Abstract

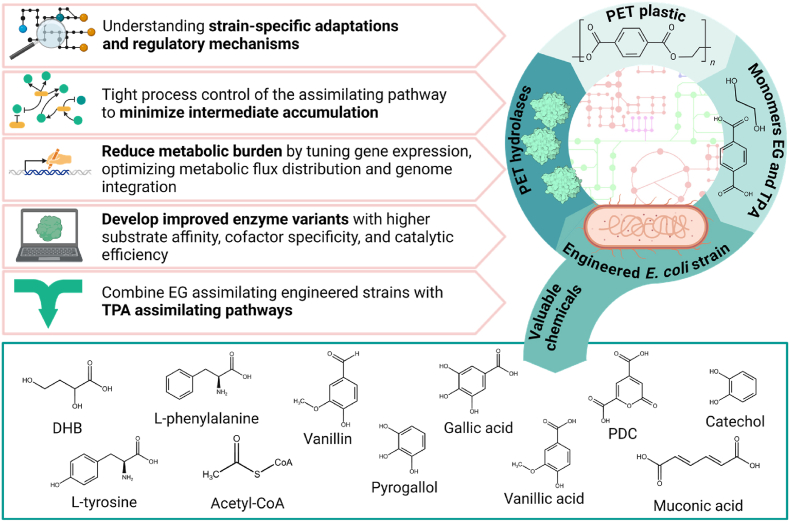

Polyethylene Terephthalate (PET) is a petroleum-based plastic polymer that, by design, can last decades, if not hundreds of years, when released into the environment through plastic waste leakage. In the pursuit of sustainable solutions to plastic waste recycling and repurposing, the enzymatic depolymerization of PET has emerged as a promising green alternative. However, the metabolic potential of the resulting PET breakdown molecules, such as the two-carbon (C2) molecule ethylene glycol (EG), remains largely untapped. Here, we review and discuss the current state of research regarding existing natural and synthetic microbial pathways that enable the assimilation of EG as a carbon and energy source for Escherichia coli. Leveraging the metabolic versatility of E. coli, we explore the viability of this widely used industrial strain in harnessing EG as feedstock for the synthesis of target value-added compounds via metabolic and protein engineering strategies. Consequently, we assess the potential of EG as a versatile alternative to conventional carbon sources like glucose, facilitating the closure of the loop between the highly available PET waste and the production of valuable biochemicals. This review explores the interplay between PET biodegradation and EG metabolism, as well as the key challenges and opportunities, while offering perspectives and suggestions for propelling advancements in microbial EG assimilation for circular economy applications.

Keywords: Escherichia coli, Ethylene glycol, Metabolic engineering, Synthetic biology, Protein engineering, PET biodegradation

Highlights

-

•

Review of PET depolymerization and its green alternative, enzymatic breakdown.

-

•

Explores E. coli's potential to metabolize ethylene glycol for bioproduction of high value compounds.

-

•

Assesses microbial pathways and protein engineering for EG assimilation.

-

•

Discusses EG as a sustainable carbon source, enhancing circular economy efforts.

1. Introduction

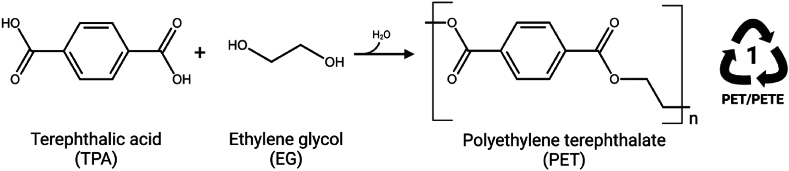

Polyethylene Terephthalate (PET) is a petroleum-based plastic polymer that is designed to endure for decades, if not centuries, which is highly disadvantageous when released into the environment via plastic waste leakage. PET is produced from a condensation reaction between ethylene glycol (EG) and terephthalic acid (TPA) (Fig. 1), two chemicals commonly derived from petroleum feedstock (Benyathiar et al., 2022). In 2021, it was estimated that global production reached 390.7 Mt of plastic, with 90.2% still originating from fossil-based feedstock (Plastics Europe, 2022). Although PET accounted for 6.2% of the annual global plastic production, this polymer is primarily and extensively used in single-use packaging, such as beverage bottles and food containers, as well as in textile manufacturing (polyester fibres), which are highly prone to being downcycled or mismanaged (Grant et al., 2022; Plastics Europe, 2022). In Europe, despite PET being one of the most recyclable plastics, the majority of PET waste is not currently managed within a circular model (Grant et al., 2022).

Fig. 1.

Chemical reaction between terephthalic acid (TPA) and ethylene glycol (EG) to form polyethylene terephthalate (PET). The PET polymer has the Resin Identification Code 1 and can be identified with acronym PET or PETE.

Consequently, plastic waste management and recycling are widely discussed topics today due to environmental concerns. The most commonly used recycling method is mechanical recycling, which entails grounding and melting the plastic waste into plastic pellets by extrusion. This process can cause undesirable changes in polymer properties in every cycle, limiting its reusability (Achilias and Karayannidis, 2004; Benyathiar et al., 2022). Alternatively, PET can be chemically recycled, partially broken down into small oligomers and other chemical substances, or completely into its monomer units, which can be repolymerized into a new oligomer. However, chemical recycling processes such as methanolysis and glycolysis are energy-intensive, requiring high pressures and temperatures, as well as downstream separation and purification steps. Additionally, the reaction catalysts employed are often difficult to remove from the final reaction, cannot be reused, and pose environmental threats (Achilias and Karayannidis, 2004; Benyathiar et al., 2022). Moreover, recycled PET faces challenges in competing with virgin PET in terms of availability, price, and quality, resulting in only a small fraction of the PET produced worldwide being recycled (Grant et al., 2022). In 2019, 91.25% of plastic was still either buried in landfills, incinerated for energy generation, or mismanaged (Benyathiar et al., 2022; OECD, 2023). The Great Pacific Garbage Patch serves as just one striking example of plastic waste being lost into the environment (National Geographic, 2024). Plastic waste pollution has thus been recognized as one of the most significant global environmental challenges of our lifetime.

In the quest for more sustainable alternatives to PET recycling and repurposing, researchers have focused on the biodegradation of PET using enzymes and engineered microorganisms. This pursuit aims to develop a biological recycling process, marking a significant area of research in recent years. Many examples include the application of enzymes in vitro that are capable of degrading the PET polymer along with derived engineered enzyme variants with catalytically improved PET breakdown capabilities (Khairul Anuar et al., 2022; Sui et al., 2023). Some of the most prominent cases include FAST-PETase, a mutant PETase from Ideonella sakaiensis engineered using a machine learning algorithm, which can completely degrade a number of different untreated postconsumer-PET products within one week, and even as quickly as 24 h (Lu et al., 2022). Another example is a variant of the leaf-branch compost cutinase (LCC), which degrades 90% of pretreated post-consumer PET in just 10 h (Tournier et al., 2020). Notably, some cases are already taking their first steps in industrial application (Carbios, 2021). Microorganisms have also been engineered to biodegrade PET in vivo, with some examples including E. coli (Benavides Fernández et al., 2022) but also some other species such as the non-conventional yeast Yarrowia lipolytica (Kosiorowska et al., 2022). Recent research has demonstrated how TPA resulting from in vitro enzymatic digestion can be repolymerized to create a new PET film with similar properties to virgin PET (Tournier et al., 2020). However, production of new PET from biologically obtained monomers has only recently started to be studied and is still not well developed. This process faces several associated hurdles, particularly regarding purity requirements. For instance, purifying EG from enzymatically obtained PET hydrolysate can be difficult and costly due to its high solubility in water and elevated boiling temperature, thus requiring complex and energy-intensive separation processes and distillation steps (Tournier et al., 2020; Wong et al., 2023). In alternative, if PET waste can be cost-effectively biodegraded, the resultant hydrolysed PET monomers could be directly used by microorganisms to fuel their metabolism and produce useful molecules and target compounds. Particularly, the two-carbon (C2) molecule EG holds great promise for fuelling microbial metabolism as a next-generation feedstock (NGF) for bioprocesses, even being considered a viable candidate for replacing commonly used microbial feedstocks such as glucose (Pandit et al., 2017). Thus, PET could potentially be recycled into new added-value compounds in a circular economy manner through microbial assimilation of EG. However, for efficient assimilation and/or upcycling of PET-derived EG, it is crucial to understand the EG assimilating pathways, as well as comprehend how bacteria can be engineered for improved EG assimilation and/or conversion.

This review aims to survey the known natural and synthetic pathways for microbial EG assimilation and recent advancements in metabolic engineering (ME) strategies. Specifically, our focus lies on the exploitation of synthetic pathways for consuming EG as a carbon source to support microbial growth and produce compounds of interest, focusing on the industrially well-established bacterium Escherichia coli. We further identify and discuss possible metabolic bottlenecks as well as other associated challenges with an EG assimilation bioprocess using PET as feedstock.

