Abstract

Numerous problems, including weathering, cracks, leaks, and bending, among others, appear in concrete after construction. The optimum procedure for treating concrete cracks is the subject of this study. The research goal is to find potential crack treatment materials and analyze the effect on the properties of concrete caused by the addition of bacterial solution to the concrete mix along with a particular method of preparation of bacterial solution. The principal results of the experimental testing showcased a successive growth in the compressive strength when the concrete cubes were casted with the bacterial addition from Bacillus family with a significant change in the quality of concrete. Following are the primary research outcomes of the method:

-

•

Use of Bacillus bacterial with direct addition in concrete improves concrete's performance.

-

•

The proposed method of concrete mix with Bacillus Sphaericus Solution in 30 ml concentration, replacing partial water cement ratio, yields maximum compressive strength on 28th day curing. For expediting setting time with high compressive strength, adding Bacillus Sphaericus solution in 45 ml concentration is recommended.

-

•

For achieving a homogenous mix with lesser cracks on 28th day, Bacillus Subtilis Spores in 30 ml concentration can be added to concrete with partial replacement of the water requirement.

Keywords: Material testing, Concrete, Compressive strength, Bacterial concrete, Property enhancement

Method name: Use of Bacillus Family Bacteria in optimal concrete mix design for performance enhancement

Graphical abstract

Specifications table

| Subject area: | Engineering |

| More specific subject area: | Concrete Technology |

| Name of your method: | Use of Bacillus Family Bacteria in optimal concrete mix design for performance enhancement |

| Name and reference of original method: | Van Tittelboom, K., De Belie, N., De Muynck, W. and Verstraete, W. (2010) “Use of bacteria to repair cracks in concrete.” Cement and Concrete Research, 4 (1), Elsevier Ltd, pp. 157–166. |

| Resource availability: | Not applicable |

Background

One of the most often utilized, reliable, robust, and reasonably priced building materials is concrete. One drawback is that concrete production in large quantities has a negative impact on the environment. Production of cement, sand, and aggregate; mining and transportation, result in increased greenhouse gas emissions, increased energy demand, and environmental damage. According to research, 7 % of all CO2 emissions worldwide are caused by the production of ordinary portland cement that converts calcium carbonate (CaCO3) into calcium oxide (CaO) with the emission of CO2 [1]. In light of this, concrete doesn't seem like an ideal material from an environmental standpoint. Concrete's propensity for cracking is another issue that lowers its durability [2]. With any type of building material, distress and faults are typically expected during the course of a structure's lifetime [3]. Particularly, cracks in the top coat of concrete shorten its lifespan because of moisture entering the cracks, hazardous chemicals deteriorating and corroding the reinforcement [4]. Due to the exposure to harsh weather, structures are subject to micro-level deterioration, threatening the structural integrity [5]. The use of polymer-based additives to improve the physical, mechanical and durability properties of concrete has become widespread [6]. A research work has detailed a procedure of utilizing carbon fiber-reinforced polymer (CFRP) sheets to strengthen the retrofitted structure [7]. The development of sustainable repair techniques for concrete structures is need of the hour. Cracks are often repaired by inspection, renovation, and the injection of epoxy, cement or other synthetic filler materials into the cracks [4]. Several laboratories are now researching a more robust repair technique based on the use of microorganisms that produce minerals [8,9]. Some of these experiments involve the biological synthesis of calcite-based minerals using ureolytic Bacillus bacteria as a substrate. These bacteria use an enzymatic chemical reaction between urea, carbon dioxide, and ammonia to produce CaCO3. This technique decreases the permeability of the concrete, making it more effective at repairing cracks in the concrete [3]. Additionally, this mixture significantly increases the compressive strength of concrete [10]. A chloride test on a concrete specimen containing bacteria reveals that the presence of bacteria minimizes weight loss brought on by chloride exposure and boosts compressive strength [11]. Jonkers et al.'s study [12] reveals that bacterial concrete specimens produce noticeably more crack-plugging minerals than control specimens.

