ABSTRACT

Introduction

Due to rising temperature extremes, workplaces are seeking new solutions, such as using personal cooling garments (PCG) to mitigate and manage workplace heat exposure. This systematic review sought to assess the physiological and perceptual effects of PCGs on workers in standard work clothing performing moderate‐to‐heavy intensity tasks in hot environments.

Methods

A peer‐reviewed search strategy was conducted in MEDLINE, Embase, CINAHL, Scopus, Global Health, and Business Source Complete with no language or time limits. A meta‐analysis using a realist evaluation framework was then performed to evaluate the effectiveness of the PCGs.

Results

Thirty‐three studies with 764 participants (98% male; average 21 ± 34 participants per study), conducted primarily in a laboratory setting (76%) were included. The studies were 193 ± 190 min in duration and consisted of a moderate‐to‐heavy work effort of 3.3 ± 1.0 METs in hot ambient conditions (temperature: 35.9 ± 3.3°C, 51.4 ± 12.1% relative humidity, wet bulb globe temperature [WBGT] 31.2 ± 2.6°C). The PCGs (n = 67) facilitated heat exchange through conduction (n = 39), evaporation (n = 4), convection (n = 2), radiation (n = 2), or hybrid combinations (n = 20). Conductive and hybrid PCGs offered the greatest thermoregulatory benefit, whereby core temperature (T c) and heart rate (HR) reductions were consistently observed (Conductive: T c: −0.3°C, HR: −12 bpm; Hybrid: Tc:−0.2°C, HR: −10 bpm), while PCGs directed at enhancing evaporative and radiative heat exchange had no or minimal effect on the physiological outcomes assessed (i.e., T C < 0.1°C, HR: < 0.7 bpm).

Conclusion

While the PCGs had a positive overall effect, conductive options offered the most consistent benefit to workers. WBGT, clothing insulation, and duration of wear significantly affected some physiological and perceptual outcomes.

Keywords: cooling strategy, heat strain, occupational health and safety, thermal comfort, thermal sensation

1. Introduction

Occupational heat stress is a complex safety concern that, due to rising temperature extremes, continues to threaten the health and productivity of workers [1, 2]. Workers in various sectors must perform physically demanding work [3, 4] in hot and humid environments, often while wearing cumbersome personal protective equipment (PPE) [5, 6, 7], which can restrict heat loss [8]. This can lead to elevated levels of physiological strain that can adversely impact worker health [1], performance [1, 9, 10, 11, 12], and productivity [13]. Left unchecked, heat‐exposed workers are also at greater risk of work‐related injuries [14, 15, 16], which include traumatic accidents (e.g., fractures) [17]. To protect workers from occupational heat stress and optimize work capabilities [18, 19], engineering controls, including ventilation and localized or site‐wide air‐conditioning [20, 21], are often implemented to enhance workplace cooling [22]. However, these strategies are impractical in many work contexts, such as outdoor job sites. Moreover, when available, they are often not financially feasible [21, 23, 24, 25], are energy intensive, or may require considerable modifications to adapt them to the worksite (e.g., underground mines, confined work spaces) [20, 26, 27, 28, 29, 30]. As such, workplaces increasingly provide employees with personal cooling garments (PCGs) that incorporate innovative cooling technologies. However, their effectiveness in mitigating potentially fatal elevations in body core temperature in workers performing their duties in hot, arduous conditions [25, 31, 32, 33, 34, 35, 36] remains unclear.

PCGs can include active systems (e.g., air or liquid; those requiring power to operate) and passive systems (e.g., phase change materials, gel–ice, ice vests), which facilitate heat exchange by various heat transfer pathways, including evaporation, convection, conduction and radiation [25, 30, 37, 38] (Panel A). Although PCGs have been around for several decades [39] and are now well‐integrated in specific industries (e.g., aerospace and firefighting [40]), the recent evolution of advanced wearable technologies and textiles, as well as the growing risk and exposure to occupational heat stress [1, 41], has resulted in an increasing number of PCGs available for use. Several studies have recently investigated [42, 43, 44] or reviewed the application and advancement of PCGs in general [37, 40, 45, 46, 47] or for their utility in specific contexts such as for workers required to wear full protective garments that create uncompensable heat stress (e.g., firefighting ensembles [48] and healthcare workers [49] operating in infectious‐disease prevention garments). However, due to climate change and rising temperature extremes, the use of cooling garments is now being recommended across a broader range of environmental extremes and for combating heat stress for other types of workers (e.g., construction, mining, electrical utilities). However, to the best of our knowledge, no studies have assessed the effectiveness of using PCGs in these other conditions (e.g., hot‐humid conditions when evaporative or convective heat loss may be restricted vs. very‐hot dry conditions where evaporative heat loss is facilitated) and work contexts (e.g., regular work clothing, moderate‐to‐heavy intensity labor).

Panel A. Cooling concepts for personal cooling garments (PCGs).

| Evaporative PCGs | Convective PCGs | Conductive PCGs | Radiative PCGs |

|---|---|---|---|

| Designed to facilitate and enhance the evaporation of sweat between the body and the environment and often include water‐soaked garments made of specialized crystals or fabrics [50, 51]. | Typically, a power source is required to enhance heat exchange between the skin and environment as facilitated by an increase in the circulation of ambient or cooled air [52, 53] throughout the garment [54, 55]. | Facilitated by employing a PCG which circulates pre‐cooled liquids [56, 57, 58, 59, 60, 61, 62] or uses phase‐change materials (e.g., ice packs, refrigerant cooling gel, nontoxic polymer ice, inorganic salt, paraffin wax) to serve as a heat sink to mitigate increases in body temperature [56, 63, 64, 65, 66, 67, 68, 69, 70, 71, 72, 73]. | Using light‐colored fabrics or fabrics that reflect visible light reduces the absorption and transfer of heat from the environment to the body [74]. |

To address this critical knowledge gap, we conducted a systematic review and meta‐analysis to assess the physiological and perceptual effects of PCGs for workers performing moderate‐to‐heavy intensity work in hot environments and standard work clothing. Further, to support occupational health and safety personnel in evaluating the application and making informed decisions on the use of PCGs in their unique workplace, we employed a realist evaluation framework [75] to succinctly characterize the effectiveness of various PCGs under a range of environmental conditions, and within divergent work sectors.

2. Materials and Methods

2.1. Search Strategy

A peer‐reviewed [76] search strategy was conducted on August 25, 2023, in MEDLINE (Ovid), Embase (Ovid), CINAHL (EBSCOhost), Global Health (EBSCOhost), Business Source Complete (EBSCOhost) and Scopus. The main search concepts comprised terms related to heat exposure, work, and cooling interventions (Supporting Information: File A). No limits to language or publication date were applied within the search design. A list of five gold‐standard papers was created by an expert in heat physiology (G.P.K.). At the same time, the search algorithm was independently developed by the lead author (E.J.T.) and a research Librarian (V.L.). The validity of the search strategy was confirmed by ensuring that all five gold‐standard papers were identified.

Search results were exported to Covidence, and duplicates were eliminated using the platform's duplicate identification feature. The title and abstract of the remaining records were screened by two independent reviewers (E.J.T. and F.K.O.), and irrelevant articles were excluded. Full‐text versions of the articles were then sought (E.J.T.), and the lead author of articles identified as inaccessible was contacted via email (A.K. and F.K.O.). A full‐text review was completed by all authors in duplicate (E.J.T., F.K.O., A.K., L.G.I., and G.P.K.). Any disagreements that arose between the reviewers were resolved by the senior author (G.P.K.).

2.2. Inclusion and Exclusion Criteria

Sources in English, regardless of publication year that focused on PCGs for humans performing moderate‐to‐heavy work under hot conditions while wearing standard work clothing were considered eligible for inclusion. As such, studies which addressed nonphysically demanding work (passive/seated office work), nonhuman (manikin studies, modeling, animal studies), nonoccupational populations (chronic‐disease groups, athletes, general public) or populations tested in non‐standard work clothing (chemical resistant clothing, firefighting ensembles, combat gear) were excluded. No exclusion criteria were applied based on the type of work performed, study setting (field and laboratory studies were included), surrogate index or measure of body core temperature employed (i.e., rectal, esophageal, sublingual, external auditory canal, tympanic, gastrointestinal) or type of PCG (evaporative, convective, conductive, radiative, and hybrid). However, articles were excluded if the PCG was only applied before or after the work period (pre‐ or post‐cooling) or was non‐preventative (used for first aid/emergency response). Lastly, studies were excluded if no control condition was presented, case studies, reviews, or physiological or perceptual outcomes were not reported.

2.3. Data Extraction

Data extraction was performed by four independent reviewers (E.J.T., F.K.O., A.K., and L.G.I.) using double data entry in the Covidence Data Extraction 2.0 Tool. Data on article characteristics (first author, year, journal, country, and funding), participant characteristics (sample size, sex, age, height, weight, body fat, fitness, health status, ethnicity, acclimation status, and hydration status) and pretrial requirements were recorded. Data extracted from the study design included work type and intensity, environmental conditions (temperature, humidity, wind speed, solar radiation, and wet‐bulb globe temperature [WBGT]), location, and occupational application where available. Features of the PCG were also recorded, including the type of garment, type of cooling mechanism, material, body area coverage, weight of garment, cost, and duration of time the garment was worn. All physiological and perceptual outcomes identified were extracted. The results were exported into a data‐charting form in Excel (Microsoft Corporation). Additionally, WebPlotDigitizer Version 4.6 (https://automeris.io/WebPlotDigitizer) was used to extract data only available in figures.

2.4. Data Curation

2.4.1. Environment

WBGT was chosen as a uniform indicator to describe the thermal environment experienced by the participants in each study. This indicator was recently proven to be an efficacious measure of heat stress within occupational settings [77]. In cases where the authors did not directly provide WBGT, it was estimated using freely available software [78], based on the reported environmental factors (temperature, humidity, wind, and solar radiation). If air velocity and solar radiation were not reported (typically in laboratory studies), we assumed 0.2 m/s (due to participant movement in the chamber) and no solar radiation, respectively [21, 26, 36, 42, 63, 71, 79, 80, 81, 82, 83, 84, 85, 86, 87, 88].

