Abstract

The rapid increase in the number of stimuli-responsive polymers, also known as smart polymers, has significantly advanced their applications in various fields. These polymers can respond to multiple stimuli, such as temperature, pH, solvent, ionic strength, light, and electrical and magnetic fields, making them highly valuable in both the academic and industrial sectors. Recent studies have focused on developing hydrogels with self-healing properties that can autonomously recover their structural integrity and mechanical properties after damage. These hydrogels, formed through dynamic covalent reactions, exhibit superior biocompatibility, mechanical strength, and responsiveness to stimuli, particularly pH changes. However, conventional hydrogels are limited by their weak and brittle nature. To address this, ionizable moieties within polyelectrolytes can be tuned to create ionically cross-linked hydrogels, leveraging natural polymers such as alginate, chitosan, hyaluronic acid, and cellulose. The integration of ionic liquids into these hydrogels enhances their mechanical properties and conductivity, positioning them as significant self-healing agents. This review focuses on the emerging field of stimuli-responsive ionic-based hydrogels and explores their potential in dermal applications and tissue engineering.

Keywords: stimuli-responsive, self-healing, ionic interaction, ionic liquids, hydrogels, dermal, tissue engineering

1. Introduction

Ionic gels are hybrid materials formed by dispersing ionic liquids within a polymer or inorganic matrix. This results in materials with high ionic conductivity in the solid state, making them suitable for various applications, including flexible electronics and biomedical devices.1,2 Ionic liquids (ILs), which are composed of organic cations and organic or inorganic anions, are salts that are present at nearly room temperature. They exhibit high thermal stability and negligible vapor at ambient temperature, contributing to their low flammability.3 The characteristics of ionic gels are influenced by the choice of cations and anions. Variations in anionic composition can lead to variations in the electronic environment of the cation, affecting the overall properties of the ILs. Commonly utilized cations in ILs include imidazolium, pyridinium, piperidinium, phosphonium and ammonium. Examples of anions include halides, carboxylates, sulfates, phosphates and various other species.4

Hydrogen bonding is crucial for affecting the reaction dynamics and viscosity and is essential for gelation, balancing gelator–gelator and solvent–gelator interactions. Electrostatic interactions between ILs and charge polymer networks enhance ionogel performance but can hinder ion transport and reduce conductivity. Solvophobic interactions cause nonpolar species to aggregate, improving the compatibility between ILs and polymers and influencing gelation. When polymers are added to the dispersion of ILs and nanoparticles, they form coils and absorb layers, leading to strong steric repulsion and nanoparticle clustering due to the bulky IL group.3 The incorporation of ionic liquids into a polymer matrix of ionogels enhances ionic conductivity by increasing the number of charge carriers and amorphicity while also acting as a plasticizer to improve ion mobility, although excessive ionic liquids can reduce mechanical strength and crystallinity. The purpose of ionic gels includes optimizing ionic conductivity for electrochemical devices, enhancing mechanical properties for flexibility and durability, and achieving self-healing capabilities. Additionally, tuning the responsiveness to external stimuli enables controlled drug release and adaptive behavior, while ensuring biocompatibility and biodegradability is crucial for biomedical applications.5−7 Ionic gels have attracted substantial interest because of their distinctive self-healing properties. Ionic gels can autonomously repair damage, recovering their original mechanical and functional characteristics after being subjected to stress or damage. Drug release from the ionogels was related to the gradual loss of ILs and internal loads. The suitability of ionogels formulated with biodegradable ILs for drug delivery applications has further increased.4

This self-healing capability is primarily due to the presence of multiple hydrogen bonds and dynamic interactions within the gel matrix, which enables the reformation of the network structure following damage.8,9 Recent advancements have produced various formulations of self-healing ionic gels that exemplify their unique capabilities. Zhang et al. developed a lignin/poly(ionic liquids) composite hydrogel dressing with exceptional self-healing properties, achieved through supramolecular interactions between lignins, which also improved the mechanical strength and antibacterial activity.10 Wang et al. fabricated Ag-lignin nanoparticles, polyurethane and ionic liquids.11 The self-healing capability was achieved through the introduction of disulfide bonds, with a self-healing efficiency of 97%.

In addition to the fundamental properties of ionogels, stimuli-responsive ionogels represent an advanced class of materials that respond dynamically to external stimuli. These innovative ionogels offer enhanced functionality, making them particularly suitable for applications requiring adaptability and self-healing properties. Stimulus-responsive polymers have undergone significant growth recently, attracting considerable attention from the academic and industrial sectors because of advancements in their synthesis and wide range of applications.6 Stimuli-responsive self-healing ionic gels are emerging as a transformative technology in the fields of dermal applications and tissue engineering. These innovative materials possess the unique ability to respond to external stimuli such as temperature, pH or light, enabling them to autonomously repair themselves after damage.4 Owing to their self-healing ability, biocompatibility, and tunable mechanical properties, these materials are ideal candidates for advanced therapeutic and regenerative applications. These gels can be categorized based on their matrix composition.

Ionic liquid-based gels are gaining attention in tissue engineering because of their versatile properties. They have been explored for applications such as artificial muscle and scaffolds.12 ILs such as [Bmim][Cl] and 1-ethyl-3-methylimidazolium trifluoromethanesulfonate [Emim][TFSI] enhance the mechanical properties and electrical conductivity of polyvinylidene fluoride (PVDF)-based electroactive films that support muscle cell proliferation.13 ILs also aid in dissolving proteins and polymers, such as silk fibroin keratin, collagen and cellulose, to form scaffolds for various tissue engineering applications, including bone and neural tissue repair.12 Hydrogels incorporating liquids have shown improved biocompatibility and functionality, such as providing cardiac tissue repair and skin generation, and have potential in cancer therapy.12,14 Overall, ionic liquid-based materials offer significant advancements in tissue engineering, with applications ranging from wound healing to cardiac patches. This review contains the fundamentals of ionic gels, their types and properties, various stimuli-responsive behaviors, the self-healing mechanisms involved and their applications in dermal and tissue engineering.

2. Fundamentals of Ionic Gels

2.1. Definitions and Characteristics

Ionic gels are advanced functional materials composed of dispersed phases containing ionic liquids (ILs) confined within a polymeric network.4,15 These materials integrate the properties of ILs and gels, enabling various applications. ILs are salts made up of organic cations and organic or inorganic anions. These exist as liquids below 100 °C. Gels, on the other hand, are three-dimensional (3D) networks containing colloidal particles dispersed in a liquid medium.15,16 In ionic gels, the ILs are confined within a 3D cross-linked network through different internal interactions, resulting in a customizable structure. The internal interactions involved in an ionic gel include hydrogen bonding, electrostatic interactions, steric interactions and solvophobic interactions. They are typically designed by forming polymer networks in an ionic medium, with the IL molecules being confined within the network of gelation.4,17 Ionic gels retain the properties of ILs, suggesting potential applications in wearable strain sensors and biochemical detection. The composition and type of an ionogel govern its properties. Ionic gels demonstrate high stability over time, even under reduced pressure, and retain the specific properties of the IL, except for outflow.3,18 The characteristic features of ionic gels include ionic conductivity, thermal stability, electrochemical stability and mechanical properties, among others.

2.2. Types of Ionic Gels

IL-based gels are classified into three types depending on their nature: ILs can serve as the continuous phase, the dispersed phase, or both phases simultaneously. These are known as poly(IL) hydrogels, ionic gels and IL gels. In poly(ILs) hydrogels, the ILs can be polymerized to form polymeric ILs (PILs) or copolymerized with other monomers to constitute the continuous phase. These gels are dispersed in an aqueous phase. In ionic gels, the continuous phase consists of non-PILs and ILs as the dispersed phase. The third type consists of IL gels, which involve the polymerization of ILs to produce PILs as a continuous phase, which are simultaneously dispersed in other ILs15,19,20

Ionic gels can also be classified based on the type of matrix: inorganic matrix, organic matrix and organic–inorganic hybrid matrix.3Inorganic ionic gels consist of ILs immobilized within an inorganic matrix with high ionic conductivity and structural stability.21 The inorganic ionic gels are further divided into bucky gels and silica-based ionogels. Bucky gels are formed by mixing ILs with carbon nanotubes, resulting in a dense suspension due to the gelification process.22 Silica-based ionogels consist of silica precursors and ILs.23,24 By forming a silica network or using silica as a nanofiller, the ionic conductivity is significantly improved. The silica network provides additional pathways for ion transport, while the nanofiller increases amorphicity, enhancing the mechanical properties.3 Khurana and Chandra synthesized silica-based ionic gels. The ionic gel was developed via the use of tetraethyl orthosilicate (TEOS) (a silica precursor), a poly(vinylidene fluoride-cohexafluoropropylene (PVDF-HFP) copolymer, lithium trifluoromethanesulfonate (LiTf) salt and EMIMTf as ILs.25 The nonaqueous method results in a high electrolyte solution content within the hybrid matrix, achieving a room-temperature ionic conductivity of 3 mS/cm, which is suitable for electrochemical applications. The ionic gel showed a wide electrochemical stability window, high thermal stability and increased amorphousness. A higher electrolyte content decreases the mechanical strength. Cheng et al. explored quasi-solid-state electrolytes with ionic liquids.26 Two ionogel quasi-solid-state electrolytes were synthesized by incorporating different lithium salts (LiOTf and LiTFSI) and a porous silica precursor (TEOS) with a [BMIM][BF4] ionic liquid. Both electrolytes have high ionic conductivity. The porous, cross-linked structures facilitate ion transport, overcoming leakage and flammability issues (Figure 1), making these ionic gel electrolytes promising candidates for use in lithium-ion batteries.

