Abstract

Cancer cells have deregulated metabolism that can contribute to the unique metabolic makeup of the tumor microenvironment. This can be variable between patients, and it is important to understand these differences since they potentially can affect therapy response. Here we discuss a method of processing and assaying metabolism from direct ex vivo murine and human tumor samples using seahorse extracellular flux analysis. This provides real-time profiling of oxidative versus glycolytic metabolism and can help infer the metabolic status of the tumor microenvironment.

Keywords: Extracellular flux, Seahorse, Metabolism, Glycolysis, Oxidative phosphorylation

1. Introduction

It is widely appreciated that cancer cells undergo metabolic reprogramming in order to enhance cell proliferation and survival. These cells increase both aerobic glycolysis and oxidative phosphorylation, resulting in a distinct metabolic landscape that has low glucose and oxygen, as well as a decreased pH due to an abundance of lactic acid [1–4]. This metabolic landscape can affect anti-tumor immunity and may have an impact on treatment selection and response to therapy [5, 6]. Understanding the metabolic variabilities between patients is important, but previous techniques including radiolabeling, mass spectrometry, and NMR analysis can be laborious and require large amounts of tissue [7]. Here we developed a method to use seahorse technology to measure tumor cell metabolism directly ex vivo using a relatively small number of cells.

Seahorse extracellular flux analysis has been used previously to quantify cell metabolism in real time with a variety of direct ex vivo cells such as lymphocytes [8–11]. The XFe96 analyzer is a 96-well instrument that can measure the uptake and secretion of metabolic products involved in glycolysis and oxidative metabolism. It detects changes in oxygen and pH in the media surrounding the cells being analyzed with fluorescent biosensors in each well [12]. Each sensor cartridge also contains four chambers to allow for the delivery of various reagents into all 96 wells during the assay. In order to quantify oxidative and glycolytic capabilities in cells, the assay we developed uses the reagents oligomycin, carbonyl cyanide-p-trifluoromethoxyphenyl-hydrazon (FCCP), 2-deoxy-d-glucose, rotenone, and antimycin A, which are loaded into the four chambers. Oligomycin is an inhibitor of ATP synthase and can be used to determine the level of ATP-linked respiration in a cell [13]. FCCP uncouples the mitochondrial membrane and allows protons to flow freely across the membrane. This results in maximal respiration in the cell after the addition of FCCP and can be used to calculate the spare respiratory capacity, or the ability of the cells to meet energy demands during times of stress [13]. 2-Deoxy-d-glucose acts as an inhibitor of glycolysis by blocking hexokinase and preventing the production of glucose-6-phosphate [12]. This causes glycolysis to decrease and can be used to determine non-glycolytic acidification of the medium. Rotenone and antimycin A together inhibit complex I and III of the electron transport chain. The combination of these two inhibitors stops oxidative metabolism through the mitochondria of the cells and can be used to calculate nonmitochondrial respiration [12]. Using this technology, we have developed a way to metabolically profile melanoma cell lines, murine tumors harvested directly ex vivo from genetically engineered mouse models of melanoma and tumors biopsied from melanoma patients so that we may better understand heterogeneity between samples.

2. Materials

2.1. Tumor Processing and Culture

RPMI-1640-based medium for tumor cell culture: Remove 50 mL of RPMI-1640 from a 1-L bottle of base medium. Add 100 mL of heat-inactivated fetal bovine serum, 10 mL of sodium pyruvate (100 mM), 10 mL of MEM nonessential amino acids (100×), 5 mL of HEPES (1 M), 10 mL of l-glutamine (200 mM), and 10 mL of penicillin (10,000 IU)/streptomycin (10,000 μg/mL). Filter through a 0.22-μm filter.

Murine tumor digestion solution: Add 100 μL of liberase (2.5 mg/mL), 100 μL of DNase I (2000 Kunitz), and 400 μL of dispase (5 U/mL) to 400 μL of serum-free RPMI-640 medium.

Human tumor digestion solution: Add 50 μL of collagenase II (100 mg/mL) and 50 μL of DNase I (10 mg/mL) to 5 mL of RPMI-1640-based medium for tumor cell culture.

