Abstract

In this contribution, we review the electrochemical upgrading of saccharides (e.g., glucose) and sugar alcohols (e.g., glycerol) on metal and metal-oxide electrodes by drawing conclusions on common trends and differences between these two important classes of biobased compounds. For this purpose, we critically review the literature on the electrocatalytic oxidation of saccharides and sugar alcohols, seeking trends in the effect of reaction conditions and electrocatalyst design on the selectivity for the oxidation of specific functional groups toward value-added compounds. Importantly, we highlight and discuss the competition between electrochemical and non-electrochemical pathways. This is a crucial and yet often neglected aspect that should be taken into account and optimized for achieving the efficient electrocatalytic conversion of monosaccharides and related sugar alcohols into valuable products, which is a target of growing interest in the context of the electrification of the chemical industry combined with the utilization of renewable feedstock.

1. Introduction

Fossil-based resources account for 86% of the global energy demand and a staggering 96% of organic chemicals,1 accounting for 614 million tons of chemicals per year in 2013.2−4 These resources are however not sustainable and their use results in the emission of greenhouse, polluting gases (CO2, CH4, NOX, etc.), inflicting environmental and health damage. This requires the search for alternative energy sources and renewable carbon-based resources, which should be environmentally friendly, cheap, and readily available.3,5 In this regard, a switch from a fossil-based economy to an electrified and circular/biobased economy could contribute to a solution.6 In this context, electricity generated from renewable resources (e.g., wind, solar, hydropower) could serve as an energy source to drive catalytic reactions, while lignocellulosic biomass derived from non-edible agricultural waste streams could serve as a carbon source.5,7−9 This biomass is composed of carbon-based compounds with a wide range of functionalities (e.g., alcohol, ketone/aldehyde carboxyl groups),10−12 which offer a large range of possibilities to produce value-added (platform) chemicals.

Currently, most biomass-based feedstocks are processed on an industrial scale via fermentation, stoichiometric, or thermocatalytic routes. However, these processes tend to have a substantial impact on the environment.11 Fermentation processes are slow and require multiple expensive downstream steps,13 while stoichiometric processes generate substantial amounts of waste salts. Yet, these routes are still the main approaches utilized for the synthesis of biomass-based platform molecules like gluconic acid, lactic acid, and nitric acid.13,14 In this regard, the conversion of biomass-based feedstock via thermocatalytic routes seems an interesting alternative, considering that the catalyst, if heterogeneous, can be readily separated from the products and reused for several runs or for prolonged time on stream, and that no waste salts are generated as byproducts.15,16 However, thermocatalysis typically requires an energy input in the form of heat to surpass the activation barrier.17,18 Thermocatalytic redox processes may also require pressurized gaseous reactants such as O2 or H2. As an alternative, electrochemical and photochemical routes have been investigated as a sustainable and clean method to carry out the conversion of biobased compounds to useful products. Both routes can generate chemicals by separating oxidation and reduction reactions. Despite this similarity, electrochemical routes offer better perspectives toward practical application as the photochemical routes generally face challenges in converting light to chemical energy efficiently, maintaining photocatalyst stability, and developing scalable, cost-effective systems.19

For electrochemical reactions, a higher potential compared to what would be needed based on the thermodynamics of the reaction (i.e., an overpotential) typically needs to be applied to overcome the reaction activation barrier.20−22 Developing electrocatalysts is crucial to minimize this overpotential and thus to optimize the energy-efficiency of the electrochemical process. In general, electrochemical routes present several potential advantages over conventional chemical production routes: (1) the possibility of using ambient temperatures and pressures resulting in mild reaction conditions, (2) the use of H2O (OH– or H+) as oxygen or hydrogen source for the oxidation/reduction allows circumventing the necessity of costly oxidizing/reducing agents, and (3) the ease of tuning the reaction conditions (e.g., by tuning the electrode potential) can enable easy control over the reaction rate and selectivity.3,23 Moreover, electrosynthesis could aid in leveraging the energy surplus generated by energy suppliers, which is subject to fluctuations depending on the availability of the sources. This is achieved by synthesizing compounds with chemical bonds containing a high amount of energy, which can then be used as feedstock in fuel cells.17 Electrosynthesis does not necessarily require an energy input, and if the redox reaction is thermodynamically favorable, it can be achieved in fuel cells that cogenerate electricity and chemicals.24 The latter is an additional asset compared to photochemical routes. Furthermore, the electrochemical oxidation of biobased compounds has been investigated as an alternative anodic reaction to replace the oxygen evolution reaction (OER) in electrolyzers used for green hydrogen production.25 This approach is referred to as hybrid water electrolysis (HWE) and can have a 2-fold benefit: decrease the energy input and generate a more valuable anodic product than O2.

The electrocatalytic valorization of biomass-based feedstock (e.g., saccharides and sugar alcohols) derived from fats, oils, and lignocellulose to obtain value-added platform molecules has been widely investigated (Figure 1).26−30 Fats and oils can be obtained from edible crops, waste cooking oils, or oleaginous microorganisms and commonly consist of glycerol linked through ester groups to one to three fatty acids, forming a triglyceride.31 These triglycerides can be subjected to hydrolysis (or transesterification) to produce free fatty acids (or esters) and glycerol. The obtained free fatty acids/esters can be used as biodiesel, while glycerol remains a byproduct,31 accounting for 4.2 million tons per year.32 Lignocellulosic biomass derived from agricultural waste has an even greater potential due to its abundance, accounting for 1470 million tons per year for rice straw, wheat straw, corn straw and bagasse.33 These lignocellulosic biomass waste streams consist of three main components: cellulose (32–47%), hemicellulose (19–35%), and lignin (5–30%), with the remainder being minor fractions of proteins and ash.33,34 Cellulose forms crystalline bundles of fibers that are intertwined by hemicellulose and lignin polymers, making it difficult to access and thus process. Hemicellulose is a branched polymer and has an amorphous structure, which makes it the easiest to hydrolyze (via an acid hydrolysis step) to yield monomeric constituents.35 The composition of hemicellulose is highly dependent on the source and may contain various saccharides (glucose, mannose, galactose, rhamnose, and xylose) and uronic acids. The fractionation of cellulose from lignocellulose is applied on an industrial scale via Organosolv and Kraft processes to obtain cellulose pulp.36 Cellulose pulp has several commercial applications in the paper and building industry but can also be subjected to an acid or enzymatic hydrolysis step to generate glucose monomers.35,36 Lignin is a polymer based on phenolic units and with an amorphous structure. Its recalcitrant and complex chemical structure hinders its depolymerization and fractionation into phenolic compounds, which could be then upgraded to BTX compounds (benzene, toluene, and xylene).37 Currently, biorefinery technology is more advanced for the conversion of triglycerides and of the cellulosic and hemicellulosic fractions of lignocellulose, and therefore, the most commonly obtained platform molecules derived from biomass-based feedstock are saccharides (e.g., glucose, xylose) and sugar alcohols (e.g., glycerol).

Figure 1.

Overview of lignocellulose and fats/oils (red) that can be fractionated to various molecules (yellow). These molecules (e.g., saccharides and sugar alcohols) have common functional groups (green) that typically can undergo oxidation and/or isomerization and dehydration (blue) to obtain value-added platform molecules (gold).

Figure 1 highlights several key molecules (e.g., gluconic acid, glucaric acid, xylonic acid, and lactic acid) that are recognized by the National Renewable Energy Laboratory as top value-added platform chemicals in various industrial applications.38 Gluconic acid finds extensive use in the food, pharmaceutical, and paper industries. Glucaric acid serves as a corrosion inhibitor and metal complexing agent, and it can also be utilized in pharmaceuticals or as a precursor for biodegradable polymers.39 Both glucaric acid and related compounds like mannaric acid and galactaric acid show promise as precursors for adipic acid, a key material in nylon production.40 Xylonic acid serves multiple functions, including as cement plasticizer, as additive for improving vitamin C absorption, and as a component in copolymerization with polyamides and polyesters. It can also serve as a precursor for valuable chemicals such as ethylene glycol and glycolic acid.41 Lastly, lactic acid is pivotal in the production of poly lactic acid, a biodegradable biopolymer widely used in the food and pharmaceutical industries.42 Overall, these platform chemicals are crucial not only for their specific uses but also as key building blocks in chemical and material sciences.

The electrochemical oxidation of sugar alcohols12,30,43−49 and saccharides50,51 typically employs metals as electrocatalytic active species. This field of research has recently gained special attention in the (electro)catalysis community, resulting in a growing number of scientific publications. However, current review papers on the electrocatalytic oxidation of sugar alcohols are limited to the selective conversion of glycerol, lacking comparison with other sugar alcohols such as erythritol,52 arabitol,53 or sorbitol.52,54−58 On the other hand, the selective electrocatalytic oxidation of glucose and other saccharides has been less extensively reviewed,50,51 with most reviews on electrochemical oxidation of saccharides being focused on electrocatalyst activity for fuel cell research.24,59,60 Sugar alcohols and saccharides both contain primary and secondary alcohol groups, while saccharides also have an aldehyde group (in the linear form) or the corresponding anomeric carbon group (in the cyclic form). This makes it interesting to evaluate whether the reaction conditions and/or the electrocatalyst properties affect the selective conversion of the two types of reactants in a similar way.

Here, we critically review the literature on the electrocatalytic oxidation of sugar alcohols and saccharides, seeking trends in the effect of reaction conditions and of the design of metal-based electrocatalysts on the activity and selectivity in the oxidation of specific functional groups toward value-added compounds. The trends have been divided according to (a) the effect of reaction conditions on the electrocatalytic conversion of monosaccharides and sugar alcohols (section 2); (b) the potential-dependent state of the metal (e.g., Au and Pt) surface (section 3); (c) the relation between the features of the electrocatalysts (type of metal, metal oxidation state, exposed facets, and mono- vs bimetallic nature) and their performance in the oxidation of sugar alcohols (under various reaction conditions); see section 4; and (d) the relation between the features of the electrocatalysts and their performance in the electrocatalytic oxidation saccharides (under various reaction conditions); see section 5.