2.4.2. Metabolic Rate

Metabolic equivalents (METs) were used as a uniform metric to describe the work intensity in each study. METs were estimated when not directly reported in the manuscript based on the 2024 Adult Compendium of Physical Activities [89] (Code: 11120 [42, 90, 91, 92, 93], Code: 11146 [63], Code: 11130 [36]) or based on other published equivalents for exercising testing and functional capacity [84]. For studies with variable work intensities, an average was taken of the values [82, 94]. If work effort was reported as W/m², an estimation was done by dividing the reported value by 58.15. If a treadmill was used and authors reported the respective walking speed and inclination, a calculation for oxygen consumption was performed using an equation from the American College of Sports Medicine as follows: (3.5 + 0.1 × speed + 1.8 × speed × grade), which is claimed to be the most accurate for the walking speeds referenced in the included studies [95]. The calculated oxygen consumption was then divided by 3.5 to calculate METs [95]. In cases where a study reported work intensity in watts, the reported values were divided by the average body surface area of the participants in each study. If body surface area was not reported, it was calculated based on the average weight and height values in each study using the Dubois method [96]. Standard values from the International Standard for Ergonomics of the Thermal Environment (ISO 7933:2023) [97] were assumed if not reported (weight 75 kg, height 180 cm) [82, 83, 87].

2.4.3. Clothing Insulation

The total clothing insulation worn by participants in each study was calculated by summarizing the standard values for the individual clothing items described in each study or based on the photos published alongside each paper. These standard clothing insulation values were derived from a report by the American Society of Heating, Refrigerating and Air‐Conditioning Engineers (ANSI/ASHRAE Standard 44‐2013) [98]. For headgear [99, 100] and gloves [100], clothing insulation values were derived from other published articles in the literature. Additionally, we assumed all participants wore underwear, socks and footwear (shoes for laboratory‐based studies and boots for field studies). For studies that reported the clothing insulation value, the provided value was used [68, 94, 101, 102].

2.4.4. Thermal Comfort

The direction of the thermal comfort scales adopted in the eligible studies was not uniform. For example, some scales indicated increased discomfort with higher values, while others indicated increased comfort with higher values. To transform all scales to a uniform direction, where an increase in the reported thermal comfort always indicates increased discomfort (positive discomfort), we reversed the outcomes for those studies that used a positive comfort scale. This was done by subtracting the maximum possible value in the scale from the mean or by multiplying by −1 for studies that used bipolar scales ranging from negative to positive values, such as −10 (uncomfortable) to 10 (extremely comfortable).

2.5. Meta‐Analysis

The PCGs were grouped into five categories based on their respective heat exchange mechanisms: conductive, convective, evaporative, radiative, and hybrid (involving more than one cooling mechanism). Subgroup meta‐analyses were performed to calculate the effect of the PCGs on select physiological (core temperature, skin temperature, heart rate, and sweat rate) and perceptual outcomes (rating of perceived exertion, thermal comfort, and thermal sensation). Further, subgroup meta‐analyses were performed to calculate the effect of the PCGs in conditions with and without radiant heat (yes or no) and based on the setting (laboratory or field) of each outcome.

All meta‐analyses were conducted using the mean and standard deviation (SD) of each outcome as recorded at the end of the protocol for control (no PCG) and experimental conditions (use of PCG). Missing SDs were imputed using the average coefficient of variation from all complete cases [103, 104]. For physiological data, this method was applied for: 11 missing core temperature SD values (17%, n = 64) from five studies [36, 81, 87, 101, 105], 18 missing skin temperature SD values (29%, n = 63) from six studies [42, 43, 68, 87, 101, 105], 12 missing heart rate SD values (22%, n = 54) from five studies [36, 42, 68, 87, 101], and 12 missing sweat rate SD values (24%, n = 51) from three studies [25, 43, 105]. For perceptual data, this method was applied for: five missing ratings of perceived exertion SD values (19%, n = 27) from two studies [43, 84], eight missing thermal comfort values (24%, n = 33) from three studies [36, 43, 68], and seven missing thermal sensation SD values (18%, n = 39) from two studies [43, 105].

Since different methods and scales were utilized in the eligible studies, we used standardized mean differences (SMDs) instead of absolute mean differences to normalize our findings to a uniform scale. In addition to the SMDs that were conducted for all physiological (core temperature [indexed by rectal, gastrointestinal, oral, tympanic, external auditory canal, or esophageal as presented in the study], skin temperature, heart rate, and sweat rate) and perceptual outcomes (rating of perceived exertion, thermal comfort, and thermal sensation) outcomes, meta‐analyses of mean differences (MDs) were conducted to examine potential differences in body core temperature and heart rate responses between control and experimental conditions, to provide the reader with more tangible metrics (core body temperature in degrees Celsius [°C], and heart rate in beats per min [bpm]) for the capacity of PCGs to mitigate potential physiological impacts. Random‐effects models were used to account for heterogeneity due to differences in study populations, environmental conditions, work intensity, clothing insulation, and the experiment duration in each study, among other factors. As the percentage of studies including females was minimal (n = 4 studies, n = 16 participants total), no sex‐based analyses were performed.

Additionally, through meta‐regressions, the effect of PCGs on all physiological and perceptual outcomes were tested with the three main pillars that define the level of heat stress, and the resulting physiological strain experienced by workers performing their duties: environment (WBGT), clothing insulation (Clo), and workload (METs). Meta‐regressions were also performed to determine the effect of the PCGs concerning anthropometrics (body surface area, body mass index) and the duration the garment was worn. All analyses were conducted using SPSS script (SPSS, v29.0.1.0, IBM). The significance level was set at an alpha level of p < 0.05. The substantiative significance (effect size) for each PCG was classified as very small d (0.01), small d (0.2), medium d (0.5), large d (0.8), very large d (1.2), and huge d (2.0) [106].

2.6. Realist Evaluation

The meta‐analysis was supplemented with a realist evaluation framework to support interpreting the findings for applying PCGs within various occupational implementations and conditions. Realist evaluation is a theory‐driven approach (founded in realism) used to evaluate social programs and can be used retrospectively for research synthesis [75]. The realist evaluation approach assumes that the same intervention will not work everywhere and for everyone [75]. The three key concepts in realist evaluation are context, mechanisms, and outcomes (Table 1). This framework holds that mechanisms are important because they generate outcomes, while context is crucial because it changes the processes by which an intervention can produce an outcome [75].

Table 1.

Description of the context, mechanisms and outcomes referenced in realist evaluation.

| Description | Relevant factors | |

|---|---|---|

| Context | Context determines whether mechanisms work [75]. Context addresses features of the condition relevant to the operation of the mechanisms and acknowledges that what is contextually significant may relate to place, systems of interpersonal, and social relationships. | The context relates to the circumstance in which the personal cooling garments were applied:

|

| Mechanism | Mechanisms are the underlying processes or structures that operate in particular contexts to generate outcomes of interest [75]. In realist evaluation, the mechanisms are also typically viewed as highly sensitive to variations in the context that can be triggered or deactivated, thus producing different outcomes. Inactive mechanisms could be activated with a slight change in some circumstances, resulting in a correspondingly significant impact on an outcome. | The mechanisms are the heat exchange pathways facilitated by the personal cooling garments:

|

| Outcome | Outcomes are the intended (or unintended) results of the intervention resulting from activating mechanisms in different contexts [75]. Outcomes are conditional upon these particular contexts and mechanisms, and they may not have the same relationship in different contexts. | The outcomes are the physiological and perceptual measures reported in the identified studies:

|

By applying this framework in combination with the meta‐analysis (described above), we then produced Context‐Mechanism‐Outcome (CMO) configurations. CMO configurations provide insight to interpret outcomes within a bigger picture and illustrate what works, for whom, and under what circumstances and contexts to bring about specific outcomes. In the context of our analysis, it follows that because each PCG uses a different cooling mechanism (evaporation, radiation, conduction, convection, or hybrid), its efficacy is impacted by the context of use (environment, work intensity, and PPE), which potentially leads to divergent outcomes (physiological and perceptual). We applied this framework to understand the critical contextual determinants of which PCGs should be effective in which setting, other potential influences, and the different outcomes achieved from the interaction between each setting and garment. However, it is essential to acknowledge that in realist evaluation, findings are always considered provisional and synthesize the best evidence available without pretending that the evaluation has covered every conceivable process or outcome.

3. Results

3.1. Included Studies

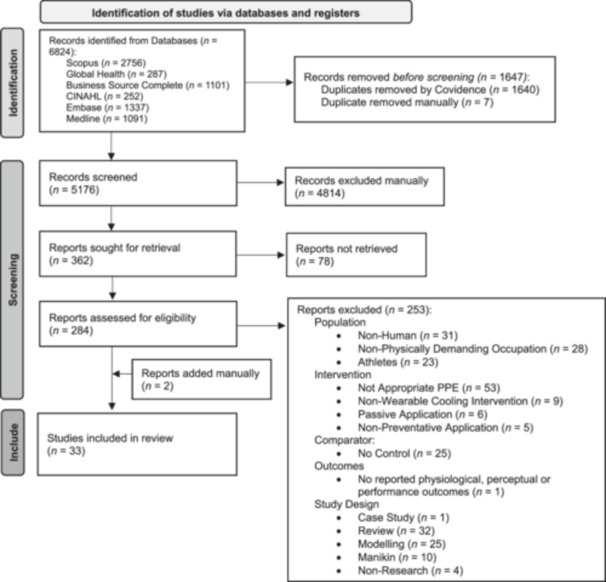

The search results are presented in a Preferred Reporting Items for Systematic Reviews and Meta‐analyses for Scoping Reviews (PRISMA‐ScR) flow diagram (Figure 1). The initial database search yielded 6824 records, from which 1647 duplicates were removed. We retained 5176 sources for title and abstract screening, to which 4814 irrelevant articles were excluded. A total of 362 articles were identified for full‐text screening. We sought 362 for retrieval and were able to assess 284 for eligibility. The 78 reports that were not retrieved were only available in other languages (i.e., not English), were identified as abstracts or conference proceedings with no further publication or were not available to the research team. Two additional articles were manually added, which resulted in 33 sources meeting the inclusion criteria.

Figure 1.

PRISMA‐ScR flow diagram of search and study selection process. PRISMA‐ScR: Preferred Reporting Items for Systematic Reviews and Meta‐analyses for Scoping Reviews. PPE, personal protective equipment.

