Abstract

In response to the growing demand of reducing greenhouse gas (GHG) emissions within maritime sector, Onboard Carbon Capture and Storage (OCCS) technologies provide as key solutions for tackling carbon dioxide (CO2) emissions from ships. This review paper offers a comprehensive overview of recent developments, challenges, and prospects of Carbon Capture and Storage (CCS) technologies considering specifically for onboard ship applications. Various Carbon Capture (CC) methods, ranging from post-combustion and pre-combustion capture to oxy-fuel combustion, are critically analysed concerning their operating principles, advantages, disadvantages and applicability in the maritime context. Temporary onboard CO2 storage is examined in its gaseous, supercritical, solid, and liquid states. In this regard, solid and liquid forms are found promising, although solid storage is not yet commercially mature. The review also addresses the challenges in implementing the CC technologies on ships, including space constraints, energy requirements, safety concerns, and economic viability. A comparative assessment is conducted to determine the most promising OCCS technologies. The study finds that post-combustion CC by chemical absorption requires more space than cryogenic and membrane separation, with the latter two deemed viable options, albeit with trade-offs in energy consumption and cost. The study would provide valuable insights and ideas for further research in the field of OCCS technologies.

Keywords: Onboard carbon capture and storage, Carbon neutral shipping, Maritime emissions challenges, Comparative assessment

Introduction

Background

It is important to control the significant increase in GHG emissions to address climate change. These gases trap heat in the atmosphere, causing global warming, rising sea levels, and extreme weather events, which harm ecosystems and human health. Reducing emissions helps stabilize the climate and protect the planet's future. In 2019, carbon dioxide (CO2) emissions from fossil fuel combustion alone reached 36.7 gigatons (Gt), contributing significantly to total GHG emissions of almost 50 Gt of CO2 equivalents (CO2,e)—a 40% increase compared to 1990 [1]. Even the brief decline in emissions in 2020 due to the COVID-19 pandemic [2] could not stop the upward trend, underlining the need for effective emission reduction strategies across all sectors.

This environmental crisis is unfolding during rapid global human development and industrial progress since the 20th century. These improvements have raised living standards, but at a significant cost to the environment. Industrial activities have greatly increased the concentration of CO2 in the atmosphere, worsening global warming and extreme climate conditions, as shown in recent studies [3, 4]. The energy and transport sectors are the main contributors, producing over two-thirds of GHG emissions [5]. Of particular concern is the transport sector, which accounts for around 25% of global emissions [6], with the shipping industry alone responsible for 12%—almost one billion tonnes annually [6]. The expected increase in global trade, which is expected to increase by almost 40% by 2050 [7], complicates this problem further. As economies grow, so does the demand for maritime transport, leading to projections of future GHG emissions. Forecasts for the year 2050 vary, with the International Maritime Organisation (IMO) predicting a range of 1100–2350 megatonnes per year (Mt/year) for maritime CO2 emissions [6]. The World Meteorological Organisation (WMO) also confirms that global warming is deviating from the targets set out in the Paris Agreement [8]. These targets include limiting global warming to well below 2 °C, striving for 1.5 °C, achieving net-zero emissions by 2050, enhancing resilience to climate impacts, and mobilising $100 billion annually to support developing nations in their climate efforts.

Considering the above, a number of measures have been suggested throughout the world to tackle this issue. In this respect, the European Union (EU) and China have set ambitious goals to combat climate change. The EU, along with its member states, is committed to making the European economy carbon-free by 2050 [9]. China has set a target to achieve carbon neutrality by 2060 [10]. Japan is planning to shift to LNG as a bridging fuel and is testing dual-fuel internal combustion engines (hydrogen/ammonia) on small coastal ships, with plans to use them on larger ocean-going ships once the technology advances [11]. Norway is targeting a 45% reduction in carbon emissions from domestic shipping before 2030, employing legislative measures and financial incentives to promote low-carbon initiatives [12].

In the UK, Lloyd’s Register has analysed the factors affecting the construction and operation of zero-emission ships, highlighting the major challenge of high operating costs when converting ships [13]. In addition, in 2018, the IMO adopted an initial strategy to reduce GHG emissions from ships, which sets out specific targets and phased measures to reduce emissions [14]. In June 2021, the IMO adopted important short-term measures with the aim of reducing the carbon intensity of all ships by at least 40% by 2030 [7]. More recently, in July 2023, the IMO adopted a revised GHG strategy that significantly raises the ambition for the global shipping industry. In contrast to the original target of a 50% GHG reduction by 2050, the updated strategy sets stricter targets [15]. Starting from 2008, the new targets include a 20% reduction in waking GHG emissions by 2030, a 70% reduction by 2040 and a commitment to achieve net-zero emissions by or around 2050 [15].

However, the future of the shipping industry depends on global standards being set and new technologies being deployed. There is an urgent need for action as the maritime sector plays a leading role in tackling this environmental challenge. This situation requires creative solutions, strict regulations and international cooperation to ensure a more sustainable future.

Alternative decarbonisation solutions for maritime transportation

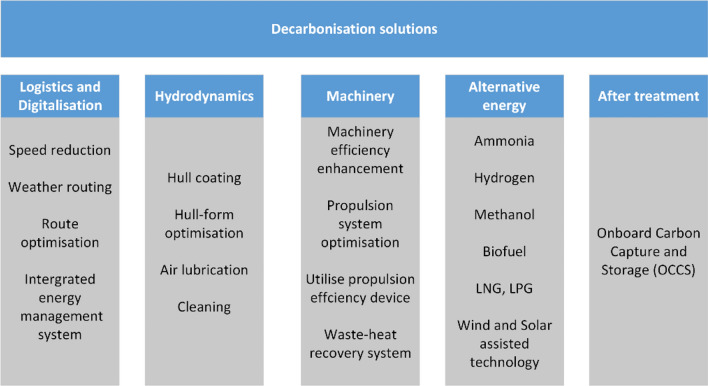

To meet the IMO’s stringent targets [15], the shipping industry needs to adopt a new operational paradigm where innovative materials, technologies, processes, designs and practises are rapidly introduced for both new and existing ships. Decarbonisation strategies suitable for ships can be broadly divided into the following five key categories [16]:

Logistics and digitalisation

Strategies such as slow steaming, weather routing, route optimisation and the integration of ship energy management systems are essential to achieving emissions reduction targets.

Hydrodynamics

Innovations in hull hydrodynamics, hull coating and air lubrication can have a significant impact on the energy efficiency of ships.

Machinery

Improving engine efficiency, optimising propulsion systems, using devices to increase propulsion efficiency and implementing waste heat recovery are crucial to improving the energy efficiency of ships.

Alternative energy

The maritime sector is exploring alternative fuels such as ammonia, hydrogen, methanol, liquefied petroleum gas (LPG), biofuels (such as bio-oils and hydrogen-treated vegetable oils) and liquefied natural gas (LNG), which is mainly used in LNG carriers. In addition, fuel cells, hybrid systems and wind and solar assist technologies could reduce emissions and improve energy efficiency. These alternatives promise to reduce GHG emissions, even if their widespread introduction is associated with challenges such as engine compatibility and bunker infrastructure.

After treatment

As zero-emission technologies evolve, CCS can serve as a medium- to long-term interim solution to reduce CO2 emissions while reducing competition for carbon-neutral fuels.

Figure 1 shows the solutions for decarbonisation, which are divided into five alternatives. Numerous studies have analysed the effectiveness of these measures and strategies in improving the energy efficiency of ships and reducing GHG emissions. While biofuels are promising due to their environmental friendliness, energy density and fungibility and have the potential to reduce GHG emissions by 100% based on a well-to-wake analysis, practical challenges such as storage, engine compatibility and bunker infrastructure limitations limit their applicability [17] and [18]. The feasibility of utilising biofuels depends on the type of feedstock used, with newer generations of biofuels offering potential solutions to some of these challenges. Furthermore, tackling emissions in shipping is primarily about improving the efficiency of main and auxiliary engines [19]. Waste heat recovery with systems such as the organic Rankine cycle is very promising for shipping [20–22]. Scientists have also looked at combined cooling, heating and power (CCHP) cycles fuelled by waste heat to meet various onboard energy needs [23].

Fig. 1.

Solutions that can contribute to decarbonise shipping

On the other hand, the majority of individual approaches relevant to logistics and digitalisation, with the exception of slow steaming, generally only lead to a limited reduction in GHG emissions, as extensive studies such as the comprehensive study by Balcombe et al. [24] showed. Their findings suggest that technologies like route optimisation and fuel management offer modest benefits, but alone they are insufficient for significant decarbonization. Slow steaming, however, provides more substantial reductions. The study emphasizes that achieving the target of a 50% GHG reduction by 2050 requires a combination of strategies, including alternative fuels, efficiency measures, and strong policy support.

