Abstract

The collaborative control of pollution and carbon emission reduction in industrial fields is crucial for improving regional air quality and mitigating climate change. However, to our knowledge, there is limited research regarding the collaborative control paths for reducing industrial pollution and carbon emissions. The present study assesses the potential for reducing emissions of air pollutants and carbon dioxide (CO2) in the industries operating in the Hohhot–Baotou–Ordos (HBO) region of Inner Mongolia. The collaborative control cross elasticity analytical method is employed to examine the synergistic effects of controlling air pollutants and CO2 emissions. The changes in fine particulate matter (PM2.5) concentrations are simulated under various scenarios. Ultimately, a collaborative control path for pollution and carbon emission reduction is proposed. The results indicate that adjusting the industrial structure, controlling energy consumption intensity, and optimizing the energy structure in collaborative control (CC) and enhanced collaborative control (ECC) scenarios effectively facilitate the coordinated reduction of air pollution and CO2 emissions. The synergistic control effects on the four evaluated air pollutants and CO2 in the ECC scenarios surpass those in the CC scenarios. The reductions in PM2.5 concentrations from 2020 to 2025 in the CC and ECC scenarios correspond to 10.81 % and 25.36 %, respectively, with even greater reductions projected for 2030 and 2035 (for all scenarios). Under CC and ECC scenarios in 2025, CO2 emissions per unit of industrial added value would be reduced by 20.12 % and 38.36 %, respectively, compared with the 2020 levels. The CC scheme is highlighted as an effective approach for collaborative pollution control and carbon emission reduction because it meets the continuous improvement requirements for air quality in the HBO region and the industrial CO2 emission reduction targets. Additionally, the results support the recommendation to prioritize the implementation of measures for controlling energy consumption intensity and adjusting industrial structures, followed by deploying measures to optimize energy structures.

Keywords: Collaborative control, Air pollutant, Carbon dioxide, Industry, Hohhot–Baotou–Ordos region

1. Introduction

China's Implementation Plan for Synergistic Efficiency in Reducing Pollution and Carbon highlights the urgency of exploring effective models of synergistic effects influencing pollution and carbon emission reductions in nationally strategic regions, regions with air pollution prevention and control, and key urban clusters [1]. Inner Mongolia represents an important energy resource and strategic region in China because it plays a key role in ensuring national energy security and unimpeded economic cycles [2]. The industrial sector in Inner Mongolia is a main contributor of air pollution and carbon emissions. In particular, emissions of sulfur dioxide (SO2), nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) in the industrial sector in 2020 accounted for 81.7 %, 62.2 %, 64.7 %, and 71.6 % of the total emissions in Inner Mongolia, respectively [3]. The Hohhot–Baotou–Ordos (HBO) region is the most important economic circle and urban belt in Inner Mongolia, with industrial SO2, NOx, PM, and CO2 emissions accounting for 43.1 %, 40.8 %, 17.9 %, and 67.6 % of the total industrial emissions in Inner Mongolia, respectively [[3], [4], [5], [6]]. Therefore, it is crucial to study and understand the collaborative control approach to reducing pollution and carbon emissions from industries in the HBO region.

Recently, numerous studies have been conducted to evaluate the collaborative control of pollution and carbon emission reduction in various fields. Dai et al. [7] assumed that all countries in the world jointly adopted policy measures to control air pollution (e.g., adjusting energy consumption structures and improving energy use efficiency) so that CO2 emissions could be reduced while also reducing air pollutants, thereby alleviating the greenhouse effect. Altintas and Kassouri [8] used linear and nonlinear methods to study the impacts of energy technology innovations on the reduction of atmospheric pollutant emissions in Europe, thus revealing the rules governing CO2 emissions characteristics. The greenhouse gas - air pollution interactions and synergies (GAINS) model and the prospective outlook for the long-term energy system (POLES) model were applied to assess the effects of greenhouse gas reduction policies on air pollutant emissions [9,10]. The synergistic effect of CO2 emission reduction measures on NOx emission reduction was quantified using the dynamic integrated model of climate and the economy (DICE) model. It has also been suggested that the two target measures (i.e., CO2 and NOx emissions reduction) should be combined to maximize the synergistic effects of energy conservation and emission reduction [11]. Xie et al. [12] studied the synergistic impacts of greenhouse gas emission reduction policies on air quality in China. Yu and Liu [13] investigated how economic growth and industrial structure adjustments influenced China's pollution and carbon emission reduction outcomes, and the results indicated that the effect of industrial structure adjustments was far greater than that of economic growth. Ma et al. [14] analyzed the synergistic effects of air pollutant emission reduction measures, such as industrial structure adjustments, energy efficiency improvements, and fossil energy substitution on CO2 emissions and residents' health in Beijing, China. Jiang et al. [15] discussed methods to achieve collaborative reductions of CO2 and air pollutant emissions in the power industry in China by implementing technical and structural measures. In addition, collaborative control paths for pollution and carbon emission reduction in the steel and cement industries in China were investigated [[16], [17], [18]].

Research on collaborative control approaches to pollution and carbon emission reduction in various industries in key regions is rare. The industrial landscape of the HBO region comprises numerous industries, including the electric power, steel, and chemical industries; however, its collaborative control path for pollution and carbon emission reduction is not clear. This study adopts a scenario-based analytical method to evaluate the potential of reducing air pollution and CO2 emissions generated by industrial fields in the HBO region. Moreover, a collaborative control cross elasticity method was applied to analyze the synergistic control effects of air pollutants and CO2 emission reduction in various scenarios. Meanwhile, an air quality forecast model system was used to simulate the changes in fine particulate matter (PM2.5) concentrations under the different scenarios. Based on the analytical results, a collaborative control path is proposed for pollution and carbon emission reduction from industrial fields in the HBO region. This approach will support the continuous improvement of ambient air quality and promote carbon emission reduction.

The remainder of this report is organized as follows. Section 2 introduces the research methodology and data. Section 3 reports the results related to air pollutants, carbon emission reduction potential, synergistic effects, and collaborative control paths for reducing pollution and carbon. Section 4 summarizes the conclusions from these results and discusses several policy implications.

2. Data and methodology

2.1. Data

The air pollutants emitted by industrial processes in the HBO region mainly include PM, SO2, NOx, and volatile organic compounds (VOCs), which served as the research objects in this study. Emissions of these air pollutants from different industrial sectors in the HBO region in 2020 were derived from the Statistical Yearbook 2021 [[4], [5], [6]]. In addition, data related to the industrial added value, energy consumptions of different industries in the region, and output of major products (e.g., crude steel, pig iron, and clinker) were obtained from the Statistical Yearbook 2021 [[4], [5], [6]].

