Abstract

The present work describes the process of the creation and analysis of the first dataset containing processing parameters and functional properties of soft magnetic composites (SMC). All data were obtained experimentally using Fe-3% MgO system. When creating samples, parameters such as a size of MgO nanoparticles, pressing pressure, sintering temperature, time and atmosphere were varied. In total, 282 samples with a unique combination of processing parameters were obtained. In each sample, density, real part of complex magnetic permeability at different frequencies, coercivity, and resonant frequency were measured. This allowed us to create the first experimentally obtained dataset devoted to SMC. Such dataset is necessary for implementing data-driven research in the field of SMCs, as well as for studying correlations in the chain: processing parameters – structure – properties. The dataset is currently being expanded both in terms of expanding the set of variable independent parameters and in terms of expanding the set of controlled properties. The dataset is hosted in Figshare open repository.

Subject terms: Magnetic properties and materials; Magnetic properties and materials; Design, synthesis and processing

Background & Summary

Power saving, miniaturization, and the emergence of a large number of novel electrical applications are the driving forces behind the development of modern soft magnetic materials1. One of the most promising classes of such materials that allows unlocking new applications and increasing the energy efficiency of devices is soft magnetic composites (SMCs)2. They are ferromagnetic/insulator composites and combine good magnetic properties with low power loss3. The advantages of SMCs in addition to low losses are the isotropy of properties, and the possibility for complex shapes to be produced directly during the compaction stage and without the need for additional machining, which greatly simplifies their integration into the industry. In addition to traditional areas of electrical engineering, they can be widely used in modern booming areas such as electric transport, the internet of things (IoT), and many others. Finally, the higher operating frequencies that can be achieved by using these materials can increase the efficiency of devices while reducing their size Therefore, development of SMCs is an effective response to the growing needs of the electrical industry.

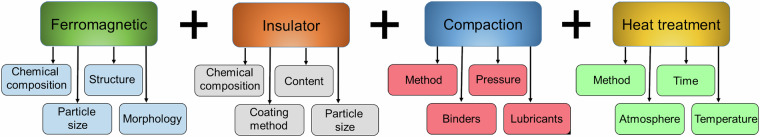

The functional properties of composites are governed by ferromagnetic and insulator component and large set of parameters, insulator content and coating method, particle size, morphology, pressing and heat treatment conditions, etc4–10. Schematically, a set of main parameters influencing the final properties of SMCs is presented in Fig. 1.

Fig. 1.

Illustration of the variety of parameters varied when obtaining SMCs.

Because of this, the opportunities to control and optimize the properties of such products are unimaginable. In order to navigate this variety and choose promising combinations of ferromagnetic, insulator, and processing parameters, attempts are made to find correlations between them and functional properties. Today, there is an understanding of some basic dependencies, for example, the effect of the particle size of a ferromagnetic on the cut-off frequency8, core losses11, permeability12, and other properties13. However, as a rule, these correlations are of a particular nature and are valid only for specific systems with the remaining parameters unchanged and under certain conditions. A huge problem is the lack of systematization and detailed analysis of the results obtained. Only basic dependencies are known, for example, an increase in the amount of insulator leads to an increase in core losses and a decrease in magnetic permeability. However, due to the complex nature of SMCs, very often the dependencies are complex and non-linear. The situation complicates by number trades off between important properties in SMCs. Namely, it is difficult to simultaneously obtain high permeability and high resonant frequency or high electrical resistivity and low coercivity. Because of the above, complex tools are needed to analyze correlations in SMCs and develop a strategy for properties optimization. However, to date, the design and research of SMCs is carried out mainly through experimental approaches only. It can be said that the experimental approach in SMCs has practically exhausted itself due to the fact that the most obvious ways to improve properties have already been tested. Today, to achieve breakthrough results and significantly improve the functional properties of SMCs, a fundamentally new approach is needed. Such a radically new approach can be the use of data-driven development and research of SMCs. Due to the large number of independent parameters and non-trivial correlations between them and dependent parameters (properties), which are difficult to analyze using traditional methods, this approach opens up enormous prospects in the development and research of SMCs.