The focus is on glycerol and glucose as reference molecules to study the reactivity of C3–C6 sugar alcohols and C3–C6 saccharides. Additionally, we look for trends between the two types of reactants, aiming at defining which set of reaction conditions and electrocatalyst properties can favor the selective conversion of each functional group to specific value-added products. This review also aims at providing a critical assessment of the current literature, as well as to propose alternatives for sugar alcohol oxidation based on saccharide oxidation and vice versa. By shedding light on the reaction pathways for the electrocatalytic oxidation of sugar alcohols and saccharides, we aim at clarifying how these pathways can be steered toward the desired products. This approach will enable future research to design catalysts and electrochemical cells that can enhance the activity and direct the selectivity toward desired products, thereby overcoming the main current challenges in the electrocatalytic oxidation of sugar alcohols and saccharides.

It is worth reporting that the electrochemical oxidation of sugar alcohols and saccharides can also be carried out in the presence of an organic mediator (e.g., TEMPO or other nitroxide-based compounds), which undergoes a redox reaction with the biobased compounds and then gets reoxidized on the surface of the metal electrocatalyst. However, this is a conceptually different field of research in which the selectivity can be determined by other factors than the nature of the metal electrocatalyst, which is the focus of this review. Additionally, the use of mediators increases the challenges in terms of upscaling, implementation, and downstream processing. The interested reader can find more information about mediated electrochemical oxidation in several recent reviews and papers.61−66

2. Effect of Reaction Conditions on the Electrocatalytic Conversion of Monosaccharides and Sugar Alcohols

In this section, the influence of various reaction conditions on the electrochemical oxidation of sugar alcohols and monosaccharides is discussed by comparing and rationalizing the behavior of different electrocatalysts that have been reported. The reaction parameters that have been found to influence the behavior of a certain electrocatalyst in the conversion of monosaccharides and sugar alcohols are (a) the reaction conditions, e.g., the pH and type of ions of the electrolyte (section 2.1), the reaction temperature (section 2.2), and reactant concentration (section 2.3); (b) the potential-dependent state of the metal (e.g., Au and Pt) surface (section 3); and (c and d) the intrinsic properties of the electrocatalyst, e.g., type of metal, metal oxidation state, exposed facets, and mono- vs bimetallic nature, under various reaction conditions (section 4 for the oxidation of sugar alcohols; section 5 for the oxidation of saccharides). First, varying these parameters can lead to a change in the configuration of the reactant, for instance by opening a pyranose ring or by forming an anionic form of a sugar alcohol. Second, the reactant or products can undergo non-electrochemical conversion in the bulk of the solution, through isomerization, dehydration, and/or retro-aldol reactions. Third, the reaction conditions can also affect the oxidation state and surface chemistry of the electrocatalyst employed, and thus its performance. Altogether, these three effects influence the interaction between the reactant and the electrocatalyst, thus contributing to its activity, selectivity, and stability. Hence, it is crucial to understand the nature of such influences in order to gain control on, and thus optimize, the performance of an electrocatalytic system. The observed trends in selectivity were mainly obtained from electrocatalysts based on Au and Pt. It is worth mentioning that the cell design also plays a crucial role in defining the performance of an electrocatalytic system. However, this parameter is not systematically addressed in the literature and will not be discussed further in this review.

2.1. Effect of pH and Electrolyte Ions on the State of Reactant and Products

2.1.1. Effect of pH and Role of Non-Electrochemical Reactions

The pH can influence the structure and, if applicable, the neutral vs ionic form of the reactant, which in turn affects the electrocatalyst performance. The pH is also related to the concentration of protons and hydroxide ions in solution, which can act as homogeneous catalysts and thereby promote non-electrochemical conversion of the reactant and products in the solution. In this section, the influence of pH on the solution-phase reactions of the reactants and products is discussed, whereas its effect on the electrocatalyst selectivity will be discussed in sections 4 and 5. It is important to discuss this effect separately and at the outset of the review, as we believe that the influence of (pH-dependent) solution-phase reactions on activity and especially selectivity has been underestimated in many literature reports.

The electrocatalytic oxidation of sugar alcohols and monosaccharides has been studied under acidic conditions (typically at pH = 1), neutral conditions, or alkaline conditions (pH > 7), with the last option being by far the most common.54,56−58,67−69 It has been proposed that alkaline conditions are more suitable for these oxidations because a basic medium promotes the formation of electroactive species like alkoxides or enediols via non-electrochemical reactions in the electrolyte solution, which then more easily adsorb and react on the electrocatalyst surface, thereby promoting the catalytic activity.28,69−72

At neutral pH, the β-anomeric form of glucose is the major equilibrium species (63–67%), followed by the α-anomeric form (33–37%) and a minor fraction of the linear form (<0.03%).70,73,74 The β-anomeric form is the dominant species as it has its alcohol group in the equatorial position (Scheme 1), which decreases the steric hindrance,75 and it has an increased number of hydrogen bonds,73 making it thermodynamically the most stable form. Importantly, under acidic conditions, the β-anomeric form was found to be the most reactive species for electrocatalytic oxidation reactions over Pt electrodes.70 β-d-Glucose has its anomeric C–H bond at the axial position, whereas α-d-glucose has its anomeric C–H bond at the equatorial position (Scheme 1). With the anomeric C–H bond at the axial position, all the OH groups remain in equatorial position, which favors a planar approach of the β-d-glucose molecule to the electrocatalyst surface due to a lower steric hindrance, thus promoting the adsorption of the reactive species and enhancing the electrocatalytic activity.70 More recently, Holade et al. showed that under neutral conditions the oxidation of the α-d-glucose on Au proceeds faster than that of β-d-glucose.76 In contrast to Largeaud et al., Holade et al. argue that the catalytic activity toward α-d-glucose is higher since the α-anomeric form with its C–OH bond in the axial position more easily adsorbs on the Au surface, which was based on DFT calculations.76 The ratio between the α-anomeric form and β-anomeric form is dependent on the pH of the solution.74 Under acidic and alkaline conditions the α-anomer:β-anomer ratio is 45:55 and 10:90, respectively.74 Moreover, the mutarotation rate from the linear d-glucose to the β-anomer is higher under alkaline conditions, followed by acidic conditions (pH < 2) and then neutral conditions.70,77 The fast mutarotation of glucose under alkaline conditions made it impossible to distinguish the reactivity of the different anomeric structures.74 Hence, the time between initiation of the experiment and the addition of d-glucose might affect the catalyst activity that is measured.

Scheme 1. Reaction Scheme Displaying the Non-Electrochemical Isomerization Reactions Taking Place in the Electrolyte in the Presence of a Base.

In alkaline electrolytes (11 < pH < 12), a sharp increase in electrocatalytic activity was observed for the oxidation of saccharides over Cu78 and sugar alcohols over Au.79,80 This effect was attributed to the formation of the anionic species upon deprotonation of glucose, yielding an enediol species (Scheme 1), or upon deprotonation of sugar alcohols79 yielding an alkoxide. These anionic species are more reactive compared to their protonated counterparts. The pH at which these anionic species are formed is dependent on the pKa of the reactant.78 When the pH is increased above 12, a further increase in electrocatalytic activity (current density) for the oxidation of sugar alcohols and saccharides is typically observed (e.g., for electrocatalysts based on Ni, Pd, PtAu, and NiPd).81−85 At highly alkaline conditions (3 M NaOH, pH ≥ 14.5), a stagnation or a decrease in activity toward glycerol and glucose oxidation has been reported.81,83,85 It has been suggested that the adsorption of hydroxide ions under these conditions prevents the adsorption of the reactants on the surface of the catalyst.83,85 However, it is important to note that if hydroxide binds to the surface as neutral hydroxyl OHads, which is usually assumed, there cannot be a higher pH-dependent OHads coverage at the same potential on the RHE scale.

Depending on the pH, protons or hydroxide ions can act as homogeneous catalysts and thereby induce non-electrochemical conversion of the reactants by isomerization, retro-aldol reaction, aldol condensation, dehydration, Cannizzaro rearrangement, oxidative degradation, and aerobic oxidation reactions. These homogeneous reactions are also affected by the presence of oxygen in solution, temperature, initial reactant concentration, and type of electrolyte.54,86,87 Most electrochemical reactions are performed below 60 °C and under anaerobic reaction conditions. At these temperatures, under acidic conditions, most homogeneous reactions do not occur at a significant rate.88,89 Therefore, only the homogeneous reactions that prevail under alkaline conditions are discussed here. Moreover, the effect of oxygen present in the solution, which can be formed at the anode surface or can be present in the case of incomplete deaeration before electrocatalytic experiments, must be considered as it strongly influences the products that are formed in homogeneous reactions.54,87

Considering isomerization reactions first, glucose tends to isomerize into the thermodynamically more stable fructose or mannose, as illustrated in Scheme 1.90 The isomerization rate of glucose is higher at more alkaline conditions (becoming significant at pH ≥ 10.0) and elevated temperatures28,91,92 but is also highly dependent on the type of electrolyte, as a combination of bromide and lithium ions can catalyze isomerization reactions in solution.93 In line with these observations, the saccharides obtained through the electrocatalytic oxidation of sugar alcohols (e.g., glucose from sorbitol and glyceraldehyde from glycerol) can undergo these non-electrochemical isomerization reactions in alkaline media. Hence, the electrocatalytically formed glyceraldehyde (GALD) can isomerize non-electrochemically to the thermodynamically more stable dihydroxyacetone (DHA) under inert conditions,94 while this reaction appears to be limited in oxygen-rich solutions.54,87 Therefore, the observation of a high DHA selectivity from glycerol oxidation in alkaline media is not necessarily the result of a selective catalyst; the influence of the solution-phase isomerization must be considered carefully.

