Abstract

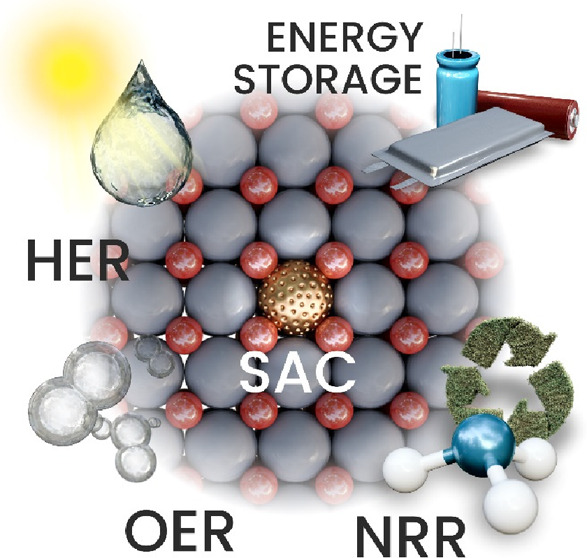

Anthropogenic activities related to population growth, economic development, technological advances, and changes in lifestyle and climate patterns result in a continuous increase in energy consumption. At the same time, the rare metal elements frequently deployed as catalysts in energy related processes are not only costly in view of their low natural abundance, but their availability is often further limited due to geopolitical reasons. Thus, electrochemical energy storage and conversion with earth-abundant metals, mainly in the form of single-atom catalysts (SACs), are highly relevant and timely technologies. In this review the application of earth-abundant SACs in electrochemical energy storage and electrocatalytic conversion of chemicals to fuels or products with high energy content is discussed. The oxygen reduction reaction is also appraised, which is primarily harnessed in fuel cell technologies and metal-air batteries. The coordination, active sites, and mechanistic aspects of transition metal SACs are analyzed for two-electron and four-electron reaction pathways. Further, the electrochemical water splitting with SACs toward green hydrogen fuel is discussed in terms of not only hydrogen evolution reaction but also oxygen evolution reaction. Similarly, the production of ammonia as a clean fuel via electrocatalytic nitrogen reduction reaction is portrayed, highlighting the potential of earth-abundant single metal species.

1. INTRODUCTION

The technological evolution of societies has been fueled by their ability to harness energy to boost production, support transportation, and improve the quality of life.1 Thus, it is not surprising that global energy consumption grows every year by 1–2%, and predictions foresee a perpetual growth2 leading to rapid exploitation of the available natural reserves, with ∼85% being nonrenewable, namely coal, oil, and natural gas. In addition, the processing and utilization of natural resources generate carbon dioxide, SOx, and NOx emissions, resulting in significant environmental pollution. This necessitates the development of new and efficient technologies for energy harvesting from renewable resources.

Renewable energy resources are dominantly intermittent due to natural periodicity and fluctuations of solar radiation and wind. This complicates their establishment as effective alternatives and sustainable energy resources because contemporary major production technologies and the current electricity network require a continuous power supply. Additionally, the past decades have witnessed a portable revolution, i.e., the emerging and enormous global spread of portable devices (laptops, mobile phones, tablets, and medical devices, among many others), which also require mobile energy resources. This trend is crowned by the rapid development of electromobility as sales of electric vehicles doubled in 2021 relative to the previous year,3 as well as the production of e-bikes and e-scooters. These developments demand efficient methods for stationary storage of energy harvested from wind and sun for continuous use, in the form of chemical fuels (e.g., hydrogen, alcohols) or rechargeable, safe, and sustainable devices storing electrical energy such as batteries, supercapacitors, or fuel cells for on-site electricity production.

Most effective technologies for energy harvesting, conversion, and storage are primarily based on catalytic and electro-, photo-, and photoelectrocatalytic processes demanding catalysts, which often contain rare metal elements. For instance, platinum is by far the best element for electrocatalytic water splitting.4,5 The price of such heavy metals is constantly growing because of their low natural abundance in the Earth’s crust (Figure 1) and their availability due to geopolitical reasons, which exemplifies another global concern.6 These reasons warrant the development of sustainable and recyclable catalysts, offering full atom economy and urgent and key-enabling technologies for our energy security. Therefore, heterogeneous single atom catalysts (SACs), whereby every single metal atom is fully exposed to the environment and available for interaction with reactants, constitute the Holy Grail in this field.7 SACs do not only offer lower prices via reducing the amount of metal to furnish the catalytic reaction, but they also enable newer functions and features. For instance, SACs empower the stabilization of metallic elements in uncommon and mixed oxidation and spin states - offering innovative and more efficient reactivity pathways.8−10 Another benefit emanating from this feature is associated with the replacement of rare and precious metals by earth-abundant ones, which can now deliver functions previously unknown in their conventional homogeneous (molecular complexes) and heterogeneous nanoparticulate catalyst forms.11−13 Readers may find general information in recent review articles related to single atom engineering applied in conversion/catalysis and energy storage technologies. Previous works involved mostly noble metals with a rather limited discussion on electrochemical energy storage (EES) technologies14−18 or were limited to metal-air chemistries,19 particularly to Zn-air.20−23 Other reviews on SACs focused particularly on Li-S,24 and Na-S batteries.25 Readers may also find useful the information on energy storage, which covers the EES field more broadly and from the perspective of single atom entrapment methods, up to the mid-2021, though not involving catalytic applications in energy conversion or on earth-abundant SACs.26 In the field of energy-related electrocatalytic applications like CO2 reduction, electrocatalytic oxygen reduction reactions (ORR), and hydrogen evolution reactions (HER), reviews on single-atom catalysis remain relatively scarce, particularly those delving into non-noble metals based SACs.27−30

Figure 1.

(a) World crust abundance (in ppm) and (b) fraction of the global production (in %) in 2020 of selected metals.38,39

In line with the ubiquitous presence and pivotal role of molecules and single atoms (SAs) with catalytic action in chemistry and biology, the strategic incorporation of such catalytic species within the field of SACs for energy conversion and storage could open new avenues for chemistries with lower activation energy barriers and promote favorable chemical reactions, thus providing additional and reversible redox sites and lower energy barriers.31,32 In this context, SA engineering and SACs can offer maximum atom economy and efficiency, well-defined active sites, and unsaturated coordination spheres for improved interactions with the starting and transient species. SACs are increasingly being explored and employed as electrode components in electrocatalytic and electrochemistry storage applications to enhance the redox kinetics and fine-tune the interactions at the reaction interface, generally boosting the efficiencies.33,34 More specifically, SACs can reduce the energy barriers between noncontinuous chemical species due to the low coordinated active sites with high surface energy.35,36 Moreover, the strong bonding between matrices and SAs and their well-defined atomic dispersion promotes the charge transfer, thus accelerating the kinetic process of the electrochemical reactions, assuring high activity and conversion efficiency for chemical reactions.26,37 In contrast to the nanostructured catalysts, SACs ensure supreme atom utilization, which is extremely valuable in terms of reducing the required metal resources and the environmental burden after the end of life. Thus, SACs refer to hybrid materials where single atomic sites are homogeneously dispersed in a matrix via steady host–guest interactions, combining the advantages of both heterogeneous and homogeneous catalysts.26,37 It is indicative that some copper-based SACs, for example, exhibited similar or better catalytic activity than their noble metal counterparts, showcasing the potency of SA engineering.12,13

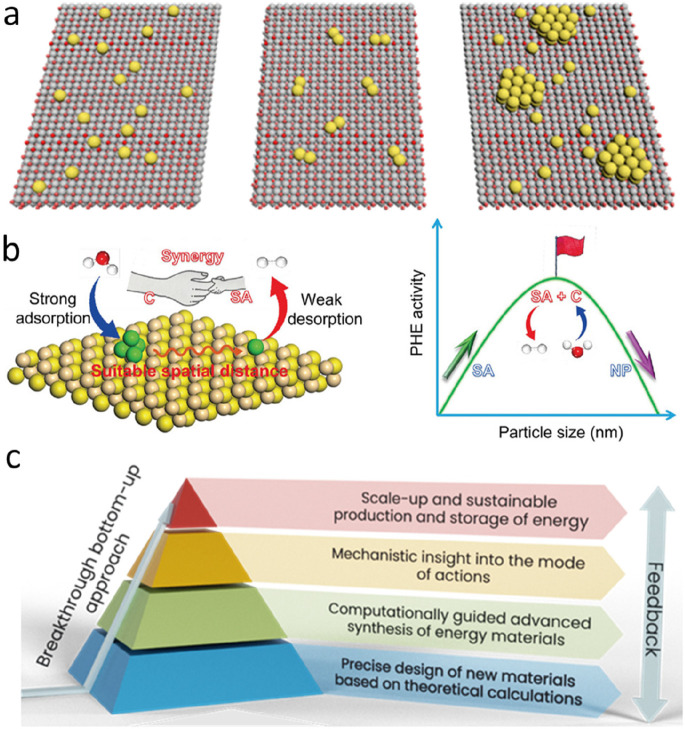

In this review, we overview the use of SACs based on earth-abundant metals in applications related to energy conversion technologies into chemicals with high energy content and to electrochemical energy storage (Figure 2). Further, we analyze how the different catalysts’ local structures provide distinctive chemical coordination environments, which in turn determine the active sites. Finally, an outlook is provided regarding SACs in terms of scale-up synthesis, high-value products, and high energy efficiency, thus offering a set of criteria that must be fulfilled in transition metal SACs aimed to attain higher performances on a practical scale.

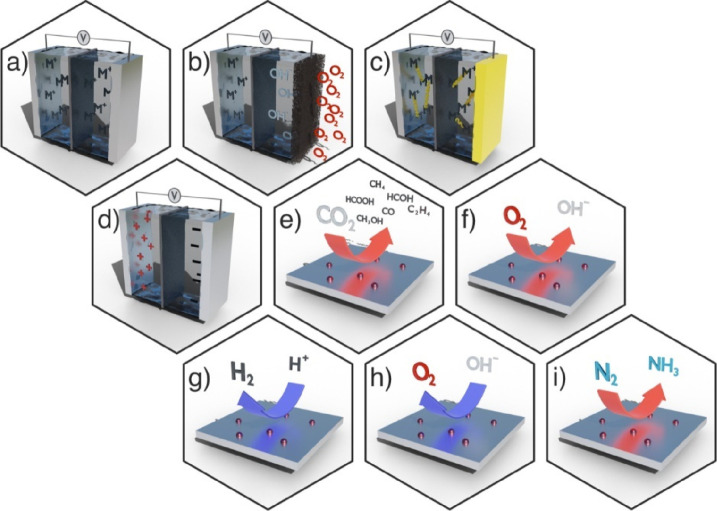

Figure 2.

