Abstract

Utilizing aerosol jet printing (AJP), this study achieves a breakthrough in fabricating luminescent fibers with superior optical performance and flexibility. The Y2O3:Eu3+ coated high silica glass fibers demonstrate luminous efficiency twice that of traditional methods, retaining 80% after 250 bending cycles and 90% after sweat immersion. This AJP technique not only elevates the potential of smart fabrics but also represents a significant innovation in lighting technology, providing new ideas for advanced functional fiber fabrication.

Keywords: New material, Optical materials, Flexible luminescent fiber, Rare-earth luminescence, AJP

Subject terms: Materials science, Materials for optics

Introduction

With the advancement of technology, textiles are not only symbols of human civilization and industrialization but also technologically advanced products integrating intelligent functions such as health monitoring1 and optical displays2. By integrating functional materials and electronic components on textiles or fibers, a variety of smart textiles have been developed, which includes multifunctional sensors3, transistors4, luminescent materials5, and devices6.Smart wearable luminescent fabrics demonstrate versatility in fields such as fashion design and stage performances7, and play a significant role in applications such as safety, anti-counterfeiting, and flexibility, showcasing their important practical value8–10.

Rare earth luminescent materials are widely applied in various fields due to their excellent chemical and physical stability, vibrant colors, high color purity, and high conversion efficiency. In recent years, with the rapid development of flexible fiber electronics and wearable technology, the development of rare-earth luminescent fiber devices has become a focus of attention in both scientific research and industry. Traditional preparation techniques for rare-earth luminescent materials involve stringent conditions, such as the requirement for high post-treatment temperatures in the solid-state method, or the uneven particle size distribution of the produced luminescent materials11. Additionally, the sol-gel method involves a lengthy process, intricate steps, and low yield12,13. In summary, traditional preparation techniques have significant limitations in the fabrication of fiber optic devices.

This study employs a novel luminescent fiber preparation technique, AJP technology, which was used to print functional materials directly onto the surface of fiber substrates. Specifically, a precursor solution containing Y2O3:0.03Eu3+ luminescent material was deposited onto high silica glass fibers by applying ultrasonic atomization. Subsequently, the fibers were sintered at low temperature, resulting in the successful creation of luminescent fibers with exceptional performance. In addition, this study also explored the performance comparison between the luminescent fibers prepared using the immersion adsorption (IA) method and the luminescent fibers prepared by the AJP method in order to verify their excellent luminescent properties and easy operation methods. It is further shown that the AJP technique is simple and efficient, the coated luminescent material particles being approximately 1 μm in size, and the post-treatment temperature as low as 500 °C. The AJP technique provides a new avenue for flexible smart textiles and lays the foundation for the application of rare-earth luminescent fibers in the field of flexible smart textiles.

Experimental sections

Preparation process

Ink Preparation: All reagents were sourced from Aladdin and used without further purification. The ink preparation followed our team’s established protocol14. For the Y2O3:0.03Eu3+ ink, YCl3⋅6H2O and EuCl3⋅6H2O were dissolved in deionized water to form a 0.5 M solution for printing, with a 3% doping ratio of Eu3+.

Fiber Substrate Pretreatment: Prior to use, high silica glass fibers with a diameter of 300 μm underwent pretreatment. This involved immersing the fibers in alcohol for 10 min, followed by drying and a 3-minute treatment with a vacuum plasma treater (model: VP-R series).

AJP of Y2O3:0.03Eu3+ Ink: The luminescent fiber precursor solution was printed using a commercial Aerosol Jet Printer (model: HMP, WE Electronics, China). Initially, 5 mL of ink was introduced into the nebulizer and aerosolized with a 1.7 MHz ultrasonic nebulizer. Aerosol droplets were carried to the nozzle by nitrogen gas (flow rate of 110 sccm) and enclosed by a nitrogen sheath flow (130 sccm) for inkjetting. The nozzle had a diameter of 30 μm. A helical line pattern was printed with the following parameters: linear speed, 1 mm/s; rotational speed, 5 rpm; nozzle height, 5 mm; and printing temperature, 90 °C. After five cycles, the luminescent fiber precursor was successfully formed.

