Highlights

This review provides a detailed account of engineered plant cell wall (CW)-mimetic soft materials, which are designed to replicate the intricate composition, structure, and mechanical properties of natural plant CWs.

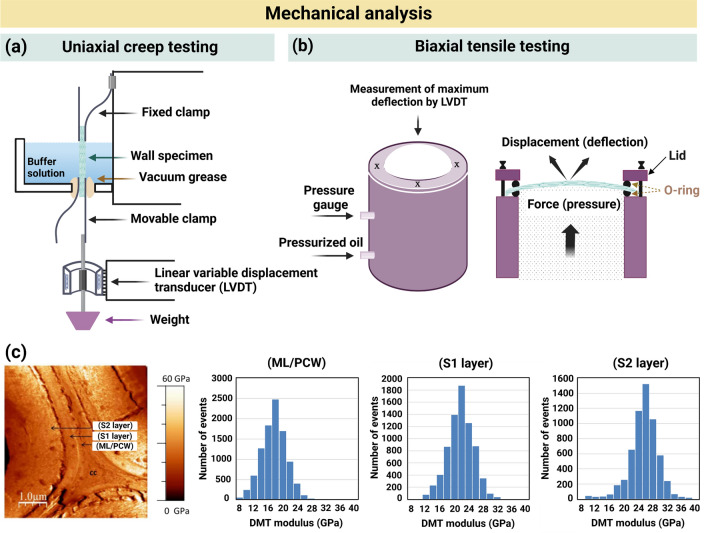

Experimental methods to create CW-like materials are reviewed, and relevant characterization techniques, including mechanical, chemical, structural, and morphological analyses, are discussed.

The applications of CW-like materials in several fields, including food packaging, edible films, drug delivery, construction materials, and biocatalysis are highlighted.

Keywords: Synthetic plants, Biomimicry, Acellular wall, Composites, Living materials, Soft matter

Abstract

Plant cell wall (CW)-like soft materials, referred to as artificial CWs, are composites of assembled polymers containing micro-/nanoparticles or fibers/fibrils that are designed to mimic the composition, structure, and mechanics of plant CWs. CW-like materials have recently emerged to test hypotheses pertaining to the intricate structure–property relationships of native plant CWs or to fabricate functional materials. Here, research on plant CWs and CW-like materials is reviewed by distilling key studies on biomimetic composites primarily composed of plant polysaccharides, including cellulose, pectin, and hemicellulose, as well as organic polymers like lignin. Micro- and nanofabrication of plant CW-like composites, characterization techniques, and in silico studies are reviewed, with a brief overview of current and potential applications. Micro-/nanofabrication approaches include bacterial growth and impregnation, layer-by-layer assembly, film casting, 3-dimensional templating microcapsules, and particle coating. Various characterization techniques are necessary for the comprehensive mechanical, chemical, morphological, and structural analyses of plant CWs and CW-like materials. CW-like materials demonstrate versatility in real-life applications, including biomass conversion, pulp and paper, food science, construction, catalysis, and reaction engineering. This review seeks to facilitate the rational design and thorough characterization of plant CW-mimetic materials, with the goal of advancing the development of innovative soft materials and elucidating the complex structure–property relationships inherent in native CWs.

Introduction

Plant cell walls (CWs) have garnered significant interest as a result of their composition, hierarchical structure, and unique mechanical properties, inspiring the engineering of biomimetic materials. Plant CWs may have high strength, stiffness, and extensibility, depending on growth stages and tissue types [1–3]. To closely mimic the characteristic properties of CWs and construct artificial plant CWs, the contribution of each component as well as the arrangements and interactions of CW building blocks need to be uncovered. To this end, considerable effort has been devoted to investigating the biological mechanisms underlying CW formation [4–6]; however, the isolation of plant CW components for in-depth studies of their native state is non-trivial [7]. The selective removal of CW building blocks via chemical or mechanical treatments may cause degradation and compromise corresponding interactions [8, 9]. To overcome the challenges associated with top-down CW investigations, bottom-up approaches such as developing artificial CWs have emerged [10–13].

CW-like materials generally comprise one to three biopolymer components produced by plants. These materials are classified into either two-dimensional (2D) or three-dimensional (3D) platforms. Fibers, monolithic composites, and films made up of polymers, particles, or their combination are considered as 2D constructs, and 3D models are fabricated using beads, droplets, or plasma membrane templates. The 3D constructs include microcapsules, microspheres, and coated beads [14]. Challenges and opportunities persist in building synthetic CW-like materials. Constructing the cross-lamellate structure and the integration of wall polymers such as lignin remains a key challenge. Additionally, the biomimetic assembly of biopolymers to develop 3D CW-mimetic composites is currently unexplored. Advancements in understanding the structure–property-function relationships of CW combined with advanced material fabrication and synthesis approaches may hold promise to overcome these challenges. Simulation methods, such as finite element analysis and coarse-grained modeling, enable the prediction of assembled CW-like material properties, such as mechanical characteristics, thermodynamic interactions, and transport phenomena [15–17]. Structural characterizations help uncover the effects of the physiochemical properties of CW polymers and inter-fibril interactions on material properties [15]. Additionally, advanced approaches such as bacteria-enabled in situ and ex situ material syntheses, microfluidics, and additive manufacturing may offer solutions for creating more complex, functional, and scalable CW-like materials.

Current studies have concentrated on fabricating plant CW-like materials either to elucidate CW structures or for biomimetic applications. To the best of our knowledge, no comprehensive review of the existing literature on this topic has been published. Furthermore, the field is disjointed due to the use of various terms to describe plant CW-like materials. The terms “artificial”, “synthetic” plant CWs, wall-like materials, wall-mimicking materials, and in vitro grown CWs are all used interchangeably to describe plant CW-like materials in the literature. In this paper, we aim to consolidate the current knowledge of this field by reviewing key studies on native plant CWs and CW-like materials. After providing a general description of plant CWs, including their composition and micro-/nanoarchitecture, we review the fabrication methods and characterization techniques for CW-like composites. Finally, the emerging applications of these materials are reviewed.

Plant CWs: Function, Architecture, and Composition

The hierarchical structure and constituent elements of plant CWs are discussed herein to provide a fundamental understanding of how CWs may be mimicked. The main function of CWs is to provide structural resilience and protect cells against biotic and abiotic stresses, while passing nutrients, gases, and cellular signals to the plasma membrane. CWs must be strong to support the mechanical integrity of plants and be extensible to enable cell expansion in growing cells [4, 5, 18]. All plant cells have a strong, extensible CW layer called the primary cell wall (PCW), while specialized cells, such as tracheary elements and wood fibers, encompass an additional secondary cell wall (SCW). Figure 1a presents the layers of CW in wood, including the middle lamella (ML), PCW, and SCW, as well as lumen. The SCW is composed of three sublayers, namely S1, S2, and S3, separating SCW from the lumen (i.e., the central void space). Each layer has unique arrangement of cellulose microfibrils (CMF), which play a key role in defining the physical and mechanical properties of plant CW [19]. The lumen in tracheary elements is responsible for water transport, and the CWs between adjacent cells are adhered to each other by the pectin-rich ML [3]. Both PCW and SCW layers contain CMF, which are frequently bundled together to provide much of the structural strength for the CWs [1, 4].

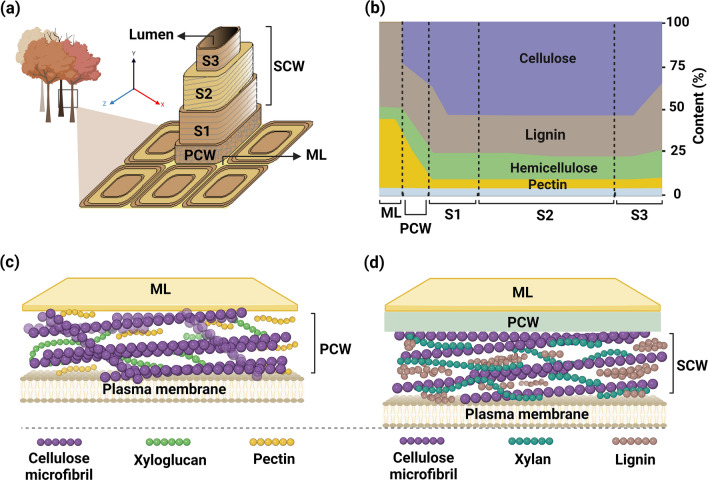

Fig. 1.

CW architecture and composition. a A cut-out schematic of a wood CW shows its layered structure, featuring a network-like arrangement in the PCW and aligned fibrils in the SCW. b The composition of wood CW in each layer after lignification. The light blue region shows the content of other compounds in the layers. c PCW schematic based on a molecular model, showing a load-bearing network of CMF in a matrix of pectin and xyloglucan. d A schematic of the SCW based on a molecular model, illustrating lignin deposits within an oriented cellulose matrix. The CMF are bound by xylan hemicelluloses, with limited interactions between cellulose and lignin. The PCW and SCW schemes were inspired by [29] and [37], respectively

The precise composition of CWs varies between species and even among the specialized tissues within the same plant [20]. Figure 1b presents the variations in composition and the corresponding content within each layer of a lignified CW in wood. It is important to note that these are final compositions after the cell growth is ceased, and the actual compositions during the cell growth are different because not all components are synthesized and deposited at the same time. The PCW is a composite material with both elastic and plastic properties, consisting of three structural polysaccharides, namely CMF (otherwise known as cellulose nanofibrils or CNF) (~ 15%-40%), hemicelluloses (~ 20%-30%), and pectin (~ 30%-50%) [2]. In lignified cells, the PCW also contains lignin (e.g., tracheid cell, up to 70%) [21]. The predominant hemicelluloses are xyloglucans in the PCW of all spermatophytes except grasses [22]. The SCW, which is formed after the plant cells stop growing, is thicker than the PCW. This layer consists of cellulose (~ 40%-48%), hemicelluloses (~ 20%-30%), and lignin (~ 20%-30%) [23]. In addition to the dominant structural polymers, growing CWs comprise small amounts of glycoproteins, also called structural proteins; however, they do not significantly contribute to the mechanical properties of CWs [18].

