Abstract

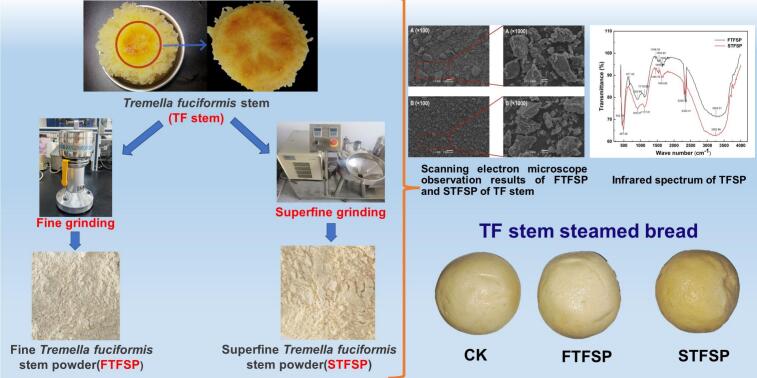

Tremella fuciformis (TF) stem accounts for about 10% of the whole mushroom, and most of them are dumped without utilization. To effectively utilize the waste, the effects of fine grinding and superfine grinding technology on the processing characteristics and physicochemical properties of Tremella fuciformis stem powder (TFSP) were investigated, and the effects of TFSP on the quality of steamed bun were analyzed. The findings indicate that the specific surface area of superfine Tremella fuciformis stem powder (STFSP) is 1.6 times larger than that of fine Tremella fuciformis stem powder (FTFSP). Despite this, the infrared spectra of STFSP and FTFSP are similar. The water solubility index and oil holding capacities of STFSP saw an increase of 18.81%, whereas its water holding capacity decreased by 11.34%. Superfine grinding not only enhanced the processing characteristics but also stabilized the powder form. Moreover, steamed buns incorporating 4% STFSP were judged to have the optimal taste. Superfine grinding significantly influences the physicochemical properties of TFSP, resulting in enhanced quality of steamed buns.

Keywords: Tremella fuciformis stem powder, Superfine grinding, Processing characteristics, Texture, Sensory evaluation

Highlights

-

•

Utilization of TF stem: Addressing the issue of wasted TF stems, this research aims to enhance their effective utilization.

-

•

Impact of grinding techniques on TFSP: The study examines fine and superfine grinding effects on TFSP processing and physicochemical properties.

-

•

Influence on steamed bun quality: superfine grinding is of significant importance in improving the quality of steamed bun.

1. Introduction

Tremella fuciformis (TF), a fungus that is both edible and medicinal, is immensely popular due to its rich nutritional, medicinal, and commercial value, and is widely cultivated and farmed, China's TF production accounts for about 90% of the world's output. As research into TF deepens, it has been discovered that the fungus not only possesses various physiological functions such as anti-inflammatory (Yuan et al., 2024), anti-aging (Zhang, Chen, Zhang, & Kang, 2023), and antioxidant properties (Li et al., 2023) but also enhances immunity (Wu et al., 2019) and has the potential to prevent senile dementia (Yang et al., 2024). Currently, while there is substantial research on TF, studies focusing on the TF stem are relatively scarce.

Due to its hard texture and low commodity value, TF stem was mostly disposed of in the form of feed or waste in past production activities, the recent study by Zuo, Zhang, Zhang, Liu, & Wang (2018) found that the main components contained in Tremella fuciformis powder (TFP) are moisture (11.95%), carbohydrates (76.33%), crude protein (10.61%), ash (4.69%) and crude fat (3.20%) and crude fiber (1.20%). Upon analysis that its protein, crude polysaccharide, and mineral content are higher than the fruiting body of the tremella, respectively, 58.4%, 56.7%, 125%, This shows that the nutritional value of TF stem is close to TF, and the crude polysaccharide content of the TF stem is greater than TF (Zhang, 2020). Combined with the above conclusions, the nutritional value of the TF head is higher and the cost is lower, if the TF stem can be developed and applied, this can not only reduce the waste of resources but also save costs and improve benefits.

In the past, TF stem has rarely been researched and applied, so as to make full use of TF resources in the future to develop high-value-added products, realize the rational utilization of TF resources, reduce waste emissions, improve the comprehensive benefits of TF, and promote the high-quality development of China's TF industry. At present, in the related research of TF, there were few studies on TF steamed bun. Among them, according to the study of 5% and 10% mushroom powder were added to the bun respectively. When 5% mushroom powder was added, better dough functionality and acceptable bun quality were obtained, and the unique aroma of mushrooms was included (Zhang et al., 2021). An earlier study by Tseng, Yang, and Li (2010) used TF powder to make bun, and analyzed that 5% TF bun could provide more beneficial health effects. In this study, the impacts of incorporating superfine powder, yeast, and water on the sensory attributes of buns were investigated through the addition of superfine powder derived from TF stem to the bun's raw material composition (Zhu et al., 2012). Most of the above studies use TF as raw materials to produce and process bun, and the cost is high. At present, there is no research on production of the bun with TFSP.

In view of the large amount of wastage of mucilage stems and the potential benefits of their utilization, we investigated the processing characteristics of superfine Tremella fuciformis stem powder (STFSP) and fine Tremella fuciformis stem powder (FTFSP) with different degrees of grinding and hypothesize that the application of superfine grinding technology can enhance the physicochemical properties of Tremella fuciformis stem powder (TFSP), thereby improving the quality of wheat dough and buns.

2. Materials and methods

2.1. Materials and reagents

TF stem (−80 °C preservation): provided by Fujian Xiangyun Biotechnology Co., Ltd. (Fujian, China). Medium Gluten Wheat Flour: Guangzhou Fuzheng Donghai Food Co., Ltd. (Guangzhou, China). High Activity Dry Yeast: Angel Yeast Co., Ltd. (Hubei, China). White Sugar: Xiamen Gulong Food Co., Ltd. (Xiamen, China). Soybean Oil: Yihai Kerry Arowana Grain and Oil Food Co., Ltd. (Yihai, China). Potassium bromide, sodium hydroxide, concentrated hydrochloric acid, the above reagents were from Shanghai-style Laboratory Equipment Co., Ltd. (Shanghai, China).

Raw material pretreatment: TF stems were washed and separated, put into the heat pump drying unit ZWH-KFX-BT12 II (HG) (Fujian Xuefeng Refrigeration Equipment Co., Fujian, China), dried at 60 °C for 48 h, and the dried products of the TF stems were obtained, with a moisture content of 10%.

Preparation of FTFSP: put the dried products of the TF stem into a Chinese medicine crusher for 30 s 103 II (RuianYongli Pharmaceutical Machinery Co., Zhejiang, China), and the crushed whole powder was 100-mesh sieve, sealed in a cool and dry place for storage.

