Abstract

The research suggests a production method of insulating composites created from lignocellulosic agricultural biomass with fungal mycelium as a binder agent and offers a deeper investigation of their thermophysical properties. Particularly, the samples were meticulously evaluated for density and thermal conductivity. The function was built on the suggestion by the authors regarding the thermal conductivity-weight ratio indicator. The metric was initially introduced to assess the correlation between these parameters and was also applied to qualitatively evaluate the biocomposite among other commonly used natural insulations. An applied polynomial trend analysis indicated that the most effective densities for the wheat, hemp, and flax, which were 60, 85, and 105 kg·m−3 respectively. It was determined that the optimal density for wheat and hemp composites corresponded to values of 0.28 and 0.20 W−1·kg−1·m4·K of the coefficient, respectively. These values were superior to those revealed in other common natural insulating materials, such as cork, cotton stalks, hempcrete, timber, etc. As a result, the proposed insulating material may offer numerous opportunities for application in industrial settings of civil engineering.

Keywords: biocomposites, agricultural biomass, mycelium, thermal characteristics, density characteristics, insulation materials, lignocellulosic materials

1. Introduction

The thermal conductivity (TC) of insulation materials is the most important factor for energy efficiency. Thermal conductivity, denoted by the symbol λ, is a fundamental characteristic of a material. It quantifies the rate of heat transfer in watts (W) across a 1 m² area and 1 m thickness of the material when there is a temperature difference of 1 Kelvin (K) between the two surfaces along the direction of heat transfer. The standard unit for thermal conductivity is W·m−1·K−1. The thermal conductivity at a mean temperature of 10 °C is considered as determined in accordance with the principles of the method described in various standards such as EN 12664, EN 12667, EN 12939, and ASTM C518. A material is considered a thermal insulator if its conductivity is below 0.07 W·m−1·K−1 (0.06 kcal·m−1·h−1·°C−1) [1,2,3]. It determines how well they can prevent heat loss or gain in a building, which directly affects energy consumption. Using materials with lower thermal conductivity can create a comfortable indoor environment and reduce the need for heating, cooling, and ventilation systems, leading to substantial energy savings and environmental benefits [4,5]. Similarly, the decreased weight of insulation materials has the potential to greatly reduce both the energy consumption and expenses associated with transportation in construction. Especially, it may hold higher significance for various other applications, such as transportation containers, household appliances, and aircraft [6].

Mycelium is a type of fibrous fungus and presents a distinctive and groundbreaking method for low-energy production and waste control. Materials derived from mycelium are cost-effective, lightweight, capable of decomposing naturally, and have a minimal ecological footprint [7]. Girometta et al. [8] described efficient transformation of agricultural biomass, usually as an agricultural waste, into sustainable substitutes for insulating materials, offering an energy-efficient route for organic synthesis. Some investigations found that the feedstock used in mycelium-based composite materials affects their mechanical and thermal properties [9,10,11]. Flax, hemp, and wheat straw containing fillers are preferred due to their relatively low moisture content of 7–13%, density of 60–134 kg·m−3, and strength at 10% deformation of 0.36–0.38 MPa [12,13]. One research fabricated composite mycelial specimens with densities even falling within the range of 30–50 g·cm−3 [14], while composites incorporating forestry by-product substrates, such as sawdust, exhibit elevated densities ranging between 87 and 300 kg·m−3 [15]. The thermal conductivities established for these composites are as follows: 0.058 W·m−1·K−1 for mycelium-flax composite, 0.040 W·m−1·K−1 for mycelium-hemp composite, and 0.042 W·m−1·K−1 for mycelium-wheat composite within a density range of 94–135 g·cm−3 [12]. In general, mycelium composites exhibit a low thermal conductivity ranging from 0.05 to 0.10 W·m−1·K−1, which is comparable to that of conventional insulation materials [16,17] and potentially could even replace them [18,19].

There are other promising insulation materials fulfilling most of the requirements. However, no single material is high performing in every aspect and therefore the choice of insulating material must take into account given conditions of the specific structure. Common thermal insulation materials in construction include mineral fiber, expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane rigid foam (PUR). They provide good thermal conductivity (0.030 to 0.040 W·m−1·K−1) and are easy to handle, but they are non-renewable, have high embodied carbon, and can be toxic when burned [5]. These materials have significant environmental impacts due to their high embodied carbon content. For example, cellulose fiber (polysaccharide (C6H10O5)n) from recycled paper or wood pulp is renewable and recyclable. Table 1 illustrates the main components of lignocellulosic biomass, such as wheat, flax, and hemp.

Table 1.

Average component content of some perspective lignocellulosic biomass.

Depending on the moisture level, cellulose insulation’s usual thermal conductivity ranges between 0.040 W·m−1·K−1 and 0.050 W·m−1·K−1 [5]. Another research [26] investigated waste wood fibers as a thermal insulating material in a timber frame wall construction and established the thermal conductivity in the range within 0.048 and 0.055 W·m−1·K−1. Cotton stalks are one more renewable and bio-based insulating material. Using high frequency hot pressing, ref. [27] created a cotton stalk fiberboard without any chemical additions. The thermal conductivity of the fiberboards ranged from 0.0585 to 0.0815 W·m−1·K−1. Thermal insulating cork, which primarily manufactured from cork oak, is also utilized in isolating. Compared to fiber materials, it has the benefit of having a very high compressive strength. Cork has a thermal conductivity between 0.040 and 0.050 W·m−1·K−1 [5]. A promising bio-based contender for use as a thermal insulating material is hemp stem fiber. This material has a few more benefits, including the ability to ward off rodents, and great durability and other potentials [28,29]. For example, one investigation [28] defined the thermal conductivity of 0.052 W·m−1·K−1 for hemp stem fiber samples with the phenol formaldehyde (PF) resin glue at density of 300 kg·m−3. Another research [29] demonstrated λ-value on the close meaning of 0.051 W·m−1·K−1 for a hemp biomass with only gypsum binder at the slightly higher density of 332 kg·m−3. One more potential eco-friendly insulating material is flax straw. It is also renewable, biodegradable, and may be recycled or composted at the end of its useful life because it is manufactured from the waste products of the flax plant [30]. For example, Cerny et al. (2023) investigated the thermal performance of flax straw separately and combined with a liquid glass Na2O(SiO2) as a binder [31]. The material’s thermal conductivity was discovered in the minimum value of 0.072 W·m−1·K−1, and the binder had little effect on the material’s thermal conductivity significantly increasing its fire resistance. Hempcrete (a combination of hemp shavings and lime binder) is a lightweight material that offers an excellent thermal conductivity property that is measured between 0.087 and 0.100 W·m−1·K−1 at 300–400 kg·m−3 [32,33]. Vacuum insulation panels (VIPs) are an alternative super-insulator with a thermal conductivity of 0.004 W·m−1·K−1, but they degrade over time. They are more expensive than traditional insulators and can lose effectiveness if punctured [34].

A similar biocomposite, for example, obtained from various substrate materials, including wood pulp, millet grain, wheat bran, natural fiber, and calcium sulfate with the addition of Irpex lacteus mycelium under three different preparation protocols, showed the best average thermal conductivity of 0.06 W·m−1·K−1 (0.05–0.07 W·m−1·K−1) and the average density of 180 kg·m−3 (165–195 kg·m−3) [35]. Another work established the thermal conductivity for chopped hemp, flax and wheat straw fibers combined with a white rot mycelium spawn Trametes versicolor, and the samples showed the best values for flax biomass of 0.057 W·m−1·K−1, for hemp and wheat, respectively, and 0.040 W·m−1·K−1 and 0.041 W·m−1·K−1 at densities of biocomposites of 134, 99 and 94 kg·m−3 relatively [12]. Other research investigated two more composites derived from cellulose fiber and rapeseed bagasse with grown Ganoderma lucidum on the substrates, where the first composition demonstrated the best thermal conductivity of 0.085 W·m−1·K−1 with the average density of 373 kg·m−3, while the second one had the λ-value of 0.057 W·m−1·K−1 and the ρ-value of 156 kg·m−3 [36]. One study employed the fungal species Ganoderma williamsianum and Lentinus sajor-caju to create mycelium-based composites, which demonstrated superior physical properties including high density of from 221.05 kg·m−3 for rice straw and up to 340.31 kg·m−3 for wooden-based sawdust, low water absorption, and minimal shrinkage, as well as enhanced mechanical properties such as high compression, tensile, flexural, and impact strengths compared to other species examined [37]. However, it is important to note that in the context of insulating materials, the increased density may be considered a disadvantage.