2.2. Design of collaborative control scenarios for pollution and carbon emission reduction

In this study, the year 2020 was used as the baseline, and three situations were projected for 2025, 2030, and 2035, each considering changes in adjustments of industrial structure, control of energy consumption intensity, and optimization of energy structures, as summarized in Table 1. The business as usual (BAU) scenario, collaborative control (CC) scenario, and enhanced collaborative control (ECC) scenario were evaluated. This study assumes that the industrial added value in 2025, 2030, and 2035 would be the same as that in 2020 under all three scenarios; we assess only the impact of industrial structure adjustments, energy consumption intensity control, and energy structure optimization on air pollution and carbon emission reductions.

Table 1.

Summary of 2025, 2030, and 2035 scenarios.

| Scenarios | Design aspects | 2025 | 2030 | 2035 |

|---|---|---|---|---|

| BAU | Industrial structure adjustment | Consistent with the industrial structure in 2020 | Consistent with the industrial structure in 2020 | Consistent with the industrial structure in 2020 |

| BAU | Energy consumption intensity control | Consistent with the energy consumption intensity of the industrial sectors in 2020 | Consistent with the energy consumption intensity of the industrial sectors in 2020 | Consistent with the energy consumption intensity of the industrial sectors in 2020 |

| BAU | Energy structure optimization | Consistent with the energy structure of the industrial sectors in 2020 | Consistent with the energy structure of the industrial sectors in 2020 | Consistent with the energy structure of the industrial sectors in 2020 |

| CC | Industrial structure adjustment |

|

|

|

| CC | Energy consumption intensity control | Compared with 2020, the energy consumption intensities of the coal mining, coal chemical, other chemical, coking, cement clinker, iron-making blast furnace process, steel-making converter process, ferrosilicon, high-carbon ferrochrome, and electrolytic aluminum industries are reduced by 23.5 %, 20.5 %, 22.6 %, 5.7 %, 1.0 %, 1.8 %, 10.0 %, 1.0 %, 1.0 %, and 2.5 %, respectively. The average coal consumption for power supply in the thermal power industry reaches 305 gce/kW·h. The energy consumption intensities of the other industries are reduced by 20.0 % compared with 2020. | Compared with 2020, the energy consumption intensities of the corresponding industries are reduced by 33.5 %, 30.5 %, 32.6 %, 10.7 %, 6.0 %, 6.8 %, 20.0 %, 6.0 %, 6.0 %, and 7.5 %, respectively. The average coal consumption for power supply in the thermal power industry is reduced by 10 % compared with the 2025 CC scenario. The energy consumption intensities of the other industries are reduced by 30.0 % compared with 2020. | Compared with 2020, the energy consumption intensities of the corresponding industries are reduced by 43.5 %, 40.5 %, 42.6 %, 15.7 %, 11.0 %, 11.8 %, 30.0 %, 11.0 %, 11.0 %, and 12.5 %, respectively. The average coal consumption for power supply in the thermal power industry is reduced by 20 % compared with the 2025 CC scenario. The energy consumption intensities of the other industries are reduced by 40.0 % compared with 2020. |

| CC | Energy structure optimization | Coal power generation accounts for 60 % of the total power generation. Coal consumption accounts for 70 % of the total comprehensive energy consumption. Electricity consumption accounts for 16 % of the total integrated energy consumption, of which 35 % is derived from renewable energy electricity. | Coal power generation accounts for 50 % of the total power generation. Coal consumption accounts for 65 % of the total comprehensive energy consumption. Electricity consumption accounts for 22 % of the total integrated energy consumption, of which 45 % is derived from renewable energy electricity. | Coal power generation accounts for 40 % of the total power generation. Coal consumption accounts for 60 % of the total comprehensive energy consumption. Electricity consumption accounts for 28 % of the total integrated energy consumption, of which 55 % is derived from renewable energy electricity. |

| ECC | Industrial structure adjustment |

|

|

|

| ECC | Energy consumption intensity control | Compared with 2020, the energy consumption intensities of the coal mining, coal chemical, other chemical, coking, cement clinker, iron-making blast furnace process, steel-making converter process, ferrosilicon, high-carbon ferrochrome, and electrolytic aluminum industries are reduced by 32.1 %, 30.9 %, 31.8 %, 10.0 %, 5.0 %, 6.8 %, 15.0 %, 5.0 %, 5.0 %, and 5.0 %, respectively. The average coal consumption for power supply in the thermal power industry reaches 295 gce/kW·h. The energy consumption intensities of the other industries are reduced by 30.0 % compared with 2020. | Compared with 2020, the energy consumption intensities of the corresponding industries are reduced by 42.1 %, 40.9 %, 41.8 %, 15.0 %, 10.0 %, 11.8 %, 25.0 %, 10.0 %, 10.0 %, and 10.0 %, respectively. The average coal consumption for power supply in the thermal power industry is reduced by 15 % compared with the 2025 ECC scenario. The energy consumption intensities of the other industries are reduced by 40.0 % compared with 2020. | Compared with 2020, the energy consumption intensities of the corresponding industries are reduced by 52.1 %, 50.9 %, 51.8 %, 25.0 %, 15.0 %, 16.8 %, 35.0 %, 15.0 %, 15.0 %, and 15.0 %, respectively. The average coal consumption for power supply in the thermal power industry is reduced by 25 % compared with the 2025 ECC scenario. The energy consumption intensities of the other industries are reduced by 50.0 % compared with 2020. |

| ECC | Energy structure optimization | Coal power generation accounts for 50 % of the total power generation. Coal consumption accounts for 65 % of the total comprehensive energy consumption. Electricity consumption accounts for 23 % of the total integrated energy consumption, of which 45 % is derived from renewable energy electricity. | Coal power generation accounts for 45 % of the total power generation. Coal consumption accounts for 60 % of the total comprehensive energy consumption. Electricity consumption accounts for 29 % of the total integrated energy consumption, of which 55 % is derived from renewable energy electricity. | Coal power generation accounts for 40 % of the total power generation. Coal consumption accounts for 55 % of the total comprehensive energy consumption. Electricity consumption accounts for 35 % of the total integrated energy consumption, of which 65 % is derived from renewable energy electricity. |

