Abstract

This study investigates the use of various industrial waste materials—silica fume (SF), cement kiln dust (CKD), calcium carbide residue (CCR), rice husk ash (RHA), and ground granulated blast furnace slag (GGBS)—as eco-friendly stabilizers for expansive clay soil (ECS). Laboratory tests were conducted to assess the impact of different proportions (3 %, 6 %, and 9 %) of these additives on the soil's physical, mechanical, and microstructural properties. Results indicated that the inclusion of industrial waste significantly improved the soil's behavior, with notable reductions in liquid limit (up to 37.66 %), plasticity index (up to 74.76 %), and swell potential. Additionally, unconfined compressive strength (UCS) and shear strength increased substantially, with UCS values rising from 114.64 kPa to 1582.91 kPa at 30 days of curing for 9 % GGBS. Microstructural analyses confirmed the formation of cementitious compounds, which enhanced soil particle bonding and durability. These findings suggest that industrial waste materials can serve as effective and sustainable alternatives to traditional soil stabilizers, offering both performance improvements and environmental benefits.

Keywords: Industrial waste ash, Expansive clay soil stabilization, Silica fume, Cement kiln dust, Sustainable geotechnical engineering, Sustainable development goals

1. Introduction

The Sustainable Development Goals (SDGs), established by the United Nations in 2015 as part of the 2030 Agenda for Sustainable Development, encompass 17 global objectives aimed at eradicating poverty, protecting the planet, and ensuring peace and prosperity for all by 2030 [1]. The construction industry plays a pivotal role in advancing these goals due to its substantial influence on economic growth, environmental sustainability, and social well-being. Through the adoption of sustainable practices such as energy-efficient building designs, integration of renewable energy sources, sustainable urban planning, and waste reduction, the construction sector can contribute to the realization of several SDGs, including Affordable and Clean Energy (SDG 7), Sustainable Cities and Communities (SDG 11), Responsible Consumption and Production (SDG 12), and Industry, Innovation, and Infrastructure (SDG 9) [[2], [3], [4]].

Likewise, geotechnical engineering, a crucial branch of civil engineering, aligns with various SDGs through its focus on infrastructure development, environmental protection, and societal well-being. Sustainable geotechnical practices, including efficient water management, renewable energy foundations, resilient infrastructure, and responsible consumption, contribute directly to goals like Clean Water and Sanitation (SDG 6), Affordable and Clean Energy (SDG 7), Industry, Innovation, and Infrastructure (SDG 9), Sustainable Cities and Communities (SDG 11), Responsible Consumption and Production (SDG 12), and Climate Action (SDG 13) [5,6]. By incorporating these sustainable practices into their projects, professionals in the construction and geotechnical engineering fields can make substantial contributions to global efforts to achieve the SDGs, thereby promoting sustainable development and environmental stewardship.

Expansive soils, renowned for their substantial volumetric alterations in response to moisture variations, pose notable challenges to civil engineering infrastructure. These soils, which are typically high in montmorillonite, swell when wet and shrink when dry, leading to structural damage, differential settlements, and increased maintenance costs [[7], [8], [9], [10], [11], [12]]. While traditional stabilization methods like lime and cement treatment are effective, they come with substantial environmental drawbacks, including high carbon emissions and significant energy consumption [[13], [14], [15], [16]]. As a result, there is a growing need to explore more sustainable and eco-friendly alternatives.

In this regard, the use of industrial waste materials for soil stabilization is seen as a promising solution. By-products such as fly ash, blast furnace slag, rice husk ash, and silica fume not only improve the engineering properties of expansive soils but also contribute to waste management and environmental conservation [[17], [18], [19], [20]]. Incorporating these materials into soil stabilization practices offers dual benefits: enhancing soil performance while reducing the environmental impact associated with conventional methods. This approach not only addresses the challenges posed by expansive soils but also promotes sustainability in civil engineering practices.

Soil improvement serves as a critical sustainable solution with diverse benefits across environmental, economic, and social spheres. Environmentally, soil improvement techniques bolster sustainability by enhancing soil health and resilience. Practices such as soil stabilization, bioremediation, and the use of organic amendments improve soil structure, nutrient retention, and water infiltration. These methods mitigate erosion, reduce soil degradation, and preserve biodiversity [[21], [22], [23], [24], [25]]. By rehabilitating degraded soils and preventing erosion, soil improvement combats desertification and land degradation, aligning with Sustainable Development Goal (SDG) 15: Life on Land.

Economically, soil improvement provides cost-effective solutions for various industries, including agriculture, construction, and infrastructure development. Improved soil fertility and stability result in higher crop yields, lower maintenance costs for infrastructure, and enhanced land productivity, thereby supporting economic growth and livelihoods [25,26]. Furthermore, the incorporation of industrial by-products and waste materials in soil improvement practices enhances resource efficiency and fosters a circular economy, thereby contributing to SDG 12: Responsible Consumption and Production. These sustainable practices not only address environmental challenges but also yield economic benefits and support social well-being, demonstrating soil improvement as a comprehensive approach to sustainable development.

Socially, soil improvement techniques enhance community resilience and well-being by ensuring the stability and safety of infrastructure and habitats. By reducing soil-related hazards like landslides, flooding, and subsidence, these techniques boost public safety, protect property, and support sustainable urban development, in line with SDG 11: Sustainable Cities and Communities [27,28]. Additionally, soil improvement initiatives can empower local communities through capacity-building, knowledge transfer, and job creation in the sustainable management of natural resources. Soil improvement is essential for sustainable development, as it addresses environmental challenges, supports economic growth, and promotes social equity. By incorporating soil improvement practices into policy frameworks, development strategies, and project implementations, societies can fully leverage soil resources to achieve sustainable development goals, ensuring a resilient and prosperous future for generations to come.

Integrating sustainable practices within the field of geotechnical engineering, particularly in the stabilization of expansive soils, plays a crucial role in advancing multiple Sustainable Development Goals (SDGs) outlined by the United Nations. SDG 11 aims to foster inclusive, secure, resilient, and sustainable cities and human settlements by enhancing soil stability and infrastructure durability. The utilization of industrial waste materials for soil stabilization presents an opportunity to fortify the resilience and longevity of urban infrastructure, consequently mitigating the risk of structural failures and enhancing the safety of urban environments. Furthermore, this approach aligns with SDG 12, which underscores the importance of responsible consumption and production. By repurposing industrial by-products, addressing waste management challenges, and minimizing the environmental impact of construction activities, this research advocates for a circular economy and underscores the necessity of embracing more sustainable construction methods by diverting waste from landfills and integrating it into soil stabilization practices. These linkages between geotechnical engineering and sustainable development goals underscore the urgent need to embrace innovative, eco-friendly approaches, thereby paving the way for a sustainable and environmentally conscious future.

While additives such as silica fume, cement kiln dust, calcium carbide residue, rice husk ash, and ground granulated blast furnace slag have been extensively studied and are known to improve soil properties, the novelty lies in systematically comparing the effectiveness of different waste materials across a range of percentages (3 %, 6 %, 9 %) and in quantifying their specific impacts on expansive clay stabilization through detailed mechanical, mineralogical, and microstructural analyses. This comprehensive approach allows for a deeper understanding of how each material contributes to soil improvement and sustainability, offering valuable insights into the optimal use of waste materials for enhanced soil stabilization. By emphasizing this comparative methodology, the authors can better demonstrate the unique contribution of their research in advancing eco-friendly solutions in geotechnical engineering.

1.1. Literature review

Expansive clays pose a significant threat to construction projects worldwide, resulting in substantial economic losses each year. The annual damage to buildings and infrastructure in the United States caused by expansive soils surpasses $15 billion, exceeding the combined costs of damages from floods, hurricanes, tornadoes, and earthquakes. Similarly, in the United Kingdom, expansive soils result in approximately £400 million in damages annually. This is often observed in the form of cracked walls, uneven floors, and distorted frames in residential buildings [[29], [30], [31]].

Australia faces annual repair costs of about AUD 150 million due to expansive soils, especially in clay-rich regions like New South Wales and Victoria. These damages affect residential properties, roads, and utility infrastructure. In African countries like Nigeria and Kenya, expansive soils frequently damage roads and buildings, necessitating costly infrastructure repairs and maintenance. In India, regions such as Gujarat and Maharashtra endure significant structural damage from expansive soils, with annual repair costs ranging from INR 300–500 million, impacting both residential and commercial properties [32,33]. These statistics highlight the widespread impact of expansive soils on construction and underscore the urgent need for effective soil management and stabilization techniques. Geotechnical investigations and the implementation of appropriate engineering solutions during planning and construction are crucial to ensuring the stability and longevity of structures built on expansive soils, mitigating their economic and structural consequences.