Hence, there exists a variety of insulation materials including similar composites derived from agricultural biomass and mycelium. However, not all are environmentally sustainable and possess competitive physical and energy-efficient parameters. Moreover, there is a lack of evidenced techniques for comparing insulating materials using a combined indicator that considers weight and thermal insulation characteristics. Current research suggests the production technology and optimal formulation of a promising biocomposite derived from agricultural lignocellulosic biomass with mycelium as a binder. Earlier, sufficient achievements regarding analogous biomass-mycelium composites have been previously demonstrated through a range of literature that has gradually emerged since the influential study conducted by Greg Holts and colleagues in 2012 [38]. Some others, for example [39,40], reported good acoustic performance of this type of mycelium in insulating materials, others [36,41,42] demonstrated rapid colonization of the substrate, good thermal properties with the lowest density and good dimension stability of materials [38], in addition to proving good fire-resistant capacity by [40,43].

Current investigation also makes an in-depth analysis of the thermal conductivity and weight characteristics of the suggested biocomposites, comparing them with other insulating choices through the application of a alternative ratio coefficient.

The hypothesis of this investigation is that “a biocomposite based on agricultural lignocellulosic biomass and mycelium spores has the best weight-thermal conductivity ratio among known biodegradable insulators”. The primary objective of this research is to incorporate fungal mycelium as a binding agent to develop and characterize samples of insulating materials using three different types of lignocellulosic agricultural biomass: hemp, flax, and wheat straw. The secondary objective is to present a new qualitative Thermal Conductivity-Weight Ratio (TC-WR) coefficient for evaluating insulation alternatives and to quantitatively compare them by thermal conductivity and density characteristics. The third objective is to project optimal production meanings of density (O) for each basis of lignocellulosic biomass at the max value of TC-WR value.

2. Materials and Methods

2.1. Sample Formation Technique

First, the study took a closer look at three lignocellulosic ‘agricultural waste’ in particular at wheat, hemp and flax basis, with making by five equal samples of each type. This amount was determined under resource constraints with an average deviation of the results from the average values for thermal conductivity of only ±0.9%, and for density ±1% (Table 1).

The samples were produced as follows. First, all types of straw were chopped manually into fractions (particle size) of 5–15 mm and moistened. Next, the material was sterilized in a constant climate chamber (KBF 240, Binder GmbH, Tuttlingen, Germany) at 100 °C and 90% relative air humidity for 3 h. The straw mass was then inoculated with Ganoderma lucidum mycelium (Reishi fungi). Already prepared commercial fungi mycelium pack was used in the experiment test, which can be acquired in available marketplaces such as Alibaba.com.

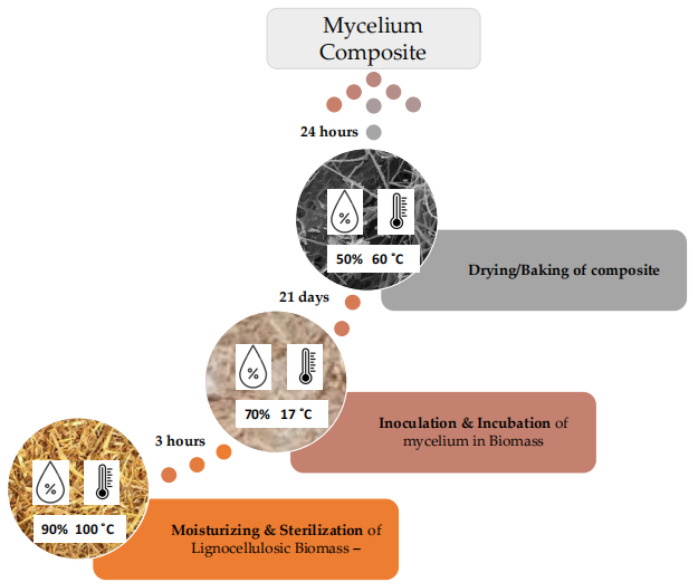

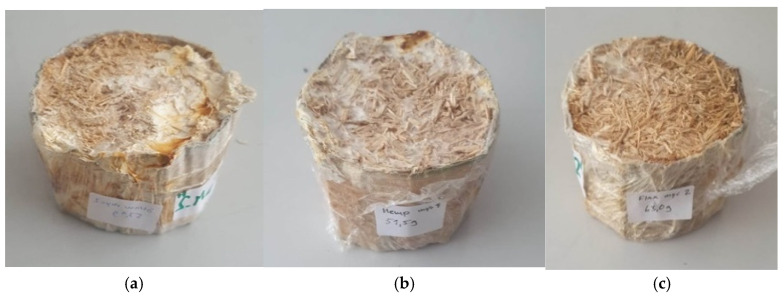

In practice, the mycelium growth process was established empirically by the authors (Figure 1) and the growth process itself was conducted in two main stages: (1) in a pile of straw for one week (growing fungi mycelium for 7 days in a small volume bulk substrate in a polyethylene bag with ventilated holes) (Figure 2) and (2) manually pressed directly into prepared cylindrical forms (Figure 3). The forms are removable cardboard, wrapped in polyethylene with ventilation holes for two weeks (14 days), totaling 21 days. Preliminary, the cardboard was made from a cellulose multilayer material, providing vapor and air permeability with a thickness of 3 mm and a density of 1890 g·m−2 and rolled them into necessary cylinders. Both are under similar environmental conditions in a climate chamber at 16–17 °C and 70–80% relative air humidity. After the growth process, the samples were removed from their forms and baked (dried) for 24 h (1 day) in a climate chamber at 60 °C and 50% relative air humidity. Thus, 15 samples had mycelium as a binder with different pure substrate fillers of wheat, hemp, and flax chopped straw (by 5 for each type) (Figure 3a–c, resp.; Figure 4). Although the mycelium growth in all 15 samples occurred under identical conditions, the resulting internal geometry of mycelium in straw, perimeter size, and density was slightly different. The samples created using cylindrical form with the diameter 96 mm and height of 65 mm.

Figure 1.

Methodology of sample formation technique.

Figure 2.

First stage: the process of fungi mycelium growth in a small substrate volume.

Figure 3.

(a) Chopped wheat with mycelium; (b) Chopped hemp with mycelium; (c) Chopped flax with mycelium. Source: Made by the authors.

Figure 4.

Preparing samples of each type in a climate chamber: wheat, hemp, and flax straw.

2.2. Thermal Conductivity and Density Measurements

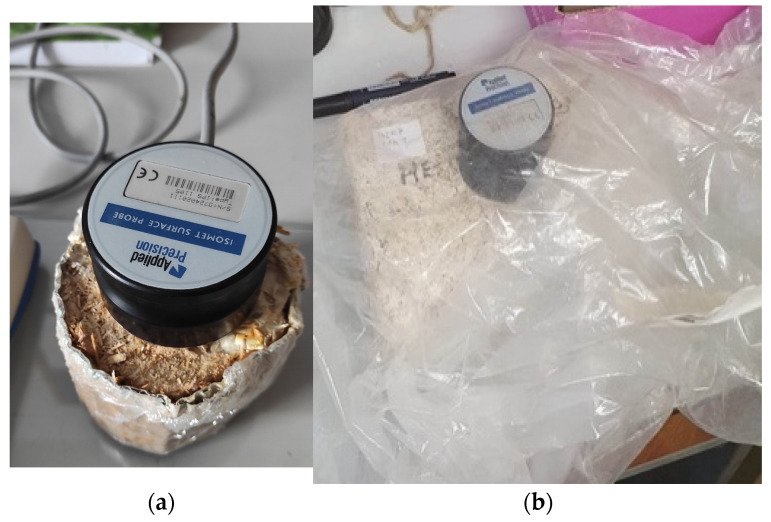

The transient method, also known as the non-steady method, was employed in accordance with ASTM D5334-08 [X+1] utilizing a thermal needle probe. Portable heat transfer analyzer (Isomet 2114, Applied Precision s.r.o., Bratislava, Slovakia) was used for measuring the thermal conductivity λ [W·m−1·K−1] of the samples. We performed the experiment in environmentally controlled laboratory area on the Faculty of Civil Engineering of the Slovak Technical University in Bratislava at constant 20 °C and 50% relative humidity to ensure stability throughout the measurement process. The Isomet 1224 is designed for high-precision thermal conductivity measurements and is equipped to compensate for minor ambient variations. In addition, the polyethylene cover was used to isolate the straw-mycelium composite samples while TC measuring (cca. 2 h), minimizing heat exchange with the surrounding environment, especially through convective air currents. In general, the heat transfer analyzer is a device that can assess heat transfer properties in various isotropic materials like cellular insulating materials, plastics, glasses, and minerals. The heat transfer analyzer has an accuracy of 5% ± 0.001 W·m−1·K−1 for thermal conductivity measurements between 0.015 and 0.70 W·m−1·K−1, and 10% for measurements between 0.70 and 6.0 W·m−1·K−1. The measurement reproducibility is 3% ± 0.001 W·m−1·K−1. These performance characteristics were within the acceptable statistical range and do not significantly affect the research findings [44].