2.2.1. Industrial structure adjustment scenarios

In terms of industrial structure adjustments, the HBO region industrial structure remained unchanged in the BAU scenario. The CC scenario includes industrial structure optimization relative to the BAU scenario, and the ECC scenario is further optimized relative to the CC scenario. The air pollution and carbon emissions of industrial fields in the HBO region are mainly from the high-energy-consuming thermal power, coking, coal chemical, other chemical, steel, electrolytic aluminum, cement clinker, and coal mining industries [3]. The industrial structure adjustment scenarios focus on the design elements eliminating the backward production capacity of these high-energy-consuming industries to optimize the relevant process technology. The average product energy efficiencies of the coal mining (16 %), steel (30 %), cement clinker (22 %), coal chemical (32 %), coking (34 %), other chemical (23 %), electrolytic aluminum (18 %), and thermal power (20 %) industries were at least 10 % lower than the energy efficiency benchmark level released by China in 2023 [19]. The backward production capacity with low energy efficiency was phased out in the scenario setting (Table 1). Additionally, field investigations indicated that the steel and coal chemical industries in the HBO region have significant room for technological improvements. In 2020, the output of electric furnace short process steelmaking (in the steel industry) accounted for 10 %, and the scrap ratio was 22 %. Meanwhile, hydrogen-powered steelmaking was not carried out. According to the development trend of the steel industry extrapolated into the future, the proportion of short process steelmaking, scrap steel, and hydrogen steelmaking will gradually increase in the CC and ECC scenarios (Table 1). A one-step process using syngas accounted for 45 % of the transformation of coal to olefins in 2020. According to the development trend of coal-to-olefin processes, the application of the one-step syngas method will gradually increase in 2025, 2030, and 2035 across the CC and ECC scenarios, as shown in Table 1.

2.2.2. Energy consumption intensity control scenarios

In terms of energy consumption intensity control, the energy consumption intensity of industries in the HBO region remained unchanged in the BAU scenario. In this study, the energy efficiencies of key industries were compared with the leading level according to relevant standards of China in order to design the energy consumption intensity CC and ECC scenarios. If 50 % of the 2020 coal mining industry's production capacity reached level Ⅱ in terms of cleaner production [20], the average energy consumption intensity would be reduced by 23.5 %. If all coal mining enterprises reach level Ⅱ cleaner production, the average energy consumption intensity will be reduced by 32.1 %. To effectively enhance energy utilization, 23.5 % and 32.1 % were set as the proportions of energy consumption intensity reduction in the 2025 CC and ECC scenarios, respectively, for the coal mining industry. If energy efficiencies of 30 % and 45 % based on the coal chemical production capacity reach the leading level [19], the average energy consumption intensity will be reduced by 20.5 % and 30.9 %, respectively, for CC and ECC scenarios. Thus, 20.5 % and 30.9 % were set as the proportions of energy consumption intensity reduction in the 2025 CC and ECC scenarios, respectively, of the coal chemical industry. Energy efficiency of 30 % and 45 % in terms of the other chemical production capacity reach the leading level [19], and the corresponding average energy intensity consumption will be reduced by 22.6 % and 31.8 %, respectively. Therefore, 22.6 % and 31.8 % were set as the proportions of energy consumption intensity reduction in the 2025 CC and ECC scenarios, respectively, of the other chemical industry. Compared with the 2025 CC and ECC scenarios, the energy consumption intensities of the coal mining, coal chemical, and other chemical industries in 2030 and 2035 were appropriately reduced in different scenarios (Table 1). The Inner Mongolia Autonomous Region "14th Five-Year" Comprehensive Work Implementation Plan for Energy Conservation and Emission Reduction proposes that the targets for comprehensive energy consumption per unit product of coke, cement clinker, iron-making blast furnace process, steel-making converter process, ferrosilicon, and high-carbon ferrochromium in 2025 will be reduced by 5.7 %, 1 %, 1.8 %, 10 %, 1 %, and 1 % respectively compared with those in 2020, while the reduction target for AC power consumption of aluminum liquid in the electrolytic aluminum industry is 2 % [21]. These targets were set according to the proportions of energy intensity reduction in the 2025 CC scenarios for the corresponding industries, and then the energy consumption intensities for 2030 and 2035 under the CC and ECC scenarios were appropriately reduced (Table 1). In 2020, the average coal consumption power supply of coal-fired generating units in the HBO region was 321 gce/kW·h. The average coal consumption target of coal-fired power generating units in 2025 projected by the Inner Mongolia Autonomous Region is 305 gce/kW·h [21]. In this study, 305 and 295 gce/kW·h were set as the respective index values of coal consumption power supply in the CC and ECC scenarios of the thermal power industry in 2025. The coal consumption power supply was appropriately reduced for the 2030 and 2035 scenarios (CC and ECC). For the other industries, the reduction of energy consumption intensity in the 2025 CC scenario was set at 20 %, which corresponds to the goal of reducing energy consumption per unit of industrial value added during the 14th Five-Year Plan period proposed by the Inner Mongolia Autonomous Region [21]. According to the industrial development trends, the energy consumption intensities under the other scenarios were appropriately reduced, as listed in Table 1.

2.2.3. Energy structure optimization scenarios

In terms of energy structure optimization, the energy structure of industries in the HBO region remained unchanged in the BAU scenario. In the CC and ECC scenarios, the energy structure was adjusted with the goals of reducing the proportion of coal consumption and increasing the proportion of renewable energy-derived power consumption. In 2020, industrial coal consumption in the HBO region accounted for 76.7 % of China's total industrial comprehensive energy consumption, while electricity consumption accounted for 8.2 %. The energy structure optimization scenarios were designed on this basis and considering the forecast results of industrial energy demands [21], as shown in Table 1.

2.3. Methods for quantifying air pollution and CO2 emissions

2.3.1. Accounting for air pollutant emissions

The emissions of PM, SO2, and NOx by different industrial sectors under different scenarios in 2025, 2030, and 2035 were calculated by multiplying the energy consumption of each industrial sector by the corresponding air pollutant emission coefficient. The VOC emissions were calculated by multiplying the output of products in different industrial sectors with the corresponding VOC emission coefficient. The PM, SO2, NOx, and VOC emission coefficients were obtained from the literatures [[22], [23], [24]].

2.3.2. Accounting for CO2 emissions

The CO2 emission calculations were based on the same method as for air pollutant emissions using the same activity data (i.e., energy consumption, industrial products, etc.). In addition, the emission factors from the Intergovernmental Panel on Climate Change (IPCC) Emission Factor Database (https://www.ipcc-nggip.iges.or.jp/EFDB/main.php) were included in the analysis.

2.4. Collaborative control cross elasticity method

Collaborative control cross elasticity can reflect whether and to what degree a certain measure or subject has a synergistic control effect on different pollutants. This factor can be calculated using Eq. (1) [25],

| (1) |

where Elsj/k is the collaborative control cross elasticity of a j-type air pollutant and a k-type greenhouse gas; ERj/Qj is the emission reduction rate of the j-type air pollutant, which is the ratio of emission reduction of the j-type air pollutant to its emission; and ERk/Qk is the emission reduction rate of the k-type greenhouse gas, which is the ratio of the emission reduction of the k-type greenhouse gas to its emission. The meaning of collaborative control cross elasticity is expanded in Table 2.

