Abstract

Herein, the recent advances in the development of resorbable polymeric‐based biomaterials, their geometrical forms, resorption mechanisms, and their capabilities in various biomedical applications are critically reviewed. A comprehensive discussion of the engineering approaches for the fabrication of polymeric resorbable scaffolds for tissue engineering, drug delivery, surgical, cardiological, aesthetical, dental and cardiovascular applications, are also explained. Furthermore, to understand the internal structures of resorbable scaffolds, representative studies of their evaluation by medical imaging techniques, e.g., cardiac computer tomography, are succinctly highlighted. This approach provides crucial clinical insights which help to improve the materials’ suitable and viable characteristics for them to meet the highly restrictive medical requirements. Finally, the aspects of the legal regulations and the associated challenges in translating research into desirable clinical and marketable materials of polymeric‐based formulations, are presented.

Keywords: clinical challenges, drug delivery, implants, medical imaging, polymer matrices, resorbable biomaterials, tissue engineering

This article provides a comprehensive overview of resorbable biomaterials, focusing on resorption mechanisms, fabrication methods, and their applications in medical devices. It explores innovations in dental tissue engineering, bone drug delivery systems, and regenerative surgery. Additionally, it discusses medical imaging techniques for bioresorbable devices, regulatory challenges, market potential, and future trends in the field.

1. Introduction

Polymeric biomaterials, as defined by IUPAC, are “polymer‐based materials or polymer devices that are exploited in contact with living tissues, organisms, or microorganisms of therapeutic or biological interest”.[ 1 ] Nowadays, they are gaining significant recognition in medical practice because of their useful utilization as appliances or their parts by physicians in various specializations. The developed polymeric medical grades with unique properties can be processed via the conventional plastic processing technologies and have been approved by the United States Food and Drug Administration (FDA).

Resorbable polymers are basically classified into two categories, natural and synthetic. The polymeric matrices of natural origin include polysaccharides (e.g., chitosan or alginate)[ 2 , 3 ] and proteins (e.g., collagen or keratin);[ 4 , 5 ] whereas, their synthetic counterparts (that have been in use for about half a century) include poly‐ε‐caprolactone (PCL), poly‐glycolic acid (PGA), poly(lactide) (PLA) or poly(d, l‐lactide) (PDLA) or their copolymers, e.g., poly(l‐lactide‐co‐d, l‐lactide) (PLDLLA), or poly(d, l‐lactide‐co‐glycolide) (PLGA).[ 6 , 7 , 8 , 9 , 10 ] Of this list, there are representatives of biostable and bioresorbable polymers that find applications in tissue engineering with the aim to restore or replace sections or even the entire human tissues, such as: bones, cartilage, blood vessels, skin, etc.[ 11 , 12 ] The latter are particularly interesting since they serve as scaffolds to rebuild deficient tissue and are later eliminated from the body through natural pathways, i.e., kidneys via glomerular filtration or lungs after metabolization,[ 1 ] thereby limiting the risk of short‐ and long‐term inflammatory responses. Polymeric material bio‐resorption, always exemplified by its biodegradation, must also be accompanied by other crucial features, such as biocompatibility and sufficient mechanical resilience.[ 1 , 7 ] The polymeric matrix can be tailored to a specific application by applying various types of modifications, including physical and chemical methods, e.g., the addition of osteoconductive ceramic fillers.[ 13 ]

Among various fillers, hydroxyapatite (HA, Ca10(PO4)6(OH)2) is a widely used bio‐ceramic filler for medical composites, since its chemical similarity to natural bone mineral (substituted with species including Na+, Mg2+, CO3 2−, Cl−, ) gives rise to good biocompatibility and bioactivity.[ 14 ] Other crystalline calcium compounds, e.g., calcium carbonate and calcium orthophosphates have also found many uses in resorbable composites. The latter can be found in a wide range of crystalline and hydration states, including tetracalcium phosphate (TetCP), α‐tricalcium phosphate (α‐TCP), dicalcium phosphate dihydrate (DCPD), dicalcium phosphate anhydrous (DCP), octocalcium phosphate (OCP), and β‐tricalcium phosphate (β‐TCP).[ 15 ] The non‐crystalline bio‐ceramics have become increasingly popular since the development of the first bioactive glass by Hench, a non‐crystalline silicate glass (45% SiO2, 24.5% Na2O, 24.5% calcium oxide (CaO), 6% phosphate (P2O5)) known as 45S5 or Bioglass.[ 16 ] Other silicate‐based bioactive glass compositions[ 17 , 18 ] and P2O5‐based glasses have also become popular in recent years.[ 19 , 20 ] These often include CaO giving chemical similarities to HA and bone mineral, while modifications to the composition can give a wide variety of dissolution rates and biological responses.[ 21 ]

Tissue engineering is an interdisciplinary field that combines the principles learned from engineering and life sciences to develop biological substitutes that restore, maintain, or improve tissue function. This definition emphasizes the integration of various scientific disciplines to create functional replacements for damaged tissues and organs, such as skin, bones, cartilage, muscles (also cardiac), blood vessels, liver, as well as nervous, pancreatic, or corneal tissues, which is essential for the advancement of regenerative medicine.[ 22 , 23 , 24 ] Bones, the most abundant hard tissues in the body, frequently suffer from diseases or fractures which require reconstruction; often ≈2M patients require bone crisis procedures, yearly.[ 25 , 26 ] Orthopedic surgeons typically use one of several different treatment methods, which can be categorized as: autografting (autologous bone), allografting and xenografting methods. Autografts, (cells and tissues grafted from one part to another of the same individual), are the most utilized since they possess osteogenic, osteoinductive, and osteoconductive features.[ 27 , 28 , 29 ] Autografts may originate from different body regions; however, the most classically utilized is the iliac crest, since it contains a valuable source of progenitor cells and growth factors, its limits immune responses, it ensures ample bone amount and enables a comfortable harvesting procedure.[ 30 ] Allografts, on the other hand, do not create a second surgical site since they are developed from processed bones, recovered from cadavers, or patients gaining hip joint prothesis, often in the form of cancellous bone.[ 25 ] This solution provides an osteoconductive environment for vascularization and bone restoration; however, it may initiate immunological response or even convey contagious diseases.[ 25 ] Xenografts involve the transmission of tissues from animals to humans, e.g., bovine bone that was previously subjected to deproteinization or sintering. The highest risk of transplantations between species, are associated with the recipient's immune rejection as well as possible xenogenic infections (xenozoonoses).[ 30 ] The above‐mentioned imperfections may be overcome by the application of alloplasts, i.e., resorbable polymer‐based tissue substitutes; therefore, their future development as novel, and future‐oriented solutions is crucial.

Bioresorbable, alloplastic scaffolds serve as temporary devices that are expected to be overgrown with natural tissue, maintaining its shape and ensuring adequate mechanical support, and later on, removed systematically by the human body when no longer needed. First, a stable layer of autologous cells is formed, followed by the cell's proliferation, and differentiation.[ 31 , 32 ] Their greatest advantage in comparison to auto‐, allo‐, and xenografts, is their controlled resorption time. Three main factors that influence the resorption rate are: morphology, geometry, and the composition of the bioresorbable device.[ 25 ] The morphology is expected to enhance the penetration of the growth factors inside the polymeric matrix in order to stimulate cell attachment, their migration and further development; therefore, porous materials (≤50 µm) or materials containing interspaces created as a result of the applied production process (e.g., Fused Deposition Modeling technology), are favored.[ 25 , 33 ] In addition, the resorption time may be controlled by various scaffold dimensions, i.e., thicker parts of the implant will generate longer resorption time. In the case of shape‐tailored scaffolds fitted to defective tissue, it is expected that the resorption time will vary as per the wall thickness; thereby, differentiating the period for the total implant disappearance. Other tactics involve the variation in the composition or structure of the material. The incorporation of sequences susceptible to degradation into polymeric backbone, greatly shortens the degradation time. Another effective route is to control the crystal structure of the polymer–amorphous structures are less resistant to resorption and known for limiting the risk of inflammation.[ 34 , 35 ] The addition of ceramic fillers in a composite greatly affects the ability of saturation of the composition with internal fluids; therefore, fastens the hydrolytic degradation of the material.[ 34 ]

In this review, an overview of the recent advances in the development of resorbable biomaterials, composites, their geometric forms, and capabilities in various biomedical applications, including tissue engineering, drug delivery, dental, and cardiovascular applications, is provided. A comprehensive discussion of the engineering approaches for the fabrication of resorbable composite scaffolds, bioresorbable stents, vascular grafts, and cardiac patches, which can offer clinical insights that can guide to improve the materials’ suitable characteristics has been carried out. Furthermore, in order to understand the internal structures of resorbable scaffolds, representative studies for the evaluation of bioresorbable scaffolds and stents by using cardiac computer tomography that can guide in the use of these scaffolds and the necessity to establish strategies for the design of multifunctional resorbable implants, for specific biomedical need, are succinctly highlighted.

