Abstract

Nanotechnology plays a pivotal role in food science, particularly in the nanoencapsulation of bioactive compounds, to enhance their stability, bioavailability, and therapeutic potential. This review aims to provide a comprehensive analysis of the encapsulation of bioactive compounds, emphasizing the characteristics, food applications, and implications for human health. This work offers a detailed comparison of polymers such as sodium alginate, gum Arabic, chitosan, cellulose, pectin, shellac, and xanthan gum, while also examining both conventional and emerging encapsulation techniques, including freeze-drying, spray-drying, extrusion, coacervation, and supercritical anti-solvent drying. The contribution of this review lies in highlighting the role of encapsulation in improving system stability, controlling release rates, maintaining bioactivity under extreme conditions, and reducing lipid oxidation. Furthermore, it explores recent technological advances aimed at optimizing encapsulation processes for targeted therapies and functional foods. The findings underline the significant potential of encapsulation not only in food supplements and functional foods but also in supportive medical treatments, showcasing its relevance to improving human health in various contexts.

Keywords: Encapsulation systems, Bioactive compounds, Nutritional benefits, Nanocarriers, Functional foods

Highlights

-

•

Encapsulation is widely used to enhance the bioavailability of nutrients and functional ingredients.

-

•

Bioactive compounds are protected from environmental factors (such as light, heat, and oxygen) that can degrade their nutritional value.

-

•

Many encapsulated compounds have antioxidant properties that help combat oxidative stress, potentially reducing the risk of various diseases.

-

•

Continued research on safety and efficacy will influence regulatory frameworks for encapsulated products in the food industry.

1. Introduction

Encapsulation technology has significantly advanced the food industry by facilitating the incorporation and stabilization of bioactive compounds within various food systems. This method involves enclosing bioactive substances within a carrier material, enhancing their stability, bioavailability, and controlled release. Bioactive compounds, such as vitamins, minerals, antioxidants, and probiotics, are recognized for their health-promoting properties, making their efficient delivery essential for maximizing their benefits. Encapsulation not only maintains the functional properties of these compounds but also protects them from adverse environmental conditions and interactions with other food components (McClements & Gumus, 2016; Zhang et al., 2024).

The nutritional benefits of bioactive compounds are extensively documented, with many studies emphasizing their role in disease prevention and health promotion. For instance, antioxidants like polyphenols and carotenoids have been shown to reduce oxidative stress and inflammation, thereby decreasing the risk of chronic diseases such as cardiovascular disease and cancer (Gasa-Falcon et al., 2020; Wang et al., 2022). Similarly, probiotics support gut health by maintaining a balanced microbiota, which is crucial for proper digestion, immune function, and overall well-being (Burgain et al., 2011). Encapsulation technology is crucial in enhancing the effectiveness of these bioactive compounds by ensuring their stability and bioavailability throughout the digestive process (Davidov-Pardo et al., 2015).

In terms of food applications, encapsulation is widely used in the development of functional foods and beverages. Functional foods are designed to provide additional health benefits beyond basic nutrition, often containing ingredients that can enhance physical and mental health (McClements, 2020). Encapsulation enables the incorporation of sensitive bioactive compounds into these foods without compromising their stability or sensory properties. For example, omega-3 fatty acids, which are prone to oxidation, can be encapsulated to prevent degradation and off-flavors in food products (Sarubbo et al., 2022). Similarly, encapsulating vitamins and minerals can prevent their interaction with other food components, thereby preserving their nutritional value (Hashim et al., 2023).

The impact of encapsulated bioactive compounds on human health is substantial and multifaceted. By improving the bioavailability and targeted delivery of these compounds, encapsulation technology can enhance their therapeutic effects (Suhag et al., 2021). Research indicates that encapsulated bioactive compounds show improved absorption and retention in the body compared to their non-encapsulated forms (Munin & Edwards-Lévy, 2011). This is particularly important for compounds with low solubility or stability, such as curcumin and resveratrol, which exhibit enhanced bioactivity when encapsulated (Samborska et al., 2021). Additionally, encapsulation can aid in developing personalized nutrition strategies, where bioactive compounds are tailored to meet individual health needs (Chew et al., 2019). Recent advancements in encapsulation technologies, such as nanoencapsulation and microencapsulation, have further expanded the potential applications and benefits of this technique.

Recent progress in encapsulation technology has broadened its applications in fields such as medicine, food, and cosmetics. In the food sector, encapsulation helps safeguard sensitive bioactives like omega-3 fatty acids, vitamins, and probiotics from degradation. This technique extends the shelf life and maintains the nutritional and sensory qualities of products. Encapsulated probiotics, for instance, are protected from harsh gastrointestinal conditions, increasing their viability and effectiveness (Bauer-Estrada et al., 2023). However, encapsulation technologies are not without challenges. High production costs, complex manufacturing, and scalability issues are common obstacles. Additionally, interactions between encapsulated compounds and their environment can occasionally diminish effectiveness. Addressing these issues is crucial to further improve the technology and expand its practical use across industries (Fangmeier et al., 2019). Nanoencapsulation, in particular, offers better control over the release and targeting of bioactive compounds, enabling the design of more effective and efficient delivery systems (Shamloo et al., 2023; Singh, 2016). These advancements hold significant promise for the future of food science and nutrition, facilitating the development of innovative products that meet the growing consumer demand for health-promoting foods (Sultana et al., 2022).

As the food industry continues to evolve, the integration of encapsulation technologies will be crucial in shaping the future of health-promoting food products (Burgain et al., 2011). Therefore, we investigated the encapsulation of bioactive compounds and related issues, including food applications, nutritional benefits and health effects.

2. Bioactive compounds

Bioactive compounds are naturally occurring substances in plants and certain foods each providing unique health benefits and playing a role in disease prevention: Antioxidant, anti-inflammatory, and disease-preventing properties highlight their importance in a balanced diet.

Bioactive compounds that require encapsulation include antioxidants (such as vitamins C and E), polyphenols (such as flavonoids, quercetin, and phenolic acids), omega-3 and omega-6 fatty acids (like EPA, DHA, and linoleic acid), carotenoids (such as beta-carotene, lycopene, and astaxanthin), curcumin, resveratrol, catechins, coenzyme Q10, probiotics, isoflavones (like genistein in soy), sulfur compounds (such as allicin in garlic and onion), essential oils (like peppermint and rosemary oil), and sensitive vitamins like D, K, and folic acid. Due to their instability under light, temperature, oxygen, and digestive conditions, these compounds require encapsulation to prevent degradation, improve absorption, and reduce undesirable taste and odor (Fraj et al., 2021; Jana et al., 2017; Lohith Kumar et al., 2020; Premjit et al., 2023; Qian et al., 2024; Sasi et al., 2023; Tavares et al., 2021; Venugopalan et al., 2021; Zhang et al., 2022).

2.1. Essential fatty acids from vegetable oils

Vegetable oils are rich in essential fatty acids, crucial for cellular health. Omega-3 and omega-6 fatty acids found in oils such as flaxseed, soybean, and canola oil are vital for cardiovascular health, inflammation control, and brain function (Abdi-Moghadam et al., 2023). Research indicates that these fatty acids can reduce chronic disease risks like heart disease and arthritis by lowering blood pressure, reducing triglycerides, and minimizing inflammation (Altememy et al., 2022; Bahmani et al., 2022; Darvishi et al., 2022; Falahi et al., 2019; Khan et al., 2023; Saini et al., 2021). For instance, alpha-linolenic acid (ALA) in flaxseed oil is linked to lower stroke and heart disease risks (Jayedi & Shab-Bidar, 2020). Similarly, omega-6 fatty acids in sunflower and safflower oils are essential for skin health and cell membrane integrity (Djuricic & Calder, 2022; Naderi et al., 2024).

2.2. Vitamins

Vitamins are organic compounds essential for various metabolic processes. Fat-soluble vitamins (A, D, E, and K) and water-soluble vitamins (C and B-complex) are critical for immune function, energy production, and cell repair. Vitamin D, sourced from sunlight and fortified foods, promotes calcium absorption and bone health, reducing osteoporosis risk (Jodar et al., 2023; Sutherland et al., 2021). Moreover, vitamin D modulates the immune response, potentially lowering autoimmune disease risks (Sîrbe et al., 2022). Vitamin C, abundant in citrus fruits, is a powerful antioxidant that boosts immune function by stimulating white blood cell production (Jafari et al., 2019). Additionally, vitamin E in nuts and seeds protects cells from oxidative damage, potentially lowering chronic disease risks such as heart disease and cancer (Didier et al., 2023).

