Abstract

Background

Bisphenol A (BPA) is one of the chemical compounds used in food packaging, so it can migrate from the packaging into food. Also, environmental pollution of this compound is high due to its high use. Therefore, it may enter food chains through the environment. Aflatoxin M1 (AFM1) is one of the common mycotoxins in milk. Its presence has been reported worldwide. Infant formula is an alternative to human milk. The main ingredient of this product is cow’s milk.

Aims

This study aimed to investigate the levels and risk assessment of BPA and aflatoxin M1 in infant formula.

Methods

Samples were purchased from 7 leading brands of infant formula in pharmacies. The samples were extracted according to common protocols and then injected into HPLC and analyzed with a fluorescence detector for both contaminants.

Results

BPA wasn’t detected in infant formula samples, but the presence of AFM1was confirmed in 11% of the samples. Of course, there is no risk in this regard with the risk assessment.

Conclusion

Infant formula samples are not of concern for infants in terms of BPA and aflatoxin M1. However, continuous monitoring is recommended for this product.

Keywords: Bisphenol A, Aflatoxin M1, Infant formula, HPLC, Food packaging, Environmental pollution, Mycotoxins

Introduction

In children, disruption in endocrine glands and metabolism causes disturbances in the growth of the children and their mental development and sexual organs. Children’s detoxification systems are less efficient. Children’s blood-brain barriers are also immature, making them more susceptible to nerve damage [1]. Their endocrine, reproductive, and renal systems are also immature [2]. One of the endocrine disruptors is bisphenol A (BPA). BPA is an estrogenic environmental pollutant that binds to the estrogen receptor even in very low doses. In children, BPA causes a decrease in IQ, interference with the thyroid and gonads, interference with brain development, and behavioral changes [3]. The tolerance daily intake(TDI) in the European Food Safety Organization was estimated at 50 micrograms per kilogram of body weight per day, which was reduced to 2 µg/kg body weight (bw) per day [4].

Milk and dairy products are major components of the diet of infants and young children, which may be contaminated with BPA. It remains in sediments and soil and enters the animal feed and can enter milk and dairy products [5]. Furthermore, studies have shown that BPA is likely to increase during milk processing and reach the highest levels in the final product [6, 7]. Packaging plays an important role in food preservation. It maintains both the quality and safety of food [8]. BPA can enter food through migration from food packaging such as polycarbonate bottles and cans with epoxy [9, 10].

Milk and dairy products in the diet of infants and young children may be a route for mycotoxins to enter their bodies [11]. Mycotoxins are produced by molds, and various types of mycotoxins can contaminate food. One of the most common mycotoxins is aflatoxins. Aflatoxins are produced by various Aspergillus species, particularly Aspergillus flavus and Aspergillus parasiticus [12]. Aflatoxins are divided into four types: B1, B2, G1, and G2. Aflatoxins type B1 are highly toxic and carcinogenic and are identified in a variety of plant food products [12]. AFM1 has been repeatedly detected in milk and its products. This mycotoxin is a hydroxylated metabolite of aflatoxin B1, which enters the animal body through fodder and feed. These two mycotoxins belong to group 1 of the IARC (International Agency for Research on Cancer) and are carcinogenic to humans [13, 14]. Every year, a significant number of liver cancers are reported due to exposure to aflatoxins [15]. Therefore, the presence of AFM1in milk cannot be ignored, and this product should be regularly evaluated in this regards. This mycotoxin is resistant to heat and is not destroyed by sterilization and pasteurization processes in milk [16].

Infant formula replaces human milk in cases where the mother cannot or does not want to breastfeed her child [17]. Infant formula is available on the market in two forms: powdered infant formula and liquid infant formula. This product undergoes pasteurization, homogenization, and drying processes and is generally enriched with minerals such as iron [18].

Considering the toxic effects of BPA and AFM 1, the sensitivity of infant formula consumers, and the possibility of contamination of these types of products with these two contaminants, this study examined samples of prominent infant formula brands sold in Tehran.