Optimising the propulsion and energy systems of ships is of central importance for improving energy efficiency. While solar and wind energy technologies are relatively mature, the low power density and volatility of these sources suggest that fuel cell and hybrid technologies will become the dominant energy sources for environmentally friendly ships [25].

Conventional marine fuels such as Marine Diesel Oil (MDO) and Heavy Fuel Oil (HFO) contain high carbon content [26], making the transition to low or zero carbon fuels an urgent concern. In this context, bridge fuels such as LNG [27] and alternative fuels such as hydrogen [28] and ammonia [29] are gaining importance as clean energy options. Orders for new ships indicate a shift towards alternative fuels, with companies such as A.P. Moller-Maersk ordering dual-fuel methanol container ships [30], followed by other industry leaders such as CMA and CGM [31], Cosco [32] and Cargill [33]. In addition, according to Clarksons Research, there were 90 newbuilding orders for ammonia-capable ships in 2022 as a whole, representing 11% of tonnage, while 43 orders (7%) were for methanol-capable ships and 3 for hydrogen-capable ships [34].

In the face of uncertainty about the availability of low-emission fuels, shipowners are adapting their strategies by either upgrading existing ships or building new fleets that can run on both conventional and alternative fuels. This approach recognises that it remains difficult to completely eliminate emissions from ships unless a complete reliance on alternative fuels becomes feasible. In this regard, one possible solution is the capture of carbon emissions from ships using commercially recognised CCS technologies. As OCCS would utilise a proven technology, it requires less research and development compared to alternative fuels. In addition, OCCS can achieve significantly higher emission reduction rates than the fuel-saving measures mentioned above and accelerate progress towards the IMO target of 85% emission reduction per ship [13]. However, the amount of energy that OCCS requires at the expense of fuel must be taken into account.

Current development of OCCS

This subsection provides an overview of key CCS projects in the maritime sector, focusing on the CC-Ocean [35], EverLoNG [36], decarbonICE [37], Green Marine [38], and emerging developments under the Bulk Carrier Carbon Capture [39] and REMARCCABLE [40] projects. Although available information from open sources is limited, the primary objectives and progress of these initiatives are presented below.

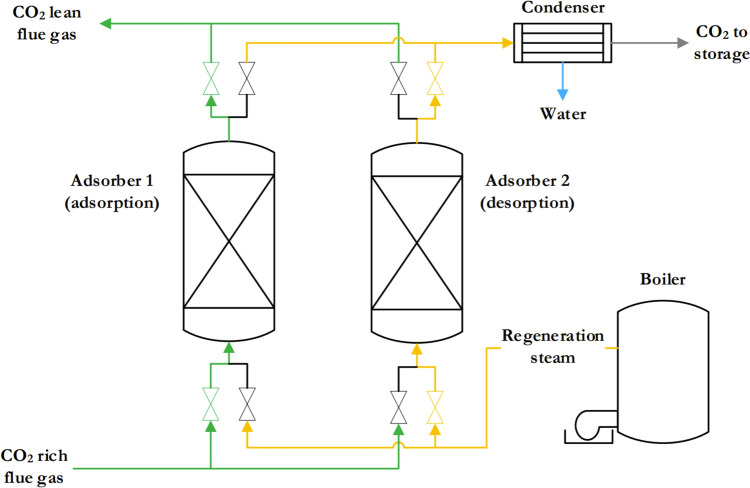

The CC-Ocean project [35] is a groundbreaking initiative focused on validating onboard CO2 capture systems aboard the Corona Utility, an 88,000-tonne bulk carrier. Led by Mitsubishi Shipbuilding Co. Ltd. and Kawasaki Kisen Kaisha Ltd., and supported by Japan’s Ministry of Land, Infrastructure, Transport, and Tourism, this project employs post-combustion chemical absorption to capture CO2 from the exhaust gases of marine engines. Six months of operation showed that the system met the initial project targets in terms of CO2 quantity, ratio, and purity (greater than 99.9%), proving the feasibility of CO2 capture in a commercial maritime context [41]. To understand the schematic of OCCS arrangement of CC-Ocean, Fig. 2 is referred.

Fig. 2.

Schematic diagram of the CCS technologies for CC-Ocean according to [35]

In the EverLoNG project [36], TotalEnergies and Carbotreat are advancing Ship-Based CC (SBCC) technology by installing a CO2 capture prototype aboard an LNG-powered carrier. This system aims to capture ten tonnes of CO2 over 3000 h of operation, with additional testing planned on other vessels. The project aims to demonstrate a 70% reduction in CO2 emissions from ships, furthering the development of market-ready SBCC solutions.

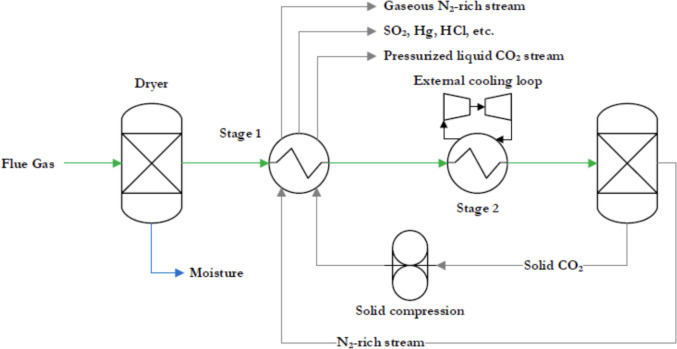

The decarbonICE project [37] is focused on an innovative cryogenic CCS system, capturing CO2 from exhaust gases, converting it into dry ice, and storing it in seafloor sediments. This project, initiated in 2019, is exploring low-energy CO2 capture technologies (predicted energy penalty below 10%), with the goal of achieving carbon-negative shipping when integrated with future carbon–neutral fuels.

Green Marine [38], funded by Horizon Europe, aims to accelerate climate neutrality in waterborne transport by retrofitting existing ships with emission control technologies. The project includes developing protocols for retrofitting engines and installing systems for CO2 capture and energy saving, with the MV Coruisk, a passenger ferry in Scotland, set to serve as the test vessel for these technologies.

Under development, two key projects are advancing CC systems for ships. The Bulk Carrier Carbon Capture project Marine [39], approved in principle by Bureau Veritas (BV), involves two bulk carriers, the Tianjin Venture and CSSC Wan Mei, equipped with a CO2 capture system that uses an organic amine solution for chemical absorption. Laboratory tests have demonstrated a CO2 capture rate of over 85%.

The REMARCCABLE project [40], approved by the American Bureau of Shipping (ABS), is testing a CO2 capture system aboard a medium-range tanker operated by Stena Bulk. This project will evaluate the performance of the system over a two-year period, with sea trials expected to involve CO2 capture during deep-sea voyages. Stena Bulk intends to extend the use of this system beyond the pilot phase, indicating strong potential for long-term integration of CCS technology in maritime operations.

Based on the limited information provided by the aforementioned OCCS projects, it is clear that the amount of CO2 that needs to be captured and stored during a typical voyage depends on several factors, such as the size of the vessel, the type of fuel used, and the operational conditions. While precise figures on CO2 mass and storage volumes for specific ships are not readily available, these ongoing projects have provided target capture rates and system designs. For instance, the CC-Ocean project [35] and EverLoNG project [36] focus on achieving CO2 capture rates of around 70–85% during operation. These systems are designed to capture and store CO2 from exhaust gases emitted by marine engines, but the precise volume of CO2 captured per day will vary depending on the engine load and fuel type used during the voyage. For example, in the EverLoNG project [36], the objective is to capture up to 10 tonnes of CO₂ over 3000 operational hours, giving an idea of the scale of CO₂ capture required.

In terms of storage, the mass and volume required depend on the method of CO2 storage, whether it’s stored as liquid CO2 or solidified into dry ice (as in the decarbonICE project [37]). The space required for onboard CO2 storage is also influenced by the storage method, with liquid CO2 requiring significant tank volumes, while solid CO2 in the form of dry ice would require more specialised storage systems. The storage capacity of a typical vessel, such as a bulk carrier or tanker, would need to be tailored to the specific CO2 capture and storage systems installed. The required space for different technologies is further discussed in Sect. 5, and the various factors influencing storage volume and mass are covered in Sect. 7.2.2.

The above is also related to the space required for CO2 purification as it depends on the purification method, the scale of CO2 capture, and the design of the system. For compact technologies like membrane separation, the space needed could be as little as a few cubic meters, while more complex systems such as cryogenic separation may require larger spaces, potentially hundreds of cubic meters due to the need for cryogenic storage tanks. Chemical absorption and oxy-fuel combustion systems also demand significant space for towers, reactors, and integration with the ship's infrastructure. Additionally, the amount of CO2 captured and stored plays a significant role in determining the space requirement, with larger ships needing more space for purification and storage systems. So far, the values are not specific and vary case to case.5

On the other hand, the rate of CO2 capture while cruising varies by technology and ship type. For example, the Bulk Carrier Carbon Capture project [39] targets a CO2 capture rate exceeding 85% from exhaust gases, while the REMARCCABLE project [40] aims for continuous CO2 capture during deep-sea voyages. The specific rate of CO2 capture is detailed in Sect. 7.2.4, which covers different technologies and their respective efficiencies.

