Abstract

The rise in ambient temperature caused by heat waves has led to increased demand for comfort cooling that affects the operational reliability of unitary air conditioning system. This study investigates the performance of a residential air conditioning unit of 1 ton equivalent by integrating adiabatic pre-cooling systems into the air-cooled condenser in the hot and humid climate of the Chennai region. Three types of adiabatic pre-cooling methods were employed: (1) evaporative cooling (EC) pad, utilising a 100 mm-thick cellulose pad; (2) mist cooling, achieved through an ultrasonic humidifier; and (3) a combination of EC pad and mist cooling, using a reduced cellulose pad thickness of 50 mm. The study assessed energy consumption, operational performance, condensate water production, condenser temperature drop, and cost benefit analysis. An experimental analysis was conducted by varying the air conditioning (AC) set point temperatures from 24 °C to 28 °C. Results showed retrofit of EC pad + mist cooling configuration to be holistically effective in terms of payback, yielding an average energy savings of approximately 39.2% when compared to other modes. Additionally, it significantly enhanced cooling system efficiency, with a mean COP increase from 2.8 to 5.0. The hybrid precooling method also effectively reduced temperature variations across the condenser up to 2 °C, showcasing moderate effectiveness. Despite requiring water consumption management, it led to reduced condenser on–off cycling frequency, indicating improved energy efficiency and system performance. EC pad + Mist cooling led to balanced energy and water efficiency without requiring additional water sources by utilizing condensate water.

Keywords: Cooling pad, Mist cooling, Water consumption, Condenser, Energy efficiency, Precooling

Subject terms: Energy science and technology, Engineering

Introduction

The global demand for air conditioning is rising rapidly particularly in hot and humid climates, driven by the escalating impacts of urban heat islands and climate change. As ambient temperatures increase, energy consumption for cooling has become a critical concern accounting 40% of overall energy use in buildings1. This trend is expected to intensify with projections indicating a five-fold increase in energy consumption for unitary air conditioners by 20302, making energy-efficient air conditioning essential to ease the strain on power grids3. The increasing demand for cooling, particularly during extreme summer conditions, presents severe operational challenges for air-cooled AC systems. High ambient air temperatures near the condenser can severely limit the heat rejection process, potentially leading to system inefficiency and shutdowns due to excessive back pressure4. To address these challenges, various techniques have been explored, such as high-pressure mist cooling, direct spray cooling, ecomesh cooling, wetted media evaporative cooling, and water vapor nozzle integration into condenser airflow5–7. Among these, adiabatic pre-cooling systems have emerged as one of the promising solutions8–11. This method lowers the air temperature around the condenser, improving heat rejection rates and overall system performance12–14. Studies have shown that this technique can increase energy savings by up to 22%, with overall COP improvements of up to 53% when using optimal cooling pad thickness15,16. Additionally, the use of condensate water for mist cooling has demonstrated increased cooling capacity by 19% and energy efficiency by 36% in air conditioning systems17. This sustainable approach highlights the potential for integrating water conservation strategies with energy-efficient cooling technologies.

Water mist pre-cooling of condenser air has also shown significant potential. Using mist coolers has been found to enhance chiller performance coefficients by up to 9.35% and reduce yearly electricity consumption by up to 2.94%. Moreover, the effectiveness of mist cooling is highly dependent on airspeed and droplet distribution, with studies highlighting the importance of optimizing the atomization process of mist droplets to maximize cooling efficiency18,19. 20found that using evaporative cooling to pre-cool the airflow resulted in a reduction of the condenser’s saturation temperature by 2.4 °C to 6.6 °C, with corresponding COP improvements ranging from 6.1% to 18%, and a power consumption reduction of 14.3%. 21explored the development of an air conditioning system with dual independent evaporative condensers, demonstrating improvements in COP and cooling capacity when the evaporator water intake temperature and air dry-bulb temperature (DBT) were optimized. Moreover, the use of innovative spray cooling techniques has shown promise in reducing sewage production while enhancing cooling performance. 22demonstrated that a novel supersonic spray cold-water set could lower the condenser’s intake temperature by 5.4 °C, resulting in increased energy savings. 23further supported these findings, showing that higher ambient air temperatures or lower relative humidity could increase the efficiency of spray systems, leading to reductions in power usage of 1.4% to 14.4% and improvements in cooling capacity. These findings underscore the substantial impact that lowering the condenser inlet temperature can have on overall system efficiency.

Reference24 provided further insights into the advantages of vertical spraying over horizontal spraying, noting that vertical spraying resulted in a higher ∆COP due to better cooling efficiency through the condenser surface. This was attributed to the shorter retention time and easier droplet fall-off in vertical spray configurations, which allowed for a larger contact area between water mist and air. Additionally25,26, experimented with using condensate water to cool ambient air before it entered the condenser, demonstrating improvements in cooling capacity, power consumption, and COP, particularly in hot and dry climates. Numerous studies have also examined the benefits of pre-cooling air before it enters the condenser using direct evaporative cooling, with remarkable results in terms of COP and cooling capacity improvements, especially in hot and dry environments27–30. The effectiveness of these techniques is closely tied to humidity levels, with higher humidity leading to greater water production and, consequently, better cooling performance31,32. However, the potential of utilizing condensate water for cooling has been relatively underexplored, despite its favorable availability in humid regions.

This research examined the impact of adiabatic precooling techniques, under same additional input energy across different modes, on improving the energy efficiency and performance of air conditioning (AC) systems, particularly in hot and humid climates such as Chennai. Building on the literature, which highlights the potential of evaporative and mist cooling methods to improve the coefficient of performance (COP) and reduce energy consumption, this study focuses on three specific configurations of adiabatic precooling systems paired with air-cooled condensers. The objectives included assessing the impact of these techniques on energy savings and system performance, evaluating the effectiveness of different precooling modes on condenser temperature differential, estimating condensate production through a predictive model by exploring the feasibility of utilizing it for mist cooling, conducting thermographic assessments of the condenser units, examining the on–off cycling behavior of the condensers and cost benefit analysis of these systems post retrofit. Through comprehensive evaluation, the study intends to advance the development of more energy-efficient and reliable fixed-speed AC systems, especially in regions with ample atmospheric moisture. This allows for the effective harnessing of water for adiabatic cooling of heat sinks, which face drastic challenges due to extreme heat.

Materials and methods

Experimental system and components

The experimental system consists of four main components: an adiabatic pre-cooling system, a water source, an air-cooled condenser unit, and an indoor air-conditioning unit. In addition to these components, there is also a parameter monitoring system. The outdoor condenser serves as the primary component mounted on a frame fixed to the wall. For detailed technical specifications of the air conditioning system used is mentioned in Table 1.

Table 1.

Technical specification of air conditioning unit.

