ABSTRACT

Background:

The aim of the present study was to assess the egg quality, food safety, and hygiene practices in egg production among commercial and non-commercial farms.

Methods:

A total of six, each commercial and non-commercial farm, were randomly selected form Barwala district, Panchkula, Haryana, for this study in 2019. A detailed interview on hygiene practices of farm workers was conducted. Egg samples were procured for external (N = 60) and internal (N = 24) egg quality determination. The swap samples (N = 24) were also analysed for bacterial contamination. Descriptive statistics were used for reporting the results, and Chi-square test was conducted for determining significant differences between commercial and non-commercial farms.

Results:

The egg yolk percentage (34.49%) and egg shell percentage (12.76) were higher among non-commercial farms. However, no significant external (P = 0.890) or internal (P = 0.367) egg quality difference was found between commercial and non-commercial farms. The biosecurity and disinfection management, daily waste disposal practice, fly and rodent control practice, farm activity record, and flock health monitoring were relatively better among commercial farms. There were no significant differences found in any of these assessments. The colony forming units (cfu) for salmonella and coliform were acceptable in three and four procured samples from commercial farms, respectively, whereas none were within acceptable levels among non-commercial farms.

Conclusion:

The internal egg quality, food safety, and hygiene practices were relatively better among commercial farms as compared to non-commercial farms. This requires further validation through a large sample-sized study.

Keywords: Egg quality, eggs, farm, food safety, hygiene

Introduction

Traditionally, chicken eggs have been regarded as a vital source of nutrition for humans because of their low cost of production, which makes them an affordable source of animal fats and proteins. Furthermore, they are not subject to any traditional or religious prohibitions and are widely accepted in global culture.[1,2] More and more research has shown that eggs have biological qualities that the food processing, cosmetics, and pharmaceutical sectors may be able to use to their advantage, proving that they are more than just a source of nutrition. Egg dry matter efficiency, measured in terms of yield and quality, is a significant topic of interest given the expanding market for industrially processed egg products.[3,4,5]

Indian poultry is one of the fastest growing industries in the world. Poultry industry grew tremendously in the past 4 decades. India ranks third in egg production and seventh in chicken meat production in the world. About 3.4 million tonnes (74 billion) of eggs are produced from 260 million layers and 3.8 million tonnes of poultry meat are produced from 3000 million broilers per annum in India. The poultry industry is contributing about Rs. 70,000/crores to the national GDP and providing employment to more than 4 million people either directly or indirectly. About 2–2.5 million tonnes of poultry litter, a valuable organic fertiliser, is produced as a by-product every year.[6]

The popularity of poultry meat is on the rise during the past 2 decades. It is presently accounting for about 45% of the total meat consumed and is the most popular meat from any single livestock species. Chicken dominates the poultry production in India with nearly 95% of the total egg production, and the rest is contributed by ducks and others. India is the home for many breeds of native chicken like Aseel, Kadak Nath, Tellicherry, Haringhata Black, and Nicobari, Danki, which are still popular among the rural and tribal areas for back yard/free range farming.[7] For the commercial farming, high-yielding crosses developed and supplied by the private sector like Babcock, Bovans (egg type) and Cobb, Ross, and Hubbard (meat type) are being used. The crosses developed under the public sector like Krishilayer and Krishibro (multi-coloured broiler etc.) are popular in certain areas.[8]

The egg production in the country has increased from around 83 billion in 2015–16 to around 88 billion in 2016–17, registering a growth of about 6%. The per capita availability of egg has increased from 61 in 2013–14 to 66 in 2015–16. In 2016–17, it was 69. The poultry meat production in the country has increased to nearly 3.46 million tons during the year 2016–17 from 3.26 million tonnes during the year 2015–16 at around 6% growth rate.[9]

Different patterns of poultry farming

Rural backyard poultry production (non-commercial)