Figure 1.

Photograph of the IE-T electrolyte and schematic of the internal microscopic three-dimensional structure of the ionogel. Adapted with permission from ref (26). Copyright 2019 Elsevier.

In another study by Wu et al., a novel solid-state ionogel electrolyte was fabricated using a silane coupling agent (SCA) to form a porous network that confines an ionic liquid electrolyte.23 Epoxy groups were grafted onto silica to enhance the ionic dissociation of Lt salts and the IL. The ionic gel with an optimal ILE/SCA molar ratio of 0.75 exhibited excellent thermal stability, a wide redox stability window and an ionic conductivity of 1.91 × 10–3 S/cm at 30 °C, surpassing the pure IL electrolyte.

The organic ionic gels consisted of a polymer matrix swollen with ILs. The backbone for organic liquids is typically formed from polymers such as polyacrylate, poly(vinyl alcohol), and elastomers, which provide structural integrity and mechanical properties.27 The organic ionic gels can be prepared by adding a low-molecular-weight gelator (LMWG) and gelation by an organic polymer. In LMWG, the LMWG (organogelator) is added to ILs at high temperatures to form a gel upon cooling. Additionally, this method uses cosolvents and results in high ionic conductivity. Cheng et al. tuned the ionic gel properties using LMWG, an amide-functionalized imidazolium-based surfactant, in various solvents and inorganic salt additives.28 Chemical (Cu+2/H2O2) and temperature stimuli induced the gel-to-sol phase transition. The addition of CuBr2 increased the mechanical strength and altered the gel morphology. In another study, Bielejewski and colleagues developed an ionic gel containing methyl-4,6-O-(p-nitrobenzylidene)-α-d-glucopyranoside (LMWG), which self-assembles in an aqueous solution of high-temperature ionic liquid tetramethylammonium bromide.29 Compared with pure liquid electrolytes, gel electrolytes exhibit enhanced ionic conductivity. These findings suggest that intermolecular interactions between ion complexes and gelator aggregates are responsible for the improved conductivity.

In the gelation of ILs by organic polymers, polymer ionic gels can be fabricated through three routes: (i) doping polymers with ILs, (ii) monomer polymerization in ILs, and (iii) polymeric ILs.3 Doping polymers with ILs involves blending or impregnating polymers with ILs to form ionic gels.30 Singh et al. studied the electrochemical, structural and photoelectrochemical properties of [EMIM][DCA] with PVDF-HFP.30 The inclusion of the [EMIM][DCA] IL enhances the charge carrier mobility, leading to increased ionic conductivity. The IL also introduces more amorphous regions within the polymer matrix, which is beneficial for conductivity, as confirmed by DSC and XRD measurements. Gupta et al. developed poly(ethylene oxide)-based polymer electrolytes containing lithium bis(trifluoromethylsulfonyl)imide and the ionic liquid 1-buty-3-methylpyridinium bis(trifluoromethylsulfonyl)imide.31 These electrolytes are thermally stable up to 360 °C. For a polymer electrolyte with 30% ionic liquid, the ionic conductivity was approximately 2.5 × 10–5 S/cm at 25 °C and 2.3 × 10–4 S/cm at 40 °C. The gel showed increased discharge capacity and decreased cell resistance at higher temperatures, which was attributed to improved electrode–electrolyte contact.

In the polymerization of monomers in ILs, the monomers are polymerized within ILs, producing flexible, self-standing films with high ionic conductivity.32 Marcinkowska et al. developed an ionic gel using a thiol–ene matrix formed from triallyl isocyanurate and trimethylopropane tris(3-mercaptopropionate) via photoinduced polymerization in ILs.32 The polymer matrix should have a phase-separated morphology and a colloid gel structure with interconnected microspheres. Polymerization was faster in ionic liquids with higher Kamlet–Taft beta parameters, whereas compatibility decreased with lower Kamlet–Taft alpha values. The ionic gel exhibited high ionic conductivity and retained most of the ionic liquid conductivity, demonstrating an antiplasticization effect due to the solubility of the ionic liquid in the matrix. In another study by Jiang and Company, free radical polymerization of methacrylate in the ionic liquid BMIPF 6 produced a new series of gel polymer electrolytes (GPEs) with high ionic conductivity.33 These GPEs were flexible, transparent and conductive with decreasing glass transition temperatures as the BMIPF 6 content increased the ionic conductivity of the GPEs, followed by the Vogel–Tamman–Fulcher equation, which reached nearly 10 at a power of 3 s/cm at room temperature, and the capacitor performance was assessed through cyclic voltmeter impedance spectroscopy with galvanostatic charging–discharging.

Organic–inorganic hybrid matrix ionic gels combine ILs, nanofillers and polymer matrices, enhancing the mechanical properties of inorganic fillers and the flexibility of organic polymers. These ionic gels are fabricated to address these issues and achieve ionic gels that are tough and have simple fabrication techniques.34,35 Su et al. developed an organic–inorganic semi-interpenetrating network.36 The ionic gel was fabricated by confining an IL with a cross-linked PIL copolymer and a glass fiber scaffold. This gel offers superior properties, including enhanced lithium and high mechanical strength, and the wire electrochemical window and fire resistance in tests allow over 1800 h of lithium plating or stripping without significant dendrite formation and demonstrated excellent cycling stability in full cycles with Li3V2 (PO4)3 ethyl. Lee et al. fabricated multifunctional ionic group-functionalized ladder-like polysilsesquixone to create hybrid ionogels with the ability to cross-link lithium-ion batteries in IL electrolyte media.37 The resulting ionogel electrolyte offers exceptional thermal stability, mechanical strength, high ionic conductivity and electrochemical stability.

2.3. Characteristics of Ionic Gels

Ionic gels exhibit diverse properties depending on the specific IL and the gel matrix utilized. The general and fundamental properties of ionic gels are their pore size or porosity, mechanical strength, ionic conductivity, and electrochemical and thermal stability (Figure 2). Additionally, these gels may exhibit specialized properties such as biocompatibility, antibacterial activity, self-healing capabilities and luminescence.4

Figure 2.

(a) Schematic representation of PVA/PVPm/ILn healable ionogels with good mechanical properties. (b) Images depicting the deformation of the PVA/PVP 0.4/IL2 ionogels (left) subjected to a load of 1500 g (right). (c) Images captured showing excellent flame retardation or thermal stability of the highly conductive organic-ionogel prepared from tributyl phosphate. (d) At 10 mV/s, linear sweep voltammograms of lithium|ionogel|stainless-steel cells with different electrolytes. Adapted from ref (49). Copyright 2020 American Chemical Society.