2. Production of EG

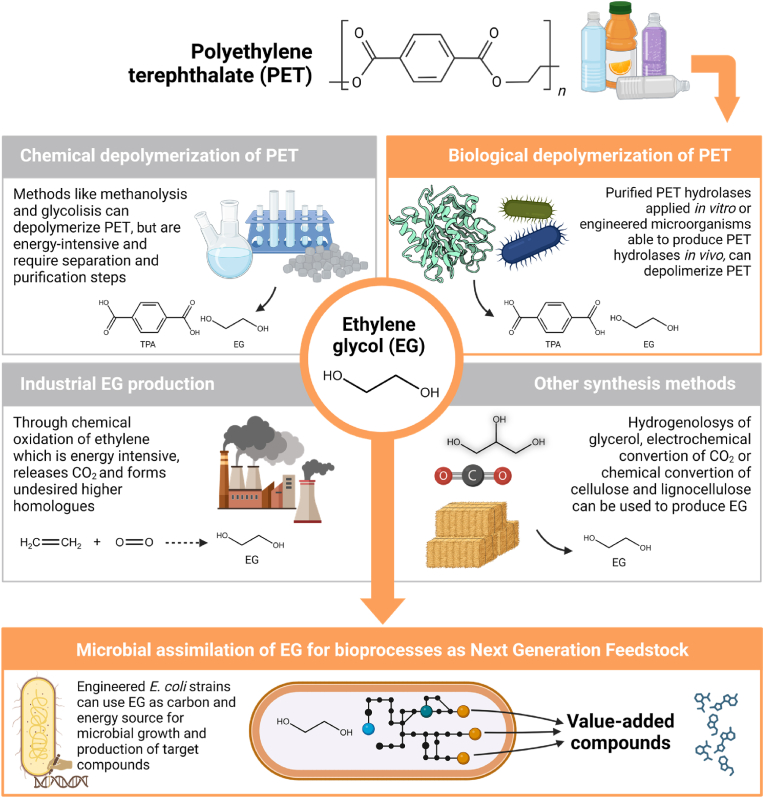

The potential use of EG as a starting compound for cellular metabolism and/or production of target compounds using ME strategies has only recently begun to be explored. EG is a commodity chemical that can be produced in a few different ways including chemical depolymerization and biological depolymerization of PET, industrial EG production, and other synthesis methods (Fig. 2). It is primarily produced by the chemical oxidation of ethylene, a process that requires high-energy consumption, resulting in a significant amount of CO2 emission and formation of undesired higher homologues (Kandasamy et al., 2019; Rebsdat and Mayer, 2000). Furthermore, the EG precursor ethylene is primarily obtained by the petrochemical industry through steam cracking of hydrocarbons from natural gas and crude oil (Rebsdat and Mayer, 2000; Yue et al., 2012). Besides being used for the production of PET plastics and polyester fibres, EG is primarily employed in antifreeze formulations, such as those used in automotive and industrial cooling systems (Rebsdat and Mayer, 2000; Yue et al., 2012). In 2023, the industry market of EG was estimated to reach 60.06 million tonnes per annum, with an expected average annual growth rate of more than 5%, between 2023 and 2028 (GlobalData, 2024). Due to its different uses and applications, a significant amount of EG enters the environment, for example through industrial manufacturing effluents or runoff water from airports, where it is used for aircraft de-icing (ATSDR, 2022; Staples et al., 2001). Hence, it is crucial to establish new methods for EG manufacturing that substitute toxic petrochemical materials and decrease environmental impact. This has prompted the scientific community to explore renewable alternatives for EG production that valorise waste feedstocks. Some examples include the hydrogenolysis of glycerol, a waste from the biodiesel industry (Kandasamy et al., 2019), the electrochemical conversion of CO2 (Chen et al., 2021; Li et al., 2020; Tamura et al., 2015), synthesis of EG using syngas (Satapathy et al., 2018), and chemical conversion of cellulosic and lignocellulosic biomass (Pang et al., 2011; Wong et al., 2023). The latter technique has been the focus of extensive research in recent years, but has not yet been commercialised mainly due to the need of complex post-reaction separation processes and high purifying cost of EG (Wong et al., 2023).

Fig. 2.

Overview of the methods used for producing ethylene glycol (EG) as feedstock and its integration into Escherichia coli metabolism to produce value-added compounds. The different routes for EG production, including chemical PET depolymerization, biological PET depolymerization by engineered microorganisms or enzymes, industrial production, and other alternative synthesis methods are shown. Created with BioRender.com.

Alternatively, EG can be biologically obtained from the enzymatic depolymerization of PET plastic, a highly abundant waste material. The biodegradation of PET and assimilation of the resulting EG could even be envisioned as a simultaneous process carried out by a single microbial cell factory. Microbial cell factories (MCFs) leverage the use of microorganisms to metabolically convert renewable raw sources into target products in an efficient manner via fermentation. These processes operate under mild conditions in terms of temperature and pressure, bypassing the use of toxic solvents and catalysts typically associated with the conventional chemical processes (Cho et al., 2022). The efficient development of MCFs often requires the application of rationally-designed ME strategies to rewire the native metabolism of the cell for the desired industrial application. This plays special importance when utilizing different carbon sources as substrates to produce non-native metabolites (Cho et al., 2022). In this respect, the model organism E. coli is one of the most widely used hosts for designing MCFs due to its extensively studied metabolism and well-established molecular tools for engineering (Lee et al., 2019). Concerning current biotechnological processes, EG has been pinpointed as a viable candidate to replace commonly used sugars such as glucose and sucrose. Sugar feedstocks used in fermentation are still commonly derived from hydrolysis of starch retrieved from crops, such as wheat and corn, which currently pose concerns such as competition with food sources in the face of a growing world population, or the intensive use of water and energy in crop processing (Tubb, 2023; Zhang et al., 2022). Lignocellulose, a non-edible residue from crop processing, has been widely studied as an alternative feedstock (second generation), however, due to its recalcitrant nature, extensive pre-treatment to release the sugars is usually required, which requires high energy consumption and often leads to the release of toxic by-products. This leads to low yields and consequently increases cost and competitiveness compared to starch processing (Ning et al., 2021; Salim et al., 2019). The use of NGFs such as C1 (methane, CO2, CO, methanol and formate) and C2 (acetate and ethanol) feedstocks has also been a key area of interest across a range of industries. However, though abundant and low-cost, the key challenge of using these molecules as feedstocks lies in the absence of native assimilation pathways in most biotechnologically relevant microorganisms, although recent advances are paving the way towards creation of C1 and C2-utilizing microorganisms (Zhang et al., 2022).

The future bioeconomy will depend on various bioprocesses that utilize carbon feedstocks. These processes will play a crucial role in the bioeconomy, generating a wide range of products, including alternative proteins, chemicals, and therapeutic pharmaceuticals. In this sense, discovering alternative feedstocks that are inexpensive, sustainable, and noncompeting with the food industry remains an important challenge yet to be overcome. In this regard, the PET-derived EG emerges as a potential source of inexpensive renewable C2 feedstock that could directly fuel bacterial metabolism. PET could be recycled and repurposed via EG for the bioproduction of high-added value compounds, aligning with the principles of a circular economy. We consider EG to be an important and relevant NGF. In the following sections, we will review the known natural EG assimilation pathways employed by microorganisms, as well as recently developed ME and synthetic biology strategies that propose new pathways for EG assimilation for biomass and value-added products in E. coli.

3. Natural EG assimilation

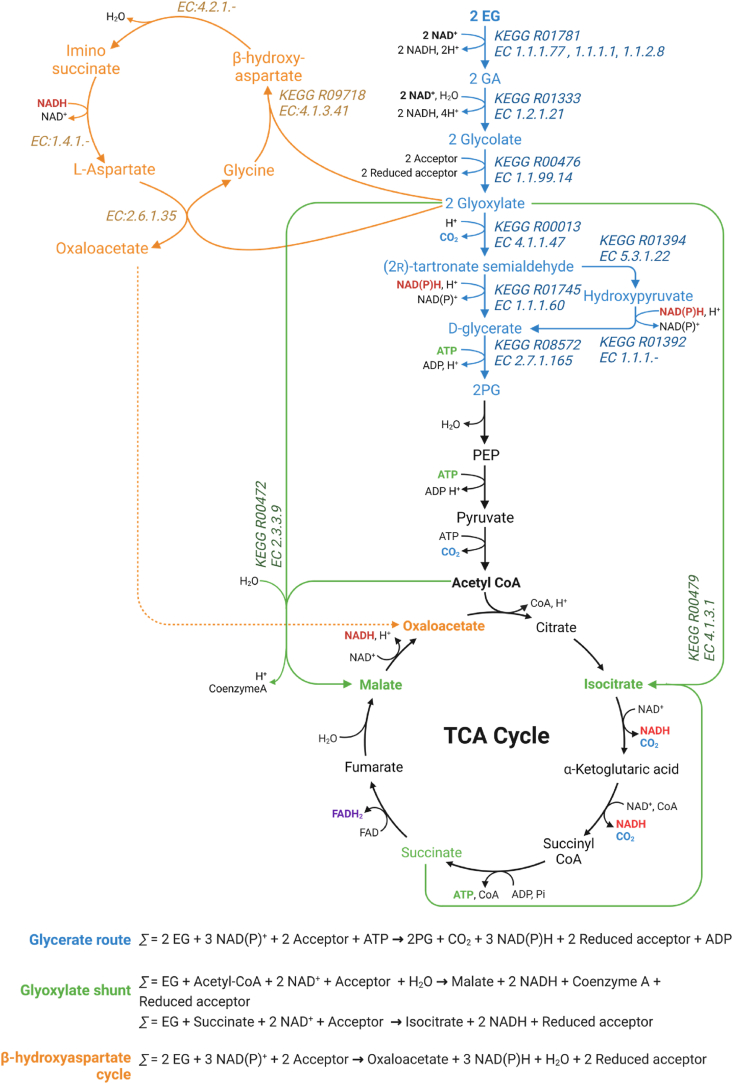

EG is considered readily biodegradable in the environment (Staples et al., 2001), and to date, several microbial species have been identified as capable of using EG as carbon and energy source, under both aerobic and anaerobic conditions. Examples include, but are not limited to, Flavobacterium sp., Clostridium glycolicum and Pseudomonas putida (Child and Willetts, 1978; Fincher and Payne, 1962; Gonzalez et al., 1972; Hartmanis and Stadtman, 1986; Kataoka et al., 2001; Mückschel et al., 2012; Toraya et al., 1979). Under aerobic conditions, EG is converted to glyoxylate in three successive steps (Boronat et al., 1983; Mückschel et al., 2012). Then, glyoxylate can be used to generate biomass through the glycerate route (Boronat et al., 1983; Li et al., 2019), or the β-hydroxyaspartate (BHA) cycle (Schada von Borzyskowski et al., 2019). Glyoxylate can also combine with acetyl-CoA to form malate or with succinate to form isocitrate, through the glyoxylate shunt (Li et al., 2019; Mückschel et al., 2012). These natural EG assimilating pathways will be discussed in this Section, and a schematic representation of each pathway is provided in Fig. 3.

Fig. 3.

Overview of the natural microbial ethylene glycol (EG) assimilation pathways. The metabolic EG assimilation pathways, namely the oxidative route (blue), the glyoxylate shunt (green), and the β-hydroxyaspartate (BHA) cycle (orange), and their integration with central metabolism (black) is shown. Each step of these three pathways is annotated with its corresponding Enzyme Commission (EC) number and Kyoto Encyclopaedia of Genes and Genomes (KEGG) reaction number, when available, along with the stoichiometric equations for each pathway. The alternative conversion of tartronate semialdehyde into glycerate via hydroxypyruvate is not considered for the stoichiometric equation of the glycerate route. Abbreviations: EG, ethylene glycol; GA, glycolaldehyde; 2 PG, 2-phospho-d-glycerate; PEP, phosphoenolpyruate; TCA, tricarboxylic acid cycle. Created with BioRender.com.

