Abstract

Various lipid and biopolymer-based nanocarriers have been developed to encapsulate food ingredients. The selection of nanocarrier type, preparation techniques, and loading methods should consider the compatibility of nutrient properties, nanocarrier composition, and product requirements. This review focuses on the loading methods for hydrophilic and hydrophobic substances, along with a detailed exploration of nanocarrier categorization, composition, and preparation methods. Both lipid-based and biopolymer-based nanoparticles exhibit the capability to encapsulate hydrophilic or hydrophobic substances. Liposomes and nanoemulsions allow simultaneous encapsulation of hydrophilic and hydrophobic ingredients, while solid lipid nanoparticles and nanostructured lipid carriers are suited for hydrophobic ingredients. The three-dimensional network structure of nanogels can efficiently load hydrophilic substances, while the functional groups in polysaccharides improve the loading capacity of hydrophobic substances through intermolecular interactions. As for protein nanoparticles, the selection of proteins with solubility characteristics analogous to the bioactives is crucial to achieve high encapsulation efficiency.

Keywords: Nanocarrier, Bioactive ingredients, Controlled release, Lipid, Protein, Polysaccharides

Graphical abstract

Highlights

-

•

Nanocarrier preparation techniques and encapsulation approach are discussed.

-

•

Both Lipid and biopolymer nanocarriers can load hydrophilic or hydrophobic compound.

-

•

Liposomes and emulsions can simultaneously load hydrophilic and hydrophobic cargo.

-

•

Improving ingredient-biopolymer interactions can increase encapsulation efficacy.

-

•

Future trends: functional carrier based on composite matrix for protecting bioactive.

1. Introduction

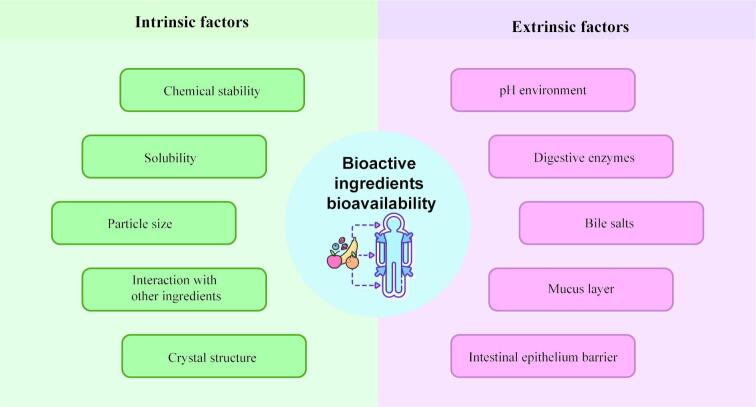

Bioactive compounds (e.g., peptides, carotenoids, fatty acids, polyphenols, etc.) are those nutrient substances extracted from cereal, meat, vegetables, or other natural sources that have physiological benefits and anti-disease activities for humans. Numerous nutritional and clinical studies provided that certain bioactive compounds have antioxidant, anti-inflammatory, antihypertensive, hypotensive, and immunomodulatory activities and also for the prevention of metabolic and degenerative diseases, as well as several forms of cancers (Saifullah, Shishir, Ferdowsi, Rahman, & Vuong, 2019). In the current scenario, there has been a growing interest in adding various bioactive ingredients to food and beverage products to improve the beneficial effects on the human body through diet. However, these nutraceuticals are easily degraded or oxidized due to intrinsic factors and environmental stress (Fig. 1), which leads to the loss of functionality and limits their utilization in the food industry. Furthermore, some bioactive compounds have low solubility in water and easy enzymatic hydrolysis in gastrointestinal fluids, resulting in low bioaccessibility and bioavailability (Rodríguez, Martín, Ruiz, & Clares, 2016). To address these challenges, encapsulation and delivery systems such as lipid-based carriers (e.g., emulsion, liposomes, solid lipid carrier) and biopolymer-based carriers (e.g., polysaccharides hydrogel and protein complex) have been employed to preserve the nutritional quality of bioactive or enhance their applicability in the food industry (Tan, Wang, & Sun, 2021).

Fig. 1.

The factors affecting the bioavaibility of bioactive ingredients.

Encapsulation is a technology in which various carrier materials coat bioactive ingredients to protect them from unfavorable environments. Concerning the carrier size, encapsulation technology can be categorized into microcarrier (1–1000 μm) and nanocarrier (1–1000 nm) (Rodríguez et al., 2016). There has been a surge of interest in nanocarriers for the protection and delivery of bioactive ingredients due to their unique advantages, such as high encapsulation efficiency, sustained release profile, improved solubility, and bioavailability. Nanocarriers can be classified into lipid-based and biopolymer-based categories according to their composition. Lipid-based nanocarriers, which include liposomes (composed of phospholipids and cholesterol), nanoemulsions (comprising oil, water, and surfactants), solid lipid nanoparticles (constructed from solid lipids and surfactants), and nanostructured lipid carriers (formed from a combination of solid and liquid lipids with surfactants), present numerous advantages such as scalability, high biocompatibility, and low toxicity. These characteristics render them particularly suitable for encapsulating hydrophobic ingredients in the food industry (Kim, Na, & Bae, 2023). Conversely, biopolymer-based nanocarriers encompass polysaccharide nanogels (fabricated from biopolymers such as chitosan, alginate, hyaluronic acid, and cellulose) and protein nanoparticles (comprised of various natural proteins like albumin, gelatin, and fibroin). The abundance of functional groups in biopolymers enhances the interaction with drugs, thereby increasing loading capacity and providing opportunities for surface modification to develop responsive nanocarriers (Machado et al., 2022). Nanocarriers create protective barriers that could mitigate the degradation of gastric juice and facilitate controlled release in the intestine (Li et al., 2022). Moreover, the stimuli-responsive nanocarrier could allow the encapsulated ingredients to be released in specific sections of the intestine, such as the ileum, cecum, and colon, helping bioactive compounds to overcome the intestinal barrier or interact with gut microbiota to achieve increased bioavailability (Chung, Jung, Keum, Kim, & Jon, 2020; Kim et al., 2023). To date, nanocarriers are used in the food industry to coat undesirable flavors, sustain color and texture, and enhance the biological activity of food nutrients (Saifullah et al., 2019).

For decades of development, edible nanocarriers have been created from food-grade materials, such as protein, lipids, polysaccharides, etc., for encapsulating various bioactive ingredients (W. Chen et al., 2019; Q. G. Liu et al., 2022; Zhao et al., 2020). In order to better preserve the active substance, it is necessary to know what kind of carrier material is suitable for encapsulating the bioactive component. For example, most hydrophobic compounds could be loaded in lipid-based carriers, while hydrophilic substances have difficulty entering the lipid cores of solid lipid particles (Mirchandani, Patravale, & S, B., 2021). The selection of nanocarrier types for food or medical applications necessitates understanding the nature of loading ingredients and the requirements of final products. Moreover, it must also be mentioned that the nanocarrier material should be regarded as “generally recognized as safe” material, especially in the food sector.

Recent advancements in nanocarriers for encapsulating food bioactive compounds have garnered significant interest in the food and nutraceutical industry, particularly in enhancing stability and bioavailability. The selection of an appropriate encapsulation strategy and loading method is critical to ensure compatibility between nutrient properties and nanocarrier composition. This review aims to provide a comprehensive overview of the preparation techniques for lipid- and biopolymer-based nanocarriers, focusing on loading techniques for hydrophilic and hydrophobic compounds.

2. Lipid-based nanocarrier for encapsulation of hydrophilic and hydrophobic ingredients

2.1. Liposomes

2.1.1. Brief overview of liposomes

Liposomes are self-assembled nanocarriers characterized by their unique self-assembled structure, consisting of aqueous compartments encapsulated within lipid bilayers. The bilayer membrane is constructed by amphipathic phospholipids, such as soybean lecithin or egg lecithin, which possess both hydrophobic tails and hydrophilic heads. When the phospholipid disperses in an aqueous medium, the tails tend to shield themselves from water exposure, while the hydrophilic heads are prone to interface with water (Chai & Park, 2024). The formation of liposomes is driven by a delicate balance of intermolecular forces. Phospholipid molecules interact through van der Waals forces and hydrogen bonding, ultimately assembling into closed vesicular structures. (Shishir, Karim, Gowd, Zheng, & Chen, 2019). This arrangement gives rise to liposomes featuring an inner aqueous core surrounded by a hydrophobic lipid bilayer (Fig. 2a). This unique architecture endows liposomes with the remarkable ability to encapsulate both hydrophobic and hydrophilic compounds simultaneously, making them versatile carriers for a wide range of bioactive molecules.

Fig. 2.

The schematic diagram of lipid based nanocarriers preparation methods and lipid-based nanocarriers loading with hydrophilic and hydrophobic bioactives: liposomes (A, a), nanoemulsions (B, b), solid lipid nanoparticles and nanostructured lipid carriers (C, c).