2.3.1. Pore Size and Porosity

Pore size and porosity are essential determinants in the efficacy of ionogels for dermal or tissue engineering applications. The liquid condition of room temperature ILs is advantageous for the production of ionogels by infiltrating the pores of a 3D gel matrix with the respective IL. The pore dimensions of the solid networks within the gel are expected to affect the behavior of the bulky IL molecules confined within the pores.38 Typically, ILs can serve as a polymeric component in scaffolds inside ionogels by chemical bonding. Poly(ionic liquids), a category of ILs, can modulate the architecture of the ionogel scaffold and pore formation by facilitating controllable hydrogen bonding, electrostatic interactions, and host–guest interactions, or they may serve as a dispersing medium within ionogels, being encapsulated in the ionogel scaffold.17,39,40 Ionogels typically have pore sizes in the range of 7–12 nm.41 The exact pore size can vary depending on the specific composition and preparation method of the ionogel. For example, ionogels prepared using silica aerogels with choline dihydrogen phosphate IL have an average pore size of around 12.2 nm.42 Increased pore size and elevated porosity facilitate enhanced cellular infiltration and proliferation, which are crucial for tissue regeneration. This facilitates cellular movement through the scaffold, enabling successful tissue formation. Elevated porosity facilitates the movement of nutrients, oxygen, and waste products, which is essential for sustaining cell viability and fostering tissue growth. Notably, appropriate pore dimensions and porosity are crucial for angiogenesis within the scaffold, which is vital for the sustenance of newly developed tissues.43 Although increased porosity can enhance biological performance, it may compromise the mechanical integrity of the scaffold. Consequently, a balance must be achieved to guarantee that the scaffold is both biologically effective and mechanically stable. In line with this, conductivity plays a significant role in tissue engineering, by providing electrical stimulation and electrical signal transmission, thereby promoting and enhancing cell proliferation, differentiation, migration, and tissue regeneration.44 Larger pore sizes within an appropriate range result in increased conductivity. Ding et al. synthesized ionogels (PAMPS-[EMIM][DCA] (1-ethyl-3 methylimidazolium dicyanamide) gel) with varying pore sizes by adjusting the polymer content, discovering that ionogels with larger pore sizes exhibit superior conductivity.45

2.3.2. Mechanical Properties

In practical applications, the mechanical properties of the gel are critical. Ionic gels prepared via covalent cross-linking typically exhibit enhanced mechanical properties, as they contain ILs and other polymers in the hydrogel network and interact through hydrogen bonding and electrostatic and hydrophobic interactions.15,46 The mechanical properties are typically evaluated via parameters such as fracture strain, fracture strength, Young’s modulus, and energy dissipation, which are all derived from the stress–strain curve. Additional critical properties include crack propagation resistance and antifatigue characteristics.47 Most ionic gels currently exhibit mechanical issues, including low strength, poor toughness, high crack sensitivity and susceptibility to fatigue damage. These strategies include the use of double networks, micro/nanocomposites, supramolecular interactions, multiscale structures, and phase separation.18,47 Rana et al. fabricated double network (DN) ionogel films with high ion conductivity, stretchability, and ultradurability.48 Compared with physically interpenetrating network (PIN) ionogels, the prepared DN ionic gels exhibited superior mechanical, thermal and electrochemical properties. Mechanically, they have higher tensile strength (3.2 MPa at 30 °C) and better energy dissipation (Uhys of 911 kJ/m3 at 30 °C and 250% strain) than PIN ionic gels. They also maintain significant strength and energy dissipation at elevated temperatures (1.4 MPa and 216 kJ/m3 at 100 °C). Compared with traditional gel electrolytes, DN ionic gels are stable for up to 300 s° and are nonflammable. DN ionic gels demonstrated enhanced ionic conductivity with increasing IL loading, stable performance under repeated stretching and high temperatures, and a broad electrochemical stability range (0–3 V), making them ideal for various applications. Wang et al. developed a multifunctional ionogel-based strain sensor using Ag-Lignin nanoparticles (Ag-Lignin NPs), polyurethane (PU) and ionic liquids.11 This gel exhibited excellent mechanical properties, such as tensile strength of 3.14 MPa and elongation at break ranging from 893 to 1241%. These properties are attributed to the plasticizing effect of the ILs and the dissolution of the crystalline regions, which increase the elongation at break. The ionogel also demonstrated a high self-healing efficiency of 97.6% due to reversible bonding and superior adhesiveness facilitated by Ag–Lignin NPs. Additionally, the ionogel possesses remarkable antifreezing, UV-shielding and antibacterial properties. They maintain their mechanical properties across a range of temperatures and exhibit high UV absorption and significant antibacterial activity against E. coli and S. aureus. As strain sensors, ionic gels display reliable performance, stable sensitivity and accurate real-time monitoring of human movement, highlighting their potential in various technologies.

2.3.3. Temperature Resistance

Ionic gels have high thermal stability, and by modifying the structure of ILs, the thermal resistance of ionic gels can be adjusted to withstand both high and low temperatures.47 Mao et al. reported an ionogel electrolyte (PAAm/IL-X) composed of a polyacrylamide (PAAm) network and the IL 1-vinyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ([VMIM] [TFSI]).50 The incorporation of [VMIM] [TFSI] enhanced both the thermal stability and conductivity of the electrolytes. The ionogel achieved up to 23 mS/cm conductivity at 90 °C, with 71% retention after 20 days at room temperature. The thermal decomposition temperature of PAAm/IL-X exceeds 220 °C, which is attributed to the presence of the IL and cross-linking structure, which enhances the thermal stability. The PEDOT/CC electrode, prepared by electroplating, demonstrates superior electrochemical performance, achieving a notable specific capacitance. The capacitance performance of ASSC-X increases by 5% at 90 °C, highlighting the potential of PAAm/IL-X as a safe electrolyte/separator for high-performance supercapacitors. In another study, Ren and colleagues developed IL-based click-ionic gels via thiol–ene click chemistry under mild conditions.51 These ionic gels retained excellent mechanical properties and resilience. They exhibited high ionic conductivity, transparency, and nonflammability across a wide temperature range (−75 to 340 °C) due to the presence of poly(1-butyl-3-vinyl imidazolium fluobutyl) (PIL-BF4), which has a low freezing point and high boiling point, preventing crystallization and maintaining elasticity at low temperatures. The combination of ionic and covalent cross-linking networks provides structural robustness, whereas strong hydrogen bonding between PIL-BF4 and polymer chains enhances mechanical strength and thermal stability. Compared with hydrogels that lost 75% of their weight in half an hour at 50 °C, IL-based gels remained stable with no weight loss even after 5 days at 250 °C, demonstrating their excellent high-temperature stability.

2.3.4. Ionic Conductivity

Ionic strength-sensitive gels change conformation in response to K+, Na+, and Ca2+ (Figure 3). They are made from ionizable and zwitterionic polymers such as alginate, deacetylated gellan gum, carboxymethyl dextran, poly(acrylic acid), and poly(itaconic acid).52,53 By increasing the swelling ratio proportionally to the ionic strength of the surrounding medium, poly(l-glutamic acid-co-l-lysine)-based hydrogels loaded with doxorubicin exhibited ionic strength sensitivity.54 Under high ionic strength, Cl– and Na+ protect NH3+ and COO– polypeptide groups, inhibiting electrostatic interactions and encouraging hydrogel expansion. The ionic conductivity of ionic gels is determined by ILs. However, the cross-coupled polymer networks restrict IL migration, resulting in a lower conductivity than that of pure ILs. The ionic conductivity of ionic gels is dependent on the viscosity and mobility of cations and anions in ILs and is influenced mainly by the chemical properties, size, viscosity of the ILs, the IL ratio, temperature and polymer matrix composition.3,17,47

Figure 3.

Schematic representation of the ionic-responsive hydrogel. An increase in the ionic strength caused increased hydrogel swelling. O, oxygen, Na+, sodium. The red circles represent hydrogel-loaded biomolecules. Adapted from ref (55). CC BY 4.0.

Traditional electrolyte hydrogels have limitations such as low ion content, water evaporation, thermal stability and limited long-term storage; to address these challenges, alternative modifications have been explored.16 In the study conducted by Yan et al., a robust and highly conductive ionogel was fabricated by combining a DN structure, composite materials and high-functionality cross-linkers.56 The use of 1-ethyl 3-methylimidazolium dicyanamide ([EMIm][DCA]) and 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIm]-[BF4]) as ILs and the charged PAMPS as the polymer network. The DN-PAMPS-GO ion gels exhibited high ionic conductivity, with the [EMIm][DCA]-containing gel achieving approximately 1.8 S/m and the [BMIm]-[BF4]-containing gel achieving approximately 0.28 S/m. These values are comparable to those of their respective neat liquids. The conductivity increases with temperature and remains stable over time, maintaining high performance even after 60 days. The addition of graphene oxide enhances the mechanical properties without significantly affecting the conductivity, making these ion gels ideal for flexible electronic and wearable devices. Weng et al. developed a PVA–PVP complex and [EMIm][DCA]-containing ionogel (PVA/PVPm/IL ionogel).49 The ionogel demonstrated high performance in terms of ionic conductivity and mechanical properties. The ionic conductivity of these ionic gels increases with temperature and IL content, reaching 19.7 mS/cm at room temperature, due to the high intrinsic conductivity of [EMIm][DCA] and the compatibility between [EMIm][DCA] and the PVA–PVP complex. Additionally, the ionic conductivity increases with increasing temperature, as higher temperatures increase the flexibility of the polymer chain and the mobility of the IL, leading to better ion movement within the matrix. Additionally, the ionogel exhibited good mechanical properties, with tensile stress and strain values varying for the IL and PVP contents. The mechanical strength decreased with increasing IL content due to the reduced density of the polymer network. By varying the molecular weight of the polymer, the electrochemical stability window can be varied. These properties make ionic gels suitable for high-performance, flexible electronic applications. A new series of hydrogen with ionic conductivity based on choline amino acid polyionic liquids was developed via double network methodology by He et al.57 These conductive ionic gels demonstrated excellent mechanical properties, self-healing ability and antimicrobial activity. The conductivity of Cho-Aa hydrogels was markedly superior to that of the control hydrogel, ranging from 0.409 to 0.798 S m–1 (Figure 4). Furthermore, the conductivity was augmented with the rising concentration of PILs. The incorporation of PILs exhibiting high ionic conductivity contributed to the enhancement of hydrogel conductivity. The network of Cho-Proa, Cho-Ilea, and Cho-Phea hydrogels was less dense than that of Cho-Glya and Cho-Sera hydrogels, facilitating the flow of ions within the hydrogel network. Consequently, Cho-Proa, Cho-Ilea, and Cho-Phea hydrogels showed enhanced conductivity. The superior conductivity of Cho-Trpa hydrogels, compared to other hydrogels, is attributed to the synergistic effects of ion migration and π–π electronic transitions of indole groups in tryptophan molecules.

