Abstract

Tissue biofabrication mimicking organ-specific architecture and function requires physiologically-relevant cell densities. Bioprinting using spheroids can achieve this, but is limited due to the lack of practical, scalable techniques. This study presents HITS-Bio (High-throughput Integrated Tissue Fabrication System for Bioprinting), a multiarray bioprinting technique for rapidly positioning multiple spheroids simultaneously using a digitally-controlled nozzle array (DCNA). HITS-Bio achieves an unprecedented speed, ten times faster compared to existing techniques while maintaining high cell viability ( > 90%). The utility of HITS-Bio was exemplified in multiple applications, including intraoperative bioprinting with microRNA transfected human adipose-derived stem cell spheroids for calvarial bone regeneration ( ~ 30 mm3) in a rat model achieving a near-complete defect closure (bone coverage area of ~ 91% in 3 weeks and ~96% in 6 weeks). Additionally, the successful fabrication of scalable cartilage constructs (1 cm3) containing ~600 chondrogenic spheroids highlights its high-throughput efficiency (under 40 min per construct) and potential for repairing volumetric defects.

Subject terms: Biomaterials - cells, Tissue engineering, Regenerative medicine, Mesenchymal stem cells

HITS-Bio, a high-throughput bioprinting platform, rapidly assembles spheroids to mimic native tissue architecture. Its intraoperative application in bone shows near-complete calvarial defect repair in rats and fabrication of scalable cartilage.

Introduction

Three-dimensional (3D) bioprinting has been making a progressive impact on medical sciences, which has great potential to facilitate the fabrication of functional tissues not only for transplantation but also for disease modeling and drug screening. It offers great precision for the spatial placement of cells, which is crucial for guiding tissue repair and regeneration1. Despite the significant progress in bioprinting of cells, the standard approach of encapsulating cells within a hydrogel bioink faces major limitations. One key challenge is achieving physiologically-relevant cell densities (100-500 million cells/mL), which is essential for effective tissue repair and regeneration2–4. However, current bioprinting techniques struggle to achieve high cell densities seen in native tissues. For instance, extrusion-based bioprinting (EBB) supports higher densities but often compromises cell viability due to shear stress5. Inkjet bioprinting is constrained by low-viscosity bioinks that limit the cell concentration6. Laser-assisted bioprinting is slow, yields lower cell viability compared to other methods and better suited to small-scale constructs, limiting its use for larger tissues7. Light-based bioprinting usually requires lower cell densities for effective curing of photo-crosslinkable bioinks8, while microvalve bioprinting is limited to bioinks within a narrow range of viscosities and cell concentrations, which increases the risk of clogging9. These limitations hamper the success in development of functional tissues as the resulting bioprinted constructs lack sufficient cell densities. Indeed, most hydrogel bioinks require a compromise between cell density and polymer density to achieve printability, often resulting in suboptimal conditions for the intended application.

In response to these challenges, tissue spheroids are considered a promising candidate. Spheroids are cellular aggregates that have been utilized in tissue fabrication due to their advantages, including native-like cell density and the capability to secrete substantial levels of extracellular matrix (ECM) components with effective communication among cells in a 3D native-like microenvironment10. Due to these advantages, spheroids have been considered as building blocks for bioprinting a variety of tissues10. Spheroid density and spatial arrangement are critical factors in achieving native-like tissue physiology, as they ensure the precise arrangement and high cell concentration necessary for effective tissue formation11. Several bioprinting techniques, each with specific advantages, have been explored for spheroid-based approaches; however, certain challenges limit their applications. For example, EBB offers high throughput by randomly mixing spheroids within a bioink and extruding them into various architectures, but this exposes cells to substantial shear stress and lacks control over the precise number and placement of spheroids5. The Kenzan method, which uses needle arrays for spheroid placement, faces limitations due to its low throughput as it assembles spheroids one at a time, often causing damage, and the fixed needle arrangement restricts its versatility12. Similarly, droplet-based bioprinting (DBB) is constrained by droplet formation, bioink viscosity, and limited precision, making it less suitable for applications requiring high spatial resolution or scalability13. Other spheroid assembly strategies, such as magnetic and acoustic methods, offer innovative approaches but come with challenges14. For example, while the magnetic technique enables spatial patterning of organoids, it requires the use of biocompatible magnetic particles, which may not be consistent across different cell types. Additionally, this method is low-throughput, as it typically manipulates one spheroid at a time, requires specialized molds, and may impact spheroid shape fidelity and viability due to magnetic forces15. On the other hand, the acoustic technique offers non-invasive, high-throughput spheroid patterning. However, it relies on acoustic nodes, which limits the ability to create fully compact cellular structures and restricts interactions between spheroids. It limits the flexibility needed for achieving desired spatial arrangements in complex geometries16. Previously, a high-precision technique, known as aspiration-assisted bioprinting (AAB)17 was introduced, where, an aspiration force is applied to position a biologic (e.g., cells, tissue spheroids or strands) during the bioprinting process. This technique enables picking and placement of biologics ranging from 80 to 800 μm in size into or onto a gel substrate with minimal cellular damage ( > 90% cell viability) and achieving high positional precision ( ~ 11% with respect to spheroid size). AAB has recently inspired applicability in magnetic lifting of neural organoids for the construction of assembloids15, 3D printing of living moving organisms (i.e., beetles18) and bioprinting of high cell-density tissues (i.e., cartilage19 and bone20) and disease models (post-myocardial infarction scarring)3. However, the major limitation of this technique is its reliance on bioprinting one spheroid at a time. While this one-at-a-time approach allows for multiple iterations in the deposition of spheroids to scale up, it significantly prolongs the bioprinting process ( ~ 20 sec/spheroid), similar to other spheroid bioprinting techniques21, which poses major challenges to increasing the scalability of fabricated tissues consistently and efficiently.

In this work, we address a long-standing problem in 3D bioprinting of spheroids and demonstrate a technology named, HITS-Bio (High-throughput Integrated Tissue fabrication System for Bioprinting). HITS-Bio represents a significant advancement in rapid bioprinting of spheroids for scalable tissue fabrication. This technique enabled the bioprinting of scalable tissues via precise positioning of spheroids (and also applicable to organoids) in a high-throughput manner at an unprecedented speed (an order of magnitude faster than the existing techniques) with high cell viability ( > 90%) using a digitally controlled nozzle array (DCNA) for the patterning and spatial distribution of several spheroids simultaneously. The capacity of the DCNA platform to pattern several spheroids at a time enabled the rapid creation of tissues, thus increasing the fabrication rate by a factor of n (the number of nozzles in DCNA) proportionally to the number of nozzles used. Herein, we presented bioinks to support spheroids during bioprinting, analogous to assembling building blocks where the bioink acts as cement and spheroids serve as bricks. To demonstrate the practical application of this technology, we first focused on calvarial bone regeneration, where critical size defects were repaired through intraoperative bioprinting (IOB) of osteogenically-committed bone spheroids. The study introduced IOB with spheroids, enabling on-demand tissue fabrication and reducing surgery time. It used combinatorial micro-RNA (miR) technology to achieve osteogenic differentiation of spheroids, and HITS-Bio enabled simultaneous or sequential aspiration and bioprinting of miR-transfected spheroids on demand. Moreover, the potential of HITS-Bio in the context of scalable tissue fabrication was exemplified through the successful creation of cm3 cartilage tissue constructs, which were precisely assembled using ~600 chondrogenically committed spheroids under 40 min per construct, representing a scale of fabrication with a high efficiency that surpasses the capabilities of current bioprinting technologies.