| Brand | MIDEA |

|---|---|

| Model No | MACS12FL3T4 |

| Model Name | 12 K FLAIR |

| Power supply | 230 V, 50 Hz |

| Rated Current | 4.5 A |

| Cooling Capacity | 1 TR |

| Input Power | 1030 W |

| Refrigerant /Qty | R22/720gm |

| Rated EER(W/W) | 3.25 |

| Variable Speed Compressor | No |

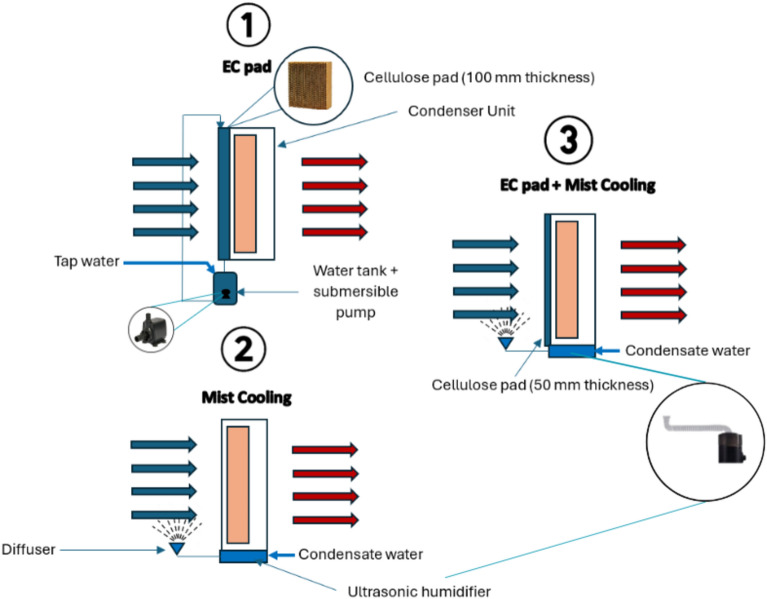

The study utilized adiabatic pre-cooling systems, including an EC pad system and an ultrasonic atomization unit for mist cooling33,34. The 3 modes of precooling strategies are applied for the experimental studies that are (1) EC pad (2) Mist cooling and (3) EC pad + mist cooling. In Fig. 1 The first mode has the vertical placement of the cellulose pad of thickness 100 mm, length 500 mm and breadth 500 mm before the condenser inlet. The pump with a power rating of 15 kW is operated to deliver water upwards from a tank of 2.5 L capacity onto the pad media. The second mode involves setting the ultrasonic humidifier nozzle at a distance of 200 mm from the middle of air inlet and spraying water mist vertically upwards towards the unit’s front. In third configuration, an EC pad with dimensions of 50 mm in thickness, 500 mm in length, and 500 mm in breadth is positioned at the larger air inlet section. Above this, at a vertical distance of 100 mm from the cellulose pad, a divergent nozzle is installed to disperse mist at a rate of 0.85 kg/hr from the ultrasonic humidifier, effectively moistening the cooling media.

Fig. 1.

Schematic diagram of adiabatic precooling techniques for air-cooled condenser system.

The ultrasonic humidifier produces micron-sized water mist particles, enabling precise control of droplet properties without pressure loss at the condenser unit incoming air stream. The heat and mass transmission of small droplets, as well as evaporation efficiency, are directly affected by atomization quality. With a low mass air/liquid ratio, the atomized droplet size can be smaller than 10 microns. Furthermore, the humidifier has a narrow operating frequency range, allowing it to maintain a consistent mist with a liquid flow rate of 0.2–0.6 kg/h at a frequency of 0.6–1.6 MHz. The spray rate may simply be adjusted to meet the demands of various scenarios. Most notably, the ultrasonic humidifier’s energy consumption is a critical consideration. While retaining excellent atomization quality, the actual power consumption is only approximately 15 W. The direct evaporative cooling (DEC) system includes cellulose pad frame, re-circulation pump, water tank, and pipes. The water source side is directly connected to the tap water. The feed water in the tank is pumped to the top of the cellulose pad and water drips down to wet the media. The remaining water gets collected at the bottom and is again recirculated back to the system. The feed water flow rate is maintained to create a uniform supply. It can quickly perform the endothermic evaporation process and reduce the temperature of ambient air which is very critical for condenser coil cooling. With respect to the inference of35, when the feed water temperature was higher than the wet-bulb air temperature, lowering the mass ratio of feed water to the circulating air caused the ambient air temperature to reduce. Therefore, the low flow rate fixed at 690 kg/h was chosen for achieving satisfactory performance with 15W energy consumption for the pump which is same as that of ultrasonic atomizer. In this experiment, for ultrasonic humidifier, the water consumption was fixed at 0.42 kg/h in which the condensate water collected is fed for producing atomised water droplets in mist cooling and EC pad + mist cooling modes.

Key performance indicators (KPI)

The ambient dry bulb temperature (DBT), ambient wet bulb temperature (WBT), relative humidity (RH), pad thickness, pad material, configuration, or other geometric factors, air flow rate ( )and water flow rate (

)and water flow rate ( ) are the influencing parameters for the media pad based evaporative cooling system36. In the case of mist based evaporative cooling feed water temperature, mist generation rate and mist size are the governing parameters. The following performance indicators have been used to assess the thermal performance, cooling capacity of the precooling unit and COP of the AC system, with respect to varying conditions37.

) are the influencing parameters for the media pad based evaporative cooling system36. In the case of mist based evaporative cooling feed water temperature, mist generation rate and mist size are the governing parameters. The following performance indicators have been used to assess the thermal performance, cooling capacity of the precooling unit and COP of the AC system, with respect to varying conditions37.

ΔTcond represents the temperature difference in the air stream across the condenser which is calculated using Eq. 1

|

1 |

The precooling capacity is determined by the amount of moisture in the wet bulb. The difference between the DBT and WBT of ambient air is referred to as the wet-bulb depression (WBD) as in Eq. 2

|

2 |

The water evaporation or consumption rate is obtained Eq. 3

|

3 |

The Coefficient of Performance of an AC system is the ratio of the cooling capacity (CC) and power input(P) as per Eq. 4

|

4 |

For COP calculation of the AC system without precooling set up, the actual power input (P) is the energy usage(kWh) of operation and the for-AC system integrated with precooling systems the total P value is taken as sum of energy consumed by air conditioning unit and adiabatic cooling devices for any mode.

The CC of an air conditioner was calculated based on set point temperature and humidity and outdoor conditions, account for both sensible heat and latent heat38.

The sensible heat (Qs) load is related to the temperature difference in the space as per Eq. 5

|

5 |

where:

V is the volume of the room in cubic meters (m3)

ρ is the air density, approximately 1.2 kg/m3

Cp is the specific heat capacity of air, approximately 1005 J/kg·°C

ΔT is the difference between the initial temperature and the desired set point temperature (°C)

The latent heat load (Ql) is calculated by to estimating the amount of water vapor that must be removed from the air to reach the target humidity level as per Eq. 6

|

6 |

where:

hl is the latent heat of vaporization of water, which is approximately 2500 kJ/kg

Δw is the change in humidity ratio (kg of water vapor per kg of dry air).

Once the sensible and latent loads are quantified, the total cooling capacity (CC) is obtained by summation of both as per following Eq. 7

|

7 |

The effectiveness(ε) of a precooling system is calculated using the Eq. 839,:

|

8 |

is the difference in temperature of the condenser outlet with and without precooling.

is the difference in temperature of the condenser outlet with and without precooling. is the difference in temperature between DBT and WBT of ambient air.

is the difference in temperature between DBT and WBT of ambient air.

For performing the cost–benefit analysis, the economic feasibility of integrating pre-cooling technologies with a 1 TR air conditioning system was evaluated. The methodology considered multiple steps, combining energy performance evaluation, cost assessment, and financial metrics calculation to ensure a comprehensive analysis25.

The baseline annual energy consumption (Eb) of 1 TR air conditioner operating under standard conditions was determined using the following Eq. 9

|

9 |

where:

P corresponds to Nominal power consumption of the air conditioner without pre-cooling (kW)

H denotes Daily operating hours (hours/day)

D is the number of operating days in a year (365 days assumed)

This served as the reference for evaluating energy savings from each pre-cooling technology.

The annual energy savings due to reduced condenser temperature were calculated using the Eq. 10

|

10 |

where:

Esa is the annual energy savings (kWh)

ΔE is the percentage energy efficiency improvement due to pre-cooling

The monetary value of energy savings annually was calculated using the Eq. 11

|

11 |

where:

Csa represents annual cost savings ($)

Ce is the cost of electricity per kWh ($)

The simple payback period40 for each pre-cooling method was calculated using the Eq. 12 as:

|

12 |

where:

Pp denotes Payback period (years)

Ci is the implementation cost of the pre-cooling method ($)

Testing procedure

The experiment involved running the unitary split AC system at full capacity in a thermally insulated leak-proof cabin stationed at Thermal Engineering Lab, Shiv Nadar University, Chennai as shown in Fig. 2. The testing was performed in a stable indoor environment during the hot and humid months of April and May 2023 characterized by an ambient dry bulb temperature (DBT) of 35 °C ± 1.5 °C and relative humidity (RH) between 65 to 75%. The Chennai region, located on the southeastern coast of India, exemplifies these conditions, experiencing high temperatures and humidity levels throughout the year with minimal seasonal variations. The supply DBT, RH, and power were recorded for room air RH set between 50 to 60% and set point DBT ranging from 24 °C to 28 °C using different techniques and arrangement modes. Predefined stable conditions included fixed AC blower speed at 2.5 m/s, heat load-controlled test room dimensions of 3 m × 3 m × 3 m, and an average condenser fan speed of 3.5 m/s. Each trial was repeated three times for data consistency and accuracy47. The internal heat load remained constant and heat load due to external condition was assumed to be same as the ambient temperature and humidity. The DBT, RH, and power consumption were recorded for room air with set RH of 50% to 60% and set point temperature of 24 °C, 25 °C, 26 °C, 27 °C, and 28 °C. The experiment utilized two techniques with three arrangement modes: cellulose pad setup; mist cooling setup; combination of both setups. All the precooling devices are linked with the power source of the condenser unit thereby avoiding unnecessary operation when condenser fan is in off condition.

