Summary

Arterial disorders such as atherosclerosis, thrombosis, and aneurysm pose significant health risks, necessitating advanced interventions. Despite progress in artificial blood vessels and animal models aimed at understanding pathogenesis and developing therapies, limitations in graft functionality and species discrepancies restrict their clinical and research utility. Addressing these issues, bioengineered arterial equivalents (AEs) with enhanced vascular functions have been developed, incorporating innovative technologies that improve clinical outcomes and enhance disease progression modeling. This review offers a comprehensive overview of recent advancements in bioengineered AEs, systematically summarizing the bioengineered technologies used to construct these AEs, and discussing their implications for clinical application and pathogenesis understanding. Highlighting current breakthroughs and future perspectives, this review aims to inform and inspire ongoing research in the field, potentially transforming vascular medicine and offering new avenues for preclinical and clinical advances.

Subject areas: Cardiovascular medicine, Bioengineering

Graphical abstract

Cardiovascular medicine; Bioengineering

Introduction

The artery serves as an essential component of the human vascular system, responsible for the delivery of oxygen-rich blood from the heart to various tissues throughout the body.1 Despite their critical role, arteries are susceptible to a range of disorders, including atherosclerosis (AS), aneurysms, stenosis, and dissection, which can significantly compromise their function and lead to life-threatening diseases.2,3 For instance, AS is the pathological basis of cardiovascular diseases (CVDs), such as heart attack and stroke,4 which account for approximately 17 million global deaths annually, representing the leading cause of mortality worldwide.5 In clinical settings where saving a patient’s life is paramount, the restoration of arterial function often involves the bypassing or replacement of the affected arteries with either autologous or synthetic vessels.6 Besides, the pathogenesis of arterial diseases remains not fully understood, impeding the advancement of innovative therapeutic strategies and effective medication.7 Therefore, there is a pressing need for reliable tools that can accurately mimic both the physiological functions and pathological responses of human arteries for clinical and research purposes.

Currently, artificial grafts used in clinical practices for artery replacement are primarily composed of synthetic polymers, such as expanded polytetrafluoroethylene and polyester (Dacron).8 These grafts are particularly effective for replacing large-diameter arteries such as the aorta and abdominal artery, where blood flow is rapid and occurs in a laminar fashion.9 Nevertheless, their application in smaller-diameter vessels is problematic due to the increased risk of thrombosis, attributable to slower and more turbulent blood flow which facilitates clot formation.10 Moreover, the inherent mechanical compliance mismatch between synthetic materials and the natural vascular tissue can lead to significant stress at the interface of the artery and the implant, potentially resulting in graft failure or neointimal hyperplasia.11 Additionally, these grafts produced from synthetic polymers may lack the capacity for adequate integration with the host’s tissues, manifesting deficiencies in crucial processes such as reendothelialization, muscularization, and extracellular matrix (ECM) remodeling, ultimately limiting their ability to transition from a foreign substance to a regenerated tissue. To address these challenges, there is a growing preference for living arterial equivalents (AEs) with biomimetic dimensions, structures, and physiological functions over rigid plastic conduits.

The concept of bioengineered blood vessels was first proposed by Weinberg and Bell in the 1980s,12 marking a significant milestone in the development of AEs as alternatives to conventional synthetic vascular grafts. With the advent of innovative biomaterials and flexible biofabrication techniques, the field of bioengineered AEs has seen considerable advancements. These biologically derived conduits are poised to transform clinical applications by closely replicating the mechanical and biological properties of native arteries.13 Not only do they facilitate the implantation process, but they also mitigate the adverse effects typically associated with synthetic products, such as clotting and stenosis,14 while promoting integration with the host through the incorporation of functional tissues such as endothelium and smooth muscles.15,16 Despite these achievements, consistent performance and long-term durability of these grafts continue to be a formidable challenge.

Given their high physiological relevance to human arteries, AEs also hold the potential for elucidating the pathogenesis of arterial diseases, serving as an alternative to traditional animal and 2D cell culture models. While in vivo and ex vivo models using experimental animals have provided invaluable insights into complex signaling pathways involved in arterial disease initiation and progression,17 discrepancies between species inevitably limit the applicability of these findings to human conditions.18 AEs, developed using human or patient-specific cells, are capable of precisely reflecting cellular responses to various stimuli, thus overcoming the limitations of animal experiments. Unlike 2D cultures, AEs offer a tissue-specific 3D microenvironment that supports controlled cell distribution, alignment, and dynamic biochemical and mechanical signals essential for promoting cellular functions and interactions.19,20 Furthermore, through thoughtful design, bioengineered AEs can be seamlessly integrated with cutting-edge techniques such as real-time biomedical imaging and artificial intelligence (AI) to conduct multifactorial analyses for accurate disease diagnosis and prognosis.21,22 However, constructing reliable and controllable AEs as in vitro models for studying arterial diseases under standardized and tunable blood flow conditions remains a critical research priority.

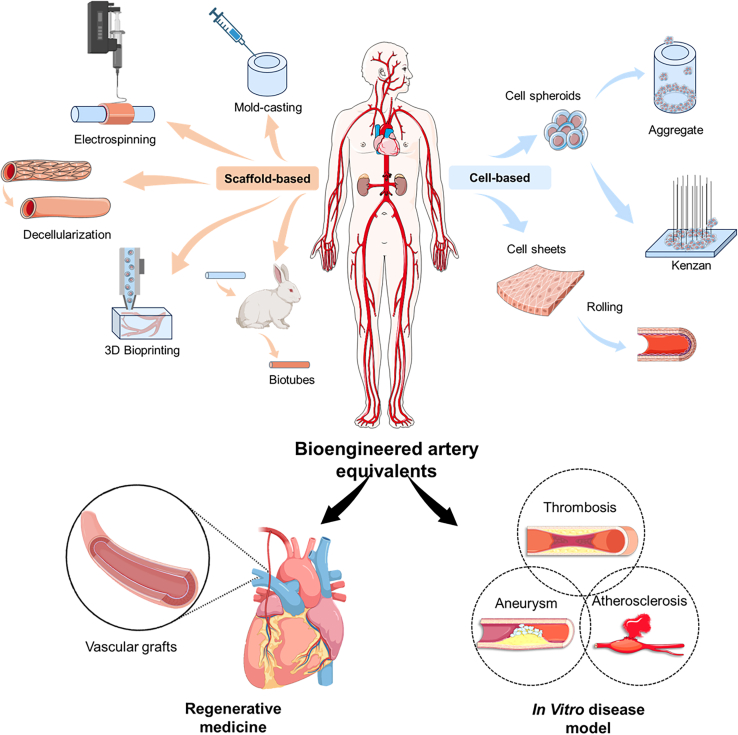

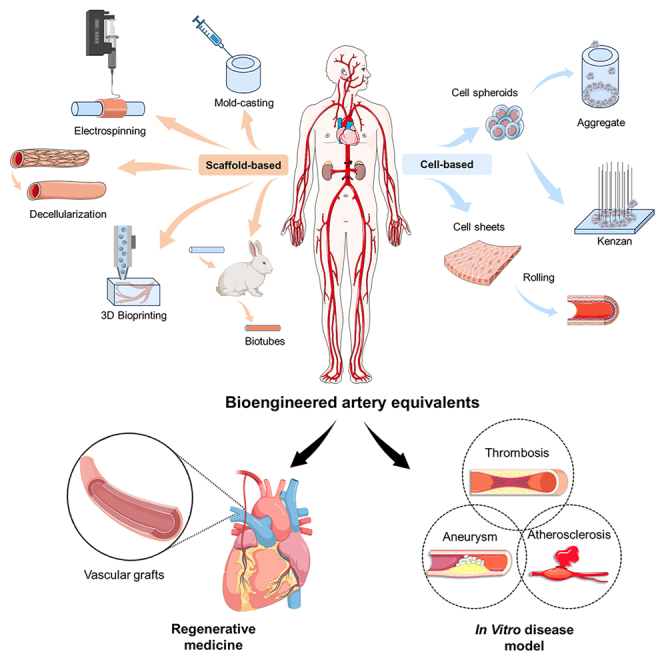

This review provides a comprehensive overview of the recent advances in bioengineered AEs and their applications in clinical practice and disease modeling (Figure 1). It begins by detailing the physiological features and functions of arteries, alongside prevalent pathogenic theories of arterial diseases, including AS, stenosis, aneurysm, and dissection. Subsequent sections systematically summarize the bioengineered technologies used to construct AEs, categorized into scaffold-based, cell-based, and dynamic devices, emphasizing their implications for clinical applications, and understanding of pathogenesis. Finally, it concludes by discussing current breakthroughs, challenges, and future perspectives in this rapidly evolving field.

Figure 1.

Overview schematic of this review

This figure was created using materials from BioRender.

Physiological function and pathological feature of the artery

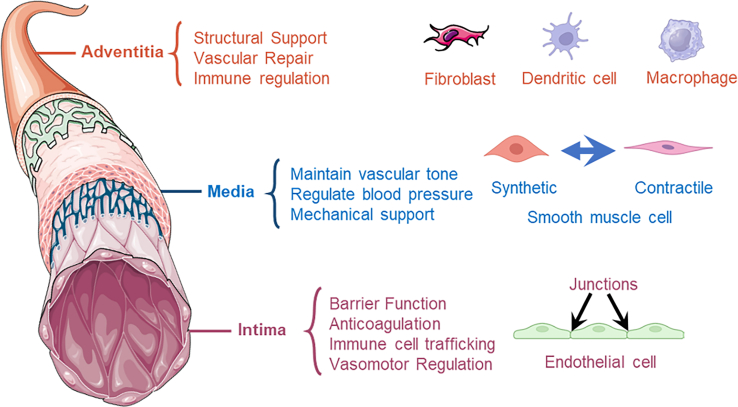

To develop biomimetic artificial tissues/organs, it is crucial to understand the fundamental characteristics of their natural counterparts thoroughly. This section delves into the anatomy, structure, composition, function, and mechanical properties of human arteries crucial for bioengineered AEs (Figure 2). It also emphasizes the significance of comprehending pathogenesis and replicating pathological microenvironments for accurately modeling arterial diseases.

Figure 2.

Structure and composition of the human arterial wall

Anatomy and function of the artery

A detailed understanding of arterial anatomy and physiological functions is critical for the structural design, and selection of appropriate biomaterials, cells, and bioengineered techniques. Human arteries are composed of three distinct layers: the tunica intima, tunica media, and tunica adventitia.23 Each layer contains specialized vascular tissues, cells, and complex ECM components essential for performing specific physiological functions.24

The tunica intima includes an elastic layer composed of elastic fibers and an endothelial tissue made up of a single layer of endothelial cells (ECs).25 The primary function of the elastic layer is to provide elasticity and flexibility to the vessel wall, enabling it to adapt to dynamic pressure changes caused by blood flow.26 ECs are optimally arranged along the direction of blood flow to reduce blood flow resistance and maintain the stability of the vascular internal environment. These cells form a selectively permeable barrier through tight junctions, adherence junctions, and gap junctions, restricting nonspecific transendothelial migration of large molecules and cells.27 In addition, ECs maintain blood fluidity and prevent blood coagulation by releasing anticoagulant factors such as nitric oxide (NO), prostacyclin, and tissue plasminogen activator, and by expressing thrombomodulin to inhibit platelet aggregation and fibrin formation.28,29 Besides, under inflammatory conditions, ECs upregulate the expression of intercellular adhesion molecules, selectins, and vascular cell adhesion molecules to promote the interaction between immune cells and ECs, guiding immune cells to migrate from the bloodstream to sites of inflammation or infection.30 Furthermore, under flow conditions, the EC initiates a signal to recruit SMCs and pericytes, contributing to the mechanical properties of the arterial wall that allow it to withstand high vascular pressures.31 The functional endothelium on the luminal surface is a critical component in the human artery and plays a significant role in the development of dependable bioengineered AEs.