Results

Working mechanism and characterization of the HITS-Bio process

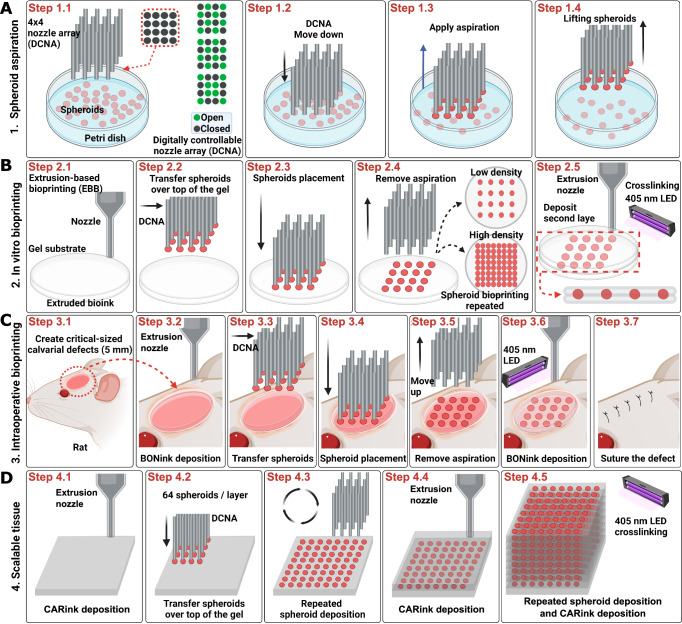

The HITS-Bio platform featured a facile assembly inside a biosafety hood due to its compact footprint, designed as a table-top system equipped with various accessories such as cameras for detailed observation and analysis. The platform had three main components: a multinozzle DCNA (Supplementary Fig. 1), a high-precision XYZ linear stage to move DCNA in 3 axes (X, Y, and Z), and an extrusion head to deposit a gel substrate (Supplementary Fig. 2). It was operated by a custom-made software interface with a control algorithm (Supplementary Movie 1, Supplementary Figs. 3 and 4). To visualize the bioprinting process in real-time and verify the actual position of DNCA in 3D, three microscopic cameras for the isometric, bottom, and side views were integrated (Supplementary Fig. 2). DCNA facilitated picking up multiple spheroids by controlling the aspiration pressure in the selectively opened nozzle depending on the design of applications, as demonstrated in Fig. 1A and Supplementary Fig. 5. To lift spheroids, DCNA was moved to a Petri dish, where spheroids were suspended in a culture medium. The spheroid transfer process was specifically designed to function within the culture medium, eliminating the need for a viscous fluid support bath. This approach simplifies handling and avoids the challenges associated with increased shear and compression forces, ensuring the integrity of spheroids during transfer. After spheroids were successfully aspirated to the end of the selectively opened DCNA, confirmed by the bottom view camera, DCNA with spheroids was gently lifted from the spheroid chamber (Fig. 1A, Step 1.4). As a substrate to place the spheroids, a bioink was extruded (Fig. 1B, Step 2.1). Next, DCNA loaded with spheroids was transferred over the substrate (Fig. 1B, Steps 2.2 and 2.3). Once the spheroids were in contact with the substrate, aspiration pressure was cut off to deposit the spheroids (Fig. 1B, Step 2.4). We exemplified the utility of HITS-Bio in three different configurations. For in-vitro bioprinting of single-layer-spheroids, low density (composed of 16 spheroids) and high density (composed of 64 spheroids) were bioprinted by repeating the process as depicted in Fig. 1A, B (Steps 1.1-1.4 and Steps 2.2-2.4). After the spheroid placement, another layer of the bioink was deposited on top of the bioprinted spheroids to envelop them, followed by photo-crosslinking using a 405 nm light-emitting diode (LED) light source for 1 min (Fig. 1B, Step 2.5). For IOB (Fig. 1C), critical-sized calvarial defects (Step 3.1) were created. Firstly, the bone ink (BONink) was extruded at the defect area (Step 3.2) and DCNA loaded with spheroids was positioned over a defect (Step 3.3). The spheroids were deposited at two different spheroid densities (low − 16 spheroids and high − 64 spheroids) using DCNA (Step 3.4–3.5). Then, another layer of the BONink was extruded over the spheroids (Fig. 1C, Step 3.6), followed by photo-crosslinking and suturing of the skin (Step 3.7). For scalable tissue bioprinting (Fig. 1D), scalable cartilage tissues (SCTs) were created, using a cartilage ink (CARink). Firstly, the CARink was extruded (Step 4.1), followed by the precise placement of 64 chondrogenic spheroids (Steps 4.2–4.3). This iterative process (Steps 4.2–4.4) was repeated nine times to assemble a construct comprising nine stacked layers and a total of 576 spheroids, followed by photo-crosslinking (Step 4.5).

Fig. 1. Schematic of the HITS-Bio process.

A Spheroid loading with DCNA, which selectively enabled or disabled aspiration according to a user-defined design in an iterative manner. B In vitro bioprinting of spheroids including extruded bioink via EBB and spheroid placement using DCNA, having different spheroid loading densities (i.e., low density – 16 spheroids and high density – 64 spheroids) in an iterative manner. C IOB of spheroids into a rat calvarial defect, where spheroids were sandwiched between the extruded BONink layers. D A 1 cm3 of scalable cartilage tissue bioprinted with CARink and ~600 spheroids. Created in BioRender. Ozbolat, I. (2024) BioRender.com/a30b873.

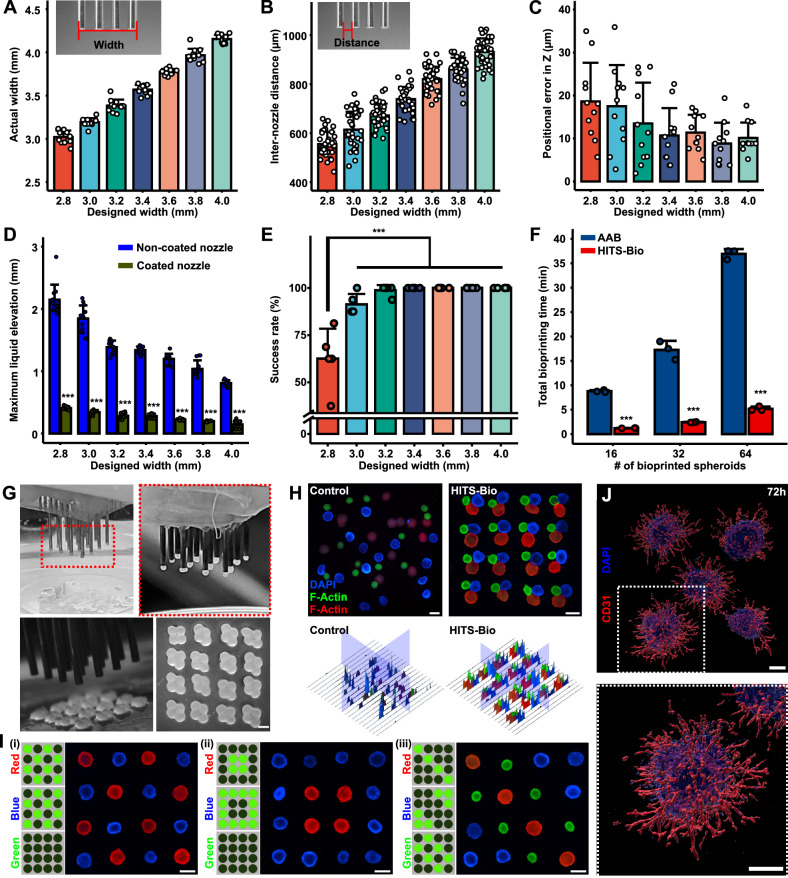

DCNA consisted of stainless-steel needles with predefined spaces between them, which were assembled by precisely stacked multiple acrylic plates (Supplementary Fig. 1). A micro-manufactured 4 × 4 nozzle array with different configurations (various designs with widths from 2.8 to 4.0 mm) was prepared as shown in Supplementary Fig. 6A. To calculate the inaccuracies during micro-manufacturing of DCNA, bottom (Supplementary Fig. 6B) and side (Supplementary Fig. 6C) views of DCNA were captured. These views allowed the measurement of inter-nozzle distance and accuracy of each nozzle against a reference point. The range of widths was determined based on the area, where spheroids could be bioprinted in a circular area with a diameter of 5 mm. As shown in Fig. 2A, B, the actual width and inter-nozzle distance of DCNA were measured and compared with the designed width and inter-nozzle distance, respectively. Considering the error expected during laser cutting, DCNA was micro-manufactured with less than 5% error. The positional errors in XY (Supplementary Fig. 6E) and Z (Fig. 2C) were less than 5% for 300 µm spheroids tested in this study. We observed that lifting spheroids from the culture medium into air resulted in entrapment of liquid (culture medium) between nozzles and its elevation from its surface acted upon by capillary forces due to its surface tension between the liquid and DCNA (Supplementary Fig. 6F, Supplementary Movie 2). The elevated liquid hindered successful spheroid lifting and placement. For example, comparing two different sizes of DCNA (2.8 v.s. 3.4 mm), higher liquid elevation was observed in the closely packed 2.8-mm DCNA, where spheroids experienced resistance in their lifting due to the elevated liquid. In contrast, the 3.4-mm DCNA showed a much lower height of liquid elevation, which resulted in successful spheroid lifting (Supplementary Movie 3). Thus, optimizing parameters, such as the inter-nozzle distance and liquid elevation, was crucial in relation to the likelihood of successful spheroid lifting.

Fig. 2. Analysis of HITS-Bio performance.

Measurement of (A) end-to-end nozzle array width (n = 12 independently prepared DCNA), (B) inter-nozzle distance (n = 36, each data point represents three inter-nozzle distances of 12 independently prepared DCNA), and (C) positional error in the Z-axis (n = 11 independently prepared DCNA). D Maximum liquid elevation in DCNA (n = 12, unpaired two-sided Student’s t-test, p = 1.43 × 10−17, 1.76 × 10−17, 1.83 × 10−20, 1.17 × 10−24, 6.01 × 10−22, 4.96 × 10−16, 3.28 × 10−19 from left to right). E The impact of interstitial distances of the silicon-coated DCNA on the success rate of spheroid lifting (n = 5 independent experiments, one-way ANOVA). F A comparison of elapsed bioprinting time between conventional single-nozzle aspiration-assisted bioprinting (AAB) and HITS-Bio (n = 3 independent experiments, unpaired two-sided Student’s t-test, p = 5.03 × 10−7, 0.00016, 9.30 × 10−7 from left to right). G Lifted spheroids from a spheroid chamber and placed on a GM10 substrate in an iterative manner to bioprint 64 spheroids to generate a rhombus pattern. Scale bar: 300 μm. H Fluorescence images and the corresponding intensity map of three different sizes and colors (stained with DAPI (blue), F-Actin (red), F-Actin (green)) of spheroids (16 spheroids per color) using manually mixed (control) and HITS-Bio. Scale bar: 500 μm. I Selectively patterned spheroids stained with DAPI (blue), F-Actin (red), and F-Actin (green) using the DCNA platform with various configurations. Scale bar: 500 μm. Representative images were obtained from at least five independent repetitions. J Fluorescent staining of iPSC-derived vascular organoids at 72 h after bioprinting into collagen type I-Matrigel mixture for CD31 (red) and DAPI (blue) (scale bar: 200 μm). Representative images were obtained from three independent repetitions. Data are presented as mean ± SD where *p < 0.05, **p < 0.01, and ***p < 0.001. Source data are provided as a Source Data file.