Information on the morphological features of plant CWs is being continuously updated, as current studies are limited to nonliving plant materials and in silico modeling [24–26]. The architecture of CWs depends on the orientation/arrangement of structural components [27, 28]. Figure 1c presents a recent model for PCW, consisting of a cross-lamellate cellulose fibril network embedded in a polysaccharide matrix [29]. Hemicellulose chains noncovalently bind to CMF, while the hydrated pectin molecules form a gel-like matrix, filling the space among the stiff cellulose networks. Since the PCW is formed during the growth phase of plant tissues, it must be extensible and capable of expanding alongside the growing plant cells [2, 5, 30]. During cell expansion, turgor pressure (i.e., the force from within the cell pushing the membrane against the CW) generates wall stresses and stores mechanical energy within the cell. Mechanical creep allows wall polymers to relax, facilitating the controlled expansion of CW. The stored mechanical energy drives cell expansion. This process is aided by wall-loosening agents, such as expansins, which disrupt crosslinks between CMF, allowing the fibrils to slide past each other more easily [4]. Additionally, plant cells are adhered to one another by a pectin-rich layer known as the ML [3].

Compared with PCW, SCW is stiffer and supports the plant weight; it is formed after the cell ceases to grow. It provides compressive and tensile strength, but not necessarily extensibility [2]. In cells containing a SCW, the PCW and ML become increasingly lignified, which are referred to as a compound middle lamella (CML) [21]. In the SCW S1 and S3 layers, CMF align roughly perpendicularly to the longitudinal axis of cell (Y axis, shown in Fig. 1a) [21, 31]. In the S2 layer, comprising the majority of CW, highly oriented CMF are directed within a specified angle (Z axis, shown in Fig. 1a), known as microfibril angle (MFA) [32–35]. Figure 1d presents a recent model of SCW, where hemicellulose binds to the CMF, and lignin is bridged to CMF through hemicelluloses, indicating that CMF and lignin do not interact directly [2]. Xylan and glucomannan (GM) are two of the most prevalent hemicelluloses in the SCW [23]. Lignin, composed of phenolic compounds, imparts strength, rigidity, and hydrophobicity to the SCW. Its composition can vary as a result of the random co-polymerization of coniferyl, syringyl, or p-coumaryl alcohols, known as monolignols, which are synthesized in the cytosol and transported to the CW. Once in the CW, these monolignols are polymerized through oxidation, facilitated by oxidase enzymes such as peroxidase [23, 36]. The deposition of lignin and hemicellulose renders the water conduits waterproof, enabling efficient water transport throughout the plants and increasing the stiffness and strength of CW [23, 37].

Fabrication and Properties of Artificial Plant CWs

Artificial plant CWs have been constructed via bottom-up approaches using bacterial cellulose pellicle growth and impregnation, layer-by-layer (LbL) assembly, film casting, 3D templating microcapsules, and particle coating. These methods, summarized in Figs. 2 and 3, are discussed in this Section.

Fig. 2.

Fabrication of plant CW-like materials via bacterial cellulose pellicle growth and impregnation or LbL assembly techniques. a A culture of cellulose-synthesizing bacteria, assembling cellulose within a growth medium, containing CW polysaccharides and other biopolymers. b Deep-etch freeze-fracture TEM micrographs of bacterial cellulose, showing differences in the arrangement of CMF with or without xyloglucan. Scale bars are 5 µm. Adapted (cropped and labeled) with permission [46].

Copyright Wiley, 1995. c Effect of expansin on the extension of hemicellulose-cellulose composites, showing a significant increase in displacement under a constant load for cellulose-xyloglucan composites with the addition of expansin. Adapted with permission. Copyright Wiley, 2000 [39]. d Schematic of the LbL assembly method, showing the formation of alternating cellulose fibril and xyloglucan layers on a primer-coated substrate. e The thickness of CNC-xyloglucan films, formed via spin coating, as a function of deposited layer number demonstrates the linear growth of layers when the xyloglucan concentration is 0.5 or 1 g mL−1. Adapted with permission [62]. Copyright American Chemical Society, 2010. f AFM topographical images show the non-uniformity of pectin and extensin layers in a pectin-extensin composite material, attributed to the imbalanced charge density between the components. Adapted with permission [65]. Copyright American Chemical Society, 2010

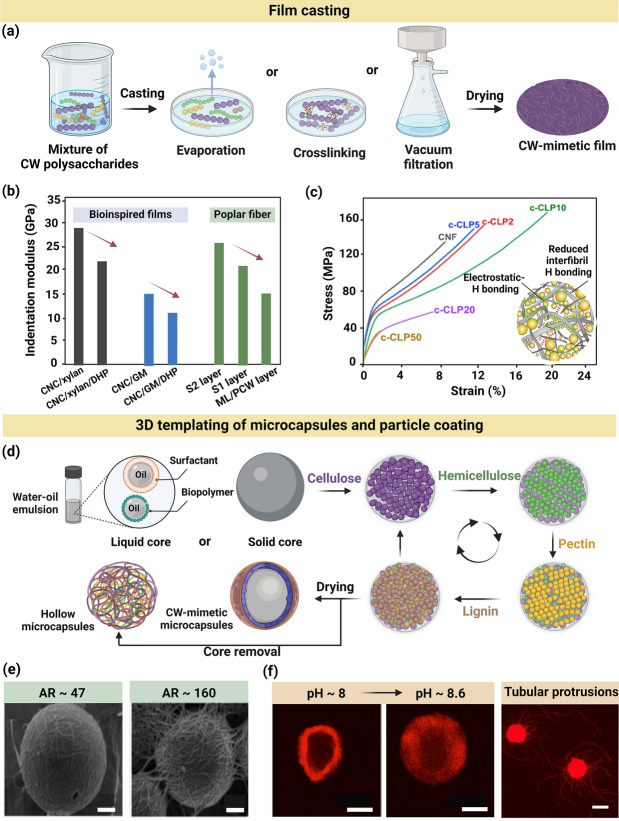

Fig. 3.

Fabrication of plant CW-like materials via film casting and 3D templating techniques. a Schematic of the film casting technique for constructing a plant CW-like film by combining CW polysaccharides, followed by solvent removal through either evaporation, crosslinking, or filtration. b Nano-indentation modulus of in situ lignified cast films, showing that an increase in lignin content and a decrease in cellulose content reduced stiffness. Adapted under terms of the CC-BY license [69].

Copyright 2017, The Authors, published by Springer Nature. c Tensile stress–strain of cast films, containing c-CLPs, showing an initial increase in both strength and elongation at break by increasing the lignin content (e.g., tensile strength at break increases from 132 to 160 MPa as c-CLPs increased from 0 to 10%), followed by a rapid decrease for films containing 20% and 50% c-CLPs [74]. Values next to c-CLP on the curves indicate the lignin content (wt%) of films. H bonding stands for hydrogen bonding. Adapted under terms of the CC-BY license [74]. Copyright 2019, The Authors, published by American Chemical Society. d LbL assembly of CW-mimetic microcapsules using liquid- or solid-based 3D templating and particle coating techniques, resulting in hollow microcapsules when the core was removed. e SEM images of microcapsules composed of CNC, isolated from bacteria or algae with varying AR, showing differences in the morphology of droplets and inter-droplet bridging. Core spheres are polystyrene particles, representing the oil droplets. Adapted with permission [85]. Copyright Royal Society of Chemistry, 2013. f Plantosomes prepared using liposome templating mimicked the mechanism of turgor pressure in native plant cells by undergoing reversible deformations and the formation of microtubular protrusions when the pH was increased from 8 to 8.6. Adapted under terms of the CC-BY license [87]. Copyright 2020, The Authors, published by Springer Nature

Bacterial Pellicle Growth and Impregnation

Bacterial cellulose has high purity and degree of polymerization (DP), whereas mechanically fibrillated and chemically treated cellulose isolated from plant sources typically have lower or less uniform DP [38]. Leveraging these advantages, bacterial cellulose pellicles are cultivated, and secondary components are impregnated into the pellicles to construct artificial plant CWs using a bottom-up approach. To achieve this, cellulose-producing bacteria are cultured in media containing the constituent components of plant CWs, facilitating in vitro cellulose assembly that mimics the structures of natural CWs. Bacterial cellulose is synthesized as large, randomly oriented ribbons, which has been used to simulate the biomechanical properties of CWs, such as extensibility, as well as physicochemical phenomena like water sorption kinetics [10, 39, 40]. Although artificial CWs can provide valuable insights, they exhibit significant structural differences compared with native plant CWs, where CMF are considerably thinner [41]. Moreover, native plant CWs are oriented in biologically determined patterns, identified by MFA, which contrast sharply with the random 3D weave of cellulose ribbons in bacterial pellicles. These differences result in distinct mechanical properties between the two materials [42, 43]. MFA, describing the angle between the CMF and the long axis of the cell, plays a crucial role in determining the mechanical properties of plant tissues, particularly in how they respond to stress and strain, influencing properties such as stiffness, flexibility, and resistance to bending or stretching [44, 45].