Preparation of STFSP: Put FTFSP into the superfine grinder ZNC-300 (Beijing Xing Shi Li He Technology Development Co., Beijing, China) to crush, and then seal the crushed powder in a dry and cool place for storage.

Dough and bun making process: The dough and buns were made by two-step fermentation method according to a modified existing procedure (Li, Li, Deng, & Liu, 2014; Masbernat, Berland, Almeida, & Michon, 2021).

2.2. Physicochemical properties of TFPS

2.2.1. Determination of particle size

Laser particle size analyzer Bettersize2600 (Dandong Baxter Instrument Co., Liaoning, China) will be used to determine the particle size and distribution of the powder at room temperature. Stirred at 1600 r/min, the refractive index of the substance was 1.46, the ultrasonic dispersion was always open, the refractive index was between 8% and 10%, D10, D50, D90 represent the cumulative particle size distribution of 10%, 50% and 90% respectively, and D [4,3] represents the average diameter of the powder volume. The particle size was expressed by D10, D50, D90, D [4,3], and specific surface area (Xu, Zhang, Liu, Sun, & Wang, 2016).

2.2.2. Microstructure observation

Specimens were secured on the sample stage of a Hitachi SU-8010 cold field emission scanning electron microscope (SEM) using conductive tape. An E-1010 ion sputter coater (Hitachi) was then employed to coat the sample surfaces for 80 s. Observations and photography were conducted using the cold field emission SEM. The SEM was set with a working distance of 8.0 mm, a filament current of 20 μA, and an acceleration voltage of 6 kV. Samples were placed on the stage according to their respective identifiers and observed at magnifications of 100× and 1000×.

2.2.3. Fourier transform infrared spectroscopy analysis

Potassium bromide be tableting method will be used, the FTFSP, STFSP and potassium bromide powder will be placed in an agate mortar according to the mass ratio of 1:100, TFSP and the potassium bromide powder will be mixed evenly and grind to particle-free state. The homogeneous mixture will then be placed into a mold and compressed into a transparent pellet using a hydraulic press. Analysis will be carried out at room temperature using Fourier Transform Infrared Spectroscopy (FTIR) with the iCAN9 spectrometer (Tianjin ENER Spectrum Technology Co., Ltd.) across the wavenumber range of 450 — 4000 cm−1.

2.2.4. Flow property analysis

Slip angle: Weigh 3.00 g of FTFSP and STFSP, sprinkle it evenly on a smooth acrylic plate (130 mm × 100 mm), slowly raise one side of the acrylic plate, when TFSP begins to slide downwards, determine the angle between the acrylic plate and the horizontal plane at this time, the angle was the sliding angle (Chun & Yoo, 2006).

Rest angle: The angle of rest (θ) was defined as the maximum angle of the surface of the powder pile relative to the plane supporting it. Use the following methods to measure the rest angle: fix the funnel on the iron frame table, the bottom of the funnel should be 3 cm away from the table, put an A4 paper at the lower end of the funnel, block the lower end of the funnel, weigh 10.00 g of FTFSP and STFSP respectively and pour into the funnel, take out the stopper at the lower end of the funnel, so that the FTFSP of the TF head falls naturally, at this time the bottom will form a conical powder pile, the diameter of the bottom of the measurement cone was recorded as 2R, the height of the cone was recorded as H, the angle of the rest angle was α, and the rest angle was calculated according to formula (1) (Huang, Dou, Li, & Wang, 2018).

| (1) |

Bulk density: Bulk density was a density that includes pores and interparticle voids. First, measure the weight of the cleaned graduated cylinder and record it as m1. FTFSP and STFSP were then added to the 10 mL graduated cylinder until they reach 10 mL as V1 and weighed as m2 (Zhao, Yang, Gai, & Yang, 2009). The bulk density of the whole powder was calculated according to Eq. (2):

| (2) |

Vibration density: The method of Talafha and Oldal (2024) was adopted and slightly modified. Accurately weigh 10.00 g of FTFSP and STFSP, the mass was recorded as m3, respectively, it was loaded into a 100 mL graduated cylinder, use the measuring cylinder on the thick rubber pad to vibrate, until the volume of the specimen in the measuring cylinder was almost no longer changing, the volume of the powder at this time was recorded as V2, calculated according to formula (3):

| (3) |

2.2.5. Functional property analysis

Accurately weigh 0.5 g FTFSP and STFSP as m4, add 50 mL distilled water to configure into a solution, stir well, pour into a 100 mL centrifuge tube, heat in a constant temperature water bath at 30 °C, 45 °C, 60 °C, 75°Cand 90 °C for 30 min, measure the change of the water solubility index of the sample at its temperature, centrifuge while hot for 15 min, turn 5000 r/min, and then the supernatant in the centrifuge tube was poured into a conical flask prepared in advance and dried to a constant weight, The residue mass after drying was recorded as m5 (Huang et al., 2020) and the water solubility index was calculated according to Eq. (4):

| (4) |

Water holding capacity: Weigh 1.00 g of the TFSP into a centrifuge tube, weigh it with the centrifuge tube and count it as m6, add 50 mL of distilled water, mix well, and then heat it in boiling water at 100 °C for 15 min. After natural cooling to room temperature, centrifuge for 15 min with a centrifuge at a speed of 7000 rpm/min at a temperature of 20 °C, then weigh the supernatant after pouring out, denote m7 (Chen & Opara, 2013), and the water holding capacity (WHC) of the TFSP was calculated according to Formula (5):

| (5) |

Oil holding capacity: Weigh 5.00 g of TFSP into a centrifuge tube, weigh it with the centrifuge tube and record it as m8, add 30 mL of vegetable oil, mix well, heat it in a constant temperature water bath pot at 100 °C for 15 min, naturally place cool to room temperature and centrifuge with a centrifuge for 15 min, turn at a speed of 3000 rpm/min, temperature of 20 °C, then weigh the supernatant after pouring out, record m9 (Kong, Wang, Gao, & Chen, 2020), the oil holding capacity (OHC) of the whole powder was calculated according to Formula (6):

| (6) |

2.2.6. Determination of freeze-thaw stability

Prepare two TFSP solutions of 36 mg/mL, take the centrifuge tube and weigh it as m10, and pour in the 30 mL configuration each. Then heated in a constant temperature water bath pot at 100 °C for 30 min, removed, naturally placed cooled to room temperature and then placed in a − 18 °C refrigerator, frozen for 24 h after removal, let it thaw naturally, completely thawed and centrifuged with a centrifuge for 15 min, the speed was 3000 rpm/min, the temperature was 20 °C, the weighing was m11 after centrifugation, and the supernatant was poured out and weighed as m12 (Obadi et al., 2018).

| (7) |

2.2.7. Determination of the condensation characteristics

Sucrose ion solutions with concentrations of 50, 100 and 150 mg/mL and solutions with pHs of 3, 5 and 7 were configured, respectively. Prepare the whole powder solution with a concentration of 36 mg/mL with the above solutions and heat them in a water bath at a temperature of 100 °C for 15 min, and then let it cool freely to room temperature. After 3 h record the paste volume as a percentage of the total volume.