Illustrative representation of various electrochemical processes covered in the review: (a) metal-ion battery, (b) metal/air battery, and (c) metal sulfur battery; (d) supercapacitors and metal-ion supercapacitors; (e) carbon dioxide reduction, (f) oxygen reduction reaction, (g) hydrogen evolution reaction, (h) oxygen evolution reaction, and (i) nitrogen reduction to ammonia.

2. ELECTROCHEMICAL ENERGY STORAGE WITH EARTH-ABUNDANT SINGLE ATOM CATALYSTS

Electrocatalysts for the ORR, the oxygen evolution reaction (OER), the carbon dioxide reduction reaction (CO2RR), and the carbon dioxide evolution reaction (CO2ER), as well as for the transformation of sulfides/polysulfides and metal oxides formed in metal-air batteries, are at the heart of the next-generation EES chemistries. For example, metal-air, metal–carbon dioxide, metal–sulfur, and pure metal anode batteries promise substantially higher energy contents and charging/discharging rates than current commercial solutions. Appropriately selected SA-engineered materials are also important in surface and interfacial processes (e.g., charge transport, redox cycles, adsorption of charge carriers, and solvent molecules), which, in turn, are critical in supercapacitors or for improving the highly reversible and homogeneous deposition and stripping of pure metal anodes. However, one of the most critical challenges is the sluggishness of the electrochemical transformations at the electrode materials, which leads to an inferior battery performance, including low energy efficiencies due to overpotentials, capacity fading, slow rate capability, and short life.40 In order to tackle such challenges, novel electrode materials offering lower energy barriers of conversion kinetics must be developed. Over the past few decades, numerous materials, including noble metals, transition metals, and metal-free carbons, have been explored as electrocatalysts, aiming to achieve high activity, durability, and selectivity for the above-mentioned reactions. Particularly in SACs, the strong interactions between the active metal atomic/ionic centers and the adjacent coordinating atoms may enhance the catalytic activity, selectivity, and durability of the active sites. Remarkable progress has been achieved so far, enabling SACs to outperform conventional metal particle-based catalysts in the race pertaining to the renewable energy landscape.41,42 Notably, SACs demonstrate their catalytic activity while employing only a minute fraction of the mass necessary for nanoparticulate catalysts to achieve roughly equivalent activity levels. This characteristic holds particular significance for EES implemented in transportation, autonomous vehicles, and portable devices, where gravimetric and volumetric performances are key features of the devices. In this section, we present the recent progress on EES systems based on earth abundant metal SACs.

2.1. SACs in Lithium-Based Batteries

Lithium-ion batteries (LIBs) have emerged as the primary EES technology within the portable electronics and telecommunications industries, and they have since extended their application into the transportation market. Their widespread adoption in the 1990s has since established them in the forefront of the battery industry.43,44 However, LIBs have several shortcomings, including safety, need for costly and critical raw materials, low charging/discharging rates, and insufficient theoretical capacity and energy density, which makes them unsuitable for the future market of electronics, electric vehicles, and large scale energy storage (Figure 3).45,46 On this basis, metal SAs could efficiently enhance the electrochemical performance of LIBs.14 It is very representative and useful as a benchmark for comparison, although extracted from the noble metal-based SACs, that platinum SAs embedded in carbon anodes in LIBs substantially promoted the formation of Pt-Li5 alloy during the charge–discharge process, lowering the lithiation energy and boosting the kinetics. As a result, the Pt SA-decorated carbon material electrode displayed improved electrochemical performances in terms of specific capacity, rate capability, and long-term cyclic stability, retaining a capacity of 846 mAh g–1 after 800 cycles at 2 A g–1 and 349 mAh g–1 after 6000 cycles at a high current density of 5 A g–1.47 Although the Pt-based SA anode displayed an excellent performance, Pt is among the rarest and most costly elements. Therefore, it is of particular importance to identify earth-abundant elements that may improve the alloy formation with Li atoms. In this direction, Sn (which is at least 3 orders of magnitude more abundant than Pt) SAs were embedded homogeneously into a carbon matrix, where each Sn atom coordinated with two O and two C atoms, forming Sn–O–C and Sn–C bonds.48 The Sn SA carbon anode exhibited enhanced lithium storage capability, in comparison with both the carbon alone and the carbon with embedded SnO2 nanoparticles, and excellent cyclic stability with a capacity of 478 mAh g–1 at 0.05 A g–1 after 100 cycles and 281 mAh g–1 at 1 A g–1 after 7000 cycles.

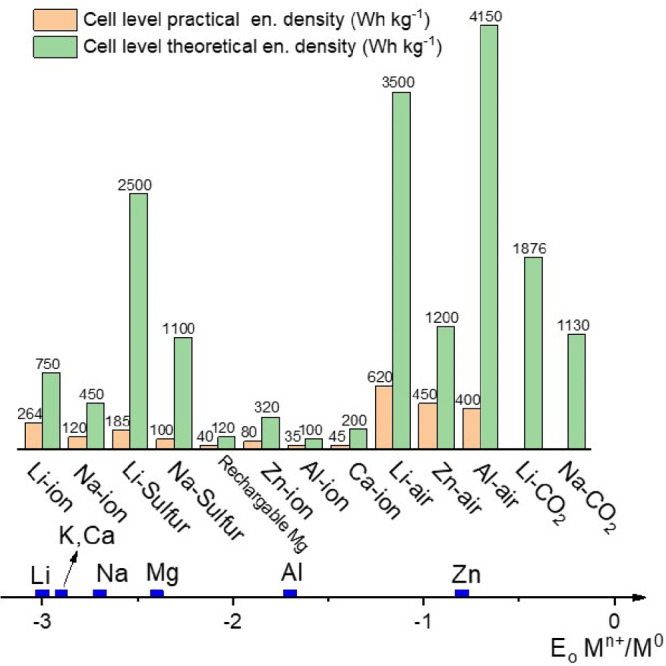

Figure 3.

Theoretical and practical technology-specific-gravimetric energy densities and standard reduction potentials of rechargeable battery technologies. Average values are given based on the available cited data and taking into consideration the full-cell systems.33,49−55

Apart from lithium-ion batteries, lithium-metal batteries are of broad practical interest in view of their particularly improved theoretical specific capacity of 3860 mAh g–1, accompanied by the lowest electrochemical potential of 3.04 V vs standard hydrogen electrode (SHE).56 However, plating and stripping of pure Li-metal electrodes face serious reversibility and safety issues due to Li dendrite growth during the charge–discharge process.57 To address these limitations, substantial efforts have been made with emphasis on the identification of alternative suitable electrolyte additives or on the addition of interphase layers,58 but also on SACs, which have demonstrated the ability to suppress the growth of lithium dendrites, while enhancing the affinity between lithium and electrolyte/active materials. Theoretical and experimental studies have shown that the heterogeneous seeds (e.g., in the form of nitrogen doping) introduced into the carbon matrix serve as lithiophilic sites, tailoring the surface chemistry, reducing the nucleation overpotential, and increasing the binding energy of Li on the electrode surface (Figure 4a–c).59 Homogeneously distributed metal SAs also appear to offer great opportunities in this area, since accumulated data demonstrate that they can guide the lithium nucleation and avoid the uncontrolled growth of dendrites. For instance, Yan et al. used Fe SAs in an N-doped carbon matrix (FeSA-N-C) as lithiophilic sites to minimize the Li nucleation overpotential, which is used to quantitatively assess the degree of affinity of the host species on the electrode’s surface.60 Both experiments and molecular dynamic simulations showed that the combination of Fe SAs and N-doping of the carbon matrix led to the uniform deposition of lithium on the modified electrode surface, restricting the lithium dendrite growth (Figure 4d), as shown in the optical microscope images after 20 min of plating (Figure 4d, inset). Therefore, the FeSA-N-C electrode exhibited a significantly lower overpotential (0.8 mV) in comparison to the same material but without the Fe SAs (18.6 mV). As a result, the FeSA-N-C on Cu current collector versus LiCoO2 as the cathode achieved a significantly improved Coulombic efficiency of 98.8% for 200 cycles in comparison to the case of cycling of metallic lithium on uncoated or on carbon-coated Cu foil (Figure 4e). According to the findings, SA engineered materials can serve as catalysts to boost the utilization of lithium metal by facilitating the stripping and electrodeposition processes. Additionally, they can effectively prevent the growth of Li dendrites, thereby reducing the risk of safety concerns associated with short-circuiting caused by membrane piercing.

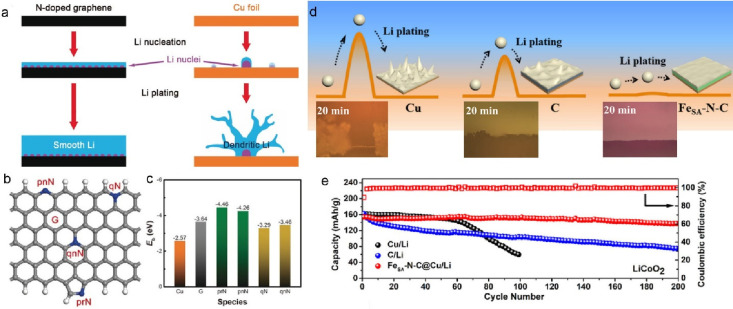

Figure 4.

(a) Schematic representation of the Li nucleation and plating process on N-doped graphene coated and uncoated Cu foil electrode. (b) Schematic diagram of N-doped graphene with pyridinic nitrogen (pnN), pyrrolic nitrogen (prN), quaternary nitrogen on the edge (qN), and quaternary nitrogen in the bulk phase (qnN) and (c) their effect on the binding energy of a Li atom with the different functional groups of N-doped graphene, in comparison with pristine Cu and graphene. Reprinted with permission from ref (59). Copyright 2017 Wiley-VCH. (d) Schematic representation of the Li plating process on Cu, C@Cu, and FeSA-N-C@Cu electrodes (the energy barriers represent the overpotential of Li deposition) along with optical microcopy images of dendrite growth on bare Cu, on carbon-coated Cu, and on Fe-SAC coated electrode (FeSA-N-C@Cu). (e) Cycling performances of the full cells with LiCoO2 as the cathode and FeSA-N-C/Li (C/Li, Cu/Li) as the anode at 1 C (1C = 274 mA g–1). Reprinted with permission from ref (60). Copyright 2019 American Chemical Society.

