., Karim M.S.A. Factorial analysis on the preparation of pineapple plantation waste as dielectric materials. Biomass Convers Biorefin. 2023 doi: 10.1007/s13399-023-04386-4. [DOI] [Google Scholar]

- 27.Giamasrow R.D., Azman A.N., Zainol N., Abdul Karim M.S., Abu Talip Yusof N. Effect of carbon composition on permittivity performance of dielectric material from agricultural waste. Mater. Today Proc. 2023 doi: 10.1016/j.matpr.2023.09.073. [DOI] [Google Scholar]

- 28.Chaturvedi R., Gupta R.K., Gorhe N.R., Tyagi P. Percolative polyurethane-polypyrrole-straw composites with enhanced dielectric constant and mechanical strength. Compos Part A Appl Sci Manuf. 2020;131 doi: 10.1016/j.compositesa.2020.105810. [DOI] [Google Scholar]

- 29.Negi P., Chhantyal A.K., Dixit A.K., Kumar S., Kumar A. Activated carbon derived from mango leaves as an enhanced microwave absorbing material. Sustainable Materials and Technologies. 2021;27 doi: 10.1016/j.susmat.2020.e00244. [DOI] [Google Scholar]

- 30.Mishra G.R., Nath G., Paikaray R. Synthesis and characterization of microwave absorbing material. Indian J. Phys. 2020;94:1749–1757. doi: 10.1007/s12648-019-01633-1. [DOI] [Google Scholar]

- 31.Mishra S., Aireddy H. Evaluation of dielectric behavior of bio-waste reinforced polymer composite. J. Reinforc. Plast. Compos. 2011;30:134–141. doi: 10.1177/0731684410388442. [DOI] [Google Scholar]

- 32.Sarker Ratna A., Verma C., Hossain S., Gupta B., Mukhopadhyay S. Development of corn husk cellulose reinforced polyvinyl alcohol bio-composite films incorporated with Zinc Oxide nanoparticles. Bioresour. Technol. Rep. 2023;23 doi: 10.1016/j.biteb.2023.101570. [DOI] [Google Scholar]

- 33.Zheng L., Zhou J., Shen J., Chen W., Qi Y., Shen S., Li S. The dielectric properties and dielectric mechanism of perovskite ceramic CLST/PTFE composites. J. Mater. Sci. Mater. Electron. 2017;28:11665–11670. doi: 10.1007/s10854-017-6969-4. [DOI] [Google Scholar]

- 34.Wang L., Yang J., Cheng W., Zou J., Zhao D. Progress on polymer composites with low dielectric constant and low dielectric loss for high-frequency signal transmission. Front Mater. 2021;8 [Google Scholar]

- 35.Rahimi-Ahar Z., Ahar L.R. Thermal, optical, mechanical, dielectric, and electrical properties of nanocomposites. Eur. Polym. J. 2024 [Google Scholar]

- 36.Bai Y., Cheng Z.-Y., Bharti V., Xu H.S., Zhang Q.M. High-dielectric-constant ceramic-powder polymer composites. Appl. Phys. Lett. 2000;76:3804–3806. doi: 10.1063/1.126787. [DOI] [Google Scholar]

- 37.Wang F., Zhou W., He Y., Lv Y., Wang Y., Wang Z. Synergetic improvement of dielectric properties and thermal conductivity in Zn@ZnO/carbon fiber reinforced silicone rubber dielectric elastomers. Compos Part A Appl Sci Manuf. 2024;181 doi: 10.1016/j.compositesa.2024.108129. [DOI] [Google Scholar]

- 38.Zhang Y., Zhang F., Zhang M., Luo J., Shi Y., Yin R., Wang G., Zhou W. Core-shell engineering of graphite nanosheets reinforced PVDF toward synchronously enhanced dielectric properties and thermal conductivity. Eur. Polym. J. 2024;215 doi: 10.1016/j.eurpolymj.2024.113236. [DOI] [Google Scholar]

- 39.Zhang Y., Zhou W., Peng W., Yao T., Zhang Y., Wang B., Cai H., Li B. Core@ double–Shell engineering of Zn particles toward elevated dielectric properties: multiple polarization mechanisms in Zn@ Znch@ PS/PVDF composites. Macromol. Rapid Commun. 2024;45 doi: 10.1002/marc.202300585. [DOI] [PubMed] [Google Scholar]

- 40.Chen X., Shi Y., Zhang K., Feng Y., Zuo J., Wu H., Ren X., Zhou W. Synergistically depressed dielectric loss and elevated breakdown strength in core@double-shell structured Cu@CuO@MgO/PVDF nanocomposites. Polymer (Guildf) 2024;307 doi: 10.1016/j.polymer.2024.127321. [DOI] [Google Scholar]