2.3. Polyphenols

Polyphenols, found in fruits, vegetables, tea, coffee, and wine, are known for their antioxidant properties. These compounds, including flavonoids, phenolic acids, and stilbenes, can neutralize free radicals, protecting cells from oxidative stress and reducing chronic disease risks such as cancer and cardiovascular diseases (Fraga et al., 2019; Rana et al., 2022; Roman et al., 2019). For example, green tea polyphenols, particularly catechins, improve endothelial function and reduce atherosclerosis risk (Farhan, 2022). Resveratrol, a polyphenol in red wine and grapes, is associated with anti-aging effects and improved cardiovascular health by enhancing mitochondrial function and reducing oxidative stress (Balanov, Smotraeva, Abdullaeva, Volkova, & Ivanchenko, 2021).

2.4. Carotenoids

Carotenoids, including beta-carotene, lycopene, lutein, and zeaxanthin, are pigments responsible for the red, yellow, and orange colors in many fruits and vegetables. These potent antioxidants help reduce certain cancers and eye diseases. Beta-carotene in carrots and sweet potatoes is a precursor to vitamin A, essential for vision and immune function (Johra et al., 2020; Mrowicka et al., 2022). Lycopene in tomatoes is linked to lower prostate cancer and cardiovascular disease risks (Cheng et al., 2019; Mirahmadi et al., 2020). Lutein and zeaxanthin in green leafy vegetables like spinach and kale are crucial for eye health, potentially reducing age-related macular degeneration (AMD) risks (Mrowicka et al., 2022).

2.5. Pigments

Natural food colorants are bioactive substances extracted from plants, animals, and microorganisms that add color to food products. With growing consumer interest in healthier, more natural ingredients, the food industry increasingly favors natural pigments over synthetic dyes. These natural pigments not only improve the appearance of food but also contribute health benefits, such as antioxidant, anti-inflammatory, and antimicrobial effects.

2.5.1. Curcumin

Curcumin, the primary polyphenol in turmeric, is widely recognized for its extensive therapeutic properties. This compound, responsible for turmeric's distinct yellow hue, has been the focus of numerous studies due to its anti-inflammatory, antioxidant, and anticancer activities. Curcumin's anti-inflammatory effects are largely due to its ability to inhibit key molecular pathways, including transcription factors such as NF-κB and enzymes like COX-2 and iNOS. These mechanisms lead to a reduction in pro-inflammatory cytokines, which are crucial in the pathogenesis of chronic inflammatory diseases like rheumatoid arthritis and inflammatory bowel disease (Hewlings & Kalman, 2017).

In addition to its anti-inflammatory role, curcumin exhibits strong antioxidant properties. It neutralizes reactive oxygen species (ROS) and promotes the activity of antioxidant enzymes, thereby protecting cells from oxidative stress (Rezagholizade-shirvan et al., 2022). This function is vital in slowing the aging process and in the prevention of neurodegenerative conditions, such as Alzheimer's disease (Gupta et al., 2013). Curcumin has also demonstrated significant potential in cancer therapy, where it induces apoptosis and inhibits the proliferation of cancer cells by regulating signaling pathways like PI3K/Akt and Wnt/β-catenin. However, its clinical use is hindered by poor bioavailability, prompting ongoing research into advanced delivery systems, such as nanoparticles and liposomes, to enhance its therapeutic potential (Maleki Dizaj et al., 2022; Rezagholizade-Shirvan, Kalantarmahdavi, & Amiryousefi, 2023).

2.5.2. Anthocyanins

Among the most commonly used natural pigments are anthocyanins, which provide red, purple, and blue colors in fruits and vegetables like berries, grapes, and red cabbage. As members of the flavonoid family, anthocyanins exhibit strong antioxidant properties (Khoo, Azlan, Tang, & Lim, 2017).

These pigments play a key role in counteracting oxidative stress by neutralizing free radicals, thereby protecting cells from damage. Additionally, anthocyanins' anti-inflammatory effects contribute to lowering the risk of cancer and cardiovascular issues. Recent studies have also linked them to improved cognitive and visual functions, with evidence suggesting that they can enhance memory and support eye health (Ma et al., 2021).

In the food industry, anthocyanins are increasingly used as natural colorants, providing a safer alternative to synthetic dyes. However, their practical application is limited by instability under environmental factors like pH changes, heat, and light exposure. To overcome these challenges, new techniques such as encapsulation are being developed to improve anthocyanin stability and bioavailability (Pereira et al., 2024). Anthocyanins face challenges in therapeutic use due to low absorption rates in the human body. Researchers are investigating methods to enhance their bioavailability, including structural modifications and encapsulation technologies (Salehi et al., 2020).

2.5.3. Chlorophyll

Chlorophyll is a group of green pigments essential for photosynthesis, allowing plants, algae, and cyanobacteria to convert sunlight into chemical energy. The main types—chlorophylls a, b, c, d, and f vary slightly in their chemical structure, with chlorophyll-a being the most prominent for energy capture. Spirulina and other microalgae are particularly rich sources of chlorophyll, often used in nutritional products (Ke et al., 2021).

Chlorophyll is a well-known pigment primarily associated with photosynthesis in green plants. Beyond imparting a green color to foods like spinach, kale, and green beans, chlorophyll has been explored for its potential health benefits, such as promoting detoxification. However, its application in food is limited by its instability under light and acidic conditions, which complicates its use as a colorant (Cortez et al., 2017). This pigment also offers several health benefits, acting as an antioxidant and anti-inflammatory agent. It has been linked to the prevention of cardiovascular diseases, regulation of blood sugar, and protection against neurodegenerative disorders (Ebrahimi et al., 2023; Martins et al., 2023).

In food and pharmaceutical industries, chlorophyll is valued as a natural colorant and health supplement, providing a safer alternative to synthetic dyes. Its bioactivity is influenced by the source, with microalgae-derived chlorophyll often showing greater effectiveness than plant-based chlorophyll (Yang et al., 2024). However, commercial production faces challenges, such as extraction efficiency and stability during processing. Advances in biotechnology are helping to overcome these limitations, making chlorophyll a promising component in health and industrial applications (Mehdipoor Damiri et al., 2021).

2.5.4. Betalains

Betalains, found in beets, Swiss chard, and amaranth, include pigments like betacyanins and betaxanthins. These pigments are valued for their antioxidant and anti-inflammatory properties, and research suggests they may help reduce oxidative stress and inflammation, contributing to the prevention of chronic diseases They are categorized into two main types: betacyanins, which impart red to violet colors, and betaxanthins, responsible for yellow to orange hues (Gengatharan et al., 2015).

Beetroots are a significant commercial source of betalains, particularly betanin, but the use of beetroot extracts can come with challenges, including earthy flavors and limited color variety. On the other hand, cactus fruits such as dragon fruit and prickly pear provide a broader spectrum of colors with fewer taste issues, making them appealing options for food applications (Fu et al., 2020).

However, betalains are sensitive to various environmental factors, including pH levels, temperature, and light exposure, which can affect their stability. They tend to be more stable in slightly acidic conditions, whereas high temperatures or light can lead to degradation. Innovations like enzymatic pre-treatment and pulsed electric field technology are being investigated to enhance extraction efficiency and preserve the integrity of these pigments during processing(Calva-Estrada et al., 2022). The growing interest in natural food additives, combined with the health-promoting properties of betalains, has led to their potential use as functional ingredients. Their antioxidant capabilities may help mitigate oxidative stress, which is linked to chronic conditions such as cancer and cardiovascular diseases (Esquivel, 2024).

Natural food colorants are generally less stable than synthetic dyes. This instability can compromise the visual quality of food products. Additionally, the processes for extracting and purifying natural pigments are often more complex and expensive than those for synthetic alternatives. Nevertheless, the increasing consumer demand for natural ingredients is driving innovations to improve the stability and application of these pigments in the food industry (Esquivel, 2024; Novais et al., 2022).

2.6. Probiotics, prebiotics, and postbiotics

The human gut microbiota, a complex ecosystem of microorganisms residing in the gastrointestinal tract, significantly influences overall health. Recent research has increasingly focused on dietary strategies to modulate this microbiota, specifically through the use of probiotics, prebiotics, and postbiotics. Each of these elements plays a distinct role in promoting gut health and maintaining balance within the microbiota (Hajiagha et al., 2022; Shojaeimeher et al., 2024).

Probiotics are defined as live microorganisms that confer health benefits when administered in sufficient quantities. Commonly utilized strains include Lactobacillus and Bifidobacterium. These probiotics help sustain a healthy microbial equilibrium in the gut by suppressing pathogenic bacteria and reinforcing the intestinal barrier. Additionally, they positively influence immune function and reduce inflammation, which has implications for managing gastrointestinal conditions such as irritable bowel syndrome (IBS) and inflammatory bowel disease (IBD). The effectiveness of probiotics can vary by strain and is influenced by factors such as the individual's health status and diet (Hill et al., 2014). Prebiotics are non-digestible components, typically fibers like inulin, fructooligosaccharides (FOS), and galactooligosaccharides (GOS), that selectively enhance the growth and activity of beneficial gut bacteria. These prebiotics reach the colon intact and are fermented by the microbiota, resulting in the production of short-chain fatty acids (SCFAs) such as butyrate, acetate, and propionate. SCFAs play a crucial role in gut health by lowering the intestinal pH, which inhibits pathogenic bacteria, and by providing energy to colonic cells (Slavin, 2013; You et al., 2022). Furthermore, prebiotics support the proliferation of probiotics, thereby amplifying their positive effects.