Aim of this study

CCS technologies are primarily used for onshore projects, such as Shell Canada's Quest in Alberta, where the CCS facility captures over one million tonnes of CO2 annually from the Scotford Upgrader and has stored over 7 million tonnes since 2015 [42], with only a limited number used on ships. The lack of current commercial shipping applications of CCS emphasises the need for further research and development. While substantial progress has been made in onshore CCS technologies, the application of these systems onboard ships presents unique challenges, such as limited space, high energy requirements, and the need for cost-effective solutions. These challenges highlight the urgency for dedicated research to adapt and develop CCS technologies suitable for maritime use.

The main objective of this study is to conduct a comprehensive review of relevant articles and project reports focussing on Onboard Carbon Capture and Storage (OCCS) to understand the operating principles, advantages and disadvantages, and recent advances of CCS technologies for onboard applications. This review aims to fill the gap in the existing literature, which predominantly focuses on land-based CCS applications. By analysing a wide range of sources, this paper provides a deeper understanding of how CCS technologies can be adapted to the unique conditions of ships. This paper also addresses the identification of OCCS-specific challenges through a thorough and structured literature review, followed by a comparative assessment of different CC technologies to identify promising solutions based on their potential to address the identified challenges. Temporary on-board CO2 storage options, including gaseous, supercritical, solid and liquid forms, are also investigated as an integral part of the analysis.

The findings of this overview study will assist stakeholders in identifying the key challenges hindering the implementation of commercially viable onboard CCS technologies. In addition, the study provides insights for selecting the most promising technology based on preferences in terms of space, energy requirements or cost, while taking other challenges into account. This dual approach of reviewing existing technologies and assessing the specific needs of the maritime industry offers a more comprehensive analysis and a valuable framework for future developments.

The paper is organised as follows: Sect. 2 outlines the methodology for selecting relevant literature and conducting a comparative assessment. Following this, Sect. 3 explores the potential of OCCS through literature and critical review. In Sect. 4, an overview of different CC technologies, is presented including their working principles, advantages, disadvantages, and different research outcomes for onboard applications. Section 5 delves into the scope of onboard temporary CO2 storage in the form of gaseous, supercritical, solid or liquid state. Section 6 lists the challenges identified for OCCS implementation. Subsequently, Sect. 7 conducts a comparative assessment among different CC technologies, considering their potential to be installed onboard, while addressing the challenges mentioned in Sect. 6. Finally, Sect. 8 concludes with the findings of this review paper.

Methodological approach

The methodology applied in this study follows a systematic approach to gather knowledge about the OCCS technologies and the associated challenges for on-board implementation and to conduct a comparative study to determine the potential of each technology to overcome these challenges. The methodology comprises five main steps: (a) literature search and selection, (b) data extraction, (c) data synthesis, (d) data analysis and (d) comparative assessments and discussion.

Figure 3 illustrates the methodological approach of this study and provides a detailed insight into the components of the individual steps. These steps are explained in more detail in the following paragraphs of this section.

Fig. 3.

Methodological flow chat

Literature search and selection

A comprehensive search was conducted in several databases, including ScienceDirect, Springer, MDPI, IEEE Xplore, ResearchGate, ACS publications, SAGE journals, Frontiers, Taylor & Francis, SSRN, institutional libraries and official websites. The aim was to find literature on Onboard Carbon Capture and Storage (OCCS) for the period 2013 to 2023 using keywords such as 'Onboard/Shipboard Carbon Capture and Storage', ' Carbon Capture and Storage for ships' and 'Carbon emission reduction technologies for ships' The search yielded 46 relevant publications dealing specifically with OCCS.

Although there is an abundance of publications dealing with CCS for industrial applications, there are few that deal with on-board implementation. To fill this gap and comprehensively analyse the operating principles, advantages, disadvantages and recent developments of CCS for both industrial and on-board applications, the authors applied the snowball method. The snowball method consisted of using source lists in relevant articles to create a network of related literature. This method was particularly useful given the abundance of literature on industrial CCS and allowed the authors to selectively choose 52 supporting documents. This curated selection served to justify and enhance the key information presented in the study, resulting in a well-rounded examination of both general CCS principles and specific considerations for on-board implementation. Table 1 contains the keywords used, the inclusion and exclusion criteria and the overall selection of 46 and 52 reports/papers for OCCS and CCS in general, respectively.

Table 1.

Literature selection for OCCS and CCS in general

| Database | Keywords | Inclusion criteria | Exclusion criteria | Final selection (OCCS) | Final selection (general CCS) |

|---|---|---|---|---|---|

| ScienceDirect | ‘Onboard/Shipboard CC and Storage’, ‘CC and Storage for ships’, ‘carbon emission reduction technologies for ships’ | OCCS/CCS methods, recent advancement, implementation challenges for ships, overcoming strategies, comparison assessments, explains advantages and disadvantages | Outdated studies, irrelevant topics, OCCS/CCS supply chain, ship/CO2 transportation, CO2 sequestration | 17 | 35 |

| Springer | 1 | 3 | |||

| MDPI | 2 | 1 | |||

| IEEE Xplore | 3 | – | |||

| ACS publications | 2 | 1 | |||

| SAGE journals | 1 | – | |||

| Wiley | – | 2 | |||

| Frontiers | 1 | 1 | |||

| Chemistry Europe | 1 | ||||

| Taylor & Francis | 2 | – | |||

| SSRN | 1 | – | |||

| Institutional libraries | 3 | 1 | |||

| Information/reports from Official webpages | 13 | 7 |

Furthermore, literature on shipping emissions statistics, chemical priorities of CO2, different codes, alternative initiatives for GHG reduction, achieving IMO's 2050 emission target, and Technology Readiness Levels (TRL) for emission reduction technologies were considered. In total, 37 reports/papers of relevant literature were identified for this purpose.

Data extraction

The literature selection section clarifies that the authors employed the keywords and databases to pinpoint relevant reports/papers related to OCCS, and snowballing technique for CCS in general. This approach facilitated the extraction of data into three distinct groups, streamlining the subsequent investigation in this study. Figure 4 illustrates the distribution of identified reports/papers based on their respective criteria, which are onboard CCS, CCS in general and other papers/reports explain shipping emission, alternatives to reduce GHG and so on.

Fig. 4.

Data extraction based on respective criteria

Data synthesis

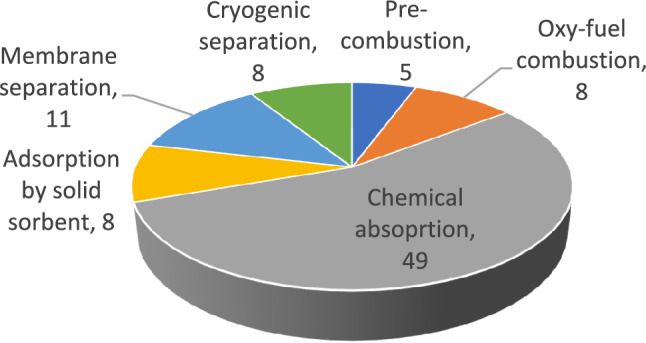

The reports/papers discussing the OCCS and CCS in general were re-organised focusing on various onboard CC and storage technologies. This included the examination of pre-combustion, oxy-fuel combustion, post-combustion by chemical absorption, adsorption by solid solvents, membrane separation, and cryogenic separation. Additionally, the temporary storage of CO2 in gaseous, subcritical solid and liquid forms was considered as an integrated component of CC. Figure 6 illustrates the distribution of identified reports/papers for different CC technologies. It is important to note that pertinent reports/papers discussing multiple CC technologies, such as review papers or those conducting comparative assessments, are counted as inputs for each respective CC technology when preparing Fig. 5.

Fig. 6.

Schematic of pre-combustion capture

Fig. 5.

Data organised based on different CC technologies

Data analysis

The study included a thematic analysis of reports/papers for each CC technology, focussing on the operating principles, advantages, disadvantages, challenges for on-board installation and their possible solutions. In addition, the thematic analysis not only highlighted the challenges but also looked for possible solutions. This approach contributed to a more holistic assessment of the individual CC technologies and provided insights not only into the hurdles, but also into the possible ways to overcome them in the context of on-board applications. By categorising the reports/papers thematically, the study aims to provide a differentiated understanding of the potential applications of the individual CC technologies in the maritime industry.