2. Resorbable Biomaterials

Since the initial applications of bioresorbable polymers in areas such as sutures, a range of different synthetic polymer classes have been investigated.[ 36 , 37 , 38 ] These are typically classified based on the type of bond present in the polymer backbone, which in turn has major effects on resorption mechanisms.[ 39 ] Polyanhydrides have long been investigated, particularly for drug delivery applications, since their hydrophobicity and surface eroding resorption mechanism give rise to a near zero‐order drug release rate.[ 40 ] Poly(ortho esters) tend to be even more hydrophobic, with a slower surface erosion rate, making them attractive for drug delivery, ophthalmic, and dental applications. Despite these advantages, wider investigation has been limited due the challenging requirements to synthesize and scale up these materials.[ 41 , 42 ] The most widely investigated class however, are poly(α‐hydroxy esters), with ester bonds in the polymer backbone that are hydrolyzed during resorption. Over the past decades, this class of bioresorbable polymers, which includes PLA, PGA, and PCL, has received extensive research interest.[ 43 , 44 ] The functionalization of these polymers is carried out by using end groups, such as OH−, Cl−, and NH2, or short polymer units of acrylate, fumarate, or ethylene glycol to tune biodegradation.[ 45 , 46 ] The use of other synthetic resorbable polymers, such as polypropylene carbonate (PPC) and polybutylene adipate terephthalate (PBAT), is not as widespread, but the utilization of such polymers, has been growing in recent years.[ 47 , 48 ] In addition, the polyhydroxylalkanoate (PHA) family, produced by bacterial fermentation, has received a considerable interest lately, e.g., polyhydroxybutyrate (PHB), polyhydroxyoctanoate (PHO), polyhydroxyvalerate (PHV).[ 49 , 50 , 51 ] The copolymers of these mentioned polymers, e.g., poly(3‐hydroxybutyrate‐co‐3‐hydroxyvalerate) (PHBHV), are also attractive due to their non‐immunogenic, biocompatibility, and surface‐eroding degradation mechanism.[ 52 ] Some other polymers, e.g., polybutylene succinate (PBS), can be produced via the natural (bacterial fermentation) and synthetic (petro‐based) methods.[ 53 ] Several commercialized products from resorbable polymers are available in the market. For, e.g., surgical suture (Vicryl, 3‐0, Luxcryl PDO, Practimono PDO, Monoderm, Henry Schein, Auro thread, and Ethicon Stratafix), medical filament (Dioxactisse100, Glycolactisse85:15 and Caprolactisse100), oral and dental suture (Glyolon and Resorba), surgical meshes (Gliko and BioMesh), absorbable punctal plug for dry eye symptoms (Vera90, Oasis Soft Plug, ProLong, Extend, Comfortear Lacrisolve 180), and bioabsorbable extrusions (Absorv).

2.1. Resorption Mechanisms of Polymeric‐Based Implants

In the biomedical applications domain, the aqueous environment experienced by implant materials is the key driver of material degradation or resorption. Different constituent materials within resorbable composites degrade in various ways, however, the processes are not yet well understood. The following section outlines the current understanding of the degradation behavior and its effects on materials properties.

2.1.1. Mechanisms of Resorption

As the most studied bioresorbable polymers, the degradation mechanisms of polyesters, e.g., PLA, are the most well understood. Initially water diffuses into the solid polymer according to the Fickian diffusion kinetics.[ 54 ] Although this takes place from the outside, leading to the initial heterogeneous absorption; this is homogenized after a short time,[ 55 ] when compared with the typical degradation times and thus for the PLA, this stage is usually ignored. The hydrolysis of the ester bonds occurs at both ends and by random chain scission,[ 56 , 57 ] leading to the production of oligomers with carboxylic end groups.[ 58 ] The sample size is observed to influence the degradation mechanism, with large specimens limiting the mass transport of the reaction products out of the material, thereby causing a build‐up of acidic products and leading to autocatalysis of the hydrolysis reaction and hence, an accelerated degradation.[ 55 , 56 ] These autocatalytic effects are generally avoided in small devices which tend to be dominated by surface degradation.[ 59 ] The reaction products are then consumed in the tricarboxylic acid cycle (Krebs cycle) to form CO2 and H2O, and then excreted.[ 60 ] Some PGA degradation products can also be directly excreted by the kidneys, and enzymatic degradation is also known to play a role in the degradation of polyesters. The acidic degradation by‐products can cause the acidification of the local area around an implant, and in some cases, leading to inflammation. However, this has been reported to have a relatively low occurrence and typically, it only occurs in a poorly vascularized tissue, e.g., cartilage, where there is little fluid flow to dilute the degradation products.[ 45 , 61 , 62 ] In addition to the polymers, viz: PLA, PGA, PCL, and their copolymers that have been the subject of research for some time, other resorbable polyesters, including PHAs, PPC, and PBS, are experiencing increasing and renewed interest. There has been limited systematic investigation into the mechanisms of their degradation, although they are known to differ significantly from the mechanisms of PLA and similar polymers. For instance, PHAs are hydrophilic and as a result, they degrade entirely by surface erosion rather than bulk degradation.[ 52 ] An understanding of the degradation criterion of composites based on these polymers will therefore require detailed studies of the polymers’ degradation mechanisms.

In addition to the polymer phase, the material degradation of the inorganic filler phase (usually and specifically, dissolution) should be considered, and in this case the physical and chemical mechanisms are entirely different. The solubility of these materials depends on many physical and geometric factors, such as the particle size and density, but also their compositions and chemical structures. HA is relatively well characterized, demonstrating a very slow dissolution rate in vivo. Other crystalline forms of calcium phosphate[ 15 ] increase the relative solubility in the order: TetCP ≈ α‐TCP > DCPD > DCP > OCP > β‐TCP > HA. By focusing on HA alone, there has been extensive work on the substituted HA with a range of cationic and anionic substitutions, both of which can alter the dissolution rate as well as the influence of the biological response to the material.[ 14 ] Several dissolution models have been established to describe the dissolution of calcium phosphates,[ 63 ] with homogeneous models that are suitable for simple HA, while the heterogeneous core‐shell models that incorporate a thin hydrated layer, are required for more complex systems, e.g., the substituted HA or nanocrystalline particles.[ 64 ] Bioactive glasses, which have similar chemical components as bioceramics, e.g., HA, but are amorphous rather than crystalline, display widely variable dissolution rates, depending on their compositions. The original and most widely used bioglass, i.e., 45S5 (45% SiO2, 24.5% Na2O, 24.5% CaO, 6% P2O5), is known to form HA in vivo and a strong bond with bone—in this sense, it is resorbed into the body rather than dissolving.[ 16 , 65 ] Other glasses can display orders of magnitude with differences in their dissolution rates, in particular the phosphate glass system, which has attracted significant research interest for biomedical applications.[ 21 , 66 ] The dissolution of these glasses typically involves a stable surface layer formation, rich in glass network formers and depleted in the network modifying components.[ 67 ] The formation of this surface layer depends on the glass composition and the surrounding fluid environment, and its stability has a profound impact on the dissolution rate of the glass. In recent years, multi‐stage models have been developed to describe the progression of glass dissolution that incorporates the formation and stabilization of this conversion layer.[ 68 , 69 , 70 ] A key remaining challenge here, is the understanding of how the restricted environment within a polymer composite, affects the progression of the glass dissolution.

When bioresorbable polymers and inorganic fillers are combined to form composites, several additional factors that affect the material degradation are introduced. The size and morphology of the filler influences the extent of the wicking or interface effect, which is becoming increasingly recognized as a significant factor in composites degradation. Smaller particles with high surface area, increase the water absorption and therefore, degradation, as does with increase in the particles’ aspect ratios (i.e., short fibers), especially for continuous fiber reinforcement.[ 71 , 72 , 73 ] The chemical composition of the filler also plays a key role. A buffering effect has been observed for certain ceramic fillers, where ion exchange occurs between protons in water and alkali ions in the glass/ceramic, resulting in a pH buffering effect at the glass surface and a reduced polymer degradation.[ 74 , 75 ] This effect can interact with the size effects, with smaller particles dissolving more quickly, and displaying a more effective buffering reaction.[ 74 ] Kim et al., observed a reduction in the composite degradation rate in phosphate glass‐PCL composites with increasing CaO content in the glass. Increased CaO in phosphate glass is known to reduce the glass dissolution rate, however, this was also observed to have reduced the rate of polymer molecular weight reduction, which was attributed to the less acidic dissolution of high CaO‐containing glasses.[ 76 ] Similar work by Mohammadi et al. on PCL composites with Si‐ or Fe‐substituted phosphate glasses did not observe this effect,[ 77 ] suggesting that the polymer‐ceramic combination must be carefully selected in order to induce the acceleration of polymer degradation. The ability to control a composite degradation via glass composition is an attractive prospect that can decouple the degradation time from the mechanical properties, however, the full control of this event, is yet to be achieved.

2.1.2. Influence of Resorption on Performance of Medical Devices

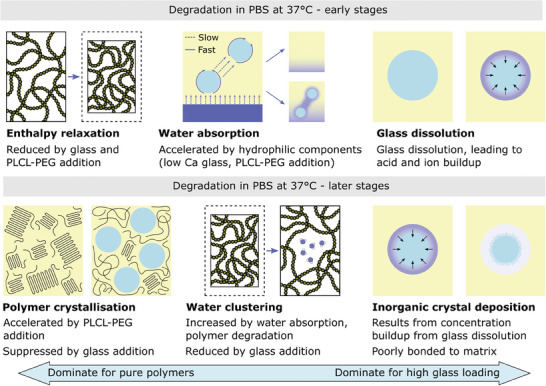

Historically, the changes in mechanical properties during material degradation have been relatively under‐investigated, despite the importance of the gradual transfer of load to the newly healed tissue. In recent years, this has been changing and more research is considering not just the initial mechanical properties and biodegradability, but also the evolution of the mechanical properties during this process.[ 78 , 79 ] In general, composites display superior mechanical properties before degradation when compared to the neat polymers, but these improved properties are often short‐lived and reduced rapidly, to the value below the neat polymer during degradation.[ 80 , 81 , 82 ] This is usually a result of the water absorption scenario, occurring along the polymer‐filler interface which reduces mechanical integrity. The exact rate of this change in the material performance, is highly dependent on the components of the composite system; in particular, the polymer and filler surface chemistry (hydrophilicity), filler morphology and the amount of the filler inclusion. Other structural changes can occur during degradation, in particular in the polymer phase where mobile polymer chains can rearrange (by aging or crystallization), which in some cases can lead to the strengthening of the composite, in the early stages of degradation.[ 83 ] Recent work[ 73 ] has begun to provide a more comprehensive view of the mechanisms of structural changes experienced during composite degradation and its effect on material properties (Figure 1 ), but further work is needed to expand this phenomenon in order to encompass the broad range of polymer and inorganic phase compositions that are commonly used.

