Abstract

The current body of literature indicates that the utilization of emerging digital safety technologies has the potential to enhance the efficacy of safety management in construction significantly. Nevertheless, there has been limited uptake of digital safety technologies within the construction industry in developing countries. This study is focused on evaluating the adoption of digital safety technologies in construction specifically from the perspective of developing countries. Questionnaire data were gathered from project management professionals in China and subjected to analysis using mean ratings, factor analysis, and fuzzy composite evaluation. The developed model for assessing safety technology adoption comprises four primary criterion groups about factors influencing adoption, namely organizational, technological, individual, and external categories. The study results indicate that factors within the technology category exert the most significant influence on the adoption assessment model, followed by those in the external and organizational categories, and finally by individual category factors. These findings contribute to advancing the theory of digital technology adoption in construction safety management research within developing countries. Practitioners can utilize this information to effectively evaluate and compare success rates of safety technology adoption, thereby informing management decisions required for projects. The insights provided by this study will equip practitioners with scientific knowledge for more effective and sustainable program management, ultimately enhancing the success of safety technologies.

Keywords: Construction safety, digital technology, safety management, technology adoption index, adoption of the assessment, developing countries

Introduction

The construction industry stands as a crucial pillar of China's economy, playing a significant role in driving economic growth and enhancing the well-being of its citizens. While construction safety remains an essential focus for ensuring the sustainable development of this industry, 1 the unique nature of construction work presents ongoing challenges in safety management. According to data from the National Ministry of Housing and Urban-Rural Development, there were 584 reported safety incidents resulting in 635 fatalities across China's construction sector in 2023, highlighting the continued severity and complexity of construction safety issues.

To increase project construction safety, the industry has attempted to implement various safety management methods such as hazard identification, 2 training methods, 3 job hazard analysis, adopting safety best practices, strengthening organizational leadership, and safety culture. 4 Although these safety approaches are valuable and beneficial, their reliability and effectiveness are still limited. More effective safety measures are required to decrease injuries and fatalities in the construction industry further. In recent years, emerging digital safety technologies have increasingly been integrated into construction site safety management to enhance workplace conditions and lower casualty rates. Digital technology can be defined as advanced information and communication technologies and tools used to increase productivity throughout the building life cycle. This study defines digital security technologies as digital technologies that monitor and improve security management throughout the project lifecycle. There are various digital safety technologies, including virtual reality, building information modeling (BIM), drones, wearable sensing devices, robotics, radio frequency identification, laser scanning, and rapid response codes, have been utilized to monitor safety on construction sites and reduce worker injuries and fatalities. 5 However, the adoption rate of these technologies remains limited, as indicated by surveys. Various obstacles have limited the adoption of safety technologies, including their high costs, employee resistance, uncertainty about their effectiveness, and issues with integrating them into existing systems. 6 Adoption and implementation of new technologies at construction sites can entail significant capital expenditures and recurring costs, which is the main reason for slow technology adoption in construction. 7

There have been previous studies abroad on the assessment of safety technology adoption, 5 but the factors influencing technology adoption and their extent are slightly different in developing countries than in developed countries. 8 Developing countries may face financial and technological infrastructure constraints, so they may be more cost-effective and usable in the application of new smart technologies. Developed countries, on the other hand, are more likely to prioritize the cutting-edge and innovative nature of technologies and promote their full integration and application. The current decision-making process model used in the domestic construction industry relies heavily on personal experience, which by itself is not sufficient to make informed decisions. In response to the shortcomings of previous studies and the context of China, 22 influencing factors for adopting digital safety equipment and technologies were identified through literature summarization and input from engineering management experts and scholars. Data processing of the 511 valid responses collected resulted in an overall index for safety technology adoption.

Our contributions can be summarized as follows:

The adoption assessment model constructed in this study may assist national practitioners in determining the success of safety technologies.

In addition, the data were categorized into Midwest and East and processed according to the methodology described in this study. Validating the overall assessment model while comparing the differences in the influencing factors of digital safety technology adoption in regions with different economic and building development situations can also provide a reference value for other developing countries.

The remainder of the paper is organized as follows. “Literature review” section outlines the methodology for the application and assessment of construction safety management and construction safety technology. “Data and methodology” section outlines the data collection, sources, and research methodology of the study. “Data analysis and results” section includes data analysis and results, followed by results and discussion in “Discussion of results” section. “Conclusions” section summarizes the main findings. Finally, “Contributions and limitations” section addresses the contributions, limitations, and prospects of this study.

Literature review

There is a wealth of prior research on safety management in construction, and with the continuous advancement of science and technology, there is an increasing focus on the utilization of modern digital technology in safety management. Additionally, scholars have devoted significant efforts to improving assessment methods within this field.

Building construction safety management

Construction safety is one of the most important issues for the sustainable development of the construction industry. 9 Construction accidents not only lead to casualties but also cause huge property losses. According to the World Health Organization, the construction industry is one of the high-risk areas for accidents and injuries, with a rate much higher than many other industries. 10 Construction safety management involves a series of activities including the collection, transmission, storage, analysis, evaluation, and response to safety-related information. This management can be assessed from two main viewpoints: (1) the managerial aspect, which covers factors such as accident causation, safety climate, risk perception and tendencies, behavioral safety, and hazard management; and (2) the technological aspect, which focuses on the integration of innovative solutions for enhancing safety in construction. 11 Compared to other sectors, the construction industry tends to be slower in adopting new technologies, primarily due to limited investment and a lack of interest in high-tech advancements. This resistance to innovation significantly impacts the effectiveness of safety management in construction. 12

In this context, the application of safety technology has become an urgent need to solve construction safety problems. 13 Construction safety technologies can be used at different stages throughout the project life cycle to maximize safety performance. 14 Implementing safety technologies can enhance safety controls beyond traditional hazard recognition training for workers. These technologies offer diverse applications, including the provision of real-time safety data, timely transmission of safety information, and the creation of extensive databases that facilitate risk assessment and accident prediction. By integrating digital safety solutions, construction site safety management can shift from a reactive stance to a more proactive strategy. 11

Application of construction safety technology

Previous research indicates that technology offers numerous safety and nonsafety benefits in the built environment, 15 although its adoption has been slower compared to industries like manufacturing. In the design and planning stages of construction, professionals have been using virtual reality to train field crews in identifying workplace hazards. 16 Virtual reality enhances the visualization of a project's physical and functional aspects, thereby increasing the chances of identifying potential safety issues.