In order to operate, the heat transfer analyzer had to be connected to the surface probe for hard materials, and the measuring range was set to 0.04–0.3 W·m−1·K−1. Each formed sample was measured by two measurements from two tangential surfaces (adjacent faces), and the median value was recorded between the two as λ [W·m−1·K−1] (Table 1). When the device was properly set up, the samples were prepared by means of measuring the dimensions and weight, and they were placed on a glass board. The surface probe was then positioned on top of the sample (Figure 3a) and a plastic foil was applied to cover the sample and probe (Figure 5b) in order to ensure the environmental conditions to stay the same for the duration of the measurement. The sample was then tested for duration of approximately five hours, after which the result was recorded.

Figure 5.

Measuring the thermal conductivity of the samples (a) the surface probe; (b) plastic foil covering for the samples.

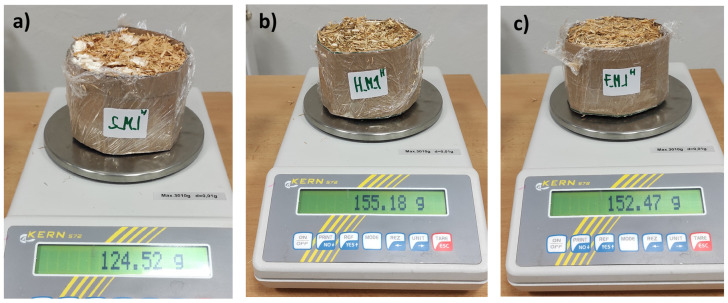

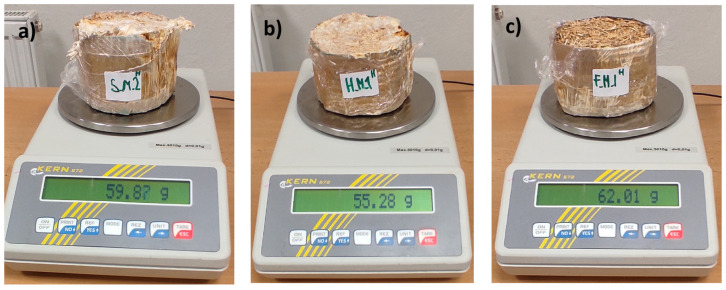

The density ρ [kg·m−3] of the material was measured manually for each of the two samples with laboratory scales (Kern 572, KERN & SOHN GmbH, Balingen, Germany) (max. measurement mass m = 3010 g; deviations d = 0.01 g) (Figure 6 and Figure 7) and a manual measuring ruler. The results of both measurements were recorded within the range of values ρmin–ρmax [kg·m−3] obtained for the material. In particular, the density of the composition was measured using the equation [45]:

| (1) |

where m is the mass of the material (in kg); is 3.14159; D is the diameter of the cylinder samples (in meters); and h is cylinder height (in meters). Diameter and height were the nominal dimensions of the molds used to produce the samples. The average values of the parameters were calculated as arithmetic means. Moisture content MC (%) in samples was manually measured by weight drying at 20 °C following ISO 16979:2003 [46] by formula (Figure 6 and Figure 7):

| (2) |

Figure 6.

Representative samples of wheat-based (a), hemp-based (b) and flax-based (c) composites injected with mycelium during the process of forming and weighing samples before drying.

Figure 7.

Representative samples of wheat-based (a), hemp-based (b) and flax-based (c) composites binded with a fungal mycelium after drying.

2.3. TC-WR Indicator and Polynomial Trend Analysis

A thermal conductivity to weight ratio (TC-WR) measurement in given form was firstly introduced by the authors and was used to qualitatively evaluate the effectiveness in reducing heat transfer relative to its weight. Since the indicator is inverse, it means that the higher the ratio, the more competitive the material is in the list of alternatives. For insulation materials, both factors were taken into account when determining the efficiency using the equation, which was suggested by the authors in current research:

| (3) |

where λ is the thermal conductivity of the material in W·m−1·K−1, and ρ is the density of the material in kg·m−3. Higher values indicate better insulation efficiency.

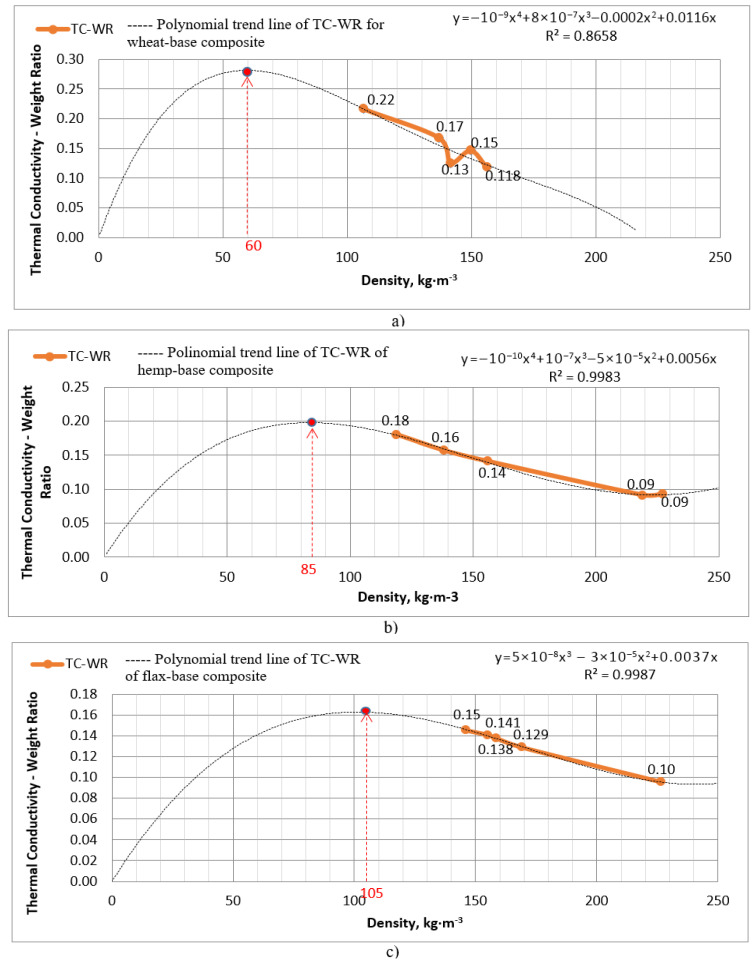

Figure 9 presents the TC-WR curve, which illustrates the TC-WR values and the correlation between samples of each biomass category. To determine the optimal density point (O-density) at the peak of the TC-WR polynomial trend line, a mathematical prediction function was employed. A polynomial trend curve is a type of prediction utilized in data analysis and graphing to depict the correlation between independent and dependent variables through a polynomial equation. These trend lines had the flexibility to bend and curve in order to accommodate a wide array of data patterns, making them valuable for capturing intricate relationships [47]. Potentially, it is able to generalize and accurately predict other meanings of TC-WR at wide range of density. The general form of a polynomial equation of degree n is [48]:

| y = a0 + a1x+ a2x2 + a3x3 +⋯+ anxn | (4) |

where y is the dependent predictable variable meaning density of the material, and x is the independent variable of density range within 0–250 kg·m−3. The actual significant range was considered to be between 50 and 250 kg·m−3 even if the maximum value will be less than the density of <50 kg·m−3 since, according to authors’ observation, such samples will not be dense enough to hold a shape for practical construction purposes. In general, composites that incorporate agricultural by-product fillers, such as bast fibers or straw, generally exhibit lower densities, ranging from 60 to 130 kg·m−3, compared to those that utilize forestry by-product materials like sawdust, which can reach densities between 87 and 300 kg·m−3 [15]. One research declared densities for treatments between 66.5 and 224 kg·m−3 [38]. Thus, a0, a1, an are the coefficients that play a crucial role in defining the precise form and orientation of the curve. These coefficients as well as the best fit function were described by software (Microsoft Excel, Microsoft Corporation, Redmond, WA, USA) and derived using polynomial regression, a method that computes values to closely match the given data points [49] which applies to five measured samples for each of three types of composite. All five samples of each type of biomass do not differ in composition, but they do differ in density, since the method of creating the forms involved manual compressing.