Village or backyard production in India has the majority of its population living in rural areas. The most basic and simple backyard production system involving a few hens and a cockerel is essentially a closed system. There are virtually no veterinary inputs, and the remaining eggs and meat produced are consumed within the household. This is very simple poultry production. In the village, poultry production is generally based on traditional local, native breeds, producing both eggs and birds for meat. In the recent past, improved backyard varieties (like Vanaraja, Gramapriya, Srinidhi, Giriraja, etc.) developed mostly by the public sector and a few by the private sector (like Kroiler, Rainbow rooster) are contributing to rural people chicken egg and meat production of the country. This provides employment to rural small-scale and marginal farmers, eggs, and meat poses with almost no or very less investment through backward poultry farming in rural areas with no marketing channel.[10]

Commercial farming with low bio-security

This type of farming matches backyard rural farming, but this farming is commercial. They have modified crossbreeds but have retained some characteristics of the traditional backyard system. They sale the live birds in wet markets or directly in retails shops. The production system is in general intermediate scale either in deep litter or in very low-quality kachha buildings made up of either mud or wooden-made housing systems. They have mixed coloured breed producing brown egg and cockerel broilers. They kept birds from 10,000 to 50,000. However, bio-security is too low and the management is also poor. Their feeds are either purchased from market or prepared as concentrate feed or customised homemade in their own feed milling.[10]

Large-scale commercial flock with bio-security

This sector in general consisted of a larger-scale commercial flock of broilers, layers, and breeders. Bio-security and management are of a very high and advanced standard. This type of poultry farming requires too much investment, and many banking and other financial companies are involved for funding these types of projects as this also requires sufficient land and infrastructures. Automation, skilled labour, and skilled consultants are involved for enhancing productivity; all advanced technology value-added services are utilised in this sector-like advanced feed formulation medicine, bio-security, rodent control, fly control, vaccines, and so on. It requires more employment like labour for enhanced production veterinarian services, medical representatives, feed grains, and veterinary medicine dealers; all are involved for this type of farming. These advantages add to those derived from the use of highly productive commercial hybrid chicks and improved technologies such as the evaporative cooling or air-conditioning of poultry houses. The four southern states, where poultry densities and flock sizes are high, together contribute 57% of the nation‘s egg production.[5,6]

Industrial and integrated production

These are the largest and industrialised enterprises involved in poultry industry. They flock at different locations like village, state, or country levels. They have more than 10 lakh birds and franchised type operation. They rear broiler or layer fully in integration as the part of parent company or are separate production units operating under contract to the parent company. They have more daughter concern companies. The whole process from chick breeding flock hatching through to distribution retailing is integrated in a single organisation. Feed milling remains as a separate business enterprise which provides high-quality compound feed for broiler, layer, and breeder birds. This sector consists of the largest and most industrialized enterprises in the poultry industry. The different stages of value chain are vertically integrated into a single industrial company or ownership. In many instances, the feed and poultry production activities are integrated, together with horizontal links to other sectors. In other cases, vertical integration is partial – from breeder down to broiler grower or from market distributor up to broiler producer. Vertical integration yields financial benefits by reducing the operational costs at different stages of the value chain. In non-integrated poultry systems, transaction costs are likely to be high because of (a) frequency and regularity of transactions resulting from the cyclical nature of poultry production; (b) disease outbreak risks and market price fluctuations; and (c) the investment in very specific types of assets or asset specificity, involved in poultry production, processing, and marketing.[7]

There is a scarcity of information regarding the egg quality, food safety, and hygiene practices among commercial and non-commercial farms. The aim of the present study was to assess the egg quality, food safety, and hygiene practices in egg production among commercial and non-commercial farms. Scope of study: This case study would be helpful for food safety and hygiene maintenance for egg production. It will also be helpful to control some zoonotic diseases and food-borne diseases to protect human beings from recoveries.

Methods

Study settings: The study is conducted in Barwala city, Panchkula districts of Haryana, according to convenient sampling convenience of the research.

Selection of respondents: Respondents were selected from Barwala city surrounding areas in 2019. They were poultry farmers and workers. Some veterinary and private laboratories were selected for data analysis of sample collection, and the management errors were checked.

Sample size and procedure: As per standard, 10% sample is required for research. Out of a total of 60 commercial and 30 backyards, rural poultry farms in Barwala district, Panchkula, six commercial and six non-commercial backyard poultry farms were selected to achieve the targets.