3.2. Studies Characteristics

The sources covered 16 years (2007–2023) and were published in 25 peer‐reviewed journals. The experimental trials in the eligible articles were conducted in 12 different countries, including Australia [101], Canada [26], China [42, 43, 44, 80, 88, 91, 93, 94, 105], Cyprus [107, 108], India [90, 92], Iran [82, 83, 87], Japan [2, 21, 85, 86, 102], Korea [63], Qatar [66, 68, 107, 108], Serbia [109], Slovenia [25], and United States of America [36, 71, 79, 81, 84]. Most studies reported government or industry funding; three studies reported no funding [85, 101, 109]. Table 2 provides a summary of the characteristics of the included studies.

Table 2.

Descriptive characteristics of studies employing personal cooling garments (PCGs) for workers performing physically demanding labor in standard work clothing in hot environments.

| Study | Application | Cooling Garment | Intervention | Participants | Outcomes | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Cooling Method | Garment Type | Body Area Coverage | Description of Intervention | Location | Trials | Environmental conditions | Sex | Age (SD) years | Physiological | Perceptual | ||

| Al Sayed et al. [26]. | Mining | 1 Hybrid (Convective & Evaporative) | 1 Liquid CO2 System | 1 Cooling Vest | 35% | Stationary cycling for 30 min at 100% of max power | Lab | 3 CON + 2 EXP Trial | 30°C, 60% RH, 0.3 m/s2 | 19 M | 26.7 (4) |

↓ Tc ↓ HR |

↓+ RPE ↓ + TC |

| Ashtekar et al. [90]. | Construction | 1 Conductive | 1 Liquid Ice‐Chilled Coolant System | 1 Cooling Vest | 35% | Construction work | Field | 2 CON + 1 EXP Trial | 40°C, 41%, 0.3 m/s2 | 29 M | 23.0 (4) |

↓ Tc ↓ Tsk ↓ HR ↓ SR |

↓+ TC ↓ + TS |

| Bach et al. [101]. | Nonspecific |

1 Hybrid (Convective & Evaporative) 2 Conductive |

1 Air Cooled System 2 Cold‐Water Perfused System |

1–2 Cooling Vest | 35% | Treadmill walking for 120 min at 387 Watts | Lab | 3 CON + 2 EXP Trials | 35°C, 53%, <1 m/s2 | 12 M | 25.5 (5) |

↓Tc 1 ↑ Tsk,2 ↓Tsk ↓ HR |

|

| Butts et al. [79]. | Nonspecific | 1 Conductive | 1 Phase Change Material | 1 Compression Clothing | 54% | Treadmill walking (1.3 km/hr) at a 2% incline, carrying boxes (5.2 m/per 7.5 s). Loosening and tightening nuts on bolts, carrying weights oversteps | Lab | 2 CON + 1 EXP Trial | 34°C, 55% | 20 M | 24.0 (4) |

↓ Tc ↓ Tsk ↓ HR ↓ SR |

↓+ RPE ↓ + TS |

| Chan et al. [110]. | Construction | 1 Hybrid (Convective & Evaporative & Conductive) | 1 Phase Change Material with Ventilation Fans | 1 Cooling Vest | 35% | Treadmill walking | Lab | 2 CON + 1 EXP Trial | 37°C, 60% | 12 M | 22.0 (3) |

↓ Tc ↑ Tsk ↑ HR |

|

| Chan et al. [91]. | Construction | 1 Hybrid (Convective & Evaporative & Conductive) | 1 Phase Change Material with Ventilation Fans | 1 Cooling Vest | 35% | Construction work | Field | 2 CON + 1 EXP Trial | ND | 140 M | 32.0 (9) | ↓ HR |

↓+ RPE ↓ + TC ↓ + TS |

| Choi et al. [63]. | Agriculture | 1‐7 Conductive | 1‐7 Phase Change Material |

1–2 Cooling Scarf 3 Cooling Hat 4 Cooling Vest 5 Cooling Hat & Scarf 6 Cooling Hat & Vest 7 Cooling Scarf, Hat & Vest |

1–2 17% 3 35% 4‐6 42% |

Red Pepper Harvest Simulation | Lab | 8 CON + 7 EXP Trials (varying combinations) | 33°C, 65% | 12 M | 25.4 (2) |

1–7 ↓ Tc 1–7 ↓ Tsk 1–7 ↓ HR 1–7 ↓ SR |

|

| Ciuha et al. [25]. | Nonspecific |

1 Conductive 2 Convective 3 Evaporative 4 Conductive 5 Hybrid (Evaporative & Conductive) |

1 Active Air‐Cooling 2 Active Water‐Cooling 3 Water‐Doused 4 Phase Change Material 5 Phase Change Material and Water Doused |

1–5 Cooling Vest | 35% | Treadmill walking for 2.5 h at 4.5 km/h with a 1% incline | Lab | 6 CON + 5 EXP Trials | 35°C, 50% RH, 0.3 m/s2 | 10 M | 22.0 (4) |

1–5 ↓ Tc 1–5 ↓Tsk 1–5 ↓ HR 1–5 ↓ SR |

|

| Cvetanović et al. [109]. | Nonspecific | 1 Conductive | 1 Ice Water Perfused | 1 Cooling Vest | 35% | Treadmill walking for 45 min at 5 km/h | Lab | 2 CON + 1 EXP Trial | 40°C, 40%, 0.1 m/s2 | 10 M | 23.4 (2) |

↓ Tc ↓Tsk ↓ HR ↓ SR |

↓+ RPE |

| Davis et al. [81]. | Forestry | 1–2 Hybrid (Evaporative & Convective) |

1 Passive Ventilation with Ambient Air 2 Ventilation Fans with Cool Air |

1–2 Cooling Hardhat | 7% | Treadmill walking for 45 min at 5.6 km/h while wearing the cooling helmet | Lab | 4 2 CON + 2 EXP Trials | 35°C, 40% RH | 8 M | 25.8 (2) | 1–2 ↑ Tc | |

| Dehghan et al. [82]. | Nonspecific | 1–2 Conductive | 1‐2 Phase Change Material | 1–2 Cooling Vest | 35% | Treadmill walking on for 30 min at 2.4 km/h and 4.8 km/hr | Lab | 4 2 CON + 2 EXP Trials | 39°C, 33% | 12 M | 23.7 (3) |

1–2 ↓ Tc 1,2 ↓Tsk 1–2 ↓ HR |

|

| Dehghani et al. [82]. | Nonspecific | 1 Conductive | 1 Cold Liquid Circulation System | 1 Cooling Vest | 35% | Treadmill walking for 4 ×20‐min phases and rest periods of 4 ×15 min at 2 km/h | Lab | 2 CON + 1 EXP Trial | 39°C, 41% | 12 M | ND |

↑ Tc ↓ Tsk ↓ HR |

↓+ RPE ↓ + TS |

| Furtado et al. [36]. | Electrical utilities | 1 Conductive | 1 Chill Water Perfused System | 1 Cooling Shirt | 35% | Arm ergometer and variable electrical utilities tasks | Field | 3 CON + 2 EXP Trial | 33°C | 1 12 M2 10 M | 24.3 (1) |

↓ Tc ↓ HR |

↓+ TC |

| Gillis et al. [84]. | Nonspecific |

1 Evaporative 2 Evaporative |

1 Doused in Cool Water 2 Doused in Methanol/Ethanol |

1–2 Cooling Long‐Sleeved T‐Shirt | 49% | Stepping for 30 min at a rate of 12 steps/min on a 22.5 cm box followed by 15 min rest | Lab | 3 CON + 2 EXP Trials | 30°C, 70% RH | 6 M | 22.0 (4) |

1 ↓ Tc,2 ↑ Tc 1–2 ↑ Tsk |

1‐2 ↓ + RPE 1‐2 ↓ + TS |

| Guo et al. [42]. | Construction | 1 Hybrid (Evaporative & Conductive) | 1 Phase Change Material with Ventilation Fans with Cool Air | 1 Cooling Vest | 35% | Construction tasks for 6 h | Field | 2 CON + EXP Trial | 31.56°C WBGT | 171 M, 2 F | 32.1 (9) |

↓ Tc ↓Tsk ↓ HR |

|

| Hashimoto et al. [85]. | Nonspecific |

1 Conductive 2 Hybrid (Evaporative & Convective) |

1 Cold Water Perfused System 2 Ventilation Fans with Ambient Air |

1–2 Cooling Jacket |

49% 35% |

Stationary cycling for 30 min at 40% VO2max | Lab | 3 CON + 2 EXP Trial | 40°C, 50% | 9 M | 24.4 (4) |

1–2 ↓ Tc 1–2 ↓Tsk 1–2 ↓ HR 1–2 ↑ SR |

1–2 ↓ + RPE 1–2 ↑ ‐ TC 1–2 ↓ + TS |

| Inoue et al. [86]. | Nonspecific | 1–2 Conductive | 1‐2 Cool Water Perfused |

1 Cooling Vest 2 Partial Cooling Vest |

35% 17.5% |

Arm ergometer for 40 min at 40% of VO2max | Lab | 3 CON + 2 EXP Trials | 40°C, 50% | 9 M | 24.8 (4) |

1–2 ↓ Tc 1–2 ↓ SR |

1–2 ↓ + RPE 1–2 ↓ + TS |

| Ioannou et al. [107]. | Agriculture Construction |

1 Hybrid (Evaporative & Conductive) 2–3 Evaporative |

1 Ventilation Fans 2‐3 Water Doused |

1–3 Cooling Shirt | 83% |

1 Agriculture tasks (202 (14) W/m2) 2 Agriculture tasks (100 (6) W/m2) 3 Construction tasks (89 (19) W/m2) |

Field | 3 CON + 3 EXP Trial |

1 26.6°C, 38.5% 2 31.7°C, 62.7% 3 35.6°C, 37.8% |

1 4 M, 2 F 2 12 M 3 32 M |

1 39.2 (12) 2 35.3 (9) 3 65.1 (8) |

1–3 ↓ Tc 1–3 ↓ Tsk 1 ↓ HR 2–3 ↑ HR |

|

| Ioannou et al. [108]. | Agriculture Construction | 1–2 Radiative | 1–2 White Color | 1–2 White Clothing | 83% |

1 Agriculture tasks (194 (54) W/m2) 2 Construction tasks (96 (17) W/m2) |

Field | 2 CON + 2 EXP Trial |

1 24°C WBGT 2 28°C WBGT |

1 4 M, 2 F 2 41 M |

1 39.2 (12)2 33.6 (8) |

1 ↓ Tc,2 ↑ Tc 1–2 ↓ Tsk 1–2 ↓ HR |

1–2 ↓ + RPE 2 ∅ TC 1–2 ↓ + TS |

| Itani et al. [111]. | Nonspecific | 1–6 Conductive | 1–6 Phase Change Material | 1–6 Cooling Vest | 35% | Stationary cycling for 45 min at 3METs | Lab | 7 CON + 6 EXP Trials (varying PCM arrangements) | 36°C, 50%, 0.4 m/s2 | 6 M | 21.5 (1) |