3.1. The EG oxidative pathway

The EG oxidative pathway (pathway depicted in blue in Fig. 3) exists in different bacteria, including E. coli, Pseudomonas and Flavobacterium species, where EG is aerobically oxidized into molecules that can enter central metabolism using nicotinamide cofactors, or other types of cofactors depending on the organism (such as pyrroloquinoline quinone – PQQ – cofactors in the first EG oxidation step in P. putida), and ATP (Boronat et al., 1983; Mückschel et al., 2012; Willetts, 1981). In this route, EG is first converted to glycolaldehyde (GA) by a propanediol/EG oxidoreductase or other alcohol dehydrogenases (refer to Section 5 for a discussion about enzymes involved in this first step of EG oxidation). Then, GA is converted into glyoxylate via the intermediate glycolate by the chained action of the enzymes GA dehydrogenase and glycolate dehydrogenase (Fig. 3) (Caballero et al., 1983; Lord, 1972). These enzymes employ cofactors such as NAD+ and proton acceptor quinones that direct electrons into the electron transport chain (Boronat et al., 1983; Mückschel et al., 2012). Both glycolate and glyoxylate molecules have economic interest, being routinely used in industrial applications. Particularly, glycolate is a C2 α-hydroxy acid that, due to its versatile properties of both alcohol and carboxylic acid, has many different applications in cosmetics and dermatology (Babilas et al., 2012). Moreover, this compound is used in the synthesis of the biodegradable packaging material polyglycolic acid and in biomedical applications (Fredenberg et al., 2011). While glyoxylate has fewer direct industrial applications, it still serves as a building block in the synthesis of many compounds used in perfumery, flavour, pharmaceuticals and agrochemicals (Jin et al., 2003), with one significant example being the production of vanillin (Kalikar et al., 1986; Mao et al., 2020). Both compounds are currently synthetized from petrochemical resources with the biotechnological production of glycolate receiving significant interest in recent years (Cabulong et al., 2021; Jin et al., 2003; Salusjärvi et al., 2019; Schad et al., 2023). Hence, the microbial conversion of EG to glycolate and glyoxylate may offer a sustainable alternative to produce these two industrially relevant compounds. In particular, the engineered production of glycolate from EG in E. coli has been reported (Pandit et al., 2021; Yan et al., 2024) and will be discussed in Section 4.2. Glyoxylate can then enter the central carbon metabolism by three different routes (Fig. 3).

3.1.1. The glycerate pathway

On the first route, the glycerate pathway (pathway depicted in blue in Fig. 3), glyoxylate can be used as the sole carbon and energy source. Two molecules of glyoxylate are first converted to (2r)-tartronate semialdehyde and CO2 by a glyoxylate carboligase, which is then converted to d-glycerate by the action of tartronate semialdehyde reductase (Chang et al., 1993; Gotto and Kornberg, 1961; Gupta and Vennesland, 1964; Njau et al., 2000). Additionally, tartronate semialdehyde can also be transformed into d-glycerate indirectly via hydroxypyruvate by the enzymes hydroxypyruvate isomerase and glyoxylate/hydroxypyruvate reductase (Ashiuchi and Misono, 1999; Nuñez et al., 2001). Finally, d-glycerate 2-kinase converts d-glycerate to 2-phopho-d-glycerate (2 PG), further entering in lower glycolysis (Fig. 3) (Zelcbuch et al., 2015). It should be noted that there are glycerate 2-kinases that convert d-glycerate into 3-phopho-d-glycerate (3 PG), however the one from E. coli produces 2 PG instead of 3 PG as initially claimed (Bartsch et al., 2008; Zelcbuch et al., 2015). In E. coli, the glycerate pathway is seemingly essential for growth on glyoxylate, since a deletion of the native glyoxylate carboligase gene (gcl) prevents growth on this substrate (Aslan et al., 2020; Ornston and Ornston, 1969). In terms of carbon molecules, the pathway from EG (C2) to the central carbon metabolite 2 PG (C3) yields 0.75 mol/mol (2 PG/EG) at the expense of one ATP molecule, releasing one molecule of CO2 and two of NADH.

3.1.2. The glyoxylate shunt

The glyoxylate shunt (pathway depicted in green in Fig. 3) acts as an alternative pathway to metabolize EG. In this pathway, glyoxylate and acetyl-CoA are converted into (s)-malate, releasing one molecule of coenzyme A, by the action of malate synthase (Dixon et al., 1960; Maloy and Nunn, 1982; Mückschel et al., 2012). Malate can enter directly into the tricarboxylic acid cycle (TCA) cycle (Boronat et al., 1983). Additionally, glyoxylate and succinate can also be fused to form isocitrate by isocitrate lyase (Fig. 3) (Ashworth and Kornberg, 1964; Maloy and Nunn, 1982; Mückschel et al., 2012).

Interestingly, studies have reported differential expression of the enzymes constituting the glyoxylate shunt in E. coli strains. During growth on glucose, E. coli strain BL21 exhibited constitutive expression of proteins isocitrate lyase (aceA) and malate synthase (aceB), while the inverse happens with E. coli JM106 due to expression of the isocitrate lyase repressor (iclR) (Phue and Shiloach, 2004). This implies that there is a higher flux through the glyoxylate shunt that, together with the also attested lower expression of isocitrate dehydrogenase in E. coli BL21, is pointed as the reason for lower acetate accumulation in glucose-based fermentations (Liu et al., 2017; Phue and Shiloach, 2004). This different expression level of the glyoxylate shunt might also impact the cell growth on EG, as will be further considered is Section 6. The glyoxylate shunt might play a complementary role to the glycerate pathway since mutant strains unable to produce malate synthase G were able to grow on glyoxylate but showed a slower growth rate than the wild-type (WT) cells (Ornston and Ornston, 1969). Also, E. coli mutants without isocitrate lyase activity were able to grow on glycolate (Ashworth and Kornberg, 1964). The oxidative route can be considered essential for growth on EG since it feeds into glycolysis and subsequently serves as a source of acetyl-CoA, which in its turn is essential for the glyoxylate shunt (Tiso et al., 2022). The glyoxylate shunt enables utilization of glyoxylate as carbon source but requiring acetyl-CoA or succinate. However, the assimilated carbon atoms would be totally lost as CO2 when acetyl-CoA and succinate are recovered through oxidative decarboxylation reactions. Consequently, these two pathways are unable to donate carbon atoms, but they can supply reducing equivalents and energy (Panda et al., 2023).

3.1.3. The β-hydroxyaspartate cycle

An alternative pathway with potential for EG metabolization is the recently characterized BHA cycle (pathway depicted in orange in Fig. 3) (Kornberg and Morris, 1963; Schada von Borzyskowski et al., 2019). This cycle was first discovered in Paracoccus denitrificans (formally Micrococcus denitrificans) (Kornberg and Morris, 1963) and it was recently fully characterized in Paracoccus denitrificans DSM413 (Schada von Borzyskowski et al., 2019). This cycle enables the direct production of oxaloacetate, a TCA cycle intermediate, from glyoxylate through four enzymatic steps. First, an l-aspartate-glyoxylate aminotransferase transaminates one molecule of glyoxylate into glycine using aspartate as the preferred amino group donor, generating oxaloacetate in the process. Then, a BHA aldolase catalyses the condensation of another glyoxylate molecule with glycine into BHA, which is then converted to iminosuccinate by BHA dehydratase. Finally, iminosuccinate is reduced to l-aspartate by iminosuccinate reductase, thus regenerating the amino donor for the first step of the cycle. Additionally, iminosuccinate can spontaneously decay into free ammonia and oxaloacetate in solution (Fig. 3) (Schada von Borzyskowski et al., 2019). Overall, the BHA cycle converts two molecules of glyoxylate (C2) into one molecule of oxaloacetate (C4) with no carbon loss, consuming one reducing equivalent, and leading to the regeneration of the catalytic amino donor l-aspartate (Schada von Borzyskowski et al., 2019). The analysis of marine metagenomes from the Tara Oceans expedition online database demonstrated this cycle is ubiquitous in marine Proteobacteria and that this route is globally distributed. On average, it was 20-fold more abundant than the glycerate route in the tested dataset (Schada von Borzyskowski et al., 2019).

Although P. denitrificans is the only organism where this pathway has been fully characterized, Schada von Borzyskowski and colleagues have implemented the BHA cycle into P. putida KT2440 with the goal of assessing whether the implementation of this cycle would permit better growth than the natural EG oxidative pathway (Schada von Borzyskowski et al., 2023). In their work, a P. putida strain unable to assimilate EG through their native glycerate pathway – due to a deletion of the glyoxylate carboligase gene (gcl) – and expressing the BHA cycle enzymes was subjected to adaptive laboratory evolution (ALE). The evolved strain was able to grow 35% faster on 20 mM EG with a 20% higher biomass yield when compared to another P. putida strain evolved to grow on EG with the glycerate pathway (Li et al., 2019; Schada von Borzyskowski et al., 2023). Interestingly, before application in P. putida, the authors implemented part of this pathway in E. coli SIJ488 (Schada von Borzyskowski et al., 2023). The expression of BhcC (BHA aldolase), BhcB (BHA dehydratase) and BhcD (iminosuccinate reductase), a linear metabolic module that transforms glyoxylate and glycine into aspartate, was able to support biomass formation in an E. coli Δgcl after ALE. The deletion of the gcl gene means that this strain is not able to grow on glycolate and glycine, unless the BHA proteins BhcCBD are used. After prolonged incubation in M9 medium with glycolate and glycine, spontaneous mutants capable of growing on both carbon sources were obtained. These mutants add acquired point mutations in genes encoding for enzymes of the TCA cycle, suggesting the need for slight adaptations in the native metabolic network to support growth using the BHA cycle (Schada von Borzyskowski et al., 2023). Thus, it would be interesting to, in the future, connect this strain to EG as feedstock.

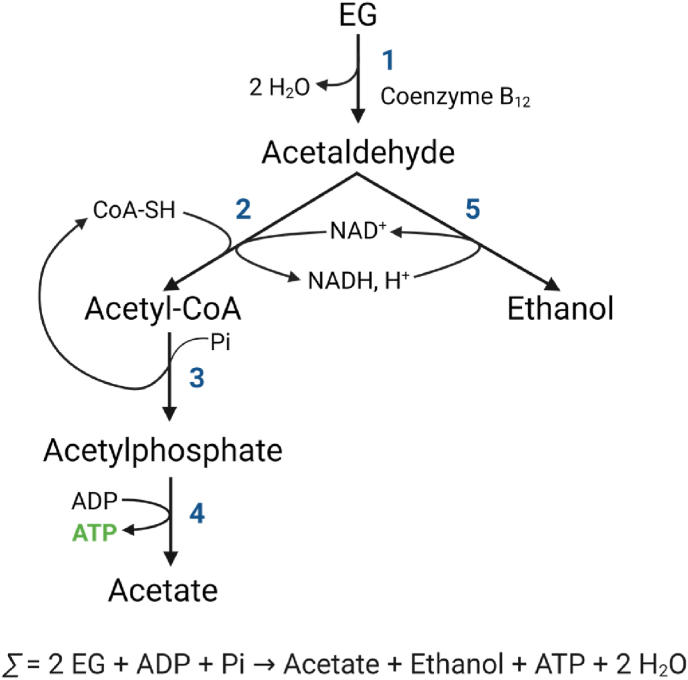

3.2. Dehydratase route

The dehydratase route (Fig. 4) is typically found in some Clostridium, Salmonella and Klebsiella species, and a few other anaerobic or facultative anaerobic organisms due to the oxygen sensitivity of the diol-dehydratase involved in this pathway (Crowley et al., 2010; Hartmanis and Stadtman, 1986; Toraya et al., 1979; Trifunović et al., 2016; Wiegant and De Bont, 1980). In this alternative route for EG assimilation, EG is dehydrated to acetaldehyde by a diol-dehydratase (Wiegant and De Bont, 1980). Acetaldehyde molecules are then used to form the alcohol ethanol and acetyl-CoA. The latter is further converted to acetic acid in two steps that are coupled to ATP formation by substrate-level phosphorylation. More specifically, a CoA and NAD+ dependent aldehyde dehydrogenase catalyses the oxidation of acetaldehyde into acetyl-CoA, which is then converted to acetylphosphate by phosphotransacetylase with regeneration of CoA. Finally, acetylphospate is hydrolysed to acetate by acetate kinase with generation of one molecule of ATP (Fig. 4) (Hartmanis and Stadtman, 1986; Toraya et al., 1979).