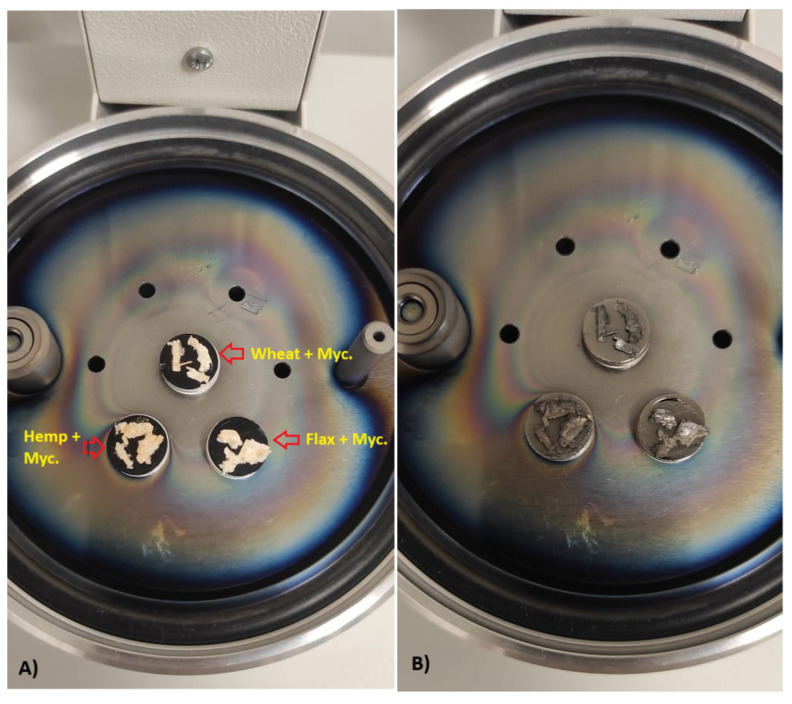

2.4. Scanning Electron Microscope (SEM) Analysis

Images of the composite surface were captured using a VEGA 3 SBU scanning electron microscope from TESCAN (TESCAN GROUP, a.s., Brno, Czech Republic). The SEM examination focused on three studied types of biomass particles measuring in average 6.5 mm (long) × 1 mm (width), which are pre-installed in rotary pumped sputter coater Quorum SC7620 (Quorum Technologies Limited, Laughton, UK) for coating with non-oxidizing metals like Au, Au/Pd, Ag, Pt and Pt/Pd required for SEM analysis (Figure 8). SEM analysis was conducted within a high vacuum environment, maintaining a pressure of less than 1 × 10−2 Pa. A 10 kV electron beam, achieving a resolution of 3.0 nm (as defined by the Vega3 TESCAN) [50], was utilized, with a working distance ranging from 7 to 9 mm. Adjustments to the incident probe current, as well as contrast and brightness settings, were made to ensure high-quality imaging for surface imaging (SE images). Each individual microscope image includes detailed information regarding the microscope mode, detector mode, working distance in millimeters, field of view in millimeters, scale, and magnification level.

Figure 8.

Prepared composites for SEM analysis (A): Coated particles with non-oxidising metals (B).

3. Results

The result of the respective density and thermal conductivity for tested wheat, hemp, and flax -based samples with a mycelium binder are presented in Table 2. All samples were then ranked in descending order by the quality indicator TC-WR among some common insulation materials (Table 3). It can be noted that the different mycelium-based materials show similar thermal conductivity properties in the range of 0.043–0.056 W·m−1·K−1.

Table 2.

Measured values of Thermal conductivity [W·m−1·K−1] and Density [kg·m−3] for 15 test samples at an ambient temperature of 20°.

| Biocomposite, Sample No. | Mass Before Drying, [kg] | Mass After Drying, [kg] | Initial Moisture Content MC [%] | Thermal Conductivity, λ [W·m−1·K−1] | Average Thermal Conductivity, λAvg [W·m−1·K−1], dev. ± 0.9% |

Density, ρ [kg·m−3] | Average Density, ρAvg [kg·m−3], dev. ± 1 % |

|---|---|---|---|---|---|---|---|

| Flax + Mycelium, 1 | 59.60 | 0.045 | 158 | ||||

| Flax + Mycelium, 2 | 0.046 | 220 | |||||

| Flax + Mycelium, 3 | 0.160 | 0.064 | 0.047 | 0.046 | 146 | 170 | |

| Flax + Mycelium, 4 | 0.045 | 155 | |||||

| Flax + Mycelium, 5 | 0.045 | 169 | |||||

| Hemp + Mycelium, 1 | 53.08 | 0.047 | 227 | ||||

| Hemp + Mycelium, 2 | 0.045 | 156 | |||||

| Hemp + Mycelium, 3 | 0.152 | 0.071 | 0.046 | 0.047 | 119 | 172 | |

| Hemp + Mycelium, 4 | 0.046 | 138 | |||||

| Hemp + Mycelium, 5 | 0.050 | 219 | |||||

| Wheat + Mycelium, 1 | 54.82 | 0.043 | 137 | ||||

| Wheat + Mycelium, 2 | 0.043 | 107 | |||||

| Wheat + Mycelium, 3 | 0.135 | 0.061 | 0.056 | 0.048 | 142 | 138 | |

| Wheat + Mycelium, 4 | 0.054 | 156 | |||||

| Wheat + Mycelium, 5 | 0.045 | 150 |

TC-WR coefficient showed quite similar meanings for flax and hemp raw fillers of 0.127 and 0.123, respectively, but the wheat-based sample appeared with a higher value of 0.148 units (Table 3). In turn, the best indication demonstrated non-organic insulations EPS, VIP, PUR, XPS reaching numbers by a wide margin between 0.840 and 1.389 units because of the high-performed average TC, which was between 0.020 and 0.040 W·m−1·K−1 (except VIP) and extra light density with the average range of 15–40 kg·m−3 [51,52,53,54,55,56]. VIP is quite dense (200 kg·m−3), but it has an extremely low thermal conductivity of 0.004 W·m−1·K−1 [6,57], which allowed it to become the first among the observed insulators in terms of qualitative ‘TC-Weight’ indicator.

Among the bio-based materials, the best values of TC-WR coefficient were revealed by sheep wool, cellulose fibers and mineral wool, respectively (Table 3). Herein, the quality ‘TC-weight ratio’ indicator of samples with mycelium fell below the leading samples from the organic matter because of a bit higher TC and much higher density in compare with sheep wool and cellulose fibers insulations. At the same time, the widespread mineral wool has quite similar density, though it has slightly better confirmed TC values between 0.034 and 0.045 [58,59].

Pure organic materials like cotton stalks and light earth, as well as bio-based composite materials such as hempcrete and flax-glass, showed TC-WR coefficient ratios between 0.041 and 0.057 and were lower in the ‘rank’ (Table 3) than the ‘agriwaste-mycelium’ composites studied. Cork showed slightly a lower meaning of 0.139 than wheat and mycelium composite (0.148) but higher than other studied composites of lignocellulosic biomass. Pure softwood showed the worst thermal conductivity to weight ratio coefficient, which is 0.015.

In Figure 9, there are polynomial trend lines of TC-WR for three types of lignocellulosic agricultural biomass. In particular, the prediction curve for wheat-based composite has the lowest approximation reliability value (R2), namely 0.865, which is still high enough to explain the ratio. R2 is a statistical measure that indicates the proportion of the variance in the dependent variable that is predictable from the independent variables in a regression model. The other two curves with hemp- and flax-based materials have the highest values of R2 which are 0.998 and 0.998, respectively, and they indicate a better fit of the regression model to the data, suggesting that the independent variables are more effective at explaining the variability in the dependent variable. The range of significance lies between 50 and 250 kg·m−3. Notably, the maximum values of TC-WR curves for wheat-, hemp-, and flax-based composites exceed a density value of 50 kg·m−3 in all three cases (Figure 9a–c) and specifically reaching their max point at density meanings of 60 kg·m−3, 85 kg·m−3 and 105 kg·m−3, respectively.

Figure 9.

TC-WR values for measured types of biomass samples (orange line) and polynomial trend lines of TC-WR for density range of 0–250 (kg·m−3) with the approximation reliability values (R2) between 0.865 and 0.998 and O-density point for wheat (a), hemp (b) and flax (c) straw composites with mycelium binder.

Table 3.