Development of an interview schedule: An interview schedule was developed to obtain the desired information on various aspects of food safety and hygiene. This interview schedule was first pre-tested on non-sampled subjects. Based on the response received during pre-testing, necessary changes were incorporated in the schedule. This pre-tested and reconstructed schedule was used to collect the final data for the present study.

Collection of data from farmers: A format was prepared, and data were collected from farmers and their employees. Qualitative measurements like hygiene of hands and eggs are performed by local private labs. People are observed during their habitual routines to understand how they interact with a product, for example, egg shape size, egg weight, egg freshness, egg albumen, yolk, and shell percentage. Quantitative measurements are performed through interview and questionnaires on farm on bio-security and disinfectant management, rodent control practices, flock health monitoring, and waste disposal practices. Swap test results for bacterial contamination were conducted with salmonella, coliform, staphylococcus, and clostridium.

Statistical analysis

Data were analysed using STATA v15 (StataCorp LLC, College Station, TX). Characteristics were described as frequencies and percentages for categorical variables. Variance, standard deviation, and coefficient of variation were documented [Supplementary file].

Results

We had selected the BV300 breed in commercial poultry farms and brown layers in non- commercial farms. All the observations were prepared as breed BV300 standards.

External egg quality

The proportion of eggs with a normal weight and size was higher in commercial (83.3%) than in non-commercial (75%) farms. Abnormal egg weight, size, and egg breakage were higher in non-commercial farms (20% and 5%, respectively) than in commercial farms (13.3% and 3.3%, respectively). All poultry farms sale their eggs either daily or in 1- or 2-day intervals the whole year. So, all eggs from commercial and non-commercial poultry farm egg freshness were 100% found [Table 1].

Table 1.

External and internal egg quality (n=120)

| External egg quality | Commercial farm Total egg procured=60 | Non-commercial farm Total egg procured=60 | ||

|---|---|---|---|---|

|

|

|

|||

| No. of eggs | % | No. of eggs | % | |

| Normal egg (weight and size) | 50 | 83.3% | 45 | 75% |

| Abnormal egg weight and size | 8 | 13.3 | 12 | 20% |

| Egg breakage and egg spot | 2 | 3.3% | 3 | 5% |

| Egg freshness | 60 | 100% | 60 | 100% |

|

| ||||

| Internal egg quality | Commercial farm Egg procured 4×4=16 % | Non-commercial farm Egg procured =2×4=8 % | ||

|

| ||||

| Egg yolk % | 26.21% | 34.49% | ||

| Egg albumen % | 62.49% | 52.73% | ||

| Egg shell % | 11.67% | 12.76% | ||

Internal egg quality

Eggs were procured, with four eggs from four different commercial poultry farms and four eggs in different two non-commercial farms. A total of 16 eggs from commercial and eight eggs in non-commercial farm were procured. A total of 24 eggs are procured in a 2:1 ratio. The eggs were broken one by one carefully and weighed. We calculated albumen, yolk, and eggshell separately in a digital weight machine and observed results in commercial farms to have 26% egg yolk, 62.25% albumen, and 11.57% eggshell. Non-commercial farms found 34.5% egg yolk 52.73% egg albumen, and 12.76% eggshell [Table 1]. Details of variance, standard deviation, and coefficient of variation are provided in supplementary Table S1, S2.

Table S1.

Commercial and non-commercial farm yolk albumen and egg shell percentage

| Yolk variance | Yolk SD | Yolk CV% | Albumen variance | Albu men SD | Albume n CV% | Shell variance | Shell SD | Shell CV% |

|---|---|---|---|---|---|---|---|---|

| 2.4013 | 1.5496 | 5.9431 | 5.4 | 2.3237 | 3.73 | 1.523 | 1.2344 | 10.573 |

| 1.4836 | 1.21 | 3.53 | 27.148 | 5.21 | 9.02 | 0.1438 | 0.3793 | 2.97 |

Table S2.