However, bottleneck of the data-driver research in materials science is small amount of data and their heterogeneity14. In the case of SMCs, this problem is especially acute. Despite the growing interest in the topic of SMC and the publication of hundreds of articles with experimental results every year, compiling a high-quality database of an acceptable size (at least several hundred of data samples) is extremely difficult. This is due to the fact that SMC-related studies suffer from a lack of standards in conducting and describing experiments. The descriptions of experiments often lack important information regarding processing parameters, for example, the duration and atmosphere of annealing or pressing pressure. If binders or/and lubricants are used, their quantity is often not indicated. The particle size of the ferromagnetic and the insulator is not always mentioned (for cases when the insulator is used in powder form). An even more critical problem with the properties of SMCs. For example, core losses measured under different conditions (frequency intervals and induction Bm). Different works use values of Bm equal to 0.01 T15, 0.02 T16, 0.05 T17, 0.1 T18, 1 T19 and others at core loss measurements. The measurement results are given either divided to volume16 or mass20, which is impossible to recalculate without information about sample’s density, which is also often missing. Not identical measurement conditions are also typical for coercivity, magnetization and permeability. Different works may provide coercivity and magnetization values obtained at different magnetic fields. Permeability is often given for a limited range of frequencies, which does not allow getting information about frequency stability and resonant frequency. Because of this, data presented in different works often cannot be compared with each other. All this is superimposed on the variation of a wide range of parameters (different ferromagnetics, insulators, coating methods, etc.) and the frequent use of non-standard approaches, which does not allow obtaining standardized data. This distinguishes SMCs from many other groups of materials, in which collection of quality data from scientific literature is a much simpler task, since there is not such heterogeneity in experiments and so many influencing parameters, for example, high-entropy alloys21, Co- and Ti-based alloys22,23, FINEMET-type alloys24 and many others.

This not only limits the possibilities of data-driven research in this direction, but also complicates the finding and analysis of correlations between processing parameters and properties and, as a consequence, deepening the understanding of the peculiarities of the formation of structure and properties in SMCs.

Our motivation is to partially solve this problem by creating first extensive data set by gradually varying separate parameters while holding others unchanged. For this purpose, at the first stage, a simple Fe/MgO system was selected. The samples were prepared by traditional powder metallurgy route, namely dry mixing of powders, cold pressing and sintering. Five independent parameters vary: MgO particle size, pressing pressure, temperature, atmosphere and time of annealing, other parameters were kept unchanged. In all samples, five dependent variables (properties) were controlled, namely: density, coercivity, real part of complex relative permeability at DC and at 3 kHz, resonance frequency. The set of variable and controllable parameters will be expanded in the future, and it is also planned to include other ferromagnetic/insulator systems. Obtaining data within one extensive experiment by one research group using the same equipment and raw materials allows us to minimize a common problem of data heterogeneity that plagues datasets collected from scientific literature.