Fig. 4.

Metabolic pathway of ethylene glycol (EG) fermentation through the dehydratase route. The metabolization of EG through this pathway is dependent of a coenzyme B12-dependent diol-dehydratase (1), an aldehyde dehydrogenase (2), a phosphotransacetylase (3), an acetate kinase (4) and an alcohol dehydrogenase (5) (Hartmanis and Stadtman, 1986; Toraya et al., 1979). Image adapted from Toraya et al. (1979). Created with BioRender.com.

In the earlier studies, diol-dehydratase (EC 4.2.1.28) is reported to be extremely oxygen-sensitive (Hartmanis and Stadtman, 1986; Toraya et al., 1979) and strictly dependent on coenzyme B12 (Toraya et al., 1979; Wiegant and De Bont, 1980). It is also reported to be strongly associated with the cell membrane, and to require monovalent or divalent ions for its activity (Hartmanis and Stadtman, 1986; Toraya et al., 1979). Furthermore, diol-dehydratase has also been identified in Salmonella enterica (Crowley et al., 2010) and Acetobacterium woodie (Trifunović et al., 2016) inside a microcompartment (Crowley et al., 2010). This compartment encapsulates the first two steps of the dehydratase route preventing cytosolic exposure of the toxic aldehyde resulting from the first diol-dehydratase reaction, which can lead to chromosomal mutations and cytotoxicity, together with enzymes required to maintain the active form of the B12 cofactor at the expense of ATP (Crowley et al., 2010). Although the dehydratase route enables the anaerobic two-steps conversion of EG into acetyl-CoA, and E. coli is capable of anaerobic growth, the challenges involved in diol-dehydratase activity would pose difficulties when expressing this pathway in industrially relevant E.coli strains. For example, E. coli, although possessing a few enzymes of the de novo biosynthetic coenzyme B12 pathway, is only capable of synthetizing coenzyme B12 if the intermediate adenosylcobinamide is supplied (Lawrence and Roth, 1995). Alternatively, the remaining enzymes lacking in the coenzyme B12 production pathway would need to be added to E. coli as well as other relevant proteins, meaning that up to 28 genes would need to be heterologously expressed in E. coli to confer ability to synthesize coenzyme B12 (Fang et al., 2018).

4. Metabolic engineering and synthetic assimilation of EG in E. coli

EG, though an unconventional feedstock, holds promise as a sustainable and renewable precursor for producing different chemical compounds of industrial interest. Recently, Pandit et al. have explored the idea of designing orthogonal network structures, which operate with minimal interaction between chemical-producing pathways and biomass-producing pathways for more efficient chemical production. According to this study, EG shows a high orthogonality score to produce target chemicals. The orthogonality score is a quantitative measure inversely proportional to the interconnectedness between pathways responsible for producing a target chemical and those involved in biomass production. It must be added that this approach is contrary to the notion of growth-coupled strain design, where cell growth is linked to product formation by removing reactions that produce biomass without producing the target chemical. In this way, biomass production and chemical production become coupled. Here, the authors argue that growth-coupled approaches may invariably lead to suboptimal production of biomass and target compounds due to the complex nature of metabolism and that orthogonal pathways may be an advantageous alternative (refer to Pandit et al., 2017 for a more detailed discussion about this topic). EG is highly promising when used as substrate for orthogonal production of a variety of chemicals since it minimizes interactions with biomass-producing pathways (Pandit et al., 2017). It is even suggested that EG should be used as an alternative substrate to sugars, such as glucose, that have significant overlap between biomass and chemical production pathways (Pandit et al., 2017).

Although E. coli, a commonly used host for ME, possesses the genetic inventory to express the EG oxidative pathway, it cannot naturally use EG as carbon source (Panda et al., 2021). However, either by genetically modifying its metabolism or by performing ALE experiments, it is possible to enable E. coli's growth on EG. Up until recently, only one study had reported EG utilization by E. coli (Boronat et al., 1983). In that study, a strain able to use EG was selected from evolved propylene glycol (or l-1,2-propanediol) utilizing mutants. In the EG-assimilating strain, the authors detected an increment of enzymatic activities of l-1,2-propanediol oxidoreductase (FucO), GA dehydrogenase (AldA) and glycolate dehydrogenase (GlcDEF). Enzyme promiscuity is an inherent and relevant element that lead to enzymatic activity with substrates others than the natural ones, including both native and non-native compounds (Khersonsky and Tawfik, 2010). In this case, enzymes that act on l-1,2-propanediol (hereafter referred to as propanediol) and other alcohols, have shown ability to accept EG as substrate as well (Child and Willetts, 1978; Hartmanis and Stadtman, 1986; Mückschel et al., 2012). In recent years, more articles reporting EG consumption by E. coli have been published. For example, a recent study demonstrated that overexpression of fucO and aldA in E. coli K-12 MG1655 strain conferred the ability to grow on EG, when 4 g/L glycerol was also added, as well as on propanediol (Szappanos et al., 2016). Other studies leverage the overexpression of FucO and AldA as a basis for metabolic engineering in EG metabolization, leading to the production of target compounds. These ME strategies will be further discussed in Section 4.2.

4.1. The FucO enzyme

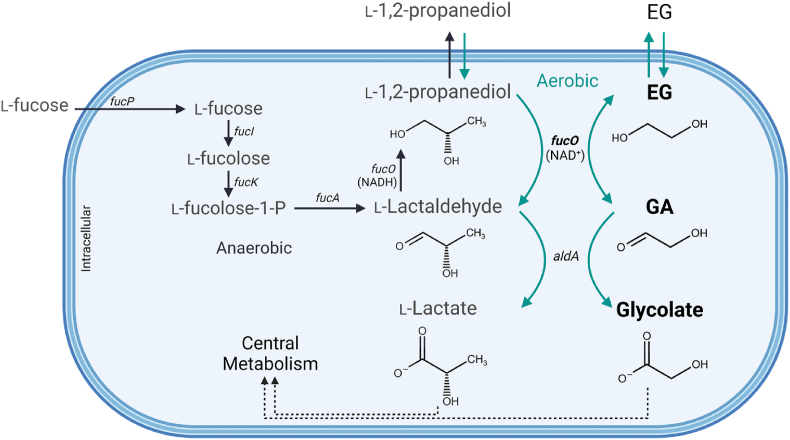

FucO (EC 1.1.1.77) is encoded by the gene fucO, a member of the fuc regulon that controls l-fucose consumption in E. coli (Fig. 5). Under fermentation, FucO is responsible for generating NAD+ by reducing l-lactaldehyde, a product from l-fucose fermentation, to propanediol. Thus, functioning as a lactaldehyde oxidoreductase under fermentation on l-fucose. FucO also catalyses the inverse reaction converting propanediol into l-lactaldehyde yielding NADH (Fig. 5) (Boronat and Aguilar, 1979; Cocks et al., 1974). Induction of the fuc regulon, and consequently of fucO, requires the presence of transcriptional activator FucR and its effector l-fuculose-1-phosphate (Bartkus and Mortlock, 1986; Chen et al., 1987). Thus, propanediol or EG cannot solely be used aerobically as carbon source since these compounds cannot induce the expression of the fuc regulon. To allow growth from propanediol or EG, the expression of FucO will need to be constitutive or induced. FucO can convert EG into GA, which is then irreversibly converted to glycolate by the action of AldA (Baldomà and Aguilar, 1987). Finally, the native GlcDEF, an oxidoreductase complex present in the cytoplasmic membrane, transforms glycolate into glyoxylate and reduces an electron-transfer quinone (Lord, 1972; Pellicer et al., 1996; Sallal and Nimer, 1989).

Fig. 5.

Metabolic pathway of thel-fucose system and its intersection with ethylene glycol (EG) metabolism. The metabolization of l-fucose is dependent of l-fucose permease (fucP), l-fucose isomerase (fucI), l-fuculose kinase (fucP), l-fuculose-1-phosphate aldolase (fucA), and NADH dependent l-1,2-propanediol oxidoreductase (fucO). Under anaerobiosis, FucO reduces l-lactaldehyde to propanediol which is excreted via a facilitator (Lu et al., 1998). Under aerobic conditions, l-lactaldehyde is instead oxidized to l-lactate by a NAD+-dependent oxidoreductase (aldA). l-lactate is further oxidized to pyruvate and enters central metabolism. Due to enzyme promiscuity, FucO can oxidize both propanediol and EG into their aldehydes, l-lactaldehyde and glycolaldehyde, respectively. Thus, when EG is available, it is oxidized to GA by the NAD+-dependent dehydrogenase function of FucO, and GA is converted to glycolate by AldA. Glycolate can then enter central metabolism via the oxidation pathway and/or the glyoxylate shunt. Abbreviations: EG, ethylene glycol; GA, glycolaldehyde; l-fucolose-1-P, l-fuculose-1-phosphate. Created with BioRender.com.