Variance, Standard deviation and CV Percentage of eggs

| Parameters | Commercial Farm Eggs n=16 | Noncommercial Farm eggs n=8 | ||||

|---|---|---|---|---|---|---|

|

|

|

|||||

| Variance | SD | CV % | Variance | SD | CV % | |

| Egg yolk | 2.4013 | 1.5496 | 5.9431 | 1.4836 | 1.21 | 5.53 |

| Egg Albumen | 5.4 | 2.3237 | 3.73 | 27.148 | 5.21 | 9.02 |

| Egg shell | 1.523 | 1.2344 | 10.573 | 0.1438 | 0.3793 | 2.97 |

Bio-security and disinfectant management, rodent control practices, and flock health monitoring

Fumigation (66.6%), terminal disinfection (100%), and vehicle/foot deep bath (83.3%) practices were conducted only in commercial farms. Only half of the commercial and non-commercial farms had storage cleaning facilities.

Foot deep and wheel deep were present, but either water was not available or dirty water was seen in foot deep protocols. In commercial farms, five of total six farms were following this wheel and foot deep protocol. So, a total of 83% of commercial farmers used this protocol, whereas all six non-commercial farms did not use this protocol. Thus, the total 0% non-commercial farmers used the wheel deep foot deep protocol. Cleaning of farms was seen better in both commercial and non-commercial farms. It was observed that the egg storage room was dirty in commercial farms and cleaning programs were not implemented on a regular basis., whereas a non-commercial farm cleaning program was followed on weekly basis. Commercial farms had good practices of rodent control and fly control daily with modern equipment and recommended chemicals. Non-commercial farms did not have any regular and irregular practices of rodent and fly control. In commercial farms, about 66.6% of farmers had practices to feed and water testing, whereas 50% farms had followed serology and farm hygiene practices. Non-commercial farms were not following these practices [Table 2].

Table 2.

Biosecurity and disinfectant management, rodent control practices, and flock health monitoring

| Variable | Commercial farm n=6 | Non-commercial farm n=6 | ||

|---|---|---|---|---|

|

|

|

|||

| n | % | n | % | |

| Biosecurity and disinfectant management | ||||

| Fumigation | 4 | 66.6% | 0 | 0 |

| Terminal disinfection | 6 | 100% | 0 | 0 |

| Vehicle/Foot deepbath | 5 | 83.3% | 0 | 0 |

| Storage cleaning | 3 | 50% | 3 | 50% |

| Rodent control practices | ||||

| Fly control method: By chemical and electricity | 5 | 83.3 | 0 | 0 |

| Rodent control method: By chemical and mechanically | 5 | 83.3 | 0 | 0 |

| Flock health monitoring | ||||

| Feed sample | 4 | 66.6% | 0 | 0% |

| Water quality | 4 | 66.6% | 0 | 0% |

| Flock serology | 3 | 50% | 0 | 0% |

| Farm hygiene | 3 | 50% | 0 | 0% |

Waste disposal practices

Litter was disposed twice in a year in commercial farms, whereas non-commercial farms dispose off litter daily or weekly. All six commercial farmers had removed litter from farms in a year. Non-commercial farms, total four in six, had daily practices of litter removal from farms; another two had weekly practices, so total 66% had daily practices and 33% had weekly followed the litter removal from farms. It was observed that all six commercial farmers were disposing off the dead birds or mortality daily, so a total of 100% commercial farmers followed these practices daily. In non-commercial farms, dead bird disposal practices were not being followed on a regular basis. Only two in six farmers were disposing the dead birds daily. Another four farmers were throwing the dead bird outside the farm for another animal (dog or cat) feeding. Therefore, a total of 33.3% used this protocol properly, whereas 66.6% farmers were not following these practices. Commercial farmers disposed off the medicine packaging material daily. Non-commercial farmers have not disposed off these wastes at all. Results showed that out of six, only four farmers disposed the packaging material including vials, bottles, plastic, and bag paper containers daily and two farmers disposed it weekly. Thus, a total of 66.6% commercial farms disposed the packaging material daily, whereas 33.3% people disposed it weekly. In commercial farms, the rodents were disposed off daily. All six farmers were using these practices daily. Thus, a total of 100% commercial farms followed this protocol daily. In non-commercial farms, five in six farms had daily rodent disposal practices and another one farmer had not followed these practices daily. So, a total of 83.3% non-commercial farms had daily practices for rodent disposal on the farm [Table 3].

