Abstract

The study aims to address challenges encountered by modern industrial enterprises, including inefficient accounting cost calculation, delayed information acquisition, and untimely management decisions. By comprehensively applying modern management, information technology, and cost control methods, this study constructs a real-time cost control model to optimize industrial enterprises. Firstly, the model employs mixed integer linear programming (MILP) to optimize production processes through mathematical modeling. Secondly, it utilizes data mining technology to assist enterprises in cost accounting and efficiency analysis. Big data analysis aids in predicting production process changes and trends, providing data support for management decisions. Intelligent production scheduling and resource optimization are facilitated by artificial intelligence (AI) technology, enabling real-time data collection, processing, and analysis. Finally, the activity-based costing method categorizes, allocates, and measures costs to enhance cost accounting accuracy and efficiency. Research results demonstrate that enterprises adopting the theoretical framework of real-time cost control can enhance the accuracy of cost accounting, cost control efficiency, and overall management effectiveness.

Keywords: Cost control, Modern technology, Information technology, Cost accounting, Management efficiency

1. Introduction

In the face of fierce market competition and changing business environment, modern industrial enterprises, as an important basis of management decision-making, are very important to the efficiency and development of enterprises [1]. However, in the past, industrial enterprises mainly relied on traditional manual and semi-automatic methods in accounting cost calculation, such as manual data collection, manual information entry and calculation based on Excel tables. There are many problems in this way: firstly, due to the scattered data sources and poor integration, it is difficult to obtain information and consumes a lot of manpower and material resources. Secondly, manual data processing is prone to errors and omissions, which affects the accuracy of cost accounting. In addition, the traditional method lacks the characteristics of real-time and instant update, which leads to the slow response speed of management decision-making and cannot adapt to the rapidly changing market environment. Meanwhile, due to the huge and complex data, traditional methods often cannot fully explore the laws and values behind the data, which limits the in-depth analysis of cost structure and efficiency [[2], [3], [4], [5]]. Therefore, the traditional accounting cost calculation method has obvious problems in information lag, low data processing efficiency and untimely management feedback, which is no longer suitable for the development of industrial enterprises today. The existence of these problems directly affects the operational efficiency and competitiveness of enterprises, making it difficult for enterprises to effectively optimize resource allocation, reduce costs and improve production efficiency, thus restricting the profitability and sustainable development of enterprises [6]. Faced with increasingly fierce market competition and rapidly changing business environment, industrial enterprises urgently need to change the way of cost accounting and introduce modern technology to improve management efficiency, accuracy and decision-making flexibility [7]. Therefore, with the help of information technology, building a cost control model that can optimize in real time has become an urgent need to improve the efficiency and management level of accounting cost calculation in industrial enterprises.

At present, the research on the role of modern technology in accounting cost accounting of industrial enterprises has made some progress. Scholars generally agree that informatization is important in reducing accounting cost, improving accounting efficiency and management decision-making. For example, the application of information technology can significantly improve the speed and accuracy of data processing, so that enterprises can obtain and analyze production data more quickly. In addition, modern management techniques such as mixed integer linear programming (MILP) and data mining have been widely used to optimize production processes and improve management efficiency. These technical means help enterprises maintain competitiveness in a dynamic market environment and improve resource utilization and production efficiency. However, although the existing research shows that the application effect of modern management technology and information technology in different fields is remarkable, how to combine these technologies organically to build a cost control model that can optimize the production process of industrial enterprises in real time has not been fully studied. Especially in the big data environment, it is still a major challenge to realize accurate cost prediction and control, intelligent production scheduling and resource optimization, and the application of activity-based costing. The existing research focuses on the application of single technology, lacking a comprehensive and multi-level research framework to systematically improve the overall management efficiency of industrial enterprises.

In today's rapidly developing industrial environment, industrial enterprises are facing more and more challenges, including low-cost calculation efficiency, delayed information acquisition and untimely management decisions. Traditional cost calculation methods and management tools can no longer meet the needs of modern industrial enterprises, so it is necessary to introduce new technical means and management models to optimize the production and management efficiency of enterprises. Although some studies have discussed the application of MILP, data mining and big data analysis, AI technology in production process optimization and cost control, these studies often lack a comprehensive evaluation of the actual application effect. In addition, most of the existing research focuses on the application of a single technology, while few studies systematically combine a variety of modern technologies to build a comprehensive real-time cost control model. For example, Arasu et al. (2022) further explored the application of MILP in resource allocation, but there were also fewer practical application scenes [8]. In data mining and big data analysis, Latif et al. (2023) demonstrated the actual effect of big data analysis in improving industrial decision-making through specific cases, but did not discuss its integrated application with other technologies in depth [9]. The application of artificial intelligence (AI) technology in industrial production has also been widely concerned. Silver and Xu et al. (2023) proved the superior performance of deep neural network in complex strategy games through experiments, and further demonstrated the potential of AI technology [10]. Therefore, the purpose of this study is to put forward a brand-new real-time cost control model by comprehensively applying a variety of modern technologies to fill this gap in the existing research. This study aims to build a cost control model that can optimize industrial enterprises in real time by comprehensively applying modern management technology, information technology and cost control technology to improve the accuracy, efficiency and overall management efficiency of accounting cost calculation. Through in-depth research and practical exploration, it is expected to provide comprehensive and efficient cost accounting solutions for industrial enterprises, help enterprises reflect market demand, optimize resource allocation, and enhance overall competitiveness.

The theoretical contribution of this study is mainly reflected in the following aspects:

Innovative application of MILP: In this study, MILP method is applied to the optimization of production process in industrial enterprises. Through mathematical modeling and solution, the optimal configuration of production process is realized and the production cost is reduced. This innovative application not only enriches the application scenarios of MILP method in production management, but also provides new theoretical support for enterprise production optimization.

Application of data mining and big data analysis: By using data mining technology to discover the hidden relationship and change law between cost items, and using big data analysis to predict production trends and changes, this study provides scientific decision support for enterprises and improves the accuracy and efficiency of cost control.

Application of artificial intelligence technology in production scheduling and resource optimization: By introducing deep learning and reinforcement learning algorithms, this study realizes the intelligence of production scheduling and resource optimization, further improves the production flexibility and response speed of enterprises, and provides a strong guarantee for enterprises to cope with market changes.

Innovative application of activity-based costing: Through the classification, distribution and measurement of costs by activity-based costing, this study improves the accuracy and efficiency of cost accounting and provides an important theoretical basis for cost control and management decision-making of enterprises.

Based on the above research gaps, this study focuses on the following specific issues: Firstly, how to optimize the production process of industrial enterprises through MILP? The study will discuss how to use MILP to carry out mathematical modeling to optimize resource allocation and production scheduling in the production process, reduce production costs and meet market demand. Secondly, how can data mining technology assist enterprises in cost accounting and efficiency analysis, and provide support for management decisions through big data analysis? This study will analyze the application of data mining technology in cost accounting in detail, and find hidden cost trends and laws through clustering, regression and other methods to improve the accuracy of accounting and the scientific management decision. Third, how does AI technology realize real-time data collection, processing and analysis in production scheduling and resource optimization? The study will discuss the application of AI technology, especially deep learning algorithm in production scheduling and resource optimization, and how to improve the intelligent level and response speed of production process through real-time data collection and analysis. Finally, how can activity-based costing improve the accuracy and efficiency of cost accounting? This study will discuss the specific application of activity-based costing in cost classification, distribution and measurement, and how to improve the accuracy and efficiency of cost accounting by refining cost items. Through the discussion of the above research problems, this study aims to build a comprehensive cost control model, optimize the production process of industrial enterprises in real time by means of modern technology, and improve the scientificity and efficiency of management decision. The effective application of this model will provide solid technical and strategic support for enterprises to maintain their advantages in the fierce market competition.