Comparative assessment and discussion

A comparative assessment was then carried out based on the findings from the thematic analysis of the reports/papers. As there are hardly any reports/papers dealing specifically with OCCS, the authors considered more general CCS-based reports/papers to gain additional information and improve the study. The assessment aimed to address the challenges identified in the thematic analysis of reports/papers in the implementation of onboard CC technologies. The assessment was conducted in two different phases. In the first phase, the focus was on determining the feasibility of the technologies for on-board installation. A follow-up assessment was then carried out, focussing on the remaining challenges that the CC technologies need to overcome.

The final conclusions were based on the suitability of on-board CC technologies, considering both the feasibility of installation and the capabilities of the technologies to overcome the identified challenges.

Potential of OCCS

In the quest to decarbonise the maritime industry, OCCS could be a promising solution for reducing CO2 emissions from ships. Although research in this field is relatively scarce, recent studies have triggered a wave of innovation and exploration, paving the way for a sustainable future on the high seas.

Lloyd's Register's (LR) readiness assessment on OCCS [43] explores alternative solutions for the capture and storage of CO2 emissions on ships. Two main methods are described: pre-combustion capture, where the ship's fuel is converted into a gas and the CO2 is captured before combustion, and post-combustion capture, which includes chemical absorption, membrane technology, cryogenic capture, oxy-fuel combustion and capture with solid sorbents. The captured CO2 can be stored on-board in liquid or solid form but must be offloaded for further processing in a harbour, either for permanent underground storage or for conversion into materials for various industries.

Luo and Wang [44] laid the foundation for maritime CC by investigating solvent-based processes for capturing CO2 from the energy system of a cargo ship. Their pioneering work opened new avenues and piqued the interest of researchers and industry experts. Building on this initial study, Feenstra et al. [45] took a significant leap forward by investigating the feasibility of integrating post-combustion CO2 capture technologies specifically for maritime applications. Various solvents, including a 30% wt aqueous solution of mono-ethanolamine (MEA) and 30% wt aqueous piperazine (PZ), were examined in detail. In addition, the potential of ammonia (NH3) as a solvent for CC on-board liquefied natural gas (LNG)-fuelled CO2 tankers has been investigated, highlighting the versatility of this approach [46].

One of the most intriguing facets of OCCS lies in its ability to liquefy the captured CO2 for storage. This transformative step is the answer to the challenge of effectively dealing with captured emissions. In addition, there are futuristic visions that propose capturing CO2 from ship exhaust, which could then be subjected to cryogenic processes and converted into dry ice, offering a new perspective on CC and utilisation [47]. While the method temporarily captures CO2 and delays its release, it requires a closed CO2 capture loop to be effective. However, the feasibility of this method remains uncertain due to its low conversion efficiency. The maritime industry envisions a hydrogen-based future in which containerised liquefied CO2 becomes a valuable feedstock to produce synthetic carbon fuels. This vision depends on the large-scale production of hydrogen (H2) from renewable sources such as solar or wind energy. When H2 is abundant, scientists and process/chemical engineers can synthesise various synthetic fuels, including methane (CH4) or methanol (CH3OH), from H2 and CO2. This transformative process not only reduces carbon emissions, but also offers the opportunity to create sustainable energy sources and lead the industry towards a greener horizon [48].

In the search for more efficient and sustainable CC technologies, researchers have proposed several innovative solutions. These advances are essential to overcome the limitations of conventional land-based CC processes. Offshore environmental conditions, such as high salinity, humidity, and harsh marine elements, present unique challenges for the durability and performance of CC technologies. One key difference between offshore and land-based applications is the need for all equipment and materials to be marine-grade or marine-approved. These materials are specifically designed to resist corrosion from seawater and other environmental factors, ensuring long-term reliability. While this requirement increases equipment costs due to the need for specialised materials and certifications, it is essential for ensuring safety and regulatory compliance.

For absorption-based technologies like MEA-based CO2 capture systems, a key challenge is the need for water to replenish the MEA solution. Using desalinated seawater offshore could be a practical solution, as it would reduce the need for separate distilled water storage. However, desalinated seawater may contain impurities that could affect the performance and longevity of the MEA solution, requiring extra treatment. If desalinated seawater isn't viable, a separate distilled water tank would be needed, adding complexity to the system. Other limitations include low vapour loading capacity, significant energy consumption during solvent regeneration, large equipment dimensions, high equipment corrosion rates and solvent degradation. The use of advanced solvents [49] and [50], optimised operating conditions [51] and state-of-the-art column internals [52] increases the efficiency of the deposition process. In addition, technologies such as intercoolers [53], reheaters [54] and flue gas precoolers [55] help to reduce energy consumption and make on-board CC a more viable option for large-scale implementation.

Flue gas compression and expansion [56] and the introduction of multiple feeds and semi-clean solvent configurations [57] optimise the capture process and ensure a higher CO2 removal rate. Rich solvent recycling systems [58] and square columns [59] further improve the overall efficiency of onboard CC systems, making them more environmentally friendly and economically viable. These advances emphasise the industry's commitment to cleaner, safer and more energy-efficient solutions for CC at sea.

In the area of process integration, innovative technologies such as heat pumps [51] and self-heat recovery techniques [52] offer a holistic approach to improving the overall energy efficiency of onboard CC systems. These integrative methods not only reduce operating costs, but also help to minimise the environmental footprint of CC processes. In addition, process intensification techniques, including reactive absorption [60] and rotating fixed beds [61], have shown remarkable potential. These methods pave the way for smaller, cleaner and safer technologies that make CC an increasingly attractive option for the maritime sector.

In addition, research efforts have focussed on evaluating on-board CC from an Energy Efficiency Design Index (EEDI) perspective. Studies by Stec et al. [26] and Lee et al. [62] have shown that OCCS technology can significantly reduce the EEDI and thus contribute to improved energy efficiency of ships.

In short, ship-based CC is at the forefront of the maritime industry's transition to sustainability. The industry is paying increasing attention to OCCS technology, with initiatives such as the OGCI and Stena Bulk report [63] emphasising its technical feasibility. Pilot implementations such as the small onboard CC system installed on a Japanese coal carrier owned by shipping company K Line [64] demonstrate the practical progress being made in the introduction of OCCS. Although challenges related to high capital expenditure (CAPEX) and operating expenditure (OPEX) remain, OCCS stands out as a proactive and pragmatic solution for significant emission reduction in the maritime sector. As OCCS research and development continues, the technology is poised to mature rapidly, making it a viable and efficient tool on the maritime industry's path to decarbonisation.

Overview of CC technologies

This section presents CC technologies (CCS) and provides insights into the current status, progress, existing literature and research, with a particular focus on the application of onboard CC. In general, three methods for CC can be distinguished: pre-combustion capture, oxy-fuel combustion capture, and post-combustion capture.

Pre-combustion capture

Operating principle

Pre-combustion capture focuses on the removal of CO2 prior to the combustion of fossil fuels. This method includes gasification and reforming processes of fossil fuels with air and water vapour, producing CO2 and H2. These processes include steam reforming, which produces CO and H2, and the water–gas shift reaction, which converts CO to CO2, as described by Wang et al. [65]. The resulting CO2 and H2 are separated using gas separation techniques, with the CO2 captured for storage and H2 available as fuel for hydrogen gas turbines. Pre-combustion capture is characterised by low-energy consumption and high separation efficiency, allowing almost 90% of CO2 to be captured from the fuel source [66]. Figure 6 illustrates the entire pre-combustion capture process flow.

Advantages and disadvantages of pre-combustion capture for onboard application

While existing reports/papers examine the advantages and disadvantages of pre-combustion capture for industrial use, this study aims to assess the pros and cons of applying pre-combustion capture technology in the context of its onboard application. Table 2 is prepared in this regard. The information provided in Table 2 is utilised in the comparative study conducted in Sect. 7 of this study.

Table 2.

Advantages and disadvantages of onboard pre-combustion capture

| Advantages | Disadvantages |

|---|---|

| Production of hydrogen (H2) for energy generation [67] | Elevated capital expenditure (CAPEX) for syngas generation components, reactor tanks, and hydrogen fuel engine modifications |

| Accelerating adoption of H2 as an alternative fuel [68] | Less economically favourable compared to post-combustion CC due to higher CAPEX [68] |

| Reduced energy requirements for CO2 compression and storage due to capturing CO2 at elevated pressure [68] | Filtration of non-convertible impurities required |

| The energy demand for the capture and stripping processes is lower compared to post-combustion CC [69] | Disruption in syngas production halts H2 production, leading to loss of propulsion and auxiliary generator fuel without a bypass [68] |

| Higher CO2 content in syngas enhances CC efficiency [69] | Need to minimise H2 production and storage in advance due to explosive nature, increasing risk mitigation efforts |

| Cannot avoid impact on ship stability even though having smaller equipment size compared to post-combustion CC | |

| Vibrations affecting pre-combustion CC process; susceptible sensors and moving parts to damage | |

| Requirement for steady-state operation due to significant effect on energy conversion process | |

| Difficulty in adapting to fluctuating H2 demand during manoeuvres, necessitating additional measures like H2 buffers or dual-fuel engines |

Research on onboard application of pre-combustion capture

So far, no literature sources have been found that deal with pre-incineration on seagoing ships. Only one example of pre-combustion capture was found, the HyMethShip concept [70]. This innovative concept integrates electromethanol energy storage, an on-board pre-combustion CC system and a dual-fuel combustion engine. The main objective of the concept is to create an almost closed loop for CO2 by integrating CC on-board. The captured CO2 is unloaded in the harbour and converted into electro-methanol, which is then used as fuel for the ship. An economic and life cycle analysis is also carried out in this context. This process is made possible by a pre-combustion process that converts electro-methanol into hydrogen and CO2. The assessment of this system extends from the wellhead to the ship's propeller, with a focus on ship operations in the North Sea until 2030 [70].

