Abstract

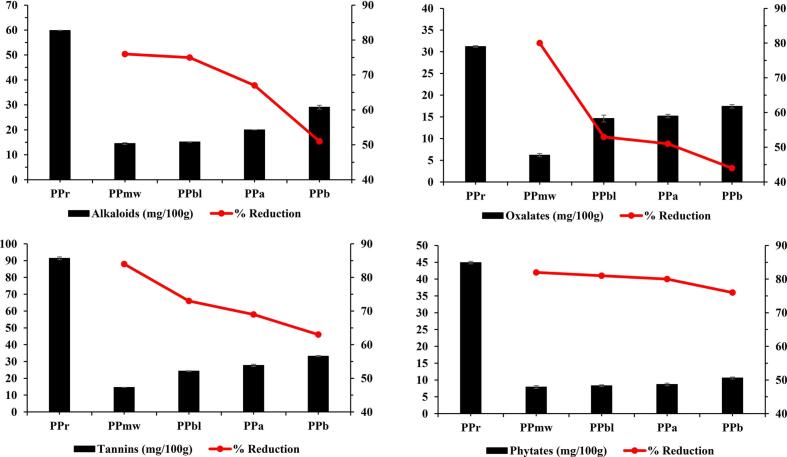

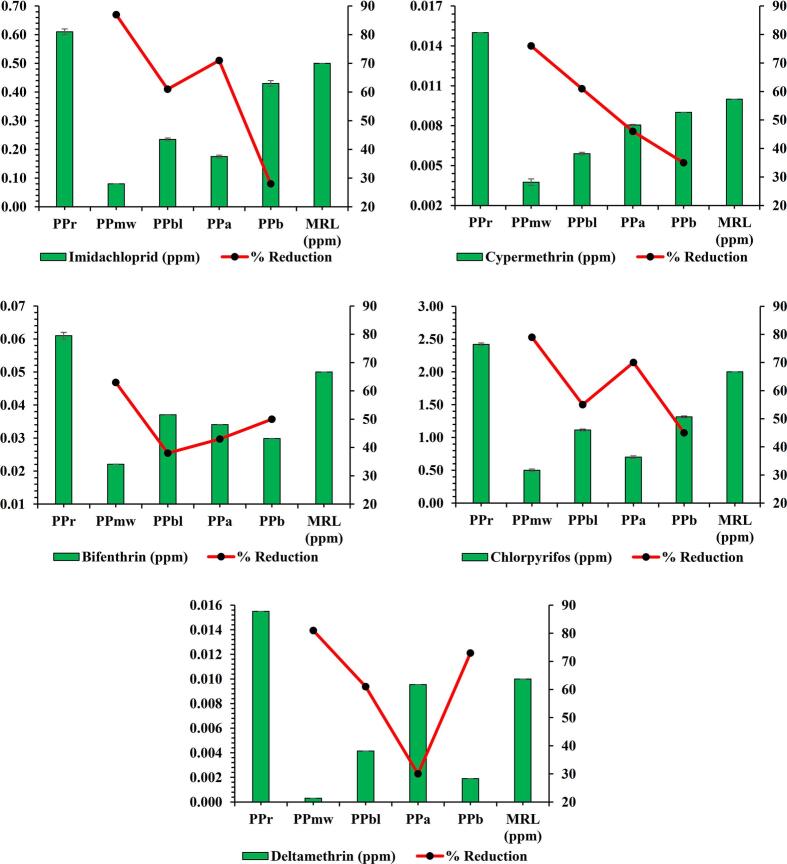

Potato is a highly nutritious staple food however, it also contains some antinutrients like alkaloids, phytates, tannins, oxalates as well as pesticide residues. Therefore, this study was conducted to reduce the loads of antinutrients and pesticides in potato powder (PP) using thermal and non-thermal processing techniques. Nutritional analysis revealed that the raw PP contained significantly (p < 0.05) higher magnitudes of dietary proteins (10.2 %), fibers (6.3 %), Na (50 mg/100 g), Ca (62 mg/100 g) and K (988 mg/100 g) when compared with the processed PP. The results demonstrated that all thermal and non-thermal processing techniques significantly reduced the antinutrients and pesticide residues. However, microwave heat treatment anticipated the highest reduction in alkaloids, oxalates, tannins and phytates contents from 60 to 14 mg/100 g (76 % reduction), 31–6 mg/100 g (80 % reduction), 91–15 mg/100 g (84 % reduction) and 45–8 mg/100 g (82 % reduction), respectively. Additionally, microwave heat processing also exhibited the highest decline in imidacloprid, cypermethrin, bifenthrin, chlorpyrifos and deltamethrin contents by 87 %, 76 %, 63 %, 79 % and 81 %, respectively. Later, microwave-treated PP (the most effective treatment) was used to develop unleavened flatbreads (i.e., chapatis) @ 2–10 %. Organoleptic evaluation of supplemented flatbreads suggested that 5 % supplementation with microwave treated PP has the highest overall acceptability. Therefore, it is concluded that thermal and non-thermal processing techniques are effective tools to reduce loads of antinutrients and pesticide burden in potatoes. Moreover, the study also suggests, PP can be efficiently used as natural food supplement for development of value-added foods.

Keywords: Solanum tuberosum, Processing, Value addition, Microwave, Pesticides, Antinutrients

Highlights

-

•

Potato powder (PP) upholds higher magnitudes of fibers, proteins, Ca, Zn & Fe.

-

•

Thermal & non-thermal processing declined pesticides & antinutrients in potato powder

-

•

Addition of processed PP in flatbreads resulted in higher consumer acceptability.

-

•

Based on technofunctional attributes PP can be used in soups, gravies & curries.

1. Introduction

Potato (Solanum tuberosum L.), a nutrient enriched food crop which belongs to family Solanaceae, is ranked at fourth after the wheat, rice and maize (Guo et al., 2023). With a global cultivation area of 17.3 MH, production statistics reveal global production of potato is about 359 million tons, while for Pakistan it is recorded as 5,872,960 tons (FAOSTAT, 2021). The leading potato producing regions around the globe include People's Republic of China, Indo-Pak region, Ukraine and Russia (Waseem, Akhtar, Ahmad, et al., 2022). Potatoes have gained global attention due to attractive nutritional profile as the tuber contain significant magnitudes of dietary fibers, essential proteins (i.e., essential amino acids), vitamins (B1, B6, B9, C, E and K) and minerals (Mn, Na, Ca, P, K and Mg) (Akonor et al., 2023; Franková et al., 2022; Mi et al., 2022; Akonor et al., 2022). Potato proteins are quite comparable with cereals and egg proteins. Therapeutic properties of potatoes are known to be linked with its health promoting phytonutrients such as anthocyanins (malvidin, peonidin, delphinidin, cyanidin and petunidin), polyphenols (flavonoids), carotenoids and patatin protein (Kita et al., 2013; Sun et al., 2021; Osei Tutu et al., 2024), which exhibit crucial role in the management of numerous health disorders such as diabetes, cardiovascular disorders, inflammation, obesity, hyperlipidemia, hypertension, allergy, neurodegenerative problems, cancers and viral infections (Kowalczewski et al., 2022; Yang et al., 2023; Osei Tutu et al., 2023). Higher water absorption and swelling capacities and better starch digestibility, potatoes are viable ingredients are supposed as viable choice in a wide array of food applications. Modes of dietary uses of potatoes are dehydrated powders for gravies, soups, cakes, bread, noodles, curries, sausages, beverages, snacks and gluten-free cookies (Osei Tutu et al., 2024; Akhobakoh et al., 2022; Kowalczewski et al., 2022; Whitney & Simsek, 2020).