2. Accounting cost calculation of industrial enterprises

In the field of accounting cost calculation in modern industrial enterprises, many scholars and researchers have conducted in-depth discussions and studies on how to use modern technology to improve management efficiency and optimize cost control. Burova et al. (2021) developed a mechanism for the cost management of innovative products of industrial enterprises in the highly fluctuating environment of digital economy [11]. Andreevna et al. (2023) provided practical suggestions on optimizing and utilizing the characteristics of overhead standard factors to increase the efficiency of industrial enterprises [12]. Nguyen (2023) used innovation diffusion theory, resource theory and cost-benefit analysis theory as the theoretical framework to explain the influence of organization and technology on the application of activity-based cost accounting system [13]. Bejarano (2023) focused on the influence of activity-based costing (ABC costing) on the profitability of small polymetallic mining companies, and used quantitative methods to determine the influence of ABC costing on profitability through regression statistical analysis, which showed the importance of data analysis in cost accounting [14]. Azeez et al. (2020) pointed out that enterprise resource planning application could support attribute cost accounting technology and provide detailed data, thus helping tourism companies to manage their costs and resource utilization efficiency, and promoting the integration of major processes to improve efficiency [15]. Le et al. (2020) investigated the factors affecting the application of management accounting in Vietnamese enterprises. The results showed that the company size, organizational culture, organizational structure, technology and human resource operation were positively correlated with the application level of management accounting [16]. Lyu et al. (2023) established a bottom-up and three-layer nested model for waste treatment in chemical industrial parks, which integrated mesophase logistics, pollutant emission reduction technology and cost accounting of the whole process [17].

Jin et al. (2023) constructed the method of enterprise cloud computing accounting service platform [18]. The method proposed in this study had the highest data availability probability of 0.98, which showed that the method had high data availability after fault-tolerant processing and could effectively realize interaction with users. Wang et al. (2023) applied recommendation system to decision-making and resource optimization of entrepreneurial projects. Neural network algorithm was used to model the project characteristics, user behavior, and content characteristics [19]. Li et al. (2023) studied the process that Artificial Intelligence (AI) affected the innovation efficiency of enterprises [20]. The results showed that the application of AI significantly improved the innovation efficiency of enterprises. In larger companies with less management power, AI had a greater impact on enterprise innovation efficiency. In addition, the higher the development level of AI in the industry and region where the enterprise was located, the stronger the impact of AI on the innovation efficiency of the enterprise. Gyamera et al. (2023) used agency theory and technology acceptance model to explore the influence of management accounting services on the financial performance of small and medium-sized enterprises (SMEs) in Ghana's commerce, service and manufacturing industry [21]. Reddi et al. (2023) clarified that the extensive application of information technology had completely changed corporate finance [22]. Ahmad et al. (2024) investigated the influence of the improvement of accounting technology on the generation of accurate and reliable financial reports in Jordan's public sector. The research results showed that the tool had a significant reliability level [23]. Hendarmin et al. (2024) discussed the influence of developing accounting information system based on cutting-edge technology on company efficiency [24]. The research results showed that the use of AI significantly improved the company's operational efficiency. Companies that adopt blockchain technology had also achieved a higher level of user satisfaction. User training and company size also had a positive impact on efficiency and better decision-making.

In today's industrial enterprises, the accuracy and efficiency of accounting cost accounting plays a vital role in strengthening cost control and improving the timeliness of management decisions. With the rapid development of information technology, the potential of modern technology in improving accounting cost accounting and management efficiency of industrial enterprises is more and more widely recognized. However, there are still some deficiencies and research gaps in the existing research on how to comprehensively integrate modern management technology, information technology and cost control technology to improve management efficiency. Firstly, the existing literature mainly focuses on the application of a single technology (for example, only focusing on big data analysis or AI technology) and fails to fully consider how these technologies can be used together to achieve the best results. For example, Li et al. (2024) clarified the role of big data in optimizing cost accounting in their research [25], but did not discuss the comprehensive application with other technologies in depth. In addition, the research of Yao et al. (2022) highlighted the potential of AI technology in improving production scheduling efficiency [26], but ignored the improvement of cost control process. Secondly, although some studies try to build a theoretical framework model to integrate different technologies, there is still a lack of a comprehensive framework model combining modern management technology, information technology and cost control technology at the specific implementation level. This was reflected in the research of Barot et al. (2020), who put forward a preliminary framework [27] to optimize cost control by using information technology, but the framework did not cover all relevant modern technologies and lacks empirical verification. Furthermore, the importance of informatization in improving management efficiency has been discussed in the existing research, but it often fails to provide enough empirical evidence to support its conclusion. For example, Zhang et al. (2021) pointed out that informatization can significantly improve management efficiency [28], but their analysis relied on theoretical inference rather than extensive practical case analysis. Therefore, this study aims to fill this research gap and optimize the production process, cost accounting and management decision-making of industrial enterprises by constructing a real-time cost control model. The comprehensive application of MILP, data mining technology, big data analysis and AI technology can optimize the production process and improve the accuracy and efficiency of cost accounting. They also can provide strong data support for management decisions. The proposal and verification of this model not only helps to promote the application of modern technology in accounting cost accounting of industrial enterprises, but more importantly, it emphasizes the key role of informatization in improving management efficiency and provides a new perspective and methodology for future related research and practice.

According to the previous research results, modern technology plays a vital role in accounting cost calculation of industrial enterprises. The application of modern technologies such as information technology, big data analysis and AI provides enterprises with brand-new management ideas and methods. However, although modern technology plays an active role in accounting cost calculation of industrial enterprises, there are still some problems and challenges to be faced. Firstly, the application of technology may bring new risks and security risks, such as data leakage and information security, which need to be effectively prevented. Secondly, the iterative speed of technology update is fast, and enterprises need to keep up with the update to improve the technical ability and adaptability of employees. In addition, the application of technology needs to be combined with the actual operation of enterprises to ensure the landing and implementation effect of technology. Therefore, although modern technology has brought great opportunities for accounting cost calculation in industrial enterprises, enterprises need to carefully evaluate risks and effectively plan implementation strategies in the process of introducing technology to ensure the best results. Therefore, in view of the problems and challenges faced by modern industrial enterprises in accounting cost calculation, this study aims to comprehensively apply modern management technology, information technology and cost control technology to build a cost control model that can optimize industrial enterprises in real time to improve the accuracy, efficiency and overall management efficiency of accounting cost calculation.

3. Research methodology

3.1. Mixed integer linear programming

Mixed integer linear programming (MILP) is a mathematical modeling and solving method widely used in production process optimization [29]. The model construction of MILP method first involves the definition of various decision variables in the production process. In this process, people need to consider various constraints in the production process, including but not limited to resource constraints, time constraints, technical constraints and so on. In general, decision variables can include production quantity, production schedule and resource allocation [30]. The application mathematical model of MILP method in optimizing production process design is shown in Fig. 1.

Fig. 1.

Mathematical model of MILP method in optimizing production process design (Image source: self-painted by the author).

Fig. 1 shows the mathematical model application of MILP method in optimizing the production process design of industrial enterprises. In this figure, suppose industrial enterprises want to optimize the configuration of their production lines to reduce production costs and meet market demand. In the MILP model, the decision variables include the output and switching state of each production line, and the objective function is to minimize the total cost, including fixed cost and variable cost. Constraints include production capacity constraints, raw material supply constraints and product demand constraints. By applying the MILP solution strategy, enterprises can get the optimal production allocation scheme, that is, which production lines should be opened, how much should each production line produce, and how to allocate raw materials to meet the market demand and minimize the cost [31].

3.2. Data mining and big data analysis

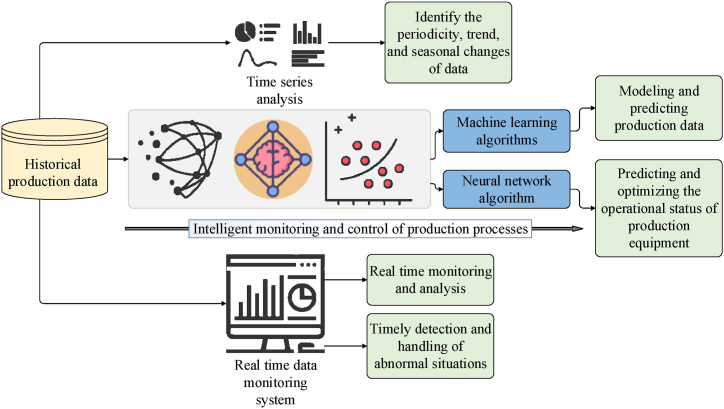

This study uses data mining technology to discover hidden rules and trends from massive data to support the accuracy and efficiency of cost accounting [32]. The application of data mining technology in cost accounting is shown in Fig. 2.