One practical method for addressing the challenges presented by expansive clays is utilizing industrial waste materials for soil stabilization. These materials, including silica fume, cement kiln dust, calcium carbide residue, rice husk ash, and ground granulated blast furnace slag (GGBS), are produced in significant quantities globally. For instance, silica fume, a by-product of silicon metal or ferrosilicon alloy manufacturing, is estimated to amount to approximately 10–15 million tons annually. Significant producers of silica fumes include China, Norway, Canada, and the United States. Similarly, cement kiln dust, a by-product of cement production, is estimated to be in the range of 100–150 million tons annually and is predominantly sourced from cement industries worldwide, particularly in China, India, the United States, and Europe [[34], [35], [36]]Calcium carbide residue, resulting from acetylene gas production, contributes around 5 to 10 million tons annually, predominantly from China. Rice husk ash, originating from rice milling, is estimated to reach around 10 to 15 million tons annually. This by-product is primarily sourced from rice-producing countries such as India, China, Thailand, and Vietnam. Ground granulated blast furnace slag (GGBS), a by-product of steel manufacturing, accounts for approximately 200–250 million tons annually. Major producers of GGBS include China, India, Japan, and the United States [[37], [38], [39]]. These industrial waste materials offer significant potential for sustainable use in various applications, including soil stabilization, concrete production, and environmental remediation. Their utilization promotes resource efficiency and supports global efforts towards environmental sustainability.

1.2. Objectives and significance of study

The primary aim of this study is to investigate and evaluate the potential use of industrial waste materials, such as silica fume, cement kiln dust, calcium carbide residue, rice husk ash, and ground granulated blast furnace slag (GGBS), for soil stabilization. This research targets explicitly addressing the adverse effects of expansive clays on construction projects. This objective aligns with Sustainable Development Goals (SDG) 11 (Sustainable Cities and Communities) and SDG 12 (Responsible Consumption and Production). SDG 11 seeks to promote the development of inclusive, safe, resilient, and sustainable urban areas, while SDG 12 focuses on encouraging responsible consumption and production practices. By adopting industrial waste materials for soil stabilization, this study supports these goals by promoting sustainable construction practices, reducing industrial waste, and enhancing the longevity and resilience of infrastructure.

The research systematically evaluates how various industrial waste materials can effectively stabilize expansive soils. Through comprehensive laboratory and field tests, the study identifies optimal mixtures and treatment methods that improve soil strength, stability, and durability. The research's significance lies in its dual impact: addressing critical geotechnical challenges and promoting sustainable waste management practices. By diverting industrial by-products from landfills and integrating them into soil improvement techniques, the study offers an economically feasible approach to enhancing construction project outcomes while advancing environmental sustainability. The findings are expected to feed valuable perceptions for engineers, policymakers, and the construction industry, facilitating development of more resilient and environmentally friendly infrastructure. This aligns with global efforts to promote sustainable development and resource efficiency.

Using industrial waste materials for soil improvement represents a sustainable and innovative approach that not only enhances soil properties but also tackles significant waste management challenges. By incorporating by-products like silica fume, cement kiln dust, rice husk ash, calcium carbide residue, and GGBS into soil, engineers can enhance its strength, stability, and durability. These materials react with soil particles, forming stronger bonds and reducing shrink-swell behavior, which effectively mitigates the risks associated with expansive clays. Adopting industrial waste for soil stabilization has been shown to reduce environmental impact by diverting waste from landfills and lowering greenhouse gas emissions. Furthermore, it offers economic advantages due to its lower cost and greater availability compared to traditional stabilizers. Moreover, this approach improves soil performance in construction projects, resulting in more resilient and stable infrastructure. However, successful implementation requires rigorous testing to determine the optimal blend and careful adherence to regulatory and environmental standards to ensure safe and efficient use [[40], [41], [42], [43]]. By integrating these sustainable practices, the construction industry can effectively address the challenges of expansive clays while promoting resource efficiency and environmental responsibility.

2. Materials and methods

Fig. 1 illustrates multiple phases of the experimental evaluation performed in the study. Initially, the expansive clay soil (ECS) and industrial waste ash were classified, and physico-mechanical analysis was then performed on expansive clay soil-stabilized samples. In this section, detailed testing protocols, sample preparations, and material classification were discussed.

Fig. 1.

Process of expansive soil stabilization.

2.1. Materials

2.1.1. Soil

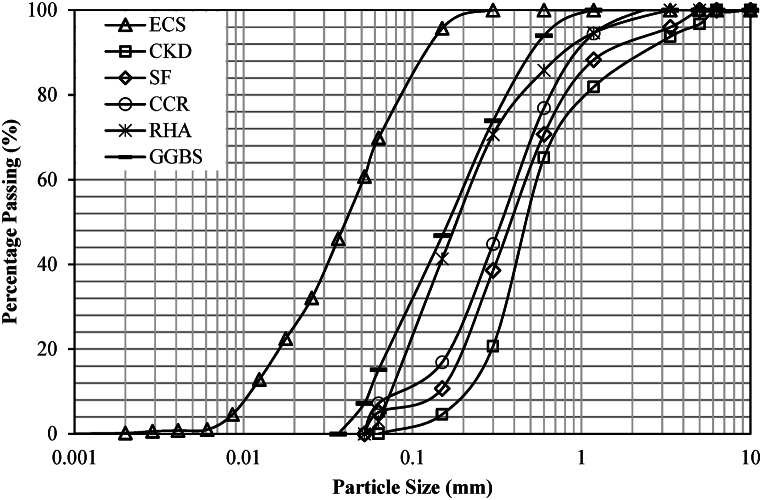

The experimental program utilized expansive clay soil (ECS) obtained at a depth of 1 m in Pahang, Malaysia. The physical characteristics and chemical compositions of the ECS are detailed in Table 1 (a), Table 1 (b)(a) and Table 1(b), respectively. Particle size distribution analysis, including sieve and hydrometer analysis, is illustrated in Fig. 2. The prevalent minerals found in ECS include quartz, illite, kaolinite, and montmorillonite, as shown in Fig. 3. The soil exhibits a substantial free-swell index (FSI) value of 57 % and is classified as CH type (clays of high plasticity) with a liquid limit (LL) of 51.70 and plastic limit (PL) of 22.10. The morphological-microstructure of ECS is presented in Fig. 4, revealing loosely packed clay platelets with significant spaces between the soil particles, indicating a high potential for swelling when water is absorbed. Kaolinite exhibits minimal water absorption and low swelling and shrinkage, while illite and montmorillonite demonstrate significantly higher swelling and shrinkage properties. These expansive characteristics highlight the importance of treating these clays before any construction activities to prevent fissures caused by contraction.

Table 1 (a).

Physical characteristics of expansive clay soil (ECS).

| Properties | ECS | Standard Designation |

|---|---|---|

| Specific Gravity | 2.71 | BS 1377: Part 2: 1990 |

| Sand (0.075–4.75 mm), (%) | 7 | ASTM D422-63 |

| Silt (0.002–0.075 mm), (%) | 40 | ASTM D422-63 |

| Clay (<0.02 mm), (%) | 53 | ASTM D422-63 |

| Unified Soil Classification | CH | ASTM D2487-06 |

| Liquid Limit, (%) | 51.70 | BS 1377: Part 2: 1990 |

| Plastic Limit, (%) | 22.10 | BS 1377: Part 2: 1990 |

| Plasticity Index, (%) | 29.60 | BS 1377: Part 2: 1990 |

| Free Swell Index, (%) | 57 | ASTM D5890-02 |

| Shrinkage Limit, (%) | 15.77 | BS 1377: Part 2: 1990 |

| Maximum Dry Unit Weight, (kN/m3) | 12.26 | BS 1377: Part 2: 1990 |

| Optimum Moisture Content, (%) | 38 | BS 1377: Part 2: 1990 |

| Coefficient of Hydraulic Conductivity (ms−1) | 1.76 × 10−8 | ASTM D5084 |

| Minerals Present | Quartz, Illite, Kaolinite, Montmorillonite | ASTM C1365–18 |

| Colour | Reddish Brown | N/A |

Table 1 (b).

Compositions of expansive clay soil (ECS).

| Elemental Oxide (%) | ECS |

|---|---|

| Na2O | 0.87 |

| MgO | 0.00 |

| Al2O3 | 10.35 |

| SiO2 | 59.60 |

| P2O5 | 0.12 |

| SO3 | 0.00 |

| K2O | 0.00 |

| CaO | 12.23 |

| TiO2 | 4.16 |

| MnO | 0.04 |

| Cr2O3 | 0.03 |

| Fe2O3 | 24.43 |

| NiO | 0.01 |

| CuO | 0.07 |

| ZnO | 0.05 |

| Rb2O | 0.09 |

| SrO | 0.17 |

| Y2O3 | 0.04 |

| ZrO2 | 0.34 |

| BaO | 0.55 |

| PbO | 0.00 |

| ThO2 | 0.06 |

| Nb2O5 | 0.00 |

| Co2O3 | 0.00 |

| V2O5 | 0.05 |

| Ga2O3 | 0.02 |

| LOI | 0.43 |

Fig. 2.

Particle size distribution curves of ECS and industrial waste additives.

Fig. 3.

Mineralogical XRD pattern of Expansive clay soil (ECS), Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast Furnace Slag (GGBS).

Fig. 4.

Microstructure FESEM of Expansive clay soil (ECS), Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast Furnace Slag (GGBS).