The tunica media is the middle layer of the arterial wall, primarily composed of smooth muscle cells (SMCs) and ECM (e.g., collagen, elastin) fibers. ECM fibers provide the main structural support for the tunica media, offering stability and elasticity to the vessel wall. SMCs can contract and relax, controlling the dilation and constriction of the aorta by this characteristic, thereby regulating the vessel’s internal diameter and resistance.32,33 Notably, SMCs exhibit different phenotypes based on their physiological or pathological states, primarily contractile and synthetic.34 While, the contractile SMCs are mainly responsible for vascular contraction, playing a crucial role in maintaining vascular tone and regulating blood pressure, the synthetic SMCs are involved in the synthesis of ECM proteins and regulating cell growth, especially during the repair and remodeling process after vascular injury.35,36,37 Therefore, the transformation of SMCs to the synthetic phenotype is a significant factor in the development of CVDs.38 Inhibition or reversal of this phenotypic transformation can slow down or even halt the process of cardiovascular remodeling, which is essential for constructing bioengineered AEs with long-term stability and functionality.

The tunica adventitia, the outermost layer, is composed of connective tissue that includes collagen and elastic fibers, vasa vasorum, adrenergic nerves, and lymphatic vessels.39 It provides structural support and elasticity, enabling the artery to withstand external pressures and protect the blood vessels. The adventitia houses various cell types, including fibroblasts, progenitor cells, and immune cells such as macrophages, T cells, B cells, and dendritic cells.40 These cells collaborate in the repair, remodeling, and tone regulation of blood vessels. In response to injury and stress, fibroblasts from the adventitia proliferate, differentiate into myofibroblasts, and migrate to the intima.41 They secrete factors that regulate the growth of ECs and VSMCs and recruit inflammatory and progenitor cells to the vessel wall.42 These processes are crucial for vascular repair and remodeling. In a majority of cases, the reconstruction of the adventitial layer is overlooked in the design and construction of bioengineered AEs. However, this layer not only provides necessary structural support and protection but also plays a crucial role in function, particularly in immune regulation, tissue remodeling, and integration, which is essential for reducing rejection reactions and enhancing the long-term stability and functionality of the implant.

Mechanical property and stimulation

Mechanical property

The natural arteries, endowed with densely packed and organized elastic and collagen fibers in the tunica media and adventitia, exhibit robust mechanical properties. Elastic fibers, with their excellent elasticity and recovery capabilities, are primarily responsible for the tissue’s extension and rebound after being subjected to force. In contrast, collagen fibers provide structural stability and tensile strength. Through stratification, directional arrangement, interweaving, spiral alignment, and guidance by ECM, these fibers form a complex network that can withstand pressure and maintain the structural integrity of the tissue. To prevent deformation and rupture from circulating blood flow, AEs should emulate key mechanical properties such as burst pressure, ultimate tensile strength, suture tension, and compliance.

Resembling the burst rupture of an inflating balloon, the burst pressure refers to the maximum pressure that a vascular vessel can withstand before an acute leak occurs and fails, depending mainly on the characteristics and arrangement of elastic and collagen fibers.43 The average burst pressure of small-diameter arteries (e.g., coronary artery) is 1681.6 ± 446.4 mmHg.44 To improve the burst pressure of the bioengineered AE, it is important to precisely control the strength and arrangement of ECM or ECM-mimicking fibers in the matrix.

Similar to burst pressure, the ultimate tensile strength measures an arterial vessel’s capacity to withstand tensile forces. This strength is enhanced by the orderly arrangement and proper cross-linking of extracellular matrix (ECM) fibers, which distribute stresses evenly and prevent the formation of local weak spots. For instance, the ultimate tensile strength ranges from 0.5–3 MPa in coronary arteries to 1.5–4 MPa in the radial, mammary, and saphenous veins, with strain values for natural blood vessels between 40 and 100%.11 Evaluating vascular tissue’s tensile strength can be performed through circumferential and longitudinal tensile strength tests.45

Suture tension, the maximum tension that arterial vessels can withstand during suturing, is a critical parameter in surgical procedures, especially in vascular anastomosis.46 Proper suture tension is essential for ensuring the stability of the anastomosis, promoting healing, preventing tissue damage, maintaining blood flow, and reducing postoperative complications. For example, a common femoral artery anastomosis usually requires a 5-0 Prolene suture, while a tibial artery may require a 6-0 or 7-0 Prolene suture.47,48 Inferior suture tension may lead to serious problems, including anastomosis narrowing, graft twisting, and angulation, which can affect the patency and dynamics of blood flow.49,50

Compliance in vascular grafts refers to the capacity for dimensional change in response to variations in intraluminal pressure.51 A mismatch between the compliance of a host artery and a graft can disrupt the hemodynamic flow and concentrate stress at the anastomosis, potentially leading to intimal hyperplasia and thrombosis.52,53 Arterial compliance, a key measure of elasticity, is commonly assessed in the central aorta, with an estimated compliance of 1.23 ± 0.48 mL/mmHg using the pulse pressure method.54 Dynamic radial compliance testing is an effective method to evaluate the compliance of grafts.55,56

A bioengineered AE, particularly for implantable grafts, should have mechanical performance similar to those of human arteries, ensuring that the graft can effectively mimic the function of natural arteries under physiological conditions and maintain structural and functional integrity after long-term implantation. Bioreactors are powerful tools for studying the effects of mechanical stimuli on the extracellular matrix structure and mechanical properties of engineered blood vessels, enabling optimal chemical biomechanical culture conditions.57

Hemodynamics

The association mechanism between hemodynamic conditions and vascular tissue is critical to mediate vascular physiopathology. Regulating flow signaling is crucial for developing arterial endothelium with physiological and pathological capabilities, and biomechanical analysis can identify patients prone to rapid plaque progression and destabilization.58 In general, the key mechanical stimulations caused by the blood flow involve shear stress, flow pattern, and wall pressure.

Shear stress is defined as the frictional force exerted by blood flow on ECs, with its magnitude being related to blood flow velocity, vascular diameter, and blood viscosity. Within the human arterial system, the normal range of shear stress values is approximately 10–70 dyne/cm2. The shear stress not only dictates cell alignment but also promotes the release of cytokines or biochemical factors from ECs.59,60 While physiological levels of shear stress can induce the release of NO from ECs, contributing to the regulation of vascular tone and offering beneficial effects such as inhibiting platelet aggregation, anti-inflammation, and anti-oxidation, excessively high shear stress may cause endothelial damage.61 In contrast, low oscillating shear stress may promote the formation of vascular diseases, such as AS.62

Flow pattern also plays a decisive role in regulating cell fates. In human arteries, the normal laminar flow pattern, characterized by orderly fluid layers parallel to the vessel wall, applies stable shear stress to ECs, promoting an anti-inflammatory and anti-thrombotic phenotype expression, which helps maintain the stability of the vascular internal environment.63 However, at arterial bends or bifurcations, the flow pattern may shift to turbulent or transitional flow, leading to ECs dysfunction and an increased risk of AS.64 This shift in flow pattern is accompanied by the generation of abnormal shear stress, which activates signaling pathways within ECs, causing significant changes in cell morphology and function, including cytoskeletal rearrangement and adjustments in intercellular junctions, ultimately promoting arterial wall remodeling and the progression of aneurysms.

Wall pressure is determined by the interplay of cardiac output and peripheral vascular resistance, which is influenced by factors such as vascular geometry, compliance, and blood viscosity. The normal arterial blood pressure range for healthy adults is approximately a systolic pressure of 90–120 mmHg and a diastolic pressure of 60–80 mmHg.65 Wall pressure affects vascular function by ensuring blood flow, inducing vascular remodeling in response to chronic hypertension, regulating the release of endothelium-derived vasoactive substances, and deteriorating the degenerative progress of arterial walls in relevant diseases such as aneurysm and dissection.66,67

Pathogenesis of human arterial diseases

Atherosclerosis

Atherosclerosis is a chronic inflammatory vascular disease, which is also related to the mechanisms of age-related diseases.68 The characterized by lipid deposition, inflammatory responses, and fibrosis within the arterial wall, leading to atherosclerotic plaque formation.69 These plaques can narrow arteries, disrupt blood flow, and increase the risk of heart disease and stroke.70

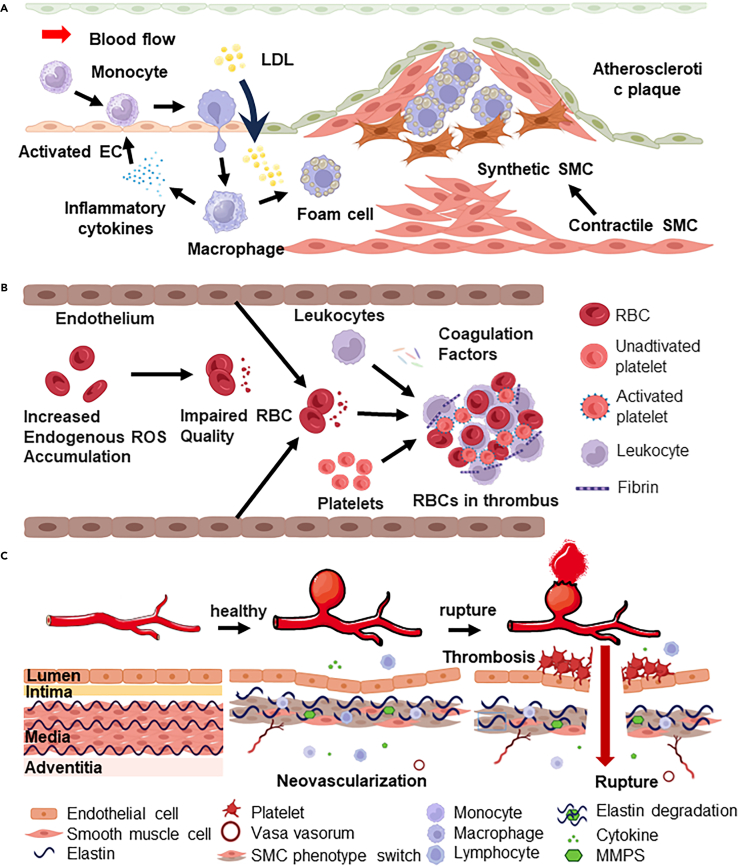

Among various hypotheses for explaining the pathogenesis of AS, the endothelial dysfunction theory is widely regarded as the central and dominant theory (Figure 3A).71 Accordingly, endothelial dysfunction is considered the initial trigger, where ECs are injured by abnormal hemodynamics, hyperlipidemia, and inflammatory stimulation, resulting in the decreased synthesis of NO and the increased expression of adhesion molecules (e.g., ICAM-1, VCAM-1, selectins), facilitating the recruitment of monocytes and T cells.72,73 Meanwhile, lipids, particularly Ox-LDL, accumulate in the arterial intima, are taken up by macrophages, and transformed into lipid-rich foam cells. These cells, along with the ECM proliferation of SMCs, form plaques that can grow and cause arterial lumen stenosis.74

Figure 3.