Postbiotics refer to the metabolic by-products or bioactive substances produced by probiotics during fermentation processes. These include SCFAs, bioactive peptides, enzymes, and cell wall components. Postbiotics exhibit various beneficial properties, such as anti-inflammatory, antioxidant, and antimicrobial effects, and they can aid in the management of metabolic disorders and gastrointestinal conditions (Yousefi et al., 2022). Unlike probiotics, postbiotics do not involve live microorganisms, thus mitigating issues related to the viability and stability of probiotics throughout storage and gastrointestinal transit (Aguilar-Toalá et al., 2018; Chaudhari & Dwivedi, 2022).

3. Encapsulation techniques

Encapsulation techniques have found extensive applications across various industries. In the food sector, they are used to enhance the stability and bioavailability of functional ingredients, such as vitamins, antioxidants, and probiotics (Reque & Brandelli, 2021). In pharmaceuticals, encapsulation improves the delivery and controlled release of drugs, thus enhancing therapeutic efficacy (Zhang, Hai, et al., 2021). The future of encapsulation lies in developing more efficient and sustainable techniques, such as using biopolymers and green solvents, to meet the increasing demand for natural and eco-friendly products (Dahiya et al., 2023). Encapsulation technology in the food sector faces several significant drawbacks that can limit its effectiveness. One of the primary challenges is the elevated production costs associated with advanced techniques, which may discourage smaller food manufacturers from adopting these methods(Misra et al., 2021; Tarone et al., 2020).

Variations in encapsulation efficiency can complicate product formulations, necessitating comprehensive testing to achieve desired outcomes (Bhatt et al., 2018; Fernandes et al., 2024).

Moreover, incomplete release of the encapsulated active ingredients during storage or consumption can diminish their effectiveness, particularly in applications focused on flavor enhancement or nutritional benefits (Bao et al., 2019; Boostani & Jafari, 2021). This issue is especially relevant for bioactive compounds, where their efficacy relies on precise release mechanisms. Among the various encapsulation techniques, spray-drying, freeze-drying, coacervation, and emulsification stand out due to their effectiveness and versatility (Premjit et al., 2022). The encapsulation of bioactive compounds is an efficient method to improve their stability, bioavailability, and controlled release. However, the effectiveness of these methods can be influenced by factors such as the type of bioactive compound, polymer selection, and processing conditions. Bioactive compounds with diverse chemical and physical properties (such as solubility and sensitivity to temperature or pH) require different encapsulation methods to be effectively protected against environmental conditions and to provide desirable functional characteristics (Dib et al., 2023; Pateiro et al., 2021). Each technique offers unique advantages and is chosen based on the specific requirements of the bioactive compound and the desired application. Ongoing research and technological advancements will continue to enhance these methods, making them more efficient and sustainable, thereby expanding their applications and benefits (Table 1) (See Fig. 1).

Table 1.

Investigations into the nanoencapsulation of bioactive substances utilizing various nanocarriers.

| Enriched/Fortified food | Bioactive compound | Capsule wall compositions | Encapsulation Techniques | Reference | |

|---|---|---|---|---|---|

Meat products |

Fresh bovine meat | Tunisian thyme essential oil | Chitosan, gum Arabic /Median-chain triacyglycerols | Nanoemulsion | (Snoussi et al., 2022) |

| Chilled pork | Satureja montana L. essential oil | Soy soluble polysaccharide | Hydrogel | (Cui et al., 2021) | |

| Sheep meat hamburger | Olive leaf extract (Olea europaea L.) | Gelatin/tragacanth gum | Coacervation | (Oliveira et al., 2022) | |

| Chicken nuggets | Fish oil | Carrageenan /Gum tragacanth | Freeze dryer | (Pourashouri et al., 2021) | |

| Pork meat (fresh post-rigor raw pork, mixture of biceps femoris, semimembranosus, semitendinosus, gracilis and aductor) and pork backfat | Olive leaves extract | Healthy oil blend (olive oil, linseed oil and fish oil, polyglycerol ester of polyricinoleic acid) | Double emulsions | (Robert et al., 2019) | |

| Hamburger-like meat products | Thyme (Thymus vulgaris) essential oil | Casein/maltodextrin | Spray drying | (Radünz et al., 2020) | |

| Minced beef | Laurus nobilis leaf extract | Lecithin | Nano-liposome | (Tometri et al., 2020) | |

| Reduced-fat meat batter | Murraya koenigii berry extract | Table oil | Double emulsion | (Kumar & Kumar, 2020) | |

| Beef | Pomegranate peel extract | Chitosan/Poly (ethylene oxide) | Electrospun | (Surendhiran et al., 2020) | |

| Chicken meat | Peel extract of Punica granatum L. | Alginate/ Calcium chloride | Nanoemulsion | (Rahnemoon et al., 2021) | |

| Beef meat | Rosemary extract | Basil seed gum /Soybean protein | Freeze dryer | (Rashidaie Abandansarie et al., 2019) | |

| Chicken meat | Phlorotannin | Sodium alginate/Poly(ethyleneoxide) | Electrospinning technique | (Surendhiran et al., 2019) | |

| Patty-type products based on beef (gluteus medius) | Fish Oil | Alginate/Chitosan/ P. alba exudate gum | Emulsion | (Vasile et al., 2019) | |

| Beef Burger Patties | Prickly Pear Fruit Extract | Alginate | Spray-Drying | (Parafati et al., 2019) | |

| Sausage | Animal fat | Pectin | Emulsification process | (Santiaguín-Padilla et al., 2019) | |

| Fresh meat | Eugenol | Gelatin-based emulgel | Spray-Drying | (Wan et al., 2020) | |

Dairy products |

Milk powders | Curcumin | Casein micelles | Spray-drying |

(Neves et al., 2019) |

| Cow milk / goat milk | Bifidobacterium longum | Alginate | Extrusion method | (Prasanna & Charalampopoulos, 2018) | |

| Whole milk | Isoflavone | Maltodextrin /Gum acacia | Spray-Drying | (Mazumder & Ranganathan, 2020) | |

| Probiotic fermented milk | Lactobacillus casei | Alginate | Extrusion method | (Dimitrellou et al., 2019) | |

| Goats' milk yogurt | Bifidobacterium | Alginate/Goats' milk/inulin | Freeze dryer | (Pradeep Prasanna & Charalampopoulos, 2019) | |

| Lassi (A milk based beverage) | Vitamin D3 | Caprylic-/Capric triglyceride | Nano-liposome | (Maurya & Aggarwal, 2019) | |

| Yogurt | Beta vulgaris | Maltodextrin/ inulin | Freeze dryer | (Flores-Mancha et al., 2021) | |

| Yogurt | Red pepper waste | Whey protein | Freeze dryer | (Šeregelj et al., 2019) | |

| Yogurt | Lacticaseibacillus rhamnosus | Ionic gelation | Emulsification process | (Romero-Chapol et al., 2022) | |

| Yogurt | Carrot waste extract | Alginate | Freeze dryer | (Šeregelj, Pezo, et al., 2021) | |

| Yogurt | Lactobacillus bulgaricus | Sodium alginate/pectin | Freeze dryer | (Hu et al., 2021) | |

| Yogurt | Anthocyanin | Gum arabic | Spray-Drying | (Barretto et al., 2020) | |

| Yogurt | Fish protein hydrolysate | Complex of whey protein concentrate / Inulin | Emulsification process | (Jamshidi et al., 2019) | |

| Cheddar cheese | Bifidobacterium bifidum | Kepa carrageenan /sodium alginate | Freeze dryer | (Afzaal et al., 2020) | |

| Ricotta Cheese | Saffron Extract | Soy lecithin | Liposome | (Siyar et al., 2021) | |

| White soft cheese | Olive polyphenolic extract | Maltodextrin / Whey protein isolate /Skim milk powder | Freeze dryer | (Farrag et al., 2020) | |

| Ricotta cheese | Broccoli sprout extract | Basil seeds gum | Freeze dryer | (Azarashkan et al., 2022) | |

| Iranian white cheese | Lactobacillus plantarum and phytosterols | Whey protein isolate / Gum Arabic | Freeze dryer | (Sharifi et al., 2021) | |