Alkali philic (alkali-resistant) spore-forming bacteria are the sort of bacteria that have the most potential for self-healing function [13]. Studies have shown that adding bacteria from the Bacillus family to concrete can mend cracks. For testing concrete, studies have primarily used encapsulation and bacterial spore addition; direct bacterial solution addition has been used far less frequently. It is necessary to assess the effects of adding bacterial solution directly to concrete [14]. The use of bacteria for remediating building materials mimics natural processes of rock cementation by calcium carbonate precipitation from microbes [15]. Richardson A. et al. [16] have tested surface application of bacterial solution in healing surface cracks and found it favourable. Maximum increase in compressive strength obtained in a study [17] is 16.1 % as compared with control concrete specimen. Many such studies provide insights on the usability of bacterial concrete [[18], [19], [20]–21]. Based on them, present study outlines a method for optimizing concrete performance using bacterial solution.

Method details

Selecting the appropriate bacteria, choosing a suitable growing method, consulting the appropriate standard, and finalizing the mix ratio of cement, fine and coarse aggregates in concrete, together with bacterial solution and water, are the preliminary tasks that must be completed.

Material procurement

The pure bacterial culture of Bacillus Subtilis and Bacillus Sphaericus is procured from National Collection of Industrial Microorganisms (NCIM), Pune, India. The ordinary portland cement Grade 53 is used for the experimentation. The cement is tested for various properties as per Indian standard IS: 4031–1988 [22] and is found to be confirming to various specifications of Indian standard IS: 12,269- 1987 [23]. The aggregates passing through 12.5 mm IS-Sieve and retaining on 10 mm sieve are used. The specific gravity of course aggregates is found out to be 2.50. The fine aggregates confirm to the zone II according to IS- 383 [24] with specific gravity of 2.48. In order to conduct the laboratory investigations, M20 grade concrete with a 1:1.5:3 mix ratio is chosen as the base mix.

Preparing bacterial culture

The pure culture of bacteria Bacillus Subtilis and Bacillus Subtilis is carefully preserved on nutrient agar slants. It forms irregular dry white colonies on nutrient agar slants. The media is prepared for subculturing by dissolving 13 gm of nutrient broth in 1000 ml of distilled water divided into 4 flasks each of 250 ml. After Four distinct bacterial colonies are inoculated into nutrient broth each of 250 ml in 500 ml capacity conical flask and incubated at the temperature of 37 °C and 170 rpm in orbital shaker incubator [14]. The medium composition utilized for growth of bacterial culture contains Peptone, sodium chloride and yeast-extract. Ingredients of Nutrient Broth in g/L include peptic digest of animal tissue 5.0 g, sodium chloride 5.0 g, beef extract 1.5 g, yeast extracts 1.5 g, final pH (at 25 °C) 7.4 ± 0.2. Processes involved is as follows (Fig 1):

-

•

Sterilization: Sterile environment is achieved in an autoclave at a temperature of 121 °C for 25 to 30 min. The sterilized media is allowed to cool. The conical flasks used for the experimentation are kept under UV light for 30 min to provide further sterilization, to kill if any bacteria which are present in the conical flask followed by inoculation step.

-

•

Inoculation: Streaking the bacteria on to the media with the help of an open loop is performed for inoculation. An open loop of each sample of bacteria is taken and heated near the flame to sterilize it. It is then dipped in the bacteria sample and streaked onto the prepared media.

-

•

Incubation: It is a done to grow and maintain the bacterial cultures. Samples are then ready to be added into an incubator. The streaked sample is kept in a rotary incubator shaker for 24 h at a temperature of 37 °C at 170 rpm. After 24 h, growth of bacteria is observed in the flasks.

Fig. 1.

Bacterial culture procedure.

Concrete mix design

For casting M20 grade (1:1.5:3 ratio) conventional concrete cubes, following mix design steps are followed (Table 1) meticulously as per IS 10,262–2009. Conversion factor from wet to dry volume is considered as 1.52. For casting 9 cubes, 15 kg cement, 21 kg fine aggregates and 42 kg coarse aggregates is the requirement obtained from the mix design. Water cement ratio is considered as 0.42 with which water requirement is computed for the mix design. The same proportion is taken to cast bacterial concrete cubes, varying in water proportion. As the bacterial solution adds to liquid content in the concrete, it leads to partial replacement of the water requirement as per the design. Table 2 provides the details of the bacterial solution requirement as per the chosen concentration and water requirement.

Table 1.