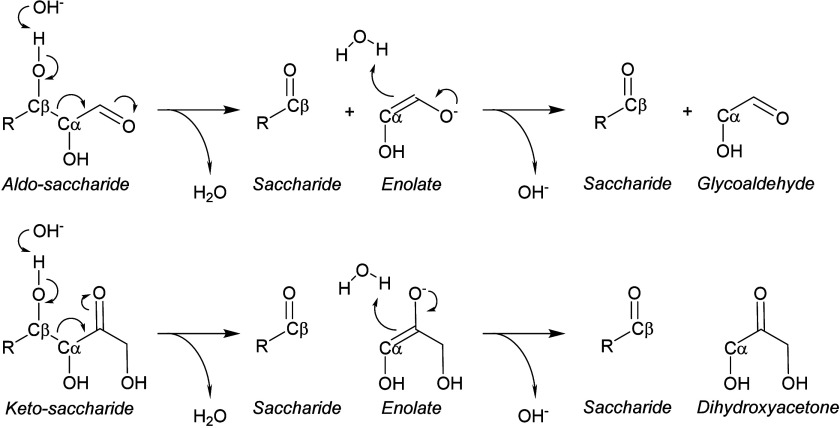

An important second class of non-electrochemical homogeneous reactions are retro-aldol reactions, which result in the cleavage of the Cα–Cβ bonds adjacent to a carbonyl of keto-saccharides or an aldehyde of aldo-saccharides in alkaline solutions already at room temperature, as illustrated in Scheme 2.86,87,95 More specifically, a hydroxide ion abstracts a hydrogen from the Cβ-OH group. As a result, the electrons rearrange and the Cα–Cβ bond breaks, resulting in the formation of two smaller molecules. Thus, the retro-aldolization of glucose (i.e., an aldo-saccharide) cleaves the C2–C3 (e.g., Cα–Cβ) bond resulting in the formation of glycol aldehyde and erythrose, while the retro-aldolization of fructose (i.e., a keto-saccharide) cleaves the C3–C4 bond resulting in the formation of glyceraldehyde and dihydroxyacetone.86,87 The successive retro-aldolization of erythrose results in the formation of two glycoaldehydes.86,95 Interestingly, the retro-aldolization of glyceraldehyde was not observed under anaerobic conditions,54 indicative that this reaction only proceeds for ≥ C4 molecules. Importantly, the retro-aldol reaction is more dominant under anaerobic conditions, as oxygen-rich conditions tend to enhance oxidative C–C cleavage reactions and the aerobic oxidation of aldehydes.87 The retro-aldol reaction is in equilibrium with the aldol condensation reaction. For example, in the case of GALD, a proton is abstracted from a hydroxide ion at Cα, resulting in an enediol which can react with GALD or DHA (isomers) forming glucose and fructose, respectively.

Scheme 2. Reaction Scheme Displaying the Retro-Aldolization of Aldo-Saccharides (e.g., Glucose) and Keto-Saccharides (e.g., Fructose) Taking Place in the Electrolyte in the Presence of a Base.

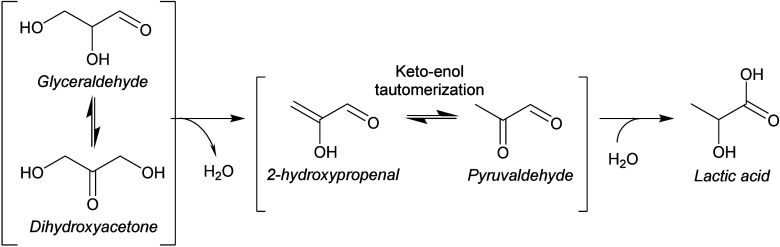

A third class of relevant non-electrochemical homogeneous reactions is the dehydration of saccharides and their corresponding isomers. Under alkaline conditions, the dehydration of glyceraldehyde or dihydroxyacetone is often reported as it is a key step in the synthesis of lactic acid,87 while the dehydration of glucose or fructose has been reported only under more acidic conditions at elevated temperatures,87,96,97 since alkaline conditions promote retro-aldol reactions.87,98 In the case of GALD and DHA, both molecules can undergo a dehydration to form 2-hydroxypropenal, which can undergo keto–enolic tautomerization to pyruvaldehyde (Scheme 3).42,87,99 Successively, pyruvaldehyde can undergo an intramolecular Cannizzaro rearrangement to form lactic acid (LA).87,99 These reactions compete with aldol condensation reactions (especially at high glyceraldehyde concentrations54) and can be promoted under optimized reaction conditions, resulting in relatively high LA selectivities.87 For example, the presence of divalent cations (e.g., Ba2+, Cu2+, Ca2+, Zn2+, and Pb2+) can redirect the pyruvaldehyde reaction toward a 1,2-hydride shift, resulting in a stabilized lactate salt, which can be acidified to produce LA.87 Li et al. showed that the dehydration of DHA to pyruvaldehyde followed by a 1,2-hydride shift is the main reaction pathway for LA formation, while the pathway from GALD to LA only plays a minor role since the LA yield was higher when starting from DHA than from GALD.87 Moreover, under oxygen-rich conditions the formation of LA was significantly lower,54,87 which was attributed to the promotion of oxidative C–C cleavage reactions and the aerobic oxidation of aldehydes under these conditions.87

Scheme 3. Reaction Scheme Displaying the Different Steps Involved in the Rearrangement of Glyceraldehyde and Dihydroxyacetone to Form Lactic Acid.

A fourth and fifth class of non-electrochemical homogeneous reactions are the oxidation of an aldehydic group to a carboxylic group (Scheme 4) and the oxidative C–C cleavage reactions of saccharides (Scheme 5), respectively. These reactions become dominant in alkaline solutions when oxygen is present in the electrolyte.54,87 For example, in the presence of oxygen and at pH = 13, Kwon et al. showed that glyceraldehyde is predominantly converted to glycerate, glycolate, and formate.54 In this case, the formation of glycerate is promoted by the oxidation of aldehydes mediated by molecular oxygen. The exact mechanism is not fully established and may vary between the nucleophile–electrophile interaction presented in Scheme 4 and a radical-driven pathway. In parallel, the formation of formate and glycolate is mediated by the oxidative C–C cleavage reactions in solution, as illustrated in Scheme 5. In this reaction, glyceraldehyde first forms an enediol. Successively, the enediol can be attacked by the nucleophilic oxygen molecule at the C1 or C2 group to produce a hydroperoxide intermediate.100 The resulting hydroperoxide intermediate undergoes a series of rearrangements, resulting in the formation of formic acid and glycolic acid. The mechanism through which this proceeds remains a topic of debate. In the case of glucose, this reaction proceeds in a similar manner and results in the formation of formic acid and arabinonic acid.100

Scheme 4. Reaction Scheme Displaying the Oxidation of the Carbonyl Group of an Aldehyde in the Presence of Molecular Oxygen under Alkaline Conditions.

Scheme 5. Reaction Scheme Displaying the Oxidative C–C Cleavage of a Saccharide in the Presence of Molecular Oxygen under Alkaline Conditions.

2.1.2. Effect of Electrolyte Ions

A less commonly studied topic is the effect of electrolyte ions on the catalyst selectivity.101 Both the cations that are present in basic electrolyte solutions (e.g., Na+, K+) and the anions present in acidic electrolyte solutions (e.g., SO42–, HPO42–, ClO4–) can influence the electrocatalytic oxidation reactions. In a recent study on the electrocatalytic oxidation of glycerol in basic medium over NiOOH, the effect of electrolyte cations on the electrocatalyst selectivity was researched experimentally and computationally.101 It was found that the aldehyde intermediates of the electrocatalytic oxidation of glycerol (glyceraldehyde and glycolaldehyde) were stabilized more effectively in the presence of smaller cations (Li+) than in the presence of larger cations (K+). As a result, Li+ inhibits the successive oxidation of the aldehydes, as was shown by chronoamperometric (CA) measurements. It was argued that the delayed oxidation of these aldehydes gives hydroxide anions more time to induce nucleophilic attacks, thereby promoting C–C cleavage reactions. This effect was substantiated by using crown ethers to coordinate the ions, thus preventing them from interacting with the aldehyde intermediates during the electrocatalytic oxidation of glycerol, which ultimately resulted in a decrease in the rate of C–C cleavage reactions. A related study was conducted with a cobalt borate electrode to electrocatalytically oxidize glycerol with dissolved borax (Na2B4O7) as a supporting electrolyte.102 The borax ions hydrolyze to form B(OH)4–, which were found to interact with the primary alcohol groups of glycerol (as revealed by NMR), consequently promoting the coordination of the secondary alcohol group with the surface of the electrode (Figure 2). This was suggested to enhance the electrocatalytic oxidation of the secondary alcohol group of glycerol, resulting in a high selectivity toward dihydroxyacetone, which could be further promoted from 50 to 60% by increasing the electrolyte concentration from 0.05 to 0.2 M borax.102 Likewise, an increase in pH promoted the formation of glycerol-borate complexes, thereby further improving the selectivity toward DHA.102 Moreover, for the electrocatalytic oxidation of glycerol in 0.2 M Na2B4O7, a ∼250 mV lower potential resulted in the same current density (e.g., catalytic activity) when compared to 0.2 M Na2SO4.

Figure 2.

Coordination of glycerol induced by borate ions in solution. By bonding to both primary alcohol groups, the secondary alcohol becomes more susceptible for the electrocatalytic oxidation promoting the formation of dihydroxyacetone and stabilizing dihydroxyacetone through the formation of a dihydroxyacetoneborate complex, hampering further oxidation reactions. Reprinted from ref (102). Copyright 2021 American Chemical Society.

The inorganic anions that are present in neutral or acidic electrolytes are also known to influence the electrocatalytic oxidation reactions.103 These anions can adsorb on the active sites of the electrocatalyst, blocking them and thus negatively affecting the activity. Different anions typically display different strength of adsorption on the electrocatalyst surface, thus influencing the activity and the selectivity to a different extent.68 For example, Melle et al. showed that the activity of Pt for the electrocatalytic oxidation of glycerol decreased in the order HClO4 < H2SO4 < H3PO4 and attributed the differences in electrocatalytic activity and selectivity to competitive adsorption phenomena.104

In conclusion, alkaline conditions promote electrocatalytic reactions by the formation of more electroactive species but can also induce numerous non-electrochemical reactions. These non-electrochemical homogeneous reactions can be coupled with electrocatalytic reactions to steer the selectivity of the system toward a desired product. Since most electrochemical studies on the electrocatalytic oxidation of sugar alcohols54,57,67,105−108 and saccharides28,60,70,78 are performed under alkaline conditions, we argue that more control experiments on the reactants and the (intermediate) products should be performed to evaluate the effect of non-electrochemical reactions on the obtained product distribution, including the effect of oxygen in solution. This will give more insight on the relation between the electrocatalyst properties and the obtained selectivity and will aid in gaining insights into how the reaction pathways can be controlled. Moreover, the effect of ions present in the electrolyte should not be overlooked as they can form complexes with the reactants or (intermediate) products or adsorb on the electrocatalyst surface and thereby affect the activity and selectivity. This will depend on the intrinsic properties of the ions, such as size, charge, and polarizability.