Various liposomal formulations have been developed to date, with categorization dependent on distinct parameters such as surface charge, particle size, and the number of membrane layers. Specifically, liposomes can be classified as negative, neutral, and positive based on the surface charge type. In terms of bilayer numbers, liposomes can be categorized as unilamellar vesicles with a single lipid bilayer or multilamellar vesicles featuring multiple bilayer membranes (Fig. 2a). Additionally, based on vesicle size, unilamellar vesicles can be further classified into large unilamellar vesicles with dimensions exceeding 100 nm, or small unilamellar vesicles with sizes below 100 nm (W. L. Liu et al., 2020). Overall, liposomes are extensively utilized to protect various bioactive, such as vitamins, polyphenols, proteins, and peptides, from harsh environments by offering the following advantages (Ajeeshkumar et al., 2021).

-

•

Lipid membranes and water cores grant simultaneous loading of hydrophilic and lipophilic bioactive molecules

-

•

Inexpensive and easy to manufacture

-

•

Toxicity worries could be avoided by preparing with food-grade phospholipids

-

•

Scale up methods in industry have been established

2.1.2. Production methods of liposomes

The commonly employed liposome preparation techniques encompass thin film hydration, injection, and, reverse-phase evaporation methods. These approaches can be outlined in a series of steps: (i) dissolution of phospholipid in an organic solvent; (ii) evaporation of the organic solvent; (iii) dispersion of lipids in an aqueous medium to form a liposomal solution; (iv) purification and modification of the liposomes.

The thin film hydration involves dissolving lipids in organic solvents, evaporating the solvent to form a thin lipid film, and subsequently hydrating this film with an aqueous medium under agitation (Fig. 2A). There are two theories of liposome formation through thin film hydration: i) budding-off/fission model and ii) open bilayer fragment re-closing models (Y. Zhang et al., 2024). As for the first model, due to asymmetric interactions across the lipid bilayers, the domain in the near aqueous layer swells with respect to the other side, leading to the bending of the lipid membrane to form a bulge. The blended lipid eventually detaches from the lipid layer and forms liposomes. These processes can occur spontaneously without any energy input. However, mechanical energy, such as sonication and agitation, is usually employed to accelerate liposome formation. For open bilayer fragment re-closing models, since a number of open bilayers are usually already present in suspensions based on the first mechanism, the strong forces can break large or bilayer vesicles into small fragments or sheets. If the open bilayers are large enough, they can reclose to produce a new generation of liposomes. The too small lipid pieces cannot be reclosed, and only if the aggregate first into larger sheets large enough to bend can they be reclosed to form a liposome (Andra, Pammi, Bhatraju, & Ruddaraju, 2022; Has & Sunthar, 2020). For reverse-phase evaporation, phospholipids are dissolved in an organic solvent and form inverted micelles (Fig. 2A). Adding water and applying sonication, the lipids are rearranged at the interface between water and oil to form liposomes (Lombardo & Kiselev, 2022). The injection method, the rapid dilution of ethanol in the aqueous phase, leads to the precipitation of lipid molecules and the successive formation of bilayer sheets encapsulating the aqueous phase. Afterward, the bilayer sheets are formed into liposomes by evaporation of ethanol (Gouda, Sakr, Nasr, & Sammour, 2021). While these conventional methods have been widely adopted in scientific investigations and industrial manufacturing for their simplicity and cost-effective equipment, these preparation methods face limitations in the food industry. The primary concerns include the incomplete removal of organic solvents and the potential degradation of sensitive bioactive compounds due to exposure to extreme pH conditions or mechanical stresses during the formation process.

To address the shortcomings of conventional techniques, the supercritical fluid method has emerged as a promising alternative. This approach significantly reduces or entirely eliminates the use of organic solvents, making it particularly attractive for food-grade liposome production (William, Noémie, Brigitte, & Géraldine, 2020). Among the various supercritical fluids, supercritical carbon dioxide is the most frequently used in supercritical fluid methods due to its non-toxicity, non-flammability, and low critical temperature and pressure (Chai & Park, 2024). At high-pressure conditions, supercritical carbon dioxide fluid combines the characteristics of both gases and liquids—it can enter solids through porous materials like gases and dissolve liposomal formulations like liquids. The preparation process can be divided into two stages. (i) mixing phospholipids and supercritical carbon dioxide. (ii) the high pressure is rapidly reduced, causing the supersaturation and the phospholipids to desolvate from carbon dioxide and form liposomes. A key advantage of this method is the complete removal of carbon dioxide from the liposomal formulation upon pressure reduction, eliminating concerns of residual solvent contamination. Moreover, supercritical preparation methods can be further categorized based on the timing of liposome hydration: the liposome hydration required before the depressurization process and the liposome hydration during the depressurization process. Despite the advantages of supercritical state fluids, including being free of organic solvents, providing a reproducible process, and offering higher encapsulation efficiency, there remains a need to reduce preparation costs and further enhance encapsulation efficiencies to achieve commercial viability.

2.1.3. Encapsulation strategies for hydrophilic and hydrophobic ingredients in liposomes

Liposome preparation techniques have evolved significantly to address the challenges of encapsulating diverse bioactive compounds. Traditional methods, such as thin film dispersion, ethanol injection, and reverse-phase evaporation, incorporate bioactive ingredients concurrently with liposome formation. These techniques exploit the amphiphilic nature of liposomes, allowing for the encapsulation of both hydrophilic and hydrophobic compounds. Hydrophilic compounds are dissolved in the aqueous phase and subsequently encapsulated within the liposomal core during hydration. In contrast, hydrophobic ingredients usually dissolve in organic solvents accompanied by phospholipids and fat-soluble additives. Upon evaporation of the organic solution, these components spontaneously form liposomes when introduced to an aqueous environment (Table 1). The approach is particularly effective for hydrophobic compounds that can interact with lipid membranes through hydrophobic interactions, facilitating their incorporation into the liposomal bilayer. However, the encapsulation of hydrophilic substances presents a significant challenge due to their limited interaction with lipid components. This often results in the dispersion of hydrophilic compounds in the external aqueous phase, ultimately leading to lower encapsulation efficiency (Favarin et al., 2024).

Table 1.

Summary of fabrication methods and encapsulation of hydrophilic and hydrophobic bioactives by liposomes.

| Bioactive encapsulant and encapsulant type | Fabrication methods | Liposomes composition | Encapsulation efficiency (%) | Loading process detail | Reference |

|---|---|---|---|---|---|

| Curcumin (Hydrophobic) |

Ethanol injection | Tilapia head glycolipids, tilapia head phospholipids, and cholesterol | 60–90 | Curcumin was added to an ethanol solution containing the liposome component. The ethanol mixture was subsequently injected into PBS and ethanol was evaporated to obtain curcumin loaded liposomes. | (Yi, Gao, Zhang, Xia, & Shen, 2023) |

| Vitamins (A, D, E and K) (Hydrophobic) |

Ethanol injection | Egg yolk phosphatidylcholine, cholesterol and tween 80 | – | Vitamins were dissolved in ethanol along with liposomal formation ingredients, followed by injecting the mixture into PBS to form milky liposomes. Then, using rotary evaporation to remove the ethanol and homogenizing the resulted liposome suspension to form final liposomes. | (Fan, Feng, Wang, Xia, & Swing, 2023) |

| Curcumin (Hydrophobic) |

Thin film hydration | Hydrogenated soy phosphatidylcholine, Distearoyl-Glycero-3-Phosphoethanolamine- methoxypolyethylene glycol2000, cholesterol, dipalmitoyl-phosphatidylglycerol | 82–89 | Curcumin powder was dissolved in DMSO and incubated with empty liposome solution | (Karimi et al., 2020) |

| Rutin (Hydrophobic) |

Thin film hydration | Soybean phospholipids | 73–88 | Rutin and soybean phospholipids with different drug-to-lipid ratios were dissolved in ethanol, and then the ethanol was evaporated to form a lipid film. This film was hydrated by PBS to form rutin-loaded liposomes. | (Hamadou, Zhang, Chao, & Xu, 2022) |

| Quercetin (Hydrophobic) |

Thin film hydration | Lecithin, cholesterol | 63–67 | Lecithin, cholesterol, and quercetin were dissolved in ethanol, followed by evaporation, hydration and sonication to form liposomes. | (Cong et al., 2023) |

| Ascorbic acid (hydrophilic) and ascorbyl palmitate (hydrophobic) | Reverse-phase evaporation | Phospholipid, polysorbate 80 and cholesterol | 37 (ascorbic acid); 79 (ascorbyl palmitate) |

Dissolve phospholipids and cholesterol in ethanol via ultrasound to create a lipid solution. Evaporate the organic solvent to create an organogel, which is converted into vesicles by adding the aqueous phase. | (Favarin et al., 2024) |

| Carotenoids extracted (hydrophobic) |

Thin film hydration | Phospholipids, cholesterol, Tween80 | 70–95 | Phospholipids and cholesterol were dissolved in ethanol, followed by incorporating Tween80 to enhance stability and encapsulation efficiency. Forming a thin film through solvent evaporation, followed by rehydration to get liposome | (X. Z. Liu et al., 2024b) |

| EGCG (Hydrophilic) and quercetin (Hydrophobic) | Thin film hydration | Lecithin, cholesterol, tween80 | 20–64 (EGCG), 30–61 (quercetin) |