Figure 4.

Conductive properties of hydrogels. (a) Conductivities of various hydrogels. (b, c) Images captured for the LED coupled with control and Cho-Trp0.8 hydrogel in sections. (d) Images captured for the LED linked to the elongated Cho-Trp0.8 hydrogel. (e, f) Images showing LED reaction to Cho-Trp0.8 hydrogel following incision and self-repair. (g) Recent modifications to the cutting and self-healing mechanisms of Cho-Trp0.8 hydrogel. Adapted with permission from ref (58). Copyright 2022 Elsevier.

2.3.5. Electrochemical Stability

The electrochemical stability of ionic gels is crucial for their performance and is influenced by their composition, structural integrity, and methods used for assessment. ILs provide a wide electrochemical stability window, enhancing the stability of ionic gels for electrochemical applications.4,16 This stability, reaching a potential of up to 5.4 V, is determined by the oxidation and reduction potential, which must exceed the electrochemical potential of both the cathode and anode and fit within the conduction band maximum (CBM) and valence band minimum (VBM) of the electrolyte.3 The structure and composition of ILs, particularly the alkyl chain length and functional groups, also influence the stability and suitability of ionic gels across a wide temperature range.3 Li et al. developed ionic skins (I-skins) by impregnating poly(urea-urethane) (PU) with the ILs 1,2-dimethyl-3-ethoxyethylimidazole bis(trifluoromethanesulfonyl)imide ([DEIM][TFSI]).59 This combination showed excellent results with properties similar to those of human skin. The PU-IL2 ionic gel-based I-skins demonstrated high ionic conductivity (1.2 mS/cm), excellent electrochemical stability, high sensitivity to a wide range of strains (0.1--300%) and pressures (0.20 kPa) and maintained performance over 10,000 strain cycles and 200 days of open-air storage. In another study by Han et al., an ionogel containing a polyurethane acrylate (PUA) oligomer and 1-ethyl-3-methyl imidazolium bis(trifluoromethylsulfonyl)imide (EMITFSI) was fabricated under UV conditions.60 The results revealed that the electrochemical stability window increased with increasing PUA content, increasing the stability but reducing the ionic conductivity. Conversely, a higher EMITFSI content improved the ionic conductivity but decreased the electrochemical stability.

3. Stimuli-Responsive Behavior

ILs within the gel matrix make up ionic gels, which exhibit properties depending on their composition, the ratio used, the matrix material and the interactions between the components.61,62 The stimulus-responsive behavior of ionic gels represents a cutting-edge area of research that merges the properties of ionic liquids with those of polymeric networks, enabling these materials to undergo significant changes in response to various external stimuli. These behaviors are characterized by their ability to change physical or chemical properties in response to external stimuli, such as temperature, pressure, magnetic signals, light, and pH.5 This responsiveness makes ionic gels particularly valuable for a variety of applications.

3.1. Physical Responsive Stimuli

Ionic gels are capable of undergoing significant changes in their physical state in response to various external stimuli, such as temperature, pressure, light, magnetic field, and strain, which aid in improving their performance. Ionic gels are versatile in applications such as drug delivery, sensors and actuators because of their sol–gel transition, enabling precise therapeutic release and responsive material design for adaptive environments1,5

3.1.1. Temperature-Responsive Stimuli

Temperature-responsive ionic gels control the transport of ions by changing their charge density in response to temperature.63 The mechanisms involved in the temperature behavior of ionic gels include ion pair decoupling-coupling, sol−gel transitions, critical temperature effects, temperature-responsive dynamic covalent bonding, supramolecular response mechanisms and the Soret effect (Figure 5).5 The influence of temperature on an ion pair dissociation and coupling is that at room temperature, most of the cations and anions in the ILs of ion gels are neutral ion pairs, with few dissociative ions free to migrate. However, with increasing temperature, electrostatic interactions between anions and cations occur, and freely flowing cations and anions are formed (Figure 5a).64 The dissociation affects the sensor’s impedance, phase angle and capacitance in the temperature range of 30–80 °C. The results from the study revealed that as the temperature increased, the impedance decreased significantly, possibly because of enhanced ionic dissociation and increased charge carriers, which in turn improved the ionic conductivity. The increased capacitance with temperature was attributed to the accumulation of decoupled ions at the interface between the ILs and the electrode, forming an electric double layer. The phase angle was decreased in the low-frequency regime because of the increased electrical double-layer capacitance. At high frequencies, the ionic conductivity led to a decreased phase angle. Sastry and Singh synthesized an amphiphilic room-temperature ionic liquid, 1-dodecyl-1-methylpiperidinium acetylsalicylate [C12mpip]-[AcSa], from [C12mpip] via ion exchange.65 The critical aggregation concentration (CAC) of [C12mpip]-[AcSa] was lower than that of the chloride precursor, indicating stronger interactions between the cation and the bulky acetylsalicylate anion as well as enhanced hydrogen bonding with water. Rheological studies have shown that the addition of sodium salicylate transforms small ellipsoid aggregates into large worm-like structures with viscoelastic gel properties. The gel network exhibited complex temperature-dependent moduli without hysteresis, and the release of the acetylsalicylate anion was triggered by dilution, leading to surface erosion and demicellization.

Figure 5.

(a) Temperature-responsive mechanisms of ionic gels: influence of temperature on ionic pair decoupling-coupling. Adapted from ref (76). Copyright 2020 American Chemical Society. (b) Sol–gel process of the ionic gels. Adapted from ref (77). Copyright 2016 American Chemical Society. (c) Illustration of the upper critical temperature and lower critical temperature. Adapted from ref (78). Copyright 2015 American Chemical Society. (d) Influence of temperature on dynamic covalent bonding. Adapted from ref (79). Copyright 2018 American Chemical Society. (e) Supramolecular ionic gels constructed by host–guest complexation. Adapted from ref (80). Copyright 2024 American Chemical Society. (f) Seebeck and Soret effect cations and anions in an n-type electronic material subjected to a temperature gradient. The arrows in (i) illustrate that electrons migrate in two distinct paths under a temperature gradient, with more electrons migrating toward the cold end than toward the hot end. The two arrows in (ii) indicate the migration of both cations and anions from the hot end to the cold end, with anions migrating at a faster rate than cations. Adapted from ref (81). Copyright 2022 American Chemical Society.

The sol–gel transition mechanism takes place in certain polymer/IL blends. Here, the polymer dissolves in the IL, resulting in micelles, which self-assemble to form a gel upon heating (Figure 5b).62 A study conducted by Kitazawa and co-workers investigated morphological modifications and concomitant sol–gel transitions using a doubly thermosensitive ABC-triblock copolymer in an IL.66 The gelation behaviors of poly(benzyl methacry-late) (PBnMA), poly(2-phenylethyl methacrylate) (PPhEt-MA) and poly(methyl methacrylate) (PMMA) were studied, revealing a sol–gel transition above certain concentrations. At 20 wt %, the dynamic moduli shifted from a solution at low temperatures to a gel at high temperatures. However, gelation occurred at a lower temperature than expected, suggesting that the system forms a jammed micelle state, not a polymer network, due to micelle jamming at intermediate temperatures. For the 10 wt % polymer solution, gelation occurred at 130 °C, indicating that the critical gelation concentration lies between 10% and 20%. The high critical concentration is attributed to the low glass transition temperature of PBnMA, which affects the toughness of the cross-linking points and the retention capacity of the IL in the polymer network.