Methods

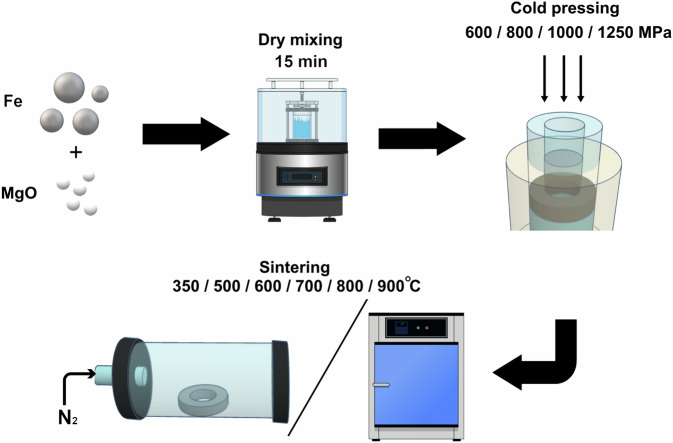

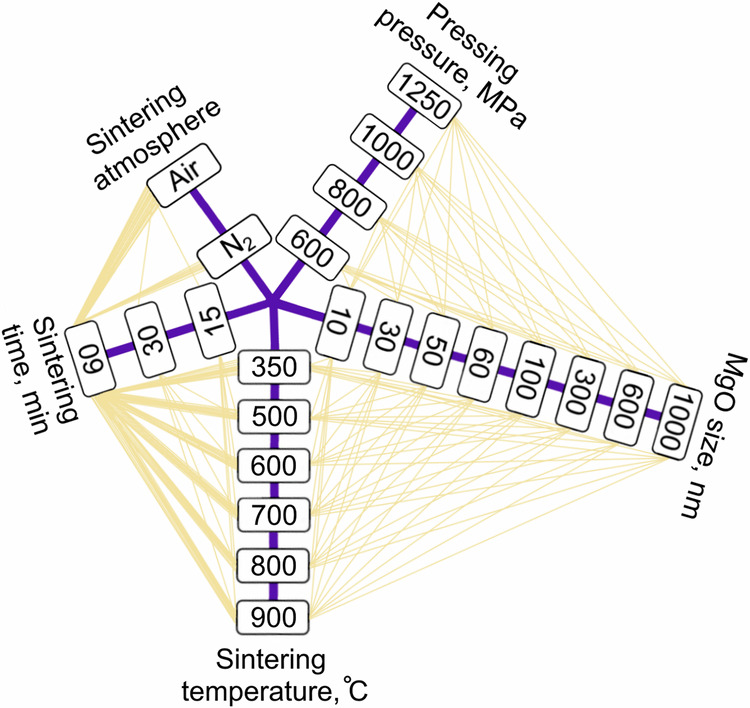

For the samples preparation Iron powder (ABC100.30) supplied by Höganäs (Sweden) and MgO powder with different particle size supplied by MTI Co. (USA) were used. The as-supplied iron powder was mixed with 3% wt. of MgO powder of a given size using resonance acoustic mixer (Resodyn LabRAM) during 15 min. As prepared powder mixes were compacted using cold pressing at various pressure to obtain ring-shape samples (outer diameter is 24 mm, inner diameter is 13.4 mm, height is about 1.5 mm). The compacted samples were sintering with varying three main parameters: temperature, time and atmosphere. Annealing was carried out at a heating rate 5°/C and cooling with a furnace. All variable parameters are schematically presented in Fig. 2. In addition, for each combination of pressure and MgO size, unannealed samples immediately after pressing (green compacts) were examined. The geometry of the ring samples corresponded to the recommendations of the international standard IEC 60404-6, the ratio of the inner diameter to the outer diameter of the ring sample was 1.79, the cross-sectional area was 8 mm2 and the thickness of the ring was 1.5 mm.

Fig. 2.

Scheme of variation of the processing parameters when planning experiments for dataset creation.

The sample manufacturing process is shown schematically in Fig. 3. In each sample we controlled skeletal density by dividing the sample volume by mass. The coercivity was measured by Foerster Koerzimat 1.097 HCJ, at the applied maximum magnetic field 440 kA/m. The frequency dependence of real part of complex permeability up to 10 MHz was obtained by the Impedance Analyzer HP 4194 A, with the contact electrodes in a configuration of two-terminal connection. The choice of an impedance analyzer as a tool for studying the magnetic properties of AC is due to the fact that it is well suited for the analysis of high-frequency characterization of ring-shaped samples fabricated using the press and sinter method. It provides a comprehensive picture of magnetic losses and permeability over a broad frequency range, which aligns better with the nature of powder metallurgy-based soft magnetic materials25–27.

Fig. 3.

Schematic representation of the process of obtaining samples for the experiment.

Data Records

The dataset is available at Figshare open repository28. The data are presented as table in .csv format. The table has 10 columns: five processing parameters and five properties. Nine of them contain numerical variables. One column (annealing atmosphere) contains categorical variables (no annealing, Air or Nitrogen), which can be transformed for example to 0, 1 and 2 correspondingly. Each column indicates the corresponding units of measurement, the permeability values are unit less.

In Table 1, it can be seen that the properties vary over a wide range depending on the combination of processing parameters. This is especially true for the resonant frequency, which varies from 0.9 to 3300 kHz. This clearly demonstrates the importance of proper selection of processing parameters when manufacturing SMCs.

Table 1.

Statistics of the dataset.

| index | Variable parameters | Controlled properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MgO size [nm] | P [MPa] | T [°C] | Time [min] | Atm. | Hc [A/m] | fr [kHz] | µ′ at DC | µ′ at 3 kHz | ρ g/cm3 | |

| unique variables | 8 | 4 | 7 | 4 | 2 | 282 | 282 | 282 | 282 | 282 |

| min | 10 | 600 | 0 | 0 | — | 227 | 0.9 | 45 | 36 | 5.89 |

| max | 1000 | 1250 | 900 | 60 | — | 822 | 3300 | 132 | 103 | 7.62 |

Technical Validation

The main requirement for sample preparation and analysis in this work was the use of standard, widely used techniques and commercially available raw materials to ensure the reliability and reproducibility of the data. All data were obtained in the same equipment using the same research protocols. The values were double cross-checked by the co-authors of the work.