1× red blood cell lysis buffer: Dilute 5 mL of proprietary 10× red blood cell lysis buffer in 45 mL of deionized water.

Sterile PBS (1×): Dilute 50 mL of 10× PBS with 450 mL of deionized water and autoclave.

Trypsin–EDTA: 0.05% Trypsin and 0.53 mM EDTA in Hank’s balanced salt solution.

Six-well tissue culture plate.

Scalpel.

5-mL syringe.

70-μm strainer.

Hemocytometer.

60-mm petri dish.

15-mL conical centrifuge tube.

Rotating platform.

2.2. Seahorse Mito Stress Test

Seahorse XFe96 Analyzer.

Seahorse XFe96 FluxPak: XFe96 sensor cartridges, XF96 cell culture microplates, and 500 mL of XF Calibrant Solution.

Standard seahorse mito stress test assay medium: Prepare medium fresh prior to the assay by mixing 98 mL of Seahorse XF Base Medium with 1 mL of l-glutamine (200 mM), 1 mL of sodium pyruvate (100 mM), and 10 mM glucose (180 mg), pH 7.4.

5 mM oligomycin: Dissolve 10 mg of oligomycin in 2.53 mL of DMSO.

5 mM FCCP: Dissolve 10 mg of FCCP in 7.87 mL of DMSO.

600 mM 2-deoxy-d-glucose: Dissolve 490 mg of 2-deoxy-d-glucose in 5 mL of DMSO.

3 mM antimycin A: Dissolve 50 mg of antimycin A in 30.38 mL of DMSO.

2.5 mM rotenone: Dissolve 1 g of rotenone in 10.14 mL of DMSO to make a stock solution of 250 mM. Further dilute stock by adding 1 μL of 250 mM rotenone to 99 μL of DMSO to reach a 2.5 mM working concentration.

Seahorse Wave Desktop Software (Agilent).

Microsoft Excel or GraphPad Prism.

3. Methods

3.1. Tumor Processing and Cell Preparation

3.1.1. Murine Tumors

Place resected tumor into a six-well tissue culture plate and use a scalpel to cut tumor into small pieces.

Add 2 mL of murine tumor digestion solution to the well and incubate at 37 °C for 15–20 min.

Grind the tumor using the back of a 5-mL syringe and filter using a 70-μm strainer.

Spin cells at 520 × g for 5 min, and discard supernatant.

Resuspend cell pellet in 1 mL of 1× red blood cell lysis buffer, and incubate at room temperature for 1 min.

Add 4 mL of RPMI-1640-based medium for tumor cell culture.

Spin cells at 520 × g for 5 min and resuspend cell pellet in RPMI-based medium. Count cells using a hemocytometer.

3.1.2. Human Tumors

Place tissue in 60-mm petri dish and mince with scalpel until pieces are around 1 mm3.

Add 5 mL of RPMI-based medium for tumor cell culture and transfer tissue and medium into a 15-mL conical tube.

Add 50 μL of collagenase II and 50 μL of DNase I to the conical tube, and incubate tissue in this human tumor digestion solution at 37 °C for to 10–30 min on a rotating platform (see Note 1).

Remove the tube from 37 °C and carefully pipette the cell suspension up and down.

Filter the cell suspension using a 70-μm strainer.

Wash the strainer using RPMI-based medium for tumor cell culture, and centrifuge at 500 × g for 5 min.

Resuspend cell pellet in RPMI-based medium, and count cells using a hemocytometer.

3.2. Preparation of Cells from Culture

For melanoma cell lines, aspirate medium in cell culture plate, rinse plate with 5 mL of 1× PBS and aspirate, and add 5 mL of Trypsin–EDTA.

Place plate in 37 °C incubator for 2–5 min (or until cells have detached from the cell culture plate).

Add 5 mL of RPMI-based medium for tumor cell culture and harvest the cells. Spin cells at 520 × g for 5 min and resuspend cell pellet in RPMI-based medium.

Count cells using a hemocytometer.

3.3. Seahorse Mito Stress Test

Hydrate a sensor cartridge the night before running the assay.

Place the sensor cartridge upside down next to the utility plate.