IA of Y2O3:0.03Eu3+ Ink: Pretreated high silica glass fibers were submerged in the ink for 2 h to ensure complete adsorption of the fluorescent material. This technique involves immersing fibers in a solution containing fluorescent material, relying on the interaction between the fiber surface and the fluorescent material in the solution to achieve effective adsorption of the fluorescent material to the fiber surface, thereby imparting fluorescent properties to the fibers15.

Low-temperature sintering post-treatment

The luminescent fiber precursor was sintered in air, with the temperature increasing from 90 to 500 °C at 2 °C/min, maintained for 3 h, and then cooled to room temperature. Following this, PDMS (from Dongsongke New Material Technology Co., Ltd., China) was used for encapsulation. PDMS and a curing agent were mixed at a 10:1 ratio and stirred for 2 min before degassing in a vacuum chamber. The fluorescent fiber was then dipped into the PDMS blend for even coating and cured in a 60 °C oven for 30 min. The encapsulated luminescent fibers weighed approximately 0.03 g more per 20 cm after being encapsulated with PDMS.

Characterization methods

Scanning Electron Microscopy (SEM, Zeiss Sigma 300) used to obtain surface morphology images of the luminescent powder. The phase purity of the samples was determined by X-ray Diffraction (XRD, Bruker D8 Advance) with a diffraction range of 10–80° and a step size of 0.0065°. Using xenon flash as the excitation source, the photoluminescence (PL) and photoluminescence excitation (PLE) spectra of the samples were measured using an F-2700 fluorescence spectrophotometer (4J1-0008). A Three-in-One Ultraviolet Analyzer (WFH-203B) was used to observe the luminescent pattern of the luminescent fibers. The bending mechanical properties of the functional fibers were tested using a flexible electronic tester (FT2000). Environmental stability testing of functional fibers coated with PDMS using simulated sweat (article number: MAP1087, MeGen Biotechnology). Contact angle measurements were conducted on the functional material using a contact angle meter (SZ-CAM).

Results and discussion

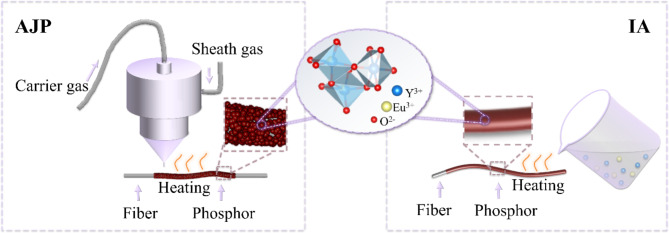

Figure 1 depicts the preparation processes of AJP and IA for luminescent fiber fabrication. The AJP technique utilizes a 1.7 MHz ultrasonic atomizer to atomize the ink within an ink bottle, generating aerosol droplets with metal ions. These droplets are carried by an air stream to the nozzle and precisely controlled by a nitrogen sheath flow prior to jetting16. This process yields a uniform coating on the plasma-treated high silica glass fiber substrate. Notably, controlling the fiber diameter within 0.05–1.5 mm is crucial for optimal coating outcomes. In addition, parameters including the number of print layers, speed, and height, as well as the focus ratio and temperature, were determined primarily based on our team’s research results14.

Fig. 1.

The process of preparing luminescent fibers by AJP.

Conversely, the IA method involves submerging the treated fibers in a solution-filled beaker. The primary goal of this method is to ensure adequate solution penetration into the fibers for a uniform coating.

Morphological and luminescent property analysis

Figure 2 displays the surface morphology and microstructure of fibers fabricated using the AJP and IA methods, along with the Y2O3:Eu3+ spectra. Specifically, Fig. 2a,b reveal the surface structure of AJP-prepared fibers, characterized by the aggregation of nanospheres into a coating layer. During spraying, ultrasonic waves nebulize the ink into microdroplets, which, upon heating, react to create particulate nanostructures17. As deposition continues, droplets coalesce, forming a continuous micro-nano sphere film that thoroughly covers the fiber surface.

Fig. 2.

(a,b) Low and high magnification images of fibers fabricated by AJP. (c,d) Low and high magnification images of fibers prepared by IA. (e,f) Excitation and emission spectra of Y2O3:Eu3+. (g) XRD comparison of phosphors produced by the two methods. (h,i) Hydrophobicity test results for luminescent fibers with and without PDMS coating. (j,k) Excitation and emission spectra of luminescent fibers with and without PDMS coating.