EGCG was dissolved in water, while quercetin and lipid ingredients were dissolved in organic solvents. The lipid film containing quercetin was then hydrated using the aqueous EGCG solution. | (W. Chen et al., 2019) |

| Egg yolk immunoglobulin (Hydrophilic) |

Supercritical fluid | Egg yolk phosphatidylcholine, soybean phosphatidylcholine and cholesterol | 76.9 | Lipid ingredients were dispersed in PBS followed by mixing with IgY solution. Then, the mixture was put into the autoclave of the supercritical fluid device to prepare liposomes. | (Dong, Tang, Xia, Sheng, & Cai, 2022) |

| Soy hydrolysate peptides (Hydrophilic) |

Thin film hydration | Phospholipon®90G, lysophosphatidylcholine, tocopherol, cholesterol and Tween-80 | 60.5 | The preheated soy peptides solution was used to hydrate lipid thin film and followed by a sonication process to form liposomes | (Pavlovic et al., 2022) |

| β-cyclodextrin/vitamin E inclusion complex (Hydrophilic) |

Thin film hydration | Lecithin | 83.8 | Lipid film was hydrated by deionized water containing β-CD/Vitamincomplex | (Souri, Almasi, Hamishehkar, & Amjadi, 2021) |

| β-lactoglobulin (Hydrophilic) |

Reverse-phase evaporation | Phosphatidylcholine and cholesterol | 10–67 | The β-Lg was dissolved in a phosphate buffer solution and then mixed with the organic phase containing the liposomal component. The mixture was subsequently ultrasonicated and evaporated to obtain the liposomes. | (Ma et al., 2014) |

| Anthocyanin (Hydrophilic) |

Thin film hydration | L-α-Phosphatidylcholine, hydrogenated soy, cholesterol, Tween 80 | 71 | The liposome solution (pH 3) was dialyzed in deionized water to form an H ion gradient. Then, the liposome solution was mixed with the anthocyanin solution to prepare anthocyanin-loaded liposomes | (Lee et al., 2019) |

| Caffeine and anthocyanin (Hydrophilic) |

Thin film hydration | Lecithin, cholesterol | – | Commence by mixing hydrated lecithin and cholesterol solutions to form the lipid phase. Subsequently, dissolve caffeine and roselle ANC powders in a phosphate buffer and gradually inject this buffer into the lipid phase while maintaining agitation. | (Javadi, Farahmand, Soltani-Gorde-Faramarzi, & Hesarinejad, 2024) |

Despite the advantages of simplicity and convenience offered by traditional loading techniques, the imperative to enhance loading efficiency persists. Guldiken and coworkers showed a positive correlation between phospholipid concentration and the encapsulation rate of liposomes with the two-stage homogenization preparation method (Guldiken, Gibis, Boyacioglu, Capanoglu, & Weiss, 2021). Similarly, investigations have identified that ratios of lecithin to polyphenols, lecithin to cholesterol, lecithin to Tween, and ultrasonic exposure during the film dispersion method exert differing effects on the encapsulation rate of compounds like epigallocatechin gallate (EGCG) and quercetin(W. Chen et al., 2019). Tripathy found that the addition of stigmasterol could increase the encapsulation efficiency of centella asiatica leaf extract (Tripathy & Srivastav, 2023). Moreover, response surface methodology has also been employed to optimize the preparation of liposomes, and caffeine achieved a maximum encapsulation efficiency of approximately 95 %. The optimization process involved adjusting parameters such as sonication power, chitosan concentration, and caffeine concentration, and it was observed that ultrasonication power and caffeine content significantly affected encapsulation efficiency (Seyedabadi, Rostami, Jafari, & Fathi, 2021). Wang et al. unitized the spectrophotometry combined with response surface methodology to get the highest encapsulation rate of over 95 % for lycopene and β-carotene by alerting temperature, phospholipid to cholesterol, and aqueous phase to lipid phase ratios (X. Z. Liu et al., 2024a). However, establishing a definitive relationship between encapsulation efficiency and the preparation parameters remains complex. Researchers must carefully select preparation methods based on the physicochemical properties of the target ingredients and judiciously modulate the drug-lipid ratio and dispersion conditions to maximize loading efficiency.

In recent years, novel active loading methods have been introduced to enhance the loading efficiency of liposomes. An early study by Modi et al. demonstrated that establishing a transmembrane proton gradient across liposomal membranes contributes to the accumulation of amphiphilic amines within liposomes (Modi, Xiang, & Anderson, 2012). Lee et al. utilized the pH-gradient loading approach to encapsulate anthocyanins within liposomes, achieving significantly higher loading efficiency and more excellent anthocyanin stability compared to passive loading methods (Lee & Na, 2019). In addition, an ionizable group in the encapsulated molecule structure could facilitate the active loading of cargo inside liposomes. However, the active loading methods are only suitable for amphiphilic soluble ingredients.

The solvent-assisted active loading method has been proposed to address the challenge of incorporating poorly soluble ingredients. This approach facilitates the introduction of insoluble compounds into the liposomal aqueous core. This method dissolves insoluble compounds in water-miscible organic solvents, such as ethanol, dimethyl sulfoxide (DMSO), or acetonitrile. The solution with hydrophobic ingredients is introduced into preformed blank liposomes possessing a proton/ion gradient, enabling efficient loading of the compound into the liposomal inner aqueous core at a high drug-lipid ratio (Karimi et al., 2020). In the current scenario, the active loading methods are only applied in the experimental stage due to the requirements for the physicochemical properties of ingredients and the introduction of more organic solvents.

Overall, despite the versatility of liposomes in simultaneously encapsulating hydrophobic and hydrophilic actives, their loading capacity is inherently limited by the finite volume of the lipid bilayer and aqueous core. Some researchers have proposed using giant unilamellar liposomes to increase the loading capacity to encapsulate large amounts of active compounds (Hanley, Ghazani, & Marangoni, 2024; Michelon, Huang, de la Torre, Weitz, & Cunha, 2019). Yet, the increased volume may result in vesicle fusion and aggregation, potentially compromising the liposomes' ability to protect the active substances. In conclusion, while significant progress has been made in optimizing liposome loading techniques, further research is needed to maximize the encapsulation of bioactive ingredients within the limited volume of liposomes. Future studies should focus on developing innovative strategies to enhance loading capacity without compromising liposome stability and functionality.

2.2. Nanoemulsions

2.2.1. Brief overview of nanoemulsions

Nanoemulsions is colloidal dispersions formed by mixing two immiscible liquids into a uniform homogeneous. In contrast to conventional emulsions with diameters exceeding 200 nm, the nano-scale droplet size imparts nanoemulsions with several advantages in comparison to traditional emulsions, including optically transparent, stable against gravitational separation, high surface area-to-volume ratio, kinetically stable during storage, and lower surfactant requirement (Sharma, Cheng, Bhattacharya, & Chakkaravarthi, 2019).

Nanoemulsions have three essential components: oil phase, aqueous phase, and emulsifier. Categorized based on the matrix of dispersed and aqueous phases, there are four types of nanoemulsions (Fig. 2b): oil in water(O/W), water in oil (W/O), oil in water in oil (O1/W/O2) and water in oil in water (W1/O/W2). The oil phase typically comprises natural triacylglycerols extracted from plants and animals, which are preferred due to their low toxicity, nutritional benefits, and consumer acceptance (Dammak, Sobral, Aquino, Neves, & Conte-Junior, 2020). Fatty acid chain length in triacylglycerols is considered a key factor affecting nanoemulsion preparation and stability. The nanoemulsions prepared from long-chain triacylglycerols have high physical stability, whereas characteristics of medium- and short-chain triacylglycerols present challenges due to their low polarity, high interfacial tension, and viscosity (Inapurapu et al., 2020).

The aqueous phase of nanoemulsion predominantly consists of water. It should be noted that the inclusion of various compounds in water, such as co-solvents, proteins, acids, and gases, can alter the aqueous medium's properties, including polarity, interfacial tension, and ionic strength. These alterations have the potential to influence the physicochemical properties and stability of the nanoemulsions, necessitating careful consideration during preparation.

Emulsifiers play a crucial role in nanoemulsion formation and stability by adsorbing the oil-water interface and reducing interfacial tension. This action prevents the breakdown of the nanoemulsions system through various mechanisms such as droplet flocculation, coalescence, Ostwald ripening, and gravitational separation (Marhamati, Ranjbar, & Rezaie, 2021). Common emulsifiers used in the food industry include proteins, phospholipids, saponins, polysaccharides, and small molecule surfactants. The choice of emulsifier significantly influences preparation techniques, stability, rheological properties, and ultimate applications of nanoemulsions. For instance, proteins and polysaccharides are generally unsuitable for low-energy nanoemulsion preparation methods, while small molecule surfactants can rapidly adsorb to oil-water interfaces, facilitating the formation of stable nanoemulsions during low-energy homogenization(Ozogul et al., 2022). The ideal emulsifier should exhibit the most significant initial decrease in interfacial tension with increasing emulsifier concentration while maintaining the lowest interfacial tension at higher emulsifier levels (Dammak et al., 2020). This characteristic ensures optimal stabilization of the nanoemulsion system and contributes to its long-term stability. The careful selection and optimization of nanoemulsion components, particularly the emulsifier, are crucial for developing stable and effective nanoemulsion systems for various applications in the food and related industries. Some advantages of nanoemulsions in the encapsulation of actives are as follows (Ozogul et al., 2022; Sneha & Kumar, 2022):

-

•

Capable of encapsulating hydrophilic and hydrophobic compounds simultaneously

-

•

Simple fabrication method

-

•

Avoiding the organic solvent involved in the preparation

-

•

High encapsulation efficiency

-

•

Various preparation methods are available for different applications

2.2.2. Production methods of nanoemulsions

Nanoemulsion preparation methods can be categorized into two groups based on their energy consumption: high-energy methods and low-energy methods. Each approach offers distinct advantages and limitations, influencing their applicability in various industrial and research contexts.