Pathological processes of human arterial diseases

(A) Atherosclerosis.

(B) Thrombosis.

(C) Aneurysm.

For in vitro modeling of AS, precise definition and control of the pathogenic microenvironment and condition is necessary. Key early events in the model must include endothelial dysfunction, marked by reduced NO production and increased adhesion molecule expression. The simulations that help to initiate AS include the introduction of inflammatory factors such as tumor necrosis factor-alpha (TNF-α), IL-1β, and IL-6, essential drivers of the inflammatory cascade at high concentrations in lesions.68 Another central is Ox-LDL, alongside the recruitment and activation of immune cells such as monocytes and lymphocytes.75 Additionally, hemodynamic changes such as alterations in shear stress and mechanical stress on vascular walls are crucial.

Thrombosis

Atherosclerosis not only thickens and hardens arterial walls but also exposes blood when its unstable plaques rupture, triggering thrombosis and heightening the risk of cardiovascular events. Thrombosis involves abnormal blood clotting within vessels, potentially leading to severe health issues such as stroke, heart attack, and deep vein thrombosis, collectively responsible for approximately 25% of global deaths.

Thrombosis is a complex physiological process that includes vascular endothelial cell injury, platelet adhesion and activation, activation of the coagulation cascade, and hemodynamic interactions (Figure 3B).76 Increased intracellular reactive oxygen species (ROS) levels activate calcium channels, resulting in red blood cell (RBC) damage and reduced deformability, thereby increasing blood viscosity.77 Elevated ROS levels and increased blood viscosity promote the activation of platelets responsible for hemostasis and thrombosis. Oxidative stress also induces the expression of adhesion molecules (e.g., ICAM-1, VCAM-1) and inflammatory factors (TNF-α, IL-6, and MCP-1), enhancing the adhesion of platelets and ECs and promoting leukocyte migration to ECs, which further elevates the risk of thrombosis.78 Additionally, the shear rate of blood flow significantly influences platelet aggregation and activation; low shear rates favor aggregation, whereas high shear rates may enhance platelet activation.

Given the intricate nature of thrombosis, encompassing cell adhesion, platelet signaling, and the precise timing and location of clot formation, conventional research methods may struggle to accurately replicate this process. This challenge underscores the growing demand for advanced in vitro models.

Aneurysm

Different from AS which is associated with a process of arterial wall thickening and hardening, the aneurysm represents the tissue degenerative pathological process. An aneurysm is the result of localized abnormal dilation of the arterial wall, primarily due to structural weakening that renders it incapable of withstanding normal blood pressure, leading to permanent expansion, which is typically manifest in two forms: saccular (asymmetric outpouchings) or fusiform (circular dilation).79

Similar to the inflammatory mechanisms observed in AS, the formation and development of aneurysms are significantly influenced by inflammatory responses (Figure 3C). Inflammation typically initiates within the dysfunctional endothelium, regulated by nuclear factor-kappa B, secrete pro-inflammatory cytokines TNF-α, IL-13, and MCP-1.80 This induces the recruitment of immune cells (monocytes, macrophages, T-cells), altering VSMC phenotypes. SMCs, key matrix-synthetic cells, proliferate with a pro-inflammatory phenotype,81 degrading the internal elastic lamina and promoting ECM remodeling.82 Both involved immune cells and phenotypically switched SMCs can express MMPs (MMP-1, MMP-2, MMP-9) that gradually degrade arterial ECM. This cascade, in turn, recruits inflammatory cells, upregulates proteolytic enzymes, and reduces contractile gene/protein expression, such as myosin heavy chain and α-actin). Ultimately, these changes diminish collagen synthesis, exacerbate VSMC loss, and weaken the arterial wall, predisposing it to aneurysm rupture.

In the development of in vitro models of aneurysms, precise design of geometric morphology and hemodynamic conditions is pivotal. Aneurysms exhibit diverse and complex shapes, and accurately replicating these features is crucial for recreating the complexity of the hemodynamics signals within the local lesions, such as blood flow velocity, pressure distribution, and fluid shear forces. Besides, as the inflammation cascade is another critical pathogenic factor of the aneurysm, it is indispensable to establish biomimetic vascular tissue analogs that are responsive to relevant stimuli for the recapitulation of the tissue degenerative process.

Prevailing technologies for bioengineered arterial equivalents

Scaffold-based technologies

Mold-casting

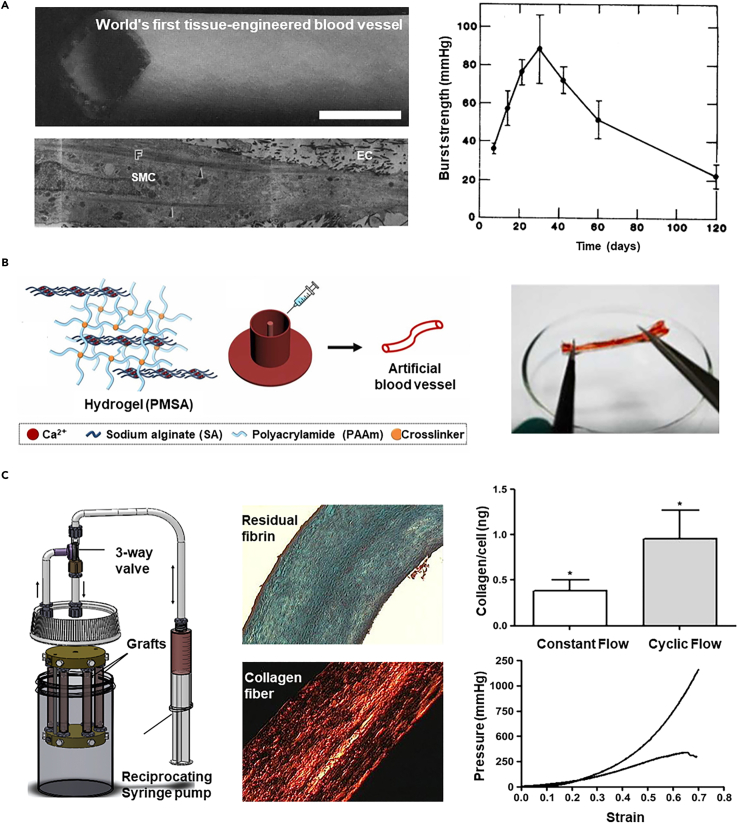

Mold-casting is a straightforward engineering technique used to create AEs by casting a solution of biomaterials and cells into an annular mold, which then crosslinks to form the designed 3D structures.83 The first bioengineered blood vessel, constructed using such a method, was 7.5 cm long with a 6-millimeter inner diameter (Figure 4A).12 It comprised layers designed to mimic natural blood vessels, using collagen with SMCs, an additional wrapped dacron mesh, and an endothelial lining created by seeding ECs on the luminal surface. However, even with the reinforcement of a polyester mesh, its burst pressure only reaches 40 to 70 mmHg which is vulnerable to implantation. The inherent softness of natural polymers such as fibrin,84,85 gelatin,86 and elastin87 pose challenges in load-bearing applications despite the biological advantages.

Figure 4.

Representative AEs constructed by mold-casting technology

(A) The panoramic view of the first three-layered vascular graft by mold-casting, the structure of its wall, and the burst strength (scale bar 5 mm). Copyright 1986, Royal Society of Chemistry, Reproduced with permission.12

(B) Mold cast vascular grafts using an interpenetrating network hydrogel model crosslinked with sodium alginate and acrylamide to enhance its mechanical properties. Copyright 2023, Elsevier, Reproduced with permission.88

(C) In the bioreactor, cells within the vascular grafts are conditioned to acquire enhanced mechanical properties. Copyright 2011, Elsevier, Reproduced with permission.89

Efforts to enhance the mechanical properties of natural hydrogels have involved modifying the crosslinking methods.90 For instance, chemical crosslinking, which creates strong covalent bonds between molecules, can significantly improve the mechanical strength of collagen compared to thermally induced self-assembly.91 This method also promotes a uniform network that distributes stress evenly, enhances resistance to enzymatic degradation, and improves stability.92 For instance, using Type I bovine collagen gel with transglutaminase-mediated crosslinking, which forms covalent amide bonds between protein fibers, significantly increases the burst pressure (71 ± 4 mmHg vs. 46 ± 3 mmHg). To reinforce the mechanical strength of hydrogels, other methods such as small molecule crosslinkers (e.g., glutaraldehyde,93 catechol compounds,94 genipin,95 and tannic acid96), photoinitiated crosslinking (ultraviolet97 or visible light98), and non-enzymatic glycation99 techniques have been applied, though some conditions may compromise cell viability.

Alternatively, interpenetrating network hydrogel paves a way to reinforce the mechanical properties of materials by integrating the merits of multiple components. For instance, an alginate/acrylamide double-crosslinked hydrogel exhibits excellent mechanical properties, in which the reversible crosslinking alginate offers elasticity while the acrylamide provides robust frames (Figure 4B). The elongation rate can optimally reach 196%, and the hydrogel tube, even after sewing, retains the shape perfectly before stretching, after stretching, and after perfusion. The small diameter graft (inner diameter: 0.2–1.2 mm) built with this material was implanted into a rabbit model for 28 days, demonstrating good patency.88 In addition, mold-casting based on 3D molds provides a new idea for the preparation of bioengineered arteries.

Besides improving the strength of biomaterials, the application of mechanical stimulation through bioreactors stimulates cells to synthesize and organize the matrix composition, thereby improving the mechanical properties of the construct.100,101,102 This process aids in forming tissue with an elastic modulus similar to that of natural tissue and promotes effective ECM production by cells.103 In a representative study, fibroblasts-laden fibrin tubes were mounted on a bioreactor that supplies pulsatile flow (pulse frequency: 0.5 Hz, peak circumferential strain: 7.3 ± 1.9%) to train the cell via cyclical distension and transmural flow (Figure 4C).89 Upon such dynamic cultures for 2–9 weeks, the vascular grafts were extensively remodeled by cells, encompassing circumferentially aligned collagen and other ECM component fibers, achieving mechanical anisotropy comparable to natural arteries, with burst pressures in the range of 1400–1600 mmHg and compliance similar to native arteries.

While traditional molding techniques face limitations in precisely controlling the microstructural organization, leading to suboptimal mechanical performance for clinical use, they are valuable as preclinical in vitro models to test drug efficacy, study disease mechanisms, and guide treatments.104,105

Electrospinning

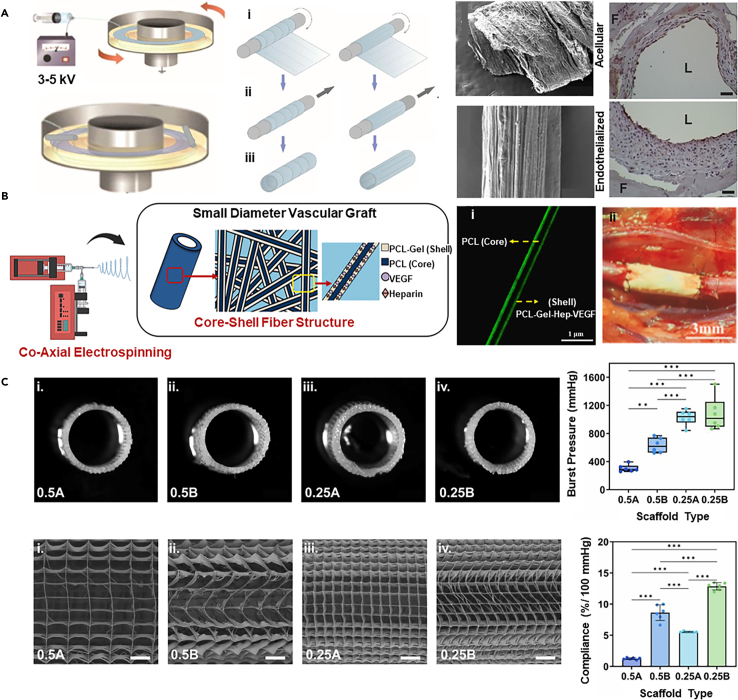

Electrospinning is a technique that utilizes a high-voltage field to eject a polymer solution or melt, generating a polymer jet to produce polymer fibers.106 This method can replicate the microstructure of ECM,107 providing a wide range of fiber diameters and pore sizes (from nanometers to microns),108 a high surface area-to-volume ratio, and porosity structures that effectively promote tissue formation after cell seeding.