Figure 2c,d illustrate the surface morphology of fibers prepared using the IA method, featuring a sheet-like coating layer. During the immersion process, the electrical charges on the fiber facilitate ink adsorption and ensure an even distribution along the fiber’s length18. A comparison of the fibers produced by the two methods reveals that the nanosphere film from AJP exhibits superior mechanical stability compared to the sheet-like structure of IA method19. This film boasts excellent interfacial bonding, effectively bearing and transferring stress, significantly enhancing the mechanical stability of flexible materials, as shown in (Fig. 2a). This characteristic is crucial for applications in flexible electronics, wearable devices, and robotics, where long-term reliability is essential.

Figure 2e shows the excitation spectrum at 612 nm and Fig. 2f shows the emission spectrum at 250 nm. This shows that the luminescent materials obtained from both preparation methods have the same spectral properties. According to research20–22, the excitation peak at 250 nm corresponds to the transition of Eu3+ from the5D0→7F0 energy level. The peaks at 582 nm and 588 nm are attributed to the5D0→7F1 transition, while the main peak at 612 nm to the5D0→7F2 transition in Y2O3. The Judd-Ofelt theory23 suggests that electric dipole transitions are significantly stronger than magnetic dipole transitions. When Eu3+ occupies a non-centrosymmetric position, it can produce high color purity and narrow-band red emission (610–620 nm). These luminescent properties are influenced by changes in the local environment surrounding the Eu[3+24.

Despite the similar spectral characteristics of the materials prepared by both methods, a notable difference in luminescence intensity is observed. Specifically, the material produced by AJP exhibits approximately twice the luminescence intensity compared to that prepared by IA, as depicted in (Fig. 2e,f). This discrepancy suggests that the preparation process significantly influences luminescence efficiency, despite having no effect on the luminescent properties. The disparity in luminescence efficiency primarily stems from differences in key material formation stages, such as nucleation, growth, and structure development, which result in varied surface properties (including roughness, morphology, chemical composition, and crystal orientation) of the materials. These surface changes directly impact the luminescence efficiency of the materials25,26. Specifically, the roughness of the fiber surface significantly influences the scattering of incident and emitted light. Upon encountering irregular structures on rough surfaces, light experiences increased path lengths, enhancing luminescence efficiency27. Surface roughness significantly affects the efficiency of extracting light from a material’s interior to its exterior. In photoluminescent materials, rough surfaces enhance light extraction efficiency by minimizing total internal reflection and facilitating more effective light escape28.

Luminescence stability is intricately linked to structural integrity, with enhanced structural rigidity bolstering luminescence stability29. The XRD patterns (2θ = 10–80°) in Fig. 2g showed a strong match with the standard reference (JCPDS#86-1107). It is a typical cubic Y2O3 (space group Ia-3(206)) by its prominent diffraction peaks distributed in (211), (222), (400), (440), and (622) lattice reflections with 2θ corresponding to 20.5°, 29.2°, 33.8°, 48.5°, and 57.6°, respectively, among which the intensity of the main peak (222) is most significant at 2θ = 29.2°. In addition, the fibers prepared by the aerosol jet printing method exhibited more significant diffraction peaks than those prepared by the impregnation adsorption method. The results show that XRD analysis confirms that the luminescent fibers prepared by the AJP method exhibit higher crystallinity compared to those prepared by the IA method, which implies that the number of lattice defects and dislocations in the fluorescent material is reduced30,31. These defects and dislocations act as centers of non-radiative leaps, which may lead to the dissipation of excited state energy through non-radiative pathways and thus reduce the luminescence efficiency32. Therefore, compared with the luminescent fibers prepared by the IA method, the luminescent fibers prepared by the AJP method exhibit superior luminescence performance.

Luminescence and hydrophilicity analysis of encapsulated fibers

In this study, we assessed the hydrophobicity of luminescent fibers by measuring their contact angle with physiological saline. As depicted in Fig. 2h,i, the fibers exhibited a contact angle of 104° without PDMS coating, indicating high hydrophobicity. Coating with PDMS solution increased the contact angle to 114°, significantly boosting hydrophobicity and firmly encapsulating the functional material. PDMS’s low surface energy creates a hydrophobic layer, significantly enhancing hydrophobicity and stability of the fibers in liquid environments33.