During lifting, a capillary reaction was observed between nozzles, where liquid rose in a narrow gap against gravity (Supplementary Fig. 6F). At equilibrium, the upward force due to surface tension balances the downward force of the liquid weight. The liquid continues to rise until these forces are equal. As detailed in Supplementary Note 1, this relationship can be expressed mathematically, displaying that the height of the elevated liquid is inversely proportional to the inter-nozzle distance and surface tension. To reduce the height of the elevated liquid, one can either increase the inter-nozzle distance or decrease the surface tension. Subsequently, various inter-nozzle distances of DCNA were explored, showing correlation between the quantified elevated liquid length with different sizes of DCNA. Subsequently, silicon coating was applied to DCNA to lower the surface tension by reducing the surface energy. The results indicated that the liquid elevation was significantly decreased after the silicon coating on the DCNA surface (Fig. 2D). In addition, the silicon-coated DCNA was lifted smoothly from the liquid, as opposed to the non-coated DCNA, which tended to drag the liquid (Supplementary Movie 2). Furthermore, as the inter-nozzle distance decreased, the liquid elevation increased. Thus, the success rate of spheroid lifting decreased with reduced designed width due to the liquid elevation (Fig. 2E). In other words, the silicon-coated DCNA with a 3.4-mm designed width showed complete success of spheroid lifting (Fig. 2E and Supplementary Movie 3) and was selected for further consideration in the HITS-Bio process.

To test the performance of HITS-Bio with the optimized DCNA, we benchmarked it against a single nozzle AAB system (Fig. 2F). The results indicated that HITS-Bio was highly efficient when a large number of spheroids were needed to be bioprinted. Using DCNA with 16 nozzles (Fig. 2G), the bioprinting process for 16 spheroids took less than 1 min, which was significantly faster than the conventional AAB system, which took nearly an order of magnitude longer (Fig. 2F) despite the AAB system being upgraded for its bioprinting speed (with full automation) compared to previous publications17,19. As the number of bioprinted spheroids increased, the disparity in total bioprinting time between AAB and HITS-Bio increased exponentially (Fig. 2F and Supplementary Movie 4). To evaluate the performance of HITS-Bio for the patterning of spheroids, various types of spheroids were selectively lifted and patterned on a gelatin methacryloyl (GM) substrate. For example, we compared HITS-Bio with manual loading of spheroids (Fig. 2H). In this regard, a total of 48 spheroids (16 green (~350 μm in diameter), 16 blue (~425 μm in diameter) and 16 red (~500 μm in diameter)) per sample were utilized (Supplementary Fig. 7C). To prepare the control group, spheroids were mixed in 10% GM using a pipette in a 3D-printed mold (Supplementary Fig. 7A, B). For HITS-Bio, spheroids were bioprinted into the GM substrate in a triplet arrangement, where triplets were patterned with precise control on their positioning while the manually-loaded spheroids resulted in random distribution with a lack of control, not just in X- and Y-axis but also Z-axis as most of the spheroids were not in the focal plane (Fig. 2H). HITS-Bio showed 100% spheroid loading efficiency, meaning all spheroids were bioprinted and loaded into GM successfully regardless of their size. In contrast, 80-85% efficiency was attained in the case of manual loading (Supplementary Fig. 7D). The reduced efficiency in manual loading was due to the fact that spheroids were sticking to the wall of the pipette tip during manual deposition (Supplementary Fig. 7B). This was further validated by Hematoxylin and Eosin (H&E) images of the manually loaded group, which revealed uneven spheroid distribution and the presence of air bubbles within the constructs, likely caused by the mixing of spheroids into the viscous bioink (Supplementary Fig. 8). One would expect that the efficiency would further decrease as the number of spheroids increased. Therefore, using HITS-Bio, the number and type of spheroids could be controlled to precisely position them with 100% loading efficiency. To further confirm the spatial placement of spheroids using HITS-Bio, the three types of spheroids were patterned in various configurations (Fig. 2I). Herein, based on the desired location of spheroids, the corresponding valves in DCNA were digitally activated and switched on, and the spheroids were loaded on the nozzles selectively as shown in Supplementary Movie 5. The spheroids were released in the designated positions on demand. Therefore, HITS-Bio facilitated the successful patterning of different types of spheroids at desired positions regardless of their size without loss of spheroids.

To test the broader applicability of HITS-Bio to soft and fragile spheroids and organoids, a wide range of samples made of different cell types were screened. Our findings indicate that spheroids with an elastic modulus greater than ~50 Pa were printable while those below 40 Pa were not (Supplementary Fig. 9). The transfected osteogenic and chondrogenic spheroids had an elastic modulus of 978 ± 96 Pa and 641 ± 110 Pa, respectively. Along with various spheroids, elastic modulus of induced pluripotent stem cell (iPSC)-derived vascular organoids was also tested, which was measured to be 133 ± 20 Pa and fell within the range of printable elastic moduli. The maximum elastic modulus limit for printability was not assessed, as it was beyond the scope of this study. Additionally, it is important to highlight that the method used in this study measured the aspirated length under a fixed aspiration force. While there are specialized instrumentation22,designed for precise stiffness measurements of spheroid based on force-displacement curves, we opted for the aspirated length-based stiffness measurement due to its direct relevance for our specific application involving aspiration forces.

Moreover, the system’s ability to precisely deposit spheroids in tightly packed, fully cellular architectures in order to better replicate tissue-specific structures was demonstrated. Human dermal fibroblast (HDF) spheroids (530 µm) were arranged in rows via bioprinting them onto a pre-crosslinked GelMA (10%) substrate, with gaps filled by smaller spheroids of HDF with human umbilical vein endothelial cells (HUVEC), HDF/HUVEC (300 µm) (Supplementary Fig. 10A). These spheroids fused to form a continuous, densely packed structure, highlighting the potential for creating vascularized tissues, as tdTomato+ HUVECs successfully migrated and formed pre-vascularized-like structures within fused spheroids. This was further supported by Von Willebrand Factor (VWF) and fibronectin (FN) staining (Supplementary Fig. 10B), where VWF staining was used to identify and confirm the presence of endothelial cells and the formation of pre-vascularized-like structures. The integration of HDF and HDF/HUVEC spheroids into a fully cellular architecture was clearly visible at the interface, supporting HITS-Bio’s capability to generate complex tissue constructs. Furthermore, examples were demonstrated for optimization of area-filling models with spheroids of varying sizes to maximize the filled area fraction on the GelMA substrate. As shown in Supplementary Fig. 11, area filling of 37.03% was achieved using large spheroids (~735 µm in diameter), which increased to 63.71% when large and small spheroids (~300 µm) were mixed. This further improved to 86.91% using small spheroids alone and ultimately reached 98.11% by combining two different sizes (~530 µm and ~300µm). These tailored patterns were designed to optimize cellular density while strategically integrating filler hydrogel substrate, utilizing various nozzle configurations to precisely balance cellular content and filler hydrogel distribution, which can be further expanded to 3D volume-filling models.

To demonstrate the further applicability of HITS-Bio, abovementioned iPSC-derived vascular organoids were also bioprinted into a composite hydrogel made of collagen type I (2 mg/mL)-Matrigel (mixed in 4:1 ratio) successfully without any visible structural damage to organoids. These organoids gradually sprouted capillaries after 72 h of culture (Fig. 2J and Supplementary Fig. 12), further validating the suitability of HITS-Bio for bioprinting organoids.

As shown in Supplementary Fig. 13, the capability of HITS-Bio to create complex architectures was also demonstrated by assembling a pyramid construct composed of 171 spheroids, each varying in size and color-tagged for distinction. Specifically, the bottom layer comprised 121 spheroids (300 µm), followed by a 2nd layer of 36 spheroids (540 µm), a 3rd layer containing 9 spheroids (735 µm) and 4 spheroids (540 µm), and the top layer featuring a single 445 µm-spheroid. This intricate structure was meticulously assembled by precisely controlling different nozzles of DCNA. The ability to accurately position and layer this number of spheroids, with such varied sizes and specific arrangements, is not feasible using conventional EBB or casting/molding techniques. This demonstrates HITS-Bio’s potential not only for constructing intricate, multi-layered structures but also for creating complex tissue architectures that require highly controlled spatial organization and varied cellular compositions.

