Abstract

Incorporating an illumination optimization plan into the worker safety management process in industrials is essential since the quality of workplace illumination has a significant impact on workers' well-being. The purpose of this study was to optimize illumination conditions in industrial workspaces using light-emitting diode (LED) technology with a color temperature of 6500 K and a CRI of 85 %. To accomplish this, the DIALux illumination simulation tool was utilized. It was validated using measured illumination data from a lux meter (ST-1300 model 1308). Four factors—the number of luminaires, the effective height of the luminaires, the illumination technology, and the light loss factor—were applied to configure sixteen simulation scenarios. Subsequently, eleven quadratic polynomial equations were proposed for estimating the changes in the average illumination in eleven workplaces using the multiple regression analysis technique on the simulatively prepared dataset. The final step was assessing the desirability degree of the suitable illumination scenario. It was discovered that the DIALux software's illumination simulation error percentage fell within an acceptable range. The illumination technology factor had the greatest impact on the average illumination of workplaces. The most impactful interaction terms of the factors were illumination technology and the number of luminaires. For every workplace, the optimized illumination's desirability degree was expected to be more than 0.9. The proposed approach yields promising results and can be a valuable tool for improving the illumination conditions of workers in industries.

Keywords: Illumination simulation, DIALux, Worker's wellbeing, Light-emitting diode (LED), Desirability degree, Design-Expert, Industrial artificial illumination

1. Introduction

Industrial workplaces are defined as a combination of all types of elements and surrounding factors that can significantly influence the mental health, performance, safety, and productivity of workers [[1], [2], [3]]. A variety of physical, chemical, and ergonomic factors are constituent elements of industrial workplaces [[4], [5], [6]]. Typical physical factors in any industrial workplace environment include humidity and temperature, acoustics, illumination, and facility layout [[7], [8], [9]]. In the meantime, illumination is recognized as one of the essential components of every industrial workplace's physical attributes [10]. Illumination is described as the application of light to achieve visibility in space, objects, or surrounding areas [11]. Because employees spend so much time at work, the quality of illumination in industrials can have a big impact on their productivity, health, and general well-being [12]. The importance of studying how illumination affects the human body in enclosed environments has increased because artificial illumination is sometimes the only or main illuminative source in industrial workplaces [13].

When it comes to addressing the sustainability of industrial settings, optimizing the illuminative system is seen as a crucial component [14]. Industrial illumination designs frequently emphasize high degrees of danger, low visual features, and energy efficiency [15]. The creative method for efficiently optimizing illumination in industrial settings necessitates knowledge of numerous engineering specialties, including ergonomics, safety engineering, and illumination architecture fundamentals [16]. Better light production, less power consumption, and a longer useable lifetime are characteristics of the best illuminative systems for industrial applications [17]. This helps us understand how to make the artificial illuminative system work at its best. In fact, the main function of illumination is to improve worker vision, and the perception, mental health, and emotional condition of employees can all be impacted by well-designed illumination [18]. Visual relaxation is one of the key components used to evaluate the illuminative system's quality [19]. A regular distribution of good color and luminance is essential for reasonable visual relaxation. This advancement in technology enables us to create an illuminative system that makes sense and is healthy [20].

Developing countries are regarded as the major producers of ceramics [21]. This industrial sector is constantly growing, giving an increasing number of people access to employment opportunities. This industry is facing some difficulties not guaranteeing a high-quality work environment, notwithstanding the industrial milieu's tremendous growth [22]. The workspace's illumination has been the subject of discussion lately in this industrial sector [23]. The illumination setup is very conducive to the comfort, productivity, and visual perfection of the workforce [24]. In order to give workers the performance they need when performing visually demanding tasks, it is necessary to ensure that there is enough illumination [17]. Numerous illumination schemes are employed in the ceramic industry. For many reasons, artificial illuminative systems that offer illumination in the ceramic industry devoid of natural sunlight have not proven to be viable. There is no natural ventilation in these areas, and the interior spaces are not exposed to solar radiation's components [22]. In such conditions, the links between the industry's internal and external components are broken. Workers' visual power gradually diminishes with time. This is exacerbated by inadequate illumination. In these industries, sustainable illumination is typically nonexistent. These sectors of the economy are constantly risky and prone to mishaps [25]. The ceramics industries are sites of intricate and delicate labor, requiring workers to perform visually for a variety of jobs, including measuring, fitting, adjusting, and general work of all kinds [22]. Due to their impaired vision, employees performing under inadequate illumination conditions have a detrimental effect on their performance. Visual pain and other characteristics are common indicators of visual comfort in this industry. Prolonged visual pain might have an impact on the output and performance of the workers. Given that workers in the industry spend 46 h a week on average in factories, it is critical to create a productive and healthy work environment. Inadequate illumination increases all of these dangers in settings.

There is no proof that illumination conditions are optimized, even in Iran, where the ceramic industry is growing. A better grasp of particular comfort needs and requirements can be achieved by illumination simulation and design employing statistical and specialist tools. Statistical models have been widely applied to optimize circumstances in a variety of fields [26,27]. This method promotes optimization, enhances performance, and guarantees that illuminative systems are in line with the changing needs and difficulties of the contemporary world. Statistical models can be a useful guide when discussing illumination design and how to improve working conditions for workers in the ceramics industry as well as other industries. Using statistical models in the illumination design also makes it possible for stakeholders to run scenario tests and virtual simulations [27,28]. These models, when combined with illumination design tools, can demonstrate the extent to which illumination is desirable for employee well-being and provide information for design and control decisions for environmental systems [26]. Prior to implementation, stakeholders can assess the effects of design adjustments, illumination methods, and the integration of new technologies in order to lower the risks involved with system alterations and make well-informed decisions [28]. Based on the aforementioned problems, our research, and consideration of international standards, it is clear that the illuminative system design for the ceramics industry is inadequate, necessitating the introduction of a different scheme that meets standard requirements for visual comfort. In summary, this study describes the illumination environment of the ceramic industry. The DIALux software is used in this study to simulate and create the illuminative system in workplaces. For this purpose, DIALux software is validated with data measured in workplaces. Prediction models to evaluate the influencing factors on the illumination in the workplace environment are developed. The design, analysis, and optimization of the illumination in workspaces are made possible by these models, which offered a theoretical foundation.

2. Literature review

2.1. Current developments in simulation-based workplace illumination research and the benefits of using a simulation-based approach for designing workplace illuminative systems

One way to attain the key to sustainability in workplace illumination design is through the application of simulation and optimization tools [29]. Illumination designers are concerned with achieving proper illumination levels within the space. Over the last ten years, computer simulation has become a viable method for managing intricate engineering systems such as industrial illumination optimization [24]. This method can enhance workplace safety, improve environmental functions and design, and develop adaptable environments that change their use based on the sort of activity being performed [30]. The word "simulation" in illumination refers to a more comprehensive idea of illumination design that computes illumination performance metrics internally through simulation [31]. A computer model is a representation of the main features or operations of a chosen process or physical system. Because of the strict requirements for accurately simulating the real world and the intricacy of the requirements for many users in related sectors, the application of illumination simulation is difficult [32]. In addition to enabling integration and compatibility of the design processes with other simulation techniques, simulations offer a number of advantages that can improve rapid and intelligent ways to compete with sophisticated outputs [33]. Along with a host of other benefits, it can provide researchers with quicker and more efficient means of comparing more complicated data sets than they otherwise would have. Researchers have employed several simulation methods in various studies to attain sustainable illumination in both industrial and non-industrial settings. They improved the computation and depiction of light falling over arbitrary volumes by developing computer algorithms [34]. Single tools and, in some circumstances, the combination of two simulation tools were employed by researchers to simulate illumination in these studies. The most popular simulation programs that were used alone in the studies include Daylight Simulation (Day SIM) [35], C Language Integrated Production System (CLIPS) [36], Energy Plus [37], MATLAB (Matrix Laboratory) [38], MATLAB-GUI (Graphical User Interface) [39], JAVA, and Laboratory Virtual Instrument Engineering Workbench (LabVIEW) [24]. The simulation output might be retrieved as real-world-like pictures or as numerical data [40]. Section 2 provides an overview of the development of illumination simulation tools and the research conducted on these tools. This section aids in locating systemic discrepancies between simulation tools and the desired values that designers aim to achieve through their creations.

2.2. Current simulation tools

In an effort to create tools that are more precise, quick, and well-suited for illumination simulation and design, academics have created a number of tools over time. A comparative study of tool functions and simulation results is nevertheless necessary, especially for researchers and engineers who need to select the best tool for the job at hand in order to produce correct and timely findings. The tool selected may vary based on the work involved. Specifically, the programs utilized in building science for illumination simulation will be covered in this section. The ensuing subsections provide a succinct overview of each tool and its operation. Table 1 provides a summary of each simulation tool's benefits and drawbacks.

Table 1.

A summary of the main benefits and drawbacks of illumination simulation programs.

| Software | Benefits | Drawbacks | Reference |

|---|---|---|---|

| TracePro | It can create intricate illumination layouts because of its effective illumination design. It has predetermined optical characteristics, including fluorescence, bulk scatter, surface characteristics, and materials (plastic, optical glass, and infrared materials). It has a library of commercially available lenses and filters. Iterative analysis and optimization with Macro language. Optimization. |

High cost due to substantial licensing or subscription fees. Complexity and training requirements. Limited compatibility with other illumination systems. A powerful computer may be needed to run TracPro's sophisticated automation and visualization functions, which could result in extra hardware expenses. Limitations in Pre-Defined Property Data |

[41] |

| AGi32 | Accurate illumination calculations for illuminance, luminance, and daylighting. Realistic rendering and visualization. It supports a wide range of photometric file formats (like IES and Eulumdat). Compliance and standards, e.g., IES and CIE. |

Its extensive features and complex interface. It's premium software with a substantial licensing fee. Although the rendering feature is beneficial, high-quality visualization can be time-consuming. It does not account for any spectral properties of the illuminative source or the surface reflectance. |

[49] |

| Velux | It has specialized in daylight analysis. User-Friendly Interface. It offers high-quality 3D renderings that provide realistic representations of daylight's impact. Supports multiple file formats. It's free to download and use. |

It lacks advanced tools for artificial illumination design. Compared to more powerful illumination simulation programs like DIALux or AGi32, which provide a more in-depth understanding of illuminance, glare, and luminance, its analysis capabilities are comparatively restricted. It's ideal for daylight studies in simple interior spaces. |

[50] |

| Relux | It offers robust simulation capabilities for both artificial and daylighting. It is designed to comply with international illumination standards (such as EN 12464). It supports integration with Building Information Modeling (BIM) and CAD software. |

Requiring a powerful system for smooth performance. Its visualization and rendering capabilities may not be as visually realistic as some other software. |