Fig. 2.

Photograph of the Experimental Setup—Both Indoor and Outdoor Components.

In this experimental investigation, the focus was on analyzing and comparing three modes of precooling system retrofitted to a split AC system of 1 TR capacity, with an emphasis on key performance metrics. The energy savings achieved was evaluated by comparing results as a percentage and absolute energy units saved when using the precooling system compared to standard operation. Operational efficiency was assessed through COP, which contrasted energy consumption against cooling output while also considering system reliability and durability by examining their impact across different operational modes. Furthermore, the measurement of temperature differential (ΔT), for understanding the system’s efficacy in reducing the air temperature entering the condenser was prioritized by recording both the condenser inlet and outlet air temperature41. Additionally, the thermal profile of the air-cooled condenser coil with and without precooling systems was assessed to quantify the average temperature for similar outdoor and indoor conditions. The investigation also involved quantification of water usage across all experimental set points42,43, focusing on the strategic use of water resources in mist-based cooling to enhance the efficiency of air conditioning systems.

Furthermore, the study developed a predictive model for estimating condensate quantity, offering a valuable method for optimizing the operation of mist-based pre-cooling systems in diverse environmental scenarios and explored its feasibility. The temperature gradient differences on the heat transfer surface were examined by assessing the heat map of the condenser coil during standard air conditioning operation and with pre-cooling modes, to elucidate the impact on heat rejection rate. Overall, the methodology encompassed comprehensive measurements alongside assessment aiming to provide a thorough understanding of each mode’s performance within varied operational conditions, optimum use of water and energy efficiency along with cost benefit analysis.

Measuring instruments

In the experimental phase, precise quantification of key parameters was achieved through the deployment of specialized instrumentation as detailed in Table 2, ensuring accuracy. The Heat Index meter was instrumental in accurately measuring DBT, WBT and RH. The air velocity was meticulously assessed using an anemometer to ensure constant flow across evaporator and condenser section of AC system. The assessment of power consumption leveraged the high-precision energy meter, which adheres to Class 1 accuracy standards. Furthermore, the multi thermometer yielded precise readings of the condensate water temperature. For the accurate quantification of collected condensate water, a glass beaker completely insulated was utilized. This complete suite of instruments facilitated a rigorous and detailed examination of the experimental parameters, contributing to the reliability and validity of the study’s findings.

Table 2.

Instruments used for measurement and data collection.

| Parameters | Instrument Name | Make & Model | Accuracy |

|---|---|---|---|

| DBT, WBT, RH | Heat index WBGT meter | Lutron, WBGT-2010SD | ± 1.5 oC, ± 3% RH |

| Air Velocity | Anemometer | Lutron, AM-4201 | ± (2% + 0.1 m/s) |

| Power Consumption | Energy meter (Single phase) | L&T | Class 1, ± 1% |

| Water Temperature | Multi thermometer | MEXTCH | ± 1 °C |

| Water Volume | Glass Beaker | Borosil, 500 ml beaker | NA |

The set point temperature of the one-ton air conditioner was maintained consistently throughout the trials. A stopwatch was utilized to measure the time required for the air conditioning unit to consume 0.1 kWh of energy in each trial, from which the energy consumption for one hour operation was extrapolated. The experimental methodology included meticulous calibration and adherence to standards, enabling comprehensive evaluations of the air conditioning unit’s performance under varying conditions, with and without the adiabatic pre-cooling system. The thermal images of the condenser unit were captured using FLIR T530 camera to monitor temperature values of the heat exchange surfaces.

Error analysis and uncertainty

The error analysis for the various measurements taken during the experiment, shows the instrument accuracy and the corresponding error margin for each measurement type and the overall uncertainty in the results. Each test was conducted for a duration of 2 h and repeated three times to ensure data consistency and accuracy. The total experimental period spanned over four weeks, with tests conducted on different days to account for environmental variability. Baseline measurements were taken without the pre-cooling systems active to serve as control data. These control measurements were used to evaluate the effectiveness of the pre-cooling methods by comparing the results with and without pre-cooling. The AC system was allowed to reach steady-state operation before data collection began for each test. A stabilization period of 30 min was observed to ensure consistent operating conditions. Measurements were taken every 5 min during each 2-h test. Continuous logging of key parameters was performed using data acquisition systems. The error margins for each type of measurement were calculated and reported. The final COP and ε values were derived, considering the accuracies of the measuring instruments. The sensitivity analysis was conducted to determine how small variations in input parameters affect the COP and precooling effectiveness calculations. The uncertainty in COP was calculated as per Eq. 13using Root Sum Squares (RSS) uncertainty method, J.R Taylor44.

|

13 |

The uncertainty for the COP, cooling effectiveness, power consumption and temperature measurements are indicated within a range of ± 5%, ± 0.03, ± 0.02 and ± 0.1 respectively. The error bars have been added, representing the standard deviation of multiple measurements. This improvement is statistically significant (p < 0.01) even when accounting for measurement uncertainties.

Results and discussion

Adiabatic precooling techniques on energy savings and AC system performance

Figure 3 illustrates the energy savings achieved by different modes of the adiabatic precooling system. EC pad displays a median energy savings of approximately 38.5%, with the lower quartile around 35.2% and the upper quartile near 42.5%. The data indicates a relatively tight distribution, suggesting consistent performance across different modes. This mode is effective in reducing energy consumption, showcasing the efficiency of evaporative cooling using a cellulose pad. Mist Cooling exhibits a broader range of energy savings, from as low as 12.14% to as high as 42.52%, with a median around 29%. This variation suggests that mist cooling can be highly effective under optimal conditions, its performance is more dependent on external factors such as ambient temperature and humidity, or specific system configurations. EC pad + Mist Cooling combines the benefits of both systems, showing a distribution of energy savings similar to that of EC alone but with instances of higher efficiency. The median energy savings for this mode is approximately 39.2%, with the data distribution indicating the potential for reliable and consistent performance above Mist precooling.

Fig. 3.

Energy savings from Adiabatic precooling system modes.

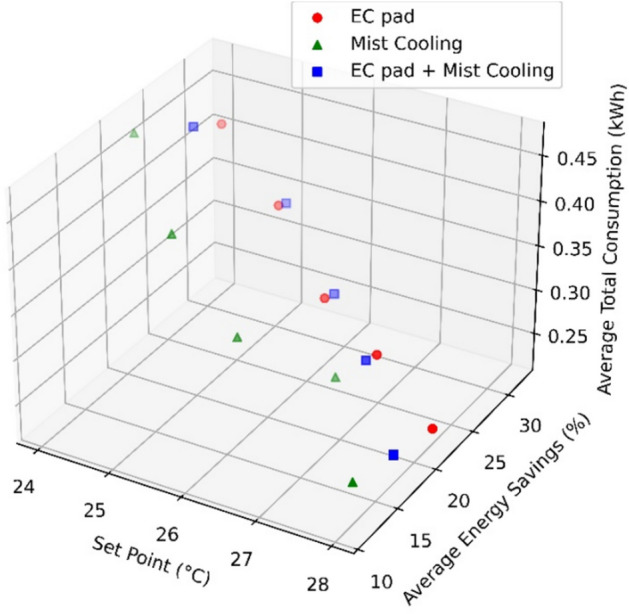

Figure 4 shows key observations regarding the performance metrics of the air conditioning systems subjected to experimental testing for different condenser precooling configurations adopted in the study across various set points between 24 °C to 28 °C. The EC pad consistently shows higher energy savings percentages across all set points compared to Mist Cooling and EC pad + Mist Cooling, with savings percentage decreasing as the set point increases. The highest percentage energy savings is observed at the lowest set point of 24 °C adopted for all adiabatic precooling types, indicating that lower set points deliver more in terms of percentage energy savings with respect to AC system without precooling mode. The total kWh consumption decreases as the set point increases for all cooling types. This suggests that higher set points are more energy-efficient, requiring less energy to maintain the desired conditions. The average improvement in COP is observed to be 38% for EC pads, 21.1% for Mist Cooling systems, and modest average COP improvement of 35.4% for combination EC pad + Mist Cooling strategies. These findings imply that although the EC pad offers higher energy savings, the combination of EC pad + Mist Cooling results in the most significant improvement in the COP, making it the most effective strategy for enhancing energy efficiency. The trade-off between energy savings and COP improvement suggests that the choice of cooling strategy should be based on specific operational goals and conditions, Cooperman et al.45.