Oxy-fuel combustion capture

Operating principle

Oxyfuel combustion converts fossil fuels into CO2 and water vapour by burning them in the absence of atmospheric oxygen, assuming a fuel composition of CxHy without sulphur and nitrogen. Despite the simplicity of capturing CO2 and water vapour in theory with complete combustion, combustion is never 100% efficient in practise. In oxyfuel combustion, CO2 and water vapour are separated by condensation, as shown in Fig. 7. The success of this process depends on efficient separation of the water vapour, aiming for very low concentrations to enable effective CO2 compression and liquefaction. To achieve this, special drying systems are required due to the extremely low concentrations. Currently, oxyfuel combustion is used in the metallurgical industry and in coal-fired power plants [71]. Coal with the general formula CxHyNzSa may contain traces of other components such as ash, which, if not processed, will cause problems downstream and ultimately result in high maintenance costs. Despite its proven effectiveness in certain industries, interest and investment in oxyfuel combustion capture is limited in other sectors, as highlighted by Gür [72].

Fig. 7.

Schematic of oxy-fuel combustion capture

Advantages and disadvantages of oxy-fuel combustion capture for onboard application

The advantages and disadvantages pertinent to oxy-fuel combustion capture for onboard application are outlined in Table 3. This table serves as a reference point for the comparative study conducted in Sect. 7 of this study.

Table 3.

Advantages and disadvantages of onboard oxy-fuel combustion capture

| Advantages | Disadvantages |

|---|---|

| Easy capture of CO2 due to exhaust primarily containing CO2 and water vapour [73] | The Air Separation Unit (ASU) required for this process incurs high initial investment costs and demands substantial electricity [74] |

| Significant reduction in NOx emissions due to absence of nitrogen in combustion process [73] | Preventing air from entering combustion process and potential engine replacements are necessary but costly measures, hindering feasibility for retrofit applications [75] |

| Possibility of 0% NOx emissions with 100% pure oxygen | High risk of oxidising effect due to substantial amounts of highly concentrated oxygen, requiring protection of all metal surfaces against contact with O2 stream |

| No impact on ship's movement due to absence of free-moving liquids or solids | Limited fuel choice as all impurities are counterproductive to objectives and need to be addressed by aftertreatment |

| No need for heat for regeneration, potentially cost-effective in processes with limited waste heat [74] | Requirement for new engine materials to withstand high temperatures and difficulties in accommodating high-power demands of Air Separation Unit (ASU) in limited ship spaces [65] |

| Generation of vibrations itself requiring a special engine for operation | |

| Safety concerns related to production and storage of oxygen add complexity to its marine application, necessitating a Hazard Identification (HAZID) and Hazard and Operability (HAZOP) study | |

| Technical defects in system may lead to loss of propulsion; inability to easily bypass compared to post-combustion capture |

Research on onboard application of oxy-fuel combustion capture

There are currently no publications outlining concepts for the implementation of oxyfuel combustion on-board ships. However, a feasibility study conducted by Li et al. [76] examines the conversion of a conventional diesel-powered inland ship to an oxyfuel combustion system. While the study focuses on reducing oxygen consumption while maintaining the same energy output, it ignores crucial aspects such as space requirements, practicalities on-board and economic considerations. Interestingly, this concept opts to store the required oxygen in cylinders instead of producing it through an ASU [76]. Despite these challenges, oxyfuel combustion is promising if these hurdles can be overcome.

Post-combustion capture

Post-combustion CC involves the capture of CO2 from exhaust gases in flue gas environments after the combustion of carbonaceous fuels (as shown in Fig. 8). This method is often used in existing power plants [72]. In shipping, this technology can be used without the need to modify the engine or the entire system, only adjustments to the existing exhaust gas cleaning system are required. Since most marine engines have a turbocharger, the post-combustion capture system must comply with the engine manufacturer's specifications regarding minimum backpressure in order not to impair the performance of the turbocharger and the overall efficiency of the engine. Compared to pre-combustion capture and oxy-fuel combustion capture, post-combustion capture is easier to implement and requires relatively low fixed investment. It is also the most technically mature and practical method for the shipping industry. Post-combustion capture utilises various techniques, including chemical absorption, adsorption, membrane separation and cryogenic separation, which are explained in the following subsections.

Fig. 8.

Schematic of post- combustion capture

Absorption by chemical solvents

Chemical absorption for CC represents a well-established and mature technology, particularly in the domain of post-combustion capture methods [77]. This approach involves utilising chemical solvents to capture CO2 emissions generated during industrial processes, making it a crucial component of GHG mitigation strategies. Significantly, large-scale applications such as coal-fired power plants have effectively implemented this technology for CO2 removal from their exhaust gases [78]. However, ongoing research efforts are dedicated to further improve the efficiency and effectiveness of this method [79].

Operating principle

Conventional absorption technology for CC consists of two main units: the absorber and the stripper. The absorber uses a lean absorption solvent to capture CO2 from the exhaust gas, while the stripper regenerates the solvent [77]. Effective mass transfer of CO2 between the gas and liquid phases is essential in both processes. The absorber, which often requires additional exhaust fans or blowers to overcome the increased pressure drop [77], is usually located in the flue gas stream and may include multiple columns of structured packing [75]. Conversely, the flue gases undergo pre-treatment to remove impurities before entering the absorber [77].

Impurities contained in the flue gas and the high exhaust gas heat, which can exceed temperatures of 300 °C and depends on the engine load and power, can lead to solvent degradation. Therefore, a pre-treatment system with a direct contact cooler is essential to cool the solvent down to room temperature [80]. During post-combustion CC, the lean absorbent flows in countercurrent with the exhaust gas and facilitates the removal of CO2 by absorption. The reversible chemical bonding between CO2 and the solvent enables efficient capture. The CO2-rich solvent is then channelled into the stripper unit, while the treated exhaust gas leaves the absorber with a reduced CO2 content.

The absorber and stripper units are connected to each other, creating a cycle of lean and rich absorbent. A cross heat exchanger preheats the solvent before it enters the stripper to minimise heat loss. The stripper works in reverse to the absorber, releasing gaseous CO2 at the top and regenerating the solvent, which then returns to the absorber. The separated pure CO2 is pressurised and sent to special storage [77]. Figure 9 shows an illustrative diagram outlining the process flow to provide a better understanding of the technological arrangement.

Fig. 9.

Schematic of chemical absorption process [73]

Overview of different chemical solvents

In the field of post-combustion separation by chemical absorption, the use of a 30 wt% by weight solution of MEA (Monoethanolamine) is the best-known method. This particular method is often used in literature as a standard for comparing different CC technologies. The main reasons for the popularity of MEA are its high reactivity and cost-effectiveness in a wide range of flue gas conditions, as stated by Sreedhar et al. [77].

Apart from MEA, which is already commercially available, there has been intensive research into alternative chemical absorbents over the last ten years [81]. Many of these alternatives are based on amines, but ammonia-solvents, other aqueous liquids (water with solutes) and ionic liquids (liquids with salts) have also been explored. Each of these chemicals has its own advantages and disadvantages for certain applications and requires specific operating conditions, which can limit their applicability. In addition, researchers have explored the combination of different chemicals to enhance their benefits while minimising their drawbacks [77, 82]. Table 21 in the Appendix summarises some of these chemical solvents studied and provides an overview of their properties.

Table 21.