High-energy methods involve the application of intense and disruptive forces generated by mechanical equipment, such as high-pressure homogenizer and ultrasonicator, to reduce emulsion droplet size to the nanoscale. This process typically consists of two steps: (i) the initial mixing of the oil and aqueous phases to form a macroemulsion, (ii) the reduction of droplet diameter through mechanical force (Fig. 2B). In a homogenizer, the macroemulsion was passed through a narrow gap to break the large droplets into smaller droplets through extreme elongational and shear stress. Conversely, an ultrasonicator generates high-energy shock waves that create turbulence through cavitation, effectively transforming the macroemulsion into a nanoemulsion. Whether a homogenizer or ultrasonicator is employed, these processes should be repeated multiple times or continued until the droplet size becomes constant (Gupta, Eral, Hatton, & Doyle, 2016). The High-energy methods are particularly advantageous due to their applicability to a broad spectrum of raw materials and their ability to produce nanoemulsions without requiring excessive emulsifiers, making them suitable for large-scale production in the food industry (Huang et al., 2021). However, it is imperative to notice that high-energy methods can produce “by-products” such as increased pressure, temperature, and shearing forces, which may disrupt the molecular structure of bioactive compounds and diminish the functional properties of the bioactive compounds, especially concerning fragile molecules like peptides and proteins.

In contrast to the formation of nanoemulsions via high-energy equipment, which necessitates significant external energy input, the primary driving force for the formation of “low-energy nanoemulsions” is the internal energy of the mixture out of chemical equilibrium (Silva & Fabi, 2022). The low-energy preparation methods could be divided into spontaneous emulsification methods (or self-emulsification) and phase inversion methods (Fig. 2B). Spontaneous emulsification methods utilize the movement of water miscible ingredients (such as solvent, surfactant, and co-surfactant) from the organic phase into the aqueous phase, typically under constant temperature and gentle stirring conditions (Safaya & Rotliwala, 2019). This process involves the dropping organic phase into an aqueous phase containing surfactants to prepare O/W nanoemulsion. The rapid migration of water-miscible components into the aqueous phase generates turbulence at the interface of the two phases, which consequently leads to the spontaneous formation of nanoemulsion upon disrupting the bicontinuous microemulsion phase. Moreover, the reverse process — the addition of aqueous into the oil phase— to form W/O nanoemulsion is equally feasible.

In contrast to spontaneous emulsification methods, phase inversion methods utilize the chemical energy released by phase transitions, often associated with changes in system composition or temperature, to form nanoemulsions and control droplet diameters. The phase inversion method could be further divided into the phase inversion temperature method (PIT) and phase inversion composition methods (PIC). In the PIT process (Fig. 2B), a W/O macroemulsion is prepared at a temperature higher than the phase inversion temperature of the mixture. When the temperature is cooled below the inversion temperature point, the crude emulsion transforms from W/O to O/W emulsion. The interfacial tension of the oil-water interface is very low at the inversion point, so the macroemulsion converts to a nanoemulsion without high energy input. For the PIC procedure (Fig. 2B), slowly dilute the pre-prepared W/O macroemulsion with water, and the transition from W/O to O/W nanoemulsion occurs as the system passes through an inversion point (Komaiko & McClements, 2016; Marhamati et al., 2021). Both PIT and PIC involve reversing the curvature of the surfactant film from positive to negative or vice versa. Consequently, the selection of appropriate surfactants and a thorough understanding of surfactant phase behavior are critical in preparing nanoemulsions using phase inversion methods. The PIT method is exclusively applicable to temperature-sensitive surfactants, such as polyoxyethylene-type nonionic surfactants, wherein temperature-induced changes in poly(oxyethylene) chain hydration lead to consequential changes in surfactant curvature (Koroleva, Nagovitsina, & Yurtov, 2018). Conversely, the PIC method initiates phase transitions through compositional changes during emulsification at a constant temperature, thereby extending its applicability to a broader spectrum of surfactants beyond ethoxylated types (Mushtaq et al., 2023). Despite the advantage of low energy consumption, the preparation of nanoemulsions by the low-energy method is still in the laboratory stage since it requires a high concentration of emulsifiers, negatively affecting both taste and safety.

2.2.3. Encapsulation strategies for hydrophilic and hydrophobic ingredients in nanoemulsions

Nanoemulsions consist of both nonpolar (oil phase) and polar (aqueous phase) regions, allowing for the encapsulation of hydrophobic and hydrophilic food ingredients within the system. During nanoemulsion preparation, the encapsulation process typically involves dissolving hydrophilic compounds in the aqueous phase and hydrophobic compounds in the oil phase. Rabelo et al. (2018a) demonstrated the efficacy of nanoemulsions in encapsulating hydrophilic compounds by dispersing berry anthocyanin in the aqueous phase prior to emulsification with medium-chain triglyceride (MCT) oil containing nitroglycerin monolaurate condensed ricinoleic acid esters as lipid phase. The fabricated W/O nanoemulsions exhibited antioxidant activity and provided high anthocyanin protection against 30 days of storage (Rabelo et al., 2018).

As for encapsulation of hydrophobic compounds, nanoemulsions have found extensive application in enhancing the water solubility and stability of various hydrophobic compounds, such as curcumin, quercetin, and coenzyme Q10 (Niu et al., 2020). Take a typical example: Das and colleagues fabricated nanoemulsions loaded with quercetin using a high-energy method. The authors initially evaluated the solubility and compatibility of quercetin with different lipid phases, followed by the incorporation of quercetin into the selected oil phase and subsequent addition of aqueous droplets. The mixture was then homogenized to produce the quercetin-loaded nanoemulsions (S. S. Das, Verma, & Singh, 2020). Furthermore, enhancing the solubility of the active molecules in the oil phase can improve the encapsulation efficiency of nanoemulsions. McClements et al. demonstrated that adjusting the pH of the system and increasing the temperature can increase the solubility of curcumin in the oil phase. Their study revealed that nanoemulsions prepared via pH-driven (93 %) and temperature-driven (76 %) methods achieved substantially higher encapsulation efficiencies compared to the conventional dissolve method (56 %) of curcumin in the oil phase (B. Zheng, Peng, Zhang, & McClements, 2018). Those bibliographic facts indicate that the solubility of hydrophobic bioactive agents in the oil phase plays a vital role in increasing the encapsulation efficiency of nanoemulsions.

The multilayer nanoemulsion system, including oil in O1/W/O2 and W1/O/W2, has been developed to accommodate both hydrophobic and hydrophilic substances. The preparation of multilayer nanoemulsions typically involves a two-step process. (i) Creation of the primary emulsion (W1/O or O1/W) by mixing and emulsifying the oil and aqueous phases; (ii) Formation of W1/O/W2 or O1/W/O2 by using the primary emulsion as either the oil or water phase in a second water (W2) or oil (O2) phase. It is noteworthy that secondary emulsification usually utilizes a milder homogenization process than primary emulsification to avoid the destruction of the primary emulsion. In an illustrative instance, Tang et al. (2021) fabricated encapsulated hydrophilic betanin and hydrophobic curcumin by first dissolving curcumin in ethanol and then adding it into MCT, followed by evaporating ethanol and creating an oil phase. The oil phase was then emulsified to W1/O pre-emulsion with an aqueous phase containing betanin. Finally, the W1/O pre-emulsion was later gradually added into W2 phase by homogenization to obtain W1/O/W2 emulsions with curcumin and betanin encapsulation efficacy of 84.1 % and 65.3 %, respectively (X. Y. Tang et al., 2021). More examples of encapsulation of bioactive ingredients by nanoemulsions are tabulated in Table 2.

Table 2.