FucO, which is Fe2+-dependent, can be irreversibly inactivated by metal-catalysed oxidation (MCO) (Cabiscol et al., 1992, 1994). Although this enzyme oxidizes EG into GA aerobically, oxygen and NADH can result in an intrinsically catalysed Fenton reaction that damages the protein, which leads to diminished efficiency of this enzyme (Lu et al., 1998). Thus far, two variants of FucO have been reported in the literature as being more oxygen-stable. One variant contains the mutations I7L and L8V at the N-terminal, identified in mutant strains that acquired the ability to grow in propanediol, demonstrating increased resistance to MCO without significant effect on catalysis (Lu et al., 1998). In a second report, another FucO variant containing a single L8M mutation is reported, also identified in evolved propanediol strains, that might alleviated MCO toxicity (Lee and Palsson, 2010). Interestingly, it was also discovered that these and other evolved E. coli strains obtained from continued selection with propanediol, were able to express fucO constitutively as a result of an IS5 insertion in the promoter region between the two fuc regulons, fucAO and fucPIKUR, simultaneously disabling ability to grow on fucose (Chen et al., 1989; Lee and Palsson, 2010; Lu et al., 1998). In the report by Lee and Palsson, it was verified that the propanediol assimilating phenotype of the evolved strain was a result of the combination of the mutation fucOL8M together with the IS5 insertion that led to the constitutive expression of FucOL8M. Interestingly, when the mutation fucOL8M and IS5 insertion were introduced in the genome of the non-evolved WT strain, together with two other identified mutations in ilvG and ylbE in the evolved strain, the propanediol assimilating phenotype could be reconstructed (Lee and Palsson, 2010). A recent in vivo comparison between FucOI7L/L8V and FucOL8M mutants report that the first leads to a markedly higher EG assimilation rate and growth rate/yield, although still maintaining some oxygen sensitivity (Pandit et al., 2021). In particular, the mutant FucOI7L/L8V has been used in a few recent EG metabolization strategies in E. coli, as will be described in the following sections. A more comprehensive discussion about the enzyme FucO is provided is Section 5.

Naturally, some of the studies focusing on engineering EG assimilation in E. coli have targeted the overexpression of FucO and AldA, making use of the existing natural EG assimilation routes. Alternatively, other studies have focused on the development of whole new synthetic routes for EG assimilation. These EG assimilation studies in E. coli will be reviewed and discussed in the following Sections 4.2, 4.3.

4.2. Overexpressing the FucO and AldA enzymes

A number of studies have successfully modified E. coli to use EG as a carbon source, using the overexpression of the native enzymes FucO and AldA as basis of the ME strategies applied (Panda et al., 2021, 2023; Pandit et al., 2021). An overview of these reports is provided in Table 1. In a recent study, orthogonality principles were used to demonstrated that EG has higher orthogonality scores then glucose, xylose, and formate when used to simulate production of four chemicals with industrial importance: succinate, ethanol, glycolate, and 2,3-butanediol (Pandit et al., 2021). Since the route converting EG into glycolate had the highest orthogonality, the authors engineered E. coli for glycolate production using EG. Flux balance analysis (FBA) results suggested that micro-aerobic conditions are required for accumulation of glycolate. The conversion of glycolate to glyoxylate is catalysed by the glycolate dehydrogese GlcDEF, reducing a proton acceptor quinone (Fig. 3). Then, the resulting quinol utilises oxygen as final electron acceptor. As such, under anaerobic conditions, the regeneration of quinone is blocked and, consequently, the activity of GlcDEF is inhibited, leading to accumulation of glycolate. Thus, oxygen levels can serve as a control mechanism to switch metabolism from cell growth to glycolate accumulation. This controllable switch for product synthesis is desired in an orthogonal branched pathway and beneficial in a two-step industrial fermentation process. (Pandit et al., 2017, 2021). Bioreactor studies with EG as main carbon source and with an E. coli strain overexpressing FucOI7L/L8V and AldA demonstrated that glycolate accumulation could be induced through a reduction in the aeration (Table 1). More specifically, two strategies were ultimately tested by these authors in fed-batch reactors with minimal media supplemented with yeast extract at 2 g/L. The first one consisting of a biomass production phase with increased aeration (600 mL/min) followed by a drop in aeration (100 mL/min) during the glycolate production phase. The second strategy used a lower continuous aeration rate (50 mL/min) with a faster agitation speed during initial growth, and a slower speed during the glycolate production stage to reduce the oxygen transfer rate. The rotor speed was decreased until the respiratory quotient (RQ) reached ∼ 0.4 since FBA results demonstrated a correlation between the RQ and glycolate production. Particularly, a RQ value between 0.15 and 0.4 was optimal for higher glycolate productivity yield on the substrate (Pandit et al., 2021). The second strategy led to the highest glycolate titres (10.4 g/L vs 6.8 g/L) and yield from EG during production phase (0.8 g/g vs 0.75 g/g) (Table 1). Finally, while oxygen limitation might benefit glycolate production and the reaction catalysed by the oxygen-sensitive FucO, it might also limit regeneration of NAD+ if the oxygen level is too low, which would limit the flux through the EG assimilation pathway. So, a trade-off between the verified oxygen sensitivity of FucO and the oxygen dependent regeneration of NAD+ would need to be fine-tuned to maximize glycolate production (Pandit et al., 2021).

Table 1.

Characteristics, experimental setup of the best result and identified challenges of the EG assimilation strategies applied to Escherichia. Coli that are based on the natural oxidative Ethylene Glycol (EG) assimilation pathway. These pathways are based on the overexpression of the first two enzymes of the natural EG oxidative pathway, FucO and AldA, except for the study by Yan et al. where Gox0313 is used instead of FucO. Abbreviations: EG, ethylene glycol; CSM, Complete Supplement mixture; P_gyrA, promoter gyrA; FucO, propanediol oxidoreductase; FucOI7L/L8V, propanediol oxidoreductase mutant I7L/L8V; AldA, glycolaldehyde dehydrogenase.

| Reference | Objective | Strategy | Carbon source | Best result | Identified challenges |

|---|---|---|---|---|---|

| Pandit et al. (2021) | Production of glycolate from EG |

E. coli MG1655 strain expressing FucOI7L/L8V and AldA under trc promoter in high copy number plasmid pTRC99a Glycolate production performed in bioreactor with two stage fermentation: aerobic growth phase followed by an oxygen limiting glycolate production phase |

M9 minimal medium supplemented with 2 g/L yeast extract with addition of EG during fermentation as to maintain 5–10 g/L EG | 10.4 g/L glycolate after 140 h at 37 °C and pH 7.0, corresponding to a yield of 0.8 g/g EG during production phase | - Oxygen sensitivity during early exponential growth phase when using FucO that is only in part alleviated by using FuCOI7L/L8V - NAD+ generation might be limited if oxygen level is too low, which limits EG uptake and EG assimilation - Many regulatory changes that occur under oxygen-limiting condition are not accounted for in metabolic models |

| Panda et al. (2021) | Improve the growth of E. coli on EG |

E. coli MG1655 DE3 expressing FucO and AldA under constitutive P_gyrA in medium copy number plasmid pEG03 Growth assays performed in shake flasks without antibiotic supplementation |

Modified M9 minimal medium with 20 g/L of EG supplemented with 2 g/L CSM | Total consumption of 10 g EG after 72 h at 30 °C, reaching an OD600 of ∼6 after 24 h | - Supplementation with glycerol (0.1 g/L) of CSM was required for efficient EG utilization, furthermore, no family of amino acids (aspartate, aromatic, pyruvate and others) could be excluded - Almost no EG is consumed at 37 °C - High EG concentrations (100 g/L) inhibited growth and only a small amount of EG was consumed |

| Panda et al. (2023) | Production of L-tyrosine from EG (synthesis of L-phenylalanine and p-coumaric acid from EG at gram per litre titre is also reported) |

E. coli MG1655 DE3 ΔtyrR ΔpheA containing a plasmid expressing aroG and tyrA under lac promoter and a second medium copy number plasmid pEG03∗ overexpressing FucOI7L/L8V and AldA under constitutive P_gyrA L-tyrosine production performed in shake flasks without antibiotic supplementation |

Modified M9 minimal medium with 2 g/L NH4+ and 20 g/L EG supplemented with 1.6 g/L CSM after | 3 g/L L-tyrosine was produced from 17 g/L EG after 96 h at 30 °C | - Supplementation with CSM was required for efficient EG utilization |

| Yan et al. (2024) | Production of glycolate from EG |

E. coli MG1655 ΔfucO ΔyqhD expressing Gox0313 (instead of FucO) and AldA under trc promoter in high copy number plasmid pTrc99a Glycolate production performed in shake flasks |

M9 minimal medium with 10 g/L EG supplemented with 2 g/L yeast extract | 5.1 g/L glycolate from 6.8 g/L EG at a yield of 0.75 g/g EG after 120 h at 37 °C, having a maximum productivity of 0.158 g/L/h during the initial 24 h | - High concentration of glycolate inhibit growth and EG uptake |

In another study by the same research group, an EG-consuming E. coli MG1655 DE3 strain was obtained by systematically optimizing the fucO and aldA gene expression together with the medium composition (Panda et al., 2021). It was verified that a low concentration of glycerol (0.1 g/L) was required for more efficient EG utilization as carbon source. Without glycerol, an initial strain overexpressing fucO and aldA under an l-arabinose inducible promoter consumed only 6% of the EG in the media (5 g/L EG) within 72 h, while adding 0.1 g/L glycerol doubled cell density and increased the percentage of EG consumed to 17%. Glycerol, in addition to being a carbon source, may stimulate the expression of transporters and enzymes related to polyol degradation which might aid in EG import, as both glycerol and EG are polyols (Panda et al., 2021). Furthermore, glycerol has a higher redox potential then EG, providing more reducing equivalents and energy which benefits cellular processes and might create a more favourable intercellular environment for EG assimilation. During process optimization, the authors saw that using a strong constitutive promoter (PgyrA) proved to be significantly better than inducible promoters in driving expression of FucO and AldA, resulting in the further tripling of cell density and 80% EG consumption. Switching between different origins of replication and different antibiotic resistance markers had no substantial effect on EG utilization. Additionally, antibiotic was not needed to maintain the plasmid expressing fucO and AldA due to the selective pressure exerted by the need of expressing these enzymes to use EG as carbon source. Additionally, the authors had initially tested another host strain (E. coli strain BW25113), which proved to be slightly outperformed by E. coli strain MG1655 DE3 in terms of cell growth and EG consumption, thus ultimately only strain MG1655 DE3 is used as best strain. While cells were able to use EG at 30 °C, almost no EG was consumed at 37 °C. Further medium optimization showed that glycerol supplementation could be substituted with a Complete Supplement mixture (CSM, a mixture of amino acids and nucleobases; 1 g/L) with an even higher cell density and almost complete consumption of EG in the media as a result. Interestingly, fucO and aldA had higher expression levels (200% and 70% higher, respectively) with CSM supplementation, compared to glycerol supplementation. Finally, the EG using strain under all verified optimal conditions, in medium containing 20 g/L EG and 2 g/L CSM, could consume all EG in 72 h (Table 1). However, when fed 100 g/L EG, the strain consumed only a small amount, suggesting that high EG concentrations inhibit growth (Panda et al., 2021). Although CSM supplementation adds to industrial fermentation costs, these are encouraging results. Future research lines could include engineering a strain able to use EG efficiently without amino acid supplementation and testing improved FucO mutants such as FucOI7L/L8V.