In vitro development and characterization of bioinks as a substrate for spheroid bioprinting

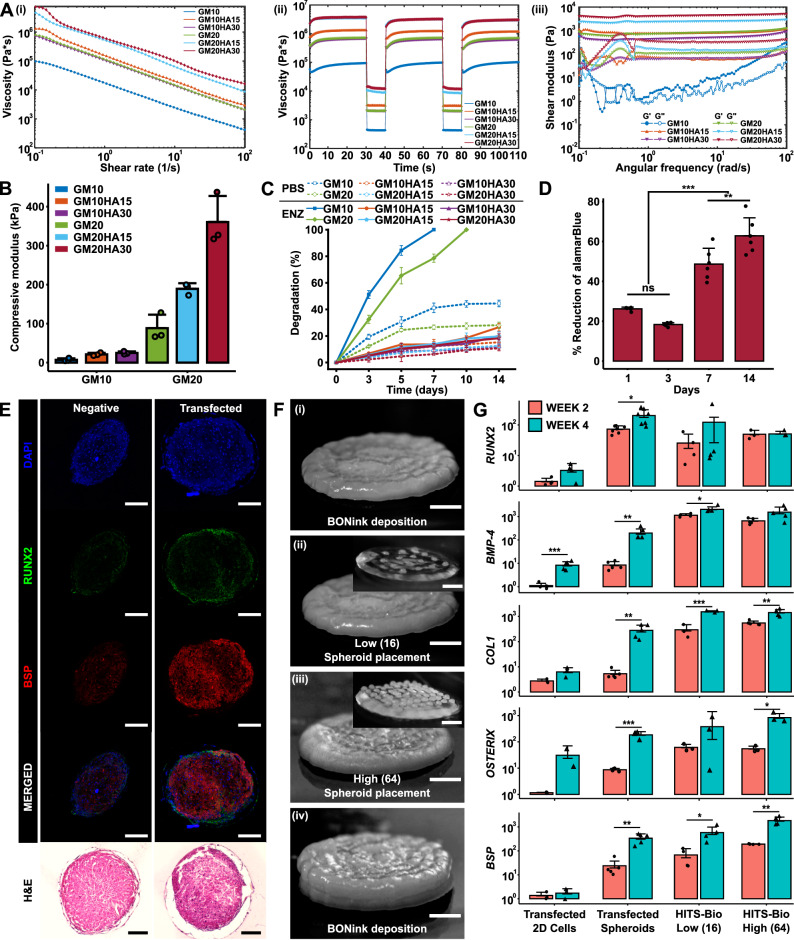

To develop bioinks akin to versatile cement-like substrate capable of assembling spheroids (bricks) into structured building blocks for bioprinting, components were chosen for their compatibility with HITS-Bio in terms of their extrusion, the ability to form a slightly adhesive cement-like substrate to retain spheroids in desired patterns, and to enhance ECM formation. The bioink base was composed of GM for its biocompatibility and tunable mechanical properties, nanohydroxyapatite (HA) to enhance osteoconductivity, and β-glycerophosphate disodium salt hydrate (β-GP) for thermal gelation. Hyaluronic acid sodium salt (HyA) was added to improve cell adhesion and proliferation, fibrinogen (Fib) for its role in promoting cell-matrix interactions, and lithium phenyl (2,4,6-trimethylbenzoyl) phosphinate (LAP) as a photoinitiator to enable light-induced crosslinking, ensuring structural integrity and stability of the bioink. These components were mixed in various ratios to obtain composite bioinks, where the bone ink (Supplementary Fig. 14A) was formulated with the same components as the cartilage ink (Supplementary Fig. 14B), but with the addition of β-GP and HA. GM at a concentration of 10% was denoted as GM10, and at 20% it was labeled GM20. Similarly, HA at 15% concentration was designated as HA15, and at 30%, it was labeled HA30. To assess the bioinks, their rheological properties, mechanical behavior, and degradation profile were evaluated. Rheological analysis was performed to test the flow characteristics of the bioinks. The viscosity profile, determined through a flow sweep across varying shear rates from 0.1 to 100 s−1, revealed a shear thinning behavior in all bioink formulations, making them suitable for extrusion (Figure 3Ai). Bioinks with higher concentrations of GM (GM20) and HA (HA30) exhibited higher viscosities compared to GM10 and HA15 formulations, respectively. The recovery sweep test (Figure 3Aii) showed that the viscosity of all samples recovered rapidly, suggesting that the bioinks exhibited a self-healing property. The viscosity profile of the bioinks during the recovery followed the same trend as that of the flow sweep. Further, the frequency sweep showed that storage modulus (G′) was higher than loss modulus (G″) in the frequency range of 0.1–100 rad/s (Figure 3Aiii). G′ and G″ were independent of frequency for the GM-alone samples, while they were slightly dependent for the composite bioinks. The compression testing of bioinks exhibited a non-linear stress-strain curve. Among the GM20 samples, GM20HA30 exhibited the highest compressive modulus at 360.7 ± 66.6 kPa, followed by GM20HA15 at 189.2 ± 14.4 kPa, and GM20 at 88.3 ± 34.7 kPa. Conversely, GM10 samples displayed lower compressive moduli, with values of 24.7 ± 3.7 kPa, 21.2 ± 4.2 kPa, and 7.2 ± 3.8 kPa for GM10HA30, GM10HA15, and GM10, respectively (Fig. 3B). Although GM20 samples exhibited a higher compressive modulus, they demonstrated a lower fracture strain ranging from 40-45%, whereas the GM10 samples fractured at a higher strain of 65-70% (Supplementary Fig. 14C).

Fig. 3. In vitro characterization of bioinks.

A Rheological characterization of BONink and CARink at different concentrations of HA and GM (n = 3 independent rheological characterizations, data are presented as mean): (i) Flow curves of bioinks from the rotational test at a shear rate ranging from 0.1 to 100 s-1 showing mean plots. (ii) Recovery behavior and viscosity measurements at five intervals at alternating shear rates (shear rate of 0.1 s-1 for 30 s and 100 s-1 for 10 s) showing mean plots. (iii) Measured shear modulus from frequency sweeps at an angular frequency ranging from 0.1 to 100 rad s-1. B Compressive modulus (n = 3 independent samples), (C) % degradation of samples for 14 days in enzyme (ENZ) and PBS (n = 3 independent samples), and (D) % reduction of alamarBlue to assess cell viability with GM20HA30 for 14 days (n = 6 biologically independent samples, one-way ANOVA, Day 1 vs. Day 3 p = 0.140902, Day 7 vs. Day 14 p = 0.003054, all other shown comparisons p < 0.0001). E Histomorphometric characterization of non-transfected and miR-(196a-5p + 21) co-transfected spheroids stained for RUNX2, BSP, and H&E at Week 4 (scale bar: 100 µm). F Steps involved during the bioprinting process for in vitro fabrication of bone constructs at two different spheroid densities: (i) BONink deposition, (ii) bioprinted spheroids at low (16 spheroids) and (iii) high density (64 spheroids), and (iv) overlaying bioprinted spheroids with another layer of BONink. Scale bar: 1 mm. Inset images demonstrate bioprinted spheroids with low and high densities on a transparent gel (CARink) for clear visualization. Scale bar: 1 mm. G Quantification of RUNX2 (n = 4, 7, 4, 3 biologically independent samples (from left to right), unpaired two-sided Student’s t-test, p = 0.06978, 0.01004, 0.42355, 0.92376 from left to right), BMP-4 (n = 5, 5, 4, 5 biologically independent samples (from left to right), unpaired two-sided Student’s t-test, p = 0.00092, 0.00505, 0.03519, 0.06384 from left to right), COL1 (n = 3, 5, 3, 5 biologically independent samples (from left to right), unpaired two-sided Student’s t-test, p = 0.08064, 0.00395, 0.00069, 0.00178 from left to right), OSTERIX (n = 2, 4, 3, 3 biologically independent samples (from left to right), unpaired two-sided Student’s t-test, p = 0.27645, 0.00041, 0.26759, 0.02095 from left to right), and BSP (n = 3, 5, 4, 4 biologically independent samples (from left to right), unpaired two-sided Student’s t-test, p = 0.54175, 0.00147, 0.04690, 0.00367 from left to right) gene expression of bioprinted bone. Unless otherwise noted, data are presented mean ± SD where *p < 0.05, **p < 0.01, ***p < 0.001, and ns not significant. Source data are provided as a Source Data file.

The degradation test results indicated a decrease in enzymatic degradation rate for GM samples upon HA incorporation, with complete degradation occurring in ~7 days for 10% GM and 10 days for 20% GM (Fig. 3C). The HA-based composites demonstrated limited degradation, with only ~18% for GM20HA30 and ~20% for GM20HA15 over 14 days. Similarly, in GM10 samples, degradation amounted to ~20% for GM10HA30 and ~27% for GM10HA15. Conversely, composite bioinks in phosphate-buffered saline (PBS) only underwent 12–15% degradation, while only GM samples in the same medium showed higher degradation levels of 30-40%. After characterizing bioinks for their rheological, mechanical, and degradation properties, the GM20 and GM20HA30 composite were selected and named CARink (cartilage ink) and BONink (bone ink), respectively, for further investigations. GM10 and its composites exhibited poor printability and mechanical properties, whereas GM20HA15 demonstrated inadequate mechanical strength.

After developing the BONink, the metabolic activity of human adipose-derived stem cells (hADSCs) in the BONink was assessed over time, which revealed significantly higher proliferation observed on Day 14 compared to Day 7 (p ≤ 0.01), and lower levels on Days 1 and 3 (p ≤ 0.001) (Fig. 3D). These results demonstrate the biocompatibility of the BONink, affirming its suitability for bone tissue engineering applications. Osteogenically-committed spheroids were then formed using miR-transfected hADSCs as shown in Supplementary Fig. 15A. Specifically, hADSCs were transfected with miR-196a-5p, or miR-21, or in combination (miR-(196a-5p + 21)). The effect of transfection was evaluated via gene expression (Supplementary Fig. 15B) and histomorphometric characterization (IHC and H&E) (Fig. 3E and Supplementary Fig. 16) of osteogenic markers at Weeks 2 and 4. In our preliminary experiments, transfection was assessed in 2D conditions, where hADSCs with and without the miR-transfection were evaluated, and the differentiation in established osteogenic medium was taken as positive control. The results of preliminary tests showed upregulated osteogenic genes (RUNX2, BMP-4, COL-1, OSTERIX, and BSP) when hADSCs were co-transfected with miR-(196a-5p + 21) compared to miR-196a-5p alone and non-transfected hADSCs (negative control) (Supplementary Fig. 15B). The expressions were significantly higher (p ≤ 0.05) at Week 4 as compared to Week 2 and comparable to the positive control. Additionally, IHC assessment of RUNX2 and BSP markers showed intense staining in the miR-(196a-5p + 21) transfected hADSCs, which was comparable to the positive control and higher than the miR-196a-5p alone and non-transfected hADSCs (Fig. 3E and Supplementary Fig. 16). These results were in agreement with real-time polymerase chain reaction (qPCR) results. Further, H&E staining showed a strong dark purple color indicating bone mineralization in the positive group (Supplementary Fig. 16). The transfected group also showed darker color compared to the negative control and miR-196a-5p alone transfected hADSCs. Overall, miR-transfection supported the differentiation of hADSCs into an osteogenic lineage. Based on these results, for the rest of this study, the co-transfection of miR-(196a-5p + 21) was used for osteogenic differentiation of hADSCs for use in spheroids as building blocks for bone tissue fabrication.