Table 3.

Waste disposal practices

| Variable | Commercial farm (n=6) n (%) | Non-commercial farm (n=6) n (%) | ||||

|---|---|---|---|---|---|---|

|

|

|

|||||

| Daily | Weekly | Crop cycle | Daily | Weekly | Crop cycle | |

| Litter | 0 (0) | 0 (0) | 6 (100.0) | 4 (66.7) | 2 (33.3) | 0 (0) |

| Mortality disposal | 6 (100.0) | 0 (0) | 0 (0) | 2 (33.3) | 4 (66.7) | 0 (0) |

| Medicines vials and others packing material | 4 (66.7) | 1 (16.6) | 1 (16.6) | 0 (0) | 0 (0) | 6 (100.0) |

| Rodents and fly | 6 (100.0) | 0 (0) | 0 (0) | 5 (83.3) | 1 (16.6) | 0 (0) |

Swap test results for bacterial contamination

The colony forming units (CFU) for salmonella and coliform were acceptable in three and four procured samples from commercial farms, respectively, whereas none were within acceptable levels among non-commercial farms [Table 4].

Table 4.

Swap test results for bacterial contamination

| Bacterial contamination of storage houses | ||||

|---|---|---|---|---|

|

| ||||

| Swap test parameters | Commercial Farm n=4×4=16 swaps sample | Non-commercial Farm n=2×4=8 swaps sample | ||

|

|

|

|||

| Pathogens | CFU Accepted <50 | Not acceptable >50 | Accepted <50 | Not Acceptable >50 |

| Salmonella | 3 | 1 | 0 | 4 |

| Coliform | 4 | 0 | 0 | 4 |

| Staphylococcus | ND | ND | 0 | 4 |

| Clostridium | ND | ND | 0 | ND |

*ND - Not detected

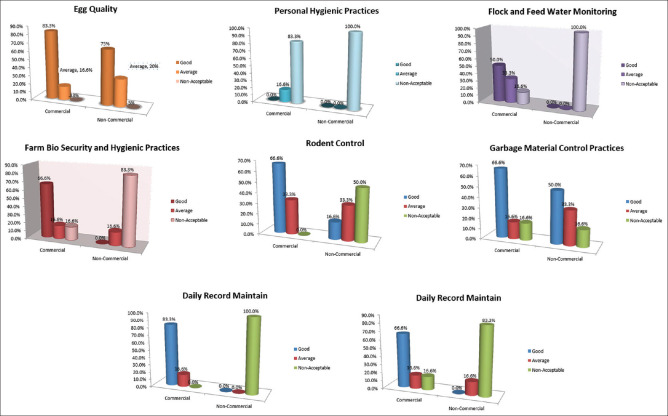

Overall, graphical comparisons among commercial and non-commercial farms are documented in Figure 1.

Figure 1.

Comparisons of various parameters related to egg quality, food safety, and hygiene practices among commercial and non-commercial farms

Discussion

This study was an attempt to provide information about the actual food safety and hygiene practices followed in commercial and non-commercial layer farming in Barwala district, Panchkula. Both commercial and non-commercial farms require implementation hygiene and food safety practices for public health. This research finds many weaknesses in food safety issues which are required to improve.

It was observed that the commercial egg quality index was 83%, feed water sample monitoring was 50%, farm biosecurity and rodent control practices were 66.6%, and garbage and overall animal husbandry practices were also 66.6% in commercial farms. But personal hygiene practices were very poor, that is, 0%.