Method and materials

Materials

Standards of Bisphenol A (purity > 99.0%) was obtained from Sigma- Aldrich and Immunoaffinity columns for AFM1was purchased from aoki immunoclean (Berlin, Germany). The HPLC grade hexane, methanol, and acetonitrile were purchased from Samchun (Seoul, Republic of Korea). Forty-two samples of 7 brands of infant formula were purchased from pharmacies in Tehran.

The extraction of BPA from infant formula samples

Initially, a 10 ppm stock solution for BPA was prepared. 0.01 g of BPA was weighted and made up to volume 10 with methanol. The stock solution of 10ppm can be stored at a refrigerator temperature of 4 °C for 1 month. To draw the calibration curve, we prepared different concentrations of 10 to 50 µg/L from this stock solution. The standard solutions were stored at 0–4◦C.

To extract bisphenol A from the samples, the method of Santonicola et al. was used with some modification [19]. First, 12.5 g of infant formula powder was weighed and mixed with boiled water to a volume of 100 mL. We poured about 20 mL of milk solution into an Erlenmeyer flask. Then 15 mL of acetonitrile and 15 mL of hexane were added. The mixture of sample and solvents was completely mixed with a magnetic shaker for 10 min. The samples were transferred to a 15 mL Falcon and centrifuged at 15 °C for 10 min at 6500 rpm. The solution was removed from the centrifuge in two phases, and the upper layer was a gel containing hexane and fat. The acetonitrile layer was introduced into the Erlenmeyer flask and, for further extraction, the layer on the ashless paper was washed with 5 mL of acetonitrile. The samples were filtered with a syringe filter and the sample was transferred to a vacuum oven at a temperature of 40 °C. Then we dissolved the dried sample with 0.5 mL of the mobile phase (methanol /water/ 70:30 v/v).

The extraction of AFM1 from infant formula samples

Previously published methods were used for extraction [20]. The procedure began with the combination of 20 g of milk sample with 80 ml of HPLC grade water, and was adjusted to a final volume of 100 ml. A portion of this solution, amounting to 60 ml, was then subjected to centrifugation. Subsequently, immunoaffinity columns were utilized for the extraction and separation process. Initially, the column was primed with an acetate buffer solution, followed by water. Next, 20 ml of the defatted sample was introduced into the column, followed by another rinse with HPLC grade water. In the subsequent step, 2.5 ml of acetonitrile solvent was passed through the column. Following this, the sample underwent drying. Once dried, the sample was dissolved in 1.0 ml of mobile phase, consisting of water, acetonitrile, and methanol at a ratio of 60:20:20 v/v/v, before being introduced into the HPLC for analysis.

High performance liquid chromatography system

Chromatographic analysis was carried out according previous studies [21, 22] using an Agilent HPLC-FLD system (Wilmington, USA) equipped with Agilent G1321B fluorescence detector (FLD) with a 1200 series quaternary pump, an Eclipse-XDB-C18 analytical column (25 cm- 4.6 mm, 5 μm) and auto sampler was used. The excitation wavelength was 275 nm and the emission wavelength was 313 nm for BPA, and the excitation wavelength 360 nm and the emission wavelength were 440 nm for AFM1. The mobile phase was maintained at a flow rate of 1 mL/min., and the volume of the injection was 20 µL.

Statistical analysis

The mean and standard deviation were calculated using SPSS software (version 20). Two-way analysis of the variance test was used for comparison between groups. P-value of less than 0.05 was considered a significant difference.