Fig. 3F demonstrates the steps for the fabrication of single-spheroid-layer bone constructs with two different densities (16 or 64) of spheroids. Spheroids (350 µm) were placed with a targeted inter-spheroid distance of 670 and 160 µm for the low density (16) and high density (64) spheroids, respectively. The BONink was first extruded in a spiral pattern with 100% infill to lay down a gel substrate with a diameter of ~ 5 mm prior to spheroid placement (Figure 3Fi). On the BONink, spheroids were bioprinted at low (Figure 3Fii) and high (Figure 3Fiii) densities. After the spheroid placement, another layer of BONink was extruded to overlay spheroids (Figure 3Fiv). It is pertinent to note that the BONink deposition did not displace the previously placed spheroids considerably (Supplementary Movies 6 and 7). The final constructs were photo-crosslinked with a 405 nm light source for 1 min and incubated thereafter. qPCR results indicated increased expression of osteogenic markers in the transfected non-bioprinted and bioprinted (low or high density) spheroids (Fig. 3G). There was a significant increase across all groups at Week 4 compared to Week 2. As shown in Supplementary Table 1, the results revealed that RUNX2, an early osteogenic marker, increased up to 4.8-fold, with the highest levels observed in the low-density group. Similarly, BMP-4, another early marker, showed a maximum increase of 23.3-fold in transfected spheroids. COL1, involved in both early and late stages of osteogenic differentiation, increased by up to 52.1-fold in transfected spheroids. OSTERIX, an intermediate to late-stage marker, increased up to 15.4-fold in the high-density spheroids group. Finally, BSP, a late-stage marker crucial for bone strength, increased by 14.1-fold in the transfected spheroids at Week 4 compared to Week 2. These results indicate that the bioprinted constructs, particularly those with lower spheroid density, show increased early osteogenic activity (RUNX2 and BMP-4). In contrast, high-density spheroids and transfected spheroids exhibit significant increases in both intermediate (OSTERIX) and late-stage (BSP) markers, suggesting more mature osteoblast activity and active-matrix mineralization. Furthermore, the gene expression results were corroborated by the IHC staining, where RUNX2 and OSTERIX markers exhibited expression profiles consistent with their roles in osteoblast differentiation (Supplementary Fig. 17). RUNX2 displayed a distinct increase in staining in the low-density group at Week 4 while the high-density group maintained its initial high intensity. On the other hand, OSTERIX showed intense staining in bioprinted constructs particularly in the high-density group, indicating successful active osteoblast differentiation. The IHC staining patterns aligned well with the observed fold-changes in gene expression, reinforcing the dynamic nature of osteogenic differentiation and the sequential involvement of related genes.

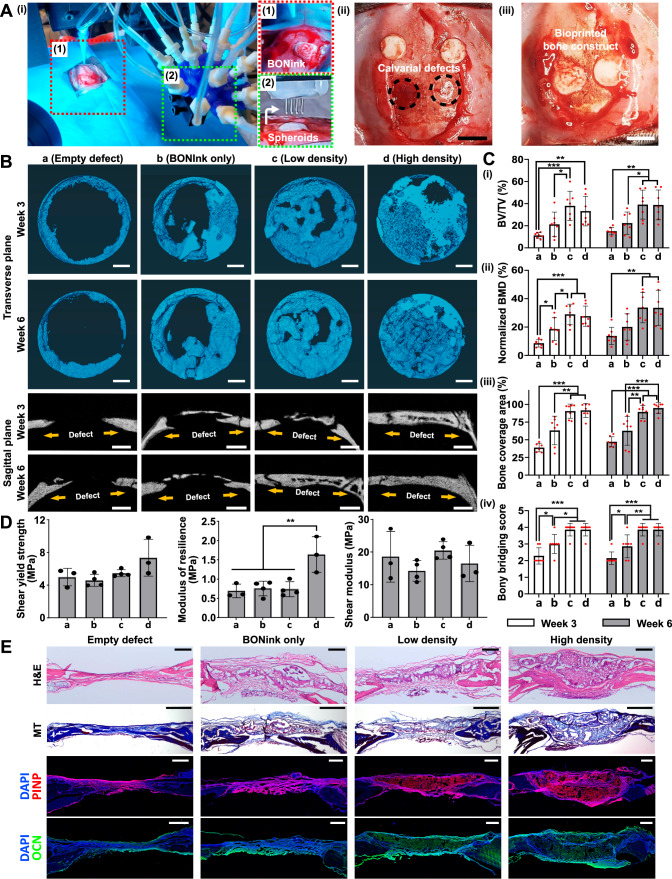

Intraoperative bioprinting for bone regeneration in calvarial defects

Following the in vitro assessment of physical properties, printability, cytocompatibility, and osteogenic potential of the BONink, we performed animal studies using a rat model. Minimizing the animal numbers, two critical-sized calvaria defects, each 5 mm in diameter, were created on either side of the parietal bone on the rat skull and IOB was performed under aseptic surgical settings (Fig. 4A and Supplementary Fig. 2A). Akin to in vitro settings, the BONink was extruded at the defect site in a spiral pattern with 100% infill (Supplementary Movie 8). Four groups were considered including (i) empty defect (control), (ii) BONInk only, (iii) low density (16 spheroids), and (iv) high density (64 spheroids). Post IOB, bone regeneration was evaluated at 3 and 6 weeks. Micro-computed tomography (µCT) results (Fig. 4B) revealed that the high-density group consisting of 64 spheroids exhibited superior bone regeneration, closing almost the entire defect in Week 6. In contrast, bone regeneration in the empty control group was mainly confined to the periphery of the defects. As a quantitative metric to assess the efficacy and extent of bone tissue formation, bone volume to total volume (BV/TV) was calculated, which revealed significantly higher bone regeneration of ~38 and 33% in Week 3, and ~39 and 39% in Week 6 for low- and high-density group, respectively, compared to the BONink-only (p ≤ 0.05) and empty group (p ≤ 0.01) (Fig. 4Ci). Moreover, the normalized bone mineral density (BMD), reflecting the density of regenerated bone normalized to the native bone density, exhibited ~29 and 28% at Week 3, and ~34 and 34% at Week 6 for low and high-density groups, respectively, compared to the BONink-only (p ≤ 0.05) and empty group (p ≤ 0.01) (Figure 4Cii). Additionally, the bone coverage area (%) for the low-density and high-density groups was ~90 and 91% at Week 3, and ~88 and 96% at Week 6, respectively (Figure 4Ciii). Moreover, the maximum intensity projections generated from µCT data (Fig. 4B) of each group were used for the scoring (1–4) of bony bridging across the defect. The results showed significantly higher scores for spheroid-involved groups compared to empty defect and BONink-only groups at both Weeks 3 and 6 (Figure 4Civ). Furthermore, given the significant role of mechanical properties in bone strength, the regenerated bone samples were subjected to a push-out test following their retrieval after Week 6 (Fig. 4D). The high-density group exhibited a higher shear yield strength, ~1.5 times greater than other groups, indicating enhanced resistance to plastic deformation or failure. Similarly, the modulus of resilience in the high-density group was significantly higher, ~2.4 times greater than the other groups (p ≤ 0.01), signifying higher energy absorption capacity up to the point of yielding. However, there was no significant difference observed among the groups in the shear modulus, representing the material’s resistance to shear deformation.

Fig. 4. IOB of bone constructs into critical-sized rat calvarial defects for bone regeneration.