Cereal products |

Cereal cookies | Bacteriophages | Alginate / Calcium ions / /Milk proteins | Spray-Drying | (Schubert et al., 2022) |

| Bread | Lemongrass essential oil | Cassava starch fibers | Electrospinning | (da Cruz et al., 2023) | |

| Bread | Lactobacillus acidophilus | Alginate/Fish Gelatin | Liposome | (Hadidi et al., 2021) | |

| Gluten-free sorghum bread | Lactobacillus acidophilus /Lactobacillus plantarum | Tragacanth gum /Sago starch | Spray-Drying | (Ghasemi et al., 2022) | |

| Bread / Biscuits | Fenugreek oil | Okra / Psyllium mucilage / Whey protein / Gum Arabic | Freeze dryer | (Mohammad et al., 2024) | |

| Wheat bread | Rosehip extract | Sodium alginate | Freeze dryer | (Şimşek & Özgen, 2023) | |

| Durum Wheat Pasta | Carrot Waste | Sunflower oil | Spray-Drying | (Šeregelj et al., 2022) | |

| Pasta | Wild Garlic (Allium ursinum) | Maltodextrin | Spray-Drying | (Filipčev et al., 2023) | |

| Modified pasta | Apple pomace /finger millet | Maltodextrin / Hydroxypropyl Methylcellulose | Spray-Drying | (Kumari, Arya, et al., 2023) | |

| Eggless cake with chia | Flax seed oil | Gum Arabic / Soy-protein isolate / Sodium caseinate / Sodium alginate | Spray-Drying | (Murugkar et al., 2021) | |

| Cake | Lacticaseibacillus rhamnous | Flaxseed oil | Spray-Drying | (Łopusiewicz et al., 2021) | |

| Biscuits | mangosteen (Garcinia mangostana L.) peel extract | Arabic gum | Spray-Drying | (Indiarto et al., 2023) | |

| Millet biscuit | Lactobacillus acidophilus | Maltodextrin / Gum arabic | Spray-Drying | (Arepally et al., 2023) | |

Drinks |

Apple Juice | Lacticaseibacillus rhamnosus | Ionic gelation | Emulsification process | (Romero-Chapol et al., 2022) |

| Apple Juice | Lactobacillus gasseri | Alginate | Emulsification process | (Varela-Pérez et al., 2022) | |

| Orange juice | Lactobacillus casei tocotrienol | Calcium alginate-Carboxymethyl cellulose hydrogel beads | Emulsification process | (Sultana et al., 2023) | |

| Raspberry juice | Fresh raspberry fruits | Gum Arabic / Maltodextrin / Waxy starch | Freeze dryer | (Nthimole et al., 2022) | |

| Clidemia japurensis / Clidemia hirta juices | Bioactive compounds | Maltodextrin | Freeze dryer | (Mar et al., 2020) | |

| Bitter melon juice | Indian bitter melon | Maltodextrin /Gum Arabic / Pectin/Soy protein isolate | Spray-Drying | (Wang et al., 2021) | |

| Orange-carrot juice | Arctium lappa L. root extracts | Maltodextrin /Gum Arabic | Spray-drying /Freeze-drying | (Esmaeili et al., 2022) | |

| Orange juice | Resveratrol / Epigallocatechin gallate | Low methoxyl pectin | Liposome | (Feng et al., 2020) | |

|

Orange juice |

Lacticaseibacillus rhamnosus | Alginate | Freeze dryer | (Bonaccorso et al., 2021) | |

|

Goldenberry (Physalis peruviana L.) juice |

Carotenoids | Maltodextrin/ Modified starch/ Inulin/Alginate/ Gum arabic | Spray-Drying | (Etzbach et al., 2020) | |

| The spray dried fruits juice powders | Vitamin C | Maltodextrin | Spray-Drying | (Rohini et al., 2024) | |

| Orange juice | Lactobacillus rhamnosus | Alginate / Xanthan gum | Emulsification process | (Ali et al., 2023) | |

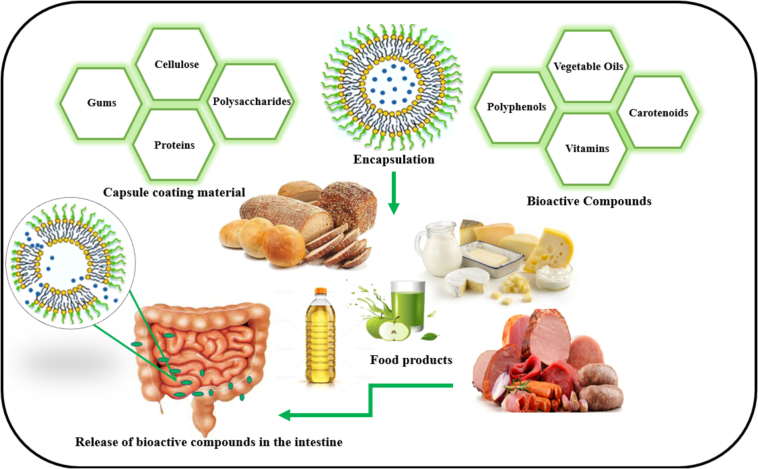

Fig. 1.

Encapsulation of bioactive compounds for food enrichment

3.1. Spray-drying

Spray-drying is a prevalent encapsulation method involving the atomization of a liquid mixture into a hot drying chamber, causing rapid solvent evaporation and dry particle formation. This method is preferred for its cost-efficiency and scalability. In the food industry, spray-drying is extensively used to encapsulate flavors, probiotics, and vitamins. For example, encapsulating probiotics using spray-drying enhances their thermal stability and survival during storage and digestion (Furuta & Neoh, 2021). Additionally, spray-dried encapsulates exhibit excellent rehydration properties, making them ideal for instant food products (Kandasamy & Naveen, 2022).

However, a significant limitation of this method is the high temperatures required, which can degrade heat-sensitive bioactives, reducing their bioactivity and overall effectiveness. To mitigate this issue, researchers have explored several strategies. One approach involves using heat-resistant wall materials, like maltodextrin or milk proteins, which act as thermal barriers and partially protect sensitive compounds from heat. Another strategy includes optimizing spray-drying parameters, such as lowering the inlet air temperature and increasing the feed flow rate, to decrease thermal stress. Additionally, alternative drying methods, such as freeze-drying, provide a gentler option, though they are more costly. The use of two-stage encapsulation techniques is also promising, as it minimizes the direct exposure of bioactive compounds to high temperatures, thereby improving their stability and preserving their functional properties in food applications (Akbarbaglu et al., 2021; Kandasamy & Naveen, 2022).

3.2. Freeze-drying

Freeze-drying, or lyophilization, involves freezing a solution and then lowering the surrounding pressure to allow the frozen solvent to sublimate directly from solid to gas. This technique preserves the structural integrity and activity of sensitive compounds, making it suitable for encapsulating heat-sensitive substances such as enzymes and probiotics (Rezvankhah et al., 2020). Freeze-drying produces porous particles that can enhance the dissolution rate of poorly soluble drugs, thereby improving their bioavailability (Jakubowska & Lulek, 2021). Moreover, freeze-dried encapsulates are characterized by their long shelf life and stability under ambient conditions (Zhang et al., 2020).

This technique is significantly more expensive compared to alternatives like spray-drying, primarily due to its high energy consumption and extended processing times necessary for water removal through sublimation. The process requires specialized equipment and precise control of temperature and pressure, leading to increased operational costs. Despite these challenges, freeze-drying remains valuable for applications where maintaining the bioactivity and quality of the compounds is crucial, such as in the food and pharmaceutical industries, as the resulting products are highly stable and retain their functional properties effectively (El-Messery et al., 2020; Eun et al., 2020; Rezvankhah et al., 2020).

3.3. Coacervation

Coacervation is a liquid-liquid phase separation process that forms a coacervate phase, rich in encapsulating material, and a supernatant phase. This technique is often employed for encapsulating hydrophobic and sensitive bioactive compounds. Coacervation can be simple or complex, depending on whether it involves a single or multiple polymers (Gómez-Mascaraque et al., 2022). For example, complex coacervation using gelatin and gum arabic has been used to encapsulate essential oils, enhancing their stability against oxidation and volatilization (Khatibi et al., 2021). Coacervates can form microcapsules with controlled release properties, beneficial for applications in controlled drug delivery (Muhoza et al., 2022).

3.4. Emulsification

Emulsification involves dispersing one liquid in another immiscible liquid, typically resulting in oil-in-water (O/W) or water-in-oil (W/O) emulsions. This technique is crucial for encapsulating hydrophobic compounds within a hydrophilic matrix. Emulsification can be achieved through various methods, including high-shear mixing, ultrasonic emulsification, and membrane emulsification (Santosa et al., 2021). Nanoemulsions, with their small droplet size, offer improved stability and bioavailability of encapsulated compounds (Pateiro et al., 2021). Emulsification is extensively used in the food industry for delivering flavors, colors, and nutraceuticals in beverages and dairy products (Tan & McClements, 2021).