To assess the impact of PDMS coating on the luminescent properties of the fibers, we compared their luminescent characteristics before and after encapsulation (Fig. 2j,k). The results revealed minimal changes in luminescence intensity, suggesting that PDMS coating did not substantially alter the optical properties of the fibers. This finding underscores the importance of maintaining the stability of the luminescent fiber performance.

Application potential

As a novel functional material, the practical application performance of luminescent fibers is pivotal. These fibers may experience mechanical stresses like stretching, compression, bending, or shearing during wear, washing, and usage, potentially impacting their structure and functionality. Moreover, luminescent fibers must maintain stability under diverse environmental conditions. Consequently, to facilitate the application of luminescent fibers across various fields, conducting practical tests is imperative.

Mechanical behavior

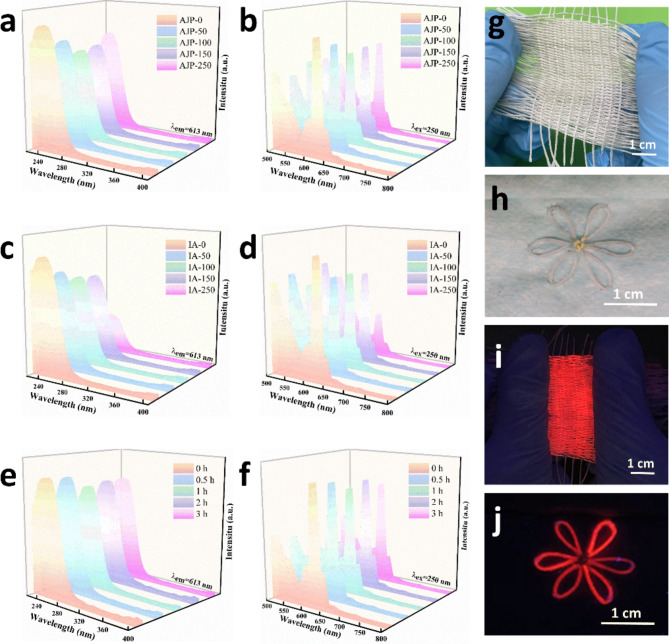

Figure 3a–d demonstrates the variation of luminescence intensity in the bent portion of the fibers prepared using AJP and IA methods after undergoing bending cycles. The fibers used in this test were treated with PDMS. Analyzing the luminescence intensity decay provides insights into the mechanical stability of functional fibers34,35. Over 100 bending cycles, the luminescence efficiency of AJP-prepared fibers slightly decreased to 81% of the initial level, then stabilized (Fig. 3b). In contrast, the luminescence efficiency of IA-prepared fibers notably declined post-bending. At 250 cycles, the efficiency dropped to 37%, a 43% decrease from 50 cycles (80%). Table 1 details the exact quantitative values for specific luminous intensity ratios. Consequently, AJP fibers exhibit enhanced stability, with their luminescence efficiency stabilizing around 80% after 250 cycles. This is consistent with previous findings that materials prepared by spraying or adsorption affect the functionality of the fibers after repeated use36. In this study, by combining the uncoated PDMS samples in Fig. 2a–d, we found that the functional layer prepared by the immersion adsorption method is prone to fracture when subjected to stress, whereas the functional layer prepared by the AJP method consists of micro- and nanosphere, a structure that can well release the stress generated by bending of the fibers and avoid the rupture of the functional layer37. Therefore, in applications involving repeated bending and stretching, the mechanical deformation of AJP fibers has less impact on the photoluminescence performance compared to functional fibers prepared by immersion adsorption38. This finding further demonstrates the advantages of the AJP method of preparing luminescent fibers in terms of mechanical stability and durability.

Fig. 3.

(a–d) Luminescence intensity variations of fibers made by AJP and IA methods during bending cycles. (e,f) Environmental stability: The correlation between immersion time in simulated sweat and luminescence intensity for AJP-prepared fibers. (g–j) Luminescent fiber fabric weaving diversity and fluorescent patterns under UV illumination.

Table 1.