Summary of preparation techniques and encapsulation of hydrophilic and hydrophobic bioactives by nanoemulsions.

| Bioactive encapsulant and encapsulant type | Fabrication methods | Nanoemulsions composition | Nanoemulsions type | Encapsulation efficiency (%) | Loading methods of bioactive ingredient | Reference |

|---|---|---|---|---|---|---|

| Curcumin (Hydrophobic) |

High-energy method | W1: gelatin, betanin, water O: medium-chain triglyceride, polyglycerol polyricinoleate, curcumin W2: serum albumin nanoparticles, PBS |

W1/O/W2 | 84 | Curcumin was dissolved in hot ethanol, followed by dropwise the ethanol solution into MCT and evaporating the ethanol. The oil phase was mixed with W1, and a high-pressure process was conducted to produce W1/O emulsion. Afterwards, the W1/O emulsion was added to W2, followed by homogenization to prepare the W1/O/W2 emulsion. | (X. Y. Tang et al., 2021) |

| Proanthocyanidins (hydrophilic) and β-carotene (Hydrophobic) | High-energy method | W1: proanthocyanidins, water O: rice bran wax, corn oil, polyglycerol polyricinoleate W2: whey protein isolate,sodium alginate, water |

W1/O/W2 | 90 | The β-carotene and proanthocyanidins were dissolved in oil and W1 phase, respectively. Primary O/W emulsion was prepared by homogenizing the oil phase and W1 phase. Afterwards, the primary emulsion was mixed with W2 and followed by homogenized to prepare W/O/W emulsion. | (Huang et al., 2021) |

| Honeybee pollen (Hydrophobic) |

High-energy method | W1: water O: lauroglycol 90, span 80, Lipoid P75, honeybee pollen extract W2: water, pluronic F68, chitosan |

W1/O/W2 | 82 | Initiate the process by combining oil phase components and water to form primary W/O emulsions. Next, the internal aqueous phase containing pluronic F68 and chitosan is incorporated. The resulting emulsions are homogenized to obtain nanoemulsion. | (Valdivia-Olivares et al., 2023) |

| Coenzyme Q10, conjugated linoleic acid (Hydrophobic) |

High-energy method | O1: coenzyme Q10, extra virgin olive oil, olive pomace oil, conjugated linoleic acid W: polyoxyethylene sorbitan monopalmitate, polyphenols, deionized water O2: span 80. |

O1/W/O2 | – | The O/W emulsions were prepared through mixing emulsifier, the water phase and oil phase with a high speed homogenizer and a high intensity ultrasonic processor. The O/W/O double emulsion fabricated by adding the above O/W emulsion to O2 phase and followed by homogenization and ultrasonication. | (Katsouli, Giannou, & Tzia, 2020) |

| Pentacyclic triterpenes-rich extract (Hydrophobic) |

High-energy method | Oil phase: soybean, sunflower, and olive oil, pentacyclic triterpenes-rich extract water phase: protein hydrolysate, distilled water |

O/W | 40 | The oil phase containing pentacyclic triterpenes-rich extract was gradrully added to the aqueous phase with agitation to homogenize the both phase. | (Calderon-chiu, Calderon-santoyo, Damasceno-gomes, & Ragazzo-Sanchez, 2021) |

| Curcumin (Hydrophobic) |

Low-energy methods. | Oil phase: soybean oil, tween 80, curcumin water phase: water, glycerol |

O/W | – | Curcumin was dissolved in the soybean oil with Tween 80 to form oil phase. Then, the water phase was added to oil phase by peristaltic pump under mechanically stirred. | (Borrin, Georges, Moraes, & Pinho, 2016) |

| Green tea catechins (Hydrophobic) |

High-energy method | Oil phase: green tea catechins, sunflower oil Water phase: soy protein isolate SPI, water, sodium azide |

O/W | – | Green tea powder was dispersed in sunflower oil to prepare the oil phase, followed by a high-speed homogenizer and high-pressure homogenizer to homogenize the mixture of the oil phase and water phase. | (Bhushani, Karthik, & Anandharamakrishnan, 2016) |

| Quercetin (Hydrophobic) |

Low-energy methods. | Oil phase: soybean oil, Tween 80, Brij 30, quercetin Water phase: water, glycerol |

O/W | – | Mixing quercetin, surfactant and soybean oil to form oil phase with stirring. The water phase was gradually added to the oil phase using a peristaltic pump to form nanoemulsion. | (de Carli, Moraes-Lovison, & Pinho, 2018) |

| Octacosanol (Hydrophobic) |

Low-energy methods. | Oil phase: olive oil, soybean oil, sunflower oil, camellia oil, linoleic acid, glycerol, anhydrous ethanol, propylene glycol Water phase: water |

O/W | – | Combine octacosanol, surfactant, co-surfactant, and oil, then heat the mixture until octacosanol dissolves completely. This process is followed by the gradual addition of deionized water under constant stirring until formation of transparent nanoemulsions. | (Valdivia-Olivares et al., 2023) |

| Tea polyphenols (Hydrophillic) |

High-energy method | Oil phase: corn oil, polysorbate-80 water phase: tea polyphenols, water |

O/W | – | Dissolving tea polyphenols into water to prepare water phase. Coarse emulsions were prepared by mixing corn oil and water phase while adding polysorbate-80 and then homogenized the mixture with a high-speed Tissue-Tearor. Finally, a high-pressure homogenizer was used to prepare nanoemulsion | (Y. R. Peng et al., 2018) |

| Açaí berry anthocyanins (Hydrophilic) |

High-energy method | Water phase: water, açaí berry anthocyanins oil phase: tetraglycerin monolaurate condensed ricinoleic acid esters, medium-chain triglyceride |

W/O | – | Mix the water phase containing açaí berry anthocyanins with the oil phase, followed by homogenization to prepare a coarse emulsion. Afterwards, the coarse emulsions were passed through a high-pressure homogenizer to prepare nanoemulsion. | (Rabelo et al., 2018) |

| Tea polyphenols (Hydrophilic) |

High-energy method | Water phase: tea polyphenols, water, Tween, glycerol oil phase: grape oil, zein, Span |

W/O | 0.053 wt% | Tea polyphones were dissolved in water phase and then dropped it in oil phase at high temperature to form coarse emulsion. Finally, the coarse emulsion was sheared to prepare the W/O emulsion. | (Ye et al., 2020) |

| Anthocyanin extract (Hydrophilic) |

Low-energy methods. | Water phase: water, oil phase: virgin coconut oil, span 80, tween 80 |

W/O | – | Add anthocyanin extract solution to the virgin coconut oil containing surfactant and incubate overnight at room temperature. | (Tamaroh, Sari, Wariyah, Huda, & Candraruna, 2024) |

In summary, the encapsulation of bioactive compounds in nanoemulsions is contingent upon the type of nanoemulsions used. Bioactive substances must be loaded into the dispersed phase of the nanoemulsions to benefit from their protective properties, regulate degradation rates, and enhance absorption. Specifically, O/W, where the hydrophobic cargo is loaded in the internal oil phase core; W/O, which encapsulates hydrophilic compounds in the aqueous core; O/W/O and W/O/W, both capable of encapsulating both hydrophilic and hydrophobic bioactive. Moreover, the solubility of hydrophobic bioactive agents in the oil phase is essential in increasing the encapsulation efficiency of nanoemulsions.

2.3. Solid lipid nanoparticles and nanostructured lipid carriers

2.3.1. Brief overview of SLNs and NLCs

Solid lipid nanoparticles (SLNs) are colloidal dispersions of non-polar lipids, featuring a well-ordered and crystalline lattice core surrounded by a monolayer surfactant shell (Fig. 2c). The distinguishing feature of SLNs is their solid lipid core, which reduces the mobility of encapsulated ingredients within the lipid matrix and enhances stability in challenging environments. However, the highly ordered core structure provides limited space for cargo accommodation, potentially resulting in drug expulsion from the lattice (Bayon-Cordero, Alkorta, & Arana, 2019). To address this limitation, nanostructured lipid carriers (NLCs) were developed by incorporating small quantities of liquid lipids into the solid lipid matrix. This modification reduces the crystalline events and maintains a liquid lipid matrix at room and body temperature, consequently enhancing storage stability and loading capacity (Costa, Moreira, Sousa Lobo, & Silva, 2021).

While both SLNs and NLCs could be characterized as solid lipid-based nanoparticles, the primary difference is the absence (SLNs) and presence (NLCs) of the liquid matrix in the particle core. Generally, solid lipid-based nanoparticles are composed of solid lipids, liquid lipids (used in NLCs), surfactants, and water. The lipid matrix is a fundamental element in both systems, so lipid components could be used to identify SLNs and NLCs. Solid lipids (e.g., stearic acid, glyceryl behenate, tripalmitin, cetyl palmitate, glyceryl monostearate, and tristearin) are predominant components of SLNs and NLCs. In contrast, NLCs contain about 0.1–30 % liquid lipids (medium chain triglycerides, isopropyl palmitate plus capric/caprylic triglyceride, oleic acid, squalene, vegetable and seed oils) (Agrawal et al., 2020). Furthermore, SLNs and NLCs offer the following advantages (Goncalves et al., 2021; C.-H. Tang, Chen, & Dong, 2023):

-

•

Organic solvents could be avoided during preparation

-

•

High stability over the storage period

-

•

Prolonged sustained release against harsh conditions via their solid lipid phase

-

•

Low biotoxicity

-

•

Controlled particle size

-

•

Low-cost and simple fabrication method

2.3.2. Production methods of SLNs and NLCs

Despite variations in lipid composition, both SLNs and NLCs could be prepared using three main methods: (i) high-pressure homogenization (HPH), (ii) microemulsion formation methods, and (iii) Solvent emulsification technique.

Among the various preparation methods, HPH is the predominant technique for SLN and NLC formulation (Fig. 2C), further classified into hot and cold HPH procedures. In the hot HPH method, the solid lipid phase must be heated above the melting temperature into liquid lipid mixture. Then, the heated lipid phase is combined with a hot surfactant solution under continuous agitation. The resulting hot liquid lipid mixture undergoes homogenization and subsequent cooling to room temperature, generating solid SLNs or NLCs. However, this process, involving high temperatures (up to 90 °C) and high-energy mechanical force, is unsuitable for encapsulating thermosensitive and fragile substances. To address this limitation, cold HPH has been proposed to encapsulate heat-sensitive molecules into SLNs and NLCs. In this approach, the completely melted lipid phase is rapidly cooled to solidify lipid particles within a cold solution. The bulk lipid particles are then milled into submicron particles and dispersed in a cold surfactant solution. Finally, the high-pressure homogenizer homogenizes the mixed solution to form nanoparticles at room temperature (Souto et al., 2020).