Figure 2a shows a representative culture of cellulose-producing bacteria within a growth medium, enriched with CW polysaccharides and other biopolymers. This method was initially demonstrated in a series of studies by Whitney et al., [10, 39, 46, 47] in which bacterial cellulose pellicles were assembled in hemicelluloses (e.g., xyloglucan and GM), followed by the addition of expansins (nonenzymatic proteins that mediate CW loosening and assist in extensibility). This technique was used to investigate how xyloglucan and GM bind to CMF and contribute to the formation of CMF networks within CWs. In a similar study based on bacterial cellulose, Gluconacetobacter xylinus (formerly Acetobacter xylinum) was grown in a hemicellulose-containing medium. The addition of xyloglucan to the culture media resulted in a preferential alignment of fibrils, which was attributed to the formation of crosslinks between bacterial CMF through hydrogen bonding. Figure 2b shows the transmission electron microscopy (TEM) micrographs of bacterial cellulose composites formed in the absence or presence of xyloglucan. The xyloglucan backbone, adopting a cellulose-like conformation, supported its binding to cellulose and facilitated CMF alignment [46]. Galactomannan (0.2 w/v%) and GM (0.5 w/v%) similarly underwent crosslinking with CMF and exhibited alignment, with a tendency to self-aggregate at higher galactomannan concentrations. This behavior is attributed to concentrations significantly exceeding the experimental entanglement concentration of approximately 0.23 w/v% for galactomannan [47]. The increased entanglement may cause polymers that do not normally bind to cellulose to become trapped within the cellulose networks.

To more closely mimic native CWs compared with composites containing only bacterial cellulose and hemicellulose, CW proteins (e.g., expansins) and other CW biopolymers (e.g., pectin) should be used to enhance extensibility, reflecting the properties of native plants. “Extensibility” refers to the ability of native CW or plant CW-mimetic materials to expand under a constant force due to the action of wall-loosening agents, which should not be confused with or used interchangeably with the extensibility of CWs under increasing tensile stress [48]. This property is crucial for artificial CW materials to replicate the ability of plant CWs to undergo extension, which is induced and mediated by expansins during cell growth. The effect of CW proteins on the mechanical properties of CW-mimic materials was examined via adding α-expansin (CsExp1) to hemicellulose-bacterial cellulose composites [39]. Figure 2c presents the effect of CsExp1 on the extensibility of hemicellulose-cellulose composites as a function of time. Here, extensibility was quantified by the extension rate: the rate of extension measured shortly after the addition of expansins, minus the rate observed before expansin addition [48]. Expansin increased the extensibility of cellulose-tamarind xyloglucan composite to a greater extent (96.3 µm min−1) compared with cellulose alone (0.4 µm min−1) and cellulose composites containing low viscosity xyloglucan (24.8 µm min−1), GM (~ 5.3 µm min−1), or galactomannan (~ 0.5 µm min−1). This was attributed to the longer chain and higher molecular weight of tamarind xyloglucan, resulting in the formation of more crosslinked domains in the bacterial cellulose composites.

Several studies suggest that the dual digestion of cellulose and xyloglucan induces CW expansion, indicating the presence of a mechanical ‘hotspot’ involving both cellulose and xyloglucan [39, 49, 50]. Inspired by this mechanism, Gluconoacetobacter xylinus was used to fabricate CW-like composites of xyloglucan-cellulose and pectin-xyloglucan-cellulose. Xyloglucan, in the presence of cellulose or pectin-cellulose, formed compliant materials with a time-dependent creep behavior within biaxial constraints. When pectin was incorporated into the material, the material strength and stiffness decreased while the ultimate strain (i.e., the maximum strain before failure) increased. The decrease in modulus and increase in extensibility were attributed to changes in the architectural organization of CMF upon pectin addition, which resulted in greater inter-fibrillar freedom [51]. The Gluconacetobacter xylinus has also been used to assemble artificial apple CW-like composites by culturing the bacteria in a medium containing apple pectin and xyloglucan [8]. The composite was compared with other CW analogs fabricated by mixing components such as bacterial cellulose, pectin, and xyloglucan. The composites produced from culturing bacterial cellulose in the presence of pectin and/or xyloglucan had mechanical properties more closely resembling native plant tissues. The bacterial cellulose-xyloglucan-pectin composites also had higher ultimate strain at a high relative humidity (i.e., ~ 95%), as the failure strain increased from ~ 0.05 in the homogenized/mixed samples to ~ 0.3 in the cultured bacterial cellulose-pectin-xyloglucan composites, which more closely reflects the extensibility of plant tissues (~ 50%) [42, 52]. The extensibility of the artificial CW-like film at high relative humidity was attributed to the hydration of pectin, facilitating the movement of CMF network under extension [8]. In a subsequent study, calcium ions were added to the bacterial cellulose-pectin-xyloglucan composite to resemble apple CW and study the effect of calcium ions on the composite mechanical properties. The effect of calcium on mechanical properties was analogous to that observed in the apple tissue, where pectin chains were crosslinked by divalent ions. In plant CW-like composites containing pectin, calcium crosslinked the pectin chains, as evidenced by an increase in failure stress from ~ 0.7 to 1 MPa when the calcium concentration was increased from 0 to 8% w/v [53].

The studies discussed above demonstrate that bacterial cellulose may be cultured in media containing various CW components to explore polymer interactions and assembly in complex CW-mimetic composites. As additional components are incorporated (e.g., biopolymers, expansins, calcium ions), the mechanical properties more closely mimic those of plant CWs under realistic conditions, such as high relative humidity. To better understand the interactions and binding kinetics of CW constituents, three hemicelluloses (i.e., xyloglucan, water soluble xylan, and galactoglucomannan) were adsorbed to in vitro-grown bacterial pellicles, and isotherms were obtained based on the equilibrium concentration of adsorbed hemicelluloses. Xyloglucan had the highest affinity for cellulose. Additionally, the hemicellulose-bacterial cellulose pellicle films were lignified by depositing coniferyl alcohol monolignols onto their surface, followed by polymerization mediated by horseradish peroxidase (HRP) and hydrogen peroxide. Xyloglucan and water-soluble xylan enhanced lignin formation on their respective cellulose matrices by facilitating the formation of aryl ether and 5–5' interunitary linkages, respectively. In contrast, galactoglucomannan inhibited lignin formation due to steric repulsion between the galactosyl substituents and the monolignols [54].

In CW-like materials, tailoring the interactions of CW components for water absorption and transport is important to mimic realistic plant conditions [55]. Gluconoacetobacter xylinus bacterial pellicles have been used to study the binding kinetics of polysaccharides to CMF, as well as to investigate how different compositions affect the water sorption–desorption kinetics of CW-like materials [40, 54]. CW-like composites made up of varying amounts of bacterial cellulose pellicles, pectin, and xyloglucan were fabricated to gain a better understanding of water exchange properties in native fruit CWs. The data collected were fitted to water absorption models, including Standard Guggenheim-Anderson-de Boer (GAB) and Ferro-Fontán [56–58]. From these models, the water retention capacity (the amount of water adsorbed and/or absorbed by the composite), water conductivity (the rate at which water molecules move through the composite), and diffusivity (the rate at which water molecules spread evenly through the composite) in the artificial CW were measured. The addition of pectin to the culture media reduced cellulose bundle size and the porosity, resulting in a denser fibril network compared with pure cellulose. This decreased the water retention capacity (~ 8.16 to ~ 6.0 kgwater kgdried−1 Pa × 10–8), water conductivity (~ 17.3 × 10–16 to ~ 11.9 × 10–16 kg m−1 Pa−1 s−1), and diffusion coefficient (~ 48.8 × 10–11 to ~ 46.8 × 10–11 m2 s−1) at 25 °C and 85% relative humidity. These values further decreased upon xyloglucan addition to the cellulose-pectin composites [40]. The significance of this study lies in the application of CW-like materials as a barrier to water exchange, inspired by the barrier properties of plant CWs, which helps preserve the moisture of plant-based products during commercial storage.

Layer-by-Layer Assembly Technique

Via dip coating, spin coating, or pipetting LbL assembly, alternating layers of plant CW components have been deposited on a variety of substrates (e.g., charged, metal, or biopolymeric surfaces). The precision of this technique in controlling material structure has enabled the creation of heterogenous domains within CW-like bulk composites [59]. Figure 2d presents the LbL assembly method via which alternating layers of CMF and xyloglucans are deposited on a primer-coated substrate. Depending on the intended application of CW-like materials, CMF may be micro- or nano-engineered prior to assembly to incorporate specific functional groups or alter their morphology. In LbL studies, the substrate is first coated with a polyelectrolyte multilayer primer to ensure a uniform coating and minimize the effects of substrate composition and texture before depositing the first layer of materials [60]. This is because the LbL technique typically relies on charged polymers to enable interlayer adhesion; however, some studies have also reported the construction of multilayered films using only hydrogen bonding or van der Waals forces [14, 61, 62]. Accordingly, CW-like films of alternating thin layers of cellulose nanocrystals (CNC) and xyloglucans were constructed via non-electrostatic interactions [62, 63]. CNC-xyloglucan films produced by spin coating were more uniform compared with the analogs generated by dip coating. At a constant CNC concentration (1 g L−1), concentrated solutions of xyloglucan (e.g., 5 or 10 g mL−1) could only build 2–4 bilayers as a result of polymer entanglement, after which the film thickness plateaued. In contrast, dilute xyloglucan solutions (e.g., 0.5 or 1 g mL−1) allowed for the formation of an unlimited number of bilayers. Figure 2e presents the thickness of CNC-xyloglucan films formed by spin-coating as a function of the number of deposited layers, confirming the linear growth of layers for composites containing 0.5 and 1 g mL−1 of xyloglucan [62].