1–6 ↓ Tsk 1–6 ↓ HR 1–6 ↓ SR |

1–6 ↓ + TC 1–6 ↓ + TS |

| Mori et al. [2]. | Nonspecific | 1–2 Hybrid (Evaporative & Convective) | 1–2 Ventilation Fans with Ambient Air | 1–2 Cooling Jacket | 49% | 60 min stationary cycling at 4METs | Lab | 2 CON + 1 EXP Trial |

1 40°C, 30%, 0.2 m/s2 2 30°C, 85%, 0.2 m/s2 |

1 9 M 2 6 M |

24.1 (4) |

1–2 ↓ Tc 1–2 ↓ Tsk 1–2 ↓ HR 1–2 ↓ SR |

1–2 ↓ + RPE 1–2 ↓ + TC |

| Ouahrania 2017 [57] | Nonspecific | 1–6 Conductive | 1–6 Phase Change Material | 1–6 Cooling Vest | 35% | Stationary cycling for 45 min at 3METs | Lab | 7 CON + 6 EXP Trials (varying PCM arrangements) | 35°C, 50%, 0.2 m/s2 | 6 M | 22.3 (2) |

1–6 ↓ Tc 1–6 ↓ Tsk 1–6 ↓ HR 1–6 ↓ SR |

1–6 ↓ + RPE 1–6 ↓ + TC 1–6 ↓ + TS |

| Sekoguchi et al. [21]. | Nonspecific | 1–3 Hybrid (Evaporative & Convective) | 1–3 Liquid Air Cooling Device | 1–3 Cooling Face Piece | 7% | Stationary cycling for 30 min at 30% of VO2max | Lab | 3 2 CON + 1 EXP Trial | 36°C, 45% | 10 M | 25.9 (7) | 1–3 ↑ Tc | |

| Shirish et al. [92]. | Iron Foundry | 1 Conductive | 1 Liquid Ice Chilled Coolant | 1 Cooling Vest | 35% | Iron foundry tasks for 90 min | Field | 2 CON + 1 EXP Trial | 36°C, 35%, 0.7 m/s2 | 24 M | 30.9 (7) |

↓ Tc ↓ Tsk ↓ HR ↓ SR |

|

| Tokizawa [102] | Nonspecific | 1–4 Hybrid (Evaporative & Convective) |

1–2 Ventilation Fans with Cool Air 3–4 Ventilation Fans with Water Doused Inner Layer |

1–4 Cooling Jacket | 35% | Treadmill walking for 3 ×20 min at 4.5 km/h and a 6.6% or 3.4% incline with 10‐min breaks | Lab | 3 CON + 2 EXP Trials (wet inner, dry inner) | 37°C, 50%, 0.3 m/s2 | 16 M (8 per group) |

26.0 (4) 67.0 (3) |

1–4 ↓ Tc 1–4 ↓ Tsk 1–4 ↓ HR 1–4 ↓ SR |

1–4 ↓ + TC 1–4 ↓ + TS |

| Udayraj et al. [105]. | Nonspecific |

1–2 Conductive 3–4 Hybrid (Evaporative & Conductive) |

1–2 Phase Change Material 3–4 Phase Change Material with Ventilation Fans with Cool Air |

1–4 Full Body Cooling Suit | 86% | Treadmill walking for 70 min at 4.5 km/h | Lab | 5 CON + 4 EXP Trials | 36°C, 59%, 0.1 m/s2 | 8 M | 22.7 (2) |

1–4 ↓ Tc 1–4 ↓ Tsk 1–4 ↓ SR |

1–4 ↓ + TC 1–4 ↓ + TS |

| Wang et al. [94]. | Nonspecific | 1 Conductive | 1 Phase Change Material | 1 Cooling Jacket and Pants | 86% | Standing (1.2METs) and packing tasks (2.5METs) | Lab | 2 CON + 1 EXP Trial | 31°C, 50%, 0.1 m/s2 |

10 M 10 F |

19.9 (1) | ↓ Tc |

↓+ TC ↓ + TS |

| Yazdanirad et al. [87]. | Nonspecific | 1–2 Conductive | 1–2 Phase Change Material | 1–2 Cooling Vest | 35% | Walking on treadmill for 30 min at 2.8 km/h or 4.8 km/h | Lab | 4 2 CON + 2 EXP Trials | 40°C, 41% | 10 M | 25.1 (4) |

1–2 ↓ Tc 1–2 ↓ Tsk 1–2 ↓ HR 1–2 ↓ SR |

|

| Yi et al. [112]. | Construction | 1–2 Hybrid (Evaporative & Convective) | 1–2 Phase Change Material with Ventilation Fans with Cool Air |

1 Cooling Vest 2 Full Body Cooling Suit |

35% | Treadmill walking for 48 min at 6 km/h at an 8% incline and 3 km/h with 2% incline (intermittent) | Lab | 3 CON + 2 EXP Trials | 37°C, 60%, 0.3 m/s2 | 10 M | 23.0 (4) |

1–2 ↓ Tc 1–2 ↓ Tsk 1–2 ↓ HR 1–2 ↓ SR |

1–2 ↓ + RPE 1–2 ↓ + TS |

| Zhang et al. [71]. | Nonspecific | 1 Convective | 1 Liquid Carbon Dioxide | 1 Cooling Shirt | 35% | Treadmill walking with arm curls at a rate of 465 W | Lab | 2 CON + 1 EXP Trial | 33°C, 75% RH | 10 M | 26.0 (3) |

↓ Tc ↓ Tsk ↓ HR ↑ SR |

↓+ TC |

| Zhao et al. [93]. | Construction | 1 Hybrid (Evaporation & Conductive) | 1 Phase Change Material with Ventilation Fans with Cool Air | 1 Cooling Vest | 35% | Treadmill walking for 30 min at 6 km/h with a 2% incline | Lab | 2 CON + 1 EXP Trial | 37°C, 60%, 0.3 m/s2 | 12 M | 22.0 (3) |

↓ Tc ↑ Tsk ↑ HR ↓ SR |

↓+ RPE ↑ ‐ TC ↓ + TS |

| Zhao et al. [88]. | Construction | 1 Hybrid (Evaporation & Conductive) | 1 Phase Change Material with Ventilation Fans with Cool Air | 1 Cooling Vest | 35% | Construction tasks for 8‐h | Field | 2 CON + 1 EXP Trial | ND | 14 M | 29.0 (3) |

↓Tc ↓ HR |

↑‐ RPE ↓ + TS |

| Zheng et al. [43]. | Mining | 1–3 Conductive | 1–3 Phase Change Material | 1 Long‐sleeved Jacket and Full‐Length Trousers | 68% | Treadmill walking at 3.5 km/h | Lab | 4 CON + 3 EXP Trials | 30°C, 80%, 0.2 m/s2 |

10 M 8 M |

24.8 (1) 24.8 (1) |

1–3 ↓ Tsk 1–2 ↓ SR,3 ↑ SR |

1–3 ↓ + RPE 1–3 ↓ + TC 1 ∅ TS, 2–3 ↓ + TS |

Abbreviations: HR, heart rate; PCM, physiological outcomes: phase change material; RPE, perceptual outcomes: rating of perceived exertion; SR, sweat rate; T c, core temperature; T sk, skin temperature; TC, thermal comfort; TS, thermal sensation; ∅, no difference; ↑ increased compared to control; ↓ decreased compared to control; ND not disclosed; SD, standard deviation; RH, relative humidity; M, male; F, female; CON, control; EXP, experimental. (Based on the various scales used, for TS and TC, ↑‐ indicates that the value increased which represents greater discomfort/hotness ↓+ indicates that the value decreased which represents improved comfort/coolness).

The participants in the experimental studies varied between six and 173, for a total of 764 participants (representing an average of 21 ± 34 participants per study). Only four studies included females (total of 16; 2%) [42, 94, 107, 108]; no studies focusing only on females were retrieved. Of the four studies that included females, none reported the use of contraception. The weighted average age of the participants was 33 years old (average range: 21–67, n = 32). Ethnicity was mentioned in seven of the studies [2, 36, 85, 86, 87, 88, 94]. Most articles (n = 30, 91%) reported focusing on healthy participants, whereas the remaining three (10%) studies did not provide information about the health status of the participants [36, 68, 84]. Participants had a weighted average body surface area of 1.8 m2 (average range: 1.5–2.0, n = 30); three (9%) articles did not provide information for body surface area [82, 83, 87].

Additionally, seven (21%) studies indicated that participants were heat‐acclimated [25, 63, 88, 90, 92, 107, 108], and two (6%) studies indicated that participants were unacclimated to the heat [71, 85]; the remaining 24 (73%) did not report acclimation status. While pretrial restrictions were noted in 20 (61%) of the studies, including abstaining from consuming caffeine, alcohol, smoking and/or strenuous exercise the day before experimental visits [2, 25, 43, 44, 63, 68, 71, 79, 82, 83, 85, 86, 87, 93, 94, 101, 102, 105, 110, 111], several did not. Lastly, 17 (52%) of the included studies provided information on fluid consumption, with seven (21%) studies providing water before the start of the trial but prohibiting during the trial [25, 26, 63, 86, 87, 90, 112], four (12%) of studies providing water during the trial period ad libitum [71, 81, 111] or in a structured method [88], and six (18%) providing water during rest breaks only, ad libitum [2, 79, 93, 102, 110] or in a structured method [85]. The remaining 16 (48%) of the assessed articles did not mention hydration.