Concrete mix design calculations.

| Sr. No. | Design step | Details |

|---|---|---|

| 1. | Calculation of quantity of concrete | Dimensions of the cube = 0.15×0.15×0.15 Number of cubes = 9 + 1 wastage Wet Volume- Quantity of concrete= 0.15×0.15×0.15×10 = 0.03375 m3 Dry Volume (Multiplying by dry wet condition factor) = 0.03375×1.52 = 0.0513 m3 |

| 2. | For M20 (1:1.5:3) grade of concrete | 1x + 1.5x + 3x = 5.5x = 0.0513 m3 x = 0.009327 m3 |

| 3. | Calculation of quantity of cement | Cement = 0.009327 m3 Density of cement = 1440 kg/ m3 Mass of cement = 13.43088 kg |

| 4. | Calculation of quantity of fine aggregates | Fine aggregate = 0.01 39905m3 Density of fine aggregate = 1500 kg/ m3 Mass of fine aggregates = 20.9858 kg |

| 5. | Calculation of quantity of course aggregates | Coarse aggregate = 0.027981 m3 Density of coarse aggregates = 1475 kg/ m3 Mass of coarse aggregates = 41.2719 kg |

| 6. | Quantity of water required | W / C ratio = 0.42 to 0.45 Quantity of water required = 0.42×15 to 0.45×15 = 6.3 to 6.75 litres |

Table 2.

Bacterial concrete mix design calculations.

| Grade of Concrete |

Bacterial Solution Concentration |

Cement (Kg) |

Fine Aggregates (Kg) |

Coarse Aggregates (Kg) |

Water Content required (ml) | Bacterial Solution Content (ml) for casting 9 cubes from the mix |

Total Water to be added (ml) |

|---|---|---|---|---|---|---|---|

| M20 (1:1.5:3) | 15 ml | 15 | 21 | 42 | 6300 | 135 | 6165 |

| 30 ml | 6300 | 270 | 6030 | ||||

| 45 ml | 6300 | 405 | 5895 | ||||

| 60 ml | 6300 | 540 | 5760 |

For measuring the compressive strength of traditional and bacterial concrete, total 12 samples with variety of bacteria, type of solution and varying amount of bacterial culture ranging from 15 ml to 60 ml are casted as shown in Table 3. Out of total 108 cubes casted, 9 cubes for each combination are casted in the laboratory with 3 each for 7, 14 and 28-days testing.

Table 3.

Cube casting details of Bacterial concrete cubes with added bacterial solution.

| Bacteria used | Number of cubes casted for varying dosage of bacterial solution/ spores |

|||

|---|---|---|---|---|

| 15 ml | 30 ml | 45 ml | 60 ml | |

| Bacillus Subtilis Solution | 9 | 9 | 9 | 9 |

| Bacillus Sphaericus Solution | 9 | 9 | 9 | 9 |

| Bacillus Subtilis Spores | 9 | 9 | 9 | 9 |

Method validation

Selected methodology of testing the bacterial composite for its characteristics and effectiveness requires validation of the test results compared to the conventional mix results. The following Table 4 illustrates the compressive strength of conventional M20 concrete found using both destructive and non-destructive testing. Values obtained from both the tests are comparative (Fig 2) providing base values of compressive strength for M20 and M40 concrete test grade at 7, 14 and 28 days intervals.

Table 4.

Compressive strength of conventional M20 concrete.

| Days | Cubes | Compressive Strength (N/sq.mm) |

||||||

|---|---|---|---|---|---|---|---|---|

| Rebound hammer |

Compression Testing Machine |

|||||||

| Corner (N/mm2) | Center (N/mm2) | Average (N/mm2) | Final Value (N/mm2) | Reading | Compressive strength (N/mm2) | Final value (N/mm2) | ||

| 7 | 1 | 20.21 | 24.00 | 22.11 | 22.22 | 500 | 22.22 | 22.37 |

| 2 | 20.10 | 25.50 | 22.80 | 500 | 22.22 | |||

| 3 | 20.50 | 23.00 | 21.75 | 510 | 22.67 | |||

| 14 | 1 | 23.00 | 27.00 | 25.00 | 24.81 | 540 | 24.00 | 24.89 |

| 2 | 23.00 | 28.00 | 25.50 | 580 | 25.78 | |||

| 3 | 21.88 | 26.00 | 23.94 | 560 | 24.89 | |||

| 28 | 1 | 27.75 | 28.00 | 27.88 | 27.79 | 620 | 27.56 | 27.85 |

| 2 | 27.50 | 28.00 | 27.75 | 640 | 28.44 | |||

| 3 | 27.00 | 28.50 | 27.75 | 620 | 27.56 | |||

Fig. 2.

