Abstract

The development of surrogate fuels with measured and predicted thermophysical properties similar to their authentic refinery stream counterparts is critical for the development of alternative fuels and the optimization of engines to increase efficiency and decrease emissions. In this work, four diesel fuel surrogates, formulated according to a reliable and proven procedure, were characterized by the advanced distillation curve (ADC) method to determine the composition and enthalpy of combustion in various distillate volume fractions. Tracking the composition and enthalpy of distillate fractions provides valuable information for determining structure−property relationships and also provides the basis for the development of equations of state that can describe the thermodynamic properties of these complex or simplified mixtures. This comparison showed that the volatility characteristic of the four surrogates is quite similar not only to the target diesel fuel but also to a number of other prototype alternative diesel fuels. The number of components in the surrogates affected how closely their volatility profiles resembled diesel fuel, as might be expected. The surrogate labeled V0a, consisting of just four components, was the most dissimilar to the target diesel fuel with respect to the initial boiling point and volatility curve shape. This suggests that, although minimizing the number of components greatly eases modeling and formulation efforts, caution should be used to avoid oversimplifying the surrogate mixtures.

INTRODUCTION

The development of surrogate fuels with measured and predicted thermophysical properties similar to their refinery stream counterparts has been the focus of much fuel-related research.1–18 Such research is necessary as the complexity and differences in the composition of refinery stream products make it difficult both to determine the effects of fuel composition on properties such as vaporization, mixing, and combustion and to compare results between different laboratories. One such research effort is under the auspices of the Coordinating Research Council (CRC) Advanced Vehicles, Fuels, and Lubricants (AVFL) technical committee. The AVFL committee has been working to overcome these difficulties by using a novel approach for the formulation of surrogates to develop fuel surrogates of less than ten compounds that are representative of market fuels.2,19 The committee has also been working to answer the question of how many compounds are required for an accurate surrogate. For example, one must determine if fuel properties are so significantly enhanced to justify the increased computational and measurement cost associated with increased surrogate-fuel complexity. Four surrogate fuels of increasing complexity have been blended in 30 L batches by an industrial collaborator (on the bsis of the algorithm discussed below), and their physical and operational properties have been extensively tested.20

The approach used in developing surrogate fuels was described in detail previously,19 and so only a brief description will be given here. The first step was to identify a target fuel; in this case, two prototype diesel fuels were chosen. The first was a fuels for advanced combustion engines (FACE) prototype referred to as FACE 9, and the second was a certified ultralow sulfur diesel fuel referred to as CFA (which we will consider here to be the target diesel fuel). Next, the design properties, property targets, and acceptable tolerances on meeting the property targets were established (such as fuel composition, ignition quality, volatility, and density.) These were selected in an attempt to match the in-cylinder vaporization, mixing, and combustion processes of the target fuel with the understanding that there was to be no guarantee that matching these design properties will produce identical engine emissions or performance. After the design properties were selected, the surrogate palette of compounds was chosen. Ideally, each palette compound would be representative of a class of compounds found in the target fuel, and each would have a chemical-kinetic oxidation mechanism available so that its combustion kinetics could be computationally simulated. The surrogate palette that was used in this initial study contains representatives from each of the major hydrocarbon families found in market diesel fuels: n-alkanes, iso-alkanes, cyclo-alkanes, aromatics, and naphtho-aromatics.21,22 The next step was to identify and apply an optimization algorithm to determine the mole fraction “recipe” for the surrogate; that is, how much of each palette compound should be included in the surrogate to achieve the property targets. The optimization algorithm used in this study is a thermophysical property regression model developed at the National Institute of Standards and Technology (NIST).23–28 Once each surrogate composition was determined, the pure palette compounds were blended together gravimetrically to produce the surrogates (FACE-9 Surr and CFA Surr). Although these resulting surrogate mixtures performed well in matching thermophysical and fit-for-purpose properties, refinements in the algorithm were sought to better match the target fuels. A detailed description of this refined algorithm has been reported previously and is beyond the scope of this paper;20 however, the result of this work was four mixtures whose ADC measurements are reported here. Two of these formulations are simple with 4 and 5 components, respectively, and two are more complex with 8 and 9 components, respectively. These are designated, in order: V0a, V0b, V1, and V2.

One of the best ways to compare the variations between different surrogates and market diesel fuels is to analyze the volatility by measuring distillation curves. This is because distillation curves are very sensitive to subtle changes in chemical composition and can serve as a simple indicator of surrogate authenticity. Indeed, the distillation curve provides the only practical avenue to assess the vapor−liquid equilibrium (volatility) of a complex mixture. In earlier work, the method and apparatus for determining composition explicit distillation curves (or advanced distillation curves, ADCs) was described, and the resulting information has proven to be especially applicable to the characterization of fuels, including the formulation of equations of state.29–38 This method offers significant improvements over previous approaches, such as ASTM D-86, and can be applied to any complex fluid.29–35,39 Indeed, in previous work on gas turbine fuels, we have used the ADC method to evaluate surrogate fidelity to the real target fuel.40,41 In this paper, we use the ADC method to compare four different diesel fuel surrogates to previously reported diesel fuel measurements. In addition, examination of the composition channels gives detailed insight into the thermochemical properties of the fuels and provides data showing that these surrogates are representative of market diesel and are ready for engine and combustion-vessel testing.

EXPERIMENTAL SECTION

Materials.