Fill each well of the utility plate with 200 μL of Seahorse XF Calibrant Solution.

Lower the sensor cartridge onto the utility plate, submerging the sensors in Seahorse XF Calibrant Solution.

Place the sensor cartridge and utility plate in a non-CO2 37 °C incubator overnight (see Notes 2 and 3).

- Plate tumor cells in XF96 cell culture microplate in 100 μL of RPMI-based tumor cell culture medium.

- For melanoma cell lines, plate cells at a seeding density of 10,000–20,000 cells per well.

- For ex vivo-derived murine or human melanoma cells, plate cells at a seeding density of 40,000–50,000 cells per well (see Note 4).

- Place the XFe96 cell culture microplate in a CO2 37 °C incubator overnight.

On the day of the assay, prepare the standard seahorse mito stress test medium as described in Subheading 2, and pH the solution to 7.4 ± 0.05. Warm to 37 °C.

- Prepare seahorse mito stress test inhibitors in standard mito stress test medium as follows:

- Dilute 12 μL of 5 mM oligomycin stock into 3 mL of assay medium to reach the concentration of 20 μM.

- Dilute 12 μL of 5 mM FCCP stock into 3 mL of assay medium to reach the concentration of 20 μM.

- Dilute 500 μL of 600 mM 2-Deoxy-d-glucose stock into 2.5 mL of assay medium to reach the concentration of 100 mM.

- Dilute 5 μL of 3 mM antimycin A stock and 6 μL of 2.5 mM rotenone stock into 3 mL of assay medium to reach the concentration of 5 μM (see Note 5).

- pH all solutions again to 7.4 ± 0.05. Warm to 37 °C.

Remove XF96 cell culture microplate with cells from the CO2 37 °C incubator.

Examine cells with a microscope to check that cells are adhering to the bottom of the plate.

Carefully aspirate RPMI-based tumor cell culture medium using a multichannel pipette, and wash one time with 100 μL of standard seahorse mito stress test medium (see Note 6).

Aspirate the medium using a multichannel pipette, and add 180 μL of standard seahorse mito stress test medium.

Examine cells again under a microscope for adherence.

Place the XF96 cell culture microplate in a non-CO2 37 °C incubator for 1 h.