Overview of single chemical solvents used in CC

| Absorbent | Advantages | Disadvantages | Energy demand for regeneration (MJ/kgCO2) | Absorption rate (relative to MEA) | Effectiveness for using onboard | Remarks | Reports/papers |

|---|---|---|---|---|---|---|---|

| Monoethanolamine (MEA) |

High Absorption Capacity, proven Technology, Low costs |

Energy Intensive, Corrosive nature, Easy to degrade, volatile |

2.2–6 | 1 | 30 wt% MEA is widely studied and effective choice in diverse ship types [44, 99, 101] | 8.2–14% efficiency penalty for a power plant | [66, 77, 82, 133] |

| Piperazine (PZ) | Less energy-intensive than MEA, Good thermal stability, Resistant to corrosion | Causticity and toxicity | About 85% of MEA | 2 | 30 wt% ME is identified as better solvent than 30–40 wt% PZ [100], whereas MEA/PZ is preferred against MEA [98] | Can be used as a blend to MEA to increase efficiency (activated MEA) | [45, 66, 77, 81, 134] |

| Aqueous ammonia | Wide range of sources, lower chemical costs than MEA, resistant to thermal and chemical degradation | High volatility | Very low, requires only 27% reboiler duty compared to MEA | 0.05–0.33 | 30 wt% MEA perform better when comparing to 2–28 wt% aqueous ammonia [100] | Tested in pilot-scale only | [46, 66, 77, 135] |

| Ionic liquids | Less costs than MEA; resistant to thermal and chemical degradation, non-volatile | Particularly toxic to aquatic organisms | Lower than MEA | Comparable to or higher than MEA | Early research stages | Some liquids show high regeneration efficiency (up to 95%), tested in pilot-scale only | [77, 138, 139] |

| Potassium carbonate (K2CO3) | High thermal & chemical stability, non-volatile, no degradation, more efficient than MEA | Low mass transfer rate, higher space demand than MEA | Lower than MEA | NA | K2CO3 is useful in pressurized combustion and fuel reforming systems [124] | [77, 82, 133] |

In this study, 26 reports/papers describing the use of CC on-board by chemical absorption were analysed. Among them, there is only one report on the CC-Ocean project [35], which describes the operation of a demo plant by the ship’s crew and assigns it a TRL 7 level for on-board operation. The other reports/papers listed are primarily simulation-based studies and case studies that could fall under TRL 2 and TRL 3. However, when looking at commercially available post-combustion CC plants, the most common and successful amine solvent for chemical absorption is 30 wt% MEA [77], which is categorised as successful at TRL 9. NH3 absorption technology is rated at TRL 6, based on successful pilot plant testing [83]. Concentrated piperazine (PZ) and its absorption capability reach TRL 6, with CO2 capture rates of 83.1–99.1% [84]. Ionic liquids for CC are at an early stage of research, with a TRL of 2–3 based on laboratory tests [85].

Advantages and disadvantages of chemical absorption for onboard application

Providing a comprehensive overview, Table 4 discusses the merits and demerits of onboard chemical absorption, serving as a basis for the comparative analysis in Sect. 7 of this study.

Table 4.

Advantages and disadvantages of onboard chemical absorption

| Advantages | Disadvantages |

|---|---|

| Remarkable adaptability for retrofitting into existing facilities without significant alterations to the power generation process [77] | Substantial energy demand required for solvent regeneration, posing a considerable challenge |

| Advanced maturity and widespread deployment across a wide range of flue gas applications [77] | Incurred energy penalties due to power needed for solvent pumps and exhaust stream blowers/fans, essential for overcoming pressure drop within the absorber [75] |

| Extensive real-world testing of components bolstering overall reliability | Toxicity and corrosiveness of certain solvents, along with their gradual degradation over time, posing operational risks |

| Continuous motion of absorber column may lead to relatively constant capture rate or slight increase, potentially enhancing overall absorption rate due to solvent redistribution [86] | Equipment demands considerable space and has substantial weight footprint, negatively impacting ship stability and limiting application in confined spaces [45] and [77] |

| Integration of SOx removal possible with ammonia-solvents (119) | Absorber diameters must be sized based on exhaust flow, which can affect the system’s reliability during ship manoeuvres |

| Challenge in optimising CO2 absorption by solvent, requiring even distribution of exhaust gases across absorber column's diameter | |

| Impact on ship stability when tilting, causing gas flow to shift and necessitating additional gas distribution zones in absorber packing [87] | |

| Absorption processes using amine-solvents may work without pre-treatment but are impacted by degradation and emissions of hazardous by-products |

Research on onboard application of CC by chemical absorption

CC by chemical absorption is proving to be the most advanced method for use on-board ships compared to other existing techniques. This is reflected not only in the abundance of research articles dealing with its application in the maritime sector, but also in various reports describing the processes and assessing the feasibility of CC by chemical absorption to reduce emissions from ships. This study identified 26 relevant articles and reports suggesting that CC by chemical absorption could help reduce carbon emissions in shipping. A summary of the key findings from these reports can be found in Table 22, where MEA, MDEA, DIPA and PZ stand for Mono-ethanolamine, N-Methyldiethanolamine, Diisopropanolamine and Piperazine, respectively.

Table 22.

Reports/papers on post-combustion chemical absorption for the application onboard ships

| Authors (year) | Aim of study | Engine type | Ship type | Solvent | Key findings | Additional information |

|---|---|---|---|---|---|---|

| Zhou and Wang [136] | CC and storage—Solidification and storage of carbon dioxide captured on ships | NaOH, CaO | Not specified | A novel method for solidifying CO2 captured from marine engine exhaust for economical onboard storage on ships. Operational costs of the proposed method are evaluated and compared with traditional CO2 liquefaction, highlighting its potential as a cost-effective solution for mitigating emissions from marine sources | Profit from selling product of CC is able to exceed operational costs | |

| Luo and Wang [44] | Study of solvent-based CC for cargo ships through process modelling and simulation | Two four-stroke reciprocating diesel engines at a total power of 17 MW | General cargo ship | MEA | Two integration options were simulated to analyse thermal performance and estimate equipment size for combining the ship energy system with the CC process. Results show that CC can only reach 73% due to limited heat and electricity supply for CCS in the integrated system | By adding a supplementary gas turbine to boost energy supply for the capture plant, the CC level could reach 90%. However, the cost of captured CO2 is approximately 163.07 €/ton CO2, primarily due to a 21.41% increase in fuel consumption for the additional diesel gas turbine |

| Van Den Akker [116] | CC onboard LNG-fuelled vessels: A feasibility study |

8000 DWT, 3000 kW dual-fuel LNG is used |

General cargo | 30 wt% MEA | An emission reduction of 87% is found compared to the reference ship. The gross cost per ton of CO2 avoided is approximately €74, with net costs being less than €20. While slightly higher than land-based CC projects, it remains in the same order of magnitude | Establishing a price for CO2 emissions could make onboard CC profitable, with a €20 per ton CO2 emitted making it cost neutral |

| Wang et al. [65] | Reviews on current carbon emission reduction technologies and projects and their feasibilities on ships | 6300 TEU, 57,059 kW | Container ship | N/A | High energy, material and space requirements as constraints, further development necessary | A concise overview of the current emissions landscape, policies, and technologies. Predictions for future developments and a comparison of various CC technologies. Includes examples of current incentives for CCS |

| Feenstra et al. [45] | Study of ship-based CC onboard of diesel or LNG-fuelled ships | Two reference ship engines of 1280 KW and 3000 kW were chosen (Diesel or LNG) | Inland ship 1280 KW, General cargo ship 8000 DWT, 3000 kW | 30 wt% MEA and 30 wt% PZ | Integrating the thermal energy of exhaust gas with the stripper reboiler resulted in reduced CAPEX and OPEX for diesel and LNG-powered ships. In LNG ship, the evaporation of LNG's cooling capacity was utilised to liquefy the captured CO2 | Diesel options are more expensive due to additional refrigeration unit for liquefying CO2 |

| Fang et al. [140] | Optimal Sizing of Shipboard CC System for Maritime Greenhouse Emission Control | Not specified | All-electric ship | N/A | Deploying Energy Storage Systems (ESS) alone cannot meet more stringent GHG emission control targets in the future. However, with the combined deployment of CCS and ESS, GHG emission reductions ranging from 10 to 60% can be achieved | The corresponding average CC level increases 11.9% with the joint management |

| Balcombe et al. [24] | How to decarbonise international shipping: Options for fuels, technologies and policies | Not specified | Not specified | N/A | A comprehensive approach involving a mix of fuels, technology, and policy, along with short-term incentives, is essential for the maritime sector's rapid and equitable decarbonization | A summary of currently studied technologies and policies designed to mitigate shipping emissions |

| Awoyomi et al. [119] | CO2/SO2 emission reduction in CO2 shipping infrastructure |

10,200 kW HFO is used |

CO2 carrier | NH3 | At 85% load with the CCS system in operation, the maximum recovered heat is 4MWth, enabling the capture of 70% of CO2 and 98% of SO2 | NH3 as a solvent enables the simultaneous removal of SOx and CO2, with the potential for selling the by-products, simulations cover various ship operation modes and are based on the Munmorah pilot plant for the CC process |

| Awoyomi et al. [46] | Process and Economic Evaluation of an On-board Capture System for LNG-Fuelled CO2 Carriers |