Ionic gels exhibit a critical temperature effect, in which the materials undergo a phase transition at a specific temperature, which is further divided into the lowest critical solution temperature (LCST) and upper critical solution temperature (UCST) depending on the temperature (Figure 5c). The thermoregulatory properties of ILs are influenced primarily by electrostatic and hydrogen bonding interactions.67 Ionic gels containing polymers such as poly(N-isopropylacrylamide)68 exhibit an LCST phenomenon in water, with a phase transition temperature. Above the LCST, the ion gel and water undergo phase separation. This increase in temperature caused an increase in the ion concentration within the gel, leading to increased ionic conductivity. Similarly, the polymers in ionic gels exhibit UCST behavior, where they undergo a phase transition from a swollen state to a shrunken state with decreasing temperature. Polymers such as poly(vinyl methyl ether) (PVME), poly(vinyl alcohol) (PVA) and poly(2-hydroxyethyl methacrylate) (PHEMA) display both UCSTs and LCSTs, although the UCSTs are below the freezing point of normal pressure water.69

In temperature-responsive dynamic covalent bonding, gels are composed of polymers linked by dynamic covalent bonds that can break and reform in response to changes in temperature (Figure 5d).70 Tang et al. fabricated thermally healable DN ionic gels containing poly(furfuryl methacrylate-co-methyl methacrylate) (P(FMA-co-MMA)) and poly(vinylidene fluoride-co-hexafluor-propylene) (P(VDF-co-HFP)).71 This design was chosen because gels with thermally reversible dynamic covalent furan–maleimide bonds transition from a static state to a dynamic state with increasing temperature, enabling thermal healing. At 70 °C, the dynamic covalent bonds in the ionic gels are cross-linked, enhancing their mechanical properties. As the temperature increased to 110 °C, these bonds broke, weakening the mechanical strength of the ionic gel. In the study by Hall et al., the process of thermoreversible gelation of a triblock terpolymer known as poly(ethylene-alt-propylene)-block-poly(ethylene oxide)-block-poly(N-isopropylacrylamide) (PON) in the presence of the ionic liquid, 1-ethyl-3-methylimidazolium bis(trifluoromethyl sulfonyl)imide ([EMI][TFSI]) was reported.72 The use of small-angle X-ray scattering, rheology, and dynamic light scattering revealed that PON ionic gels have a wider sol–gel transition. The expected rheological behaviors were achieved at the point of gelation and as viscoelastic fluids at high temperatures. With 10 wt % polymer loading, the network had 98% elastically effective strands. This allowed the gel to withstand stresses of up to 70% at 0 °C. This was attributed to the distinct thermoresponsive phase behavior of poly(N-isopropylacrylamide) in ionic liquids and water. Overall, the results concluded that the PON system generates a more efficient gel network, allowing lower polymer concentrations.

The supramolecular response mechanism involves noncovalent interactions. Qin et al. fabricated pillararene-containing polymers with various backbones to study the effect of the polymer structure on the conductivity (Figure 5e).73 Different polymers were created by the polymerization of pillar[5]arene-functionalized norbornene monomers (NMP5A) and 1,6-pyridyl monomers (DYP5A). The supramolecular interactions occur primarily between the pendant pillararenes in the polymer (host H1–H5) and the pyridinium moieties in the guest molecules. These polymers formed complexes with dipyridinium-functionalized poly(ethylene glycol) ILs (G1 and G2) through host–guest interactions, forming supramolecular IL gels. The conductivity of the gels was studied at 30, 40, 50, and 60 °C. The H3-G1 system conductivity decreased upon the addition of LiTFSI, whereas the H3-G2 system conductivity increased. This difference is attributed to the physical state and number of EO units in PEG400 and PEG1000.

The Soret effect involves the thermal diffusion of ionic components; when an ionic gel is subjected to a temperature gradient, cations and anions accumulate at the hot and cold ends due to the Soret effect, which creates a voltage difference that can be used to determine the ambient temperature range (Figure 5f).5,74 The migration rates of anions and cations in ionic components differ due to variations in their volume and functional groups, leading to concentration differences at the cold and hot ends. This results in a voltage difference between the ends, which can be used to determine the ambient temperature range.75

3.1.2. Pressure-Responsive Stimuli

To determine the pressure-responsive mechanism, the device design is more important for realizing a sensitive pressure response than the influence of the structure and properties of ionic gels. The different types of pressure response mechanisms involve piezoresistive, piezoelectric, capacitive and triboelectric mechanisms.5 In the piezoresistive mechanism, when pressure is applied to an ionic gel, the ions within the gel structure are displaced, causing changes in the electrical properties that can be detected as a pressure signal. The sensitivity and detection range of the piezoresistive response can be tuned by adjusting the composition and stiffness of the ionic gels, which provides high sensitivity at low pressure. Zhang et al. fabricated ionic gels via in situ synthesis of 1-vinyl-3-ethylimidazolium dicynamide ([VEIm][DCA]) ILs containing a carbon–carbon double bond.82 The electrical properties were measured via a Keithley 4200 semiconductor meter. The sensor responded to changes in pressure and exhibited high sensitivity, a low detection limit and a rapid response with slight pressure changes.

In the piezoelectric response, materials can generate an electric charge in response to the applied mechanical stress and vice versa.83 They respond to low frequencies and offer isotropic electromechanical responses. These materials exhibit polarization when subjected to intense electric fields, a process known as poling. In a study conducted by Villa et al., barium titanate (BaTiO3) nanoparticles were fabricated into a gel matrix with an IL, creating a material that responds to low-frequency mechanical stimuli with improved output voltages and anisotropic behavior.84 The gel retained elastomeric-like properties, which are beneficial for low-frequency electrochemical response along with mechanical stability.

The pressure response concerning the capacitive mechanism refers to the ability of a gel to change its capacitance in response to applied pressure. Zhang and colleagues developed a capacitive flexible pressure sensor for positive and negative pressures.85 The flexible sensor demonstrated high sensitivity, with negative and positive pressures of 84.45 nf/kPa and 25.61 nf/kPa, respectively. It maintained stability over 100 pressure cycles and remained functional under bending, with response times of approximately 250 ms.

3.1.3. Light-Responsive Stimuli

Ionic gels respond to light in addition to temperature and pressure signals and have applications in the biomedical industry. The incorporation of light-responsive ILs can impart these properties to ionic gels. The different light-responsive mechanisms involved include aggregation-induced emission (AIE), photothermal substances and inorganic nanoion composites (Figure 6). Yang et al. synthesized AIE-based poly(IL) containing 4-(1,2,2-triphenylvinyl)phenyl acrylate (TPE), which is a polymeric material whose fluorescence is enhanced upon aggregation or solid-state formation. TPE showed a synergistic effect on AIE-based poly(ionic) liquids with enhanced quantum yield.86 Zhang et al. developed a hydrogel actuator that is responsive to multiple stimuli.87 The actuator was made of poly(N-isopropylacrylamide) coated with a spiropyran moiety, which is a photochromic and hydrophobic molecule. This combination allowed the gel to exhibit reversible bending behaviors driven by changes in temperature and solvent, as well as the ability to form patterns in response to light. The isomerization of spiropyran during Vis/UV light irradiation altered both hydrophobicity/hydrophilicity and resulted in distinct fluorescence characteristics. Due to the photoisomerization of spiropyran, the PNIPAAm-SP hydrogel exhibited photoswitchable “on/off” fluorescence activity. When irradiated with white light in H2O, the gel displayed mild fluorescence emission at 610 nm, primarily due to the fluorescence produced by the ring-closing form; under UV illumination, the gel exhibited a pronounced emission at 665 nm, characterized by intense red fluorescence. Following eight cycles of UV/white light irradiation, the fluorescence intensity at 665 nm of the gel exhibited no significant alteration, demonstrating the gel’s remarkable reversibility and resistance to fading.

Figure 6.

(a) Polymer backbone functionalized with light-emitting moieties. (b) Tuning of the luminescence spectrum through variation in the mixing ratio of these luminescent groups. (c) Mechanistic insights into the photothermal conversion process. (d) Mechanism underlying the light-responsive behavior of PIL. (e) Interaction dynamics between carbon nanotubes and ILs. (f) Schematic representation of the photothermal conversion mechanism of ion gels. Adapted from ref (88). CC BY 4.0.

ILs containing UV or light-responsive materials exhibit changes in their properties upon exposure to UV or visible light. These gels can be prepared by physically mixing ILs with light-sensitive compounds. Ionic gels with a UV response can emit blue fluorescence at a wavelength of 480 nm.5,16 A study conducted by Patel et al. formulated photoresponsive ILs into a polymeric hydrogel. This study aimed to develop a photoresponsive ionic gel with good mechanical properties, thermal stability, a thermoresponsive reversible transition into a sol form, and the ability to convert it into a sol form only through light irradiation.89 The hydrogel containing [C8EMorph][MO], which has photoresponsive characteristics, exhibited significant photoresponsive behavior when irradiated with light at a wavelength of 460 nm. When the IL concentration exceeds its critical micelle concentration (CMC) of 8.0 mM, the hydrogel transitions from a gel to a sol after prolonged light exposure. This transformation is irreversible and occurs without a significant increase in temperature. Below the CMC, no photoresponsive behavior was observed. SEM images revealed that the hydrogel’s 3D fibrous network was disrupted upon irradiation, indicating that the IL azobenzene group underwent trans-to-cis isomerization, altering its conformation and breaking the hydrogel structure. The rheological measurements indicated that the hydrogel is stable and exhibits viscoelastic behavior up to certain critical strain levels and angular frequencies, and the hydrogel displayed a temperature-dependent gel–sol transition. The hydrogel exhibited distinct and irreversible photoresponsive behavior due to the trans-to-cis isomerization of [C8EMorph][MO] under light irradiation, resulting in a gel-to-sol transition. Additionally, it demonstrates reversible thermoresponsive behavior, transitioning between gel and sol states with temperature changes.