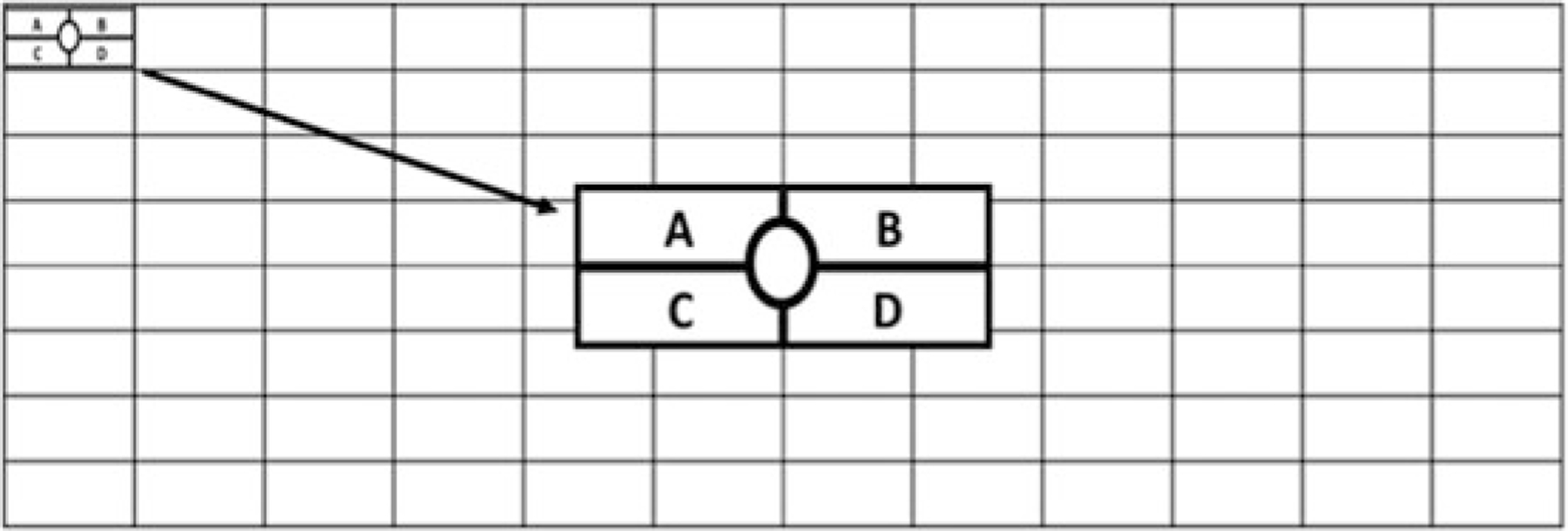

Using the provided Seahorse loading guides (see Notes 7–11), load the mito stress test inhibitors as described in Table 1 into the appropriate injection ports in the sensor cartridge (Fig. 1) using a multichannel pipette.

Using Seahorse Wave Desktop Software, create an experimental template for the standard seahorse mito stress test. Open up a new template in Wave, and add injection strategies, cell types and seeding density, cell plate layout, and measurement cycles for each injection (see Note 12).

Calibrate the Seahorse XFe96 Analyzer by starting the run and adding the sensor cartridge and utility plate containing Seahorse XF Calibrant Solution to the machine.

After calibration is complete (or after the XFe96 cell culture microplate has been in the non-CO2 37 °C incubator for 1 h), begin the assay by removing the utility plate containing Seahorse XF Calibrant Solution and replacing it with the XFe96 cell culture microplate containing the tumor cells.

Table 1.

Loading schematic and volumes of mito stress test inhibitors that are to be loaded in the 96-well sensor cartridge

| Injection port | Inhibitor | Volume |

|---|---|---|

| A | Oligomycin | 20 μL |

| B | FCCP | 22 μL |

| C | 2-Deoxy-d-glucose | 25 μL |

| D |

Rotenone + Antimycin A |

27 μL |

Fig. 1.

Representative image of loading ports for injections on the 96-well sensor cartridge

3.4. Data Analysis

After the assay is complete, remove the XFe96 cell culture microplate from the Analyzer, and view the results by clicking on the add view, overview icon.

Examine oxygen consumption rate (OCR) and extracellular acidification rate (ECAR) measurements for each well for all experimental groups for any outliers, and remove wells by clicking on that well of the plate so that it is highlighted gray.

Export data into a Prism or Excel file by clicking on the export icon (see Note 13).

Determine baseline OCR and ECAR by calculating the overall average between all the wells of the groups for the last reading measured before the oligomycin injection.

Calculate spare respiratory capacity by subtracting the average maximum OCR measurement and the average baseline OCR measurement from step 4 of this section (see Note 14).

Calculate glycolytic reserve by subtracting the average maximum ECAR measurement and the average baseline ECAR measurement from step 4 of this section.

Acknowledgments

This work was supported by the UPMC Hillman Cancer Center Melanoma and Skin Cancer SPOREs (P50CA121973–09 to YGN, JMK, and GMD); Stand Up To Cancer—American Association for Cancer Research (SU2C-AACR-IRG-04–16 to GMD); an NIH Director’s New Innovator Award (DP2AI136598 to GMD); Young Investigator Award from Alliance for Cancer Gene Therapy/Swim Across America (to GMD); the Hillman Fellows for Innovative Cancer Research Program funded by the Henry L. Hillman Foundation; Cancer Center Support Grant P30CA047904 and the UPMC Hillman Cancer Center.

Footnotes

Digestion time will depend on the size of the biopsy or the number of cores received. Digest tissue from 2 to 4 cores for 10 min. Larger pieces of tissue from surgery should be digested for 20–30 min.

To prevent evaporation of the Seahorse XF Calibrant Solution overnight, verify that the non-CO2 incubator is properly humidified.

The sensor cartridge should be hydrated at least 3 h before the assay and can be used up to 72 h after hydration as long as the calibrant solution has not evaporated.

Cell numbers per well may vary between cell lines and should be titrated in the seahorse before experimentation.