Comparison of rebound hammer and compression testing results for M20 and M40 grade of concrete.

Observations from tests on bacterial concrete

Followed by conventional concrete cube testing, all the 108 bacterial concrete cubes of 150×150×150 mm dimensions are tested for quality and strength using ultrasonic pulse velocity meter, rebound hammer and compression testing machine.

Ultrasonic pulse velocity test results

From the results of the ultrasonic pulse velocity test (Table 5), it is determined that adding 15 ml of a bacteria called Bacillus Subtilis to M20 grade concrete for 7 days results in concrete that mirrors a good quality grading, and that adding the same amount for 28 days also results in concrete that compares to a good functionality grading.

Table 5.

Ultrasonic pulse velocity test result on concrete cubes treated with a bacillus subtilis solution.

| Bacterial solution used | Bacterial concentration | 7 days pulse velocity km/s | 14 days pulse velocity km/s | 28 days pulse velocity km/s |

|---|---|---|---|---|

| Bacillus Subtilis | 15 ml | 3.84 | 3.92 | 4.22 |

| 30 ml | 3.6 | 3.85 | 4.21 | |

| 45 ml | 3.52 | 3.57 | 4.13 | |

| 60 ml | 3.39 | 3.56 | 4.06 |

Adding 15 ml of the bacteria Bacillus Sphaericus to M20 grade concrete for 7 days indicates that the standard of grading and quality of the concrete is excellent, and adding 30 ml of Bacillus Sphaericus to concrete grade of M20 for a total of 28 days indicates the same (Table 6). Similarly, based on the Ultrasonic technology pulse velocity test results (Table 7), it is determined that adding 60 ml of bacteria Bacillus Subtilis spores to M20 grade concrete for 7 days indicates excellent grading of concrete, and adding 30 ml of the bacteria Bacillus Subtilis spores to M20 grade concrete for 28 days indicate an excellent quality grading of the concrete with improved homogeneity. Addition of 30 ml of Bacillus Sphaericus solution shows highest percentage increase in 28 days compressive strength compared to conventional M20 mix results (Table 8).

Table 6.

Ultrasonic pulse velocity test results on concrete cubes infused with a bacillus sphaericus solution.

| Bacterial solution used | Bacterial concentration | 7 days pulse velocity km/s | 14 days pulse velocity km/s | 28 days pulse velocity km/s |

|---|---|---|---|---|

| Bacillus Sphaericus | 15 ml | 4.52 | 4.4 | 4.42 |

| 30 ml | 4.26 | 4.63 | 4.63 | |

| 45 ml | 4.13 | 4.72 | 4.41 | |

| 60 ml | 4.19 | 4.53 | 4.24 |

Table 7.

Ultrasonic pulse velocity test results for spores of bacillus subtilis added to concrete.

| Bacterial solution used | Bacterial concentration | 7 days pulse velocity km/s | 14 days pulse velocity km/s | 28 days pulse velocity km/s |

|---|---|---|---|---|

| Bacillus Subtilis spores | 15 ml | 4.19 | 4.53 | 4.53 |

| 30 ml | 4.17 | 4.31 | 4.73 | |

| 45 ml | 4.3 | 4.25 | 4.59 | |

| 60 ml | 4.23 | 4.12 | 4.36 |

Table 8.