Table 2.

The meaning of collaborative control cross elasticity.

| Calculated value | Meaning |

|---|---|

| Elsj/k > 0 (both the numerator and denominator are positive) | It has emission reduction effects on both the j-type air pollutant and the k-type greenhouse gas, and it has a synergistic control effect. |

| Elsj/k < 0 | It can reduce the emission of either the j-type air pollutant or the k-type greenhouse gas, while increasing the emission of the other one, which is a non-synergistic measure. |

| Elsj/k = 1 | The degrees of emission reduction of the j-type air pollutant and the k-type greenhouse gas are the same. |

| 0<Elsj/k < 1 | The degree of emission reduction of the k-type greenhouse gas is greater than that of the j-type air pollutant. |

| Elsj/k > 1 | The degree of emission reduction of the j-type air pollutant is greater than that of the k-type greenhouse gas. |

| Elsj/k > 0 (both the numerator and denominator are negative) | It promotes the emissions of both the j-type air pollutant and the k-type greenhouse gas. |

| ERj/Qj = 0 | It has no effect on the j-type air pollutant emission reduction. |

| ERk/Qk = 0 | It has no effect on the k-type greenhouse gas emission reduction. |

2.5. The WRF-CMAQ model

In this study, the Weather Research and Forecasting and Community Multi-Scale Air Quality (WRF-CMAQ) model was used to simulate the average annual PM2.5 concentrations under different collaborative control scenarios involving pollution and carbon emission reduction in the HBO region to analyze the impacts of different emission reduction paths on PM2.5 concentrations. The simulation results can guide the optimization of collaborative control-based approaches for pollution and carbon emission reductions in the industrial fields in the HBO region. The simulation method is described in detail in a previous report [26].

3. Results and discussion

3.1. Air pollutants and CO2 emission reduction potential

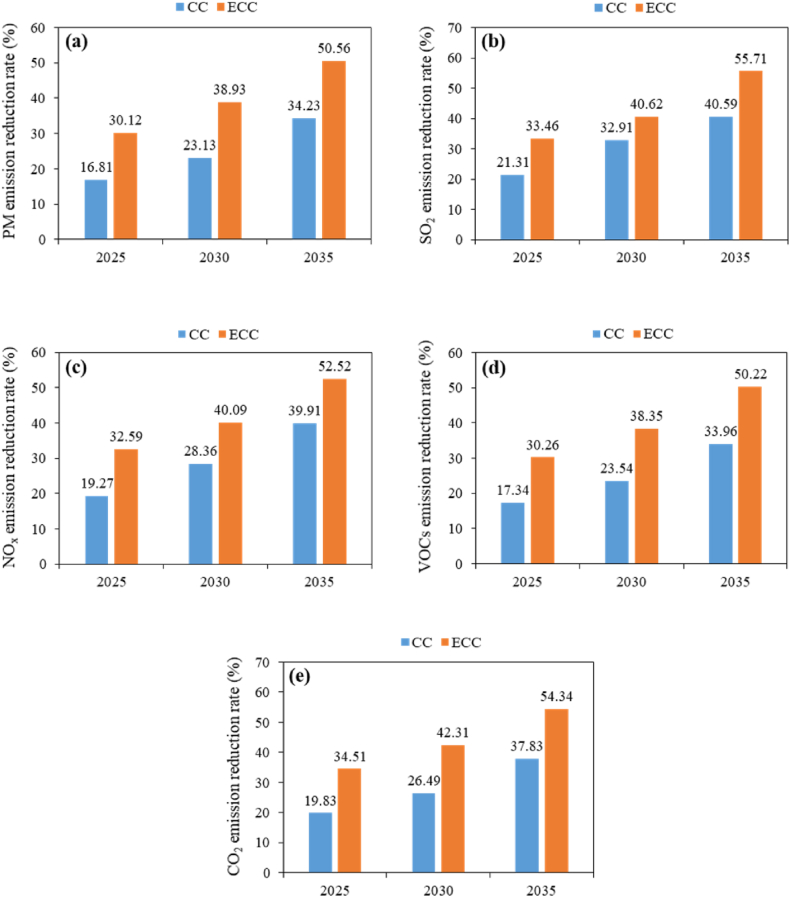

In 2020, the emissions of PM, SO2, NOx, and VOCs from industries in the HBO region were 82,700.58, 96,400.43, 120,657.00, and 20,358.93 tons, respectively, while the CO2 emissions were 548.36 million tons [[4], [5], [6]]. Air pollutants and CO2 emissions in the 2025, 2030, and 2035 BAU scenarios were the same as those in 2020. Compared with the BAU scenarios, the air pollutants and CO2 emission reduction rates in 2025, 2030, and 2035 under different scenarios are shown in Fig. 1. Under the ECC scenarios of 2025, 2030, and 2035, the PM emissions were reduced by 30.12 %, 38.93 %, and 50.56 %, SO2 by 33.46 %, 40.62 %, and 55.71 %, NOx by 32.59 %, 40.09 %, and 52.52 %, VOCs by 30.26 %, 38.35 %, and 50.22 %, and CO2 by 34.51 %, 42.31 %, and 54.34 %, respectively, compared with the BAU scenarios. Among all evaluated air pollutants, SO2 had the largest emission reduction rate, followed by NOx, PM, and VOCs. The emission reduction rate of CO2 was similar to that of SO2.

Fig. 1.

Emission reduction rates of air pollutants and CO2 in the CC and ECC scenarios.

By 2035, the SO2 emission reduction intensity was the highest under the CC and ECC scenarios, and the emission reduction rates were 40.59 % and 55.71 %, respectively. The emission reduction rates of NOx were 39.91 % and 52.52 %, and those of PM were 34.23 % and 50.56 %, respectively. Among the evaluated air pollutants, the emission reduction rates of VOCs were the smallest (33.96 % and 50.22 %, respectively). The CO2 emission reduction rates were 37.83 % and 54.34 %, respectively (between those of PM and SO2).

Overall, deep adjustments of the industrial structure, in-depth control of energy consumption intensities, and continuous optimization of energy structures can effectively promote the coordinated reduction of air pollutants and CO2 emissions.