3.3. Context: Environment, Workload, Clothing

Of the 33 experimental studies included, 25 (76%) were conducted in laboratory settings using environmental chambers, while eight (24%) were conducted in the field [36, 42, 88, 90, 91, 92, 107, 108]. The average WBGT, ambient temperature and relative humidity were 31.2 ± 2.6°C (average range: 27.9–36.1°C, n = 33), 35.9 ± 3.3°C (average range: 29.5–40.0°C, n = 30) and 51.4 ± 12.1% (average range: 30–80%, n = 29), respectively. However, three (12%) studies did not provide the ambient temperature [42, 88, 91, 107], five (15%) studies did not provide the relative humidity [36, 42, 88, 91, 107] and 15 (45%) studies did not provide the WBGT [21, 26, 68, 79, 80, 84, 85, 86, 87, 94, 101, 102, 105, 109, 111]. In most studies (n = 24, 77%), participants completed work and rest bouts (if applicable) in the same environmental conditions. In contrast, in nine (27%) studies, participants rested in cooler and less humid environmental conditions compared with the work bout [2, 21, 43, 63, 83, 85, 86, 102, 105]. For these studies, the average ambient temperature and relative humidity of the rest/break room (e.g., antechamber) was 25.1 ± 2.6°C (average range: 21.0–28.0°C, n = 5) and 49.3 ± 6.1% (average range: 40–60%, n = 5), respectively. Only 12 (36%) of the studies mentioned the presence of radiant heat, including four (12%) field studies [90, 92, 107, 108], and seven (21%) laboratory studies that attempted to increase ecological validity by adding artificial radiation (e.g., metal halide lamps) [63, 71, 81, 82, 84, 93, 112], and one study declared the absence of solar radiation (0 W/m2) [25]. Further, 16 (49%) of the studies reported air velocity (average: 0.3 ± 0.2 m/s2, average range: 0.1–0.7 m/s2, n = 16) [2, 25, 26, 43, 68, 90, 92, 93, 94, 101, 102, 105, 108, 109, 111, 112], whereas the remaining 17 (51%) studies did not report values for air velocity.

Fifteen of the studies were industry‐specific, including agriculture [63, 107, 108], construction [42, 88, 90, 91, 92, 93, 107, 108, 110, 112], electrical utilities [36], forestry [81] and underground mining [26, 43]; two articles were multi‐industry [107, 108]. The remaining 18 articles simulated general labor/work in the heat. Most of the studies (n = 21, 64%) used a single task such as treadmill walking [25, 43, 81, 82, 83, 87, 93, 101, 102, 105, 109, 110, 112], stationary cycling [2, 21, 26, 68, 85, 111], arm ergometer [86] or block stepping [84]. The remaining 12 (36%) studies incorporated specific occupational tasks related to agriculture (i.e., red pepper harvesting, straw harvesting, and grape‐picking) [63, 107, 108], construction [42, 88, 90, 91, 92, 107, 108], electrical utilities (i.e., load carrying and loosening nuts on bolts) [36, 79], and general laboring, such as standing and packing [94], and walking with arm curls [71]. Most of the studies (n = 24, 75%) used a fixed‐pace strategy, such as fixed exercise intensity at a given metabolic rate, a fixed rate of metabolic heat production, or fixed at a given level of heart rate or perceived effort. The remaining nine (27%) studies used self‐paced workloads [36, 42, 63, 88, 90, 91, 92, 107, 108]. The average work intensity of the included studies was 3.3 ± 1.0 METs.

The average total protocol duration, including work and rest periods (where applicable), was 193 ± 190 min (average range: 30–660 min, n = 33). The study protocols employed different strategies for PCG use, with most (n = 21, 64%) requiring the participants to wear the garment while completing the work bout only [2, 25, 26, 36, 43, 68, 71, 81, 82, 85, 86, 87, 90, 92, 93, 94, 101, 108, 109, 111]. The remaining studies either had the participants wear the PCGs only during break periods (between work bouts) (n = 4, 12%) [42, 88, 91, 110], or during work and rest bouts (n = 8, 24%) [21, 63, 79, 83, 84, 102, 105, 112]. Of the studies that used the PCGs during the work bout only, the garments were typically worn for 146 ± 203 min (average range: 30–660 min, n = 21), which accounts for wearing the PCGs for 78 ± 25% of the trial length (average range: 43–100%, n = 21). Of the studies that used the PCGs only during breaks (between work bouts), the garments were typically worn for 83 ± 38 min (average range: 30–120 min, n = 4), which accounts for wearing the PCG for an average of 15 ± 7% of the trial length (average range: 9–25%, n = 4). Lastly, of the studies that used the PCGs during both breaks and work bouts (both continuous and intermittent use), the garments were typically worn for 75 ± 26 min (average range: 30–100 min, n = 8), which accounts for wearing the PCG for an average of 89 ± 25% of the trial length (average range: 31–100%, n = 8).

Most studies (n = 30, 91%) reported details about the work uniform worn (including undergarments); three studies did not provide details [42, 83, 90]. Most studies offered general information about the type of clothing worn and their materials (i.e., percentage of cotton); however, only six (18%) reported clothing insulation, which ranged from 0.16 to 1 Clo m2K/W [68, 93, 94, 101, 102, 105].

3.4. Mechanisms: Personal Cooling Garments

Within the 33 included studies, 67 PCGs were tested, including garment variations (i.e., different number or placement of phase change material packs) or garment combinations (i.e., cooling vest and cooling scarf). The 67 different PCGs used various methods of cooling, including conduction (n = 39) [25, 36, 43, 63, 68, 79, 82, 83, 85, 86, 87, 90, 92, 94, 101, 105, 109, 111], convection (n = 2) [25, 71], evaporation (n = 4) [25, 84, 108], radiation (n = 2) [107] or a combination of methods (i.e., hybrid cooling garments) (n = 20). The hybrid PCGs included enhancement of heat exchange via either evaporative and convective (n = 13) [2, 21, 26, 81, 85, 93, 101, 102, 108, 112], evaporative and conductive (n = 5) [25, 42, 88, 105], or the combination of evaporative, convective and conductive (n = 2) [80, 91]. The PCGs also employed various types of cooling materials, including phase change materials (e.g., ice, frozen gel packs) (n = 38) [25, 42, 43, 63, 68, 79, 80, 82, 87, 88, 91, 94, 105, 111, 112], cool/cold/ice water (n = 9) [25, 36, 42, 84, 85, 86, 108, 109] or other liquid coolants (n = 6) [21, 83, 84, 90, 92, 101], ambient/cool/cold air (n = 21) [2, 21, 25, 26, 42, 80, 81, 85, 88, 91, 101, 102, 105, 108, 112] or other gases (e.g., carbon dioxide) [71], and the color white (n = 2) [107].

The styles of PCGs included cooling vests (n = 38) [25, 26, 42, 63, 68, 80, 82, 83, 85, 86, 87, 88, 90, 91, 92, 93, 101, 108, 109, 111, 112], jackets (n = 12) [2, 85, 94, 102, 105, 113], trousers (n = 10) [43, 94, 105, 107, 108], headwear (i.e., cap or hardhat) (n = 7) [63, 81, 107], t‐shirts (n = 4) [36, 71, 107, 108], long‐sleeve shirts (n = 2) [84], scarfs (n = 2) [63], face masks (n = 2) [21], overalls (n = 1) [107], and compression undergarments (n = 1) [79]. Typically, the PCGs covered an average of 40 ± 20% of the wearer's body surface area (average range: 7%–86%, n = 31). The weight of the PCGs was reported in 18 (55%) studies [26, 36, 44, 63, 68, 71, 79, 80, 81, 85, 87, 90, 91, 92, 94, 102, 105, 113], with an average weight of 1.8 ± 1.2 kg (average range: 0.1–5.1 kg, n = 18).

3.5. Outcomes: Physiological and Perceptual

Core temperature data were presented for 31 (94%) of the studies with two (6%) studies not reporting any data [43, 91]. Core temperature was measured as rectal temperature (n = 12, 36%) [2, 21, 25, 63, 71, 79, 81, 84, 85, 86, 101, 102], gastrointestinal temperature (e.g., via an ingestible telemetry capsule) (n = 8, 24%) [25, 42, 93, 105, 107, 108, 110, 112], oral temperature (n = 5, 15%) [82, 83, 87, 90, 92], tympanic temperature (n = 5, 15%) [36, 68, 88, 109, 111], auditory canal temperature (n = 4, 12%) [2, 26, 86, 94], and esophageal temperature (n = 3, 9%) [2, 85, 86]. Additionally, in four studies (12%), core temperature was indexed by more than one measurement site [2, 25, 85, 86].

Skin temperature was presented in 27 (82%) studies using 1 to 10 sites (e.g., iButtons, thermal imaging); six (18%) studies did not present skin temperature data [21, 26, 36, 86, 88, 91]. Heart rate using chest straps, wristbands or electrocardiogram was reported in 31 (94%) studies; two (6%) did not represent heart rate data [42, 43]. Additional physiological outcomes were measured in various studies, including blood pressure (e.g., electrosphygmomanometer) (n = 4, 12%) [36, 92, 94, 102], oxygen uptake (n = 4, 12%) [21, 36, 82, 85], oxygen saturation (n = 1, 3%) [94], and skin blood flow using laser Doppler flowmetry (n = 1, 3%) [102]. A few studies also reported hydration indicators, including fluid consumption (e.g., mean water intake rate) (n = 3, 9%) [71, 79, 102], and blood osmolality (n = 1, 3%) [101]. Studies also reported local or whole‐body sweat rate (n = 19, 59%), including sweat production, evaporation rate, and evaporation efficiency; only one (3%) study directly measured sweat rate using dew point hygrometry [102]. Lastly, body heat storage was reported as an outcome in eight (24%) [63, 68, 71, 93, 102, 105, 110, 112] studies.

Of the 33 included studies, the most common perceptual outcomes assessed were thermal sensation (e.g., Taylor categorical scale, ASHRAE, ISO10551) (n = 16, 49%) [57, 66, 67, 70, 79, 82, 83, 84, 85, 87, 89, 91, 92, 93, 95, 97], effort perception (e.g., Borg's rating of perceived exertion) (n = 15, 52%) [2, 26, 43, 68, 79, 83, 84, 85, 86, 88, 91, 93, 107, 109, 112], thermal comfort (n = 14, 42%) [2, 26, 36, 43, 68, 71, 85, 90, 91, 93, 94, 102, 107, 111] and skin wettedness (n = 6, 18%) [26, 43, 68, 91, 105, 112]. Additional perceptual outcomes were measured in various studies, including fatigue (n = 3, 9%) [79, 91, 102], clothing stickiness (n = 2, 6%) [68, 71], perceived sweating response (n = 1, 3%) [90], thirst (n = 2, 6%) [79, 102], ergonomic comfort (n = 1, 3%) [25], thermal satisfaction, cold stimuli sensation, thermal preference (n = 1, 3%) [94], muscle pain (n = 1, 3%) [79], overall wellbeing (n = 1, 3%) [26], and perceived environmental temperature (n = 1, 3%) [71]. Further, we found four indices referenced as outcomes, including the Heat Strain Score Index (HSSI) (n = 1, 3%) [82], Perceptual Strain Index (n = 8, 25%) [63, 79, 88, 91, 93, 105, 109, 110], Physiological Strain Index (n = 3, 9%) [79, 88, 110], Perceptual Strain Alleviation (n = 1, 3%) [91], Sweat Feeling Index (n = 1, 3%) [94], the Craig Index (n = 1, 3%) [63]. A few of the studies also reported metrics specific to the garments, including garment‐specific design factors (e.g., breathability, movement restriction, heaviness) (n = 4, 13%) [42, 43, 81, 87, 92, 93], ratings of overall garment performance (n = 2, 6%) [90, 91], perceived cooling effect, impact on fitness, and effectiveness to combat heat stress (n = 1, 3%) [91].