2.2. Effect of Reaction Temperature

The number of publications on the effect of temperature on the electrocatalytic oxidation of sugar alcohols and saccharides is limited. Yet, the temperature becomes an increasingly important factor for large scale electrocatalytic systems, since these systems suffer more significantly from heat generated by resistances (e.g., ohmic drop). Therefore, research on the electrocatalytic oxidation of sugar alcohols and saccharides should dedicate more attention to the effect of temperature. The role of temperature on the performance of Au and Pt electrocatalysts toward the oxidation of sugar alcohols and saccharides was found to be independent of the functional groups of the reactant itself (C–OH vs C=O). It is worth highlighting that almost all the publications in which the influence of temperature was studied were performed under alkaline conditions28,109−117 with, to the best of our knowledge, only one paper studying temperature effects under acidic conditions.118

Most studies that report an effect of temperature on the electrocatalytic oxidation of sugar alcohols and saccharides show that an increase in temperature results in an expected increase in current density, as measured by LSV (linear-sweep voltammetry) or cyclic voltammetry (CV).109,110,112−117 In fact, several researchers have shown that there is an approximate linear relationship between the natural logarithm of the peak current density and the inverse of the temperature for the oxidation of both sugar alcohols (glycerol and sorbitol)110,116 and saccharides (glucose),115,117 which is in line with the Arrhenius equation. Likewise, for Pt/C at pH = 8, with increasing temperatures from 20 to 50 °C, the cell potential decreased and the glucose oxidation reaction rate increased.119 By contrast, for Au-based electrocatalysts (at E = 0.4–1.3 V) in the presence of glucose and under alkaline conditions (pH = 13), when increasing the temperature from 35 to 55 °C the catalyst activity dropped (Figure 3).115 This effect was attributed to the formation of poisoning species, as indicated by the coloration of the electrolyte solution.

Figure 3.

LSV of an Au-based electrode in 0.1 M NaOH at 20 mV s–1 scan rate in the presence of 10 mmol L–1 glucose at different temperatures in the 5–55 °C range. Adapted from ref (115). Copyright 2015 American Chemical Society.

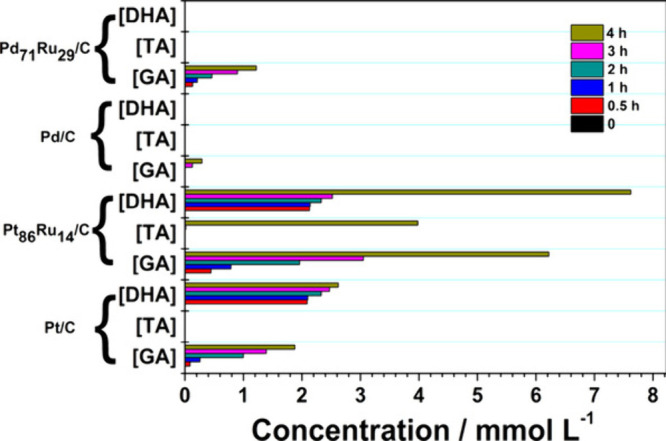

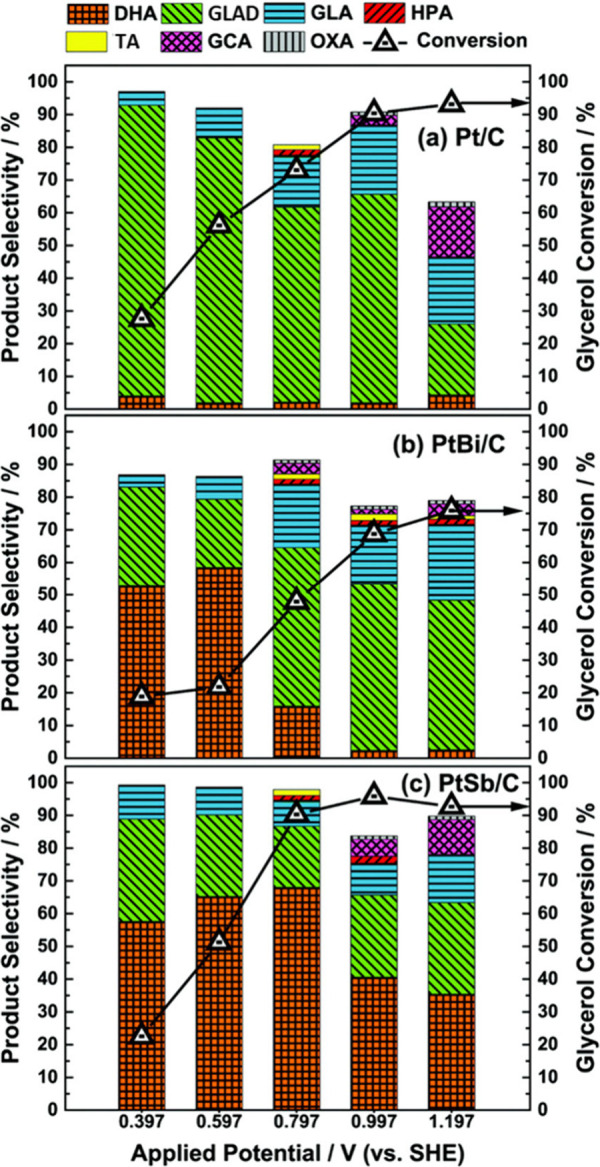

The reaction temperature can have a negative effect on the selectivity, as was shown for the electrochemical oxidation of glycerol over Pt/C and PtRu/C electrocatalysts in terms of the production of tartronic acid (TA).112,113 In this system, the selectivity toward C3 oxidation products was reduced from 96 to 91% and down to no more than 7% when the temperature was increased respectively from 30 to 60 to 90 °C, as C–C cleavage reactions were boosted at high temperature. Similarly, for the electrocatalytic oxidation of glucose to gluconic acid (GA) over Au-based electrodes, high temperatures resulted in higher concentrations of fructose (isomerization) and C–C cleavage products (degradation).28 The C–C cleavage products prevail at high temperatures, as higher activation energy barriers are more easily surpassed. Under alkaline conditions (pH > 10), an increase in temperature can induce two effects in the conversion of glucose. First, the reactant concentration can decrease due to non-electrochemical reactions such as the isomerization of glucose (mainly to fructose) and retro-aldol reactions forming C1–C3 products. Second, an increase in the concentration of these products can induce a lower catalytic activity as they are less reactive toward oxidation, e.g., in the case of fructose when compared to glucose.109

Some studies also report a positive temperature effect on the electrocatalyst selectivity, as was shown for the production of gluconic acid and glucaric acid from glucose and dihydroxyacetone or lactic acid (LA) from glycerol.27,111,118,120 For instance, under acidic conditions (0.5 M H2SO4), a selectivity of 63% dihydroxyacetone was achieved at 60 °C with PtSb/C,118 being the highest selectivity in the temperature range of 25–70 °C. Lam et al. achieved 34% LA selectivity with a Co-based electrocatalyst at 60 °C,111 while the selectivity toward LA was only 16% if the process was carried out at 40 °C. The enhanced selectivity toward LA at higher temperature can be attributed to non-electrochemical reactions (section 2.1.1, see discussion on dehydrogenation and Cannizzaro rearrangement). Other studies show that high temperatures decrease the selectivity for the electrocatalytic oxidation of sugar alcohols and saccharides.28,112,113 For the oxidation of glucose under neutral conditions, it was shown that glucaric acid (selectivity = 65%) is best achieved at 15 °C, while at 30 °C the highest selectivity was obtained toward gluconic acid, whereas even higher temperatures resulted in a loss in selectivity toward glucaric acid and gluconic acid.27 A possible explanation could be the use of acidic conditions in this study, which limit isomerization and C–C cleavage reactions.111

In summary, there is only limited research on the effect of temperature in electrosynthesis studies for sugar alcohols and saccharides oxidation. Yet, large scale electrocatalytic systems suffer not only from overpotentials but also ohmic drop, leading to heating effects, thereby affecting the temperature of the system. Hence, it is crucial to gain more insight on the effect of temperature on electrocatalytic systems. The studies that have been devoted to the effect of temperature are often performed under alkaline conditions, which are likely to be severely affected by (temperature-dependent) non-electrochemical reactions (see section 2.1). This issue should be addressed more carefully in future studies.

2.3. Effect of Reactant Concentration

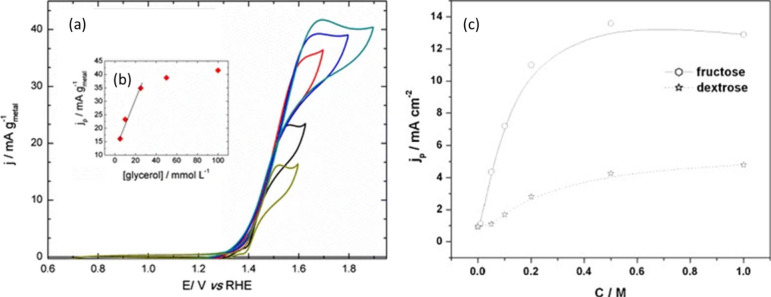

There have been several studies on the electrocatalytic oxidation of monosaccharides and sugar alcohols in which the influence of the reactant concentration was assessed.28,56,71,82,110,121−127 Some trends can be identified by comparing the results of various systems, irrespective of the type of reactant.