As mentioned, charged biopolymers such as pectin are particularly advantageous for the LbL technique [64, 65]. The balance between the biopolymer charge densities is crucial in determining layer organization and architecture. Using electrostatically driven LbL assembly, pectin-extensin films were fabricated on silicon wafers. Extensins are positively charged hydroxyproline-rich glycoproteins, existing in the CWs of higher plants [66]. Since pectin and extensin have opposite charges, each layer adheres to the adjacent layer through electrostatic interactions. A non-uniform growth of the pectin-extensin LbL film was observed, resulting from diffusive mixing at the interface of the polymer layers, as confirmed by atomic force microscopy (AFM) topographical images (Fig. 2f). It was theorized that the film non-uniformity resulted from extensin being weakly charged while pectin was strongly charged. This imbalance in charge density led to non-linear growth of the pectin and extensin layers [65]. In both linear and non-linear growth of layers, LbL assembly has facilitated the investigation of interactions between specific components (e.g., cellulose and xyloglucan, pectin and extensin) in WC-like materials.

LbL assembly has also been adopted to study the interactions (particularly non-covalent) between CW polysaccharides and lignin model compounds in CW-like materials. Lignified CNC films were prepared using a dehydrogenation polymer (DHP), a model lignin derived from the polymerization of monolignols with hydrogen peroxide and peroxidase, to mimic wood CW lignification [67]. The DHP was prepared via the “Zutropfverbaten” method, entailing the slow, continuous coniferyl alcohol and hydrogen peroxide addition to a peroxidase solution, and was spin coated alternatively with CNC. The AFM topographical analysis confirmed that the DHP formed globular structures, which helped CNC adhere to the coating. Spectroscopic ellipsometry, along with classical or Tauc-Lorentz model fitting, were used to measure DHP thickness on CNC films. The apparent layer thickness of DHP increased from ~ 7.5 to ~ 141 Å after 6 h of contact, followed by a decrease to ~ 80 Å after rinsing with water and drying. This suggests non-covalent interactions between DHP and CNC, primarily through hydrogen bonding and hydrophobic interactions [67]. Together, LbL techniques have enabled the precise investigation of interactions between two CW components, which would be challenging to achieve in systems with more complex compositions.

Film Casting

Film casting is a scalable and biologically relevant technique for fabricating CW-like materials. This method involves mixing several components of interest in a solution, followed by casting the mixture into a film, which allows for the investigation of interactions among CW components, particularly their effects on mechanical, morphological, and hygroscopic properties [68, 69]. Castings may be solidified by evaporation or filtering out the excess solvent, followed by physical and/or chemical crosslinking [70–74]. Figure 3a presents the construction of a plant CW-like film via casting wherein the solvent is either evaporated or filtered. Film casting has been used to visualize biomass recalcitrance in situ, specifically examining the effect of lignin content on cellulose accessibility [68, 69]. To investigate the impact of lignin content on its recalcitrant behavior during enzymatic hydrolysis, suspensions of lignin and CNF (0.4 wt%) were prepared, and the lignin concentration was increased up to 40 wt%, followed by casting the mixtures in Petri dishes. Small pieces of films were submerged in a Cellic CTec2 enzyme solution (0.5 wt%) at 40 °C for 2 h. Increasing lignin content significantly impeded enzymatic cellulose hydrolysis because the CNF were embedded within the lignin matrix, restricting their accessibility, which was observed through the in situ AFM analysis of film morphology [68].

Artificially lignified films have also been fabricated via film casting for SCW studies [69, 70, 72]. Muraille et al., constructed films from a single polymer (CNC, hemicellulose, or DHP), binary polymers (hemicellulose/CNC, DHP/CNC, or DHP/hemicellulose), and ternary polymers (DHP/hemicellulose/CNC) [69, 70]. The films were either lignified by the in situ surface polymerization of DHP or mixing with lignin directly, followed by casting. As opposed to in situ surface polymerization, the mixing method led to higher film heterogeneity due to the polysaccharides-DHP phase separation, as well as water evaporation during film formation. Notably, the in situ polymerized films were more hygroscopic than the cast films of lignin-polysaccharide mixture. Compared with the simple mixing-casting method by which lignin hydrophobicity was well expressed, in situ DHP polymerization resulted in more interactions between lignin and polysaccharides (e.g., CNC and hemicellulose), limiting the lignin contribution to hydrophobic interactions. Besides lignin, the composition and ratio of CNC and hemicelluloses had significant impacts on the hygroscopic properties of lignified films as a result of varying affinities between lignin and the CW polysaccharides. Accordingly, the increase in the water adsorption and retention of in situ polymerized films was attributed to the covalent bonds formed in the hemicellulose-DHP during the polymerization process [70].

In another study, lignified composites were fabricated via film casting using varying ratios of CNC, hemicellulose, and DHP to analyze composite mechanical properties. Figure 3b presents the indentation moduli of bioinspired films (i.e., CNC/xylan, CNC/xylan/DHP, CNC/GM, and CNC/GM/DHP) and natural fibers. The indentation moduli of CNC/hemicellulose/DHP (4/1/1 ratio) films were within the same order of magnitude as the CW of natural fibers (15–25 GPa). Films composed of CNC/GM/DHP or CNC/xylan/DHP had an indentation modulus of 11 or 22 GPa, respectively. All lignified films underwent a decrease in modulus compared with lignin-free films, except for the CNC/DHP films (not shown in Fig. 3b, ~ 55 GPa). For instance, the modulus of CNC/xylan films decreased from 28 to 22 GPa by DHP addition. The decrease in mechanical properties was proportional to the reduction in CNC content in lignified ternary films (~ 66% CNC) compared with binary films (~ 80% CNC), which indicated that a higher cellulose content mitigated the impact of lignin on the mechanical properties [69]. Several studies have highlighted that reactive functional groups of cellulose (e.g., hydroxyl groups) and its surface roughness facilitate electrostatic and van der Waals interactions with both hydrophilic and hydrophobic polymers, such as lignin [75, 76], likely resulting in the improved mechanical properties.

Since the interactions between cellulose and lignin depend on lignin morphology, film casting has also been used to investigate the effect of lignin morphology within lignocellulose matrices on the mechanical characteristics of films. Figure 3c presents tensile stress–strain curves of nanocomposite films, containing varying contents of cationic spherical colloidal lignin particles (c-CLP). While many studies have reported that film stiffness and strength decrease as lignin content increases, incorporating ~ 10 wt% of c-CLPs (hydrodynamic diameter ~ 102 nm) in CNF films increased the strength at break and toughness compared with pure CNF films. The well-defined spherical morphology of c-CLPs allowed lignin to fill the interstitial areas and void spaces, leading to effective stress transfer to the CMF and increased ductility and toughness. This feature closely resembles the biological role of lignin in natural plant CWs, where it supports the interconnection of cellulose network. In contrast, in other composites, lignin typically forms large aggregates that disrupt the interfibrillar hydrogen bonding within cellulose networks [75]. To mimic the covalent bond formation in lignin-carbohydrate complexes (LCC) within plant CWs, the casting method was used to form lignocellulosic composite films and hydrogels via physical entanglement or epichlorohydrin-mediated chemical crosslinking. Films and hydrogels were prepared from carboxyl-modified CNF, alkali lignin, and GM as a compatibilizer. Both types of crosslinks similarly altered physical and mechanical properties: strength and stiffness decreased, while hydrophobicity increased by increasing the lignin content. However, films with LCC-mimicking bonds had greater stiffness (and higher hydrophobicity) compared with those with physical crosslinks, with Young’s moduli of approximately 10.1 and 7.6 GPa, respectively [73].

Film casting has also been used to study the interactions between cellulose and hemicelluloses, which have an opposite effect on mechanical properties compared with lignin [71, 77]. CNF-hemicellulose films were prepared using three types of CNF with similar dimensions and varying hemicellulose content, namely, holo-CNF (i.e., CMF bearing a high hemicellulose content), enzymatically-treated CNF, and carboxyl-modified CNF, prepared via 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO)-mediated oxidation. The mechanical properties of films composed of chemically treated fibrils were compared with those made from fibrils subjected to less intensive mechanical processing. The mechanical processing which preserved a high amount of hemicellulose on the CNF resulted in films with the highest strength compared with those made with carboxyl-modified and enzymatically treated CNF. This trend was evident even at high relative humidity levels (i.e., 50% or 90%). Dry, holo-CNF films had a Young’s modulus of 24.9 GPa and ultimate strength of 348 MPa. Notably, these films were much stronger than the ones composed of biaxially oriented polyethylene terephthalate. The remarkable mechanical properties of holo-CNF films were attributed to: (i) the intrinsic high modulus and strength of holo-CNF as a result of mild isolation processing and (ii) well-preserved hemicelluloses surrounding the nanofibers, increasing interfibrillar bonding and stress transfer among the fibrils [77].