Results

Analytical performance of method

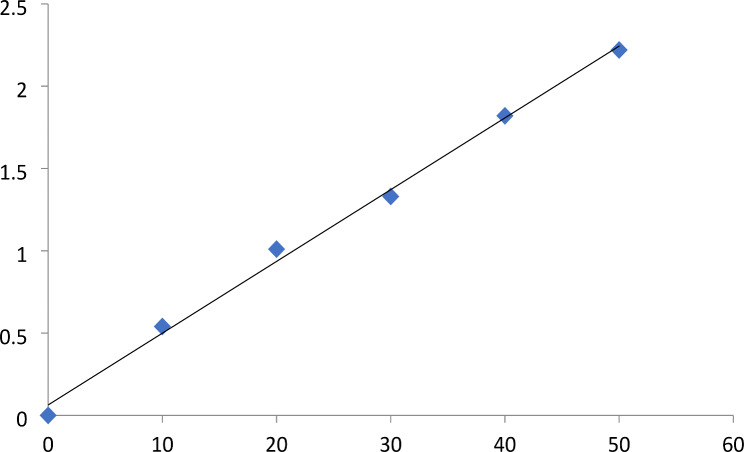

Analytical method performance including limit of detections and quantifications (LODs and LOQs, respectively), linear dynamic ranges (LDRs), extraction relative recoveries and intra and inter-day precision (RSDs) were calculated by two spiking levels of BPA (Table 1). Linearity dynamic ranges of 10.0–50.0 µg/ kg (R2 = 0.99) were obtained. The LOD and LOQ for BPA were obtained at 0.3 and 1 µg/kg practically based on signal-to-noise ratios of 3 and 10. RSDs for intra and inter day precision were obtained in the range of 2.92–3.11%, respectively. The obtained relative recoveries of BPA at a spiking level of 20 (µg/kg) were from 96.4 to 103.9%. To draw a standard curve and linear equation, concentrations of 0, 10, 20, 30, 40, and 50 ppb bisphenol A were injected into the device (Fig. 1).

Table 1.

Validation parameters

| Parameters | Analytical feature (BPA) |

Analytical feature (AFM1) |

|---|---|---|

| Limit of detection (µg/kg) | 0.3 | 0.05 |

| Limit of quantification (µg/kg) | 1 | 0.125 |

| Recovery percent | 101.85 | 89.12%. |

| Linear dynamic range (µg/ kg) | 2.0–50.0 | - |

| Regression equation | y = 0.0372x − 0.0144 | y = 3828x – 36.89 |

| r2 | 0.9968 | 0.9994 |

Fig. 1.

Bisphenol A standard curve

Determination of BPA and AFM1in infant formula samples

In our study, it was found that in the evaluated infant formula samples, the measurable amounts of BPA were lower than the detection limit of the HPLC device, and BPA was not detected in any of the samples. However, aflatoxin M1 was detected in 11% of the samples, and its average level was determined to be 0.002 µg/kg (Table 2). A significant difference was also observed between brands in the amount of aflatoxin M1. The risk assessment for aflatoxin M1 was calculated using the determined average.

Table 2.

The amount and Health risk assessment for BPA and AFM1

| (Total) | BPA | AFM1 |

|---|---|---|

| Mean ± SD | ND |

0.002 ± 0.008 µg/kg |

| Positive percentage | 0 | 11% |

| HQ (0–6 months) | - | 0.2 |

| HQ (6–12 months) | - | 0.17 |

| HQ (1–2 years) | - | 0.16 |

The risk assessment for AFM1in infant formula

Milk consumption for infants is calculated as follows [23]. Infants (0–6 months): 120 gr with an average weight of 5.9 kg, Children (6–12 months): 160 g with an average body weight of 9.3 kg, and Children (1–2 years): 200 g with an average weight of 12.2 kg.

The estimation of daily intake (EDI) for AFM1was determined using the following formula: 𝐸𝐷𝐼 = 𝐶𝑖 × 𝐶𝑐 / BW or body weight. Ci represents the mean concentration of AFM1, Cc is the ingestion rate of milk, and BW is the average body weight of children.

TDI (tolerable daily intake) is considered 0.2 ng/kg/day [24]. Hazard quotient (HQ) is calculated as EDI/TDI. The results of risk based on three age groups are summarized in Table 2. It was calculated as less than 1 in all age groups(Table 2).

Discussion

In this study, BPA was not detected in any of the infant formula samples. In the past, an epoxy resin layer was used in infant formula cans [25]. But, due to the toxicity of BPA and the harmful effects on the health of babies, in recent years, most brands of infant formulas removed the epoxy resin layer in the cans. Therefore, the amount of BPA in infant formula has decreased significantly.