Plant origin antinutrients such as tannins, phytic acids, oxalates, enzyme inhibitors and saponins interfere with the minerals and adversely affect their bioavailability and absorption(Akonor et al., 2023). These intrinsic toxicants are of serious concern where legumes, cereals, pulses and fresh vegetables are consumed as staple diets, which however; may cause deleterious health effects like micronutrient inadequacies, kidney stones, hepatic issues and neuro problems (Faizal et al., 2023). Pesticides are abundantly used in fruits and vegetables as sustainable means of controlling insects, pests and weeds to overcome the ever-rising plant diseases (Tang et al., 2023). According to recent global statistics, the use of pesticides has exceeded over 4.1 million tons per year, of which herbicides reveal about 71.4 % use, followed by fungicides, insecticides and rodenticides by 10.4 %, 18.2 % and 17 %, respectively (Centanni et al., 2023). Indiscriminative use and over dependence on pesticides to overcome agricultural insects and pests' leads to the accumulation of pesticides in edible food crops, which consequently affects neuro functionalities, reproductive organs, liver functioning, kidney, respiratory system and cancer (Rani et al., 2021). The maximum residue limits (MRL's) of different pesticides including imidacloprid, cypermethrin, bifenthrin, chlorpyrifos and deltamethrin for potatoes have been documented by FAO/WHO, Codex Alimentarius Commission range between 0.01 and 2 ppm (CAC, 2011). Potato tubers are among the vegetables which are considered among the most susceptible food crops towards the attack of insects and pests. In the same sense, potatoes have been listed among the ‘dirty dozen’ fruits and vegetables holding the highest levels of pesticides (Nguyen et al., 2020). Earlier studies report the presence of pyrethroids (deltamethrin and cypermethrin) and organochlorines (γ-chlordane, lindane, heptachlor and dimethachlor) in potatoes beyond their allowed MRL levels (Terfe et al., 2023). Globally, indiscriminate use, weaker legislative controls and dietary exposure to pesticides have raised a number of health challenges in humans (Terfe et al., 2023), including kidney failure, neurotoxicity, obesity, bronchitis, musculoskeletal abnormalities, bronchitis, infertility problems, congenital malformations, endocrine alterations, neurodegenerative issues, neuropsychiatric disorders, genotoxicity, behavioral disorders, liver dysfunction and cancer (Cancino et al., 2023; Panis et al., 2022).

In recent years, scientists have explored new approaches like thermal and non-thermal processing to mitigate the ever increasing burden of intrinsic and extrinsic toxicants in fruits and vegetables to improve their nutritional quality (Waseem, Akhtar, Qamar, et al., 2022). Retrospective studies are evident of employing the thermal, non-thermal, physical, chemical and biological food processing techniques including blanching, boiling, acid soaking, saline soaking, alkaline soaking, freezing, fermentation, frying and drying (Acheampong et al., 2024; Faizal et al., 2023; Tang et al., 2023), peeling, washing, baking and juicing (Nguyen et al., 2020; Terfe et al., 2023) as viable, cost-effective and labor-less techniques to reduce the pesticides and antinutrients burden in vegetables. Recent studies have indicated that microwave heat processing and autoclaving as the most effective thermal techniques in declining antinutrients in vegetables typically attributed to the leaching and rupturing of plant cell walls (Natesh et al., 2017; Samtiya et al., 2020). Available literature have endorsed the great potential of microwave heat processing and blanching as viable techniques in mitigating the loads of antinutrients in vegetables when compared with the various processing methods like soaking and resulted in decline of about 90 % of the antinutrients and pesticides and improved the safety of vegetables for the human consumption (Javed et al., 2024). Likewise, earlier studies have also validated the use of blanching, microwave heating, acid soaking and base soaking to exert significant reduction in intrinsic (antinutrients like phytates, tannins, oxalates and alkaloids) and extrinsic toxicants (i.e., pesticide residues) between 80 and 92 % in vegetables (Waseem et al., 2024).

Plethora of useful information is available on nutritional and anti-nutrient indices of raw potatoes and its food uses. However, earlier studies have identified a gap in the availability of a comparison of detoxification techniques for the efficient detoxification of potatoes and their effects on the physicochemical and technofunctional characteristics of the processed versions of potatoes. Therefore, this study was strategized to investigate the impact of thermal and non-thermal processing to detoxify antinutrients and pesticide residues in potatoes to set maximum allowable limits and to utilize the detoxified PP in the development of unleavened flatbread with better sensory acceptability.

2. Materials and methods

2.1. Procurement of raw materials, chemicals and reagents

Fifteen kilograms of disease, insect and pest-free fresh potatoes were purchased from Dua Enterprises, Agro-Farm, Multan, Pakistan. The potatoes were manually washed with clean drinking water, peeled with a knife, sorted and graded for quality and sliced with a household slicer in the laboratory of the Department of Food Science & Technology, Faculty of Food Science and Nutrition, Bahauddin Zakariya University, Multan, Pakistan. Reagents and chemicals used in nutritional, technofunctional and physicochemical trials were all analytical grade and procured from local distributors of Sigma Chemical Co., Ltd. (St. Louise, MO) and Merck (Darmstadt, Germany). Standards used in the determination of antinutrients including alkaloids, oxalates, tannins and phytates, minerals (Ca, Na, K, Fe and Zn) and pesticide residues (cypermethrin, imidacloprid, bifenthrin, deltamethrin and chlorpyriphos) were purchased from BDH Chemicals Ltd. (Shanghai, China).

2.2. Processing treatments of potatoes

2.2.1. Microwave heat processing and blanching

After preliminary operations potatoes were microwave heat processed at 1.1 kW for 2 min (Waseem, Akhtar, Ahmad, et al., 2022), blanched in clean distilled water at 100 ± 2 °C for 1.5 min. On completion of blanching, the slices were removed from distilled water and pre-dried using absorbent paper.

2.2.2. Acid and alkali soaking

Uniformly sized potatoes were soaked in 2 M hydrochloric acid (HCl) for acid soaking. Contrarily, the slices were soaked in alkaline solutions consisting of 1 % sodium bicarbonate and, a mixture of salt solutions (i.e., 1.5 % and 0.5 % of sodium bicarbonate and sodium carbonate) for a period of 16–18 h (Waseem, Akhtar, Qamar, et al., 2022).

2.3. Raw and processed PP preparation

The protocol of (Akter et al., 2023) was followed to prepare powders from raw and processed potatoes. Uniformly sliced pieces of raw and processed potatoes were evenly laid over the nylon mesh (dimension = 0.186 × 0.186 m2) for cabinet drying (Pamico Tech, Faisalabad, Pakistan) at 45 ± 2 °C, 12–14 h to a moisture content of 8–10 %. Thereafter, dehydrated slices were converted into fine powders (mesh size = 80 mm) using heavy-duty grinder (Pamico Tech, Faisalabad, Pakistan). PP were stored in airtight glass jars at 4–6 ± 2 °C for further analyses.

2.4. Functional properties of raw and processed PP

2.4.1. Bulk density

Bulk densities of PP were estimated in accordance with the protocol as documented by (Buzera et al., 2022). Ten grams of each powder was filled into a 100 mL graduated cylinder and final bulk volume (V) was measured. Bulk density was calculated as:

| (I) |

2.4.2. Rehydration ratio (RR)

PP rehydration ratios were determined as outlined by (Okonkwo et al., 2022). Accurately measured five-gram sample was mixed in 50 mL distilled water for 30 min. Subsequently, filtration was performed using Whatman filter no. 41. Permeates of each sample were weighed and RR was estimated as:

| (II) |

2.4.3. Water solubility index (WSI) and water absorption index (WAI)

WSI and WAI of dehydrated powders were measured in accordance with the protocols as measured by (Castro-Mendoza et al., 2022). Accurately weighed one gram of sample was added into 10 mL distilled water and mixed for 30 min. Subsequently, the mixture was centrifuged (Hermle Z236K, Wehingen, Germany) at 4300 rpm for 20 min. The supernatant was collected in a pre-weighed dish and evaporated using hot air oven (Memmert UNB 200, Munich, Germany) at 105 ± 2 °C for 8 h to obtain constant weight. The results for water solubility index and water absorption index were determined using the following eqs. (III), (IV):

| (III) |

| (IV) |

2.4.4. Swelling power

(Moreno-Ochoa et al., 2023) method was followed to determine the swelling power of each sample. Three grams of each sample was mixed in 30 mL of distilled water in a pre-weighed falcon tube (i.e., 50 mL) to make powder-water slurry and heated in water bath (WNB-29, Memmert, Schwabach, Germany) at 60 °C for 30 min with constant stirring. Falcon tubes containing hot slurry were centrifuged at 1500 rpm for 10 min. Subsequently, supernatants and solid residues were collected and weighed in pre-weighed dishes and falcon tubes, respectively. Swelling powers of all samples were calculated by using equation mentioned hereunder (V):

| (V) |

2.4.5. Hygroscopicity

Hygroscopicity of dehydrated powders were determined as laid down by (Arebo et al., 2023). Two gram of powder sample was kept in desiccator at 25 °C already containing saturated NaCl solution at 70 % relative humidity. After one week, each sample was measured again for weight and hygroscopicity values were expressed as given below.

| (VI) |

2.5. Nutritional composition

Nutritional composition consisting of moisture (No. 925.10), crude ash (No. 923.03), fat (No. 920.85), fiber (No. 32–10) and protein (No. 920.87) contents of raw and processed PP and supplemented unleavened flatbread were estimated as mentioned in standardized methods of Official Methods of Analysis (Latimer, 2019). Whereas carbohydrates and calorie contents were calculated as;

| (VII) |

| (VIII) |

However, mineral elements consisting of Ca, K, Na, Fe and Zn in powder samples were estimated by following the method as mentioned by (Raletsena et al., 2023).