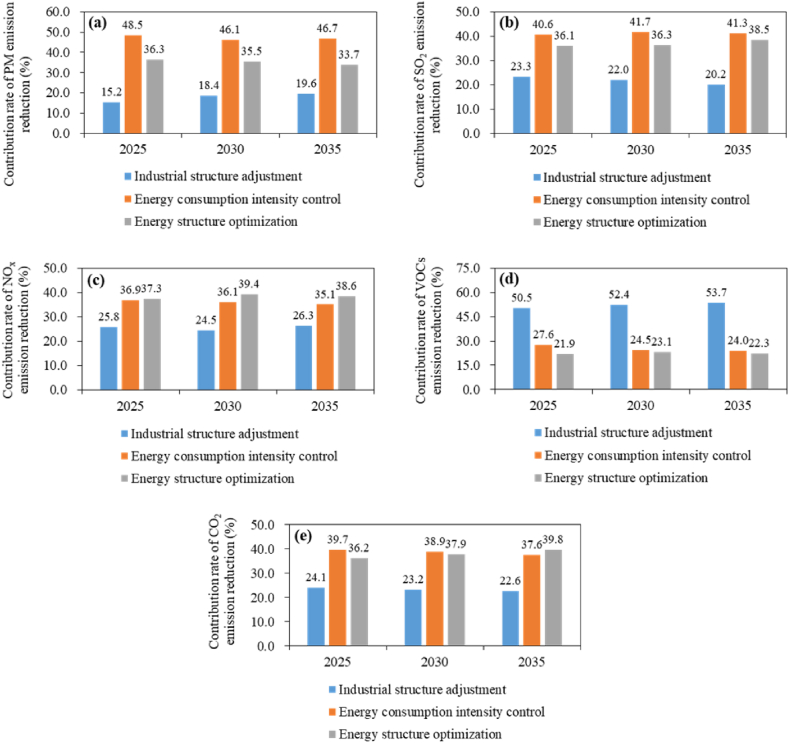

The contributions of different measures to air pollutants and CO2 emission reduction in the CC scenario are displayed in Fig. 2 and compared with the BAU scenario. In 2025, 2030, and 2035, the contributions of energy consumption intensity control measures to the PM and SO2 emission reduction potentials were greater than those of energy structure optimization and industrial structure adjustment measures, whereas NOx emission reduction relied primarily on energy structure optimization measures. The reduction of VOC emissions mainly depended on industrial structure adjustment measures, and the reduction of CO2 emissions primarily depended on the control of energy consumption intensity and the optimization of energy structures. The PM emission reduction potentials under energy consumption intensity control measures in 2025, 2030, and 2035 accounted for 48.5 %, 46.1 %, and 46.7 %, respectively, of the total emission reduction of all measures. The SO2 emission reduction potentials under energy consumption intensity control measures in 2025, 2030, and 2035 accounted for 40.6 %, 41.7 %, and 41.3 %, respectively, of the total emission reduction of all measures. The NOx emission reduction potentials under energy structure optimization measures in 2025, 2030, and 2035 accounted for 37.3 %, 39.4 %, and 38.6 %, respectively. The VOC emission reduction potentials under industrial structure adjustment measures in 2025, 2030, and 2035 accounts for 50.5 %, 52.4 %, and 53.7 %, respectively. The CO2 emission reduction potentials under energy consumption intensity control measures in 2025, 2030, and 2035 accounted for 39.7 %, 38.9 %, and 37.6 %, respectively, exhibiting a slight decreasing trend. The proportions of CO2 emission reduction under energy structure optimization measures were 36.2 %, 37.9 %, and 39.8 %, respectively, showing a slight increasing trend.

Fig. 2.

Contributions of different measures to air pollutants and CO2 emission reductions in the CC scenario.