4. Nano-carrier systems for encapsulation

This technique involves encasing active ingredients within nanometer-sized carriers, which enhances their stability, controlled release, and targeted delivery. One key advantage of nanoencapsulation is the protection it provides to bioactive compounds from environmental factors like light, oxygen, and pH changes, thereby extending the shelf life of sensitive ingredients such as vitamins, antioxidants, and probiotics (Lin et al., 2023). The nanoscale size of these carriers also allows for better penetration and absorption in biological systems, enhancing the bioavailability of the encapsulated compounds (Le et al., 2021).

Controlled release is another important feature of nanoencapsulation. By adjusting the composition and structure of nanocarriers, it is possible to achieve sustained and targeted release of active ingredients, reducing required dosages and minimizing potential side effects. This is particularly beneficial in pharmaceutical applications, such as cancer therapy, where targeted delivery of chemotherapeutic agents to tumor cells can improve treatment efficacy and reduce systemic toxicity (Mohtashami et al., 2024; Parveen et al., 2023).

In the food industry, nanoencapsulation is used to fortify foods with essential nutrients without altering taste, texture, or appearance. It also allows for more efficient and controlled incorporation of flavors, colors, and preservatives (Hosseini et al., 2021). Additionally, this technology supports the development of functional foods with enhanced health benefits by delivering bioactive compounds more effectively to the site of action within the body (Hosseini et al., 2021). Some of the most important carrier systems are described below:

4.1. Liposome

Liposomes are spherical vesicles composed of one or more phospholipid bilayers. They are extensively used as delivery systems for bioactive compounds due to their biocompatibility, biodegradability, and ability to encapsulate both hydrophilic and hydrophobic substances (Subramani & Ganapathyswamy, 2020). The formation of liposomes involves several steps designed to optimize encapsulation efficiency and the stability of the encapsulated compounds.

The process typically starts with dissolving phospholipids in an organic solvent. Phosphatidylcholine, a common phospholipid found in cell membranes, is frequently used (Kirby & Gregoriadis, 2019). The solvent is then evaporated under reduced pressure to form a thin lipid film on the walls of a round-bottom flask. This lipid film is hydrated with an aqueous solution containing the active ingredient, followed by agitation, leading to the formation of multilamellar vesicles (MLVs) due to the hydrophobic interactions between the phospholipid tails and the aqueous medium (Tagrida et al., 2021).

To achieve uniform and smaller vesicles, the MLVs undergo processes such as sonication or extrusion. Sonication uses ultrasonic waves to break down MLVs into small unilamellar vesicles (SUVs), while extrusion forces the vesicle suspension through membranes with defined pore sizes to produce vesicles of uniform size (Olson et al., 1979; Sarode et al., 2022). These methods enhance the encapsulation efficiency and stability of liposomes.

Additionally, advancements in liposome preparation techniques, such as the ethanol injection method and reverse-phase evaporation, have improved control over liposome size and encapsulation parameters (ENARU et al. 2023). These methods facilitate the creation of vesicles with varying bilayer compositions and surface modifications, enabling targeted delivery and controlled release of encapsulated compounds (De Leo et al., 2021).

4.2. Hydrogel

Hydrogels are three-dimensional polymer networks that can absorb significant amounts of water, making them excellent candidates for encapsulation applications. Their ability to simulate natural tissue environments and regulate the release of encapsulated substances has led to their widespread use in drug delivery, tissue engineering, and food processing (Zheng et al., 2021).

The process of forming hydrogels usually involves polymerizing monomers in the presence of cross-linking agents, which connect polymer chains to create a network structure. Both natural polymers, such as alginate, chitosan, and gelatin, and synthetic ones like polyvinyl alcohol (PVA) and polyethylene glycol (PEG) are utilized due to their biocompatibility and customizable characteristics (Tang et al., 2022). The selection of polymer and cross-linker, along with the polymerization conditions, greatly affects the mechanical properties and swelling behavior of the hydrogel (Xue et al., 2022).

Encapsulation within hydrogels can occur through various techniques, including physical entrapment, covalent bonding, or ionic gelation. The simplest method is physical entrapment, where the bioactive substance is mixed into the polymer solution prior to gelation. In covalent bonding, bioactive molecules form stable covalent bonds with the polymer network through functional groups (Ahmed, 2015; Montà-González et al., 2022). Ionic gelation, commonly employed with alginate, relies on the interaction between polymer chains and multivalent cations, such as calcium ions, leading to rapid gel formation and encapsulation (Milivojević et al., 2023).

Hydrogels can be designed to respond to specific stimuli, including pH, temperature, or enzymatic activity, allowing for controlled release of encapsulated substances. This feature is particularly advantageous in drug delivery systems, where targeted and sustained release is essential (Li & Mooney, 2016).

4.3. Hybrid Nano-carriers

Hybrid nano-carriers, which combine both organic and inorganic materials, are emerging as key technologies in the encapsulation of food ingredients. These advanced systems enhance the stability, bioavailability, and functionality of various components by utilizing the distinct advantages of both organic and inorganic substances (Assadpour & Jafari, 2019; Khosravi-Darani et al., 2019).

Typically, hybrid nano-carriers consist of organic materials such as polysaccharides, proteins, or lipids combined with inorganic elements like silica, metal nanoparticles, or clay. This combination allows for the development of nano-carriers with improved properties, such as greater mechanical strength, thermal stability, and controlled release capabilities (Farhadi et al., 2022; Mohtashami et al., 2024; Rout et al., 2022; Shokri et al., 2024). For example, silica nanoparticles contribute structural stability and protection, while organic polymers enhance the carrier's biocompatibility and processing ease (Kankala et al., 2020). A significant use of hybrid nano-carriers in food encapsulation is the protection of sensitive bioactive compounds, including vitamins, probiotics, and antioxidants. These compounds are vulnerable to degradation from light, oxygen, or high temperatures during food processing and storage. By encapsulating these ingredients in hybrid nano-carriers, their stability and efficacy can be preserved, thereby extending their shelf life (Meng, 2017; Rezagholizade-Shirvan et al., 2024). For instance, hybrid nano-carriers have been used to improve the stability and release properties of vitamin C, ensuring its effectiveness in various food products (Comunian et al., 2022).

Moreover, hybrid nano-carriers enable controlled and sustained release of encapsulated substances. Through the precise design of these carriers, it is possible to achieve a gradual release of ingredients over time, enhancing the functionality of food products. This controlled release can be utilized to improve flavor or nutritional content by providing a steady release of components. Additionally, hybrid nano-carriers can be engineered to respond to specific environmental triggers, such as changes in pH or temperature, allowing for targeted ingredient release in different food matrices (Men et al., 2019). A study focused on the use of F-ZnO nanoparticles (NPs) as antibacterial agents, which were immobilized onto a pectin/cellulose nanofiber (CNF) aerogel skeleton through the adhesive properties of mussel-inspired dopamine. The resulting antimicrobial mats were designed for safety, long-lasting efficacy, and high performance. This aerogel was lightweight, maintained its shape on petals, featured a uniform pore structure, and exhibited strong tensile and compressive properties alongside significant antibacterial and antifungal activity. When strawberries were packaged in the F-ZnO@D-CNF aerogel, they enjoyed an extended shelf life of five days. Additionally, strawberries showed notable advantages in weight loss, color retention, and firmness compared to other groups. The final zinc ion concentration in the strawberries was measured at 3.71 ± 0.28 μg/g, which is well below the recommended dietary intake, ensuring safety for consumers (Wu et al., 2023).

5. Absorption, stability, functionality, bio accessibility and bioavailability of encapsulated bioactive compounds

The encapsulation of bioactive compounds is increasingly vital in food science and pharmaceuticals, aimed at improving the effectiveness and delivery of nutrients and active ingredients. Compounds such as polyphenols, vitamins, and essential fatty acids are prone to environmental degradation, low solubility, and poor bioavailability, which limits their therapeutic impact (Ghorbani et al., 2024; Klojdová et al., 2023).

Stability is essential for maintaining the effectiveness of bioactive compounds. Encapsulation methods like spray drying, freeze drying, and coacervation provide a protective barrier against factors such as oxidation, heat, and light (Eun et al., 2020). For instance, encapsulated curcumin shows significantly better stability compared to its non-encapsulated form. Research by Chen et al. (2020) indicates that encapsulation shields curcumin from hydrolytic degradation, prolonging its shelf life and preserving its antioxidant properties (Chen et al., 2020).