Aggregated findings of different basic insulation materials are sorted by ‘Thermal Conductivity—Weight Ratio’ in descending order.

| Insulation Material | Thermal Conductivity at 10 °C, λmin–λmax [W·m−1·K−1] | Dry Density (Own Mean.), ρmin–ρmax [kg·m−3] |

Bio 1 | Reference | Average Thermal Conductivity *, λAvg [W·m−1·K−1] |

Average Density *, ρAvg [kg·m−3] |

Thermal Conductivity-Weight Ratio *, 1/(λAvg·ρAvg) [W−1·kg−1·m4·K] |

|---|---|---|---|---|---|---|---|

| Vacuum Insulation panels (VIP) | 0.004 | 160–200 | N | [6,57] | 0.004 | 180 | 1.389 |

| Polyurethane rigid foam (PUR) | 0.020–0.030 | 30–45 | N | [51,52] | 0.025 | 38 | 1.053 |

| Expanded polystyrene (EPS) | 0.030–0.040 | 15–40 | N | [53,54] | 0.035 | 27.5 | 1.039 |

| Sheep wool | 0.032–0.054 | 10–40 | Y | [60,61,62] | 0.043 | 25 | 0.930 |

| Extruded polystyrene (XPS) | 0.028–0.040 | 25–45 | N | [55,56] | 0.034 | 35 | 0.840 |

| Cellulose Fibers | 0.036–0.042 | 40–70 | Y | [63,64] | 0.039 | 55 | 0.466 |

| Wheat + mycelium Trametes versicolor | 0.042 | 94 | Y | [12] | 0.042 | 94 | 0.252 |

| Hemp + mycelium Trametes versicolor | 0.040 | 99 | Y | [12] | 0.040 | 99 | 0.250 |

| Mineral Wool | 0.034–0.045 | 120–140 | Y | [58,59] | 0.039 | 130 | 0.197 |

| Wheat + mycelium Ganoderma lucidum * | 0.043–0.056 | 107–156 | Y | Current research | 0.048 | 138 | 0.148 |

| Cork | 0.040–0.050 | 80–240 | Y | [65,66] | 0.045 | 160 | 0.139 |

| Flax + mycelium Trametes versicolor | 0.058 | 135 | Y | [12] | 0.058 | 135 | 0.128 |

| Flax + mycelium Ganoderma lucidum * | 0.045–0.047 | 146–220 * | Y | Current research | 0.046 | 171 | 0.127 |

| Hemp + mycelium Ganoderma lucidum * | 0.045–0.050 | 119–227 | Y | Current research | 0.047 | 172 | 0.123 |

| Soybean straw + Mycelium Ceriporia lacerata | 0.054 | 160 | [67] | 0.054 | 160 | 0.116 | |

| Rapeseed bagasse + mycelium Ganoderma lucidu | 0.057 | 156 | Y | [36] | 0.057 | 156 | 0.112 |

| various substrate materials + mycelium Irpex lacteus | 0.060 | 180 | Y | [35] | 0.060 | 180 | 0.092 |

| Bark fiber | 0.044–0.063 | 164–276 | Y | [68] | 0.0535 | 220 | 0.084 |

| Flax + waterglass | 0.066–0.068 | 235–284 | Y | [31] | 0.0672 | 259.5 | 0.057 |

| Cotton Stalks | 0.058–0.081 | 150–450 | Y | [2,27] | 0.070 | 300 | 0.048 |

| Hempcrete | 0.057–0.066 | 389–441 | Y | [32] | 0.0619 | 365 | 0.044 |

| Light-earth | 0.060–0.120 | 190–353 | Y | [69] | 0.090 | 271.5 | 0.041 |

| Cellulose fiber + mycelium Ganoderma lucidu | 0.085 | 373 | [36] | 0.085 | 373 | 0.031 | |

| Timber (softwood) | 0.130 | 500 | Y | [70] | 0.130 | 500 | 0.015 |

Legend: *—Established averages by the authors, Bio 1—Biodegradability (N—No, Y—Yes).

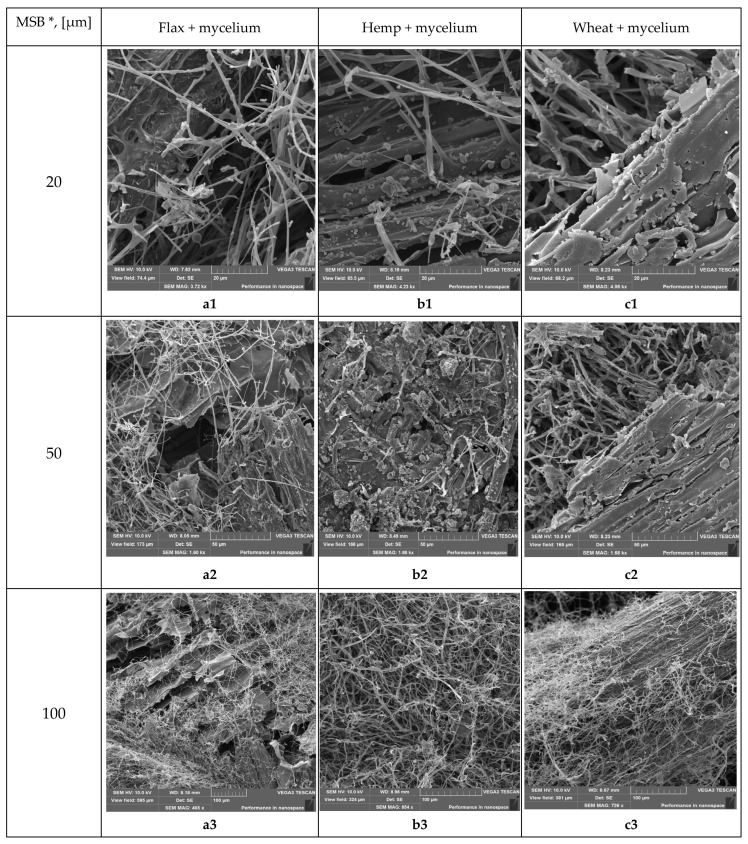

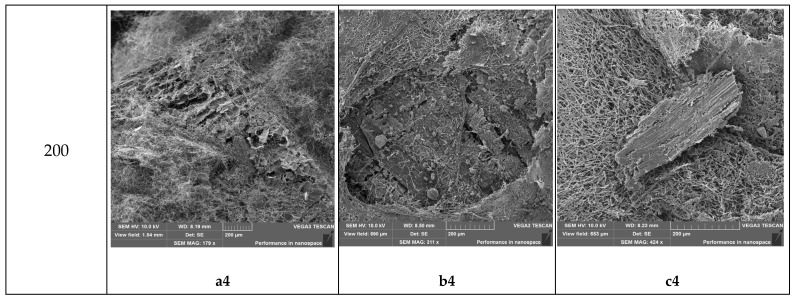

The morphological characteristics of straw–micelium composites were examined by SEM. It was found in Figure 10 that, in all three composite types, flax + mycelium (a1–a4), hemp + mycelium (b1–b4), wheat + mycelium (c1–c4), the fungi established robust adhesion to the substrate surfaces, which is a critical factor for material cohesion and structural integrity. The hyphae are intricately interwoven within the composites, creating a dense network that enhances structural integrity and strength. The coverage of the straw surface in all cases was thorough, demonstrating that the fungal growth could adapt to the morphology of this substrate. In particular, it is clearly seen at the 20 μm magnification scale (Figure 10a1,b1,c1). The natural growth behavior of the mycelium played a pivotal role in binding the substrates, demonstrating that fungi not only act as a natural adhesive but also enhance the composite’s integrity by bridging gaps between fibers and ensuring a uniform composite matrix. The morphological characteristics of the lignocellulosic biomass—micelium composites discussed within this study were similar to those in alternative research [10,37,71].

Figure 10.

Scanning electron microscopic images of biomass–micelium composites obtained in this study: The surfaces of straw-micelium composites produced from Ganoderma lucidum mycelium with flax straw (a1–a4), hemp straw (b1–b4) and with wheat straw (c1–c4). Legend: MSB *—Magnification scale bar.

4. Discussion

4.1. General Perspectives

Despite the painstaking work of measuring thermal conductivity, density, and the qualitative relationship between the first two, other factors also influence the characteristics and quality of insulating materials, they include: durability, resistance to fire, rodents and microorganisms, mechanical strength, toxicity, workability, freezing/thawing cycles, water resistance and cost efficiency, scalability, resource availability, etc. In addition, specific application requirements also play significant roles in selecting the most suitable insulation material, which is out the scope of current research. In summary, our hypothesis was only partially confirmed. We can now state that biocomposites made from agricultural biomass and fungal mycelium demonstrate impressive characteristics regarding weight and thermal conductivity, positioning them among the top bio-based choices available. On the other hand, the evaluation of sheep wool, cellulose fibers, and mineral wool showed a higher coefficient. Although the thermal conductivity values were found to be average in the data examined, we believe that the suggested composites hold the most potential and promise for mass industrial production. Due to its 100% biodegradability, better availability, potentially lower cost of the biocomposite, and lack of regulation compared to other alternatives, it is more attractive than others. Moreover, these materials have the fastest rate of resource renewal, typically within 6 months on average. The mathematical analysis applied indicated a significant potential for reducing the density of suggested these materials while minimizing the decrease in thermal conductivity.