2.1.2. Industrial waste ash

Silica fume (SF), calcium carbide residue (CCR), rice husk ash (RHA), cement kiln dust (CKD), and ground granulated blast furnace (GGBS) are the industrial waste ash implemented in this research to enhance the characteristics of the ECS. SF is obtained from Elpion Silicon Sdn. Bhd. situated in Selangor, Malaysia, while CKD is obtained from Graymont suppliers located in Kuala Lumpur, Malaysia. CCR, RHA, and GGBS are acquired from Magnilium Sdn. Bhd., Perak, Malaysia, LLH Biomass Sdn. Bhd., Kedah, Malaysia, and Hume Cement Sdn. Bhd., Perak, Malaysia. The particle size analysis of various industrial waste ash are portrayed in Fig. 2. All of the industrial waste ash obtained in the study were evaluated to be non-plastic and non-swelling materials as highlighted in Table 2(a). The X-ray fluorescence (XRF) test (Table 2(b) conducted on SF, CKD, CCR, RHA, and GGBS reveals that calcium oxide (CaO) and silicon dioxide (SiO2) are significantly found in the additives. The X-ray diffraction (XRD) test (Fig. 3) performed on various industrial waste additives reveals the mineralogical characteristics of SF and GGBS to be consisting of cristobalite, while quartz, calcite, and zincite are present in CKD. On the other hand, calcite and portlandite were found in CCR, while diopside, akermanite, and merwinite exist in GGBS. The morphological-microstructure of various industrial waste ash are depicted in Fig. 4. SF is made up of fine, smooth, spherical particles with a high surface area, which boosts its reactivity. In contrast, CKD comprises irregular, rough particles with a wide range of sizes and a heterogeneous mix, reflecting its complex production process. CCR appears as flaky, irregular particles that sometimes cluster together, mainly consisting of calcium hydroxide. RHA displays highly irregular and porous particles that are rich in silica, enhancing its reactivity. GGBS, on the other hand, features angular, glassy particles with surfaces ranging from smooth to slightly rough, rich in calcium silicates, making it an excellent cementitious material. Understanding these varied microstructural characteristics is crucial for optimizing the performance of these materials in different applications.

Table 2(a).

Physical characteristics of Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast Furnace Slag (GGBS).

| Properties | SF | CKD | CCR | RHA | GGBS | Standard Designation |

|---|---|---|---|---|---|---|

| Specific Gravity | 2.25 | 2.57 | 2.33 | 2.24 | 2.62 | BS 1377: Part 2: 1990 |

| Specific Surface Area, (m2/kg) | 16.56 | 385.70 | 25.55 | 184.40 | 418.5 | BS 4359: Part 1: 1984 |

| Free Swell Index (%) | Non-swelling | Non-swelling | Non-swelling | Non-swelling | Non-swelling | D5890-02 |

| Unified Soil Classification | Non-plastic | Non-plastic | Non-plastic | Non-plastic | Non-plastic | D2487-06 |

| Minerals Present | Cristobalite | Quartz, Zincite, Calcite | Portlandite, Calcite | Cristobalite | Diopside, Akermanite, Merwinite | ASTM C1365–18 |

| Colour | Grey | Off-White | Light Grey | Grey | White | N/A |

Table 2(b).

Compositions of Silica fume (SF), cement kiln dust (CKD), calcium carbide residue (CCR), rice husk ash (RHA), and ground granulated blast furnace slag (GGBS).

| Elemental Oxide (%) | SF | CKD | CCR | RHA | GGBS |

|---|---|---|---|---|---|

| Na2O | 0.33 | 0.30 | 0.88 | 3.80 | 0.18 |

| MgO | 3.73 | 0.99 | 0.55 | 0.80 | 6.89 |

| Al2O3 | 0.45 | 1.80 | 11.43 | 0.50 | 16.86 |

| SiO2 | 74.02 | 9.23 | 40.72 | 90.03 | 34.60 |

| P2O5 | 0.00 | 0.00 | 0.00 | 3.65 | 0.03 |

| SO3 | 2.20 | 0.14 | 0.90 | 0.71 | 1.43 |

| K2O | 4.27 | 1.20 | 0.04 | 4.55 | 0.40 |

| CaO | 0.00 | 45.82 | 42.14 | 2.03 | 37.28 |

| TiO2 | 0.17 | 0.50 | 0.75 | 0.05 | 0.80 |

| MnO | 0.16 | 0.12 | 0.05 | 0.15 | 1.00 |

| Cr2O3 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 |

| Fe2O3 | 0.71 | 5.58 | 8.33 | 0.50 | 0.77 |

| NiO | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 |

| CuO | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 |

| ZnO | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 |

| Rb2O | 0.01 | 0.00 | 0.00 | 0.00 | 0.01 |

| SrO | 0.01 | 0.00 | 0.00 | 0.00 | 0.05 |

| Y2O3 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| ZrO2 | 0.01 | 0.00 | 0.00 | 0.00 | 0.03 |

| BaO | 0.01 | 0.11 | 0.02 | 0.04 | 0.09 |

| PbO | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 |

| ThO2 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Nb2O5 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Co2O3 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| V2O5 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Ga2O3 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| LOI | 3.83 | 16.28 | 26.33 | 14.43 | 0.40 |

2.2. Sample preparation

ECS was prepared in a tray and were oven-dried at 105 °C for 24 h precedent to 475 μm sieving and crushing. To ensure the uniformity of ECS dampness distribution, the soil was air-dried for 4 days following AS 1289.9.1.1:2014. After four (4) days of maturing, the air-dried ECS was mixed with various dampness percentage ranging from 5 % to 30 % via compaction test to acquire the optimum dampness percentage of the virgin ECS. The compaction test were further conducted on the blended ECS with various industrial waste ash at a ratio of 3, 6, and 9 % by soil dry weight in obtaining the optimum dampness percentage of stabilized soil. The proportion of these soil additives were adopted from the earlier study on eggshell ash-stabilized soils [21] and lime-stabilized soil [44].

2.3. Test program

The functionality of stabilized ECS was assessed by performing physical, mechanical, mineralogical, microstructural, leachate, and strength analyses. The laboratory setup is highlighted in Table 3(a), Table 3(b)(a) and Table 3(b). ECS-SF, ECS-CKD, ECS-CCR, ECS-RHA, and ECS-GGBS were blended at a proportion of 3, 6, and 9 % of dry soil weight. 3, 6, and 9 % of ECS-Industrial waste ash implies to 3, 6, and 9 % by soil dry weight. For instance, if the dry soil content was 500 g, then the ECS-Industrial waste ash utilized is 15g, 30g, and 45 g.

Table 3(a).

Laboratory plan for stabilized ECS with various industrial waste ash.

| Property | Test Type | Type of Stabilizer | Stabilizer Content (%) | Curing Period (day) | Testing Standard |

|---|---|---|---|---|---|

| Physical Characterization | Consistency Limits | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 0 | BS 1377: Part 2: 1990 |

| Shrinkage Limits | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 0 | BS 1377: Part 2: 1990 | |

| FSI | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 1 | ASTM D5890-02 | |

| Mechanical Characterization | Compaction | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 0 | BS 1377: Part 2: 1990 |

| Mineralogical Characterization | XRD | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 30 | ASTM C1365–18 |

| Microstructural Characterization | FESEM | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 30 | – |

| Leachate Characterization | TCLP | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 30 | EPA Method 1311 |

| Strength Characterization | UCS | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 1, 7, 14, 30 | ASTM E1621-16 |

| CIU | SF, CKD, CCR, RHA, GGBS | 3, 6, 9 | 1, 7, 14, 30 | BS 1377: Part 7: 1990 |

Table 3(b).

Industrial waste ash mix designations by proportion dry weight of ECS.

| Sample Desigations | SF (%) | CKD (%) | CCR (%) | RHA (%) | GGBS (%) | ECS (%) |

|---|---|---|---|---|---|---|

| ECS3SF | 3 | 0 | 0 | 0 | 0 | 97 |

| ECS6SF | 6 | 0 | 0 | 0 | 0 | 94 |

| ECS9SF | 9 | 0 | 0 | 0 | 0 | 91 |

| ECS3CKD | 0 | 3 | 0 | 0 | 0 | 97 |

| ECS6CKD | 0 | 6 | 0 | 0 | 0 | 94 |

| ECS9CKD | 0 | 9 | 0 | 0 | 0 | 91 |

| ECS3CCR | 0 | 0 | 3 | 0 | 0 | 97 |

| ECS6CCR | 0 | 0 | 6 | 0 | 0 | 94 |

| ECS9CCR | 0 | 0 | 9 | 0 | 0 | 91 |

| ECS3RHA | 0 | 0 | 0 | 3 | 0 | 97 |

| ECS6RHA | 0 | 0 | 0 | 6 | 0 | 94 |

| ECS9RHA | 0 | 0 | 0 | 9 | 0 | 91 |

| ECS3GGBS | 0 | 0 | 0 | 0 | 3 | 97 |

| ECS6GGBS | 0 | 0 | 0 | 0 | 6 | 94 |

| ECS9GGBS | 0 | 0 | 0 | 0 | 9 | 91 |

2.3.1. Consistency limit tests

The plasticity range of clay soil is quantified through its consistency limits, which measure the soil's moisture content and plastic behavior. ECS was examined using these tests due to its particle size being finer than 63 μm. The tests followed the method outlined in BS 1377: Part 2: 1990, focusing on air-dried samples passing through a 425 μm sieve. The liquid limit (LL), plastic limit (PL), and shrinkage limit (SL) were assessed according to the guidelines outlined in BS 1377: Part 2: 1990.