Functionality of bioactive compounds depends on their ability to remain biologically active after ingestion. Enhancing functionality is critical for creating effective nutraceuticals and functional foods that provide health benefits (Banwo et al., 2021). Encapsulation can enhance the solubility and dispersibility of hydrophobic compounds in water, improving their functionality. For example, the solubility and antioxidant activity of resveratrol, a hydrophobic polyphenol, are improved when encapsulated in cyclodextrin complexes (Yang et al., 2022).

Encapsulation significantly enhances bioaccessibility by protecting bioactives during digestion and facilitating their release in the intestines. Encapsulated omega-3 fatty acids in alginate beads, for instance, demonstrate improved bioaccessibility due to protection against gastric degradation and controlled release in the intestines. This ensures a higher proportion of the compound is available for absorption (Kovsari et al., 2024; Salvia-Trujillo et al., 2021).

There are instances when not all encapsulated compounds are released during digestion, which can limit their absorption and overall effectiveness. Several factors influence the release of these compounds, including the choice of encapsulating material, the gastrointestinal environment, and the interactions between the encapsulated compounds and food matrices. Incomplete release can impede the anticipated health benefits associated with these bioactive compounds. To improve the efficacy of encapsulated products, researchers are focusing on developing innovative delivery systems that enhance the controlled release of these compounds throughout the digestive tract, thereby boosting their absorption and maximizing their therapeutic potential in various applications, including functional foods and nutraceuticals(Carrasco-Sandoval et al., 2021; Gonçalves et al., 2021).

Bioavailability refers to the fraction of a bioactive compound that reaches the systemic circulation and exerts its physiological effects. Techniques such as liposomes, nanoparticles, and polymeric micelles are used to address challenges related to poor solubility, instability, and low permeability (Gorantla et al., 2021; Yang et al., 2020). For example, liposomal encapsulation of quercetin enhances its bioavailability by increasing its solubility and facilitating its transport across intestinal barriers (Tomou et al., 2023). However, their stability can be compromised under certain conditions, such as fluctuations in temperature, pH, or ionic strength, which can result in the leakage of encapsulated compounds. This leakage can severely impact the efficacy of bioactive substances, thereby undermining the advantages of encapsulation. To overcome these limitations, researchers are investigating various approaches to enhance the stability of liposomes, including the incorporation of stabilizing agents, optimization of formulation parameters, and the development of hybrid systems that integrate liposomes with other encapsulation techniques. By improving liposomal stability, it becomes feasible to preserve the integrity of encapsulated compounds and enhance their delivery and effectiveness in diverse applications, including pharmaceuticals and functional foods(Hamad et al., 2024; Maritim et al., 2021). Additionally, polymeric nanoparticles improve the oral bioavailability of poorly soluble drugs by enhancing their dissolution rate and protecting them from enzymatic degradation (Bhalani et al., 2022).

Besides enhancing bioactive properties, encapsulation also enables targeted delivery and controlled release, which are crucial for maximizing therapeutic efficacy and minimizing side effects. Stimuli-responsive delivery systems, which release their payload in response to specific triggers like pH, temperature, or enzymatic activity, are particularly promising. For example, pH-responsive polymeric nanoparticles have been designed to release encapsulated compounds in the acidic environment of the stomach, ensuring site-specific delivery and improved therapeutic outcomes (Ding et al., 2022; Kong et al., 2020).

Actually, encapsulating bioactive compounds offers a comprehensive approach to enhancing their stability, functionality, bioaccessibility, and bioavailability. By protecting bioactives from environmental and physiological degradation, improving solubility, and allowing for controlled release, encapsulation technologies significantly enhance the efficacy of bioactive compounds in food and pharmaceutical applications. Future research should aim to optimize encapsulation methods and materials to further improve the delivery and effectiveness of bioactive compounds, with a focus on the interactions between encapsulated bioactives and biological systems.

6. Compositions of the capsule wall

6.1. Polysaccharides

Polysaccharides are large carbohydrate molecules made up of long chains of monosaccharides linked by glycosidic bonds. These macromolecules exhibit a wide range of structural and functional diversity, playing essential roles in various biological systems. Polysaccharides can be categorized into two main types based on their monosaccharide composition: homopolysaccharides, which consist of identical monosaccharides, and heteropolysaccharides, which are made up of different monosaccharides (Shokri et al., 2023; Silva et al., 2021).

Polysaccharide-based encapsulation systems are often chosen for their biocompatibility and ability to effectively encapsulate bioactive compounds. However, a major limitation of these systems is their potential lack of mechanical strength, which can lead to capsule rupture under stress or during handling. This susceptibility may cause premature release of the encapsulated compounds, compromising their stability and effectiveness. Factors influencing the mechanical weakness of polysaccharide capsules include the type of polysaccharide used, the encapsulation method, and the drying and storage conditions. To mitigate these issues, researchers are investigating various strategies to enhance the mechanical properties of polysaccharide-based systems. Approaches such as cross-linking with other materials, integrating reinforcing agents, and optimizing encapsulation techniques are being explored to improve the robustness of these capsules, ensuring effective delivery of bioactive compounds in diverse applications, including food products and pharmaceuticals(Junaid et al., 2024; Papagiannopoulos & Sotiropoulos, 2022; Visan & Cristescu, 2023).

In Table 1 polysaccharides, including alginates, chitosan, amylopectin, and amylose, are widely used for food encapsulation. Amylopectin and amylose, create gel-like matrices that are useful for encapsulating oils and oxygen-sensitive substances. Amylose has a linear and unbranched structure, which makes it less soluble in water and results in the formation of a more stable gel. In contrast, amylopectin has a branched structure that allows it to dissolve more easily in water, leading to a gel with lower viscosity and less stability. (Zhu, 2017). Alginates, derived from brown seaweeds, can form stable gels in the presence of calcium ions, making them suitable for encapsulating probiotics, nutrients, and flavors (Bennacef et al., 2021).

Other notable polysaccharides include pectin, found in fruit cell walls and used in the food industry for gelling, and chitin, a structural polysaccharide in the exoskeletons of arthropods and fungal cell walls. Hyaluronic acid, a heteropolysaccharide, is vital in the extracellular matrix of connective tissues, helping maintain hydration and elasticity (Van Audenhove et al., 2023).

Chitosan is a biopolymer obtained from the deacetylation of chitin, which is mainly sourced from the shells of crustaceans. Owing to its non-toxic, biodegradable, and biocompatible properties, chitosan has become highly valued in various biomedical fields, particularly in drug delivery and encapsulation. In the context of encapsulation, chitosan acts as an efficient vehicle for active compounds, improving their stability, bioavailability, and providing controlled release mechanisms. Its cationic nature at acidic pH enables it to bind with anionic molecules, making it suitable for encapsulating a wide range of substances, including pharmaceuticals, proteins, and vaccines. Also, it is valued for its antimicrobial properties and biodegradability, ideal for encapsulating probiotics and extending food shelf life (Maleki et al., 2022).

Gums are natural polysaccharides that are extensively used in the food industry, particularly for the encapsulation of various food ingredients. Sourced from plants, seaweeds, and microbial processes, these biopolymers are known for their ability to gel, stabilize emulsions, and regulate the release of encapsulated materials (Taheri & Jafari, 2019b).

Gum arabic, extracted from the acacia tree, is a versatile emulsifier and film-forming agent, often used for encapsulating flavors, essential oils, and vitamins. Its low viscosity and high solubility in water make it particularly suitable for spray drying, where it forms a stable matrix that protects bioactive compounds, thereby enhancing their stability and shelf life (Taheri & Jafari, 2019a).

Xanthan gum, produced by Xanthomonas campestris, is another key gum in encapsulation, known for its high viscosity and gel-forming capabilities. It is particularly effective in encapsulating hydrophilic compounds and regulating their release within the digestive system. Xanthan gum is frequently combined with other gums or proteins to strengthen the encapsulation matrix (Zabot et al., 2022).

Guar gum, derived from guar seeds, is a galactomannan known for its high water-binding and thickening properties. It is commonly used to create gel matrices that encapsulate and protect sensitive ingredients such as probiotics, enzymes, and vitamins. Its strong gel formation at low concentrations makes it a cost-effective option for large-scale applications (Rezagholizade-Shirvan, Kalantarmahdavi, & Amiryousefi, 2023; Rostamabadi et al., 2023).

Alginate and carrageenan, both seaweed-derived, are popular in the creation of encapsulation beads and capsules. Alginate is particularly valued for its ability to gel in the presence of calcium ions, making it ideal for encapsulating probiotics and enzymes in matrices that resist acid. Carrageenan, known for forming thermally reversible gels, is often used in controlled release systems for flavors and other bioactive (Dong et al., 2021; Li et al., 2021).

The application of these gums in encapsulation not only enhances the stability and shelf life of bioactive compounds but also improves their bioavailability and controlled release. These qualities are essential in the production of functional foods, which require precise delivery of health-promoting ingredients (Jayakody et al., 2022).