Figure 1.

Schematic summary of the mechanisms of structural changes that occur in polymer‐glass composites during degradation, over different timescales, and for different filler loadings. Reproduced with permission.[ 73 ]

Changes in the composite mechanical properties during degradation can also be understood from a fundamental perspective by computational modeling. The models are based on the foundational work of Pan et al. describing simultaneous molecular weight reduction and crystallization of bioresorbable polymers during degradation,[ 84 ] and the linking of this to the mechanical properties by using a constitutive law.[ 85 ] Such models are now used to describe the degradation of medical devices in vivo.[ 86 ] Despite the advantages of being able to predict the evolution of the mechanical properties of a material during degradation, attempts to extend these models to bioresorbable composites, have been limited. Pan et al. extended their polymer model to include calcium phosphate dissolution and the resulting buffering effect,[ 87 ] while Kobayashi and Yamaji focused on the role of ceramic particles in increasing the water content.[ 88 ] Moreno‐Gomez[ 89 ] developed a generalized modeling framework, based on the work of Pan et al. that could then be particularized to describe the degradation of composites containing TCP, HA, and calcium carbonate. Despite these recent advances, further work in this area is necessary to bridge the gap between experimental observations and phenomenological models to accurately capture the range of mechanisms experienced by the variety of different composites, including a wider range of polymers, and fillers. This should enable the prediction of not just the mass loss and molecular weight reduction in the polymer, but also the evolution of the mechanical properties during degradation.

2.2. Fabrication of Resorbable Medical Devices

The fabrication of resorbable composite materials based on the traditional composite processing techniques often requires various adaptations to protect the sensitive nature of degradable materials. Melt and solvent processing methods are widely used,[ 90 , 91 , 92 ] with several recent implementations for resorbable implants. In recent years, additive manufacturing has also been of a particular focus, since it has been the subject of significant research efforts.[ 93 , 94 ] The ability to produce engineered porous architectures and the potential for the design of patient‐tailored implants, make additive manufacturing ideal for many biomedical applications.

2.2.1. Thermal/Melt Processing

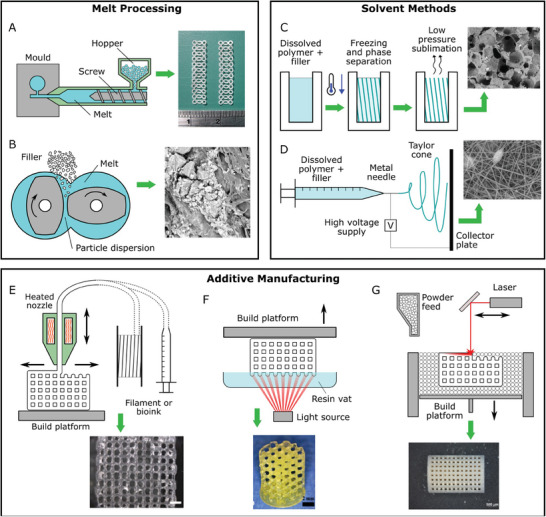

The melt processing methods, such as injection molding and extrusion (Figure 2A), are widespread across many industries, including the medical and biomedical domains. Their advanced stage of development makes the melt processing methods to be highly scalable from the pilot scale up to industrial production, where large volumes of parts can be made quickly and at a relatively low cost. Despite their popularity, they have several drawbacks, including being limited to relatively simple device geometries without intricate features. The large scale, equipment cost, and amount of material required, pose further obstacles to their use in research and development of bioresorbable composites. More recently, the microinjection molding has gained popularity, however, the high cost of such equipment is still a limitation, leading to the development of low‐cost pilot‐scale injection molding systems.[ 102 ]

Figure 2.

Illustrations of common fabrication techniques for bioresorbable polymers and composites. Melt processing: A) injection molding or micro‐injection molding, B) melt compounding (twin‐screw extrusion); Solvent processing: C) freeze drying, D) electrospinning; and Additive manufacturing: E) materials extrusion or direct ink writing, F) vat photopolymerization, and G) powder bed methods like powder bed fusion or binder jetting. Reproduced with permission[ 95 , 96 , 97 , 98 , 99 , 100 ] and under CC BY‐NC‐ND 4.0.[ 101 ]

The greatest challenge in the melt processing of polymeric composites is ensuring a good filler dispersion within the matrix. The traditional melt blending process, uses the screw rotation approach to mix the ingredients (Figure 2B). This exposes the polymer to high temperatures and shear forces, which may cause premature polymer degradation.[ 103 , 104 ] This is a particular problem for resorbable polymers, e.g., polyesters, which are vulnerable to hydrolysis, initiated by absorbed water.[ 105 ] In addition, polyesters are sensitive to reaction with bioactive glass at high temperature, leading to a significant reduction in the molecular weight and mechanical properties.[ 106 , 107 ] This is believed to occur by thermal catalysis of the reaction between the SiO− species in the glass, and the ester groups in the polymer, thereby forming carboxylate salts and oligomer fragments.[ 105 , 106 ] Sarasua et al. employed the plasma surface modification of the bioactive glass to hinder this reaction and prevent degradation during processing, however, this technique requires further optimization and additional processing steps.[ 106 ]

Another notable melt processing technique for resorbable composites is the fiber mat stacking, employed by Ahmed et al.[ 71 , 108 , 109 , 110 , 111 ] This method is akin to the lay‐up of conventional fiberglass that is ubiquitous in construction materials, but instead uses PLA and melt‐spun phosphate glass fibers. The capability to selectively orient the glass fibers to provide reinforcement in certain directions is attractive, however, the technique has not been widely adopted for bioresorbable composites due to the extensive water wicking along the continuous fibers, which in turn leads to the deterioration of mechanical properties and accelerated degradation of the resulting composite.

2.2.2. Solvent Processing

The solvent processing methods involve dissolving a polymer in a suitable organic solvent, mixing it with the filler, if needed, thereby, shaping the composite, and finally evaporating solvent (Figure 2C). This method can be employed to produce a composite feedstock for further processing by thermal methods, e.g., injection molding, hence, avoiding the excessive thermal‐ and shear‐induced degradation associated with an additional high‐temperature mixing step before molding. This method is popular due to its simplicity and lack of expensive equipment requirements. Such materials have been used as feedstocks for further thermal molding.[ 112 , 113 , 114 ] The main disadvantage of solvent casting method, involves the filler sedimentation that occurs during drying leading to particles’ agglomeration and mechanical properties’ deterioration.[ 115 ] Possible solutions include the alteration of the matrix viscosity[ 116 , 117 ] or the usage of a solvent‐solvent precipitation method[ 115 ] to reduce the tendency for aggregation and the creation of large defects that could initiate early fracture.

Another drawback of the solvent‐based methods is the solvent itself. Some commonly used solvents, e.g., dichloromethane, chloroform, are toxic and potentially carcinogenic, leading to safety concerns over their usage in the production of biomedical implants. Although they are intended to be completely removed, residual solvent has been found to be retained within polymer films at levels of ≈10 wt.%.[ 118 ] Being not only a toxicity concern, but it also affects the mechanical properties of the materials.[ 118 , 119 , 120 ] Residual solvent may act as a plasticizer or lead to a reduction in the PLA tensile strength by >60%.[ 118 ]

Electrospinning is an established fabrication method for polymers, wherein ultrafine fibers can be spun from solutions by using a strong electric field that produces a randomly oriented or aligned mat[ 61 , 121 ] (Figure 2D). Inorganic particles can also be added to the polymer solution to enable a composite production, typically by using nanoparticles of bioactive glass, resulting in enhanced mechanical properties, improved biological performance, and in some cases, antibacterial properties.[ 121 ] Ao et al. examined the electrospun composites of cellulose and HA nanoparticles. Electrospinning was able to fabricate fiber diameter distributions comparable to those of natural extracellular matrix (ECM) fibers, in the range of between 100 and 200 nm, with high strength and good biocompatability.[ 122 ] The pore size distribution in electrospun fiber mats is another key parameter that governs their biocompatibility. Typical electrospun mats have pore sizes in the order of several microns, and up to tens of microns. For bone tissue engineering purposes, the optimal pore size is thought to be approximately 300 µm, which is significantly larger than that produced by electrospinning. However, the loose bonding of electrospun fiber mats is thought to allow cell migration by mechanical interaction with the material, expanding the size of the pore.[ 123 ] Recent work by Liverani et al. successfully produced electrospun composites of PCL/chitosan/bioactive glass by using more benign, non‐toxic solvents (acetic acid, formic acid), showing a potential pathway to alleviating the negative effects of the solvent processing method, mentioned above.[ 101 ]

Thermally induced phase separation (TIPS), or freeze‐drying, is another technique that enables the production of porous composite materials, however when compared with the additive manufacturing technique (see below) the structure cannot be designed on a pore‐by‐pore basis. TIPS freezes the solvent/polymer/filler mixture, and then reduces the pressure to sublime the solvent and leaves a highly porous scaffold. In contrast to many other composite production methods, the incorporation of filler particles (up to 15 wt.%) into porous scaffolds, produced by TIPS, has minimal effect on the scaffold mechanical properties. It was observed to be more effective in imparting bioactivity than it was in controlling the mechanical or degradation behaviors.[ 124 , 125 ] A more recent study by Szustakiewicz et al.,[ 126 ] investigated scaffolds with very high HA content, and began to observe a significant increase in the Young's modulus, once the HA content reached 75 wt.%. The key advantage of incorporating inorganic fillers into polymer scaffolds produced by TIPS is the biological effect, with the ion release from PCL/biomineral scaffolds, encouraging apatite nucleation for bone regeneration,[ 127 ] and other formulations, based on PLLA/bioactive glass demonstrating the ability to maintain osteochondral cell phenotype for articular cartilage repair.[ 128 ]

2.2.3. Additive Manufacturing

Developments in additive manufacturing (AM) technology have enormous potential for the fabrication of resorbable composites for biomedical applications. The accurate control over material macro‐ and micro‐structures, provided by AM, offers many possibilities for resorbable composite scaffolds in areas, such as bone or soft tissue scaffolds (Figure 2E–G). The main modes[ 129 , 130 ] of AM, include powder bed fusion (PBF), binder jetting (BJT), material extrusion (MEX), material jetting (MJT), and vat photopolymerization (VPP).