Recently, the synthesis of atomically dispersed CoNx-doped graphene (CoNC) with 0.40 wt % Co was also reported, to achieve dendrite-free lithium deposition.61 More specifically, N heteroatoms were coordinated to Co atoms to form Co-Nx-C moieties in conductive CoNC hosts. The strong Co–N interaction contributes to charge transfer from metal dopants to the carbon matrix, and the higher electronegativity of the CoNx center in the CoNC matrix ascribes them to stronger affinity for Li-ions (Figure 5a). The atomically distributed Co atoms formed uniform lithium nucleation sites after 5 min of deposition on carbon supports at 0.1 mA cm–2, which are clearly shown in high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images (Figure 5b, c). The combination of Co SAs and N dopants in the graphene framework can tune the local electronic structure and facilitate the adsorption of lithium ions and the subsequent nucleation process. First-principle calculations were performed to investigate the lithiophilicity of CoNC materials wherein Li could be strongly absorbed on one top Co atom (site T) and three hollow sites (H1, H2, and H3, Figure 5d). H1 site had the largest binding energy (−1.58 eV) for Li, but all sites showed larger binding energies than that of N sites in NG without Co (−0.86 eV). In addition, it was found that Li interacted with N and Co, simultaneously highlighting the synergy of N and Co for the enhanced lithiophilicity of the CoNC centers. As a result, CoNC anodes in full cells with a lithium iron phosphate (LFP) cathode retained 98.4% of the initial capacity with a CE of 99.9% after 340 cycles, while the capacity retention in a routine Li|LFP cell was lower than 90.0% after 150 cycles, with an average CE of 98.4%. Overall, the results suggest that the CoNC coating on the copper current collector exerts a lithiophilic action, maintaining a stable SEI and a high utilization of Li metal upon the long and challenging cycling. Therefore, the CoNC anode could mitigate the unsatisfactory performance of conventional Li|LFP full cells which is primarily attributed to the depletion of Li metal in the anode, due to the sluggish and highly irregular plating/stripping process. The CoNC-Li|LFP cell also delivered a better rate capability (Figure 5e, f), which was more pronounced at high rates of 2.0 and 3.0 C. A capacity of ∼115 and ∼85 mAh g–1 was obtained, respectively, which is much higher than that of routine Li|LFP cells (∼75 and ∼1 mAh g–1, respectively). These results convincingly demonstrate a stable and uniform deposition behavior in the CoNC host, which can efficiently increase the reversibility of Li metal anodes upon cycling. Importantly, dendrite formation is not only detrimental for the performance of the device, but also for the safe operation, inducing huge fire risks. It is indicative that in April 2022 two fires involving electric buses were recorded in central Paris, where one vehicle was destroyed. As a safety precaution, the public transport provider decided to temporarily suspend 149 electric buses belonging to the same series.62 Automakers are also forced to withdraw some electric vehicle models due to fires, sudden losses of power, and failures to start. Some car companies, for example, spent $800 million to recall a specific model following several reports on battery fires.63 Amid several instances documented in the literature,64 a fire incident involving an electric vehicle occurred during the charging process, stemming from an error in the onboard charging system. This gave rise to a conflagration that subsequently spread throughout the vehicle, including the battery pack. Upon ignition, the battery pack started to eject sparks and jet flames. The battery pack of the same car model caught fire after collision with a metallic object which penetrated the battery pack. These incidents are characteristic examples of electrical vehicle fires due to battery failure among a series of at least 10 similar accidents since 2019.65 Over the past two decades, there have been several reports on fires in portable devices that use LIBs. These have led to the recall of over 9.6 million LIBs from notebooks of prominent computer manufacturers at an estimated direct cost of $360 million. Additionally, 2.5 million smartphones were recalled, with an estimated direct cost of $5.3 billion ($17 billion including the loss of profit).66 In China, 31 LIB fires are recorded every year, with the most common cause being sudden ignition (36.9%), followed by charging (26.2%). The USA Federal Aviation Administration has recorded 252 air and airport fire incidents involving LIBs in cargo or baggage since 2006. The USA Consumer Product Safety Commission reported 25,000 fire incidents in more than 400 consumer products between 2012 and 2017.66 According to calculations from car insurance companies, fires from hybrid vehicles account for 3.4%, from gas vehicles for 1.5%, and from fully electric vehicles for 0.25%.67

Figure 5.

(a) Schematic diagram of CoNC material and preferential Li nucleation sites. The carbon, nitrogen, and cobalt are marked with gray, blue, and dark pink, respectively. (b) HAADF-STEM image of CoNC materials and (c) TEM image of Li nucleation sites on CoNC at 0.1 mA cm–2 for 5 min. (d) Li adsorption sites on CoNC, (e) long-term cycling at 1.0 C (1.0 C = 0.170 A g–1), and (f) rate capability performance of CoNC-Li|LFP and Li|LFP full cells and. Reprinted with permission from ref (61). Copyright 2019 Wiley-VCH.

The application of earth-abundant SAs in both Li-ion and Li metal batteries is still quite limited, with most of the recent works being focused on Fe-N-C and Co-N-C systems. The experimental data show that the homogeneously distributed metal SAs display high Li utilization and restriction of dendrite growth compared to nanoparticulate counterparts. Moreover, the Li-metal-N interactions contribute to an improved charge transfer of ions and electrons to the carbon matrix, enhancing to the electrode’s conductivity, rate capability, and overall energy efficiency during charging discharging. However, to maintain the high activity of the SAs, it is necessary to develop synthetic strategies that prevent the agglomeration of metal atoms.68 As synthesis methodologies advance, it is becoming increasingly feasible to produce SACs on a large scale and loadings, while maintaining their atomic dispersion for securing full active site availability. These developments could have significant practical applications in the field of batteries, further driving technological and commercial innovations.

2.2. SACs in Metal-Air Batteries

LIBs involve several critical raw materials (CRMs) both in the anode and in the cathode.69 Particularly, the anode is primarily based on natural graphite (which is in the list of CRMs), while lithium itself is also included in the list and the prices are increasing alarmingly with a 5-fold jump during the last year. Regarding the cathodes, the current dominant electrodes are based on nickel, cobalt manganese oxides, where both nickel and cobalt are CRMs. Recent advances in non-noble-metal-based catalyst development have led to comparable catalytic activity and superior fuel tolerance compared to benchmark catalysts, e.g. Pt (∼0.45 V for ORR) and RuO270 (∼0.42 V for OER). Carbon-based nanomaterials are of particular interest due to their favorable electrical conductivity, reasonable cost, unique molecular structures with large surface areas, and versatile electronic and microstructural properties. However, pristine carbon is not suitable for practical cathode catalyst application, as it is unreactive and inefficient. Therefore, the research has focused on introducing active sites in carbon-based catalysts through various methods such as doping (single, dual-, and multidoping), defect engineering, and hybridization.71,72 With the increasing uncertainty in the global supply chains and with the widening energy crisis, electrochemical energy storage has become one of the key-enabling technologies for a sustainable future, where novel battery chemistries and hybrid supercapacitors will play a central role for the exploitation of renewable, but intermittent, energy resources.73 Among them, metal-air batteries are electrochemical cells that may employ a pure metal anode and an external cathode working in ambient air, typically with an aqueous or aprotic electrolyte.74 Their theoretical energy density is substantially higher than that of LIBs, making them a promising candidate toward the next-generation EES technology for electric vehicles or grid energy storage (Figure 3). The utilization of air for the reaction at the cathode, operating as a fuel without having to be stored in the device, is particularly attractive for smart and lightweight wearable electronics.52,75,76 Several (Li, Si, Zn, Al, Mg)-air cell chemistries are currently being considered,77 with theoretical energy densities much higher than those of the current intercalation chemistry LIBs.78

2.2.1. Lithium-Oxygen Batteries

Among them, lithium-oxygen batteries have garnered considerable attention as a future EES technology offering one of the highest energy densities,79 along with the aluminum–oxygen ones (Figure 3). A Li-O2 battery consists of a Li-metal anode and a porous cathode. During the discharge process for the ORR, Li metal atoms are oxidized at the anode to Li+, releasing electrons that travel through an external circuit to the cathode. Oxygen molecules are reduced at the cathode (ORR) to form superoxide (O2–), which then reacts with lithium ions to form lithium peroxide (Li2O2). In the course of charging, the formed Li2O2 is oxidized at the cathode and converted back to Li and the OER takes place, forming H+ and O2.54 However, challenging problems have so far limited its commercial viability. These pertain to the high overpotential of the OER (oxidation of Li2O2) and inferior operation stability, originating from the insoluble (blocking the pores in the cathode) and insulating discharge product of Li2O2, as well as from decomposition problems of the cathode and the electrolyte due to the high reactivity of peroxide and superoxide.80 The sluggish ORR/OER reaction kinetics ought to be enhanced and the overpotentials could be ameliorated by potent electrocatalysts to improve the reaction rates, the electrochemical efficiencies, yields and selectivity, and subsequently the cell performance.81 Therefore, the identification and development of highly active and nonprecious metal catalysts for Li–O2 batteries, along with homogeneous Li plating and stripping, are crucial toward their commercialization.

To date, platinum, ruthenium, and iridium oxides have been generally regarded as the benchmark electrocatalysts for the ORR and the OER. For instance, a nano-Li2O preloaded cathode composed of catalytic Ir nanoparticles and reduced graphene oxide (rGO) substrate provided a flat 2.78 V output vs Li/Li+ with a stable reversible capacity of 400 mAh g–1 (based on the full cathode mass). This performance sustained over 2,000 cycles with a Coulombic efficiency of up to 99.5%, as confirmed by in situ spectroscopic characterizations and chemical quantifications.82 However, the insufficient catalytic bifunctionality, scarcity, poor stability, and, importantly, the high cost of the precious metal-based catalysts hinder their practical use.83 In order to employ less rare yet electroactive metals, the research has also focused on exploiting molybdenum-based 2D compounds.84,85 Molybdenum nitrides displayed high capacities and low overpotentials, primarily due to their superior electronic conductivity, and were able to run for 70 cycles, keeping a 1000 mAh g–1 capacity.85 Molybdenum sulfide metallic nanosheets (1T-MoS2) hybridized with carbon nanotubes also exhibited a high reversible capacity of 500 mAh g–1 at a current density of 200 mA g–1 for around 100 cycles86 or, in another example, of around 400 mAh g–1 for 350 cycles.87 In another interesting work, MoS2 nanosheets as a cathode, with a lithium-carbonate protected anode in an ionic liquid dimethyl sulfoxide electrolyte, consistently delivered 500 mAh g–1 for at least 700 cycles at a particularly high rate of 0.5 Ag1–. The Li-O2 battery operated with the same performance even under simulated-air conditions, i.e. containing both humidity and CO2. In 2012, a study on atomically dispersed Fe/N/C SACs as a cathode in a tetra(ethylene glycol) dimethyl ether-based electrolyte88 showed substantial advantages over the benchmark systems used until then (α-MnO2 on carbon89). The Fe/N/C cathode SAC performed the OER during charging at much lower voltage with reduced overpotential during both charging and discharging, thus motivating further research in studying non-noble metal catalysts and particularly SACs for such applications.