3D Templating Microcapsules and Particle Coating

To fabricate synthetic plant CWs or tissues, one approach involves subjecting biopolymers to more geometrically relevant 3D constructs [78–81]. Coating of polysaccharides such as dextran, pullulan, and hemicelluloses onto liposomes [78, 79] and cells [81] originated in the early 1990s. Figure 3d presents the construction of CW-mimetic constructs via liquid- or solid-based 3D templating of microcapsules and particle coating in a LbL fashion. CW-like core–shell particles have been developed using two distinct 3D templating strategies: (i) liquid cores, where the interior space of capsules is filled with either an emulsion or an aqueous phase, and (ii) solid cores, where colloidal particles are used as templates for the deposition and assembly of components. In the latter case, the core may be removed to generate a hollow polymeric shell. The solid templates may be silicon dioxide or carbonate microparticles such as manganese, calcium, or cadmium species [80], or crosslinked polymers (e.g., polystyrene) [82].

The solid core templating approach has been used to construct synthetic multilayer capsules based on electrostatic interactions. Inspired by the structure and composition of plant PCW, 3D templated solid-core microcapsules (diameter ~ 16 µm) were fabricated using calcium carbonate as a template and plant polysaccharides (e.g., cationic CNF, pectin, and xyloglucan) as a shell [80, 83]. The calcium carbonate particles were treated with citric acid (50 mM) for 3 h to generate hollow microcapsules. The microcapsules had properties that mimic those of plant CWs, particularly in terms of permeability and mechanical stability. The barrier properties of microcapsules were examined using fluorescein isothiocyanate (FITC)-labelled dextran molecules with varying hydrodynamic sizes (e.g., 6.6, 12, or 54 nm). In water, only dextran molecules with a hydrodynamic diameter of 6.6 nm could penetrate the capsule wall, made of apple pectin, xyloglucan, and CNF. The wall consisted of a percolating network of CNF, with xyloglucan and pectin located among the nanofibers. When exposed to saline (NaCl, 10 mM), larger dextran molecules with a hydrodynamic diameter of 12 nm also permeated the capsule wall. The results indicated that capsule walls were responsive to saline, becoming more porous and permeable as a result of a salt-mediated decrease in the hydrodynamic size of pectin. The subsequent uptake/release of molecules using the same microcapsule for multiple cycles was possible by changing the media from water to saline and vice versa. Microcapsules containing water-soluble pectin had high integrity and robustness after multiple cycles of salt loading/unloading, which was attributed to the percolating CNF networks [80].

The permeability of microcapsules is tunable via tailoring the capsule wall composition. To investigate this effect, two types of microcapsules were assembled using 5 bilayers of cationic CNF and xyloglucan, with and without pectin. Increasing the xyloglucan and decreasing the pectin contents resulted in microcapsules with decreased permeability in saline solutions. Although the microcapsules in water were permeable to all sizes of FITC-dextran molecules (i.e., 6, 12, and 54 nm), only the 6 nm dextran molecules and a small fraction of the 12 nm molecules permeated into the microcapsules in saline. The opposite permeability of this microcapsule in water with the above-described one was explained by the citric acid-mediated physical crosslinking of capsule wall, decreasing the swelling degree and pore size. In saline, the low permeability of cationic CNF/xyloglucan/pectin microcapsules was attributed to the electrical double layer (EDL) screening of charged polymers by NaCl, allowing nonionic interactions such as hydrogen bonding and van der Waals attraction among CNF. As a result, the capsule wall thickness decreased, resulting in the decrease in pore size [83].

Liquid core templating has also been used to create CW-mimetic constructs. This approach was inspired by the assembly of nanocelluloses in Pickering emulsions. In 2011, varying concentrations of bacterial CNC (0 to 5 g L−1) were used to stabilize hexadecane-water emulsions, forming liquid-core microspheres (diameter ~ 4 μm). The CNC-coated oil-in-water droplets were stable at ambient condition for several months [84]. The droplet stability was associated with the irreversible interfacial adsorption of CNC and the formation of 2D cellulosic network at the interface. This study was further expanded by the same group to investigate how CNC origin and dimensions affect the stability of liquid core systems (i.e., oil-in-water emulsion) [85]. Particle aspect ratio (AR) had a significant impact on droplet surface coverage. Figure 3e presents scanning electron microscopy (SEM) images of the microspheres coated with CNC (AR ~ 47 or 160). Short CNC (length ~ 189 nm, AR ~ 47) densely coated the droplets with a surface coverage of more than 80%, whereas long nanocrystals (length ~ 4000 nm, AR ~ 160) formed a loose interconnected network with a reduced coverage of ~ 40% [85]. The high coverage achieved by shorter CNC was attributed to their ability in aligning side by side via the strong and long-range capillary attractive forces. However, obtaining uniform alignment throughout the droplet is challenging for elongated nanocrystals with a high AR.

To mimic the architecture and properties of fruit and vegetable parenchyma cells, liquid-core capsules with high mechanical strength were fabricated using a blend of short CNF (length < 1 µm) and CNC (length ~ 140 nm) via the Pickering mechanism. A crosslinked network of CNF-CNC was formed at the interfaces using isophorone diisocyanate, wherein a urethane bond was generated by reacting cellulose hydroxyl groups with isocyanate. In this reaction, urea bonds were also formed via reacting diisocyanate groups with water. As a result, the outer and inner layers of shell wall structure consisted of covalently crosslinked CNF-CNC and aromatic polyurea, respectively. Combining short CNF and CNC favored a close-packed arrangement, resulting in capsule walls with a high cellulose content. When the total dry content of CNF/CNC was 17 wt%, the capsules attained an indentation modulus of ~ 4.84 GPa, which was 6 times higher than that of polyurea capsules (~ 0.79 GPa) and 3 orders of magnitude higher than that of capsules composed of dissolved cellulose (~ 0.0074 GPa). The high modulus was attributed to the close-packed structure of capsule wall outer layer, which was formed by the oriented CNF and CNC. This structure was reinforced by both covalent bonds (between the urethane matrix and CNF/CNC) and hydrogen bonds (between CNF and CNC or between the urethane matrix and CNF/CNC). The wall structure of capsules closely mimicked the CW of seedling stem cells in embryonic cucumber [86].

In another study, more complex microcapsules that mimicked both plant CW and membrane were fabricated via liquid-core 3D templating. The outer shell of microcapsules consisted of PCW polysaccharides, including chemically modified cationic CNF and pectin, and the inner shell consisted of a thin layer of lipids, including oleic acid, oleate, and structural plant phospholipids surrounding a water core [87]. The microcapsules (diameter ~ 27 µm) with a plasma membrane-like core, covered by a continuous fiber layer, were referred to as plantosomes. At pH > 7, oleic acid may self-assemble into organized structures including vesicles, micelles, and cubic phases [88]. By leveraging the pH-dependent phase behavior of lipids, plantosomes with vesicle-rich cores were developed to mimic the expansion observed in native plant cells during growth. Plantosomes absorbed water at a final pH of 8.6 in an ammonium acetate solution, a solute known to enhance the permeability of vesicle membranes. The water uptake was also attributed to the pH-mediated self-assembly of interior oleic acid/oleate/phospholipids mixture into vesicles, increasing the plantosome radius and surface area. Figure 3f shows the plantosome radius change (~ 29%) by increasing pH, mimicking the physical expansion of plant cells. Notably, this is distinct from plant cell growth, which occurs when pH decreases. During expansion, the lipid molecules diffused from the core toward the outer shell, generating tubular structures that stretch across the plant CW-like shell, as shown in Fig. 3f. The formation of lipid tubular protrusions was attributed to the restrictive, cage-like CNF/pectin wall, which limited indefinite expansion, allowing the lipids to protrude only through the pores of polysaccharide wall. Upon the addition of magnesium ions (10 mM), the expanded plantosomes collapsed as a result of ion-mediated bridging and the merging of smaller vesicles into larger ones, causing the protrusions to disappear [87].

Through a similar liquid core templating strategy, CW-mimetic microcapsules were fabricated using alternating layers of pectin, xyloglucan, and CNC, deposited on giant unilamellar vesicles (GUV) via LbL assembly. The average diameter of microcapsules with 10.5 layers of polysaccharides was ~ 25 µm. Upon glucose-mediated osmotic shocks, the microcapsules underwent a significant reversible deformation as a result of shell elasticity. The GUV membrane (i.e., shell) permitted the microcapsules to expand and contract in response to the osmotic pressure changes, leading to the reversible shape changes. The indentation modulus of shells was in the range of ~ 300–900 kPa, resembling the plant CWs of Arabidopsis thaliana shoot apical meristem and epidermal cells/dark grown hypocotyl [14]. Implementing 3D templating for CW-like material fabrication enables the investigation of more realistic CW properties, such as biomimetic permeability, mechanical stability, and deformation/expansion. Additionally, these CW-like materials respond to external stimuli, such as pH, humidity, and pressure in a biomimetic manner, providing insights into the dynamic behavior of plant CWs under varying conditions.

In Silico Studies

In silico studies of plant CWs using molecular dynamics (MD) simulations have been conducted to investigate how molecular interactions among CW components influence mechanical properties [15]. A comprehensive review on the in silico studies of plant biomass has recently been published, explaining the details of methodologies and mechanisms [89]. Here, we review several examples to illustrate the capabilities of MD simulations in studying plant CW analogs. Zhang et al., developed a coarse-grained MD model that offers insights into molecular mechanisms of PCW mechanics. The model consisted of chains of beads that represented the physical parameters of various wall polymers and their interaction potentials. After energy equilibration, it successfully yielded modeling results that accurately reflect the complex structure of CWs, where each lamella featured aligned CMF, embedded within matrix polymers (Fig. 4a) [29]. The model enabled the analysis of stress–strain responses of individual CW components, showing that CMF bore the stress, even at a high content of pectin and under the interactions of xyloglucans with CMF (Fig. 4b). This model also facilitated the mechanical analysis of single lamellae with varying CMF orientations, revealing distinct polymer movements and stress contributions that depended on orientation (Fig. 4c). Via cyclic loadings in the CW model, the mechanical mechanisms of energy dissipation in the wall were uncovered (Fig. 4d).