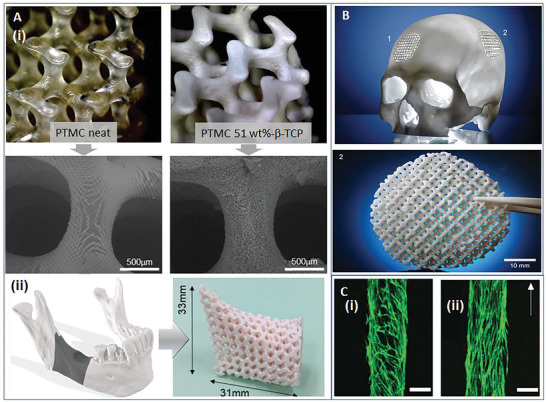

The PBF is mainly used for permanent medical implants, however, it has recently been extended to resorbable composite materials.[ 134 ] It is well suited for composite fabrication due to the ease of tailoring the composition by the simple mixing of powders. Gatto et al. employed the PBF technique to produce fully resorbable porous composite scaffolds from PCL and HA, enabling the design and control of macro‐porosity into specific unit cell geometries, which determined the mechanical properties and influenced biological response.[ 135 ] Several similar works[ 132 , 136 ] were also used to establish bioresorbable polymers and ceramics, such as PLA, HA, and calcium carbonate (Figure 3 ), which are known for favorable biological responses for bone regeneration applications. Recent works are taking advantage of the versatility of material selection, with Wang et al. incorporating bioactive glass into poly‐ether‐ether‐ketone (PEEK) to improve the material stiffness and promote mineralization.[ 137 ] PBF, taking advantage of the high resolution, was initially limited to engineering thermoplastics, e.g., nylon, however, these early examples have demonstrated a shift towards resorbable polymers and composites for medical implants.

Figure 3.

A) (i) SEM images of the scaffolds produced by using the VPP, showing the neat polymer (with smooth surface), and composites with β‐TCP (with microscale surface roughness). (ii) Example of the route to produce a porous and personalized composite implant for a large mandibular defect. Reproduced with permission.[ 131 ] B) Example of a fully resorbable cranial implant manufactured by the PBF technique from a composite of PLA and calcium carbonate. Reproduced with permission[ 132 ] under the CC‐BY 4.0 license. C) A magnetically assisted orientation of fibers in a composite produced by the DIW technique, showing cell orientations on the composites with: random (i) and aligned (ii) fibers. Scale bar = 250 µm. Reproduced with permission.[133.]

VPP (also known as digital light processing, DLP) is emerging as a fabrication technique for resorbable composites due to its exceptional resolution that can be down to ≈10 µm, enabling the construction of highly complex scaffolds. With the photopolymerization method, a key technical challenge is the availability of polymer resins that are both photopolymerisable and resorbable. The polymers used in VPP include PCL,[ 138 , 139 ] PLA,[ 140 ] poly(propylene fumarate),[ 141 ] and poly(l‐lactide‐co‐ε‐caprolactone).[ 142 ] Saed et al. used functionalized PLA with biphasic calcium phosphate (BCP), by successfully incorporating ≈45 wt.% BCP in additively manufactured scaffolds, while resins with higher proportions of BCP were too viscous for successful printing.[ 143 ] Dienel et al. used the VPP to fabricate composites by using poly(trimethylene carbonate) and β‐TCP.[ 131 ] Up to 60 wt.% β‐TCP was successfully incorporated into printed scaffolds. This provided a significant mechanical reinforcement, and the bioactive agent (β‐TCP) was observed on the external surface, in contrast to the melt processing technique, where polymer forms a skin over the entire surface. This immediate availability of the bioactive agent is another advantage of the VPP. The achievement of an appropriate resin viscosity can be challenging when using the VPP, however composite paste has been used to successfully fabricate polyethylene glycol diacrylate (PEGDA) composites with ≈40 wt.% HA.[ 144 ] To polymerize the resin, a photoinitiator must be used to catalyze the curing process; these are often industrial curing agents like TPO (diphenyl(2,4,6‐trimethylbenzoyl)phosphine oxide) or similar compounds, which can demonstrate cytotoxicity.[ 145 ] There is thus a focus on developing new, more biocompatible photoinitiators with suitable photochemical properties, such as TPA‐DTP (2,6‐bis(triphenylamine)dithieno[3,2‐b:2′,3′‐d]phosphole oxide).[ 146 ] Future works need to focus on the degradation of these new materials, photopolymerization side effects, and the effective parameters for the process. For instance, recent work of Herwig et al. using poly(orthoester‐thioether) (POETE), considered not only the photopolymerization and cytocompatibility, but also characterized the degradation rate and surface‐eroding degradation mechanism.[ 147 ]

Within the AM, the BJT technique is still an emerging technology, however some recent implementations have demonstrated its potential for resorbable composite materials. As a powder‐based process, it has traditionally been popular for ceramics. This includes Bioglass and β‐TCP as recently demonstrated by Bose et al.[ 100 ] Such ceramic scaffolds may be later infiltrated with a polymeric matrix, as demonstrated by Ahn et al. by the melt infiltration of 40 vol.% PCL into a BCP scaffold.[ 148 ] Inzana et al. demonstrated an alternative method that incorporated a resorbable polymer (collagen) into the binder solution during the BJT of calcium phosphate.[ 149 ] This takes advantage of the low‐temperature nature of the BJT process to use a more thermally sensitive biopolymer. A different approach was employed by Dini et al. who used a mixture of HA and polymer powders (carboxymethyl chitosan, polyvinylpyrrolidone, and dextrin) to print composites with 60 wt.% HA.[ 150 ] From these examples, it is obvious that the BJT method is a promising method for production of composites with higher ceramic content (≥60 wt.%), which are well suited to hard tissue applications in bone regeneration.

The MJT technique has an important role in the production of resorbable implant materials. This method is popular for bioprinting where live cells are included to create living bioactive materials due to low temperatures and liquid‐based processing. Despite the shear stresses applied, cell viability can often be maintained.[ 151 ] However, the utilization of this method for resorbable composites is challenging since the incorporation of ceramic particles increases the viscosity, leading to nozzle clogging and difficulties in ejecting the droplets. As a result, to date, few works have been carried out in this area.[ 152 ] By using inkjet printing Gao et al. were able to successfully print composites of polyethylene glycol dimethacrylate with HA, bioactive glass, and human mesenchymal stem cells.[ 153 ] The inclusion of these inorganic phases increased the mechanical properties and improved osteogenic differentiation, applicable for both hard and soft tissues, however their low elastic modulus (typically ≤100 kPa) makes them unsuitable for load‐bearing applications.

There are two main sub‐types of MEX relevant for resorbable materials, fused deposition modeling (FDM) and direct ink writing (DIW). FDM is a ubiquitous method that applies melting and solidification of thermoplastic filament, while DIW typically uses viscoelastic inks (polymer liquids or gels) that flow easily through the nozzle under shear, forming rigid structures once the shear stress is removed. These inks can include living cells, but the viscosity requirements are less stringent, and hence composite production is more viable. These composite inks are intensively researched as detailed in the review by Heid and Boccaccini.[ 152 ] Although these materials show great potential, further improvement in their mechanical properties and more in‐depth knowledge of filler‐matrix interactions are still required. Recently, works have begun by Heid et al. to control a composite degradation, demonstrating tuneable crosslinking of printed hydrogels by the addition of calcium silicate,[ 154 ] and the work of Allen et al. showing that HA addition to hydrogels, decreased swelling and resisted enzymatic degradation.[ 155 ] Novel materials, e.g., hydrogels containing nano‐attapulgite for improved mechanical properties, and greater osteogenic and angiogenic responses,[ 156 ] or the composite hydrogels that contained fibers, functionalized with magnetic iron oxide nanoparticles, enabling fiber alignment to mimic tissue anisotropy,[ 133 ] are still in their emerging stages. Resorbable composites produced by FDM have also been the subject of extensive research efforts.