Luminescence intensity values of fibers prepared by AJP and IA methods at different number of bends.

| Bending times (cycles) | 0 | 50 | 100 | 150 | 250 |

|---|---|---|---|---|---|

| Intensity value by AJP | 4194 | 3826 | 3379 | 3484 | 3497 |

| Intensity value by IA | 3740 | 3001 | 2989 | 2887 | 1393 |

Environmental resistance

Extensive research has been conducted on integrating functional fibers into conventional wearable fabrics to produce luminescent fabrics39–42. Nonetheless, these fibers encounter several challenges regarding environmental stability. Specifically, daily use may expose the fibers to perspiration and other environmental elements, potentially impacting their performance and lifespan. To evaluate the environmental stability of functional fibers, this study examined their reaction to simulated sweat. As shown in Fig. 3e,f, there is some effect of simulated sweat on the luminescence intensity as the immersion time increases. Notably, the functional fibers retained about 90% of their initial efficiency after being immersed in simulated sweat for 3 h. Specific luminous intensity values are shown in (Table 2). These findings indicate that the functional fibers examined in this study exhibit environmental stability.

Table 2.

Luminescence intensity values at different immersion times in simulated perspiration.

| Soaking times (h) | 0 | 0.5 | 1 | 2 | 3 |

|---|---|---|---|---|---|

| Intensity value | 5252 | 5041 | 4684 | 4898 | 4576 |

Wearability and potential applications

Luminescent fibers fabricated using AJP, known for their superior optical performance and flexibility, represent a novel method for developing smart fabrics. This technique allows for the seamless integration of luminescent fibers into diverse textile patterns, unlocking multifunctionality. As illustrated in Fig. 3g, incorporating these fibers into fabrics results in a distinct, uniform fluorescent glow under UV light, as seen in (Fig. 3i). This suggests that the use of luminescent fibers in textiles transcends mere decoration, encompassing more sophisticated functionalities.

Meanwhile, the PDMS-coated luminescent fibers were woven into floral patterns, as depicted in Fig. 3h,j, enhancing the fabrics’ aesthetic and practical value. Upon UV exposure, these patterns display a clear and consistent fluorescence, emphasizing their aesthetic appeal. Such smart fabrics are particularly innovative in lighting applications and introduce novel concepts to fashion design and interior decoration.

Conclusion

In summary, this paper details the preparation process and performance testing of Y2O3:Eu3+ luminescent fibers, utilizing two distinct fabrication methods: AJP and IA. Analysis indicates that fibers produced by AJP display higher crystallinity and a luminescence intensity twice that of immersion-adsorbed fibers. Mechanical testing demonstrates that these fibers retain 80% of their initial luminescence efficiency after 250 bending cycles, highlighting their exceptional durability and functionality. Environmental stability testing reveals that the fibers maintain 90% of their luminescence efficiency after 3 h of immersion in simulated sweat, showcasing their robustness in varied conditions. The research also involves weaving the fibers into floral shapes and testing their fluorescent performance under UV light, underscoring their aesthetic appeal.

The research delineated herein constitutes a seminal advancement in the domain of functional fiber materials. Utilizing AJP technology for the first time, the study has successfully fabricated flexible luminescent fibers with stable optical properties, strong environmental stability and flexibility. The outcomes of this investigation not only establish a solid theoretical and practical foundation for the progression of smart fabric technology but also herald novel avenues for scholarly exploration. Additionally, the study underscores the significant innovative potential within the realm of lighting technology. The contributions of the present work to the evolution of functional fiber materials are considerable, heralding a pioneering milestone in the field.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This work was supported by National Natural Science Foundation of China (51962006) and the High-level Talents Research Initiation Project of JXUST (205200100545).

Author contributions

Keke Wang: Writing—original draft, Investigation, Data curation. Zhi Liu: Data curation, Methodology. Chenxin Zhou: Investigation, Formal analysis, Data curation. Baixiong Liu: Resources, Funding acquisition. Shixian Xiong: Writing—review & editing, Data curation. Feng Gu: Writing—review & editing, Resources, Methodology. Jianfeng Liu: Project administration. Munan Yang: Visualization, Validation, Conceptualization.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due to the manuscript being in the submission phase, which requires adherence to the principle of anonymous peer review for academic journals, but are available from the corresponding author on reasonable request.