With this perspective, earth-abundant SACs have demonstrated improved performance in Li-O2 batteries even compared to standard noble metal systems. In an indicative study, a hollow N-doped carbon sphere architecture, with isolated single Co sites (N-HP-Co SACs), was proposed to promote both the ORR and OER reactions and the fast charge and mass transfer of electrons, electrolytes, and O2 via their hollow structure.90 The synthetic procedure included the polymerization of cobalt complexes mixed with dopamine monomers in spherical silica templates (Figure 6a). Afterward, the product was obtained by pyrolysis to convert the coated poly dopamine into carbon, followed by etching of the silica core with HF. The resulting nanospheres with uniform diameters of ∼400 nm were homogeneously decorated with Co SAs, as confirmed by HAADF-STEM (Figure 6b). The ORR activity of N-HP-Co SACs was studied as the cathode showing a low discharge voltage (0.145 V); the cathode demonstrated a higher onset potential and larger peak current density in comparison to a commercial Pt/C catalyst-loaded equivalent, suggesting an enhanced activity for ORR. Rate performance investigations (Figure 6c) also revealed that the discharge voltage plateau was higher than that of Pt/C catalyst at all current densities. Moreover, the morphology of Li2O2 on the discharged cathodes was studied in situ with scanning electron microscopy (SEM), showing nanosheets grown uniformly on the wall of the porous carbon spheres (Figure 6b, inset), which directly signified the strong interaction of the metal atoms with the supports and the dynamic structural transformation during the discharge process. Benefiting from these merits, Li-O2 batteries with these N-HP-Co SACs exhibited relatively low overpotential, high-rate capability, long cycle life (261 cycles at a current density of 0.1 A g–1 with a cut off capacity of 1000 mAh g–1), and a high discharge capacity (∼14,777 mAh g–1 at a current density of 0.1 A g–1). The N-HP-Co SAC cathode appears to exhibit improved performance not only in comparison to the nanoparticulate Pt/C catalyst, but even compared to a Pt-SAC cathode with a cutoff capacity of 600 mAh g–1 at 0.1 A g–1 and reported stability at least up to 100 cycles.

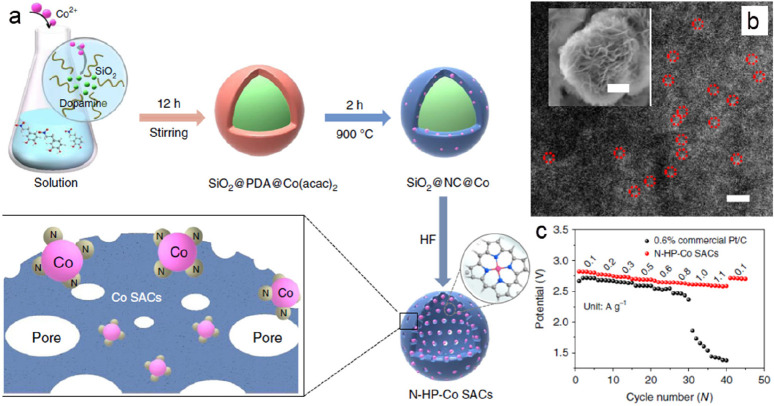

Figure 6.

(a) Schematic illustration showing the synthesis of N-HP-Co SACs. (b) HAADF-STEM image of N-HP-Co SACs, 2 nm in, and inset FESEM images of the discharged N-HP-Co SACs cathodes. (c) Full range rate performances of Li-O2 batteries at different current densities. Reprinted with permission from ref (90). Copyright 2020 Springer Nature.

Wang et al. developed an environmentally friendly method to synthesize isolated cobalt atoms embedded in ultrathin and nitrogen-rich carbon as a dual-catalyst for lithium–oxygen batteries.91 In particular, the authors developed a green gas-migration-trapping strategy to synthesize desirable Co SAs embedded in ultrathin a Zn-hexamine complex-derived nitrogen-doped carbon matrix (Co-SAs/N-C) as a bifunctional-catalyst for lithium–oxygen batteries. Benefiting from the advantages of both 2D metal organic frameworks (MOFs) and framework (MOF) precursor and of the uniformly isolated dispersion of atomic metal sites, the well-defined Co-SAs/N-C catalyst could provide low-impedance charge transfer pathways and offer large specific surface area for Li2O2 accommodation. In the lithium-oxygen battery, the Co-SAs/N-C electrode affords remarkably decreased charge/discharge polarization (0.40 V) and long-term cyclability (260 cycles at 0.400 A g–1) and high discharge capacity (11098 mAh g–1 at 1 A g–1).

A universal synthesis strategy for SACs for different metal atoms (Ti, V, Cr, Mn, Fe, Ni, Cu, Zn) immobilized on the surface of Co3O4 nanosheet arrays grown on a carbon cloth was also reported, aiming at comparing the effect of the different transition metal SAs under the same testing conditions as cathodes for Li-O2 batteries.92 The results revealed that not all SACs showed enhanced catalytic activity, and some showed decreased catalytic activity in comparison to the pristine Co3O4 nanosheets. The nickel-doped Co3O4 displayed the best performance, while the V-doped the worst. The differences in the catalytic activity of SACs with various metal atoms were evaluated by the density functional theory calculations. By combining experimental results, it was concluded that the different SAs mainly affected the energy barriers of the reaction paths on the active sites and the interaction (adsorption energy and electron transfer) between the doped metal atoms and the key intermediate reactants. The Ni-Co3O4 SAC displayed stability for 128 cycles at a current density of 0.2 A g–1 and cutoff capacity of 1000 mAh g–1.

2.2.2. Zn-Air Batteries (ZABs)

Apart from the Li-O2 batteries, (ZABs also exhibit several advantages, chiefly due to the low cost of zinc, its earth abundance, and safer chemistry in comparison to lithium and other analogues.93 Although their energy density is inferior to that of Li-air batteries, it is still significantly higher than that of LIBs (Figure 3), which makes them quite attractive, particularly in synergy with their sustainable and critical raw material-free components. In the various applications of EES devices, safety and weight play a critical role, whereby ZABs are advantageous, since zinc metal is substantially more stable than metals like Li, Na, K, and Mg in the presence of humidity and oxygen, and the cathode is lightweight due to the utilization of oxygen from air as redox component. Furthermore, ZABs can operate both with aqueous or solid electrolytes.94 Briefly, a ZAB cell comprises a Zn metal anode while O2 acts as the active material at the positive electrode, an alkaline electrolyte, and a separator. During discharge, the oxidation of Zn atoms to Zn2+ ions takes place, and the electrons travel from the anode to the air positive electrode. There, O2 reduction into OH– occurs at the cathode via the ORR route (O2 + 2H2O + 4e– → 4OH–). The OH– ions combine with Zn2+ ions, forming Zn(OH)42–, which decomposes to ZnO under supersaturated conditions.95 During the charging process, the O2– species must be oxidized back to molecular oxygen, storing chemical energy through the OER.96 This process requires electrical reversal of the reaction, using, ideally, a bifunctional catalyst at the air cathode to reduce oxygen during ORR and to oxidize and liberate oxygen upon the discharge reaction during OER, which is especially challenging. It is certainly more viable to offer charge and discharge functions using two unifunctional electrode materials (electrocatalysts); however, this increases the cell size, the weight, and complexity. Thus, bifunctional electrocatalysts to effectively perform both of the reactions are crucial for advancing metal-air battery technologies.83 Additional bottlenecks for the effective operation of ZABs include the low stability/reversibility of the processes and the low energy conversion efficiency, since the kinetics of the ORR/OER are relatively slow and high overpotentials are needed to drive the reactions even at moderate rates.97

ZABs can also operate in organic electrolytes and perhaps even more effectively with respect to aqueous electrolytes.98 A study in 2021 showed that when using a hydrophobic electrolyte, water is excluded from the cathode’s surface, which makes the OER more effective. By eliminating water, instead of the four-electron reduction required in aqueous environment forming Zn(OH)42–, the zinc-O2/zinc peroxide (ZnO2) chemistry dominates that proceeds through a 2e–/O2 process, enabling more reversible and faster redox reactions.93 The nonaqueous ZAB not only tolerates stable operation in ambient air (a common problem for aqueous ZABs due to CO2 parasitic reactions) but also exhibits substantially better reversibility than its alkaline counterpart. Although the energy consumed during charging (OER) is still significantly higher than the energy released during discharging (ORR), the process is beneficial for storing energy from renewable resources. Inspired by the catalytic properties of SAs, recent research efforts have targeted SACs as viable and potentially more effective alternatives to noble metal-based catalysts (e.g., Pt) and metal oxides (e.g., RuO2 and MnO2) traditionally used for ORR and OER, respectively.83 In this scope, the potential application of utilizing SACs in ORR and OER catalysis at the air electrode cathode of rechargeable ZABs is enormous.7