In recent years, filament extrusion systems have become available at a small scale, enabling the formulation of novel composites for FDM containing a range of resorbable materials, such as PLA, PCL, HA, TCP, and bioactive glass.[ 157 , 158 , 159 , 160 ] Inorganic filler contents of ≈10 wt.% are common, resulting in an improved bioactivity. Improvements in mechanical properties are not always observed with the inclusion of inorganic filler particles, often leading to stress concentrations and reduced toughness when compared with pristine polymers. Although these composites often display superior mechanical properties, and when compared to the softer gel‐based composites, they are frequently insufficient for load‐bearing medical applications, therefore, addressing this concern remains valid. It is obvious that the modern manufacturing techniques, especially the AM methods, have given scientists and engineers the unparalleled ability to produce resorbable composites with highly controllable structures and compositions, at a range of length scales. A complete understanding of how the processes affect the degradation behavior, and the complex evolution of mechanical properties upon degradation is however, lagging.[ 161 ] More importantly, it is desirably needed to translate advances in the fabrication capabilities into actual medical outcomes.

2.3. Geometrical Forms of Currently Utilized Implants

Amongst all the biomedical applications, bone substitutions are the most often applied; therefore, implants for their reconstruction display the widest variety. Before the process of tissue reconstruction may begin, the polymeric biomaterial must be appropriately shaped, as detailed above. This is to ensure a close matching between the implant and defective tissue.[ 162 ] There are several approaches that are currently under consideration for tissue engineering, namely, the standardized products, devices with undefined geometrical structures, and the implants that are personalized in terms of their shapes and compositions. The latter approach is of the highest interest bearing future‐oriented solutions that are adjustable to each patient's needs. All the approaches are summarized herein.

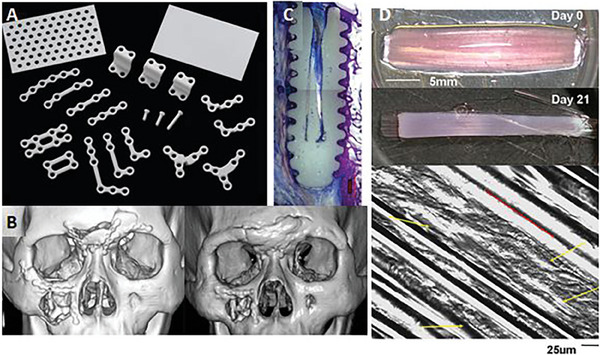

2.3.1. Standardized Implants

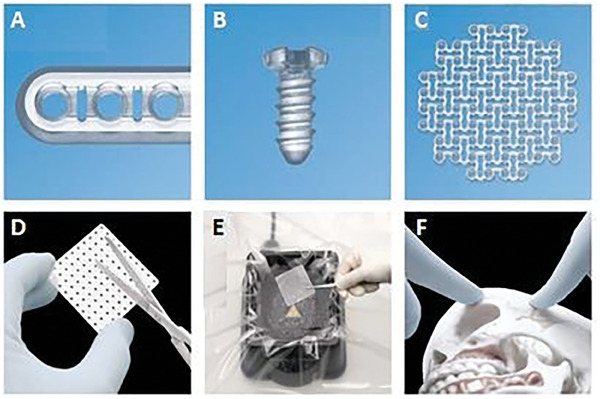

The standardized medical devices are mainly used in oral, maxillofacial, and orthopedic surgeries, for the fixations of fractures (trauma) as well as securing autografts, osteotomies, orthognathic procedures, and many more.[ 163 ] These three‐dimensional systems include a wide variety of screws, plates, meshes, and membranes (Figure 4A–C) and they are frequently based on PLA, PGA, or their copolymers and doped with ceramic fillers, e.g., hydroxyapatite.[ 163 , 164 ] These types of implants are usually manufactured by using the standard polymer processing methods, e.g., injection molding. Because of the varieties in the geometries, sizes, and compositions of these implants, their biodegradation kinetics may be controlled and adjusted from weeks to years.[ 164 ]

Figure 4.

RapidSorb fixation system for maxillofacial procedures: A) plate, B) screw, C) mesh/foil, D) adjustment of implant size during operation, E) water bath, and F) adjustment of implant shape during operation. Reprinted from [178116.pdf (llnwd.net)].

These types of systems are quite universal since the manufacturers provide a large diversity of sizes, e.g., different screw diameters and lengths. However, these solutions have a form of flat surface and often, do not correspond to the curvature of damaged bone, especially in the case of maxillofacial surgeries. Therefore, the medical procedure must foresee additional preparation steps during the surgery. Firstly, the implant size must be adjusted according to the patient's needs (Figure 4D). Thereafter, the appropriate curvature needs to be obtained and in the case of naturally stiff PLA, it is not a straightforward procedure. It is, therefore, necessary to heat up a mesh or plate above its glass transition temperature[ 165 ] (usually ≈60 °C); therefore, in the surgical site, water baths are used to increase the implant temperature that is later hand‐shaped (Figure 4E,F). This procedure extends the applicability of such systems, however, it is also time‐consuming, increases the risk of implant contamination, and depends on the medical staff's experience and skills.

2.3.2. Products with Undefined Geometry

For medical cases where geometrically standardized products cannot be utilized, for instance, in the case of open, undefined, or relatively minute defects, solutions with undefined geometries are preferred. These solutions, include granules of different types, usually with a diameter of ≈5 mm, porous blocks, cement pastes, putties, and recently developed hydrogel‐based formulations. These may be categorized as materials in solid or liquid states.[ 25 ]

The first class includes granules and blocks that were successfully used for open defects with easy access. The granules may be composed of human or animal (usually bovine) deproteinized or sintered bone, which limits the biological risks that are related to organic contamination.[ 25 , 166 ] They induce bone formation throughout the entire defect; however, they exhibit negligible mechanical strength and often migrate even through the stitched wounds during convalescence. Porous blocks, made of allografts or polymeric materials, can alternatively be used for specified defect shapes, e.g., rectangular, or cylindrical, with an open access. An effective usage of such materials has been already studied in vivo with promising results.[ 167 , 168 , 169 ] Like granules, sponges can form a mature bone throughout the entire damage with a negligible mechanical support for the defect. Because of the compact form, migration during and after handling is limited, however, some difficulties may arise to adjust the shape to the defective site.[ 25 ]

The second class of bone substitutes, includes materials that are injectable due to their liquid or paste form. Hydraulic cements usually contain osteoconductive calcium phosphate particles and they undergo hardening processes upon the addition of aqueous solutions,[ 25 , 170 ] leading to the physical entanglement of crystals and their mutual inter‐growth. Putties, on the other hand, do not yield curing processes since they consist of hard particles, often allograft or ceramic, dispersed within viscous binding matrix. A range of putties are now approved and available for clinical use. These often include bioactive glass as a filler, ensuring osteoconductive properties, and collagen or polyethylene glycol as the polymeric matrix. Commercially available products,[ 20 ] include NovaBone, Medpor‐Plus, Bonalive, and OssiMend Bioactive. This injectable class creates a non‐invasive method to pack defects with limited access or even in closed spaces. However, this ability may be limited by the high viscosity of the material or the premature hardening process.[ 25 ] Recently, a new class of injectable hydrogels for tissue regeneration was developed, often with chitosan, alginate, or hyaluronic acid‐based, which are able to undergo sol–gel reaction, induced by either the body temperature upon implementation (thermosensitive) or pH‐induced gelation (pH sensitive)[ 171 , 172 , 173 , 174 ]

2.3.3. Customized Products

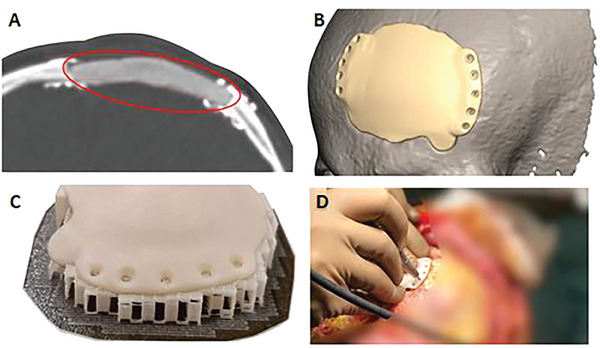

This approach is the most promising since it ensures an individualized approach to each patient's needs, in terms of the shape and the chemical composition of the implant. Although this process is time‐bound and multi‐step, it is certainly worth the effort since it provides the most comprehensive solutions for the patients (Figure 5 ). For all customized products, the first integral step is to develop an imitation (model) of an anatomically defective tissue that is to be regenerated. These structures are computed from standard medical imaging techniques, such as computed tomography (CT) or magnetic resonance imaging (MRI). These methods enable the construction of 3D model of the patient's defective tissues.[ 175 , 176 ] Modeling precision is highly dependent on the parameters selected upon imaging with the most important ones, such as the resolution and thickness of the individual layer. This model serves as a substrate for the development of a bioresorbable implant geometric shape. This process is also computer‐aided, often with the use of the haptic systems.[ 177 ] This model is later used to produce an implant via the typical processing methods, most often, via additive manufacturing. A description of a step‐by‐step procedure for three medical cases aiming to reconstruct craniofacial defects is detailed in the work of Targońska et al.[ 178 ]

Figure 5.

Personalized maxillofacial osteosynthesis system: A) computed tomography image of a frontal lobe defect temporarily filled with neurosurgical cement, B) reconstruction of the patient's skull and the creation of a three‐dimensional implant model fitted to the defective bone, C) 3D‐printed implant manufactured of poly(l‐lactide‐co‐d,l‐lactide) and nanohydroxyapatite formulation, and D) surgical procedure of a scaffold implantation in the patient's skull. Reprinted from [www.cyberbone.eu].

This solution is very convenient from certain points of view. First, before the surgery even begins, the trial of physical models of anatomical structures as well as the implant can be manufactured and assessed by the doctor to aid in the planning procedure. In addition, the application of shape‐adapted implant, massively reduces the operational time, in comparison with similar procedures, conducted by using the golden standard methods, such as the auto‐ or the allografting, even by 50–70%. This ensures significant work convenience and increases the patient's safety. This approach also allows to produce several implant copies, in case of the occurrence of damage, the doctor may continue with a new piece. In conclusion, in the case of polymeric biomaterials and unlike titanium protheses, it is possible to adjust their shapes, if needed, in the operating room by using the standard surgical tooling, e.g., to drill holes for fixations, level the surface, etc.