Beyond virtual reality, construction professionals have also employed BIM to enhance safety design, 17 improve design functionality, 18 aid in construction planning, 19 and facilitate better communication among project teams, 20 all aimed at reducing workplace accidents. Building Information Modeling has been utilized for visualization and management, with 4D-BIM projects demonstrating cost savings and data accuracy improvements. 21 Similarly, drones have been increasingly used to bolster construction safety. Yaacoub et al. 22 evaluated drone usage for safety inspections and found them to be effective and efficient for remote inspections through smart devices. Drones are also used for reality capture in high-risk situations, minimizing worker exposure to hazards. 23 Recently, wearable safety devices, such as smart helmets, have gained popularity in construction due to their effectiveness, user-friendliness, and cost-effectiveness. 24 Other technologies, including robotics, radio frequency identification, sensing devices, laser scanning, and rapid response codes, have also been tested in construction safety management and have proven effective in improving working conditions and reducing injury severity. 25

Assessment methodology

Adoption assessment of construction safety technologies is typically uncertain and subjective, and fuzzy set theory (FST) allows researchers to deal with imprecise, fuzzy, and subjective judgments. 26 Fuzzy syndrome evaluation (FSE) is an offshoot of FST, developed by Zadeh 27 to represent and manipulate “fuzzy “ terms, which uses the degree of affiliation in the set rather than strict true/false affiliation. The degree of affiliation can take any value in a closed interval between 0 and 1 and defines the degree to which an element belongs to a fuzzy set. Artificial neural network technique is also a commonly used evaluation method, but fuzzy synthetic evaluation is superior to artificial neural networks in terms of the accuracy of the results. 28 Fuzzy synthetic evaluation mathematically calculates the operators of the fuzzy domains of these variables, 29 and available data on the linguistic aspects can be quantified. Hu et al. 30 emphasized that FSE was developed to deal with complex problems with multilevel variables. According to Wu and Zhang, 31 it is a well-known technique for multicriteria synthetic evaluation problems, which is effective in capturing diversified and uncertain information from a multitude of sources for decision-makers.

However, the use of safety technology in actual construction projects is not high due to the inability to quantify the potential of safety technology through direct measurement of effectiveness. Moreover, the current decision-making process model used in the construction industry relies heavily on personal experience, which is subjective. Therefore, this study utilizes mean score (MS) ranking, factor analysis (FA), and fuzzy comprehensive evaluation to construct an assessment model for the adoption of construction safety technology. A scientifically informed assessment method is used to evaluate the adoption of construction safety technologies.

Data and methodology

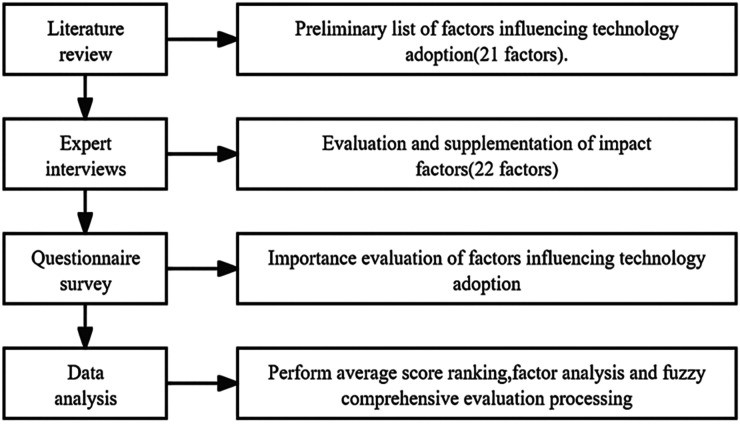

In this study, we reviewed the literature on technology adoption influencing factors and initially identified the influencing factors affecting safety technology adoption. After that, professionals from the construction industry with many years of management experience as well as experts and scholars from engineering management academia were invited to present the current findings to the experts and scholars and were asked to reassess and refine the initially identified technology adoption influencing factors, and finally we identified all the adoption influencing factors for this study. We distributed and collected questionnaires both on-site and online. Finally, the collected data underwent rigorous scientific screening, and analysis was conducted using data analysis tools (Figure 1). This approach minimized respondent subjectivity and bolstered the robustness of the findings.

Figure 1.

Impact factor selection and data processing.

Identify factors of technology adoption

Factors influencing digital technology adoption were identified and summarized from the existing literature, and the experts on the panel were then invited to assess the importance of each factor. They were given the option of eliminating factors they considered unimportant and were encouraged to add other factors that may have been omitted from the literature review in the context of industry developments. By analyzing the feedback from the participants, a list of factors influencing the adoption of construction safety technologies in this study was finalized.

Questionnaires and data collection

To ensure the quality of the data, practitioners from construction and development units, survey and design units, construction units, consulting organizations, research and educational institutions, and government or industry authorities in the construction industry were selected as respondents. They were asked to have many years of working experience and to be familiar with understanding the current situation of construction project management. To increase the representativeness of the sample, the survey should cover as wide an area as possible. Therefore, the survey was distributed to regions covering North China, South China, East China, Central China, Northeast China, Northwest China, and Southwest China. The survey is divided into three main sections. The first section gathered basic demographic information from the respondents. The second section presented definitions and examples of safety technologies, asking participants to identify which technologies they believe will be promoted in the coming years based on industry trends and their assessments. The third section asked respondents to rate the importance of the identified construction safety technology adoption influences on a 5-point Likert scale to measure the importance of each influence, where 1 = very unimportant; 2 = unimportant; 3 = neutral; 4 = important; and 5 = very important.

Data analysis tools

Mean score ranking and FA technique

Several studies in construction management have utilized the MS method to assess the relative significance of various project factors. 29 The MS for each factor was computed using equation (1):

| (1) |

where s represents the respondents’ ratings for each influence, ranging from 1 to 5 (1 = very unimportant, 5 = very important); f represents the frequency of each rating (1–5) for each influence; and N represents the total number of responses about the particular influence.