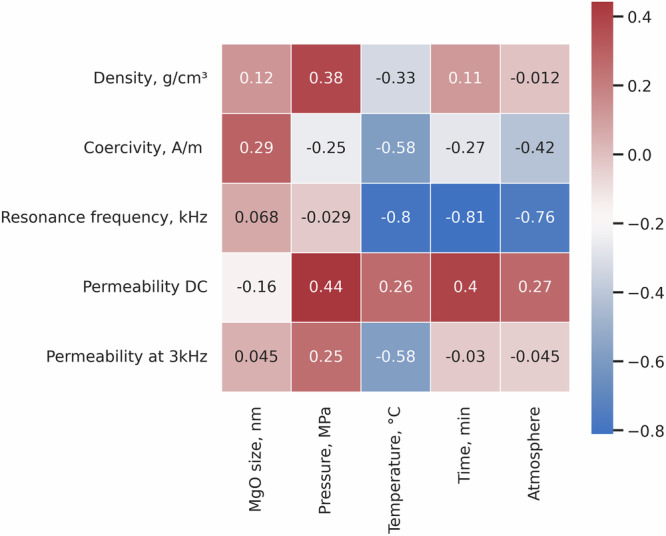

The data obtained in this work was primarily statistically analysed to evaluate the variability of correlations between processing parameters and properties of SMCs using the simple Fe/MgO system. Figure 4 shows a heatmap of Pearson correlation coefficients for all independent and dependent variables. The dataset’s suitability for machine learning was evaluated using statistical parameters such as mean, standard deviation, correlation matrix, and variance for all variables as presented in Table 2.

Fig. 4.

Heatmap of Pearson correlation coefficients.

Table 2.

Descriptive statistics of the dataset.

| Variable | Mean | Median | Standard Deviation | Variance | Coefficient of Variation |

|---|---|---|---|---|---|

| MgO size (nm) | 219.65 | 50 | 312.98 | 97957.88 | 1.42494 |

| Pressure (MPa) | 916.49 | 1000 | 244.48 | 59771.62 | 0.26676 |

| Temperature (°C) | 579.43 | 600 | 265.05 | 70251.63 | 0.45743 |

| Time (min) | 48.67 | 60 | 21.29 | 453.3 | 0.43745 |

| Density (g/cm³) | 7.09 | 7.11 | 0.33 | 0.11 | 0.04705 |

| Coercivity (A/m) | 372.63 | 335.5 | 115.29 | 13292.47 | 0.3094 |

| Resonance frequency (kHz) | 283.88 | 7.8 | 718.47 | 516199.32 | 2.53091 |

| Permeability (DC) | 83.87 | 83.5 | 17.23 | 296.81 | 0.20542 |

| Permeability (3 kHz) | 66.1 | 66 | 14.96 | 223.68 | 0.22626 |

The dataset contains a good variety of values across the independent variables, particularly in MgO size, temperature, and pressure. High standard deviation in resonance frequency suggests significant variability, which could positively influence model performance. High variability is observed in MgO size and resonance frequency, as indicated by their large standard deviation and variance. Moderate variability exists in pressure, temperature, coercivity, and permeability values. Low variability is found in the density, which is consistent with the controlled nature of this property due to the same elemental and phase composition. The median values for some variables (e.g., MgO size, resonance frequency) suggest non-symmetric distributions, influenced by outliers.

Moderate to strong correlations between variables highlight the dataset’s ability to capture complex, physically meaningful relationships.

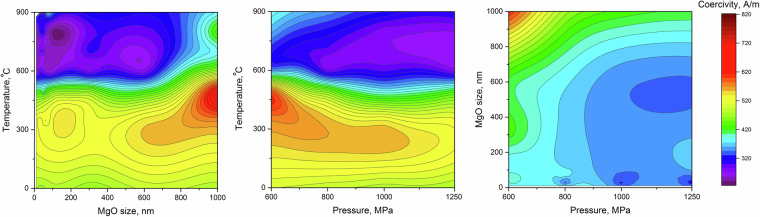

In order to visualize the correlations, we used contour plots using the example of coercive force and various combinations of two processing parameters (Fig. 5). Of course, this visualization method does not provide a complete picture; this would require constructing graphs in multi-dimensional space. Nevertheless, some general patterns can be identified.