In a more recent work by Panda and colleagues, an E. coli strain was engineered to produce l-tyrosine from EG (Panda et al., 2023). In this study, the mutant FucOI7L/L8V was tested instead of the WT FucO (Lu et al., 1998; Pandit et al., 2021). Using FucOI7L/L8V resulted in slightly faster growth on EG. Subsequently, FucOI7L/L8V and AldA under control of PgyrA, were introduced in an E. coli MG1655 DE3 strain previously engineered for l-tyrosine overproduction from glucose (Ma et al., 2020). Specifically, this strain contains the deletion of two genes: tyrR (to alleviate the transcriptional repression of l-tyrosine production) and pheA (to prevent formation of the competition aromatic amino acid phenylalanine), and a plasmid overexpressing feedback-resistant aroG and tyrA (Ma et al., 2020). In this work, the authors added a lower concentration of isopropyl β-d-1-thiogalactopyranoside (IPTG; 0.01 mM) upon inoculation avoiding the monitorization of cell growth to induce gene expression, which increased biomass growth and l-tyrosine titre and productivity (Panda et al., 2023). Also, when supplementing 20 g/L EG, the cells stopped growing after 48 h, point at which 1.5 g/L l-tyrosine was achieved and around 10 g/L EG was left. By considering that the nitrogen and/or phosphorous sources might become depleted after 48 h, the authors doubled the initial ammonium concentration to 2 g/L, observing an improvement in growth and l-tyrosine production (Panda et al., 2023). Overall, the developed strain yielded a titre of 3 g/L l-tyrosine after 96 h, when supplementing the medium with 20 g/L EG and 1.6 g/L CSM (Table 1). These conditions led to the maximum titres outperforming the value (1.2 g/L) achieved when growing the cells solely on glucose (Panda et al., 2023).

Interestingly, in this work transcriptome analysis was used to investigate the reasons for the increased l-tyrosine synthesis using EG as carbon source compared to glucose (Panda et al., 2023). It was revealed that fucO and aldA were upregulated by 2-fold in the presence of EG and that most of the transcripts came from the plasmid, which may suggest that PgyrA is either activated by EG or repressed by glucose. Also, when growing on EG, the glycolate dehydrogenase encoding genes (glcDEF) and the genes in the EG oxidative pathway from glyoxylate up until 2 PG – glyoxylate carboligase (gcl), tartronate semialdehyde reductase (glxR) and glycerate 2-kinase (glxK/garK) – were upregulated by > 100-fold. Malate synthase (glcB or aceB) and isocitrate lyase (aceA) were upregulated by > 20-fold, suggesting that the glyoxylate shunt also operate during growth on EG (Panda et al., 2023). During growth on glucose, through glycolysis, enolase (eno) converts 2 PG into phosphoenolpyruvate (PEP), a precursor for both l-tyrosine and acetyl-CoA synthesis. PEP is converted into pyruvate, which is primarily transformed into acetyl-CoA by pyruvate dehydrogenase (PDH) complex (aceEF/lpd). However, when growing on EG, an upregulation of two alternative routes to convert pyruvate into acetyl-CoA were identified (Panda et al., 2023). The first route involves the conversion of pyruvate to acetate by PoxB, which was upregulated by 17-fold, followed by its transformation into acetyl-CoA by acetyl-CoA synthetase (ACS), which was upregulated by 44-fold. In the second route, upregulated by 2-fold, pyruvate is converted to acetyl-CoA and formate by pyruvate formate-lyase (PflB). Since the transcription of eno and aceEF/lpd was halved, the expression of enzymes might be inactivated during growth on EG. This would divert pyruvate from glycolysis and facilitate the accumulation of PEP, resulting in a higher l-tyrosine titre (Panda et al., 2023). Furthermore, in this study, E. coli was also engineered to synthesize l-phenylalanine, achieving 1.5 g/L phenylalanine from 10 g/L EG (Panda et al., 2023). EG-derived production of p-coumaric (pCA) was also engineered by additionally expressing tyrosine ammonia lyase (Tal), which transforms l-tyrosine into pCA (∼1 g/L pCA from 10 g/L EG) (Table 1) (Panda et al., 2023). Finally, it was demonstrated that the grade of EG used in these experiments could be replaced by EG derived from acid-hydrolysed PET bottles, with similar titres of l-tyrosine, supporting the concept that plastic waste can be transformed into value-added chemicals (Panda et al., 2023).

Lastly, a recent report successfully constructed an E. coli MG1655 strain able to produce glycolate from EG (Yan et al., 2024). Different enzyme candidates were tested for the initial EG oxidation step into GA, concluding that expressing the NAD+-dependent alcohol dehydrogenase Gox0313 from Gluconobacter oxydan also capable of oxidizing EG, in place of FucO, could lead to a complete assimilation of 10 g/L EG as major carbon source in 96 h (further discussion about the enzyme Gox0313 and results obtained regarding the comparison of different enzyme candidates for EG oxidation reported by Yan et al. is provided in Section 5). Thus, a new strain was engineered by heterologous expression of Gox0313, by overexpressing aldA, and by knocking out the endogenous GA reductase genes fucO and yqhD to prevent the reconversion of GA into EG. This strain achieved a glycolate titre of 5.1 g/L and a yield of 0.75 g/g EG in shake flaks with M9 medium with 10 g/L EG as major carbon source (Table 1) (Yan et al., 2024). Although the maximum productivity reached 0.158 g/L/h during the initial 24 h, as growth continued, the reported strain could not fully use 10 g/L EG and eventually stopped consuming it, which was confirmed to be caused by growth inhibition when high concentrations of glycolate are achieved. In fact, growth could be inhibited by exogenous glycolate in a linear manner (Yan et al., 2024). The high glycolate titre of the engineered strain where related to high levels of gox0313 transcription, which was promoted by the deletion of fucO and yqhD and the overexpression of aldA. The transcriptional level of aldA was also high and, while it was boosted by deletion of fucO and yqhD, it was hindered by knocking out the endogenous glcDEF. Genes glcDEF were also overexpressed and their transcription was promoted by the fucO and yqhD deletions and the aldA overexpression (Yan et al., 2024). This engineered strain had a higher content of various amino acids such as l-tryptophan and l-tyrosine, and curiously produced a new compound rosmarinic acid (Yan et al., 2024) which might hold interest for further production of derived value-added compounds.

4.3. Glycolaldehyde as a metabolic hub

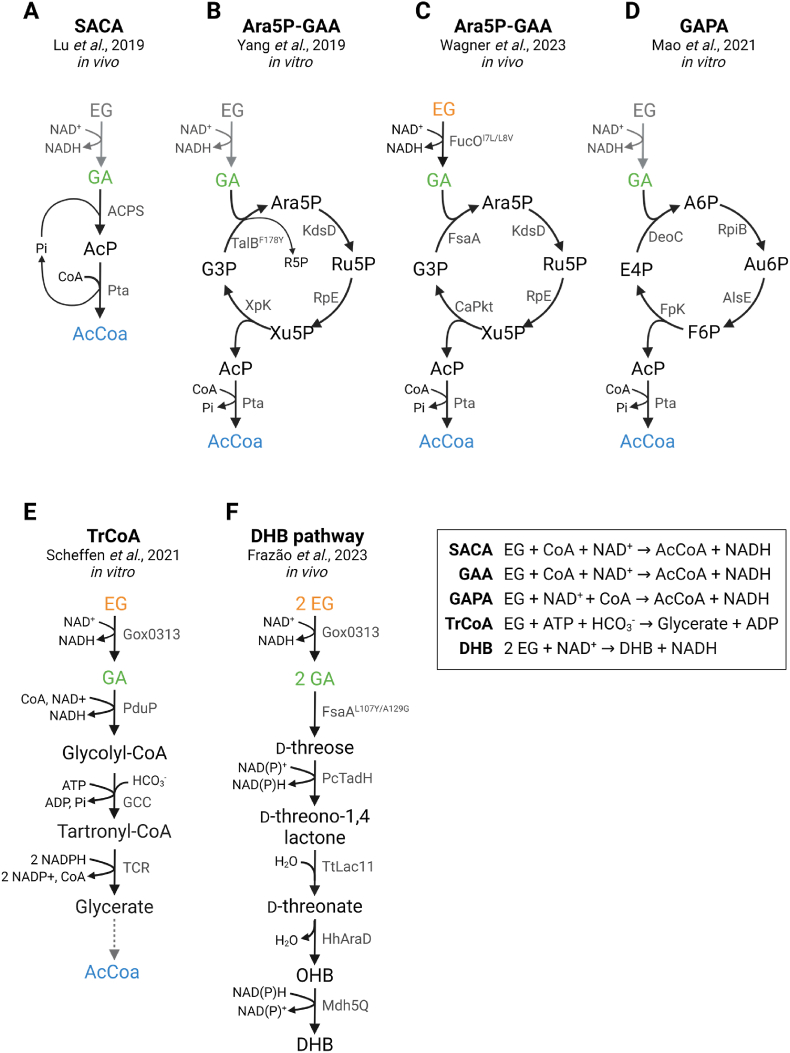

In E. coli, the microbial assimilation of EG proceeds via the intermediate GA through the natural oxidative pathway discussed previously. GA can be considered a crucial molecular intermediate and metabolic hub for EG metabolism, from which carbon can be used to fuel metabolism. A few recent studies have developed new synthetic pathways that use GA as intermediate or precursor to produce, for example, acetyl-CoA in vitro (Mao et al., 2021; Yang et al., 2019) or in vivo (Lu et al., 2019; Wagner et al., 2023) using E. coli, as well as other compounds of interest such as glycerate (Scheffen et al., 2021) or 2,4-dihydroxybutyric acid (DHB) (Frazão et al., 2023). It is worth noting that some of these studies focus on the use of GA as an intermediate primarily for the assimilation of one-carbon (C1) molecules due to the recent development of a novel engineered enzyme termed GA synthase (Gals), which converts two C1 formaldehyde (FA) molecules into GA (Lu et al., 2019; Yang et al., 2019). Since different C1 compounds, such as methanol and methane, are all converted to FA before being further assimilated by natural pathways that inherently have poor carbon yields, improving FA assimilation through novel pathways can lead to more efficient assimilation of C1 compounds (Yang et al., 2019). Thus, the discovery of the Gals enzyme opened new possibilities for C1 feedstock assimilation trough GA (Lu et al., 2019; Mao et al., 2021; Yang et al., 2019). Nevertheless, the reaction that converts EG into GA, if coupled to these novel synthetic GA-assimilating pathways, can lead to novel ways of assimilating PET by microorganisms such as E. coli, and for that reason they will be reviewed and discussed in this section. The different pathways discussed throughout this Section are outlined in Fig. 6. Also, the pathways applied in vivo are described in more detail in Table 2.