The other method involves incorporating nanoion composites of ionic gels, which enable an effective photothermal response, leveraging their high photothermal conversion efficiency. In the study conducted by Gao et al., a system containing photosensitive ILs and carbon nanotubes was fabricated.90 The photosensitive IL was developed by dispersing carbon nanotubes in 1-octyl-3-methylimidazolium chloride ([OMIm]Cl), increasing their light absorption and photothermal properties. The system demonstrated remarkable stability, conductivity and thermal stability, making it highly effective for light detection and solar tracking applications.

3.1.4. Magnetoresponsive Stimuli

Magnetic ion gel materials are fabricated by incorporating magnetic substances into a polymer matrix or by using magnetic ionic liquids.1 Shojaee et al. fabricated magnet-responsive ionic gels containing carbomers and choline hydroxide.91 The catalytic performance of the magnetic ionogel was assessed via a one-pot condensation reaction between benzaldehydes, dimedone and malononitrile in water. It achieved a 68% yield at room temperature in 4 h, which improved to 96% in 1 h at 60 °C. Solvent effects were studied, with only water proving effective. Increasing the ionogel amount to 100 mg did not affect the yield or time, whereas reducing it to 10 mg required a longer reaction time. The temperature impacts the reaction kinetics and equilibrium, shifting toward higher yields at elevated temperatures. Kulshrestha et al. developed a magnetoresponsive hydrogel by combining gelatin with a valine-based magnetic ionic liquid surfactant [ValC16][FeCl4] without nanoparticles.92 The biocompatibility was confirmed through interactions with animal DNA, as evaluated by circular dichroism (CD), zeta potential, ethidium bromide assay and agarose gel electrophoresis. CD spectroscopy indicated that [ValC16][FeCl4] maintains the DNA structure up to 0.7 mM but causes compaction at higher concentrations. Zeta potential measurements and EB exclusion assays confirmed the formation of the DNA-surfactant complex. Agarose gel electrophoresis revealed no DNA degradation at lower concentrations, with charge neutralization at higher concentrations.

3.1.5. Ultrasound-Responsive Stimuli

Ultrasound (US) is a potent external stimulation, utilized as needed, to facilitate the controlled release of drugs from gels to a targeted site within the body. The efficacy of these systems is ascribed to cavitation, which occurs due to the alternating expansion and contraction of gas-filled microbubbles caused by the pressure fluctuations produced by ultrasonic energy. Ultimately, these cavitating microbubbles collapse, producing localized shock waves that may disturb nearby polymer assemblies.93 Ionic gels that react to the US have a variety of possible uses in the biomedical industry. When subjected to ultrasonic vibrations, these gels, which are usually made of ILs, may change physically. Ye et al. reported the fabrication of multifunctional visualized electronic skin (e-skin) based on the novel poly IL-ionogel.94 The translucent and conductive poly-IL ionogel (P(AAm-IL)) was synthesized through the photopolymerization of acrylamide (AAm) with 1-vinyl-3-butylimidazolium tetrafluoroborate (IL) in ethylene glycol (EG). The preparation of ionogel was attained using magnetic stirring and US treatment. The fabricated ionogel demonstrated superior stretchability (>4300%), enhanced conductivity (1.44 × 10 S·m–1), commendable transparency (>80%), and an extensive operational temperature range (20 to 80 °C) The luminous e-skin displayed both highly sensitive electrical responses and observable fluorescence alterations in reaction to external strain fluctuations. Rizzo and co-workers investigated the gelation properties of cyclodextrins and dicationic imidazolium salts. They also examined the self-healing capabilities of these gels when exposed to external stimuli, such as magnetic stirring or US irradiation.95 The qualities of the resultant soft materials in gel formation were examined by assessing their thermodynamic stability, analyzing their optical characteristics by UV/Visible spectroscopy, and investigating their shape via scanning electron microscopy. The obtained data indicated that the characteristics of these two-component gels could be regulated by altering the kind of cyclodextrin, the salts, or, more straightforwardly, by adjusting the host/guest ratio. Yan et al. performed experiments to assess the self-repairing properties of gels by magnetic stirring or US irradiation.96 All gel phases exhibited a good response to mechanical stimulation. Billeci et al. synthesized organic salts using diimidazolium and dipyrrolidinium ions to formulate gels in both organic solvents and ILs.97 These materials displayed sonotropic behavior and revealed self-repairing capabilities upon exposure to US irradiation. Upon comparison of the data from pyrrolidinium and imidazolium salts, it was apparent that the aromatic salts had a more favorable reaction to both magnetic stirring and US irradiation. The effect of US on the structural integrity of the fabricated hydrogels was reported by Li and his colleagues and the results showed that US obliterated the gelatinous matrix between PVA, and IL ([BMI]Cl).98 FT-IR data indicated that the intensities in the OH stretching were amplified following US exposure. The results indicated that US exposure could disrupt the hydrogen bonds in the PVA/[BMI]Cl composites, with the hydrogen bonds produced by adjacent OH groups, OH groups in disparate PVA chains, and the OH group interacting with the Cl– anion being readily affected by ultrasound exposure.

Guo et al. demonstrated a US-induced reversible sol–gel transition approach driven by modified noncovalent interactions.99 The resulting gels exhibited self-healing properties and tunable emission colors upon the incorporation of inorganic ions into the gel matrices. Through a heating–cooling process, the gel reverted to a sol state. Concurrently, a vesicle-tube morphology transition, governed by sonication and heating–cooling, was observed, alongside the aggregation-induced emission enhancement (AIE) property of the gel. The findings indicated that the US facilitated the J-aggregation of terpyridine motifs and augmented the hydrogen bonding interactions of TEC molecules, thereby initiating the gelation process. Hydrogel scaffolds serve as delivery vehicles for regenerative growth factors in tissue engineering. US has been investigated as a stimulus for attaining spatial and temporal control with responsive scaffolds due to its potential for translatability of the interactions of US with droplets and related bubbles in sonosensitive hydrogels.100 The acoustic droplet vaporization (ADV) and inertial cavitation (IC) thresholds were influenced by alterations in acoustic responsive scaffold (ARS) parameters, including fibrin concentration, emulsion shell material, PFC core, emulsion structure, and the number of acoustic cycles. ADV transpired within an ARS with negligible impact on cell viability, whereas IC resulted in diminished viability. This study recommended an ARS composition for growth factors (GFs) administration including 5 or 10 mg/mL fibrin with a double emulsion containing PFH or a mixture of PFP/PFH. For US exposure, an increased number of acoustic cycles was also advised. Notably, studies by Huang et al. showed the influence of ILs (1 mg/mL 1-butyl-2,3-dimethyl imidazolium chloride) and US on the enhanced solubility of soy protein isolate to 71.8%, thereby modifying the microstructure of the globular proteins.101

3.2. Chemical Stimuli

The majority of ILs include quaternary ammonium structures and are sensitive to gases such as carbon dioxide, hydrogen sulfide and ammonia.5 Ionic gels containing imidazolium show reversible sol–gel transitions in interactions with CO2. In the study conducted by Zhang and colleagues, a CO2-responsive ionic gel was fabricated.102 When CO2 is bubbled through the IL solution, it converts into a transparent, stable gel, which can be reverted to the initial solution state by purging with N2. Another study conducted by Tanaka et al. reported the simultaneous detection of hydrogen, ammonia and ethanol by an ionic gel with four electrodes.103 This study presented a multielectrode gas sensor comprising an [EMIM][BF4]-based ionic gel combined with Au, Cr, Pt and Rh electrodes. The gate voltage modulates the transistor drain current, which varies based on the electrode pairs and unintentionally absorbed gases. The voltage difference at the electrode or ionic gel interface changes the drain current in the transistor. For an effective sensor response, the electrode area must be larger than the gate area of the transistor, enabling potential downsizing and integration at the nanoscale. The bilayer interface plays a crucial role in gas detection, with chemisorbed hydrogen on Pt electrodes being the dominant factor in the sensor response.