2.6. Antinutrients

2.6.1. Determination of alkaloids

Dehydrated PP were assessed for alkaloid contents as described by (Khan et al., 2019). Five grams of each sample was amalgamated in 10 % ethanol-acetic acid solution (i.e., 100 mL) and were given stay for 4 h and filtered via Whatman filter no. 41 and filtrate was concentrated using water bath. Afterwards, filtrate was mixed with concentrated ammonium hydroxide (NH4OH) to form alkaloid precipitates. The residues were given second filtration and washing using 1 % ammonium hydroxide. Finally, the mixture was oven dried at 60 °C for 30 min to record the alkaloid contents as:

| (IX) |

2.6.2. Determination of oxalates

Two grams of each sample was digested in 190 mL distilled water and 10 mL, 6 M hydrochloric acid in water bath. After digestion, centrifugation was performed at 2000 rpm for 10 min and was concentrated on hot plate to adjust the final volume up to 25 mL. Thereafter, filtration was performed via Whatman filter paper no. 41 to collect the brown colored precipitates. Then, three drops of methyl indicator were added followed by the addition of concentrated ammonia to obtain faint yellowish appearance. Subsequently, 10 mL of 5 % calcium chloride was added with constant stirring to precipitate the oxalates and final filtration was performed. Filtrates were titrated against 0.5 % potassium permanganate until pink colored end point not persisted for 30 s (Abdullahi et al., 2021). Oxalates were measured by formula as mentioned below.

| (X) |

| (XI) |

2.6.3. Determination of tannins

(Khan et al., 2019) protocol was adopted to assess tannin contents in dehydrated powders. Accurately measured 0.5 g of each sample was mixed with 50 mL of distilled water and stirred for 1 h. Thereafter, reaction mixture was filtered and 5 mL supernatant was taken to mix with 2 mL, 0.1 M ferric chloride in a test tube. The absorbance of each sample was measured in 10 min at 395 nm on spectrophotometer (UV–Vis 3000, Darmstadt, Germany). Final concentrations of tannins (mg/100 g) were computed against tannic acid standard curves.

2.6.4. Determination of phytates

(Sharma et al., 2022) method was followed to estimate phytates in PP. About 0.5 g of each sample was digested in 0.2 N hydrochloric acid on hot plate (LMS-1003, Daihan Labtech Co. Ltd., Namyangju, South Korea) for 30 min with persistent stirring and then allowed to stay for 10 min. Afterward, 0.5 mL of each extract was taken in test tube and covered with stopper. Thereafter, one milliliter ferric solution (Conc. i.e., 0.2 g ammonium iron III sulphate mixed with 2 N, HCL reaching to a final volume of 1 L) was added to reaction mixture and heated in water bath for 30 min and cooled to room temperature using ice water. Subsequently, the mixture was centrifuged for 30 min at 3000 rpm and 1 mL of supernatant was thoroughly mixed with 2 mL of 2,2′-bipyridine solution (Conc. i.e., 10 g of 2,2′-bipyridine and 10 mL of thioglycolic acid dissolved to a total volume of 25 mL in distilled water). Sodium phytate-phosphorous standards were prepared for development of standard curves. Absorbance reading of standard, reagent blank and sample was taken at 519 nm using UV–Vis Spectrophotometer. The results for phytates contents were expressed as mg/100 g of phytates.

2.7. Pesticide residues extraction, cleanup and determination

Precisely measured 50 g homogeneous sample of each powder was mixed with 20 g of anhydrous sodium sulfate in 250 mL Erlenmeyer flask. Then, 10 mL saturated sodium chloride and 70 mL ethyl acetate in were added in it and gently mixed at 50 rpm for 1 h in orbital shaker (MaxQ4000, Thermo Scientific TM, Waltham, MA, USA) and filtered using Whatman filter paper no. 1. Filtered samples were stored at 2–4 ± 2 °C in plastic vials. Now, the extracts were passed through anhydrous sodium sulfate column followed by activated charcoal and silica gel 7:5 (w/w) columns adjusted @ 1 mL/min flow rate for cleanup of any color residues. Afterwards, the contents were also eluted for 2nd cleanup using 50 mL of methanol: acetone (7:3 v/v) solution. The eluent was collected in plastic vials and evaporated to a final volume of 1–2 mL using rotary evaporator at 45 °C under vacuum. Thereafter, cleaned up elute was now washed with high performance liquid chromatography (HPLC) grade methanol. Nitrogen gas streaming was also done in controlled conditions of pressure in petri plates for impurities removal (Ashraf et al., 2022).

A protocol by (Hussain et al., 2020) was followed to determine the imidacloprid, bifenthrin, cypermethrin, chlorpyrifos and deltamethrin contents in dehydrated PP using HPLC system installed with UV–visible detector (PerkinElmer, Series 200, Waltham, MS, USA). Twenty microliter sample was injected into analytical C18 column (250 mm × 4.6 mm, I.d.; Supelco, Bellifonte, PA, USA) by an autosampler with Methanol: water (45:55 v/v) as mobile phase. The flow rate of mobile phase was set at 1.5 mL/min with a run time of 20 min for each sample at 254 nm. Standard curves of each pesticide were recorded @ 2, 4, 6, 8 and 10 ppm alongside a reagent blank. Results for pesticide residues were noted in ppm.

2.8. Sensory evaluation of microwaved heat-treated PP supplemented unleavened flatbread

From the premix, fifty grams of dough of each treatment was prepared using whole wheat flour (T0, control), whole wheat flour supplemented with microwave heat-treated PP @ 2.5, 5, 7.5 and 10 % in clean drinking water. The dough was sheeted into unleavened flatbread and both sides of flatbread were evenly baked at 200 ± 5 °C for 2–3 min on griddle. Raw and microwave heat treated PP supplemented unleavened flatbread were tested for sensory acceptability by a nominated panel of sensory experts (n = 15) known for better sensory ability. Sensory experts were already briefed for unbiased assigning of sensory scores for appearance, taste, color, folding ability, texture and overall acceptability of raw and processed unleavened flatbreads in accordance with the 9-Point Hedonic Scale i.e., 1-dislike extremely, to 9-like extremely.

2.9. Statistical analysis

Two independent experiments of each analysis were performed. Results for technofunctional properties, physico-chemical composition, mineral profile, antinutrients and extrinsic toxicants i.e., pesticide residues in raw and microwave heat treated PP samples were expressed as means ± standard error (S.E.). Data obtained from the independent experiments of raw and processed PP and supplemented unleavened flatbreads consisting of sensory evaluation study were statistically analyzed via analysis of variance (ANOVA) on the Statistics 8.1 software (Tallahassee, FL) and the results of this section were also presented as means ± standard error (S.E.). Whereas mean values of all analyses were tested for level of significance by least significance difference (LSD) test at 5 % confidence level.

3. Result and discussion

3.1. Technofunctional properties of raw and processed PP

The data from technofunctional characteristics of dehydrated PP reported significantly (p < 0.05) higher magnitudes of rehydration ratio, water solubility index, water absorption index and hygroscopicity i.e., 6.6, 5.5 %, 6.2 g/g and 7.4 in microwave heat processed PP when compared with control and other processing treatments (Table 1). However, the lowest mean concentrations of rehydration ratio, water solubility index, water absorption index and hygroscopicity were observed in acid soaking, acid soaking, alkali soaking and alkali soaking i.e., 5.9, 5.0 %, 5.5 g/g and 6.9, respectively. A retrospective study by (Rodriguez-Sandoval et al., 2012) suggested comparable findings for the water solubility index, water absorption index and swelling power in PP i.e., 7.5 %, 4.5 g/g, and 4.8 %, respectively. However, slight differences in technofunctional characteristics of vegetables powders on processing could be attributed to variation in processing conditions, morphology, cultivars and nutritional composition of vegetables. Presence of higher water absorption index, water solubility index and swelling power in PP could be linked with the phosphate groups repulsion properties of amylopectin, increased hydration ratios on weakening of bonds among crystalline structures.