The results of this study were compared with the results of other similar studies. In one study conducted in China in 2017 on 76 milk powder samples across China, BPA was not detected in any of the samples, which is very similar to our study [26], in which BPA was not found in any of the samples in this study. Similar results were also observed in another study conducted in Spain in 2012 on infant formula samples. In this study, the amount of BPA was lower than the permissible limit [27]. The permissible limit is set at 0.6 mg/ kg according to European Union regulations [27].

In 2010, Ackerman et al. conducted a study in the United States of America to investigate the amount of BPA in infant formula cans by LC-MS/MS. Based on the results obtained on 36 different samples of liquid and powdered infant formula, only one sample showed the amount of BPA above the permissible limit. The amount of BPA detected ranged from 0.48 to 11 ng/g [28]. Furthermore, in 2004, a study was conducted in Spain to determine the amount of bisphenol in infant food. None of the samples exceeded the permissible limit. The amount of bisphenol in the samples was reported to be 0.28 ± 0.02 µg/kg [29]. In that year, the ban on the use of BPA in infant food packaging had not yet been implemented. In 2021, Karsauliya et al., conducted a study on the measurement of bisphenols in powdered infant formulas available in Indian markets. The presence of seven bisphenols (A, AF, E, ZC, FL, S, Z) in infant formula was evaluated and liquid chromatography and tandem mass spectrometry (UPLC-MS/MS) were used. The highest concentration was for BPA with an average of 5.46 ng/g, and then the highest value was estimated for bisphenol Z and S. Other bisphenols were not detected in any of the samples. In this study, the estimated daily intake (EDI) was also determined, and its value was calculated to be less than the TDI [30]. A study was also conducted to evaluate the presence of BPA in infant formula samples in Brazil. In this study, the measured concentrations were lower than the migration limit set by the European Union and Brazil (600 µg/kg) and the concentration range was 0.2 to 10.2 µg/kg [31].

In 2015, Cirillo et al. investigated the contamination of powdered infant formula and liquid infant formula with phthalates and bisphenol in the United States. The samples included 28 infant formula powders, and the method of performing was gas chromatography with a flame ionization detector and high performance liquid chromatography with the fluorometric detector. Contrary to the results of the current study, BPA was detected in milk samples in this study. The concentration of BPA was 0.003 up to 0.375 µg/g with an average of 0.015 µg/g reported for the samples [32].

Another contaminant measured in infant formula samples in this study was AFM1. The results of the levels of this mycotoxin were also compared with other studies. Sartori et al., 2023 in Brazil carried out research on AFM1 in 123 Infant Formulas by ultra-high performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS). AFM1 was detected in 18 (14.6%). The concentration levels ranged from 0.016 to 0.057 µg /kg. Three of the examined samples (0.040, 0.044, and 0.057 µg/kg) had AFM1values higher than the threshold set by EU limits (25 ng/kg) [33]. The detected ranges of AFM1 in this study were higher than in the current study (Table 2).

In 2023, Demir and Agaoglu determined the level of AFM1 in powdered infant formula (72 samples for premature, hipoallergenic, 0–6, 6–9, 9–12 and 12–36 months) by Enzyme Linked Immunosorbent Assay (ELISA) in Turkey. Results showed that AFM1 was quantified in 49% of the analyzed samples and the group of infant formulae aged 12–36 (8 samples) months had the highest level of AFM1 contamination. Five samples of baby formula exhibited AFM1 levels exceeding the local maximum permissible concentration (Türkiye Food Codex Regulation standards: 0.025 µg/kg). The percentage of contamination of infant food was higher than in the current study [34].

Hooshfar et al., 2020 in Iran measured the amount of AFM1 in 29 infant formula samples using HPLC-FLD and also performed a risk assessment with the resulting amount. AFM1 was determined in 3.4% of evaluated samples. The calculated HQ values were less than one, similar to the results of the current study. These findings suggest that there is no significant health concern related to this level of exposure [35].