2.2.8. Determination of rheological properties

Prepare different concentrations of TFSP solution (30 mg/mL, 36 mg/mL, 42 mg/mL, and 48 mg/mL) and heat the samples in boiling water for 15 min. The rheological properties of the powder were determined using a rheometer MCR102e (Anton Paar Austria (China) Co., Shanghai, China), and the viscosity and shear stress of the powder solution of TF stem head were determined with the change of shear rate, and the measurement conditions were as follows: the measuring rotor was a coaxial cylinder with a shear rate of 1 — 2000 s−1.

2.3. Dough properties

Texture: Add FTFSP and STFSP to wheat flour in the proportions of 4%, 6% and 8% respectively, add the appropriate yeast, and mix well. Using pure wheat flour as a control, the elasticity, viscosity and firmness of the wheat dough were determined by a texture analyzer SMS (Stable Micro Systems, UK). The probe was P/1 SP and the probe descent depth was 18 mm.

Chromatic aberration: The brightness value (L*), redness value (a*) and yellowness value (b*) of the front of the leaf were measured by the chromatic aberration meter, and the effect of the two TFSP on the opposite group chromatic aberration was compared when the amount of addition was not the same.

2.4. Bun characteristics

Texture: The fine powder and superfine powder were added to the wheat flour in the proportion of 4%, 6% and 8%, respectively, and the appropriate yeast was added. After mixing, the steamed bun was made by kneading and fermentation with the steamed bun machine. The hardness and chewiness of steamed bun were measured by texture analyzer. The probe is A / MORS with a drop depth of 18 mm.

Color difference: The lightness value (L*), redness value (a*) and yellowness value (b*) of the front of the leaves were measured by a colorimeter, and the effects of two kinds of whole powder on the color difference of steamed bun were compared.

Sensory evaluation: The sensory evaluation group composed of 12 sensory evaluation experts (aged 18–24 years old, 6 boys and 6 girls) was used to evaluate the sensory quality of tremella steamed bun. The evaluation criteria are shown in Table S1. The study was approved by the Institute of Food Science and Technology, Fujian Academy of Agricultural Sciences Ethics Committee and written consent was given by all volunteers. (INFORMED CONSENT FORM is detailed in the supplementary information).

2.5. Statistical analysis

Each set of experiments was paralleled three times, and the experimental data was expressed as the average ± standard deviation, and the SPSS 26 software was used for statistical and P value <0.05 was regarded as statistically significant., and the Origin2021 was used for the plot.

3. Results and analysis

3.1. Particle size distribution

The FTFSP and STFSP obtained by different degrees of crushing of the TF stem were compared, and the results were shown in Table 1.It can be observed that the particle size of FTFSP of TF stem was large and uneven, and after superfine grinding, the particle size of the powder was significantly smaller, and there were significant differences in the D10, D50, D90, average particle size and specific surface area of the FTFSP and STFSP (P < 0.05), and the specific surface area of the STFSP increased by 61.27% compared with the FTFSP. Hence, it was evident that superfine grinding could enhance the particle size distribution of the powder, increase the surface energy, and enlarge the specific surface area. According to the research by Gao, Chen, and Wang (2020), the solubility and water holding capacity of TFSP. (See Fig. 1.)

Table 1.

Measurement results of total powder particle size of TF stem.

| project | D10(μm) | D50(μm) | D90(μm) | D[4,3](μm) | Specific surface area(m2/kg) |

|---|---|---|---|---|---|

| FTFSP | 25.43a | 121.50a | 339.90a | 156.20a | 1795.22b |

| STFSP | 16.81b | 59.02b | 134.40b | 69.23b | 4634.89a |

Note: Different lowercase letters in the same column indicate significant differences (P < 0.05).

Fig. 1.

A graphic summary of this article.

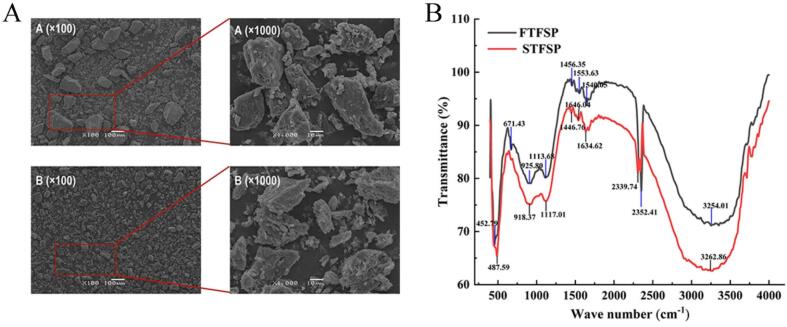

3.2. SEM of TFSP powders

It can be seen from Fig. 2(A) that the size of the FTFSP after 100 times magnification is uneven, and there were larger bulk particles, which may be related to the uneven force of fine crushing, and the force of action on the sample is limited, which can only make it achieve initial crushing, and the degree of uniformity needs to be improved (Zeng, Hu, Gao, Sun, & Ma, 2016); Compared with FTFSP, the 100× electron microscopy scan results of STFSP can be clearly seen that the particle size is more uniform and there were no larger bulk particles. Under the 1000× electron microscope scan, it can be seen that there is not much difference in the surface structure of the two, indicating that the superfine grinding has not changed the internal structure of the TFSP. Subsequently, we had used the Image J software to enhance the imaging quality of the figures and had measured the particles to obtain their areas. Additionally, had conducted a statistical analysis of the particle data presented in Fig. S1. In Fig. S2(A) and Fig. S2(C), it had been observed that STFSP exhibited more concentrated peaks due to a higher degree of particle fragmentation, whereas FTFSP had shown a greater number of peaks and higher dispersion due to lesser fragmentation. From Fig. S2(B) and Fig. S2(D), we had discerned that STFSP, due to significant fragmentation, presented longer boxplots with a more shifted median (Mazzoli & Favoni, 2012).

Fig. 2.

(A) Scanning electron microscopy observations and (B) Infrared spectra of the TFSP.

Note: A100 and A1000 represent 100× and 1000× magnification of the FTFSP, and B100 and B1000 indicate STFSP magnification 100× and 1000×.