10,305 kW dual-fuel LNG is used |

CO2 carrier, | NH3 | The design of the CC system must consider the operational profile specific to the ship | Exhaust Gas Recirculation (EGR) diminishes plant size and enhances capture efficiency, with the lowest achieved cost being 117 $/tCO2 at a capture rate of 90% |

| Lee et al. [122] | Comparative analysis of on-board methane and methanol reforming systems combined with HT-PEM Fuel cell and CO2 capture/liquefaction system for hydrogen fuelled ship application |

3000 DWT, 3800 kW Methane and methanol |

General cargo | MEA | Excess heat from HT-PEMFC and reformer in both methane- and methanol-based systems supports CO2 capture, with LNG cold energy reducing compressor power consumption in the methane system. Despite slightly higher compressor power in the methanol system, it maintains higher efficiency | Conducting an energetic analysis of methane/methanol-based systems for comparison |

| Long et al. [88] | Improvement of marine CC onboard diesel fuelled ships | 3000 kW diesel engine | Not specified | MEA, MEA/PZ, MDEA/PZ | MEA/PZ and MDEA/PZ show respective increases of 1.7% and 2.8% in CO2 removal compared to the MEA solution. The MDEA/PZ process with an intercooler achieves 90.6% CO2 removal, while the MDEA/PZ process with multiple feeds achieves 90.5% | Several mixed solvents, an intercooler and multiple feeds are used to improve CO2 removal in the absorber |

| Lee et al. [137] | Novel methodology for EEDI calculation considering onboard CC and storage system |

3800 TEU, 53,000 DWT, 18,200 kW with dual-fuel LNG with pilot fuel is used |

Container feeder | 22 wt% MDEA with 8 wt% PZ | The CO2 capture rate must exceed the planned EEDI reduction to offset the additional power demand for CC | The engine's waste heat is enough to meet the energy needs for regenerating the solvent in all simulated scenarios. However, compression and liquefaction consumes more power than CC process itself |

| Stec et al. [26] | Reducing the energy efficiency design index for ships through a post-combustion CC process |

47,000 DWT, 9960 kW HFO is used |

Medium range tanker | MEA | Utilizing waste heat in post-combustion CC is a viable means to meet Energy Efficiency Design Index (EEDI) requirements | A simulation study examining the CC process is conducted under diverse ambient conditions such as arctic, ISO, and tropical environments. The capture rate is adjusted to match the available waste heat, and exhaust gas desulphurization is implemented to safeguard the amine solvent from degradation |

| Ji et al. [141] | Post-combustion CC for tank to propeller via process modelling and simulation |

11,700 kW dual-fuel MFO is used |

Tanker with dual-fuel | MEA, DIPA, and MDEA-PZ | A blended-amine maritime CC model is firstly proposed with good validation outputs, and MDEA-PZ system could capture more than 57% CO2 and save 25% specific reboiler duty compared to MEA system | 40 simulations are conducted to identify the optimal combination of solvents, absorber/stripper packing, and liquid-to-gas ratio in the CC process |

| Güler and Engin [121] | An investigation on the solvent-based CC and storage system by process modelling and comparisons with another carbon control methods for different ships | 27.44 MW for VLCC, 2 × 16.02 MW for large conventional, 2 × 19.88 MW for Q-Flex and 2 × 22.72 MW for Q-Max @100% MCR | A VLCC tanker and three different sizes of LNG carriers (Q-Max, Q-Flex, and conventional LNG carrier) | 35 wt% MEA | Compared different carbon control methods—speed reduction, LNG usage, and CCS. Speed reduction is found the most cost-effective for low-freight ships, while CCS is more cost-effective for high-speed, high-freight ships like Q-Max and Q-Flex and LNG carriers | CCS system cost analysis for ships showed equipment and capital costs had a greater impact on total life cycle costs than operating expenses. Capture equipment comprised 21.6%, and liquefaction equipment 27.2% of total life cycle costs for VLCC tankers. Moreover, as CO2 emissions increased, the total life cycle cost per captured CO2 decreased |

| Ros et al. [86] | Advancements in ship-based CC technology on-board of LNG-fuelled ships | LNG-fuelled ships | Not specified | 30 wt% MEA, 30–40 wt% PZ, 2–28 wt% aqueous ammonia | MEA is found to be the solvent of choice for OCCS technology. Proper heat integration in the OCCS technology on LNG-fuelled ships can drastically reduce the OPEX of the process, making the costs CAPEX dependent | The cost of CO2 capture for the OCCS process on-board of the Sleipnir ship is calculated at 119 €/ton CO2 at an effective capture rate of 72.5% |

| Einbu et al. [120] | Energy assessments of onboard CO2 capture from ship engines by MEA-based post-combustion capture system with flue gas heat integration | LNG or Diesel | Not specified | 30 wt% MEA | Ship engine exhaust alone is insufficient to meet the thermal energy needs of a CO2 capture unit operating above 50%. A fuel afterburner is necessary, leading to a 6–9% increase in fuel consumption with LNG and an 8–12% increase with diesel as the fuel source | In MEA-based CO2 capture, absorber height has a limited effect on energy consumption, especially at lower capture rates. Nevertheless, it remains crucial for optimizing the trade-offs between capital and operating expenses (CAPEX/OPEX) |

| Kawamata et al. [35] | Development of onboard CO2 capture system | 88,715 DWT, 9960 kW | Coal carrier operated by ‘K’ Line | Not specified | N/A | Outcome of project ‘CC-Ocean’. World’s first demonstration project of a marine-based CO2 capture system on actual voyage to successfully separate and capture CO2 from flue gas |

| MMMCZCS [94] | The role of onboard CC in maritime decarbonization | LSFO, LNG, Methanol | Container (15,000 TEU), Tanker-LR2, Tanker-VLCC (300,000 DWT), Bulk-Kmax (82,000 DWT), Bulk-Capesize (205,000 DWT) | Amine based | Newbuilds are more promising for OCC, as retrofits are costly and can require major modifications. Partial CC has higher CO2 abatement costs due to high initial CAPEX. Large tankers offer the best business cases, while small bulk carriers face more challenges | The results from a work package on onboard CC completed as part of the Green Fuels Optionality Project (GFOP) |

| Negri et al. [89] | Navigating within the safe operating space with CC on-board |

8500 TEU ICE engine with HFO |

Container ship | 30 wt% MEA | The capture on-board scenario can achieve 94% efficiency on the net CO2 emissions at 85 $/tCO2 while substantially reducing impacts on core planetary boundaries | CCS outperforms direct air capture (DAC), decreasing the carbon footprint of the set scenario by 52% |

| Negri et al. [90] | Sustainable Development Goals assessment of CC on-board | A standard internal combustion engine with HFO | 8500 TEU container ship | 30 wt% MEA | Upgraded container ship with CC reduces emissions by 94% at $85 per ton of CO2. Overall, it diminishes climate change impact by 50%, while the standalone direct air capture technology achieves a 45% reduction | The results are assessed in relation to five Sustainable Development Goals, utilizing 16 life cycle impact assessment metrics and their corresponding absolute thresholds |

| Wang et al. [125] | Study on optimization and characteristics of ship-based CC system based on intercooling process |

3000 kW dual-fuel LNG is used |

LNG ship | 25–40%wt MEA | Intercooling process consistently captured more carbon than the basic one. With solvent flow ratio adjustment, intercooling showed a 6.60% increase in capture and a 12.27% reduction in solvent usage compared to the base process |

The unit CC energy consumption magnified only 0.201 MJ/kgCO2 |

| Dong et al. [123] | Ship-based CC of LNG ships under off-design conditions |

8000 DWT, 3000 kW dual-fuel LNG is used |

LNG cargo ship | MEA | The liquid-to-gas ratio for optimal CC efficiency in the ship's main engine is approximately linearly related to both design and off-design conditions, correlating with the main engine load, at 100% MCR, a 72.38% decarbonization rate is achieved at 6.118 GJ/T CO2, and at 50% MCR, nearly 93.24% decarbonization is achieved at 11.023 GJ/T CO2 | At 75% MCR main engine load, treating 73.7–100% of exhaust gas (10,088–13,691 kg/h) with a recirculation flow of 10,120–11,080 kg/h achieves a decarbonization rate exceeding 49% |

| Bayramoğlu [91] | Application of post-combustion CC process in marine diesel engine | 5400 kW @100% load | Not specified | 25 wt% MEA | The optimal exhaust absorber inlet temperature is 50 °C, resulting in an average CC performance of 95%. In the applied system, the EEDI is reduced by 14% with the ORC system and by 90% with the CC system | The ORC system turbine output power varies between approximately 414 kW and 606 kW for different CC system inlet temperatures under 100% load conditions |

| Güler and Ergin [124] | An investigation of the cooling, heating and power (CHP) systems integration with CC and storage for LNG carriers | CLNG (31,400 kW), Q-Flex (39,300 kW), Q-Max (45,200 kW) |

Q-Max (265,000 m3), Q-Flex (210,000 m3) and CLNG (150,000 m3) LNG-fuelled engines |

30% PZ | Employing a CCS system is more cost-effective than paying the European Union carbon tax for LNG carriers | The ORC-based CHP system raises the total Life Cycle Cost (LCC) due to initial expenses and efficiency issues. However, CHP integration helps mitigate some of the exergy losses incurred by the CCS system |

| Hua et al. [66] | Research progress of CCS technology based on the shipping industry | Not specified | Not specified | N/A | Covers the research progress on OCCS including CO2 transportation | Challenges and risks for CO2 sequestration is discussed |

In order to get the insights of the articles and reports mentioned in Table 22 (see Appendix), the major findings are grouped into the following categories:

Effectiveness of different solvents

Various researchers have investigated different solvents for chemical absorption during carbon deposition. The solvents studied include MEA, PZ, MDEA, DIPA and ammonia.