Fig. 4.

Average energy savings & average total consumption at different set point temperature for all adiabatic precooling system modes.

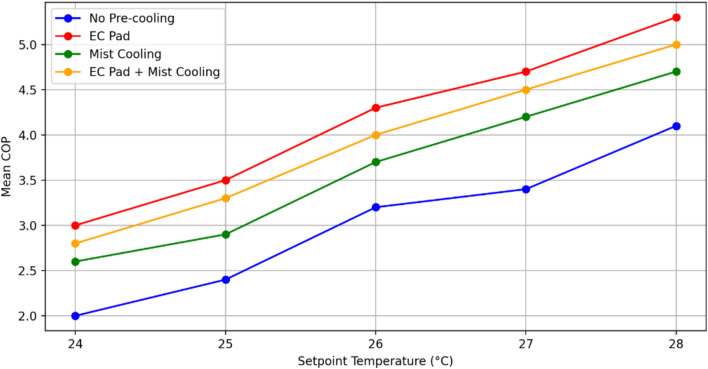

Figure 5 illustrates the trends in the mean COP for all precooling modes and no precooling across all chosen setpoint temperatures. The curve demonstrates that precooling techniques considerably enhance cooling efficiency, with all precooling modes showing a consistent increase in mean COP as set point temperature rises. The EC pad mode’s efficiency increases from a mean COP of 3.0 at 24 °C to 5.3 at 28 °C setpoint temperature, while Mist Cooling improves from 2.6 to 4.7 over the same temperature range. As per the experimental data the growth rate of the COP increases first and then decreases with the increase of the mist supply. This is due to the water mist sprayed accumulated on excess quantity converges on the condensing coil to form a water film, which reduced the heat transfer between the condensing coil and the surrounding air. When the cooling load of the AC unit is increased subsequently, the growth rate of the COP increased. Moreover, the COP increased by about 4—7% when the ambient temperature rises by about 1 °C. The combined EC pad + Mist Cooling mode exhibits the most efficiency gain, starting at 2.8 and reaching 5.0, suggesting that integrating both techniques can maximize cooling performance. In contrast, the No precooling mode serving as a baseline, shows the lowest efficiency across all temperatures underscoring the effectiveness of precooling in enhancing cooling processes. This analysis highlights the net benefits of employing precooling strategies to improve the efficiency of cooling systems, especially as the setpoint temperature increases. Among all 3 modes of adiabatic precooling, the EC pad maintains consistent performance due to uniform cooling of the condenser surface whereas for EC pad + mist cooling the COP delivery consistency was partial and non-uniformity in COP improvement in mist cooling mode for same cooling capacity and external conditions. The overall analysis suggests that integrating adiabatic precooling systems on air cooled condenser can augment the energy efficiency of AC systems, potentially providing a more adaptable solution capable of achieving greater energy savings.

Fig. 5.

Mean COP Trends for each precooling mode across different setpoint temperatures.

Cooling capacity

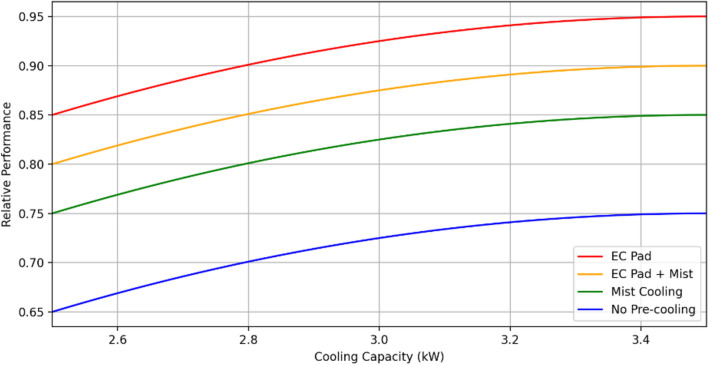

The Fig. 6 illustrates the relative performance of various pre-cooling technologies as cooling capacity increases from 2.5 kW up to 3.5 kW. The EC pad consistently outperforms the other technologies, starting just below 0.85 in relative performance at 2.5 kW and maintaining the highest efficiency across the range, albeit with a slight decline near 3.5 kW. The EC pad + Mist Cooling combination also demonstrates strong performance, though it remains slightly below the standalone EC pad, starting near 0.80 at 2.5 kW and following a similar downward trend. Mist Cooling alone around 0.75, shows decline in performance drop-off as cooling capacity increases, positioning it as a less efficient option compared to EC pad based modes. In contrast, the baseline performance without pre-cooling is noticeably lower, starting around 0.65 and further declining as the cooling capacity increases.

Fig. 6.

Effect of Cooling Capacity on Pre-cooling technology performance.

The performance of pre-cooling technologies is most effective when the CC is close to the rated 3.517 kW. All pre-cooling technologies show optimal energy efficiency at 2.5 kW, with diminishing efficiency as CC deviates. The EC pad maintains the highest relative performance across a wider range of CC particularly when the air conditioning system operates at or near its designed capacity.

Effectiveness of precooling modes on condenser temperature differential

Table 3 above shows the minimum, maximum, and average temperature drop across the condenser with and without the precooling system, along with the effectiveness for different adiabatic precooling systems: EC pad, Mist Cooling, and EC pad + Mist Cooling. To understand the impact of temperature, drop on condenser efficiency, we can correlate the temperature drop data with the effectiveness values for each system. The EC pad precooling system has the highest average difference between the condenser inlet and outlet temperatures without precooling (2.64℃) compared to the Mist Cooling (1.78℃) and EC pad + Mist Cooling (1.82℃). With precooling, all three systems show a reduction in the average difference between the condenser inlet and outlet temperatures. The EC pad precooling system has the lowest average difference (2.56℃), followed by EC pad + Mist Cooling (1.92℃), and Mist Cooling (1.92℃).

Table 3.

Temperature differential across condenser for different adiabatic precooling configurations.

| Type of Adiabatic Precooling System | ΔT Condenser air Inlet and Outlet without Precooling (℃) | ΔT Condenser air Inlet and Outlet with Precooling (℃) | Effectiveness |

|---|---|---|---|

| EC pad | Min: 1.8 | Min: 1.4 | Min: 0.45 |

| Max: 3.2 | Max: 3.2 | Max: 0.63 | |

| Avg: 2.64 | Avg: 2.56 | Avg: 0.55 | |

| Mist Cooling | Min: 1.5 | Min: 1.5 | Min: 0.32 |

| Max: 2.1 | Max: 2.5 | Max: 0.48 | |

| Avg: 1.78 | Avg: 1.80 | Avg: 0.43 | |

| EC pad + Mist Cooling | Min: 1.4 | Min: 1.4 | Min: 0.40 |

| Max: 2.5 | Max: 2.5 | Max: 0.58 | |

| Avg: 1.82 | Avg: 1.92 | Avg: 0.49 |

The EC pad precooling system exhibits the highest effectiveness with a maximum value of 0.63 and an average effectiveness of 0.55. The Mist Cooling system shows slightly lower effectiveness with a maximum value of 0.48 and an average effectiveness of 0.43. The EC pad + Mist Cooling system demonstrates moderate effectiveness, with a maximum value of 0.58 and an average effectiveness of 0.49. In summary, the EC pad precooling system tends to have higher temperature differences without precooling, but it also achieves the highest effectiveness in reducing these differences with precooling. The Mist Cooling system shows slightly lower effectiveness but maintains lower temperature differences overall. The EC pad + Mist Cooling system combines aspects of both, demonstrating moderate effectiveness and temperature reduction. This analysis indicates that the temperature drop across the condenser has an impact on the efficiency of adiabatic precooling systems. Systems that achieve a higher temperature drop across the condenser, such as the EC pad, tend to have higher efficiency. This insight can be crucial for optimizing cooling technologies in air conditioning systems, as it highlights the importance of maximizing temperature drop across the condenser to improve overall system efficiency.