Fig. 2.

Application of data mining technology in cost accounting (Image source: self-drawn by the author).

Fig. 2 classifies data points with similar characteristics into the same category by clustering data, thus revealing the internal relations and laws between different cost items. For example, classifying similar production processes into one category can help enterprises identify the key nodes of high and low costs and control costs in a targeted manner. By analyzing the correlation among different cost items, the causal relationship and common change law are found. This helps enterprises to understand the complexity of cost composition and formulate cost reduction strategies accordingly. By establishing a regression model between cost and various influencing factors, the future cost trend is predicted. This will help enterprises to make long-term cost management and investment planning, and cope with possible cost growth in advance.

A large number of data packets produced in the production process of industrial enterprises contain rich information. Through in-depth analysis of these data, people can reveal the potential trend of production changes and provide scientific basis for future production planning and resource allocation of enterprises [33]. Fig. 3 shows the role of big data analysis in forecasting production trends.

Fig. 3.

The role of big data analysis in forecasting the changing trend of production (Image source: self-drawn by the author).

Fig. 3 identifies the periodicity, trend and seasonal changes of historical production data through time series analysis, thus predicting the trend of future production changes. This helps enterprises to arrange production plans and inventory management reasonably, and reduce production costs and inventory risks. The machine learning algorithm is used to model and predict the production data, and the intelligent monitoring and control of the production process is realized. For example, neural network algorithm is used to predict and optimize the running state of production equipment, which can reduce downtime and improve production efficiency. A real-time data monitoring system is established to monitor and analyze the key indicators in the production process in real time, find and deal with abnormal situations in time, and ensure the stable operation of production. This helps enterprises to improve the flexibility and response speed of production and adapt to the changes in market demand.

3.3. Application of AI in production scheduling and resource optimization

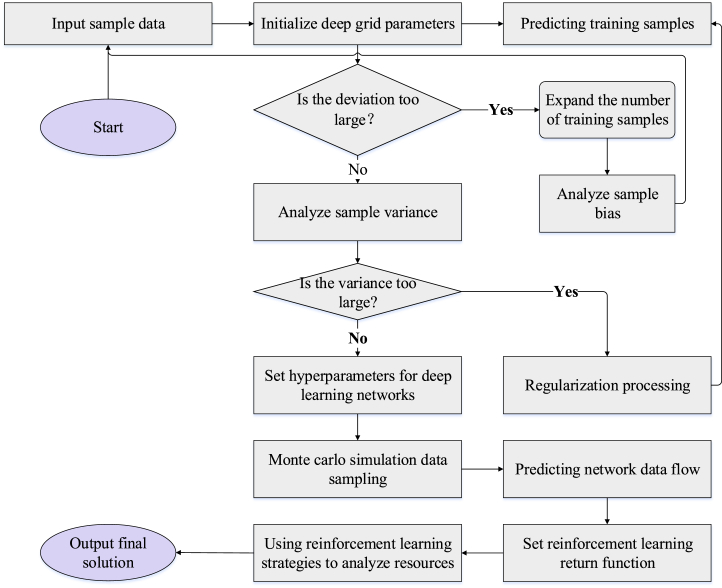

AI technology plays a key role in production scheduling and resource optimization of modern industrial enterprises. Traditional production scheduling is usually based on static rules and experience, and it is difficult to cope with the dynamic changes of production environment. AI technology can realize intelligent production scheduling by analyzing a large number of production data and environmental information [34]. Among them, the application of deep learning algorithm in production scheduling is particularly prominent. By constructing neural network model, people can realize automatic learning and prediction of various factors in the production process, thus achieving more accurate and efficient production scheduling [35]. In this study, a new deep learning model-Dynamic Resource Allocation Optimization (DRAO) is established to predict the demand in the production process to guide the arrangement of production scheduling. The application process of DRAO in production scheduling and resource optimization is shown in Fig. 4.

Fig. 4.

Application process of DRAO in production scheduling and resource optimization (Image source: self-drawn by the author).

In Fig. 4, DRAO algorithm plays an important role in production scheduling and resource optimization. Firstly, in the distributed environment, each branch node collects traffic data in real time through a data collector as training samples. Then, according to the scale and real-time requirements of the training samples, the number of hidden layers and nodes of the deep learning network are determined, and the network parameters are initialized. In the training process of the deep learning model, the loss function is used for fitting, and the deviation of fitting results is analyzed. If there is a large fitting deviation, it indicates that it is currently in an under-fitting state, and it is necessary to increase the number of training and re-analyze the fitting. Then, the data of each node are collected as test samples again, and the existing neural network is used to predict and analyze the variance of the data. If the fitting variance is large, it indicates that the sample is in an over-fitting state, and it is necessary to regularize the deep learning network and readjust the network. According to the trained deep learning network, the corresponding hyperparameters are set to optimize the performance of the model. Aiming at the high flow peak and flow dynamics in distributed environment, Monte Carlo simulation is used to predict the maximum flow direction of sampled data, and the prediction results are output. According to the prediction results given by Monte Carlo, the reward function of reinforcement learning is set. Finally, the reinforcement learning strategy is used to dynamically allocate network resources, and the optimal resource allocation result is given. Among them, the loss function of deep learning model and the return function of reinforcement learning are shown in equation (1) and equation (2):

| (1) |

| (2) |

In the above equation, is the number of training samples. is the true value of the samples, and is the predicted value of the model for the samples. The loss function measures the difference between the predicted value of the model and the real value, and adopts the mean square error as the loss function, that is, the average of the sum of squares of the prediction errors of each sample. The goal of the optimization model is to minimize the loss function and make the prediction result of the model closer to the real value. is the reward of time step . is the discount factor, and is the reward of time step .

3.4. Construction of cost control model

In the process of constructing real-time cost control model, human-computer interaction plays a vital role. Although modern software and automation systems have made great progress in data input, they still need human beings to operate and make decisions in some links. In order to minimize human intervention and improve the real-time and accuracy of data, the following methods are introduced in this study:

Automatic data acquisition: By deploying sensors and Internet of Things (IoT) devices, all kinds of data (such as production speed, equipment status, raw material consumption, etc.) in the production process can be automatically acquired. In this way, the system can continuously obtain high-frequency and high-accuracy data streams without manual intervention, thus improving the efficiency and real-time performance of data input.

Real-time data analysis and feedback: AI technology is used to analyze the collected real-time data, the system can automatically identify abnormal situations and potential problems in the production process, and feed back to managers through friendly user interfaces (such as dashboard and real-time alarm system). In this way, managers can know the production trends in time and make decisions quickly according to the suggestions provided by the system.

Minimization of human intervention: The frequency and complexity of human operation through intelligent algorithms and automated processes are minimized. For example, deep learning model is used to predict production demand and automatically adjust production plan. By strengthening learning, people can optimize resource allocation and reduce the errors caused by human decision-making. When manual intervention is needed, the system will provide clear operational guidelines to simplify the decision-making process of managers.

Through these technical means, this study builds an efficient and intelligent real-time cost control model, which can significantly improve the accuracy and efficiency of cost control while reducing human intervention.