4.2. Industrialization and Distinctive Features

In order to facilitate the industrialization of the material and ensure consistent thermal and weight characteristics, it is imperative to maintain strict control over the moisture content, particle size, and pressing force of the samples. Although the article does not delve into these factors in depth, it is worth noting that the samples were exclusively produced for the purpose of the study. Due to some research limitations, mycelium materials, similar to all other materials, are expected to encounter various challenges that may influence their performance. For example, the variation in optimal density among the ostensibly lightest wheat, medium hemp, and heavier flax biomass composites can likely be attributed to the inherent properties of the materials, as the disparity in thermal conductivity is minimal. The study [35] has the same order as wheat-, hemp-, and flax-based with densities of 94 kg·m−3, 99 kg·m−3 and 135 kg·m−3, respectively. In a view of properties of the materials, hemp and flax fibers have very low lignin content (usually under 3%), whereas wheat straw and wood fibers possess high lignin content (higher than 10% and 20%, respectively). Lignin is a polyphenolic thermoplastic compound, similar to that of gluten [72]. Moreover, polyphenolic structures are well known for their strong interactions with proteins [73], which may explain the better adhesive capacity of wheat straw and the formation of stable forms of lower density and greater porosity. In general, the mycelium composites demonstrate a significantly porous microstructure (Figure 10). It is proposed that this porosity plays a crucial role in enhancing thermal insulation while simultaneously decreasing density. The network of interconnected pores is likely to hinder heat transfer, resulting in a reduction in the composite material’s thermal conductivity. Furthermore, the existence of voids contributes to a lower overall material density, rendering these composites lightweight and potentially beneficial for applications that necessitate a decrease in material mass. These results align with the findings of Alaneme et al. (2023) [74], who noted a relationship between increased porosity and the enhancement of thermal and mechanical properties in bio-based composites. Therefore, further testing is needed to confirm these findings and assess the material’s potential for industrial production and, in general, for sustainable development and circular economy.

5. Conclusions

This study demonstrates the author’s method for creating an insulating material using agricultural biomass with fungal mycelium as a binder and thoroughly analyzed for thermal conductivity, density characteristics, and their qualitative relationship.

Research on thermal conductivity. In particular, the thermal conductivity coefficient measurements indicated quite close results across three lignocellulosic material variations and lie between 0.435 and 0.585 W·m−1·K−1. It is evident that the value remains consistent regardless of the type of agricultural residues.

Analysis by thermal conductivity—weight ratio (TC-WR) coefficient. During the investigation, the suggestion was made to utilize a qualitative TC-WR coefficient in evaluating thermal insulation materials, considering the inverse correlation between the density and thermal conductivity derivatives. The flax- and hemp-based samples displayed quite a close TC-WR meanings of 0.127 W−1·kg−1·m4·K and 0.123 W−1·kg−1·m4·K, respectively. However, the wheat-based sample showed a higher value of 0.148 W−1·kg−1·m4·K, which can be attributed to its lower density. In particular, the biomass with fungal mycelium binder demonstrated excellent values for this ratio and was one of the leading among biodegradable conventional materials included in the comparison. There were three that performed better: sheep wool (0.93 W−1·kg−1·m4·K), cellulose fibers (0.466 W−1·kg−1·m4·K), and mineral wool (0.197 W−1·kg−1·m4·K). Cork showed a middle performance among cellulosic agro ‘waste’, with mycelium having the indicative ratio of 0.139 W−1·kg−1·m4·K appropriately. Among the known analog composites derived from biomass and mycelium, suggested composites ranked third, fifth, and sixth out of ten types based on the TC-WR indicator (Table 3). Two first mycelium containing compounds in ranking may be attributed to the lower density of samples.

Predicting an optimal density. Our analysis aimed at identifying the optimal density to achieve the best proposed TC-WR coefficient. The values obtained exhibit a strong correlation with the findings from other comparable studies, although they show minor differences in absolute terms. For instance, Elsacker et al (2019) reported densities of 99 kg·m−3 for hemp biomass with mycelium, whereas our findings demonstrated the optimum density for this biomass at 85 kg·m−3. Specifically, a polynomial trend line was utilized to determine the most optimal production densities for wheat, hemp, and flax biomass, resulting in recommendations of 60–85–105 kg·m−3, respectively, to achieve the optimal TC-WR value for them. These densities strike a balance between thermal conductivity and weight of the insulating material, leading to TC-WR coefficients of 0.28–0.20–0.165 W−1·kg−1·m4·K for wheat–hemp–flax composites, respectively, which has a better potential for wheat with mycelium Ganoderma lucidum against mineral wool insulation with 0.197 W−1·kg−1·m4·K on average and wheat biomass with mycelium Trametes versicolor at 0.252 W−1·kg−1·m4·K.

Author Contributions

M.B.—Conceptualization, methodology, investigation, data acquisition, software; Y.K.—methodology, data curation, investigation, writing—original draft preparation; P.B.—Project administration, formal analysis, funding acquisition; U.P.—Formal analysis, Resources; F.S.—visualization, validation; T.Z.—validation, visualization; P.K.—writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Some pictures on test methodology and lab data will be available at Mendeley Data, V1, reserved DOI: 10.17632/2f38ktnt92.1.

Conflicts of Interest

The authors declare no conflicts of interests.

Funding Statement

This research received no external funding.

Footnotes

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

- 1.Dilmac S., Kesen N. A comparision of new Turkish thermal insulation standard (TS 825), ISO 9164, EN 832 and German regulation. Energy Build. 2003;35:161–174. doi: 10.1016/S0378-7788(02)00020-8. [DOI] [Google Scholar]

- 2.Asdrubali F., D’Alessandro F., Schiavoni S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015;4:1–17. doi: 10.1016/j.susmat.2015.05.002. [DOI] [Google Scholar]

- 3.Humaish H.H. Ph.D. Thesis. Université de Picardie Jules Verne; Amiens, France: 2016. Thermal Techniques for Characterizing Building Insulation Materials. [Google Scholar]

- 4.Lassandro P. Durability of Building Components After the Useful Life of a Building: Reuse or Recycling of Materials/Components. 2003. [(accessed on 1 March 2023)]. Available online: https://www.researchgate.net/publication/306365258_Durability_of_building_components_after_the_useful_life_of_a_building_reuse_or_recycling_of_materialscomponents.

- 5.Jelle B.P. Traditional, State-of-the-Art and Future Thermal Building Insulation Materials and Solutions—Properties, Requirements and Possibilities. Norwegian University of Science and Technology (NTNU); Trondheim, Norway: 2011. [(accessed on 23 February 2023)]. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/2436166/Traditional+State-of-the-Art+and+Future+Thermal+Building+Insulation+Materials+and+Solutions+-+Properties+Requirements+and+Possibilities57823.pdf?sequence=1. [Google Scholar]

- 6.Tenpierik M., Cauberg H. Vacuum Insulation Panel: Friend or foe?; Proceedings of the PLEA2006—The 23rd Conference on Passive and Low Energy Architecture; Geneva, Switzerland. 6–8 September 2006. [Google Scholar]

- 7.Sydor M., Cofta G., Doczekalska B., Bonenberg A. Fungi in Mycelium-Based Composites: Usage and Recommendations. Materials. 2022;15:6283. doi: 10.3390/ma15186283. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Girometta C., Picco A.M., Baiguera R.M., Dondi D., Babbini S., Cartabia M., Pellegrini M., Savino E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability. 2019;11:281. doi: 10.3390/su11010281. [DOI] [Google Scholar]

- 9.Ziegler A.R., Bajwa S.G., Holt G.A., McIntyre G., Bajwa D.S. Evaluation of Physico-Mechanical Properties of Mycelium Reinforced Green Biocomposites Made from Cellulosic Fibers. Appl. Eng. Agric. 2016;32:931–938. doi: 10.13031/aea.32.11830. [DOI] [Google Scholar]

- 10.Appels F.V., Camere S., Montalti M., Karana E., Jansen K.M., Dijksterhuis J., Krijgsheld P., Wösten H.A. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019;161:64–71. doi: 10.1016/j.matdes.2018.11.027. [DOI] [Google Scholar]

- 11.Haneef M., Ceseracciu L., Canale C., Bayer I.S., Heredia-Guerrero J.A., Athanassiou A. Advanced Materials from Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017;7:41292. doi: 10.1038/srep41292. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Elsacker E., Vandelook S., Brancart J., Peeters E., De Laet L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE. 2019;14:e0213954. doi: 10.1371/journal.pone.0213954. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Babenko M., Estokova A., Unčik S., Savytskyi M. Comparative study of lightweight concretes based on hemp and flax straw. Slovak J. Civ. Eng. 2022;30:11–16. doi: 10.2478/sjce-2022-0023. [DOI] [Google Scholar]