[51] |

| Raywiz | File format for a script-based system that allows for a great deal of user design flexibility. It features quick simulation, optimized code for big systems, and a DataView for a variety of analytics. A single calculation can be used to analyze both photometric and radiometric systems. Reduces the design time by offering non-linear optimization functions. Perform large automatic repetitive calculations through ∗.rbt files. |

Raywiz may be less comprehensive for certain applications, such as large-scale outdoor or street illumination projects, where other software like DIALux or AGi32 might be more suitable. It may lack certain advanced features, such as extensive daylighting simulations or emergency illumination compliance tools. It can be costly, making it less accessible for smaller firms or individual designers. |

[44] |

| DIALux | Simulate natural and artificial illumination in various environments. Giving users access to a vast library of illumination products. Users easily find the right fixtures to match their design needs in a residential space, an office, or a public area. It has features such as daylight simulation, energy consumption calculations, and the ability to generate detailed reports. Since it is a free tool, small enterprises, independent designers, and students can all use it. |

Although it offers a wide fixture library, the ability to import custom models or create completely unique illumination designs can be limited. It just computes overall photometric quantities without taking into account the radiation's spectral distribution. It is therefore purposefully set aside for the evaluation of non-visual impacts. The software merely takes into account the surfaces' ability to change the illumination levels based on their overall reflectance. |

[31] |

2.2.1. TracePro

A commercial illumination simulation software package called TracePro that works in non-sequential mode is routinely used for the design and analysis of optical instruments, UV disinfection systems, light guides, tissue optics, LED optics, and LIDAR. Since 1994, the program has been continuously developed by Lambda Research Corporation, located in Littleton, Massachusetts, USA, with funding from NASA's SBIR program. Although it is a general-purpose optical CAD, illumination simulations for commercial and architectural use are its primary uses. Compared to freeware or home-made software solutions, TracePro offers certain advantages because it is a commercial software suite. TracePro is a complete and reliable macrolanguage that solves a wide range of novel illumination design challenges by combining Monte Carlo ray tracing, analysis, CAD import/export, and optimization techniques. It makes use of cutting-edge graphic features and incorporates a complex model to account for the interaction of surfaces with light radiation [41].

2.2.2. AGi32

AGI32 is a computational program that can be used to compute incident direct or reflected light numerically, point-by-point, on any real or imaginary plane. AGi32 is developed and maintained by Lighting Analysts, Inc., a company specializing in illumination design software and solutions. The software offers rapid, high-quality rendering for nearly any interior or outdoor scenario, including daylighting, together with thorough illumination calculations and ease of modeling [26]. It is also used to anticipate the illumination performance of electric luminaires and/or daylight in a simulated environment. Nonetheless, importing and exporting DXF (Drawing Exchange Format) or DWG (AutoCAD native format) files from CAD software is a typical method of input and output in AGi32. Despite being primarily a calculating tool, AGi32 can also be used to visualize the illumination design without producing any numerical results. Above all, AGi32 is a tool for precise photometric prediction calculations. A technical instrument capable of calculating illumination in any circumstance, aiding in the positioning and direction of luminaires, and verifying compliance with numerous illumination standards. AGi32 becomes a mock-up substitute that can save time and money by generating a virtual model of a proposed design, allowing outcomes to be readily seen for the duration of the project [42].

2.2.3. Velux

Velux is a potentially full suite used by easy-phase designers for illumination simulation. Velux is a tool for early-stage design. Without consulting the engineer, architects utilize this tool to assess the building's thermal performance. Gives the user access to a collection of prefabricated 3D objects. Luxion and the Velux company developed the Velux daylight visualizer for reenactment programming. In addition, the program facilitates the simulation of different daylighting conditions, which aids in the development of daylight strategies. It is a dependable simulation and visualization tool set for modeling daylighting. To help with model geometry flexibility, this modeling tool offers the ability to import CAD files. The daylight factor under 16 sky types is calculated by the Velux daylight visualizer in accordance with the CIE standard general sky. Images and numerical values were produced as the simulation's output. Both inexperienced and seasoned designers are drawn to this program because of its user-friendly interface and efficient workflow. The key criterion for Velux energy is the amount of energy used for illumination, ventilation, heating, and air conditioning. This is because these activities have an impact on the indoor environment [40].

2.2.4. Relux

Developed in Switzerland by Relux Informatik AG, Relux Suite is freeware backed by several luminaire, sensor, and bulb manufacturers. The visual design components of a building, such as the materials, furnishings, and color, can be recreated using this straightforward but practical illumination simulation tool. It is possible to simulate artificial illumination and daylighting using this helpful graphical tool. As part of IEA SHC Task 31, two illumination simulation programs were validated in 2006 under thirty-two different situations. One illumination simulation tool, Relux, produced results that, in the majority of test scenarios, agreed well with the analytical estimate. Additionally, Relux's ability to integrate with databases of illumination makers and be readily imported into simulations is another appealing feature [43].

2.2.5. Raywiz

Ray & Wave Optics Wizard is shortened to Raywiz. This program was developed by Inside Optics Co., Ltd. Raywiz is frequently used for interior and architectural illumination applications. It is well-known for its visualization skills and can be a helpful tool for engineers, architects, and lighting designers. Like other ray-tracing programs, it computes luminance and luminous data, as well as radiance data, including color mixing and Moiré [44].

2.2.6. DIALux

One of the most popular programs used by designers of illumination is DIALux. This program was developed by the DIAL company. Since the program in question is free, its pricing is by far its greatest benefit [30]. The design process is facilitated by this software's extremely user-friendly environment. Furthermore, it offers crucial information regarding the nature of the intended illumination, including crucial illuminative system parameters. The most recent software platform has the ability to assign illumination from a variety of global manufacturers, including Osram, Panasonic, Philips, LG Electronics, and others. It enables designers to confirm that the computed values for illumination, Unified Glare Rating (UGR), and uniformity meet the requirements of the National Standards. DIALux provides illumination designers with easy access to illumination analysis through the implementation of fast, accurate, and simple analysis [45]. It uses the radiosity method to determine how much illumination is exchanged between surfaces and illuminative sources. This technique divides the space into meshes, which are regarded as Lambertian reflectors [46]. In DIALux, users can change the luminaire definition's parameters, such as the mounting height, luminous flux output, color, and dimension of the light. The comparative analysis reveals that DIALux has a greater daylight deviation percentage than RELux. The calculation of the necessary number of luminaires for a given space is made easier with the help of DIALux and Velux. The operation's intricacy makes it more useful for research. Compared to other illumination applications, this one has a number of benefits, including alerts to meet minimum values, simultaneous visualization modeling, compliance with EN 12464-2, and a transparent spreadsheet for summarizing results [30]. Sun et al. designed and simulated several correlated color temperatures, illuminance standards, and color rendering indices for residential situations using the LightTools and DIALux tools [33]. Using the most widely used illumination design support software, DIAUX and RELUX, Pawlak assessed the accuracy of the modeling of escape route illumination installations as well as any potential inaccuracies related to the emergency escape illumination's illuminance measurement [47]. Guerry et al. used MATLAB software in conjunction with DIALux to create an optimal illuminative system [48]. The DIALux program is used in references like Mangkuto, Meshkova, and Budak in order to validate the illuminative system [31,32]. With reference to Dupláková et al., the writers talked about how well DIALux software handled the illuminative systems in the workspace [34].

2.3. Regression analysis

Finding the relationship between the dependent and independent variables is possible through the process of regression models [52]. Simple linear regression is used for prediction with only one factor. Multi-variable or non-linear regression is used when the predictions are more complicated and involve multiple factors [53]. The proper implementation process must be employed for complex systems, such as predicting a building's illumination intensity, when multiple variables enter the computation. Therefore, it is evident that multiple regression analysis is a prominent and practical statistical technique for explaining the connections between different design parameters and illumination quality and energy indicators [52]. During the literature review, multiple regression analysis was used to predict changes in indoor illuminance parameters exclusively and to directly estimate outdoor illuminance parameters and illumination installation energy efficiency. Jo et al. used linear regression to estimate interior daylight illumination while controlling for daylight-related illumination using straightforward observations [54]. Belany et al. performed multiple regression analysis to propound a model that could be utilized to compute predicting energy consumption in buildings and systems [55]. In their study, Fumon and Biswas examined various regression analysis techniques and how they are used to forecast electricity use. They explained the process of using linear regression analysis to forecast building energy usage [53]. Additionally, the regression models have also been applied outdoors in other studies. In order to ensure maximum energy efficiency, Peña-García et al. conducted a simulation of road illumination for both single-sided and double-sided siting of high-pressure sodium (HPS) vapor (70 W, 100 W, and 150 W), high-pressure mercury (HPM) vapor (125 W), and metal halide (MH, 150 W) luminaires in DIALux. They also proposed general equations for illumination design based on linear regression and presented empirical relationships between energy efficiency and overall uniformity of illuminance [27]. Using multiple regression analysis, Rabaza et al. developed a model with two equations that could be used to calculate the average road surface illuminance (Eav) and overall uniformity of illuminance. This model could be used for quick illumination project planning or verification [56]. For both HPS and LED luminaire-based road illumination systems, Roy et al. proposed a multiple regression-based model with six equations. They also investigated the luminaire power rating—road surface average illuminance characteristics for geometric configurations that are often used [57]. In order to estimate road surface average luminance with respect to a standard observer position, Bhattacharya et al. first proposed a multiple regression-based model. They then expanded their model to include overall uniformity of luminance and energy efficiency of illumination installations for both HPS (between 130 and 465 W) and LED (between 40 and 250 W) luminaire-based road illumination systems [58]. Wang et al. investigated the impact of several explanatory variables on driving safety in the setting of tunnel illumination using multiple regression analysis based on the ordinary least squares methodology [59]. In these studies, the Excel Data Analysis package's "regression function" was used to create the polynomial regression. Excel is chosen because of its simplicity and widespread distribution throughout the world. However, in these investigations, the scenario setup was not presented as a test plan using specialized tools like Design Expert. Illumination simulation programs or experimental data can be used to bridge the information gap and perform the best simulation by utilizing statistical experimental design packages. By creating experimental scenarios for illumination optimization, designers and engineers can methodically examine how various factors affect illumination performance, find optimal configurations, and adjust illuminative systems to satisfy particular needs like energy efficiency, visual comfort, and aesthetic appeal. Using experimental design tools also makes it possible to consider additional aspects that effect illumination, whether indoors or outside. This can be used to build more complex regression models that predict the optimal illumination intensity.

3. Methodology

This study examined the illumination conditions at a ceramic industry located in the Yazd area of Iran. The two parts of this study's methodology are measurements and simulations carried out in different environments where workers have direct contact with the ceramic production process. Fig. 1 presents the process in detail.