Activity-based costing is a cost accounting method, which allocates the cost of an enterprise to various activities or cost drivers, and then associates the cost with products or services. This study uses activity-based costing to classify, allocate and measure costs to improve the accuracy and efficiency of cost accounting. Specifically, it divides the cost into direct cost and indirect cost, and allocates the indirect cost to each activity according to the driving factors of activity cost to accurately measure and analyze each cost. The mathematical expression of the cost control model is based on the MILP method. It abstracts the production process of industrial enterprises into a mathematical model, including key elements such as production activities, resource allocation and cost control. The objective function and constraint conditions is set to realize the optimal design with minimum cost. Specifically, it considers the activities in the production process, the availability of resources, cost constraints and other factors, and builds a comprehensive mathematical model to achieve accurate control and management of costs. The basic structure of the mathematical model is shown in equation (3):

| (3) |

In equation (3), is the objective function and represents the total cost. is the unit cost of item resources. is the usage of item resources. is a binary variable whether the activity is carried out or not. is the consumption of item resources in item . is the number of resources. is the number of activities. By adjusting the value of , different activities can be turned on and off, thus optimizing the utilization of resources and minimizing the cost. Table 1 shows the solution strategies and applications adopted in the study:

Table 1.

The solution strategy adopted in the study and its application.

| Modern optimization algorithm | Algorithm principle | Solution strategy | Scholar's research |

|---|---|---|---|

| Genetic algorithm | It simulates the mechanism of natural selection, crossover and mutation in the process of biological evolution. | The resource allocation scheme is coded as chromosome and optimized by selection, crossover and mutation. | Li et al. (2021) proposed a two-dimensional constraint model, which considered the constraints of maximizing economic value, minimizing water shortage, minimizing groundwater consumption and meeting domestic water demand. By improving the genetic algorithm, the optimization ability of the algorithm was enhanced to adapt to the water resources optimization problem with specific constraints [36]. |

| Simulated annealing algorithm | By simulating the physical annealing process, the non-optimal solution is accepted with a certain probability to avoid falling into local optimum. | Starting from the initial solution, the global optimal solution is gradually approached through iterative adjustment. | Tufano et al. (2020) used meta-heuristic simulated annealing algorithm to solve the optimization model and identify the Pareto frontier of the problem [37]. |

| Branch and bound method | The original problem is decomposed into several sub-problems, and the search space is reduced by pruning technology. | Each subproblem is solved and pruned according to the boundary. | Chen et al. (2023) designed a new graph transformation method and a customized branch-and-bound algorithm to solve the path optimization problem, and pointed out that its algorithm is superior to genetic algorithm in efficiency [38]. |

The assumptions of the model include: the production process of industrial enterprises can be accurately described by mathematical methods. All the cost and resource data obtained are accurate. Market demand remains stable during the forecast period. The initial resource allocation and market environment are known and remain unchanged during the study period.

3.5. Experimental data

The data of this study mainly comes from many authoritative channels to ensure the accuracy and comprehensiveness of the data. The data of manufacturing industry comes from official website (http://www.stats.gov.cn), National Bureau of Statistics. This website provides the production and operation data of various industrial enterprises in China. The data of electronic industry is obtained from China Electronic Information Industry Development Research Institute (http://www. miit.gov.cn). It provides detailed statistical information about electronic industry. The data of the automobile industry comes from the comprehensive data of global automobile companies (https://www.kaggle.com/datasets/shiivvvaam/car-companies-in-the-world), and the association has released the production and sales data of the automobile industry. Data of consumer goods industry are obtained from sales data of Amazon, Alibaba and eBay (https://www.kaggle.com/datasets/Patrick Ford/Amazon-Alibaba-and-eBay-2013-2023), and the center provides relevant statistics of consumer goods market. The data used in the study include production process data, cost accounting records, resource consumption reports and market demand data. Among them, the production process data includes information such as production quantity, downtime and product defects. Cost accounting records include direct costs, indirect costs and total costs. The resource consumption report records the power consumption, water consumption and raw material consumption. Market demand data involves changes in market demand and market price. The data covers the period from January 1, 2019 to December 31, 2023 to ensure that the data can reflect the operating status of enterprises in different economic cycles. In the process of data processing, this study strictly screens the collected data, removes duplicate and missing data, corrects obviously wrong data, and converts data from different sources into unified formats and standards to ensure the consistency and reliability of data.

To ensure the representativeness and timeliness of the data, this study pays special attention to the impact of the COVID-19 epidemic from early 2020 to 2022 on the operation of industrial enterprises. During this period, the global economy was severely impacted, the production of some industries was interrupted, and the market demand plummeted or fluctuated abnormally. Therefore, this study strictly screens and processes the data of this period. It removes the abnormal fluctuation data, and uses Monte Carlo simulation and other statistical analysis methods to fit and adjust the data to reduce the possible impact on the data accuracy and analysis results during the epidemic period. Meanwhile, considering that the COVID-19 epidemic may have an uneven impact on the operating conditions of different types of enterprises, especially in the aspects of market demand fluctuation, supply chain interruption and cost structure change, this study have specially increased the sensitivity test on the impact of the epidemic in data processing. These tests are helpful to evaluate the effectiveness and robustness of the proposed cost control model in different economic scenarios under the economic fluctuation caused by the COVID-19 epidemic.

Through the analysis of these data, the effect of the proposed cost control model in practical application can be evaluated more accurately. In order to ensure the accuracy and credibility of the data, this study has strictly screened and processed the data, removed the abnormal values and noise data, and ensured the consistency and reliability of the data. In the research process, people have strictly screened and processed the data, and removed the abnormal values and noise data to ensure the accuracy and credibility of the analysis results. The specific data processing steps include: remove duplicate and missing data and correcting obvious erroneous data, convert data from different sources into unified formats and standards to ensure data consistency. Examples of experimental data are shown in Table 2:

Table 2.

Example of experimental data.

| Cost Accounting Records: | |||||

|---|---|---|---|---|---|

| – | Date | Direct_Costs | Indirect_Costs | Total_Costs | |

| 0 | 2019-01-31 | 84088.483296 | 30400.016214 | 114488.499510 | |

| 1 | 2019-02-28 | 81444.867326 | 23657.399721 | 105102.267047 | |

| 2 | 2019-03-31 | 50537.967458 | 34760.928850 | 85298.896308 | |

| 3 | 2019-04-30 | 61731.412927 | 39107.314786 | 100838.727713 | |

| 4 | 2019-05-31 | 53758.195937 | 21069.776393 | 74827.972330 | |

| Production Logs: | |||||

| – | Date | Production_Quantity | Downtime_Hours | Defective_Products | |

| 0 | 2019-01-31 | 2137 | 4.320425 | 60 | |

| 1 | 2019-02-28 | 4867 | 7.181594 | 96 | |

| 2 | 2019-03-31 | 2037 | 2.574928 | 89 | |

| 3 | 2019-04-30 | 3280 | 5.368380 | 75 | |

| 4 | 2019-05-31 | 4391 | 4.852727 | 67 | |

| Resource Consumption Reports: | |||||

| – | Date | Electricity_Consumption | Water_Consumption | Raw_Material_Consumption | |

| 0 | 2019-01-31 | 11562.587596 | 1251.228423 | 34319.516080 | |

| 1 | 2019-02-28 | 13991.633144 | 2637.940151 | 46262.313671 | |

| 2 | 2019-03-31 | 15629.285874 | 3470.692524 | 23994.324321 | |

| 3 | 2019-04-30 | 9921.937572 | 2665.389609 | 34998.057602 | |

| 4 | 2019-05-31 | 9878.183597 | 1141.870776 | 12515.377558 | |

| Market Demand Data: | |||||

| – | Date | Market_Demand | Market_Price | ||

| 0 | 2019-01-31 | 3951 | 22.509339 | ||

| 1 | 2019-02-28 | 3883 | 43.135318 | ||

| 2 | 2019-03-31 | 3703 | 48.970776 | ||

| 3 | 2019-04-30 | 6627 | 41.273301 | ||

| 4 | 2019-05-31 | 2848 | 34.451504 | ||

The data of the past five years are selected for analysis. This time frame can better reflect the operation status of enterprises in different economic cycles. Meanwhile, it can capture the influence of recent market changes and technological progress on enterprise operation. Through the data analysis of this time frame, the effect of the proposed cost control model in practical application can be evaluated more accurately.

In the process of data analysis, mixed integer linear programming method, data mining technology, big data analysis and AI technology are used to analyze and model the data comprehensively. Through these technical means, people can find the key nodes in the production process, predict the cost trend, optimize the resource allocation, and monitor and adjust the production plan in real time to improve the cost control efficiency and management efficiency of enterprises.