Fig. 5.

Contour plots representing coercivity dependency on combination of two different processing parameters.

This visualisation offers valuable insights into the complex, non-linear relationships between processing conditions and material properties in SMC. The plots reveal significant interaction effects between different processing parameters. The coercivity is affected by individual parameters such as MgO particle size or pressing pressure and their combinations. This underscores the importance of considering multiple parameters simultaneously when optimising material properties. The non-linearity is evident in the contour plots, where changes in coercivity do not follow a simple, linear trend with varying parameters. The complex dependencies highlight the necessity for advanced analytical methods, like machine learning, to model and predict material behaviour. Parameter sensitivity can be studied because the contour plots help identify which combinations of parameters have the most significant impact on different physical properties. For example, certain ranges of annealing temperature and time may produce optimal coercivity values, while others may lead to less desirable properties. This sensitivity analysis is crucial for fine-tuning the processing conditions to achieve desired material characteristics. Examining the contour plots allows for identifying potential pathways for optimising properties such as coercivity. For instance, if a particular combination of lower MgO particle size and higher pressing pressure consistently results in lower coercivity, this combination can be targeted for further refinement and validation. This information provides a foundation for systematic and data-driven approaches to material optimisation, ultimately contributing to the development of more efficient and effective soft magnetic composites.

Now work is underway to expand it by adding new properties under study (electrical resistivity, core losses), new processing parameters and also using other simple oxides such as SiO2 and Al2O3 as insulators. It is expected that this dataset will begin the formation of a new scientific direction: data-driven research and development of soft magnetic composites.

Acknowledgements

This work was realized within the frame of the project “FUCO” financed by Slovak Research and Development Agency under the contract APVV-20-0072 and by Scientific Grant Agency of Ministry of Education, Research, Development and Youth of the Slovak Republic and Slovak Academy of Sciences - project VEGA 2/0099/24. V.A.M. acknowledges support of Ministry of Science and Higher Education of the Russian Federation (“Magnet”122021000034-9).

Author contributions

R.B. conception, supervision, resources, manuscript reviewing. V.A.M. conception, experiment, data processing, manuscript composition. M.F. experiment, data validation. Z.B. experiment, data validation. P.K. resources. J.F. resources.

Code availability

Data processing and visualization were performed using Python 3.10.12 and standard libraries Pandas 1.5.3, numpy 1.25.2, and Matplotlib 3.7.1. No custom code has been used.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Silveyra, J. M., Ferrara, E., Huber, D. L. & Monson, T. C. Soft magnetic materials for a sustainable and electrified world. Science (80-.). 362 (2018). [DOI] [PubMed]

- 2.Périgo, E. A., Weidenfeller, B., Kollár, P. & Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev.5, 31301 (2018). [Google Scholar]

- 3.Shokrollahi, H. & Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol.189, 1–12 (2007). [Google Scholar]

- 4.Streckova, M. et al. A comparison of soft magnetic composites designed from different ferromagnetic powders and phenolic resins. Chinese J. Chem. Eng.23, 736–743 (2015). [Google Scholar]

- 5.Yang, T. et al. Fe-6.5 wt%Si soft magnetic composites with significant improvement of magnetic properties by compositing nano-MnZn ferrites. J. Alloys Compd.909, 164660 (2022). [Google Scholar]

- 6.Luo, Z. et al. High-performance Fe–Si soft magnetic composites with controllable silicate/nano-Fe composite coating. J. Mater. Res. Technol.27, 6264–6274 (2023). [Google Scholar]

- 7.Luo, P. et al. Properties Optimization of Soft Magnetic Composites Based on the Amorphous Powders with Double Layer Inorganic Coating by Phosphating and Sodium Silicate Treatment. Metals (Basel).13, 560 (2023). [Google Scholar]

- 8.Jin, X., Li, T., Jia, Z., Shi, H. & Xue, D. Over 100 MHz cut-off frequency mechanism of Fe-Si soft magnetic composites. J. Magn. Magn. Mater.556, 169366 (2022). [Google Scholar]

- 9.Li, S., Peng, K. & Zou, L. The improved magnetic properties of FeSi powders cores composed with different size particles. J. Mater. Sci. Mater. Electron.33, 607–616 (2022). [Google Scholar]

- 10.Zhang, X. B. et al. Particle size selection principle of Fe-Si-Al SMCs for high-frequency and high-power applications. J. Magn. Magn. Mater. 563 (2022).