If we consider the example of the oxidation of glycerol in alkaline environment (Figure 4a), in which the reaction is carried out with a large excess of base compared to glycerol (as it generally is the case), an approximately first-order reaction kinetics in reactant concentration is observed up to a certain concentration, above which the reaction order decreases. Such a behavior has been reported for the electrocatalytic oxidation of both monosaccharides and sugar alcohols, showing an initially linear increase in current density in cyclic voltammetry (CV) experiments with increasing reactant concentration (Figure 4b shows an example for fructose and glucose, from a neutral solution).71,82,110,121−124 At lower concentrations, the diffusion rate of the reactant from the bulk to the electrode (which depends on the reactant concentration) is lower than the conversion rate of the reactant at the electrode, implying that all the reactant that reaches the electrocatalyst surface is immediately converted, and first-order kinetics are observed. At higher concentrations, the conversion rate of the reactant at the electrode becomes the limiting factor, implying that the active sites of the catalyst are saturated with the adsorbed reactant, and zeroth-order kinetics are observed in the CV tests (Figure 4b, c).82,122,123,125,126 It should be noted that very high concentration of saccharides and sugar alcohols can be detrimental as it can lead to an increased viscosity of the solution, which can decrease the conductivity of the electrolyte and thus result in higher ohmic losses. Moreover, the high reactant concentrations can result in an excess of (oxidized) compounds on the electrocatalyst surface, hindering the adsorption of hydroxide ions and thus decreasing the oxidation rate of the adsorbed reactants.119

Figure 4.

(a) CV of a Ni/C electrode in 0.1 M NaOH at different glycerol concentrations and (b) the influence of glycerol concentration on the anodic peak current density, as derived from plot (a). Adapted with permission from ref (82). Copyright 2015 Springer Nature. (c) Peak current density for fructose and glucose (dextrose) oxidation on a MnO2/Pt electrode in 0.5 M Na2SO4, as a function of reactant concentration. Adapted with permission from ref (122). Copyright 2008 Elsevier.

At similar reaction times in batch cells28,56,127 and at similar hydraulic retention times in flow cells128 but different initial reactant concentrations, the selectivity can significantly differ as different reactions may have different reaction orders. For example, low reactant concentrations tend to lead to high conversions in chronoamperometry tests (i.e., longer tests than those by CV), resulting in the formation of primary oxidation products (e.g., glyceraldehyde from glycerol and gluconic acid from glucose) together with further oxidation products (e.g., glyceric acid in the case of glycerol and glucaric acid in the case of glucose).28,56,127,128 For higher reactant concentrations, the conversion decreases, together with a rise in the selectivity toward primary oxidation products: the reactant tends to occupy the electrocatalyst surface, thereby decreasing the formation of sequential oxidation products.28,56,127 For the electrochemical oxidation of glycerol in 0.1 M KOH on AuPt bimetallic catalysts during 12 h,81 the overall conversion decreased from 58 to 15% when the glycerol concentration was increased from 0.1 to 1 M, but the selectivity toward lactic acid remained unaltered. A possible explanation is that the initial oxidation product of glycerol, glyceraldehyde, is converted non-electrochemically in the basic solution into lactic acid (see section 2.1.1).

To conclude, the initial reactant concentration can strongly influence the reaction rate and the reaction selectivity. Studies showed that an increase in reactant concentration changes the kinetics from quasi-first order, dominated by diffusion rates of the reactant to the surface of the catalyst, to zeroth order, dominated by intrinsic kinetic rates of the catalyst. Moreover, considering similar reaction times, low initial reactant concentrations result in multiple oxidation products, while high initial reactant concentrations result in fewer oxidation products, resulting in less complex reaction mixtures and thus easier downstream processing procedures. Hence, to compare the performance of catalysts between different studies it is recommended to use similar reactions conditions, such as initial reactant concentrations, pH, temperature, reaction times, and number of catalytic active sites.

3. Potential-Dependent State of the Surface of Metal-Based Electrodes

In electrocatalytic oxidation processes, the kinetics and selectivity of the reaction can be controlled by means of the applied potential. Yet, an increase in applied potential can have two effects: (1) it lowers the activation energy for electron transfer reactions and thereby increases the rate of electrocatalytic oxidation, and (2) it can change the oxidation state of the electrocatalyst surface from metallic to oxidic (i.e., metal hydroxide, oxyhydroxide, or oxide), which in turn can affect the activity and selectivity of the electrocatalyst. Therefore, in this section we distinguish between these two effects by considering the surface oxidation state of the electrocatalyst as a function of potential, with particular focus on Au and Pt electrodes.

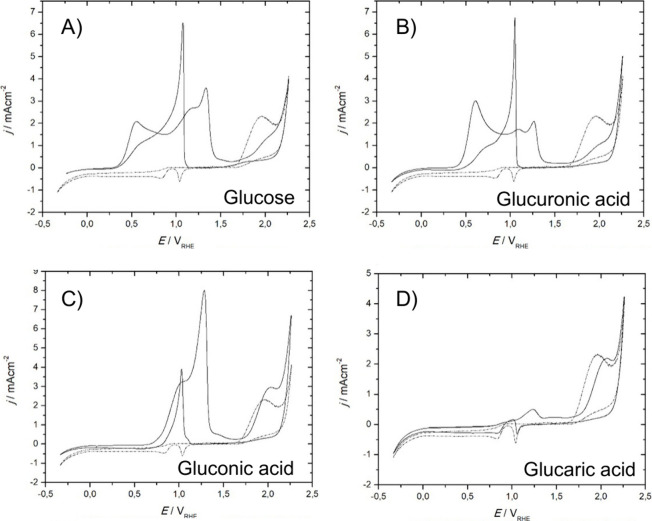

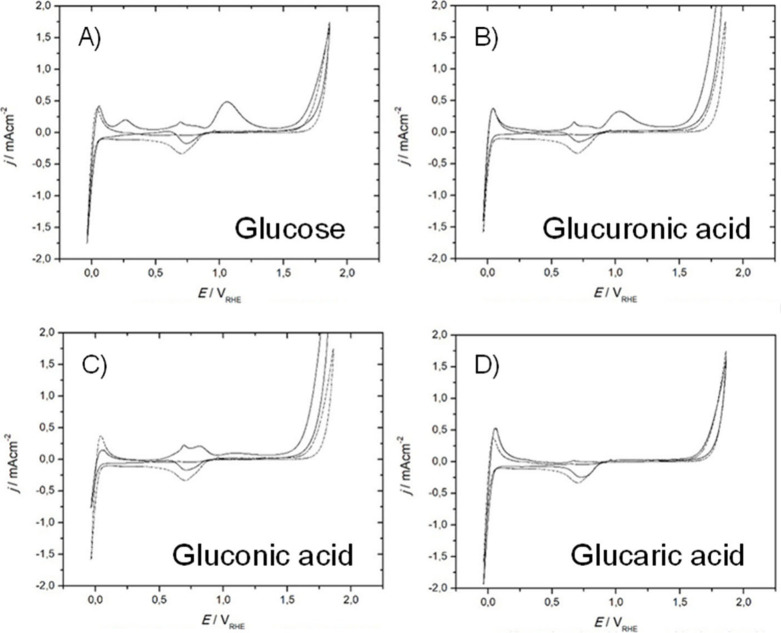

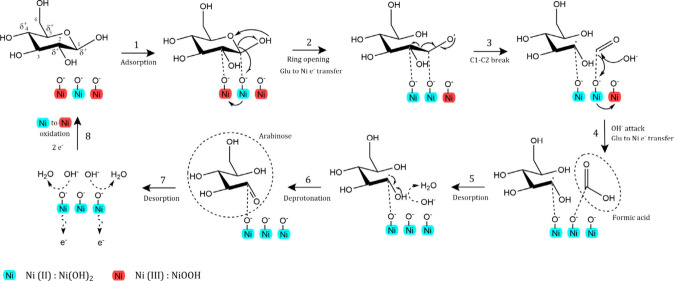

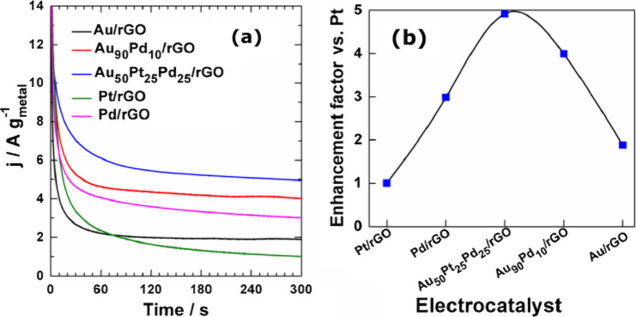

A common approach to evaluate the oxidation state of electrodes is by deriving it from the Pourbaix diagrams. However, these diagrams do not only consider the surface oxidation state but also the bulk oxidation state. Therefore, to illustrate the effect of the potential on the state of the electrode surface, we present in Figure 5 the so-called blank cyclic voltammograms of polycrystalline Au and Pt in three representative electrolytes.

Figure 5.

Cyclic voltammograms of (A) polycrystalline Au and (B) polycrystalline Pt, obtained under acidic conditions (0.1 M H2SO4 and 0.1 M HClO4) and alkaline conditions (0.05 M NaOH), measured in a flow cell at 50 mV s–1. Adapted with permission from ref (129). Copyright 2014 The Electrochemical Society.