- 14.Islam M.R., Tudryn G., Bucinell R., Schadler L., Picu R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017;7:13070. doi: 10.1038/s41598-017-13295-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Jones M., Mautner A., Luenco S., Bismarck A., John S. Engineered Mycelium Composite Construction Materials from Fungal biorefineries: A Critical Review. Mater. Des. 2020;187:108397. doi: 10.1016/j.matdes.2019.108397. [DOI] [Google Scholar]

- 16.Dias P.P., Jayasinghe L.B., Waldmann D. Investigation of Mycelium-Miscanthus composites as building insulation material. Results Mater. 2021;10:100189. doi: 10.1016/j.rinma.2021.100189. [DOI] [Google Scholar]

- 17.Mbabali H., Lubwama M., Yiga V.A., Were E., Kasedde H. Development of Rice Husk and Sawdust Mycelium-Based Bio-composites: Optimization of Mechanical, Physical and Thermal Properties. J. Inst. Eng. India Ser. D. 2024;105:97–117. doi: 10.1007/s40033-023-00458-x. [DOI] [Google Scholar]

- 18.Abu-Jdayil B., Mourad A.H., Hittini W., Hassan M., Hameedi S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019;214:709–735. doi: 10.1016/j.conbuildmat.2019.04.102. [DOI] [Google Scholar]

- 19.Erlandsson M., Byfors K., Lundin J.S. Byggsektorns Historiska Klimatpåverkan och en Projektion för nära noll. IVL Svenska Miljöinstitutet; Stockholm, Sweden: 2017. [Google Scholar]

- 20.Geremew A., Winne P., Demissie T., Backer H. Characterization of Wheat Straw Fiber Grown Around Jimma Zone, ETHIOPIA. J. Nat. Fibers. 2022;20:2134268. doi: 10.1080/15440478.2022.2134268. [DOI] [Google Scholar]

- 21.Zhang L., Larsson A., Moldin A., Edlund U. Comparison of lignin distribution, structure, and morphology in wheat straw and wood. Ind. Crops Prod. 2022;187:115432. doi: 10.1016/j.indcrop.2022.115432. [DOI] [Google Scholar]

- 22.Bakisgan C., Dumanli A., Yürüm Y. Trace elements in Turkish biomass fuels: Ashes of wheat straw, olive bagasse and hazelnut shell. Fuel. 2009;88:1842–1851. doi: 10.1016/j.fuel.2009.04.027. [DOI] [Google Scholar]

- 23.Al-Akhras N.M., Abu-Alfoul B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002;32:859–863. doi: 10.1016/S0008-8846(02)00716-0. [DOI] [Google Scholar]

- 24.Liu M., Thygesen A., Summerscales J., Meyer A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crops Prod. 2017;108:660–683. doi: 10.1016/j.indcrop.2017.07.027. [DOI] [Google Scholar]

- 25.Ding J., Liang L., Meng X., Yang F., Pu Y., Ragauskas A.J., Yoo C.G., Yu C. The physiochemical alteration of flax fibers structuring components after different scouring and bleaching treatments. Ind. Crops Prod. 2021;160:113112. doi: 10.1016/j.indcrop.2020.113112. [DOI] [Google Scholar]

- 26.Cetiner I., Shea A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018;168:374–384. doi: 10.1016/j.enbuild.2018.03.019. [DOI] [Google Scholar]

- 27.Zhou X., Zheng F., Li H., Lu C. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010;42:1070–1074. doi: 10.1016/j.enbuild.2010.01.020. [DOI] [Google Scholar]

- 28.Gaujena B., Agapovs V., Borodinecs A., Strelets K. Analysis of Thermal Parameters of Hemp Fiber Insulation. Energies. 2020;13:6385. doi: 10.3390/en13236385. [DOI] [Google Scholar]

- 29.Florea I., Manea D.L. Analysis of Thermal Insulation Building Materials Based on Natural Fibers. Procedia Manuf. 2019;32:230–235. doi: 10.1016/j.promfg.2019.02.207. [DOI] [Google Scholar]

- 30.Babenko M., Estokova A., Savytskyi M., Unčík S. Study of Thermal Properties of Lightweight Insulation Made of Flax Straw. Slovak J. Civ. Eng. 2018;26:9–14. doi: 10.2478/sjce-2018-0008. [DOI] [Google Scholar]

- 31.Cerny P., Babenko M., Bartos P., Kononets Y., Kriz P., Rabenseifer R., Spalek F. Complex Study of the Composite Building Material Based on Flax Straw Organic Waste: Hygrothermal and Physicochemical Properties. Waste Biomass Valorization. 2024;15:2231–2247. doi: 10.1007/s12649-023-02273-7. [DOI] [Google Scholar]

- 32.Bedlivá H., Isaacs N. Hempcrete—An Environmentally Friendly Material? Adv. Mater. Res. 2014;1041:83–86. doi: 10.4028/www.scientific.net/AMR.1041.83. [DOI] [Google Scholar]

- 33.Abdellatef Y., Khan M.A., Khan A., Alam M.I., Kavgic M. Mechanical, thermal, and moisture buffering properties of novel insulating hemp-lime composite building materials. Materials. 2020;13:5000. doi: 10.3390/ma13215000. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Kalnæs S.E., Jelle B.P. Vacuum insulation panel products: A state-of-the-art review and future research pathways. Appl. Energy. 2014;116:355–375. doi: 10.1016/j.apenergy.2013.11.032. [DOI] [Google Scholar]

- 35.Yang Z., Zhang F., Still B., White M., Amstislavski P. Physical and mechanical properties of fungal mycelium-based biofoam. J. Mater. Civ. Eng. 2017;29:04017030. doi: 10.1061/(ASCE)MT.1943-5533.0001866. [DOI] [Google Scholar]

- 36.Gauvin F., Tsao V., Vette J., Brouwers H.J.H. Construction Technologies and Architecture. Trans Tech Publications Ltd.; Wollerau, Switzerland: 2022. Physical properties and hygrothermal behavior of mycelium-based composites as foam-like wall insulation material. [DOI] [Google Scholar]

- 37.Aiduang W., Kumla J., Srinuanpan S., Thamjaree W., Lumyong S., Suwannarach N. Mechanical, physical, and chemical properties of mycelium-based composites produced from various lignocellulosic residues and fungal species. J. Fungi. 2022;8:1125. doi: 10.3390/jof8111125. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Holt G.A., Mcintyre G., Flagg D., Bayer E., Wanjura J.D., Pelletier M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mater. Bioenergy. 2012;6:431–439. doi: 10.1166/jbmb.2012.1241. [DOI] [Google Scholar]

- 39.Pelletier M.G., Holt G.A., Wanjura J.D., Bayer E., McIntyre G. An evaluation study of mycelium based acoustic absorbers grown on agricultural by-product substrates. Ind. Crops Prod. 2013;51:480–485. doi: 10.1016/j.indcrop.2013.09.008. [DOI] [Google Scholar]

- 40.Pelletier M.G., Holt G.A., Wanjura J.D., Greetham L., McIntyre G., Bayer E., Kaplan-Bie J. Acoustic evaluation of mycological biopolymer, an all-natural closed cell foam alternative. Ind. Crops Prod. 2019;139:111533. doi: 10.1016/j.indcrop.2019.111533. [DOI] [Google Scholar]

- 41.Xing Y., Brewer M., El-Gharabawy H., Griffith G., Jones P. Growing and testing mycelium bricks as building insulation materials. IOP Conf. Ser. Earth Environ. Sci. 2018;121:022032. doi: 10.1088/1755-1315/121/2/022032. [DOI] [Google Scholar]

- 42.Ridzqo I.F., Susanto D., Panjaitan T.H., Putra N. Sustainable Material: Development Experiment of Bamboo Composite Through Biologically Binding Mechanism. IOP Conf. Ser. Mater. Sci. Eng. 2020;713:012010. doi: 10.1088/1757-899X/713/1/012010. [DOI] [Google Scholar]

- 43.Jauk J., Vašatko H., Gosch L., Christian I., Klaus A., Stavric M. Digital Fabrication of Growth-Combining Digital Manufacturing of Clay with Natural Growth of Mycelium; Proceedings of the 26th CAADRIA Conference; Hong Kong, China. 29 March–1 April 2021; Hong Kong, China: Association for Computer Aided Architectural Design Research in Asia (CAADRIA); 2021. [(accessed on 12 November 2024)]. pp. 753–762. Available online: https://papers.cumincad.org/data/works/att/caadria2021_282.pdf. [Google Scholar]

- 44.ISOMET 2114 Thermal Properties Analyzer User’s Guide Version 1.57 ISOMET 2114 User’s Guide. [(accessed on 7 April 2024)]. Available online: https://www.appliedp.com/download/manual/isomet2114_ug_en.pdf.