6.2. Proteins

Proteins such as gelatin and whey protein are essential in food encapsulation due to their emulsifying and gelling properties. Gelatin, sourced from animal collagen, forms gels at low temperatures, making it useful for encapsulating flavors, nutrients, and in producing gummy candies and processed meats (Akbarbaglu et al., 2021). A significant limitation is gelatin tendency to denature at elevated temperatures. This denaturation can negatively impact their encapsulating capabilities, resulting in compromised structural integrity and diminished stability of the encapsulated bioactive compounds. When proteins denature, their three-dimensional structures unfold, which can impair their ability to encapsulate and safeguard sensitive bioactive ingredients from degradation. Factors such as the type of protein, temperature, and exposure duration significantly influence the degree of denaturation. To address these challenges, researchers are investigating various strategies to enhance the thermal stability of protein-based encapsulation systems, including the incorporation of stabilizing additives, cross-linking techniques, and the creation of hybrid encapsulation materials(Luo et al., 2022; Milano et al., 2023; Mohanto et al., 2023).

Bovine serum albumin (BSA) and human serum albumin (HSA) are increasingly recognized for their application in the nanoencapsulation of bioactive compounds within the food sector. These serum proteins are particularly beneficial due to their excellent biocompatibility, stability, and capacity to form robust nanoparticles that can encapsulate a diverse range of bioactive substances, such as vitamins, antioxidants, and essential fatty acids. Utilizing BSA and HSA in nanoencapsulation offers significant benefits, including the protection of sensitive bioactive compounds from environmental stressors like light, oxygen, and moisture, which can otherwise compromise their effectiveness. In food industry applications, BSA and HSA nanoparticles enhance the stability and bioavailability of these bioactive compounds, ensuring their efficacy throughout the product's shelf life. This method not only prolongs the shelf life of the bioactives but also boosts their absorption in the digestive system, thereby amplifying their nutritional and health benefits. Furthermore, the use of BSA and HSA for nanoencapsulation allows for the controlled release of bioactive compounds, which can be customized for specific delivery needs, such as targeted release during digestion. This feature is particularly advantageous for developing functional foods with improved health benefits. The natural origin and safety of BSA and HSA make them suitable for use in food applications, complying with regulatory standards and ensuring consumer safety (Chen et al., 2023; Mainardes & Khalil, 2019; Visentini et al., 2023).

Casein, a primary protein found in milk, is extensively utilized in the food industry due to its versatile functional properties, such as its capacity to form gels, emulsions, and micelles. One of the key applications of casein is in the encapsulation of bioactive compounds, which is particularly important in preserving the nutritional value and health benefits of food products. This encapsulation protects sensitive bioactives like vitamins, probiotics, and antioxidants—from environmental factors that could cause degradation. The use of casein in encapsulation offers numerous benefits. Its amphiphilic structure allows it to effectively encapsulate both hydrophilic and hydrophobic bioactive compounds. Moreover, casein's natural micelle-forming ability contributes to the stabilization and controlled release of these compounds. Additionally, casein's biocompatibility and ease of digestion ensure that these bioactives are efficiently delivered and released in the gastrointestinal tract, thereby improving their bioavailability and absorption. Casein's application in nanoencapsulation is particularly promising for the development of functional foods that aim to deliver health-enhancing compounds in a controlled manner. As research advances, the potential for casein-based encapsulation systems to improve the stability, efficacy, and delivery of bioactive compounds in the food industry continues to grow (Mohite & Waghmare, 2020; Sadiq et al., 2021).

6.3. Fats and oils

The continuous innovation in lipid-based encapsulation technologies holds promise for the development of next-generation functional foods that deliver enhanced health benefits. Triglycerides and liposomes are employed to encapsulate fat-soluble compounds like vitamins A, D, E, K, antioxidants, and omega-3 fatty acids (Nowak et al., 2021). Lipid-based encapsulation systems, such as liposomes, solid lipid nanoparticles, and nanoemulsions, have been extensively researched and applied in functional foods. These systems not only protect bioactives from oxidation, light, and temperature fluctuations but also enhance their absorption in the gastrointestinal tract. Moreover, the use of edible oils and fats aligns with consumer demand for natural and safe food ingredients, making them suitable for clean-label products. Different oils and fats, including those derived from plants (e.g., soybean oil, coconut oil) and animals (e.g., fish oil), are employed based on their unique physicochemical properties. These lipids are particularly effective in encapsulating hydrophobic bioactives due to their ability to form stable emulsions and lipid-based nanoparticles. The selection of specific oils or fats depends on factors such as the desired release profile, the compatibility with the encapsulated compound, and the intended application in food products (Assadpour & Jafari, 2019; Barroso et al., 2021; Gasa-Falcon et al., 2020). A study compared three preparation methods dispersion, ultrasonication, and microfluidization for encapsulating citral in nanostructured lipid carriers (NLC). Results showed that ultrasonication produced NLC with superior stability and lower citral release rates over 35 days compared to microfluidization. The optimized NLC had a particle size of 192.8 nm and an encapsulation efficiency of 78.37 % (Feng et al., 2023).

A significant limitation is lipid-based encapsulation systems susceptibility to oxidation, which can lead to the deterioration of both the encapsulated bioactive substances and the lipids themselves. Oxidative degradation can generate free radicals and harmful by-products, compromising the stability and efficacy of the encapsulated ingredients. Factors such as the type of lipid employed, along with exposure to light, oxygen, and heat, can accelerate oxidation rates. To address these concerns, researchers are exploring various strategies to enhance the oxidative stability of lipid-based encapsulation systems. These strategies may include the incorporation of antioxidants, the use of oxygen-resistant materials for encapsulation, and optimizing processing conditions to minimize oxidative stress. By improving the oxidative stability of these lipid-based systems, the integrity and functionality of encapsulated bioactive compounds can be maintained, thereby enhancing their effectiveness in applications across food, pharmaceuticals, and nutraceuticals(Da Costa De Quadros et al., 2023; Gbian & Omri, 2022; Patel et al., 2024).

6.4. Biodegradable synthetic polymers

Polylactic acid (PLA) is a biodegradable polymer made from renewable resources like corn starch. PLA is used for producing biodegradable packaging and encapsulating food ingredients, offering an environmentally friendly alternative to traditional plastics (Chen et al., 2022). Also, alginate dissolves well in water and can be used to produce biopolymer films, nanoparticles, and microcapsules.

6.5. Cellulose and derivatives

Cellulose, a common homopolysaccharide composed of β-d-glucose, is a key structural element in plant cell walls, providing support and strength. Another significant polysaccharide is starch, which also consists of glucose but in the form of α-d-glucose. (Chaudhary et al., 2022). Cellulose derivatives, such as methylcellulose, hydroxypropyl methylcellulose (HPMC), and carboxymethylcellulose (CMC), are increasingly recognized for their roles in the food industry, particularly in the encapsulation of bioactive compounds like vitamins, probiotics, and antioxidants. These derivatives are valuable for enhancing the stability, solubility, and bioavailability of these compounds.

The ability of cellulose derivatives to form films facilitates the production of micro- and nano-capsules, which function as carriers for bioactive substances. This encapsulation approach not only extends the shelf life of these compounds but also supports their controlled release, ensuring that they are delivered to their target locations in the digestive system. Additionally, cellulose derivatives are favored for their safety, non-toxicity, and environmental friendliness, making them ideal for food applications where consumer safety and sustainability are critical (Casalini & Giacinti Baschetti, 2023; Grover, 2020; Liu et al., 2021; Yi et al., 2020).

6.6. Starch and Derivates

Starch and its derivatives, including hydroxypropyl starch, acetylated starch, and cross-linked starch, are increasingly utilized in food encapsulation due to their adaptable properties (Liang et al., 2024; Witczak et al., 2016). These derivatives are particularly valued for their ability to form stable gels and films, which are crucial for effective encapsulation processes. Starch-based encapsulation methods offer multiple benefits, such as protecting sensitive bioactive compounds from environmental damage, enabling controlled release, and enhancing the stability of the encapsulated materials over time. Additionally, starch derivatives are noted for their safety, biodegradability, and environmental friendliness, making them suitable for food applications where health and sustainability are important. Recent studies demonstrate that starch-based encapsulation systems are effective in preserving the functionality and bioavailability of various food components, indicating their significant potential for advancing food formulation and processing (Egharevba, 2019, Liang et al., 2024).

7. Application of encapsulation in food industries

Encapsulated flavors and colors can be precisely controlled to achieve the desired sensory attributes without compromising the stability of the compounds. For example, essential oils encapsulated in biodegradable polymers improve stability and allow for controlled flavor release, enhancing the sensory experience of foods (Ghosh et al., 2021; Premjit et al., 2022). Different encapsulation methods in the food industry are selected based on the type of bioactive compound, production conditions, and desired properties of the final product. These methods help enhance the stability of sensitive compounds, and allow for controlled release (Timilsena et al., 2020).