Figure 7 represents radar chart comparison between EC pad, Mist cooling, and EC pad + Mist cooling methods across four metrics—Temperature drops with and without precooling, Effectiveness, and the difference between Dry Bulb Temperature (DBT) and Wet Bulb Temperature (WBT)—reveals insightful distinctions in their cooling performances. While all three methods demonstrate a capability to enhance cooling effects through precooling, the combination of EC pad and Mist Cooling showcases a marginally superior effectiveness. This suggests that a synergistic approach, leveraging both cooling strategies, can potentially yield the most efficient temperature reduction. The similarity in the DBT-WBT difference across methods indicates that the moisture content of the air remains relatively unaffected by the choice of precooling strategy, underscoring the primary focus of these methods on temperature regulation rather than humidity control.

Fig. 7.

Effectives vs environmental parameters for adiabatic condenser precooling methods.

The analysis underscores the importance of precooling in air-cooled condenser systems, particularly in enhancing the efficiency of the cooling process. The slight advantage observed with the combined EC pad and Mist Cooling method points towards the benefits of integrating multiple cooling technologies to achieve optimal performance. This hybrid approach not only improves the effectiveness of temperature drop but also maintains the air’s moisture content, ensuring a balanced cooling solution. The findings from this comparison can guide the selection and implementation of precooling strategies in air conditioning systems, emphasizing the potential for increased efficiency and effectiveness through the thoughtful combination of cooling technologies.

Water consumption & condensate quantity estimation

This study estimated the quantity of water used across all experimental set points. Water consumption for the evaporative cooling (EC) pad in the pre-cooling mode ranged from 1.3 to 1.7 kg/hr, influenced by evaporation losses and the on–off timing of the condenser unit. The AC system generated condensate at a rate ranging from 0.6 to 0.92 kg/hr, which was then efficiently employed in other two mist-based pre-cooling modes. The variance between the amount of condensate produced and the water consumption rate of the EC pad, in comparison to the mist cooling mode, suggests a strategic utilization of water resources in mist-based cooling to augment the energy efficiency of AC systems. The quantity of condensate generated was maximum for lower set point temperature of 24 ℃ and minimum for 28℃. In scenarios where the ambient temperature is elevated and the relative humidity is low, employing a spray cooling system proves to be more feasible. However, under these conditions, the generation of condensate water is minimal, thereby limiting the capacity for mist generation. On the contrary, higher relative humidity levels facilitate the sourcing of water for mist cooling activities as evident from data collected.

To predict the quantity of condensate water based on various independent variables a linear regression model was employed. The model yielded specific coefficients and an intercept, culminating in the following equation for estimating condensate quantity (R) as a function of set point (A), dry bulb temperature (H), relative humidity (I), wet bulb temperature (J), ΔTcond (K), and condenser water temperature (Q):

|

This equation facilitates the estimation of condensate quantity based on the specified parameters, offering a valuable tool for optimizing the operation of mist-based pre-cooling systems in varying environmental conditions.

The analysis indicates that the condensate production from the air conditioning system averages 0.76 kg/hr. This amount can meet approximately 95% of the water demand for EC pad + mist cooling, 50.7% for the mist cooling, and 38.0% for the EC pad system. The insufficiency of condensate water demands additional water will be required from external sources to support standalone EC pad and mist generation systems. This could lead to increased operational costs and water usage. To address the insufficiency, we propose the use of alternative water sources such as rainwater harvesting or greywater recycling. These sources can supplement the condensate water and reduce the dependency on potable water. The reliance on external water sources may affect the overall efficiency and sustainability of the system, especially in regions where water scarcity is a concern. Developing optimized water usage strategies, such as adjusting the misting frequency and duration based on real-time environmental conditions, can help minimize water consumption while maintaining cooling efficiency.

This study did not focus on the quality of the condensate water generated and its effects on health. Recent studies have extensively examined the quality and potential risks associated with using AC condensate water. 46reported promising findings, demonstrating that water samples from split air conditioning units contained elements within acceptable thresholds for both drinking water and irrigation purposes. Their study found only limited bacterial presence, with all detected bacteria being non-pathogenic, suggesting that HVAC condensate water could be safely utilized in various applications. However, earlier research has identified potential risks that need to be addressed. Multiple studies have discovered various microorganisms in AC condensate, including the pathogenic Legionella. Building on this, further research findings emphasized the potential for biofilm formation in condensate collection systems, which could harbor harmful bacteria. Former investigations stressed the importance of proper treatment and monitoring of reclaimed water in HVAC systems to ensure safety. Given that the condensate water is exclusively sprayed on the outdoor section of the AC unit and does not come into direct contact with human-occupied spaces, the potential health risks associated with its use are significantly minimized. The outdoor application ensures that any aerosolized water droplets are dispersed in open air, far from human breathing zones, substantially reducing the likelihood of exposure to any potential contaminants. This spatial separation between the cooling system’s water application and inhabited areas serves as a natural safeguard, effectively mitigating concerns related to water quality or bacterial presence in the context of human health impacts.

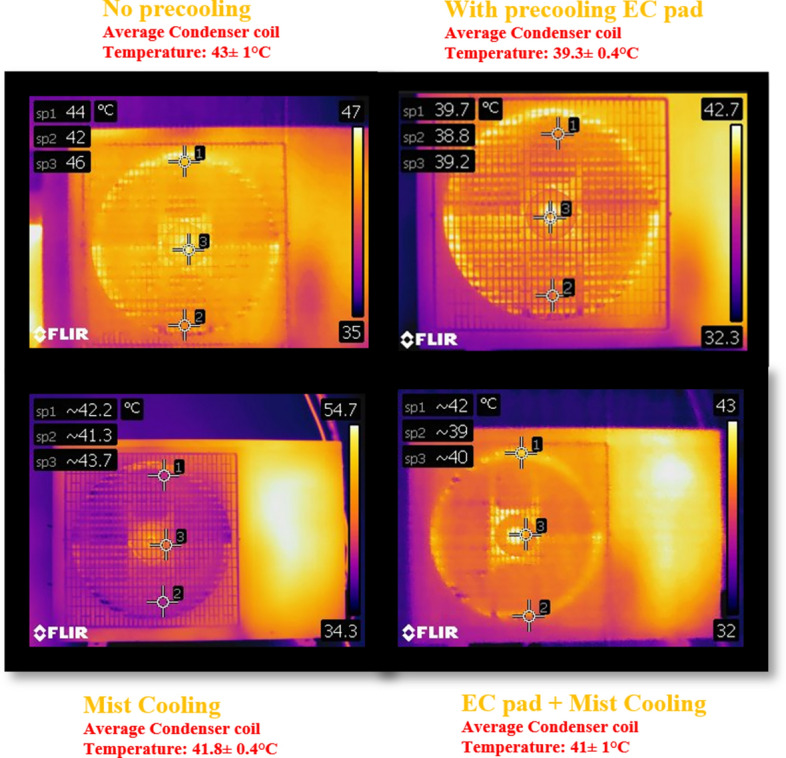

Thermography assessment of the condenser unit with and without precooling systems

The distribution of temperature on the air outlet face of condenser with or without adiabatic precooling was experimentally tested at 35 °C ± 1.5 and 60 to 70% RH as shown in Fig. 8. The highest temperature was recorded to be 44 °C, without precooling and the lowest temperature was 42 °C with a mean value of 43 °C. For EC pad, the condenser coil temperature reduction is evenly distributed on the surface with temperature below 40 °C which is maximum among all 3 modes of precooling. The condenser coil thermal gradient was unevenly distributed with Mist cooling mode. The temperature was in the range of 41 °C to 42 °C with a mean value of 41.8 °C. It illustrated that the air outlet temperature of condenser could be effectively reduced, and the performance of the unit could be improved by using adiabatic precooling system in all 3 modes and average reduction of temperature for EC pad, Mist cooling and EC pad + Mist cooling systems to be 3.7 °C, 1.2 °C and 2 °C respectively.