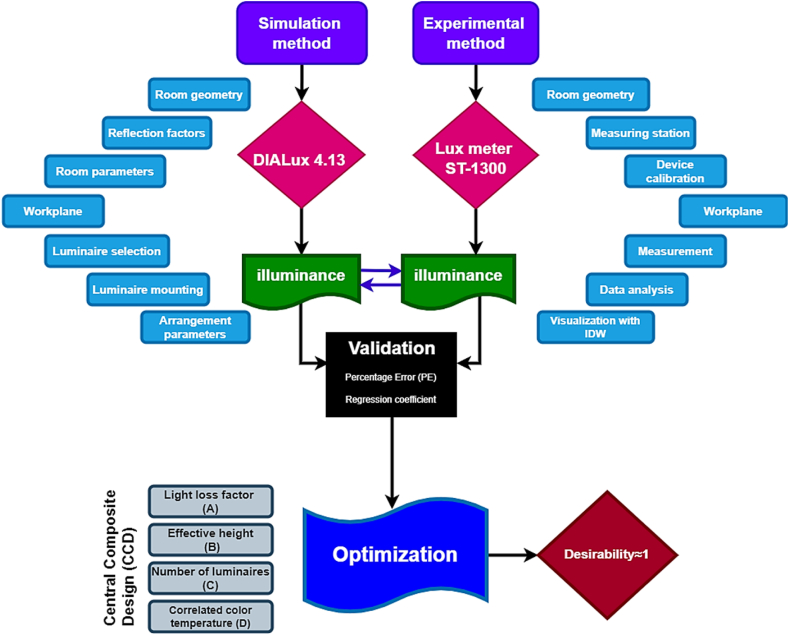

Fig. 1.

Overview of the research methodology.

3.1. General characteristics of the ceramic industry

The dimensions of the ceramic industry that is set up for the study are as follows: 982 m × 351 m × 11 m. As depicted in Fig. 2, the ceramic industry can be studied in eleven separate workplaces. The dimensions of each workplace are presented in Table 1. These workplaces' names are listed below with their respective abbreviations: spray-ballmilling-1 (SBM1); spray-ballmilling-2 (SBM2); press-dryer-1 (PD1); press-dryer-2 (PD2); glazing (G); glazing line-1 (GL1); glazing line-2 (GL2); furnace-1 (F1); furnace-2 (F2); squaring and packaging-1 (PS1); and squaring and packaging-2 (PS2). Each of the workplaces is furnished with apparatus and support tables that served as instruments for the ceramic manufacturing machinery. The windows regulate the amount of daylight that enters each workplace. The tables are used for activity monitoring and were located beneath the windows. It is possible to see surfaces with varying hues and degrees of light reflection. The chocolate-brown floors, pale-yellow hue walls, and silver-gray shed with an insulation ceiling are present in all workplaces. This industry has extremely inadequate ventilation. The average concentration of inhalable dust in this industry is reported to be 4.06 mg/m3 based on previous research [22]. However, the technologies used for illumination installation are impacted by inadequate ventilation and a lack of dust collection equipment. There have been reports of typical temperatures as high as 48 °C in certain workplaces, including F1, F2, PD1, and PD2. This reduces the useable lifespan of the illuminative system, especially for compact fluorescents. Reports state that there are 189 workers spread across all locations. These employees all work three shifts. SP1, SP2, GL1, and GL2 are the workplaces with the highest employee counts. Nonetheless, inadequate illumination has been cited as the primary cause of the greatest number of workplace accidents in these workplaces.

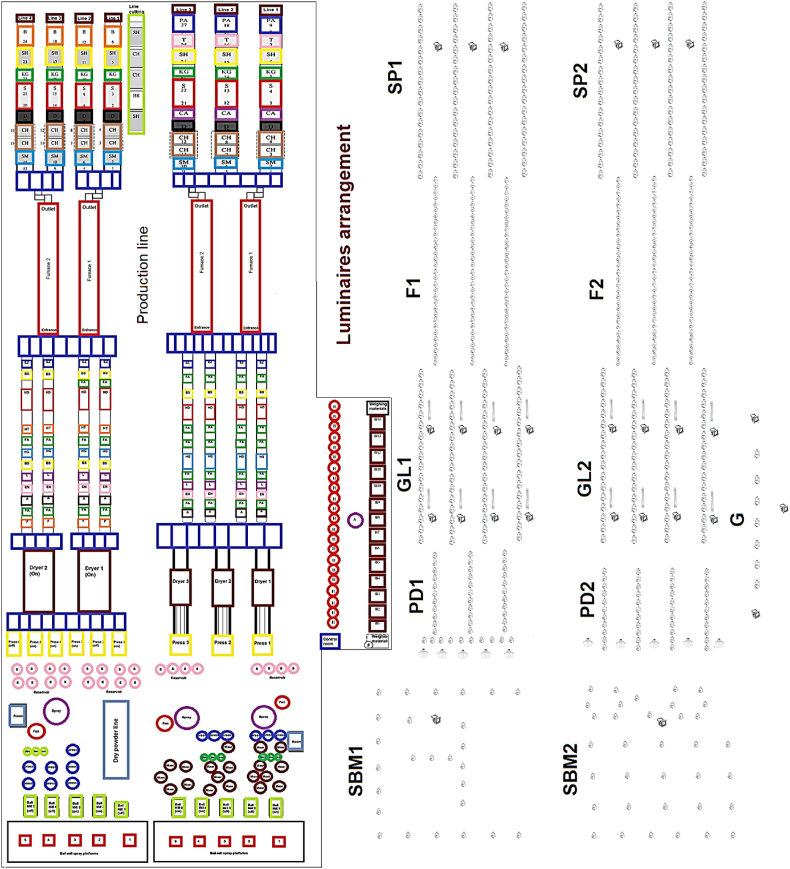

Fig. 2.

Schematic of workplaces and illuminative system.

Projectors, linear/cylindrical LEDs, and compact fluorescents are among the luminaire types used in the ceramics sector. Nonetheless, in this sector, the most prevalent kind of illuminative system is the compact fluorescent luminaire. Compact fluorescent lights are located in the bowl of Delta brand aluminum, which causes the light to shine at a specific angle on the working plane. The drying press and the glazing line are two examples of workplaces where LED luminaires are utilized sparingly. Some workplaces require a minimum amount of illumination, which the luminaires in the current illuminative system are unable to provide. The locations of the luminaires in the current illuminative system are depicted in Fig. 3. Direct-type illumination is employed in this sector. By definition, direct lighting occurs when an illuminating source shines in only one direction. This kind of illumination is intended to draw attention to a certain location. However, this leads to uneven and sometimes dangerous illumination. Compact fluorescent luminaires are arranged in the industry so that they are four rows parallel in some workplaces (GL1, GL2, SP1, and SP2) and three rows parallel in others (F1, F2, PD1, and PD2). One compact fluorescent luminaire has a luminous flux of 3300 Lum and a power consumption of 50 W. It features an 80 % CRI and a CCT of 2700 K. The main angle at which compact fluorescent luminaires illuminate a workspace is 210°. The most effective sources of illumination are cylindrical LED luminaires, which can illuminate a 360° angle and have a luminous efficacy of 80. It has an 85 % CRI and a 6500 K CCT. With the same CCT and CRI values as cylindrical LEDs, linear LEDs were exclusively put in the GL1 and GL2 workspaces. Numerous projector kinds, including SDM, Opal ECO, and NOVA, have been used in workplaces to help lighten the areas. The luminaire group's specs are displayed in Table 2.

Fig. 3.

Schematic of the studied ceramic industry workplaces and their luminaire arrangements.

Table 2.

Specification of illuminative systems in workplaces.

| Workplace | Illuminative system |

||||||

|---|---|---|---|---|---|---|---|

| Source type |

Layout pattern |

Type of illumination |

Color rendering index |

Luminous flux |

Luminous efficacy |

Angle of diffusion |

|

| (Dimensionless) | (Dimensionless) | (Lum) | (Lum/w) | (Degree) | |||

| SBM1 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Projector, SMD (20 W) | Pointwise | 80 | 2700 | 135 | 180 | ||

| SBM2 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Projector, SMD (20 W) | Pointwise | 80 | 2700 | 135 | 180 | ||

| PD1 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Cylindrical LED, E27 (50 W) | Irregular | 85 | 8000 | 80 | 360 | ||

| PD2 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Cylindrical LED, E27 (50 W) | Irregular | 85 | 8000 | 80 | 360 | ||

| G | Compact fluorescent, lotus delta head, E27 (50 W) | Pointwise | Direct | 80 | 3300 | 66 | 210 |

| Projector, SMD (20 W) | Pointwise | 80 | 2700 | 135 | 180 | ||

| GL1 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Linear LED, G13 (40 W) | Irregular | 80< | 3500 | 87 | 114 | ||

| Projector, Opal ECO (150 W) | Irregular | 80 | 12000 | 160 | 120 | ||

| GL2 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Linear LED, G13 (40 W) | Irregular | 80< | 3500 | 87 | 114 | ||

| Projector, Opal ECO (150 W) | Irregular | 80 | 12000 | 160 | 120 | ||

| F1 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| F2 | Compact fluorescent CFL lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| PS1 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 55–65 | 210 |

| Projector LED, NOVA (100 W) | Pointwise | 100 | 16000 | 160 | 180 | ||

| PS2 | Compact fluorescent, lotus delta head, E27 (50 W) | Irregular | Direct | 80 | 3300 | 66 | 210 |

| Projector LED, NOVA (100 W) | Pointwise | 100 | 16000 | 160 | 180 | ||

3.2. Experimental method

In 2023, researchers looked into the level of artificial illumination present in workplaces during the night shift. There was only illumination available as artificial illumination. From 22 p.m. until 6 a.m., the measurements were taken. Station recording was used as the sampling strategy for illuminance measurement. To achieve this, a map of the workspaces was created that showed the locations and configurations of the equipment and luminaires. The Illuminating Engineering Society's (IES) recommended network technique was used to divide the site of interest's surface area into rectangular cells. The dimensions of the rectangular cells were established based on the workspace area, the illuminative system's installation height, and the illumination distribution of the luminaires and their arrangement. After that, the map was coded, and each code's associated data was input. This included the workers' working hours, the level of precision needed, traffic and stopping locations, and other important information [60]. Each station's artificial illumination levels were measured at a height of 100 cm above the ground, which is the same as the work table's height. The digital lux meter used for the measurement was an ST-1300 model 1308, with a definition of 0.1 lux, a measurement time of 0.25 measurements per second, and an accuracy rating of ±5 % and ±10 % [66]. Every measurement was conducted without any alterations to the condition environment, such as the production of unsettling shadows or semi-shades. In this way, the lux meter's photocell was positioned horizontally on the work plane, and its placement angle did not change. Specifically, the device was positioned so that, either entirely or mostly, when reading, the photocell surface would be along the plane that the user's eye interacts with during operation. This allowed for the measurement of all illumination samples using the lux (one lumen per square meter) standard. The illumination measurements were made five times for every light situation in order to minimize measurement error. The average illumination was then calculated. A total of 387 samples were collected. Accredited laboratories of the Central Office of Measures (COM) in Yazd, Iran, calibrated all standards and measuring devices that had an impact on the measurements taken on the measuring stand at a fixed frequency [67]. The Iran Center for Accreditation has certified this laboratory, which includes luxmeter calibration [68]. In the lab, calibration was done using a standard illuminative source. At a specific distance, coherent radiation from the full-spectrum light source was directed onto the photocell's surface. This made calibration easy because the illumination on the receiving surface was known. A specific lever included in the gadget darkened the receiving cell in order to calibrate the luminance measurement component with an internal cell. The screen's luminance dropped to zero at the same moment. Otherwise, either the deviation number was recorded as a correction number or the adjustment screw set it to zero.