By regulating intermolecular interactions through pH, changes in the pH environment can modify the optical, electrical, or mechanical properties of ion gels.5 Lin et al. fabricated a biocompatible hyperbranched poly(IL) containing gluconate (HPIL-Glu) to combat bacterial biofilms.104 The IL moieties consist of an ammonium-based cation and a Glu organic counter. The data indicated that HPIL-Glu forms a uniform nanoassembly in water and exhibits a pH-responsive charge conversion property. Under neutral conditions, Glu shields the positively charged surface, reducing toxicity. In a mildly acidic environment, Glu becomes protonated, exposing cationic groups that aid in the eradication of biofilms. Antimicrobial studies revealed that HPIL-Glu effectively kills bacteria and aids in healing bacterium-infected chronic wounds. In another study by Liu and colleagues, molecularly implanted poly(ILs) (MIPILSs) were imprinted onto multiwall carbon nanotubes to produce a pH-responsive surface by modifying MIPILs and bovine serum albumin (BSA) onto 3-aminopropyl triethoxysilane-modified MWCTs, resulting in a pH-responsive gel.105 Adsorption experiments revealed that the adsorption capacity of BSA by MWCNTs@BSA-MIPILs and MWCNTs@MIPILs decreases significantly with increasing pH from 7.7 to 9.9, with the imprinting factors increasing from 1.30 to 5.06. The optimal imprinting effect at pH 9.9 was due to weak electrostatic and hydrogen bonding interactions, which enhanced specific binding from the imprinted cavities. Santiago et al. fabricated spiropyran-based ionogel membranes using a florinated polymer, an IL and NO2BIPS spiropyran, which exhibited optimal thermos-, photo, halo-, and electrochromic switching behavior.106 The membranes are transparent, flexible and stretchable, exhibiting high ionic conductivity due to the plasticizing effect of the IL. NO2BIPS within IGs shows preserved photochromic, photohalochromic, thermochromic and electrochromic behavior, enabling reversible color changes under UV light, acid, heat and electric stimuli, respectively.

4. Self-Healing Mechanisms and Influential Aspects of Ionic Gels

A self-healing material is a substance that can autonomously repair and restore any damage it sustains. Self-healing ionic gels or polymeric gels can undergo self-repair in response to external triggers such as light, heat, or changes in pH. This repair process is facilitated by the interaction of covalent and noncovalent interactions between functional groups within the gel after it has been distorted or damaged.52,107,108 The self-healing properties of self-healing ionic gels or polymeric gels address their inherent limitations: they cannot recover spontaneously after being damaged. This advancement has significantly increased the potential of ionic gels and has expanded their applications in the field of biomedicine. This section summarizes and categorizes the design strategies of self-healing ion-based polymeric gels, which are based on dynamic covalent and noncovalent interactions, by considering the self-healing mechanism of these hydrogels.

4.1. Self-Healing Mechanism in Ionic Gels

The self-healing mechanisms of ionic gels rely primarily on the reversible nature of their cross-linking structures, which frequently involve dynamic covalent bonds,109,110 such as Schiff base bonds, borate ester bonds,111 Diels–Alder reactions,112 disulfide bonds,113 and dynamic noncovalent bonding interactions, such as hydrogen bonding interactions,110 ion interactions (metal coordination),114,115 host–guest interactions,116,117 and hydrophobic interactions118 (Figure 7). The stability, self-healing ability, and mechanical qualities of ionic gels are directly influenced by the quantity and strength of the chemical bonds utilized in their production. Hence, researchers must understand the self-repair mechanism to devise ionogels with variable degrees of self-healing properties.

Figure 7.

Schematic representation of the physical and chemical mechanisms involved in the formation of ionic gels. This image was created under a Creative Commons license using BioRender.

On a different note, the ions present in the ionic liquids also influence the gel’s properties to a greater extent. Owing to a greater number of anions and cations, ion–ion, ion–polar, and supramolecular contacts have greater strength than weak π–π interactions.119 Supramolecular ion interactions, specifically, exhibit exceptional stability and convenient accessibility, hence facilitating the development of self-healing materials.120−123 Simultaneously, the strong attraction between ion pairs promotes the reformation and unrestricted modification of polymeric chain structures. Thus, ionic liquids show great potential for integration into the production of self-healing ionic gels or composite gels. Ling et al. introduced physical doping of polydopamine nanoparticles (pDA-NPs) to enhance the mechanical characteristics and increase the pore size of a dynamic covalently cross-linked chitosan-arginine (CA) hydrogel via the use of a Schiff base.124 The administration of pDA-NPs successfully facilitated the healing process of significant skin injuries, augmented the formation of new blood vessels, and diminished the appearance of scars. In the context of tissue engineering, Lei et al. synthesized hydrogels by incorporating tannic acid (TA) and human-like collagen (HLC) into a dynamic cross-linking network of poly(vinyl alcohol) (PVA) and borax.125 In this system, borax acted as both a cross-linking agent and an ionic conductor. The incorporation of HLC and TA altered the cross-linking density and pH of the hydrogels, hence modifying the flexibility of the PVA-borax matrix and imparting hemostatic, antibacterial, anti-inflammatory, cell proliferative, and collagen deposition properties.

4.2. Factors Influencing Self-Healing Processes

Self-healing functional materials are influenced by several external and internal influences. Internal considerations include the potential for ionic transport within the material and the compatibility between ionic liquids and polymers. Conversely, certain intelligent self-repairing materials are sensitive to a range of external stimuli. Further investigations of these aspects may enhance our understanding of healing mechanisms and expand the range of potential applications.

4.2.1. Ability to Diffuse Ions

The self-healing characteristics are significantly influenced by ion mobility. The utilization of hydrophobic interactions could be a viable approach for enhancing ion transport. To this end, Lee et al. developed polyampholyte hydrogels that exhibited high toughness, self-recovery and self-gealing characteristics that mimic those of human tissue.126 This was achieved by tuning the structure of the ion–pair associations, which act as cross-links in a polyampholyte terpolymer hydrogel with improved skin adhesion by adding a neutral monomer component to the network without changing the total charge balance. Variations in the neutral monomer feed concentration affected the network structure. In a different investigation by Sharma et al., an ionogel consisting of gelatin and 1-ethyl-3-methylimidazolium chloride was fabricated.127 When the ionogel was incised with a surgical blade, between 68% and 96% of the stiffness of the gel was restored at 20 °C within 10 h without the need for any external triggers. During the self-healing process, ion diffusion was driven by a hydrophobic contact between the alkyl tails of the ionic liquid molecules. Adequate chain mobility facilitates the active reorganization of ions accumulated on the fracture surface, resulting in the material possessing self-healing qualities that can enhance its mechanical and healing capabilities. Therefore, establishing the ideal equilibrium between superior mechanical strength and the dynamics of chains and ions is crucial.

4.2.2. Interaction Compatibility of ILs with Polymeric Chains

The interaction between ILs and polymer chains has a significant effect on the self-healing capability and practical use of self-healing materials. To this end, a set of self-healing polymeric ionic liquid (PIL) hydrogels was created via hydrophobic association, resulting in hydrogels that possess both high mechanical strength and electrical conductivity.128 Hydrophilic monomer vinyl ionic liquids (VILs) derived from choline and amino acids, acrylamide, and the hydrophobic monomer stearyl methacrylate (C18) were combined in a micellar solution of sodium dodecyl sulfate (SDS) and polymerized together. Additionally, bacterial cellulose was added to improve the mechanical properties of the hydrogels. The hydrogels obtained displayed exceptional mechanical robustness, with a strength of 5.8 MPa, significant elongation at the point of rupture (4250%), and remarkable self-healing capability (85%) without the need for external intervention. Despite undergoing healing, the majority of the hydrogels achieved a tensile strength of only 2.5–3.9 MPa. Simultaneously, the integration of ionic liquids provided hydrogels with excellent electrical conductivity, reaching a maximum value of 1.258 S/m. Prasad et al. synthesized a form of guar gum (GG) by using 1-butyl-3-methyl imidazolium chloride [C4mim]Cl.129 In this solution, [C4mim]Cl served as both a solvent and a junction promoter, effectively connecting guar gum chains to create a network structure. Additionally, [C4mim]Cl facilitated the transformation of guar gum into a mechanical gel. The three-dimensional structure was reconstructed, resulting in the ability to self-heal itself. In a study reported by Zhu et al., a novel triple-network ion gel was synthesized using sustainable cellulose nanocrystals (CNCs) and ionic liquids instead.130 The gel exhibited greater mechanical strength and self-healing ability. By including graphene oxide and sustainable CNCs, the BmimHSO4-c ion gel showed enhanced mechanical properties, including high tensile strength (15.9 MPa), exceptional elongation (610%), and satisfactory toughness (53.8 kJ/m3). Furthermore, the presence of ions between Bmim+ in the ionic liquid and −OH in poly(vinyl alcohol) (PVA), along with hydrogen bonding inside the gel, led to a 93.8% increase in strength and a 93.3% increase in elongation after 24 h. Furthermore, the developed self-healing ion gel had notable and enduring self-healing capabilities.