For Au in 0.1 M H2SO4, an increase in current density can be observed at 1.35 V vs RHE, which corresponds to the formation of gold oxyhydroxide/gold oxide (AuOOH/Au2O3), as was shown by in situ surface-enhanced Raman spectroscopy (SERS).130 In 0.1 M HClO4, the onset potential for the formation of AuOOH/Au2O3 is ∼1.28 V, based on DFT calculations131 and in situ SERS,132 which is 0.07 V lower than in 0.1 M H2SO4 (as also deduced from the different onset potential for surface oxidation in Figure 5A). By contrast, at pH = 12.7 (0.05 M NaOH) an increase in current density already takes place at 1.2 V vs RHE and results in the formation of a gold hydroxide/gold oxide (Au(OH)3/Au2O3) species.130 This shows that metallic Au has a larger potential window under acidic conditions than under alkaline conditions129,130 and that in acidic media anions strongly influence the surface oxidation potential.129,130,132 The presence of Au2O3 at potential above 1.70 V under acidic conditions (0.1 M HClO4) and above 1.57 V under alkaline conditions (0.05 M NaOH) was shown by in situ electrochemical surface-enhanced Raman spectroscopy.132 The surface gold oxides reduce again with decreasing potential conditions at 1.18 V in acidic conditions and at 1.1 V in alkaline conditions.129,130 The difference in reduction peak potential under acidic and alkaline conditions is an indication of the formation of different surface oxide species under these conditions.129,130

The typical CVs of Pt at different pH conditions are illustrated in Figure 5B. For Pt at pH = 1 and pH = 13, the positive current from 0.1 to 0.35 V vs RHE corresponds primarily to the desorption of adsorbed hydrogen.133−135 At step edges and corner sites, the desorbed hydrogen is replaced by adsorbed *OH species under both acidic and alkaline conditions in this potential region.133−136 At pH = 1, for systems containing H2SO4 or HClO4, an onset potential for surface oxidation can be observed at 0.85 V vs RHE, which is related to the chemisorption of hydroxide and/or oxygen on the Pt surface (PtO/PtOHsurf),129,137−139 while at pH = 12.7 the onset potential for PtO/PtOHsurf formation can be observed at 0.75 V vs RHE.129,134 This shows that the potential window for metallic Pt is larger under acidic conditions than under alkaline conditions. Independent of the pH, above 1.15 V the place exchange of oxygen and platinum atoms occurs, and oxygen penetrates the Pt lattice up to a few monolayers to form PtO.133,134,140,141 At 1.2–1.3 V vs RHE, PtO is converted into PtO2, and when the potential is decreased, PtOx reduces back to metallic Pt at ∼0.75 V under both acidic and alkaline conditions.133,134,137,142,143 We note that the exact surface composition of the surface oxide is mixed and very dependent on the structure of the underlying metallic Pt. Our usage of the terms PtO/PtOHsurf, PtO, and PtO2 is therefore indicative of the expected dominant surface oxide but should not be taken as an accurate indication of a single Pt surface oxidation state.

The above discussion shows that the surface oxidation state of Au and Pt depends on the applied potential and pH of the electrolyte. For Au, the following surface oxidation states can be distinguished: (1) metallic Au from 0.1 to 1.28 V vs RHE under acidic conditions,131,132 from 0.1 to 1.20 V vs RHE under alkaline conditions130 and (2) AuOOH/Au2O3 above 1.28 V vs RHE under acidic conditions,131,132 and (3) Au(OH)3/Au2O3 above 1.20 V vs RHE under alkaline conditions.130,132 For Pt, the following surface oxidation states can be distinguished: (1) metallic Pt from 0.1 to 0.85 V vs RHE under acidic conditions129,137,138 and from 0.1 to 0.75 V vs RHE under alkaline conditions,129,134 (2) PtO with possible surface hydroxide groups exists from 0.85 to 1.3 V vs RHE under acidic conditions129,137,138 and from 0.75 to 1.3 V vs RHE under alkaline conditions,129,133,134,140,141 and (3) PtO2 at > 1.3 V vs RHE.133,134,137,142,143 As mentioned, in reality mixed oxidic phases are expected to exist on the surface of the electrode.

When the electrode is in the metallic state, the oxidation of biobased reactants occurs through a direct pathway, i.e., a mechanism in which the oxidation of the reactant is driven by the applied potential, and the larger the potential, the higher the reaction rate (potential-dependent mechanism). On oxidized metal surfaces, besides the direct pathway, the oxidation may also proceed through an indirect pathway. In the indirect mechanism, the reactant is chemically oxidized by metal species that are in a high oxidation state: the metal gets thus chemically reduced in the redox process, after which it is electrochemically reoxidized to its original high oxidation state. Examples of the two pathways are given in sections 4 and 5.

In this review, all the reference potentials found in the literature have been converted to RHE to avoid potential shifts caused by the pH of the electrolyte.144 Therefore, the potentials reported in this paper (which are referred to RHE) may deviate from potentials in the cited articles (which are typically referred to Ag/AgCl or Hg/HgO). These calculated RHE potentials can then be used to estimate the oxidation state of the Au and Pt catalyst under acidic and alkaline conditions, based on the cyclic voltammetry shown in Figure 5. This approach enables us to group studies that have been conducted under similar reaction conditions and define trends for the electrocatalytic oxidation of sugar alcohols and saccharides. Yet, it must be noted that the actual surface oxidation state of Pt and Au is often not precisely known and that this approach only gives a first approximation. Other factors that might affect the surface oxidation state of Au and Pt are the type of electrolyte, the pH of the electrolyte, the adsorption of reactant/products, and (if present) the support of the metal species in the electrocatalyst. For example, a different electrolyte, such as sulfate or perchlorate, slightly changes the onset of oxidation of Au and Pt.145 In addition, the pH affects the type of surface oxide formed,130 while the support can either withdraw or donate electrons to the supported metal,146,147 thereby affecting the oxidation state of the electrocatalyst. Therefore, we will consider these factors when there is evidence that they had a significant impact on catalyst performance.

4. Effect of Electrocatalyst Properties under Various Reaction Conditions on the Oxidation of Sugar Alcohols

This section presents and discusses the trends reported for the electrocatalyst activity and selectivity in the electrochemical oxidation of sugar alcohols. In the majority of the studies that address this topic, Au and Pt (sections 4.1.1 and 4.1.2, respectively) were employed as electrocatalysts, for which it has been possible to define trends with respect to the electrocatalyst properties such as the type of metal used, the oxidation state of the metal, and the type of bimetallic catalyst. Au is discussed first as it is generally found to be a less active but more selective electrocatalyst for oxidation reactions when compared to Pt. Studies with other metals are scarcer, but some of them allow achieving high selectivity toward specific value-added products (see section 4.1.3–4.1.5). Before discussing in detail the trends observed in the literature, the main mechanistic pathway for the electrocatalytic oxidation of glycerol is summarized.

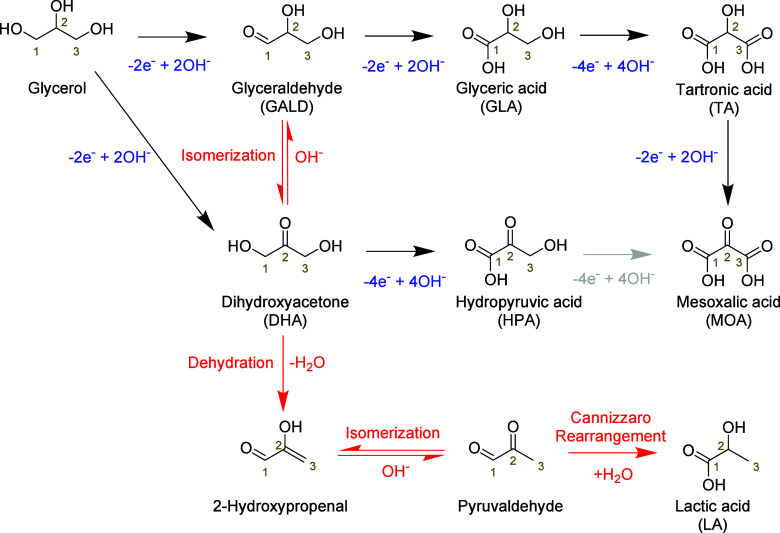

The most commonly studied sugar alcohol in electrocatalytic oxidation reactions is glycerol, which we use in this review as a basis to define trends found in the literature. The trends observed with glycerol were compared to the electrocatalytic oxidation of other sugar alcohols. Scheme 6 gives an overview of the different reaction pathways published.54,81 The scheme shows that glycerol can either be electrocatalytically oxidized at the primary or secondary alcohol group, forming respectively glyceraldehyde (GALD) or dihydroxyacetone (DHA). GALD and DHA interisomerize in the electrolyte under alkaline conditions, with DHA being the more stable isomer (see section 2.1.1). Under oxidative potentials, the aldehyde group of GALD can be electrochemically oxidized to form glyceric acid (GLA), which in turn can be further oxidized at the remaining primary alcohol group to form tartronic acid (TA). TA can also be oxidized electrochemically at the secondary alcohol to form mesoxalic acid (MOA). DHA can be oxidized electrochemically at the primary alcohol to form hydropyruvic acid (HPA). HPA could potentially be oxidized electrochemically to MOA,148 although this pathway has not yet been observed. Alternatively, under alkaline conditions GALD and DHA can be dehydrated non-electrochemically in the electrolyte to form 2-hydroxypropenal, which can undergo keto–enolic tautomerization to pyruvaldehyde (see section 2.1.1). Successively, pyruvaldehyde can undergo an intramolecular Cannizzaro rearrangement (see section 2.1.1) to form lactic acid (LA).

Scheme 6. Main Reaction Pathways for the Electrocatalytic Oxidation (Black Arrows with Number of Electrons/Hydroxides in Blue), Potential but Non-Observed Electrocatalytic Oxidation Pathway (Grey Arrow), and Non-Electrochemical Conversion (Red Arrows) of Glycerol and Derivatives Observed in the Literature.

4.1. Monometallic Electrocatalysts for the Oxidation of Sugar Alcohols

This section describes the trends for the selective electrocatalytic oxidation of sugar alcohols over the most studied electrocatalysts, being those based on Au (section 4.1.1) and Pt (section 4.1.2), and compares the trends with electrocatalysts based on Pd, Ir, and Ru (section 4.1.3), Ni and Co (section 4.1.4), and Cu and Mn (section 4.1.5). The trends for these electrocatalysts have been categorized based on increasing pH and potential.

4.1.1. Au-Based Electrocatalysts for the Oxidation of Sugar Alcohols

This section discusses the electrocatalytic oxidation of glycerol on Au at different pH and potentials. To our knowledge, only Valter et al. studied the differences in activity for glycerol oxidation on different Au facets.68 Moreover, only a few studies have reported the electrocatalytic oxidation of sugar alcohols over Au electrodes under acidic67,68 and neutral conditions.54 On the other hand, alkaline conditions have been widely studied, as these conditions give higher activity due to the higher reactivity of the alkoxides (see section 2.1.1).54,57,67,105−108 Acidic conditions are considered first, to distinguish between electrochemical and non-electrochemical reactions, even though the activity of Au is poor under acidic conditions.