3.3. Analysis of experimental data

3.3.1. Statistical analysis

Because statistical techniques offer a way to condense vast volumes of data into a format that is simple to read and comprehend, they are crucial in the engineering field. The experimental illumination data set in this investigation was analyzed using this technique. The following statistics were performed using the SPSS software version 22: minimum, maximum, mean, coefficient of variation, skewness and kurtosis, and standard deviation. The normality of the illumination data was assessed using the Kolmogorov-Smirnov test. P-values >0.05 for this test suggested that the experimental data were abnormal. To assess whether there were any notable variations between the illumination data and the standard illumination values established for each workplace, the t-test was used. Workplaces were categorized using cluster analysis based on illumination levels. P-values >0.05 were considered significant for these tests.

3.3.2. Visualization of illumination

To predict the impact of different luminaire designs on real-world light and surface interactions and to understand changes in illumination for diverse materials and surface attributes, visualization is crucial. Any point in the grid can have its illumination values assigned to it using geo-statistics based on neighboring measured points. Various programs with the ability to interpolate data can be effectively utilized to visualize 3D illumination data. In this study, Golden Software Surfer version 25.2.259 was used to interpolate the thematic maps of illumination for each workplace using the inverse distance-weighted (IDW) method. The illuminance measured at each station with coordinates was produced as an Excel file (.XLS). The transformation of point data into surface data was then accomplished using a geometrical technique. The IDW approach was used in this study to visualize themed maps of illumination [64,65]. What sets IDW apart from other techniques for estimating distant sites is the power strength, which in this study ranged from 1 to 5. To give values to the unknown sites, this method computed the weighted average by the inverse of the distance between the data values. The following model was created for the IDW approach:

| (1) |

where hi is the Euclidean distance between the point of interest and the location of the station i, and p is the power used (varying from 1 to 5 in this manuscript).

3.4. Simulation method

Measurements taken at ceramics industry workplaces served as the basis for the development of the illumination simulation. DIALux (Version 4.13), a plug-in utility developed by DIAL GmbH, was used in this study's simulations. The DIALux application includes a classical technique, which we have chosen to use in our investigation. In the worker's work zone, each computer area was located where real measurements were taken. The simulation model identified each of these separate calculation zones, with the placements being the only difference. This software's input parameters are explained in the subsections that follow.

3.4.1. Dimensions of workplaces

In order to simulate the current and proposed illuminative systems of the workplaces, the architectural information, including dimensions, size, height, and structure of the ceramic industry, was calculated and then entered into the DIALux software. All of the data pertaining to the geometric dimensions of workplaces is included in Table 3.

Table 3.

Dimensions of workplaces in the ceramic industry.

| Workplace | Dimensions |

||

|---|---|---|---|

| Length |

Width |

Total height |

|

| (m) | |||

| SBM1 | 60 | 36 | 15 |

| SBM2 | 60 | 35 | 15 |

| PD1 | 60 | 36 | 12 |

| PD2 | 36 | 30 | 12 |

| G | 60 | 18 | 10 |

| GL1 | 120 | 35 | 10 |

| GL2 | 120 | 30 | 10 |

| F1 | 160 | 35 | 10 |

| F2 | 162 | 30 | 10 |

| PS1 | 72 | 36 | 10 |

| PS2 | 72 | 30 | 10 |

3.4.2. Calculate the number of luminaires

Interior space illumination design involves figuring out how many luminaires exist. DIALux makes it easier to determine how many luminaires are needed in a given area. The Chartered Institute of Building Services Engineers (CIBSE) advised using the Lumen Method in 2002 to determine the necessary number of luminaires. A further suggested method for calculating luminaire numbers is the Zonal Cavity Method, according to the IESNA. The manual Lumen Method is used to calculate the number of luminaires and assess the legitimacy of the illumination program. The amount of luminous flux that shines on a unit of surface is called illumination; its unit is Lux. The value of this parameter can be obtained through Eq. (2):

| (2) |

where Φ is the luminous flux (lum); and A is the area (m2) [61].

The ability of an illuminative source to produce visible light is measured by its luminance efficacy (ƞ). The luminaire's illumination efficiency, or luminous efficacy, is determined by dividing its illumination power (illumination current) by its electric power. Equation (3) can be used to get the value of this parameter:

| (3) |

where P is the electric power of the luminaire (W) and Φ is the luminous flux (lum). The light that is received by a surface or emitted by a source, like a luminaire, regardless of direction, is known as luminous flux (φ) [61]. This parameter's value can be found using Eq. (4):

| (4) |

E is the illumination (lux); A is the area of the workplace (m2); CU is the coefficient of utilization (dimensionless); LLF is the loss of light factor (dimensionless). Four classes with unique values for this coefficient have been identified in the DIALux program: 1) very clean workplace, low yearly usage (0.8); 2) clean room, 3-year maintenance cycle (0.67); 3) exterior installation, 3-year maintenance cycle (0.57); 4) interior or exterior installation, high pollution (0.50) [62].

The light output of each luminaire is proportional to the amount of light reflection from the ceiling, wall, and floor. Each luminaire has a special CU table, which includes the RCR value and the light reflection percentages from the ceiling, wall, and floor. The value of RCR can be obtained through Eq. (5):

| (5) |

hr is the effective height (m); W is the width (m); and L is the length (m). Using these parameters, it was possible to determine the amount of CU in the compact fluorescent luminaire [62].

To determine the total number of luminaires required for each workplace, we used Eq. (6):

| (6) |

where Φ is the luminous flux (lum); and φ1 is the luminous flux of the selected luminaire (lum) [61].

3.4.3. Determination of reflection factors

The software's second set of data included surface characteristics of the workspace, like the proportion of light reflected by the floor, wall, and ceiling. The computation takes into account the reflection factor. A surface's reflection factor is the ratio of radiation incident on it to radiation reflected off it. This factor was calculated for each workplace surface in accordance with the DIALux criteria. The interior of the offices was composed of pale-yellow brick walls with about 20 % reflectance, chocolate-brown floors with 6 % reflectance, and silver-gray shed roof insulation with 32 % reflectance for the ceilings.

3.4.4. Luminaire selection

DIALux luminaires can only be used with the free version. The DIALux software includes well-known illumination brands. In its free version, DIALux provides more than 403 luminaire manufacturers. The two parameters of the luminous flux (Lum) and the quantity of electricity consumption (w) for DIALux software were used in this study to define all of the luminaires installed in the working spaces.

3.4.5. Other settings

One of the other requirements for the DIALux implementation is mounting height, which aids in precisely positioning illumination fixtures and guarantees that the design satisfies the necessary illumination levels for the space's intended use. Effective, suspension, and work plane heights were among the mounting height parameters for DIALux configurations. The distance between the luminaire and the work plane was known as the effective height. The distance between the ceiling and the light fixture was known as the suspension height. Tasks were typically conducted at the height of the work plane, which is typically conceived of as 1 m above the floor and reflects the height of working desks in the workplace. The value of this input for every workplace is shown in Table 4.

Table 4.

Luminaire mounting height for each workplace.

| Workplace | Average height |

||

|---|---|---|---|

| Effective |

Suspension height |

Work plane |

|

| (m) | |||

| SBM1 | 5 | 9 | 1 |

| SBM2 | 6 | 8 | 1 |

| PD1 | 6 | 5 | 1 |

| PD2 | 6 | 5 | 1 |

| G | 6 | 3 | 1 |

| GL1 | 4.5 | 4.5 | 1 |

| GL2 | 6 | 3 | 1 |

| F1 | 6 | 3 | 1 |

| F2 | 5 | 4 | 1 |

| PS1 | 5 | 4 | 1 |

| PS2 | 5 | 4 | 1 |

3.4.6. Interpreting DIALux outputs

DIALux output takes into account a number of illumination design-related factors, including uniformity and illumination levels. The main outputs of a DIALux report are described as follows.

-

•

Illuminance (Lux), which consists of three parameters: minimum, maximum, and average illuminance (Emin, Emax, and Eaverage).

-

•

The longitudinal uniformity coefficient, which represents the ratio of the minimum illuminance to the maximum of that at the surface (Emin/Emax).

-

•

Uniformity ratio (U0), which represents the minimum illumination divided by the average illumination. It is generally preferred in working environments to have a more even illuminance distribution, which is indicated by a higher uniformity ratio (Emin/Eaverage).

-

•

Luminaire arrangement, which represents the specifics of the luminaires' quantity, kind, and arrangement in the workplace.

3.4.7. Validation of DIALux

DIALux's ability to accurately depict the real world must be assessed in order for it to be considered validated. In this study, the simulated illuminance outputs were compared with the relevant measurement data. In any event, it is important to emphasize that the sole objective of this section is to determine how reliable the DIALux is for calculating illumination. DIALux was validated in this study using the percentage of error (PE) metric and the regression coefficient. Since regression coefficients shed light on the connections between measured and simulated values, they are essential for DIALux validation. PE provides information on how much the simulated values are higher or lower than the measured ones by comparing them (Eq. (7)).

| (7) |

where Esim is the simulated illumination and Emeas is the measured one [46]. A 2011 study by Jack Osborne and Michael Donn at Victoria University of Wellington revealed that, depending on the measurement point, the internal illuminance model's inaccuracy should range from 1 to 14 % [47]. But as of yet, there isn't a single, accepted reference that explains how trustworthy simulations are in relation to observations. For this reason, the definition of threshold limits for tolerable errors is based on the following reasoning: A simulation error of less than 14 %, for example, denotes a medium degree of simulation accuracy, where the mistake is considered acceptable.