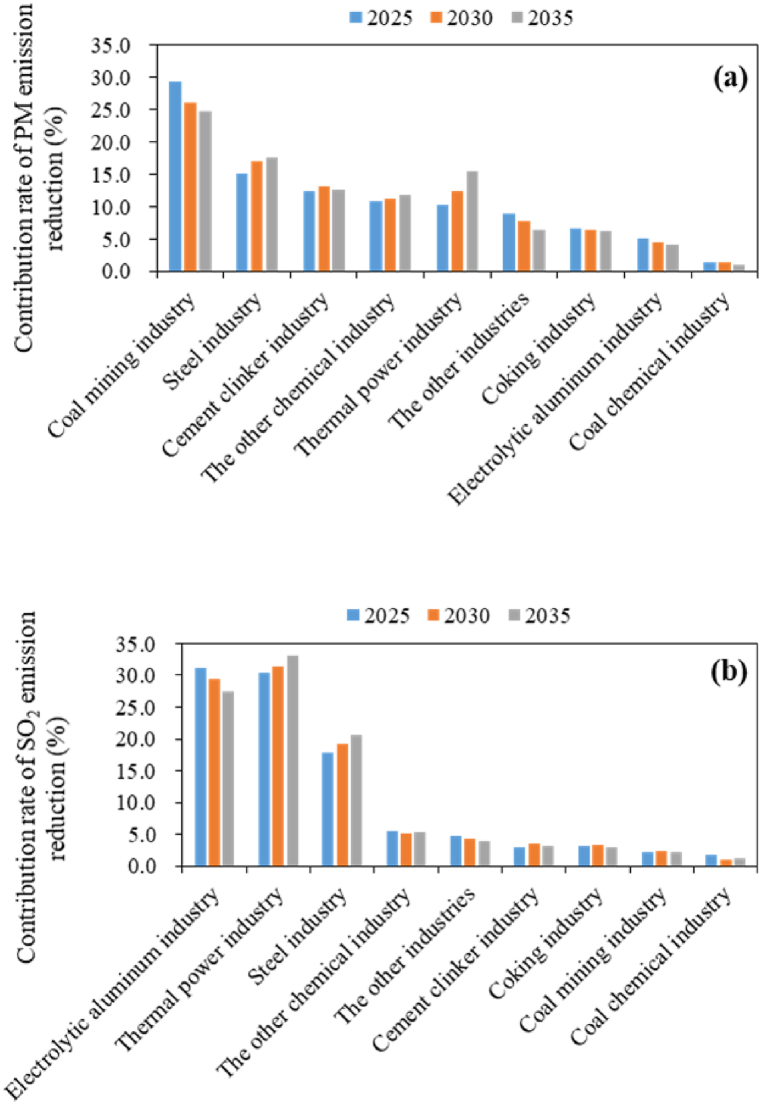

To compare the impacts of different industries on the reductions of air pollutants and CO2 emissions, the contributions of key industries to the emission reduction of different pollutants and CO2 were analyzed, as illustrated in Fig. 3. In terms of PM, the coal mining industry had the greatest potential to reduce emissions, contributing 29.3 %, 26.1 %, and 24.8 % in 2025, 2030, and 2035, respectively, followed by the steel industry with 15.1 %, 17.0 %, and 17.5 %, and the cement clinker industry with 12.4 %, 13.1 %, and 12.6 %. In terms of SO2, the electrolytic aluminum industry exhibited the greatest emission reduction potential, contributing 31.2 %, 29.4 %, and 27.4 %, respectively in 2025, 2030, and 2035, followed by the thermal power industry with 30.4 %, 31.3 %, and 33.1 %, and the steel industry with 17.8 %, 19.3 %, and 20.6 %. In terms of NOx, the thermal power industry had the greatest emission reduction potential, with contributions of 48.8 %, 49.9 %, and 50.6 % in 2025, 2030, and 2035, respectively, followed by the steel industry with 20.4 %, 21.2 %, and 19.5 %. In terms of VOCs, the other chemical industries had the greatest emission reduction potential, contributing 41.5 %, 43.4 %, and 43.7 % in 2025, 2030, and 2035, respectively, followed by the coking industry with 28.2 %, 28.9 %, and 30.6 %. In terms of CO2, the thermal power industry had the greatest emission reduction potential, contributing 37.9 %, 39.1 %, and 40.4 % in 2025, 2030, and 2035, respectively, followed by the coal mining industry with 16.8 %, 15.2 %, and 14.5 %, and the steel industry with 15.7 %, 17.3 %, and 17.6 %.

Fig. 3.

Contributions of key industries to air pollutants and CO2 emission reductions in the CC scenario.

In general, the thermal power and steel are the industries exhibited the greatest potential for reducing PM, SO2, NOx, and CO2 emissions, consistent with the previous studies [15,23]. Meanwhile, the other chemical and coking industries had the greatest potential for reducing VOC emissions. Thus, it is crucial to promote the green and low-carbon transformation of these industries.