Table 1.

Technofunctional properties of raw and processed potato powders.

| Treatments | B.D. (g/mL) | R.R. | WSI (%) | WAI (g/g) | Sp (g/g) | Hg (%) |

|---|---|---|---|---|---|---|

| Raw PP | 0.77 ± 0.04a | 6.40 ± 0.12ab | 5.21 ± 0.02b | 5.94 ± 0.03b | 8.02 ± 0.01a | 7.14 ± 0.03c |

| Microwave Heating | 0.73 ± 0.00b | 6.58 ± 0.01a | 5.47 ± 0.01a | 6.15 ± 0.04a | 7.97 ± 0.01a | 7.42 ± 0.01a |

| Blanching | 0.78 ± 0.01a | 6.00 ± 0.00c | 5.07 ± 0.02c | 5.90 ± 0.07b | 7.83 ± 0.03b | 7.21 ± 0.00c |

| Acid Soaking | 0.69 ± 0.00c | 5.89 ± 0.01c | 5.00 ± 0.00c | 5.58 ± 0.01c | 7.00 ± 0.00c | 7.32 ± 0.01b |

| Alkali Soaking | 0.66 ± 0.01d | 6.15 ± 0.04bc | 5.05 ± 0.04c | 5.47 ± 0.01c | 6.98 ± 0.00c | 6.92 ± 0.01d |

Values are expressed as means ± standard error (n = 2). Mean values having similar lettering in a column are non–significant at p > 0.05; PP = Potato powder.

3.2. Nutritional composition of raw and processed PP

Nutritional composition of raw and processed PP portrayed raw PP to exhibit significantly (p < 0.05) higher contents of ash, protein and fiber contents i.e., 2.5 %, 10.2 % and 6.3 %, respectively. However, on comparing the treatment efficacies of processing treatments, the data elucidated higher contents of ash, protein and dietary fibers in microwave heat processed PP i.e., 3.1 %, 10 % and 5.7 %, respectively (Table 2). Earlier studies by (Das et al., 2018; Whitney & Simsek, 2020; Yang et al., 2023) indicated the presence of comparable magnitudes of ash, protein and dietary fibers in raw PP ranging between 2.5 and 2.8 %, 7.3–8.3 %, 1.6–11 %, respectively. Likewise, other retrospective studies by (Hidayat, 2019) and (Nascimento & Canteri, 2018) reported the positive correlation of blanching on ash, protein and fiber contents of blanched PP which significantly increased from 3.5 to 7 %, 10.4–11.3 % and 1.3–1.8 %, respectively, however, slight decrease in fat contents of blanched PP from 0.7 to 0.6 % was also observed. The increase in protein contents of blanched PP could be attributed to the ceased catalytic activities of proteases and pectinolytic enzymes in blanched PP. Likewise, slight increment in fiber contents of blanched PP could be attributed to the residues including quinones and melanins produced as a result of polyphenol oxidases and peroxidases actions, which are quantified as insoluble fibers (Nascimento & Canteri, 2018). Another study by (Tian et al., 2016) exhibited significant effect of microwave heat processing on PP ash, protein and fiber contents i.e., 3.8 %, 6.6 % and 9.1 %. However, the same study also portrayed significant impact of blanching on ash protein and fiber contents of PP i.e., 4.1 %, 6.6 % and 5.5 %, respectively. Therefore, potatoes are suggested as plausible source of high quality proteins, inorganic elements and health promoting dietary fibers which are known to combat numerous health disorders such as hypertension, obesity, cardiovascular, diabetes, colon cancer, cerebrovascular disorders, constipation, intestinal problems and micronutrient malnutrition (Osei Tutu et al., 2024; Singh et al., 2023; Yang et al., 2023). On comparing the nutritional potential with the staple cereals, potatoes are known to exhibit lower fats and high-quality proteins (biological value = 0.99), which reveals it as a healthy food for humans (Liang et al., 2019).

Table 2.

Nutritional composition of raw and processed potato powders (g/100 g).

| Treatments | Moisture | Ash | Protein | Fat | Fiber | Carbohydrates | Caloric values (Kcal/100 g) |

|---|---|---|---|---|---|---|---|

| Raw PP | 9.38 ± 0.05a | 2.54 ± 0.01cd | 10.22 ± 0.47a | 0.90 ± 0.01a | 6.26 ± 0.04a | 70.69 ± 0.37b | 331. 60 ± 0.28c |

| Microwave Heating | 8.85 ± 0.04b | 3.10 ± 0.07a | 10.00 ± 0.00ab | 0.82 ± 0.01b | 5.76 ± 0.18ab | 71.47 ± 0.14c | 333.24 ± 0.65c |

| Blanching | 8.11 ± 0.08d | 2.73 ± 0.05bc | 9.72 ± 0.04ab | 0.63 ± 0.02c | 5.22 ± 0.16bc | 73.57 ± 0.25b | 338.85 ± 0.67b |

| Acid Soaking | 8.65 ± 0.04c | 2.44 ± 0.02d | 8.40 ± 0.28bc | 0.54 ± 0.01d | 5.55 ± 0.04c | 74.42 ± 0.27b | 337.03 ± 0.18b |

| Alkali Soaking | 7.60 ± 0.03e | 2.88 ± 0.01b | 8.43 ± 0.02c | 0.47 ± 0.02d | 4.11 ± 0.08d | 76.50 ± 0.04b | 343.98 ± 0.26a |

Values are expressed as means ± standard error (n = 2). Mean values having similar lettering in a column are non–significant at p > 0.05; PP = Potato powder.

3.3. Mineral composition of raw and processed PP

The findings on mineral elements of all PP shown significantly higher concentrations of Na, Ca, K, Fe and Zn in raw PP i.e., 50.2 mg/100 g, 62 mg/100 g, 988 mg/100 g, 1.6 mg/100 g and 0.9 mg/100 g, respectively. The Na concentrations varied between 43 and 50 mg/100 g among all thermal and non-thermal processed PP (Table 3). However, Ca and K results showed significantly higher concentration in microwave heat processed and blanched PP i.e., 60.5 mg/100 g and 980.4 mg/100, respectively. Non-significant (p < 0.05) effect of processing was recorded in Fe and Zn concentrations of the processed PP. Dietary intake of micronutrients like potassium, sodium and calcium could be helpful in performing several health functions like maintaining the intracellular fluid, osmoregulation, fluid balance, controlling high blood pressure, bone and growth development and supports protein synthesis (Liang et al., 2019). Retrospective studies have validated the presence of Na, Ca, K, Fe and Zn in potato flours from 29 to 35 mg/100 g, 61–71 mg/100 g, 413–1100 mg/100 g, 2.3–2.5 mg/100 g and 2.1–2.2 mg/100 g, respectively (Liang et al., 2019). Another study by (Rahman et al., 2015) portrayed slight decline in K and Ca contents of PP from 413 to 400 mg/100 g and 10–8 mg/100 g, respectively on blanching potatoes for few minutes.

Table 3.

Mineral contents of raw and processed potato powders (mg/100 g).

| Treatments | Na | Ca | K | Fe | Zn |

|---|---|---|---|---|---|

| Raw PP | 50.16 ± 0.59a | 62.00 ± 0.71a | 987.80 ± 0.57a | 1.60 ± 0.04a | 0.90 ± 0.02a |

| Microwave Heating | 48.09 ± 0.29a | 60.50 ± 0.35ab | 974.50 ± 2.76bc | 1.53 ± 0.02a | 0.80 ± 0.02ab |

| Blanching | 45.17 ± 0.59b | 57.27 ± 1.22bc | 980.35 ± 1.87ab | 1.44 ± 0.03a | 0.75 ± 0.04b |

| Acid Soaking | 44.44 ± 0.64b | 59.50 ± 0.35ab | 968.00 ± 0.71c | 1.50 ± 0.07a | 0.82 ± 0.02ab |

| Alkali Soaking | 43.17 ± 0.12b | 55.30 ± 0.21c | 974.50 ± 0.35bc | 1.51 ± 0.01a | 0.72 ± 0.00b |

Values are expressed as means ± standard error (n = 2). Mean values having similar lettering in a column are non–significant at p > 0.05; PP = Potato powder.