This study employed FA to statistically identify potential clusters of technology adoption factors. Factor analysis is a statistical method designed to reduce a large set of interrelated variables into a smaller number of distinct subgroups. It is mostly used to explain complex phenomena. 32 In addition, the technique is also powerful in identifying and explaining groups of unrelated elements. 33

Fuzzy synthetic evaluation

Fuzzy syndrome evaluation is an application of FST. In recent years, an increasing number of researchers have employed FST (FSE) as a powerful statistical tool for creating measurement instruments, such as multicriteria decision support frameworks. Fuzzy syndrome evaluation is a versatile modeling technique applicable in management and engineering research, as well as for quantifying multilevel, multiassessment, and multiattribute scenarios.29,30 This technique has been used in different research areas to evaluate multicriteria decision-making such as health risk assessment, risk assessment and allocation, and program delivery assessment.6,29

The FST minimizes the subjectivity of the respondents and the assessment method established in this way is scientific and practical. In this study, FSE was used as the main tool to adopt the index for decision-making measurement of construction safety technologies. This method can objectify and manipulate subjective judgments compared to the common weighting method. 26

Data analysis and results

Based on the previous literature study to identify 21 influencing factors for adopting construction safety technologies (as shown in Table 1) and incorporating experts’ recommendations, we added an influencing factor: Corporate Social Responsibility. A questionnaire was developed to conduct the survey based on the final 22 influencing factors. A pilot survey was initiated before the distribution of the questionnaire, in which five persons with more than 15 years of experience in engineering management were invited to participate to determine the questionnaire's face and internal validity. Managers of 156 large civil engineering and construction projects nationwide were contacted. Three to four senior managers from each project were randomly invited to participate in the survey. A total of 673 questionnaires were recovered from the study, excluding 162 questionnaires due to incomplete or unexplained answers, resulting in a valid sample of 511 questionnaires, with a validity rate of 76%.

Table 1.

Factors identified in the literature.

| Factors | References |

|---|---|

| Proven technical effectiveness | Lee et al. 34 ; Chan et al. 35 ; Nnaji et al. 36 |

| Technically reliable | Algassim et al. 37 , Wimalasena and Gunatilake 38 |

| Technical durability | Algassim et al. 37 , Chan et al. 35 |

| Have the required functionality. | Nnaji et al. 36 , Ozumba and Shakantu 39 |

| Multifunctional | Pan and Pan 7 , Nnaji et al. 36 |

| Observable | Sepasgozar et al. 40 , Watfa et al. 41 |

| Trialability | Watfa et al. 41 , Ozorhon and Cinar 42 |

| Complexity level | Wang et al. 43 , Choi et al. 44 |

| Level of technical support available | Ozumba and Shakantu 39 , Al Yahya et al. 45 |

| Level of training required | Antwi-Afari et al. 46 , Ozorhon and Cinar 42 |

| Colleague Influence | Nnaji et al. 36 , Algassim et al. 37 |

| The initial cost of technology | Sun et al. 47 , Nnaji et al. 36 , Chan et al. 48 |

| Company culture | Lee et al. 34 , Al Yahya et al. 45 |

| Project cost savings | Ozorhon et al. (2017), Antwi-Afari et al. 46 |

| Compatibility with current technology | Mittal et al. 49 , Welch et al. 50 , Al Yahya et al. 45 |

| Senior management support | Sun et al. 47 , Lee et al. 34 , Ozorhon and Cinar 42 |

| Competitive advantages | Rogers et al. 51 |

| Competitors use similar technology. | Jia et al. 52 , Chan et al. 35 |

| Stakeholder support | Lau et al. 53 |

| Client demand | Yigitcanlar et al. 54 , Rogers et al. 51 |

| Government policies and regulations | Jia et al. 52 , Chan et al. 35 |

The survey respondents were geographically distributed across North, South, East, Central, Northeast, Northwest, and Southwest China (Table 2). The Northeast, which had the lowest data, also had approximately 6% of the participants. Approximately 91% of the participants had a bachelor's degree or higher, and 57% had more than 5 years of experience in the construction industry, their feedback provided valuable insights due to their extensive expertise. This survey asked the participants about their workplaces, and over 55% of the participants were from construction organizations, understood the real developments and needs of construction project management, and had extensive field experience. This added to the confidence and reliability of the survey.

Table 2.

Sample characteristics.

| Characteristics | Attributes | Number | Percentage (%) |

|---|---|---|---|

| Working experience | 5 years and below | 220 | 43.1 |

| 5–10 years | 214 | 41.9 | |

| 10–20 years | 65 | 12.7 | |

| 20 years and more | 12 | 2.4 | |

| Education | Specialized and below | 47 | 9.2 |

| Undergraduate | 343 | 67.1 | |

| postgraduates | 121 | 23.7 | |

| Enterprise Type | State-owned enterprise | 436 | 85.3 |

| Private enterprise | 60 | 11.7 | |

| The foreign-invested or joint venture | 12 | 2.3 | |

| Other | 3 | 0.6 | |

| Area | North China | 67 | 13.1 |

| South China | 57 | 11.2 | |

| East China | 128 | 25.1 | |

| Central China | 123 | 24.1 | |

| Northwest China | 56 | 11.0 | |

| Southwest China | 50 | 9.8 | |

| Northeast China | 30 | 5.9 |

Selection of critical adoption factors for safety technology

The questionnaire of this study investigated a total of 22 construction safety technology adoption influencing factors, but not all 22 factors will be included in the adoption assessment model, the adoption influencing factors need to be screened. Ultimately, 19 key adoption factors were left. Table 3 shows the mean ratings and rankings for each influencing variable. Respondents identified compatibility with current technology, technology reliability, validated technological validity, complexity, and level of technical support available as the five most important influencing factors. Although all 22 factors average a rating higher than 3, the index should be developed to include only the most important variables. Therefore, only impact variables with relatively high importance should be selected. One way to identify key factors is to standardize the mean values obtained from descriptive analysis. 29 Normalization typically entails evaluating the significance of each impact variable about the other variables being assessed. [normalized value = (actual value − min. value) / (max. value − min. value)].

Table 3.

Average rating and significance of factors influencing technology adoption.

| Factors | MS | SD | Rank | Normalization |

|---|---|---|---|---|

| Compatibility with current technology | 4.47 | 0.679 | 1 | 1.000 |

| Technically reliable | 4.44 | 0.686 | 2 | 0.964 |

| Proven technical effectiveness | 4.43 | 0.804 | 3 | 0.952 |

| Complexity level | 4.43 | 0.751 | 4 | 0.952 |

| Level of technical support available | 4.40 | 0.655 | 5 | 0.916 |

| Senior management support | 4.38 | 0.725 | 6 | 0.892 |

| Project cost savings | 4.36 | 0.801 | 7 | 0.867 |

| Multifunctional | 4.36 | 0.677 | 8 | 0.867 |

| Have the required functionality | 4.34 | 0.642 | 9 | 0.843 |

| Competitive advantages | 4.33 | 0.784 | 10 | 0.831 |

| Technical durability | 4.32 | 0.803 | 11 | 0.819 |

| Client demand | 4.32 | 0.797 | 12 | 0.819 |

| Corporate Social Responsibility | 4.31 | 0.755 | 13 | 0.807 |

| Stakeholder support | 4.29 | 0.832 | 14 | 0.783 |

| Observable | 4.29 | 0.840 | 15 | 0.783 |

| Government policies and regulations | 4.27 | 0.922 | 16 | 0.759 |

| Level of training required | 4.19 | 0.883 | 17 | 0.663 |

| The initial cost of technology | 4.16 | 0.904 | 18 | 0.627 |

| Colleague Influence | 4.12 | 0.920 | 19 | 0.578 |

| Competitors use similar technology | 3.95 | 1.158 | 20 | 0.373 |

| Company Culture | 3.89 | 1.171 | 21 | 0.301 |

| Trialability | 3.64 | 1.372 | 22 | 0.000 |

Consistent with past research, 32 influence variables with normalized values equal to or higher than 0.5 were retained, while influence variables with normalized values lower than 0.5 were deleted. Therefore, the influence variables “trialability,” “company culture,” and “competitors’ adoption of similar technologies” were removed from the catalog. From the initial list of 22 influence variables, only 19 influence variables remain.