3.3. Infrared spectroscopic analysis of TFSP

It can be seen from the Fig. 2(B) that the superfine grinding has not changed its group structure, and the main components have not changed. The spectrum of the superfine grinded whole powder has a redshift phenomenon compared with the fine crushing, indicating that under the same conditions, the transmittance of the superfine grinded whole powder is lower. It can be seen from the map that FTFSP has absorption peaks at 3254.01 cm−1, 2352.41 cm−1, 1646.04 cm−1, 1553.63 cm−1, 1456.35 cm−1, 1113.68 cm−1, 925.8 cm−1, 671.43 cm−1, 452.79 cm−1. 3200–3700 cm−1 A wide peak is O—H telescopic vibration; 3254.01 cm−1 is O—H telescopic vibration; 2352.41 cm−1 and 452.79 cm−1 were CO2 absorption peaks; 1540 — 1695 cm−1 is the telesco pic vibration of C C, 1634.62 cm−1 and 1553.63 cm−1 were the telescopic vibration of C=C; 1350 — 1460 cm−1 and 665 — 910 cm−1 were the bending vibrations of C—H, and 1456.35 cm−1 and 671.43 cm−1 were the bending vibrations of C-H; The characteristic peaks of 950–1200 cm−1 were C—O telescopic vibration of C-O-C intracyclic ether and variable angle vibration of C-O-H, 1113.65 cm−1 is the C—O telescopic vibration of C-O-C intracyclic ether and the variable angle vibration of C-O-H O-H; 870–950 cm−1 is the bending vibration of O—H, and 925.8 cm−1 is the bending vibration of O—H.

STFSP has absorption peaks at 3262.86 cm−1, 2339.74 cm−1, 1634.62 cm−1, 1540.05 cm−1, 1446.76 cm−1, 1117.01 cm−1, 918.37 cm−1, 487.59 cm−1. 3262.86 cm−1 is O—H telescopic vibration; 2339.74 cm−1 and 487.59 cm−1 were CO2 absorption peaks; 1634.62 cm−1 and 1540.05 cm−1 were the telescopic vibrations of C=C; 1446.76 cm−1 and 918.37 cm−1 were O—H bending vibrations; 1117.01 cm−1 is the C—O telescopic vibration of the C-O-C intracyclic ether and the variable angle vibration of the C-O-H O—H.

3.4. Flow property analysis

Slip angle and repose angle can better reflect the flow processing characteristics of the powder, in general, the smaller the sliding angle and the rest angle, the better the fluidity of the powder, and vice versa. As shown in Fig. S3(A), the difference in slip angle between FTFSP and STFSP is significant (P < 0.05), 47.33° for FTFSP and 57.33° for STFSP. Which may be because with the decrease of the particle size of the powder, the specific surface area of the powder continues to increase, the surface polymerization force and adhesion were correspondingly enhanced, and the agglomeration fluidity of the powder becomes poor. The difference in the rest angle between FTFSP and STFSP was not significant (P < 0.05), but the rest angle of FTFSP was still smaller than that of STFSP. According to the study (Zhang et al., 2014), the results show that superfine grinding will make the slip angle rest angle of powder larger and the fluidity worse (Ge, Duan, Fang, Zhang, & Wang, 2009). Based on the study. the results show that the reduction of particle size will make the slip angle and rest angle of the ginger powder become larger and the fluidity worse. This result is consistent with the previous analysis of particle size (Zhang et al., 2014; Zhao, Yang, Gai, & Yang, 2009).

It can be seen from Fig. S3(B) that there were significant differences in the bulk density and vibration density of the FTFSP and STFSP of TFSP(P < 0.05), as the particle size decreases, the bulk density and vibration density of the powder decrease, the pores of the powder become smaller, and the filling becomes worse, which may be because the particle size of the powder decreases, the specific surface area increases, the contact area between the particles becomes larger, the surface polymerization energy increases, and the particles were easily agglomerated into false clumps, which increases the void, resulting in a smaller bulk density (Zhang, Zhang, & Shrestha, 2005).

3.5. Functional property analysis

The water solubility of TFSP in the different sizes is shown in Fig. S4(A) The water solubility of TFSP increased when their particle size was small. When the temperature was gradually increased, the solubility was also elevated, and the water solubility of its STFSP reached 23.7% at 60 °C. The results showed that superfine grinding could improve the water solubility of TFSP, and it was inferred that superfine grinding could change the physicochemical properties of TFSP macromolecules, and thus improve its solubility in water. The reason may be that the fibers were degraded during superfine grinding, and the surface area of STFSP was enlarged, which led to the enhancement of the binding ability with water. The water solubility of TFSP in the different sizes is shown in Fig. S4(A). The water solubility of TFSP increased when their particle size was small. When the temperature was gradually increased, the solubility was also elevated, and the water solubility of its STFSP reached 23.7% at 60 °C. The results showed that superfine grinding could improve the water solubility of TFSP, and it was inferred that superfine grinding could change the physicochemical properties of TFSP macromolecules, and thus improve its solubility in water. The reason may be that the fibers were degraded during superfine grinding, and the surface area of STFSP was enlarged, which led to the enhancement of the binding ability with water. The water solubility index is an important indicator of the edible quality of the powder. The greater the water solubility index, the better the digestion and absorption of the product (Liu, Mu, Sun, Zhang, & Chen, 2016). It can be seen from Fig. S4(B) that the water solubility index of STFSP is greater than that of FTFSP at arbitrary temperatures, and the water solubility index of the powder was the highest at 60 °C, which is the same as the research results of Hao, Shi, Hui, Cheng, and Huang (2021). It may be because the TFSP was crushed by superfine grinding, its wall breaking rate is better, the macromolecular substances in the cells were crushed into smaller substances, and the soluble components flow out more, so that the water solubility index is larger, so that the STFSP has better digestion and absorption characteristics. The recent study found that WHC and OHC are imperative in food processing applications. As depicted in Fig. S4(B), the WHC of TFSP exhibited a significant reduction following ultrafine milling treatment, evidenced by a statistically significant difference (P < 0.05), whereas the OHC experienced a slight augmentation (Özdemir, Görgüç, Gençdağ, & Yılmaz, 2022). The diminution of WHC associated with reduced particle size suggests that the finer TFSP likely harbors substantial amounts of hydrophilic dietary fibers. The study shows that the mechanical force exerted during the superfine grinding process amplifies the surface energy of powder particles. This augmentation in surface energy leads to an increased void ratio and a higher density of active sites, substantially enhancing the affinity of hydroxyl and other functional groups present on the particle surfaces for water molecules. Consequently, this alteration reduces their water-binding capacity, culminating in a decrease in WHC. Such a reduction in WHC contributes to a more stable powder state, diminishing the susceptibility to deterioration (Chen & He, 2017). After the superfine grinding treatment, it may be that the particle size of TFSP was reduced, the specific surface area was increased, and the contact area between the individual particles and the oil was increased, so the oil holding was slightly improved.

3.6. Freeze-thaw stability analysis of TFSP

There were cold storage and cold processing steps in the processing of food, in this process, the flow and freezing of water in the food body may cause the food to deteriorate. The stability of food in processing and storage can be measured by freeze-thaw stability, generally expressed by the size of the water evolution rate, and the smaller the water evolution rate, the better the stability. It can be seen from Table 2 that after superfine grinding, the water evolution rate of TFSP, but there was no significant difference (P < 0.05), indicating that the superfine grinding had almost no effect on the water evolution rate of TFSP.