Noncritical metal-ion SACs could transform into the next generation sustainable alternatives to Pt-based electrocatalysts for ORR catalysis. Among the reported noncritical element electrocatalysts, Fe-based catalysts are by far the most extensively studied, owing to their excellent ORR activity in both alkaline and acidic electrolytes.99−103 Most of SA-based bifunctional electrocatalysts for oxygen electrocatalysis are supported by N-doped carbon-based materials, encompassing the typical metal–nitrogen–carbon structure.104−109 For instance, Chen et al. anchored Fe SAs with a loading of 1.96 wt % on a nitrogen doped porous carbon. In order to achieve increased number of active sites, a “polymerization-pyrolysis-evaporation” strategy to synthesize Fe-N4 sites from a bimetallic Zn/Fe polyphthalocyanine precursor was accomplished.110 Each Fe atom had 2+ or 3+ oxidation state, and after coordination with N atoms the Fe-N4 active sites were formed favoring the O2 activation for the ORR reaction (Figure 7a). Although Zn atoms evaporated during pyrolysis, they were crucial for attaining the single-atomic state of the Fe cations, since in the absence of Zn, iron-based nanoparticles were formed. Possibly the evaporation of Zn2+ cations generated uncoordinated N sites to stabilize Fe SAs during pyrolysis. The catalyst was also very effective for the OER, a very challenging process of the ZAB chemistry. Density functional theory (DFT) calculations revealed the beneficial role of the Fe SAs for the O–O bond formation during the conversion of O* to OOH*, which was identified as the rate-determining step. The catalyst was more active than the commercial RuO2 and IrO2 for the OER. Benefiting from the synergistic effects between atomically dispersed Fe-N4 sites and a porous conductive carbon support, the ensued ZAB showed a power density of 232 mW cm–2 without voltage changes after 108 cycles (Figure 7b). In another example, Fe SAs were grown in situ while incorporating iron-1,10-phenanthroline (Fe-Phen) complexes into nanocages during the growth of zeolitic imidazolate framework-8 (ZIF-8), followed by pyrolysis under inert atmosphere.111 The atomically dispersed Fe-Nx-C catalyst showed an ultrahigh ORR activity and excellent electrochemical performance. However, the activity of the OER was suboptimal and substantially lower than that of RuO2. A high open-circuit voltage (OCV) of 1.51 V was recorded, with a power density of 96.4 mW cm–2, significantly lower than the previously described Fe-SASC for ZAB, which was more effective for the OER charging process. ZIF-8 was likewise employed to create a functionalized hollow structure and achieve electronic modulation of an active center by near-range coordination with nitrogen and long-range interaction with sulfur and phosphorus (Fe-SAs/NPS-HC).112 As primary active sites, the isolated Fe-N4 species activated and reduced O2. The homogeneously dispersed P and S atoms did not coordinate with Fe atoms directly but modulated the electrical states via long-range interactions, which weakened the binding toward OH* intermediates to release OH–, boosting the four-electron ORR during discharging. The positive half-wave potential (E1/2) value of 0.912 V vs reversible hydrogen electrode (RHE) in acidic media showed outstanding catalytic activity. Moreover, when the Fe-SAs/NPS-HC was used as the air cathode, ZAB exhibited an OCV of 1.45 V, higher than that of the Pt/C-based battery, alongside a higher current density, reaching 195.0 mW cm–2 at a current density of 375 mA cm–2, while the Pt-C battery cathode delivered 177.7 mW cm–2 at 283 mA cm–2.112 It is observed that despite the excellent catalytic activity of this SAC for the ORR, the system did not surpass the Zn/Fe polyphthalocyanine-derived SAC cathode, which performed better toward OER charging.110 The heteroatom employment for tweaking the charge balance via push–pull phenomena was leveraged as well in another recent work, with N and P dual-coordinated iron sites. The carbon nanosheets embedded with nitrogen and phosphorus dual-coordinated iron active sites (denoted as Fe-N/P-C) were prepared via the pyrolysis of a polypyrrole hydrogel accompanied by treatment with sulfuric acid to produce the carbon nanosheets that contain nitrogen and phosphorus dual-coordinated iron active sites (Figure 7c, d). The Fe-N/P-C SAC showed high oxygen activation for the ORR process, with low energy required for the release of adsorbed *OH into reduced OH– form, resulting in accelerated ORR kinetics.113 The fast ORR was theoretically found to be promoted by the dual doped system with P in addition to N. However, the performance in the OER process was suboptimal. Thus, the evaluation of the material as a ZAB cathode delivered an OCV of 1.42 V and a maximum power density of 133.2 mW cm–2 at a current density of 219.6 mA cm–2 (Figure 7e). This relatively low value could be as well connected to the sluggish performance in the OER charging process.

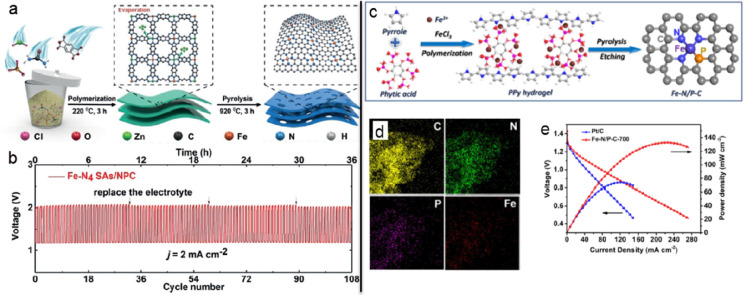

Figure 7.

(a) Schematic illustration of the Fe-N4 SAs/NPC material synthesis and (b) its charge–discharge cycling performance. Reprinted with permission from ref (110). Copyright 2018 Wiley-VCH. (c) Schematic of the synthesis process of the Fe-N/P-C catalyst. (d) EDS elemental mapping of Fe-N/P-C-700 and (e) polarization and power density plots of the Zn-air batteries equipped with Fe-N/P-C-700 and Pt/C catalysts. Reprinted with permission from ref (113). Copyright 2020 American Chemical Society.

Interest in flexible and low weight wearable electronics has emerged in the past several years, and particularly for systems that can integrate energy storage properties with both high energy and power density for powering various wearable and portable devices.114 Thus, extensive efforts have been devoted for developing various types of flexible, thin, and low weight rechargeable batteries and supercapacitors.115 In 2022, a flexible and binder-free ZAB cathode was synthesized by a simultaneous construction of carbon nanotube (CNT)-linked N-doped porous carbon nanofibers (NCFs) and the dispersion of cobalt SAs via an electrospinning and carbonization strategy.116 The NCFs presence guarantees the active site’s accessibility, while the interior CNTs enhance the flexibility and mechanical strength of the porous fibers. Benefiting from the self-supporting structure obtained by electrospinning, Co SA/NCFs can be used as a binder-free air cathode while a zinc plate employed as an anode and a gel electrolyte (6 M KOH + 0.2 M Zn(CH3COO)2) completed the all solid state ZAB. The as-prepared catalyst delivered a high specific capacity of 796 mAh gZn–1 at a current density of 10 mA cm–2, as well as super durability of 600 h at 10 mA cm–2 for aqueous ZABs with a small voltage gap for all-solid-state ZABs. Furthermore, the cathode’s increased flexibility paves the way for self-supporting electrodes for aqueous ZABs and flexible all-solid-state zinc-air batteries. Later in the same year, the development of a high-rate and robust quasi-solid-state ZAB using atomically dispersed cobalt sites anchored on wrinkled nitrogen-doped graphene as the air cathode and a polyacrylamide organohydrogel electrolyte was also reported.117 This design enabled a cycling current density of 100 mA cm–2 over 50 h at 25 °C and a low-temperature cycling stability of over 300 h (at 0.5 mA cm–2) with over 90% capacity retention at −60 °C and a broad temperature adaptability (−60 to 60 °C). The highly wrinkled graphene created a large charge gradient around the Co-N4 sites, strengthening the adsorption of oxygenated intermediates. After benchmarking under the same conditions, it became evident that the performance of the developed Co SAC cathode surpassed that of Pt/C-based aqueous ZABs. Copper SAs anchored on nitrogen-doped porous carbon (Cu-N/PC) derived from zeolitic imidazolate frameworks (ZIFs) were also employed as ZAB cathodes.118 Zn/Cu bimetallic ZIFs are promising precursors for Cu-N/C catalysts with Zn acting as a “fence” to avoid Co aggregation during pyrolysis and N-groups serving as a “coordinator” to protect and stabilize the copper SAs in nitrogen-doped carbon. Specifically, the spatial isolation of Cu SAs was regulated by tuning the zinc dopant content in Cu-ZIF-8 precursors followed by direct pyrolysis. The sample with 20% of Cu2+ precursor with respect to the Zn2+ precursor had a polyhedral shape with an average size of ∼120 nm and generally better Cu dispersion. The electron transfer mechanism involved in the ORR of the catalyst in potential ranges of 0.3–0.6 V indicated an efficient 4e–-dominated ORR and a low percentage of H2O2. As a result, Cu SAs, in combination with the micromesoporous structures of the carbon matrix, generated a synergistic effect providing fast electron transfer pathways to enhance the electrocatalytic properties toward ORR. The developed ZAB equipped with Cu-N/PC delivered improved performance, including a specific capacity of 704.9 mAh gZn–1 at a discharge current density of 10 mA cm–2.