The diesel fuel surrogates used in this work were formulated and provided by participants in CRC Projects AVFL-18 and 18a;20 the compositions, as prepared gravimetrically, are given in the Supporting Information Table S1.20 No phase separation was observed as a result of the storage conditions (tightly sealed, room temperature), but to further ensure homogeneity prior to distillation, the containers were manually mixed before being sampled. The surrogate compositions were investigated using a gas chromatographic (GC) method (30 m capillary column of 5% phenyl:95% dimethyl polysiloxane having a thickness of 1 μm; the column temperature was held at 60 °C for 2 min, increased at 20 °C per minute to 300 °C, and finally held at 300 °C for 4 min) with both flame ionization detection (FID) and mass spectrometric (MS) detection in separate analyses. Samples were injected with a syringe into a split/splitless injector set with a 100:1 split ratio. The injector was operated at a temperature of 325 °C and with a constant head pressure of 55.2 kPa (8 psig). Mass spectra were collected for each peak from 15 to 550 relative molecular mass (RMM) units. Peaks were identified with guidance from the NIST/EPA/NIH mass spectral database and also on the basis of retention indices.42,43 The GC-MS/FID analyses were consistent with the gravimetric preparation of the surrogates.

Advanced Distillation Curve Measurements and Sampling.

Previous papers have described the ADC apparatus and procedure in detail.31,36–38,44–48 For each measurement, 200 mL of diesel fuel surrogate was placed into a boiling flask at atmospheric pressure. Two thermocouples were positioned to record (1) the kettle temperature (Tk), the temperature in the fluid, and (2) the head temperature (Th), the temperature of the vapor at the bottom of the takeoff position in the distillation head. In terms of significance, Tk is a thermodynamically consistent bubble point temperature, and Th approximates what might be obtained from the classical distillation measurement procedure.29,30,34,35,39,49 Heating was performed with a model-predictive temperature controller. A description of the development of the model-predictive controller procedure for various fuels has been published previously.33 The heating program used led the temperature in the kettle by approximately 20 °C throughout the distillation. Volume measurements were made in a level-stabilized receiver, and sample aliquots were collected at the receiver adapter hammock.45 Because of the concentration of high molecular weight compounds (such as octadecane) in some surrogates, an external heat source was used at the receiver adapter hammock and sampling needle to prevent the solidification of distillate at distillate volume fractions greater than 80%. In addition, it was important to mix the distillate volume in the level-stabilized receiver frequently to maintain a homogeneous sample and prevent solidification. The temperature readings were adjusted with the modified Sydney Young equation utilizing a constant term corresponding to a carbon chain of 12 (0.000109).50–52 The composition of each distillate volume fraction of fuel was also studied by the same gas chromatographic (GC) method as was used for the neat samples discussed above.53,42,54

We were able to sample and analyze the individual fractions of condensed vapor as they appeared from the condenser, as stated above in the Experimental Section. Following the analytical procedure described above, 7 μL of each sample was collected in autosampler vials containing a known mass of acetone. Chemical analyses of each fraction were done by GC-MS and GC-FID. Calibration for GC-FID was done by both the external standard method with four solutions of known concentrations of octane (prepared gravimetrically in acetone) and also by calibration to the neat fuels. There was no significant difference between the two calibration methods.

RESULTS AND DISCUSSION

Initial Boiling Temperatures.

To establish initial boiling behavior, we recorded the onset of bubbling, the temperature at which bubbling is sustained, and the temperature at which the vapor rises into the distillation head. It has previously been demonstrated that this last temperature is the initial boiling temperature (IBT, an approximation of the bubble-point temperature at ambient pressure) of the fuel.40,41 This measurement is noteworthy because it can be modeled with an equation of state and is the only point at which the temperature, pressure, and liquid composition are known. Experience with previous mixtures, including n-alkane standard mixtures that were prepared gravimetrically, indicates that the uncertainty in the onset of bubbling temperature is approximately 3 °C and the uncertainty in the vapor rise temperature is approximately 0.3 °C. In Table 1, we present the initial temperature observations for the fuel samples.

Table 1.

Summary of the Average Observed Initial Boiling Behavior of the Diesel Fuel Surrogatesa

| observed temperature | V0a 83.2 kPa (°C) | V0b 83.5 kPa (°C) | V1 83.7 kPa (°C) | V2 83.5 kPa (°C) |

|---|---|---|---|---|

| sustained | 229.4 | 212.1 | 209.4 | 215.0 |

| vapor rise | 238.8 | 225.6 | 224.9 | 224.8 |

The vapor rise temperature is that at which vapor is observed to rise into the distillation head and is considered to be the initial boiling point (IBT) of the fluid. These temperatures have been adjusted to 1 atm with the modified Sydney Young equation; the average experimental atmospheric pressures are provided to allow recovery of the average measured temperatures. The uncertainties are discussed in the text.

Distillation Curves.