2.3.2. Free Swell Index tests (FSI)

To conduct Fluidity-Swell Index (FSI) test, 10 g of soil specimens with particle sizes smaller than 425 μm are placed into separate 0.1 L cylindrical jars. One jar contains the test liquid, while the other contains kerosene as a reference liquid. Both jars are left undisturbed for 24 h to observe swelling behavior. Afterward, the final volumes of the samples in both cylindrical jars are measured. The FSI is calculated using Equation (1).

| (1) |

where, Vt is the volume of virgin ECS or stabilized ECS containing the test liquid, while Vk is the volume of virgin ECS or stabilized ECS containing kerosene.

2.3.3. Compaction Characterization tests

The Standard Proctor compaction test was carried out in accordance with the BS 1377–2:1990 guidelines using a 2.5 kg hammer and a 9.45 × 10−4 m3 capacity mold. The objective was to assess the relationship between optimum moisture content (OMC) and maximum dry density (MDD) in both treated and untreated ECS. The test involved compacting the soil into three layers, each receiving twenty-five blows from a hammer dropped from a height of approximately 30 cm. The OMC and MDD were determined by plotting the dry unit weights against the moisture content.

2.3.4. Unconfined compressive strength tests

The unconfined compressive strength (UCS) tests were conducted on 15 soil specimens, as detailed in Table 3(b). These tests assessed the undrained shear strength of the materials being studied. Both treated and untreated ECS specimens maintained a consistent density of 1.37 g/cm³, a critical factor in ensuring uniform data in the UCT tests. The UCT tests were carried out by ASTM E1621-16 to evaluate soil strength under unconfined compression, subjecting the samples to axial load without lateral support. Soil specimens were prepared by compressing them at their optimal moisture content in a cylindrical steel mold (100 mm height, 50 mm diameter). These specimens underwent curing for 1, 7, 14, and 30 days in airtight containers at a constant room temperature of 25 °C. The test recorded the axial load at failure and the corresponding axial stress. For the UCS test, five samples were prepared for each mixture.

2.3.5. Consolidated isotropic undrained (CIU) triaxial Test

The consolidated isotropic undrained (CIU) triaxial test was utilized to evaluate the shear strength parameters of expansive clay soil (ECS) and ECS treated with varying amounts of industrial waste ash. Both treated and untreated ECS samples were maintained at a density of 1.37 g/cm³. The CIU tests adhered to BS 1377: Part 7: 1990 standards. Soil specimens, compacted at their optimal moisture content, were molded in cylindrical steel forms (100 mm height, 50 mm diameter) and then cured for 1, 7, 14, and 30 days in airtight containers at 25 °C. Three samples were prepared and tested for each mixture.

2.3.6. Mineralogical and morphological microstructure Characterization

X-ray diffraction (XRD) analysis was performed on untreated ECS and ECS stabilized with various industrial waste additives including S.F., CKD, CCR, RHA, and GGBS. The analysis was conducted using a Bruker D8 Advance Diffractometer following ASTM C1365–18 standards at a 2-theta (2θ) position. Furthermore, field emission scanning electron microscopy (FESEM) analysis was performed on both untreated ECS and stabilized ECS after a 30-day curing period using a ZEISS EVO 50 model.

2.3.7. Metal content and TCLP Test

ECS samples weighing 0.981 g each were stabilized and subjected to microwave digestion by DIN EN 13346 standards. This process was carried out in 0.075-liter digestion vessels (PerkinElmer Titan MPS) using a 70 % HNO3 and 30 % HCl mixture. Post-digestion, the samples underwent filtration through 0.4 mm filters and subsequent 40-fold dilution. A 0.01-liter aliquot of the filtered sample was then subjected to ICP-OES analysis for As, Cr, Cu, Ni, Pb, Cd, Ag, and Co. Samples were cured for 30 days to assess leachability and leachability tests were conducted using the U.S. Environmental Protection Agency TCLP method (Method 1311).

3. Results and discussion

3.1. Consistency limits of virgin ECS and stabilized ECS with various industrial waste additives

The outcomes from the consistency limit test on virgin ECS and ECS treated with various industrial waste ash at 3, 6, and 9 % of utilization are illustrated in Fig. 5. As it is obviously shown in figure, the liquid limit (LL) of the ECS is significantly reduced with the increment proportion of the SF, CKD, CCR, RHA, and GGBS. The highest reduction of the LL was recorded in stabilized ECS-GGBS specimens, followed by stabilized ECS-SF specimens, ECS-CCR specimens, ECS-CKD specimens, and ECS-RHA specimens. The most significant reduction of the LL was observed in ECS9GGBS specimens (LL = 32.23 %) with a percentage reduction of 37.66 %, while ECS3RHA specimens (LL = 50.25 %) recorded the lowest LL reduction with a percentage reduction of 2.80 %. The findings of the present study are aligned with the investigation conducted by Jain et al. [45], Kishor et al. [46], and Varaprasad et al. [47] conducted on various industrial waste which summarized that the utilization of fly ash, SF, CKD, CCR, RHA, and GGBS can reduce the LL of the expansive soil.

Fig. 5.

Plasticity of ECS improved with (a) SF, (b) CKD, (c) CCR, (d) RHA, and (e) GGBS content.

As the percentage of soil stabilizers increases, the LL of the ECS tends to decrease due to a combination of factors. Stabilizers cause fine soil particles to clump together into larger aggregates, which reduces the surface area that can absorb water. Soil additives also trigger cation exchange and flocculation, forming larger particle clusters that hold less water. Additionally, the utilization of SF, CKD, CCR, RHA, and GGBS undergo pozzolanic reactions, producing cement-like compounds that bind the soil particles into a denser matrix with less affinity for water. These changes lead to a reduction in the soil's plasticity and surface charge, improving its structure and drainage while decreasing its capacity to retain water. Therefore, with more stabilizer content, the soil becomes more stable and less plastic, which in turn lowers its liquid limit [[48], [49], [50], [51]].

The high R2 values observed in Fig. 5(a)–5(e) indicate a strong relationship between the stabilizer content and the LL of the soil. This means that changes in the amount of stabilizer lead to highly predictable changes in the LL. Specifically, the R2 values are 0.9988 for SF, 0.9181 for CKD, 0.9648 for CCR, 0.9968 for RHA, and 0.9457 for GGBS. These values validate the precision of our model in describing the relationship between stabilizer content and LL. The minimal unexplained variance, such as 0.12 % for SF, 8.19 % for CKD, 3.52 % for CCR, 0.32 % for RHA, and 5.43 % for GGBS, substantially shows that the established model captures nearly all the variability in the LL resulting from changes in stabilizer content. Such high R2 values suggest that there is very little uncertainty or error in the model's predictions. Practically, this confirms that adding various industrial waste additives as a stabilizer has a clear and consistent impact on the LL of the soil.

The results of the consistency limits show a significant increase in the plastic limit (PL) of the ECS as the proportion of soil additives is increased. The greatest rise in PL was seen in the ECS-GGBS specimens, followed by ECS-SF, ECS-CCR, ECS-CKD, and ECS-RHA specimens. Notably, the ECS9CCR specimens exhibited the highest PL at 36.37 %, marking a 64.57 % increase. In contrast, the ECS9GGBS specimens had the lowest PL increase, reaching 24.76 %, which actually represented a 12.04 % decrease. The findings of the present study are aligned with the investigation conducted by Hasan et al. [48], Sakr et al. [52], Ahmad et al. [53], and Ishak et al. [54] conducted on various industrial waste which summarized that the utilization of various industrial waste can reduce the PL of the expansive soil.

The increase in the plastic limit (PL) with higher percentages of soil stabilizers is due to several interrelated factors. Stabilizers such as SF, CKD, CCR, RHA, and GGBS enhance the cohesion and binding between soil particles, making the soil more resistant to deformation and water absorption. These materials trigger pozzolanic reactions that produce cement-like compounds, strengthening the soil structure and creating a more stable matrix. This results in the soil retaining its shape better when wet, thereby raising the PL. Additionally, soil additives reduce the soil's overall plasticity by altering its mineral composition and decreasing its tendency to swell. As more soil additives are added, the ECS becomes more cohesive and less likely to deform, leading to an increased PL [26,48].

Fig. 5(a)–5(e) clearly demonstrate a strong relationship between the stabilizer content and the plastic limit (PL) of the soil. This means that as the amount of stabilizer changes, the PL of the soil changes in a highly predictable manner. The R2 values, for instance, 0.9709 for SF, 0.9828 for CKD, 0.8748 for CCR, 0.9824 for RHA, and 0.9022 for GGBS, confirm the accuracy of the model in describing this relationship. The minimal unexplained variance, such as 2.91 % for SF, 1.72 % for CKD, 12.52 % for CCR, 1.76 % for RHA, and 9.78 % for GGBS, indicates that the model effectively captures nearly all the variability in the PL due to changes in stabilizer content. These high R2 values suggest that the model's predictions have very little uncertainty or error. This practical finding confirms that using various industrial waste additives as stabilizers has a clear and consistent impact on the PL of the soil.