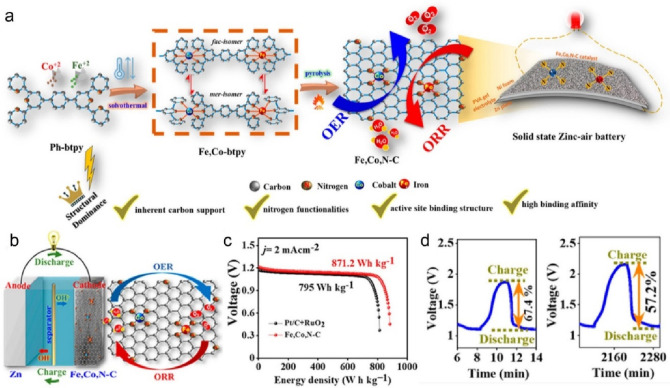

The already described SAC electrode materials contained SAs from one metal. In 2022, Dey et al. reported the development of a bifunctional dual-metal SA electrocatalyst with Co and Fe ions in Fe-N4/C and Co-N4/C isolated active sites, exhibiting a symbiotic effect on overall oxygen electrocatalysis performances.119 It was previously known that cobalt oxides are a popular choice as bifunctional catalysts due to their relatively good performance in both ORR and OER compared to other metal oxides. Moreover, the interfacial dynamics developed upon combination of Co oxides with carbon structures has been proven as a potent toll for altering the performance of the resulting catalysts.120 The high conductivity of carbon materials, such as graphene, can boost the relatively low conductivity of Co oxides while providing increased catalytic surface area and a host structure for Co to be embedded in to form active sites.121 The study was also triggered by theoretical calculations suggesting that the introduction of another metal active center in the presence of Fe-Nx motifs could favor the ORR/OER activity and that Fe-Co bimetallic catalysts promote oxygen binding with a low activation energy and improve the initial onset of ORR. On this basis, the authors bound the Fe and Co precursors to 4′,4⁗-(1,4-phenylene)bis(2,2′,6′,2″-terpyridine) molecules (denoted as Ph-btpy) during solvothermal treatment (Figure 8a). The Ph-btpy ligand was able to anchor two metal atoms at its two open ends containing pyridinic N centers, which provides a highly consistent metal–ligand coordination site. The final product had a square planar coordination of the M-Nx moieties, which enabled synergistic function toward a bifunctional SAC for both OER and ORR and which could be utilized as an air cathode in ZABs (Figure 8b). Moreover, the presence of N dopants and the electronic synergism between the metal centers altered the metal orbital positions and led to the downshift of the energies of the metal d-orbitals, which weakened the adsorption of the reaction intermediates. Thus, the dual metal doping reduced the overpotential of the electrocatalytic processes (ΔEORR-OER = 0.74 ± 0.02 V vs RHE), resulting in a battery with an energy density higher even than that obtained by using a noble-metal-based Pt cathode (Figure 8c, d). Finally, the Fe, Co,N-C ZAB showed a high areal power density of 198.4 mW cm–2 and 158 mW cm–2 in the respective liquid and solid-state ZABs, demonstrating its high proclivity as an air cathode material in ZABs.119 The voltaic efficiency degraded by 10.2% after 38 h of operation. Overall, the Fe and Co SACs with the M-N-C structure are the most commonly used catalytically active species as cathode materials in ZABs. Fe-based SACs have shown advantages in terms of ORR performances, while the Co-based SACs appear to be beneficial in rechargeable batteries due to their bifunctional activity.122

Figure 8.

(a) Schematic illustration of the two-step synthesis strategy for the fabrication of the Fe, Co, N-C electrocatalyst toward high-performance zinc-air batteries and the possible chemical structure formed. (b) Schematic diagram of a cell-based rechargeable zinc-air battery with a 6 M KOH + 0.2 M Zn(acetate)2 electrolyte. (c) Energy density plots at a current density (j) of 5 mA cm–2 of cell-based rechargeable zinc-air batteries with liquid electrolyte using the Fe, Co, N-C dual SAC or a Pt/C + RuO2 noble metal-based cathode. (d) Initial and final (after 34 h) charge–discharge curves transformation of an all-solid-state rechargeable zinc-air battery with Fe, Co, N-C dual SAC as the air cathode. Reprinted with permission from ref (119). Copyright 2022 American Chemical Society.

2.2.3. Li-CO2 Batteries

Despite the substantial superiority of Li-O2 batteries (with a full-cell theoretical capacity of ∼3500 Wh kg–1), their operation is restricted in normal atmosphere by side-reactions which occur due to the presence of H2O and CO2. Moisture reacts with Li2O2 discharge products by forming LiOH, which is not easily reversible back to the metallic Li and O2. In addition, CO2 is quite soluble in the electrolytes and combines with superoxide radicals to form the insulating Li2CO3, which has higher decomposition potential than Li2O2 during the recharging, resulting in inferior energy balance and cycle-life.123 In 2011, Takechi et al. studied a battery utilizing both O2 and CO2, presenting a 3-fold capacity higher than that of a pure O2-based battery.124 This motivated subsequent studies on pure Li-CO2 batteries due to their ability to capture CO2 and thus contribute to a carbon neutral economy.125 In addition, they offer promising energy storage systems for extraterrestrial missions, such as in the CO2-rich atmosphere of Mars. Therefore, metal-CO2 batteries, which involve the CO2RR and CO2ER, have recently evolved as an attractive sustainable EES technology with high added value due to carbon recycling.55,126 Current metal-CO2 batteries mainly embrace Li- or Na-CO2 and Zn or Al-CO2 systems. Due to the high reactivity of Li and Na, their operation requires organic electrolytes, thus allowing for high operation voltages, which translate into higher energy densities (1876 Wh kg–1 and 1130 Wh kg–1 for Li and Na-CO2 batteries, respectively). The driving force for energy conversion and storage in Li-CO2 batteries is the reversible redox reaction between a lithium anode and CO2 gas cathode to form (during discharge) and decompose (during charging) Li2CO3, according to the following reaction: 3CO2 + 4Li ↔ Li2CO3 + C.127 During discharge, Li-ions are released to the gas electrode and react with CO2 to produce Li2CO3 precipitates. Thus, a large surface area of the gas electrode is required to accommodate these insulating and insoluble salts of the discharge process. Accordingly, the effective processing of Li2CO3 is a major limitation, since it deposits and accumulates on the cathode during discharge.128 Notably, this dramatically hinders the kinetics of CO2 evolution during charging, leading to a high voltage (>4.5 V vs Li/Li+) required for decomposing Li2CO3.129 The result is poor reversibility and low energy efficiency.130,131 Therefore, identifying effective catalysts at the gas electrode for the fast and low-energy decomposition of Li2CO3 (i.e., the CO2 evolution reaction) is among the primary challenges for the practical applicability of Li-CO2 batteries. In general, the principles for the design of effective Li-CO2 batteries cathode catalysts could be summarized as the following: (i) good CO2 capture capability, (ii) uniform and well-defined catalytic sites for CO2 reduction/evolution, (iii) fast Li ion transfer pathways, and (iv) efficient electron transfer.132

In an interesting work, theoretical calculations were performed to screen SACs on N-doped graphene (noted as SAMe@NG, Me = Cr, Mn, Fe, Co, Ni, Cu) for CO2 reduction and evolution reaction.133 Among them, Cr SAs showed promising activity as an effective electrocatalyst for reversible Li-CO2 batteries due to the superior CO2 adsorption and Li2CO3 decomposition ability. Thus, the SACr@NG with strong Li2CO3 adsorption had the lowest decomposition potential barriers of 1.674 eV, suggesting that Cr-N4 moieties effectively improve the reaction kinetics in the charge process, indicating that SACr@NG is the best candidate for CO2ER and CO2RR, respectively, in Li-CO2 batteries. To confirm the applicability of the catalyst as electrode, the authors constructed batteries with a SACr@NG/PCF cathode which exhibited the narrowest overpotential of 1.39 V over 350 cycles at a rate of 100 μA cm–2 and showed an extraordinary stability with a long cycle life of over 350 cycles at a current density of 100 μA cm–2. Graphene oxide (GO) has been likewise employed for anchoring Co SAs on its surface with a high loading of 5.3 mass% and used as an efficient and durable electrocatalyst for Li-CO2 batteries.134 The average Co–Co distance between adjacent Co atoms was 1.79 Å, which facilitated the synergistic action of the dispersed Co SAs, providing adjacent catalytically active sites to decompose Li2CO3. The synergistic Co/GO exhibited greater capacity and Coulombic efficiency and lower charge overpotential in comparison to control systems, such as SA Co/GO and Co nanoclusters/GO. This resulted in a high and sustained discharge capacity of 17358 mAh g–1 at 0.1 A g–1 for >100 cycles. In terms of better understanding the activity of such cooperative Co SAs, DFT calculations identified an increased energy of adsorption of the LiCO3 discharge product on the catalyst only in the case where the Co atoms were in close proximity.

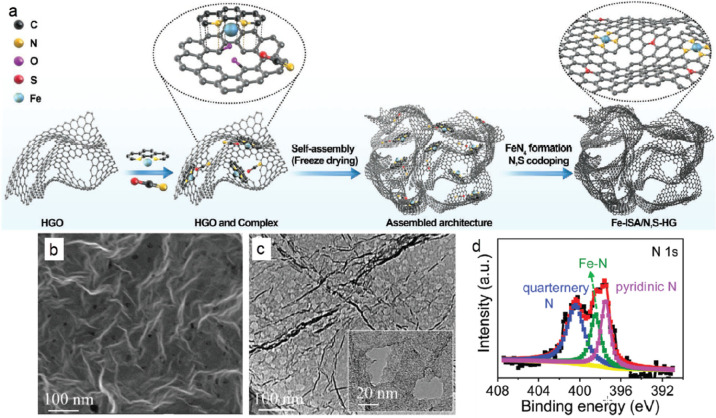

Dai et al. implanted iron SAs into 3D porous carbon architectures, consisting of interconnected N,S-co-doped holey graphene sheets as a highly efficient catalyst for CO2RR and CO2ER in rechargeable Li-CO2 batteries.135 The synthesis of catalyst included a two-step approach, involving a complexation reaction of Fe cations between 1,10-phenanthroline units and holey graphene, followed by postannealing in the presence of thiocyanates, leading to the formation of networks via π–π stacking and coordination with the Fe ions (Figure 9a). SEM images confirmed the well-defined and interconnected 3D porous network, while transmission electron microscopy (TEM) analyses demonstrating the presence of 5–20 nm pores and the atomic dispersion of Fe species (Figure 9b, c). Moreover, the characteristic components of the HR-XPS N 1s spectrum centered at 400.4, 398.5, and 397.1 eV were attributed to quaternary N, Fe–N, and pyridinic N, respectively, confirming the incorporation of N into the carbon skeleton and the developed interactions between Fe and N (Figure 9d). Theoretical calculations indicated that both N and S dopants and “FeN4” in the final catalyst act as dual active sites for CO2 reduction and evolution reactions. Furthermore, the hierarchical porous structure with the interconnected holey graphene framework can facilitate the electron/ion transport channels, while ensuring an effective exposure of the active sites leading to the formation of small Li2CO3 nanoparticles. As a result, the prepared Li-CO2 battery exhibited a high capacity of 23174 mAh g–1 based on the catalyst mass, low polarization (1.17 V at 0.1 A g–1), and long-term stability over 200 cycles, at a cutoff capacity of 1 Ah g–1, at 1.0 A g–1.

Figure 9.

(a) Illustration of the synthesis process of the bifunctional catalyst for CO2 reduction and evolution reactions (b) SEM image of the catalyst with the pores evident in the structure. (c) TEM and HR-TEM (inset) images and (d) HR-XPS spectra of the N 1s region. Reprinted with permission from ref (135). Copyright 2020 Wiley-VCH.