By using a rotating drum for fiber deposition, it is easy to construct vessel-like constructs with tunable microstructures.109 With the increased concentration of electrospun polymer solutions, the fiber diameter, pore size, porosity, and pore interconnectivity significantly increase.110 Adjustments to collector rotational speed or the use of metal plates can improve fiber orientation.111,112 For example, electrospun fibrin fibers can be wrapped around a mandrel forming a controlled microstructure with circumferential and longitudinal alignment (Figure 5A).113 The controlled surface morphology of the hollow fibrin ultrafine fiber tubes guides the formation of confluent ECs both in vitro and in vivo. Within 3-4 days in vitro, the cells immediately and controllably adhere to form confluent endothelial layers, while generating stable endothelialization can be observed after 4 weeks’ implantation, representing a promising approach for arterial bypass surgery.

Figure 5.

Representative AEs constructed by electrospinning

(A) Electrospinning achieves controlled microstructures with circumferential and longitudinal alignment, guiding ECs to converge and form an endothelial layer (scale bar 30 μm). Copyright 2019, National Academy of Sciences, Reproduced with permission.113

(B) Coaxial electrospun vascular grafts with heparin-VEGF and polycaprolactone/gelatin demonstrate 100% patency and complete endothelialization in rats after four months (scale bar i: 1 μm, ii: 3 mm). Copyright 2024, Elsevier, Reproduced with permission.114

(C) The MEW technology regulates the fiber arrangement of the stent, mimicking the arrangement of collagen fibers to achieve a vascular graft with a wavy circumferential ultra-fine fiber arrangement, exhibiting good biomechanical compliance (scale bar 500 μm). Copyright 2023, IOP Publishing, Reproduced with permission.115

Electrospinning offers strong adaptability in materials, enabling the combination of natural polymer (e.g., collagen,116 gelatin,117 fibrin,118 alginate119) with synthetic polymers (e.g., polylactic acid (PLA),120,121,122 polycaprolactone (PCL),120,123,124,125 poly(lactic-co-glycolic acid)126,127,128) for co-spinning to optimize both bioactivity and mechanical properties. In constructing electrospun multilayer scaffolds for arterial grafts, varying materials, pore sizes, and fiber orientations allow for a flexible definition of each layer’s properties (mechanical, topological, biological), effectively mimicking the structure of native arteries.129 For instance, the technology to fabricate scaffolds from bovine gelatin and PCL involves sequential electrospinning and co-electrospinning.130 The sequential approach enables layer-by-layer structure development, whereas co-electrospinning achieves better fiber alignment and a more optimal pore area ratio. The resulting structure exhibits a yield strain of 38.72 ± 3.23% and a tensile strength of 3.46 ± 0.088 MPa. Furthermore, the mesh membrane produced by co-electrospinning enhances NIH3T3 fibroblasts' adhesion and proliferation, demonstrating excellent biocompatibility.

Another advantage of electrospinning lies in the incorporation of various bioactive factors for co-manufacturing, thereby enhancing bioactivity or anticoagulation. The fabrication of vascular grafts through the use of coaxial electrospinning involves the incorporation of heparin-VEGF and PCL (as the core) as well as a shell composed of a blend of PCL and gelatin (Figure 5B).114 The shell structure undergoes degradation to release heparin-VEGF, while the core provides mechanical strength. Upon implantation into the aorta of rats for a period of four months, they demonstrate smooth muscle cell regeneration and complete endothelialization, with a patency rate of 100%. The introduction of bioactive molecules provides an alternative option for small-diameter peripheral or arterial vascular remodeling and repair.

Electrospun vascular grafts, while beneficial, still exhibit several limitations that affect their clinical effectiveness and need addressing. First, the degradation of synthetic polymers can release by-products that potentially alter pH levels, disrupt cellular functions and growth, and may trigger local inflammatory responses.131,132 Second, controlling the degradation rate, which involves both hydrolytic and enzymatic processes, remains a challenge. Additionally, a critical issue is the mismatch of radial mechanical compliance at the anastomotic site, which can lead to intimal hyperplasia and ultimately graft failure.133,134 To overcome these issues, it is crucial to optimize the scaffold structure for uniform morphology and mechanical properties. Using melt electrospinning writing (MEW) provides superior control over the scaffold’s morphological structure. For instance, scaffolds with a wavy circumferential microfiber arrangement mimic natural collagen fiber alignment and exhibit physiological compliance (12.9 ± 0.6% per 100 mmHg),115 enhancing their potential for successful integration and function in clinical applications (Figure 5C).

Decellularized arterial tissue

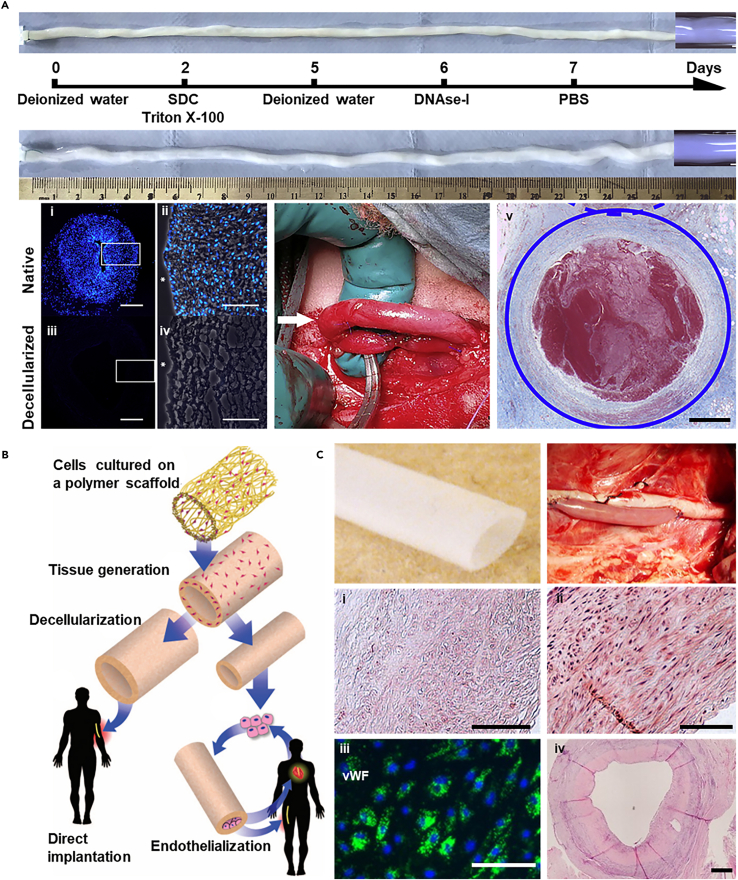

Decellularized arterial tissue represents a significant advancement in replicating the natural ECM microenvironment, overcoming the limitations of artificial structures made from biomaterials. This technique, which involves removing cellular components while preserving essential ECM features such as microstructures and protein compositions, is critical for promoting cell adhesion, differentiation, and proliferation. It has been successfully applied to various tissues including blood vessels,135 skin,136 heart,137 lungs,138 liver,139 and kidneys.140,141

The process for decellularizing blood vessels typically combines physical (freeze-thaw cycles and agitation), chemical (detergents, chelating agents), and biological (enzymes) treatments.142 An example is the human umbilical artery (HUA), which, after decellularization, has been tested in sheep models for carotid artery bypass, showing initial success but also challenges such as immunological mismatch leading to occlusion (Figure 6A).143

Figure 6.

Representative AEs constructed by decellularized arterial tissue

(A) Decellularized HUA were tested in a sheep carotid artery bypass model, demonstrating initial compatibility with arterial pressures but ultimately occluding on the seventh day (scale bar i, iii: 500 μm, ii, iv: 100 μm, v: 1 mm). Copyright 2020, Elsevier, Reproduced with permission.143

(B) Strategy for producing tissue-engineered vascular grafts. Copyright 2011, American Association for the Advancement of Science, Reproduced with permission.144

(C) A tissue-engineered vascular graft with a robust ECM was obtained by culturing aortic SMCs on a biodegradable PGA mesh scaffold, followed by decellularization, which was evaluated in a porcine model (scale bar i-iii: 100 μm, iv: 500 μm). Copyright 2011, National Academy of Sciences, Reproduced with permission.135

Human vascular tissues, such as saphenous vein,145 human umbilical vein,146 and human common femoral artery,147 are ideal for creating decellularized grafts, though sourcing human tissues for large-scale production presents challenges. Alternatively, animal tissues (e.g., pig,148 bovine,149 ovine150) are considered, ensuring minimal immunogenicity and safety. The effectiveness of decellularization is leveled by the absence of nuclear material and dsDNA content below 50 ng/mg ECM (dry weight).142,151 Additionally, any toxic biochemical reagents (e.g., SDS,152,153 Triton X-100,154 and so forth) used in the process must be thoroughly removed to avoid adverse effects.

Commercially, decellularized vascular products from mammalian sources such as bovine carotid arteries are available, but these lack control over dimensions such as diameter, wall thickness, and length, limiting their use in personalized medicine. To address this, integrating decellularization with advanced bioengineered techniques has been explored (Figure 6B).144 For instance, vascular grafts enhanced with multiple layers (15–20 layers) of SMCs have been developed using a biodegradable polyglycolic acid (PGA) mesh scaffold within a bioreactor, followed by decellularization, leaving a robust collagen ECM (Figure 6C).135 These bioengineered vessels, seeded with recipient-specific ECs, showed reduced neointimal hyperplasia and proliferative cell activity.

Moreover, transforming decellularized tissues into tractable biomaterials such as hydrogels or powders expands their application potential. For example, dECM bioink derived from porcine aortic tissue has been used to 3D bioprint dual-layered vascular grafts with adjustable dimensions, offering enhanced support for ECs and SMCs, and leading to functional AEs suitable for in vivo studies.155,156 This approach not only addresses dimensional limitations but also enhances the functionality and applicability of decellularized tissues in clinical settings.