3.4. Decline in antinutrients in raw and processed PP

Antinutrients data of PP revealed the highest load of antinutrients consisting of alkaloids, oxalates, tannins and phytates in raw PP i.e., 59.9 mg/100 g, 31.2 mg/100 g, 91.4 mg/100 g and 44.9 mg/100 g, respectively. Alkaloids, oxalates, tannins and phytates contents of processed PP varied between 13.9 and 28.9 mg/100 g, 6.2–17.4 mg/100 g, 14.9–33.2 mg/100 g and 7.9–10.6 mg/100 g, respectively (Fig. 1). Among processing treatments, microwave heat processing of raw PP reported the highest reduction in alkaloids, oxalates, tannins and phytates contents from 60 to 14 mg/100 g (i.e., 77 % reduction), 31–6 mg/100 g (80 % reduction), 91–15 mg/100 g (84 % reduction) and 45–8 mg/100 g (82 % reduction), respectively. Antinutrients are involved in binding of essential minerals i.e., Ca, Zn and Fe and adversely affect absorption and bioavailability. Tannins decrease protein digestibility on intervening with the pH mechanisms and oxalates are linked with formation of kidney stones. Likewise, dietary intake of alkaloids may cause neurological and gastrointestinal disorders (Thakur et al., 2019). An earlier study by (Lakra & Sehgal, 2009) on the antinutrients of PP based food products revealed the presence of higher magnitudes of tannins and phytates i.e., 173 mg/100 g and 139 mg/100 g, respectively. Likewise, another research by (Irakli et al., 2020), depicted the notable effect of microwave heat processing (i.e., 650 W, 2 min) on the rice bran and resulted in the decline of oxalates by 35 %. An earlier investigation by (Gemed, 2014) showed a significant effect of blanching on Anchote tuber flour wherein the results delineated measurable decline in phytates, oxalates and tannins contents by 15 %, 51 % and 41 %, respectively. In another trial by (Thakur et al., 2019), boiling of foods anticipated 20 % reduction in phytates. The decrease in antinutrients like oxalates on soaking, boiling and cooking could be attributed to higher water solubility losses, leaching, lower heat stability and considerable skin rupturing on heat processing, thermal degeneration and complex formation (Thakur et al., 2019). Moreover, available literature has validated the inactivation of phenylalanine-ammonia-lyase enzyme in heat processing of PP which could be collaborated with the reduction of tannins in thermally processed PP (Palharini et al., 2015). Another study by (Waseem et al., 2024) anticipated significant positive correlation of thermal (microwave heat processing and blanching) and non-thermal (acid and base soaking) techniques to ameliorate / decline the antinutrients (oxalates, phytates, tannins and alkaloids) in leafy green vegetables up to 90 %.

Fig. 1.

Antinutrients of raw and processed forms of potato powder.

3.5. Decline in pesticide residues in raw and processed PP

Results for the residual pesticides of PP portrayed the highest contents of imidacloprid, cypermethrin, bifenthrin, chlorpyrifos and deltamethrin in raw PP i.e., 0.610 ppm, 0.015 ppm, 0.061 ppm, 2.420 ppm and 0.015 ppm, respectively. Contrarily, the residual contents of imidacloprid, cypermethrin, bifenthrin, chlorpyrifos and deltamethrin among processed PP varied between 0.080 and 0.430 ppm, 0.004–0.009 ppm, 0.022–0.037 ppm, 0.500–1.313 ppm, and 0.001–0.009 ppm, respectively (Fig. 2). However, on comparing treatment efficiencies, microwave heat processing reported the highest decline in imidacloprid, cypermethrin, bifenthrin, chlorpyrifos and deltamethrin residues by 87 %, 76 %, 63 %, 79 % and 81 %, respectively. A previous research by (Zhang et al., 2022) elucidated a significant reduction in chlorpyrifos, bifenthrin, malathion, dichlorvos, hexaconazole, kresoxim-methyl, myclobutanil, tebuconazole, triadimefon, cyhalothrin and epoxiconazole contents in fruits and vegetables from 67 to 93 % on microwave heat processing at 700 W for 2 min. A report by (Terfe et al., 2023) showed the washing and boiling to reduce O,P′-DDT pesticide residues by 100 % in potatoes. Also, (Randhawa et al., 2007) portrayed an appreciable reduction in chlorpyriphos contents by 24 % and 53 % on soaking and blanching, respectively. A study of (Kin & Huat, 2010) demonstrated a significant reduction of pesticide residues in potatoes from 44 to 70 %, 30–50 %, and 23–40 % on blanching, alkali soaking and salt soaking, respectively. (Klinhom et al., 2008) showed normal water soaking to alleviate carbaryl and methomyl contents by 88 % and 38 %, respectively. However, the study also delineated the soaking of potatoes in a mixture of salts consisting of NaCl, NaHCO3 and acetic acid decreased methomyl contents by 39 %, 43 % and 43 %, respectively while, lowering the forcarbaryl contents by 91 %, 91 % and 90 %, respectively. The reduction in pesticide contents of processed potatoes could be linked to co-evaporation, thermal degradation and leaching losses (Nguyen et al., 2020). Lower efficacy of acid and alkali soaking in eliminating the pesticides could be linked with the higher skin wax, low temperatures, iconic strengths, hydrolytic rates, volatility and water solubility (Hussnain et al., 2021; Yigit & Velioglu, 2020). Earlier data on detoxification of pesticide residues in vegetables have validated the use of thermal and non-thermal detoxification techniques as viable in mitigating the pesticide residues in vegetables ((Waseem et al., 2024).

Fig. 2.

Pesticide residues of raw and processed forms of potato powder.