3.5. Optimizing the illumination conditions of workplaces

When designing the illumination system, multiple illumination parameters were taken into consideration. This would allow the system to be changed such that the work area is always lit between 250 and 300 lux. The working environment needs to be optimized from the standpoint of the factor being studied, illumination, since the results of the evaluation of the simulated data by DIALux and the experimental data did not match the standards and requirements mentioned in the article's theoretical section. Therefore, this section's objectives are to increase workplace illumination's average level and improve illumination uniformity according to work tasks.

3.5.1. Design scenarios

3.5.1.1. Choosing illumination technology

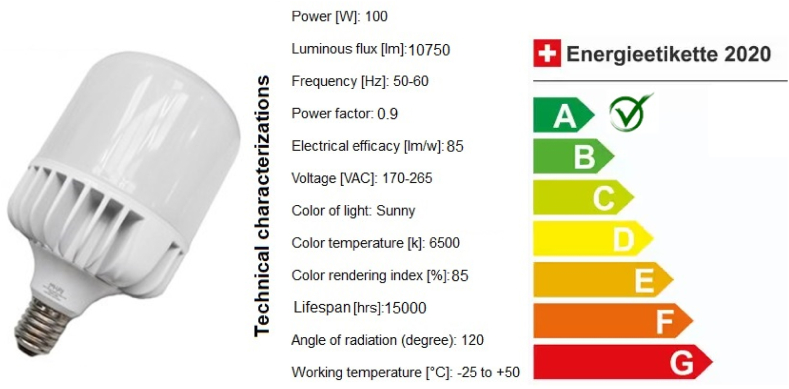

For illumination design, one of the best ways to improve workers' visual comfort and energy efficiency is to use efficient illuminative sources. Due to their longevity and energy efficiency, light-emitting diodes (LEDs) are an excellent choice for sustainable illumination [63]. The market for commercial LED illuminative products has boomed in recent years, and scientists generally agree that because of their excellent color reproduction, LEDs are a viable option for indoor illuminance applications [64]. In this study, our alternative illuminative system uses 100 W LEDs to provide a uniform illumination distribution. The illumination was selected from Schvan Company's inventory since the ceramic industry has a relationship with them. The following factors were taken into account while choosing the right luminaire: color temperature, luminous flux, color rendering index, luminance, and glare. The desired luminaire's specifications are shown in Fig. 4.

Fig. 4.

Technical characterizations of the luminaire selected to optimize illuminance conditions of the workplaces.

3.5.1.2. Selection of key factors in illumination design

Orthogonal experimental design techniques are commonly employed in intricate multifactor and two-level investigations to identify representative experimental combinations for testing. Thus, in order to create the experimental plan, we used an orthogonal experimental design. The light loss factor (A), effective height (B), number of luminaires (C), and illumination technology (D) were the four factors in this study, each of which had two parameter levels. Below is a succinct description of reasons for choosing these factors:

Light loss factor (LLF): One important metric that is utilized in illumination design computations is the LLF. It's a multiplier that's used to calculate the real light levels after accounting for different losses that happen to illuminative systems over time. LLF is computed by multiplying a number of independent variables, including ambient temperature (TF), electric voltage (V), surface changes of the luminaire (LSD), percentage coefficient of burnt and not replaced luminaires (LBF), room surface dirt depreciation (RSDD), ballast factor (BF), luminaire dirt depreciation (LDD), and luminaire lumen depreciation (LLD) [65]. By including the LLF, designers may ensure the long-term sustainability and effectiveness of illumination designs. This makes it simpler to ensure that the design satisfies the requirements and maintains sufficient illumination as the system ages. In DIALux, this is frequently decided by the industry's standards for cleanliness. Therefore, in the presence of significant pollution levels, the value of this parameter was determined to be 0.5. When there was adequate ventilation and cleanliness, the value of this metric was found to be 0.8.

Effective height: The effective height affects overall design aesthetics and is important for accurate illumination distribution, optimal illuminance levels, visual comfort, and standard compliance. Both the contrast between bright and dark areas and the shadowing effects in a place can be influenced by the effective height. The effective height of luminaires influences the angle at which light strikes surfaces and reaches the observer's eyes. As effective height increases, the unified glare rating (UGR) values can decrease if luminaires are positioned to minimize direct sightlines. To reduce glare and enhance visual comfort, one should take into account the effective height and choose the ideal height that strikes a compromise between comfort and efficient illumination. The effective height value varies depending on the type of activity, the type of luminaire, and the illuminance needs. Table 3 presents the selected values for this factor.

Number of luminaires: The number of luminaires utilized in a place closely correlates with the overall amount of illumination in that place. The proper number of luminaires must be used and placed strategically to prevent uneven illumination. Illumination standards frequently specify uniformity ratios and illuminance values for various kinds of venues. Achieving these standards depends critically on the number of luminaires used. Insufficient illumination from too few luminaires can make a workplace uncomfortable or dangerous. Consequently, choosing the right number of luminaires is crucial to enhancing workplace illumination. In this study, the number of luminaires was adjusted to the ideal illumination level in accordance with the suggested requirements in order to maximize workplace illumination.

Illumination technology: Compact fluorescent illumination technology is the foundation of most industrial illuminative systems. Therefore, using more efficient illumination technologies, like LEDs, is more acceptable. It is important to consider the specific correlated color temperature (CCT) and color rendering index (CRI) for optimizing an illuminative system [63]. CCT is a key factor in illumination design as it influences the mood and functionality of a space by determining whether the light feels warm, neutral, or cool. Warmer lights (2700–3000 K) create a relaxing and comfortable environment, while cooler lights (5000–6500 K) can make a space feel more alert and energetic [66]. The LED luminaire with a light temperature of 6500 K produces a bright, bluish-white light that mimics daylight. This color temperature plays a crucial role in the design of illuminative systems, especially in ceramic industries. This value enhances the visibility of colors and textures, making them ideal for quality control in ceramic production. Warmer light produced by illuminative systems with compact fluorescent luminaires can distort visibility, making them less suitable for quality inspections. The importance of CCT as an illuminating source is further highlighted by research on the relationship between it and workplace efficiency [66]. High-CRI illumination also improves job visibility and reduces eyestrain, among other health benefits. Because of this, the CRI and CCT are essential for satisfying both visual and nonvisual requirements when constructing artificial illuminative systems [67]. It is typically considered ideal to have a CRI of 80 or higher for safety purposes. Consequently, the two metrics CRI and CCT for LED and compact fluorescent technologies are the primary focus of this factor's optimization procedure. CCT and CRI values were given in the previous sections for the technology currently employed in the ceramics industry as well as the technology proposed (CCT = 2700 and CRI = 80 % for compact fluorescent technology and CCT = 6500 and CRI = 85 % for LED technology).

3.5.1.3. Configure scenarios

Table 3 shows the optimization schedule for the illumination. The Design Expert software, version 13.0.5.0, was utilized to create scenarios for optimizing workplace illumination. The Central Composite Design (CCD) was utilized in this context to elucidate the effects of the illumination-related elements. CCD is a popular experimental design (DOE) used in response surface methodology (RSM) to optimize illumination [52]. CCD consists of three types of points: factorial points, axial points, and center points. Factorial points are the corner points of the experimental space, representing all combinations of the levels of the factors. Axial points are located at a distance from the center of the design space along each factor's axis. They help estimate curvature in the response surface. Center points are replicated to provide an estimate of experimental error and to check for any curvature in the response surface. The types of designs used in CCD can be divided into full CCD and fractional CCD. Full CCD includes all factorial, axial, and center points [68]. Fractional CCD includes a subset of the full design that reduces the number of scenarios while still allowing for estimation of the quadratic model. In this study, fractional CCD was used to reduce the number of scenarios.

While other DOE techniques like factorial designs or Taguchi methods have their own advantages, CCD stands out for its ability to efficiently explore complex relationships, estimate quadratic models, and optimize illumination with fewer experimental scenarios. Its flexibility and robustness make it a preferred choice in many research and industrial applications. CCD is specifically designed to estimate second-order (quadratic) models, which allows for the detection of curvature in the response surface. This is particularly useful when the relationship between factors and responses is not linear. Compared to full factorial designs, CCD requires fewer scenarios to achieve similar levels of precision in estimating the response surface. The inclusion of center points allows for an assessment of experimental error and helps identify any lack of fit in the model. This is critical for validating the assumptions of the analysis. CCD is particularly effective for optimization problems, allowing researchers to identify the best settings for multiple factors simultaneously to achieve desired results [52]. In this study, the factors were coded with a central coefficient (α = 2). The factors that were altered were changed on two different levels: a high level denoted by (+1) and a low level denoted by (−1). Table 5 provides the range of the chosen factors.

Table 5.

Value of desired factors to optimize illuminance in workplaces.

| Workplace | Light loss factor (A) |

Effective height of luminaire (B) |

Number of luminaires (C) |

Illumination technology (D) |

|---|---|---|---|---|

| Dimensionless | m | – | – | |

| SBM1 | 0.8 (1.00) | 8 (1.00) | 81 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 5 (−1.00) | 25 (−1.00) | Fluorescent (−1.00) | |

| SBM2 | 0.8 (1.00) | 9 (1.00) | 90 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 6 (−1.00) | 35 (−1.00) | Fluorescent (−1.00) | |

| PD1 | 0.8 (1.00) | 8 (1.00) | 81 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 6 (−1.00) | 48 (−1.00) | Fluorescent (−1.00) | |

| PD2 | 0.8 (1.00) | 8 (1.00) | 52 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 6 (−1.00) | 49 (−1.00) | Fluorescent (−1.00) | |

| G | 0.8 (1.00) | 7 (1.00) | 48 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 6 (−1.00) | 7 (−1.00) | Fluorescent (−1.00) | |

| GL1 | 0.8 (1.00) | 6 (1.00) | 170 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 4.5 (−1.00) | 68 (−1.00) | Fluorescent (−1.00) | |

| GL2 | 0.8 (1.00) | 7 (1.00) | 175 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 6 (−1.00) | 66 (−1.00) | Fluorescent (−1.00) | |

| F1 | 0.8 (1.00) | 7 (1.00) | 195 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 6 (−1.00) | 93 (−1.00) | Fluorescent (−1.00) | |

| F2 | 0.8 (1.00) | 7 (1.00) | 168 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 5 (−1.00) | 93 (−1.00) | Fluorescent (−1.00) | |

| SP1 | 0.8 (1.00) | 7 (1.00) | 110 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 5 (−1.00) | 68 (−1.00) | Fluorescent (−1.00) | |

| SP2 | 0.8 (1.00) | 7 (1.00) | 96 (1.00) | LED (1.00) |

| 0.5 (−1.00) | 5 (−1.00) | 68 (−1.00) | Fluorescent (−1.00) |

3.5.1.4. Impact of factors and sensitivity analysis

With DIALux software, illumination values were estimated for every intended scenario. Five parameters were used to display the DIALux program's results for each scenario: Emin, Emax, Eaverage, Emin/Eaverage, and Emin/Emax. The Emin/Eaverage value was assessed in order to determine the optimal scenario. In the way, the simulated scenario was favorable when the Emin/Eaverage value was close to 1. To determine which factors are most important and contribute most to reliability, sensitivity analysis was employed. Sensitivity analysis, which determines search direction based on function gradients, is a key stage in addressing an optimization issue. Additionally, information for reliability-based design could be obtained through sensitivity analysis. According to research, sensitivity analysis techniques include variance-based methods, Monte Carlo simulations, Morris's screening, and linear regression of Sobol's decomposition method [69]. When doing computational experiments with a factorial design, analysis of variance (ANOVA) can be utilized as a sensitivity analysis technique. Additional information about how a parameter affects the model output (linear, quadratic, and cubic) can be obtained by breaking down the ANOVA input factors into orthogonal polynomial effects. In this study, sensitivity analysis was performed using ANOVA in RSM. Sensitivity analysis was performed on four factors: light loss factor (A), effective height (B), number of luminaires (C), and illumination technology (D). A non-linear quadratic equation containing interaction terms was used to illustrate the link between the operating factors and illumination (Eq. (8)).