3D bioprinting

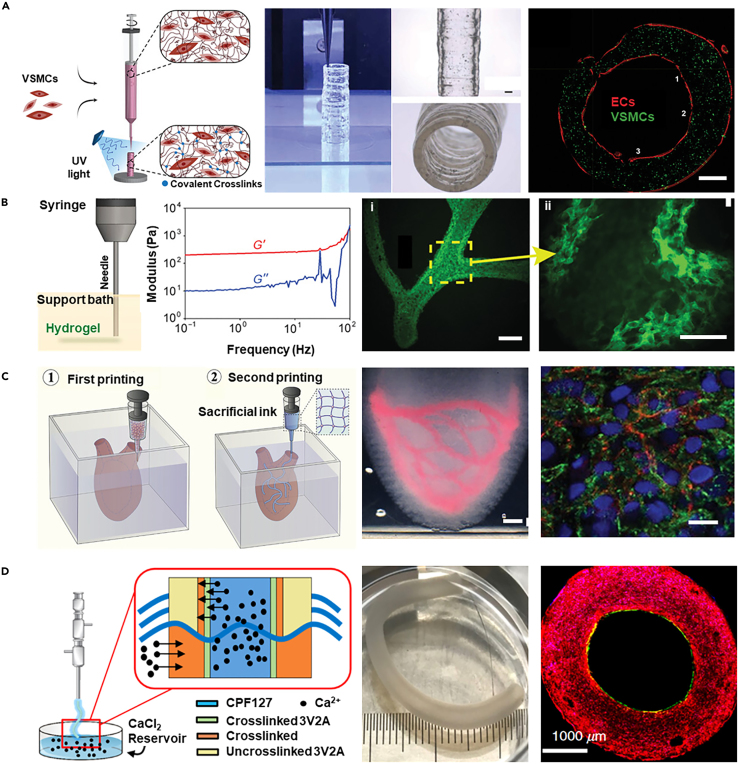

3D bioprinting is a cutting-edge biofabrication technology that strategically places cells, biomaterials, and bioactive molecules in three-dimensional arrangements to reconstruct complex vascular structures in vitro.157,158,159 This technology incorporates various biofabrication strategies for crafting artificial blood vessel grafts and models, each offering unique benefits and challenges.

One approach is the classical layer-by-layer deposition, which provides meticulous control over the vascular architecture, allowing for the emulation of natural blood vessel multilayered tissue. Utilizing a high-viscosity nano-engineered bioink made from gelatin methacryloyl, polyethylene glycol diacrylate, and nanosilicate, this method encapsulates SMCs and extrudes them to form cylindrical structures (Figure 7A).160 ECs are subsequently seeded to complete the 3D bioprinted vessels. Despite its precision, this strategy typically relies on the use of high-viscosity bioinks to ensure stable material deposition and precise structure formation during the printing process. However, the viscous bioink can compromise cell viability due to the necessary high shear forces during printing.161

Figure 7.

Representative AEs constructed by 3D bioprinting

(A) Utilizing a high-viscosity colloidal nanoengineered bioink encapsulating VSMCs, cylindrical blood vessels were printed using layer-by-layer 3D bioprinting technology, followed by seeding with ECs to form the vascular construct (scale bar 2.5 mm). Copyright 2021, Wiley, Reproduced with permission.160

(B) Gelatin, serving as a thermo-reversible support bath material that does not negatively impact cell integration, was rheologically analyzed to exhibit Bingham plastic properties, enabling the printing of an arterial tree structure with alginate hydrogel that features well-defined internal lumens and bifurcations (scale bar i: 2.5 mm, ii: 1 mm). Copyright 2015, American Association for the Advancement of Science, Reproduced with permission.162

(C) Sequential suspension 3D bioprinting technology employs MB bioink as a support matrix to facilitate the embedding printing of free-form vascular networks using a HUVECs-enriched sacrificial gelatin bioink (scale bar i: 2 mm, ii: 10 μm). Copyright 2023, Wiley Blackwell, Reproduced with permission.163

(D) Utilizing a bioink containing HUVECs and HAoSMCs, along with a triple coaxial 3D bioprinting, a biomimetic vascular graft with distinct endothelial and muscular layers is directly constructed (scale bar 1000 μm). Copyright 2019, AIP Publishing, Reproduced with permission.15

To address this problem by improving the printability of soft hydrogels, a suspension 3D bioprinting approach has been developed, which allows for the freeform deposition of low-viscosity bioinks into a supporting medium with shear-recovery properties.164 Using gelatin, which does not negatively impact cellular integration and is thermally reversible, as a support bath material, rheological analysis indicates that the gelatin slurry behaves and remains a Bingham plastic at room temperature (Figure 7B).162 Alginate hydrogel was used to print arterial tree structures (wall thickness: 1 mm, diameter: 1–3 mm) within this support bath, resulting in well-formed internal lumens and bifurcations.

An innovative method involves the sequentially suspended 3D bioprinting of different cell-laden bioinks to create multi-layered arterial models.165,166 Such a strategy first employs microgel-based biphasic (MB) bioink as a supportive embedding medium for 3D bioprinting, which facilitates the creation of complex external geometries of natural vessels (Figure 7C).163 Using sacrificial gelatin bioink enriched with human umbilical vein endothelial cells (HUVECs), embedded printing is performed into newly printed but uncrosslinked constructs. This process generates free-form vascular networks by leveraging the reversible self-healing behavior of the MB bioink. Following the photopolymerization of the suspension medium, the gelatin strands with HUVECs are liquefied at 37°C. The printed constructs are flipped, ensuring uniform adhesion of cells to the luminal surface, and post-cultivation results in the formation of a uniform, confluent endothelial layer. The sequentially suspended 3D bioprinting provides unmatched bioprinting capabilities to accelerate the replication of complex organ geometries and internal structures, facilitating the biomanufacturing of tissues and organs.

Coaxial 3D bioprinting, another impressive method, allows the simultaneous deposition of different cell types and bioinks, tailored for replicating the intricate, multi-layered vascular system.167 This method necessitates meticulous technical control over bioink flow and intermixing to fabricate composite cell-layered vessels. Using vascular tissue-specific bioink containing HUVECs and human aortic smooth muscle cells (HAoSMCs), and a reservoir-assisted triple coaxial nozzle (18G/14G/10G) where the intermediate and shell needles contain Ca2+-laden Pluronic F127, extrusion through the core nozzle supports vessel fabrication (Figure 7D).15 This triple coaxial cell printing technique directly constructs biomimetic vascular grafts composed of a separate endothelial layer and muscle layer (inner diameter: 2 mm, wall thickness: 1 mm). The technology also permits customized adjustments to bio-ink properties, facilitating the design of vessels with tailored elasticity and cell-supportive characteristics, holding promise for advancing cardiovascular therapies and enabling more personalized and effective medical solutions.

In short, selecting the right 3D bioprinting strategy depends on the specific requirements and intended functions of the fabricated blood vessels. While each method has its applications and limitations, ongoing advancements in 3D bioprinting technology are expected to further enhance artificial blood vessel performance and open new avenues for treating CVDs.

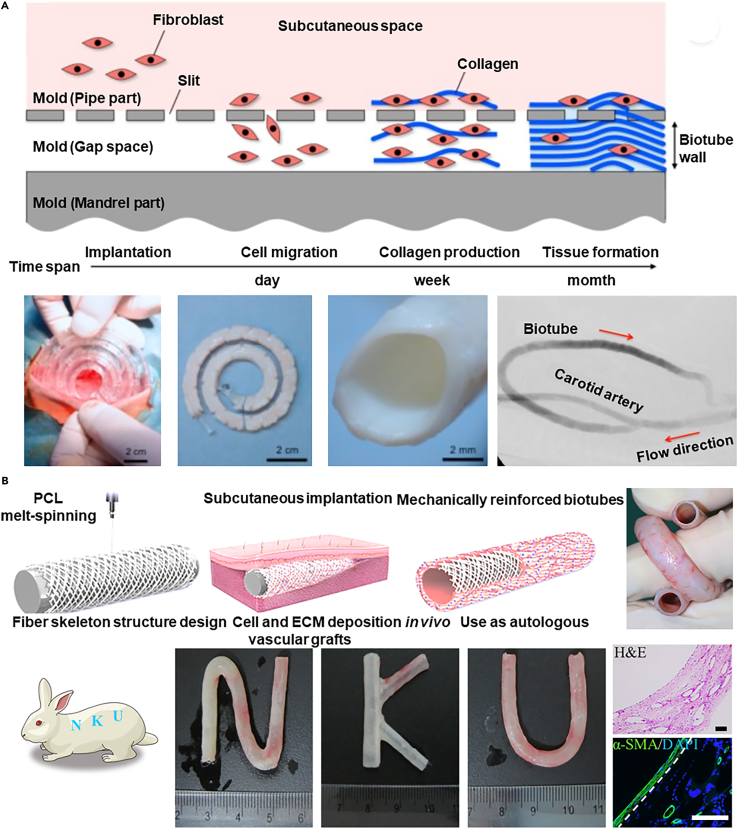

In vivo bioengineered biotubes

In vivo bioengineered techniques leverage the interaction between host tissues and implants to construct AEs, known as biotubes, by subcutaneously embedding specially designed molds.168 This process involves the immune system recognizing the implant as a foreign body, which stimulates the formation of fibrous capsules around the molds, ultimately forming biotubes. Additionally, the structure and size of the biotubes can be tailored according to the specifications of the implant.

This method has been used to create fully autologous vascular grafts directly within the body, eliminating issues such as immune mismatch or infection risks associated with ex vivo manufactured vascular structures. For example, a transparent nylon mold with a helical shell (inner diameter: 7 or 8 mm) and a core rod (outer diameter: 4 or 5 mm) was implanted in Beagle dogs' subcutaneous pouches for one or two months (Figure 8A).169 This resulted in the formation of a tubular collagen tissue within the mold, and after its removal, a 25 cm biotube (inner diameter: 4 mm) was obtained. When used as an arterial graft in dogs, arterial reconstruction occurred three months post-transplantation. Despite good biocompatibility, endothelialization, and vascular regeneration, these grafts may lack sufficient mechanical strength (unit breaking force: 0.7 N/mm, burst pressure: 1500 mmHg), which can lead to post-transplant rupture and aneurysm formation.

Figure 8.

Representative AEs constructed by in vivo bioengineered

(A) Implanting transparent nylon molds subcutaneously in beagle dogs, tubular collagenous tissue is formed, which, after decellularization to acquire a biotube and allogeneic transplantation, successfully facilitates arterial reconstruction three months post-procedure. Copyright 2018, Elsevier, Reproduced with permission.169

(B) The integration of polymer melt spinning technology with in vivo engineering has enhanced the mechanical properties of hMPBs, ensuring their maintenance of original shape and structure post-surgical manipulations (scale bar 100 μm). Copyright 2022, American Association for the Advancement of Science, Reproduced with permission.170

To further improve its mechanical properties, integration of polymer melts spinning technology with in vivo bioengineered has been explored, resulting in heat-treated medium-fiber-angle poly(ε-caprolactone) fiber skeletons-reinforced biotubes (hMPBs). These enhanced biotubes maintain their shape and structure even after common surgical manipulations such as coiling, folding, twisting, and clamping (Figure 8B).170 While polymer implants offer a simple, cost-effective solution with the potential for broad application, the bio-integration period for these grafts often spans several weeks, which may not suit acute surgical needs. Additionally, achieving the required lengths for procedures such as coronary artery bypass grafting may be challenging with in situ engineered vessels.