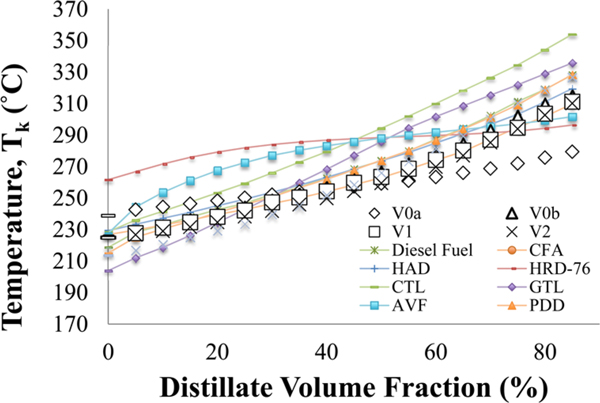

The temperatures at both Tk and Th were recorded, as well as the ambient pressure, throughout the measurement of the distillation curves at set distillate volume fractions. Three distillation curve measurements were taken for each fuel. The uncertainty in temperature measurements, Tk, was approximately 0.3 °C. The uncertainty in the volume measurement that is used to obtain the distillate volume fraction was 0.05 mL in each case. Average kettle and head temperatures, as well as the average measured atmospheric pressure, are reported at each distillate volume fraction for the diesel fuel surrogates in Table 2. These data are also represented graphically in Figure 1 along with the previously measured distillation curve for CFA.19 The IBT is indicated as a hatch mark on the temperature axis. There was no indication of azeotropy in the measured curves. In addition, the distillation curves of the diesel surrogates were compared to those of the target diesel fuels discussed earlier as well as to other prototype diesel fuels that have been the topic of recent research. These diesel fuels included (1) 2007 #2 ULSD Certification Fuel Batch A (CFA),19 (2) an algae-based hydrotreated renewable diesel fuel (lot number 12119–04718-000) provided by the Naval Fuels and Lubricants Cross Function Team at Patuxent River, Maryland (HRD-76),19 (3) a type 2D grade high-aromatic diesel fuel (HAD),55 (4) a renewable diesel fuel composed of hydrotreated animal and vegetable fats (AVF),56 (5) a Fischer−Tropsch gas-to-liquid fuel (GTL),56 (6) a coal-to-liquid diesel fuel (CTL),56 and (7) a petroleum-derived diesel fuel (PDD).56 These curves are shown graphically in Figure 2. Although not explicitly the same, the distillation curves of the diesel fuel surrogates are very similar to market diesel fuel and diesel fuel alternatives, suggesting that the surrogate development method can be used to build simplified surrogates of less than ten compounds that have thermophysical properties representative of market fuels. This is significant as these surrogate fuels will allow researchers to determine the effects of fuel composition on thermophysical properties and provide the necessary data for equations of state development.

Table 2.

Representative Distillation Curve Data (Given as the Average of Three Distillation Curves) For Diesel Fuel Surrogatesa

| V0a 83.2 kPa |

V0b 83.5 kPa |

V1 83.7 kPa |

V2 83.5 kPa |

|||||

|---|---|---|---|---|---|---|---|---|

| distillate volume fraction, % | Tk, °C | Th, °C | Tk, °C | Th, °C | Tk, °C | Th, °C | Tk, °C | Th, °C |

| 5 | 240.5 | 217.1 | 228.6 | 212.5 | 227.8 | 200.1 | 226.7 | 213.9 |

| 10 | 242.6 | 224.2 | 232.5 | 217.6 | 231.3 | 207.6 | 229.0 | 217.6 |

| 15 | 244.4 | 231.8 | 236.6 | 222.9 | 234.7 | 215.6 | 231.6 | 220.5 |

| 20 | 246.4 | 231.4 | 240.4 | 227.3 | 238.1 | 221.2 | 234.6 | 224.0 |

| 25 | 248.4 | 239.3 | 244.6 | 232.3 | 242.2 | 226.6 | 238.2 | 228.1 |

| 30 | 250.3 | 242.6 | 249.0 | 237.6 | 247.4 | 230.8 | 241.8 | 232.4 |

| 35 | 252.3 | 246.3 | 253.0 | 241.6 | 250.4 | 236.3 | 245.9 | 236.4 |

| 40 | 254.1 | 249.0 | 257.0 | 245.9 | 254.3 | 239.4 | 249.8 | 240.7 |

| 45 | 255.9 | 251.6 | 261.8 | 250.9 | 259.8 | 245.8 | 254.4 | 245.9 |

| 50 | 257.5 | 253.9 | 266.8 | 255.4 | 263.6 | 248.8 | 259.5 | 251.2 |

| 55 | 259.4 | 255.8 | 272.2 | 260.4 | 268.7 | 253.2 | 264.4 | 256.0 |

| 60 | 261.1 | 257.8 | 278.5 | 266.2 | 274.3 | 258.3 | 269.8 | 261.3 |

| 65 | 263.5 | 260.1 | 284.8 | 270.8 | 280.3 | 261.6 | 277.0 | 267.7 |

| 70 | 266.1 | 262.8 | 293.4 | 266.7 | 287.2 | 258.0 | 285.3 | 273.7 |

| 75 | 268.9 | 265.0 | 302.3 | 264.1 | 294.7 | 217.8 | 294.0 | 273.6 |

| 80 | 272.0 | 265.4 | 310.1 | 262.2 | 303.7 | 191.1 | 302.8 | 235.7 |

| 85 | 275.8 | 266.8 | 315.0 | 192.9 | 311.3 | 198.0 | 310.2 | 223.6 |

The uncertainties are discussed in the text. These temperatures have been adjusted to 1 atm with the modified Sydney Young equation; the average experimental atmospheric pressures are provided to allow recovery of the actual measured temperatures.

Figure 1.

Distillation curves of diesel fuel surrogates with the distillation curve of 2007 #2 ULSD Certification Fuel Batch A (CFA) added for comparison. The uncertainties are discussed in the text. The hash marks on the y-axis are IBT (vapor rise temperature).

Figure 2.