A HITS-Bio setup under surgical settings. Inset images (1–2) demonstrate deposited BONink and spheroid placement, (ii) created calvarial defects ( ~ 5 mm in a diameter), and (iii) bioprinted bone constructs with BONink and spheroids. Scale bar: 5 mm. B Visualization of newly regenerated bone in calvarial defects with transverse and sagittal planes at Weeks 3 and 6 via µCT, including empty, BONink only, low-density and high-density groups. Scale bar: 1 mm. C Relevant quantification for bone regeneration within the defect examined at Weeks 3 and 6 (n = 7 independent defects, one-way ANOVA, all other shown comparisons p < 0.0001), including (i) BV/TV (new bone volume to total bone volume, %) (Week 3: a vs. b p = 0.35139, a vs. c p = 0.00074, a vs. d p = 0.00545, b vs. c p = 0.04183, b vs. d p = 0.20350, c vs. d p = 0.85065, Week 6: a vs. b p = 0.60072, a vs. c p = 0.00186, a vs. d p = 0.00212, b vs. c p = 0.03614, b vs. d p = 0.04048, c vs. d p = 0.99995), (ii) normalized BMD (bone mineral density, %) (Week 3: a vs. b p = 0.045, b vs. c p = 0.03277, b vs. d p = 0.07177, c vs. d p = 0.98269, Week 6: a vs. b p = 0.63421, a vs. c p = 0.00473, a vs. d p = 0.00528, b vs. c p = 0.07204, b vs. d p = 0.07910, c vs. d p = 0.99996), (iii) bone coverage area (%) (Week 3: a vs. b p = 0.06611, b vs. c p = 0.00656, b vs. d p = 0.00464, c vs. d p = 0.99893, Week 6: a vs. b p = 0.11033, b vs. c p = 0.00259, b vs. d p = 0.00032, c vs. d p = 0.83536) (The outlier was not included in the data plot), and (iv) scores for bony bridging (Week 3: a vs. b p = 0.03791, b vs. c p = 0.01013, b vs. d p = 0.01013, c vs. d p = 1.0, Week 6: a vs. b p = 0.04481, b vs. c p = 0.00326, b vs. d p = 0.00326, c vs. d p = 1.0). D Mechanical properties of the retrieved defect area 6 weeks after the surgery (n = 3, 4, 4, 3 independent defects (from left to right), one-way ANOVA) (Shear yield strength: a vs. b p = 0.97205, a vs. c p = 0.95577, a vs. d p = 0.14142, b vs. c p = 0.74719, b vs. d p = 0.05602, c vs. d p = 0.23294) (Modulus of resilience: a vs. b p = 0.98816, a vs. c p = 0.99588, a vs. d p = 0.00672, b vs. c p = 0.99957, b vs. d p = 0.00692, c vs. d p = 0.00598) (Shear modulus: a vs. b p = 0.65248, a vs. c p = 0.95136, a vs. d p = 0.94709, b vs. c p = 0.31149, b vs. d p = 0.92926, c vs. d p = 0.69672). E Histomorphometric characterization of sectioned defect after decalcification and stained for H&E (scale bar: 500 µm), MT (scale bar: 1 mm), and IHC (P1NP and OCN) (scale bar: 500 µm). Representative images were obtained from at least three independent repetitions. Data are presented as mean ± SD where *p < 0.05, **p < 0.01, and ***p < 0.001. Source data are provided as a Source Data file.

Decalcified sections were then stained with H&E and Masson’s trichrome (MT) to evaluate the morphology of the regenerated bone (Fig. 4E). The H&E images of the high-density group exhibited bridging of the calvarial defect and thicker regenerated bone compared to the soft tissue observed in other groups. MT staining predominantly showed soft tissue formation in the empty defect group, while both spheroid-containing groups showed signs of immature bone formation, which was increased in the high-density group. Thus, histological evaluations of the defects showed that high-density samples illustrated bone formation in 6 weeks, along with active bone healing and mineral deposition. The repair site exhibited characteristics like intramembranous bone formation, aligning with the fact that the development of calvaria is primarily associated with intramembranous ossification23. Procollagen type I N-terminal propeptide (P1NP) and Osteocalcin (OCN), synthesized and secreted by osteoblasts, are well-established markers for bone formation. IHC images revealed that OCN staining intensity was lowest in the empty and BONink-only groups, increased in the low-density group, and was highest in the high-density group (Fig. 4E). Notably, both native and newly formed bone tissues were stained with OCN, suggesting that OCN plays a crucial role not only in the formation of new bone but also in the ongoing maintenance of the existing bone matrix24. This could be attributed to OCN binding to HA, which is more prominent in areas of active bone formation. Similarly, P1NP staining followed a comparable pattern, with increased intensity in spheroid-containing groups, particularly in the high-density group, where the intensity was highest. Importantly, P1NP staining was predominantly observed in the newly formed tissue, suggesting its specific involvement in early collagen synthesis during the initial stages of bone formation25. Furthermore, higher expression levels of RUNX2 were observed in the bioprinted groups compared to the empty defect and BONink-only groups. In contrast, OSTERIX was predominantly localized in the host bone rather than the regenerated bone (Supplementary Fig. 18), suggesting that the newly formed bone was in an early developmental stage, consistent with the MT staining results. Overall, the IHC analysis for P1NP, OCN, RUNX2 and OSTERIX, offer a robust assessment of different stages of osteogenesis, from early osteoblast differentiation to collagen synthesis and mineral deposition, ensuring a thorough evaluation of new bone formation and its integration with the native bone.

Fabrication of scalable cartilage tissues (SCTs)

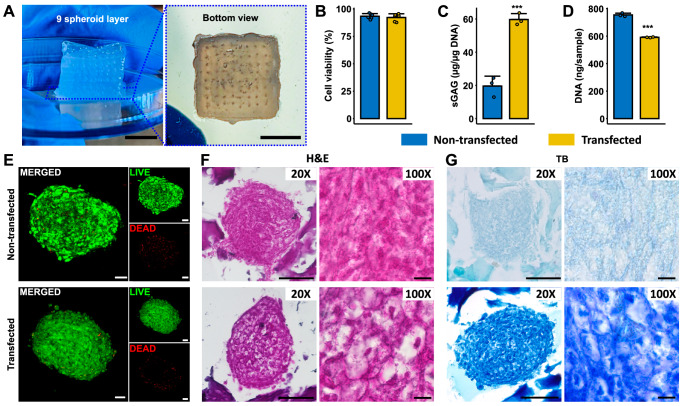

To illustrate the potential of HITS-Bio in generating volumetric tissues, we fabricated a SCTs (as shown in Fig. 1D and Supplementary Movie 9). For this purpose, the CARink (i.e., GM20) was used as a bioink along with miR-(140 + 21) co-transfected chondrogenic spheroids prepared according to Supplementary Fig. 19A, as this combination of miRs has shown promising results for cartilage regeneration in a previous study26. To fabricate the constructs, we extruded a layer of CARink, followed by the precise placement of 64 chondrogenic spheroids. This iterative process was repeated nine times to assemble a construct with a volume of 1 cm3, comprising 9 stacked tissue layers and a total of 576 spheroids taking under 40 min (Fig. 5A). SCTs were then assessed for cell viability and cartilaginous ECM formation. LIVE/DEAD staining revealed that the transfection and tissue fabrication did not impair the cell viability in spheroids, with bioprinted transfected spheroids exhibiting over 90% viability, comparable to non-transfected spheroids (Fig. 5B, E). Further, SCTs with co-transfected spheroids exhibited a significantly higher sulfated glycosaminoglycan (sGAG) content compared to the non-transfected control group (p ≤ 0.001) at Week 2 (Fig. 5C). Interestingly, the DNA content was significantly lower (p ≤ 0.001) in the transfected samples compared to the non-transfected samples (Fig. 5D). At Week 2, the identification and morphology of chondrogenic spheroids within bioprinted constructs were assessed using H&E. The staining showed the presence of spheroids in the CARink bioprinted constructs, with the chondrogenic spheroids exhibiting more intense staining, indicative of a higher density of ECM deposition and displayed a characteristic cobblestone-like morphology in transfected group at Week 2 (Fig. 5F). The compressive modulus of the bioprinted SCTs was found to be 116.8 ± 22.1 kPa (Supplementary Fig. 19C). Additionally, qualitative evaluation of proteoglycans and sGAG was conducted using toluidine blue (TB) staining. In agreement with the quantified sGAG expression (Fig. 5C), images of transfected spheroids stained with TB exhibited intense staining, indicating a higher level of sGAG deposition compared to non-transfected samples (Fig. 5G). From H&E and TB staining, the co-transfected group indicated chondrogenic lacunae-like properties. IHC staining was also performed to identify the expression of chondrogenic markers, ACAN and COLII, in SCTs. The findings revealed stronger fluorescence intensity indicating significantly elevated levels of ACAN (p ≤ 0.01) and COLII (p ≤ 0.001) in SCTs at Week 2, suggesting the formation of new chondrogenic ECM (Supplementary Fig. 19B).

Fig. 5. HITS-Bio for SCT fabrication.

A 1 cm3 of cartilage tissue was bioprinted with 576 spheroids in the CARink. Scale bar: 5 mm. Comparison between non-transfected and co-transfected spheroids cultured in 1 cm3 tissue at Week 2 for (B) cell viability measurements (n = 6 biologically independent samples, unpaired two-sided Student’s t-test, p = 0.51096), C sGAG normalized with DNA content (n = 3 biologically independent samples, unpaired two-sided Student’s t-test, p = 0.00056), and (D) the total DNA content of tissue constructs (n = 3 biologically independent samples, unpaired two-sided Student’s t-test, p = 0.00003). E LIVE/DEAD staining of non-transfected and transfected spheroids at Week 2 in SCT constructs (Scale bar: 50 µm). Histomorphometric characterization of sectioned SCTs stained with (F) H&E with 20X and 100X magnification and (G) TB-stained images captured at 20X and 100X magnification (scale bar: 100 µm (20X) and 10 µm (100X)). Representative images were obtained from at least four independent repetitions. Data are presented as mean ± SD where ***p < 0.001. Source data are provided as a Source Data file.