MEA is commonly studied and is consistently effective in various applications and ship types.

Researchers such as Long et al. [88], Luo and Wang [44] and Ros et al. [86] found that MEA is a favoured solvent that achieves high CO2 removal efficiency.

MEA is a commonly favoured option due to its effectiveness in scenarios ranging from diesel-powered ships to cargo and container ships.

Ongoing efforts are aimed at finding optimal solutions tailored to specific operating contexts and ship types.

Energy efficiency and operational considerations

Research into CC by chemical absorption in marine applications focuses not only on the environmental impact, but also on energy efficiency and operational aspects.

Studies range from research into different solvents to innovative approaches such as the use of waste heat, the integration of additional gas turbines and the optimisation of the liquid-to-gas ratio.

There are concerted efforts to improve the overall efficiency of CC processes on ships.

Studies are looking at emissions reduction as well as capital and operating cost considerations and the integration of exhaust, heat and power systems.

Notable achievements include a significant emissions reduction of 94% on a container ship by [89, 90] and a 14% reduction in the Energy Efficiency Design Index (EEDI) by Bayramoğlu [91] incorporating an Organic Rankine Cycle (ORC) system, demonstrating the tangible benefits of these efforts.

Economic considerations and cost analysis

Economic assessments of on-board CC by chemical absorption in shipping emphasise the need for tailored strategies for different types of ships.

The variability in cost-effectiveness is evident across the different methods.

Key findings highlight the impact of capital expenditure and the importance of heat integration in reducing operating costs.

Novel methods, such as the solidification of captured CO2 to realise a potential profit, and integrations such as cooling, heating and power systems, show economic benefits.

Overall, the studies underline the potential for economic optimisation and efficiency improvements when implementing chemical absorption technologies on-board.

Adsorption by solid sorbents

During adsorption, atoms, molecules or ions from a gas or liquid attach themselves to the surface of an adsorbent and form an adsorbate film. Physisorption occurs due to van der Waals forces, while chemisorption occurs due to covalent bonds [75] and [92]. Chemisorption is slower as it requires electron transfer, making it less suitable for the uptake of large amounts of CO2, while physisorption offers a faster process and requires less energy to regenerate the sorbent [75] and [92]. In addition, physisorption is associated with a lower heat of adsorption, while chemisorption generally has a higher heat of adsorption [75] and [92].

Operating principle

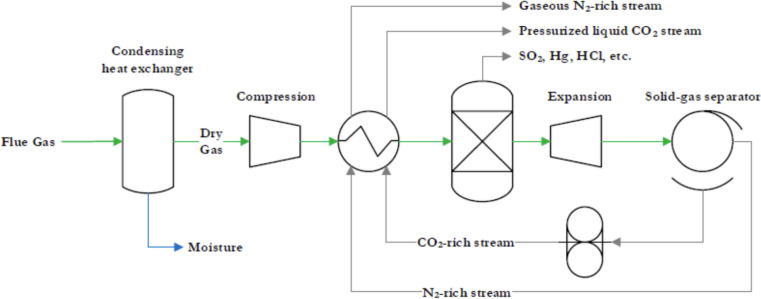

The process of CO2 adsorption takes place in an adsorber system in which solid sorbents are arranged in columns. The effectiveness of this process, especially with dilute CO2 mixtures, is enhanced by physisorption, which involves the selective adsorption of CO2 molecules on the surface of the adsorbent [75]. Two main technologies for CC are fixed bed adsorbers and moving bed adsorbers. In fixed bed systems, the separation and desorption phases alternate cyclically within the same unit. Moving bed systems, on the other hand, feed the saturated adsorption material into a regeneration unit that provides a continuous off-gas stream without pressure drop issues. However, these systems face challenges in terms of wear and tear [75]. The adsorption system involves the use of auxiliary equipment such as blowers, fans and heat exchangers to facilitate the process. Different adsorption cycles, including pressure swing adsorption (PSA), vacuum swing adsorption (VSA) and temperature swing adsorption (TSA), can be used depending on factors such as gas volume and CO2 concentration. Each cycle comprises different phases, including adsorption, saturation, desorption and regeneration processes [75] and [92]. A simplified representation of a fixed bed adsorber with temperature swing adsorption (TSA) can be seen in Fig. 10, which provides a visual reference for the process [73].

Fig. 10.

Schematic of a fixed bed adsorber using TSA [73]

In order to make CC by adsorption effective, certain important properties of the sorbent used are required. These properties include selectivity, capacity, ease of desorption, energy requirements, mechanical strength, chemical stability and cost [92] and [93]. Researchers are also investigating various adsorbents for CC. These include zeolites, metal–organic frameworks (MOF), porous silica, carbon-based materials (e.g. activated carbon) and solid amine-based materials [81].

Advantages and disadvantages of adsorption by solid sorbents for onboard application

In the context of onboard implementation, Table 5 sheds light on the advantages and disadvantages of adsorption by solid sorbents, laying the groundwork for the comparative study in Sect. 7 of this study.

Table 5.

Advantages and disadvantages of onboard adsorption by solid sorbents

| Advantages | Disadvantages |

|---|---|

| Physical adsorbents like zeolites and metal–organic frameworks (MOFs) exhibit high selectivity and capacity, making them effective for capturing CO2, especially at high pressures and low-temperatures [81] | Challenges in higher-temperature flue gases for physical adsorbents, leading to decreased capacity, especially at elevated temperatures [93] |

| Solid amine-based sorbents demonstrate a remarkable capability to capture high capacities of CO2 at low partial pressures, with superior CO2 selectivity when compared to physical adsorbents [81] | Susceptibility to oxidation and thermal degradation of amine adsorbents, limiting overall efficiency in CO2 capture |

| Versatility of adsorption technologies is underscored by their potential to capture CO2 directly from the air rather than from high-temperature flue gases [81] | Incompatibility of adsorbents with sulphur oxides (SOx) and nitrogen oxides (NOx) contaminants present in flue gas, potentially causing degradation [94] |

| Efficiency of zeolites and MOFs is compromised by the presence of water vapor in flue gas because these adsorbents have a tendency to adsorb water before CO2 [95] | |

| Not suitable for flue gases of Internal Combustion Engines (ICEs) due to operational challenges and inefficiencies [81] | |

| Overall feasibility of CC by solid adsorption technology, when applied to flue gases from ICEs, currently deemed not feasible |

Research on onboard application of CC by adsorption by solid sorbents

Only two articles were identified in this study, one of which focuses exclusively on the use of adsorption by physical solvents in marine applications. The second study focuses on road transport applications, but suggests that the technology could be extended to make it useful for capturing CO2 from marine exhaust. It is noteworthy that TSA is used in both articles.

Erto et al. [96] investigated the use of alumina-supported K2CO3 to capture CO2 from marine diesel engine exhaust. Their fixed bed adsorption process showed several advantages over solvent absorption, such as the use of non-hazardous materials, operational flexibility and the ability to capture CO2 at temperatures below 100 °C. Despite the need for a sulphur scrubber when using fuels with high sulphur content, the proposed method showed a CO2 reduction rate of 27.8 to 28.4% in a case study on a RoPax ferry. On the other hand, Sharma and Maréchal [97] proposed a concept for an energy self-sufficient CC and liquefaction system. Their technology is based on a TSA cycle using PPN-6-CH2-TETA as adsorption material and integrates a Rankine cycle, a heat pump and a CO2 compression and liquefaction unit. The system, originally designed for a lorry engine, achieved a capture rate of 90% in simulations. The researchers proposed to transfer the system to various combustion engines, including marine diesel engines.

The main information from both articles is summarised in Table 23 mentioned in Appendix.

Table 23.

Reports/papers on post-combustion chemical absorption for the application onboard ships

| Authors (year) | Aim of the study | Engine type | Ship type | Solvent | Key findings | Additional information |

|---|---|---|---|---|---|---|