Identification of critical factors category groupings for safety technology

In general, two main requirements should be met before conducting FA. First, the adequacy of the variable-to-sample ratio needs to be assessed. Previous research in construction management has recommended a ratio of 1:5 (i.e. 5 samples per variable). In this study, the ratio was approximately 1:26, which exceeds the recommended threshold. Second, it is essential to evaluate the strength of relationships among variables. The results of the analysis showed that KMO value of 0.919, which satisfies the prerequisite requirements for FA; and p < 0.001, indicating that the research data is suitable for FA.

Fulfillment of both requirements. Principal component extraction with maximum variance rotation was performed using the Statistical Package for the Social Sciences (SPSS). Varimax rotation was chosen because of its ability to simplify interpretation and the lack of a high degree of intercorrelation between components. 35 After seven iterations, four category groups were extracted, which accounted for 53% of the variance of the responses received, and the variance explained (information extracted) for the four categories were 17.654%, 14.669%, 11.742%, and 9.080%, respectively, which is a relatively even distribution of information extracted, which comprehensively indicates that the results of this FA are good. As shown in Table 4, the categories were named organizational variables (category grouping [CG] 1), technology quantities (CG 2), individual variables (CG 3), and external variables (CG 4). Based on the characteristics of the impact variables within each category. The correlations between the variables within the categories (in this case the influence variables) are called factor loadings. For example, the correlation between “level of technical support available” and “CG 1” is 0.536. According to Osei-Kyei and Chan, 29 a factor loading above 0.5 indicates an acceptable correlation. Only two of the 19 impact variables (“initial cost of technology” and “having the required functionality”) had factor loadings below 0.5. Although below the threshold, “initial cost of technology” and “having the required functionality” had factor loadings below 0.5. Although below the threshold, the factor loadings for “initial cost of technology” and “having the required functionality” are relatively high at 0.460 and 0.470, and are therefore retained. 5

Table 4.

Classification of factors influencing the adoption of safety technologies.

| Number | Factors | Factor loadings | Eigenvalue | PVE | CPVE |

|---|---|---|---|---|---|

| CG 1: Organizational | 6.666 | 17.654 | 17.654 | ||

| 1 | Level of technical support available | 0.536 | |||

| 2 | The initial cost of technology | 0.460 | |||

| 3 | Project cost savings | 0.557 | |||

| 4 | Compatibility with current technology | 0.559 | |||

| 5 | Competitive advantages | 0.651 | |||

| 6 | Stakeholder support | 0.598 | |||

| 7 | Government policies and regulations | 0.688 | |||

| CG 2: Technology | 1.391 | 14.669 | 32.323 | ||

| 1 | Have the required functionality | 0.470 | |||

| 2 | Technically reliable | 0.735 | |||

| 3 | Proven technical effectiveness | 0.651 | |||

| 4 | Technical durability | 0.714 | |||

| 5 | Multifunctional | 0.612 | |||

| 6 | Observable | 0.539 | |||

| CG 3: Individual | 1.102 | 11.742 | 44.065 | ||

| 1 | Complexity level | 0.687 | |||

| 2 | Level of training required | 0.752 | |||

| 3 | Colleague Influence | 0.526 | |||

| CG 4:External | 0.940 | 9.080 | 53.145 | ||

| 1 | Corporate Social Responsibility | 0.568 | |||

| 2 | Client demand | 0.682 | |||

| 3 | Senior management support | 0.500 | |||

PVE: percentage of variance explained; CPVE: cumulative percentage of variance explained.

In addition, reliability tests were conducted using Cronbach's coefficient alpha model to ensure internal consistency among the impact variables. First, data reliability was assessed for the impact variables within each proposal category, and then overall reliability was tested for all 19 impact variables. According to Olatunji et al., 11 an alpha coefficient greater than 0.6 indicates acceptable internal consistency among the responses received from participants. The alpha coefficient values for the Technology, Organizational, External, and Individual categories were 0.796, 0.784, 0.645, and 0.708, respectively. The overall Cronbach's alpha for the categories was 0.893, which is in line with the requirements.

Calculation of weights and affiliation functions for influencing factors and CGs

Calculate the weights of the adoption influencing factors and category groups (Table 5). Apply equation (2) to calculate the weights for each Adoption Influencer and for each of the four main category groups. To determine the weights of each impact factor, begin by calculating the total MS for each category group. The total MS is obtained by summing the average scores of all impact factors within that category. The weight of each technology adoption impact factor is then found by dividing the average score of the specific impact factor by the total MS:

| (2) |

where Wi represents the weight; Mi represents the MS of the influencing factor; and ∑Wi represents the 1 is the sum of the mean ratings.

Table 5.

Average ratings and weights of impact factors and categories for technical adoption.

| Number | Factors | MS | Weightings | Total MS for each CG | Weightings of each CG |