Discussion

Current bioprinting techniques face critical challenges, such as achieving physiologically-relevant cell densities, enhancing throughput for scalable tissue fabrication, developing bioinks tailored for specific applications, and enabling in situ fabrication capabilities. Towards this, the pursuit of high-throughput bioprinting marks a vital development in achieving rapid and efficient tissue fabrication, driven by automation. These advancements are essential for meeting the increasing demand for complex tissue constructs that replicate native tissue architecture and function. In this study, a High-throughput Integrated Tissue Fabrication System for Bioprinting, termed HITS-Bio, comprising four key components was developed. These include (i) software for customized control, (ii) DCNA facilitating precise and multiple spheroid placement, (iii) compatible bioinks (BONink and CARink) ensuring smooth extrusion and printability, and (iv) miRNA transfected osteogenic and chondrogenic spheroids for de novo tissue fabrication. The platform was assessed for its applicability in in situ osteogenesis of bone tissue and scalability by fabrication of volumetric cartilage tissues. The developed HITS-Bio platform was operated by a custom-made hardware-software interface as shown in Supplementary Fig. 2 and Supplementary Movie 1. The automation control was executed via the LabView Software Control Panel, managing motion stages with high precision ( ~ 1 µm in X, Y, and Z axis). DCNA allowed customization, where selective nozzles could be activated depending on the target design. Initial testing of HITS-Bio was performed using 16 spheroids, which were selectively picked and placed alternately between red and blue dyed spheroids (Fig. 2I). The process was completed under 30 sec, representing a significant speed compared to the existing benchmark in the literature17, which required nearly 30 min. A pressure sensor was used to monitor internal pressure in the platform, but the primary method for spheroid picking relied on a visual confirmation via a camera-based system. This camera-based system provided real-time visual feedback, ensuring precise positioning and adaptability across various spheroid types, regardless of differences in shape, size, or surface texture. While dynamic pressure control could be advantageous in certain situations, such as monitoring pressure changes during spheroid loading, we found the camera-based approach to be more versatile. Additionally, spheroid debris can interfere with pressure-based sensors, leading to false positives during spheroid placement.

The HITS-Bio process was optimized for spheroids within the 300–350 µm range using a 30 G needle, which was proven effective for this size range. It is important to note that the spheroid size must be larger than the inner diameter of the nozzle used. For smaller spheroids, adjustments in nozzle size would be necessary to prevent them from being inadvertently drawn into the nozzles, though this is currently limited by the availability of commercial nozzles with a diameter smaller than 30 G. Larger spheroids may require modifications in nozzle size and spacing to avoid spatial interference and ensure efficient transfer. This can also be managed by selectively controlling (On/Off) adjacent nozzles in DCNA, to accommodate the transfer of larger spheroids. Additionally, while the current 4-mm exposed nozzle length was sufficient for bioprinting onto gel surfaces, extending the exposed nozzle length could optimize the system for embedded bioprinting applications, enabling more complex or deeper spheroid placements. Future iterations of DCNA could benefit from the inclusion of independently height-adjustable nozzles and an increased number of nozzles, enhancing the system’s flexibility and versatility across a broader range of applications.

Spheroids are promising candidates as building blocks for tissue fabrication as they recapitulate the native tissue environment with similar cell density and ECM composition and have the potential to rapidly induce tissue regeneration due to initially-delivered large pre-committed cell numbers17. When spheroids are loaded in gels, they show better cell spreading and proliferation, and tissue-specific differentiation, compared to conventional cell-laden hydrogels27. Until now, spheroid bioprinting techniques enabling the deposition of spheroids onto a gel substrate have been mainly limited to EBB28 and AAB17. EBB with spheroids has been used to overcome the limitation of increasing cell density in an extrudable bioink29,30. However, spheroids are randomly dispersed in the bioink, making their controlled positioning a challenge, resulting in inconsistencies and limitations in loading efficiency in bioprinted constructs, similar to the case shown in Supplementary Figs. 7 and 8. To overcome these limitations, AAB has been utilized for high-precision bioprinting, where various tissue complexes have been fabricated inside functional hydrogels as well as support baths depending on the application19. However, in these strategies, the placement of only one spheroid at a time was feasible, rendering scalable tissue fabrication a challenging task. Alternatively, multiple studies have demonstrated the potential of multi-nozzle bioprinting for rapid tissue fabrication31,32. For example, a study by Hansen et al. used a multi-nozzle array to produce a hierarchically branched, microvascular network and exhibited high-throughput printing of single and multiple extrudable inks over large areas (1 m2). The strategy resulted in a significant reduction in printing time, where a 3D construct that takes a day to print using a single nozzle printhead took only 22 min to print using a system with 64 nozzles33. However, to demonstrate large-scale patterning, the study used wax as an ink to print onto a 1-m2 glass substrate using the 64-nozzle printhead.

In terms of experimental duration, it is pertinent to note that as the complexity increases, particularly with multilayer deposition and non-repeating patterns, the loading process becomes a critical factor influencing the overall efficiency. For physiologically relevant and complex constructs, the experimental duration can vary significantly based on the intricacy of deposition patterns. While the DCNA streamlines simultaneous loading and deposition of multiple spheroids, non-repeating patterns introduce additional challenges. In this context, a total of 50 spheroids were successfully bioprinted in 8 min using two different types and sizes of spheroids (Supplementary Fig. 10). This process involved non-repeating patterns to fill gaps (without a predesigned travel path) for a fully cellular architecture and took ~8 min compared to ~5 min for a repetitive pattern of 64 spheroids using DCNA and ~25 min using a single nozzle AAB. Although the efficiency of non-repeating patterns was not as high as with repeated patterns, it was still significantly faster than the existing benchmark. The use of pre-designed travel path for bioprinting and enhancing the system with more nozzles and incorporating height-adjustable nozzles could significantly improve versatility, particularly for non-repeating patterns.

In the current work, HITS-Bio was used to accelerate the spatial positioning of spheroids via their simultaneous deposition onto a gel substrate for scalable tissue fabrication. Spatial positioning of spheroids is important for mimicking native tissue microenvironments and promoting effective cell-cell communications, ensuring tissue functionality and organization11. The spheroid-based approach offers significant advantages for bone and cartilage tissue engineering by effectively mimicking the hierarchical native structures essential for these tissues20,34. Spheroids enable physiologically relevant cell-cell and cell-matrix interactions, which are crucial for the differentiation and maturation of chondrocytes and osteoblasts10. Moreover, the relative avascularity of cartilage and the minimal vascularization requirements in early-stage bone tissue reduce complexity. Additionally, bone and cartilage are among the most extensively studied tissues, offering a great amount of reference data, making them ideal models for developing and validating new bioprinting technologies. Herein, DCNA enabled the spatial arrangement of miR transfected spheroids. A combination of miR-196a-5p and 21 was used for the co-transfection of hADSCs to create osteogenically-committed spheroids. miR-196a-5p plays a crucial role in bone homeostasis and is highly expressed in osteoclast precursors35. Kim et al. reported that miR-196a-5p regulates the proliferation and osteogenic differentiation of human ADSCs, which may be mediated through HOXC836. Concurrently, miR-21 has been proven to play a role in bone formation by mediating mesenchymal stem cell proliferation and differentiation37,38. It activates the ERK-MAPK (extracellular signal-regulated kinases (ERKs)-mitogen-activated protein kinases (MAPKs)) signaling pathway, promoting osteogenesis by suppressing the expression of its target gene SPRY139. In a study, when combined, miR-196a-5p and -21 exhibit synergistic effects to enhanced osteogenesis, where miR-196a-5p stimulates osteogenic ability, while miR-21 further supports osteoblastic differentiation and amplified proliferation rate, confirming the hypothesis of Abu-laban et al.40 and Celik et al.26 Thus, spheroids with ~8k cells/spheroid were formed in the current work and maintained a week in growth medium in vitro. After a week, spheroids reached ~350 µm in diameter with sufficient structural properties for bioprinting purposes. These spheroids were then used along with the developed BONink for bone bioprinting.

This study introduced bioinks, characterized by their paste-like shear-thinning property enabling both in vitro and in vivo EBB. Bioink comprises GM (10 or 20% w/v), β-GP, HyA, Fib, HA (15 or 30% w/v), and the photocrosslinker LAP. GM and HA served as bulk polymers influencing the bioink’s properties, while HyA and Fib mimic ECM, promoting cell growth and tissue regeneration. β-GP enhances osteogenesis and mineralization, making these polymers ideal for bone regeneration applications41,42. The developed bioinks were characterized rheologically, where flow sweep results indicated that the bioinks had shear-thinning attributes meeting the basic requirement for EBB. The decrease in viscosity upon increasing the shear rate implies a decrease in the extrusion pressure, facilitating smooth extrusion through smaller nozzles43. Additionally, the bioinks possessed self-healing capability, which is essential for maintaining the integrity of bioprinted constructs. Self-healing shear-thinning bioinks stand out as promising materials for EBB44. These bioinks can be extruded as their viscosity decreases under the shear, and subsequently self-heal once the shear is removed. This dual property ensures safe bioprinting of cells and the maintenance of shape fidelity post bioprinting44. Further, the assessment of mechanical properties of bioinks showed that the modulus falls within the range observed in native trabecular or cancellous bone, which typically exhibits elastic moduli of 0.02–2 GPa45. Additionally, construct degradation at physiological conditions is considered advantageous because it allows for the construct to diminish so that the new ECM can slowly replace the degraded portions of the construct. The results indicated that an increase in the concentration of GelMA resulted in slower degradation, which may be attributable to increased methacrylamide crosslinks46. The addition of HA and other components reduced the degradation rate further. This aligns with a prior study by Allen et al., where a GelMA-gelatin-HA bioink was utilized for 3D bioprinting of bone constructs and their degradation with Type IV collagenase was significantly reduced by the addition of HA in a concentration-dependent manner47. Based on these results, GM20HA30 composite was selected as a base cement material and termed ‘BONink,’ which was found to be biocompatible, affirming its suitability for bone tissue engineering applications.