Declarations

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Feng Gu, Email: feng.gu@jxust.edu.cn.

Shixian Xiong, Email: s.xiong@jxust.edu.cn.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-025-86047-2.

References

- 1.Zhang, X. et al. High-performance multimodal smart textile for artificial sensation and health monitoring. Nano Energy103, 107778 (2022). [Google Scholar]

- 2.Lee, S. et al. LEGO-like assembly of fibrous modules for display textiles. ACS Appl. Mater. Interfaces15, 41688–41696 (2023). [DOI] [PubMed] [Google Scholar]

- 3.Jin, C. et al. MXene-based textile sensors for wearable applications. ACS Sens.7, 929–950 (2022). [DOI] [PubMed] [Google Scholar]

- 4.Gualandi, I. et al. Textile organic electrochemical transistors as a platform for wearable biosensors. Sci. Rep.6, 33637 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Esraa, A. et al. Imparting cotton textiles glow-in-the-dark property along with other functional properties: photochromism, flame-retardant, water-repellency, and antimicrobial activity. Cellulose30, 4041–4055 (2023). [Google Scholar]

- 6.Wu, R. et al. From mesoscopic functionalization of silk fibroin to smart fiber devices for textile electronics and photonics. Adv. Sci.9, 2103981 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Shen, J. et al. Luminous fabric devices for wearable low-level light therapy. Biomed. Opt. Express4, 2925–2937 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Jiang, Q. et al. Continuous and scalable manufacture of aggregation induced emission luminogen fibers for anti-counterfeiting and hazardous gas detecting smart textiles. Mater. Des.205, 109761 (2021). [Google Scholar]

- 9.Wang, C. et al. Multicolor and multistage response electrochromic color-memory wearable smart textile and flexible display. ACS Appl. Mater. Interfaces13, 2314861 (2021). [DOI] [PubMed] [Google Scholar]

- 10.Qu, C. et al. A sensing and display system on wearable fabric based on patterned silver nanowires. Nano Energy104, 107965 (2022). [Google Scholar]

- 11.Jia, H. et al. Eu3+@SiO2 nanocomposites as a convertor for a broadband solar-blind UV photodetector. J. Am. Ceram. Soc. 105Y2O3, 5252–5261 (2022). [Google Scholar]

- 12.Yu, Z. et al. Rare earth ions doped Bi2MoO6 luminescent materials: Pechini sol-gel synthesis, down-conversion and up-conversion multicolor emissions, and potential applications. Ceram. Int.49, 25987–25997 (2023). [Google Scholar]

- 13.Van Hao, B. et al. Synthesis of Y2O3: Eu3+ micro-and nanophosphors by sol-gel process. In: Journal of Physics: Conference Series). (IOP Publishing, 2009).

- 14.Lin, A. et al. Flexible droplet printing of prominently luminescent patterns of europium-doped yttrium oxide nanospheres. Addit. Manuf.63, 103412 (2023). [Google Scholar]

- 15.Amin, A. et al. Photoluminescent and chromic nanomaterials for anticounterfeiting technologies: recent advances and future challenges. ACS Nano14, 14417–14492 (2020). [DOI] [PubMed] [Google Scholar]

- 16.Zhao, D. J. et al. 3D networks of silver nanorod–nanoparticle hybrids via aerosol jetting printing for flexible electrode. Adv. Eng. Mater.25, 2200719 (2023). [Google Scholar]

- 17.Zhang, Y. et al. Droplets patterning of structurally integrated 3D conductive networks-based flexible strain sensors for healthcare monitoring. Nanomaterials13, 181 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Chen, S. et al. Heat soaking pretreatment for greener production of phosphorylated cellulose nanofibrils with higher charge density. ACS Sustainable Chem. Eng.10, 8876–8884 (2022). [Google Scholar]

- 19.Wu, Y. et al. Aerosol jet printing of hybrid Ti3C2Tx/C nanospheres for planar micro-supercapacitors. Front. Chem.10, 933319 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Wang, L. et al. High-pressure induced phase transitions of Y2O3 and Y2O3:Eu3+. Appl. Phys. Lett.94, (2009).