As for microemulsion formation methods (Fig. 2C), the process entails separately melting lipids and preheating a water phase containing surfactants to the lipid melt point. The hot lipid and preheated water phases are combined under continuous stirring to generate the microemulsion. If necessary, a surfactant solution is gradually added to the mixture until the turbid liquid transforms into a transparent emulsion. The final step entails solidifying the hot microemulsion into nanoparticles by diluting it with cold water (Gonçalves, Vicente, & Pinheiro, 2023).

The solvent emulsification technique utilizes organic solvents to facilitate the dissolution of solid lipids in water and subsequently removes the organic solvents. Initially, both liquid and solid lipids are dissolved in organic solvents. Then, the organic solution is slowly poured into the water solution containing surfactant. The resulting dispersion maintains the high temperature until the organic solvent is completely removed from the system. Finally, the mixture is cooled to form nanoparticles (Duong, Nguyen, & Maeng, 2020).

2.3.3. Encapsulation strategies for hydrophilic and hydrophobic ingredients in SLNs and NLCs

Due to the excellent compatibility of lipid matrices with most hydrophobic compounds, SLNs, and NLCs have been found to be extensively used in the encapsulation of hydrophobic food bioactives via various preparation methods, including but not limited to rutin, curcumin, carotene, and essential oils (Gunawan & Boonkanokwong, 2024). The loading of hydrophobic substances into SLNs or NLCs is achieved by incorporating hydrophobic substances, with or without organic solvents, into the lipid phase. One prominent method for encapsulating hydrophobic ingredients is the hot-HPH technique. Pezeshki et al. (2019) utilized the hot-HPH method to prepare β-carotene-NLCs to increase the stability of β-carotene. They reported a remarkable encapsulation efficiency of 97.7 % by first melting carotene and mixing it with liquid oil, then introducing this mixture into the melted solid lipid phase supplemented with a surfactant solution. The subsequent homogenization and cooling processes resulted in successfully prepared β-carotene-loaded NLCs (Pezeshki et al., 2019). Another frequently employed method is the solvent emulsification technique, which utilizes organic solvents to enhance the concentration of hydrophobic substances within the aqueous-lipid system. This process involves dissolving both hydrophobic compounds and solid lipids in a minimal amount of organic solvent, followed by the addition of a surfactant solution. The mixture then undergoes homogenization or ultrasonication to form an emulsion, which is subsequently maintained at a mild temperature with stirring to remove the organic solvent and solidify the SLNs (Gonçalves et al., 2021).

While SLNs and NLCs excel in encapsulating hydrophobic compounds, their lipid matrix-based composition presents challenges for encapsulating hydrophilic substances. For encapsulating hydrophilic ingredients into SLNs or NLCs, it is essential to incorporate hydrophilic compound solutions during their preparation (Pimentel-Moral et al., 2019; Ravanfar, Tamaddon, Niakousari, & Moein, 2016). As the solution to this challenge, the W/O or W1/O/W2 emulsion (microemulsion formation methods) has been employed in SLNs and NLCs fabrication to facilitate the encapsulation of hydrophilic compounds. The loading process is similar to the multiple emulsion preparation techniques as presented in Section 2.2.3. Ravanfar et al. (2016) demonstrated the efficacy of this approach in developing anthocyanin-loaded SLNs. Optimizing formation parameters using Plackett-Burman and Box-Behnken experimental designs achieved an impressive encapsulation efficiency of approximately 89 %. Their method involved adding an anthocyanin solution dropwise to a preheated lipid phase containing surfactants to form a W/O pre-emulsion. This pre-emulsion was then dispersed in a cold aqueous surfactant solution and homogenized to produce anthocyanin-loaded NLCs (Ravanfar et al., 2016). Similarly, Pimentel-Moral et al. (2019) prepared Hibiscus sabdariffa extract-loaded NLCs using multiple emulsion technology. Under the appropriate formation parameters, they achieved an encapsulation efficiency of about 84 % and a particle size of approximately 344 nm (Pimentel-Moral et al., 2019). Furthermore, studies reported that the hydrophobic ion pairing technique, which involves linking hydrophilic molecules to surfactants carrying a surface charge opposite to the water-soluble molecules, can facilitate their incorporation into SLNs and NLCs (Abedi, Akhavan, Mohammadi, & Banasaz, 2023). However, this method presents challenges for use in the food industry due to potential toxicity concerns. Table 3 summarizes various studies on encapsulating bioactive ingredients using different preparation methods with SLNs and NLCs, providing a comprehensive overview of the current state of research in this field.

Table 3.

Summary of fabrication methods and encapsulation of hydrophilic and hydrophobic bioactives by SLNs and NLCs.

| Bioactive encapsulant and encapsulant type | Fabrication methods | Nanoemulsions composition | Nanocarrier type | Encapsulation efficiency (%) | Loading methods of bioactive ingredient | Reference |

|---|---|---|---|---|---|---|

| Fisetin (Hydrophobic) |

High-pressure homogenization method | Lipid phase: lexemul AR, Lexemul 561 and Labrasol aqueous phase: pluronic F-127 |

NLCs | 78 | Dissolve fisetin in lipid phase above its melting point; concurrently dissolve surfactant in aqueous medium. Gradually introduce drug-loaded lipid phase into heated aqueous components, followed by homogenization for nanoparticulate dispersion. | (Kumar et al., 2023) |

| Vitamin D3 (Hydrophobic) |

High pressure homogenization method | Lipid phase: MCT, VD3, GM aqueous phase: rhamnolipids, ultra-pure water |

NLCs | 51–72 | Homogenize and heat lipid and aqueous phases at 75 °C, with the lipid phase pre-containing Vitamin D3. Combine both phases under high shear homogenization and followed by sonication. Conclude by cooling in ice to obtain nanoparticles. | (Azevedo, Cerqueira, Goncalves, Amado, & Pastrana, 2023) |

| Citral (Hydrophobic) |

High pressure homogenization method | Lipid phase: glyceryl monostearate, medium chain triglycerides, citral aqueous phase: surfactant, water |

NLCs | 45–73 | Dissolve citral in a melted lipid mixture and combine this lipid phase with an aqueous surfactant solution under high-shear homogenization. The system is then subjected to ultrasonic treatment to yield the NLCs | (Feng, Sheng, Yu, Lin, & Shao, 2023) |

| Vitamin D3 (Hydrophobic) |

High pressure homogenization method | Lipid phase: anhydrous milk fat, vitamin E acetate, polyglycerol ester, vitamin D3 aqueous phase: |

NLCs | >72 | Melt the lipid phase with vitamin D3 at 70 °C. Emulsify sodium caseinate gradually into the lipid phase under homogenization, followed by sonication in a hot bath. Solidify the nanoemulsions at 4 °C to produce the NLCs. | (Barri, Ghanbarzadeh, Mohammadi, & Pezeshki, 2023) |

| β-carotene (Hydrophobic) |

Solvent emulsification method | Lipid phase: corn oil, palmitic acid, β-carotene, vitamin E and butylated hydroxytoluene aqueous phase: Vitamin C, Tween 80, double distilled water |

NLCs | – | Dissolve the β-carotene-containing lipid phase in ethanol at 70 °C. Introduce the solution into the preheated aqueous phase. Cool the resulting dispersion to room temperature for NLCs formation. | (Hejri, Khosravi, Gharanjig, & Davarani, 2019) |

| Formononetin (Hydrophobic) |

melt-emulsification ultrasonic method | Lipid phase: formononetin, glyceryl distearate, perilla seed oil, Tween 80, propylene glycol Water phase: distilled water |

NLCs | 96.3 | Heat and melt the lipid mixture of lipids, surfactants, and formononetin. The mixture is then combined with heated distilled water to form a pre-nanoemulsion. Finally, the system undergoes sonication in an ice bath to produce NLCs. | (L. J. Zheng et al., 2023) |

| Citral (Hydrophobic) |

Microemulsion formation method | Lipid phase: glyceryl monostearate aqueous phase: Tween 80, Span 80 |

SLNs | 57–72 | Heat solid lipid and citral to 65 °C for the lipid phase. Form emulsion by adding surfactant solution under stirring. Cool the emulsion below the melting point to generate SLNs. | (Tian, Lu, Li, & Hu, 2018) |

| β-carotene (Hydrophobic) |

High pressure homogenization method | Lipid phase: octyl octanoate, precirol ATO5 aqueous phase: ploxamer 407, water |

NLCs | 97 | Melt β-carotene, mix with liquid oil, and add to melted solid lipid at 70 °C. A preheated surfactant solution was added to the lipid phase. The NLCs was obtained by homogenizing the lipid mixture and cooling it down to 22 °C for recrystallization. | (Pezeshki et al., 2019) |

| β-carotene (Hydrophobic) |

Solvent emulsification method | Lipid phase: tristearin aqueous phase: sodium caseinate or lactoferrin |