|---|---|---|---|---|---|

| CG 1: Organizational | 30.28 | 0.368 | |||

| 1 | Level of technical support available | 4.40 | 0.145 | ||

| 2 | The initial cost of technology | 4.16 | 0.137 | ||

| 3 | Project cost savings | 4.36 | 0.144 | ||

| 4 | Compatibility with current technology | 4.47 | 0.148 | ||

| 5 | Competitive advantages | 4.33 | 0.143 | ||

| 6 | Stakeholder support | 4.29 | 0.142 | ||

| 7 | Government policies and regulations | 4.27 | 0.141 | ||

| CG 2: Technology | 26.18 | 0.318 | |||

| 1 | Have the required functionality | 4.34 | 0.166 | ||

| 2 | Technically reliable | 4.44 | 0.170 | ||

| 3 | Proven technical effectiveness | 4.43 | 0.169 | ||

| 4 | Technical durability | 4.32 | 0.165 | ||

| 5 | Multifunctional | 4.36 | 0.167 | ||

| 6 | Observable | 4.29 | 0.164 | ||

| CG 3: Individual | 12.74 | 0.155 | |||

| 1 | Complexity level | 4.43 | 0.348 | ||

| 2 | Level of training required | 4.19 | 0.329 | ||

| 3 | Colleague Influence | 4.12 | 0.323 | ||

| CG 4: External | 13.01 | 0.158 | |||

| 1 | Corporate Social Responsibility | 4.31 | 0.331 | ||

| 2 | Client demand | 4.32 | 0.332 | ||

| 3 | Senior management support | 4.38 | 0.337 | ||

| Total groups MS | 82.21 | ||||

The affiliation function in FST is typically derived at two or three levels, depending on the research goals. 26 This function, which ranges from 0 to 1, measures how strongly elements belong to a fuzzy set. 29 These levels involve creating an affiliation function for a subset (level 2) before developing one for the broader category (level 1). 5 In this study, Level 2 pertains to the affiliation function for the variable measuring the impact of technology adoption, while Level 1 relates to the affiliation function for the overall category. Level 2 affiliation functions were determined based on the distribution of responses from survey participants, who rated the impact variables using the previously described 5-point Likert scale.

Once the membership function for Layer 2 has been established, equation (3) will be utilized to determine the membership function for Layer 1. In this equation, Wi denotes the weights of all factors within each category, while Ri represents the fuzzy matrix:

| (3) |

where D represents the final FSE evaluation matrix; ○ represents the fuzzy synthesis operator.

Table 6 shows the level 1 and level 2 affiliation functions. Next, the adoption index (AI) for each category is calculated using the equation:

| (4) |

where D represents the final FSE assessment matrix; L represents the scale measure for the hierarchical category set.

Table 6.

Membership functions (MF) for all factors and categories.

| Number | Factors | Weightings | MF for Level 2 | MF for Level 1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CG 1: Organizational | 1 | 2 | 3 | 4 | 5 | 0.006 | 0.032 | 0.073 | 0.406 | 0.484 | ||

| 1 | Level of technical support available | 0.145 | 0.000 | 0.008 | 0.071 | 0.433 | 0.489 | |||||

| 2 | The initial cost of technology | 0.137 | 0.004 | 0.076 | 0.088 | 0.419 | 0.413 | |||||

| 3 | Project cost savings | 0.144 | 0.002 | 0.012 | 0.067 | 0.462 | 0.458 | |||||

| 4 | Compatibility with current technology | 0.148 | 0.002 | 0.010 | 0.065 | 0.362 | 0.562 | |||||

| 5 | Competitive advantages | 0.143 | 0.000 | 0.043 | 0.067 | 0.403 | 0.487 | |||||

| 6 | Stakeholder support | 0.142 | 0.012 | 0.029 | 0.090 | 0.391 | 0.478 | |||||

| 7 | Government policies and regulations | 0.141 | 0.020 | 0.047 | 0.067 | 0.374 | 0.493 | |||||

| CG 2: Technology | 0.005 | 0.021 | 0.086 | 0.384 | 0.505 | |||||||

| 1 | Have the required functionality | 0.166 | 0.002 | 0.004 | 0.071 | 0.503 | 0.421 | |||||

| 2 | Technically reliable | 0.170 | 0.006 | 0.000 | 0.076 | 0.384 | 0.534 | |||||

| 3 | Proven technical effectiveness | 0.169 | 0.008 | 0.022 | 0.088 | 0.296 | 0.587 | |||||

| 4 | Technical durability | 0.165 | 0.004 | 0.031 | 0.096 | 0.380 | 0.489 | |||||

| 5 | Multifunctional | 0.167 | 0.004 | 0.029 | 0.094 | 0.352 | 0.521 | |||||

| 6 | Observable | 0.164 | 0.006 | 0.039 | 0.090 | 0.391 | 0.474 | |||||

| CG 3: Individual | 0.005 | 0.045 | 0.110 | 0.371 | 0.469 | |||||||

| 1 | Complexity level | 0.348 | 0.004 | 0.016 | 0.088 | 0.331 | 0.562 | |||||

| 2 | Level of training required | 0.329 | 0.008 | 0.051 | 0.112 | 0.401 | 0.429 | |||||

| 3 | Colleague Influence | 0.323 | 0.004 | 0.071 | 0.133 | 0.384 | 0.409 | |||||

| CG 4: External | 0.004 | 0.026 | 0.075 | 0.421 | 0.474 | |||||||

| 1 | Corporate Social Responsibility | 0.331 | 0.002 | 0.027 | 0.084 | 0.434 | 0.452 | |||||

| 2 | Client demand | 0.332 | 0.006 | 0.033 | 0.072 | 0.409 | 0.480 | |||||

| 3 | Senior management support | 0.337 | 0.004 | 0.018 | 0.069 | 0.419 | 0.491 | |||||

The AI values for the four category groups (CG1 represents the Organizational, CG2 represents the Technology, CG3 represents the Individual, and CG4 represents the External) were calculated as follows:

Development of digital technology adoption index for construction safety (CS-DTAI)

Nonsignificant correlations between variables often indicate the presence of nonlinearity. Previous studies have used a similar approach to create benchmark success indices using FSE. 5 In developing the CS-DTAI, the influence indices for each category of variables were normalized to ensure that they summed to 1. As shown in Table 7, the summary of the weights indicates that the factors in the technology category have the greatest influence on the potential adoption of digital security technologies. That is, the inherent characteristics of the technology are critical to its adoption and subsequent diffusion.

Table 7.

AI and the coefficient for each CG.

| Number | CG | Adoption index (AI) | Coefficient |

|---|---|---|---|

| CG 1 | Organizational factors | 4.330 | 0.251 |

| CG 2 | Technology factors | 4.363 | 0.252 |

| CG 3 | Individual factors | 4.253 | 0.246 |

| CG 4 | External factors | 4.336 | 0.251 |

| Total | 17.281 | 1.000 |

Note: .

The index to measure the acceptance of digital technology in construction safety management is represented by equation (5):

| (5) |

There is a widely recognized consensus that a significant economic development gap exists between the eastern part of China and its central and western regions. The difference in economic development will affect the development of the construction industry. On the one hand, the economy of the eastern region is developed, while the economic base of the central and western regions is relatively weak. As a result, the east part of the country has a high level of urbanization and good infrastructure. In contrast, the central and western parts of the country have a low level of urbanization and insufficient infrastructure. On the other hand, the better economic development of the eastern part of the construction market demand will be more vigorous, promoting the innovative development of construction technology and design. Due to the gap in economic and construction development between the Midwest and the East, are there also differences in the factors considered when selecting construction safety technologies? To conduct a more in-depth study, the researcher again partitioned the data according to the Midwest and the East, analyzed the data according to the above methodological process (Table 8), and made the CS-DTAI respectively:

| (6) |

| (7) |

Table 8.