The plasticity index (PI) value, which is the difference between the liquid limit (LL) and the plastic limit (PL), indicates the range of water content within which the soil exhibits plastic behavior. It provides insight into the soil's plasticity and its capacity to deform without cracking or transitioning to a different state. From the analysis conducted in Fig. 5, the plasticity of the ECS significantly decreased when higher proportions of SF, CKD, CCR, RHA, and GGBS were utilized. ECS9GGBS specimens show the highest plasticity reduction from 29.6 % to 7.47 %, with a percentage reduction of 74.76 %. On the other hand, ECS3SF (PI = 8.20 %) shows the lowest reduction of plasticity with a percentage reduction of 27.70 %. The analysis of the plasticity of the soil reveals that ECS stabilized with GGBS is the most effective soil additive in improving the plasticity of the soil, followed by CCR, CKD, RHA, and SF. The results of the present study are in good agreement with the study conducted by Hasan et al. [21], Zaini et al. [26], Hasan et al. [48], and Ishak et al. [54] conducted on various industrial waste which summarized that the utilization of various industrial waste can reduce the plasticity of the expansive soil.

Higher percentages of soil stabilizers can decrease the plasticity index (PI) of soil through specific interactions and changes in soil characteristics induced by the stabilizer. Stabilizers such as SF, CKD, CCR, RHA, and GGBS alter the soil's chemical composition, affecting its water absorption and retention capabilities. These additives typically diminish soil plasticity by promoting chemical reactions that modify the structure of soil particles. Moreover, soil additives can encourage clay particles to clump together (flocculation), which reduces the soil's ability to hold water. Additionally, stabilizers can initiate pozzolanic reactions that strengthen the bonds between soil particles, resulting in a denser soil structure that exhibits lower plasticity [[48], [49], [50]]. Consequently, the plastic limit (PL) of the soil decreases, indicating a narrower range between the LL and PL and a lower PI.

Similar to the variation observed in the liquid limit (LL) and plastic limit (PL) values for SF, CKD, CCR, RHA, and GGBS, the relationship between the plasticity index (PI) and stabilizer content also shows a strong correlation, as depicted in Fig. 5. Increasing the amount of stabilizer leads to significant and predictable changes in the PI values of the ECS. The R2 values, which include 0.9930 for SF, 0.9428 for CKD, 0.9179 for CCR, 0.9928 for RHA, and 0.9569 for GGBS, validate the model's accuracy in describing this relationship. The minimal unexplained variance (0.70 % for SF, 5.72 % for CKD, 8.21 % for CCR, 0.72 % for RHA, and 4.31 % for GGBS) indicates that the model effectively captures nearly all the variability in the PI due to changes in stabilizer content. These high R2 values suggest that the model's predictions have very little uncertainty or error. This practical finding confirms that using various industrial waste additives as stabilizers has a clear and consistent impact on the plasticity of the soil.

3.2. Shrink-swell behaviour of virgin ECS and stabilized ECS with various industrial waste additives

The Free Swell Index (FSI) measures the swelling potential of expansive soils when they absorb water. FSI quantifies the increase in soil volume upon contact with water, which is essential for understanding the behavior of soils that can expand and contract significantly with moisture changes. Conversely, the Shrinkage Limit (SL) represents the maximum moisture content at which soil maintains its volume during drying. Once SL is reached, further drying does not cause additional volume reduction. As one of the Atterberg limits, along with the liquid limit (LL) and plastic limit (PL), the SL offers valuable insight into the soil's shrinkage properties and behavior as it dries. Hence, a necessary assessment on shrink-swell behavior was conducted to evaluate the behavior of the stabilized ECS under various proportions. Fig. 6(a)–6(e) illustrates the impact of various utilizations of industrial waste ash at different proportions on the shrink-swell behavior of ECS as per the presented of mixture highlighted in Table 3(b). The analysis showed that the maximum reduction of FSI and maximum increment of SL were observed in ECS9GGBS specimens (FSI = 37.77 %, SL = 31.49 %) with a proportion margin difference of 19.23 % and 15.72 %, respectively, when compared to the virgin ECS. On the other hand, the minimum reduction of FSI and minimum increment of SL were observed in ECS3CKD specimens (FSI = 55.11 %, SL = 14.60 %) with a proportion margin difference of 1.89 % and 0.12 %, respectively. These findings align with previous research demonstrating the effectiveness of industrial waste stabilizers in improving the shrink-swell behavior of expansive clays [[55], [56], [57]].

Fig. 6.

Shrink-swell behaviour of ECS improved with (a) SF, (b) CKD, (c) CCR, (d) RHA, and (e) GGBS.

As the percentage of stabilizers increases, both the Free Swell Index (FSI) and Shrinkage Limit (SL) of stabilized soil exhibit significant changes due to the introduction of soil additives like SF, CKD, CCR, RHA, and GGBS. These additives trigger chemical reactions, particularly pozzolanic reactions, which create cement-like compounds binding soil particles together. This reduces the soil's ability to absorb water and swell and promotes flocculation, leading to larger particle clusters with reduced water absorption capacity. The resulting soil structure becomes more stable and less prone to volume changes with fluctuating moisture levels due to decreased plasticity and enhanced aggregation of fine particles. Additionally, cation exchange processes, where calcium ions replace sodium ions in clay particles, further contribute to soil stability by forming stronger aggregates that resist shrinking [[55], [56], [57]]. Overall, these improvements enhance the density, cohesion, and stability of the soil, thereby increasing its suitability for construction applications where maintaining consistent soil volume in varying moisture conditions is crucial.

Fig. 6(a)–6(e) depicts a strong correlation between the SF, CKD, CCR, RHA, and GGBS content and the shrink-swell behavior of the ECS-stabilized soil. The analysis of the correlation between the industrial waste ash content with the FSI and SL presents that the SL value is directly proportional to the industrial waste ash content. In contrast, FSI value is inversely proportional to the industrial waste ash content. As the soil additives content increases, the SL value will increase while the FSI value will decrease. The results on the R2 value generated in the graph illustrated in Fig. 6 portrays that, 98.83 %, 99.84 %, 93.75 %, 99.72 %, and 90.76 % of the data can be used to forecast the FSI value, while 98.90 %, 94.72 %, 99.42 %, 99.67 %, and 95.02 % of the data can be used to forecast the SL value. The changes in the amount of stabilizer lead to highly predictable alterations in the FSI and SL values. The minimal unexplained variance in the FSI-R2 values (1.10 % for SF, 0.16 % for CKD, 6.25 % for CCR, 0.28 % for RHA, and 9.24 % for GGBS) and in the SL-R2 values (1.10 % for SF, 5.28 % for CKD, 0.58 % for CCR, 0.33 % for RHA, and 4.98 % for GGBS) indicates that the model effectively captures nearly all the variability in FSI and SL due to changes in stabilizer content. These high R2 values suggest that the model's predictions are highly accurate with very little uncertainty or error. This finding confirms that using various industrial waste additives as stabilizers has a clear and consistent impact on the FSI and SL of the ECS, enhancing its stability for construction applications.

3.3. Compaction Characterization of virgin ECS and stabilized ECS with various industrial waste additives

Compaction characteristics of virgin ECS and stabilized ECS describe how the soils respond when compacted. The outcomes from the compaction test on virgin ECS and stabilized ECS with different proportions and types are presented in Fig. 7(a)–7(e). As it is evidently demonstrated in Fig. 7, the optimum moisture content (OMC) and maximum dry density (MDD) of the stabilized ECS is directly proportional and inversely proportional, respectively, with soil additives content. When the proportion of the soil additives increased, the OMC of the stabilized ECS increased, while the MDD of the stabilized ECS decreased. Pertaining to the five (5) different soil additives (SF, CKD, CCR, RHA, and GGBS) utilized in the study, ECS stabilized with GGBS shows the highest increment of OMC (from 38.00 % to 46.27 % observed in ECS9GGBS specimens), and significant reduction of MDD (from 1.25 g/cm3 to 1.12 g/cm3 observed in ECS9GGBS). Contrarily, ECS stabilized with CKD demonstrates the lowest increment of OMC (from 38.00 % to 38.63 %% observed in ECS3CKD specimens), and a slight reduction in MDD (from 1.25 g/cm3 to 1.24 g/cm3 observed in ECS3CKD). Aslan & Gürocak [58], Zaini and Hasan [59], Li et al. [60], Phanikumar & Raju [61], and Zaini and Hasan [62] confirm that by utilizing different types of soil additives can alter the value of OMC and MDD. The previous studies show that using industrial waste ash can reduce the MDD value and increase the OMC value of the expansive clay soil. The findings are coherent with the results obtained in the present study.

Fig. 7.

Variation of OMC and MDD of the virgin ECS and stabilized ECS with (a) SF, (b) CKD, (c) CCR, (d) RHA, and (e) GGBS.