Seahorse mito stress test inhibitors are made at 10× concentrations so that they are 1× upon injection into the cell-containing wells.

For direct ex vivo tumors, cells may need to be washed more than once if there is debris left in the well after the first wash.

Carefully wash until most of the debris is out of the well. Before loading the sensor cartridge, lift sensors up and down from utility plate containing the Seahorse XF Calibrant Solution a few times until all bubbles in the plate are gone.

Check that the appropriate loading guides are used for the appropriate injection ports.

Check that the blue triangle on the sensor cartridge and utility plate is in the bottom left-hand corner before loading any ports. This ensures that the injections are loaded in the correct orientation.

Be sure to change the pipette volume each time you switch inhibitors, and monitor the volume in the multichannel pipette tips to ensure everything is loading evenly in all of the wells.

Before loading the next inhibitor with the loading guides, check for leftover residue liquids on the loading guide from the previous inhibitor loaded. You do not want to transfer one inhibitor into another port by accident.

We usually do 3–5 measurement cycles for any seahorse run, but this can be modified according to user preference.

Older versions of the Wave Desktop Software will not have this export option. Newer versions of the software will export the data for all wells, excluding those that were selected as outliers.

Maximum respiration usually occurs after FCCP is injected, but for some experiments, there can be an increase in OCR after 2-deoxy-d-glucose. Always use the highest OCR measurement to calculate spare respiratory capacity.

References

- 1.Warburg O (1956) On the origin of cancer cells. Science 123(3191):309–314 [DOI] [PubMed] [Google Scholar]

- 2.Vander Heiden MG, Cantley LC, Thompson CB (2009) Understanding the Warburg effect: the metabolic requirements of cell proliferation. Science 324(5930):1029–1033 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Gogvadze V, Orrenius S, Zhivotovsky B (2008) Mitochondria in cancer cells: what is so special about them? Trends Cell Biol 18 (4):165–173 [DOI] [PubMed] [Google Scholar]

- 4.Scharping NE, Delgoffe GM (2016) Tumor microenvironment metabolism: a new check-point for anti-tumor immunity. Vaccines (Basel) 4(4):46. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Wegiel B, Vuerich M, Daneshmandi S, Seth P (2018) Metabolic switch in the tumor microenvironment determines immune responses to anti-cancer therapy. Front Oncol 8:284. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Najjar YG, Menk AV, Sander C et al. (2019) Tumor cell oxidative metabolism as a barrier to PD-1 blockade immunotherapy in melanoma. JCI Insight 4(5):e124989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Pike Winer LS, Wu M (2014) Rapid analysis of glycolytic and oxidative substrate flux of cancer cells in a microplate. PLoS One 9(10):e109916. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Scharping NE, Menk AV, Moreci RS et al. (2016) The tumor microenvironment represses T cell mitochondrial biogenesis to drive intratumoral T cell metabolic insufficiency and dysfunction. Immunity 45 (2):374–388 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Scharping NE, Menk AV, Whetstone RD et al. (2017) Efficacy of PD-1 blockade is potentiated by metformin-induced reduction of tumor hypoxia. Cancer Immunol Res 5 (1):9–16 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Menk AV, Scharping NE, Rivadeneira DB et al. (2018) 4–1BB costimulation induces T cell mitochondrial function and biogenesis enabling cancer immunotherapeutic responses. J Exp Med 215(4):1091–1100 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Menk AV, Scharping NE, Moreci R et al. (2018) Early TCR signaling induces rapid aerobic glycolysis enabling distinct acute T cell effector functions. Cell Rep 22(6):1509–1521 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Wu M, Neilson A, Swift AL et al. (2007) Multiparameter metabolic analysis reveals a close link between attenuated mitochondrial bioenergetic function and enhanced glycolysis dependency in human tumor cells. Am J Physiol Cell Physiol 292(1):C125–C136 [DOI] [PubMed] [Google Scholar]

- 13.Reily C, Mitchell T, Chacko BK et al. (2013) Mitochondrially targeted compounds and their impact on cellular bioenergetics. Redox Biol 1 (1):86–93 [DOI] [PMC free article] [PubMed] [Google Scholar]