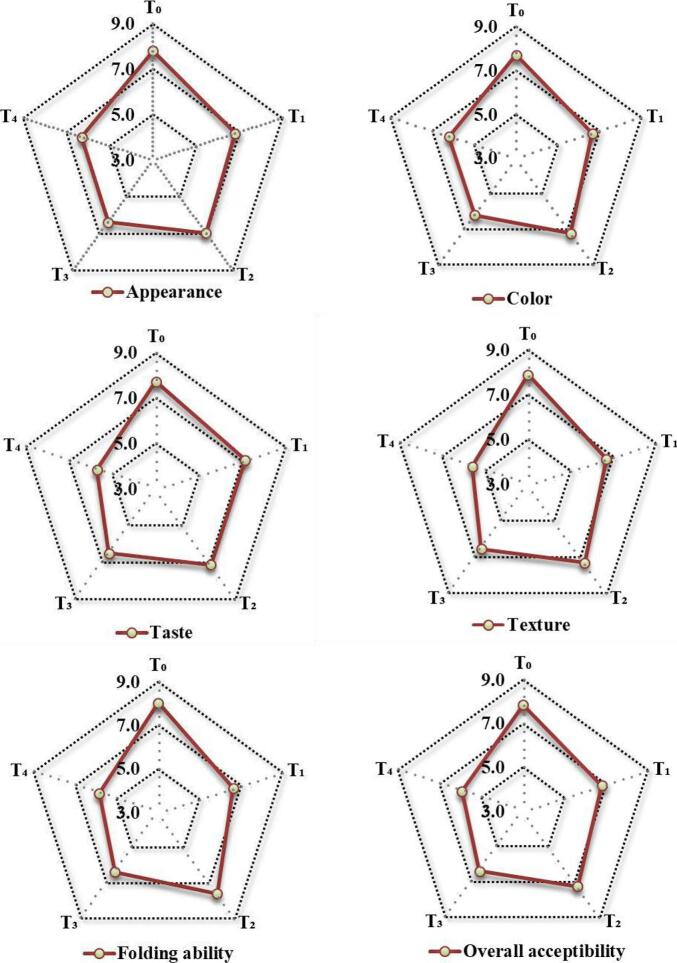

3.6. Sensory qualities of microwave processed potato powder (PPmw) supplemented unleavened flatbreads

Sensory evaluation of microwave heat processed PP supplemented unleavened flatbreads indicated variable impact on the sensory traits. The data reported the highest sensory scores for color, taste, texture and overall acceptability for control i.e., 7.7, 7.7, 7.9 and 7.8, respectively. However, among treatment groups the highest sensory scores were assigned to T2 (i.e., 5 % supplementation) for color (7.3), taste (7.2), texture (7.3) and overall acceptability (7.3) followed by T1 (i.e., 2.5 %), T3 (7.5 %), and T4 (10 %), respectively (Fig. 3). The sensory scores for texture and folding ability showed non-significant (p < 0.05) effect of addition of microwave heat processed PP in the supplemented unleavened flatbreads. The results exhibited the highest sensory acceptability of the finished product ≤5 % supplementation level. Earlier studies by (Das et al., 2018) and (Rahman et al., 2015) have revealed the sensorial acceptability of PP supplemented biscuits <15 % supplementation levels. Likewise, another study by (Chakraborty et al., 2015) depicted better sensory scores for color, flavor and taste of PP supplemented cookies i.e., 6.9, 7.2 and 7.4, respectively and exhibited the best sensory acceptability of the supplemented cookies <10 % replacement. Similarly, a study (Akter et al., 2023) depicted the highest sensory acceptability of dehydrated PP incorporated composite cakes @ 4 % compared with the control. The varied levels of PP sensory acceptability between 4 and 15 % could be attributed to the hydrophilic nature of patatin proteins, weaker gluten networking and hygroscopic nature of PP starches which results in poor sensory scoring of PP value-added food products beyond 15 % supplementation (Jian et al., 2021; Tao et al., 2021). Sensory evaluation results further suggest the use of PP up to 5 % for value addition food products other than baked items like in snack food products, nuggets and confectionery.

Fig. 3.

Sensory qualities of microwave processed potato powder (PPmw) supplemented flatbreads.

4. Conclusions

The key results of this study suggest PP as a plausible carrier of health featuring phytonutrients such as high-quality proteins, dietary fibers and essential minerals, which can contribute significant health ameliorating features when consumed in combination or alone. Contrarily, presence of higher levels of antinutrients and pesticides above the allowable limits in tuber crops results in acute to chronic health maladies and nutritional disparities. This study anticipated all the processing techniques to diminish antinutrients and pesticide loads of PP and consequently improved the overall nutrients of all processed PP. Present study suggests a new finding i.e., the microwave heat processing at 1.1 kW for 2 min not merely improved the nutritional status but also resulted in the highest reduction of antinutrients and pesticide residues in potatoes. In conclusion, the study also refers to microwaved heat processed PP as a natural food supplement that is culturally acceptable, sustainable and cheaper source to ameliorate micronutrient inequalities and protein energy malnutrition. Further, the future perspectives of the PP elucidate its utilization in novel food recipes like gravies, soups and curries with improved technofunctional attributes.

Ethical approval

Informed consent of all participants was obtained before participating in the sensory evaluation of samples. Appropriate protocols for protecting the rights and privacy of all participants were utilized during the execution of the sensory evaluation. All tested samples were safe for consumption. This study is covered by ethical clearance from the Ethics Committee of the College of Basic and Applied Science (ECBAS), University of Ghana, Legon, Accra, Ghana, for the sensory evaluation using trained assessors.

CRediT authorship contribution statement

Muhammad Waseem: Investigation, Formal analysis, Writing – original draft, Methodology. Saeed Akhtar: Conceptualization, Project administration, Visualization, Supervision, Resources. Tariq Ismail: Conceptualization, Supervision, Visualization, Resources. Tawfiq Alsulami: Writing – review & editing, Data curation. Muhammad Qamar: Writing – review & editing, Writing – original draft, Validation, Supervision, Software, Methodology, Investigation, Formal analysis. Dur-e-shahwar Sattar: Writing – review & editing, Investigation. Raheel Suleman: Writing – review & editing, Visualization. Wisha Saeed: Writing – review & editing, Methodology, Investigation. Crossby Osei Tutu: Writing – review & editing, Validation, Software, Resources, Methodology, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors extend their appreciation to Researchers Supporting Project number (RSPD2024R641), King Saud University, Riyadh, Saudi Arabia.

Contributor Information

Muhammad Waseem, Email: muhammadwaseem9499@gmail.com.

Tariq Ismail, Email: tariqismail@bzu.edu.pk.

Tawfiq Alsulami, Email: Talsulami@ksu.edu.sa.

Dur-e-shahwar Sattar, Email: dsattar@bzu.edu.pk.

Raheel Suleman, Email: dr.raheel@bzu.edu.pk.

Crossby Osei Tutu, Email: coseitutu@ug.edu.gh.

Data availability

The data associated with this study are included in article/supp. material/referenced in article.

References

- Abdullahi A.I., Mohammed T., Lalai W., Hassan N.M.Z., Ibrahim Y. Proximate composition, mineral content and anti-nutrient of raw and sun-dried sweet potato peel. Asuu Journal of Science. 2021;8(1):34–47. https://ejournals.asuu.org.ng/archives.php?page=10&type=33 [Google Scholar]

- Acheampong, R., Osei Tutu, C., Amissah, J.G.N., Danquah, A.O., & Saalia, F.K. (2024). Physicochemical and sensory characteristics of a breakfast cereal made from sprouted finger millet-maize composite flour. Cogent Food & Agriculture, 10(1), 2363003, 2024. 10.1080/23311932.2024.2363003. [DOI]

- Akonor, P.T., Osei Tutu, C., Affrifah, N.S., Budu, A.S., & Saalia, F.K. (2023). Effect of Different Drying Techniques on the Functionality and Digestibility of Yellow-Fleshed Cassava Flour and Its Performance in Food Application. Journal of Food Processing and Preservation, 2023. 10.1155/2023/1775604. [DOI]

- Akonor, P.T., Osei Tutu, C., Affrifah, N.S., Budu, A.S., & Saalia, F.K. (2023). Kinetics of β-Carotene Breakdown and Moisture Sorption Behavior of Yellow Cassava Flour during Storage. Journal of Food Processing and Preservation, 2023. 10.1155/2023/2155029. [DOI]

- Akhobakoh M., Zing Zing B., Ngatchou A., Mbassi J.E.G., Nchanji E.B. Potato (Solanum tuberosum L.) flour enriched with date palm fruit (Phoenix dactylifera L.) powder and bean milk for cookies production. Agricultural Sciences. 2022;13(9):973–988. doi: 10.4236/as.2022.139060. [DOI] [Google Scholar]

- Akonor P.T., Osei Tutu C., Arthur W., Adjebeng-Danquah J., Affrifah N.S., Budu A.S., Saalia F.K. Granular structure, physicochemical and rheological characteristics of starch from yellow cassava (Manihot esculenta) genotypes. International Journal of Food Properties. 2022;26(1):259–273. doi: 10.1080/10942912.2022.2161572. [DOI] [Google Scholar]

- Akter M., Anjum N., Roy F., Yasmin S., Sohany M., Mahomud M.S. Effect of drying methods on physicochemical, antioxidant and functional properties of potato peel flour and quality evaluation of potato peel composite cake. Journal of Agriculture and Food Research. 2023;11 doi: 10.1016/j.jafr.2023.100508. [DOI] [Google Scholar]

- Arebo M.A., Feyisa J.D., Tafa K.D., Satheesh N. Optimization of spray-drying parameter for production of better quality orange fleshed sweet potato (Ipomoea batatas L.) powder: Selected physiochemical, morphological, and structural properties. Heliyon. 2023;9(1) doi: 10.1016/j.heliyon.2023.e13078. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ashraf H.N., Walayat N., Saleem M.H., Niaz N., Hafeez A., Atiq M.N.…Ali S. Determination of pesticide residues from grapes procured from different markets using through high performance liquid chromatography (HPLC) Pakistan Journal of Botany. 2022;54(2):737–741. doi: 10.30848/PJB2022-2(19). [DOI] [Google Scholar]

- Buzera A., Gikundi E., Orina I., Sila D. Effect of pretreatments and drying methods on physical and microstructural properties of potato flour. Foods. 2022;11(4):507. doi: 10.3390/foods11040507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- CAC C.A.C. 2011. International food standards. Available online:https://www.fao.org/fao-who-codexalimentarius/codex-texts/dbs/pestres/commodities-detail/en/?c_id=347. In. [Google Scholar]

- Cancino J., Soto K., Tapia J., Muñoz-Quezada M.T., Lucero B., Contreras C., Moreno J. Occupational exposure to pesticides and symptoms of depression in agricultural workers. A systematic review. Environmental Research. 2023;116190 doi: 10.1016/j.envres.2023.116190. [DOI] [PubMed] [Google Scholar]