% increase in 28 days compressive strength compared to conventional M20 mix results.

| Solution | Bacterial concentration | 28 days Compressive Strength (N/mm2) | % increase in compressive strength compared to conventional M20 mix results |

|---|---|---|---|

| Bacillus Subtilis solution | 15 ml | 26.27 | −6.014 % |

| Bacillus Sphaericus solution | 30 ml | 48.43 | 42.49 % |

| Bacillus Subtilis spores | 30 ml | 34.97 | 20.36 % |

Compressive strength test results

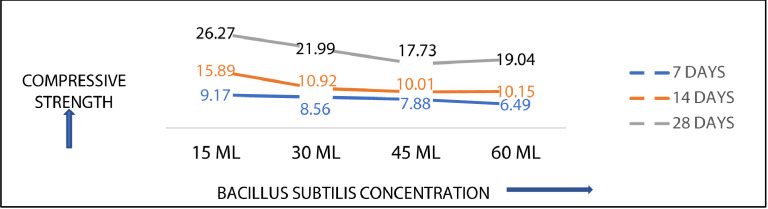

M20 grade bacterial concrete is prepared by incorporating varying proportions of Bacillus Subtilis solution, as determined through a design of experiments approach. The concrete samples are subjected to compressive strength testing using a compression testing machine at 7, 14, and 28 days of curing. The mix that has been observed to achieve the highest average compressive strength is the M20 composite with 15 ml of Bacillus Subtilis solution (Fig. 3).

Fig. 3.

Compression strength testing results for concrete cubes treated with a Bacillus Subtilis solution.

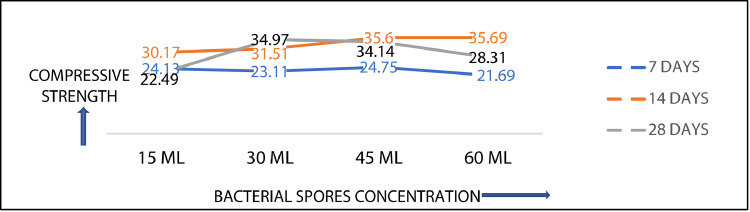

As shown in Fig. 4, the maximum median compressive strength is observed on the 28th day of curing when 30 ml of Bacillus Sphaericus solution is added to the M20 concrete mix. Similarly, Fig. 5 indicates that the highest average compressive strength under compression is recorded on the 28th day of curing when 30 ml of Bacillus subtilis spores are added into the M20 concrete mix.

Fig. 4.

Compression strength test results for the addition of the Bacillus Sphaericus solution to the concrete cube.

Fig. 5.

Compression strength testing results for Bacillus Subtilis spores added to concrete cubes.

Bacillus subtilis solution in 15 ml concentration exhibits highest compressive strength, however records 6.014 % decrease as compared with conventional M 20 grade concrete. Bacillus Sphaericus records the maximum strength in all the composites for 30 ml concentration with 42.49 % increase in the compressive strength of M20 grade of concrete, 22.61 % increase in the compressive strength of M40 grade of concrete. Bacillus subtilis spores as well, provide 20.36 % rise in the compressive strength of concrete mix.

Rebound hammer test results

M20 grade bacterial concrete, incorporating varying proportions of Bacillus Subtilis solution as determined through a design of experiments, is tested for compressive strength using a rebound hammer on cube specimens cured for 7, 14, and 28 days. The mix that yields the highest average compressive strength is the M20 composite with 30 ml of Bacillus Subtilis solution (Fig. 6).

Fig. 6.

Average compression strength using rebound hammer for concrete with Bacillus Subtilis solution.

As shown in Fig. 7, the highest average compressive strength reading is achieved when 30 ml of Bacillus Sphaericus solution is mixed into the M20 concrete and cured for 28 days. Similarly, Fig. 8 indicates that the maximum average compressive strength under compression is recorded on the 28th day of curing when 30 ml of Bacillus Subtilis spores are added to the M20 concrete mix. Among all the bacterial solution combinations and concentrations tested, Bacillus Sphaericus with a 30 ml concentration produces the highest average compressive strength in the rebound hammer test.

Fig. 7.

Average Compression strength using rebound hammer for concrete with Bacillus Sphaericus solution.

Fig. 8.

Compression strength testing results using rebound hammer for concrete with Bacillus Subtilis spores.

Discussion

Microbial mineral precipitation appears to be a promising technique. The type of bacterial culture and medium composition has a profound impact on the final strength and performance of the composite [25]. As per a study [26], the bacterial cell walls significantly increase compressive strengths of concrete by 15 % and also decrease porosity at 28 days of curing when using Bacillus Subtilis. Surface treatment of concrete slabs with bacterial solution have shown results that improve surface quality and reduce percolation through the surface increasing water retention [27].