Distillation curves of diesel fuel surrogates and various diesel fuels including (1) 2007 #2 ULSD Certification Fuel Batch A (CFA), (2) an algae-based hydrotreated renewable diesel fuel (lot number 12119-04718-000), (3) a type 2D grade high-aromatic diesel fuel (HAD), (4) a renewable diesel fuel composed of hydrotreated animal and vegetable fats (AVF), (5) a Fischer-Tropsch gas-to-liquid fuel (GTL), (6) a coal-to-liquid diesel fuel (CTL), (7) a petroleum-derived diesel fuel (PDD), and (8) diesel fuel standard FACE Diesel No. 9 Batch A (FD9A).56 The uncertainties are discussed in the text. The hash marks on the y-axis are IBT (vapor rise temperature).

Distillate Fraction Composition and Energy Content.

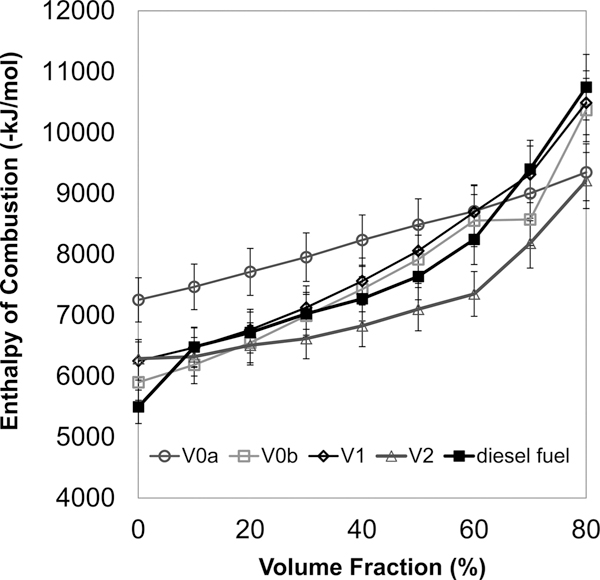

We can add thermochemical information to the distillation curve when the composition channel of data is used to provide quantitative analysis on specific distillate fractions.34,35,45 A composite enthalpy of combustion is calculated based on the enthalpy of combustion of individual (pure) components of a distillate fraction and the measured mole fractions of those components. The major components of the neat fuels determined by GC-MS agree with the known composition of the surrogates.57,58 The enthalpy of combustion of the individual (pure) components is taken from the DIPPR database.59 Uncertainty in this calculation has been discussed thoroughly and will not be repeated here.34,35,45,59 A 5% uncertainty is estimated to the molar enthalpy calculations reported in this work.

Figures 3–5 show the enthalpy of combustion as a function of the distillate fraction for each of the diesel fuel surrogates (provided in multiple units for completeness.) The enthalpies with their uncertainties are provided in Tables 3–5. The molar enthalpy of combustion (Table 3, Figure 3) increases with distillate fraction as the concentration of heavier paraffins increases in the later distillate fractions and roughly corresponds to the variation in distillation curves reported above for the diesel fuel surrogate samples. As shown in Tables 4 and 5, the enthalpies by mass and volume for all distillate cuts and fuels show similar behavior due to the similar densities of all distillate fractions.

Figure 3.

Energy content on a mole basis, presented as the composite enthalpy of combustion, −ΔHc, as a function of the distillate volume fraction for diesel fuel surrogates. The uncertainties are discussed in the text. Lines are drawn to guide the eyes of the viewer and do not represent a fit. The marks on the y-axis are the first drops of the distillations (0.05% volume fraction).

Figure 5.

Energy content on a mass basis, presented as the composite enthalpy of combustion, −ΔHc, as a function of the distillate volume fraction for diesel fuel surrogates. The uncertainties are discussed in the text. Lines are drawn to guide the eyes of the viewer and do not represent a fit. The marks on the y-axis are the first drops of the distillations (0.05% volume fraction).

Table 3.

Energy Content on a Mole Basis, Presented as the Composite Enthalpy of Combustion, −ΔHc, as a Function of the Distillate Fraction for Diesel Fuel Surrogatesa

| composite enthalpy of combustion (kJ/mol) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| distillate volume fraction | 0.03% | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | neat |

| V0a | 7253.4 (362.7) | 7467.3 (373.4) | 7712.8 (385.6) | 7954.7 (397.7) | 8235.7 (411.8) | 8486.9 (424.3) | 8708.5 (435.4) | 9001.8 (450.1) | 9348.5 (467.4) | 8459.1 (423.0) |

| V0b | 5902.0 (295.1) | 6188.0 (309.4) | 6549.0 (327.5) | 6993.8 (349.7) | 7429.6 (371.5) | 7919.7 (396.0) | 8554.4 (427.7) | 8573.5 (428.7) | 10371.5 (518.6) | 7965.7 (398.3) |

| V1 | 6250.9 (312.5) | 6470.5 (323.5) | 6761.0 (338.1) | 7126.6 (356.3) | 7562.4 (359.9) | 8058.8 (381.3) | 8694.5 (434.7) | 9314.5 (465.7) | 10490.2 (524.5) | 8120.5 (406.0) |

| V2 | 6287.9 (314.4) | 6320.1 (316.0) | 6509.7 (325.5) | 6617.8 (330.9) | 6827.2 (341.4) | 7100.5 (355.0) | 7350.7 (367.5) | 8184.0 (409.2) | 9213.0 (460.7) | 7561.6 (378.1) |

The uncertainties are discussed in the text and are provided in parentheses.

Table 5.