Table 2.

Test results of freeze-thaw stability of TFSP.

| Project | FTFSP (%) | STFSP (%) |

|---|---|---|

| Water evolution rate | 98.04 ± 0.32a | 97.96 ± 0.33a |

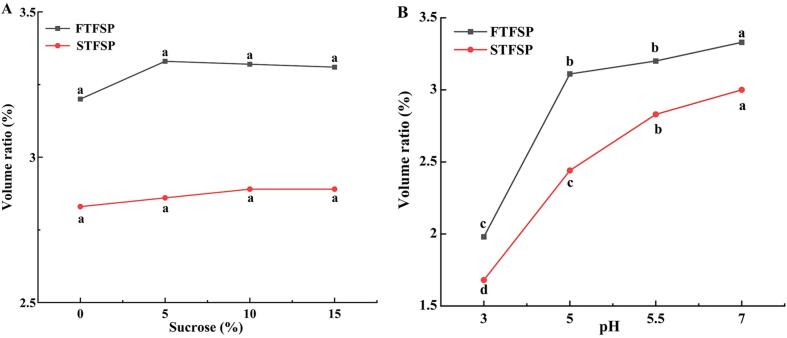

After frozen processing, the ability of a product to remain intact is often measured by its coagulation properties. As can be seen from Fig. 3(A), the coagulation characteristics of the coagulation characteristics of adding different concentrations of sucrose ions to the TFSP did not change significantly, but there were significant differences between the FTFSP solution and the STFSP solution adding different concentrations of sucrose (P < 0.05), and it can be seen that superfine grinding can significantly improve the condensation characteristics of the TFSP (P < 0.05). From Fig. 3(B), it can be seen that the condensation characteristics of TFSP solution in different pH solutions were also different, and reducing the pH of the solution can also improve the coagulation characteristics of the whole powder solution, and the coagulation characteristics of the STFSP solution were the strongest when the pH is 3.

Fig. 3.

Effects of (A) Different concentrations of sucrose solution and (B) pH values on the coagulation characteristics of TFSP, among them that pH 5.5 is CK.

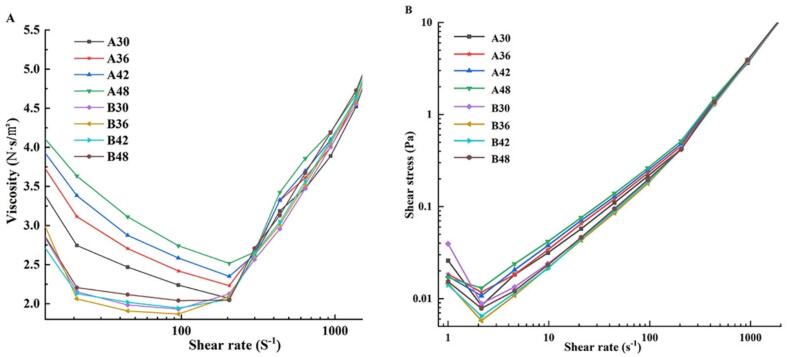

3.7. Rheological properties analysis of TFSP

The variation of TFSP solution changed with the shear rate, and the results showed that under the experimental concentration conditions, the viscosity of TFSP solution at shear rate below 205 s−1 is smaller with the increase of shear rate, which is a typical non-Newtonian liquid in the shear thinning phenomenon. When the shear rate in 205 s−1 after, the viscosity of the solution of TFSP with the increase in shear rate and increase, showing the phenomenon of shear thickening, from Fig. 4(A) shows the viscosity tends to straight line, the fluid should belong to Bingham plastic fluid, and the viscosity of the FTFSP was above the STFSP.

Fig. 4.

Effect of Shear rate on (A)Viscosity and (B)Shear stress of TFSP.

Note: In the Fig. 4, A30, A36, A42, A48 and B30, B36, B42, B48 respectively represent the FTFSP solution with a concentration of 30 mg/mL, 36 mg/mL, 42 mg/mL, 48 mg/mL and STFSP solution with a concentration of 30 mg/mL, 36 mg/mL, 42 mg/mL, 48 mg/mL, Fig. A shows the effect of shear rate on the viscosity of TFSP, and Fig. B shows the effect of the shear rate on the shear stress of TFSP.

As can be seen from Fig. 4(B), the shear stress of superfine grinding on TFSP has almost no effect, whether it is FTFSP or STFSP, the shear stress is minimized under the condition of shear rate of 2.14 s−1, and then increases with the increase of shear rate, and the shear stress of FTFSP is greater than that of STFSP.

3.8. Effect of TFSP on the color and texture of wheat dough

From Table 3, it is apparent that the addition of TFSP did not significantly affect the L* value (color lightness) of wheat dough (P > 0.05), suggesting minimal impact on color lightness with varying TFSP concentrations. Conversely, significant differences were observed in the a* (red-green) and b* (yellow-blue) values (P < 0.05), where STFSP exhibited higher values than FTFSP. Relative to the control (dough without any addition), the inclusion of FTFSP and STFSP imparted a reddish and yellowish hue, respectively, with the intensity of these colors increasing proportionally with the additive concentration.

Table 3.

Effect of adding different amounts of TFSP on color difference and texture of wheat doughs.