Midwest and east adoption index (AI) and coefficients for each CG.

| Number | CG | Midwest | Coefficient | East | Coefficient |

|---|---|---|---|---|---|

| (AI) | (AI) | ||||

| CG 1 | Organizational factors | 4.347 | 0.250 | 4.326 | 0.251 |

| CG 2 | Technology factors | 4.381 | 0.252 | 4.327 | 0.251 |

| CG 3 | Individual factors | 4.348 | 0.250 | 4.320 | 0.251 |

| CG 4 | External factors | 4.302 | 0.248 | 4.245 | 0.247 |

| Total | 17.378 | 1.000 | 17.218 | 1.000 |

Discussion of results

National model

From the results of the national technology adoption assessment model, the highest coefficient is found for the technology category factor (0.252), followed by the organization category (0.251) and the external category (0.251), and lastly, the individual category (0.246). The coefficients were obtained by normalizing the adoption index for each category of influencing variables, which represents the weight of each category in the CS-DTAI.

The highest coefficient for the technology category factor indicates that the technology category factor has the greatest impact on the technology adoption model. This is consistent with the findings of Sepasgozar and Davis 55 that technology attribute factors are critical for technology adoption. In the technology category, “technology reliability” and “validated technology effectiveness” are the two factors with the highest weights, which is consistent with the findings of Nnaji et al. 36 Regardless of the country, the most favorable way to increase the likelihood of technology adoption is to improve the reliability of the technology and demonstrate validity in its dissemination. In the second-ranked organizational category, the factor “Compatibility with current technology” has the highest factor weight. This is similar to the Harris et al. 56 argument that when considering the adoption of a new technology, there is a preference for it to be compatible with the technology currently in use. The highest factor weight was given to “support from top management” in the external category, where support from the top management of the company would make it more likely for a safety technology to be adopted, and the study by Abbasnejad et al. 18 suggests that communicating with the top management of a company and getting their support is very beneficial for a new technology to be adopted.

Regional models

Because of the imbalance in development between the Midwest and the East, we conducted another subregional study. From the results of the regional technology adoption assessment model, the coefficient of the technology category factor of the Midwest assessment model is the highest (0.252), followed by the organization category (0.250) and the external category (0.250), and lastly, the individual category (0.248). The Eastern assessment model has coefficients for the technology, organizational, and external factors (0.251) and the individual category (0.247). It is more consistent with the national assessment model, which proves the generalization of the national technology assessment model. However, there are some differences in the degree of influence of certain factors.

For the Midwest study, the Midwest data were analyzed in comparison to the East and the overall study results. In terms of organization, the average rating of “competitive advantage” is higher in the Midwest (4.38) than in the East (4.32), and there is more room for the development of the construction industry in the Midwest and firms want to take advantage of the competition. This further validates Lacal-Arántegui 57 research. Research on the competitiveness of the construction industry tends to focus on how to measure and improve competitiveness, and enterprises that continue to grow are more sincere in their desire to take advantage of the competition. The “government policies and regulations” factor had the highest average rating in the Midwest. In a study by Ding et al., 58 it was noted that the government may initiate demonstration programs to prove the economic benefits and effectiveness of adopting safety technologies. The construction industry in the central and western regions is lagging, and it is more beneficial to receive the government's attention and support, so construction companies in the central and western regions are more concerned about meeting the government's requirements. As a result, the rating of “corporate social responsibility” is also higher in the Midwest (4.34) than in the East (4.29) and overall (4.31). Jamali and Karam 59 found that socially responsible companies in China are more likely to be well-liked and supported. The mean rating for “level of training required” was higher in the Midwest (4.21) than in the East (4.17) and overall (4.19), while the mean rating for “level of technical support available” was also higher in the Midwest (4.43) than in the East (4.38) and overall (4.40). The average rating for “level of technical support available” is also higher in the Midwest (4.43) than in the East (4.38) and overall (4.40). This demonstrates that employees in Midwestern organizations want less training and easier access to technology and that technical support is readily available when needed.

Adoption assessment models in the East compared to the Midwest and overall adoption assessment models. The factors “influence of colleagues” and “initial cost of technology” have the lowest average ratings in the East. The East has better economic development and more financial support, so the initial cost of the technology is less important when choosing a technology. Among the factor mean ratings, “complexity” has a higher mean rating in the East (4.43) than in the Midwest (4.39). Due to the better development of the construction industry in the East, the employees of the companies in the East have more technologies available to them, and they would prefer the technology to be simple and less cumbersome to operate. This is consistent with Walczuch et al. 60 study, which found that when choosing from a wide range of technologies, users preferred those that were easier to use.

Practical significance

From a practical standpoint, this research holds significant implications for the management of safety in construction. Firstly, by quantifying the probability of adopting digital technology in construction safety management, practitioners can accurately evaluate the effectiveness of their technological adoption. To calculate an adoption index, an index must be computed for each construction group (CG). There are two methods available for calculating an index for a subgroup: (1) Practitioners should assess the true score for each factor under each subgroup within a given program using any measurement scale (e.g. 5-point or 7-point scale). The average adoption index for each CG is then determined and substituted into the adoption index (equation (5)), and (2) Practitioners should reimplement the entire fuzzy synthetic evaluation methodology proposed in this study using a new dataset.

Secondly, practitioners can utilize the adoption index to conduct a reliable and objective comparison of various digital safety technologies, to establish benchmarks and enhance control measures. The comparison process may adhere to any of the methodological procedures previously discussed. Furthermore, this study examines the significance of influencing factors on safety technologies and explores variations in these factors between the Midwest and East regions, each with distinct developmental profiles. These findings aim to offer insights for domestic practitioners seeking to enhance the implementation of construction safety technologies.

Conclusions

This study has developed an index for the adoption of digital safety technology to quantitatively assess the likelihood of its implementation in construction safety management. The findings suggest that technical factors exert the greatest influence on the adoption of digital safety technologies, followed by organizational and external factors, with personal factors being the least influential. Within technological factors, “technological reliability” and “proven technological effectiveness” were found to carry the most weight.

Additionally, the results of the partitioning study indicate that the construction safety technology adoption assessment model is generalizable. However, there are variations in the impact of certain factors. Construction companies in less developed regions in central and western China prioritize whether technology adoption facilitates obtaining government support and enhancing their competitive advantage. Conversely, firms in more developed eastern regions show less concern about the initial cost of the technology, while emphasizing employees’ preference for user-friendly technology.

Contributions and limitations

This study developed an index model for adopting digital technology in construction safety management, investigated the factors influencing the uptake of digital safety technology, and conducted a comparative analysis of regions with varying levels of economic and construction development. The findings may offer valuable insights for enhancing the adoption rate of digital safety technology.