Energy Content on a Volume Basis, Presented as the Composite Enthalpy of Combustion, −ΔHc, as a Function of the Distillate Fraction for Diesel Fuel Surrogatesa

| composite enthalpy of combustion (kJ/mL) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| distillate volume fraction | 0.03% | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | neat |

| V0a | 36.4 (1.8) | 36.3 (1.8) | 36.2 (1.8) | 36.0 (1.8) | 35.8 (1.8) | 35.6 (1.8) | 35.4 (1.8) | 35.1 (1.8) | 34.6 (1.7) | 35.5 (1.8) |

| V0b | 37.2 (1.9) | 37.2 (1.9) | 37.2 (1.9) | 37.1 (1.9) | 36.9 (1.8) | 36.5 (1.8) | 35.9 (1.8) | 35.8 (1.8) | 34.4 (1.7) | 36.2 (1.8) |

| V1 | 36.7 (1.8) | 36.7 (1.8) | 36.7 (1.8) | 36.7 (1.8) | 36.5 (1.8) | 36.2 (1.8) | 35.7 (1.8) | 35.1 (1.8) | 33.8 (1.7) | 35.9 (1.8) |

| V2 | 36.4 (1.8) | 36.7 (1.8) | 36.9 (1.8) | 37.3 (1.9) | 37.5 (1.9) | 37.8 (1.9) | 38.0 (1.9) | 37.6 (1.9) | 37.4 (1.9) | 37.2 (1.9) |

The uncertainties are discussed in the text and are provided in parentheses.

Table 4.

Energy Content on a Mass Basis, Presented as the Composite Enthalpy of Combustion, −ΔHc, as a Function of the Distillate Fraction for Diesel Fuel Surrogatesa

| composite enthalpy of combustion (kJ/g) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| distillate volume fraction | 0.03% | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | neat |

| V0a | 42.3 (2.1) | 42.3 (2.1) | 42.4 (2.1) | 42.4 (2.1) | 42.5 (2.1) | 42.6 (2.1) | 42.7 (2.1) | 42.9 (2.1) | 43.3 (2.2) | 42.7 (2.1) |

| V0b | 41.2 (2.1) | 41.2 (2.1) | 41.4 (2.1) | 41.5 (2.1) | 41.7 (2.1) | 42.0 (2.1) | 42.4 (2.1) | 42.4 (2.1) | 43.5 (2.2) | 42.1 (2.1) |

| V1 | 41.8 (2.1) | 41.8 (2.1) | 41.9 (2.1) | 41.9 (2.1) | 42.1 (2.1) | 42.3 (2.1) | 42.6 (2.1) | 43.0 (2.1) | 43.9 (2.2) | 42.4 (2.1) |

| V2 | 42.2 (2.1) | 42.0 (2.1) | 41.9 (2.1) | 41.7 (2.1) | 41.6 (2.1) | 41.5 (2.1) | 41.4 (2.1) | 42.0 (2.1) | 42.8 (2.1) | 42.1 (2.1) |

The uncertainties are discussed in the text and are provided in parentheses.

Hydrocarbon Classification.

The analysis of distillate composition may be further enhanced by the use of a mass spectrometric classification technique, similar to ASTM D-2789, which gives the percent of the sample found in various hydrocarbon family types.60,61 This method uses the measurement of a global mass spectrum for the sample and then compares the intensity of characteristic ion fragments (m/z, defined as the ratio of ion mass to ion charge) for the determination of hydrocarbon types. Although characteristic ion fragments are good indicators of hydrocarbon family types, they are not completely unique to those families and occasionally give nonzero results even when the hydrocarbon type is not present. Although the method is specified only for application to low olefinic gasoline and has significant limitations, it is of practical relevance to many complex fluid analyses and is often applied to gas turbine fuels, rocket propellants, and missile fuels.61 The procedures, uncertainty, and potential difficulties of this method have been reported previously.34 This analysis was applied to the diesel fuel surrogates. Table 6 gives the percent of the neat fuel found in each hydrocarbon family type, and Figure 6 shows the changes in the percent hydrocarbon family through the distillations of the diesel fuel surrogates. In fuels that contain aromatic compounds, alkylbenzenes decrease throughout the distillation, whereas the amount of paraffins increases. This analysis is in agreement with what is seen in traditional fuels containing alkylbenzenes.

Table 6.

Hydrocarbon Family Types Resulting from the ASTM D-2789 Analysis Performed on the Neat Samples of Diesel Fuel Surrogates

| sample | paraffins (%) | monocycloparaffins (%) | dicycloparaffins (%) | alkylbenzenes (%) | indanes and tetralins (%) | naphthalene (%) |

|---|---|---|---|---|---|---|

| V0a | 65.1 | 15.3 | 5.9 | 0.5 | 0.0 | 13.3 |

| V0b | 56.7 | 13.0 | 0.9 | 9.4 | 8.5 | 11.6 |

| V1 | 59.3 | 16.0 | 3.2 | 5.5 | 5.17 | 10.4 |

| V2 | 35.8 | 24.7 | 7.4 | 12.4 | 6.9 | 12.8 |

Figure 6.

Plots of the hydrocarbon family types resulting from the moiety family analysis performed on diesel fuel surrogates. The uncertainty is discussed in the text.