When soil additives are introduced, the OMC generally increases while the MDD decreases due to several important factors. Additives such as SF, CKD, CCR, RHA, and GGBS have finer particles and larger surface areas compared to natural soil particles. This greater surface area demands more water for adequate lubrication and compaction, resulting in a higher OMC. Furthermore, these additives trigger chemical reactions, such as pozzolanic or hydration processes, which consume water to form cementitious compounds that bind soil particles together, further increasing water requirements. The incorporation of stabilizers also alters the soil structure, often leading to the formation of flocculated or aggregated structures with more void spaces. These structural changes trap more water, necessitating a higher moisture content for optimal compaction. Additionally, the stabilizers create bonds between soil particles, enhancing the overall strength of the soil but leading to a less dense matrix. This results in a lower MDD, as the stabilizer particles are typically less dense than the original soil particles [61]. Consequently, while these additives enhance soil stability and reduce plasticity and shrink-swell potential, SF, CKD, CCR, RHA, and GGBS also make the soil less compactable, explaining the observed increase in OMC and decrease in MDD.

Fig. 7(a)–7(e) demonstrates a good correlation between the industrial waste additives content with the improvement of OMC and MDD value. The analysis of the correlation between the SF, CKD, CCR, RHA, and GGBS content with the OMC and MDD verifies that the improvement of the OMC and MDD significantly depends on the proportions and types of soil additives. Different types of soil additives resulted in the variation in the MDD and OMC improvement. The results on the R2 value produced in the graph demonstrates that 99.32 %, 96.67 %, 99.40 %, 99.76 %, and 99.99 % of the data can be used to forecast the OMC value, while 98.93 %, 98.00 %, 100.00 %, 100.00 %, and 99.11 % of the data can be used to forecast the MDD value. The alterations in the soil additives proportions resulted to highly predictable modifications in the OMC and MDD values. The minimal unexplained variance in the OMC-R2 values (0.68 % for SF, 3.33 % for CKD, 0.60 % for CCR, 0.24 % for RHA, and 0.01 % for GGBS) and in the MDD-R2 values (1.07 % for SF, 2.00 %% for CKD, and 0.89 % for GGBS). No unverified variances were found in MDD-CCR and MDD-RHA, as the graph shows the perfect correlation between the observed parameters. The data suggests that the model effectively captures nearly all the variability in MDD and OMC due to an increment in stabilizer content. These high R2 values suggest that the model's predictions are highly accurate with very little uncertainty or error. This finding confirms that using various industrial waste additives as stabilizers has a clear and consistent impact on the OMC and MDD of the ECS.

3.4. Unconfined compression strength (UCS) of virgin ECS and stabilized ECS with various industrial waste additives

Testing UCS is crucial for assessing how well soil stabilization methods work by means of utilizing the industrial waste ash as soil additives to enhance the strength of the ECS. The UCS test was conducted on ECS after 1, 7, 14, and 30 days of curing with 3, 6, and 9 % of various industrial waste ash. Fig. 8 a(i) to Fig. 8 e(i) show UCS value with respect to various types, proportions, and curing periods of stabilized ECS specimens. The UCS value of ECS was 114.64 kPa for 1 day of curing and slightly increased to 117.98, 121.11, and 123.61 for 7, 14, and 30 days of curing. With an increment in SF, CKD, CCR, RHA, and GGBS content, the UCS value increased significantly. Besides, the curing periods also play a crucial role in the assessment to further enhance the UCS value of the ECS.

Fig. 8.

Variation of unconfined compressive strength (kPa) and strength improvement with respect to type of soil additives, various proportions, and curing periods of stabilized ECS utilizing; (a) SF; (b) CKD; (c) CCR; (d) RHA; and (e) GGBS.

Based on Fig. 8 a(i) to Fig. 8 e(i), the results showed that by utilizing 3, 6, and 9 % of SF, CKD, CCR, RHA, and GGBS at curing period of 1 day, the strength of the ECS increased from 114.64 kPa to 239.44, 282.83, and 343.41 kPa (for SF), 213.78, 227.94, and 252.31 kPa (for CKD), 249.18, 280.02, and 360.46 kPa (for CCR), 228.66, 250.33, and 287.69 kPa (for RHA), and 253.16, 295.03, and 355.96 kPa (for GGBS). At curing period of 7 days, the strength of the ECS enhanced from 117.98 kPa to 399.71, 606.60, and 763.44 kPa (for SF), 341.80, 506.16, and 630.76 kPa (for CKD), 421.70, 644.75, and 813.82 kPa (for CCR), 375.37, 564.39, and 707.68 kPa (for RHA), and 430.70, 660.35, and 834.44 kPa (for GGBS). Besides, at 14 and 30 days of curing periods, the UCS of the stabilized ECS shows a more significant value compared to ECS samples treated at 1 and 7 days of curing periods. At 14 and 30 days of the curing period, the UCS value of the stabilized ECS increased from 121.11 to 123.61 kPa to 481.52, 719.26 kPa; 663.59, 921.83 kPa; and 1244.11, 1238.29 kPa (for SF), 407.44, 510. 29 kPa; 588.41, 819.56 kPa; and 771.05, 1044.45 kPa (for CKD), 509.66, 765.75 kPa; 827.04, 984.14 kPa; and 1089.55, 1293.70 kPa (for CCR), 450.39, 593.63 kPa; 616.72, 852.87 kPa; and 783.76, 1201.11 kPa (for RHA), and 521.17, 748.78 kPa; 917.04, 1232.13 kPa; 1307.08, and 1582.91 kPa (for GGBS). Identical increasing trends were also evaluated by Hasan et al. [21], and Zaini and Hasan [63].

The increase in Unconfined Compressive Strength (UCS) when soil stabilizers like Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast-furnace Slag (GGBS) are added, especially with extended curing periods, can be explained by several interconnected reasons. These stabilizers work by chemically and physically interacting with the soil. For instance, SF, with its fine particles and high pozzolanic activity, reacts with calcium hydroxide to form calcium silicate hydrates (CSH), which fill voids and create a denser soil structure. CKD, which contains free lime and other cementitious materials, hydrates to form binding agents that strengthen the soil. Likewise, CCR, rich in calcium hydroxide, undergoes pozzolanic reactions to form CSH and calcium aluminate hydrates (CAH), which bind soil particles together and boost UCS. RHA, due to its high silica content, reacts with lime or cement to produce more CSH, while its fine particles help reduce soil porosity. GGBS, with its cementitious and pozzolanic properties, forms binding compounds when activated by lime or cement, further enhancing soil strength [64].

The effectiveness of these chemical reactions and structural improvements increases with the amount of stabilizer used, as more reactive material is available to form cementitious compounds and improve particle packing. Additionally, longer curing periods allow these hydration and pozzolanic reactions to continue and complete, resulting in a progressively stronger and more cohesive soil structure. This extended curing time also reduces the soil's plasticity and sensitivity to moisture, leading to a more stable and consistent soil matrix with higher UCS [65,66]. Overall, the combined effect of these processes significantly enhances the soil's ability to withstand compressive forces, making it more suitable for construction and infrastructure projects.

Over longer curing periods, hydration and pozzolanic reactions continue, producing more calcium silicate hydrates (CSH) and calcium aluminate hydrates (CAH). These compounds enhance the soil's binding properties and fill voids in the matrix. As these reactions progress, the soil-stabilizer mixture develops a stronger microstructure, with better particle bonding and less porosity, leading to a denser and more cohesive material. The initial strength gain is rapid, but it keeps increasing as the compounds stabilize over time [67]. Additionally, the soil's plasticity and swelling potential decrease significantly with longer curing, improving stability and integrity. Internal stresses within the soil are also redistributed and relieved, making the structure more capable of withstanding compressive forces. These combined effects explain why UCS increases significantly with longer curing periods, ensuring better performance and durability in construction projects.

Fig. 8 a(ii) to 8 e(ii) illustrates the relationship between strength improvement of the stabilized ECS specimens with respect to various types of industrial waste ash, proportions, and curing periods. The analysis on the correlation between the various industrial waste ash content (SF, CKD, CCR, RHA, and GGBS) with the strength improvement confirms that the improvement of the UCS is also significantly influenced by the proportions and types of soil additives. Different types of soil additives resulted to the variation on the UCS and strength improvement. A strong relationship was established between the soil additives content and the increment of UCS value. Results show that utilizing 3, 6, and 9 % of soil additives of different types of stabilizer can significantly increase the UCS of the ECS. The significant R2 values established for the strength improvement confirm the accuracy of the model in describing the relationship, as 85 % of the data can be used to forecast the strength improvement of the ECS stabilized with SF, CKD, CCR, RHA, and GGBS. The minimal unexplained variance, which is less than 10 % observed in all of the stabilized ECS specimens, indicates that the model effectively captures nearly all the variability in the UCS due to changes in stabilizer content and curing periods. These high R2 values suggest that the model's predictions have a small uncertainty and error. This practical finding confirms that using various industrial waste additives as stabilizers has a clear and consistent impact on the UCS of the ECS.