Quevedo-Garza et al., 2020 studied the AFM1 contamination in infant formula (n = 55) using HPLC with fluorimetric detection in Mexico. AFM1 was detected in eleven of the analyzed samples (20%), which was higher than the allowable limit set by the European Union, ranging from 40 to 450 ng/L. The determined value is higher than the current study. The carcinogenic risk value revealed a high risk for the all groups of age (ranges of 0–6 and 6–12 months, and 1–2 years) [36].

Conclusion and future research

In this study, BPA and AFM1 in powdered milk available in pharmacies were quantified by HPLC containing a fluorescence detector after extraction with appropriate solvents. The amount of bisphenol A was not detected in all samples and the amount of aflatoxin M1 was lower than the permissible level. The results obtained are due to the absence of BPA in the packaging of infant formula and also the safety of raw milk used for infant formula. Overall, with the risk assessment conducted for AFM1, the most prominent and widely consumed brands of infant formula in pharmacies are safe in terms of the presence of BPA and AFM1.

Acknowledgements

The authors would like to thank Tehran University of Medical Sciences.

Abbreviations

- BPA

Bisphenol A

- AFM1

Aflatoxin M1

- TDI

Tolerance daily intake

- ELISA

Enzyme linked immunosorbent assay

- UHPLC-MS/MS

Ultra-high performance liquid chromatography-tandem mass spectrometry

- EDI

Estimated daily intake

- HQ

Hazard quotient

- LOD

Limit of detections

- LOQ

Limit of quantifications

- LDRs

Linear dynamic ranges

- FLD

Fluorescence detector

- BW

Body weight

- IARC

International agency for research on cancer

Author contributions

The samples was extracted by two authors G.M and E.MA. The analysis were performed by N.Y. Writing and editing was done by P.S, G.M, and N.S.

Funding

This study received financial support from Tehran University of Medical Sciences (project No: 14003).

Data availability

No datasets were generated or analysed during the current study.

Declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Di Pietro G, Forcucci F, Chiarelli F. Endocrine disruptor chemicals and children’s health. Int J Mol Sci. 2023;24(3):2671. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Ghassabian A, Vandenberg L, Kannan K, Trasande L. Endocrine-disrupting chemicals and child health. Annu Rev Pharmacol Toxicol. 2022;62(1):573–94. [DOI] [PubMed] [Google Scholar]

- 3.Kim JI, Lee YA, Shin CH, Hong Y-C, Kim B-N, Lim Y-H. Association of bisphenol A, bisphenol F, and bisphenol S with ADHD symptoms in children. Environ Int. 2022;161:107093. [DOI] [PubMed] [Google Scholar]

- 4.EFSA Panel on Food Contact, Materials E, Aids P, Lambré C, Barat Baviera JM, Bolognesi C, Chesson A, Cocconcelli PS, Crebelli R, Gott DM, Grob K, et al. Re-evaluation of the risks to public health related to the presence of bisphenol A (BPA) in foodstuffs. EFSA J. 2023;21(4):e06857. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Careghini A, Mastorgio AF, Saponaro S, Sezenna E, Bisphenol A. Nonylphenols, benzophenones, and benzotriazoles in soils, groundwater, surface water, sediments, and food: a review. Environ Sci Pollut Res. 2015;22:5711–41. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.van Asselt ED, Van der Fels-Klerx H, Marvin H, Van Bokhorst‐van de Veen H, Groot MN. Overview of food safety hazards in the European dairy supply chain. Compr Rev Food Sci Food Saf. 2017;16(1):59–75. [DOI] [PubMed] [Google Scholar]

- 7.Santonicola S, Ferrante MC, Murru N, Gallo P, Mercogliano R. Hot topic. Bisphenol A in cow milk and dietary exposure at the farm level. J Dairy Sci. 2019;102(2):1007–13. [DOI] [PubMed] [Google Scholar]