However, it is important to acknowledge the limitations of this study. Firstly, the results were obtained through analysis of data provided by industry professionals, which may introduce bias due to respondents’ subjective judgment. Fortunately, applying FST helps mitigate subjectivity and strengthens the robustness of the findings compared to using clear values directly. Secondly, it should be noted that this study was conducted in China, and as such, the influencing factors and their significance may differ in other countries, particularly those that are more developed. Nonetheless, the insights gained from this study can still provide valuable information for researchers in other countries. Future studies could supplement these influencing factors by considering their own country's specific circumstances and current state of development within the construction industry. Additionally, it is recommended that future research incorporate actual project cases to further facilitate the practical application of the technology adoption assessment model.

Footnotes

Author contribution statement: Jinjing Xu: conceptualization, methodology, resources, software, data curation, writing—original draft, writing—review & editing. Jintao Li: conceptualization, methodology, resources, supervision, writing—review & editing. Xiaohong Chen: supervision, revision of the manuscript, acquisition of funding for the research, manuscript language embellishment. All authors have read and agreed to the published version of the manuscript.

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Funding: The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This study was financially funded by the MOE (Ministry of Education of China) Project of Humanities and Social Sciences Research (Grant Number 19YJA630035) and the Teaching Research Project of Hubei University of Technology (grant number: S2022003).

ORCID iD: Jinjing Xu https://orcid.org/0009-0009-4006-8978

References

- 1.Bhandari S, Hallowell MR, Boven LV, et al. Using augmented virtuality to examine how emotions influence construction-hazard identification, risk assessment, and safety decisions. J Constr Eng Manag 2020; 146: 04019102. [Google Scholar]

- 2.Perlman A, Sacks R, Barak R. Hazard recognition and risk perception in construction. Saf Sci 2014; 64: 22–31. [Google Scholar]

- 3.Jeelani I, Albert A, Azevedo R, et al. Development and testing of a personalized hazard-recognition training intervention. J Constr Eng Manag 2016; 143: 04016120. [Google Scholar]

- 4.Alkaissy M, Arashpour M, Ashuri B, et al. Safety management in construction: 20 years of risk modeling. Saf Sci 2020; 129: 104805. [Google Scholar]

- 5.Nnaji C, Gambatese J, Karakhan A, et al. Development and application of safety technology adoption decision-making tool. J Constr Eng Manag 2020; 146: 04020028. [Google Scholar]

- 6.Okpala I, Nnaji C, Gambatese J. Assessment tool for human-robot interaction safety risks during construction operations. J Constr Eng Manag 2023; 149: 04022145. [Google Scholar]

- 7.Pan M, Pan W. Determinants of adoption of robotics in precast concrete production for buildings. J Manag Eng 2019; 35: 05019007. [Google Scholar]

- 8.Na S, Heo S, Choi W, et al. Artificial intelligence (AI)-based technology adoption in the construction industry: a cross-national perspective using the technology acceptance model. Buildings 2023; 13: 2518. [Google Scholar]

- 9.Lima L, Trindade E, Alencar L, et al. Sustainability in the construction industry: a systematic review of the literature. J Cleaner Prod 2021; 289: 125730. [Google Scholar]

- 10.Xu Q, Xu K. Analysis of the characteristics of fatal accidents in the construction industry in China based on statistical data. Int J Environ Res Public Health 2021; 18: 2162. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Olatunji SO, Olawumi TO, Aje IO. Rethinking partnering among quantity-surveying firms in Nigeria. J Constr Eng Manag 2017; 143: 05017018. [Google Scholar]

- 12.Yap JBH, Chow IN, Shavarebi K. Criticality of construction industry problems in developing countries: analyzing Malaysian projects. J Manag Eng 2019; 35: 04019020. [Google Scholar]

- 13.Zhang M, Shi R, Yang Z. A critical review of vision-based occupational health and safety monitoring of construction site workers. Saf Sci 2020; 126: 104658. [Google Scholar]

- 14.Zhou Z, Goh YM, Li Q. Overview and analysis of safety management studies in the construction industry. Saf Sci 2015; 72: 337–350. [Google Scholar]

- 15.Wang N, Xu Z, Liu Z. Innovation in the construction sector: bibliometric analysis and research agenda. J Eng Tech Manage 2023; 68: 101747. [Google Scholar]

- 16.Li X, Yi W, Chi HL, et al. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom Constr 2018; 86: 150–162. [Google Scholar]

- 17.Alizadehsalehi S, Yitmen I, Celik T, et al. The effectiveness of an integrated BIM/UAV model in managing safety on construction sites. Int J Occup Saf Ergon 2020; 26: 829–844. [DOI] [PubMed] [Google Scholar]

- 18.Abbasnejad B, Nepal MP, Ahankoob A, et al. Building information modelling (BIM) adoption and implementation enablers in AEC firms: a systematic literature review. Archit Eng Des Manag 2020; 17: 411–433. [Google Scholar]

- 19.Gao H, Koch C, Wu Y. Building information modeling based building energy modeling: a review. Appl Energy 2019; 238: 320–343. [Google Scholar]

- 20.Panteli C, Kylili A, Fokaides PA. Building information modeling applications in smart buildings: from design to commissioning and beyond A critical review. J Cleaner Prod 2020; 265: 121766. [Google Scholar]

- 21.Swallow M, Zulu S. Students’ awareness and perception of the value of BIM and 4D for site health and safety management. J Eng Des Technol 2020; 18: 414–430. [Google Scholar]

- 22.Yaacoub JP, Noura H, Salman O, et al. Security analysis of drone systems: attacks, limitations, and recommendations. Internet Things 2020; 11: 100218. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Sharma A, Shoval S, Sharma A, et al. Path planning for multiple targets interception by the swarm of UAVs based on swarm intelligence algorithms: a review. IETE Tech Rev 2021; 39: 675–697. [Google Scholar]

- 24.Abioye SO, Oyedele LO, Akanbi L, et al. Artificial intelligence in the construction industry: a review of present status, opportunities, and future challenges. J Build Eng 2021; 44: 103299. [Google Scholar]

- 25.Skibniewski MJ. Research trends in information technology applications in construction safety engineering and management. Front Eng Manag 2015; 1: 246–259. [Google Scholar]

- 26.Ameyaw EE, Chan AP. Evaluation and ranking of risk factors in public-private partnership water supply projects in developing countries using fuzzy synthetic evaluation approach. Expert Syst Appl 2015; 42: 5102–5116. [Google Scholar]

- 27.Zadeh LA. Fuzzy sets. Inf Control 1965; 8: 338–353. [Google Scholar]