3.5. Shear strength of virgin ECS and stabilized ECS with various industrial waste additives

Cohesion and friction angle are key properties that define the shear strength, stability, and load-bearing capacity of soils. Properly assessing these factors is essential for the safe and effective design of many geotechnical engineering projects. Fig. 9 illustrates the relationship between the proportions of industrial waste ash (SF, CKD, CCR, RHA, and GGBS) and the cohesion and internal friction angle of the stabilized ECS. The inclusion of SF, CKD, CCR, RHA, and GGBS at different proportions resulted in a significant increment in the cohesion and internal friction angle of the stabilized ECS. The cohesion and internal friction angle of the stabilized ECS is further increased when all of the samples were treated for 7, 14, and 30 days.

Fig. 9.

Variation of cohesion and internal friction angle of the stabilized ECS with (a) SF, (b) CKD, (c) CCR, (d) RHA, and (e) GGBS.

Based on Fig. 9 a to Fig. 9 e, the outcomes verified that by utilizing 3, 6, and 9 % of various types of industrial waste ash at curing period of 1 day, the cohesion and internal friction angle of the ECS increased from 66.43 kPa to 24.68° to 117.09, 149.04, 343.41 kPa; and 37.34°, 51.67°, 54.00° (for SF), 70.67, 75.43, 83.73 kPa; and 26.21°, 30.34°, 36.67° (for CKD), 91.76, 120.40, 145.73 kPa; and 31.01°, 41.34°, 47.67° (for CCR), 81.32, 90.75, 101.73 kPa; and 28.12°, 36.36°, 42.98° (for RHA), and 144.81, 180.07, 198.78 kPa; and 46.08°, 61.72°, 67.38° (for GGBS). At a curing period of 7 days, the cohesion and internal friction angle of the stabilized ECS enhanced from 67.11 kPa to 24.71° to 119.97, 156.20, 187.53 kPa, and 42.53°, 59.14°, 71.90° (for SF), 75.74, 80.87, 89.44 kPa; and 28.62°, 32.38°, 43.14° (for CKD), 93.54, 124.87, 156.20 kPa; and 33.62°, 46.38°, 59.14° (for CCR), 83.39, 99.11, 123.85 kPa; and 30.62°, 41.33°, 54.77° (for RHA), and 148.79, 189.92, 221.25 kPa; and 53.85°, 74.31°, 90.07° (for GGBS).

Identical to the analysis made in the previous section, at 14 and 30 days of curing periods, the UCS of the stabilized ECS shows a more significant value compared to ECS samples treated at 1 and 7 days of curing periods. At 14 days of the curing period, the cohesion and internal friction angle of the stabilized ECS increased from 67.32 kPA and 24.75° to 123.54, 163.87, 185.87 kPa, and 45.53°, 61.76°, 69.23° (for SF), 79.11, 86.65, 93.88 kPa; and 31.66°, 35.45°, 49.33° (for CKD), 95.43, 129.65, 157.76 kPa; and 35.14°, 48.45°, 58.84° (for CCR), 87.21, 103.65, 133.16 kPa; and 33.33°, 42.19°, 54.39° (for RHA), and 154.04, 200.48, 216.37 kPa; and 60.18°, 79.65°, 90.36° (for GGBS). Lastly, at 30 days of curing period, the cohesion and internal friction angle of the stabilized ECS raised from 67.81 kPa to 24.80° kPa to 132.07, 172.86, 200.66 kPa; and 54.42°, 69.55°, 85.77° (for SF), 82.49, 89.91, 93.87 kPa; and 38.11°, 39.67°, 55.17° (for CKD), 99.94, 136.40, 168.53 kPa; and 42.11°, 53.33°, 69.55° (for CCR), 90.94, 116.22, 147.87 kPa; and 40.14°, 49.67°, 62.73° (for RHA), and 166.59, 211.71, 35.18 kPa; and 69.14°, 88.18°, 107.64° (for GGBS). Identical increasing trends were also assessed by Zaini et al. [65], and Zaini and Hasan [66].

Increasing the percentages of soil additives such as Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast-furnace Slag (GGBS) at optimal percentages of 9 % improves both the cohesion and internal friction angle of the soil through a combination of chemical and physical processes. These additives react with soil minerals and water to form cementitious compounds, such as calcium silicate hydrates (CSH) and calcium aluminate hydrates (CAH), which bind the soil particles together and enhance cohesion. The fine particles of the stabilizers fill voids between soil particles, leading to denser packing and increased interparticle friction, which raises the internal friction angle. The pozzolanic activity of some stabilizers contributes to long-term strength development by continuously forming stable compounds. Adding stabilizers modifies the soil structure, creating a more rigid and interlocked matrix that resists deformation and shear forces, further improving cohesion and the friction angle. This denser, more cohesive soil structure distributes loads more evenly, reducing settlement and increasing stability. Enhanced durability and weather resistance from the stabilizers also prevent structural degradation, maintaining high cohesion and friction angle over time. These combined effects result in a stronger, more stable soil suitable for construction and other geotechnical applications [64,66].

3.6. Mineralogical Characterization of virgin ECS and stabilized ECS with various industrial waste additives

X-ray Diffraction (XRD) offers detailed insights into the soil's mineral composition, tracks chemical reactions, and evaluates how effective the stabilization process by controlling the quality, optimizing the use of soil additives, and predicting the long-term behavior and environmental impact of stabilized soil. Fig. 10(a)–10(e) demonstrates the effect of utilizing various industrial waste ash on the mineralogical alterations of the ECS. All of the soil specimens were cured 30 days prior to conducting the XRD test. The diffractogram of ECS-treated specimens with SF, CKD, CCR, RHA, and GGBS showed a decrease in montmorillonite peak intensities. The decrease in montmorillonite peak intensities primarily results from chemical and physical changes during the soil stabilization process. When SF, CKD, CCR, RHA, and GGBS are added, they react with the montmorillonite. This reaction causes cation exchange and forms cementitious compounds such as calcium silicate hydrates (CSH) and calcium aluminate hydrates (CAH), which consume and alter montmorillonite, thereby reducing its characteristic XRD peaks. The findings are coherent with the investigation made by He et al. [64] and Zaini and Hasan [66].

Fig. 10.

X-rays diffraction (XRD) pattern for stabilized ECS using (a) SF, (b) CKD, (c) CCR, (d) RHA, and (e) GGBS.

Stabilizers also encapsulate montmorillonite particles, decreasing their detectable surface area and further reducing peak intensities. Physical changes, including particle size reduction from mixing or grinding and partial amorphization, also play a role, as smaller or amorphous particles create broader and less intense XRD peaks. Additionally, these processes decrease the crystallinity of montmorillonite, disrupting its orderly atomic arrangement and resulting in less defined peaks. These chemical reactions, structural changes, and physical modifications combine to lower montmorillonite peak intensities, indicating an effectiveness of the soil stabilization process. Besides, the general presence of the quartz, montmorillonite, and illite decreases, indicating that these minerals are chemically weathered with the interaction of the soil additives content (i.e., SF, CKD, CCR, RHA, and GGBS), which resulted in the formation of CSH gel. The CAH and CSH are responsible in increasing the UCS values and strength enhancement in the stabilized ECS. Moreover, the reflections of the stabilized ECS using various industrial waste ash are more intensified compared to the virgin ECS, which validates the raised in cementitious compounds found in the mix blend [64,68].

3.7. Morphological microstructure Characterization of virgin ECS and stabilized ECS with various industrial waste additives

A series of micrograph were captured to analyze the effect of utilizing SF, CKD, CCR, RHA, and GGBS at 30 days of curing on the microstructure behavior of the stabilized ECS (Fig. 11). Based on Fig. 11, the FESEM micrograph clearly shows that when the ECS was stabilized with various types of industrial waste ash, the stabilized ECS transforms significantly due to the formation of calcium silicate hydrates (CSH) and calcium aluminate hydrates (CAH). Initially, the ECS is rough and uneven, often showing visible cracks and voids. When these stabilizers are added, they react with the soil's minerals and water, creating CSH and CAH compounds. Then, the CAH and CSH compounds bind the soil particles together, causing finer particles to cluster into larger, more stable groups. This process not only smooths the surface but also significantly reduces its roughness.

Fig. 11.

FESEM micrographs of stabilized ECS at 30 days of curing periods using (a) SF, (b) CKD, (c) CCR, (d) RHA, (e) GGBS.

After stabilization, the surface becomes noticeably smoother and more uniform as the stabilizers fill in the gaps, creating a more consistent texture. These compounds form on the surfaces of soil particles and grow into fibrous or gel-like structures that fill the spaces between the particles, making the soil denser. Besides, creating these cementitious compounds leads to the development of crystalline phases, observable under a microscope, which further contributes to the soil's improved mechanical properties and durability. SF, with its fine particles, enhances particle packing and reduces porosity. CKD and CCR contribute additional binding materials that strengthen the soil. RHA and GGBS engage in pozzolanic reactions, producing more CSH over time and further densifying the soil. The result is a tightly packed, cohesive network of interlocked particles with minimal voids. This interconnected network improves particle bonding, reduces soil plasticity, and increases load-bearing capacity. Over time, the continued formation of CSH and CAH results in a more stable and durable soil structure.