- Castro-Mendoza M.P., Navarro-Cortez R.O., Hernández-Uribe J.P., Bello-Pérez L.A., Vargas-Torres A. Sweet potato color variety and flour production drying method determine bioactive compound content and functional properties of flour. Journal of Food Processing and Preservation. 2022;46(10) doi: 10.1111/jfpp.16852. [DOI] [Google Scholar]

- Centanni M., Ricci G., De Girolamo A., Romano G., Gentile F. A review of modeling pesticides in freshwaters: Current status, progress achieved and desirable improvements. Environmental Pollution. 2023;316 doi: 10.1016/j.envpol.2022.120553. [DOI] [PubMed] [Google Scholar]

- Chakraborty S., Mazumder S., Banerjee S. Effect of potato powder supplementation and spices addition on physical and sensory properties of cookies. International Journal of Research in Enginerring & Technology. 2015;3:408–416. http://www.ijret.org [Google Scholar]

- Das P.C., Rana M.S., Saifullah M., Islam M.N. Development of composite biscuits supplementing with potato or corn flour. Fundamental and Applied Agriculture. 2018;3(2):453–459. doi: 10.5455/faa.292438. [DOI] [Google Scholar]

- Faizal F., Ahmad N., Yaacob J., Halim-Lim S.A., Rahim M.A. Food processing to reduce antinutrients in plant-based foods. International Food Research Journal. 2023;30(1):25–45. doi: 10.47836/ifrj.30.1.02. [DOI] [Google Scholar]

- FAOSTAT Data of crops production in the world. Data Division. 2021 https://www.fao.org/faostat/en/#data/QCL In. Available online: [Google Scholar]

- Franková H., Musilová J., Árvay J., Harangozo Ľ., Šnirc M., Vollmannová A., Lidiková J., Hegedűsová A., Jaško E. Variability of bioactive substances in potatoes (Solanum tuberosum L.) depending on variety and maturity. Agronomy. 2022;12(6):1454. doi: 10.3390/agronomy12061454. [DOI] [Google Scholar]

- Gemed H. Effects of boiling methods on anti-nutritional factors of Anchote (Coccinia Abyssinica (lam.) Cogn) tubers grown in Western Ethiopia. Food Science and Quality Management. 2014;27:39–40. doi: 10.1080/15538362.2023.21666. [DOI] [Google Scholar]

- Guo S., Wu H., Liu X., Zhao W., Zheng J., Li W. Structural, physicochemical and digestive property changes of potato starch after continuous and repeated dry heat modification and its comparative study. Foods. 2023;12(2):335. doi: 10.3390/foods12020335. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hidayat T. Earth and Environmental Science; IOP Conference Series: 2019. Effect of pre-treatment on the physicochemical characteristics of potato powder dried by drum dryer. [Google Scholar]

- Hussain M., Aftab K., Iqbal M., Ali S., Rizwan M., Alkahtani S., Abdel-Daim M.M. Determination of pesticide residue in brinjal sample using HPTLC and developing a cost-effective method alternative to HPLC. Journal of Chemistry. 2020;2020:1–12. doi: 10.1155/2020/8180320. [DOI] [Google Scholar]

- Hussnain A., Amir R.M., Khan M.A., Ahmad A., Ali S.W., Nadeem M.…Hayat I. Mitigating the impact of organochlorine and pyrethroid residues in fresh and chemically washed spinach. Food Science and Technology. 2021;41:59–64. doi: 10.1590/fst.37019. [DOI] [Google Scholar]

- Irakli M., Lazaridou A., Biliaderis C.G. Comparative evaluation of the nutritional, antinutritional, functional, and bioactivity attributes of rice bran stabilized by different heat treatments. Foods. 2020;10(1):57. doi: 10.3390/foods10010057. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Javed M.R., Ahmad Z., Waseem M., Mehmood T., Hussain A., Adil M.…Abdi G. Effect of microwave heat processing on nutritional, antioxidant, antinutrient, and sensory indices of soy flour enriched functional noodles. Journal of Agriculture and Food Research. 2024;101426 [Google Scholar]

- Jian Y., Cheng L., Yan H., Li Z.-F., Li C.-M., Ban X.-F., Gu Z.-B. Use of two-stage dough mixing process in improving water distribution of dough and qualities of bread made from wheat–potato flour. Journal of Integrative Agriculture. 2021;20(1):300–310. doi: 10.1016/S2095-3119(20)63433-5. [DOI] [Google Scholar]

- Khan W., Subhan S., Shams D.F., Afridi S.G., Ullah R., Shahat A.A., Alqahtani A.S. Antioxidant potential, phytochemicals composition, and metal contents of Datura alba. BioMed Research International. 2019;2019 doi: 10.1155/2019/2403718. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kin C.M., Huat T.G. Headspace solid-phase microextraction for the evaluation of pesticide residue contents in cucumber and strawberry after washing treatment. Food Chemistry. 2010;123(3):760–764. doi: 10.1016/j.foodchem.2010.05.038. [DOI] [Google Scholar]

- Kita A., Bąkowska-Barczak A., Hamouz K., Kułakowska K., Lisińska G. The effect of frying on anthocyanin stability and antioxidant activity of crisps from red-and purple-fleshed potatoes (Solanum tuberosum L.) Journal of Food Composition and Analysis. 2013;32(2):169–175. doi: 10.1016/j.jfca.2013.09.006. [DOI] [Google Scholar]

- Klinhom P., Halee A., Methawiwat S. The effectiveness of household chemicals in residue removal of methomyl and carbaryl pesticides on Chinese-kale. Agriculture and Natural Resources. 2008;42(5):136–143. [Google Scholar]

- Kowalczewski P.Ł., Olejnik A., Świtek S., Bzducha-Wróbel A., Kubiak P., Kujawska M., Lewandowicz G. Bioactive compounds of potato (Solanum tuberosum L.) juice: From industry waste to food and medical applications. Critical Reviews in Plant Sciences. 2022;41(1):52–89. doi: 10.1080/07352689.2022.2057749. [DOI] [Google Scholar]

- Lakra P., Sehgal S. Anti-nutritional content of products developed from potato flour. Nutrition & Food Science. 2009;39(6):636–642. doi: 10.1108/00346650911002968. [DOI] [Google Scholar]

- Latimer J.G. 2019. Official methods of analysis of the Association of Official Analytical Chemists: Official methods of analysis of AOAC international. In: 21st ed., Gaithersburg (MD), USA. [Google Scholar]

- Liang Z., Mu T.-H., Zhang R.-F., Sun Q.-H., Xu Y.-W. Nutritional evaluation of different cultivars of potatoes (Solanum tuberosum L.) from China by grey relational analysis (GRA) and its application in potato steamed bread making. Journal of integrative. Agriculture. 2019;18(1):231–245. doi: 10.1016/S2095-3119(18)62137-9. [DOI] [Google Scholar]

- Mi X., Hao S., Zheng Y., Yang X. Effects of addition of inulin and β-glucan on selected physicochemical and thermal properties of ultrasonic modified potato flour. Journal of Food Processing and Preservation. 2022;46(11) doi: 10.1111/jfpp.17134. [DOI] [Google Scholar]

- Moreno-Ochoa M.F., Calderón De La Barca A.M.A., Cárdenas-López J.L., Robles-Sánchez R.M., Rouzaud-Sández O. Technological properties of orange sweet potato flour intended for functional food products as affected by conventional drying and milling methods. ACS Food Science & Technology. 2023;3(2):283–291. doi: 10.1021/acsfoodscitech.2c00308. [DOI] [Google Scholar]

- Nascimento R.F.D., Canteri M.H.G. Effect of blanching on physicochemical characteristics of potato flour. Horticultura Brasileira. 2018;36:461–465. doi: 10.1590/S0102-053620180406. [DOI] [Google Scholar]

- Natesh H., Abbey L., Asiedu S. An overview of nutritional and antinutritional factors in green leafy vegetables. Horticulture International Journal. 2017;1(2):00011. doi: 10.15406/hij.2017.01.00011. [DOI] [Google Scholar]

- Nguyen T.T., Rosello C., Bélanger R., Ratti C. Fate of residual pesticides in fruit and vegetable waste (FVW) processing. Foods. 2020;9(10):1468. doi: 10.3390/foods9101468. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Okonkwo C.E., Olaniran A.F., Adeyi A.J., Adeyi O., Ojediran J.O., Erinle O.C.…Taiwo A.E. Neural network and adaptive neuro-fuzzy inference system modeling of the hot air-drying process of orange-fleshed sweet potato. Journal of Food Processing and Preservation. 2022;46(3) doi: 10.1111/jfpp.16312. [DOI] [Google Scholar]

- Osei Tutu, C., Amissah, J.G.N., Amissah, J.N., Akonor, P.T., Arthur, W., Budu, A.S., & Saalia, F.K. (2023). Physicochemical and microstructural characteristics of Frafra potato (Solenostemon rotundifolius) starch. International Journal of Food Properties, 26:1, 1624-1635. doi: 10.1080/10942912.2023.2228513.