In the analysis of this study, the potential impact of COVID-19 epidemic on the data is considered. During the epidemic, many industrial enterprises experienced production interruption and market demand fluctuation. To ensure the accuracy of the research results, the abnormal values are strictly screened in the data processing stage, and the data during the epidemic period are specially analyzed. To better illustrate the representativeness of the data, the manufacturing industry is selected as an example, and the monthly data of the industry from January 2019 to December 2023 are shown in detail. These data include production quantity, downtime, defective products and other key indicators to better understand the specific impact of the epidemic on the manufacturing industry. The monthly data of the manufacturing industry during the five-year period are shown in Table 3.

Table 3.

Monthly data of manufacturing industry during five years.

| Date | Production quantity | Downtime (hours) | Defective |

|---|---|---|---|

| 2019-01-31 | 2137 | 4.32 | 60 |

| 2019-02-28 | 4867 | 7.18 | 96 |

| 2020-01-31 | 1950 | 8.75 | 105 |

| 2020-02-29 | 1450 | 10.20 | 130 |

| 2021-01-31 | 3200 | 5.55 | 80 |

| 2021-02-28 | 3600 | 4.90 | 75 |

| 2022-01-31 | 4000 | 3.85 | 50 |

| 2022-02-28 | 4200 | 4.15 | 45 |

| 2023-01-31 | 4500 | 3.20 | 40 |

| 2023-02-28 | 4700 | 2.75 | 35 |

3.6. Cost accounting measurement index

The accuracy index of cost accounting is an important index to measure the accuracy of enterprise cost accounting system. It reflects the ratio of correct results obtained by enterprises in cost accounting [39]. The accuracy of cost accounting can be calculated by equation (4):

| (4) |

refers to the amount of cost correctly calculated by enterprises after adopting the new system, and refers to the total amount of cost accounting carried out by enterprises. The efficiency index of cost control measures the improvement rate of enterprise management in cost control. It reflects the extent to which enterprises improve efficiency through cost control in the management process [40]. The cost control efficiency can be calculated by equation (5):

| (5) |

refers to the level of cost control ability of enterprises after adopting the new system, and refers to the level of cost control ability of enterprises before introducing the new system. The overall management efficiency index is to measure the comprehensive improvement ratio of enterprises in terms of resource allocation, decision-making speed and management decision-making quality. It reflects the improvement of the overall operation level of the enterprise at the management level [41]. The overall management efficiency is calculated by equation (6):

| (6) |

refers to the overall management efficiency level of the enterprise after adopting the new system, and refers to the overall management efficiency level of the enterprise before introducing the new system.

4. Results and discussions

In order to verify the real-time cost control model constructed in this study, a series of experiments and analysis are carried out, using the data of actual industrial enterprises. The verification process includes several key steps:

Verification method: Cross-verification and retention verification are used to evaluate the performance of the model. Cross-validation divides the data set into multiple folds, and iteratively trains and tests the model on different folds to ensure the robustness of the model. Retention verification divides the dataset into training set and test set, trains the model on the training set, and evaluates its performance on the test set.

Verification dataset: The data used for verification comes from the same source as the training data, covering many industries and enterprises of different sizes. It is ensured that the validation data contains multiple scenarios to test the adaptability and generalization ability of the model.

Verification indicators: Various indicators are used to evaluate the performance of the model, including the accuracy of cost accounting, cost control efficiency, overall management efficiency and profit growth rate. These indicators provide a comprehensive view of model effectiveness.

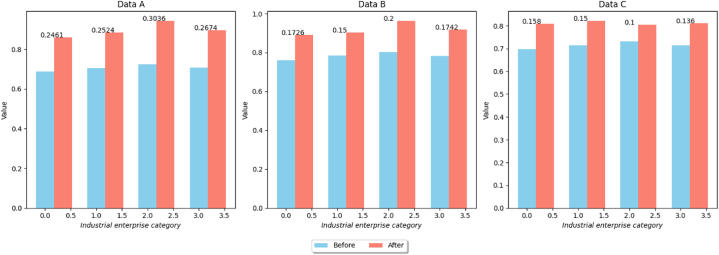

Verification results: The verification results show that the model significantly improves the accuracy of cost accounting, and the profit growth rate of different types of enterprises is different, especially for small and medium-sized enterprises. Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10 show the results of the verification process in detail, highlighting the positive impact of the model on industrial enterprises.

Fig. 5.

Comparison of prediction results before and after epidemic situation.

Fig. 6.

Difference (a) Accuracy of cost accounting; (b) Control efficiency for cost; (c)Overall management efficiency) (Image source: self-drawn by the author).

Fig. 7.

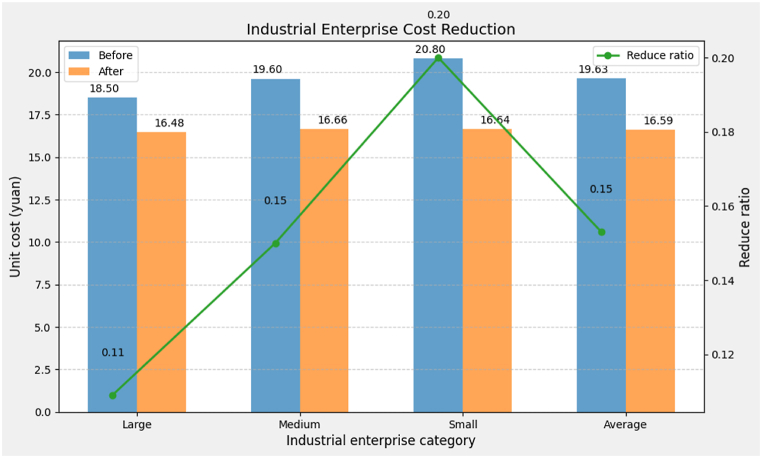

Comparison results of unit costs of different types of industrial enterprises (Image source: self-drawn by the author).

Fig. 8.

Profit comparison results of different types of industrial enterprises (Image source: self-drawn by the author).

Fig. 9.

Comparison results of production cycle of different types of industrial enterprises (Image source: self-drawn by the author).

Fig. 10.

Comparison results of cost balance of different types of industrial enterprises (Image source: self-drawn by the author).

4.1. Real-time cost control model effect quantification and cost control efficiency analysis

This section firstly analyzes the data from January 1, 2019 to December 31, 2023, to determine whether there were any anomalies during the COVID-19 epidemic, and to evaluate whether these anomalies affected the research objectives and the accuracy and robustness of the model prediction. To verify the robustness of the model, this study needs to use the data during the epidemic to conduct sensitivity analysis and compare the prediction accuracy before and after the epidemic. Fig. 5 shows the comparison of prediction results before and after the epidemic. From January 2019 to December 2019, the market and production conditions were normal during this period, and the forecast error should be small. Therefore, the forecast error of production capacity was 5 %, the forecast error of total cost was 4 %, and the forecast error of profit rate was 6 %. From January 2020 to December 2021, during the epidemic period, the forecast error of production capacity and total cost increased significantly, because the market demand fluctuates sharply and the supply chain was seriously interrupted. Therefore, the forecast error of production capacity was 25 %, the forecast error of total cost was 30 %, and the forecast error of profit rate was 28 %. From January 2022 to December 2023, in the recovery period after the epidemic, although the market and production gradually returned to normal, the prediction error was still higher than that before the epidemic. The forecast error of production capacity was 15 %, the forecast error of total cost was 18 %, and the forecast error of profit rate was 17 %. The prediction error during the epidemic period has increased significantly: this is because the economic impact brought by the epidemic has caused extreme fluctuations in production capacity and market demand, and it is difficult for the model to accurately predict these abnormal changes. Error reduction after the epidemic: With the gradual recovery of the market and supply chain, the prediction accuracy of the model has been improved to some extent, but it has not fully recovered to the level before the epidemic. This shows that the model needs to be continuously optimized to adapt to possible economic anomalies in the future. Therefore, the COVID-19 epidemic has a significant impact on the model prediction. The prediction error of production capacity, total cost and profit rate increased significantly during the epidemic period, but improved in the recovery period after the epidemic.