In 2021, a Li-CO2 battery cathode catalyst of a porphyrin-based covalent organic framework (TTCOF-Mn) with single metal Mn sites was reported, via the covalent connection between the electron-donating ligand and the catalytically active moiety of tetrakis(4-aminophenyl)-porphinato manganese(II).136 These covalent organic frameworks (COFs) with metalloporphyrin moieties provided a promising platform to construct single-site catalysts due to the spatially separated and unsaturated coordination sphere of the single-metal sites.137 Both the electron-donating properties of the ligand and the uniform micropore channels ensured the effective electron transfer, high CO2 adsorption, and rapid Li ion transport, while simultaneously contributing to the efficient discharge–charge processes on the TTCOF-Mn cathode catalyst. The battery with TTCOF-Mn exhibited a low overpotential of 1.07 V at 0.1 A g–1, a capacity of 13018 mAh g–1, as well as an excellent stability of 180 cycles, at a cutoff capacity of 1 Ah g–1, at 0.3 A g–1. For comparison, a SAC that contains the precious metal Ru absorbed on rGO-templated sandwich carbon sheets with rich nitrogen doping can deliver an ultrahigh capacity of 44.7 Ah g–1, an ultralow charge/discharge polarization of 0.97 V at 0.1 A g–1 (1.90 V at 2 A g–1), and a long-term cycling stability up to 367 cycles at 1 Ah g–1.138 In general, Ru nanoparticles or SAs of Ru ions provide highly active reaction sites for Li2CO3 decomposition during charging, resulting in enhanced cycling performance.139 However, the significantly high cost and scarcity of noble metals limit their application potential.

2.2.4. Zn-CO2 Batteries

The high activity of Li/Na-CO2 batteries, in the absence of protic solvents, produces primarily low carbon content products during discharging (CO2 reduction), such as carbonates. Zn- and Al-CO2, on the other hand, can operate in more safe and cost-effective aqueous electrolytes. However, this limits the operation potential due to water electrolysis, resulting in lower energy densities. Nevertheless, the discharging process of CO2 reduction in water affords CO, C2H4, HCOOH, and C2H5OH, contributing to a high-level of CO2 valorization and carbon circular economy.55 Using SACs in this case proved to be particularly beneficial for improving the kinetics of the reactions. In a related work, Fe SAs on a carbon support (Fe1NC) demonstrated acceleration for the CO2 electron reduction kinetics in rechargeable Zn-CO2 batteries, reaching a CO Faradaic efficiency (FE) up to 96% at −0.5 V and a turnover frequency of 2225 h–1, along with outstanding stability.140 In particular, Fe-N3 sites appear to be key for the optimization of the *COOH/*CO intermediates adsorption energies, at neither too strong nor too weak levels, boosting the final conversion to CO. The resulted catalyst achieved an ultrahigh power density of 526 mW cm–2 and ran for 72 cycles at 0.5 mA cm–2, demonstrating the potential of utilization of SACs in Zn-CO2 batteries.140

Apart from studies of SACs based on one type of metal, SAs from two different metals may interact with each other through their microenvironment and work cooperatively to activate more effectively the reactants or for improving the sorption–desorption balance of reactants, intermediates, and products. However, often, further improvements are required for lowering the onset potential (reaction energy barriers) or releasing easier intermediates, such as CO, which seriously compromise Faradaic efficiencies and catalyst stability. Moreover, too strong binding strength of TM sites with electron-donating intermediates lowers the catalytic activity for oxygen evolution reaction.141 For example, in nature, the Ni-Fe carbon monoxide dehydrogenase with Fe and Ni SA sites bridged by sulfide ligands can synergistically catalyze the efficient interconversion of CO2 and CO under mild conditions.142 Inspired by this Nature’s blueprint, Jiang et al. synthesized a novel Fe1-Ni1-N-C catalyst with Fe and Ni SA pairs decorated on nitrogen-doped carbon.143 Given the great advantages on structural and component regulation, MOFs represent a particularly attractive platform for the construction of SACs.144 Among various types of MOF-derived SACs, SA decorated nitrogen-doped carbons (M-N-C), with planar and conjugated carbon motives, can readily achieve the required long-range electron delocalization and couple adjacent nonbonding single metal atoms.106 Theoretical simulations revealed that the Fe SACs can be highly activated by adjacent Ni SAs via nonbonding interactions, significantly facilitating the formation of COOH* intermediate and thereby accelerating the overall CO2 reduction. More specifically, by the direct pyrolysis of Fe- and Ni-doped ZnO nanoparticles anchored on zeolitic imidazolate frameworks (ZIF-8) and via a Zn-assisted atomization strategy during pyrolysis, a ZIF-derived nitrogen-doped carbon implanted by adjacent Fe-N4 and Ni-N4 sites was obtained. Thanks to the synergism of the neighboring Fe and Ni SA pairs, the catalyst offered significantly enhanced performances for electrocatalytic reduction of CO2, far surpassing the one-metal type SACs of Fe or Ni SAs. For the Zn-CO2 battery testing, an H-shaped cell divided by a bipolar membrane was used with the cathode compartment being bubbled with CO2. The charge and discharge voltages under different current densities showed rechargeable behavior and excellent selectivity to CO with a FE up to 93.4% at 1 mA. In the same period, Zeng et al. also described the development of a bimetallic SAC consisting of nickel–iron heterodiatomic pairs anchored on nitrogen-doped graphene for performing both the CO2RR and OER.141 The catalyst/cathode was synthesized by pyrolyzing l-alanine, ferric (II) acetate, nickel(II) acetate tetrahydrate, and melamine together in argon atmosphere. adding Fe acetate (or Ni acetate). The synthesis resulted in a mixture of nanoparticles and SA metal cations. Thus, the product was ground and washed by 2 M HCl solution at 80 °C for 24 h under stirring to remove metal particles. The Ni-Fe SAC exhibited extraordinary and stable electrocatalytic performance for CO2RR and OER, and the rechargeable Zn-CO2 battery equipped with such bifunctional catalyst showed high FE and outstanding rechargeability. The electronic structure analysis revealed that the Fe cations in the Ni-Fe heteroatomic pairs served as the catalytic centers, while the Fe orbital coupling with Ni lead to a higher oxidation state weakening the binding strength with the intermediates. The Zn-CO2 battery equipped with a NiFe bimetallic SAC cathode offered the largest discharge voltage and the lowest charge voltage as compared to the batteries with a Ni-SAC or Fe-SAC cathode. The Zn-CO2 battery could be operated under large discharge current densities over 10 mA cm–2, delivering a maximum power density of 1.36 mW cm–2 at 8.5 mA cm–2. The Zn-CO2 battery exhibited a high FE of 90% at 5 mA cm–2. The authors found that the 3d states of Fe in the NiFe-SAC were less localized than those in Fe-SAC, attributed to the strong d-d orbital coupling between the heteroatoms, leading to decreased orbital energy levels and delocalization of electrons, beneficial to *CO desorption. This finding is of particular importance, considering that the rate limited step of CO2RR for Fe-SAC is the desorption of CO intermediate.145

2.2.5. Al-Air Batteries

Having the same principles as ZABs, Al-air batteries are another promising energy storage chemistry. This is mainly due to the low equivalent weight of aluminum leading to high specific energies, its low reactivity with humidity and oxygen rendering it a safe metallic anode, and nontoxic and environmentally friendly charging and discharging products. Theoretically, Al contains approximately half of gasoline’s energy content per unit weight (8100 Wh kg–1 for Al-air batteries and 13 000 Wh kg–1 for gasoline) and three times the energy per unit volume (21 870 Wh L–1 for Al-air and 9700 Wh L–1 for gasoline).146 However, as presented in Figure 3 that the practical cell-level values are significantly lower, dropping below 400 Wh kg–1 for Al-air batteries in comparison to 1700 Wh kg–1 for an internal combustion engine.147 Although the specific energy of Al-air batteries is the highest after Li-air batteries, Al has the great privilege of low cost, which is only 1/6 of that of Li, and an earth-abundance 4.5 thousand times higher than that of Li.148 Al-air batteries consist of an Al or Al alloy anode, an air electrode cathode, and an alkali or salt electrolyte that incorporates additives to suppress corrosion and H2 evolution, such as ZnO.149 During discharge the anode material (Al) dissolves to cations, while the oxygen molecules are reduced, producing electrical energy. The process can be summarized as the following reaction: Al + 3/4O2 + 3/2H2O → Al(OH)3.150 However, a highly negative potential is required for the reverse process of depositing Al metal at the anode, in an aqueous system, making the recharging process of Al-air batteries quite challenging and energy inefficient. Moreover, on Al anode’s surface a passivating oxide layer is formed, which not only reduces the operating cell voltage but also increases both the charge and mass transfer resistance. In turn, the OCV drops from −2.34 V to −1.87 V vs SHE at high pH, limiting the cell operating voltage and thus the energy density.151 Last but not least, particularly in alkaline electrolytes, the oxide passivating layer can be removed, which then gives rise to a high corrosion rate, further limiting the operating cell voltage between 1.2 and 1.6 V instead of the theoretical of 2.74 V.148

To overcome these bottlenecks, the introduction of catalytic sites is studied with high intrinsic ORR activity in order to push the reaction kinetics at the three-phase interface.152,153 Recently, 3D N-doped carbon aerogels embedded with Fe SAs were prepared and studied for Al-air batteries.154 Three kinds of biomass starch hydrogels were evaluated as 3D templates, mixed and interconnected with Fe ions coordinated with melamine, acting as the metal and N source, respectively (Figure 10a). The hydrogels after pyrolysis formed the Fe SA porous carbon hosts (NCA/Fe, Figure 10b), which showed excellent electrocatalytic performance in O2-saturated 0.1 M KOH toward ORR with an onset potential of+1.05 V and half-wave potential of +0.88 V, all more positive than those of commercial 20 wt % Pt/C (Figure 10c), due to the higher activity of the Fe-N4 catalytic motifs in the biomass-derived, hierarchical porous carbon aerogels. The onset potential determination is an excellent tool to characterize the catalytic performance of a material, being the highest for cathodic reactions (ORR) and lowest for anodic reactions (OER), in which a reaction product is produced at a given electrode and defined conditions.155 Therefore, the application of the aerogel SACs as an Al-air battery cathode exhibited a higher OCV (1.81 V) and power density (181.1 mW cm–2) and more stable discharge voltage of 1.70 V at 20 mA cm–2, substantially better than those with a Pt/C cathode (Figure 10d).

Figure 10.