| (8) |

where Y, xi and xj, β0 and ε are the response variables (illumination), coded independent variables, coded intercept coefficient of the model, and the residual term accounting for the differences between observed and predicted results, respectively. β1, β2, and βij are linear, quadratic, and interaction effects in the prediction model, respectively. i and j represent the index numbers for the patterns, in which i [68]. A number of statistical metrics were employed to adapt the responses to the proper mathematical model created by design, including the probability value (p-value), the regression coefficient (R2-value), the Fisher model value (F-value), and the lack of fit F-value [52]. The H0 hypothesis for these tests was that each parameter's coefficient in the model was equal to zero; in other words, the term under consideration was ineffective in the model and ought to be eliminated. The probability of significance, often known as the P-value, is the lowest value for α that can be used in this test to reject the H0 hypothesis. The smaller this value is than α, it indicates a strong rejection of the H0 hypothesis. The standard assumption is that α is equal to 0.05. Consequently, in this test, the null hypothesis is accepted if the P-value is larger than 0.05. This test should therefore be conducted separately for each of the factors, and it should be decided whether each factor must be present in the model or if it should be removed. This allows for the removal of factors that have little effect on the P-value associated with each model coefficient, resulting in a modified and simpler model with fewer parameters.

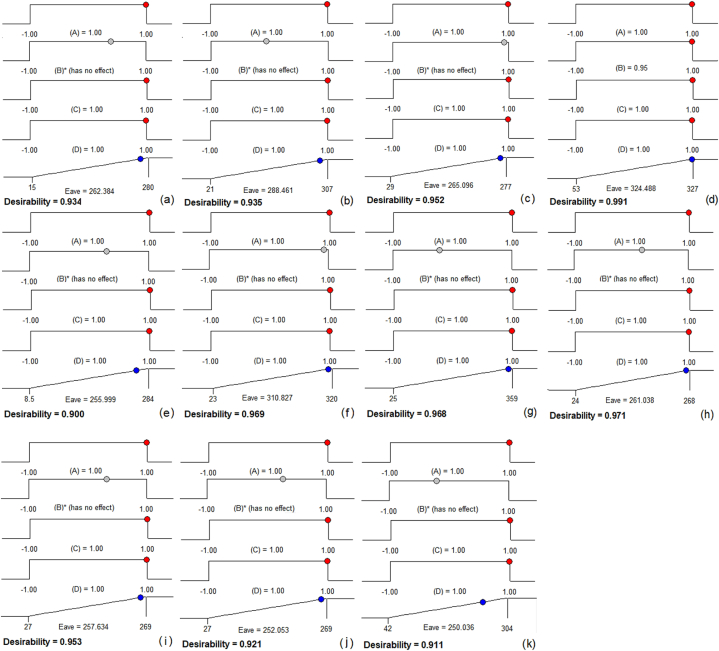

3.5.1.5. Evaluation of the desirability degree of illumination scenario

The "degree of desirability" is a statistic used in Design Expert to assess how well an illumination scenario satisfies the intended objectives or standards. It is a component of the desirability function technique, which creates a single composite desirability score by combining several criteria or replies. The score usually goes from 0 (totally undesired) to 1 (very desirable), where 1 denotes that the scenario fully satisfies the ideal requirements and 0 denotes that the scenario does not fulfill the minimal criteria or is unsuitable [68]. Each factor can be assigned individual desirability functions, and their combined effect determines the overall desirability of the scenario.

4. Results

4.1. Statistical analysis of experimental illumination data

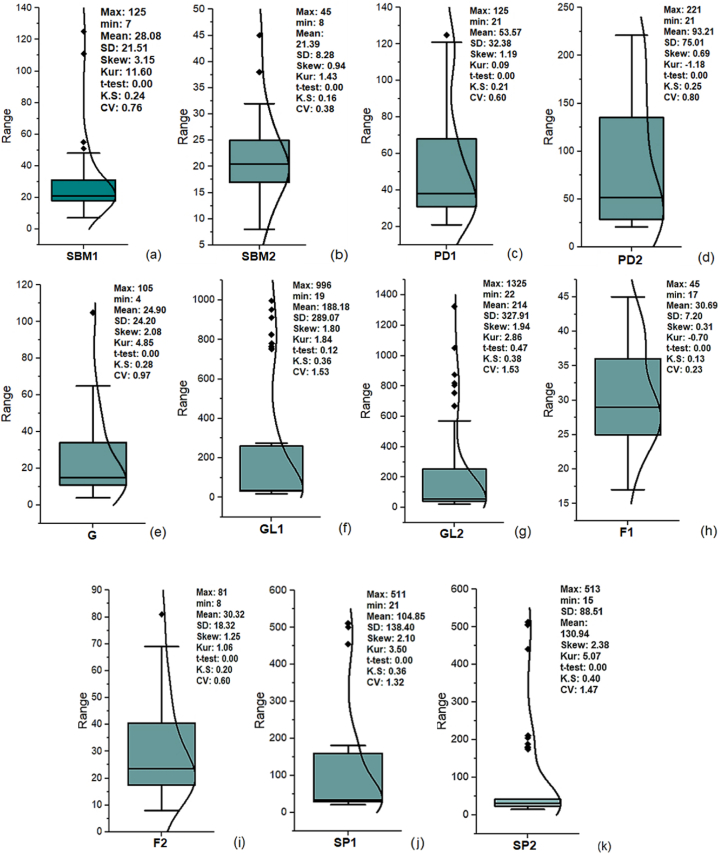

Fig. 5 displays the results of the illumination experimental data for every workplace. The workplaces with GL2 and F1 (SBM2) had the highest and lowest illumination values, respectively. The range of illumination in the ceramic industry was measured between 4 and 1325 lux. According to the basic statistical evaluation, the standard measurement error was ±4.66 %. The workplaces were arranged in the following descending order based on average illumination values: GL2> GL1> SP2> SP1> PD2> PD1> F1> F2> SBM2> G > SBM1. According to the findings of the Kolmogorov-Smirnov test, the measured illumination data in the examined ceramic industry workplaces do not have a normal distribution, demonstrating the workplaces' heterogeneous illumination distribution. The findings of additional statistical measures, including variation coefficient, kurtosis, and skewness, supported this assertion. The experimental data was compared to the standard workplace illumination values using the t-test. The results showed that there is a significant difference between the experimental data and the standard values (p-value<0.05).

Fig. 5.

Descriptive statistics of experimental illumination in the SBM1 (a), SBM2 (b), PD1 (c), PD2 (d), G (e), GL1 (f), GL2 (g), F1 (h), F2 (i), SP1 (j), and SP2 (k) workplaces.

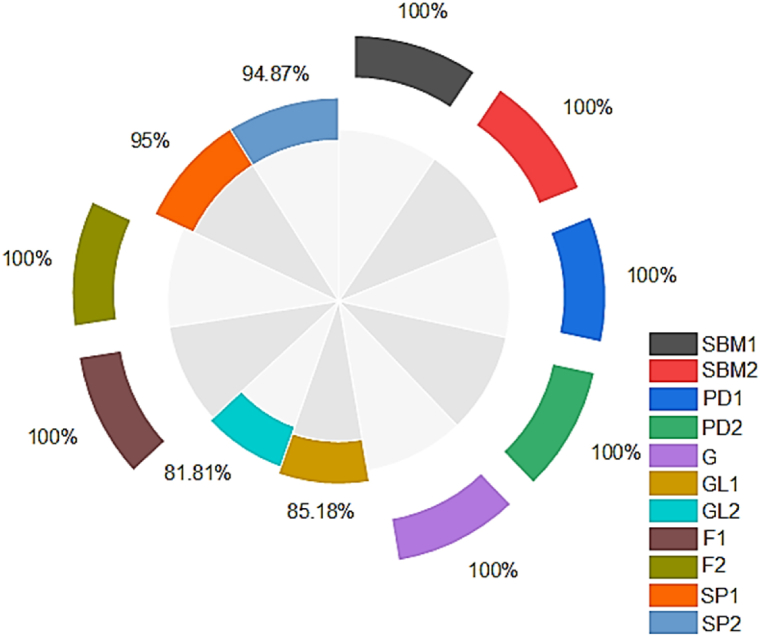

In industrial settings, the type of illumination needed depends on the task being performed. Considering the behavior of employees in every workplace, an average standard illumination of 250–300 lux was taken into consideration. In Fig. 6, the frequency of stations with light below the standard value is shown. It is clear that the illumination in ceramic industry workplaces is not up to the necessary range of 250–300 lux. For example, it was discovered that every illumination level sample for the workplaces SBM1, SBM2, PD1, PD2, G, F1, and F2 was less than 250 lux. The lux levels in GL1, GL2, SP1, and SP2 were below 300, with values of 85.18, 81.81, 95, and 94.87 %, respectively. Some workstations in these workplaces, however, require additional illumination.

Fig. 6.

The frequency of stations with unfavorable illumination in workplaces of the ceramic industry.