4.2.3. Self-Healing Initiated via Stimuli-Responsive Behavior

Self-healing gels or polymers can respond to many external stimuli to enhance their mechanical properties and healing capabilities. These stimuli include pH and temperature adjustments, electric current, and magnetic changes, among others.131−134 Alterations in environmental variables can expedite advancement and the ability to regenerate. In the case of thermally responsive self-healing materials, the enhancement of chain movement and diffusion, which is crucial for the healing process, can be achieved by increasing the temperature. To this end, Le et al. developed a bioinspired hydrogel depot that can be formed in the body and is sensitive to changes in pH and temperature.135 This hydrogel can be injected and used to manage the release of DNA-containing polyplexes. An array of multiblock copolymers, consisting of water-soluble poly(ethylene glycol) (PEG) and pH- and temperature-responsive poly(sulfamethazine ester urethane) (PSMEU), was used to create injectable hydrogels in situ. The PEG–PSMEU copolymer sols, which were in a free-flow state at high pH (pH 8.5) and room temperature (23 °C), were transformed into stable gels under physiological conditions (pH 7.4, 37 °C). A skin-mounted electrostimulation-augmented photothermal hydrogel patch (eT-patch) with a transparent ionic gel doped with MXene (Ti3C2Tx) was developed and applied to treat melanoma at 0.5 W/cm2.136 These ionic gels showed great photothermal conversion efficiency and electrical conductivity, improving the eT-patch. The exceptional optical transparency of the ionic gel-based eT patch allowed real-time skin reaction and melanoma treatment monitoring under photothermal and electrical stimulation. A systematic cellular study on the antitumor mechanism of eT patches under PES treatment revealed that they synergistically induce cancer cell apoptosis and pyroptosis, killing melanoma cells. Taken together, these findings suggest that owing to their safety and low side effects in healthy organs, eT patches are promising cost-effective treatments for skin tumors and could lead to new biomedical uses for ionic gels.

Magnetic gels are materials that possess both the magnetic properties of ferrofluids and the elastic qualities of hydrogels.137 For example, the magnetic–elastic connection enables the utilization of remote actuation by applying an external magnetic field.138 To this end, ferrofluid was developed by Hayashi and colleagues; it rapidly changes into a gel within tumors and produces heat when exposed to an alternating magnetic field (AMF).139 This ferrofluid was a result of magnetic substances (Fe3O4 nanoparticles), natural polysaccharides (alginate), and amino acids (cysteine). Notably, the fabricated gel also acted as a contrast agent for magnetic resonance imaging. The anticancer drug doxorubicin was loaded through the formation of hydrogen bonds. The application of AMF-induced thermal energy in gels made from ferrofluid-containing doxorubicin leads to the contraction of the gel and the release of doxorubicin. In vivo studies revealed that ferrofluid can be transformed into a gel specifically within the tumor and that this gel remains localized within the tumor.

5. Dermal Applications

Human skin can be replicated by a promising option as an ionic skin that is currently attracting significant interest in several applications.140−142 In general, a wide variety of hydrogels that can function as ionic skin are considered perfect because of their transparency, stretchability, and exceptional sensitivity. However, the limitations of conventional hydrogels, including poor environmental durability, can be overcome by ionic gels or ionogels that consist of a polymer network and several ionic liquids. Ionic liquids possess exceptional ionic conductivity and thermal stability, as well as significant contact with polymer chains.143 Self-healable materials are considered excellent for addressing the longevity of ionic skin, as they have the potential to repair mechanical damage. Several polymer materials with self-healing capabilities have been effectively engineered to improve durability and extend lifespan. The healing behavior can occur independently through the reversible nature of dynamic covalent connections.133,144,145

The growing need for biomaterials that can assist in the regeneration or replacement of injured tissue has led to the creation of novel engineered tissue structures in recent years. Nonetheless, ionic gels have been considered alternatives to these biomaterials in several biomedical applications, including contact lenses,146 wound dressings,147 and drug delivery vehicles,148−150 owing to their exceptional biocompatibility and biomimetic features. These self-healable ionic gels have been shown to possess specific characteristics that arise from their structure, which consists of a three-dimensional network of hydrophilic polymers that are highly swollen. This network can be chemically or physically cross-linked to create a material that imitates the beneficial properties of the well-hydrated extracellular matrix (ECM). Additionally, the porous structure of these gels enables the transport of nutrients and oxygen.151

5.1. Stimuli-Responsive Ionic Gels in Dermal Wound Healing

ILs have garnered significant interest because of their exceptional electrical conductivity, broad electrochemical range, and long-lasting nature. In the realm of biomedicine, exogenous electrical stimulation has proven to be a potent supplement to wound care. This is because the natural process of wound healing can be replicated by the use of internal electric fields to expedite the regeneration of skin.152 These self-healing qualities have great potential in the field of wound healing and protection. They can avoid secondary injuries, extend the lifespan of dressing materials, and provide additional protection for wound sites through various self-repair mechanisms. Kuddushi and colleagues created ester and salicylate-based ionic gels that possess the ability to repair themselves.149 These authors attributed this self-healing property to the dissociation and reforming of numerous hydrogen bonds between ionic liquids and polymers. A conductive and multifunctional hydrogel dressing was developed and reported by Liu et al.153 The dressing was fabricated using a combination of polymerized ionic liquid and konjac glucomannan. The hydrogel dressing showed exceptional mechanical qualities and biocompatibility. Additionally, it offered long-lasting and effective sterilization action without the need for the release of antibacterial substances. The utilization of this hydrogel dressing greatly increased the migration and proliferation of fibroblasts, as well as the therapeutic efficacy for diabetic skin wounds, by enhancing electrical stimulation.

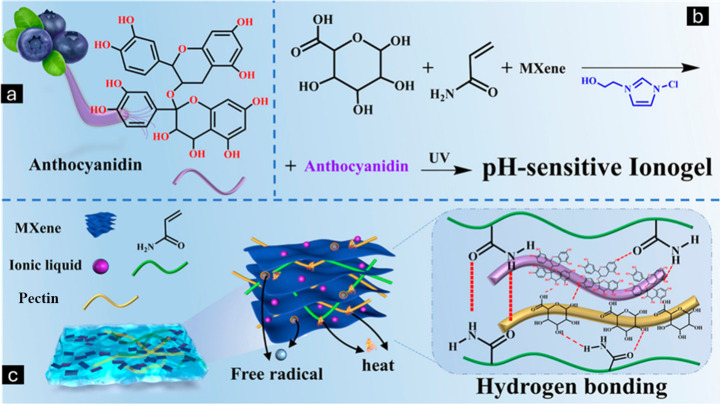

Shou et al. developed HBCS-C hydrogels that are thermosensitive, injectable, tissue adhesive, biodegradable, biocompatible, and capable of promoting wound hemostasis.154 The liquid–gel transition displayed a high level of excellence at various temperatures because of variations in the hydrophilic–hydrophobic interactions and the formation of hydrogen bonds facilitated by the hydroxybutyl groups. Frequent interactions between tissues and catechol/amino groups enable biocompatible hydrogels to strongly adhere to tissue surfaces. In the study reported by Bhar et al., a wearable electroceutical platform (WEP) that produces weak electrical pulses was delivered to the wound site via a breathable electrical bandage patch.155 This patch was equipped with a silk-based antimicrobial ionogel interface. The evaluation of the in vivo efficacy of WEP revealed a notably accelerated wound-healing process. Histological and immunostaining examinations revealed that pulsed electrical stimulation (ES) led to an increased rate of granulation tissue creation, remodeling of the extracellular matrix, and regrowth of the epithelium. These modifications likely play a role in the reported improvements in the healing process. A transparent, pH-sensitive, extremely stretchable, and biocompatible anthocyanidin ionogel dressing was developed for precise and reliable green detection.156 The ionogel dressing demonstrated exceptional re-epithelialization during the 14-day wound healing process due to the antibacterial properties of the ionic liquid, the biocompatibility of the pectin, and the ability to eliminate free radicals from anthocyanidin. In addition, the pH values of the ionogel aligned with those of the usual wound exudate over 3 days were monitored. The resulting ionogel also exhibited favorable characteristics, such as effective water retention, swelling qualities, mechanical stretchability, and stability for 5 weeks. These findings highlight its significant potential for use in wound dressings (Figure 8).

Figure 8.

(a) Chemical structure of anthocyanidins. (b) Synthesis of the pH-sensitive ionogel. (c) Diagram illustrating the reaction dominated by hydrogen bonding. Adapted from ref (156). Copyright 2023 American Chemical Society.