Fig. 6.

Synthetic ethylene glycol (EG) assimilation pathways that use glycolaldehyde (GA) as key intermediate. The pathways (A) Synthetic Acetyl-CoA (SACA) pathway, (B) Ara5P-dependent GA assimilation (GAA) pathway, (C) Ara5P-GAA pathway applied in vivo, (D) GA-allose 6-phosphate assimilation (GAPA) pathway, (E) The tartronyl-CoA (TrCoA) pathway and (F) 2,4-dihydroxybutyric acid (DHB) production pathway are shown, along with the stoichiometric equations for each pathway where the EG to GA reaction is hypothetically considered. When the EG to GA pathway is depicted in grey means that this reaction was not included in the referred report. List of abbreviations in alphabetical order: A6P, allose 6-phosphate; AcCoa, acetly-CoA; AcP, acetyl-phosphate; ACPS, acetyl-phosphate synthase from Actinobacteria; AlsE, d-allulose-6-phosphate 3-epimerase from Escherichia coli; Ara5P, d-arabinose 5-phosphate; Au6P, d-allulose 6-phosphate; CaPkt, phosphoketolase from Clostridium acetobutylicum; DeoC, 2-deoxy-d-ribose-5-phosphate aldolase from E. coli; DHB, 2,4-dihydroxybutyric acid; E4P, erythrose 4-phosphate; EG, ethylene glycol; F6P, d-fructose 6-phosphate; FA, formaldehyde; FpK, F6P phosphoketolase from Bifidobacterium adolescentis; FsaA, d-fructose 6-phosphate aldolase from E. coli; FucO, EG oxidoreductase from E. coli; G3P, glyceraldehyde-3-phophate; GA, glycolaldehyde; Gals, GA synthase from Pseudomonas putida; GCC, engineered glycolyl-CoA carboxale from Methylorubrum extorquens; Gox0313, alcohol dehydrogenase from Gluconobacter oxidant; HCO3−, hydrogen carbonate; HhAraD, l-fuconate dehydratase from Herbaspirillum huttiense; KdsD, Ara5P isomerase from E. coli; Mdh5Q, malate dehydrogenase mutant from E. coli; OHB, 2-oxo-4-hydroxybutyrate; PcTadH, d-threo-aldose 1-dehydrogenase from Paraburkholderia caryophylli; PduP, aldehyde dehydrogenase of Rhodopseudomonas palustris; Pta, phosphate acetyltransferase from E. coli; R5P, ribose 5-phosphate; RpE, d-ribulose 5-phosphate epimerase from E. coli; RpiB, allose-6-phosphate isomerase/R5P isomerase B from E. coli; Ru5P, ribulose 5-phosphate; TalBF178Y, transaldolase B mutant F178Y from E. coli; TCR, tartronyl-CoA reductase from Chloroflexus aurantiacu; TtLac11, gluconolactonase from Thermogutta terrifontis; XpK, xylulose 5-phosphate phosphoketolase from Pseudomonas stutzeri; Xu5P, d-xylulose 5-phosphate. Created with BioRender.com.

Table 2.

Characteristics, experimental setup of the best result and identified challenges of the synthetic glycolaldehyde (GA) or ethylene glycol (EG) assimilating pathways reported in the literature and that were tested in in vivo. Abbreviations: FA, formaldehyde; GA, glycolaldehyde; MVA, melavonate; DHB, 2,4-dihydroxybutyric acid; Gals, GA synthase; ACPS, acetyl-phosphate synthase; Pta, phosphate acetyltransferase; FucOI7L/L8V, propanediol oxidoreductase mutant I7L/L8V; FsaA, D-fructose 6-phosphate (F6P) aldolase; CaPkt, phosphoketolase from Clostridium acetobutylicum; KdsD, D-arabinose 5-phosphate (Ara5P) isomerase; Rpe, D-ribulose 5-phosphate epimerase; Gox0313, alcohol dehydrogenase from Gluconobacter oxydan; FsaAL107Y/A129G, F6P aldolase mutant L107Y/A129G; Mdh5Q, malate dehydrogenase; HhAraD, L-fuconate dehydratase from Herbaspirillum huttiense; Re.kdgT, D-threonate importer system.

| Pathway | Objective | Type of pathway | Strategy | Carbon source | Best result | Identified challenges | Reference |

|---|---|---|---|---|---|---|---|

| SACA pathway | Production of acetyl-CoA from FA (through GA) | Linear with 2 steps from GA to acetyl-CoA |

E. coli BL21 DE3 expressing Gals, ACPS and Pta in plasmid pET-28a Growth assays performed in shake flasks |

LB medium with 0.4 g/L GA | Strain grew better with GA supplementation and reached an OD600 of ∼7 (vs ∼ 5.5 without GA) after 20 h at 37 °C | - ACPS might have low affinity for GA (Km = 51 mM) | Lu et al. (2019) |

| Ara5P-GAA pathway | Production of acetyl-CoA from EG | Cyclic with 6 steps from EG to acetyl-CoA |

E. coli MG1655 ΔyqhD ΔaldA overexpressing FucOI7L/L8V, FsaA and CaPkt in plasmid pZS23 and KdsD, Rpe and Pta in plasmid pZS13 (for GA metabolization); strain contains plasmid pMEV-7 harbouring the MVA pathway genes Acetyl-CoA production in shake flasks |

M9 minimal medium with 500 mM EG, 250 mM glycerol, 5 g/L yeast extract and 100 mM CaCO3 | 0.82% of MVA from EG after complete glycerol consumption at 46 h and 30 °C, with a maximum of 1.24% MVA at 22 h | - No growth detected at elevated GA concentrations - The main by-products were EG and D-threose - Extremely low acetyl-CoA yield |

Wagner et al. (2023) |

| DHB production pathway | Production of DHB from EG | Linear with 6 steps from EG to DHB |

E. coli MG1655 ΔyqhD ΔaldA ΔlldD expressing Gox0313, FsaAL107Y/A129G, PcTadH, TtLac11 in plasmid pACT3, expressing Mdh5Q, HhAraD in plasmid pEXT22, and Re.kdgT in plasmid pEXT21; all genes are under the control of the tac promoter DHB production in concentrated IPTG-induced pre-cultures |

M9 minimal medium with 320 mM (∼20 g/L) EG (no co-substrate) LB medium with 320 mM EG and supplemented with L-cysteine and FeCl3 |

2.14 mM of DHB from EG after 48 h at 37 °C in the M9 medium 6.75 mM (1 g/L) of DHB from EG after 48 h at 37 °C in the LB medium |

- High GA concentrations led to increased accumulation of D-threose and almost no DHB production - Substrate affinities of FsaAL107Y/A129G and PcTadH may be low - The main by-products were EG and D-threose - Low production rates and titres are obtained from EG or GA |

Frazão et al. (2023) |

4.3.1. Acetyl-CoA yielding pathways

The natural oxidative EG-assimilation route yields only 0.5 mol acetyl-CoA per mole of EG, at the expense of 1 molecule of ATP and 2 molecules of NAD+. Besides being a critical intermediate metabolite for the cell, acetyl-CoA can serve as a precursor for many industrially relevant products, such as biofuels (Guo et al., 2015) and bioplastics like polyhydroxyalkanoates (PHA) (Kudo et al., 2023). Hence, this prompts the search for more effective aerobic routes for converting EG (via GA) into acetyl-CoA using pathways that are carbon conserving, independent of energy or reducing equivalents, and have higher carbon yield. A few synthetic pathways have been developed to produce acetyl-Coa (Lu et al., 2019; Mao et al., 2021; Wagner et al., 2023; Yang et al., 2019) that have the potential to be applied in connected to a bioprocess of EG metabolization. These pathways will be discussed throughout this Section and a schematic representation of each pathway can be found in Fig. 6A–D.

4.3.1.1. Synthetic Acetyl-CoA (SACA) pathway

The Synthetic Acetyl-CoA (SACA) pathway (Fig. 6A) converts GA into acetyl-CoA without carbon loss and is independent of energy and reducing equivalents (Lu et al., 2019). In this linear pathway, two molecules of FA are first condensed into GA by Gals from P. putida. Then, GA is converted into acetyl-phosphate (AcP) in a single step by a novel reaction catalysed by a phosphoketolase (Pkt) from Actinobacteria, termed acetyl-phosphate synthase (ACPS), using inorganic phosphate. E. coli's phosphate acetyltransferase (Pta) then converts AcP into acetyl-CoA (Fig. 6A). A calculated total Gibbs energy change suggested that this pathway is highly thermodynamically favourable (−96.7 kJ/mol). Although a yield of over 80% AcP from GA was achieved in vitro, only 33% acetyl-CoA yield was reached starting from FA, possibly due to inhibition of ACPS by FA, and to instability of acetyl-CoA and AcP in solution (Lu et al., 2019). Pathway expression in E. coli BL21 DE3 confirmed that the SACA pathway is functional in vivo and leads to production of acetyl-CoA and derived metabolites such as oxaloacetate from FA or GA (Lu et al., 2019). To mitigate the cellular toxicity arising from FA supplementation, the methanol dehydrogenase gene from Bacillus stearothermophilus was added to the engineered strain. This way, methanol is instead supplemented which is converted into FA by the methanol dehydrogenase, helping maintain a constant but low FA concentration. Still, the SACA pathway only contributed to around 3% biomass from methanol. One of the reasons for this low yield might be the low substrate affinities of the enzymes Gals (Km = 165 mM) and ACPS (Km = 51 mM) to methanol and GA, respectively. Nonetheless, and since the goal of this review is to contemplate EG metabolization, if we consider GA as starting compound, that can be derived from EG, this synthetic pathway does enable the carbon-conserved and ATP-independent conversion of EG into acetyl-CoA through only three steps (Fig. 6A). Interestingly, by supplementing rich medium with more than 0.4 g/L GA resulted in a remarkably higher OD600 for strains expressing the SACA pathway than for those without GA or the SACA pathway (Table 2) (Lu et al., 2019). In this context, increasing the substrate affinity of ACPS through protein engineering would be one relevant way to improve the production of acetyl-CoA from GA, and eventually from EG.