3.6. Context‐Mechanism‐Outcome (CMO) Configurations

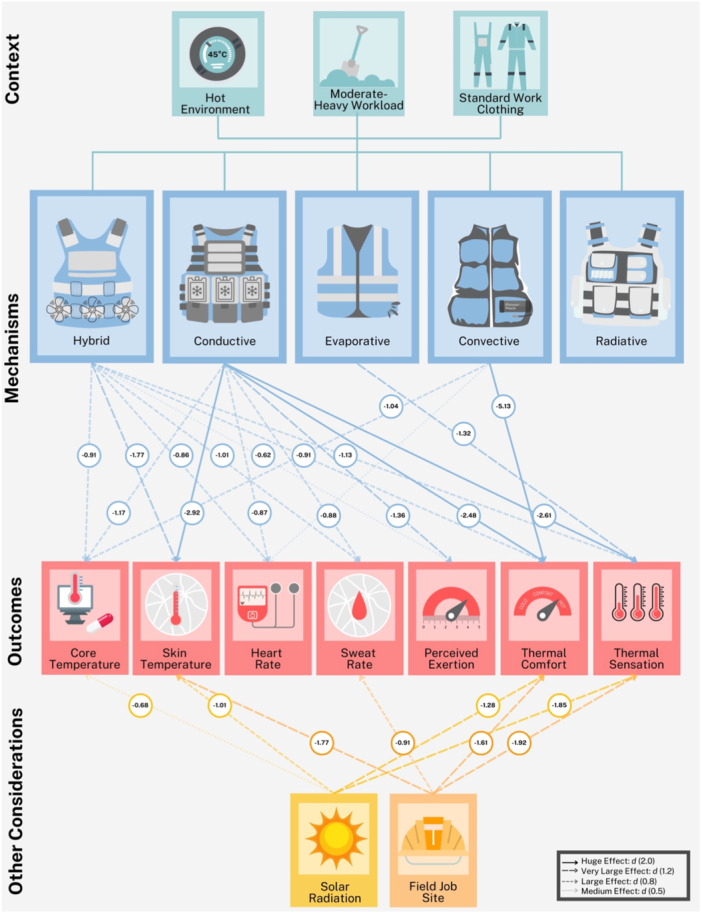

The findings are visualized in Figure 2 to depict the produced CMO configurations and reflect which PCGs were effective in which setting, in the presence or absence of which moderating factors, and the physiological and perceptual outcomes achieved from the interaction between each setting and cooling mechanism. Additionally Supporting Information: File [B] and [C] present the figures for all meta‐analysis and meta‐regressions conducted.

Figure 2.

Visualization of the context‐mechanism‐outcome (CMO) configurations explored through the meta‐analysis and application of the realist evaluation framework. The lines between the mechanisms, outcomes and other considerations represent the substantiative significance (effect size) for each PCG[104], where huge d (2.0) is represented by a solid fully transparent line, very large d (1.2) is represented by a long dashed line at 75% transparency, large d (0.8) is represented by a short dashed line at 50% transparency, and medium d (0.5) is represented by a dotted line at 25% transparency. Small d (0.2) and very small d (0.01) effects are not visualized.

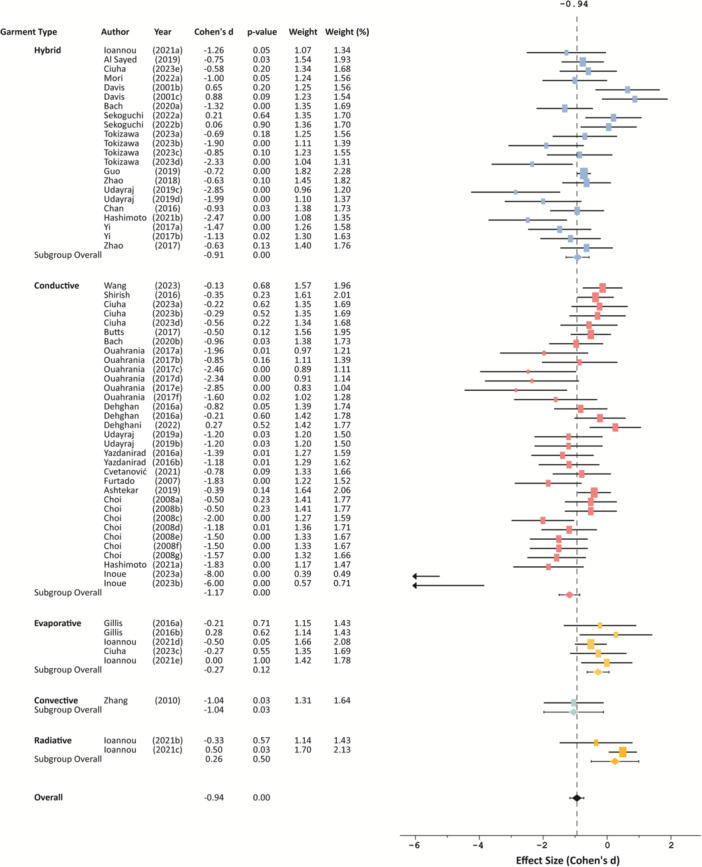

When worn during moderate‐to‐heavy work in a hot environment with standard work clothing, the PCGs had a moderate to very large overall effect on core temperature (d = −0.94, p = 0.00), skin temperature (d = −2.24, p = 0.00), heart rate (d = −0.78, p = 0.00) and sweat rate (d = −0.88, p = 0.00). More specifically, hybrid and conductive garments had a large to huge effect on core temperature (d = −0.91, p = 0.00; d = −1.17, p = 0.00), skin temperature (d = −1.77, p = 0.000; d = −2.92, p = 0.00), heart rate (d = −0.86, p = 0.000; d = −0.87, p = 0.00) and sweat rate (d = −1.01, p = 0.000; d = −0.88, p = 0.00) outcomes, respectively. In contrast, evaporative and radiative garments had no or minimal effect on the physiological outcomes assessed, and convective garments only affected core temperature (d = −1.04, p = 0.03) (Figure 3). On average, there was a reduction of 0.2°C in core temperature and 10 bpm in heart rate when using the PCGs. A summary of the magnitude of change for core temperature and heart rate by PCG type, presence of solar radiation and setting is presented in Table 3.

Figure 3.

Subgroup analysis of body core temperature (outcome) by heat exchange type (mechanisms) for workers performing physically demanding work in hot environments and in standard work clothing (context).

Table 3.

Summary of the magnitude of change for core temperature and heart rate by personal cooling garment (PCG) type, presence of solar radiation and setting.

| Physiological outcome | |||

|---|---|---|---|

| Core temperature | Heart rate | ||

| Personal cooling garment type | Hybrid | −0.2°C | −10 bpm |

| Conductive | −0.3°C | −12 bpm | |

| Evaporative | −0.1°C | −1 bpm | |

| Convective | −0.3°C | −9 bpm | |

| Radiative | 0.1°C | −1 bpm | |

| Solar radiation | None | −0.3°C | −14 bpm |

| Present | −0.2°C | −3 bpm | |

| Setting | Laboratory | −0.3°C | −12 bpm |

| Field | −0.1°C | −4 bpm | |

| Overall | −0.2°C | −10 bpm | |

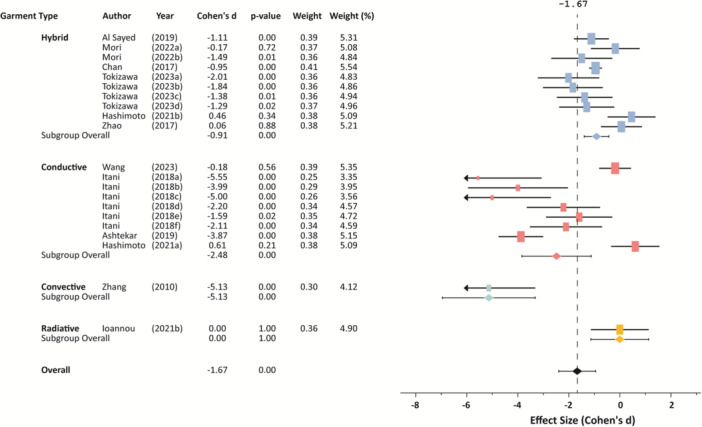

Similarly, the PCGs had a positive overall effect on workers perceived exertion (d = −0.84, p = 0.00), thermal comfort (d = −1.67, p = 0.00) and thermal sensation (d = −1.96, p = 0.00) (Figure 4). In particular, the PCGs that used conduction as the pathway for heat exchange had a very large to huge effect on the worker's perceived exertion (d = −1.36, p = 0.00), thermal comfort (d = −2.48, p = 0.00) and thermal sensation (d = −2.61, p = 0.00). The hybrid cooling garments greatly impacted the wearer's comfort (d = −0.91, p = 0.00) and sensation (d = −1.13, p = 0.00), convective garments only influenced thermal comfort (d = −5.13, p = 0.00) and evaporative garments impacted thermal sensation (d = −1.32, p = 0.02). The radiative PCGs had no or minimal effect on any perceptual outcomes.

Figure 4.

Subgroup analysis of thermal comfort scores (outcome) by heat exchange type (mechanisms) for workers performing physically demanding work in hot environments and in standard work clothing (context).

The WBGT statistically significantly affected core temperature (p = 0.023). Clothing insulation had a statistically significant effect on heart rate (p = 0.006), thermal comfort (p = 0.047) and thermal sensation (p = 0.048). The duration of time the cooling garment was worn had a statistically significant effect on heart rate (p = 0.001). Physical characteristics indexed by body surface area and body mass index, as well as METs, did not have a statistically significant impact on any outcomes (p > 0.05). However, 22% of the variance in cooling garment effectiveness was driven by METs, such that when the METs increased, the effectiveness of the garment decreased.