Fig. 4.

In silico studies of plant CWs using MD simulations. a Top and side views of a four-lamella CW after equilibration (Scale bars are 200 nm) along with their corresponding close-ups (Scale bars are 25 nm). Reproduced with permission [29].

Copyright Science, 2021. b Stress–strain behavior of PCW, consisting of CMF, xyloglucan, and pectin, showing that the stress is mainly tolerated by CMF. Reproduced with permission [29]. Copyright Science, 2021. c Normalized average end-to-end length of CMF (LE/LE0, where LE is the average end-to-end length and LE0 is its initial value at strain of 0%) as a function of strain, applied via the uniaxial stretching of single lamellae at varying CMF orientations of 0°, 30°, 45°, 60°, or 90°. Reproduced with permission [29]. Copyright Science, 2021. d Stress–strain response of onion epidermal CW during cyclic loading and unloading, showing a large hysteresis, stemming from energy dissipation and irreversible (plastic) deformation in the epidermal wall. Reproduced with permission [29]. Copyright Science, 2021. e Molecular model of wood CW, encompassing CNC, hemicellulose, and lignin molecules, assembled in a layered nanocomposite. M1 and M2 indicate the molecular orientation of CW matrix during yielding and sliding, respectively. Reproduced with permission [91]. Copyright Elsevier, 2015. f Stress–strain response in the CW model (blue), indicating 3 separate regimes: an initial elastic regime and two plastic regimes. The unloading (red) and reloading (green) curves indicate the irreversible deformation of CW after yielding. Reproduced with permission [91]. Copyright Elsevier, 2015

Overall, in silico models enable the study of CW structure–function relationships in ways that are not yet feasible experimentally. Coarse-grained models, in particular, simulate dynamic polymer behaviors that offer unique insight into the molecular mechanisms underlying macroscale mechanical behaviors of CWs. MD simulation has also been used to explore the structural, physical, and mechanical influences of hydration on wood CW. To construct a composite material mimicking softwood CW S2 layer via a bottom-up approach, CNC were modeled as a hexagonal packing of 36 chains each of which containing 10 monomer units [90]. CNC clusters were embedded in a composite matrix to mimic the CMF. Branched and unbranched lignin, GM, and xylan were modeled as multicomponent matrices with varying compositions to assimilate the distinct enriched domains surrounding the CMF. The CW S2 layer underwent highly anisotropic swelling with minimal swelling along the longitudinal direction and significant swelling in the transverse direction (170 times the longitudinal direction). The findings showed that the CW modulus and swelling along the longitudinal direction were mainly governed by CMF. Moreover, in contrast to CMF and lignin derivatives, hemicelluloses, interfacing lignin and cellulose, were ultrasensitive to water sorption. Therefore, water easily reached the cellulose-hemicellulose interfaces, disrupted the intermolecular hydrogen bonds, and weakened the fibril-matrix interface. The modeling results also indicated that the CW modulus and swelling along the transverse direction were mainly regulated by hemicelluloses. Lignin was a hydration-independent component, functioning as an interfibrillar space filler [90].

The mechanical behavior of wood CW under shear loading has been investigated using MD simulation to explore the underlying deformation mechanisms at the molecular scale. The shear loading was applied by pulling the outermost layers of cellulose in opposite directions. Figure 4e presents the molecular model of wood CW, encompassing cellulose, hemicellulose, and lignin [91]. The CW was modeled as a layered nanocomposite of stiff CMF and soft hemicellulose and lignin matrices. Figure 4f shows the stress–strain response of CW model with 3 separate regimes, including an initial elastic regime and two plastic regimes (i.e., the yielding of matrix and matrix sliding on the cellulose surface). By subjecting the composite to the shear loading, an elastic deformation followed by plastic deformation was observed. The plastic behavior was a result of matrix yielding (onset of plastic deformation) along the cellulose surface at shear strain of ~ 0.03, followed by sliding at shear strain of ~ 0.18. In nature, this type of “self-healing” interface is found in materials with excellent mechanical resilience [91]. In silico studies therefore enable the investigation of CW components at the molecular scale under stimuli, such as hydration, deformation/shear, and stretching/reorientation. Table 1 presents a summary of advantages and disadvantages of varying methods used for the micro-/nanoengineering of plant CW-like materials.

Table 1.

Advantages and disadvantages of methods used for fabricating artificial plant CW-like materials

| Fabrication method | Advantages | Disadvantages |

|---|---|---|

| Bacterial pellicle growth and impregnation |

High purity and uniformity of bacterial cellulose [38] Mimicking biomechanical properties, such as extensibility and water sorption [10, 39, 40] Enabling the in vitro study of CW formation and interactions via bottom-up approaches [10, 39, 46, 47] |

Structural differences with native plant CWs, as bacterial CMF have an Iα structure and are ribbon-like, while plant CMF (except algae) have an Iβ structure and are more like cylindrical wires [41–43] Randomly oriented cellulose ribbons [47], lacking the native CMF’s structural patterns [44, 45] |

| Layer-by-layer (LbL) assembly |

Precisely controlling layer composition and thickness [59] Compatibility with varying substrates (e.g., charged, metal and biopolymeric surfaces) and multiple deposition methods (e.g., dip coating, spin coating, and pipetting) [59] Adaptability to different interactions (e.g., electrostatic, hydrogen bonding, and van der Waals forces) [61–63] |

Time-consuming and labor-intensive Complexity in thick layers especially for polymers with high viscosity or complex morphologies [62] Non-uniformity as a result of imbalanced charge density or polymer entanglement [65] Sensitivity to solvents (film thickness and uniformity are affected by solvents) [67] |

| Film casting |

Scalable and biologically relevant [68, 69] Versatility in component inclusion [68, 70] Enabling the visualization of biomass recalcitrance [68, 69] Allowing physical and chemical crosslinking to tune mechanical and hygroscopic properties [70–74] |

Time-consuming Heterogeneity due to the phase separation [69], leading to sample-to-sample variability Film properties are affected by humidity [77] |

| 3D templating and particle coating |

Geometrically relevant for mimicking 3D structures [78–81] Enabling the construction of multilayer shells [80, 83] Tunable permeability, mechanical stability, and elasticity, enabling the realistic studies of plant cell behavior [80, 83, 86] Enabling stimuli-responsive microcapsules, allowing for the investigation of plant CW-like dynamic behaviors [87] |

Complexity in achieving consistent 3D structures [80, 83] Removal of templates or additional steps [80], increasing fabrication complexity and time |

| In silico |

Uncovering molecular interactions and mechanisms that are difficult to assess experimentally [15] Simulating dynamic behaviors, such as stress–strain responses, hydration effects, and energy dissipation [29] Revealing CW structure–function relationships at the molecular level [90] Simulating anisotropic behaviors, such as the anisotropic swelling and mechanical responses of CWs at varying conditions (e.g., hydration and shear stress) [90] Facilitating bottom-up approaches for constructing composite models that mimic natural CWs and predict CW properties at multiple scales [90] |

Significant computational resources and time [89] as well as dependence on the potential field used to model CW constituents Loss of accuracy in representing complex CW structures and behaviors as a result of model simplifications [29] Requiring experimental data for validation and calibration [91] Cannot fully replace experimental data, requiring real-world validation for most results [90] Limited to small systems due to computational constraints, which may not represent macroscopic behaviors accurately [90] |

Characterization Techniques to Assess CW-Like Materials

Natural CWs and plant CW-like materials have been characterized from chemical, structural, and/or mechanical perspectives using varying techniques, summarized in Fig. 5. Here, we briefly describe these techniques and provide examples of analyses for both native and artificial CWs.

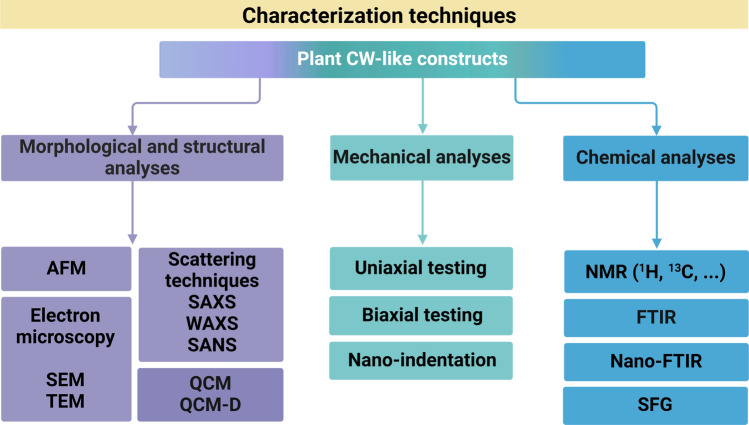

Fig. 5.