Fig. 8.

Thermography of air-cooled condenser with and without adiabatic precooling systems at 35 °C.

Without any pre-cooling, the condensing temperature of the air conditioning system reaches 44 °C. The use of EC pad + Mist Cooling significantly reduced this temperature by 4.5 °C, bringing it down to 39.5 °C. Mist Cooling offers a moderate improvement, lowering the condensing temperature to 41 °C, a 3 °C reduction from the baseline. However, the EC pad Cooling proves to be the most effective, achieving a substantial 5 °C reduction and bringing the condensing temperature down to 39 °C, demonstrating the highest efficiency among the tested methods. The combined EC pad Cooling system showed the best performance, which aligns with our findings on improved COP and overall system efficiency.

Condenser unit on—off cycling

The experimental results show a marked decrease in the air conditioner’s on–off cycling frequency when precooling measures are used. Without precooling, the condenser system had 7 cycles per hour. However, integrating precooling systems like EC pad or EC pad with mist cooling remarkably reduced the On—Off cycling frequency. Specifically, both EC pad and EC pad with mist cooling configurations resulted in a lower cycling frequency of about 5 cycles per hour, while using mist cooling alone decreased it to approximately 6 cycles per hour. This reduction indicates that precooling measures effectively optimize system operation, improve energy efficiency, and stabilize indoor temperatures. Furthermore, addressing the consequences of short cycling such as decreased energy efficiency, increased wear on components, and compromised comfort levels is crucial for prolonging system longevity and ensuring optimal performance. Therefore, the observed decrease in cycling frequency highlights the adoption of precooling strategies can mitigate these adverse effects and ultimately enhance reliability while conserving energy in air conditioning applications.

Cost benefit analysis

The Table 4 provide a detailed cost–benefit analysis of three pre-cooling technologies modes employed in this study for a 1 TR air conditioner assumed to operate for 8 h on daily basis and cost of one unit of electricity as $0.072.

Table 4.

Cost benefit analysis of integrating precooling technologies.

| Parameter | EC pad | Mist Cooling | EC pad + Mist |

|---|---|---|---|

| Annual Energy Savings (kWh) | 438 | 219 | 657 |

| Annual Cost Savings (USD) | $31.54 | $15.77 | $47.30 |

| Implementation Cost (USD) | $12.00 | $9.60 | $24.00 |

| Simple Payback Period (Years) | 0.38 (≈4.6 months) | 0.61 (≈7.3 months) | 0.50 (≈6.1 months) |

The combination of EC pad + Mist provides the highest annual energy savings, followed by EC pad alone, and then Mist Cooling. The cost savings follow the same pattern as energy savings, with EC pad + Mist offering the highest savings. The implementation cost is highest for the combination of EC pad + Mist, followed by EC pad alone, and then Mist Cooling. EC pad has the shortest payback period, followed by EC pad + Mist, and then Mist Cooling.

The study demonstrated that the use of adiabatic pre-cooling systems can lead to enhanced energy savings. By reducing the condenser temperature, the air conditioning unit operates more efficiently, consuming less electricity. The energy savings translate to lower utility bills for both residential and commercial users, providing a cost-effective solution for cooling in hot and humid climates. The use of condensate water for mist cooling is a sustainable approach that minimizes the need for additional water resources. By recycling the condensate water, the system reduces water consumption and operational costs, making it an economically viable solution. The combination of EC pads and mist cooling offers a balanced approach, providing effective cooling while minimizing water consumption. The lower operating temperatures achieved through pre-cooling can reduce the wear and tear on the air conditioning system, leading to lower maintenance and repair costs. The extended lifespan of the equipment further contributes to cost savings over time. Moreover, the proposed cooling methods can be adapted to various climatic conditions, making them suitable for a wide range of geographical locations. In regions with lower humidity levels, the effectiveness of evaporative cooling pads may be enhanced, while mist cooling can be optimized for areas with higher humidity. Additionally, the modular design of the adiabatic pre-cooling systems allows for easy integration into existing air conditioning units and cooling systems. The scalability of the system in air-cooled air-conditioning systems enables it to be implemented in both small-scale residential units and large-scale industrial facilities.

Conclusion

The application of an adiabatic pre-cooling system in air cooled systems has the potential to reduce energy consumption unit. In the conducted study, the effects of two adiabatic precooling methods in 3 different modes on the performance of the air-cooled condenser in a split air conditioning system were methodically investigated, focusing on fixed mass flow rates of air and water and equal associated additional energy consumption for all precooling modes in hot and humid environment. The following findings are detailed below:

The EC pad condenser precooling method consistently saves about 38.5% of energy more as compared to non-modified AC system operation. The Mist Cooling varies more, with savings between 12.14% and 42.52%. Combining both methods, EC pad + Mist Cooling, shows similar consistency to EC pad alone but with potential for even higher efficiency, averaging around 39.2% in energy savings.

Mean COP trends indicate precooling enhances cooling system efficiency, especially as setpoint temperature increases. EC pad system efficiency increased from a mean COP of 3.0 at 24 °C to 5.3 at 28 °C indoor set point temperature. Mist Cooling’s efficiency improved from 2.6 to 4.7 over the same set point temperature range. EC pad + Mist Cooling mode showed the most improvement in COP from 2.8 to 5.0, optimizing the air conditioning system’s performance. Additionally, for every 1 °C increase in ambient temperature, the COP experienced a boost of approximately 4 to 7%.

The EC pad precooling system emerged as the most efficient method for reducing temperature variations across the condenser, showcasing an average effectiveness of 0.55 and maximum of 0.63. This system maintained a consistent temperature reduction across the condenser coil’s surface. Whereas the Mist Cooling system demonstrated slightly lower effectiveness compared to the EC pad, with an average effectiveness of 0.43 and a peak at 0.48. This was attributed to an uneven thermal gradient across the condenser coil, resulting from inconsistent precooling performance. However, the hybrid EC pad + Mist Cooling system displayed moderate effectiveness, averaging 0.49 and maximum of 0.58. This combination benefited from the enhanced uniformity in the cooling process across the condenser surface, achieved through the initial wetting of the cellulose pad followed by mist cooling.

The water consumption for the EC pad pre-cooling mode was observed to range from 1.3 to 1.7 kg/hr, with the AC system of one ton of refrigeration equivalent producing condensate at a rate of 0.6 to 0.92 kg/hr, peaking at a set point temperature of 24 ℃ and minimizing at 28℃. A linear regression model, yielding the equation, effectively predicts condensate quantity, underscoring the importance of managing water consumption to optimize mist-based pre-cooling systems under varying environmental conditions.

Thermography assessment showed the highest temperature in the absence of precooling was 44 °C at an average ambient DBT of 35 °C ± 1.5 and 60 to 70% RH. Among the tested systems, the EC pad system was the most effective in lowering the temperature of the condenser coil, achieving temperatures below 40 °C closely followed by EC pad + Mist cooling mode. The average reductions in temperature across condenser unit observed for the EC pad, Mist Cooling, and the combined EC pad + Mist Cooling systems were 3.7 °C, 1.2 °C, and 2 °C, respectively.

Performance curves plotted over a range of cooling capacities from 2.5 kW to 3.5 kW demonstrated that the EC pad achieved the relative performance with a metric of 0.85 at the rated capacity. The other modes which had performance metrics of 0.80 for EC pad + Mist Cooling and 0.75 for Mist Cooling, compared to 0.65 for no pre-cooling.