3. Applications of Resorbable Biomaterials

Resorbable biopolymers are used in many fields of medicine, from the standard outpatient procedures, e.g., removal of birthmarks, through digestive tract operations, intradermal suturing, organs’ ligation, ophthalmological procedures (e.g., strabismus surgery), microsurgeries (e.g., peripheral nerve anastomosis), to the complex techniques involving bone substitutes. Surgical sutures are currently the most often used standard absorbable medical devices with the first utilized device, being the plain catgut, i.e., collagen fibers obtained from healthy sheep or cattle undergoing enzymatic digestive degradation in the human body.[ 179 ] Nowadays, surgical sutures are made of synthetic materials, such as PLGA, glycolide, ε‐caprolactone, poly‐4‐hydroxybutyrate, or poly(p‐dioxanone) that are absorbed via the hydrolysis process. These threads are available in various thicknesses, ranging from 0.01 to >1.10 mm, and different types, i.e., mono‐ and multifilament. Depending on the biopolymer type, they also differ in handiness, resorption time (max. 180 days), and tissue support profile that can be adjusted to a specific type of sutured wound/tissue or patient's age. Work comfort that can be provided by a vast array of suture materials and suturing methods, results from the observations and the medical procedures that have been performed over many decades.[ 180 , 181 , 182 ] Surgical meshes, loosely woven sheets for temporary supports are another commonly used absorbable medical device that are often utilized to treat wounds without stretching their edges. This type of prosthesis is mainly applied for the treatment of post‐operative and post‐traumatic wounds, hernias, or reparation of abdominal wall defects.[ 183 ] Day et al. used the PGA mesh with 45S5 Bioglass, which proved in vivo increased vascularization, thereby ensuring a good supply of nutrients and oxygen to new tissue,[ 184 ] while the more recent work by Perez‐Amodio et al. used PLA‐glass fibrous mats[ 185 ] and showed increased vascularization, granulation tissue formation, collagen deposition, and accelerated wound closure in vivo. However, the most extensively used meshes are only partially resorbable and are made of half of glycolide copolymer fibers and the other half is composed of non‐resorbable polypropylene yarns. The resorbable part, which can fully be absorbed within 70 days, provides stiffness and improves convenience during the application, while the non‐absorbable mesh part remains in the body, creating a scaffold for the collagen structure to overgrow.[ 186 , 187 ] The last class of the required materials are the implantable surgical sheets, i.e., films made of carboxy‐methyl‐cellulose and hyaluronic acid, oxidized and regenerated cellulose, poly(p‐dioxanone), copolymers of lactide or ε‐caprolactone. They are recommended for adhesion, ossification prophylaxis, and wound dressing.[ 188 ] Despite these many promising applications, to date, only a few composite systems for soft tissue engineering have reached clinical use in humans. However, it is envisaged that these materials and their biological performance will continue to improve, and society at large will soon experience increasing clinical studies and applications in these areas.

3.1. Dental Tissue Engineering

Teeth are a delicate dental organ and they play a pivotal role in the daily digestion of food and speech. The teeth and the periodontal tissues that support the teeth are constantly confronted with a harsh oral environment, which leads to the inflammation and damage of the dental structures, including pulp, dentin, periodontal ligament (PDL), cementum, and alveolar bone. Indeed, tooth decay and periodontal diseases are two of the most common chronic diseases.[ 189 , 190 ] More than 90% of all the population over the age of 20 in the United States, have some degree of tooth decay.[ 189 ] In addition, it was estimated that 47% of the population in the U.S.A., aged 30 years or older, suffered from periodontal diseases.[ 190 ]

Biomaterial‐based tissue regeneration is a promising strategy to replace damaged dental and supporting structures and to restore their biological functions. Biomaterials play pivotal roles during tissue regeneration, including acting as cell carriers, providing mechanical support, and controlling the delivery of bioactive molecules. As the biomaterials serve as temporary templates for tissue regeneration, they should be biocompatible and biodegradable. Many types of biodegradable materials have been explored for dental tissue regeneration. Table 1 summarizes the biomaterials that are commonly tested for dental tissue regeneration.

Table 1.

Summary of the commonly used biomaterials for dental tissue regeneration.

| Biomaterials | Target tissues | Characteristics | References |

|---|---|---|---|

| Collagen | Pulp, Periodontal ligament (PDL) | Major ECM component, excellent biocompatibility, low mechanical properties, need to be combined with other biomaterials to enhance mechanical properties. | [191, 192, 193, 194] |

| Gelatin | Pulp, dentin, periodontal tissues | Hydrolysis product of collagen, water‐soluble, easily modified to incorporate other bioactive molecules, low mechanical strengths. | [195, 196, 197, 198] |

| Chitosan | Pulp, alveolar bone, PDL | Good biocompatibility, antibacterial activity, need to be combined with other biomaterials to enhance properties. | [199, 200, 201, 202] |

| Alginate | Pulp, alveolar bone | Ionic cross‐linking, ease of manipulation, low cell adhesion, poor dimensional stability | [203, 204] |

| Hyaluronic acid | Pulp, PDL | Excellent biocompatibility, regulating osmotic pressure and tissue lubrication, promoting healing, rapid degradation | [205, 206, 207] |

| Fibrin | Pulp, dentin | Excellent biocompatibility, activation by thrombin to assemble into fibrin gels, binding sites for growth factors and integrins, rapid degradation | [208, 209, 210] |

| PLA, PLGA |

Pulp, dentin, alveolar bone PDL |

Controlled degradation rate, tunable mechanical strengths, good biocompatibility, lack of cell recognition sites. | [211, 212, 213] |

| PCL |

Alveolar bone, PDL |

Controlled degradation rate, tunable mechanical strengths, good biocompatibility, slow degradation rate, lack of cell recognition sites. | [214, 215, 216, 217] |

| Hydroxyapatite (HA) | Alveolar bone, cementum | Similar chemical composition to bone, osteoinductive, direct bonding effect to natural bone, slow degradation rate. | [218, 219, 220, 221] |

| Beta‐tricalcium phosphate (β‐TCP) | Alveolar bone, cementum | Similar chemical composition to bone, bioabsorbable, osteoinductive, fast degradation rate. | [222, 223] |

| Biphasic calcium phosphate (BCP) | Alveolar bone, cementum | Mixture of HA and TCP, tunable degradation rate, osteoinductive. | [224, 225, 226] |

| Bioactive glass (BG) | Alveolar bone, cementum | Osteogenic and angiogenic activities, tunable degradation rate, low fracture resistance | [227, 228] |

Since each biomaterial has certain and peculiar disadvantages, composite biomaterials that combine the advantages of different components, are increasingly, being used for dental tissue regeneration.[ 229 , 230 ] Composite biomaterials can better mimic the compositions of natural ECM to support cell growth and tissue formation. The ECM of periodontium is composed of soft and hard tissues, therefore, polymers and mineralized inorganic biomaterials are often combined as templates to support periodontal tissue formation.[ 231 ] However, most biomaterials that serve as scaffolds cannot provide the biological signals necessary to regulate cell proliferation, chemotaxis, differentiation, and tissue formation. Therefore, bioactive molecules are widely incorporated into the biomaterials to control cell fates and guide tissue regeneration.[ 232 ] Most of the bioactive molecules[ 233 ] contain growth factors, such as vascular endothelial growth factor (VEGF), platelet‐derived growth factor (PDGF), bone morphogenetic proteins (BMPs), insulin‐like growth factor (IGF), and transforming growth factor beta (TGF‐β). In addition, the mixture of bioactive molecules, including platelet‐rich plasma (PRP), platelet‐rich fibrin (PRF), and enamel matrix proteins, have been used to enhance the dental tissue regeneration.[ 234 , 235 , 236 ] The major challenge to achieving desired outcomes is the delivery of bioactive molecules in a controlled manner, to the defective area.

Self‐assembled peptides are a type of new biomaterials that form an ECM‐like architecture and have recently been explored for dental regeneration.[ 237 , 238 , 239 ] These multi‐domain peptides are amphiphilic and are self‐assembled into hydrogels under mild conditions. The addition of oppositely charged ions or change of pH values initiates the physical cross‐linking, and forms nanofibrous peptide hydrogels. For example, RADA16 peptide is assembled into nanofibers in a neutral pH solution to form a three‐dimensional (3D) hydrogel.[ 238 ] When compared to conventional biomaterials, these self‐assembled peptides have custom‐designed molecular compositions and configurations and they can be further modified by other functional motifs to obtain better biological properties. However, peptide biomaterials usually have very low mechanical strength that limits their applications in regenerative dentistry.

When biomaterials are used for dental regeneration, they are fabricated into 3D scaffolds with high porosity and adequate mechanical stability to support cell growth. The pores within the scaffold must be interconnected to facilitate cell migration. The degradation rate of the scaffold must be tailored to match the rate of new tissue formation. In addition, the scaffold should have suitable surface recognition able to facilitate cell‐material interactions. Depending on when the scaffolds are shaped, they can be classified as pre‐formed scaffolds and injectable scaffolds. A pre‐formed scaffold has a definite shape and size, prior to the implantation, while an injectable scaffold, forms the shape after injecting it into the defective area. An injectable scaffold holds several advantages, including, the performance in a minimally invasive manner to reduce the risk of infection and improve comfort, readily fixing any irregularly shaped defects, and facilitating cell adhesion and growth, over a pre‐formed scaffold. Given the complicated morphology and structures of dental tissues, injectable scaffolds are more attractive than the pre‐formed scaffolds.