Varying techniques for mechanical, morphological, structural and chemical characterizations of natural and artificial plant CWs. Abbreviations are defined as follows: AFM (atomic force microscopy), SEM (scanning electron microscopy), TEM (transmission electron microscopy), SAXS (small angle X-ray scattering), WAXS (wide angle X-ray scattering), SANS (small angle neutron scattering), QCM (quartz crystal microbalance), QCM-D (quartz crystal microbalance with dissipation monitoring), FTIR (Fourier transform infrared), NMR (nuclear magnetic resonance), and SFG (sum frequency generation). Some abbreviations have been redefined here as per the request of a reviewer

Morphological and Structural Analyses

AFM

AFM is one of the most frequently used microscopy techniques for mapping the topography of intact plant CWs and CW-like composites at the nanoscale [92–94]. Compared with other microscopy techniques, AFM may be more advantageous under physiological conditions as it requires less sample preparation and typically avoids extensive drying processes. This is particularly important for studying CW-like materials that mimic the native, hydrated tissues [27]. Nanostructure and assembly of xyloglucan isolated from tamarind seed as a model system were investigated via AFM. Figure 6a shows AFM height images of self-assembled bundles of xyloglucan chains. The topological image (Fig. 6a-i) showed that xyloglucan had a rod-like morphology with length ~ 640 nm and height ~ 2.3 nm. Furthermore, an individual xyloglucan fibril had a helical structure with a period of ~ 115 nm and bending angle of ~ 128°. As observed in Fig. 6a-ii, xyloglucan chains were able to form parallel assemblies of fibers (shown with white arrows). The parallel assembly resembled the mechanism of xyloglucan linking to cellulose in PCWs, where a smooth, flat region of xyloglucan attached to cellulose through hydrogen bonds [95].

Fig. 6.

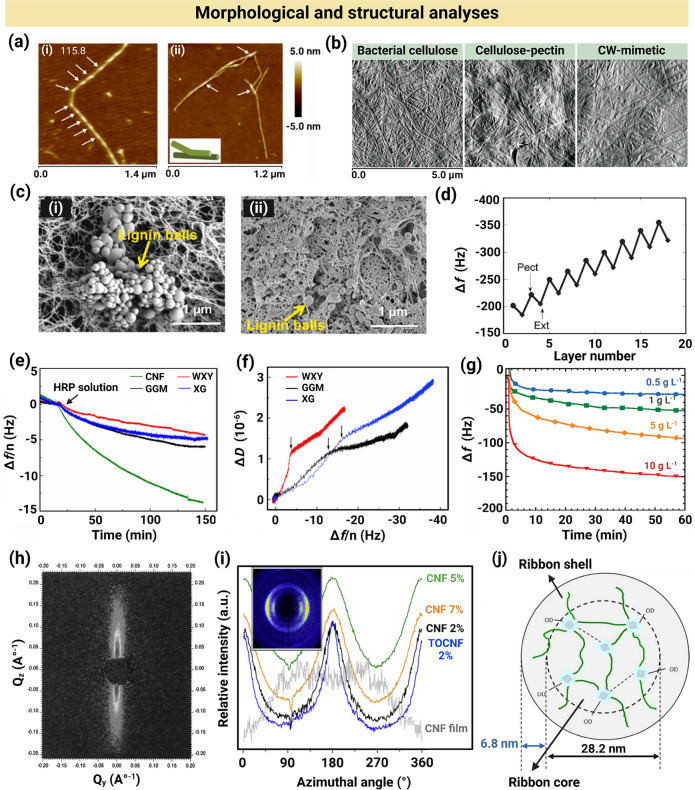

Morphological and structural characterizations of plant CW-like materials. a AFM height images of xyloglucan chains and xyloglucan assemblies. Reproduced under terms of the CC-BY license [95].

Copyright 2015, The Authors, published by Springer Nature. b AFM images of bacterial cellulose, bacterial cellulose-pectin, and bacterial cellulose-pectin-xyloglucan composites. Adapted under terms of the CC-BY license [96] Copyright 2010, The Authors, published by Institute of Agrophysics. c SEM images of physically and chemically crosslinked composites, consisting of cellulose/glucomannan/lignin, showing the extensive aggregation of lignin particles in physically crosslinked composites compared with the chemical analog. Reproduced with permission [73]. Copyright Elsevier, 2022. d QCM-based frequency changes (Δf) versus deposited pectin (Pect) and extensin (Ext) layer number. Reproduced with permission [65]. Copyright Langmuir, 2010. e QCM-D-derived normalized frequency shift (Δf/n) of hemicelluloses, including xyloglucan (XG), galactoglucomannan (GGM), and water-soluble xylan (WXY), initially deposited on bacterial cellulose films, showing the effect of HRP adsorption on polysaccharides over time. Reproduced with permission [54]. Copyright Springer Nature, 2021. f QCM-D-derived dissipation shift (ΔD) versus Δf/n of hemicellulose adsorption to CNF. Reproduced with permission [54]. Copyright Springer Nature, 2021. g QCM-derived Δf for xyloglucan adsorption to CNC-spin-coated quartz crystals versus time. Reproduced with permission [62]. Copyright Langmuir, 2010. h The 2D SAXS pattern of water-swollen horizontally-oriented individual single flax fiber. Reproduced with permission [106]. Copyright American Chemical Society, 1998. i Azimuthal integration of X-ray diffractograms in wet-spun filaments, obtained at a scattering vector of 15.8 nm−1. Reproduced under terms of the CC-BY license [112]. Copyright 2016, The Authors, published by Springer Nature. j A representative core–shell model, proposed for the structure of hydrated bacterial cellulose-xyloglucan composites. Reproduced with permission [119]. Copyright Royal Society of Chemistry, 2016

AFM has also been used to visualize and compare nanostructures in the native apple CW, reconstituted CW, and artificial CW-like composites. The artificial composite consisted of bacterial cellulose (26%), pectin (44%), and xyloglucan (20%), making up ~ 90% of dry polysaccharide mass in PCWs, and had similar morphological and structural features to native PCW models. Figure 6b shows the AFM images of artificial bacterial cellulose, bacterial cellulose-pectin, and bacterial cellulose-pectin-xyloglucan composites [96]. CMF in a bacterial cellulose-pectin-xyloglucan composite were thicker (~ 75 nm) compared with those in bacterial cellulose (~ 59 nm) and bacterial cellulose-pectin (~ 68 nm) composites. The thickness variations suggested that the bacterial CMF were coated with a monolayer of xyloglucan, consistent with PCW models. Composite roughness was determined by analyzing the AFM images and calculating the deviation of surface height values from the mean surface height over a given area. This deviation was then normalized by dividing it by the root mean square (RMS) roughness of surface. Therefore, the roughness value, a dimensionless quantity, indicated the degree of variation in the height of surface features. The roughness of artificial bacterial CWs (12) was comparable to that of natural CWs (13.1) [96]. Overall, AFM may combine nanoscale imaging with indentation-based mechanical measurements, providing unique insights into the structure–function of CWs and CW-like materials.

SEM and TEM

Electron microscopy techniques, such as SEM and TEM, have been extensively used to visualize the morphology and alignment of CMF and other CW biopolymers, such as hemicellulose, pectin, and lignin particles at the micro- and nanoscales [97, 98]. Deep-etch freeze-fracture TEM, which involves rapidly freezing the sample to prevent network disruption by ice crystal formation and producing clear, high-resolution replica images, was used to investigate the morphology of CMF in CW-like composites. This technique, applied to bacterial cellulose pellicles and xyloglucan composites, revealed a highly aligned, cross-bridged structure of CMF within the composites [46]. The association of xyloglucan with CMF enabled lateral alignment, which was not observed in the TEM image of xyloglucan-free composite (Fig. 6b). Thin strands of xyloglucan were detectable in the composite TEM image, which were distinguished as bridges (length ~ 20–70 nm), linking adjacent fibers and creating a ladder-like structure [96].

SEM was used to examine the surface coverage and integrity of hollow CW-like microcapsules formed via water–oil emulsification. Since emulsions could not be imaged using SEM, styrene particles were used to replace the oil cores. Styrene-water emulsions were prepared with the same CW-like composition and emulsification technique to facilitate imaging. SEM images showed a homogenous distribution of CNC (nanorods) parallel to the droplet surface, independent of CNC length; however, a dense interfacial network was observed for short nanorods (length ~ 189 nm) compared with long ones (length ~ 4000 nm). Loose networks of long nanorods limited dense packing as a result of steric hindrance and resulted in a porous multilayer organization of CNC [85].

SEM has also been used to image the internal structure of physically and chemically crosslinked CW-like cellulose/GM/lignin composites. SEM images showed that the pore of both kinds of composites became finer and denser by adding lignin (5–20 wt%). As presented in Fig. 6c-i, highly aggregated lignin balls were formed in the physical composites, whereas no apparent aggregation of lignin nanoparticles occurred in the epichlorohydrin-mediated chemically crosslinked composites (Fig. 6c-ii), corresponding to the formation of covalent ether bonds between lignin-cellulose or lignin-GM [73].

QCM and QCM with Dissipation Monitoring (QCM-D)

QCM is a surface-sensitive, real-time tool to determine the thickness of deposited layers in CW-mimetic materials, wherein polysaccharides adsorb to substrates such as films and beads. When a species is adsorbed to the QCM sensor surface, the increase in mass at the nanogram to microgram levels is correlated with the changes in the resonance frequency of a quartz crystal resonator. The Sauerbrey equation is used to calculate the mass of adsorbed layers when the added layers are thin, rigid, and firmly attached to the sensor surface [64, 99, 100]. QCM has been used to evaluate the LbL growth of pectin-extensin films [65]. Figure 6d presents the frequency shift of a QCM crystal (Δf) versus the number of deposited pectin and extensin layers. When pectin was deposited, Δf decreased, indicating successful pectin adsorption; however, upon extensin deposition, Δf increased, which was attributed to extensin low charge density (with only ~ 5% of monomers carrying charge). This resulted in material removal from the surface due to weak electrostatic interactions. The Δf of a total sorption cycle (pectin-extension adsorption) decreased, indicating LbL film growth [65].