CONCLUSIONS

This study compares the volatility profile of four diesel fuel surrogates, and then compares these to the “real-world” target diesel fuel CFA. This comparison shows that the volatility characteristic of these four surrogates is indeed quite similar not only to CFA but also to a number of other prototype alternative diesel fuels. The number of components in the surrogates affected how closely their volatility profiles resembled diesel fuel, as might be expected. The surrogate V0a, consisting of just four components, was the most dissimilar to CFA with respect to the initial boiling point and volatility curve shape. This suggests that, although minimizing the number of components greatly eases modeling and formulation efforts, caution should be used to avoid oversimplifying the surrogate mixtures. V0b, which included just one more component, performed far better in its comparison with CFA. A quotation attributed to Einstein, “everything should be made as simple as possible, but not simpler,” would appear to be particularly applicable in surrogate development.62

These results add to a growing body of literature that supports the development of simple surrogates by the methodology published previously.19 The development of these surrogates, and the development of surrogates based on other market fuels, will provide the fuel research community with surrogates whose predicted thermophysical properties are similar to their refinery stream counterparts and will allow researchers to determine the effects of fuel composition on properties such as vaporization, mixing, and combustion and to compare results between different laboratories. Successful surrogates have the potential for great positive impact on the development and future of alternative fuels.

Supplementary Material

Figure 4.

Energy content on a volume basis, presented as the composite enthalpy of combustion, −ΔHc, as a function of the distillate volume fraction for diesel fuel surrogates. The uncertainties are discussed in the text. Lines are drawn to guide the eyes of the viewer and do not represent a fit. The marks on the y-axis are the first drops of the distillations (0.05% volume fraction).

ACKNOWLEDGMENTS

J.B. acknowledges the PREP postdoctoral associateship program support for research performed at NIST-Boulder for this work. M.H. acknowledges the PREP graduate fellowship program support for research performed at NIST-Boulder for this work.

Footnotes

ASSOCIATED CONTENT

Supporting Information

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acs.energyfuels.6b00107.

Table of major components found in neat samples of diesel fuel surrogates as prepared gravimetrically (PDF)

The authors declare no competing financial interest.

REFERENCES

- (1).Mueller CJ; Boehman AL; Martin GC An experimental investigation of the origin of increased NOx emissions when fueling a heavy-duty compression-ignition engine with soy biodiesel. SAE Int. J. Fuels Lubr 2009, 2 (1), 789–816. [Google Scholar]

- (2).Pitz WJ; Mueller CJ Recent progress in the development of diesel surrogate fuels. Prog. Energy Combust. Sci 2011, 37, 330–350. [Google Scholar]

- (3).da Cruz AP; Dumas J-P; Bruneaux G. Two-dimensional in-cylinder soot volume fractions in diesel low temperature combustion mode. SAE International Journal of Engines 2011, 4 (1), 2023–2047. [Google Scholar]

- (4).Brakora JL; Ra Y; Reitz RD Combustion model for biodiesel-fueled engine simulations using realistic chemistry and physical properties. SAE International Journal of Engines 2011, 4 (1), 931–947. [Google Scholar]

- (5).Imren A; Golovitchev V; Sorusbay C; Valentino G. The full cycle HD diesel engine sumulations using KIVA-4 code. SAE Tech. Pap. Ser 2010, 2010-01-2234. [Google Scholar]

- (6).Liang L; Naik CV; Puduppakkam K; Wang C; Modak A; Meeks E; Ge H-W; Reitz R; Rutland C. Efficient simulation of diesel engine combustion using realistic chemical kinetics in CFD. SAE Tech. Pap. Ser 2010, 2010–01-0178. [Google Scholar]

- (7).Sarathy SM; Kukkadapu G; Mehl M; Wang W; Javed T; Park S; Oehlschlaeger MA; Farooq A; Pitz WJ; Sung C-J Ignition of alkane-rich FACE gasoline fuels and their surrogate mixtures. Proc. Combust. Inst 2015, 35 (1), 249–257. [Google Scholar]

- (8).Gauthier B; Davidson D; Hanson R. Shock tube determination of ignition delay times in full-blend and surrogate fuel mixtures. Combust. Flame 2004, 139 (4), 300–311. [Google Scholar]

- (9).Lenhert DB; Miller DL; Cernansky NP; Owens KG The oxidation of a gasoline surrogate in the negative temperature coefficient region. Combust. Flame 2009, 156 (3), 549–564. [Google Scholar]

- (10).Tian G; Daniel R; Li H; Xu H; Shuai S; Richards P. Laminar burning velocities of 2, 5-dimethylfuran compared with ethanol and gasoline. Energy Fuels 2010, 24 (7), 3898–3905. [Google Scholar]

- (11).Vanhove G; Petit G; Minetti R. Experimental study of the kinetic interactions in the low-temperature autoignition of hydrocarbon binary mixtures and a surrogate fuel. Combust. Flame 2006, 145 (3), 521–532. [Google Scholar]

- (12).Andrae J. Comprehensive chemical kinetic modeling of toluene reference fuels oxidation. Fuel 2013, 107, 740–748. [Google Scholar]

- (13).Mehl M; Chen J-Y; Pitz WJ; Sarathy S; Westbrook CK An approach for formulating surrogates for gasoline with application toward a reduced surrogate mechanism for CFD engine modeling. Energy Fuels 2011, 25 (11), 5215–5223. [Google Scholar]

- (14).Kukkadapu G; Kumar K; Sung C-J; Mehl M; Pitz WJ Experimental and surrogate modeling study of gasoline ignition in a rapid compression machine. Combust. Flame 2012, 159 (10), 3066–3078. [Google Scholar]

- (15).Ahmed A; Goteng G; Shankar VS; Al-Qurashi K; Roberts WL; Sarathy SM A computational methodology for formulating gasoline surrogate fuels with accurate physical and chemical kinetic properties. Fuel 2015, 143, 290–300. [Google Scholar]