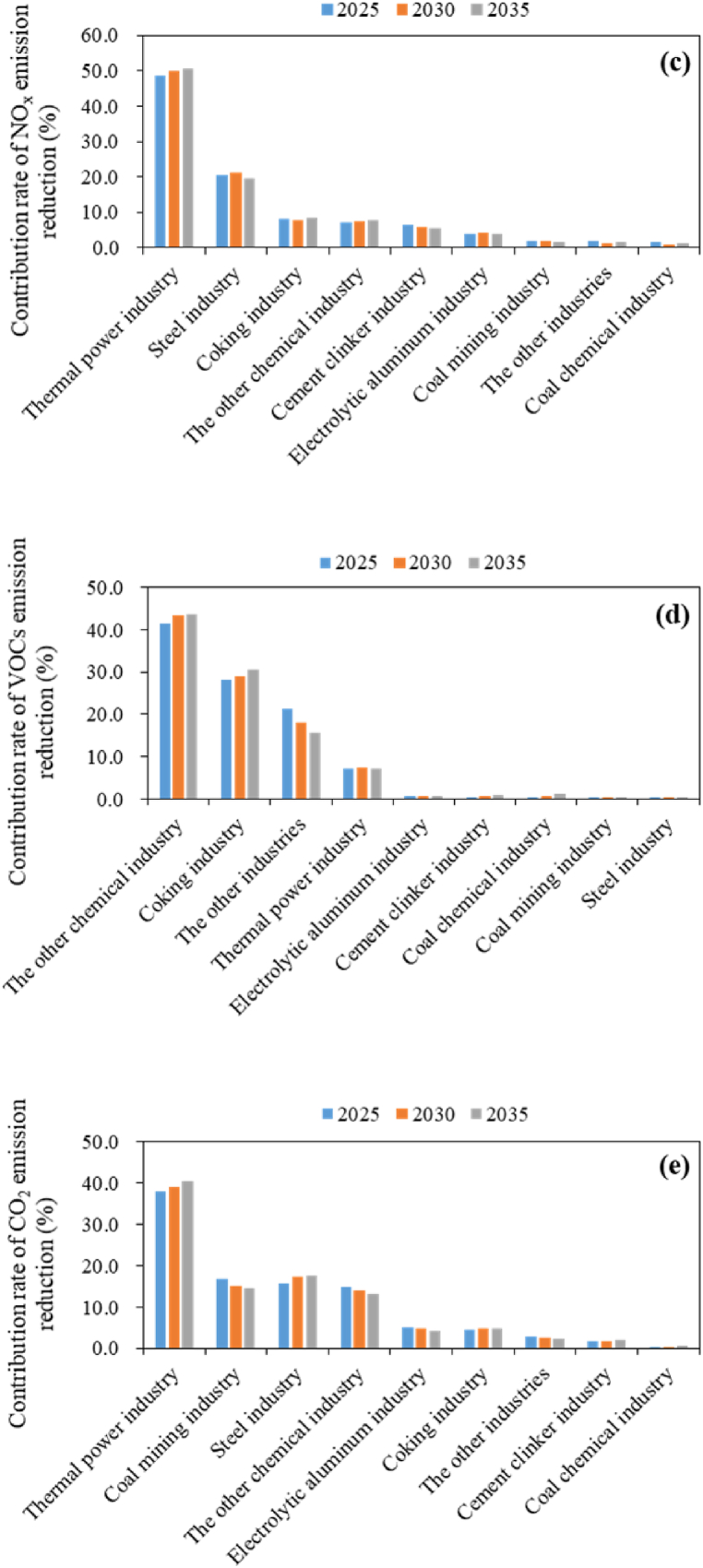

3.2. Analysis of synergistic effects

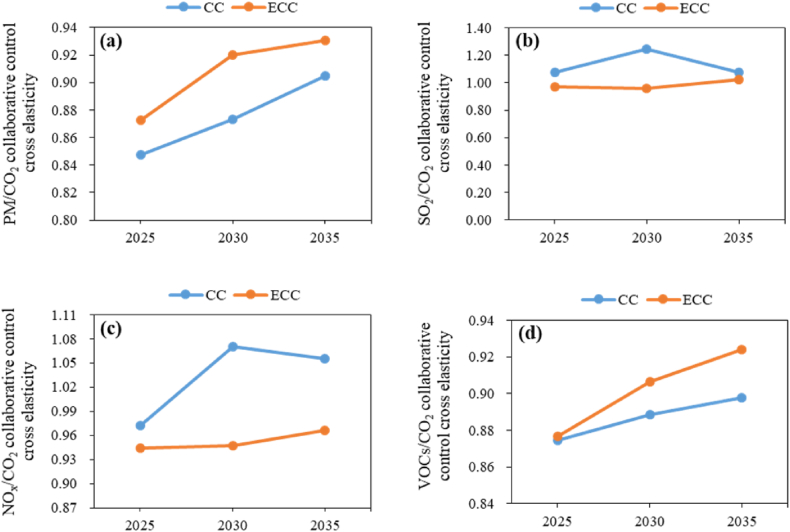

Fig. 4 presents the collaborative control cross elasticity results for different scenarios. The collaborative control cross elasticities of PM and CO2 were less than 1 and gradually increased from 2025 to 2030 and 2035 under different scenarios, indicating that the collaborative control effect increases (Fig. 4a). Under the CC scenarios, the collaborative control cross elasticities of SO2 and CO2 in 2025, 2030, and 2035 were all greater than 1 (Fig. 4b). Compared with the CC scenarios, the collaborative control cross elasticities of SO2 and CO2 under the ECC scenarios were closer to 1, indicating a better synergistic control effect. The collaborative control cross elasticities of NOx and CO2 were close to 1 in both the CC and ECC scenarios (Fig. 4c), suggesting that the synergistic control effect was strong in these cases as well. Under the CC and ECC scenarios, the cross elasticities of VOCs and CO2 were significantly less than 1, indicating that their synergistic control effects were relatively weak (Fig. 4d). Meanwhile, the results showed that the VOC emission reduction effect was not as strong as that of CO2. Overall, the synergistic control effects of VOCs and CO2 in the ECC scenario were better than those in the CC scenario.

Fig. 4.

Collaborative control cross elasticities of air pollutants and CO2 in different scenarios.

In summary, when the CC scenario evolves to the ECC scenario, the synergistic control effects of the four air pollutants and CO2 are enhanced.

3.3. PM2.5 concentrations and CO2 emission intensity analyses

3.3.1. PM2.5 concentration

To elucidate the effects of different scenarios on ambient air quality in the HBO region, the WRF-CMAQ model was used to analyze changes in the average annual PM2.5 concentrations [26], as shown in Table 3. For the model simulation, it was assumed that the emissions of air pollutants from mobile sources, dust sources, catering sources, agricultural sources, and other emission sources in the HBO region in 2025, 2030, and 2035 would be consistent with the corresponding emissions in 2020.

Table 3.

Simulated average annual PM2.5 concentration reduction ratios in the HBO region under different scenarios compared with 2020.

| Scenario | Reduction ratio of PM2.5 concentration (%) |

|---|---|

| CC scenario in 2025 | 10.81 |

| CC scenario in 2030 | 17.36 |

| CC scenario in 2035 | 28.14 |

| ECC scenario in 2025 | 25.36 |

| ECC scenario in 2030 | 33.62 |

| ECC scenario in 2035 | 44.93 |

The results indicated that compared with 2020, the reduction of average annual PM2.5 concentration in the ECC scenario would be greater than that in the CC scenario for the same target year. Under a given scenario, the reduction of PM2.5 concentration in 2035 was greater than that in 2030 and 2025. In 2025, the PM2.5 concentration reductions in the CC and ECC scenarios were 10.81 % and 25.36 %, respectively, thus meeting the requirement of continuous air quality improvement in the HBO region.

3.3.2. CO2 emission intensity

In general, CO2 emissions per unit of industrial added value in the HBO region under the 2025 CC and ECC scenarios will be reduced by 20.12 % and 38.36 % compared with 2020, respectively, which would meet the 18 % CO2 emission reduction target proposed by China [27]. Therefore, the relevant decision-makers in the HBO region can consider the CC and ECC scenario measures to facilitate low-carbon transformation in various industries.

3.4. Collaborative control path for reducing pollution and carbon emissions

Based on the analyses presented above, the CC scheme can meet the requirement of continuous improvement of air quality in the HBO region and ensure CO2 emission reduction across industrial fields. The CC scenario (Table 1) therefore represents an effective approach for promoting collaborative control of industrial pollution and carbon emission reduction in the HBO region.

Among the three emission reduction measures evaluated in this study, energy consumption intensity control measures contributed the most to the reduction of PM and SO2 emissions. Energy consumption intensity control and energy structure optimization measures made similar contributions to NOx and CO2 emission reductions, which were greater than those of industrial structure adjustment measures. These results are supported by the previous study [22]. However, industrial structure adjustment measures contributed the most to reducing VOC emissions. Therefore, on the basis of the designed collaborative control path for pollution and carbon emission reduction, we propose that energy consumption intensity control and industrial structure adjustment measures should be prioritized, followed by the implementation of energy structure optimization measures. Refer to Table 1 for the specific collaborative control measures.

4. Conclusions

In this study, the potentials for PM, SO2, NOx, VOC, and CO2 emission reductions under CC and ECC scenarios in various industrial fields in the HBO region were assessed. The synergistic control effects of air pollutants and CO2 in different scenarios were also analyzed. The WRF-CMAQ model was used to analyze changes in the average annual PM2.5 concentrations in the HBO region, and CO2 emission intensities were calculated for different scenarios. In addition, a collaborative control path for pollution and carbon emission reduction was proposed. The results demonstrated that industrial structure adjustments, energy consumption intensity control, and energy structure optimization in the CC and ECC scenarios could facilitate the coordinated reduction of air pollutants and CO2 emissions. Among the evaluated industries, the thermal power and steel industries contributed more to the reduction of PM, SO2, NOx, and CO2 emissions, while the other chemical and coking industries contributed more to the reduction of VOC emissions. The synergistic control effects of the four air pollutants and CO2 in the ECC scenarios were stronger than those in the corresponding CC scenarios. Compared with 2020, the reduction of PM2.5 concentrations in the 2025 CC and ECC scenarios were 10.81 % and 25.36 %, respectively, and those in 2030 and 2035 were greater than in 2025 in the same scenario, thus fulfilling the requirement of continuous improvement of air quality in the HBO region. Moreover, under the CC and ECC scenarios in 2025, CO2 emissions per unit of industrial added value in the HBO region would be reduced by 20.12 % and 38.36 % compared to 2020, respectively, thus meeting the 18 % CO2 emission reduction target set by China. Considering these results, the CC scheme was selected as the most effective approach for collaborative pollution control and carbon emission reduction in the industrial sector in the HBO region. Furthermore, prioritizing the implementation of energy consumption intensity control and industrial structure adjustment measures is recommended, followed by deploying energy structure optimization measures.

CRediT authorship contribution statement

Yazhou Zhao: Writing – review & editing, Writing – original draft, Methodology, Data curation. Zhou Yin: Methodology. Xin Zhang: Data curation. Yue Kuang: Investigation. Yishu Zhao: Formal analysis. Jing Liu: Investigation. Qingling Zhang: Formal analysis. Yanping Li: Writing – review & editing, Conceptualization.

Data availability statement

Data will be made available on request.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Key Research and Development Program of China (No. 2022YFB2703404).