- 45.Halliday D., Resnick R., Walker J. 10th ed. Wiley; Hoboken, NJ, USA: 2013. Fundamentals of Physics. [Google Scholar]

- 46.Wood-Based Panels—Determination of Moisture Content. ANSI; Washington, DC, USA: 2003. [Google Scholar]

- 47.Pollock D. Handbook of Time Series Analysis, Signal Processing, and Dynamics. Elsevier; Amsterdam, The Netherlands: 1999. Estimation of Polynomial Trends; pp. 261–291. [DOI] [Google Scholar]

- 48.Stewart J. 8th ed. Cengage Learning; Boston, MA, USA: 2015. Calculus: Early Transcendentals. [Google Scholar]

- 49.Michaelides M., Spanos A. On modeling heterogeneity in linear models using trend polynomials. Econ. Model. 2020;85:74–86. doi: 10.1016/j.econmod.2019.05.008. [DOI] [Google Scholar]

- 50.Scanning Electron Microscope Tescan Vega 3 SEM/SBU: Instruction for Use. TESCAN, a.s.; Brno, Czech Republic: 2013. [(accessed on 2 November 2024)]. Available online: https://www.csuchico.edu/sem/_assets/documents/vega-manual-2014.pdf. [Google Scholar]

- 51.Federation of European Rigid Polyurethane Foam Associations (FERPFA) Thermal Insulation Materials Made of Rigid Polyurethane Foam (PUR/PIR) Properties-Manufacture. [(accessed on 12 November 2024)]. Available online: https://highperformanceinsulation.eu/wp-content/uploads/2016/08/Thermal_insulation_materials_made_of_rigid_polyurethane_foam.pdf.

- 52.Carriço C., Fraga T., Carvalho V., Pasa V. Polyurethane Foams for Thermal Insulation Uses Produced from Castor Oil and Crude Glycerol Biopolyols. Molecules. 2017;22:1091. doi: 10.3390/molecules22071091. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Doğan B., Tan H. The Numerical and Experimental Investigation of the Change of the Thermal Conductivity of Expanded Polystyrene at Different Temperatures and Densities. Int. J. Polym. Sci. 2019;2019:e6350326. doi: 10.1155/2019/6350326. [DOI] [Google Scholar]

- 54.Thermal Insulation Products for Buildings—Factory Made Expanded Polystyrene (EPS) Products—Specification. European Committee for Standardization; Brussels, Belgium: 2017. [Google Scholar]

- 55.Thermal Insulation Products for Buildings—Factory Made Products of Expanded Polystyrene (EPS)—Specification. British Standards Institution; London, UK: 2015. [(accessed on 12 November 2024)]. Available online: https://assets.grenfelltowerinquiry.org.uk/BSI00001739_BS%20EN%2013164-2012%2BA1-2015--2020-11-19--12-08-51%20PM.pdf. [Google Scholar]

- 56.Yousefi Y., Tariku F. Thermal Conductivity and Specific Heat Capacity of Insulation materials at Different Mean Temperatures. J. Phys. Conf. Ser. 2021;2069:012090. doi: 10.1088/1742-6596/2069/1/012090. [DOI] [Google Scholar]

- 57.Simmler H., Brunner S., Heinemann U., Schwab H., Kumaran K., Mukhopadhyaya P., Quénard D., Sallée H., Noller K., Kücükpinar-Niarchos E., et al. HiPTI-High Performance Thermal Insulation IEA/ECBCS Annex 39. 2005. [(accessed on 12 November 2024)]. Available online: https://www.iea-ebc.org/Data/publications/EBC_Annex_39_Report_Subtask-A.pdf.

- 58.Thermal Insulation Products for Buildings—Factory-Made Products of Polyethylene Foam (PEF)—Specification. European Committee for Standardization; Brussels, Belgium: 2012. [Google Scholar]

- 59.Bai Q., Bai Y. Subsea Pipeline Design, Analysis, and Installation. Elsevier B.V.; Amsterdam, The Netherlands: 2014. Pipe-in-Pipe and Bundle Systems; pp. 405–433. [DOI] [Google Scholar]

- 60.Hetimy S., Megahed N., Eleinen O.A., Elgheznawy D. Exploring the potential of sheep wool as an eco-friendly insulation material: A comprehensive review and analytical ranking. Sustain. Mater. Technol. 2024;39:e00812. doi: 10.1016/j.susmat.2023.e00812. [DOI] [Google Scholar]

- 61.Dénes T.-O., Iştoan R., Tǎmaş-Gavrea D.R., Manea D.L., Hegyi A., Popa F., Vasile O. Analysis of Sheep Wool-Based Composites for Building Insulation. Polymers. 2022;14:2109. doi: 10.3390/polym14102109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Zach J., Korjenic A., Petránek V., Hroudová J., Bednar T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012;49:246–253. doi: 10.1016/j.enbuild.2012.02.014. [DOI] [Google Scholar]

- 63.Thermal Insulation Products for Buildings—Factory-Made Products of Expanded Polystyrene (EPS)—Specification. European Committee for Standardization; Brussels, Belgium: 2012. [Google Scholar]

- 64.Pavatex S.A. Environmental Product Declaration. 2014. [(accessed on 7 April 2024)]. Available online: https://www.lifepanels.com/wp-content/uploads/2022/08/2.-PAVAFLEX-PLUS-Environmental-Product-Declaration-EPD.pdf.

- 65.Simões N., Fino R., Tadeu A. Uncoated medium density expanded cork boards for building façades and roofs: Mechanical, hygrothermal and durability characterization. Constr. Build. Mater. 2019;200:447–464. doi: 10.1016/j.conbuildmat.2018.12.116. [DOI] [Google Scholar]

- 66.Thermal Insulation Products for Buildings—Factory-Made Products of Extruded Polystyrene Foam (XPS)—Specification. European Committee for Standardization; Brussels, Belgium: 2012. [Google Scholar]

- 67.Shao G.B., Yang P., Jiang W.X. Research and preparation of mycelium-soybean straw composite materials; Proceedings of the 2nd Annual International Conference on Advanced Material Engineering (AME 2016); Wuhan, China. 15–17 April 2016; Amsterdam, The Netherlands: Atlantis Press; 2016. [DOI] [Google Scholar]

- 68.Giannotas G., Kamperidou V., Barboutis I. Tree bark utilization in insulating bio-aggregates: A review. Biofuels Bioprod. Biorefin. 2021;15:1989–1999. doi: 10.1002/bbb.2291. [DOI] [Google Scholar]

- 69.Colinart T., Vinceslas T., Lenormand H., De Menibus A.H., Hamard E., Lecompte T. Hygrothermal properties of light-earth building materials. J. Build. Eng. 2020;29:101134. doi: 10.1016/j.jobe.2019.101134. [DOI] [Google Scholar]

- 70.Building Regulations (BR) Part L2. Office of the Deputy Prime Minister (ODPM) [(accessed on 12 November 2024)];2001 Available online: https://www.legislation.gov.uk/uksi/2001/3335/made.

- 71.Gou L., Li S., Yin J., Li T., Liu X. Morphological and physico-mechanical properties of mycelium biocomposites with natural reinforcement particles. Constr. Build. Mater. 2021;304:124656. doi: 10.1016/j.conbuildmat.2021.124656. [DOI] [Google Scholar]

- 72.Kunanopparat T., Menut P., Morel M.-H., Guilbert S. Reinforcement of plasticized wheat gluten with natural fibers: From mechanical improvement to deplasticizing effect. Compos. Part A Appl. Sci. Manuf. 2008;39:777–785. doi: 10.1016/j.compositesa.2008.02.001. [DOI] [Google Scholar]

- 73.Bennick A. Interaction of plant polyphenols with salivary proteins. Crit. Rev. Oral Biol. Med. Off. Publ. Am. Assoc. Oral Biol. 2002;13:184–196. doi: 10.1177/154411130201300208. [DOI] [PubMed] [Google Scholar]

- 74.Alaneme K.K., Anaele J.U., Oke T.M., Kareem S.A., Adediran M., Ajibuwa O.A., Anabaranze Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023;83:234–250. doi: 10.1016/j.aej.2023.10.012. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Some pictures on test methodology and lab data will be available at Mendeley Data, V1, reserved DOI: 10.17632/2f38ktnt92.1.