SLNs | – | β-carotene and tristearin were solubilized in ethanol and heated to 80 °C to form the organic phase. Organic phases were gradually added in preheated aqueous phases containing protein under stirring. The dispersions were rapidly cooled to form SLNs | (Oliveira, Furtado, & Cunha, 2019) |

| EGCG (Hydrophillic) |

High pressure homogenization method | Lipid phase: Precirol® ATO 5, Mygliol® 812, Tween® 60 aqueous phase: EGCG, ultrapure water |

NLCs | 85–91 | Pre-heated ultrapure water with EGCG was added to the lipid phase, followed by stirring and ultrasonication. The produced nanoemulsions was cooled at room temperature to obtain NLCs. | (Granja et al., 2017) |

| Anthocyanin (Hydrophillic) |

High pressure homogenization method | Lipid phase: palmitic acid, Span 85, egg lecithin, ethanol or isobutanol aqueous phase: cabbage extract, pluronic F127, distilled water |

SLNs | 27–93 | Heat lipid phase to 60 °C, add ethanol/isobutanol as a co-surfactant. Formulate w/o microemulsion by titrating aqueous phase with active compounds. Disperse microemulsions in Pluronic F127 solution via homogenization to create SLNs. | (Ravanfar et al., 2016) |

| EGCG (Hydrophillic) |

High pressure homogenization method | Lipid phase: cocoa butter, Mono- and diglycerides of fatty acids (MDG), sodium stearoyl-2-lactylate (SSL) aqueous phase: green tea polyphenol, water |

SLNs | 60–70 | Emulsify the green tea polyphenol solution into the organic phase with melted cocoa butter and MDG through homogenization. Re-emulsify the blend into water with SSL. Cool the resulting hot nanoemulsions in a thermostat at 1 °C. | (Shtay, Keppler, Schrader, & Schwarz, 2019) |

| EGCG (Hydrophillic) |

Solvent emulsification method | Lipid phase: glycerol monostearate (GMS), stearic acid (SA), and soya lecithin aqueous phase: EGCG, distilled water, Pluronic F68 |

SLNs | 67–89 | Dissolve GMS, SA, and soya lecithin in dichloromethane. Create a water-in-oil (w/o) primary emulsion by adding EGCG and Pluronic F68 solution to the lipid mixture. Sonicate and transfer the mixture into Pluronic F68 solution for a double emulsion. The emulsion was then centrifuged and washed with water. | (Radhakrishnan et al., 2016) |

| Saffron extract (Hydrophillic) |

High shear homogenization method | Lipid phase: butter, polyglycerol esters, olyglycerol polyricinoleate, thyme and pennyroyal essential oil, aqueous phase: affron extract, Tween 80 |

NLCs | 59–79 | The process integrates an internal aqueous phase containing saffron extract into a heated lipid phase consisting of butter and essential oils with surfactants. Subsequently, this primary emulsion is dispersed into a secondary aqueous phase containing Tween 80 and cool down to form NLCs. | (Binazir et al., 2024) |

It is important to note that despite these advancements, SLNs and NLCs are still primarily employed for loading hydrophobic compounds. The challenges associated with dissolving hydrophilic compounds in the oil phase often result in lower encapsulation efficiency and potential expulsion of the active substance from the solid lipid during storage. To achieve higher encapsulation efficiency and loading capacity for hydrophilic compounds, further research is necessary to explore alternative carriers with improved compatibility.

3. Nature biopolymer-based nanocarrier for encapsulation of hydrophilic and hydrophobic ingredients

3.1. Polysaccharides nanogel

3.1.1. Brief overview of polysaccharides nanogel

Nanogels, also known as nanohydrogels or hydrogel nanoparticles, are innovative nanostructures fabricated through the crosslinking of hydrophilic polymers into a three-dimensional network. Nanogels exhibit both characteristics of hydrogels and nanoparticles, such as non-immunogenicity, flexible chemistry, large surface area, and minimal size. These attributes collectively enhance their ability to overcome adverse environments and penetrate biological barriers, such as intestinal and blood-brain barriers (Z. Zhang et al., 2021).

Over the past decades, there has been a significant emergence of nanogels composed of food-grade polysaccharides. These formulations offer improved biocompatibility and more efficient protection for various food-bioactive molecules and pharmaceutical compounds (Luckanagul et al., 2018). Polysaccharides have garnered considerable attention as desirable materials for nanogel synthesis due to their abundant availability, cost-effectiveness, non-toxic nature, and water solubility. The polysaccharide backbone, rich in reactive functional groups such as hydroxyl and carboxylic acid, facilitates derivatization, thereby enhancing the structural and functional diversity of the nanocarrier (Meng et al., 2024). In the food and biomedical sector, various nanogel have been developed utilizing polysaccharides derived from diverse sources, encompassing animal origins (e.g., dextran, pullulan, xanthan gum, and gellan gum, etc.), plant origins (e.g., pectin, cellulose, starch, etc.), and microbial origins (e.g., agar, alginate, and carrageenan, etc.) to prevent degradation of active substances (Z. Wu, Li, Zhao, Ye, & Zhao, 2022; Z. Zhang et al., 2021). The utilization of these varied polysaccharide sources in nanogel formulation has significantly contributed to the prevention of active substance degradation, thereby enhancing the stability and efficacy of encapsulated bioactive compounds.

The versatility of polysaccharide nanogels is further exemplified by their ability to respond to various stimuli, such as pH, temperature, and enzymatic activity. This responsiveness allows for targeted and controlled release of encapsulated substances, making polysaccharide nanogels particularly attractive for applications in nutraceutical delivery and functional food development. The distinctive advantages of nanogel are as follows (Papagiannopoulos & Sotiropoulos, 2022; Y. Zhang et al., 2022):

-

•

Flexible chemistry of nanogel gives them a better affinity with hydrophilic or hydrophobic compounds.

-

•

Varying fabrication methods could produce stimuli-responsive nanogels for improving drug release behavior in the gastrointestinal tract and protecting bioactive from adverse environments

-

•

Functional groups in polysaccharides offer the potential to produce functional hydrogels

-

•

Many methods could prepare nanogel and easy to scale up for industry

-

•

Plenty of food-based material could be selected to fabricate nanogel and avoid toxicity concerns.

-

•

High drug encapsulation capacity and diversity of actives that can be encapsulated

3.1.2. Production methods of polysaccharides nanogel

The synthesis of polysaccharide nanogels encompasses a diverse array of methodologies, encompassing coacervation, thermal-denaturation, emulsification, injection or extrusion, shearing, spray chilling, etc. (Silva & Fabi, 2022). These preparation techniques can be broadly categorized based on the crosslinking structure of the resultant nanogel, distinguishing between chemically crosslinked and physically crosslinked nanogels. Chemically crosslinked nanogels utilize the active groups of polymers, such as carbonyl, carboxyl, and amino groups, to form covalent bonds, resulting in a permanent, stable, and rigid three-dimensional structure (Mohammadi, Arabi, & Alibolandi, 2020). In contrast, physically crosslinked nanogel is formed through the entanglements of the polymer chain and physical interactions between several polymers in formulation, such as hydrogen bonds, electrostatic, van der Waals, and hydrophobic interactions (Mauri, Giannitelli, Trombetta, & Rainer, 2021).

Physically crosslinked nanogels are predominantly prepared through amphiphilic self-assembly and electrostatic self-assembly, owing to the mild reaction conditions these methods offer. Amphiphilic polysaccharides, derived from the modification of hydrophilic polysaccharide chains with hydrophobic groups (e.g., fatty acids, steroids, adenylosuccinate, cholesterol, etc.), can spontaneously self-assemble into shell-core structured in water (Z. Wu et al., 2022). Once the amphiphilic polysaccharide is dispersed in water, the hydrophobic moieties have a tendency to assemble via intra- or intermolecular associations and form nanogel a hydrophobic core (Fig. 3A). The hydrophobic core serves to load hydrophobic cargo while the hydrophilic outer shell prolongs circulation time. In the preparation of amphiphilic polysaccharide nanogels, the typical process involves dispersing polysaccharides in water, followed by ultrasonic treatment and dialysis against water. Additionally, the thin film hydration method mentioned above in 2.1.2 has been reported to form nanogels with a liposome structure (Bu et al., 2021).

Fig. 3.

The schematic diagram of biopolymer-based nanocarriers preparation methods and biopolymer-based nanocarriers loading with hydrophilic and hydrophobic bioactive: polysaccharides based nanogel (A, a), protein based nanoparticles (B, b).

The electrostatic self-assembled nanogels are formed by electrostatic interactions between at least two oppositely charged polysaccharides. Electrostatic self-assembly relies on the attraction between oppositely charged molecules, such as cationic and anionic polymers or zwitterionic molecules. These interactions form the backbone of nanogel structures, creating a three-dimensional network. For instance, chitosan's amino groups, which are positively charged in mildly acidic solutions, form electrostatic interactions with anionic polymers or polyanions in aqueous environments (Silva & Fabi, 2022). Yang et al. (2015) prepared the chitosan-hyaluronic acid nanogel via the cationic amino group in chitosan interaction with anionic carboxyl groups of hyaluronic acid, achieved by simply mixing chitosan solution with a hyaluronic acid solution (Yang et al., 2015). Furthermore, the addition of ionic cross-linking agents can facilitate the formation of a nanogel network. For example, anionic sodium tripolyphosphate is commonly used to connect with positively charged amines of chitosan nanogels due to its low toxicity and multivalent properties (Shitrit & Bianco-Peled, 2021). Similarly, divalent cations such as Ca2+, Zn2+, and Mn2+ have been used to fabricate sodium alginate and pectin based nanogels, interacting with hydroxyl and carboxyl groups within polysaccharides (Du, Lu, Zhang, Mata, & Fang, 2021).