- 28.Liao L, Teo Ai Lin E, Low SP. Assessing building information modeling implementation readiness in building projects in Singapore: a fuzzy synthetic evaluation approach. Eng Constr Archit Manag 2019; 27: 700–724. [Google Scholar]

- 29.Osei-Kyei R, Chan AP. Developing a project success index for public-private partnership projects in developing countries. J Infrastruct Syst 2017; 23: 04017028. [Google Scholar]

- 30.Hu Y, Chan AP, Le Y, et al. Developing a program organization performance index for delivering construction megaprojects in China: fuzzy synthetic evaluation analysis. J Manag Eng 2016; 32: 05016007. [Google Scholar]

- 31.Wu Y, Zhang T. Risk assessment of offshore wave-wind-solar-compressed air energy storage power plant through fuzzy comprehensive evaluation model. Energy 2021; 223: 120057. [Google Scholar]

- 32.Zhao X, Hwang BG, Gao Y. A fuzzy synthetic evaluation approach for risk assessment: a case of Singapore's green projects. J Cleaner Prod 2016; 115: 203–213. [Google Scholar]

- 33.Lee S, Yu J. Comparative study of BIM acceptance between Korea and the United States. J Constr Eng Manag 2016; 142: 05015016. [Google Scholar]

- 34.Lee S, Yu J, Jeong D. BIM Acceptance model in construction organizations. J Manag Eng 2015; 31: 04014048. [Google Scholar]

- 35.Chan APC, Darko A, Ameyaw EE. Strategies for promoting green building technologies adoption in the construction industry—an international study. Sustainability 2017; 9: 969. [Google Scholar]

- 36.Nnaji C, Gambatese J, Karakhan A, et al. Influential safety technology adoption predictors in construction. Eng Constr Archit Manag 2019; 26: 2655–2681. [Google Scholar]

- 37.Algassim H, Sepasgozar SM, Ostwald M, et al. A qualitative study on factors influencing technology adoption in the architecture industry. Buildings 2023; 13: 1100. [Google Scholar]

- 38.Wimalasena NN, Gunatilake S. The readiness of construction contractors and consultants to adopt e-tendering: the case of Sri Lanka. Constr Innov 2018; 18: 350–370. [Google Scholar]

- 39.Ozumba AOU, Shakantu W. Exploring challenges to ICT utilization in construction site management. Constr Innov 2018; 18: 321–349. [Google Scholar]

- 40.Sepasgozar SME, Loosemore M, Davis SR. Conceptualising information and equipment technology adoption in construction: a critical review of existing research. Eng Constr Archit Manag 2016; 23: 158–176. [Google Scholar]

- 41.Watfa M, Bykovski A, Jafar K. Testing automation adoption influencers in construction using light deep learning. Autom Constr 2022; 141: 104448. [Google Scholar]

- 42.Ozorhon B, Cinar E. Critical success factors of enterprise resource planning implementation in construction: case of Turkey. J Manag Eng 2015; 31: 04015014. [Google Scholar]

- 43.Wang YS, Li HT, Li CR, et al. Factors affecting hotels’ adoption of mobile reservation systems: a technology-organization-environment framework. Tour Manag 2016; 53: 163–172. [Google Scholar]

- 44.Choi B, Hwang S, Lee S. What drives construction workers’ acceptance of wearable technologies in the workplace?: indoor localization and wearable health devices for occupational safety and health. Autom Constr 2017; 84: 31–41. [Google Scholar]

- 45.Al Yahya M, Skitmore M, Bridge A, et al. e-Tendering readiness in construction: the posterior model. Constr Innov 2018; 18: 183–205. [Google Scholar]

- 46.Antwi-Afari MF, Li H, Pärn EA, et al. Critical success factors for implementing building information modeling (BIM): a longitudinal review. Autom Constr 2018; 91: 100–110. [Google Scholar]

- 47.Sun C, Jiang S, Skibniewski MJ, et al. A literature review of the factors limiting the application of BIM in the construction industry. Technol Econ Dev Econ 2017; 23: 764–779. [Google Scholar]

- 48.Chan APC, Darko A, Olanipekun AO, et al. Critical barriers to green building technologies adoption in developing countries: the case of Ghana. J Cleaner Prod 2018; 172: 1067–1079. [Google Scholar]

- 49.Mittal S, Khan MA, Romero D, et al. Smart manufacturing: characteristics, technologies, and enabling factors. Proc Inst Mech Eng Part B: J Eng Manuf 2019; 233: 1342–1361. [Google Scholar]

- 50.Welch LS, Russell D, Weinstock D, et al. Best practices for health and safety technology transfer in construction. Am J Ind Med 2015; 58: 849–857. [DOI] [PubMed] [Google Scholar]

- 51.Rogers J, Chong HY, Preece C. Adoption of building information modelling technology (BIM): perspectives from Malaysian engineering consulting services firms. Eng Constr Archit Manag 2015; 22: 424–445. [Google Scholar]

- 52.Jia M, Komeily A, Wang Y, et al. Adopting Internet of Things for the development of smart buildings: a review of enabling technologies and applications. Autom Constr 2019; 101: 111–126. [Google Scholar]

- 53.Lau C, Lu Y, Liang Q. Corporate social responsibility in China: a corporate governance approach. J Bus Ethics 2016; 136: 73–87. [Google Scholar]

- 54.Yigitcanlar T, Desouza KC, Butler L, et al. Contributions and risks of artificial intelligence (AI) in building smarter cities: insights from a systematic review of the literature. Energies 2020; 13: 1473. [Google Scholar]

- 55.Sepasgozar SME, Davis S. Digital construction technology and job-site equipment demonstration: modelling relationship strategies for technology adoption. Buildings 2019; 9: 158. [Google Scholar]

- 56.Harris M, Cox KC, Musgrove CF, et al. Consumer preferences for banking technologies by age groups. Int J Bank Mark 2016; 34: 587–602. [Google Scholar]

- 57.Lacal-Arántegui R. Globalization in the wind energy industry: contribution and economic impact of European companies. Renew Energy 2019; 134: 612–628. [Google Scholar]

- 58.Ding Z, Zuo J, Wu J, et al. Key factors for the BIM adoption by architects: a China study. Eng Constr Archit Manag 2015; 22: 732–748. [Google Scholar]

- 59.Jamali D, Karam C. Corporate social responsibility in developing countries as an emerging field of study. Int J Manag Rev 2018; 20: 32–61. [Google Scholar]

- 60.Walczuch R, Lemmink J, Streukens S. The effect of service employee's technology readiness on technology acceptance. Inf Manag 2007; 44: 206–215. [Google Scholar]