3.1.1. Pulp Regeneration

The initial scaffolds that were used for the pulp regeneration were pre‐formed scaffolds, and most of the scaffolding materials were PLA or collagen sponges.[ 240 , 241 , 242 ] These studies showed that the dental pulp stem cells differentiated and formed pulp‐like tissues under conducive conditions. However, the tooth root canal has an irregular shape with only a small opening at the apical end; therefore, injectable scaffolds are preferred for pulp regeneration. When collagen was injected inside the root canal and transplanted into a nude mice, pulp‐like vascular tissue was regenerated in the canal space after a few weeks.[ 243 ] However, the low mechanical property of the collagen gel led to the contraction of the construct. Restylane, a HA‐based gel, approved by the FDA for certain applications, was tested as an injectable hydrogel for dental pulp regeneration.[ 205 ] An in vitro study showed that the restylane gel supported the viability of stem cells of the apical papilla and their odontoblastic differentiation. However, it is unknown whether this material promotes in vivo pulp tissue regeneration. PuraMatrix a commercial peptide hydrogel, was tested for pulp regeneration[ 244 ] which supported the DPSC survival, migration, and capillary network formation without adding exogenous growth factors. Similarly, the self‐assembling peptide amphiphiles were also evaluated as injectable cell carriers for pulp regeneration purposes.[ 237 ] These studies proved the feasibility of regenerating pulp‐like tissues when combining dental stem cells with injectable biomaterials.

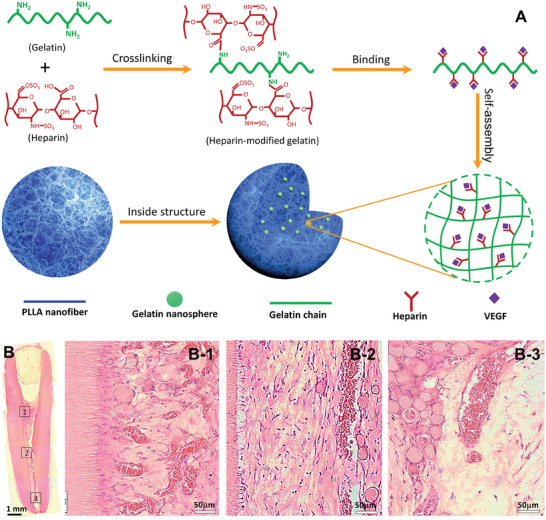

The human tooth root has a long canal with a narrow opening that limits nutrient diffusion and new blood vessels in‐growth. Therefore, fast revascularization has long been a challenge for pulp regeneration in a full‐length root. In one study, angiogenic growth factor VEGF was incorporated into injectable RGD‐alginate/laponite hydrogel microspheres for endodontic regeneration.[ 203 ] The subcutaneous implantation experiment indicated the fact that the VEGF‐loaded microspheres significantly enhanced the pulp‐like tissue regeneration and new blood vessel formation. Further examination, however, showed that the regenerated vascularized soft tissue had a length of <4 mm, which was considerably shorter than the length of a full‐length root, i.e., between 11–13 mm. Similar results were reported when DPSCs were co‐cultured with umbilical vein endothelial cells (HUVECs) to enhance angiogenesis.[ 245 ] Our group,[ 246 ] recently developed a unique hierarchical nanofibrous microsphere system for a full‐length pulp regeneration.[ 246 ] In this system, VEGF was encapsulated into heparin‐conjugated gelatin nanospheres and the VEGF‐loaded nanospheres were further immobilized into nanofibrous PLLA microspheres (Figure 6 ). Since VEGF has binding domains with heparin, the binding of VEGF to heparin‐conjugated nanospheres protected the VEGF from enzymatic degradation and prolonged its sustained release. Indeed, the release of VEGF from the hierarchical spheres was regulated by a multiple‐layer manner, including the binding with the heparin, the degradation of heparin‐conjugated nanosphere, and the physical adsorption of the microsphere nanofibers. This hierarchical injectable microsphere scaffolding system provided an excellent environment for the pulp tissue regeneration in a full‐length tooth root.

Figure 6.

A) Schematic illustration of the synthesis of heparin‐conjugated gelatin nanospheres and the hierarchical VEGF‐loaded nanofibrous microspheres and B) H&E stained images of regenerated pulp‐like tissues in the full‐length root canal after in vivo implantation for nine weeks. Adapted from.[ 247 ] Copyright 2016 Elsevier Ltd.

The in vitro study showed that the nanofibrous microspheres integrated the ECM‐mimicking architecture with a highly porous injectable form and efficiently supported the DPSC growth and pulp‐like tissue formation. The in vivo study further indicated the successful regeneration of highly vascularized pulp tissues that filled the entire two thirds of the root space and reached the coronal third space of the canal. The result was further confirmed by using a multi‐functional peptide‐conjugated non‐viral gene nanocarrier,[ 198 ] indicating the feasibility of regenerating to pulp tissue in a full‐length root with one end sealed by using a single installation, which is a significant step towards regenerative endodontics in clinical settings.

3.1.2. Dentin regeneration

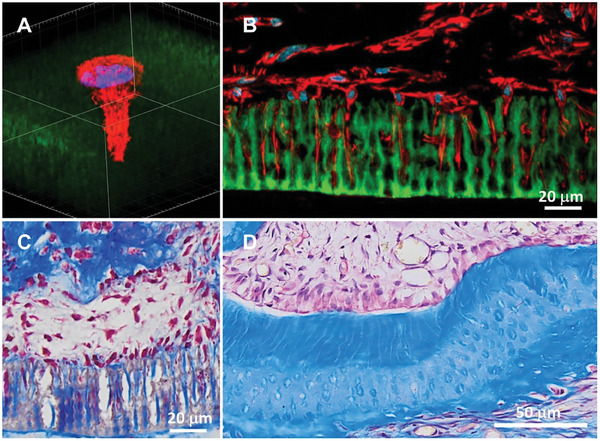

Dentin is composed of millions of well‐organized dentinal tubules[ 248 ] that have diameters of between 2–4 µm. This tubular architecture provides channels for fluid/stimulus signals transformation and mechanical support for the tooth. Therefore, regeneration of the tubular dentin is essential to fully recover the physiological function of a tooth. Due to the technical challenge of fabricating a tubular matrix to guide the DPSC migration and differentiation, the effort of regenerating tubular dentin was not successful and only the bone‐like mineralized tissues or the sporadic dentinal tubules were formed in the root canal chamber after an in vivo tissue regeneration.[ 212 , 249 ] For example, DPSCs formed a dentin‐like structure in a small area of the HA/TCP microparticle surfaces, 6 weeks post‐transplantation.[ 250 ] When the dental progenitor cells were seeded onto the PLGA scaffolds and inserted into a human root fragment, a layer of mineralized tissue was deposited on the root canal wall, four months after implantation.[ 212 ] However, the well‐organized tubular dentin structure was not observed. A maskless micropatterning technology was recently developed to create a 3D nanofibrous tubular matrix for tubular dentin regeneration.[ 251 ] Firstly, the micropattern was designed by using computer software. Subsequently, a laser micro‐dissection machine was applied to the nanofibrous matrix to generate tubular matrix by precisely controlling the fabrication parameters, e.g., laser output power, aperture, laser writing and laser pulse frequency. The synthetic tubular matrix had the same size and density of the tubules when compared to those of the natural dentin. When the DPSCs were cultured on the tubular matrix, in differentiation media for 2 weeks, a layer of odontoblasts with long processes was aligned on the tubular matrix surface, confirming the essential role of the tubular architecture to guide the DPSC polarization and differentiation (Figure 7 ). The in vivo implantation experiment further showed that a layer of a well‐ordered tubular dentin with an average length of ≈45 µm was deposited on the tubular matrix. This work demonstrated the fact that the tubular architecture of the matrix was a pivotal physical factor for tubular dentin regeneration. Future work should integrate this micropatterning technique with other scaffolding fabrication methods and generate a hierarchical matrix for pulp/dentin regeneration.

Figure 7.

Nanofibrous tubular matrices‐guided tubular dentin regeneration. A) A confocal image showing a DPSC extending its process into a tubule, B) Confocal image after the DPSC/tubular matrix construct was cultured in vitro for seven days, C) Trichrome staining after the DPSC/tubular matrix construct was cultured in vitro for two weeks and D) Tubular dentin regeneration after implantation for four weeks. Adapted from ref.[252] Copyright 2017 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim.

3.1.3. Alveolar bone regeneration

For several decades, Guided Bone Regeneration (GBR) has been used for alveolar bone regeneration in clinical settings.[ 253 ] Polymeric materials are usually selected as the GBR barrier membranes that aim to prevent soft tissue downgrowth and maintain the defect space during alveolar bone regeneration. The initial GBR membranes, e.g., expanded polytetrafluoroethylene (ePTFE), were non‐resorbable. Consequently, a second surgery is needed to retrieve the ePTFE after new tissue formation which increases the risks of infection and site morbidity. Therefore, the current research focuses on the development of resorbable GBR membranes for alveolar bone regeneration.

Collagen has been extensively explored as a GBR resorbable membrane and there have been several collagen‐based commercial GBR membranes in the market.[ 253 ] Collagen membranes support osteogenic differentiation, however, their low mechanical strength impairs the function of space maintenance for new bone ingrowth. To increase the mechanical strength, synthetic biodegradable polymers, especially poly(alpha‐hydroxy esters), have been tested as resorbable GBR membranes. However, these synthetic biomaterials often need surface modification or their combinations with other bioactive components to promote cell adhesion, migration, and differentiation.