- 11.Shokrollahi, H. & Janghorban, K. The effect of compaction parameters and particle size on magnetic properties of iron-based alloys used in soft magnetic composites. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol.134, 41–43 (2006). [Google Scholar]

- 12.Anhalt, M. Systematic investigation of particle size dependence of magnetic properties in soft magnetic composites. J. Magn. Magn. Mater.320, 366–369 (2008). [Google Scholar]

- 13.Ding, W. et al. Effect of iron particle size and volume fraction on the magnetic properties of Fe/silicate glass soft magnetic composites. J. Magn. Magn. Mater.378, 232–238 (2015). [Google Scholar]

- 14.Morgan, D. & Jacobs, R. Opportunities and Challenges for Machine Learning in Materials Science. Annu. Rev. Mater. Res.50, 71–103 (2020). [Google Scholar]

- 15.Guo, R. et al. Regulation of magnetic and electrical performances in core-shell-structured FeSiCr@BaTiO3 soft magnetic composites. J. Alloys Compd.895, 162724 (2022). [Google Scholar]

- 16.Luo, Z. et al. Formation mechanism and magnetic performance of Fe-Si soft magnetic composites coated with MnO-SiO2 composite coatings. Adv. Powder Technol.32, 3364–3371 (2021). [Google Scholar]

- 17.Li, X. et al. Structure evolution of Fe-based nanocrystalline soft magnetic powder cores with excellent properties. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol.285, 115965 (2022). [Google Scholar]

- 18.Wang, J. et al. Reduction of core loss for FeSi soft magnetic composites prepared using atomic layer deposition-based coating and high-temperature annealing. J. Alloys Compd.909, 164655 (2022). [Google Scholar]

- 19.Meng, B. et al. Low-loss and high-induction Fe-based soft magnetic composites coated with magnetic insulating layers. J. Magn. Magn. Mater.492, 165651 (2019). [Google Scholar]

- 20.Zhang, Q., Zhang, W. & Peng, K. In-situ synthesis and magnetic properties of core-shell structured Fe/Fe3O4 composites. J. Magn. Magn. Mater.484, 418–423 (2019). [Google Scholar]

- 21.Fan, X. et al. Dataset for Fracture and Impact Toughness of High-Entropy Alloys. Sci. Data10, 1–9 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Gorsse, S., Gouné, M., Lin, W. C. & Girard, L. Dataset of mechanical properties and electrical conductivity of copper-based alloys. Sci. Data10, 1–8 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Salvador, C. A. F., Maia, E. L., Costa, F. H., Escobar, J. D. & Oliveira, J. P. A compilation of experimental data on the mechanical properties and microstructural features of Ti-alloys. Sci. Data9, 1–6 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Wang, Y. et al. Accelerated design of Fe-based soft magnetic materials using machine learning and stochastic optimization. Acta Mater.194, 144–155 (2020). [Google Scholar]

- 25.McCurrie, R. A. Ferromagnetic Materials: Structure and Properties. Academic Press (1994).

- 26.IEC Standard 60404-3: Methods of Measurement of the Magnetic Properties of Magnetic Sheet and Strip by Means of a Single Sheet Tester (2022).

- 27.IEC Standard 60404-6: Magnetic materials - Part 6: Methods of measurement of the magnetic properties of magnetically soft metallic and powder materials at frequencies in the range 20 Hz to 100 kHz by the use of ring specimens (2018).

- 28.Milyutin, V. et al. The first experimentally obtained data set on processing parameters and properties of soft magnetic composites. Figshare10.6084/m9.figshare.25975198.v1 (2024). [DOI] [PMC free article] [PubMed]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Citations

- Milyutin, V. et al. The first experimentally obtained data set on processing parameters and properties of soft magnetic composites. Figshare10.6084/m9.figshare.25975198.v1 (2024). [DOI] [PMC free article] [PubMed]

Data Availability Statement

Data processing and visualization were performed using Python 3.10.12 and standard libraries Pandas 1.5.3, numpy 1.25.2, and Matplotlib 3.7.1. No custom code has been used.