Throughout the stabilization process, the swelling potential is reduced. Stabilizers react with swelling clays such as montmorillonite, diminishing their ability to absorb water and swell. This reaction results in a more stable surface morphology that is less prone to changes in volume due to moisture variations. Additionally, the chemical reactions harden the soil surface, making it more resistant to erosion and mechanical stress. This increased surface hardness enhances the soil's load-bearing capacity, making it more suitable for construction.

3.8. Toxicity characteristic leaching procedure (TCLP) of stabilized ECS with various industrial waste additives

The Characteristic Leaching Procedure (TCLP) of virgin ECS and stabilized ECS with various proportions and types of industrial waste additives are highlighted in Table 4. From the leachate results, the concentration of all analyzed elements complies with the TCLP regulatory limits. The results of the TCLP test for the soil sample stabilized with various proportions of SF, CKD, CCR, RHA, and GGBS indicate that the arsenic, copper, lead, cadmium, silver, and cobalt concentration is absent, and the chromium and nickel concentration is 1.0 mg/L. All of the TCLP leachate values are below the EPA regulatory limits of 5 mg/L for As, Cr, Pb, and Ag; 25 mg/L for Cu; 20 mg/L for Ni; 1 mg/L for Cd; and 80.0 mg/L for Co. This demonstrates that the soil stabilization process with various proportions and types of industrial waste additives is deemed suitable for construction applications, posing minimal environmental risk.

Table 4.

Leaching potential of metals from stabilized expansive clay soil-industrial waste ash after curing for 30 days, as determined by the toxicity characteristics leaching procedure (TCLP).

| Sample | TCLP Leachate (mg/L) |

|||||||

|---|---|---|---|---|---|---|---|---|

| As | Cr | Cu | Ni | Pb | Cd | Ag | Co | |

| ECS | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS3SF | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS6SF | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS9SF | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS3CKD | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS6CKD | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS9CKD | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS3CCR | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS6CCR | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS9CCR | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS3RHA | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS6RHA | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS9RHA | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS3GGBS | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS6GGBS | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| ECS9GGBS | 0.0 | 1.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| TCLP Regulatory Limits (mg/L) | 5.0 | 5.0 | 25.0 | 20.0 | 5.0 | 1.0 | 5.0 | 80.0 |

3.9. Industrial waste ash-clay interaction

Stabilizing expansive clay with industrial waste ash involves intricate mechanisms and interactions that greatly enhance soil properties. When SF, CKD, CCR, RHA, and GGBS are mixed with ECS, a series of pozzolanic reactions take place. Fig. 12 demonstrates the process and mechanism of stabilizing ECS by using different proportions of SF, CKD, CCR, RHA, and GGBS. The chemical interactions between expansive clay soils and various soil additives lead to significant changes in the soil's properties, improving its stability. Expansive clays are known for their high plasticity and tendency to undergo significant volume changes with moisture fluctuations. When mixed with additives such as Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast Furnace Slag (GGBS), these soils experience transformative reactions that enhance their performance. SF and RHA, which are rich in amorphous silicon dioxide (SiO₂), react with calcium hydroxide (Ca(OH)₂) from the hydration process of ECS with water to form additional calcium silicate hydrate (C-S-H), which improves the soil's strength and reduces its permeability by effectively binding the clay particles and filling in gaps. CKD and GGBS, containing calcium oxide (CaO), silica (SiO₂), and alumina (Al₂O₃), interact with water to create calcium silicate hydrate (C-S-H) and calcium aluminate hydrate (C-A-H). These compounds form a gel-like matrix that increases the soil's rigidity and cohesion by holding the clay particles together. CCR, rich in reactive alumina and silica, engages in pozzolanic reactions with calcium hydroxide from the hydration reaction between calcium oxide in ECS and water, producing C-S-H and C-A-H. This process stabilizes the soil by enhancing its structural integrity and reducing susceptibility to volume changes.

| (1) |

| (2) |

| (3) |

Fig. 12.

Mechanism of expansive clay soil stabilization using various types of industrial waste ash.

Overall, these chemical reactions generate additional cementitious compounds that enhance the strength, stability, and durability of expansive clay soils, helping to mitigate their natural tendency to expand and contract with moisture changes.

3.10. Environmental Ramifications

Using industrial by-products such as Silica Fume (SF), Cement Kiln Dust (CKD), Calcium Carbide Residue (CCR), Rice Husk Ash (RHA), and Ground Granulated Blast Furnace Slag (GGBS) as soil stabilizers in construction has substantial environmental benefits and some challenges. On the upside, these materials reduce industrial waste by repurposing by-products that would otherwise end up in landfills, thus decreasing pollution [[71], [72], [73]]. The utilization of industrial waste additives also cuts down on the need for traditional stabilizers such as cement and lime, which have high carbon emissions during production, thereby lowering the carbon footprint of construction projects [62,77]. The current investigation affirmatively validated the effectiveness of industrial waste ash treatment in controlling the behavior of the ECS and its utilization as a soil additive. The UCS of the industrial waste ash treated ECS cured at 30 days was more than 200 kPa respectively, which is higher than the ECS stabilized soil with fly ash as reported by previous researchers [[69], [70], [71], [72], [73], [74]] which are below than 140 kPa at more than 28 days curing periods.

The stabilization process enhances soil durability and longevity, which reduces the frequency of maintenance and conserves resources over time. Stabilized soils are less prone to erosion, thus protecting water bodies from sedimentation [75,76]. However, there are potential downsides, such as the risk of contaminants, such as heavy metals leaching into the soil and groundwater, and the high alkalinity of traditional stabilizers potentially altering soil pH. For leaching analysis via TCLP, the current investigation proves that the utilization of SF, CKD, CCR, RHA, and GGBS do not pose any danger to the environment, especially to the soil, as the leachate content is below the TCLP regulatory limits. Overall, these additives can change the makeup of leachate by altering its pH and the movement of contaminants, leading to different levels of environmental risk. Additionally, while the by-products themselves are recycled, their initial production still involves energy consumption and emissions. Therefore, although the environmental benefits are significant, careful management and monitoring are essential to mitigate any adverse impacts and ensure the sustainable and safe application of these industrial by-products in soil stabilization.

4. Conclusions

This study demonstrates that using industrial waste ashes such as silica fume (SF), cement kiln dust (CKD), calcium carbide residue (CCR), rice husk ash (RHA), and ground granulated blast furnace slag (GGBS) can significantly improve the engineering properties of expansive clay soil (ECS). The treated soil showed reduced plasticity, less shrink-swell behavior, and increased unconfined compressive strength (UCS) and shear strength. Longer curing times further enhanced these properties, showcasing the long-term effectiveness of these stabilizers. Microstructural analysis revealed the development of cementitious phases and better soil particle bonding, resulting in a denser and stronger soil matrix. These results highlight the potential of using industrial waste for sustainable soil stabilization, providing an eco-friendly method to enhance soil performance in construction and geotechnical engineering.

CRediT authorship contribution statement

Sultan Almuaythir: Funding acquisition, Conceptualization. Muhammad Syamsul Imran Zaini: Writing – original draft, Conceptualization. Muzamir Hasan: Formal analysis, Conceptualization. Md. Ikramul Hoque: Writing – review & editing.

Data availability statement

Data will be made available upon request.

Ethics approval and consent to participate

Not Available.

Additional information

No additional information available for this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work repor

Acknowledgments

This project is sponsored by Prince Sattam Bin Abdulaziz University (PSAU) as part of funding for its SDG Roadmap Research Funding Programme project number PSAU-2023-SDG-72.

References

- 1.United Nations-The General Assembly . 2015. Transforming Our World: the 2030 Agenda for Sustainable Development. [online] Available at: THE 17 GOALS | Sustainable Development (un.org) [Google Scholar]

- 2.Mansell P., Philbin S.P., Broyd T., Nicholson I. Assessing the impact of infrastructure projects on global sustainable development goals. Proc. Inst. Civ. Eng. Eng. Sustain. 2019 doi: 10.1680/jensu.19.00044. [DOI] [Google Scholar]

- 3.Delanka-Pedige H.M.K., Munasinghe-Arachchige S.P., Abeysiriwardana-Arachchige I.S.A., Nirmalakhandan N. Wastewater infrastructure for sustainable cities: assessment based on UN sustainable development goals (SDGs) Int. J. Sustain. Dev. World Ecol. 2021 doi: 10.1080/13504509.2020.1795006. [DOI] [Google Scholar]

- 4.Srivastava S., Iyer-Raniga U., Misra S. Integrated approach for sustainability assessment and reporting for civil infrastructures projects: delivering the UN SDGs. J. Clean. Prod. 2024 doi: 10.1016/j.jclepro.2024.142400. [DOI] [Google Scholar]

- 5.Zolkepli M.F., Ishak M.F., Yunus M.Y.M., Zaini M.S.I., Wahap M.S., Yasin A.M., Sidik M.H., Hezmi M.A. Application of unmanned aerial vehicle (UAV) for slope mapping at Pahang Matriculation College, Malaysia. Phys. Chem. Earth. 2021 doi: 10.1016/j.pce.2021.103003. [DOI] [Google Scholar]