| Chromatism | Addition /% | Griding |

|||||

|---|---|---|---|---|---|---|---|

| FTFSP |

STFSP |

||||||

| * | # | * | # | ||||

| L * | 0 | 70.90 ± 0.35 | b | ||||

| 4 | 73.14 ± 0.50 | a | ab | 72.95 ± 0.41 | b | b | |

| 6 | 73.46 ± 0.43 | a | ab | 73.03 ± 0.37 | b | ab | |

| 8 | 73.93 ± 0.39 | a | a | 73.54 ± 0.27 | a | a | |

| a * | 0 | 0.31 ± 0.002 | b | ||||

| 4 | 0.35 ± 0.001 | b | b | 0.48 ± 0.002 | a | b | |

| 6 | 0.40 ± 0.003 | b | ab | 0.53 ± 0.004 | a | ab | |

| 8 | 0.46 ± 0.003 | b | a | 0.59 ± 0.004 | a | a | |

| b * | 0 | 11.68 ± 0.28 | b | ||||

| 4 | 13.89 ± 0.26 | b | ab | 15.69 ± 0.28 | a | b | |

| 6 | 15.68 ± 0.35 | b | a | 16.26 ± 0.15 | a | b | |

| 8 | 15.73 ± 0.36 | b | a | 18.09 ± 0.15 | a | a | |

| Texture | Addition /% | Griding | |||||

| FTFSP | STFSP | ||||||

| * | # | * | # | ||||

| Elasticity /% | 0 | 16.98 ± 0.47 | a | ||||

| 4 | 13.47 ± 0.50 | b | b | 15.19 ± 0.42 | a | a | |

| 6 | 11.82 ± 0.57 | b | b | 12.81 ± 0.38 | a | b | |

| 8 | 9.71 ± 0.34 | b | c | 10.22 ± 0.50 | a | c | |

| Viscosity /g·sec | 0 | 56.2 ± 4.43 | a | ||||

| 4 | 40.89 ± 2.59 | b | b | 45.09 ± 2.98 | a | a | |

| 6 | 37.66 ± 1.82 | b | b | 41.72 ± 1.74 | a | b | |

| 8 | 33.06 ± 2.48 | b | c | 38.55 ± 2.00 | a | c | |

| Firmness /g | 0 | 326.37 ± 6.19 | c | ||||

| 4 | 378.2 ± 5.87 | a | b | 363.23 ± 7.65 | b | c | |

| 6 | 392.76 ± 11.93 | a | b | 383.77 ± 4.80 | b | b | |

| 8 | 418.11 ± 12.04 | a | a | 409.48 ± 10.68 | b | a | |

Note: Table 3 shows the Effect of adding different amounts of TFSP on color difference and texture of wheat doughs L * value, color difference a * value and color difference b * value. “*” significant difference among blanching methods at the same time, “#” significant difference among treatment time at the same blanching method. Different letters indicate significant differences (P < 0.05). (the same below).

In addition, reveals that the elasticity and viscosity of both FTFSP and STFSP decrease with increasing addition levels, showing significant differences (P < 0.05). Concurrently, the firmness of FTFSP and STFSP exhibits a proportional increase with the addition amount, also displaying significant differences (P < 0.05). This trend may be attributed to TFSP's absorption and expansion in water upon addition to wheat dough, diminishing the dough's softness and impacting yeast activity, which in turn affects the dough's elasticity, viscosity, and firmness. Comparatively, at equivalent addition levels, STFSP demonstrated greater elasticity and viscosity but lower firmness than FTFSP. This phenomenon could be ascribed to the reduced water retention capacity following superfine grinding, leading to decreased water absorption by STFSP. Consequently, when the same volume of water is introduced, the increased water absorption by the wheat flour results in higher elasticity and viscosity for the dough compared to FTFSP, and a reduction in firmness.

3.9. Effect of TFSP on texture characteristics and quality of steamed bun

Fig. S5 reveal that both the hardness and chewiness of FTFSP were significantly higher than those of STFSP (P < 0.05), with these properties increasing concomitantly with the addition of the substance. With the increase of addition amount, the hardness and chewiness also increased. The reason may be that TFSP was added to the wheat dough and swelled, which reduced the softness of the dough and affected the activity of the yeast, thus affecting the hardness and chewiness of the steamed bun. At the same addition amount, the hardness and chewiness of STFSP were lower than those of FSTSP, which may be due to the decrease of water holding capacity and less water absorption after superfine grinding. When the same amount of water was added, the water absorption of wheat flour increased, which increased the elasticity and viscosity of the wheat dough and decreased the firmness. The hardness and chewiness of steamed bun were lower than those of FTFSP, but higher than those of blank control group.

Based on Table 4, there was no significant difference in the L* value of color difference (P > 0.05), indicating that TFSP with different additions had little effect on the L* value of color difference of steamed bun; it can be seen from Table 4 that there are significant differences in color difference a* and b* values, and the values of STFSP are higher than those of FTFSP. Compared with steamed bun without addition, the color of FTFSP and STFSP is redder and yellower, and with the increase of addition amount, the color gradually becomes redder and yellower.

Table 4.

Effects of adding different amounts of TFSP to steamed buns on color difference and sensation.

|

Chromatism |

Griding | Adding amount of FTFSP /% |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 |

4 |

6 |

8 |

||||||||||

| * | # | * | # | * | # | * | # | ||||||

| L* | FTFSP | 69.93 ± 0.64 | b | 72.87 ± 0.28 | a | ab | 72.96 ± 0.75 | b | ab | 73.13 ± 0.78 | a | a | |

| STFSP | 72.97 ± 0.45 | a | b | 73.02 ± 0.44 | a | a | 73.16 ± 0.34 | a | a | ||||

| a * | FTFSP | 0.62 ± 0.002 | b | 0.69 ± 0.004 | b | ab | 0.72 ± 0.005 | b | ab | 0.77 ± 0.005 | b | a | |

| STFSP | 0.72 ± 0.003 | a | b | 0.78 ± 0.003 | a | b | 0.83 ± 0.002 | a | a | ||||

| b * | FTFSP | 11.20 ± 0.43 | b | 14.42 ± 0.54 | b | ab | 15.30 ± 0.56 | a | ab | 15.76 ± 0.42 | b | a | |

| STFSP | 14.96 ± 0.40 | a | b | 15.39 ± 0.40 | a | a | 15.97 ± 0.40 | a | a | ||||

|

Parameter |

Griding | Adding amount of FTFSP /% | |||||||||||

| 0 | 4 | 6 | 8 | ||||||||||

| * | # | * | # | * | # | * | # | ||||||

| Appearance | FTFSP | 12.50 ± 0.48 | ab | b | 13.20 ± 0.50 | a | b | 12.30 ± 0.38 | ab | b | 11.80 ± 0.48 | b | b |

| STFSP | 12.50 ± 0.78 | ab | a | 13.50 ± 0.83 | a | a | 12.40 ± 0.62 | ab | a | 11.90 ± 0.64 | b | a | |

| Color | FTFSP | 8.50 ± 0.35 | b | a | 9.30 ± 0.61 | a | b | 8.80 ± 0.28 | ab | b | 7.70 ± 0.54 | bc | b |

| STFSP | 8.50 ± 0.68 | b | a | 9.40 ± 0.83 | a | a | 9.00 ± 0.49 | ab | a | 7.80 ± 0.66 | bc | a | |

| Structure | FTFSP | 13.80 ± 0.57 | a | a | 13.30 ± 0.61 | a | b | 12.70 ± 0.48 | ab | a | 11.90 ± 0.50 | b | b |

| STFSP | 13.70 ± 0.68 | a | a | 13.60 ± 0.84 | a | a | 12.80 ± 0.72 | ab | a | 12.10 ± 0.68 | b | a | |

| Elasticity | FTFSP | 13.40 ± 0.34 | a | a | 13.10 ± 0.46 | ab | b | 12.70 ± 0.50 | ab | a | 11.60 ± 0.42 | b | a |

| STFSP | 13.60 ± 0.63 | a | a | 13.40 ± 0.84 | a | a | 12.80 ± 0.68 | ab | a | 11.70 ± 0.78 | b | a | |

| Viscosity | FTFSP | 12.70 ± 0.72 | b | a | 13.10 ± 0.68 | a | b | 12.70 ± 0.42 | b | b | 12.80 ± 0.64 | ab | a |

| STFSP | 12.80 ± 0.84 | bc | a | 13.30 ± 0.70 | a | a | 12.90 ± 0.68 | b | a | 12.80 ± 0.80 | bc | a | |

| Flavor | FTFSP | 12.60 ± 0.48 | a | a | 12.80 ± 0.52 | a | a | 12.20 ± 0.48 | ab | a | 11.70 ± 0.48 | b | a |

| STFSP | 12.50 ± 0.68 | ab | a | 12.90 ± 0.64 | a | a | 12.40 ± 0.72 | ab | a | 11.80 ± 0.52 | b | a | |

| Aroma | FTFSP | 12.50 ± 0.50 | a | a | 12.80 ± 0.48 | a | a | 11.70 ± 0.50 | ab | 11.30 ± 0.50 | ab | b | |

| STFSP | 12.60 ± 0.68 | a | a | 12.90 ± 0.80 | a | a | 11.80 ± 0.72 | b | 11.60 ± 0.78 | b | a | ||