(a) Chemical structure of the starch and schematics representing the pore-forming SiO2 nanoparticles and the melamine-Fe complex. (b) Schematic illustration for the synthesis of single Fe atoms dispersed in N-doped carbon aerogels (NCA/Fe). (c) Eonset, E1/2, and Jk (at +0.85 V) of one type of the NCA/Fe carbon aerogel catalyst and comparison with the performance obtained from a commercial Pt/C catalyst. (d) Constant current discharge tests of the same catalysts in panel c, at the current density of 20 mA cm–2; inset: photo of parallel red, yellow, and green LEDs (rated voltages of 1.8 to 2.0 V) simultaneously powered by only one Al-air battery assembled using NCA/Fe as the cathode catalyst. Reprinted with permission from ref (154). Copyright 2019 Royal Society of Chemistry.

The elaborate exploration of nonprecious metal catalysts for efficient ORR is imperative for the practical development of fuel cells and metal-air batteries.156 Among the reported non-Pt ORR catalysts, the molecular catalyst of iron phthalocyanine (FePc) has aroused much attention due to its special Fe-N4 active site and low reaction energy barrier during ORR.157 However, FePc, with the typical two-dimensional and plane symmetric structure, leads to the symmetric electron distribution in the FeN4-active sites and is not conducive to the O2 adsorption and activation.158 In order to improve the ORR activity of the FePc catalyst, Liu et al. broke the symmetry of electronic density with a composite catalyst (FeAB-O) by coordination of the FePc molecule with oxygen-containing groups on an O2 plasma-treated acetylene black (AB-O) matrix to achieve efficient O2 adsorption and ORR.157 Theoretical calculations showed that although the number of charges and spin polarization of the symmetrical FeN4 site did not significantly change, the axial O coordination accepts partial charges from the Fe-N4, breaking the symmetry of the electronic density near the Fe-N4 site. As a result, the FeAB-O showed much higher O2 adsorption energy by 0.92 eV. Thus, the stable adsorption of oxygen could facilitate the process of ORR having an ORR overpotential of 0.70 V. This FeAB-O catalyst exhibited one of the best half-wave potentials of 0.90 V vs RHE, which is superior to that of commercial Pt/C. Thus, the introduction of axial O coordination in O-FeN4 sites makes the catalyst superior to most of the reported Fe-N-C catalysts.

Apart from Fe-based SACs, Li et al. synthesized Co-N4 active centers on high specific surface area and pore-rich biomass-derived 3D ultrathin porous carbons, to increase the active sites and boost mass transfer. Using this as catalyst for the cathode in a homemade Al-air battery, the authors achieved a high OCV, reaching 1.80 V, which is comparable to that of Pt/C (1.82 V), displaying a particularly improved peak power density of 494 mW cm–2, than that of Pt/C (449 mW cm–2). Interestingly, the high activity of the catalyst, boosting the Al-air battery performance during discharging, was supported by theoretical calculations, which revealed downhill free energy changes for the ORR individual reaction steps (or small energy barriers depending on the potential where the DFT calculations were studied). The most demanding step in this case was the adsorption of oxygen, electron/proton transfer, and reduction to OOH* species. On the contrary, the OER reaction steps were very demanding in all cases, reflecting the challenging recharging process of oxygen generation from the Al(OH)3 precipitates and Al reduction and homogeneous deposition back to the anode.159 In summary, the Fe and Co SAs on nitrogen-doped carbon hosts are most commonly employed and studied in metal-air batteries as active catalytic sites on the cathode. It appears that Fe SACs favor the ORR performance while the Co SACs show some interesting properties with bifunctional catalytic activity, which might be advantageous in metal-air batteries.

The application of nonprecious metal SACs for metal-air and metal-CO2 batteries has undoubtedly attracted increased attention over the past few years (Table 1) because SACs can enhance the ORR and OER in metal-air batteries and the CO2RR and the CO2ER in metal-CO2 batteries. The results have demonstrated substantial reduction in the overpotentials at the cathode, which is a major limiting factor in the performance of metal-air and metal-CO2 batteries regarding their energy efficiency. SACs can also improve the electron transfer between the cathode and the electrolyte, reducing the resistance and improving the rate of the battery. Despite these advancements, further research is needed to overcome several challenges. Metal-air batteries typically struggle in ambient air because of water and carbon dioxide. While membranes that can separate moisture from the atmosphere have shown some success, the difficulty separating oxygen from carbon dioxide in ambient air has led to researching metal-CO2/O2 batteries, where the gas separation would not be required.160 Highly selective and multifunctional catalysts in the cathode would be thus very beneficial in order not only to perform both the ORR and the CO2RR but also to decompose effectively the variable discharge products. Potent multifunctional catalysts based on bi- or even multimetallic cooperative SACs for tandem catalysis will probably play a primary role in the development of these technologies.141,161 Effective formations and transformation of solid intermediates which are less corrosive for the battery components is another valuable strategy, such as the reversible formation of Li2O instead of Li2O2.80 Li2O2 involves the superoxide and peroxide species which are detrimental to the stability of the cathode materials and the electrolytes; however, for being thermodynamically more favorable during discharging, it has been the main chemistry in Li-air batteries. In metal-CO2 batteries, on the other hand, the matter of carbon capture and sequestration implementation is usually both expensive to build and energy intensive to operate.160 SACs could offer promising opportunities toward the acceleration of metal-CO2 battery reactions, but the decomposition of their discharge products during charging should be given particular attention in order to achieve good performance in full cells and a long battery life.

Table 1. Electrochemical Performance of SAC-Based Materials Studied as Electrodes for Energy Storage Devices in Terms of Their Synthesis Method, Battery Type, Specific Capacity, Power Density and Cycling Stability.

| Material | SAC | Synthesis method | Battery | Current density | Max. cycles | Capacity (mAh g–1) | Power density (mW cm–2) | Ref |

|---|---|---|---|---|---|---|---|---|

| N-HP-Co SACs | Co | polymerization of cobalt complexes and pyrolysis | Li-O2 | 0.1 A g–1 | 261 | 1000 cutoff | (90) | |

| Co-SAs/N-C | Co | green gas-migration-trapping strategy | Li-O2 | 0.4 A g–1 | 260 | 1000 cutoff | (91) | |

| Fe, Co-SA/CS | Fe, Co | heat and acidic treatments of ZIFs grown on carboxylic polystyrene nanospheres | ZAB | 5 mA cm–2 | - | 819.6 | 86.65 | (103) |

| Fe-N-C/N-OMC | Fe | KIT-6 as template and Fe(II)-Phen complex/2-methylimidazole as the Fe, N, C precursors | ZAB | 10 mA cm–2 | - | 711 | 113 | (104) |

| 3DOM Fe-N-C | Fe | pyrolysis of ferrocene-encapsulated macro-microporous ZIF-8 precursor | ZAB | 20 mA cm–2 | - | 768.3 | 235 | (108) |

| Fe-N4 SAs/NPC | Fe, Zn | polymerization–pyrolysis evaporation strategy to synthesize N-doped porous carbon with atomically dispersed Fe-N4 units | ZAB | 50 mA cm–2 | 108 | - | 232 | (110) |

| Fe-Nx-C | Fe | Fe-Phen encapsulated in nanocages during the growth of ZIF-8 and pyrolysis to isolate Fe-Nx-C SACs | ZAB | 10 mA cm–2 | - | 641 | 96.4 | (111) |

| Fe-SAs/NPS-HC | Fe | ZIF-8/Fe@PZS formation via core–shell composites via polymerization followed by pyrolysis | ZAB | 375 mA cm–2 | 500 | - | 195.0 | (112) |

| Co SA/NCFs | Co | one-step electrospinning and carbonization | ZAB | 10 mA cm–2 | - | 796 | 154.5 | (116) |

| Cu-N/PC | Cu | tuning Zn dopant content in Cu-ZIF-8 followed by direct pyrolysis and acid dissolution | ZAB | 10 mA cm–2 | - | 704.9 | 215.8 | (118) |

| Fe, Co,N-C | Fe, Co | Fe and Co precursors bound during solvothermal treatment. The resulted Ph-btpy ligand was able to anchor two metal atoms. | ZAB | 330 mA cm–2 | 726 | 198.4 | (119) | |

| SACr@NG/PCF | Cr | two step pyrolysis from natural cotton and metal acetylacetonate mixing with GO | Li-CO2 | 0.1 mA cm–2 | 350 | 1500 μAh cm–2 | - | (133) |

| SA Co/GO | Co | acid leaching of Co nanoclusters/GO | Li-CO2 | 0.1 A g–1 | 100 cutoff 1000 mAh g–1 | 17358 | - | (134) |

| Fe-ISA/N,S-HG | Fe | Complexation reaction of Fe cations with 1,10-phenanthroline and holey graphene followed by annealing with thiocyanates | Li-CO2 | 1 A g–1 | 200 cutoff 1000 mAh g–1 | 23174 | - | (135) |

| TTCOF-Mn | Mn | Solvothermal method via Schiff-base condensation between TAPP-Mn and TTF in the presence of aqueous acetic acid | Li-CO2 | 0.3 A g–1 | 180 | 13018 | - | (136) |

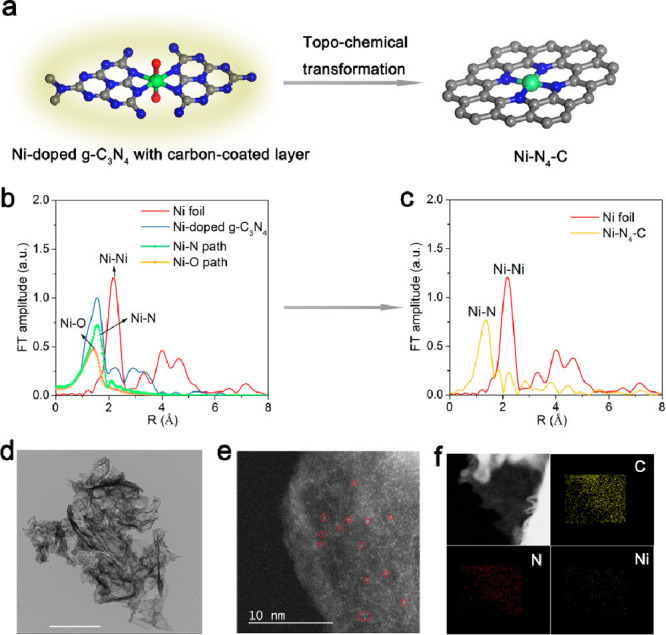

| Fe1NC/S1-1000 | Fe | N-doped porous carbon support derived from ZIF-8 precursor carbonized with diffused ferrocene ligand steam | Zn-CO2 | 0.5 mA cm–2 | 72 | - | 526 | (140) |