Special characteristics of incorporating bacterial solution in self-healing bacterial concrete have been observed and tested in this study especially with genus Bacillus Subtilis and Bacillus Sphaericus of the Bacillus family. It is profoundly observed that the bacterial concrete mimics the process of bone healing in human body. The bacterial culture can remain dormant for 200 years in dry condition and germinates on contact with water during the course of time. As the oxygen is consumed in the process of releasing carbonates in bacterial concrete, it helps in preventing the corrosion of steel within RCC members. The material and process has proven to be economical, sustainable and effective in addressing the frequent maintenance issues and diminishing structural integrity of concrete structures. To ensure bacterial survival during concrete mixing and hardening, encapsulation of bacteria in suitable carriers is preferable [28].

It can be observed from Table 9 that, adding Bacillus Sphaericus solution to the concrete results in the highest possible compressive strength assessment findings for the 28-day test. Acoustic pulse velocity increases when bacteria from the Bacillus family, including Bacillus Subtilis and Bacillus Sphaericus, are added to concrete cubes in the form of solution or spores. It is apparent from the table below, that, for a 28-day Ultrasonic technology Pulse Velocity test, adding Bacillus Subtilis spores to the concrete yields the absolute maximum pulse velocity test results (Table 10), demonstrating that the mixture of concrete is identical and regular, while there are very few cracks inside the cubes of concrete.

Table 9.

Maximal value of compressive strengths for 7, 14 and 28 days on mixture of bacterial solution and spores.

| No. of Days of curing |

15 ml concentration in concrete mix | 30 ml concentration in concrete mix | 45 ml concentration in concrete mix | 60 ml concentration in concrete mix |

|---|---|---|---|---|

| 7 | Bacillus Subtilis Spores 24.13 N/mm2 |

Bacillus Subtilis Spores 23.11 N/mm2 |

Bacillus Sphaericus Solution 27.74 N/mm2 |

Bacillus Sphaericus Solution 24.68 N/mm2 |

| 14 | Bacillus Subtilis Spores 30.17 N/mm2 |

Bacillus Subtilis Spores 31.51 N/mm2 |

Bacillus Subtilis Spores 35.6 N/mm2 |

Bacillus Subtilis Spores 35.69 N/mm2 |

| 28 | Bacillus Sphaericus Solution 28.57 N/mm2 |

Bacillus Sphaericus Solution 48.43 N/mm2 |

Bacillus Sphaericus Solution 36.73 N/mm2 |

Bacillus Sphaericus Solution 30.78 N/mm2 |

Table 10.

Maximal value of pulse velocity for 7, 14 and 28 days on addition of Bacterial solution and spores.

| No. of Days of curing |

15 ml concentration in concrete mix | 30 ml concentration in concrete mix | 45 ml concentration in concrete mix | 60 ml concentration in concrete mix |

|---|---|---|---|---|

| 7 | Bacillus Sphaericus Solution 4.52 km/s | Bacillus Sphaericus Solution 4.26 km/s | Bacillus Subtilis Spores 4.3 km/s | Bacillus Subtilis Spores 4.23 km/s |

| 14 | Bacillus Subtilis Spores 4.53 km/s |

Bacillus Sphaericus Solution 4.63 km/s | Bacillus Sphaericus Solution 4.72 km/s | Bacillus Sphaericus Solution 4.53 km/s |

| 28 | Bacillus Subtilis Spores 4.53 km/s |

Bacillus Subtilis Spores 4.73 km/s |

Bacillus Subtilis Spores 4.59 km/s |

Bacillus Subtilis Spores 4.36 km/s |

According to the above data, adding Bacillus Sphaericus solution into concrete at concentrations of 15 ml, 30 ml, and 60 ml results in the absolute maximum value of average compressive strength test results during testing at the end of 28 days of curing. The maximum mean compressive strength over the course of 28 days was obtained when 45 ml Bacillus Subtilis spores were injected in the concrete mix.

Upon addition of bacterial solution and spores in various concentrations, a significant increase in the compressive strengths is noticed. Addition of Bacillus Sphaericus in solution form, leads to the concrete possessing the maximal compressive strength, when added to the concrete mix in 30 ml concentration. For the industries requiring initially faster setting concrete with a high compressive strength, addition of Bacillus Sphaericus solution in 45 ml concentration to the concrete mix would yield them the desired results, whereas if higher compressive strength is desired on and after 28 days, the mixing of Bacillus Sphaericus solution in 30 ml would lead to the higher value of compressive strength.