3.10. Effect of tremella pedicel powder on sensory quality of steamed bun

From Table 4, it can be seen that after adding TFSP, the appearance, color, viscosity, flavor, aroma score and total score all showed a trend of increasing first and then decreasing, and the structural score and elastic score decreased, indicating that adding an appropriate amount of TFSP can improve the sensory score of steamed buns. When the TFSP was not added, the appearance, color, viscosity, flavor and fragrance of steamed bun were not obvious, but the structure and elasticity were better. With the increase of content of TFSP flour, the gluten structure of the dough is complicated to form, the structure becomes worse, the elasticity decreases, and the score decreases. This is consistent with the steamed bun made by Tseng et al. (2010). When the addition amount of STFSP was 4%, the steamed bun had the best effect in appearance, color, viscosity, flavor and aroma, and the total score reached 89.3. It may be due to the decrease of water holding capacity and less water absorption after superfine grinding. When the same amount of water is added, the water absorption of wheat flour increases, the damage to the gluten structure is low, and the flavor and aroma of steamed bun are improved.

4. Conclusion

In this study, TFSP powders with different particle sizes were obtained through superfine grinding and fine grinding, which the characterization and performance analysis of FTFSP and STFSP were conducted. Additionally, the sensory and physical properties of wheat dough and steamed buns produced with FTFSP and STFSP were analyzed.

Superfine powders showed a narrower and more uniform particle size distribution compared to coarse ground TFSP powders and also showed a greater specific surface area, and the specific surface area of STFSP increased by 61.27% compared with FTFSP. After superfine grinding, the fluidity of the whole powder becomes poor, the filling becomes worse, the water holding is weakened, the absorption characteristics and oil holding were slightly enhanced, the viscosity decreases when the shear rate is <205 s−1, and the powder state is more stable. It can be seen from the microstructure diagram and infrared spectrogram of TFSP after superfine grinding only changes the size of the powder, does not change the internal structure, and does not generate new substances. When the addition amount of STFSP was 4%, the steamed bun had the best effect in appearance, color, viscosity, flavor and aroma, with a total score of 89.3. The results demonstrating that superfine grinding significantly improves the physicochemical properties of TFSP, particularly in terms of its specific surface area, water solubility index, and oil holding capacities.

These findings not only validate our hypothesis but also highlight the importance of optimizing processing techniques to leverage underutilized resources like TF stems. Which provides a theoretical basis and data support for the resource development and production and processing of the by-products of the TF stem head in the future. In production, manufacturers can choose different crushing methods according to the needs of different products, and suppliers can also provide powders of different particle sizes according to the needs of the products.

Funding

This work was supported by funding from Fujian provincial department of science and tech-nology, China [2023R1099, 2023R1100, 2023R1030005, 2023S0006, 2022R1032005, 2022R1032008, 2023J01201], Fujian Academy of Agricultural Sciences [YC20210007, CXTD2021018–2 and NJG2020002], the “5511” collaborative innovation project of Fujian province and the Chinese Academy of Agricultural Sciences on the high-quality development and transcendence of agriculture (XTCXGC2021014), Fujian province modern edible fungus industry technology system construction project (Min-caizhi [2019] No.897).

CRediT authorship contribution statement

Kexin Yi: Writing – review & editing, Writing – original draft, Software, Methodology, Data curation, Conceptualization. Liting Wu: Writing – review & editing, Supervision, Project administration, Conceptualization. Li Wu: Writing – review & editing, Supervision, Project administration. Xinpeng Song: Writing – review & editing, Software, Conceptualization. Qing Xia: Writing – review & editing, Project administration. Yuping Cao: Writing – review & editing, Project administration. Yibin Li: Writing – review & editing, Supervision, Project administration, Funding acquisition, Conceptualization.

Declaration of competing interest

The authors declare no conflict of interest.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.fochx.2024.101529.

Appendix A. Supplementary data

Supplementary material

Data availability

Data is contained within the article or supplementary material.

References

- Chen L., Opara U.L. Approaches to analysis and modeling texture in fresh and processed foods–a review. Journal of Food Engineering. 2013;119:497–507. doi: 10.1016/j.jfoodeng.2013.06.028. [DOI] [Google Scholar]

- Chen R., He L. Effect of superfine grinding on physicochemical properties of apple powder. Food Science. 2017;38:150–154. doi: 10.7506/spkx1002-6630-201713025. [DOI] [Google Scholar]

- Chun S.Y., Yoo B. Steady and dynamic shear rheological properties of sweet potato flour disper-sions. European Food Research and Technology. 2006;223:313–319. doi: 10.1007/s00217-005-0205-9. [DOI] [Google Scholar]

- Gao W., Chen F., Wang X. Recent advances in processing food powders by using superfine grinding techniques: A review. Comprehensive Reviews in Food Science and Food Safety. 2020;19(4):2222–2255. doi: 10.1111/1541-4337.12580. [DOI] [PubMed] [Google Scholar]

- Ge Y., Duan Y., Fang G., Zhang Y., Wang S. Polysaccharides from fruit calyx of Physalis alkekengi var. francheti: Isolation, purification, structural features and antioxidant activities. Carbohy-drate Polymers. 2009;77:188–193. doi: 10.1016/j.carbpol.2008.12.020. [DOI] [Google Scholar]

- Hao J.X., Shi F., Hui J., Cheng Y., Huang Z.W. Effects of fine grinding and ultrafine grinding on physical properties of Agrocybe cylindracea powder. Food and Fermentation Industries. 2021;47(3) doi: 10.13995/j.cnki.11-1802/ts.025078. [DOI] [Google Scholar]

- Huang X., Dou J.Y., Li D., Wang L.J. Effects of superfine grinding on properties of sugar beet pulp powders. LWT. 2018;87:203–209. doi: 10.1016/j.lwt.2017.08.067. [DOI] [Google Scholar]