Cell-based technologies

Cell-based technologies are advancing bioengineered by leveraging the natural tissue-forming capabilities of cells, bypassing the limitations of scaffolds-based techniques that can inhibit cell-cell interactions due to the presence of biomaterials.171,172 These methods utilize spheroidal cell aggregates and cell sheets, allowing cells to self-organize without scaffold interference. This approach eliminates biomaterials, significantly enhances cell density, and fosters robust cell-cell interactions, crucial for developing functional tissues. This shift toward scaffold-free bioengineered aims to more naturally and efficiently replicate the complexity of natural arteries.

Cell spheroids assembly

Cell spheroids serve as the foundational units for cell-based biofabrication, produced through various techniques including hanging-drop,173 low-adherence substrate,174 microwells,175 microfluidic.176 The assembly of these spheroids forms cellular structures without scaffolds and promotes extensive cell interactions and ECM production. A key aspect of this method involves safely manipulating these "biobricks" to construct complex structures.

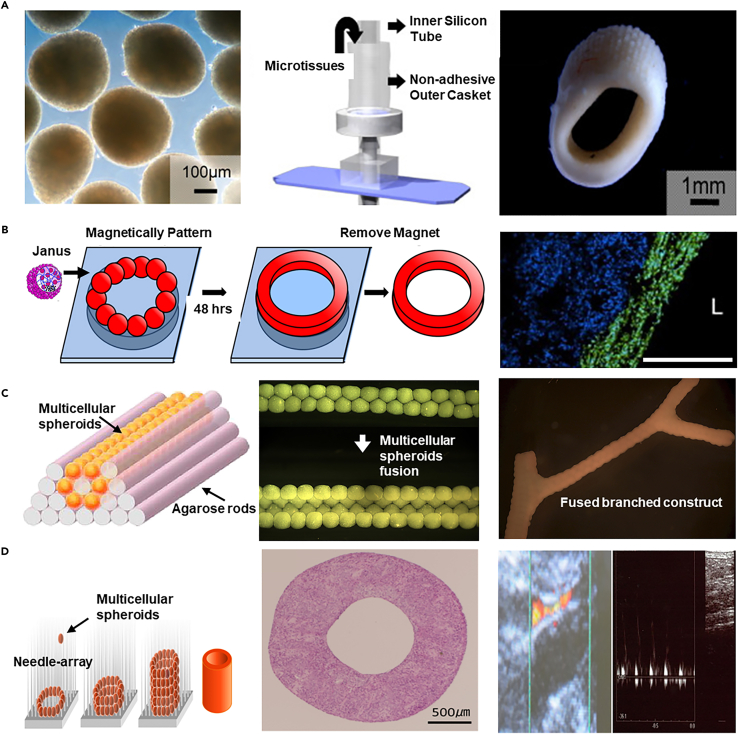

Introduced in 2010, the cell spheroid assembly technique utilized primary human arterial fibroblasts cultured in a 60-well plate, leading to the development of a bioreactor integrated with a ring-shaped mold that could hold 4000 to 5000 micro-tissues (Figure 9A).177 After 14 days of flow and mechanical stimulation, fibroblasts reorganized along the vascular axis, forming small-diameter vessels (diameter: 3 mm, length: 5 mm, wall thickness: 1 mm).

Figure 9.

Representative AEs constructed by cell spheroids technology

(A) Primary human arterial fibroblast microtissues cultivated in 60-well plates are assembled using a mold integrated with a bioreactor, allowing the casting of microtissues, which after 14 days of flow and mechanical stimulation, reorganize along the vascular axis to form small-diameter blood vessels. Copyright 2010, Elsevier, Reproduced with permission.177

(B) Magnetic nanoparticles incorporated into cell spheroids facilitate the assembly of thousands of magnetic cell aggregates into vascular tissue constructs (scale bar 500 μm). Copyright 2014, Elsevier, Reproduced with permission.178

(C) Employing 3D bioprinting technology, multicellular spheroids are assembled onto a molded agarose rod template, resulting in the formation of branched, large vascular-like tubular structures within 5–7 days post-assembly. Copyright 2009, Elsevier, Reproduced with permission.179

(D) The Kenzan bioprinting method fabricates small-diameter vascular grafts by stacking cell spheroids onto a needle and integrating 3D bioprinting technology. Copyright 2015, Public Library of Science, Reproduced with permission.180

The cell spheroid can also be magnetically assembled for the manufacturing of arterial grafts. In a representative study, magnetic nanoparticles were incorporated into the spheroids to facilitate the assembly and fusion of cellular aggregates, with thousands of magnetic cell spheroids assembled into a vascular tissue structure with a diameter of 5 mm (Figure 9B).178 Despite concerns over the impact on cell viability, optimization of nanoparticle internalization has enhanced cell vitality and maintained phenotype in this report.

Further integration with 3D bioprinting technology has allowed for the precise construction of tubular structures (diameter: 900 μm, wall thickness: 300 μm) using multicellular spheroids containing SMCs and fibroblasts on a template built by agarose rods, which fuse over a period of 5–7 days to form branched, large blood vessel-like structures (Figure 9C).179 By designing vessels of different shapes and using different cell types, intricate arterial structures are constructed in composition and architecture.

However, challenges remain in placing and stabilizing spheroids without supportive materials (e.g., agarose strands). To address this problem, an innovative assembly approach called the Kenzan method additionally uses a micro-needle array for precise 3D layering and stacking of spheroids, promoting three-dimensional organization and conferring specific tissue architecture and mechanical strength.159,181,182 Upon the spheroids fusion and removal of needle arrays, such a 3D assembly method can manufacture tubular constructs as vascular grafts (Figure 9D).180 The Kenzan approach has been successfully applied to reconstruct small-diameter blood vessels (diameter: 1.5 mm, length: 7 mm) using the spheroid of human dermal fibroblasts for the transplantation into an immunodeficient pig model, showing no immune rejection and maintaining structural integrity as a blood flow channel over three months.183

While promising for producing arterial grafts, the cell spheroid assembly method faces challenges in maintaining cell viability, enhancing mechanical strength, and scaling for industrial applications. Future research should focus on refining these techniques to improve the efficiency, cost-effectiveness, and clinical applicability of manufacturing arterial grafts.

Cell sheets assembly

Cell sheet technology differs from spheroid-based methods by cultivating cells into a paper-like structure that can be harvested intact without enzymes by simply adjusting the culture conditions.184,185,186 This technique allows for the wrapping of cell sheets around a temporary mandrel to create bio-conduits easily.

L'Heureux et al.187 pioneered a scaffold-free method for producing vascular grafts by cultivating layered sheets of ECs, SMCs, or other relevant cells, which are then rolled to form functional grafts. This cell sheet technique was used to assemble the first tissue-engineered blood vessel suitable for autologous small-diameter arterial reconstruction in adult patients.188 Dermis fibroblasts cultured to enhance ECM protein production fused into a uniform tissue after about 10 weeks, creating multilayered vessels with burst pressures over 3,000 mmHg9.

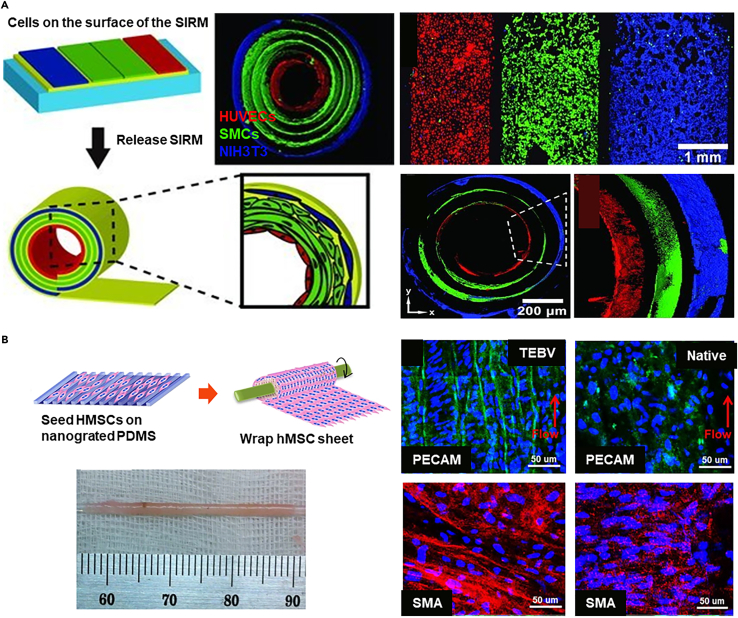

However, manually wrapping cell sheets may limit the development of artificial arteries with precise dimensions and cell alignment. Integrating technologies such as electrospinnig189 and surface engineering190 with cell sheets can produce size-tunable and morphology-controllable sheets. In a representative study, the stress-induced rolling membrane (SIRM) technique, which is based on the release of internal stress due to the stretching of the top layer, allows for the adhesion of two layers with different surface morphologies, resulting in the formation of a cohesive structure that can roll freely at one end, yielding a tube with controllable dimensions. Using the SIRM technology, vascular grafts with an inner diameter ranging from 10 μm to 2 mm can be fabricated (Figure 10A).191 Concurrently, through the rolling process, simple patterns on a 2D membrane are transformed into complex patterns within a 3D tube. These tubes are capable of simulating the unique inner layer of HUVECs, the middle layer of SMCs, and the outer layer of NIH3T3 fibroblasts, replicating their natural arrangement within the body.

Figure 10.

Representative AEs constructed by cell sheets

(A) The SIRM technique fabricates vascular grafts with an inner diameter ranging from 10μm to 2mm, replicating the complex patterns of HUVECs, SMCs, and NIH3T3 fibroblasts within 3D tubes through a rolling process, simulating their natural in vivo arrangement. Copyright 2012, Wiley-VCH, Reproduced with permission.191

(B) Employing nanogrid alignment and layer-by-layer wrapping techniques, a tubular construct with circumferentially aligned HMSCs is fabricated, achieving uniform integration and alignment of HMSCs through perfusion maturation. Copyright 2015, Springer Nature, Reproduced with permission.192

Additionally, to replicate the 3D helical and interwoven organization of SMCs in natural vessels, aligned human mesenchymal stem cells (HMSCs) sheets were prepared on nanogrates and wrapped around a mandrel layer-by-layer (Figure 10B).192 After two weeks of maturation and removal from the mandrel, a tubular structure with circumferentially aligned HMSCs is formed, showing integration and uniform alignment after three weeks of perfusion maturation. Based on the cell sheet technology, the loss of scaffold-based mechanical support is compensated for by employing additional cell layers and extended maturation periods to mitigate the adverse effects on in vivo applications. However, in the pursuit of these improvements, it is also necessary to consider the increased material consumption and time costs.

Despite the innovative approach, cell sheets technology faces challenges including high costs, complex processes, and total production cycles for clinical availability (an average of 7.5 months).193,194,195 Issues such as inconsistent layer fusion due to individual variability, inadequate ECM formation in the short term, and difficulty in controlling graft geometry and mechanical properties during the rolling process affect the production consistency and quality of the grafts.

Bioengineered dynamic devices as arterial equivalents

Regular AEs, while dimensionally and structurally biomimetic, struggle with real-time imaging due to the thick arterial walls (>500μm) that reduce imaging quality and necessitate sectioning and staining. This complicates the observation of cellular responses and the integration of advanced technologies such as AI and big data, which could foster significant breakthroughs. Additionally, constructing these arterial models is both time-consuming and expensive, requiring vast quantities of cells and materials. Bioengineered dynamic devices, including organ-on-a-chip systems, are showing potential as tools for modeling human arteries. These devices may offer advantages over traditional isometric artery equivalents in certain aspects of pathological research and drug screening by providing more dynamic and physiologically relevant environments.