When the bacterial concrete cubes are tested with ultrasonic pulse velocity meter, the pulse velocity observed in that of all the specimens is approximately above 4.0 Km/sec and ranging till 4.7 Km/sec. This indicates an excellent quality of concrete in terms of standardization, absenteeism of interior cracks and showing that the concrete mix is homogeneously consistent. In case of an early determination of the quality of concrete, addition of Bacillus Sphaericus solution results in the higher value of desired pulse velocity, whereas for 28 days and after, the addition of Bacillus Subtilis spores delivers the highest value of pulse velocity indicating an excellent grade of concrete.

The cost of concrete for 1 m3 of concrete is INR 5301.41 for M20 grade and that of M40 grade is approximately INR 9100.91 based on te calculations of the dry volume of mix and bacterial solution required. As M20 grade concrete with bacterial solution in prescribed dosage attains compressive strngth of that of M40, it can be easily used for repacing M40 requirement on field saving a huge cost percentage on the material. The proposed method, hence, is extremely benefial not just from the sustianability aspect but also from the economic perspective during construction and post construction as it also saves money in maintenance.

Limitations

The study provides future scope for research in assessing the long-term durability and resistance of the bacterial-treated concrete to environmental factors such as moisture, temperature fluctuations, or chemical exposure providing future scope fo research. The study focuses on Bacillus Sphaericus and Bacillus Subtilis, which restricts the results' applicability to other bacterial strains that may have distinct effects on compressive strength and pulse velocity. The study's findings may be limited to the experimental scale and may not fully reflect performance when scaled up for large-scale applications.

Supplementary material and/or additional information [OPTIONAL]

NA.

Ethics statements

NA.

CRediT authorship contribution statement

Sayali Sandbhor: Conceptualization, Methodology, Testing, Writing original draft, Supervision. Sayali Apte: Writing- Reviewing and Editing, Supervision. Shubham Puranik: Conceptualization, Methodology, Investigation, Testing, Writing original draft. Mansi Asati: Writing- Reviewing and Editing. Samyak Rai: Writing- Reviewing and Editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the Symbiosis International (Deemed University) Major Project Research Grant. We are grateful for their generous support.

Footnotes

Related research article: None.

For a published article: None.

Data availability

No data was used for the research described in the article.

References

- 1.Worrell E., Price L., Martin N., Hendriks C., Ozawa Meida L. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001;26:303–329. 3. [Google Scholar]

- 2.FHWA-RD-01-156 . Report By CC Technologies Laboratories, Inc. to Federal Highway Administration. (FHWA) Office of Infrastructure Research and Development; 2001. Corrosion cost and preventive strategies in the United States. [Google Scholar]

- 3.De Muynck W., De Belie N., Verstraete W. Microbial carbonate precipitation in construction materials. Ecol. Eng. 2010;6(2):118–136. [Google Scholar]

- 4.Neville A.M. Pearson Higher Education. 4th edition. Prentice Hall; New Jersey: 1996. Properties of Concrete. [Google Scholar]

- 5.Van Tittelboom K., De Belie N., De Muynck W., Verstraete W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010;4(1):157–166. [Google Scholar]

- 6.Hasan D., Furkan B., Coşkun P., Mehmet S.G. Mechanical performance improvement of super absorbent polymer-modified concrete. Methods X. 2023;10 doi: 10.1016/j.mex.2023.102151. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Hanoon A.N., Abdulhameed A.A., Al-Zuhairi A.H., Ansari M., Ahmed W.Z., Qais S.B., Haider A.A. Strength evaluation of CFRP-strengthened RC Slab-beams system by load test to satisfy the safety requirements: a case study. Int. J. Civ. Struct. Eng. 2024;22:1871–1891. doi: 10.1007/s40999-024-00991-0. [DOI] [Google Scholar]

- 8.Chaturvedi S., Chandra R., Rai V. Isolation and characterization of Phragmitesaustralis (L.) rhizosphere bacteria from contaminated site for bioremediation of colored distillery effluent. Ecol. Eng. 2006;27:202–207. [Google Scholar]