4.3.1.2. Ara5P-dependent GA assimilation (GAA) pathway

Two other studies have computationally predicted two cyclic synthetic pathways for the assimilation of GA that circumvents CO2 loss and ATP/NAD(P)H consumption. One of these examples is the Ara5P-dependent GA assimilation (GAA) pathway (Fig. 6B) that converts FA into acetyl-CoA with a calculated standard Gibbs free energy change of −86.8 kJ/mol (Yang et al., 2019). In this pathway, FA is first condensed to GA by Gals. The pathway progresses through the aldol addition of GA into the acceptor molecule glyceraldehyde-3-phophate (G3P) by an engineered transaldolase B from E. coli (TalBF178Y), yielding d-arabinose 5-phosphate (Ara5P) (Fig. 6B). This process also generates the isomers ribulose 5-phosphate (Ru5P) and ribose 5-phosphate (R5P). Although R5P could be converted to Ru5P by R5P isomerase (Rpi) from E. coli, the small amount of R5P produced could be converted without Rpi due to the promiscuous activities of the other enzymes in the pathway. Then, after two isomerization reactions, Ara5P is converted into d-xylulose 5-phosphate (Xu5P) via d-ribulose 5-phosphate (Ru5P), by chaining the Ara5P isomerase (KdsD) and d-ribulose 5-phosphate epimerase (Rpe) enzymes from E. coli. Finally, the xylulose 5-phosphate Pkt (Xpk) from Pseudomonas stutzeri cleaves Xu5P into AcP and 3 GP, thus regenerating the precursor and closing the loop. AcP can be then converted to acetyl-CoA by Pta from E. coli (Fig. 6B). The viability of the full pathway was only demonstrated in vitro, reaching 88% product carbon yield. (Yang et al., 2019).

Recently, the Ara5P-GAA pathway has been implemented in vivo by Wagner et al., to convert EG to acetyl-CoA, using E. coli as host (Wagner et al., 2023). Some modifications to the original pathway designed by Yang et al. were made, such as the replacement of TalBF178Y with the F6P aldolase FsaA from E. coli that catalyses the cross-aldol addition of GA to G3P without formation of the by-product R5P (Fig. 6C). Also, a Pkt from Clostridium acetobutylicum (CaPkt) was used instead of Xpk. In vitro testing resulted in a low yield of 18.1% AcP from GA, possibly due to aldehyde-induced enzyme(s) inactivation in vitro (Wagner et al., 2023). Subsequently, a mutant E. coli strain – whose genes encoding YqhD, a major endogenous GA reductase, and AldA were deleted to direct GA assimilation through the synthetic pathway – was used as host for the expression of the Ara5P-GAA pathway together with the less oxygen-sensitive FucOI7L/L8V. Glycerol was used as co-substrate for growth and labelled 13C EG and GA were used to assess the pathway for the formation of the acetyl-CoA proxy melavonate (MVA). After enzymes expression optimization, 16.12% of MVA was originated from GA. However, the pathway performance was extremely poor when EG was used as major carbon source, with a maximum of 1.24% of MVA originated from EG (Table 2) (Wagner et al., 2023). Although able to function in vivo, the Ara5P-GAA pathway led to an extremely low acetyl-CoA yield, and a few possible bottlenecks hindering carbon flow were considered. The FucOI7L/L8V oxidation reaction is suggested to be thermodynamically unfavourable (ΔrG’° = 23.7 kJ/mol, Wagner et al., 2023), potentially constraining metabolic flux. Despite employing a high EG concentration to promote initial GA production and assessing adequate gene expression levels, the authors were not able to further improve MVA formation (Noor et al., 2014; Wagner et al., 2023). As such, to increase the metabolic flux towards acetyl-CoA, it is hypothesized that the GA affinity of the next enzyme in the pathway must be very high. However, the GA affinity of FsaA might not be sufficient to enable carbon flux (Wagner et al., 2023). In fact, Yang's study reports a high Km of 11.59 mM and very low kcat of 0.08 s−1 for FsaA when using GA as substrate (Yang et al., 2019). Also, FsaA catalyses the reversible dimerization of GA both as donor and acceptor, into threose, which was one of the by-products detected when GA was used as substrate (Wagner et al., 2023). Interestingly, the other major reaction that drained GA was EG formation, which might suggest the existence of unspecific GA reductases that convert GA to EG. As comparison, AldA from the natural EG oxidative pathway has a very low Km of 0.14–0.38 mM for GA, allowing flow of EG as carbon source (Baldomà and Aguilar, 1987; Rodríguez-Zavala et al., 2006). Overall, the second enzyme in this cyclic pathway needs to be carefully selected, specially targeting a high affinity for GA as donor. Secondly, a better understanding of the apparent limiting role of Pta is currently missing. Although this enzyme was thought to be naturally present in excess, the overexpression of the Pta enzyme led to an increase in acetyl-CoA production, potentially indicating an unforeseen bottleneck (Wagner et al., 2023).

4.3.1.3. GA-allose 6-phosphate assimilation (GAPA) pathway

The other cyclic pathway is the GA-allose 6-phosphate (A6P) assimilation (GAPA) pathway (Fig. 6D), developed by Mao and colleagues (Mao et al., 2021). This pathway is mechanistically similar to the GAA pathway and also relies on an aldolase that condenses the donor GA and an acceptor, which in this case is erythrose 4-phosphate (E4P). First, FA is converted into GA by Gals. Then, 2-deoxy-d-ribose-5-phosphate aldolase (DeoC) from E. coli catalyses the aldol reaction between GA and E4P into A6P. Next, A6P also goes through two isomerization reactions into d-fructose 6-phosphate (F6P) via d-allulose 6-phosphate (Au6P), by the chained activities of allose-6-phosphate isomerase/R5P isomerase B (RpiB) and d-allulose-6-phosphate 3-epimerase (AlsE) from E. coli. The acetyl-CoA precursor AcP and E4P are then produced from F6P, by the enzyme F6P Pkt (Fpk) from Bifidobacterium adolescentis (Mao et al., 2021). AcP is then converted to Acetyl-CoA by Pta (Fig. 6D). This novel pathway was tested in vitro with E4P and GA as reaction substrates and a high carbon yield of 94% was achieved (Mao et al., 2021). However, both the GAA and GAPA pathway are subject to a kinetic trap caused by the broad substrate activity of X/Fpk, with both reports revealing a low but non-neglectable breakdown of other substrates, such as Ru5P, R5P, E4P and GA, into AcP and G3P/E4P. Although it is reported that these unwanted activities were very low compared with those for Xu5P or F6P, they can still cause pathway imbalance. Thus, the yield of these pathways could benefit from future enzyme engineering to increase substrate specificity by X/Fpk, and/or from screening for alternative enzymes.

Overall, these cyclic pathways (Fig. 6B–D) are complex, and any kinetic or stoichiometric imbalance has the potential to trigger the collapse of GA assimilation. Also, since they rely on the recycling of a metabolite (G3P and E4P) that can be diverted into other metabolic reactions, it might be very difficult to implement these pathways in vivo with a significant production yield. Particularly, this was observed in the case of the Ara5P-GAA pathway, where the extremely low acetyl-CoA yields obtained in vivo from EG suggest the requirement for a co-substrate, such as glycerol, to replenish G3P and support cellular growth (Wagner et al., 2023). Overall, further research is essential to enhance the applicability of GA-assimilating circular pathways within industrial context. Conversely, the adoption of a linear GA assimilating pathway like the SACA pathway may offer greater efficacy due to its simplicity and its independence from an acceptor molecule, and further reports are highly expected.

4.3.2. The tartronyl-CoA (TrCoA) pathway

Although not specifically targeting acetyl-CoA production, the tartronyl-CoA (TrCoA) pathway theoretically converts GA to glycerate in four linear reactions (Trudeau et al., 2018). Since glycerate is a direct route to acetyl-CoA production in vivo, this pathway will also be considered in this section (Fig. 6E). This pathway was first developed and tested in vitro by Trudeau et al. as an effort to find alternative synthetic pathways to bypass the energy dissipation and CO2 release from photorespiration. Recently, this pathway was adapted and tested in vitro for EG conversion (Scheffen et al., 2021). EG is converted to GA by FucO, then GA is converted into glycolyl-CoA by aldehyde dehydrogenase of Rhodopseudomonas palustris (PduP). Glycolyl-CoA is converted into glycerate via tartonyl-CoA, by the chained action of a novel glycolyl-CoA carboxale (GCC) obtained after protein engineering of a propionyl-CoA carboxylase from Methylorubrum extorquens and of the bifunctional malonyl-CoA reductase from Chloroflexus aurantiacus (tartronyl-CoA reductase; TCR) (Fig. 6E). After in vitro implementation, only 77 μM (approximately 8.16 mg/L) of glycerate after 2 h were produced. By replacing FucO with Gox0313 (refer to Section 5 for further discussion about the enzyme Gox0313), adding a water forming NADH oxidase to maintain a high NAD+ concentration, and including an efficient ATP regeneration system, a glycerate yield of 485 μM (approximately 51.4 mg/L) from 100 mM EG (approximately 6.2 g/L) was reached. Although this reaction requires ATP and reducing equivalents, the reaction catalysed by GCC fixates carbon by using hydrogen carbonate (HCO3−) as substrate. Overall, the in vivo application of this pathway in E. coli is anticipated.

4.3.3. C4 carbon molecules yielding pathways

A recently proposed synthetic route established the production of the non-natural chemical 2,4-dihydroxybutyric acid (DHB) from GA and EG in E. coli (Frazão et al., 2023). DHB is an important industrial precursor for the chemical synthesis of the amino acid methionine analogue 2-hydroxy-4-(methylthio)butyrate (HTMB) (Walther et al., 2017), or to produce 1,3-propanediol (Frazão et al., 2019). In this pathway, GA is converted to DHB via five carbon conserving steps (Fig. 6F). First, two molecules of GA are fused by FsaAL107Y/A129G, a mutant FsaA with increased efficacy for self-aldol GA addition yielding the C4 compound d-threose (thus, a d-threose aldolase). The resulting four-carbon sugar is oxidized into d-threono-1,4-lactone by a d-threo-aldose 1-dehydrogenase from Paraburkholderia caryophylli with d-threose dehydrogenase activity (PcTadH), which is then converted to d-threonate in a reaction catalysed by a gluconolactonase from Thermogutta terrifontis with d-threono-1,4-lactonase activity (TtLac11). A l-fuconate dehydratase from Herbaspirillum huttiense (HhAraD) with activity on d-threonate converts this molecule to 2-oxo-4-hydroxybutyrate (OHB), which is later converted into DHB by an OHB reductase, which in the case was a malate dehydrogenase mutant from E. coli (Mdh5Q) (Fig. 6F) (Frazão et al., 2023). To connect EG to this pathway, Gox0303 was selected to perform the initial conversion of EG to GA. The computed standard Gibbs free energy indicates the thermodynamic viability of this synthetic sequence, either starting from GA (−116.2 kJ/mol) or EG (−92.5 kJ/mol) (Frazão et al., 2023).