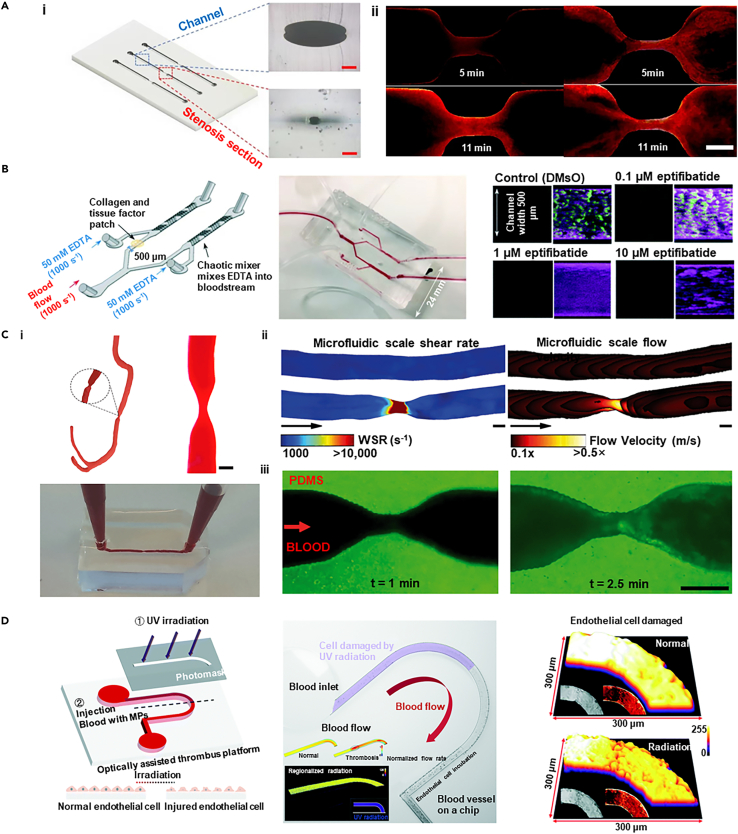

Using advanced bioengineered techniques, dynamic devices, such as vasculature-on-a-chip,196 capture complex flow dynamics seen in blood vessels, including the unstable turbulent flows at bifurcations and curvatures that expose ECs to uneven shear forces, potentially triggering inflammation and AS.197 Various specialized vascular structures have been engineered to replicate these conditions, including stenosis-integrated channel,198 continues channel,199 branching channels,200 H-shaped channel,201 T-shaped channel,202 Y-shaped channel,203 using techniques such as sacrificial molding,204,205 self-assembled microfluidic approaches,206,207 stereolithography, and 3D printing.208 Yet, these models often feature only a single endothelial layer, limiting their ability to explore interactions under pathological conditions between ECs and SMCs, which failed to be categorized as AEs.

In contrast, the AE dynamic device (or artery on-a-chip) should recapitulate the key physiological features of the human artery. For instance, the chip should reconstruct the dual-layered structure that separately embeds ECs and SMCs, resembling the characteristics of an arterial wall.209 Moreover, the device should be also able to provide physiological hemodynamic signals such as flow rate, flow pattern, and shear stress.

Various techniques are being explored to construct and shape rapidly perfused vascular-such as structures. Fabrication of biomimetic vascular structures via coaxial bioprinting techniques, utilizing a 3D-printed porous poly(ethylene glycol) diacrylate mold. SMCs are suspended within a bioink composed of a mixture of alginate, gelatin methacryloyl (GelMA), and fibronectin, and then coaxially printed to obtain cell-laden vascular constructs (Figure 11A).210 After perfusion culture for seven days to allow for SMC stretching and migration to form a confluent layer on the luminal surface, HUVECs are seeded. Cultivation results in a multi-layered structure resembling that of a blood vessel.

Figure 11.

Representative bioengineered dynamic devices as AEs

(A) Utilizing 3D-printed porous PEGDA molds and coaxial bioprinting techniques, a biomimetic vascular construct loaded with SMCs and HUVECs is fabricated, which after perfusion culture forms a multi-layered structure, demonstrating potential in modeling pathophysiological conditions such as AS, upon TNF-α stimulation (scale bar i: 500 μm, ii: 100 μm). Copyright 2022, Wiley-VCH, Reproduced with permin.210

(B) Sequential suspension 3D-printed multi-layered arterial models, matured into functional vascular tissues through simulated blood flow and co-culture, are utilized for the observation of early arterial disease markers (scale bar i: 1 mm, ii, iii: 50 μm, iv: 500 μm). Copyright 2023, IOP Publishing, Reproduced with permission.211

(C) The elastic membrane within a microfluidic device transmits uneven strain to cells in an ex vivo AS model, assessing the efficacy of atorvastatin in inhibiting foam cell formation under LDL and strain conditions (scale bar i: 10 μm, ii: 50 μm, iii: 100 μm). Copyright 2019, Springer Nature, Reproduced with permission.212

To manufacture the in silico AEs with multi-layered structures and tunable geometries, 3D bioprinting has demonstrated its unique advantages. The construction of multi-layered arterial models with varying internal diameters and wall thicknesses was accomplished using sequentially suspended 3D bioprinting technique technology.211 These models are capable of simulating the complex geometric structures of human arteries (Figure 11B). The models were utilized for the in vitro simulation of the pathophysiological processes initiating arterial diseases. Through co-culture and the simulation of fluid shear stress (FSS), the models mature into functionally competent vascular tissues. By simulating local turbulent flow, researchers observed the onset of EC dysfunction, which is a hallmark of arterial diseases.

Except for the cellular interaction and hemodynamics, another essential dynamic factor is the arterial vascular wall undergoing continuous contraction and relaxation. The mechanical stimulation of the model through isometric and isotonic forces is crucial for the pathophysiological functions of the vasculature. This can be simulated using mechanisms of elongation and contraction. Techniques such as using a Transwell elastic membrane213 and vacuum control,214 have been employed to induce deformation. In in vitro models of early AS (Figure 11C),212 elastic membranes embedded in microfluidic devices can transmit non-uniform strain to VSMCs, ECs, and adhering monocytes. Stretchable microfluidic devices have been used to induce foam cell formation under low-density lipoproteins (LDL) and stretch treatments and to evaluate the efficacy of atorvastatin in inhibiting foam cell formation.

Overall, the integration of microfluidic and bioengineered technologies in dynamic AE devices offers a promising pathway for advancing the simulation of human vascular structures and diseases, combining the simplicity, usability, and cost-effectiveness of traditional models with enhanced physiological relevance.

Bioengineered clinical-level arterial equivalents

Artificial blood vessels are imperative tools for clinical surgeries such as coronary artery bypass, treating peripheral artery disease, and establishing hemodialysis access. The implantation conditions, which involve exposure to strong blood pressure and a complex physiological microenvironment, require vascular grafts to meet stringent specifications. For successful implantation, these grafts must not only resist and facilitate effective blood flow but also maintain structural integrity post-implantation. They need to demonstrate essential mechanical properties such as ultimate tensile strength, suture retention, burst pressure, compliance, and long-term fatigue resistance qualities that are comparable to natural arteries to withstand physiological blood flow conditions, as detailed in section 2.2.1. Additionally, to ensure long-term success and integration with host tissue, the grafts must also mitigate risks such as acute thrombosis and stenosis and support cellular functions.215 This involves incorporating anti-thrombogenic properties and promoting endothelialization to prevent immune rejection, ensuring the grafts perform effectively in clinical settings. This section highlights recent progress in bioengineered AEs that have brought these technologies closer to clinical application, marking significant advancements in the field.

Before progressing to clinical trials, vascular grafts require thorough preclinical evaluations using both small (e.g., mice,216 rabbit217,218) and large animal models (e.g., dog,170 pig,219 sheep169). These evaluations primarily assess biocompatibility, mechanical properties, and initial biological responses to ensure the safety, efficacy, and functionality of the grafts. While many studies have reported on the in vivo performances of bioengineered AEs using animal models, the number of these products that advance to clinical trials remains limited. This discrepancy highlights the challenges in translating preclinical successes into clinically approved therapies.

The first bioengineered vascular graft used for the clinical trial was developed in 2001 using the cells from peripheral venous walls expanded and seeded onto biodegradable polymer conduits made from PCL and PLA copolymers, which was reinforced with woven PGA (diameter 10 mm, length 20 mm, thickness 1 mm). These scaffold-based tissue-engineered vascular grafts were implanted in a four-year-old patient with a single ventricle and pulmonary atresia,220 successfully recanalizing an occluded pulmonary artery without postoperative complications. Subsequent checks showed full patency and no adverse changes seven months post-implantation.

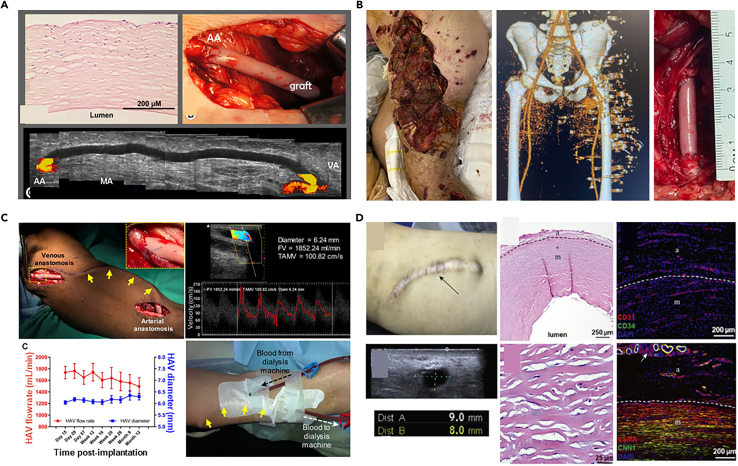

As an innovative way for bioengineered vascular grafts, cell sheet technology has been used for autologous small-diameter arterial reconstruction in adults.188 Fibroblasts isolated from patient’s own body are cultured to deposit ECM, forming detachable viscous sheets. These sheets are layered to create three-dimensional tissues or organs, exhibiting physiological mechanical strength. A clinical trial involving 10 end-stage renal disease patients demonstrated these grafts could withstand arterial pressures for at least three months, with ongoing monitoring up to 13 months post-implantation. However, the lengthy production time of 7.5 months poses significant logistical and cost challenges.221 Utilizing off-the-shelf allogeneic grafts that have been cryopreserved at −80°C post-production as an alternative can mitigate the potential risks associated with autologous tissue harvesting and processing, thereby demonstrating the feasibility and safety of transitioning to an allogeneic nonliving platform (Figure 12A).193

Figure 12.