- (16).Payri R; Viera JP; Pei Y; Som S. Experimental and numerical study of lift-off length and ignition delay of a two-component diesel surrogate. Fuel 2015, 158, 957–967. [Google Scholar]

- (17).Xu Z; Zhao Z; Li J; Wang M; Liu J; Lee C-F; Chang W; Jie H. A reduced chemical kinetic mechanism of toluene reference fuel (toluene/n-heptane) for diesel engine combustion simulations 2015, 2015-01-0387 DOI: 10.4271/2015-01-0387. [DOI] [Google Scholar]

- (18).Pei Y; Mehl M; Liu W; Lu T; Pitz WJ; Som S. In A Multi-Component Blend as a Diesel Fuel Surrogate for Compression Ignition Engine Applications, ASME 2014 Internal Combustion Engine Division Fall Technical Conference, 2014; American Society of Mechanical Engineers, 2014; pp V002T006A012−V002T006A012. [Google Scholar]

- (19).Mueller CJ; Cannella WJ; Bruno TJ; Bunting B; Dettman HD; Franz JA; Huber ML; Natarajan M; Pitz WJ; Ratcliff MA; Wright K. Methodology for formulating diesel surrogate fuels with accurate compositional, ignition-quality, and volatility characteristics. Energy Fuels 2012, 26 (6), 3284–3303. [Google Scholar]

- (20).Mueller CJ; Cannella WJ; Bays JT; Bruno TJ; DeFabio K; Dettman HD; Gieleciak RM; Huber ML; Kweon C-B; McConnell SS; Pitz WJ; Ratcliff MA Diesel Surrogate Fuels for Engine Testing and Chemical-Kinetic Modeling: Compositions and Properties. Energy Fuels 2016, 30, 1445–1461. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (21).Lemmon EW, McLinden MO, Huber ML REFPROP, Reference fluid thermodynamic and transport properties. NIST Standard Reference Database 23, V9.1. National Institute of Standards and Technology: Gaithersburg, MD, 2013. [Google Scholar]

- (22).Bruno TJ; Fortin TJ; Lovestead TM; Widegren JA Chemical and thermophysical characterization of 1,3,5-triisopropylcy-clohexane. J. Chem. Eng. Data 2012, 57, 2343–2349. [Google Scholar]

- (23).Huber ML; Smith BL; Ott LS; Bruno TJ Surrogate Mixture Model for the Thermophysical Properties of Synthetic Aviation Fuel S-8: Explicit Application of the Advanced Distillation Curve. Energy Fuels 2008, 22, 1104–1114. [Google Scholar]

- (24).Huber ML; Lemmon E; Diky V; Smith BL; Bruno TJ Chemically authentic surrogate mixture model for the thermophysical properties of a coal-derived liquid fuel. Energy Fuels 2008, 22, 3249–3257. [Google Scholar]

- (25).Huber ML; Lemmon E; Kazakov A; Ott LS; Bruno TJ Model for the thermodynamic properties of a biodiesel fuel. Energy Fuels 2009, 23, 3790–3797. [Google Scholar]

- (26).Huber ML; Lemmon E; Ott LS; Bruno TJ Preliminary surrogate mixture models for rocket propellants RP-1 and RP-2. Energy Fuels 2009, 23, 3083–3088. [Google Scholar]

- (27).Huber ML; Lemmon E; Bruno TJ Effect of RP-1 compositional variability on thermophysical properties. Energy Fuels 2009, 23, 5550–5555. [Google Scholar]

- (28).Huber ML; Lemmon EW; Bruno TJ Surrogate mixture models for the thermophysical properties of aviation fuel Jet-A. Energy Fuels 2010, 24, 3565–3571. [Google Scholar]

- (29).Bruno TJ Improvements in the measurement of distillation curves - part 1: a composition-explicit approach. Ind. Eng. Chem. Res 2006, 45, 4371–4380. [Google Scholar]

- (30).Bruno TJ; Smith BL Improvements in the measurement of distillation curves - part 2: application to aerospace/aviation fuels RP-1 and S-8. Ind. Eng. Chem. Res 2006, 45, 4381–4388. [Google Scholar]

- (31).Ott LS; Bruno TJ Corrosivity of fluids as a function of distillate cut: application of an advanced distillation curve method. Energy Fuels 2007, 21, 2778–2784. [Google Scholar]

- (32).Ott LS; Bruno TJ Modifications to the copper strip corrosion test for the measurement of microscale samples. J. Sulfur Chem. 2007, 28 (5), 493–504. [Google Scholar]

- (33).Smith BL; Bruno TJ Advanced distillation curve measurement with a model predictive temperature controller. Int. J. Thermophys 2006, 27, 1419–1434. [Google Scholar]

- (34).Smith BL; Bruno TJ Improvements in the measurement of distillation curves: part 3 - application to gasoline and gasoline + methanol mixtures. Ind. Eng. Chem. Res 2007, 46, 297–309. [Google Scholar]

- (35).Smith BL; Bruno TJ Improvements in the measurement of distillation curves: part 4- application to the aviation turbine fuel Jet-A. Ind. Eng. Chem. Res 2007, 46, 310–320. [Google Scholar]

- (36).Bruno TJ; Ott LS; Lovestead TM; Huber ML Relating complex fluid composition and thermophysical properties with the advanced distillation curve approach. Chem. Eng. Technol 2010, 33 (3), 363–376. [Google Scholar]

- (37).Bruno TJ; Ott LS; Smith BL; Lovestead TM Complex fluid analysis with the advanced distillation curve approach. Anal. Chem 2010, 82, 777–783. [DOI] [PubMed] [Google Scholar]