- Huang X., Liang K.H., Liu Q., Qiu J., Wang J., Zhu H. Superfine grinding affects physico-chemical, thermal and structural properties of Moringa Oleifera leaf powders. Industrial Crops and Products. 2020;151 doi: 10.1016/j.indcrop.2020.112472. [DOI] [Google Scholar]

- Kong F., Wang L., Gao H., Chen H. Process of steam explosion assisted superfine grinding on particle size, chemical composition and physico-chemical properties of wheat bran powder. Powder Technology. 2020;371:154–160. doi: 10.1016/j.powtec.2020.05.067. [DOI] [Google Scholar]

- Li X.G., Zhang F.Y., Jiang C.X., Jiang J., Hou Y.H., Zhang J.W. Structural analysis, in vitro antioxidant and lipid-lowering activities of purified Tremella fuciformis polysaccharide fractions. Process Biochemistry. 2023;133:99–108. doi: 10.1016/j.procbio.2023.06.005. [DOI] [Google Scholar]

- Li Z., Li H., Deng C., Liu C. Effect of mixed strain starter culture on rheological properties of wheat dough and quality of steamed bread. Journal of Texture Studies. 2014;45(3):180–186. doi: 10.1111/jtxs.12064. [DOI] [Google Scholar]

- Liu X.L., Mu T.H., Sun H.N., Zhang M., Chen J.W. Influence of potato flour on dough rheo-logical properties and quality of steamed bread. Journal of Integrative Agriculture. 2016;15:2666–2676. doi: 10.1016/s2095-3119(16)61388-6. [DOI] [Google Scholar]

- Masbernat L., Berland S., Almeida G., Michon C. Stabilizing highly hydrated wheat flour doughs by adding water in two steps. Journal of Cereal Science. 2021;98 doi: 10.1016/j.jcs.2021.103179. [DOI] [Google Scholar]

- Mazzoli A., Favoni O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by scanning electron microscopy and image processing program. Powder Technology. 2012;225:65–71. doi: 10.1016/j.powtec.2012.03.033. [DOI] [Google Scholar]

- Obadi M., Zhu K.X., Peng W., Sulieman A.A., Mohammed K., Zhou H.M. Effects of ozone treatment on the physicochemical and functional properties of whole grain flour. Journal of Cereal Science. 2018;81:127–132. doi: 10.1016/j.jcs.2018.04.008. [DOI] [Google Scholar]

- Özdemir E.E., Görgüç A., Gençdağ E., Yılmaz F.M. Physicochemical, functional and emulsifying properties of plant protein powder from industrial sesame processing waste as affected by spray and freeze drying. Lwt. 2022;154 doi: 10.1016/j.lwt.2021.112646. [DOI] [Google Scholar]

- Talafha M.S., Oldal I. The combined effect of normal stress and sechanical vibration on wheat packing density. Journal of Engineering Mechanics. 2024;150(1):04023111. doi: 10.1016/j.jcs.2021.103179. [DOI] [Google Scholar]

- Tseng Y.H., Yang J.H., Li R.C. Quality of bread supplemented with silver ear. Journal of Food Quality. 2010;33(1):59–71. [Google Scholar]

- Wu Y.J., Wei Z.X., Zhang F.M., Linhardt R.J., Sun P.L., Zhang A.Q. Structure, bioactivities and applications of the polysaccharides from Tremella fuciformis mushroom: A review. International Journal of Biological Macromolecules. 2019;121:1005–1010. doi: 10.1016/j.ijbiomac.2018.10.117. [DOI] [PubMed] [Google Scholar]

- Xu J.L., Zhang J.C., Liu Y., Sun H.J., Wang J.H. Rheological properties of a polysaccharide from floral mushrooms cultivated in Huangshan Mountain. Carbohydrate Polymers. 2016;139:43–49. doi: 10.1016/j.carbpol.2015.12.011. [DOI] [PubMed] [Google Scholar]

- Yang Y., Zhu D., Qi R., Chen Y., Sheng B., Zhang X. Association between intake of edible mushrooms and algae and the risk of cognitive impairment in Chinese older adults. Nutrients. 2024;16(5):637. doi: 10.3390/nu16050637. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yuan Q., Liu W., Hao W., Chen Y., Xiao Y., Li H.…Wang S. Glycosidic linkages of fungus polysaccharides influence the anti-inflammatory activity in mice. Journal of Advanced Research. 2024;2(4):297–303. doi: 10.1016/j.jare.2024.01.037. [DOI] [PubMed] [Google Scholar]

- Zeng J., Hu Y., Gao H., Sun J., Ma H. Fructooligosaccharides impact on the hydration and ret-ro-gradation of wheat starch and gel. International Journal of Food Properties. 2016;19:2682–2692. doi: 10.1080/10942912.2015.1136937. [DOI] [Google Scholar]

- Zhang L. Analysis of nutritional composition and heavy metal and pesticide residue content of silver fungus tips. Fujian Agricultural Science and Technology. 2020;07:46–49. doi: 10.13651/j.cnki.fjnykj.2020.07.010. [DOI] [Google Scholar]

- Zhang M., Wang F., Liu R., Tang X., Zhang Q., Zhang Z. Effects of superfine grinding on physicochemical and antioxidant properties of Lycium barbarum polysaccharides. LWT- Food Science and Technology. 2014;58:594–601. doi: 10.1016/j.lwt.2014.04.020. [DOI] [Google Scholar]

- Zhang M., Zhang C.J., Shrestha S. Study on the preparation technology of superfine ground powder of Agrocybe chaxingu Huang. Journal of Food Engineering. 2005;67(3):333–337. doi: 10.1016/j.jfoodeng.2004.04.036. [DOI] [Google Scholar]

- Zhang Y., Wang D., Chen Y., Liu T., Zhang S., Fan H.…Li Y. Healthy function and high valued utilization of edible fungi. Food Science and Human Wellness. 2021;10(4):408–420. doi: 10.1016/j.fshw.2021.04.003. [DOI] [Google Scholar]

- Zhang Z., Chen Z., Zhang C., Kang W. Physicochemical properties and bioogical activities of Tremella hydrocolloids. Food Chemistry. 2023;407 doi: 10.1016/j.foodchem.2022.135164. [DOI] [PubMed] [Google Scholar]

- Zhao X., Yang Z., Gai G., Yang Y. Effect of superfine grinding on properties of ginger powder. Journal of Food Engineering. 2009;91(2):217–222. doi: 10.1016/j.jfoodeng.2008.08.024. [DOI] [Google Scholar]

- Zuo S., Zhang R., Zhang Y., Liu Y., Wang J. Studies on the physicochemical and processing properties of Tremella fuciformis powder. International Journal of Food Engineering. 2018;14(1):20170288. doi: 10.1515/ijfe-2017-0288. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material

Data Availability Statement

Data is contained within the article or supplementary material.