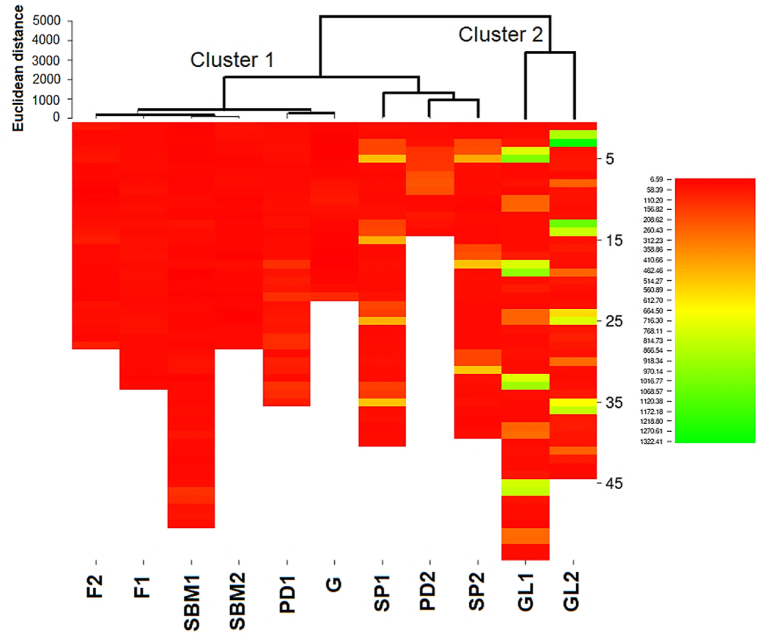

Cluster analysis can be a powerful tool in optimizing workplace illumination. Cluster analysis can be used to group similar work areas based on illumination requirements and employee satisfaction. A dendrogram is used to illustrate this analysis's findings. This information can guide decisions on adjustable illumination solutions. In this study, cluster analysis was used to classify the workplaces in terms of illumination in order to make decisions on adjustable illumination solution setups. In this way, the Ward method with Euclidean distances was used to cluster the workplaces. The result of this analysis is presented in Fig. 7. The results showed that the illumination level in GL1 and GL2 workplaces is different from other workplaces, which can be attributed to the higher illumination of these workplaces.

Fig. 7.

Dendrogram of CA of the workplaces using Euclidean distances and the Ward method.

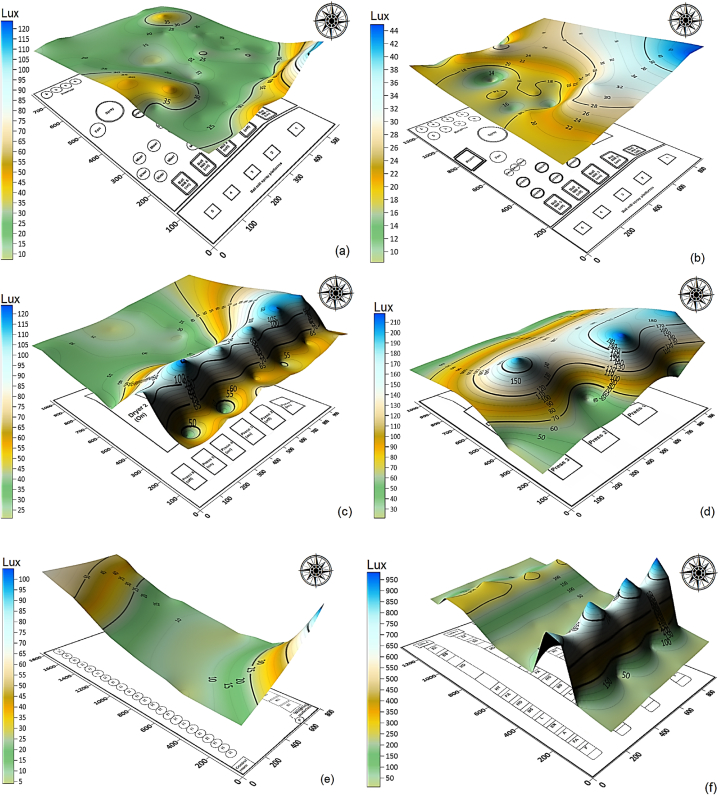

4.2. Visualization of experimental illumination

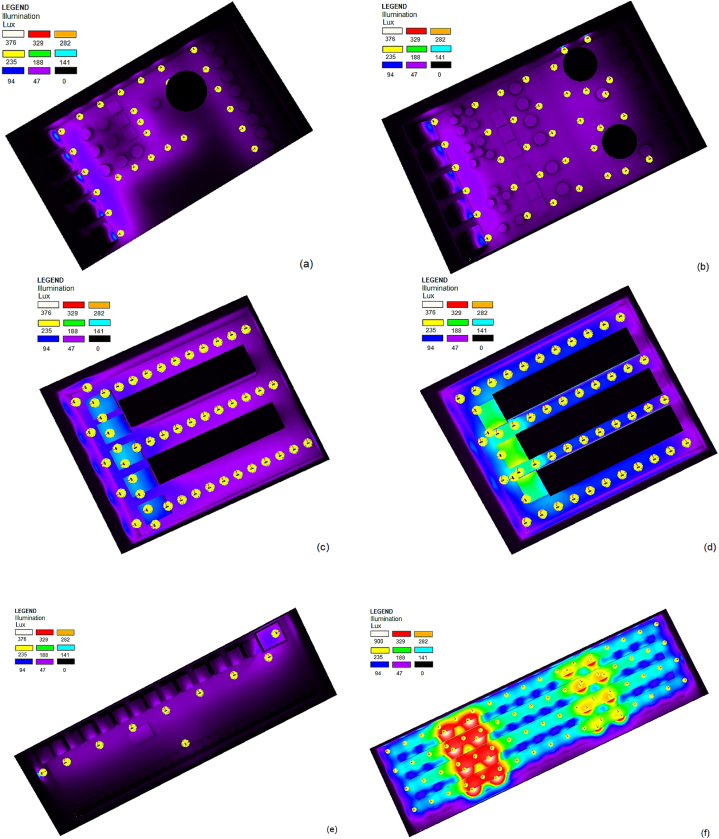

One of the greatest ways to forecast how illumination will be distributed in the workplace and improve the design of illuminative systems is to visualize illumination. The experimental illumination in this investigation was visualized using the IDW method. Fig. 8 displays the visualization's outcomes. As is evident, many workplaces' illumination dispersion was approximated as non-uniform. There were areas with extremely low illumination. For example, the BMS1 (120 lux) and BMS2 (44 lux) workspaces had the highest levels of illumination at the press operating points. In other critical work areas, such as the vicinity of mixers, sieves, and sprays, the illumination level was reduced to 10 lux (Fig. 8a and b). The press points in PD1 and PD2 workplaces had the highest illumination levels, which were 120 and 210 lux, respectively. The dryer regions had 20 lux of illumination, especially at the PD1 workstation (Fig. 8c and d). Workspace G's glazing material weighing section had the highest illumination value (100 lux). The illumination value for important work points, like mixers and ball millings, was 20 lux (Fig. 8e). The maximum illumination levels in the GL1 and GL2 workspaces were interpolated in the engob and glazing points (between 996 and 1325 lux). Very low illumination levels, up to 19 lux, were interpolated in various working areas, such as roller printing and ceramic edge wear (Fig. 8f and g). Workplaces F1 and F2 exhibited notable variations in the distribution of illumination (Fig. 8h and i). The maximum illumination (500 lux) in SP1 and SP2 workplaces was interpolated primarily in ceramic grading points. Other working points, like the stacker, had illumination levels as high as 20 lux (Fig. 8j and k). Generally, these results show that the illuminative system in the workplaces was designed in a non-standard way and without following a specific recipe.

Fig. 8.

Visualization of experimental illumination for SBM1 (a), SBM2 (b), PD1 (c), PD2 (d), G (e), GL1 (f), GL2 (g), F1 (h), F2 (i), SP1 (j), and SP2 (k) workplaces.