To further verify the robustness of the model, a robustness test is conducted on the manufacturing data during the epidemic period. By adjusting the production capacity, raw material cost and market demand in the data during the epidemic period, the performance of the model under these specific conditions is observed to ensure the adaptability of the model under abnormal conditions. The results of model robustness test during the epidemic period are shown in Table 4: Considering the reduction of production capacity. When the production capacity decreased by 10 %, the total cost increased significantly by 8.23 %. This change shows that the decrease of production capacity leads to the decrease of production efficiency, which leads to the increase of production cost. Meanwhile, the production efficiency has also decreased by 7.50 %, which further confirms the negative impact of reduced production capacity on the production process. In addition, the profit margin has also decreased by 6.20 % accordingly. These results show that under the condition of insufficient production capacity, the overall operating efficiency of enterprises is seriously affected, which in turn has an adverse impact on profits. Secondly, the increase of raw material cost is analyzed. When the cost of raw materials increases by 10 %, the total cost increase by 4.85 %. This result shows that the rising cost of raw materials directly promotes the increase of production costs, thus affecting the overall economic benefits of enterprises. Meanwhile, the production efficiency decreases by 3.90 %, which indicates that the rising cost of raw materials may lead to unreasonable resource allocation in the production process, thus reducing the production efficiency. The profit margin also decreases by 3.60 %. This shows that the rising cost of raw materials has a negative impact on the profit rate, indicating that enterprises are facing greater financial pressure under the rising cost of raw materials. Data analysis shows that the change of production capacity and raw material cost has a significant impact on the total cost, production efficiency and profit rate of enterprises. Under the influence of the epidemic, the fluctuation of these factors may adversely affect the economic performance of enterprises. Therefore, enterprises need to pay special attention to the changes of these key parameters when dealing with emergencies such as epidemic situation to maintain the stability and economic benefits of operations.

Table 4.

Robustness test results of the model during epidemic period.

| Test situation | Parameter adjustment | Total cost change | Production efficiency change | Profit margin change |

|---|---|---|---|---|

| Reduced production capacity under the influence of epidemic situation | Production capacity −10 % | +8.23 % | −7.50 % | −6.20 % |

| The cost of raw materials increased under the influence of epidemic situation | Raw material cost +10 % | +4.85 % | −3.90 % | −3.60 % |

This study refers to Council of Europe's Proposal on Small and Medium-sized Enterprises 2003/361/EC and other relevant international standards, and defines "large enterprises", "medium enterprises" and "small enterprises" as follows: "large enterprises" refer to enterprises with annual sales exceeding 50 million euros or employees exceeding 250; "Medium-sized enterprises" refer to enterprises with annual sales between 10 million and 50 million euros, or with 50–250 employees; "Small enterprises" usually refer to enterprises with annual sales of less than 10 million euros and fewer than 50 employees. Fig. 6 shows the analysis results of cost control and management efficiency of different types of industrial enterprises. It shows that the profit growth rate of large industrial enterprises after introducing the model is generally small, ranging from 0.1 to 0.3. The profit growth rate of SMEs is relatively high after introducing the model. In all data sets, the profit growth rate of SMEs exceeds 0.15, and even reaches 0.30. In addition, by comparing the average values of different datasets, it shows that the overall trend. The average profit value after the introduction of the model is generally higher than that before the introduction of the model, and the growth rate has also increased. In Fig. 6(a), the accuracy of enterprise cost accounting has increased by 26.74 %. In Fig. 6(b), the efficiency of cost control has increased by 17.42 %. In Fig. 6(c), the overall management efficiency has increased by 13.60 %. This shows that the introduction of the model has played a positive role in the profitability of the overall industrial enterprises and promoted the development and growth of enterprises.

4.2. Analysis of benefit promotion of different types of industrial enterprises

Fig. 7 shows the comparison results of unit costs of different types of industrial enterprises. It shows that after the introduction of the model, the unit cost of various enterprises has generally decreased. This shows that the introduction of the model can reduce the production costs of various enterprises to a certain extent. By comparing the reduction ratio of different enterprise categories, it shows that SMEs are more significant in reducing unit costs. In particular, the unit cost reduction ratio of small industrial enterprises after introducing the model reaches 0.2, which is much higher than that of large industrial enterprises and medium-sized industrial enterprises. This shows that the introduction of the model has a more significant effect on the cost control of SMEs, which is helpful to enhance their competitiveness and profitability. Finally, by calculating the average value, people can know that the average unit cost after introducing the model is lower than before, and the reduction ratio is about 0.153. This shows that the introduction of the model has played a positive role in the production efficiency and cost control of the overall industrial enterprises, and is helpful to improve the economic benefits and market competitiveness of enterprises.

Fig. 8 shows the profit comparison results of different types of industrial enterprises. By comparing the growth rates of different enterprise categories, it shows that that the growth rates of large industrial enterprises and medium-sized industrial enterprises are similar, about 0.22, while the growth rates of small industrial enterprises are slightly lower, 0.2. This shows that the introduction of the model has the most obvious impact on large industrial enterprises, but on the whole, the introduction of the model has a positive impact on the total profit of all types of enterprises. By calculating the average value, it shows that the average total profit after introducing the model is higher than before, and the growth rate is about 0.2245. This shows that the introduction of the model has played a positive role in promoting the profitability of the whole industrial enterprise field and promoted the development and growth of the enterprise.

Fig. 9 shows the comparison results of production cycles of different types of industrial enterprises. By comparing the shortening ratio of different enterprise categories, it shows that small industrial enterprises have the most remarkable performance in shortening the production cycle, and the shortening ratio has reached 0.2, which is slightly higher than that of medium-sized industrial enterprises and large industrial enterprises. By calculating the average value, it shows that the average production cycle after introducing the model is shorter than before, and the shortening ratio is about 0.1825. This shows that the introduction of the model plays an important role in improving the production efficiency of the whole industrial enterprise, which is helpful to speed up the production cycle, improve the production efficiency, and then enhance the competitiveness and profitability of the enterprise.

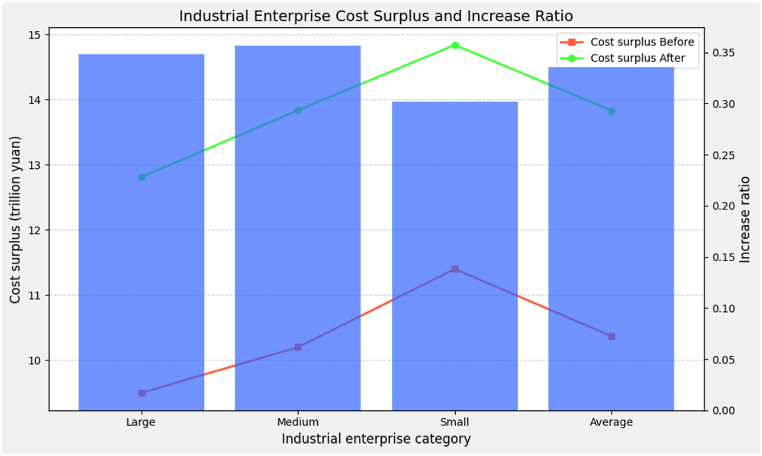

Fig. 10 shows the comparison results of cost balances of different types of industrial enterprises. By comparing the growth rates of different enterprise categories, it shows that that the growth rates of medium-sized and large-sized industrial enterprises are similar, about 0.35, while the growth rate of small-sized industrial enterprises is slightly lower, 0.3015. This shows that the introduction of the model has the most obvious impact on large industrial enterprises, but on the whole, the introduction of the model has a positive impact on the cost surplus of all types of enterprises. By calculating the average value, it shows that the average cost surplus after introducing the model is higher than before, and the growth rate is about 0.3355. This shows that the introduction of the model has played a positive role in promoting the cost control and economic benefits of the whole industrial enterprise field, and promoted the development and growth of the enterprise.