In spray drying process, the bioactive compound mixed with a liquid carrier is sprayed into a chamber with high-velocity hot air, which rapidly evaporates the solvent and produces dry particles. These tiny particles, which contain the active compound, are more stable against environmental factors and can be easily incorporated into various food products (Piñón-Balderrama et al., 2020).

Freeze drying is ideal for preserving heat-sensitive compounds, commonly used for encapsulating probiotics, enzymes, and other thermosensitive ingredients. This results in dry particles that retain their biological properties and remain stable under environmental conditions, enhancing the shelf life of food products containing these bioactive ingredients(da Silva et al., 2019; Kuo et al., 2022; Rajam & Subramanian, 2022). Lipid-based encapsulation uses liposomes, lipid nanoparticles, and emulsions to encapsulate fat-soluble compounds. This method is suitable for encapsulating fatty acids, fat-soluble vitamins, and antioxidants. Due to their bilayer structure, liposomes can easily pass through cellular barriers, increasing the absorption and bioavailability of bioactive compounds (Alu'datt et al., 2022; Barroso et al., 2021; Wijekoon et al., 2023). Additionally, nanoemulsions improve the texture and mouthfeel of beverages and dairy products by providing a smooth, creamy consistency (Aliabbasi & Emam-Djomeh, 2024). In their study, Raeisi et al., nanoencapsulated fish oil and garlic essential oil using various percentages of chitosan and Persian gum-chitosan. They then investigated the stability of the emulsion. The results showed that the 2:1 w/w ratio of Persian gum and chitosan will offer the best performance for use in the food industry (Raeisi et al., 2019). According to Oprea et al., nanoencapsulation is a practical method for utilizing citrus essential oil in industrial applications. This essential oil is used in the food industry as flavoring, antioxidant and antibacterial and its antibacterial properties have been proven to produce edible films and preserve food. Therefore, nanoencapsulation of citrus essential oil can facilitate the use of this natural flavoring over artificial compounds in the industry (Oprea et al., 2022). The application of natural pigments and stabilization methods of anthocyanins for food applications has been explored, demonstrating the potential of nanoparticles in enhancing food safety and quality (Chatterjee et al., 2021; Fierri et al., 2023; Rosales et al., 2021; Yao et al., 2021). In the research conducted by Salah et al., anthocyanins and β-lactoglobulin from red raspberry pomace were encapsulated to investigate the effect of desolvation. The efficiency of nanoencapsulation was 77 %, and the SEM images showed a square shape. Despite the significant benefits of nanoencapsulation in the food industry, Comprehensive risk assessments and toxicity studies are essential to evaluate the potential health impacts of nanoencapsulated ingredients. Regulatory agencies such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) provide guidelines and frameworks for the safe use of nanotechnology in food products (Committee et al., 2018; Kumari, Arya, et al., 2023).

8. Advantages of encapsulation in the food area

8.1. Sensory improvement

When designing a food product, key factors to consider include the taste, solubility, and stability of the active ingredients. Modifying taste involves altering how taste characteristics are perceived and has a wide range of applications within the food sector (Fig. 2). For instance, it is used to improve the palatability of fortified foods, reduce sugar and fat content, mask the bitterness of pharmaceutical ingredients (particularly in pediatric formulations), preserve flavors, and protect against the degradation and oxidation of both flavors and active compounds. Flavors in foods are volatile compounds that play a significant role in human sensory perception and are extensively used across various products. Due to their volatile nature and sensitivity to factors such as pH, temperature, and oxidation, they require proper protection to extend their shelf life. Encapsulation is a highly effective method for taste modification by trapping undesirable functional ingredients. This technique is crucial for protecting food flavors, enhancing their thermal and oxidative stability, reducing issues related to volatility, and ensuring controlled release, which ultimately improves the bioavailability of these compounds in food products (Rezagholizade-shirvan, Masrournia, et al., 2023; Szymczak, 2023).

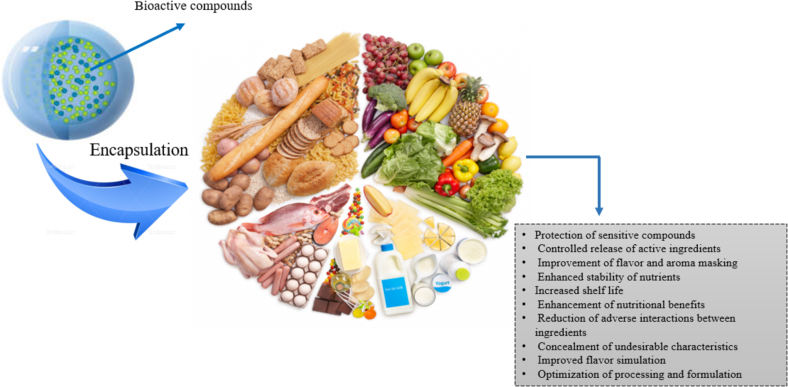

Fig. 2.

Advantages and Applications of Encapsulation in the Food Industries.

8.2. Extend shelf life

The shelf life of food products is impacted by numerous factors, particularly chemical and microbial processes, leading to a significant decrease in consumer acceptance. There is a growing trend toward replacing synthetic preservatives with natural, plant-based bioactive compounds that are considered safer. However, the full integration of these natural ingredients is hindered by several challenges, such as their low chemical stability, undesirable taste, poor solubility, and limited effectiveness over time. Encapsulation provides a potential solution to mitigate these limitations.

This review discusses the latest trends in utilizing naturally encapsulated ingredients for food preservation, categorized by components such as essential oils, plant extracts, phenolics, and carotenoids, with a focus on their role in extending shelf life through antimicrobial, anti-browning, and antioxidant properties. Encapsulation methods, particularly nanoencapsulation, present a promising approach to overcoming the limitations of these bioactive ingredients. Combining proteins and polysaccharides as encapsulating materials yields better results compared to using single polymers. The encapsulation technique and choice of encapsulants significantly influence the release mechanisms and physicochemical properties of the bioactive compounds. Optimizing these factors, along with refining the encapsulation process, results in a cost-effective, well-encapsulated ingredient that is more effective than its unencapsulated form in extending shelf life. Well-designed encapsulation systems have been shown to enhance the shelf-life-promoting properties of bioactive ingredients, primarily by improving their solubility, distribution within food matrices, and interaction with spoilage agents. Additionally, they prolong the presence of these compounds during food storage and processing by enhancing their thermal and processing stability, while controlling their release on food surfaces or within packaging (Hosseini et al., 2021).

8.3. Increase nutritional value

Numerous companies and research institutions are actively exploring new ingredients that offer potential health benefits. Examples include phytochemicals, wood-derived compounds like phytosterols, as well as pro- and prebiotics, novel carotenoids, trace minerals, and polyphenols. Many of these components are currently available or will become available in purified forms within the next decade. Incorporating them into food products will frequently necessitate technological advancements. Encapsulation is expected to play a significant role in this process, although it may increase the cost of using such ingredients, and careful consideration of bioavailability is essential (Rezaei, Nickfar, et al., 2023).

8.4. Food preservation

Nano-encapsulation is a nanoscale technique that involves packaging materials within nanocapsules, ensuring the functionality of the final product through controlled release mechanisms. Encapsulated ingredients offer several benefits, such as the sequential delivery of multiple active components, extended shelf life, enhanced stability, and pH-triggered controlled release. The primary goal of encapsulation is to maintain the stability of active compounds during processing and storage, while also preventing unfavorable interactions with the food matrix (Rezaei, Salari, et al., 2023).

8.5. Functional foods

Functional foods, which contain natural antioxidants, unsaturated fatty acids, probiotics, bioactive compounds, and vitamins, represent a key trend in the food industry. However, many of these components are unstable under typical conditions or have residual tastes that limit their use. These functional ingredients can enhance the nutritional value and functionality of food products. Encapsulation is a process that forms a protective barrier (a matrix or polymer coating) around the active component, preventing chemical interactions, shielding it from environmental factors (such as temperature, pH, enzymes, and oxygen), and enabling the controlled release of the component under specific conditions. The primary goals of this approach are to enhance the stability of bioactive compounds against unfavorable environmental factors, to facilitate their incorporation into food matrices, thus imparting functional properties to the products, and to ensure their controlled release at targeted sites in the gastrointestinal tract following consumption (Corrêa-Filho et al., 2019).

9. Encapsulation: Safety and cytotoxicity

In general, the toxicity and safety of various encapsulation methods depend on the type of encapsulation materials and the production processes. The use of biodegradable and natural polymers, precise control of production processes, and comprehensive toxicity testing are essential to assess the potential risks associated with each method.