In this study, the differences in egg shape index and egg height between weeks were found insignificantly (P > 0.05). The proportions of components for fresh egg are 32% yolk, 58% albumen, and 10% shell (Lesson, 2006). Both commercial and non-commercial internal egg quality did not match this research. Similar results were documented by other studies.[11,12,13] There were differences with respect to internal and external egg quality, where commercial farms had an upper hand in providing relatively good quality eggs. Various researches documented similar results.[13,14] It is well recognised that a variety of factors, including age, nutrition, parents’ average body weight, and genotype, influence egg weight. It is reasonable to believe that the causes account for the non-commercial egg’s lower weight in this study. The calcium in the shell is what gives non-commercial eggs their high shell thickness. Since calcium is abundant in forage, free-range birds ingest enough calcium to maintain their high calcium content.[15,16,17] Variations in the quality of eggs can result from several factors such as housing conditions, age, storage conditions, and the feed that the hens scavenge.[18]

Both types of farms were not hygienic for egg storage and need to conduct cleaning programs on a daily basis. Another study was conducted and demonstrated for bio-security in the terai zone, West Bengal, in 2015; biosecurity practices were observed as preparation of feed with boiled water (3%), cleaning frequency of feeding utensils and drinking trough (0% daily/weekly), frequency of change of drinking water in the trough (3.3% weekly), frequency of change of litter (0% daily), disposal of carcass by garden burial, washing of eggs (6%), and storage of eggs in room temperature (93%). In the studied area, scavenging of the birds was mostly observed near the house (93%). The other birds such as crows (93%) and wild birds (6%) were observed in the studied area. The restriction of the visitors to the backyard premises was followed in the studied zone.[19] Bacterial contamination was higher in commercial farms, probably due to improper and irregular cleaning, hygiene practices, and lack of vaccination and guided antibiotic usage.[20,21]

The strength of this study was that it was one of the very few studies to explore the egg quality, food safety, and hygiene practices among commercial and non-commercial farms in rural North India. There were some limitations. Being a cross-sectional study, temporality and causation could not be explored. Chances of recall bias and social desirability bias could not be completely ignored. Being more focussed in the rural areas of North India, generalisability could not be up to mark.

Recommendations

For the Government: Setting of poultry research centres and local agriculture colleges for training programmes for poultry farmers throughout the year. There should be short-term courses. For public: Food safety and hygiene practices are necessary to be followed in egg production sites, retailing, and kitchens for highly nutritive food safety and hygiene maintenance. For production sites: Eggs are perishable food, and they get rotten in the limited time periods. So, egg production and expiration dates should be mentioned on egg trays or eggshells.

For dieticians and doctors: The majority of consumers believe that eggs are non-vegetarian diet. They are forbidden to consume in summer and other festivals in India. So, proper awareness programmes should be implemented to reveal actual nutritive values of eggs and food components of balanced diet and can ward off all the myths associated with eggs. People should consume at least one egg every day throughout the year for a better nutritional status and to fulfil micronutrient requirement of our body.

Conclusion

The internal egg quality, food safety, and hygiene practices were relatively better among commercial farms as compared to non-commercial farms. This requires further validation through evidence-based multi-centric large sample-sized studies with regular and strict follow-ups.

Ethics

Ethical clearance was obtained from Institute Ethical committee of School of Continuing Education Indira Gandhi National Open University, New Delhi, 14/01/2019.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

References

- 1.Nys Y, Sauveur B. The nutritional value of eggs. Prod Anim. 2004;17:385–93. [Google Scholar]

- 2.Nau F. Comparative study of egg quality traits in two Belgian local breeds and two commercial lines of chickens-European Poultry Science. [Last accessed on 2024 Mar 30]. Available from:https://www.european-poultry-science.com/comparative-study-of-egg-quality-traits-in-two-belgian-local-breeds-and-two-commercial-lines-of-chickens,QUlEPTQyMTk3OTEmTUlEPTE2MTAxNCZQQUdFX1RQTD1QcmludHByZXZpZXcuaHRtJk1FVEFfUk9CT1Q9T0ZG.html .