A composite hydrogel, composed of hydroxyapatite‐calcium sulfate‐hyaluronic acid (HA/CS/HRA) with the encapsulation of collagenase was developed to repair alveolar bone defects.[ 254 ] The combination of the three components, provided a fast absorption of the substrates that facilitated new bone formation. In addition, the release of collagenase from the composite hydrogel could initiate bone remodeling by accelerating wounded trabecular bone digestion. Twelve weeks after implantation, histological images showed that ≈78.3% of the defective site was occupied by the newly formed bone in the HA/CS/HRA group. However, a rapid initial burst release (>80% within the first 24 h) of collagenase from the hydrogel was observed, indicating that an improvement of the collagenase release is needed. In another study, metformin was used as an anti‐inflammatory agent and it was encapsulated into a β‐TCP/chitosan/mesoporous silica composite hydrogel.[ 255 ] The metformin‐loaded composite scaffold promoted alveolar bone regeneration in a periodontitis rat model. Other materials/drugs that are often used for antibacterial/anti‐inflammation during alveolar bone regeneration include: Ag and ZnO nanoparticles, aspirin, and tetracyclines.[ 256 ]

Since periodontitis‐induced alveolar bone loss is a chronical inflammation disease. An immunomodulatory strategy was recently developed for alveolar bone regeneration.[ 257 ] This strategy is targeted to regulate immune cells, especially macrophages that play a central role in inflammation regulation. It is known that M1 macrophages are pro‐inflammatory and M2 macrophages are pro‐healing. Therefore, switching of the macrophage phenotype from M1 to M2 is crucial during the wound‐healing process. In one study, interleukin 4 (IL4) was used to moderate macrophage phenotypes during alveolar bone regeneration.[ 257 ] IL4 was first incorporated into heparin‐conjugated nanospheres, and the binding of IL4 with heparin in the nanospheres protected the IL4 from degradation and controlled its sustained release. Next, the IL4‐loaded nanospheres were encapsulated into the nanofibrous microspheres. In‐vitro and in vivo studies demonstrated the fact that the immunomodulatory microspheres effectively switched the pro‐inflammatory M1 macrophages into anti‐inflammatory M2 macrophages, and therefore significantly enhanced new bone regeneration. Future studies by using large animals are needed to verify the results in a more clinically related disease model.

3.1.4. Alveolar bone/PDL/cementum complex regeneration

Alveolar bone, PDL and cementum are a structural and functional entity of periodontium; therefore, a functional periodontal tissue regeneration should include all the three components. A tri‐layered composite scaffold was fabricated to regenerate alveolar bone, PDL, and cementum.[ 258 ] In that design, chitin/PLGA was selected as the substrate materials for all the three layers, while bioactive glass ceramic nanoparticles were added to the cementum and alveolar bone layers. In addition, platelet‐rich plasma, fibroblast growth factor 2, and cementum protein 1, were introduced to the alveolar bone, PDL, and cementum layers, respectively. Histological images showed the formation of a new alveolar bone, fibrous PDL and cementum, three months after their implantation in a rabbit periodontal defect model. In another study, cell sheet was used to replace the cementum layer and a biphasic scaffold was fabricated for periodontal regeneration.[ 259 ] Cementum‐like and PDL‐like tissues as well as new bone were regenerated after the multilayer scaffold was attached to a dentinal slice, followed by subcutaneous implantation for 8 weeks.

PDL principal fibers and Sharpey's fibers were pivotal to anchor a tooth to the alveolar bone.[ 260 ] One study developed a 3D printing technique to create micro‐patterned channels for PDL principal fibers formation.[ 261 ] Results indicated that the micro‐patterned PCL matrix increased collagen fiber alignment along the surface of the grooved pillars. One limitation of this study is that the micro‐patterned scaffold could only guide the PDL fibers to align on the surface of the grooved pillars and there were no Sharpey's fiber insertions into the cementum/bone portions.

A multi‐compartmental scaffold was fabricated to regenerate PDL and alveolar bone by using the Melt electrowriting (MEW) technology.[ 262 ] Human periodontal ligament fibroblasts and primary human calvarial osteoblasts were seeded onto the PDL and the alveolar regions of the scaffold, respectively. Four weeks after the co‐culture in a differentiation medium, high calcium content in the bone region, moderate calcium content in the transition region, and low calcium content in the PDL region, were observed in the construct. However, the insertion of PDL fibers into the bone compartment of the construct was barely observed, suggesting that no functional PDL was regenerated.

A biphasic scaffold for PDL and alveolar bone regenerations were fabricated by two 3D printing techniques.[ 263 ] Specifically, the PDL compartment was fabricated by a DLP printer, and the alveolar bone compartment was fabricated by a DIW printer. The DLP printer had a high resolution, needed to provide topographical cues to guide the PDL fiber formation and the DIW printer generated the grid structure to support osteoblast growth. Porcine dental follicle‐derived de‐cellularized ECM bioink was further added into the matrix to provide favorable biochemical cues to improve the viability of the encapsulated dental follicle cells and osteogenic differentiation. An in vivo study showed that the biphasic scaffold promoted the regeneration of periodontal tissues, including the PDL fibers and mineralized the alveolar bone. However, the integration of the PDL module with the alveolar bone module is not clear. However, cementum regeneration was not considered in this study.

Overall, significant progress has been made over the last two decades to develop biodegradable materials and fabrication technologies for dental tissue regeneration. Future research should focus on the development of new bio‐inspired ECM‐like materials that can precisely mimic the in vivo micro‐environment to accelerate the pulp/dentin and periodontal tissue regenerations.

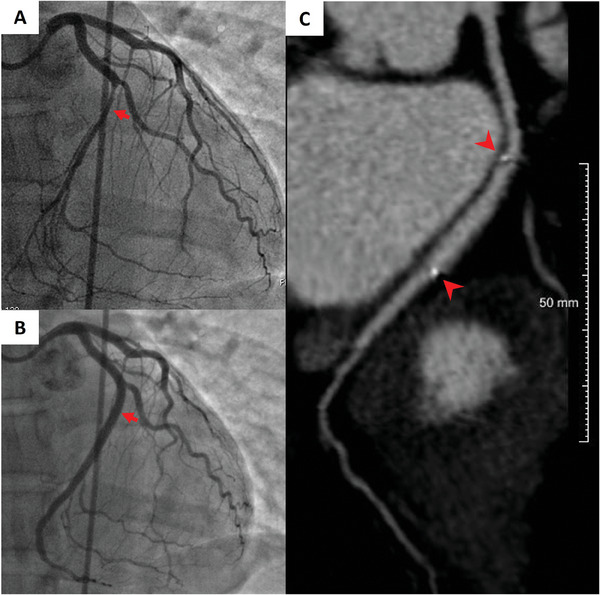

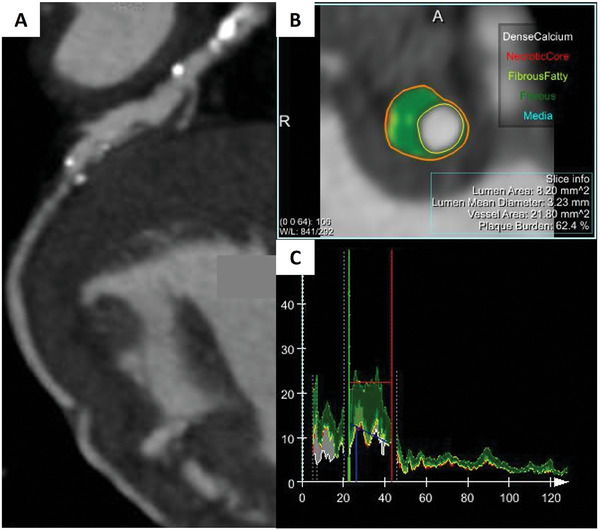

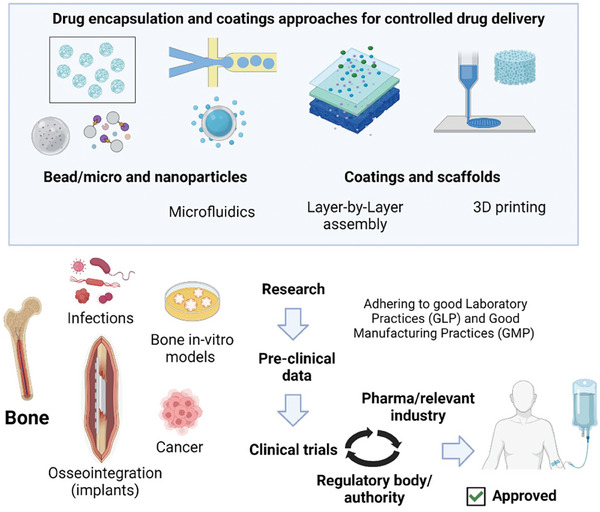

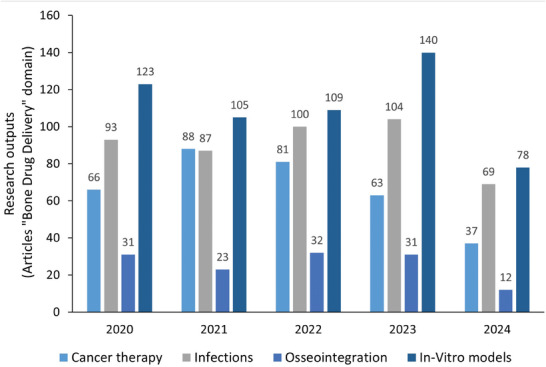

3.2. Bone drug delivery systems