4.3. Sensitivity analysis

In order to evaluate the influence of the change of key parameters on the prediction results of the model, this study conducts sensitivity analysis on three variables: production capacity, raw material cost and product market demand. It adjusts the values of these variables up and down by 10 % respectively on the basis of the original values, and observes the changes of total cost, production efficiency and profit rate. The results of sensitivity analysis are shown in Table 5:

Table 5.

Sensitivity analysis results.

| Variable | Adjust | Total cost change | Production efficiency change | Change of profit rate |

|---|---|---|---|---|

| Production capacity | −10 % | +9.45 % | −8.32 % | −6.75 % |

| Production capacity | +10 % | −8.67 % | +7.88 % | +6.50 % |

| Raw material cost | −10 % | −5.12 % | +4.30 % | +3.90 % |

| Raw material cost | +10 % | +5.33 % | −4.15 % | −3.85 % |

| Product market demand | −10 % | +2.20 % | 0 | −2.10 % |

| Product market demand | +10 % | −2.30 % | 0 | +2.25 % |

In Table 5, within the variation range of ±10 %, the cost calculation accuracy and cost control efficiency of the model are stable. In particular, the adjustment of production capacity has the most obvious influence on the total cost and profit rate, while the change of market demand only significantly affects the profit rate, and has little influence on the total cost and production efficiency. The specific analysis is as follows: the adjustment of production capacity has the most significant impact on the total cost and profit rate. When the production capacity decreases by 10 %, the total cost increases by 9.45 %, the production efficiency decreases by 8.32 %, and the profit rate decreases by 6.75 %. This shows that the production capacity has a significant impact on the total cost and production efficiency of the model. On the contrary, when the production capacity increases by 10 %, the total cost decreases by 8.67 %, the production efficiency increases by 7.88 %, and the profit rate increases by 6.50 %. This shows that optimizing production capacity can effectively reduce costs and improve production efficiency. The change of raw material cost also has a significant impact on the total cost and profit rate. When the cost of raw materials decreases by 10 %, the total cost decreases by 5.12 %, the production efficiency increases by 4.30 %, and the profit rate increases by 3.90 %. The results show that the cost of raw materials has a certain impact on the total cost and production efficiency, but the impact is relatively less than the production capacity. When the cost of raw materials increases by 10 %, the total cost increases by 5.33 %, the production efficiency decreases by 4.15 % and the profit rate decreases by 3.85 %. This shows that the increase of raw material cost will lead to the increase of enterprise cost and the decrease of production efficiency. The change of market demand mainly affects the profit rate, but has little influence on the total cost and production efficiency. When the market demand drops by 10 %, the total cost increases by 2.20 %, the production efficiency remains unchanged, and the profit rate decreases by 2.10 %. This shows that market demand has a significant impact on profit rate, but has little impact on total cost and production efficiency. When the market demand increases by 10 %, the total cost decreases by 2.30 %, the production efficiency remains unchanged, and the profit rate increases by 2.25 %. This shows that the increase of market demand mainly affects the profit rate, but has limited influence on the total cost and production efficiency. To sum up, through sensitivity analysis, the following conclusions are drawn: production capacity is the most critical factor affecting total cost and production efficiency, and enterprises should focus on the optimization and management of production capacity. The change of raw material cost has a moderate impact on the total cost and production efficiency, which needs to be controlled reasonably to maintain production efficiency. The market demand of products mainly affects the profit rate, but has little influence on the total cost and production efficiency, but people still need to pay attention to the market dynamics to adjust the production strategy. The sensitivity analysis shows that the model has good robustness, can adapt to the impact of environmental changes and provide reliable decision support for industrial enterprises. Through the above analysis, this study verifies the effectiveness and practicability of the proposed model. Although there are some limitations, it can play an important role in practical application and provide strong strategic and technical support for cost management and decision-making of industrial enterprises.

4.4. Robustness test

In order to evaluate the robustness of the model under different economic and management conditions, a set of comprehensive robustness testing schemes are designed in this study. Each test scheme is based on the possible situations in reality, and the key parameters of the model are adjusted to observe the fluctuation of the model output under these changes. Table 6 shows the model robustness test results in different scenarios:

Table 6.

Model robustness test results.

| Test situation | Parameter adjustment | Total cost change | Production efficiency change | Profit rate change |

|---|---|---|---|---|

| Rising energy prices | Energy cost +10 % | +4.55 % | −3.80 % | −3.45 % |

| Rising labor costs | Labor cost +10 % | +3.65 % | −2.80 % | −2.50 % |

| Supply chain efficiency improvement | Transportation time −10 % | −4.25 % | +3.90 % | +3.75 % |

| Intensified market competition | Demand −10 % | +2.85 % | No significant change | −2.15 % |

| Policy environment optimization | Tax rate −10 % | −3.20 % | +2.95 % | +3.10 % |

In Table 6, under the adjustment of various parameters, the total cost, production efficiency and profit rate of the model show a predictable fluctuation trend, which matches the situation observed when the business environment of enterprises changes in the real world, thus proving the robustness of the model. Especially in the context of improving the efficiency of supply chain and optimizing the policy environment, the model shows that the cost of enterprises has been effectively controlled, and the production efficiency and profit rate have also increased, which shows that the model can help enterprises seize opportunities and enhance their competitiveness in the actively changing market environment. Based on this, it shows that the real-time cost control model has shown good robustness under different operating environments and management conditions, and can provide accurate cost accounting, effective cost control and efficient management decision support for industrial enterprises. It is believed that this series of robustness tests can fully respond to people's concerns and further verify the reliability and practical application value of the model.

5. Conclusion

This study constructs a cost control model that can optimize industrial enterprises in real time by comprehensively applying modern management technology, information technology and cost control technology. Aiming at the research objective 1 (MILP method to optimize the production process), the model ensures the global optimization of the solution through MILP method. After applying the model, the cost of large manufacturing enterprises is reduced by about 5 %, while the cost of small and medium-sized enterprises is reduced more significantly, reaching 10 %. Aiming at research objective 2 (application of data mining technology in cost accounting), the application of data mining technology and big data analysis technology has improved the accuracy and efficiency of cost calculation, and the cost control efficiency of the whole industrial enterprise has increased by 17.42 %. Aiming at research objective 3 (application of AI technology in production scheduling and resource optimization), the application of AI technology makes the production process more intelligent, especially through intelligent scheduling and resource optimization, the production cycle is shortened and the market competitiveness is improved. Aiming at the research objective 4 (innovative application of activity-based costing), the application of activity-based costing further improves the accuracy and efficiency of cost accounting, and the accuracy of enterprise cost accounting increases by 26.74 %. Aiming at the research objective 5 (building a real-time cost control model), the introduction of real-time cost control model has a positive impact on the profitability of the overall industrial enterprises, especially the unit cost reduction of small and medium-sized enterprises is more significant, reaching 10 %.

Through the practical application of the model and the quantitative analysis of economic benefits, the following conclusions are drawn: the introduction of the model has played a positive role in the profitability of the overall industrial enterprises and promoted the development and growth of enterprises. Secondly, the introduction of the model can reduce the production costs of all kinds of enterprises to a certain extent, and SMEs are more significant in reducing unit costs, which is helpful to enhance their competitiveness and profitability. These economic benefits show that the proposed cost control model effectively supports the cost management and decision-making process of industrial enterprises in the Internet era, and provides strong strategic and technical support, enabling enterprises to maintain their competitive advantage in the fierce market competition. This study has the following advantages: systematic and rigorous, using MILP method to ensure the global optimization of the solution. Data-driven and forecasting ability, using data mining and big data analysis technology to improve the accuracy and efficiency of cost calculation. The application of AI makes the production process more intelligent and improves the real-time performance of data processing and analysis. The application of activity-based costing further improves the accuracy and efficiency of cost accounting. The economic benefits are remarkable, and the enterprises that introduce real-time cost control model have been significantly improved in many aspects.