- 8.Vilarinho F, Sendón R, van der Kellen A, Vaz MF, Silva AS. Bisphenol A in food as a result of its migration from food packaging. Trends Food Sci Technol. 2019;91:33–65. [Google Scholar]

- 9.Agarwal A, Gandhi S, Tripathi AD, Gupta A, Iammarino M, Sidhu JK. Food contamination from packaging material with special focus on the Bisphenol-A. Crit Rev Biotechnol 2024:1–11. [DOI] [PubMed]

- 10.Ghahremani M-H, Ghazi-Khansari M, Farsi Z, Yazdanfar N, Jahanbakhsh M, Sadighara P. Bisphenol A in dairy products, amount, potential risks, and the various analytical methods, a systematic review. Food Chemistry: X. 2024;21:101142. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Seid A, Mama A. Aflatoxicosis and occurrence of aflatoxin M1 (AFM1) in milk and dairy products: a review. Austin J Veterinary Sci Anim Husb. 2019;1(1):1–12. [Google Scholar]

- 12.Awuchi CG, Ondari EN, Nwozo S, Odongo GA, Eseoghene IJ, Twinomuhwezi H, et al. Mycotoxins’ toxicological mechanisms involving humans, livestock and their associated health concerns: a review. Toxins. 2022;14(3):167. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Foerster C, Monsalve L, Ríos- Gajardo G. Occurrence of aflatoxin M1 in milk and exposure estimation for its consumption in the Chilean population. Food Control. 2023;148:109677. [Google Scholar]

- 14.Awuchi CG, Ondari EN, Ogbonna CU, Upadhyay AK, Baran K, Okpala COR, et al. Mycotoxins affecting animals, foods, humans, and plants: types, occurrence, toxicities, action mechanisms, prevention, and detoxification strategies—A revisit. Foods. 2021;10(6):1279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Akhtar S, Shahzad MA, Yoo S-H, Ismail A, Hameed A, Ismail T, et al. Determination of aflatoxin M1 and heavy metals in infant formula milk brands available in Pakistani markets. Korean J food Sci Anim Resour. 2017;37(1):79. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Hernández-Falcón TA, Monter-Arciniega A, Cruz-Cansino NdS, Alanís-García E, Rodríguez-Serrano GM, Castañeda-Ovando A, et al. Effect of thermoultrasound on aflatoxin M1 levels, physicochemical and microbiological properties of milk during storage. Ultrason Sonochem. 2018;48:396–403. [DOI] [PubMed] [Google Scholar]

- 17.Blanchard E, Zhu P, Schuck P. Chap. 21 - Infant formula powders. In: Handbook of Food Powders (Second Edition). edn. Edited by Bhandari B, Bansal N, Zhang M, Schuck P: Woodhead Publishing; 2024: 375–386.

- 18.El-Waseif M, Hashem H. Utilization of palm oils in improving Nutritional Value, Quality properties and Shelf-Life of Infant Formula. Middle East J Agric Res. 2017;6:274–81. [Google Scholar]

- 19.Santonicola S, Ferrante MC, Colavita G, Mercogliano R. Development of a high-performance liquid chromatography method to assess bisphenol F levels in milk. Italian J Food Saf 2021, 10(4). [DOI] [PMC free article] [PubMed]

- 20.Vaz A, Cabral Silva AC, Rodrigues P, Venâncio A. Detection methods for aflatoxin M1 in dairy products. Microorganisms. 2020;8(2):246. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Kılınçer M, Özyürek M. Comparison between top-down and bottom-up approaches in the estimation of measurement uncertainty in Bisphenol A analysis by HPLC-FLD. J Chem Metrol 2023, 17(2).