- 3.Suk YO, Park C. Effect of breed and age of hens on the yolk to albumen ratio in two different genetic stocks. Poult Sci. 2001;80:855–8. doi: 10.1093/ps/80.7.855. [DOI] [PubMed] [Google Scholar]

- 4.Tixier-Boichard M, Joffrin C, Gourichon D, Bordas A. 8th world congress on genetics applied to livestock production. Belo Horizonte, MG, Brasil: 2006. [Last accessed on 2024 Mar 30]. Improvement of yolk percentage by crossbreeding between a commercial brown-Egg layer and a local breed, The fayoumi. Available from:https://library.wur.nl/WebQuery/titel/1875823 . [Google Scholar]

- 5.Mine Y, Kovacs-Nolan J. Biologically active hen egg components in human health and disease. J Poult Sci. 2004;41:1–29. [Google Scholar]

- 6.Digital edition of WATT 2015 Poultry Trends available now. 2015. [Last accessed on 2024 Mar 30]. Available from:https://www.wattagnet.com/egg/egg-production/article/15516109/digital-edition-of-watt-2015-poultry-trends-available-now-wattagnet .

- 7.Chatterjee RN, Rajkumar U. An overview of poultry production in India. Indian J Anim Hlth. 2015;54:89–108. [Google Scholar]

- 8.ICAR-Directorate of Poultry Research. Refresher Training programme (RTP) on poultry management. 2021 [Google Scholar]

- 9.Department of Animal Husbandry, Dairying and Fisheries Ministry of Agriculture and Farmers Welfare Government of India. Seeking Comments on National Action Plan- Poultry-2022 by 12-12-2017. [Last accessed on 2024 Mar 30]. Available from:https://www.dahd.nic.in/sites/default/filess/Seeking%20Comments%20on%20National%20Action%20Plan-%20Poultry-%202022%20by%2012-12-2017.pdf .

- 10.Sharma RP, Chatterjee RN. Backyard poultry farming and rural food security. Indian Farm. 2009;59:36–7. [Google Scholar]

- 11.Delgado C, Rosegrant M, Steinfeld H, Ehui S, Courbois C. Livestock to 2020: The next food revolution. Food, Agriculture, and the Environment Discussion Paper 28, International Food Policy Research Institute, Washington, DC, 1999 [Google Scholar]

- 12.Islam Z, Khan S, Jan A, Khalil ZUR, Khalil R, Khan F, et al. Comparative study of egg quality traits in local breeds and commercial lines of chickens. Int J Biosci. 2017;10:1–15. [Google Scholar]

- 13.Cicek T, Kartalkanat A. Comparison of village eggs and commercial eggs in terms of egg quality. J Anim Vet Adv. 2009;8:2542–5. [Google Scholar]

- 14.Yakubu A, Ogah D, R E B. Productivity and egg quality characteristics of free range naked neck and normal feathered Nigerian indigenous chickens. Int J Poult Sci. 2008;7:579–85. [Google Scholar]

- 15.Boitumelo P. Influence of Limestone Particle Size in Layer Diets on Shell Characteristics at Peak Production. University of the Free State. 2004 [Google Scholar]

- 16.Yakubu P. Productivity and Natural Disease Resistance Potential of Free-ranging Local Chicken Ecotypes in Tanzania. [Last accessed on 2024 Mar 30]. Available from:https://www.lrrd.cipav.org.co/lrrd14/3/msof143.htm .

- 17.Hussein SM, Harms RH, Janky DM. 1993. Effect of age on the yolk to albumen ratio in chicken eggs. Poult Sci. 1993;72:594–7. doi: 10.3382/ps.0720594. [DOI] [PubMed] [Google Scholar]

- 18.Zaman MA, Ahmed A, Sutradhar BC. Study on the egg quality of a breed and three crossbreds at various ages under semi scavenging system of management. Pak J Biol Sci. 2005;28:211–4. [Google Scholar]

- 19.Samanta SN, Joardar D, Ganguli PK, Dasand U.Sarkar. [Last accessed on 2024 Mar 30]. Available from:https://www.veterinaryworld.org/Vol.8/February-2015/8. EISSN .

- 20.Chousalkar KK, Khan S, McWhorter AR. Microbial quality, safety and storage of eggs. Curr Opin Food Sci. 2021;38:91–5. [Google Scholar]

- 21.Spitzer H. An analysis of bacterial contamination of chicken eggs and antimicrobial resistance. Celebrating Scholarship and Creativity Day. College of Saint Benedict and Saint John's University. 2015:77. [Google Scholar]