- 9.Jugnia L.B., Cabral A.R., Greer C.W. Biothic methane oxidation within an instrumented experimental landfill cover. Ecol. Eng. 2008;33:102–109. [Google Scholar]

- 10.Khaliq W., Ehsan Muhammad Basit. Crack healing in concrete using various bio influenced selfhealing techniques. Constr. Build. Mater. 2015:349–357. [Google Scholar]

- 11.Meera C.M., Lakshmi L., Eldhose Cheriyan. Durability and self- healing behaviour of bacterial impregnated concrete. Int. J. Innov. Res. Sci. Eng. Technol. (An ISO 3297: 2007 Certified Organization) 2016;5(8) [Google Scholar]

- 12.Jonkers H.M., Thijssen A., Muyzer G., Copuroglu O., Schlangen E. Application of bacteria as self healing agent for the development of sustainable concrete. Ecol. Eng. 2010;36(2):230–235. [Google Scholar]

- 13.Kudatakar P., Mahalaxmi M.M., Madan V.R., Joshi T. An experimental investigation on strength aspects of bacterial concrete. IRJET. 2014;6(4) [Google Scholar]

- 14.Puranik S.A., Jain S., Sritam G., Sandbhor S. Bacterial concrete- a sustainable solution for concrete maintenance. Int. J. Innov. Technol. Explor. Eng. (IJITEE) ISSN: 2278-3075. 2019;8(11S):227–232. [Google Scholar]

- 15.Dhami N.K., Reddy S.M., Mukherjee A. Advanced Topics in Biomineralization. 2012. Biofilm and microbial applications in bio mineralised concrete; pp. 137–164. [DOI] [Google Scholar]

- 16.Richardson A., Coventry K., Pasley J. Vol. 4. SCMT; Las Vegas, USA: 2016. (Bacterial Crack Sealing and Surface Finish Application to Concrete). [Google Scholar]

- 17.Krishnapriya S., Venkatesh Babu D.L., Prince Arulraj G. Isolation and Identification of bacteria to improve the strength of concrete. Microbiol. Res. 2015;174:48–55. doi: 10.1016/j.micres.2015.03.009. [DOI] [PubMed] [Google Scholar]

- 18.Joshi B.S., Ghosh D.M. Biotechnological innovations in concrete: a review on bacterial self-healing. Biotechnol. Adv. 2022;50 [Google Scholar]

- 19.Harris R.J., Williams S.L. Optimization of bacterial concrete for enhanced crack healing and mechanical properties. Adv. Civ. Eng. Mater. 2021;4(3):102–114. [Google Scholar]

- 20.Sharma P.K., Mehta H.K. Durability improvement of concrete using microbial mineral precipitation: a laboratory study. Cem. Concr. Res. 2020;133 [Google Scholar]

- 21.Kim M.H., Park J.Y. Self-healing of concrete cracks using bacterial agents: a case study. Constr. Build. Mater. 2019;221:419–428. [Google Scholar]

- 22.IS 4031-1988, methods of physical tests for hydraulic cement, is 4031-4 (1988): methods of physical tests for hydraulic cement, part 4: determination of consistency of standard cement paste (resource.org)

- 23.IS 12269- 1987 ordinary portland cement, 53 grade — specification is 12269 (1987): 53 grade ordinary portland cement (resource.org)

- 24.IS 383 (1970) specification for coarse and fine aggregates from natural sources for concrete is 383 (1970): specification for coarse and fine aggregates from natural sources for concrete (resource.org)

- 25.Siddique R., Chahal N.K. Effect of ureolytic bacteria on concrete properties. Constr. Build. Mater. 2011;25(2011):3791–3801. [Google Scholar]

- 26.Pie R., Liu J., Wang S., Yang M. Use of bacterial cell walls to improve the mechanical performance of concrete. Cem. Concr. Compos. 2013;39(2013):122–130. [Google Scholar]

- 27.Sandbhor S., Sritam G., Puranik S.A., Jain S. Bacterial concrete- a sustainable solution for concrete maintenance. (2019) Int. J. Innov. Technol. Explor. Eng. (IJITEE) 2019;8(11S):227–232. [Google Scholar]

- 28.Belie N.D. Application of bacteria in concrete: a critical review. RILEM Technic. Lett. (2016) 2016;1:56–61. doi: 10.21809/rilemtechlett.2016.14. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.