Notable decrease in condenser on–off cycling frequency from approximately 7 cycles per hour without precooling to about 5 cycles per hour with the application of EC pad or a combination of EC pad and Mist Cooling, and 6 cycles per hour with Mist Cooling alone. This reduction is indicative of enhanced energy efficiency, improved stability of indoor temperatures, diminished wear on AC components, and overall superior system performance. However, the EC pad-based precooling method, despite its effectiveness, necessitates substantial water consumption and system modifications, including increased pad thickness and moderate capacity tanks, thereby requiring an additional water supply. Conversely, the Mist Cooling method, while reducing cycling frequency, suffers from a lack of effectiveness and non-uniform cooling across the condenser surface. The integration of EC pad and Mist Cooling emerges as the most efficacious approach, striking a balance between energy and water efficiency without necessitating an additional water source, as the condensate water generated suffices for the misting process. This comprehensive evaluation emphasizes the potential of the EC pad + Mist Cooling method in optimizing AC system performance while addressing environmental sustainability concerns.

All three pre-cooling technologies demonstrate maximized energy savings, cost benefits, and quick payback periods. The combination of EC pad + Mist provides the highest energy and cost savings, while the EC pad alone offers the quickest payback period. The choice between these options may depend on specific priorities: If maximizing energy and cost savings is the primary goal, the EC pad + Mist combination is the best choice, despite its higher implementation cost. If seeking the quickest return on investment, the EC pad alone provides the shortest payback period. If minimizing initial investment is crucial. The final decision may also depend on practical considerations such as installation requirements, maintenance needs, and compatibility with existing systems.

The current research on adiabatic pre-cooling systems demonstrates their potential to enhance the efficiency of cooling technologies, yet several limitations and areas for improvement have been identified. One of the primary limitations is the need for a deeper understanding of the factors influencing performance variability particularly in combined systems such as EC pad + Mist Cooling across different climates and operational contexts. While these systems have shown effectiveness in specific scenarios, they may not be fully optimized for diverse conditions, leading to performance inconsistencies. Additionally, the lack of long-term data limits the ability to assess the durability and reliability of these systems under continuous operation. The current work does not provide sufficient insights into the maintenance requirements or the expected lifespan of the systems, making it difficult to evaluate their long-term viability. The study also overlooks the need for a detailed economic analysis, which is essential for understanding the cost–benefit ratio of implementing these systems across various settings.

The research aimed to ascertain capabilities of precooling strategies that could enhance operational efficiency and overall system performance. Future research directions should explore the impact of developing advanced materials to improve scalability and cost-effectiveness, varying air–water mass flow rates and alternative installation positions alongside the application of evaporative cooling techniques to establish a precise relationship between the air-cooled condenser’s efficiency and the air conditioning system’s performance. Anticipated from this line of analysis is the development of a sensor-based control mechanism for ultrasonic mist cooling operations, leveraging condensate water level and condenser fan on/off sensors, marking a pivotal technological advancement in decentralized air conditioning technology.

Supplementary Information

Acknowledgements

The authors acknowledge the financial aid “from ISHRAE, New Delhi, and SSN—Trust, Project No. SRPG UG 48 and AICTE—NDF

Abbreviations

- AC

Air conditioner

- ACE

Atomization cooling element

- DBT

Dry bulb temperature

- DEC

Direct evaporative cooling

- EC

Evaporative cooling

- HVAC

Heating ventilation and air conditioning

- RH

Relative humidity

- TR

Ton of refrigeration

- WBT

Wet bulb temperature

- WBD

Wet bulb depression

List of symbols

- T

Temperature[oC]

- ε

Effectiveness

- v

Air velocity [m/s]

- L

Litres

Mass flow rate [kg/h]

- w

Humidity ratio

- h

Latent heat of vaporization of water [kJ/kg]

- V

Volume of the room[m3]

- Cp

Specific heat capacity of air [J/kg·°C]

Subscripts

- a

Air

- b

Baseline

- cond

Condenser

- e

Electricity

- i

Implementation

- in

Inlet

- l

Latent heat

- out

Outlet

- p

Period

- w

Water

- s

Sensible heat

- sa

Savings

Author contributions

The authors confirm contribution to the paper as follows: study conception and design: Ahmed; data collection: Ahmed; analysis and interpretation of results: Ahmed, Ramana. Ahmed; draft manuscript preparation: Ahmed. Ramana. All authors reviewed the results and approved the final revised version of the manuscript: Ahmed, Ramana, Jayakumar.

Funding

The Indian Society of Heating,Refrigerating and Air Conditioning Engineers (ISHRAE),SRPG UG 48,SRPG UG 48

Data availability

Data is provided within the manuscript and supplementary information files.

Declarations

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-024-82863-0.

References

- 1.Vakiloroaya, V., Samali, B., Fakhar, A. & Pishghadam, K. A review of different strategies for HVAC energy saving. Energy Convers. Manage77, 738–754. 10.1016/j.enconman.2013.10.023 (2014). [Google Scholar]

- 2.IEA. The Future of Cooling: Opportunities for Energy-Efficient Air Conditioning; Annual report; IEA: Paris, France (2018).

- 3.Shah, N., Park, W. Y. & Ding, C. Trends in best-in-class energy-efficient technologies for room air conditioners. Energy Reports7, 3162–3170. 10.1016/j.egyr.2021.05.016 (2021). [Google Scholar]

- 4.Alawadhi, M. & Phelan, P. E. Review of residential air conditioning systems, operating under high ambient temperatures. Energies10.3390/en15082880 (2022). [Google Scholar]

- 5.Abraham, J. & Chitharthan, R. K. Performance evaluation of air-conditioning system with evaporative cooled condenser. Int. J. Appl. Eng. Res.10, 11356–11361 (2015). [Google Scholar]

- 6.Aglawe, K., Matey, M. & Gudadhe, N. Experimental analysis of window air conditioner using evaporative cooling. Int. J. Eng. Res. Technol.2, 1–6 (2013). [Google Scholar]

- 7.Alhamdo, M. H., Theeb, M. A. & Abdulhameed, J. J. Using evaporative cooling methods for improving performance of an air-cooled condenser. Univ. J. Mech. Eng.3(3), 94–106 (2015). [Google Scholar]

- 8.Eidan, A. A., Alwan, K. J., Alsahlani, A. & Alfahham, M. Enhancement of the performance characteristics for air-conditioning system by using direct evaporative cooling in hot climates. Energy Procedia142, 3998–4003. 10.1016/j.egypro.2017.12.311 (2017). [Google Scholar]

- 9.Harby, K., Gebaly, D. R., Koura, N. S. & Hassan, M. S. Performance improvement of vapor compression cooling systems using evaporative condenser: An overview. Renew. Sustain. Energy Rev.10.1016/j.rser.2015.12.313 (2016). [Google Scholar]

- 10.Teeraphong Borirak, P. K. The performance enhancement of split type Air conditioning system by decreasing temperature before inlet condensing unit using PVC filling. EAU Herit. J.6, 147–155 (2012). [Google Scholar]

- 11.Ongthanasuk, T., Chirakalwasan, R. The Performance of An Evaporative Condenser Air Conditioner (Chulalongkorn University) 2546. http://www.thaithesis.org/detail.php?id=1082546000341.