Blood vessel grafts for clinic trials

(A) An 80-year-old female patient with a history of glomerulonephritis and coronary artery disease underwent the implantation of an allogeneic tissue-engineered vascular graft for the first time, with post-transplant Doppler ultrasound showing stable blood flow, normal blood indices, and negative panel reactive antibody tests, indicating successful arteriovenous anastomosis. Copyright 2014, Mosby, Reproduced with permission.193

(B) A 29-year-old Ukrainian male combat casualty sustained a blast injury to the left leg, with pre-operative computed tomography (CT) scans revealing shrapnel in the vascular bundle adjacent to the inguinal ligament; subsequent repair of the left common femoral artery using HAVs was uncomplicated by infection during follow-up. Copyright 2023, Elsevier, Reproduced with permission.222

(C) Patients with end-stage renal disease successfully underwent the implantation of HAVs as an arteriovenous conduit, with postoperative monitoring showing no significant changes in vascular performance, and the HAVs proved suitable for repeated cannulation for hemodialysis. Copyright 2019, American Association for the Advancement of Science, Reproduced with permission.223

(D) A case study of six-year hemodialysis using a HAV demonstrates that despite a long-term puncture and catheter dilation, vascular ultrasound, and immunofluorescence staining indicate the preservation of structural and functional integrity of the HAVs. Copyright 2022, Elsevier, Reproduced with permission.224

Another representative case for clinical application is the decellularized bioengineered biotubes. In particular, human VSMCs were seeded onto a PGA mesh scaffold within a bioreactor. Once the constructs have completed their ex vivo growth, they are decellularized to eliminate the potential for immunogenicity, thereby yielding human acellular vessels (HAVs) that possess compositional, biomechanical properties, and structural similarities to native vascular tissue. Currently, HAVs are undergoing clinical trials in adults for vascular trauma and end-stage renal disease (ESRD) requiring hemodialysis.225 Thirteen patients lacking autologous venous repair have been treated with HAVs to repair various arteries, including the superficial femoral artery, common femoral artery (Figure 12B), popliteal artery, and brachial artery.222 All HAVs maintained primary patency, with no reported infections or amputations of the affected limbs, and no reports of HAVs conduit infections or mechanical failures during a 7-month follow-up period. For ESRD patients unsuitable for fistulas, hemodialysis access grafts represent the optimal choice for chronic hemodialysis. HAV implantation in the arms of adults with ESRD for hemodialysis has been reported (Figure 12C).223 After five years, one patient maintained primary patency, and ten patients maintained secondary patency (Figure 12D).224 Considering deaths and dropouts, the secondary patency rate at five years was 58.2%, providing ESRD patients with a long-term, durable, and functional hemodialysis access.

Despite advances, bioengineered AEs as vascular grafts face challenges such as the need for faster production and increased availability. Issues with mechanical properties in small-caliber grafts also persist, necessitating further development of reinforced in vivo engineered vessels. Moreover, graft infections remain a serious concern, requiring ongoing research to optimize treatment strategies. Epidemiologic studies, treatment evaluations, diagnostic imaging, and immunomodulatory approaches are crucial for addressing these challenges. Continued post-marketing clinical follow-up is essential to confirm the safety and efficacy of vascular grafts in clinical settings, enhancing therapeutic options for patients.

In vitro arterial disease models

Biomedical research is experiencing a significant shift toward human disease modeling, driven by the development of bioengineered tissue equivalents. These models circumvent the limitations posed by species differences in animal models and enable detailed studies of disease pathogenesis and the interactions of key factors by isolating the complex microenvironment of the disease sites.226,227,228 This approach holds immense potential for advancing the understanding of arterial diseases and enhancing drug discovery efforts. This section will focus on the in vitro disease models of arterial diseases including AS, stenosis, and aneurysm.

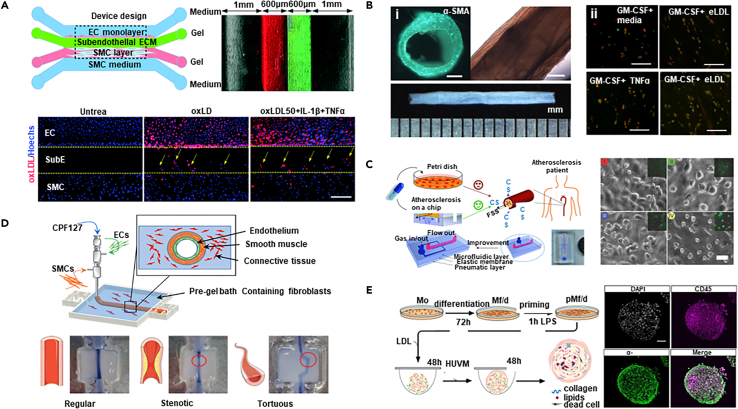

In vitro atherosclerosis model

To study of atherosclerosis mechanisms, a prerequisite is to build a human artery model that can reveal the interplays between ECs, SMCs, and ECM. The bioengineered AE mimics the anatomy and structure of the arterial wall and thus can intrinsically contribute to recapitulating the cellular activities and responses during atherosclerosis. To monitor the dynamic changes that occurred in the relevant process, the models adaptable to real-time bioimaging are desired. In this regard, the artery-on-a-chip devices exhibited unparalleled advantages over other bioengineered AEs. A new microfluidic-based arterial wall on-a-chip simulates the intima-media interface of the artery by co-culturing ECs and SMCs, as well as precisely controlling the ECM microenvironment (Figure 13A).229 This chip uses collagen and basement membrane matrix to simulate the sub-endothelial ECM layer and the 3D culture environment of SMCs in two hydrogel channels, respectively. Upon such a model, the study investigated the effects of vitamin D (1,25(OH)2D3) and metformin in alleviating monocyte-endothelial cell adhesion and smooth muscle cell migration induced by cytokines.

Figure 13.

Representative examples that show in vitro model of AS

(A) The micro-engineered arterial wall device on a chip and the migration of SMCs under hyperlipidemic conditions (scale bar 500 μm). Copyright 2021, Royal Society of Chemistry, Reproduced with permission.229

(B) Bright-field views of TEBVs, along with macrophage polarization within these vessels following exposure to eLDL and/or TNF-α (scale bar i: 200 μm, ii: 100 μm). Copyright 2020, Springer Nature, Reproduced with permission.105

(C) The structure of the early-stage AS model and the actual model, as well as the morphology of HUVECs under different mechanical stimuli (scale bar 50 μm). Copyright 2016, Wiley-VCH, Reproduced with permission.230

(D) The schematic diagram illustrates the fabrication process of triple-layered AEs, resulting in arterial constructs with controlled geometries. Copyright 2021, Wiley-VCH, Reproduced with permission.231

(E) The schematic view depicts the assembly of ps-plaques with blood-derived cells and reveals the inner architecture of these ps-plaques (scale bar 100 μm). Copyright 2018, Elsevier Science, Reproduced with permission.232

Upon the construction of functional AE, the successful establishment of an atherosclerotic model relies on the recreation of core pathogenic signals to stimulate cells for the recapitulation of the downstream initiation and progression events. To achieve this, a viable method uses enzymatically modified low-density lipoprotein (eLDL) and TNF-α to mimic the atherosclerotic environment under physiological shear stress in tissue engineered blood vessels (Figure 13B).105 This leads to the activation of ECs, accumulation of monocytes, formation of foam cells, and expression of pro-inflammatory cytokines. Enzymatically modified LDL is more effective in producing foam cells than oxidized LDL,233 causing the upregulation of ICAM-1 and E-selectin in ECs, and readily inducing foam cell formation in SMCs234 and macrophages.233 The model also exhibits partial disease regression upon eLDL removal, demonstrating the potential for discovering effective therapies.

Besides the biochemical signals, the pathogenesis of AS is also significantly influenced by biomechanical stimuli, such as mechanical stress and hemodynamics that play critical roles in regulating cellular behaviors. The bioengineered AEs with regular geometries cultivated under laminar flows may face difficulties in providing these biomechanical signals. Therefore, the dynamic AE devices have gained attention. A stretchable microfluidic chip has been designed, integrating a microfluidic layer, an elastic PDMS membrane, and a pneumatic layer, which successfully constructed an early AS model capable of applying both FSS and cyclic stretch (Figure 13C).230 By precisely controlling fluid flow and vacuum, this model simulated the mechanical hemodynamic signals presenting in arteries. Equipped with this design, the study demonstrated the unique advantages of this model over 2D culture conditions in drug evaluation and screening. The AE device facilitated the discovery of new evidence regarding the cytotoxicity of the clinical drug probucol underscores its indispensable role in drug evaluation and screening, which is conducive to the study of the pathological microenvironment on the early occurrence of atherosclerosis.

Another innovative in vitro atherosclerosis model has utilized a creative 3D suspended coaxial bioprinting technology to construct a three-layered AE with controllable geometry and dimensions (Figure 13D).231 The model employed vascular tissue-derived decellularized extracellular matrix as a supportive bath for gel-embedded 3D bioprinting, as well as adjusting the printing path and speed to precisely control the inner diameter and wall thickness of the AE. This method overcame the limitations of traditional vascular models in terms of structural stability and geometric control. The direct construction of vascular models with adjustable geometries, including normal, stenotic, and tortuous shapes, simulated the complex hemodynamics in AS.

Currently, most of the established in vitro models focus on the early stage of atherosclerosis which only contributes to understanding the pathological mechanism of disease initiation (e.g., endothelial dysfunction, SMCs phenotype switch, foam cell formation). A few efforts attempted to construct the flatforms that are capable of recreating the build-up of atherosclerotic plaques composed of fibrose caps and necrotic cores, which are more significant to evaluate medications for the disease recovery.

Among the limited relevant reports, a three-dimensional human fibrous atherosclerotic plaque model that simulates late-stage atherosclerosis, marking an important step in the continuous study from lipid deposition and inflammatory responses in the early stages of the disease to plaque formation in the later stages (Figure 13E).232 Using the suspension droplet technique, spherical cellular structures that include a fibrous cap and necrotic core can be created using myeloid cells, THP-1 cells, and human umbilical vein smooth muscle cells. These cell spheres form structures in three-dimensional space that are similar to atherosclerotic plaques, mimicking the inflammatory microenvironment in the vascular subendothelial space induced by cholesterol. Despite this, the model still has some shortcomings, such as the precise control of the composition, structure, and dimension of the plaques, as well as the consistent production, which limits their applications for high-throughput screening.

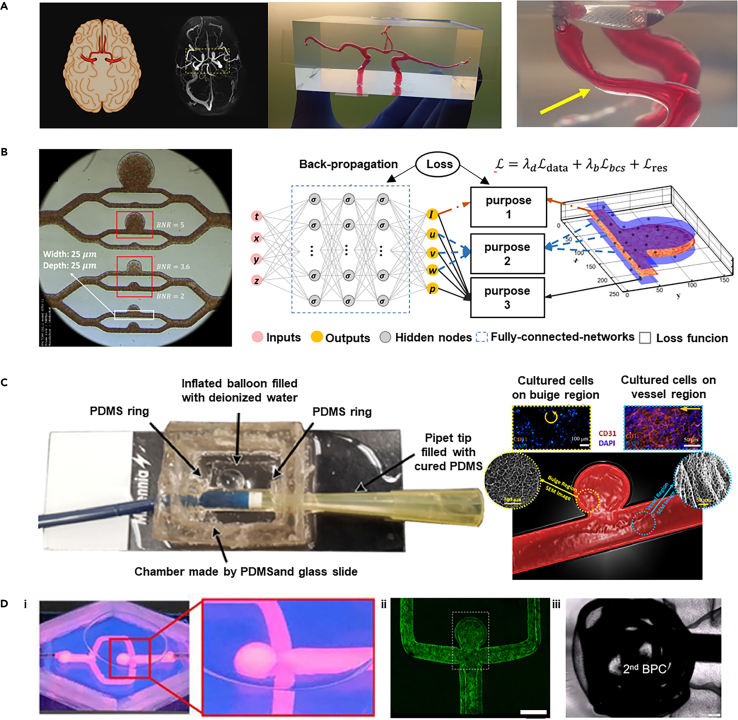

In vitro thrombosis model