- 22.Kolarič L, Šimko P. Development and validation of HPLC-FLD method for aflatoxin M determination in milk and dairy products. Acta Chim Slovaca. 2023;16(1):99–108. [Google Scholar]

- 23.Iwegbue CM, Edeme JN, Tesi GO, Bassey FI, Martincigh BS, Nwajei GE. Polycyclic aromatic hydrocarbon concentrations in commercially available infant formulae in Nigeria: estimation of dietary intakes and risk assessment. Food Chem Toxicol. 2014;72:221–7. [DOI] [PubMed] [Google Scholar]

- 24.Ghaffarian-Bahraman A, Mohammadi S, Dini A. Occurrence and risk characterization of aflatoxin M1 in milk samples from southeastern Iran using the margin of exposure approach. Food science & nutrition; 2023. [DOI] [PMC free article] [PubMed]

- 25.Cao X-L, Popovic S, Dabeka RW. Trends of bisphenol a occurrence in canned food products from 2008–2020. Food Addit Contaminants: Part A. 2023;40(6):781–6. [DOI] [PubMed] [Google Scholar]

- 26.Sun X, Wang C, Wang H, Guo M. Effects of processing on structure and thermal properties of powdered preterm infant formula. J Food Sci. 2018;83(6):1685–94. [DOI] [PubMed] [Google Scholar]

- 27.Molina-García L, Fernández-de Córdova ML, Ruiz-Medina A. Analysis of Bisphenol A in milk by using a multicommuted fluorimetric sensor. Talanta. 2012;96:195–201. [DOI] [PubMed] [Google Scholar]

- 28.Ackerman LK, Noonan GO, Heiserman WM, Roach JA, Limm W, Begley TH. Determination of bisphenol A in US infant formulas: updated methods and concentrations. J Agric Food Chem. 2010;58(4):2307–13. [DOI] [PubMed] [Google Scholar]

- 29.Casajuana N, Lacorte S. New methodology for the determination of phthalate esters, bisphenol A, bisphenol a diglycidyl ether, and nonylphenol in commercial whole milk samples. J Agric Food Chem. 2004;52(12):3702–7. [DOI] [PubMed] [Google Scholar]

- 30.Karsauliya K, Bhateria M, Sonker A, Singh SP. Determination of bisphenol analogues in infant formula products from India and evaluating the health risk in infants asssociated with their exposure. J Agric Food Chem. 2021;69(13):3932–41. [DOI] [PubMed] [Google Scholar]

- 31.Brandão MLL, Umeda NS, Carvalho KR, de Filippis I. Investigação De um surto causado por Cronobacter malonaticus em um hospital maternidade em Teresina, Piauí: caracterização e tipificação por eletroforese em gel de campo pulsado. Vigil Sanit Debate Rio De Janeiro. 2015;3(3):91–6. [Google Scholar]

- 32.Cirillo T, Latini G, Castaldi MA, Dipaola L, Fasano E, Esposito F, et al. Exposure to di-2-ethylhexyl phthalate, di-n-butyl phthalate and bisphenol A through infant formulas. J Agric Food Chem. 2015;63(12):3303–10. [DOI] [PubMed] [Google Scholar]

- 33.Sartori AV, de Moraes MHP, dos Santos RP, Souza YP, Candido FS, da Nóbrega AW. Determination of Aflatoxins M1, M2, B1, B2, G1, G2 and ochratoxin A in infant formulas from Brazil using a modified QuEChERS method and UHPLC-MS/MS. Food Anal Methods. 2023;16(5):841–9. [Google Scholar]

- 34.Demir T, Ağaoğlu S. Exposure assessment of aflatoxin M1 through ingestion of infant formula in Türkiye. Turkish J Agriculture-Food Sci Technol. 2023;11(2):396–402. [Google Scholar]

- 35.Hooshfar S, Khosrokhavar R, Yazdanpanah H, Eslamizad S, Kobarfard F, Nazari F, et al. Health risk assessment of aflatoxin M1 in infant formula milk in IR Iran. Food Chem Toxicol. 2020;142:111455. [DOI] [PubMed] [Google Scholar]

- 36.Quevedo-Garza PA, Amador-Espejo GG, Salas-García R, Ramos-Peña EG, Trujillo A-J. Aflatoxin M1 determination in infant formulae distributed in Monterrey. Mexico Toxins. 2020;12(2):100. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No datasets were generated or analysed during the current study.