- 12.Islam, M., Jahangeer, K. & Chua, K. Experimental and numerical study of an evaporatively-cooled condenser of air-conditioning systems. Energy87, 390–399 (2015). [Google Scholar]

- 13.Jassim, L. I. Enhancement the performance of condenser of split type air conditioning system by using evaporative cooling. Al-Ma’mon Coll. J.17, 230–246 (2011). [Google Scholar]

- 14.Shah, B., Dwivedi, S. & Singhal, A. Energy saving in split air conditioner using evaporative cooling pad at the ODU. Int. J. Innov. Technol. Explor. Eng.9(1), 1858–1862. 10.35940/ijitee.A4765.119119 (2019). [Google Scholar]

- 15.Harby, K. & Al-amri, F. An investigation on energy savings of a split air-conditioning using different commercial cooling pad thicknesses and climatic conditions. Energy182, 321–336. 10.1016/j.energy.2019.06.031 (2019). [Google Scholar]

- 16.Martínez, P. et al. Experimental study on energy performance of a split air-conditioner by using variable thickness evaporative cooling pads coupled to the condenser. Appl. Thermal Eng.105, 1041–1050. 10.1016/j.applthermaleng.2016.01.067 (2016). [Google Scholar]

- 17.Ramzan, M., Kamran, M. S., Saleem, M. W., Ali, H. & Zeinelabdeen, M. I. M. Energy efficiency improvement of the split air conditioner through condensate assisted evaporative cooling. Arabian J. Sci. Eng.46(8), 7719–7727. 10.1007/s13369-021-05494-x (2021). [Google Scholar]

- 18.Wang, S.-L., Zhao, W.-S, Liu, Y., & Lin, A.-B. Numerical study on spray humidification system used in the direct air-cooled unit. 28, 28–33 (2008).

- 19.Yu, F. W. & Chan, K. Application of direct evaporative coolers for improving the energy efficiency of air-cooled chillers. J Sol Energy Eng.10.1115/1.1866144 (2005). [Google Scholar]

- 20.Wang, T., Sheng, C. & Nnanna, G. Experimental investigation of air conditioning system using evaporative cooling condenser. Energy Build.81, 435–443. 10.1016/j.enbuild.2014.06.047 (2014). [Google Scholar]

- 21.Liu, H., Zhou, Q., Liu, Y., Wang, P. & Wang, D. Experimental study on cooling performance of air conditioning system with dual independent evaporative condenser. Int. J. Refrig.10.1016/j.ijrefrig.2015.03.012 (2015). [Google Scholar]

- 22.Huang, C. N. & Ye, Y. H. Development of a water-mist cooling system: A 12,500 Kcal/h air-cooled chiller. Energy Rep.1(2015), 123–128 (2015). [Google Scholar]

- 23.Kabeel, A., El-Samadony, Y. & Khiera, M. Performance evaluation of energy efficient evaporatively air-cooled chiller. Appl. Therm. Eng.122, 204–213 (2017). [Google Scholar]

- 24.Yang, H. et al. Experimental research on spray evaporative cooling system applied to air-cooled chiller condenser. Energy Reports10.1016/j.egyr.2020.04.001 (2020). [Google Scholar]

- 25.Yang, H., Pei, N., Liu, L., Fan, M. & Qin, Y. Experimental study on the effect of condensate water on the performance of split air conditioning system. Energy Reports10.1016/j.egyr.2021.01.037 (2021). [Google Scholar]

- 26.Yang, H., Pei, Na., Liu, L., Fan, M. & Qin, Y. Experimental study on the effect of condensate water on the performance of split air conditioning system. Energy Reports.7, 840–851. 10.1016/j.egyr.2021.01.037 (2021). [Google Scholar]

- 27.Chaktranond, C. & Doungsong, P. An experimental evaluation of energy saving in a split-type air conditioner with evaporative cooling systems. Int. Trans. J. Eng. Manag. Appl. Sci. Technol.1(1), 009–018 (2010). [Google Scholar]

- 28.Chua, K. J., Chou, S. K., Yang, W. M. & Yan, J. Achieving better energy-efficient air conditioning–a review of technologies and strategies. Appl. Energy104, 87–104 (2013). [Google Scholar]

- 29.Kulkami, M., Khandagale, A., Singh, P., Choudhary, S. & Sharma, R. Experimental investigations of evaporative-cooled condenser split air conditioner. Int. J. Eng. Sci. Comput. (IJESC)6, 7–19 (2016). [Google Scholar]

- 30.Prajapati, M. Enhancement the performance of condenser of split type air conditioning system by using evaporative cooling: a review. Int. J. Eng. Sci. Res. Technol. 6 (2014)

- 31.Algarni, S., Saleel, C. A. & Mujeebu, M. A. Air-conditioning condensate recovery and applications—current developments and challenges ahead. Sustain. Cities Soc.37, 263–274. 10.1016/j.scs.2017.11.032 (2018). [Google Scholar]

- 32.Cattani, L., Magrini, A. & Cattani, P. Water extraction from air by Refrigeration—Experimental results from an Integrated System Application. Appl. Sci.8, 2262. 10.3390/app8112262 (2018). [Google Scholar]

- 33.Navarro, P., Ruiz, J., Martínez, P. & Lucas, M. Numerical study of an ultrasonic spray atomiser as an evaporative cooler. Appl. Thermal Eng.10.1016/j.applthermaleng.2023.121455 (2023). [Google Scholar]

- 34.Martínez, P., Ruiz, J., Martín, I. & Lucas, M. Experimental study of an ultrasonic mist generator as an evaporative cooler. Appl. Thermal Eng.10.1016/j.applthermaleng.2020.116057 (2020). [Google Scholar]

- 35.Ketwong, W., Deethayat, T. & Kiatsiriroat, T. Performance enhancement of air conditioner in hot climate by condenser cooling with cool air generated by direct evaporative cooling. Case Stud. Thermal Eng.26(January), 101127. 10.1016/j.csite.2021.101127 (2021). [Google Scholar]

- 36.Chiesa, G., Huberman, N. & Pearlmutter, D. Geo-climatic potential of direct evaporative cooling in the Mediterranean region: A comparison of key performance indicators. Build. Environ.151(November), 318–337. 10.1016/j.buildenv.2019.01.059 (2019). [Google Scholar]

- 37.ASHRAE. Evaporative cooling. In ASHRAE handbook – HVAC applications. Atlanta, GA: ASHRAE. (2019).

- 38.Nandagopal, N.S. (2024). Cooling and heating load calculations. In: HVACR Principles and Applications. (Springer, 2024). 10.1007/978-3-031-45267-3_6

- 39.Soylu, S. K., Atmaca, I. & Doğan, A. Investigation of evaporative cooling effectiveness on the performance of air–cooled chillers. Online J. Sci. Technol.6(3), 3–39 (2016). [Google Scholar]

- 40.Weerasinghe, A. S. & Ramachandra, T. Costs and Benefits of Green Retrofits: A Case of Industrial Manufacturing Buildings in Sri Lanka. In The 10th International Conference on Engineering, Project, and Production Management. Lecture Notes in Mechanical Engineering (eds Panuwatwanich, K. & Ko, C. H.) (Springer, 2020). [Google Scholar]

- 41.Ibrahim, N. I., Al-Farayedhi, A. A. & Gandhidasan, P. Experimental investigation of a vapor compression system with condenser air pre-cooling by condensate. Appl. Thermal Eng.10.1016/j.applthermaleng.2016.09.042 (2017). [Google Scholar]

- 42.Ali, M. A., Saifur, S. & Ali, M. A. Quantification of condensate water generated from air conditioning system. Global Sci. Technol. J.6, 44–56 (2018). [Google Scholar]

- 43.Ardita, I. & Subagia, I. The application of condensate water as an additional cooling media intermittently in condenser of a split air conditioning. In J. Phy. Conf. Ser. IOP Publishing953, 012059 (2018). [Google Scholar]

- 44.Taylor, J. R. An Introduction to Error Analysis: The Study of Uncertainties in Physical Measurements (University Scientific Books, 1997). [Google Scholar]

- 45.Cooperman, B. A., Dieckmann, J., & Brodrick, J. Water/electricity trade-offs. ASHRAE J. 118–120 (2011)

- 46.AlGhamdi, S. A. et al. Heavy metals and microbial assessment of air conditioning condensate water in Jeddah city-Saudi Arabia: concept of sustainable water resources. Sustain. Water Resour. Manag.10, 139. 10.1007/s40899-024-01122-2 (2024). [Google Scholar]

- 47.Commission, I.E.; IOF Standardization; Iso/iec guide 98–3: Uncertainty of measurement. Part 3: Guide to the expressión of uncertainty in measurement (gum :1995). Partie 3: Guide pour l’expression de l’incertitude de mesure (gum: 1995). ISO (2008).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data is provided within the manuscript and supplementary information files.