QCM-D, an extended version of QCM technique, has been used to study the interactions between cellulose, lignin, and hemicelluloses, including xylan, galactoglucomannan, and xyloglucan [54]. QCM-D measures not only Δf but also a parameter related to energy loss or dissipation, known as dissipation shift (ΔD). While Δf reflects changes in the mass attached to the sensor surface, ΔD provides information about the viscoelastic properties of adsorbed layer. QCM-D is used to characterize mass deposits, which induce frictional dissipative losses because of their viscoelastic nature. Higher ΔD values indicate that the material is more viscous or energy-absorbing, whereas lower ΔD values suggest that the material is more elastic or energy-preserving [101]. Accordingly, QCM-D was used to determine the adsorption of hemicelluloses and lignin in the form of DHP on CNF to investigate the effect of cellulose, xylan, galactomannan, and xyloglucan on lignification. Figure 6e shows the normalized Δf profile during HRP adsorption to polysaccharide matrices. To study lignification, QCM sensors were spin-coated with thick layers of CNF (> 4000 ng m−2) and either used uncoated or coated with a thin layer of hemicellulose. HRP was then deposited onto these surfaces. The value of Δf/n (n denotes the overtone number) for the sensor coated with only CNF was the lowest (-15 Hz after 150 min) at all deposition time points and decreased most rapidly, indicating a higher amount of HRP adsorption and a faster adsorption rate on CNF-coated sensors compared with the hemicellulose-coated CNF, which had a Δf/n of ~ -5 Hz after 150 min. This increase in HRP adsorption to CNF was attributed to the hydrophobic interactions between CNF and HRP, which decreased by coating CNF with hemicelluloses. Figure 6f presents the ΔD of CNF-coated crystals versus Δf/n upon hemicellulose adsorption to CNF surface. The ΔD values for xylan, galactoglucomannan, and xyloglucan rapidly increased (from 0 to 1 × 10–6) during the early stages of adsorption, implying the formation of a hydrated soft surface. This was followed by a gradual increase in ΔD as the adsorption layer became thick and difficult to harden [54].

QCM-D has also been used in situ to examine the kinetics of polysaccharide adsorption to CW-mimetic bacterial cellulose-based films [40] and to the interfaces of droplets within emulsions [87]. Xyloglucan adsorption to CNC-spin-coated quartz crystals over time was monitored using QCM, as shown in Fig. 6g. As the xyloglucan concentration increased from 0.5 to 10 g L−1, Δf decreased, with a significant drop in Δf observed within the first 5 min for all concentrations, indicating rapid adsorption during the LbL buildup of PCW-like CNC-xyloglucan films. Subsequently, a slight decrease in Δf was recorded up to 60 min without reaching a plateau, which was attributed to the continuous self-rearrangement of xyloglucan chains on the surface, impairing the adsorption equilibrium [62]. In the fabrication process of PCW-inspired plantosomes, the QCM-D measurements showed a significant decrease in Δf to -90 Hz and an increase in ΔD to 20 × 106 after pectin adsorption to cationic CNF-coated crystals. In contrast, direct pectin adsorption to the crystal resulted in a decrease in Δf and an increase in ΔD. These Δf and ΔD values confirmed the formation of outer LbL CNF-pectin shell of plantosomes [87]. Combining QCM and surface plasmon resonance (SPR) can provide a more comprehensive understanding of interactions at interfaces, particularly in LbL assemblies. While QCM detects changes in the mass of adsorbed layer, including dry mass and any associated water, SPR measures changes in the refractive index of materials near the sensor surface, which occur when substances attach to or detach from the surface [102].

Scattering Techniques

Scattering techniques involve the use of radiation sources, such as X-rays or neutrons, to detect patterns scattered by the electrons or nuclei, respectively. For CW-like materials, scattering techniques provide information on the size, orientation, and/or arrangement of components that may not necessarily have a crystalline order [103, 104]. Small-angle X-ray scattering (SAXS) probes nanoscale features [103], and wide-angle X-ray scattering (WAXS) is more suited for crystallographic studies and molecular scale characteristics [105]. SAXS was used to investigate the arrangement of CMF in native flax CWs, without requiring additional treatments often necessary for other techniques like electron microscopy. For a horizontally oriented fiber, the scattering pattern appeared in the vertical direction, as shown in Fig. 6h [106]. The SAXS pattern of CMF in a single flax fiber also showed well-defined streaks, which was attributed to the semi-crystalline structure of microfibrils and void spaces among microfibrils [106, 107]. Indeed, the anisotropic SAXS pattern from CMF is well known; the fluctuations in scattering density in the equatorial plane (on a 10 Å length scale) arise from the electron density differences between the crystalline CMF and the void spaces, i.e., regions of less dense material.

SAXS has been used to investigate CMF orientation in native primary and secondary CWs as well as in synthetic CW-like materials [103]. For investigations on the SCW, flax fibers were studied because of their composition and thick SCW, rendering them a suitable representative for SCW. SAXS was used to study the hydration effect on the microstructure of flax fibers, and a considerable structural change was observed for flax fibers in the wet and dry states, demonstrated by the scattering patterns. The azimuthal intensity of CMF followed a Gaussian distribution, and the full width at half maximum (FWHM) decreased from 15° to 11° as the flax fibers transitioned from the wet to dry state. As water evaporated from the fibers and the scattering from water diminished, a meridional reflection appeared at a scattering vector of 0.095 Å−1. Upon fully drying, the meridional scattering intensity increased at a scattering vector of less than 0.06 Å−1, which indicated an increase in CMF alignment [108]. Although X-ray scattering investigations of SCW are more common than those of PCW because of the disordered cellulose packing and lack of fibril orientation, SAXS has successfully been used to determine the CMF orientation in PCW [109]. The changes in CMF orientation in native collenchyma CWs through various developmental stages were studied with SAXS. In the early growth stage, the SAXS pattern was isotropic, and upon further plant growth, it became anisotropic and vertically elongated, which suggested CMF alignment in a specific direction. Accordingly, the intensity profile of CMF initially exhibited a broad angular distribution (from 0° to 80°). As the development of CMF in the walls of collenchyma cells progressed, this distribution narrowed, eventually shifting to a range between 0° and 15° in the later stages of growth [110]. Using SAXS, the PCW structure of Chara corallina and Arabidopsis thaliana in the native hydrated state was analyzed, showing a bimodal microfibril angle distribution and indicating that the majority of CMF were oriented either longitudinally or transversely. These distributions had a broad scattering around mean microfibril angles of ~ 0° (longitudinally oriented microfibrils) and 90° (transversely oriented microfibrils).

WAXS has been used to determine the crystal type, crystallinity (%), and cellulose alignment and orientation within hydrated CW-like composites [103, 111]. WAXS diffractograms of wet-spun filaments, made by spinning CNF hydrogels or colloidal suspensions with solid contents typically between 2% and 7%, had the characteristic peaks of cellulose I crystals at a scattering vector of 15.8 nm−1. This indicated that the wet-spinning process did not affect CNF crystallinity. The degree of orientation fc = (180 – FWHM/180) × 100 was calculated by extracting the FWHM from the azimuthal intensity distribution profile. Figure 6i presents the azimuthal integration of X-ray diffractograms, showing fibril orientations in wet-spun filaments, recorded at a scattering vector of 15.8 nm−1. Filaments made up of TEMPO-oxidized CNF (2%) had the highest degree of orientation (~ 83%), tensile strength (297 MPa), and Young’s modulus (21 GPa) [112]. WAXS has shown that CNF, produced via dry spinning, may be aligned within single-filament fibers, which is reflected in equatorial arc patterns in the diffractograms. The arcs were identified as the 0 and 200 cellulose planes, which confirmed the alignment of CNF. The degree of orientation had a maximum value of 0.68 for the filaments spun at a high spinning rate (216 mm s−1) because of a high external shear force [113].

WAXS has also been used to study the alignment of bacterial CNF that were assembled into macrofibers via wet-spinning and stretching. These macrofibers mimicked the mechanical properties of native cellulose bundles, with tensile strength of 6–7 GPa and Young’s modulus of 120–140 GPa. The WAXS patterns that were obtained from an untreated bacterial CNF film showed reflections corresponding to the (200) and () planes, which indicated the random orientation of untreated nanofibers; however, the WAXS pattern of wet-spun aligned macrofibers had an arc pattern of () and (200) reflections, implying crystallite alignment along the longitudinal axis of fibers. As the stretching ratio (SR) increased, the more defined reflections and narrower FWHM in the scattering patterns confirmed a greater degree of alignment in the macrofibers [114]. In addition, WAXS can detect changes in the length of crystalline cellulose via the peak position of (004), which corresponds to a quarter of the unit length of cellulose. This allows for the analysis of the nanoscale load-bearing properties of cellulose under tension. Studies have demonstrated that cellulose can withstand significant stress, exceeding 600 MPa, in PCW and SCW [115]. Further research on this characteristic is warranted to provide deeper insights into how nanoscale polymer deformations contribute to the overall mesoscale load-bearing abilities of CWs.