- Osei Tutu C., Amissah J.G.N., Amissah J.N., Akonor P.T., Budu A.S., Saalia F.K. Physical, chemical, and rheological properties of flour from accessions of Frafra potato (Solenostemon rotundifolius) Journal of Agriculture and Food Research,15. 2024;2024(100974) doi: 10.1016/j.jafr.2024.100974. [DOI] [Google Scholar]

- Osei Tutu C., Amissah J.G.N., Amissah J.N., Akonor P.T., Budu A.S., Saalia F.K. Application of Frafra potato (Solenostemon rotundifolius) flour in the development of gluten-free bread. Heliyon. 2024;10(2) doi: 10.1016/j.heliyon.2024.e24521. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Palharini M.C., Santos C.A., Simionato E.M., Kodawara R.K., Kluge R.A. Dióxido de cloro no controle da microbiota e do escurecimento enzimático de vagem minimamente processada. Horticultura Brasileira. 2015;33:181–188. doi: 10.1590/S0102-053620150000200008. [DOI] [Google Scholar]

- Panis C., Kawassaki A.C.B., Crestani A.P.J., Pascotto C.R., Bortoloti D.S., Vicentini G.E.…Vieira V.K. Evidence on human exposure to pesticides and the occurrence of health hazards in the Brazilian population: a systematic review. Frontiers in Public Health. 2022;9 doi: 10.3389/fpubh.2021.787438. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rahman M.A., Ali M.A., Hasan S.K., Sarker M. Effects of peeling methods on mineral content of potato and development of potato based biscuit. International Journal of Nutrition and Food Sciences. 2015;4(6):669. http://www.sciencepg.com/journal/ijnfs. [Google Scholar]

- Raletsena M.V., Munyai R., Mongalo N.I. Accumulation of heavy metals, yield and nutritional composition of potato (Solanum tuberosum L.) cultivars irrigated with Fly-ash-treated acid mine drainage. Sustainability. 2023;15(2):1327. doi: 10.3390/su15021327. [DOI] [Google Scholar]

- Randhawa M.A., Anjum F.M., Ahmed A., Randhawa M.S. Field incurred chlorpyrifos and 3, 5, 6-trichloro-2-pyridinol residues in fresh and processed vegetables. Food Chemistry. 2007;103(3):1016–1023. doi: 10.1016/j.foodchem.2006.10.001. [DOI] [Google Scholar]

- Rani L., Thapa K., Kanojia N., Sharma N., Singh S., Grewal A.S.…Kaushal J. An extensive review on the consequences of chemical pesticides on human health and environment. Journal of Cleaner Production. 2021;283 doi: 10.1016/j.jclepro.2020.124657. [DOI] [Google Scholar]

- Rodriguez-Sandoval E., Sandoval G., Cortes-Rodríguez M. Effect of quinoa and potato flours on the thermomechanical and breadmaking properties ofwheat flour. Brazilian Journal of Chemical Engineering. 2012;29:503–510. doi: 10.1590/S0104-66322012000300007. [DOI] [Google Scholar]

- Samtiya M., Aluko R.E., Dhewa T. Plant food anti-nutritional factors and their reduction strategies: An overview. Food Production, Processing and Nutrition. 2020;2:1–14. doi: 10.1186/s43014-020-0020-5. [DOI] [Google Scholar]

- Sharma S., Kataria A., Singh B. Effect of thermal processing on the bioactive compounds, antioxidative, antinutritional and functional characteristics of quinoa (Chenopodium quinoa) Lebensmittel-Wissenschaft & Technologie. 2022;160 doi: 10.1016/j.lwt.2022.113256. [DOI] [Google Scholar]

- Singh L., Kaur S., Aggarwal P., Kaur N. Characterisation of industrial potato waste for suitability in food applications. International Journal of Food Science & Technology. 2023;58(5):2686–2694. doi: 10.1111/ijfs.16023. [DOI] [Google Scholar]

- Sun Q., Du M., Navarre D.A., Zhu M. Effect of cooking methods on bioactivity of polyphenols in purple potatoes. Antioxidants. 2021;10(8):1176. doi: 10.3390/antiox10081176. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tang T., Zhang M., Ju R., Mujumdar A.S., Yu D. Novel drying and pretreatment methods for control of pesticide residues in fruits and vegetables: A review. Drying Technology. 2023;41(2):151–171. doi: 10.1080/07373937.2022.2041029. [DOI] [Google Scholar]

- Tao C., Shi W., Bai Q., Wang K. Effects of potato powder on wheat dough properties and fresh noodles quality. CyTA-Journal of Food. 2021;19(1):588–595. doi: 10.1080/19476337.2021.1936192. [DOI] [Google Scholar]

- Terfe A., Mekonen S., Jemal T. Pesticide residues and effect of household processing in commonly consumed vegetables in Jimma zone, Southwest Ethiopia. Journal of Environmental and Public Health. 2023;2023 doi: 10.1155/2023/7503426. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Thakur A., Sharma V., Thakur A. An overview of anti-nutritional factors in food. International Journal of Chemical Studies. 2019;7(1):2472–2479. doi: 10.22271/chemi. [DOI] [Google Scholar]

- Tian J., Chen J., Lv F., Chen S., Chen J., Liu D., Ye X. Domestic cooking methods affect the phytochemical composition and antioxidant activity of purple-fleshed potatoes. Food Chemistry. 2016;197:1264–1270. doi: 10.1016/j.foodchem.2015.11.049. [DOI] [PubMed] [Google Scholar]

- Waseem M., Akhtar S., Ahmad N., Ismail T., Lazarte C.E., Hussain M., Manzoor M.F. Effect of microwave heat processing on nutritional indices, antinutrients, and sensory attributes of potato powder-supplemented flatbread. Journal of Food Quality. 2022;2022 doi: 10.1155/2022/2103884. [DOI] [Google Scholar]

- Waseem M., Akhtar S., Mehmood T., Qamar M., Saeed W., Younis M., Perveen S., Ismail T., Esatbeyoglu T. Nutritional, safety and sensory quality evaluation of unleavened flatbread supplemented with thermal and non-thermal processed spinach powder. Journal of Agriculture and Food Research. 2024;16 [Google Scholar]

- Waseem M., Akhtar S., Qamar M., Saeed W., Ismail T., Esatbeyoglu T. Effect of thermal and non-thermal processing on nutritional, functional, safety characteristics and sensory quality of white cabbage powder. Foods. 2022;11(23):3802. doi: 10.1155/2022/2103884. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Whitney K., Simsek S. Potato flour as a functional ingredient in bread: Evaluation of bread quality and starch characteristics. International Journal of Food Science & Technology. 2020;55(12):3639–3649. doi: 10.1111/ijfs.14698. [DOI] [Google Scholar]

- Yang L., Zhang H., Huang B., Hao S., Li S., Li P., Yu H. Studying the role of potato powder on the physicochemical properties and dough characteristics of wheat flour. Gels. 2023;9(2):73. doi: 10.3390/gels9020073. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yigit N., Velioglu Y.S. Effects of processing and storage on pesticide residues in foods. Critical Reviews in Food Science and Nutrition. 2020;60(21):3622–3641. doi: 10.1080/10408398.2019.1702501. [DOI] [PubMed] [Google Scholar]

- Zhang A.-A., Sutar P.P., Bian Q., Fang X.-M., Ni J.-B., Xiao H.-W. Pesticide residue elimination for fruits and vegetables: The mechanisms, applications, and future trends of thermal and non-thermal technologies. Journal of Future Foods. 2022;2(3):223–240. doi: 10.1016/j.jfutfo.2022.06.004. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data associated with this study are included in article/supp. material/referenced in article.