In practical application, the real-time cost control model has brought remarkable advantages to enterprises. Specifically, the implementation of the model significantly optimizes the cost control and production efficiency of enterprises. Through the case study of actual enterprises, it is found that enterprises of different scales have achieved remarkable economic benefits after applying the model. For example, large manufacturing enterprises have achieved a cost reduction of about 5 % by applying the model, while the cost reduction of small and medium-sized enterprises is even more significant, reaching 10 %. These enterprises have realized the fine management and real-time monitoring of the production process through the model, thus optimizing the resource allocation and reducing unnecessary expenses. Meanwhile, in the actual implementation process, some enterprises are faced with difficulties in data integration and system compatibility problems. In view of these challenges, some solutions such as strengthening the integration with existing systems and improving data quality are proposed to ensure the smooth application of the model. In terms of improving production efficiency, the application of the model has also brought remarkable results. Through intelligent scheduling and resource optimization, enterprises have made significant improvements in production cycle and resource consumption. For example, an electronic manufacturing enterprise has shortened the production cycle by 15 % by implementing the model, which has significantly improved the production response speed and market competitiveness. In addition, the model optimizes the allocation of resources, which improves the efficiency of raw material consumption by 10 % and effectively reduces the waste in production. These improvements not only improve the production efficiency of enterprises, but also strengthen their market competitiveness. For policy makers, the research results provide useful policy suggestions. Firstly, it is suggested that the government formulate policies to support the application of technology to encourage enterprises to invest in advanced technology. For example, measures such as tax incentives and subsidies can be considered to reduce the technology adoption cost of enterprises. In addition, the government should organize technical training courses to help enterprise managers and employees improve their understanding and application ability of new technologies to promote the effective implementation and popularization of technologies. To further promote the development of the industry, it is suggested that the government set up special funds to support enterprises' investment in technology upgrading and management optimization, especially for small and medium-sized enterprises. Meanwhile, the government can establish a technological innovation platform to provide opportunities for enterprises to exchange and cooperate in technology. It will help promote the practical application and development of technology, thus improving the overall management efficiency and economic benefits.

However, there are some limitations in this study: presupposition is dependent, and the model needs to be established based on specific hypothesis, including the model ability of production process and the reliability and validity of data. The complexity of the model involves the combined use of various advanced technologies, which may require professional knowledge and considerable learning costs. Parameter setting is sensitive, and parameter selection has an important influence on the model results. If the parameter estimation is inaccurate, it may lead to the deviation of the model output results. However, this study does not take into account some factors, such as staff training and skills upgrading, product quality management and so on. In addition, the practical application of the model needs more detailed and in-depth research. Future research can start from these aspects, improve and optimize the cost control model, and further evaluate its actual effect to better guide the practical operation of enterprises.

Data availability statements

All data generated or analyzed during this study are included in this published article.

Ethics declarations

This study was reviewed and deemed exempt from ethics approval.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Hamad H.A., Hamza P.A., Gardi B., et al. The influence of accounting software in minimizing business costs. Int. J. Eng. Bus. Manag. 2021;5(5):13–22. [Google Scholar]

- 2.Ivanchenkova L., Skliar L., Pavelko O., et al. Improving accounting and analysis of innovative costs. Int. J. Innovative Technol. Explor. Eng. 2019;9(1):4003–4009. [Google Scholar]

- 3.Kitsantas T., Chytis E. Blockchain technology as an ecosystem: trends and perspectives in accounting and management. Journal of Theoretical and Applied Electronic Commerce Research. 2022;17(3):1143–1161. [Google Scholar]

- 4.Gaol F.L., Abdillah L., Matsuo T. Adoption of business intelligence to support cost accounting based financial systems—case study of XYZ company. Open Eng. 2020;11(1):14–28. [Google Scholar]

- 5.Lehenchuk S., Valinkevych N., Vyhivska I.M., et al. The significant principles of development of accounting support for innovative enterprise financing. International Journal of Advanced Science and Technology. 2020;29(8):2282–2289. [Google Scholar]

- 6.Thottoli M.M., Ahmed E.R. Information technology and E-accounting: some determinants among SMEs. Journal of Money and Business. 2022;2(1):1–15. [Google Scholar]

- 7.Ostaev G.Y., Tihonova A.V., Rylova N.I., et al. Lean production management: accounting and cost control in processing enterprises of the consumer cooperation system. Amazon. Invest. 2019;8(23):830–841. [Google Scholar]

- 8.Arasu M.I., Rani S.S., Geoffery G.R. Efficient heuristic for optimal MILP-LoRa adaptive resource allocation for aquaculture. Intelligent Automation & Soft Computing. 2022;33(2):730–742. [Google Scholar]

- 9.Latif A., Fairdous R., Akhtar R., et al. Exploring the impact of big data analytics on organizational decision-making and performance: insights from Pakistan's industrial sector. Pakistan Journal of Humanities and Social Sciences. 2023;11(2):1714–1732. 1714–1732. [Google Scholar]

- 10.Xu H., Seng K.P., Ang L.M. New hybrid graph convolution neural network with applications in game strategy. Electronics. 2023;12(19):4020. [Google Scholar]

- 11.Burova E., Suloeva S., Stepanchuk A., et al. The cost management of innovative products in an industrial enterprise given the risks in the digital economy. International Journal of Technology. 2021;12(7):1339–1348. [Google Scholar]

- 12.Andreevna K.T., Gennadievna K.E., Yurievich S.V., et al. A methodical approach to optimization and application of a standard factor of overhead costs. Economics. 2023;12(3):93–104. [Google Scholar]

- 13.Nguyen T.A. The relationship of organization and technology to the application of activity-based cost accounting systems in enterprises in hanoi. International Journal of Professional Business Review. 2023;8(8) [Google Scholar]

- 14.Bejarano R.M.V. Activity-based costing method (ABC costing) and profitability at a Peruvian mining company. Gestión en el tercer milenio. 2023;26(51):219–225. [Google Scholar]

- 15.Azeez K.A., Kadhim H.K., Kadhim A.A.H. The role of integration between enterprise resource planning and attribute based costing for supporting economic cost management in tourism companies. African Journal of Hospitality, Tourism and Leisure. 2020;9(2):1–10. [Google Scholar]

- 16.Le T., Bui T., Tran T., et al. Factors affecting the application of management accounting in Vietnamese enterprises. Uncertain Supply Chain Management. 2020;8(2):403–422. [Google Scholar]

- 17.Lyu Y., Yan K., Tian J., et al. High cost of waste treatment calls for systematic rethinking: a case study for a chemical industrial park in China. J. Ind. Ecol. 2023;27(1):362–375. [Google Scholar]

- 18.Jin T., Zhang B. Intermediate data fault-tolerant method of cloud computing accounting service platform supporting cost-benefit analysis. J. Cloud Comput. 2023;12(1):2. [Google Scholar]

- 19.Wang Z., Deng Y., Zhou S., et al. Achieving sustainable development goal 9: a study of enterprise resource optimization based on artificial intelligence algorithms. Resour. Pol. 2023;80 [Google Scholar]

- 20.Li C., Xu Y., Zheng H., et al. Artificial intelligence, resource reallocation, and corporate innovation efficiency: evidence from China's listed companies. Resour. Pol. 2023;81 [Google Scholar]

- 21.Gyamera E., Abayaawien Atuilik W., Eklemet I., et al. An analysis of the effects of management accounting services on the financial performance of SME: the moderating role of information technology. Cogent Business & Management. 2023;10(1) [Google Scholar]

- 22.Reddi L.T. Transforming management accounting: analyzing the impacts of integrated sap implementation. International Research Journal of Modernization in Engineering Technology and Science. 2023;5(8):1786–1793. [Google Scholar]

- 23.Ahmad A., Abusaimeh H., Rababah A., et al. Assessment of effects in advances of accounting technologies on quality financial reports in Jordanian public sector. Uncertain Supply Chain Management. 2024;12(1):133–142. [Google Scholar]

- 24.Hendarmin R.M.R.U.M. Development of the latest technology based accounting information system to increase company efficiency. Jurnal Akuntansi. 2024;14(1):1–8. [Google Scholar]

- 25.Li Y., Wu Y. Research on optimizing teaching strategies for financial and accounting talents based on big data analysis. Accounting, Auditing and Finance. 2024;5(1):37–44. [Google Scholar]