Only three studies report that Au has some activity for the electrocatalytic oxidation of sugar alcohols under acidic conditions,67,68,149 while other studies argue that Au has no appreciable activity79 or is inactive under these conditions (based on LSV).54,150 CV experiments on an Au electrode in 0.1 M HClO4 showed that the currents are higher in the presence of glycerol than in its absence, in a broad potential range (at E = 0.55–1.65 V). However, current densities are (very) low (< 0.1 mA cm–2), with somewhat higher current densities (0.4 mA cm–2) obtained at E ≥ 1.30 V.68 On the basis of the range of potentials in which activity toward glycerol oxidation was observed and considering that Au is expected to be in an oxidized state at E ≥ 1.30 V (see section 3), it can be inferred that both metallic and oxidized Au species at the electrode surface are mildly active for glycerol oxidation. By contrast, in 0.1 M H2SO4, CV experiments showed that in the presence of glycerol a significant current density was achieved only at E ≥ 1.30 V,68 with an ∼0.1 mA cm–2 lower activity than in HClO4. This was attributed to the stronger adsorption of the sulfate anions compared to perchlorate anions, thereby blocking active sites.68 DFT calculations predicted that the catalytic oxidation of glycerol on Au(111) at the primary and secondary alcohol group to form DHA and 2,3-dihydroxy-2-propenal would occur at 0.39 V,68,149 the cleavage of C–C bonds of glycerol to form CO at 0.5 V,68 and catalytic oxidation of the primary alcohol group of glycerol to form GALD at 0.6 V,68,149 although experimental analysis was not performed to detect these products.68,149 On the basis of FTIR experiments on Au-based electrodes in 0.1 M H2SO4, it was argued that at E ≥ 1.20 V Au catalyzes primary alcohol oxidation to produce TA and induces C–C cleavage reactions to form formic acid (FA) and carbon dioxide (CO2).67

Kwon et al. reported the selectivity of the electrocatalytic oxidation of glycerol over Au electrodes under neutral conditions (0.1 M Na2SO4).54 LSV was combined with online HPLC, showing that between 0.8 and 1.2 V the Au electrode performs the electrocatalytic oxidation of glycerol at the primary alcohol group with >99% selectivity, forming GALD,54 similarly to the results suggested by DFT calculations on Au(111).68 At E > 1.2 V, the formation of CO2 was observed by gas chromatography (not quantitatively determined), indicative of C–C cleavage reactions.54

Most studies on the electrocatalytic oxidation of sugar alcohols with Au electrodes were conducted under alkaline conditions.54,57,67,105−108 The reason for this is that for Au catalysts, the first deprotonation step of the Hα proton of the primary alcohol of a sugar alcohol (HβR–OHα) is thermodynamically favorable only in alkaline media (base-promoted), while the step involving the abstraction of Hβ is fast and Au-catalyzed.79 The alkaline conditions thereby promote the formation of the alkoxide in solution (see section 2.1.1), which reacts at the Au catalyst surface (Scheme 7). The Au-based electrocatalyst abstracts the Hβ from the alkoxide and acts as electron acceptor promoting the formation of the aldehyde (saccharide).79,80 The high activities achieved under alkaline conditions with Au are therefore attributed to base-promotion and not to the catalyst-hydroxide interaction.79 By contrast, DFT calculations do suggest that higher activities are achieved at potentials close to the onset potential (∼0.8 V vs RHE) for hydroxide adsorption on metallic Au.149 The DFT calculations indicated that adsorbed OH could lower the barrier for β-elimination,151 suggesting that some interaction with (hydroxylated) Au surface is required.152 However, it is likely that this adsorbed OH in the DFT calculations plays a similar role to the hydroxide in alkaline solution.

Scheme 7. Mechanistic Pathway Described by Kwon et al. for the Electrocatalytic Oxidation of Sugar Alcohols at the Primary Alcohol Group to the Terminal Aldehyde on Au and in Alkaline Conditions, Where the First Step Is Non-Electrochemical (Red Arrows) and the Successive Step Is Electrochemical (Black Arrows).

Adapted from ref (79). Copyright 2011 American Chemical Society.

The selectivity for the electrocatalytic oxidation of glycerol on Au-based electrocatalysts was evaluated by LSV combined with online HPLC under alkaline conditions (pH = 13).54,106 Under these conditions, significantly higher current densities (up to 20 mA cm–2) were achieved compared to the results under acidic and neutral conditions.54,79,106 At high potential (E = 1.4–1.6 V), the activity of the Au electrode dropped dramatically,54,79 due to the formation of Au surface-oxide species (Au2O3, see section 3) that passivate the surface.106 With an Au electrode in basic medium, 20% GLA was formed with a high content of C–C cleavage products, namely 80% glycolic acid and FA. GALD was not detected, which indicates that this compound is quickly oxidized to GLA and successively cleaved at the C–C bond to glycolic acid and FA as a result of the high potentials.54,106 Long-term electrolysis of glycerol over Au electrodes at pH = 13 were run at 1.1 and 1.3 V.108 After 20 h at E = 1.1 V, the conversion of glycerol was 10%, and the main products were FA and glycolic acid (selectivity = 82%) and to a lesser extent GLA (8%) and TA (10%).108 At E = 1.3 V, the conversion of glycerol was slightly higher (14%) with higher selectivity toward FA and glycolic acid (91%) and 9% GLA. The increase of C–C cleavage products seems to correlate with an increase in applied potential and the alkalinity of the electrolyte. Results obtained by LSV measurements at pH = 13 combined with FTIR were interpreted differently.67 This study suggested that the oxidation of glycerol on Au electrode at 0.7 V < E < 1.2 V) could also produce DHA, while at higher potentials (E > 1.2 V) higher oxidation products were obtained, such as TA, MOA, glycolic acid, and CO2.67 It is worth noting that the formation of DHA and MOA has not been reported in the other studies conducted under similar conditions.54,106,108 Additionally, similar studies conducted with HPLC did not detect the formation of TA.54,106,108 This discrepancy could potentially be attributed to the analytical method employed, where TA is an intermediate product that does not desorb from the surface and could therefore not be detected by HPLC but would be identifiable by FTIR. Moreover, the assignment of bands in FTIR spectra to specific species is not unambiguous, creating uncertainty in the products that are being reported.153,154 Finally, controversies exist for peak identification caused by convolution of peaks which may mask weak bands or shift the center of peaks.155 In general, we consider product assignment based on HPLC more reliable. Therefore, this review will focus primarily on papers that use HPLC for product analysis, even though FTIR has been a main analytical technique applied to the electrocatalytic oxidation of glycerol.155

Under extreme alkaline conditions (pH = 14.3–14.9) and high temperatures (T = 50–60 °C), 3 nm Au particles supported on carbon (Au/C) promote the electrocatalytic oxidation of the two primary alcohol groups of glycerol producing TA at E < 0.9 V, and also promote the electrocatalytic oxidation of the secondary alcohol group of TA to form MOA.105,107 This has been observed employing both a batch-electrolysis cell and an anion-exchange-membrane-based direct glycerol cell (AEM-DG cell), where the latter was operated by controlling the cell potential. In an electrolysis cell, at pH = 14.3 and 50 °C, 10% of glycerol was oxidized over an Au/C electrocatalyst (5.0 mgmetal cm–2) at E = 0.5 V to MOA (selectivity = 47%), TA (25%), GLA (14%), and oxalate (14%).107 At higher potentials (E = 0.9–1.2 V), the formation of C–C cleavage products (glycolate, glyoxylate, and oxalate) was promoted.107 At the same pH and in an anion-exchange membrane cell, with an Au/C electrocatalyst (1.0 mgmetal cm–2) at E = 0.3 V cell potential, 10% glycerol was converted to MOA with ∼50% selectivity. In a follow-up study, using the same electrochemical cell, under harsher conditions (pH = 14.9 and 60 °C) and with continuous flow of fresh reactant (1.0 mL min–1), the Au/C electrocatalyst (0.3–0.5 V vs RHE) was able to promote the oxidation of 90% glycerol to TA (selectivity = 70%), GLA (15%, primary alcohol oxidation), LA (15%, primary or secondary alcohol oxidation), and traces of MOA (primary and secondary alcohol oxidation) and of oxalate.105 The lower selectivity toward MOA and higher selectivity toward TA in this system was attributed to the optimized reaction conditions (flow rate through the electrochemical reactor, temperature, pH, catalyst loading) to prevent the successive oxidation of TA to MOA.105 In summary, these studies show that an increase in temperature and pH at lower potentials allows achieving a high degree of oxidation while avoiding C–C cleavage reactions.

In conclusion, Au is barely active under acidic and neutral conditions but can selectively form GALD under neutral conditions from glycerol. By contrast, under alkaline conditions (pH = 13), at room temperature, oxidation of glycerol on Au mainly produces C–C cleavage reactions. In general, the importance of the alkaline medium must be considered for the C–C cleavage reactions, and more clear-cut data are needed to determine to what extent the medium or the electrocatalyst promote these reactions. The overall trend shows that Au is likely only able to catalyze the oxidation of primary groups of sugar alcohols. However, if the alkalinity is increased to very extreme conditions (pH ≥ 14.3) and the temperature is increased to 50–60 °C, while the potential is kept low (E ≤ 0.9 V), Au can catalyze with relative high selectivity the formation of TA or MOA, depending on the tuning of the reaction conditions.

4.1.2. Pt-Based Electrocatalysts for the Oxidation of Sugar Alcohols

This section discusses the electrocatalytic oxidation of glycerol on Pt at different pH and potentials. In contrast to gold, platinum is well-known for its good electrocatalytic performance over a broad range of reaction conditions, e.g. from acidic to alkaline pH.54,67,106,156 Therefore, Pt is one of the most widely studied metals for the electrocatalytic oxidation of sugar alcohols. In this section, the most relevant trends regarding the performance of Pt toward the electrocatalytic oxidation of glycerol (and other sugar alcohols) are summarized.

Figure 6 shows the relation between the activity of Pt and Au for the electrocatalytic oxidation of glycerol and the pH of the electrolyte (acidic, neutral, or alkaline).54 Pt is known to outperform Au with respect to activity for the electrocatalytic oxidation of sugar alcohols under acidic and neutral conditions, while under alkaline conditions Au can surpass the activity of Pt.54,67 The latter observation has been attributed to the late (high-potential) surface oxidation of Au compared to Pt (see section 3), meaning that the surface of Au changes its features and thus its activity only at higher potentials.