- (38).Bruno TJ; Ott LS; Lovestead TM; Huber ML The composition explicit distillation curve technique: relating chemical analysis and physical properties of complex fluids. J. Chromatogr 2010, A1217, 2703–2715. [DOI] [PubMed] [Google Scholar]

- (39).Standard Test Method for Distillation of Petroleum Products at Atmospheric Pressure. ASTM Standard D 86–04b, Book of Standards; American Society for Testing and Materials: West Conshohocken, PA, 2004; Vol.: 05.01. [Google Scholar]

- (40).Bruno TJ; Smith BL Evaluation of the physicochemical authenticity of aviation kerosene surrogate mixtures Part I: Analysis of volatility with the advanced distillation curve. Energy Fuels 2010, 24, 4266–4276. [Google Scholar]

- (41).Bruno TJ; Huber ML Evaluation of the physicochemical authenticity of aviation kerosene surrogate mixtures Part II: Analysis and prediction of thermophysical properties. Energy Fuels 2010, 24, 4277–4284. [Google Scholar]

- (42).NIST/EPA/NIH Mass Spectral Database, S. R. D SRD Program; National Institute of Standards and Technology: Gaithersburg, MD, 2005. [Google Scholar]

- (43).Bruno TJ, Svoronos PDN CRC Handbook of Basic Tables for Chemical Analysis, 3rd. ed.; Taylor and Francis CRC Press: Boca Raton, FL, 2011. [Google Scholar]

- (44).Bruno TJ; Smith BL Enthalpy of combustion of fuels as a function of distillate cut: application of an advanced distillation curve method. Energy Fuels 2006, 20, 2109–2116. [Google Scholar]

- (45).Bruno TJ Method and apparatus for precision in-line sampling of distillate. Sep. Sci. Technol 2006, 41 (2), 309–314. [Google Scholar]

- (46).Ott LS; Smith BL; Bruno TJ Experimental test of the Sydney Young equation for the presentation of distillation curves. J. Chem. Thermodyn 2008, 40, 1352–1357. [Google Scholar]

- (47).Ott LS; Smith BL; Bruno TJ Advanced distillation curve measurement: application to a bio-derived crude oil prepared from swine manure. Fuel 2008, 87, 3379–3387. [Google Scholar]

- (48).Burger J; Widegren J; Lovestead T; Bruno T. 1H and 13C NMR Analysis of Gas Turbine Fuels As Applied to the Advanced Distillation Curve Method. Energy Fuels 2015, 29 (8), 4874–4885. [Google Scholar]

- (49).Windom BC; Bruno TJ Improvements in the measurement of distillation curves. 5. reduced pressure distillation curve method. Ind. Eng. Chem. Res 2011, 50, 1115–1126. [Google Scholar]

- (50).Young S. Correction of boiling points of liquids from observed to normal pressures. J. Chem. Soc., Trans 1902, 81, 777. [Google Scholar]

- (51).Young S. Fractional distillation. Macmillan and Company, Ltd.: London, 1903. [Google Scholar]

- (52).Young S. Distillation principles and processes. Macmillan and Company, Ltd.: London, 1922. [Google Scholar]

- (53).Windom BC, Lovestead TM, Riggs JR, Nickell C, Bruno TJ Assessment of the compositional variability of RP-1 and RP-2 with the advanced distillation curve approach. In Proceedings of the 57th JANNAF Conference; Colorado Springs, CO, 2010. [Google Scholar]

- (54).Bruno TJ, Svoronos PDN CRC Handbook of Fundamental Spectroscopic Correlation Charts. Taylor and Francis CRC Press: Boca Raton, FL, 2006. [Google Scholar]

- (55).Windom B; Huber M; Bruno T; Lown A; Lira C. Measurements and modeling study on a high-aromatic diesel fuel. Energy Fuels 2012, 26 (3), 1787–1797. [Google Scholar]

- (56).Gough R; Bruno T. Comparison of Alternative Diesel Fuels with the Composition-Explicit Distillation Curve Method. Energy Fuels 2012, 26 (11), 6905–6913. [Google Scholar]

- (57).Cannella W; Foster M;G,G; Leppard WR CRC Report No. AVFL-24, 2014. [Google Scholar]

- (58).Zigler BT Fuels for Advanced Combustion Engines, http://energy.gov/sites/prod/files/2014/03/f10/ft002_zigler_2012_opdf (accessed Sept. 9th, 2014).

- (59).Rowley RL; Wilding WV; Oscarson JL; Zundel NA; Marshall TL; Daubert TE; Danner RP DIPPR(R) Data Compilation of Pure Compound Properties; Design Institute for Physical Properties, A.: New York, 2008. [Google Scholar]

- (60).Gong YF; Liu SH; Guo HJ; Hu TG; Zhou LB A new diesel oxygenate additive and its effects on engine combustion and emissions. Appl. Therm. Eng 2007, 27 (1), 202–207. [Google Scholar]

- (61).Shafer LM, Striebich RC, Gomach J, Edwards T. In Chemical class composition of commercial jet fuels and other specialty kerosene fuels; 14th AIAA/AHI Space Planes and Hypersonic Systems and Technologies Conference, paper 7972; American Institute of Aeronautics and Astronautics: Reno, NV, 2006; pp 1–6. [Google Scholar]

- (62).Shapiro FR The Yale Book of Quotations; Yale University Press: New Haven, CT, USA, 2006. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.