References

- 1.Ministry of Ecology and Environment of the People's Republic of China Implementation plan for synergistic efficiency in reducing pollution and carbon. 2022. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk03/202206/t20220617_985879.html

- 2.Zhou Y., Zhao L. Impact analysis of the implementation of cleaner production for achieving the low-carbon transition for SMEs in the Inner Mongolian coal industry. J. Clean. Prod. 2016;127:418–424. [Google Scholar]

- 3.Inner Mongolia Autonomous Region Bureau Statistics Inner Mongolia statistical Yearbook 2021. 2021. https://tj.nmg.gov.cn/files_pub/content/PAGEPACK/83e5521da4e94d50ab45483b58e5fa7e/zk/indexch.htm

- 4.Hohhot Municipal Bureau Statistics Hohhot statistical Yearbook 2021. 2021. http://tjj.huhhot.gov.cn/nj/2021nj/zk/indexch.htm

- 5.Baotou Municipal Bureau Statistics Baotou statistical Yearbook 2021. 2021. http://tjj.baotou.gov.cn/u/cms/btstjj/btstjjndsj/2021/indexch.htm

- 6.Ordos Municipal Bureau Statistics Ordos statistical Yearbook 2021. 2021. http://sj.tjj.ordos.gov.cn/files_pub/content/pdfview/web/viewer.html?file=/files_pub/content/PDF/ed4dc7cc720a4b91a106e275c6c8e78a/ed4dc7cc720a4b91a106e275c6c8e78a.pdf

- 7.Dai Y.H., Zheng H., Jiang Z.X., et al. Comparison of different crop residue-based technologies for their energy production and air pollutant emission. Sci. Total Environ. 2020;707 doi: 10.1016/j.scitotenv.2019.136122. [DOI] [PubMed] [Google Scholar]

- 8.Altintas H., Kassouri Y. The impact of energy technology innovations on cleaner energy supply and carbon footprints in Europe: a linear versus nonlinear approach. J. Clean. Prod. 2020;276 [Google Scholar]

- 9.Amann M., Bertok I., Borken-Kleefeld J., et al. Cost-effective control of air quality and greenhouse gases in Europe: modeling and policy applications. Environ. Model. Software. 2011;26:1489–1501. [Google Scholar]

- 10.Russ P., Criqui P. Post-Kyoto CO2 emission reduction: the soft landing scenario analysed with POLES and other world models. Energy Pol. 2007;35:786–796. [Google Scholar]

- 11.Xie X., Weng Y.W., Cai W.J. Co-benefits of CO2 mitigation for NOx emission reduction: a research based on the DICE model. Sustainability-Basel. 2018;10:1109. [Google Scholar]

- 12.Xie Y., Wu Y.Z., Xie M.J., et al. Health and economic benefit of China's greenhouse gas mitigation by 2050. Environ. Res. Lett. 2020;15 [Google Scholar]

- 13.Yu Y., Liu H.R. Economic growth, industrial structure and nitrogen oxide emissions reduction and prediction in China. Atmos. Pollut. Res. 2020;11:1042–1050. 2020. [Google Scholar]

- 14.Ma Y.X., Yang S.X., Zhou J.D., et al. Effect of ambient air pollution on emergency room admissions for respiratory diseases in Beijing, China. Atmos. Environ. 2018;191:320–327. [Google Scholar]

- 15.Jiang P., Khishgee S., Alimujiang A., et al. Cost-effective approaches for reducing carbon and air pollution emissions in the power industry in China. J. Environ. Manag. 2020;264 doi: 10.1016/j.jenvman.2020.110452. [DOI] [PubMed] [Google Scholar]

- 16.Xu B., Lin B.Q. Regional differences in the CO2 emissions of China's iron and steel industry: regional heterogeneity. Energy Pol. 2016;88:422–434. [Google Scholar]

- 17.Zheng C.Y., Zhang H.R., Cai X.R., et al. Characteristics of CO2 and atmospheric pollutant emissions from China's cement industry: a life-cycle perspective. J. Clean. Prod. 2020;282:1–10. [Google Scholar]

- 18.Zhou S.Y., Li W., Lu Z.G., et al. A technical framework for integrating carbon emission peaking factors into the industrial green transformation planning of a city cluster in China. J. Clean. Prod. 2011;344 [Google Scholar]

- 19.National Development and Reform Commission . 2023. Energy Efficiency Leading and Benchmark Levels in Key Industrial Areas.https://www.ndrc.gov.cn/xxgk/zcfb/tz/202307/t20230704_1358113.html 2023 Version. [Google Scholar]

- 20.National Development and Reform Commission Evaluation index system of cleaner production in coal mining industry. 2019. https://www.ndrc.gov.cn/xxgk/zcfb/gg/201909/t20190919_1181886.html

- 21.People's Government of Inner Mongolia Autonomous Region Inner Mongolia autonomous region “14th five-year” comprehensive work implementation plan for energy conservation and emission reduction. 2022. https://www.nmg.gov.cn/zwgk/zfxxgk/zfxxgkml/202206/t20220606_2067067.html

- 22.Yuan R.X., Ma Q., Zhang Q.Q., et al. Coordinated effects of energy transition on air pollution mitigation and CO2 emission control in China. Sci. Total Environ. 2022;841 doi: 10.1016/j.scitotenv.2022.156482. [DOI] [PubMed] [Google Scholar]

- 23.Zhang L.X., Wang Y., Feng C.Y., et al. Understanding the industrial NOx and SO2 pollutant emissions in China from sector linkage perspective. Sci. Total Environ. 2021;770 doi: 10.1016/j.scitotenv.2021.145242. [DOI] [PubMed] [Google Scholar]

- 24.Tao C.L., Zhang Q.Z., Huo S.S., et al. PM2.5 pollution modulates the response of ozone formation to VOC emitted from various sources: insights from machine learning. Sci. Total Environ. 2024;916 doi: 10.1016/j.scitotenv.2024.170009. [DOI] [PubMed] [Google Scholar]

- 25.Mao X.Q., Xing Y.K., Gao Y.B., et al. Study on GHGs and air pollutants co-control: assessment and planning. China Environ. Sci. 2021;41:3390–3398. (In Chinese) [Google Scholar]

- 26.Fang C.S., Qiu J.X., Li J., et al. Analysis of the meteorological impact on PM2.5 pollution in Changchun based on KZ filter and WRF-CMAQ. Atmos. Environ. 2022;271 [Google Scholar]

- 27.Ministry of Industry and Information Technology of the People's Republic of China “14th five-year” industrial green development plan. 2021. https://www.miit.gov.cn/jgsj/ghs/zlygh/art/2022/art_dd7cf9f916174a8bbb7839ad654a84ce.html

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.