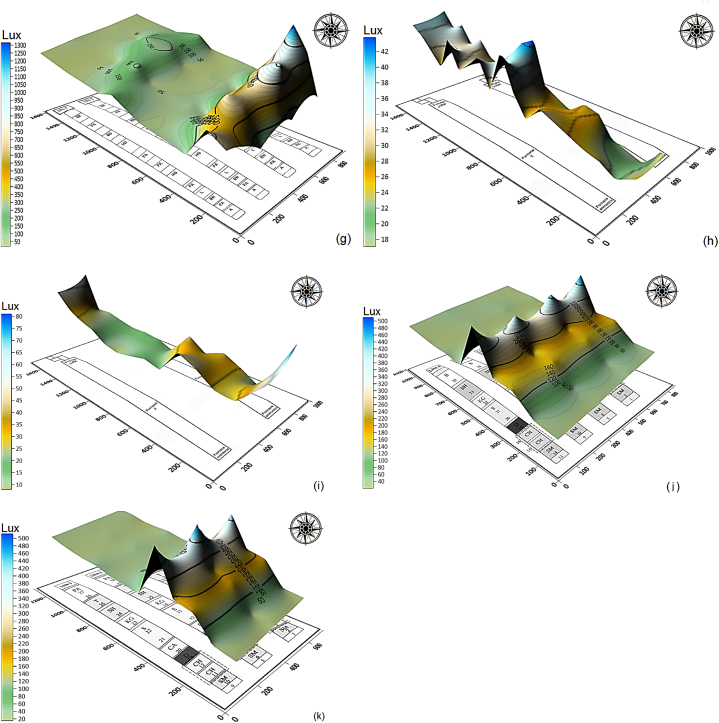

4.3. Simulated illumination analysis

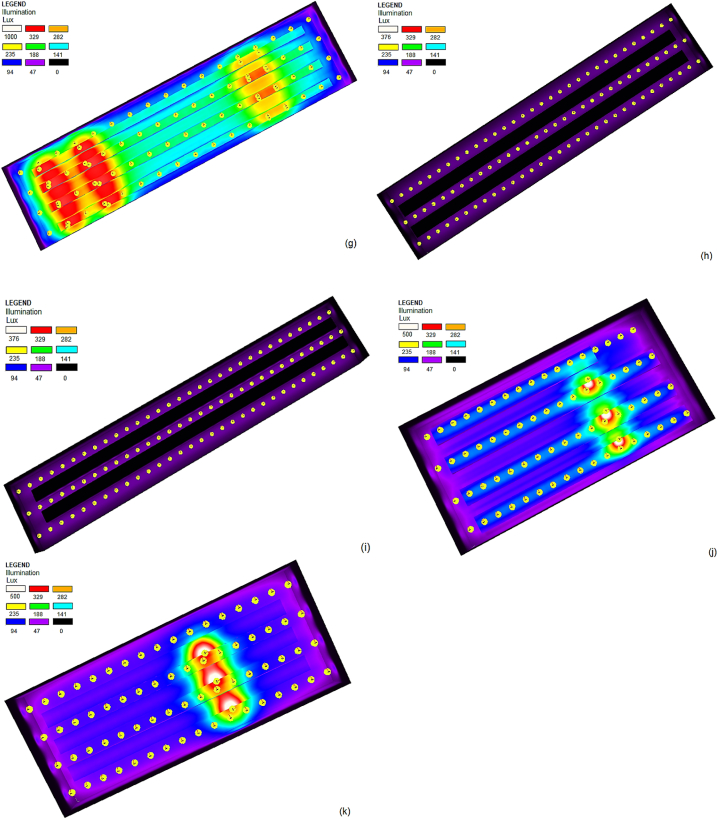

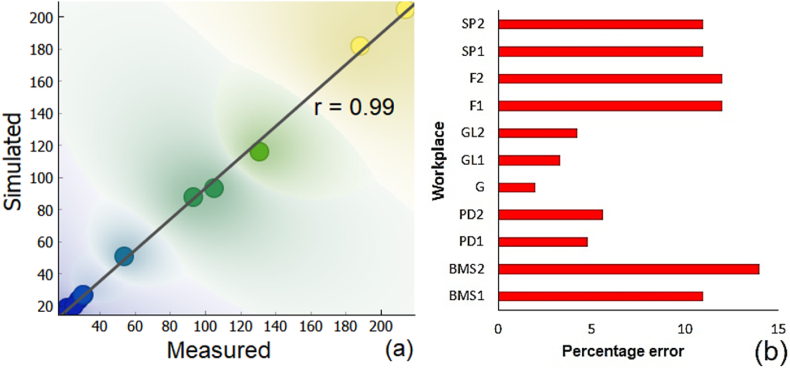

The illumination simulation analysis findings for each workplace are shown in Fig. 9. The types of luminaires installed in the industry under study served as the basis for this simulation. The results of the spatial distribution of experimental illumination were nearly identical to the simulated illumination distribution at each workplace. The findings of the simulation demonstrated that the illumination in the ceramics sector is not evenly distributed. Consequently, the DIALux results were entirely in line with the experimental data in this regard. The workplaces were arranged in the following descending order based on the simulated average illumination values: GL2 (205 lux) > GL1 (182 lux) > SP2 (116 lux) > SP1 (93 lux) > PD2 (88 lux) > PD1 (51 lux) > F1 (27 lux) = F2 (27 lux) > SBM2 (24 lux) > G (20 lux) > SBM1 (19 lux). The maximum and average simulated illumination values were lower than the experimental illumination values. It can be acknowledged that DIALux software has the ability to simulate illumination data lower than the experimental value.

Fig. 9.

Illumination simulated by DIALux software for SBM1 (a), SBM2 (b), PD1 (c), PD2 (d), G (e), GL1 (f), GL2 (g), F1 (h), F2 (i), SP1 (j), and SP2 (k) workplaces.

4.4. Validation of the model

Comparing experimental and simulated illumination data is essential for illumination optimization in the ceramic industry. In this study, the regression analysis and error percentage were used to assess the relationship between simulated and experimental data. Fig. 10a and b showed the regression coefficient and error percentage to compare simulated data with experimental data, respectively. The coefficient of regression obtained in this study was 0.99. A high coefficient of regression indicates the validity of the simulation software and its applicability to future forecasts. The percentage error of the simulations often shows results within a range of 1.96–14 % of experimental values, which can be acceptable depending on the context and standards (e.g., CIE guidelines).

Fig. 10.

Validation of simulated average values versus measured average values through regression coefficient (a) and percentage error (b) values.

4.5. Optimizing illumination

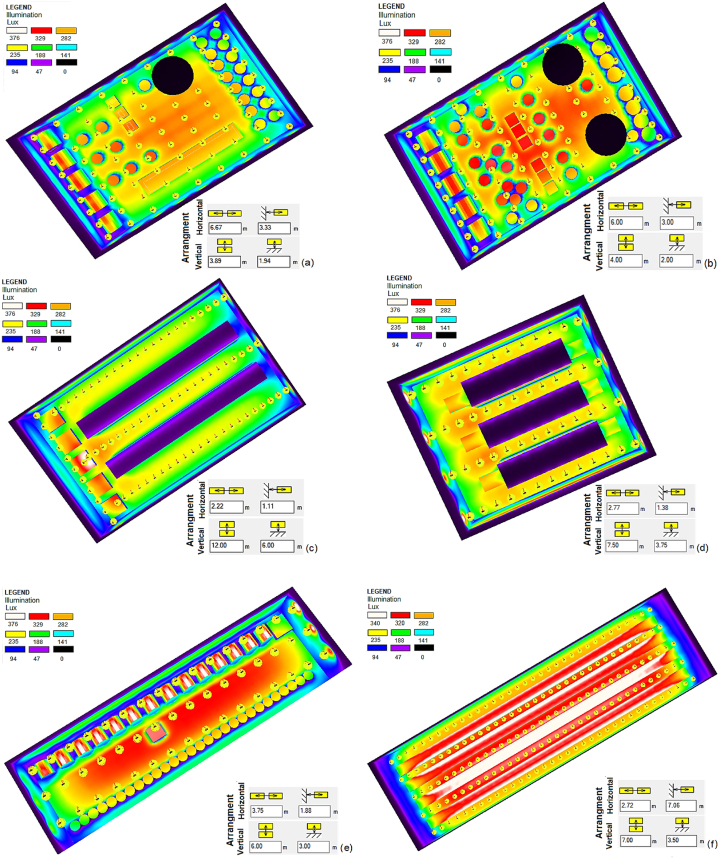

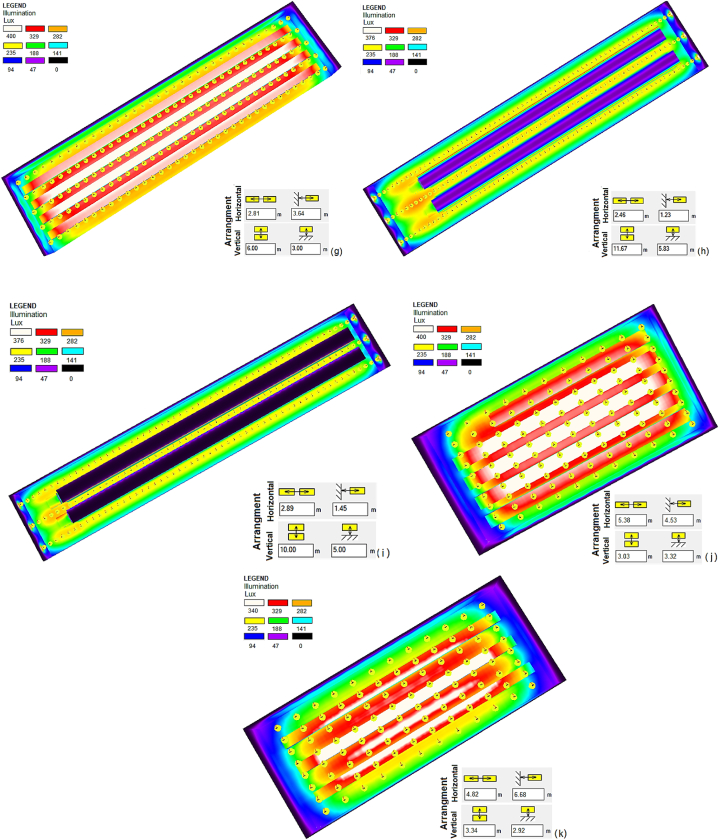

4.5.1. DIALux outputs for the most suitable scenario of optimization

Only the predominant illuminative system in the studied ceramic industry was optimized for illumination. It means that the different luminaires with small numbers, such as projectors and linear/cylindrical LEDs, were excluded from this optimization and that low-consumption fluorescent luminaire technology was selected. Therefore, LED technology was selected to optimize the ceramic industry's illuminative system. According to the CCD technique, sixteen scenarios were chosen at random for each workplace to serve as the experimental design. Tables S1–S11 of the supplemental information file display the results of the 16 scenarios that were simulated in the DIALux software for every workplace. On the basis of five parameters—Eave, Emin, Emax, Emin/Emax, and Emin/Eave—which represented the average, minimum, and maximum illumination, the ratio of minimum to maximum illumination, and the ratio of minimum to average illumination, respectively—the optimal scenario was selected to optimize illumination conditions. Emin/Eave, which denotes the ideal illuminative system design, is the most crucial of these parameters for assessing the most suitable scenario. The design is more advantageous for optimizing illumination conditions when the Emin/Eave index value is near one. Table 6 displays the results of the optimal scenarios for maximizing illumination conditions in every workplace. The optimal conditions for improving workplace illumination were those with the highest light loss factor, luminaire effective height, and color temperature of 6500 k. The height of the work plane and the workspace's proportions determined how many luminaires were needed for each workplace. In this manner, DIALux software calculated that the number of luminaires needed was nearly double that of those that were already placed.

Table 6.

The most suitable scenario selected for illumination optimization in the ceramic industry.

| Workplace | Light loss factor (A) |

Effective height of luminaire (B) |

Number of luminaires (C) |

Illumination technology (D) |

Eave |

Emin |

Emax |

Emin/Emax |

Emin/Eave |

|---|---|---|---|---|---|---|---|---|---|

| Dimensionless | m | – | – | Lux | Dimensionless | ||||

| SBM1 | 0.8 (1.00) | 5 (−1.00) | 81 (1.00) | LED (1.00) | 252 | 106 | 311 | 0.34 | 0.42 |

| SBM2 | 0.8 (1.00) | 6 (−1.00) | 90 (1.00) | LED (1.00) | 277 | 119 | 348 | 0.34 | 0.43 |

| PD1 | 0.8 (1.00) | 6 (−1.00) | 81 (1.00) | LED (1.00) | 258 | 97 | 336 | 0.29 | 0.38 |

| PD2 | 0.8 (1.00) | 6 (−1.00) | 52 (1.00) | LED (1.00) | 297 | 131 | 377 | 0.35 | 0.44 |

| G | 0.8 (1.00) | 6 (−1.00) | 48 (1.00) | LED (1.00) | 268 | 119 | 330 | 0.36 | 0.44 |

| GL1 | 0.8 (1.00) | 4.5 (−1.00) | 170 (1.00) | LED (1.00) | 305 | 94 | 415 | 0.23 | 0.31 |

| GL2 | 0.8 (1.00) | 6 (−1.00) | 175 (1.00) | LED (1.00) | 347 | 133 | 430 | 0.31 | 0.38 |

| F1 | 0.8 (1.00) | 6 (−1.00) | 195 (1.00) | LED (1.00) | 260 | 94 | 333 | 0.28 | 0.36 |

| F2 | 0.8 (1.00) | 5 (−1.00) | 168 (1.00) | LED (1.00) | 251 | 95 | 309 | 0.31 | 0.38 |

| SP1 | 0.8 (1.00) | 5 (−1.00) | 110 (1.00) | LED (1.00) | 300 | 123 | 359 | 0.34 | 0.41 |

| SP2 | 0.8 (1.00) | 5 (−1.00) | 96 (1.00) | LED (1.00) | 304 | 127 | 367 | 0.35 | 0.42 |

4.5.2. Assessing the optimized illumination level based on the workers' occupational duties