Chemical crosslinking differs fundamentally from physical crosslinking as it entails the formation of covalent bonds between polysaccharide chains, thereby imparting stability and rigidity to the nanogel structure. This process is typically facilitated by reactions involving bifunctional or multifunctional crosslinkers that connect the polymer chains. The covalent crosslinking strategies include radical polymerizations, Schiff-base reaction, thiol-disulfide exchange reaction, click chemistries, and photoreactions. The selection of covalent crosslinking strategies depends on the functional group in the polysaccharide chains. A comprehensive review of these methodologies has been conducted by Zhang et al. (X. J. Zhang, Malhotra, Molina, & Haag, 2015). Various crosslinker agents, such as glutaraldehyde, formaldehyde, and glyoxal, have been reported for preparing nanogel (X. Chen et al., 2023; Silva & Fabi, 2022). These crosslinkers induced the reaction in polysaccharides-based nanogel, usually involving hydroxyl or carboxyl groups in polysaccharides. Based on these chemical cross-linking mechanisms, several technologies have been developed to synthesize nanogels, such as precipitation polymerization and nanoprecipitation methods (Paliya et al., 2023). However, the residual monomers or cross-linking agents of chemically crosslinked nanogel have adverse effects on cells or tissues, limiting chemically crosslinked nanogel in the food industry.

3.1.3. Encapsulation strategies for hydrophilic and hydrophobic ingredients in polysaccharides nanogels

The presence of hydrophilic groups, such as -OH, –CONH– and –CONH2– within the polysaccharides chain, enables nanogels to exhibit water absorption properties and the ability to encapsulate hydrophilic ingredients. Furthermore, the insoluble yet hydrophilic polysaccharides forming a three-dimensional network structure through physical or chemical bonds lead to nanogels having superior water absorption capacity and higher hydrophilic drug loading capacity than individual hydrophilic polymers (Hawthorne, Pannala, Sandeman, & Lloyd, 2022).

The majority of studies employ a straightforward approach for encapsulating hydrophilic bioactive ingredients. This typically involves dissolving the hydrophilic compounds in water, followed by the formation of nanogels through either physical or chemical crosslinking within the aqueous solution containing the hydrophilic compounds (Table 4). For instance, Rahaiee, Hashemi, Shojaosadati, Moini, and Razavi (2017) prepared chitosan-alginate nanogels to enhance the bioavailability of crocin by adding the crocin-alginate solution into the chitosan solution (Rahaiee et al., 2017). Similarly, in a study by Zhao et al. (2020), spherical nanogel was fabricated by mixing anthocyanins and cationic chitosan solutions. The obtained chitosan-pectin-anthocyanins nanogel with 66.7 % encapsulation efficiency protects anthocyanins from stomach acid environment damage and delayed release cargo into the intestinal fluid (Zhao et al., 2020).

Table 4.

Summary of fabrication methods and encapsulation of hydrophilic and hydrophobic bioactives by polysaccharide nanogel.

| Bioactive encapsulant and encapsulant type | Encapsulation technique | Nanogel composition | Encapsulation efficiency (%) | Loading methods of bioactive ingredient | Reference |

|---|---|---|---|---|---|

| Curcumin (Hydrophobic) |

Physically crosslinked method | Aminated chitosan, tripolyphosphate, folate acid | 94 | Curcumin was dispersed in an aminated chitosan, folate acid, or tripolyphosphate solution followed by ultrasound treatment. Centrifuged the dispersion and washed the precipitates with acetic acid solution and deionized water to obtain the nanogel. | (X. Sun et al., 2019) |

| Curcumin (Hydrophobic) |

Physically crosslinked method | Sodium alginate, CS, calcium chloride | 10–13 | Incorporating curcumin-ethanol stock solution in calcium chloride solution. The solution was added to the sodium alginate aqueous solution, and the CS solution was dropped into the system. | (R. K. Das, Kasoju, & Bora, 2010) |

| Curcumin (Hydrophobic) |

Physically crosslinked method | Soybean protein isolate-dextran conjugate (SDC) | 89.1 | SDC was dissolved in water through pH adjustment and thermal treatment. Subsequently, incorporate curcumin ethanolic solution into the system through homogenization. The final curcumin-loaded nanogel is obtained through centrifugation and lyophilization processes. | (Y. X. Sun et al., 2024) |

| Resveratrol (Hydrophobic) |

Physically crosslinked method | Trimethyl chitosan | 46–72 | Add RV to TMC aqueous solution. Introduce a TPP, alginate, or a mixed solution of TPP and alginate dropwise into the resultant solution. | (Min et al., 2018) |

| Curcumin (Hydrophobic) |

Chemically crosslinked method | Chitosan hydrochloride, carboxymethyl starch | 89–94 | A curcumin-ethanol solution was added to the CHC solution to prepare the Cur-CHC stock solution. CMC solution of carboxyl groups activated by EDC was added into the stock solution to form amide bond and followed by washing and centrifugation to get nanogel. |

(X. M. Li et al., 2019) |

| β-Carotene (Hydrophobic) |

Physically crosslinked method | Pectin, 2-hydroxypropyl-β-cyclodextrin (HP-CD) | – | β-Carotene-acetone solution was added to the preheated HP-CD solution with stirring. After evaporating acetone, the resultant solution was dropwise to pectin solution to obtain the final nanoparticle. | (Celitan et al., 2022) |

| Riboflavin (Hydrophillic) and quercetin (Hydrophobic) | Physically crosslinked method | Gallic acid modified chitosan (GCS), Ovalbumin (OVA) | 66 (riboflavin) 96 (quercetin) |

Add riboflavin-water or quercetin-ethanol solution to the OVA solution with stirring. Introduce the resultant solution into GCS solution and supplement with calcium chloride solution to obtain nanoparticles. | (L. Li et al., 2022) |

| Green coffee extract (Hydrophillic) |

Chemically crosslinked method | Carrageenan, | – | Dissolve Carrageenan in water, then incorporate green coffee extract at varying concentrations. Subsequently, the mixture is combined with glutaraldehyde to form crosslinked networks and purified through dialysis to yield the final nanogel systems. | (Khalaf, Gouda, Taleb, Heakal, & El-Lateef, 2024) |

| Blueberry anthocyanins (Hydrophillic) |

Physically crosslinked method | Olive pectin (PC), chitosan (CS) | 92 | ANCs and PC solution were added to CS-acetic acid solution and followed by adjusting pH of this system. |

(C. Xie et al., 2023) |

| Oyster peptides (Hydrophillic) |

Physically crosslinked method | Carboxymethyl chitosan, carboxymethyl cellulose | 92.7 | Commence by incorporating oyster peptide solution into carboxymethyl chitosan to form a homogeneous mixture. Subsequently, introduce this mixture into the carboxymethyl cellulose solution. The nanogel was obtained by pH adjustment and thermal treatment | (P. Zhang et al., 2024) |

| Blueberry anthocyanins (Hydrophillic) |

Physically crosslinked method | Pectin, lysozyme | 73 | Mix the pectin, lysozyme, and anthocyanin solution with pH 5 in the ice bath, followed by stirring at room temperature to form a nanogel. | (Rosales, da Silva, Lourenço, Hassimotto, & Fabi, 2021) |

| Anthocyanins (Hydrophoillic) |

Physically crosslinked method | Chitosan, pectin | 67 | Anthocyanin powder was added to the chitosan solution to form CS-ANC complexes, followed by dropwise pectin solution into the mixture to form nanogel. | (Zhao et al., 2020) |

| Cyanidin-3-glucoside (Hydrophillic) |

Physically crosslinked method | Carboxymethyl chitosan (CMC), β-cyclodextrin graft epichlorohydrin (β-CD-EP), CaCl2 | 48 | Combine C3G, β-CD-EP, CMC solution, and CaCl2 solution with carboxymethyl chitosan solution. Stir at 800 rpm for 30 min to form a nanogel. | (J. Sun et al., 2022) |

While the conventional approach involves incorporating the loaded ingredients into the hybrid polysaccharide solution before nanogel formation, studies have shown that bioactive ingredients can also be loaded into the system after nanogel formation. This process is facilitated by passive diffusion and interactions between the bioactive molecules and polysaccharides. Moreover, the unrestricted mobility of small hydrophilic compounds within the expanded nanogel network promotes rapid diffusion of the drug into the surrounding aqueous environment, leading to an undesired burst release phenomenon (J. Li & Mooney, 2016). To address this concern, researchers have developed stimuli-responsive nanogels to address this concern, such as pH-responsive, light-sensitive, and temperature-sensitive nanogels, allowing for the controlled release of encapsulated compounds in specific environmental conditions (Farazi et al., 2020).