- 21.Cui, H. et al. Photoluminescence properties and energy transfer in Y2O3: Eu3+ nanophosphors. Chin. Phys. B23, 057801 (2014). [Google Scholar]

- 22.Dang, P. et al. Thermally stable and highly efficient red-emitting Eu3+-doped Cs3GdGe3O9 phosphors for WLEDs: non-concentration quenching and negative thermal expansion. Light Sci. Appl.10, 29 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Blasse, G. et al. Radiative return to the ground state: Emission. Luminescent Mater., 33–70 (1994).

- 24.Wang, S. et al. A red phosphor LaSc3(BO3)4: Eu3+ with zero-thermal-quenching and high quantum efficiency for LEDs. Chem. Eng. J.404, 125912 (2021). [Google Scholar]

- 25.Wu, Q. et al. Influence of preparation technology on the microstructure and properties of Ag/SnO2Bi2O3CuO composite materials. Mater. Charact.183, 111537 (2021). [Google Scholar]

- 26.Lai, C. Q. et al. Influence of microstructure topology on the mechanical properties of powder compacted materials. Int. J. Mech. Sci.198, 106353 (2021). [Google Scholar]

- 27.Hulst, H. C. et al. Light scattering by small particles. Cour. Corp. (1981).

- 28.Liu, D. S. et al. Emerging light‐emitting materials for photonic integration. 33, 2003733 (2021). [DOI] [PubMed] [Google Scholar]

- 29.Strobel, P. et al. Ultra-narrow‐band blue‐emitting oxoberyllates AELi2[Be4O6]: Eu2+(AE = Sr, Ba) paving the way to efficient RGB pc‐LEDs. Angew. Chem. Int. Ed.57, 8739–8743 (2018). [DOI] [PubMed] [Google Scholar]

- 30.Mandal, S. et al. Investigation of structural, optical and photoluminescence properties of the sol–gel synthesized powder ZnS nanoparticles. 129, 219 (2023).

- 31.Biju, C. S. et al. Effect of lattice strain on the polychromatic emission in ZnO nanostructures for white light emitting diode application. Superlatt. Microstruct.120, 363–369 (2018). [Google Scholar]

- 32.Ali, S. I. et al. Modulation of micro-structural, opto-electronic and photo-induced fluorescence properties in sol-gel derived Pb1-xZnxO nanoparticles through the analytical study of vacancy-type defects. Ceram. Int.50, 30345–30358 (2024). [Google Scholar]

- 33.Marc, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci.83, 97–134 (2018). [Google Scholar]

- 34.Kim, S. J. et al. Mechanoluminescence and mechanical quenching of afterglow luminescent particles for wearable photonic display. J. Mater. Chem. A 2314861 (2024).

- 35.Li, L. et al. Stress-triggered mechanoluminescence in ZnO‐based heterojunction for flexible and stretchable mechano‐optics. Adv. Funct. Mater.33, 2301372 (2023). [Google Scholar]

- 36.Ding, W. et al. Stretchable multi-luminescent fibers with AIEgens. J. Mater. Chem. C7, 10769–10776 (2019). [Google Scholar]

- 37.Niazi, P. et al. Mechanical and thermal insulation performance of hollow glass microsphere (HGMS)/fumed silica/polyester microcomposite coating. Prog Org. Coat.176, 107387 (2023). [Google Scholar]

- 38.Gao, S. L. et al. Nanostructured coatings of glass fibers: improvement of alkali resistance and mechanical properties. Acta Mater.55, 1043–1052 (2007). [Google Scholar]

- 39.Gong, Z. et al. Wearable fiber optic technology based on smart textile: a review. Mater12, 3311 (2019). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Wang, F. et al. Recent progress on general wearable electrical heating textiles enabled by functional fibers. Nano Energy 109497 (2024).

- 41.Zhang, Y. et al. Elastic fibers/fabrics for wearables and bioelectronics. Adv. Sci.9, 2203808 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Hou, Z. et al. Smart fibers and textiles for emerging clothe-based wearable electronics: materials, fabrications and applications. J. Mater. Chem. A. 11, 17336–17372 (2023). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The datasets generated and/or analysed during the current study are not publicly available due to the manuscript being in the submission phase, which requires adherence to the principle of anonymous peer review for academic journals, but are available from the corresponding author on reasonable request.