It was determined that the effect size of the cooling garments was much greater when radiant heat was not present. In the absence of radiant heat, the PCGs had a large to huge effect on core temperature (d = −1.12, p = 0.00), skin temperature (d = −2.93, p = 0.00), heart rate (d = −1.17, p = 0.00), sweat rate (d = −1.09, p = 0.00), perceived exertion (d = −1.06, p = 0.00), thermal comfort (d = −1.72, p = 0.00) and thermal sensation (d = −1.97, p = 0.00). The only noteworthy effects identified when radiant heat was present were skin temperature (d = −1.01, p = 0.01), thermal comfort (d = −1.28, p = 0.33) and thermal sensation (d = −1.85, p = 0.01).

Similarly, the PCGs were more effective during laboratory simulation studies than field studies. When studies were conducted in the laboratory, the PCGs had a large to huge effect on core temperature (d = −1.04, p = 0.00), skin temperature (d = −2.32, p = 0.00), heart rate (d = −0.94, p = 0.00), sweat rate (d = −0.89, p = 0.00), perceived exertion (d = −0.95, p = 0.00), thermal comfort (d = −1.68, p = 0.00) and thermal sensation (d = −1.91, p = 0.00). Whereas in the field, the PCGs only had a large to very large effect on skin temperature (d = −1.77, p = 0.03), sweat rate (d = −0.91, p = 0.00), thermal comfort (d = −1.61, p = 0.16) and thermal sensation (d = −1.92, p = 0.15).

4. Discussion

We found that the PCGs positively affected most of the measured physiological and perceptual outcomes, although not all were effective for all conditions assessed. Specifically, conductive and hybrid cooling garments offered the most consistent benefit to the sample of workers studied, predominantly young to middle‐aged, healthy males. In contrast, PCGs designed to enhance evaporative and radiative heat exchange were the least effective in the context of our analysis (hot environment, moderate‐to‐heavy workload, standard PPE). We also found that the effect size of the PCGs was much greater when radiant heat was not present and that the garments were less effective when tested in the field (i.e., actual worksites) compared to laboratory settings. Further, it was also noted that while the PCGs enhanced thermal comfort and thermal sensation in some cases, this was not paralleled by a corresponding reduction in physiological strain.

We found that the PCGs reduced indicators of physiological heat strain for primarily young to middle‐aged, healthy male workers performing moderate‐to‐heavy intensity tasks in hot environments and standard work clothing. Specifically, we showed that conductive and hybrid PCGs offered a greater thermoregulatory advantage, whereby core temperature and heart rate reductions were consistently observed (Conductive: T c: −0.3°C, HR: −12 bpm; Hybrid: T c: −0.2°C, HR: 10 bpm). In contrast, convective cooling garments elicited an impact to core temperature (T c: −0.3°C), but only modest impacts on heart rate (HR: −9 bpm), while PCGs directed at enhancing evaporative and radiative heat exchange had no or minimal effect on the physiological outcomes assessed (i.e., T C < 0.1°C, HR: <0.7 bpm). However, our analysis demonstrated that these outcomes were dependent on the presence or absence of specific factors. For example, we found that the variance in cooling garment effectiveness was influenced by WBGT, clothing insulation, duration and metabolic rate.

To illustrate this further, in our analysis, primarily unacclimated, healthy, young to middle‐aged male workers performed moderate‐to‐heavy work in hot ambient conditions (average: 31 ± 3°C WBGT) in standard work clothing. Based on the American Conference of Governmental Industrial Hygienists (ACGIH) action limit values (ALVs), which are the most commonly referenced heat stress management guidelines [114], this combination of workload, environment and clothing insulation level would suggest that unacclimated workers can only operate in these conditions for approximately 0%–25% of an 8‐h workday to prevent a worker's core temperature from reaching potentially unsafe levels (e.g., >38°C) [115]. Therefore, in such a circumstance and based on our findings, occupational health and safety personnel may consider the use of a conductive (e.g., pre‐cooled liquid and phase change materials) or hybrid (e.g., phase change material with ventilation fans) PCG to enhance heat exchange and extend work capacity, as we showed that these garments offered the greatest benefit to the sample of workers physically and perceptually. However, while on average workers felt better (e.g., improved thermal comfort), with only a 0.2°C reduction in core temperature on average and minimal/modest impacts to other physiological outcomes (e.g., heart rate, sweat rate), the use of these PCGs should not be viewed as a stand‐alone strategy for mitigating increases in physiological strain and should be integrated with a larger heat management program.

Further, while conductive and hybrid PCGs both improved core and skin temperatures, a substantial difference in the effect size was observed wherein the impact on skin temperature was much greater than the effect on core temperature. This can largely be attributed to the enhanced skin cooling caused by the direct contact of the PCG with the skin surface. While this may explain the positive effect on perceived thermal strain and thermal comfort evidenced in our findings, there is concern that without a parallel physiological response, workers may have a false sense of protection or security from the cooling garment and may still be at risk of experiencing a heat‐related injury. This is akin to the response observed in heat vulnerable adults accessing a cooling center mid‐day during an extreme heat event [116]. For workers, this sense of protection could also impact worker self‐pacing (i.e., continuing to work at a higher metabolic rate without recognizing heat gain) or delay activation of other behavioral interventions to mitigate heat strain (e.g., taking breaks and hydrating). The incongruences between perceptual and physiological strain have previously been demonstrated during simulated occupational heat stress in both males and females [117] as well as older adults [118, 119], with and without the presence of chronic conditions. Under these conditions, continued vigilance and use of appropriate countermeasures to mitigate physiological strain from strenuous work in the heat would be required.

Across the included studies, the duration of time that the garments were worn was considerably different, ranging from short duration bouts (e.g., 30 min) to extended periods of wear (e.g., 8 h). We found that the duration of time the garment was worn had an important effect on heart rate. This demonstrates that some PCGs, based on design, may offer a limited duration of benefit [27], and thus may only be appropriate for specific tasks. For example, in Gillis et al. [84], the ethanol‐soaked shirt appeared to cool the skin immediately after application; however, the influence wore off after 35 min to the point that there was no visible difference in skin temperature between conditions. This suggests that the period was too long to maximize evaporative cooling potential and would thus require reactivation (e.g., re‐immersion). Therefore, although some garments may not be practical for long‐duration tasks (e.g., full work shifts), our analysis demonstrates that there could be use cases for short‐duration work (e.g., confined space assignments and intermittent tasks), applied during work to rest cycles, or for opportunities to help extend the work duration (tolerance time). Additionally, it is also important to consider that once the cooling capacity of a time‐limited garment (e.g., phase change material) is exhausted, the garment becomes an additional layer of insulation, potentially further hindering sweat evaporation from the body.

The PCGs had a greater overall effect on the physiological and perceptual outcomes during the laboratory simulation studies compared to the field investigations due to the absence of solar loading and radiant heat sources which represents an added thermal burden to workers performing their duties outdoors. For example, between laboratory and field studies, the effect of the PCGs on core temperature was reduced two‐fold (−0.3°C to −0.1°C) and heart rate was reduced three‐fold (−12 bpm to −4 bpm), respectively.

It was also noted that most studies controlled for participant hydration status by ensuring participants were euhydrated pretrial, as well as providing water before, during or on breaks within the trial period. This is relevant to highlight because hydration plays a critical role in a person's ability to sweat (the bodies primary method of heat loss under the environmental and experimental conditions assessed) [119]. Therefore, controlling for it within the study design may have enhanced the efficacy of the garment and thus may not reflect real‐world circumstances, as workers often begin work in a state of dehydration and maintain a depleted hydration status throughout the day [120, 121], as well as the next work day [122]. While it is hard to draw accurate conclusions from these findings, they bring into question the use of laboratory‐based work simulation studies and ‘best‐case scenarios’ (i.e., hydrated workers) to assess countermeasures to mitigate physiological strain.

Lastly, we showed that body surface area and body mass index did not have a statistically significant effect on any outcomes. This may reflect the lack of representation of varied population groups within the current literature and included studies. For example, most studies analyzed were conducted on relatively healthy young‐to‐middle‐aged males. Thus, the findings may not reflect the efficacy of PCGs for different population groups within the workforce [102], such as females, older adults [102], those with pre‐existing health conditions [120] and others where body morphology and heat loss capacity could differ markedly from their younger counterparts [121, 122]. For example, females have a reduced heat loss capacity driven by differences in the activation of heat loss responses of skin blood flow and sweating. Combined with their smaller size, heat production per unit body mass or surface area, the resultant rise in core temperature would be greater in females during weight‐supported work [123]. Similarly, older adults have impaired heat‐loss capacity driven primarily by reductions in sweat production [102]. These differences may impact the cooling effect of certain PCGs, such that these workers may benefit more from the combination of wetted garments and ventilation strategies [102]. In contrast, garments that enhance skin wettedness for young workers may negatively affect sweat gland response and reduce natural sweat production [102]. Therefore, while we propose that occupational health and safety personnel should consider the demographic make‐up of their given workforce and look to utilize garments and interventions that may optimize cooling potential, our review clearly highlights the lack of scientific evidence supporting the use of PCGs across a diverse range of populations, and in particular, those with reduced thermoregulatory capacity. This presents as both a significant knowledge gap and an important area for future research.

4.1. Perspectives and Practical Implications

The findings of our systematic review and meta‐analysis highlight various important points and practical considerations for occupational health and safety managers to contemplate when making an informed decision for their workforce. Table 4 presents the key evidence and proposes potential actions that could help occupational health and safety personnel with the selection and application of PCGs with a holistic understanding of the various factors that may influence the effectiveness of a PCG in mitigating heat strain within their unique workplace.

Table 4.