The in vitro assessment results suggested that bioprinted constructs containing spheroids co-transfected with miR-(196a-5p + 21) showed superior upregulation of osteogenic genes. Interestingly, the expression of osteogenic markers may be influenced by the spheroid density. Early-stage markers like RUNX2 and BMP-4 show higher expression in low-density groups, likely due to better nutrient diffusion and efficient paracrine signalling, where factors can diffuse more evenly, promoting early differentiation. Conversely, high-density spheroids exhibit increased expression of intermediate to late-stage markers, such as OSTERIX and BSP, indicating enhanced maturation and mineralization, which may be due to closer cell-cell interactions and higher local concentrations of paracrine factors. These results suggest the role of spheroid density in optimizing osteogenic differentiation through paracrine signalling and mechanical cues. IHC staining confirmed the expression patterns, particularly highlighting intense staining for RUNX2 in the low-density group and OSTERIX in the high-density group, aligning with gene expression profiles. To mimic the native tissue physiology, engineered tissues require optimum cellular density and microstructural complexity48. Studies have shown that spheroids play a crucial role in enhancing osteogenic differentiation. For instance, spheroids facilitate cell-to-cell interactions, leading to increased osteogenic potential10,49. Moreover, the upregulation of osteogenic markers like RUNX2, BSP, and OSTERIX in miR-transfected spheroids has been linked to enhanced osteogenic differentiation26.

Meanwhile, IOB is transforming surgical procedures by offering in situ fabrication of patient-specific tissue constructs directly at the surgical site50. It enables precision customization, minimizing infection risks through the elimination of pre-fabricated implants, and improving healing due to freshly bioprinted tissues, while eliminating storage and transportation concerns. IOB has been previously utilized in repairing calvarial bone defects via laser-based bioprinting (LBB), where nano-HA was combined with collagen and MSCs to serve as the ink and deposited directly onto the calvarial defects in mice, resulting in a significant increase in bone formation observed after 2 months51. However, LBB method is challenged by its slow deposition of biomaterials into a defect site. In another study, IOB was used for the reconstruction of craniomaxillofacial (CMF) tissues, including bone, skin, and composite (hard/soft) tissues. The use of a hybrid IOB approach (EBB and DBB) reconstituted hard/soft composite tissues in a stratified arrangement resulted in ≈80% skin wound closure in 10 days and 50% bone coverage area at Week 652. In the current work, bioprinting was performed intraoperatively using spheroids under surgical settings to repair rat calvarial defects. The results showed that the newly formed bone invaded from one defect edge to another (Fig. 4B) with a bone coverage area of 91 and 96% in 3 and 6 weeks for the high-density group, respectively. This demonstrates substantial bone regeneration in a short timeframe, attributed mainly to the innovative use of IOB with miR-transfected spheroids, which is quite challenging using other similar methods and materials. The maximum intensity projections from µCT data, used to score bony bridging, revealed significantly higher scores (3.85 ± 0.37 out of 4) for spheroid involved groups indicating near-complete bridging and enhanced bone regeneration, likely due to the superior osteogenic properties imparted by the miR transfection and BONink (Fig. 4C). Moreover, the regenerated bone in this group exhibited significantly enhanced shear yield strength and modulus of resilience (Fig. 4D). Histological analysis depicted the connectivity and compactness of the newly formed bone tissue with MT staining revealing dense blue islands indicative of immature bone tissue formation, particularly prominent in the high-density group. The study demonstrated superior regenerated bone in situ, supported by histological analysis showcasing dense, immature bone formation, which can be expected to develop into a mature bone in a longer timeframe in vivo.

Bioprinting using transfected spheroids contributed to earlier defect closure, particularly by Week 3, which is a significant improvement over existing approaches. This early bone formation reduced the difference observed between Weeks 3 and 6, which is consistent with our approach’s ability to expedite bone healing compared to other approaches in the literature. Despite significant bone regeneration, we observed variations in fusion between the implant and host bone, which may be attributed to localized mechanical loading differences and ongoing remodeling. The histological evidence of dense, immature bone tissue suggests that complete maturation and integration could require long-term studies. In this study, a control group with manually loaded spheroids was initially included with randomly distributed spheroids, but this method encountered significant technical challenges, such as spheroid loss during their transfer, spheroid aggregation, and air bubble formation, leading to uneven distribution and reduced reproducibility as also highlighted in in-vitro studies (Supplementary Figs. 7 and 8). These issues compromised the reproducibility and data accuracy. Consequently, we did not pursue this method further in animal studies, in accordance with the principles of the 3Rs, to minimize unnecessary animal experimentation. Instead, the BONink (ink only) was selected as the control, which provided a consistent, cell-free matrix that isolated the effects directly attributable to material properties without interference from the addition of exogenous cells (hADSCs). This approach allowed for a more reliable and clear assessment of the impact of spheroid deposition using HITS-Bio. Additionally, although the spheroids were deposited uniformly, their direct visualization and distribution in vivo was not feasible due to technical limitations associated with embedding spheroids within the tissue matrix. Moreover, the uniformity of the original spheroid distribution was challenging to assess during histological evaluations of retrieved explants, as tissue remodeling and integration processes could alter the initial arrangement of spheroids. Overall, the findings support the feasibility of HITS-Bio as a powerful tool in IOB of spheroids for bone tissue with superior osteogenic potential, and high-throughput and speed, completing each construct in about 4.5 min.

Furthermore, the HITS-Bio platform was explored for the scalability of bioprinted tissues. Thus, SCTs were successfully fabricated by depositing layers of CARink (representing GM20) using EBB followed by the precise placement of chondrogenic spheroids using DCNA, creating constructs with nine stacked tissue layers, comprising around 600 spheroids per SCT, demonstrating the potential for creating intricate, multi-layered tissues. The CARink, being transparent, allowed real-time monitoring of deposited spheroids with favorable extrusion properties (inset images in Figure 3Fii, Fiii, and Supplementary Movie 7). A combination of miR-140 and -21 was used for co-transfection of hADSCs to create chondrogenically-committed spheroids as per a previous report26. Importantly, the results revealed that the process of transfection and tissue fabrication did not compromise spheroid viability ( > 90%) compared to non-transfected spheroids. The dual miR-transfected SCTs exhibited a significantly higher sGAG content compared to the non-transfected control group (Fig. 5C). sGAGs play a critical role in cartilage function, providing mechanical support and maintaining tissue hydration53. The results suggest that HITS-Bio supported enhanced ECM deposition that is essential for cartilage formation. Interestingly, the DNA content was significantly lower in the transfected samples compared to the non-transfected samples (Fig. 5D). This might be due to miR suppressing genes associated with stemness and promoting chondrocyte-specific markers and by downregulating cyclins and cyclin-dependent kinases that limit cell proliferation, favoring differentiation36. However, further investigation is warranted to understand the underlying mechanisms. Histological assessment using H&E and toluidine blue (TB) imaging confirmed the presence of chondrogenic spheroids within bioprinted constructs, where spheroids exhibited intense staining, indicating a higher density of ECM deposition with a developed lacunae-like structure (Fig. 5F, G). Further, TB staining supported the presented quantitative sGAG data, where transfected spheroids displayed intense TB staining, emphasizing enhanced sGAG production (Fig. 5G). Overall, the results demonstrated the efficacy of HITS-Bio and its potential application for the rapid bioprinting of cartilage tissues. Using HITS-Bio, the tissue dimensions were scaled up from a volume of ~30 mm3 (disc with a diameter of 5 mm and a height of 1.5 mm) involving 64 spheroids for bone tissue bioprinted in 4.5 min per construct, to a volume of 1 cm3 (cube of 1 × 1 × 1 cm), incorporating 576 spheroids for cartilage tissue bioprinted in under 40 min (including EBB of the CARink). The ~10-fold increase in the bioprinting speed was achieved through the integration of the aforementioned factors in HITS-Bio. However, because of the thick tissue, hypoxia in SCTs is possible and needs to be investigated in further studies. Nevertheless, in cartilage, it has been reported that the hypoxia condition protects against cartilage loss by regulating Wnt signalling54.

Regarding mechanical properties, the BONink (GM20HA30) formulation without spheroids exhibited a compressive modulus of 360.7 ± 66.6 kPa. When compared to engineered bone reported in the literature, which ranges from 0.1 to 10 MPa55, our in vitro results were within the expected range for early-stage bone constructs. Further, the in vivo retrieved explants demonstrated a significantly higher shear modulus of ~20 MPa, which corresponds to a compressive modulus of ~52 MPa56. For reference, the compressive modulus of cranial or flat bone in rats ranges from 5 to 9 MPa (depending on the age)57–59, while in humans, cortical bone ranges from 10 to 20 GPa and trabecular bone from 0.1 to 2 GPa56,60. It is important to note that mechanical properties of the implanted constructs do not necessarily need to mimic those of native bone, as they can be supplemented with plate osteosynthesis during implantation61. However, the constructs must possess sufficient mechanical strength to provide initial support ensuring stability and facilitating proper integration with the surrounding tissue during the early stages of bone regeneration. For human articular cartilage, the aggregate equilibrium compressive modulus was reported to be in the range of 0.1 to 2 MPa depending on the specific location and health of the tissue62. Reported values for bioprinted cartilage are lower with a compressive modulus typically ranging from 50 to 500 kPa63. In this study, the compressive modulus of CARink (GM20) without spheroids was measured at 88.3 ± 34.7 kPa, which increased in SCTs containing spheroids with a compressive modulus of 116.8 ± 22.1 kPa after 2 weeks of in vitro maturation. This limited increase in compressive modulus was likely due to insufficient localized ECM formation, indicating that longer maturation might be needed for further mechanical improvements. It is also crucial to recognize that standardized protocols for mechanical testing of bioprinted constructs are still being developed, with American Society for Testing and Materials (ASTM) standards yet to be fully established (latest as of April 2024, ASTM F3659-24). Therefore, comparisons with other studies may not be entirely accurate without standardized methodologies.