Figure 6.

Electrocatalytic activity of Pt and Au toward the oxidation of glycerol as a function of the pH of the electrolyte. Reprinted with permission from ref (54). Copyright 2011 Wiley-VCH.

Under acidic conditions (pH = 1), Pt shows four distinct regions of activity for the catalytic oxidation of glycerol based on CV57 and LSV combined with product analysis by online HPLC.54,55 In the first region, where the Pt surface is metallic (at E = 0.37–0.8 V), the highest current densities and product concentrations were measured, specifically at E = 0.8 V. In the second region, where surface PtO/PtOHsurf is expected to form (at E = 0.9–1.1 V), a substantial drop in current density accompanied by a drop in product yields was observed at E = 1.0 V,54,55,57 indicative that the oxidized Pt surface is less active for catalyzing glycerol oxidation. In the third region (at E = ∼1.2 V), the current density and the quantity of oxidation products increase again,54,55,57 indicative that this oxidized Pt surface species can show activity for glycerol oxidation at sufficiently high potential. Finally, at even higher potentials (E > 1.2 V), the current density increases more steeply accompanied by an increase in the formation of more oxidized products (specifically glycolic acid and FA),54,55 indicative that the surface under these conditions is more active for catalyzing C–C cleavage reactions.

Pt catalyzes the oxidation of glycerol under acidic conditions (pH = 1) between 0.37 and 0.6 V, mainly at the primary alcohol group, resulting in a selectivity of > 99% GALD (Scheme 6).54,55 With an increase in potential to 0.6–1.1 V, the main product remains GALD, but the selectivity decreases due to the parallel oxidation of the secondary alcohol group of glycerol to form DHA (∼5%) and an increase in selectivity toward GLA (i.e., the successive oxidation product of GALD) as well as the formation of CO2.54,55 In a chronoamperometric study at lower potentials and short reaction times (at E = 0.75 V and 20% glycerol conversion), GALD was produced with 90% selectivity,56 while an increase in potential (at E = 0.9 and 1.1 V) and longer reaction times (with a corresponding higher conversion of glycerol) resulted in a decrease in selectivity toward GALD and an increase in selectivity toward GLA (up to 87%).56,58,118 These studies performed with chronoamperometry also show that over Pt-based electrocatalysts at E ≤ 1.1 V, only minor fractions of C–C cleavage products and higher oxidation products, such as TA and HPA, are generated.56−58 The detection of 4% HPA after converting 69% glycerol at 0.9 V, suggests that DHA is quickly oxidized to higher oxidation products during long-term electrocatalytic experiments. LSV combined with online HPLC showed that a successive increase in potential from 1.1 to 1.5 V (at which PtOx species are expected to be present at the electrocatalyst surface) results in a gradual increase in C–C cleavage products as was shown by an increase in selectivity toward glycolic acid, FA and CO2,54,55 which is in agreement with chronoamperometry studies where the content of C–C cleavage products increases when the potential is increased from 1.1 to 1.3 V (e.g., 20% at 97% glycerol conversion).57,58 Under acidic conditions, it has been suggested that the formation of the surface platinum oxide at E > 1.1 V changes the adsorption of glycerol and its oxidation mechanism.57Scheme 8 illustrates that when the O/Pt ratio increases, the interaction of two Pt–O with two C atoms from the glycerol molecule may be favored, which changes the oxidation mechanism and results in C–C bond breaking reactions.57 The cleavage of C–C bonds is likely catalyzed by surface Pt oxide rather than taking place via non-electrochemical reactions, since non-electrochemical reactions that induce C–C cleavage reactions, such as retro-aldol reactions only occur under alkaline conditions (see section 2.1.1). The detection of minor fractions of DHA or HPA indicate that Pt does not only catalyze the oxidation of the primary alcohol group but is also able to promote the electrocatalytic oxidation of the secondary alcohol group,54−56,58,118 in contrast to what has been observed for Au.54,106,108 It is assumed that the electrocatalytic oxidation of the secondary alcohol group is made possible by simultaneously adsorbing the glycerol molecule through both the primary carbon and secondary carbon,22 which is strongly dependent on the surface structure that is exposed.

Scheme 8. Proposed Adsorption Mechanism of Glycerol on Surface Pt Oxide (E > 1.1 V), Where Both the C1-OH and the C2-OH Groups Are Involved in the Adsorption, Resulting in C–C Cleavage to Glycolic Acid (Glycolate) and Formic Acid (Formate).

Adapted with permission from ref (57). Copyright 1994 Elsevier.

Metal-based electrocatalysts can be synthesized with different surface structures containing low-index facets (LIFs) or high-index facets (HIFs), which influence their performance. The HIFs have a higher density of edges, corners and kinks, which have a low coordination number and thus fewer bonds, generally making them catalytically more active.157 The selectivity can be tuned by modifying the electrode so that it presents a specific crystal structure, as was shown for the selective electrocatalytic oxidation of glycerol.22,90 The electrocatalytic oxidation of glycerol on Pt(111) and Pt(100) was investigated by combining LSV with online HPLC.22Scheme 9 illustrates the reaction pathways that were inferred for the electrocatalytic oxidation of glycerol on the different Pt facets and the resulting products. On Pt(111), several products were found, including GALD, GLA, and DHA, indicative of the electrocatalytic oxidation of the primary and secondary alcohol of glycerol. On the other hand, on the Pt(100) surface, only GALD was detected, thus presenting a higher selectivity toward the oxidation of the primary alcohol group. The distinct electrochemical response on the two Pt surface structures indicates that there might be different reaction intermediates on the surface, which was supported by DFT modeling:22 on Pt(100) the dehydrogenated glycerol intermediate binds to the surface through a Pt=C bond, while on Pt(111) the intermediate is formed through the simultaneous binding of the carbon of the primary and secondary alcohol group on the surface (Pt–C bond), therefore yielding different products on the two surfaces.22

Scheme 9. Proposed Reaction Pathways and the Corresponding Intermediates for the Electrochemical Oxidation of Glycerol on Pt (111) and Pt (100) Electrodes.

Reprinted from ref (22). Copyright 2016 American Chemical Society.

Polycrystalline Pt-based electrocatalysts have also been found to be selective toward the electrocatalytic oxidation of sorbitol at the primary alcohol group in acidic medium (0.1 M HClO4).158 At E = 0.55 V, the (metallic) Pt-based electrocatalyst promotes the formation of glucose and, to a lesser extent, of glucuronic acid (GLU) with traces of gluconic acid (GA) and C–C cleavage products. At slightly higher potentials (0.65 V), glucose remains the major product with a slight increase in selectivity toward the successive oxidation products, GLU and GA, and traces of C–C cleavage products. This increase in potential does not induce more C–C cleavage reactions,158 which is in agreement with the electrocatalytic oxidation of glycerol.54,55 At E = 1.35 V, the (oxidized) Pt-based electrocatalyst leads to the formation of glucose as the major product (selectivity ∼90%), but it also promotes C–C cleavage products (8% glyoxylic acid and FA) and a very small amount of GA,158 confirming the results for the electrocatalytic oxidation of glycerol.54,55,57,58 The formation of ketoses (secondary alcohol oxidation) was not reported, in contrast to a more recent study that proved the formation of ketoses for the electrocatalytic oxidation of glycerol, erythritol, and sorbitol.52,53 Since both studies use similar reaction conditions, this difference is tentatively explained by the difference in analytical technique (e.g., type of HPLC column and detector), as will be discussed later (vide infra, section 5). A combination of LSV with online HPLC showed that the electrocatalytic oxidation of sorbitol in 0.5 M H2SO4 on Pt/C resulted in a mixture of C1-OH/C6-OH (primary) oxidation products (glucose and gulose) and C2-OH/C5-OH (secondary) oxidation products (fructose and sorbose).53 At E ≤ 0.9 V, primary alcohol oxidation products were observed (∼90% glucose and gulose) and to a lesser extent secondary alcohol oxidation products (∼5%), while at higher potentials (E ≥ 0.9 V, where the Pt surface is expected to be oxidized) the selectivity increases toward secondary alcohol oxidation products, resulting in ∼25% fructose and sorbose at E = 1.2 V.53 Continuous cyclic voltammetry was employed to oxidize sugar alcohols in 0.1 M HClO4, and the results were compared to long-term electrolysis at a fixed potential (at E = 0.7).52 In comparison to chronoamperometry (CA), the use of cyclic voltammetry between 0.02 and 1.1 V was found to improve the reaction rate by 3-fold and selectivity toward ketoses by a 3- to 5-fold, when compared to aldehydes and carboxylates, independent of the sugar alcohol (glycerol, erythritol, sorbitol) that was electrocatalytically oxidized. It was argued that the low current densities achieved during CA measurements, generally found in literature, can be related to a loss in oxidative power of Pt, as the surface reaches an oxidized (PtOx) steady state.52 As a result, Pt loses its oxidative activity for sorbitol. This hypothesis was supported by operando Raman spectroscopy and by injecting sorbitol at different time points during CA measurements. On the basis of Tafel slope analysis and previous research, it was postulated that the first step of sorbitol oxidation becomes rate limiting as the CA measurement proceeds. This first step involves a proton–electron transfer from an alcohol group, resulting in an oxygen-bound intermediate, which can readily be achieved on non-equilibrated Pt surfaces (e.g., surfaces that have not reached an oxidized steady state). Yet, as CA measurements proceed, the Pt surface reaches an oxidized steady state, which limits the first step of sorbitol oxidation. The increase in selectivity toward ketoses was attributed to a change in adsorption configuration of the reactant on the oxidized Pt surface. A metallic Pt surface enables the adsorption of sugar alcohols at the C2-OH/C5-OH (secondary) group, thereby promoting the oxidation of these groups and thus the formation of ketoses. These results on the electrocatalytic oxidation of sugar alcohols over Pt are consistent in the sense that both primary alcohol and secondary alcohol groups are catalytically oxidized for glycerol and erythritol, and the C1-OH/C6-OH (primary) groups and the C2-OH/C5-OH (secondary) groups are oxidized for sorbitol.52,54−56,58