Evidence to action: Considerations for occupational health and safety personnel.

| Evidence | Potential action | |

|---|---|---|

| 1 | Conductive and hybrid garments were the most effective overall for individuals performing moderate‐heavy work in hot conditions with standard work clothing. | Develop a list of physically demanding jobs performed in hot environments at your site to determine applicability of the findings. |

| 2 | The PCGs had a greater impact on reducing skin temperature than core temperature. | Provide training on the capacity and limitations of the garment. |

| 3 | Improvement in thermal comfort and thermal sensation was not always paralleled with a physiological effect. | Provide additional education for workers regarding the signs and symptoms of heat‐related illness to ensure employees understand the importance of remaining vigilant to physiological effects, despite the perceptual benefit. |

| 4 | The PCGs were more effective during laboratory simulation trials and when radiant heat was absent. | Apply caution when referencing the efficacy of PCGs. Consider incorporating PCG audits into existing job‐site assessments to determine best practices for on‐site use within your specific context. |

| 5 | Most of the studies controlled for hydration status which plays a critical role in evaporative heat loss. | PCGs should not be recommended as a stand‐alone strategy to mitigate heat strain or improve perceptual outcomes. Encourage combining with other protective measures, including ensuring hydration at the beginning of a shift and measures in place to replenish water loss due to sweating continuously, as well as self‐pacing, and taking breaks to optimize the benefits. |

| 6 | The duration of time that the PCGs were worn had a statistically significant effect on heart rate. | Factor in task duration to determine if the garment is appropriate for the job, if it can help extend the work duration (tolerance time) or if it would require additional logistical planning and feasibility considerations (e.g., reactivation, refills, re‐dousing procedures). |

| 7 | WBGT had a statistically significant effect on core temperature. | Incorporate WBGT measurements (i.e., via a handheld portable data logger) as part of your broader environmental monitoring to help determine the appropriateness and potential effectiveness of the PCG within a given work area. |

| 8 | Clothing insulation had a statistically significant effect on heart rate, thermal comfort and thermal sensation. | Consider the combined clothing insulation value of the PPE workers are required to wear when determining the application and potential effectiveness of layering on a PCG. |

| 9 | When the metabolic rate increased, the effectiveness of the garment decreased. | Determine the approximate metabolic rate of the tasks workers are performing when determining the application and potential reduction in effectiveness when work rate increases. |

| 10 | Most studies analyzed were conducted on healthy, young males. | Reflect on the demographics of your workforce (e.g., age, sex, health status) when considering the application of a PCG and the possible limitations in protection for workers with potentially reduced thermoregulatory capacity (e.g., older workers, workers with comorbidities). |

Abbreviations: PCGs, personal cooling garments; WBGT, wet bulb globe temperature.

4.2. Limitations

The results of this systematic review should be considered within the limits of our search, which was restricted to English citations and peer‐reviewed articles, thereby excluding potentially relevant studies in other languages as well as other data from non‐peer‐reviewed sources (e.g., industry reports, white papers, and conference proceedings). Moreover, our review also highlights a lack of multi‐day and field‐based intervention studies. While single‐exposure, laboratory‐based studies provide a high level of control, they often do not simulate the reality of the work environment and tasks that workers could be expected to complete on a given day, nor do these studies account for the next‐day effects of environmental heat exposure [122]. Thus, future research could aim to assess the impact of PCGs in field‐based settings across multiple days of heat exposure. Further, as reported, only seven laboratory studies attempted to increase ecological validity by adding artificial radiation. Individuals conducting studies on the efficacy of wearable cooling garments that intend to simulate real‐work conditions with radiant heat (e.g., open‐pit mining, agriculture, construction) should consider using artificial radiation sources (e.g., metal halide lamps) to help enhance the ecological validity of the study. It is also important to note that because this is an evolving research area, additional studies may have been published in the time since completing the initial literature search. Therefore, this work must be considered as a snapshot of knowledge at the time of the literature search. Future work should continue to expand on this study and be updated based on need and priority as newly identified studies emerge [124].

It is also important to note that the observed modest 0.23°C mean difference in core temperature may be due to the different methods adopted for measuring core temperature. As the various studies used different techniques (e.g., tympanic, auditory canal, rectal) with varying degrees of sensitivity, it is possible that not all studies captured potential changes in core temperature, and thus did not yield meaningful results. Although we sought to address this concern by reporting standardized mean differences for most outcomes it is an important consideration when interpreting the findings. Similarly, it was also noted that for some metrics, there was considerable variability in the protocols implemented by the researchers. In particular, skin temperature demonstrated a high degree of variation in the number of sites measured (range: 1–10), as well as the method of assessment (e.g., iButtons, thermal imaging) and reporting (e.g., localized or whole body). Further, we observed a large degree of heterogeneity (I 2 in the Forest plots). This indicates that factors other than the cooling garments themselves play a significant role in the cooling capacity of the tested wearables, as confirmed by our meta‐regressions. Therefore, although it is important to conduct field studies to examine real‐world scenarios, it is also crucial to use a standardized protocol and reliable measurement tools/sites when assessing the capacity of such cooling systems to determine which are best suited for different conditions and populations. As such, there is a need to encourage compliance with standard test methods for measuring the performance of personal cooling systems using physiological testing (e.g., ASTM F 2300:2010 [125]) to support future inquiries and comparisons.

An important consideration not addressed in this analysis was the technological feasibility and practical constraints of implementing PCGs in real‐world settings. For example, cost is an important factor that OHS personnel must consider when selecting a cooling strategy. However, only one of the included studies reported the cost of the PCG tested (i.e., Ashtekar et al. Rs. 3000 [USD $50] [90]). Therefore, our capacity to comment on the average cost or cost‐effectiveness was limited. To supplement the presented work, an economic/cost analysis considering the direct cost (purchase price), as well as the anticipated frequency and duration of use, the cost of training, consumables, cleaning, maintenance, repair and replacement costs, and other potential fees (e.g., calibration costs charged by the manufacturer/supplier) should be conducted. Additional work exploring the utility and suitability of the different types of PCGs by industry would also allow for a deeper understanding of other points of consideration to ensure that the use of the PCGs does not inadvertently pose additional safety hazards (e.g., in workplaces at risk of explosions and outbursts the PCGs may be limited to those made with fire retardant or ballistic or arc‐flash resistant materials). Further, documenting front‐line workers' opinions on usability, comfort, and perceived safety benefits would support occupational health and safety personnel considering the use case and potential compliance for their workforce.

5. Conclusion

The PCGs generally had a positive overall effect on the primarily young to middle‐aged, healthy male workers. However, they provided different levels of physiological and perceptual benefit such that conductive and hybrid PCGs offered the most consistent benefit to workers, and evaporative and radiative were the least effective. Factors such as environmental conditions, clothing insulation, and duration of use had a significant effect on some, but not all, outcomes. Occupational health and safety personnel considering the application of PCGs within their organization's heat stress management program should consider these factors to ensure that the most optimal personal cooling garment is selected for their context and workforce to reduce heat strain.

Author Contributions

Conceptualization: Emily J. Tetzlaff, Glen P. Kenny, and Antonia Kaltsatou. Methodology: Emily J. Tetzlaff, Valentina Ly, Glen P. Kenny, and Leonidas G. Ioannou. Formal analysis: Emily J. Tetzlaff and Leonidas G. Ioannou. Data curation: Emily J. Tetzlaff, Leonidas G. Ioannou, Fergus K. O'Connor, and Antonia Kaltsatou. Visualization: Emily J. Tetzlaff and Leonidas G. Ioannou. Writing—original draft preparation: Emily J. Tetzlaff. Writing—review and editing: Emily J. Tetzlaff, Leonidas G. Ioannou, Fergus K. O'Connor, Antonia Kaltsatou, Valentina Ly, and Glen P. Kenny. Supervision: Glen P. Kenny. Project administration: Emily J. Tetzlaff. All authors have read and agreed to the published version of the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

Disclosure

The authors have nothing to report.

Supporting information

Supporting information.

Supporting information.

Supporting information.

Acknowledgments

The authors would like to acknowledge Victoria Cole BScN, MScN, MIS (Health Sciences Library, University of Ottawa) for peer review of the MEDLINE search strategy. The authors would also like to thank Elie Nehme for his assistance in the early development of this project. The authors report that there was no funding source for the work that resulted in the article or the preparation of the article.

Disclosures: None.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

- 1. Flouris AD, Dinas PC, Ioannou LG, et al. Workers' health and productivity under occupational heat strain: a systematic review and meta‐analysis. Lancet Planet Health. 2018;2(12):e521‐e531. 10.1016/S2542-5196(18)30237-7 [DOI] [PubMed] [Google Scholar]

- 2. Mori K, Nagano C, Fukuzawa K, et al. Mitigation of heat strain by wearing a long‐sleeve fan‐attached jacket in a hot or humid environment. J Occup Health. 2022;64(1):e12323. 10.1002/1348-9585.12323 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3. Du Y, Gai W, Jin L, Sheng W. Thermal comfort model analysis and optimization performance evaluation of a multifunctional ice storage air conditioning system in a confined mine refuge chamber. Energy. 2017;141:964‐974. 10.1016/j.energy.2017.09.123 [DOI] [Google Scholar]

- 4. Rupp RF, Vásquez NG, Lamberts R. A review of human thermal comfort in the built environment. Energy Build. 2015;105:178‐205. 10.1016/j.enbuild.2015.07.047 [DOI] [Google Scholar]

- 5. Bernard TE, Matheen F. Evaporative resistance and sustainable work under heat stress conditions for two cloth anticontamination ensembles. Int J Ind Ergon. 1999;23(5‐6):557‐564. 10.1016/S0169-8141(98)00019-5 [DOI] [Google Scholar]

- 6. Delkumburewatte GB, Dias T. Wearable cooling system to manage heat in protective clothing. J Text Inst. 2012;103(5):483‐489. 10.1080/00405000.2011.587647 [DOI] [Google Scholar]

- 7. Holmér I. Protective clothing in hot environments. Ind Health. 2006;44(3):404‐413. 10.2486/indhealth.44.404 [DOI] [PubMed] [Google Scholar]

- 8. Amorim FT, Yamada PM, Robergs RA, Schneider SM. Palm cooling does not reduce heat strain during exercise in a hot, dry environment. Appl Physiol Nutr Metab. 2010;35(4):480‐489. 10.1139/H10-040 [DOI] [PubMed] [Google Scholar]

- 9. Walters TJ, Ryan KL, Tate LM, Mason PA. Exercise in the heat is limited by a critical internal temperature. J Appl Physiol. 2000;89(2):799‐806. 10.1152/jappl.2000.89.2.799 [DOI] [PubMed] [Google Scholar]

- 10. MacDougall JD, Reddan WG, Layton CR, Dempsey JA. Effects of metabolic hyperthermia on performance during heavy prolonged exercise. J Appl Physiol. 1974;36(5):538‐544. 10.1152/jappl.1974.36.5.538 [DOI] [PubMed] [Google Scholar]